Accura 25 is a remarkable photopolymer resin widely used in stereolithography (SLA) 3D printing. It is highly regarded for its unique combination of flexibility and strength, closely mimicking the properties of polypropylene. This material offers a great balance of durability and flexibility. And it has good elongation at break, allowing it to stretch to a certain extent before breaking, which is quite an advantage compared to many rigid photopolymers. Its tensile strength is moderate, making it suitable for non – load bearing applications. Additionally, Accura 25 shows relatively high impact resistance, enabling it to withstand minor stresses and impacts, which is beneficial for functional prototypes and parts.

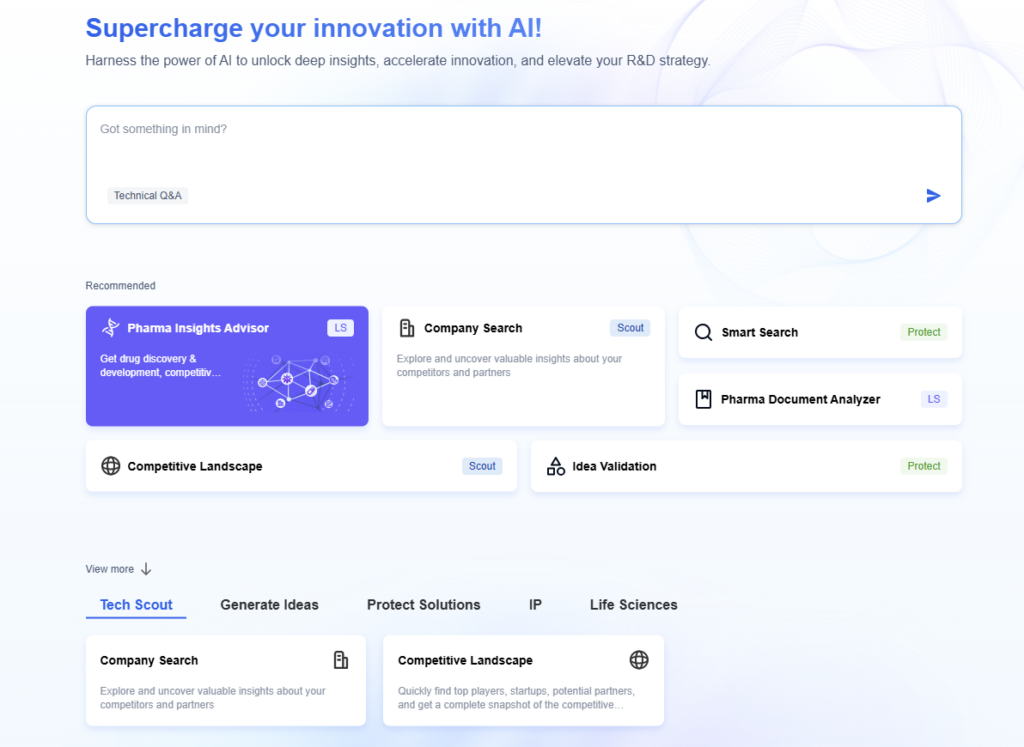

This blog explores Accura 25’s composition, performance, industrial applications, market trends, and sustainability factors. Moreover, We’ll also highlight how the PatSnap Eureka AI Agent empowers materials teams to analyze competitive insights and innovation trends in the additive manufacturing space.

Material Overview (Material Composition & Properties)

Accura® 25 is a polypropylene-like photopolymer used primarily in stereolithography (SLA) 3D printing processes. It’s designed to simulate the mechanical properties and appearance of molded polypropylene (PP), making it suitable for functional prototyping and fit testing.

Chemical & Technical Classification

- Material Type: UV-curable photopolymer resin

- Base Chemistry: Acrylate-based oligomers and monomers with photoinitiators

- Curing Mechanism: Radical polymerization initiated by UV laser exposure

- Product Number (3D Systems): 24138

Physical & Mechanical Properties

| Property | Value Range | Description |

|---|---|---|

| Appearance | Translucent, off-white | Mimics the look of injection-molded PP |

| Density (solid) | ~1.1 g/cm³ | Close to standard SLA resin, slightly denser than PP |

| Tensile Strength | ~42 MPa | Suitable for semi-rigid applications |

| Elongation at Break | 14–18% | Excellent for snap-fit assemblies |

| Flexural Modulus | ~1,380 MPa | Offers stiffness for structural parts |

| Shore D Hardness | 83D | Durable, stiff surface suitable for mechanical contact |

| HDT (0.46 MPa) | ~52°C | Limited heat resistance for non-high-temp uses |

| Water Absorption (24hr) | ~0.3% | Low enough for prototyping under normal humidity conditions |

Performance Attributes

- High feature detail and surface resolution

- Good dimensional stability and accuracy

- Excellent for living hinges, snap fits, and flexing features

- Paintable and post-processable for visual prototypes

- Printable on large-format SLA platforms (ProX®, iPro®, SLA 7000)

Material Grades & Designations

Accura 25 is typically available under a single commercial grade for SLA use, but often modified or post-processed depending on customer-specific needs.

- Standard Reference:

- Proprietary SLA material (by 3D Systems)

- Compatible Printers:

- SLA systems like ProX 800, iPro 8000/9000 series

- Post-Processing Options:

- UV curing, polishing, painting, or dyeing

- Typical Data Sheet Summary:

| Property | Value |

|---|---|

| Tensile Strength | ~42 MPa |

| Elongation at Break | ~14–18% |

| Flexural Modulus | ~1380 MPa |

| HDT (0.46 MPa) | ~52°C |

Application Landscape

- Key Industries:

- Automotive

- Aerospace

- Consumer electronics

- Industrial tooling

- Healthcare (non-biocompatible prototyping)

- Use Cases:

- Snap-fit assemblies

- Concept models

- Jigs and fixtures

- Enclosures and housings

- Trends:

- Growing replacement of CNC parts with SLA prototypes

- Hybrid designs using Accura 25 + silicone molding

- Design validation in high-volume prototyping workflows

Market Demand & Industry Players

- Market Insights:

- Global SLA resin market CAGR: ~8% (2024–2030)

- Rapid growth in functional prototyping applications

- Regional Hotspots:

- North America, Europe, and expanding adoption in East Asia

- Key Players (via Eureka):

- 3D Systems (Accura series)

- Stratasys, Formlabs (alternative SLA resins)

- Henkel, DSM (resin chemistry suppliers)

- Research institutions innovating in UV-curable polymer chains

Technology Landscape

- Manufacturing Technology:

- SLA (Stereolithography Apparatus)

- Resin bath + laser-based UV curing

- Key Milestones:

- 1990s: First commercial SLA resins

- 2000s: Introduction of engineered performance resins

- 2010s–2020s: Accura 25 gains traction for snap-fit and test-fit parts

- Material Comparison:

- Compared to ABS-Like resins: more flexible

- Compared to Accura ClearVue: lower transparency but higher ductility

Breakthrough Innovations & PatSnap Eureka AI Agent Insights

- Recent Patent Highlights:

- Photoinitiator tuning to reduce yellowing over time

- Enhanced curing profiles for faster post-processing

- PatSnap Eureka AI Agent Eureka-Driven Insights:

- Hot Innovation Keywords: “flexible SLA resin”, “UV polymer matrix”, “fine-feature resolution”

- Leading Entities: 3D Systems, Evonik, BASF Forward AM

- White Space: Mid-temperature SLA resins with superior ductility and low warpage

- Case Study:

A recent 3D Systems patent reveals a new variant of Accura 25 optimized for complex snap-fit geometries with reduced creep behavior over time.

Sustainability & Environmental Impact

- Lifecycle Considerations:

- Not biodegradable or recyclable

- Requires careful handling and disposal

- Energy Consumption:

- Lower than FDM/CNC for small batch runs

- Regulatory Status:

- Non-biocompatible; not certified for medical implant use

- Must comply with industrial workplace safety standards

- Not suitable for food-contact unless further treated

Conclusion & Recommendations

- Summary:

Accura 25 offers a strong balance of detail, flexibility, and durability, making it ideal for snap-fit parts and functional SLA prototypes. It’s widely respected for its polypropylene-like behavior and high feature resolution. - Recommendations:

- Ideal for designers seeking high-performance prototypes without tool investment

- Consider hybrid use with injection molding for scalability

- Not suitable for end-use parts requiring heat or chemical resistance

- Final Tip:

Use PatSnap Eureka AI Agent to monitor new resin technologies, explore patent-protected material properties, and stay ahead in SLA material innovation.

FAQs

Accura 25 is an acrylate-based photopolymer resin composed of UV-curable monomers, oligomers, and proprietary photoinitiators. We can use it to simulate the look and flexibility of molded polypropylene.

No, Accura 25 is not biocompatible and is not certified for use in medical implants or skin-contact devices. It’s intended for non-sterile prototyping only in the medical field.

Accura 25 offers higher flexibility and elongation compared to rigid SLA resins like Accura ClearVue or Accura Xtreme. It’s ideal for snap-fit designs and parts requiring mild deformation.

Yes. Printed parts can be sanded, dyed, painted, or coated. Proper UV post-curing is recommended to achieve full mechanical performance before finishing.

Store the resin in cool, dark environments. Avoid exposure to moisture or sunlight. Always wear gloves and handle in well-ventilated areas. The resin has a limited shelf life and may degrade with age.