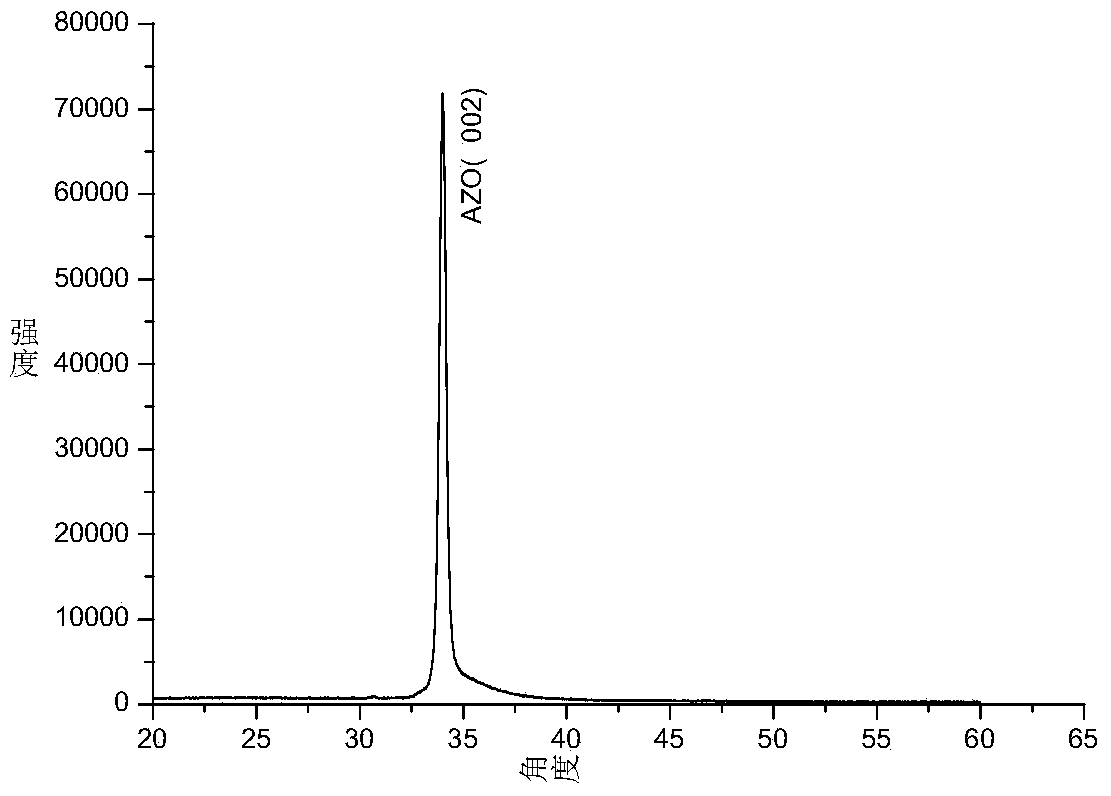

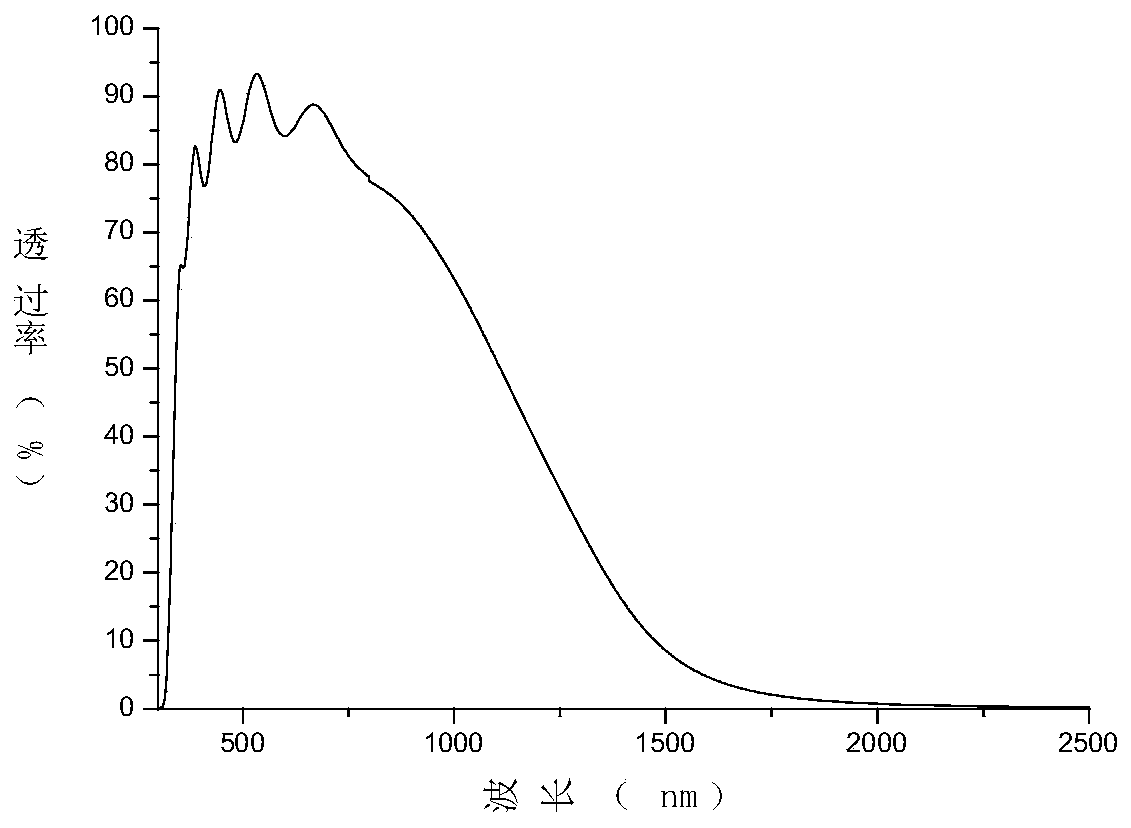

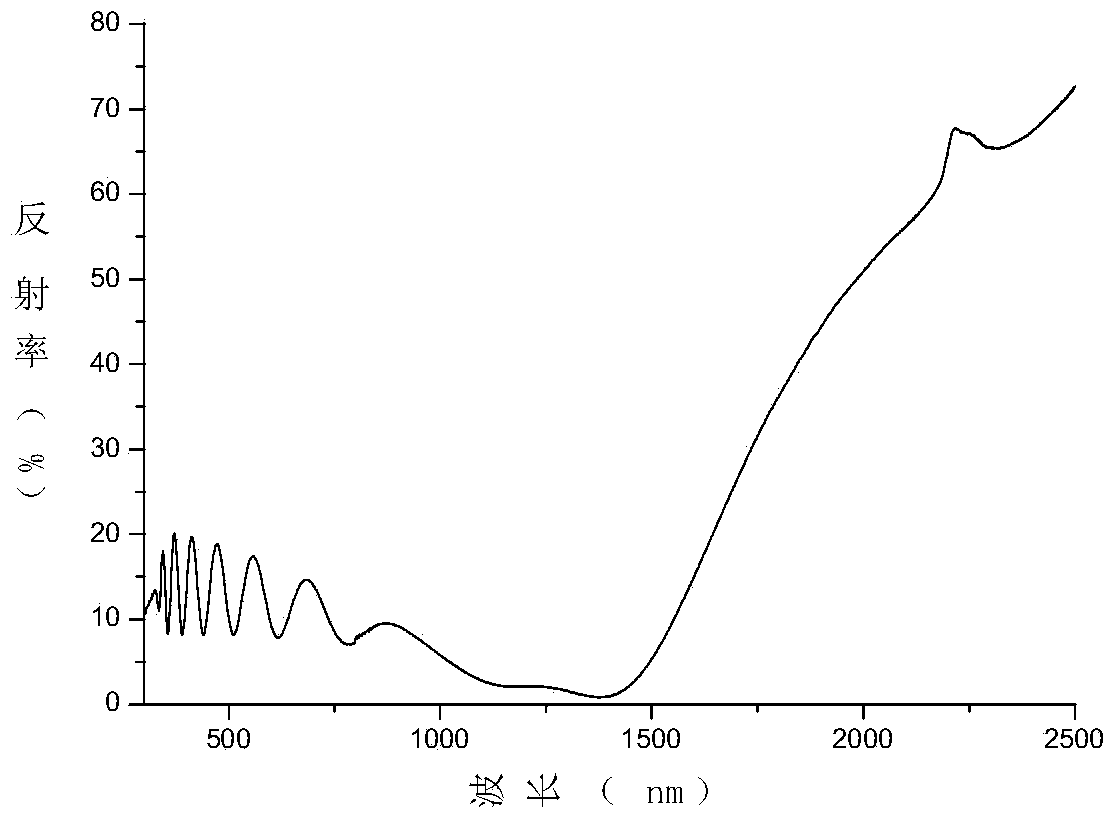

Preparation method of aluminum-doped zinc oxide (AZO) transparent conducting film

A technology of transparent conductive film and aluminum-doped zinc oxide, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of poor process stability and high cost of AZO process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Using Al 2 o 3 The hot-pressed AZO ceramic target with a doping amount of 2% is a sputtering target, the target size is Φ75×5mm, the deposition atmosphere is a hydrogen atmosphere, the sputtering power is 80W, and the distance between the target and the base is 160mm. The AZO transparent conductive film is prepared Specific steps are as follows:

[0034] (1) use aqua regia (V HCl :V HNO3 =3:1) Soak for 15 minutes, rinse with deionized water, then ultrasonically clean in acetone and alcohol for 5 minutes, and then dry in an oven for use;

[0035] (2) Install the above-mentioned cleaned glass sheet on the sample stage of the magnetron sputtering equipment, install the AZO ceramic target material, and adjust the target base distance to 160mm;

[0036] (3) Vacuumize the deposition chamber of the magnetron sputtering equipment, and pre-pump the argon and oxygen gas paths until the vacuum degree of the magnetron sputtering deposition chamber is better than 8.5×10 -4 At P...

Embodiment 2

[0040] Using Al 2 o 3The hot-pressed AZO ceramic target with a doping amount of 2% is a sputtering target, the target size is Φ75×5mm, the deposition atmosphere is a hydrogen atmosphere, the sputtering power is 80W, and the distance between the target and the base is 160mm. The AZO transparent conductive film is prepared Specific steps are as follows:

[0041] (1) use aqua regia (V HCl :V HNO3 =3:1) Soak for 15 minutes, rinse with deionized water, then ultrasonically clean in acetone and alcohol for 5 minutes, and then dry in an oven for use;

[0042] (2) Install the above-mentioned cleaned glass sheet on the sample stage of the magnetron sputtering equipment, install the AZO ceramic target material, and adjust the target base distance to 160mm;

[0043] (3) Vacuumize the deposition chamber of the magnetron sputtering equipment, and pre-pump the argon and oxygen gas paths until the vacuum degree of the magnetron sputtering deposition chamber is better than 8.5×10 -4 At Pa...

Embodiment 3

[0047] Using Al 2 o 3 The hot-pressed AZO ceramic target with a doping amount of 2% is a sputtering target, the target size is Φ75×5mm, the deposition atmosphere is a hydrogen atmosphere, the sputtering power is 80W, and the distance between the target and the base is 160mm. The AZO transparent conductive film is prepared Specific steps are as follows:

[0048] (1) use aqua regia (V HCl :V HNO3 =3:1) Soak for 15 minutes, rinse with deionized water, then ultrasonically clean in acetone and alcohol for 5 minutes, and then dry in an oven for use;

[0049] (2) Install the above-mentioned cleaned glass sheet on the sample stage of the magnetron sputtering equipment, install the AZO ceramic target material, and adjust the target base distance to 160mm;

[0050] (3) Vacuumize the deposition chamber of the magnetron sputtering equipment, and pre-pump the argon and oxygen gas paths until the vacuum degree of the magnetron sputtering deposition chamber is better than 8.5×10 -4 At P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com