Process for preparing alkylated oil

A technology of alkylate oil and high octane number, which is used in the preparation of alkylate oil, uses ionic liquid as a catalyst to prepare alkylate oil, can solve problems such as low efficiency, and achieve high reaction activity and recycling operation. Simple and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

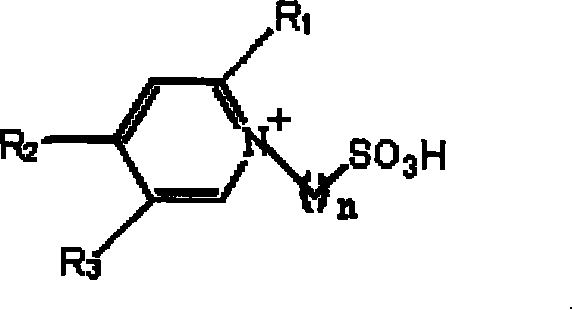

[0042] The toluenesulfonic acid ionic liquid catalyst of 6.0 grams of pyridine butylsulfonic acid is added in the autoclave with stirring, with N 2 Pressing pressure to 0.5MPa, feed 80g of isobutane and butene-1 mixed raw material, the alkene ratio in the raw material is 6:1. Start stirring, raise the temperature to 70°C within 30min, and use N 2 Ensure the pressure is 1.6MPa, and react for 0.5h. After the reaction, cool down and release the pressure. The reaction solution is poured into a separatory funnel and left to stand for stratification, the lower layer is the catalyst phase, and the upper layer is the alkylated oil phase.

Embodiment 2

[0044] Add 2.0% trifluoromethanesulfonic acid ionic liquid catalyst of 2-butylpyridine propylsulfonate into the autoclave with stirring, and use N 2 Pressing pressure to 0.5MPa, feed 80g of isobutane and butene-1 mixed raw material, the alkene ratio in the raw material is 6:1. Start stirring, raise the temperature to 70°C within 30min, and use N 2 Ensure the pressure is 1.6MPa, and react for 0.5h. After the reaction, cool down and release the pressure. The reaction solution is poured into a separatory funnel and left to stand for stratification, the lower layer is the catalyst phase, and the upper layer is the alkylated oil phase.

Embodiment 3

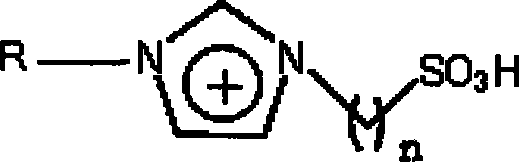

[0046] The toluenesulfonic acid ionic liquid catalyst of 6.0 grams of 1-butyl imidazole sulfonic acid butyl ester is added in the autoclave with stirring, with N 2 Pressing pressure to 0.5MPa, feed 80g of mixed raw material of isobutane and butene-1, the ratio of alkene in the raw material is 10:1. Start stirring, raise the temperature to 70°C within 30min, and use N 2 Ensure the pressure is 1.6MPa, and react for 0.5h. After the reaction, cool down and release the pressure. The reaction solution is poured into a separatory funnel and left to stand for stratification, the lower layer is the catalyst phase, and the upper layer is the alkylated oil phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com