Vegetation basis and method of production thereof

一种植被、芯型的技术,应用在植物学设备和方法、种植基质、挖方等方向,能够解决小粘结强度、土壤流失、降低植被基耐久性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

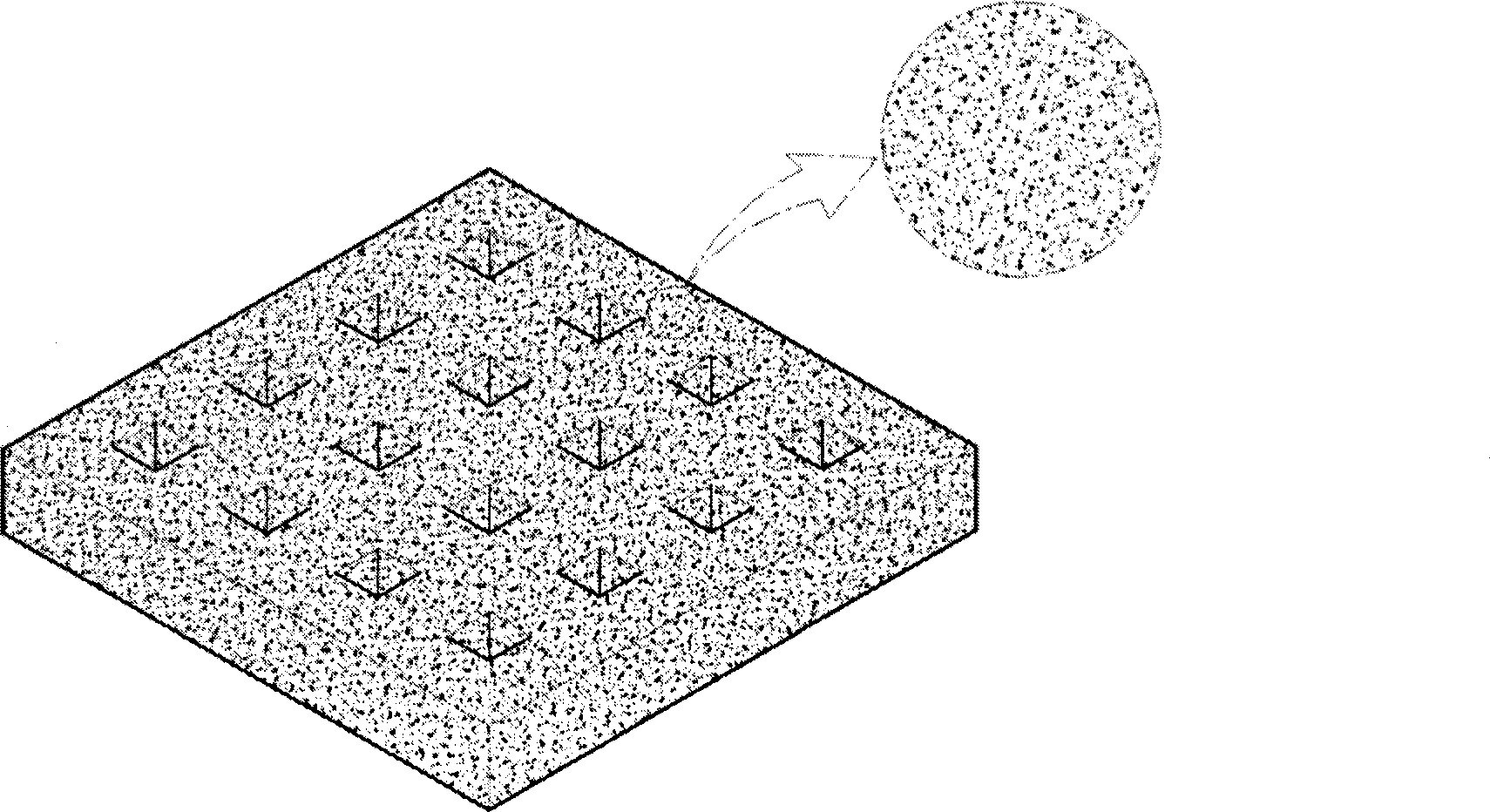

[0079] Example 1: Production of Vegetation Mats Comprising Sheath-Core Polyester Staple Fibers

[0080] The artificial soil was sold by Seoul Bio Co., Ltd. Bed soil, its consumption is 100 parts by weight. Sheath-core polyester fiber ( Saehan Industrial Co., Korea) dosage is 20 parts by weight, and cut into lengths of 6 mm. This was fed into a rotary mixer and mixed together at 3000 rpm. It is believed that the mutual twisting causes the sheath-core polyester staple fibers to be loosened and thoroughly mixed with the artificial soil. The mixture is filled into a grid pattern mold, and then sent to a high frequency heater ( Jeenyang Platech Co., Ltd., Korea), at 4kg / cm 2 Under the pressure of 200 seconds at a temperature of 170 ° C to produce a lattice pattern of vegetation mats containing sheath-core polyester staple fibers ( Figure 2a , 2b). The frequency used is 2.45GHz. It can be determined that the soil in the vegetation mat is made into a loose structure ( ...

example 2

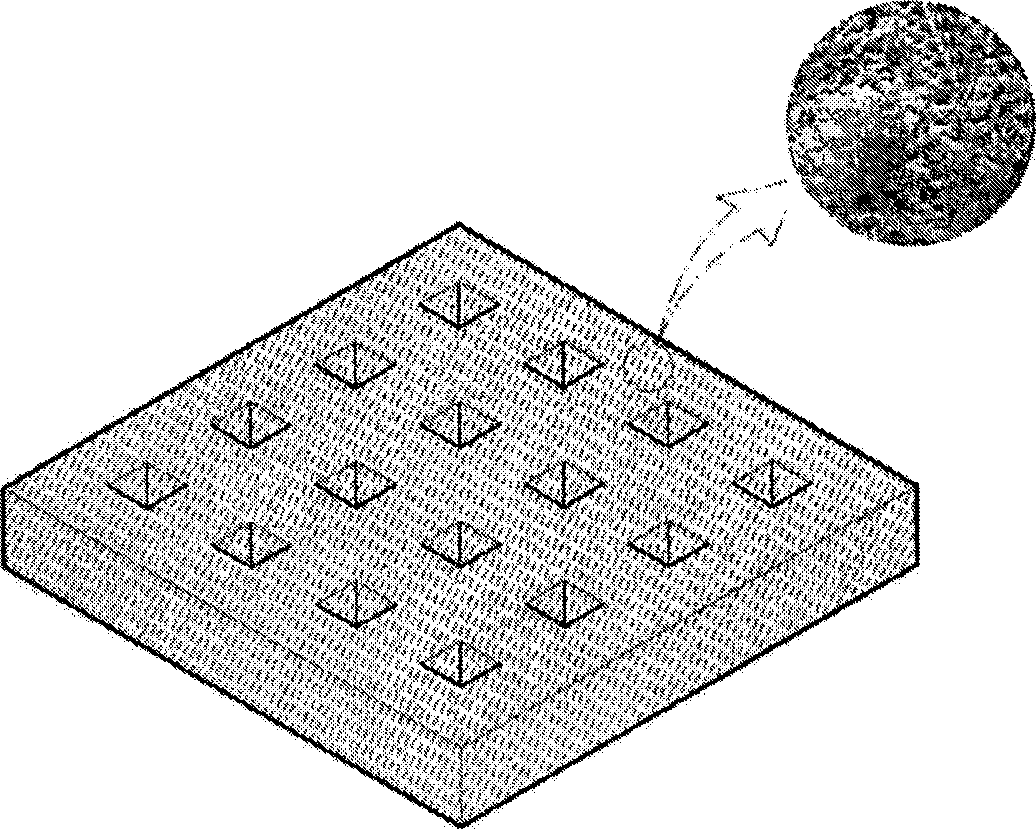

[0081] Example 2: Production of Vegetation Mats Comprising Sheath-Core Polyester Staple Fibers and Hot Melt Adhesives

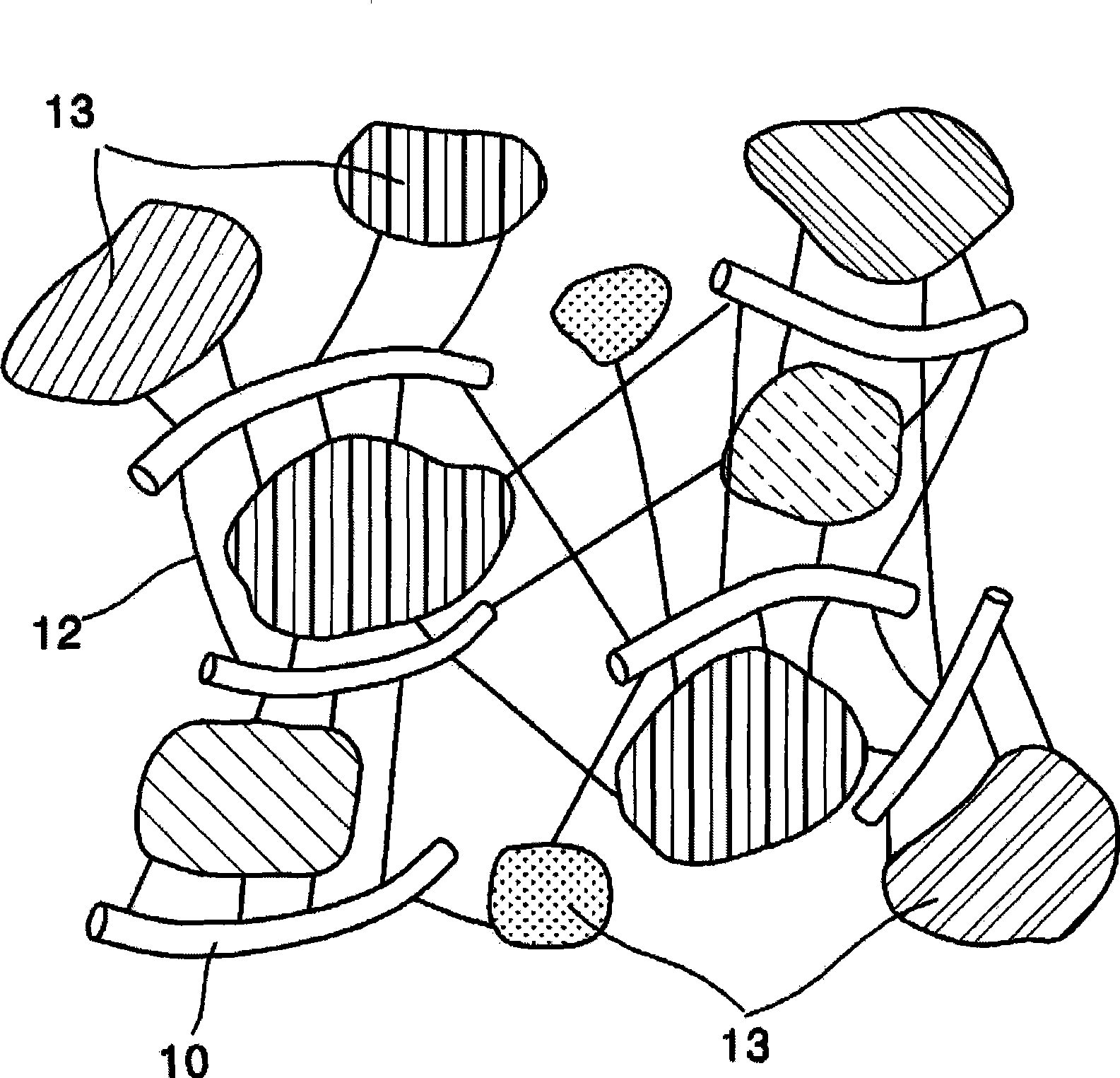

[0082] Vegetation mats with animal shapes are produced by the same method as example 1 except adding polyurethane resin (UNEX4073, DAKOTA, Belgium) as hot melt adhesive, and the consumption of this adhesive is 5 parts by weight ( Figure 3a , 3b ). It is believed that the soil in the vegetated mat is made into a loose structure ( figure 1 ).

example 3

[0083] Example 3: Production of Vegetable Base Containing Polyester Staple Fibers

[0084] The artificial soil was sold by Seoul Bio Co., Ltd. Bed soil, its consumption is 95 parts by volume. The amount of polyester fiber is 3 parts by volume, and it is cut into a length of 10 mm. As the hot-melt adhesive, a polyurethane resin (UNEX4073, DAKOTA, Belgium) with a melting point of 130° C. purchased from the market was used in an amount of 2 parts by volume. This was fed into a rotary mixer where it was mixed together at 4000 rpm. It is believed that the mutual twisting causes the sheath-core polyester staple fibers to be loosened and thoroughly mixed with the artificial soil. The mixture is filled into a grid pattern mold, and then sent to a high frequency heater ( Jeenyang Platech Co., Ltd., Korea), at 5kg / cm 2 A vegetation mat containing polyester staple fibers ( Figure 2a , 2b). The frequency used is 2.45GHz. It is believed that the soil in the vegetated mat is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com