Zirconia (ZrO₂), or zirconium dioxide, is a high-performance ceramic renowned for its exceptional mechanical strength, thermal resistance, and biocompatibility. As industries demand smarter, longer-lasting, and more sustainable materials, zirconia has emerged as a critical solution across healthcare, energy, aerospace, and electronic sectors.

From dental implants to solid oxide fuel cells and advanced coatings, zirconia’s multifunctional properties continue to unlock new engineering possibilities. In this blog, we examine its composition, key performance features, diverse application domains, material advantages and drawbacks, and the future outlook—enhanced through insights from PatSnap Eureka AI Agent.

Material Composition & Key Properties

Zirconia is a polymorphic material that can exist in monoclinic, tetragonal, and cubic phases, each contributing to its stability and strength. It is often stabilized with yttria (Y₂O₃) to retain high-strength phases at room temperature, known as Yttria-Stabilized Zirconia (YSZ).

🔹 Key Properties

- High fracture toughness and flexural strength

- Excellent thermal insulation and shock resistance

- Biocompatibility and corrosion resistance

- Ionic conductivity (especially in YSZ)

- High melting point (~2700°C)

🔬 Processing Methods

- Powder metallurgy and sintering

- Injection molding and additive manufacturing

- Plasma spraying for coatings

- Nanoparticle synthesis for biomedical uses

| Property | Zirconia | Alumina | Silicon Carbide |

|---|---|---|---|

| Fracture Toughness | High | Moderate | High |

| Ionic Conductivity | High (YSZ) | Low | Low |

| Thermal Stability | Excellent | High | High |

| Biocompatibility | Excellent | Moderate | Limited |

| Processability | Moderate | Easy | Difficult |

Application Domains

Biomedical & Dental Applications

Zirconia’s biocompatibility, high strength, and aesthetic appeal make it a leading material in medical and dental fields. In dentistry, it addresses limitations of metal-based implants by offering improved tissue response and natural coloration. In biomedical devices, its resistance to corrosion and wear enhances reliability.

Recent innovations include zirconia crowns, nanoparticle-based prosthetics, and coatings for bone-contact implants. Researchers are exploring hybrid designs to reduce brittleness and improve long-term functionality.

Related Reports:

- Zirconia in Dental Implants: Enhancing Durability

- Zirconia’s Impact on Modern Dentistry: A Review

- Latest Trends in Zirconia-Based Biomaterials

- Zirconia Dental Restorations: Key Benefits and Trends

- Zirconia Nanoparticles: Exploring Biomedical Applications

- Zirconia’s Significance in Medical Prosthetics

- Zirconia in Biocompatible Material Research

- Zirconia in High-End Biomedical Research Projects

Energy & Environmental Technologies

As clean energy becomes critical, zirconia plays a vital role in fuel cells, energy storage, and catalytic systems. Its ionic conductivity and thermal stability are essential for solid oxide fuel cells (SOFCs) and catalytic converters. Zirconia also supports carbon capture and hydrogen production innovations.

Research focuses on improving zirconia electrolyte efficiency, reducing sintering temperature, and hybridizing with nanostructures for better environmental performance.

Related Reports:

- Zirconia’s Role in Advanced Fuel Cell Technologies

- Zirconia for Energy Storage: Innovative Approaches

- Zirconia in Solid Oxide Fuel Cells: Innovations and Challenges

- Zirconia’s Role in Carbon Capture Technologies

- Zirconia in Hydrogen Production: Efficiency Improvements

- Zirconia-Based Ion Conductors: Applications in Electronics

- Zirconia as a Catalyst for Positive Environmental Impact

- Innovations in Zirconia-Based Environmental Catalysts

Electronics & Optics

Zirconia’s electrical insulation, low thermal conductivity, and optical transparency make it suitable for sensors, electronic components, and optical devices. It enhances device longevity and clarity while operating under extreme conditions.

Research highlights include optical-grade zirconia for lenses, electronic insulators, and transparent coatings for flexible displays.

Related Reports:

- Zirconia in Electronics: Reducing Thermal Conductivity

- How to Optimize Zirconia for Optical Clarity?

- Latest Advances in Transparent Zirconia Coatings

- Application of Zirconia in Modern Electronic Devices

- How to Implement Zirconia in Optical Sensor Technology?

- Zirconia in Advanced Optics: New Developments

- Zirconia in Smart Device Applications

- Zirconia Interface Designs: Latest Research Developments

Structural & Industrial Applications

In aerospace, automotive, and heavy industry, zirconia provides mechanical robustness, high-temperature resistance, and wear protection. It serves as a core material in cutting tools, heat shields, coatings, and friction-resistant parts.

Current trends include 3D-printed zirconia components, advanced sintering techniques, and zirconia-toughened composites.

Related Reports:

- Zirconia in Aerospace: Improving Component Reliability

- Zirconia in Automotive Sensors: Enhancing Sensor Accuracy

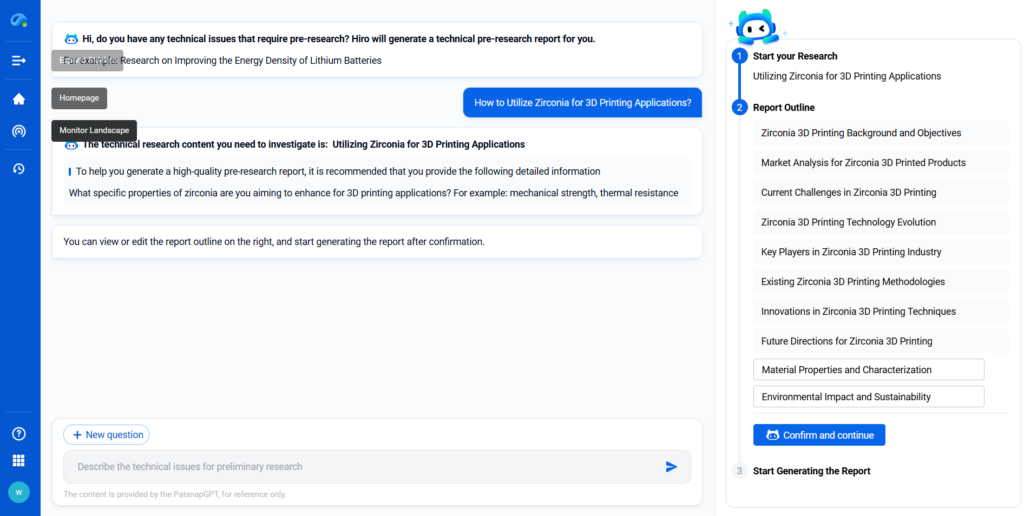

- How to Utilize Zirconia for 3D Printing Applications?

- Zirconia Processing Techniques: Enhancing Material Quality

- Zirconia Coated Surfaces: Enhancing Corrosion-Resistance

- Zirconia in Additive Manufacturing: Emerging Techniques

- Advanced Zirconia Coatings for Industrial Machinery

- Zirconia for Enhanced Structural Integrity in Vehicles

Emerging & Multifunctional Uses

Beyond traditional applications, zirconia is enabling innovations in robotics, smart textiles, construction, and energy-efficient systems. It’s being integrated into wearables, environmental monitors, and sustainable infrastructure.

Cutting-edge research involves zirconia’s role in nanotechnology, antimicrobial surfaces, smart coatings, and responsive materials.

Related Reports:

- Zirconia in Wearable Tech: Creating Durable Components

- Emerging Applications of Zirconia in Construction

- Zirconia in Environmental Monitoring: Key Innovations

- Zirconia in High-Tech Textiles: New Functionalities

- Zirconia’s Role in Smart Material Development

- Zirconia-Based Composites: Future Material Trends

- Zirconia in Advanced Robotics: Enhancing Component Life

- Zirconia in Future-Ready Infrastructure Projects

Comparative Advantages & Limitations

Zirconia offers a strong combination of mechanical strength, thermal stability, and biocompatibility, making it indispensable in various sectors. However, like all materials, it has trade-offs that limit certain applications.

✅ Key Advantages

- Excellent fracture toughness and hardness

- High-temperature and corrosion resistance

- Biocompatibility for medical and dental use

- Electrical insulation and low thermal conductivity

- Aesthetic benefits (natural white color)

Limitations

- Brittleness in some forms without toughening agents

- Complex sintering and processing requirements

- Lower electrical conductivity (limits active electronics use)

- Higher cost compared to common ceramics

- Susceptible to phase transformation under moist conditions

Future Outlook & Research Frontiers

Zirconia is poised to expand its footprint across emerging sectors with breakthroughs in processing and composite design. Researchers are working to overcome its brittleness while unlocking new electrochemical and optical functionalities.

🔮 Emerging Trends

- Zirconia composites: Incorporating nanomaterials to boost toughness and conductivity

- Bioactive coatings: Improving osseointegration and tissue compatibility

- Green processing: Reducing sintering temperatures and environmental impact

- Smart systems integration: Responsive coatings and structural health monitoring

- Zirconia inks and pastes: For additive manufacturing and flexible electronics

- High-performance catalysis: Surface-tuned zirconia for selective reactions

🧪 From Lab to Market Timeline

- 2025: Expansion of zirconia use in bio-implants with nanoporous structures

- 2026: Commercial deployment in high-temperature electronics and sensors

- 2027: Integration into hydrogen fuel and carbon capture systems

Conclusion & Key Takeaways

Zirconia stands at the forefront of advanced material innovation, offering a balance of strength, biocompatibility, and thermal endurance. It enables precision applications in energy, health, electronics, and structural engineering.

As industries prioritize sustainable, high-performance materials, zirconia’s role will only grow. Now is the time for engineers, material scientists, and product designers to explore its full potential.

Whether designing aerospace parts or next-gen dental solutions, zirconia offers unmatched versatility.

Accelerate Innovation with PatSnap Eureka AI Agent

Innovation in advanced ceramics is a complex, data-driven endeavor. Staying competitive means tracking material trends, understanding patents, and uncovering research gaps.

PatSnap Eureka AI Agent empowers R&D teams to:

- Identify white spaces in zirconia-based innovations

- Analyze competitor strategies and publication hotspots

- Discover technology convergence and potential collaborators

👉 Ready to lead the next wave of zirconia breakthroughs? Request a demo of PatSnap Eureka today.