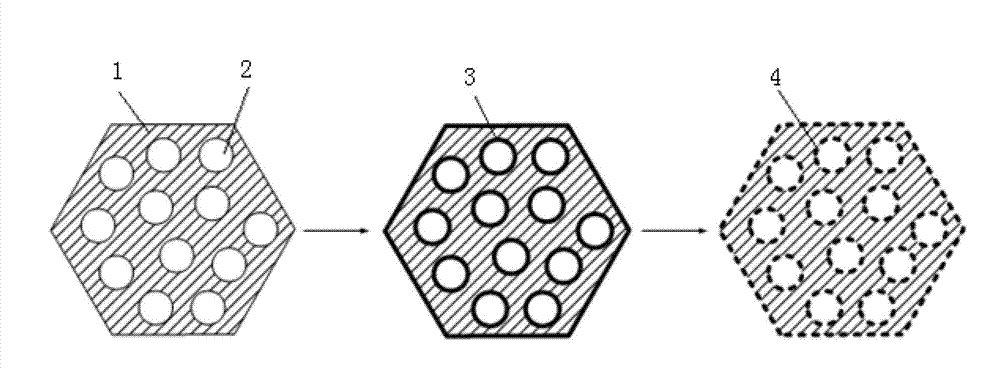

Silicon-carbon composite material, preparation method of silicon-carbon composite material, and lithium ion battery containing silicon-carbon composite material

A technology of silicon-carbon composite materials and composites, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as expensive raw materials and difficult large-scale production, and achieve the effects of enhancing electrical conductivity, saving costs, and shortening diffusion paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

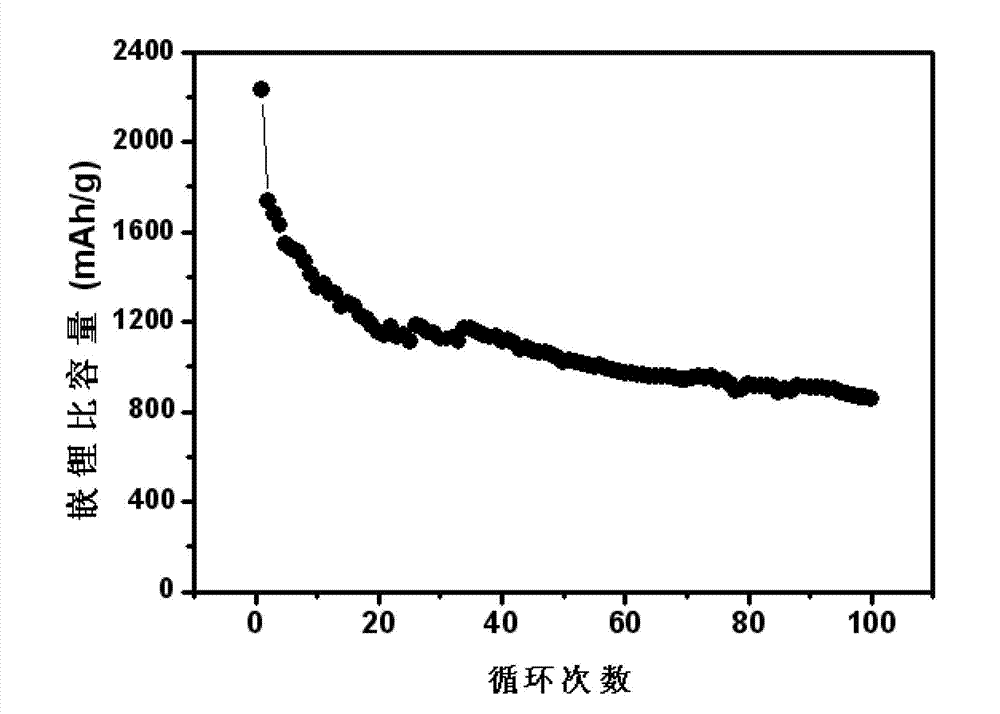

Examples

Embodiment 1

[0031] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0032] (1) Weigh fumed silica powder (particle size: 30nm) and calcium particles (particle size: 1mm), wherein the amount of calcium is 100% of the theoretical amount that can completely reduce the fumed silica powder. The two were mixed, toluene was added thereto, and steel balls were added, put into a planetary ball mill, and ball milled at 350 rpm for 6 hours to obtain a mixed slurry. Transfer the above mixed slurry into a crucible, then put the crucible into an atmosphere furnace, raise the temperature to 600°C at 5°C / min under the protection of argon, and keep it warm for 1 hour; then raise the temperature to 800°C at 5°C / min , and keep warm for 1 hour to obtain a composite of porous silicon-calcium oxide.

[0033] (2) Put the porous silicon-calcium oxide composite into a beaker, and add hydrochloric acid to it, wherein the amount of hydrochloric ...

Embodiment 2

[0042] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0043] (1) Weigh mesoporous silica powder (SBA-15, which is a kind of mesoporous molecular sieve), potassium (particle size 1mm), and the amount of potassium is such that the mesoporous silica powder can completely 80% of the theoretical amount of reduction. The two were mixed and cyclohexane was added thereto, and then steel balls were added, put into a planetary ball mill, and ball milled at 350 rpm for 8 hours to obtain a mixed slurry. Transfer the above mixed slurry into the crucible, then put the crucible into the atmosphere furnace, raise the temperature to 550°C under the protection of argon at 5°C / min, and keep it for 5 hours; then raise the temperature to 800°C at 5°C / min , and kept for 12 hours to obtain a composite of porous silicon-potassium oxide.

[0044] (2) Put the composite of porous silicon-potassium oxide into a beaker, and add acet...

Embodiment 3

[0048] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0049] (1) Weigh quartz sand and magnesium (particle size: 1mm), and the amount of magnesium is 110% of the theoretical amount that can completely reduce the quartz sand. The two were mixed and cyclohexane was added thereto, and then steel balls were added, put into a planetary ball mill, and ball milled at 300 rpm for 6 hours to obtain a mixed slurry. Transfer the above-mentioned mixed slurry into a crucible, then put the crucible into an atmosphere furnace, raise the temperature to 650°C at 5°C / min under the protection of argon, and keep it warm for 2 hours; then raise the temperature to 900°C at 5°C / min , kept for 3 hours to obtain a composite of porous silicon-magnesia.

[0050] (2) Put the porous silicon-magnesia composite into a beaker, and add a mixture of acetic acid and hydrochloric acid to it, wherein the amount of the mixture of acetic acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com