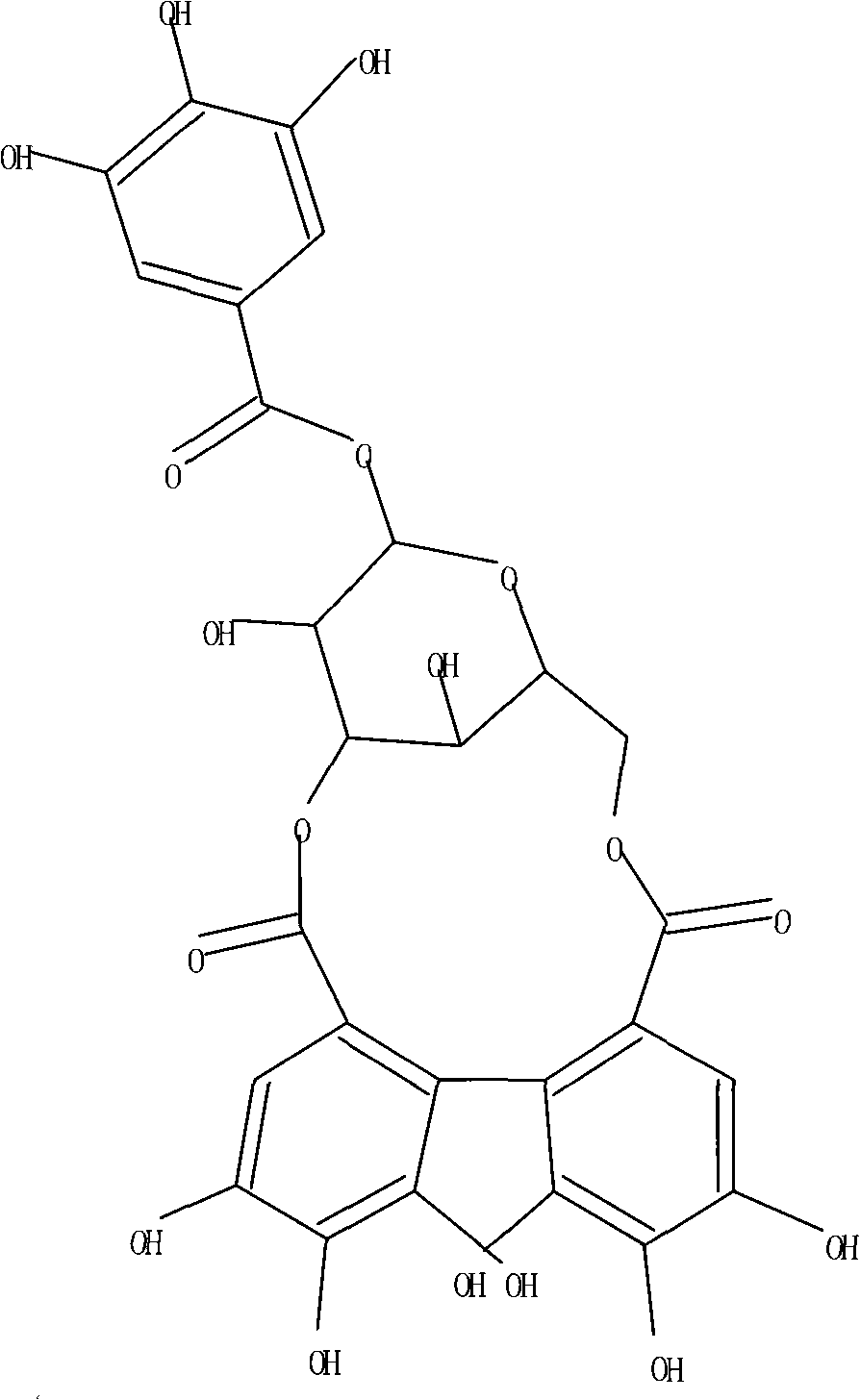

Preparation method of corilagin

A supercritical, pore adsorption technology, applied in the preparation of sugar derivatives, chemical instruments and methods, production of bulk chemicals, etc., can solve problems such as the lack of reports on large-scale industrial production and preparation of high-purity corylazine, and achieve the benefits of large-scale production. Production operation, less pollution and less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Get phylloxera coarse powder 10Kg, join in CO 2 In the supercritical extractor, ethyl acetate is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 3%, the extraction pressure is 10MPa, the temperature is 35°C, and the CO 2 Flow rate 1ml / g crude drug min, extraction time 80min, get extract, add water to dissolve, filter, filtrate is adsorbed by HPD700 type macroporous adsorption resin, 20% ethanol is eluted, collects the eluent of 3 times of column volume, reduces Recover ethanol under pressure and concentrate, add acetic acid to the concentrated solution to adjust the pH to 4-4.5, carry out 6-stage countercurrent extraction with ethyl acetate-water mixed solvent with a ratio of 10:2, the volume ratio of the concentrated solution to the total amount of mixed solvent is 1: 6. Combine the extracts, recover the solvent under reduced pressure, add absolute ethanol to crystallize, separate the crystals, wash, and dry to obtain...

Embodiment 2

[0028] Get phylloxera coarse powder 10Kg, join in CO 2 In the supercritical extractor, ethyl acetate is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 8%, the extraction pressure is 30MPa, the temperature is 55°C, and the CO 2 Flow rate 3ml / g crude drug min, extraction time 150min, get extract, add water to dissolve, filter, filtrate is adsorbed by H50 type macroporous adsorption resin, eluted with 60% ethanol, collects the eluate of 8 times of column volume, reduces Recover ethanol under pressure and concentrate, add acetic acid to the concentrated solution to adjust the pH to 4-4.5, carry out 10-stage countercurrent extraction with ethyl acetate-water mixed solvent with a ratio of 10:2, the volume ratio of the concentrated solution to the total amount of mixed solvent is 1: 10. Combine the extracts, recover the solvent under reduced pressure, add absolute ethanol to crystallize, separate the crystals, wash, and dry to obta...

Embodiment 3

[0030] Get phylloxera coarse powder 10Kg, join in CO 2 In the supercritical extractor, ethyl acetate is used as an entrainer, and the volume percentage of the entrainer in the total extraction solvent is 5%, the extraction pressure is 20MPa, the temperature is 45°C, and the CO 2 Flow rate 2ml / g crude drug min, extraction time 100min, get extract, add water to dissolve, filter, filtrate is absorbed by AB8 type macroporous adsorption resin, 40% ethanol elutes, collects the eluent of 5 times of column volume, reduces Recover ethanol under pressure and concentrate, add acetic acid to the concentrated solution to adjust the pH to 4-4.5, carry out 8-stage countercurrent extraction with ethyl acetate-water mixed solvent with a ratio of 10:2, the volume ratio of the concentrated solution to the total amount of mixed solvent is 1: 8. Combine the extracts, recover the solvent under reduced pressure, add absolute ethanol to crystallize, separate the crystals, wash, and dry to obtain 12.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com