Magnesium silicate is a naturally occurring mineral compound, most commonly recognized as talc or synthetic silicate blends, used across various industries. Known for its excellent adsorption, thermal stability, and inert nature, it plays a vital role in cosmetics, pharmaceuticals, plastics, and even food processing.

This article dives deep into magnesium silicate’s properties, applications, industry standards, and latest innovations. Leveraging the PatSnap Eureka AI Agent, researchers and R&D teams can access real-time patent intelligence, innovation trend maps, and competitive material comparisons to inform material selection and product development.

What is Magnesium Silicate?

Magnesium silicate is an inorganic compound composed of magnesium, silicon, and oxygen. It naturally occurs as talc or serpentine and can also be produced synthetically. It appears as a white or off-white powder. Moreover Magnesium silicat is odorless, insoluble in water, and chemically inert under normal conditions. These traits make it ideal for diverse applications across cosmetics, pharmaceuticals, plastics, and industrial formulations.

Composition & Performance

Chemical Identity:

- Chemical Formula: MgSiO₃ (for synthetic magnesium metasilicate)

- CAS Number: 1343-88-0

- Alternate Names: Talc (natural form), Hydrated Magnesium Silicate

Chemical Composition:

- Magnesium Oxide (MgO): 30–35%

- Silicon Dioxide (SiO₂): 55–65%

- Water (in hydrated forms): up to 10%

Physical & Mechanical Properties:

| Property | Typical Value |

|---|---|

| Appearance | White powder or granular solid |

| pH (1% aqueous solution) | 9.5–10.5 |

| Bulk Density | 0.3–0.8 g/cm³ |

| Surface Area | ~100–200 m²/g |

| Thermal Stability | Up to 900°C |

| Solubility | Insoluble in water and alcohol |

| Conductivity | Non-conductive |

Functional Characteristics:

- High adsorption capacity (ideal for oils, toxins)

- Inert and non-toxic

- Acts as an anti-caking, opacifying, and suspending agent

- Chemically stable under normal conditions

Material Grades & Designations

Common Standards & Grades:

- USP/NF: Pharmaceutical-grade magnesium silicate

- FCC: Food-grade for anti-caking or clarification

- ASTM D6059: For industrial filtration and fillers

- GB 25576-2010: China standard for cosmetic-grade talc

Global Equivalency Table:

| Standard System | Grade/Designation | Application |

|---|---|---|

| USP/NF | Talcum USP | Oral tablets, topicals |

| FCC | Magnesium Silicate FCC | Food additives |

| JIS | JIS K 5101 | Industrial filtration |

| GB | GB/T 15342 | Plastics and coatings |

Key Technical Data Summary:

| Parameter | Spec Range |

|---|---|

| Loss on Ignition | ≤10% |

| Residue (325 mesh) | ≤0.1% |

| Specific Surface Area | ~150 m²/g |

| Heavy Metals | ≤10 ppm (Pharma grade) |

Application Landscape

Core Industries Using Magnesium Silicate:

- Cosmetics: Foundation, powders, eye shadows

- Pharmaceuticals: Tablet disintegrants, antacids

- Plastics & Rubber: Fillers and reinforcement

- Paints & Coatings: Matte finish and anti-caking

- Food Industry: Clarification of oils and syrups

Use Case Examples:

- A leading cosmetics brand uses USP-grade talc for pressed powder foundations to improve skin feel.

- Edible oil manufacturers employ synthetic magnesium silicate for bleaching and purification.

- In drug formulations, it’s added to prevent clumping and improve flow.

Emerging Application Trends:

- Replacement for microplastics in scrubbing agents

- Base material for drug delivery nanoparticles

- Used in biodegradable polymer composites

Magnesium Silicate vs Similar Materials

| Property | Magnesium Silicate | Calcium Silicate | Kaolin Clay |

|---|---|---|---|

| Oil Adsorption | High | Moderate | Low |

| pH Stability | Slightly alkaline | Neutral | Slightly acidic |

| Heat Resistance | Excellent | Good | Moderate |

| Typical Form | Powder | Powder | Fine powder |

| Cost Efficiency | Moderate | Low | High |

Why Choose Magnesium Silicate?

- Superior oil and moisture absorption

- Non-toxic, making it suitable for personal care

- High-temperature stability

- Versatile across formulation types

Innovations & Technology

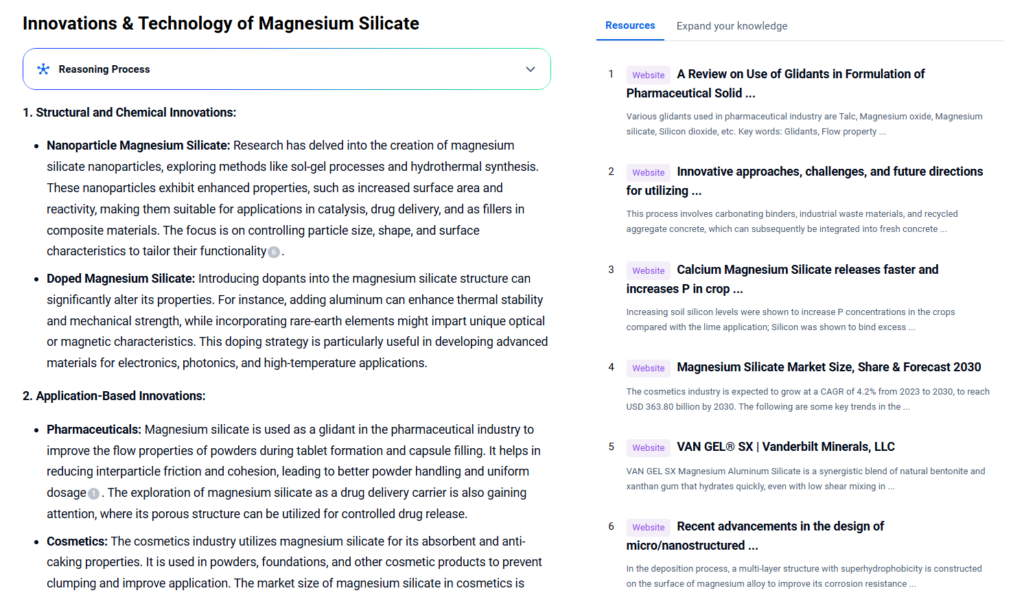

UsingPatSnap Eureka AI Agent, we identified the latest patent activity around

1. Structural and Chemical Innovations

- Nanoparticle Magnesium Silicate

Researchers actively develop magnesium silicate nanoparticles using techniques like sol-gel processing and hydrothermal synthesis. These methods create particles with higher surface area and greater reactivity. As a result, the nanoparticles show strong potential in catalysis, drug delivery, and composite fillers. Scientists focus on controlling particle size, shape, and surface features to fine-tune their functions. - Doped Magnesium Silicate

Adding dopants into magnesium silicate dramatically changes its properties. For example, aluminum doping improves thermal stability and mechanical strength. Meanwhile, rare-earth elements can introduce optical or magnetic effects. This approach is especially valuable for creating advanced materials in electronics, photonics, and high-temperature environments.

2. Application-Based Innovations

- Pharmaceuticals

It plays a key role as a glidant. It enhances powder flow during tablet compression and capsule filling by reducing friction and cohesion between particles. Additionally, researchers are exploring its potential as a drug delivery carrier. Thanks to its porous structure, it may enable controlled release of active ingredients. - Cosmetics

In cosmetics, it provides absorbency and anti-caking properties. It appears in products like powders, foundations, and face masks, preventing clumping and improving user experience. The market is expanding, reflecting its rising importance. A related compound, magnesium aluminum silicate, was once used as a colorant, although it’s now delisted. - Agriculture

It serves as a soil amendment. It boosts silicon levels, which can in turn raise phosphorus uptake in crops. Moreover, silicon can bind excess phosphorus, reducing runoff and helping prevent eutrophication. - Construction

In construction, it works as a binder. Some innovative methods involve carbonating the binder and incorporating it into fresh concrete. These approaches make use of industrial waste and recycled aggregates, promoting sustainable building practices. - Corrosion Protection

Engineers have developed multi-layer coatings with superhydrophobic properties using it. These coatings significantly improve corrosion resistance, making them ideal for equipment exposed to harsh environments.

3. Processing Innovations

- Synergistic Blends

One example is VAN GEL® SX, a synergistic blend combining magnesium aluminum silicate, bentonite, and xanthan gum. This formulation hydrates efficiently—even under low-shear mixing—making it highly adaptable in different formulations. - Micronization

Micronizing it into fine powders enhances its use in cosmetics and pharmaceuticals. This process improves flowability, coverage, and surface adhesion, all critical for performance.

4. Sustainability Innovations

- Use of Industrial By-products

Researchers are turning to slag and other by-products from metal refining as a low-cost and eco-friendly source of magnesium silicate. This reuse reduces industrial waste and promotes circularity. - Biodegradable Composites

It is also under study for use in biodegradable composites. These materials can serve in packaging, agriculture, and other areas where sustainability is essential.

Summary

Innovations in magnesium silicate cover its structure, application, processing, and environmental performance. Across the board, advancements aim to deliver better functionality, greater efficiency, and lower environmental impact. Driven by both industry demands and regulatory pressure, it continues to evolve as a multi-purpose material for the future.

Sustainability & Environmental Impact

Environmental Benefits:

- Naturally abundant and non-toxic

- Can be processed with minimal chemical treatment

- Biodegradable in mineral-rich soil environments

Environmental Considerations:

- Mining impact for natural talc forms must be regulated

- Dust emission control required in industrial handling

- Energy-intensive when synthetically produced

Compliance & Certifications:

- REACH: Compliant for most industrial applications

- RoHS: Suitable in electronics and coatings

- FDA: Approved for indirect food contact (depending on grade)

- Eco-label Certifications: Possible with sustainable sourcing

PatSnap Eureka AI Agent Capabilities

The PatSnap Eureka AI Agent empowers R&D and innovation teams to work smarter with magnesium silicate and related materials. It helps users uncover hidden opportunities, accelerate material discovery, and monitor competitive movements in real time.

WithPatSnap Eureka AI Agent, you can:

- Search global patent databases to track the latest magnesium silicate innovations

- Compare technical specifications across competing materials or grades

- Identify emerging technologies like surface-modified silicates or hybrid nanocomposites

- Map innovation trends in key industries such as cosmetics, pharma, and construction

- Spot whitespace opportunities for product development or IP strategy

- Evaluate regulatory compliance via integrated insights on REACH, RoHS, and FDA statuses

- Visualize R&D networks and key inventors in the magnesium silicate landscape

By leveraging Eureka, material scientists can make faster, data-driven decisions—from formulation optimization to supply chain insights—and stay ahead in a rapidly evolving materials market.

Conclusion

Magnesium silicate is a highly versatile, stable, and safe material used across industries from personal care to pharma and beyond. With its strong adsorption properties and thermal resilience, it stands out among other silicates and fillers.

Thanks to the PatSnap Eureka AI Agent, material scientists can stay on top of technical innovations, regulatory updates, and competitive benchmarking—making smarter, faster, and greener decisions in material selection and product design.

FAQs

Yes, talc is a naturally occurring form of magnesium silicate with water molecules in its structure.

Yes, food-grade magnesium silicate (FCC) is used as an anti-caking agent and for purification.

Inhalation of talc dust can be hazardous, but regulated, treated forms are safe for intended use.

No, magnesium silicate is insoluble in water and alcohol.

It offers better oil absorption, smoother texture, and more pH stability, making it ideal for sensitive formulations.

For more detailed scientific information of magnesium silicate, try PatSnap Eureka AI Agent.