Novel method for preparing high-purity chlorogenic acid

A chlorogenic acid, high-purity technology, used in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc. Adsorption and extraction, continuous and simple operation, and the effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

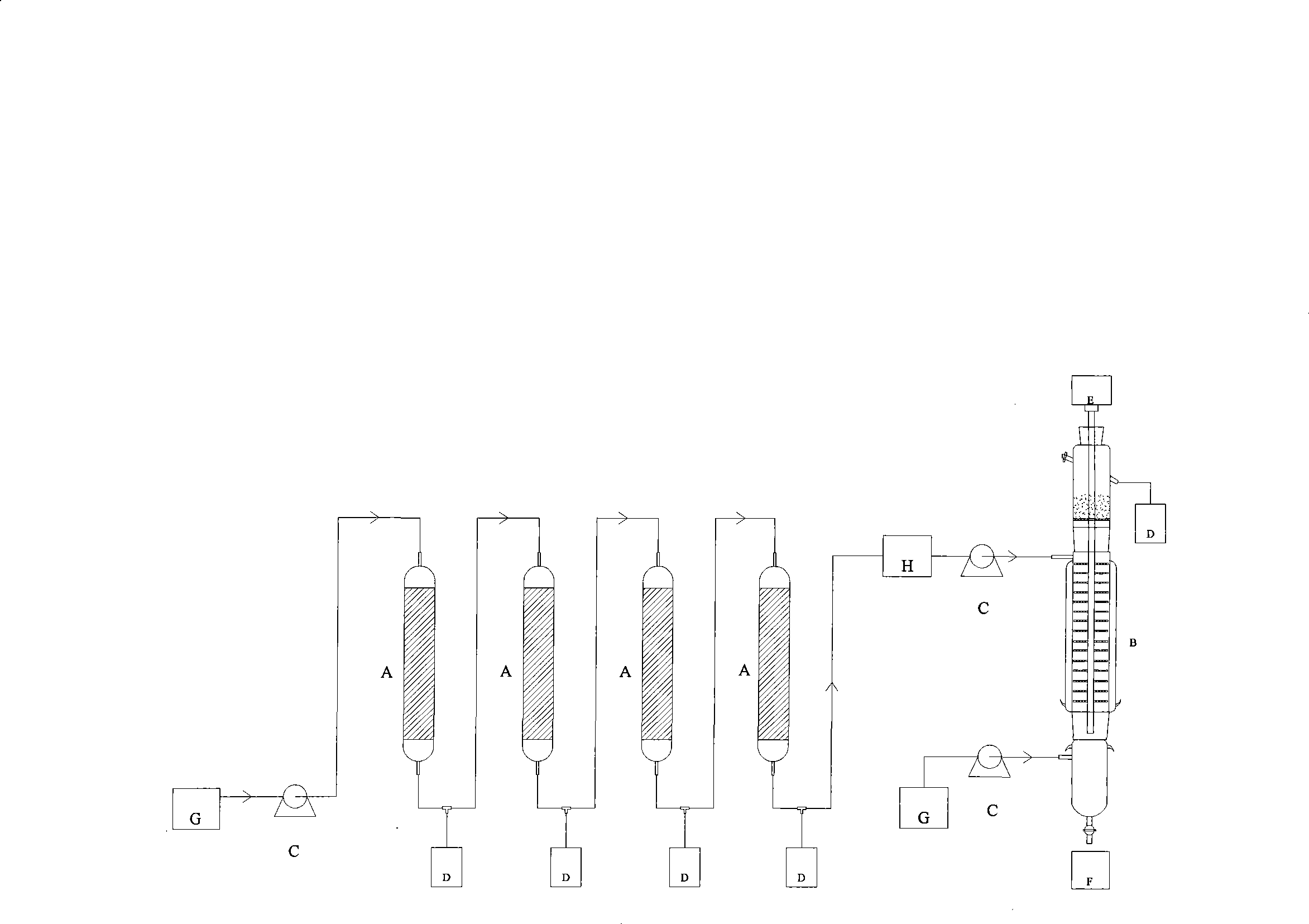

Image

Examples

Embodiment 1

[0051] The water extract of honeysuckle after deoiling with a pH value of 1 and a concentration of chlorogenic acid of 0.5g / L was used as a raw material, and a 4-stage multi-column series device was selected, and the filler was non-polar adsorption resin HPD-100A (Cangzhou Baoen Adsorption Material Science and Technology Co., Ltd.), the washing solution is hydrochloric acid aqueous solution with pH 3, the eluent is 10% ethanol-water solution, and the regeneration solution is absolute ethanol. Pump the raw material into the first-stage adsorption column at a flow rate of 1BV / h, switch to the second-stage adsorption column for adsorption at the same flow rate of the adsorption liquid after breakthrough, and press the flow rate of 5BV / h for the first-stage adsorption column after penetration. h, 1BV / h and 5BV / h are sequentially pumped into the washing liquid, eluent and regeneration liquid. After the second-stage column is adsorbed and penetrated, it is switched, and the impurity...

Embodiment 2

[0054] The water extract of Eucommia ulmoides after deoiling with a pH value of 4 and a chlorogenic acid concentration of 10 g / L was used as a raw material, a 64-stage multi-column series device was selected, and the filler was medium polarity adsorption resin AB-8 (Cangzhou Baoen Adsorption Material Technology Co., Ltd. Co., Ltd.), the washing liquid is hydrochloric acid aqueous solution of pH 3, the eluent is 50% ethanol, and the regeneration liquid is absolute ethanol. Pump the raw material into the first-stage adsorption column at a flow rate of 5BV / h, switch to the second-stage adsorption column for adsorption at the same flow rate of the adsorption liquid after breakthrough, and press the flow rate of 10BV / h for the first-stage adsorption column after penetration. h, 5BV / h and 10BV / h are sequentially pumped into the washing liquid, eluent and regeneration liquid. After the second-stage column is adsorbed and penetrated, it is switched, and the impurity washing, elution a...

Embodiment 3

[0057] The deoiled water extract of coffee beans with a pH value of 2 and a chlorogenic acid concentration of 1 g / L was used as raw material, a 32-stage multi-column series device was used, and the filler was polar adsorption resin HPD-600 (Cangzhou Baoen Adsorption Material Technology Co., Ltd. Co., Ltd.), the washing solution is hydrochloric acid aqueous solution with pH3, the eluent is 20% ethanol, and the regeneration solution is absolute ethanol. Pump the raw material into the first-stage adsorption column at a flow rate of 1BV / h, switch to the second-stage adsorption column for adsorption at the same flow rate of the adsorbent after breakthrough, and press the flow rate of 8BV / h for the first-stage adsorption column after penetration. h, 2BV / h and 8BV / h are sequentially pumped into the washing liquid, eluent and regeneration liquid. After the second-stage column is adsorbed and penetrated, it is switched, and the impurity washing, elution and regeneration are carried out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com