High-toughness carburized bearing steel with ultra-long contact fatigue life and preparation method thereof

A tough carburizing bearing, contact fatigue technology, applied in the field of alloy steel, to achieve the effect of less Paralympics, bearing impact load, toughness and fatigue performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

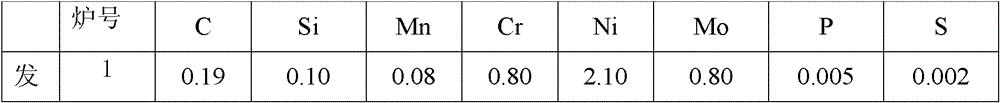

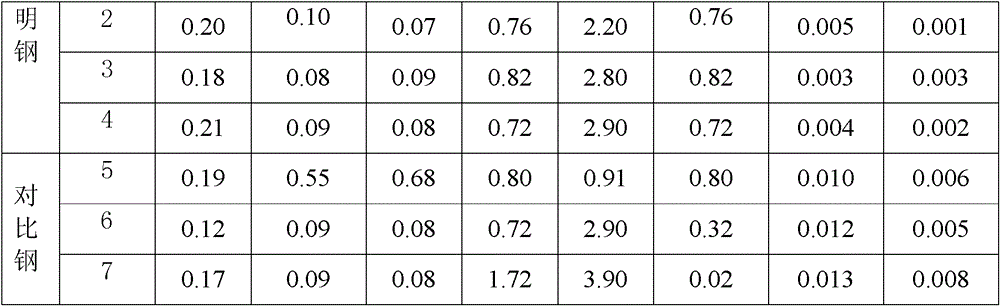

[0025] According to the chemical composition range designed by the present invention, 4 furnaces (number 1-4) of the invention steel were smelted on a 400kg vacuum induction furnace and a vacuum consumable furnace, and in addition 3 groups of Cr-Ni-Mo comparison steel (number 5-7) , No. 5 is 20GrNiMo, No. 6 is 18Gr2Ni4Mo, and No. 7 is 20Gr2Ni4A. The specific chemical composition is shown in Table 1. The content of P and S elements in the invention steel is significantly lower than that of the comparison steel.

[0026] Invention Steel first carries out the ratio of alloying elements on the basis of selected low-phosphorus-sulfur raw materials. Through vacuum smelting, it is cast into ingots. The diameter of the ingot is not less than Φ360mm. The temperature is 1050°C, the final forging (rolling) temperature is 880°C, and finally rolled into Φ120 and Φ85 bars. Invention steel and comparison steel were processed into standard room temperature tensile specimens, Charpy notch impa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| bending fatigue strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com