Preparation method for material special for polythene PE/waste and old tire glue powder

A technology of waste tires and polyethylene, applied in the product field, can solve the problems of poor comprehensive properties of rubber powder/PE blend materials, difficulty in ensuring reactive modification, and affecting mechanical properties of output, so as to improve mechanical properties and improve mechanical properties , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

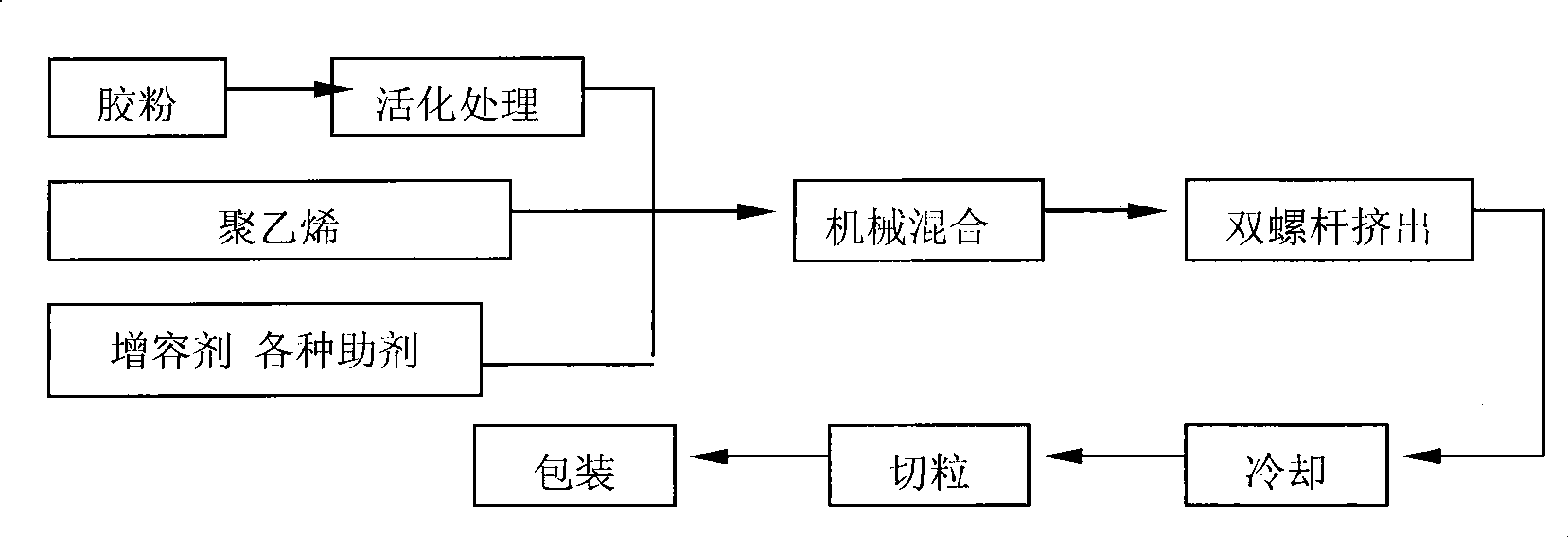

[0023] The preparation process of the embodiment of the present invention is:

[0024] (1) Drying of waste tire rubber powder

[0025] Dry the rubber powder moderately at 70°C for 2 hours.

[0026] (2) Mixing

[0027] Add the dried rubber powder and high-efficiency powder regeneration activator into the high-speed mixer, and stir at a high speed for 5-10 minutes at a temperature of 70-100°C. After cooling to below 50°C, put the mechanically mixed Add PE, reactants, and compatibilizers into the high-speed mixer and continue mixing at high speed for 5-10 minutes, then take them out for use.

[0028] (3) Extrusion granulation

[0029] The uniformly mixed material is extruded and granulated in a twin-screw extruder. The processing temperature range is 120-200°C, the screw speed is 30-60r / min, the feeding speed is 25-50r / min; heat-cut or air-cooled granulation is used for extrusion granulation.

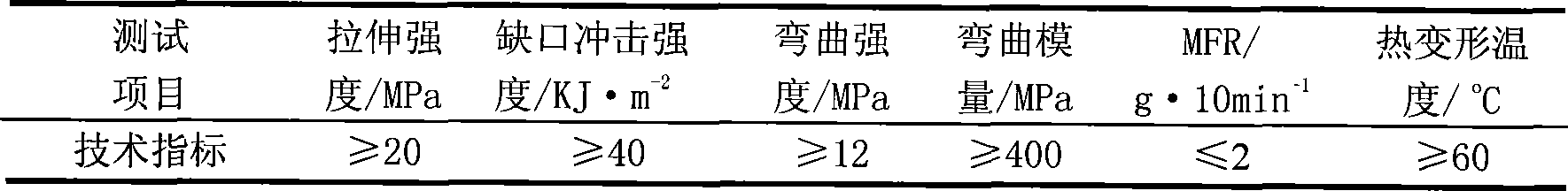

[0030] The formulas of the examples are shown in Table 2, and the properties of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com