Process for preparing black iron oxide by utilizing wastewater generated in production of chlorinated benzene

A technology of iron oxide black and chlorinated benzene, which is applied in the directions of ferrous oxide, iron oxide/iron hydroxide, etc., can solve the problem of difficult treatment of waste water, and achieves lower waste water treatment costs, lower production costs, and stable operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

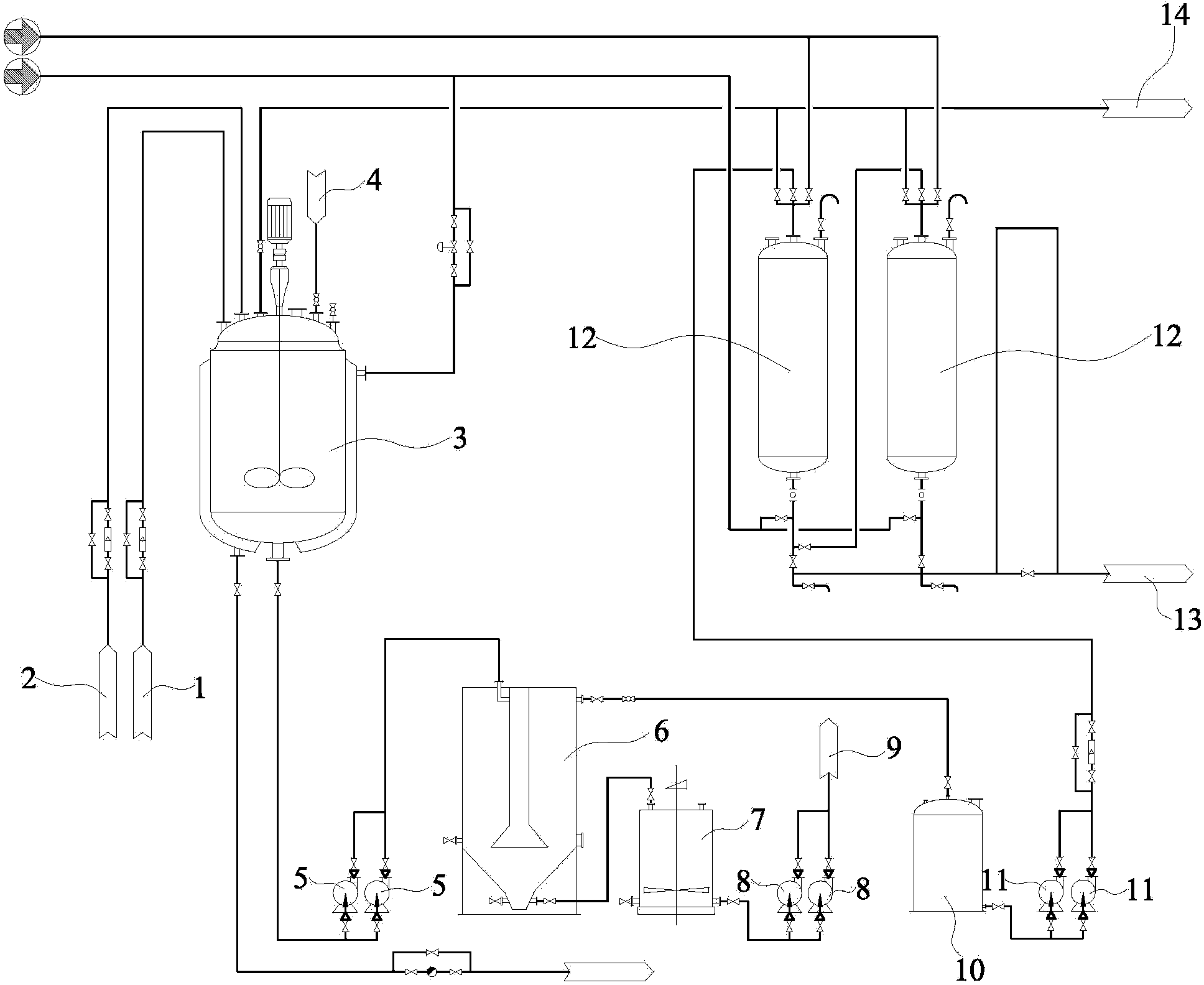

[0032] Such as figure 1 Shown:

[0033] Utilize the waste water produced by chlorinated benzene to prepare the technique of iron oxide black, concrete steps are as follows:

[0034] (1) Waste acid water feeding: check the liquid level of washing waste water tank 1, and feed waste acid water into titanium reactor 3. When the liquid level reaches 70% of the volume of reactor 3, stop feeding waste acid water and open the steam valve , the steam pressure is controlled at 0.1 MPa, and the stirring speed is controlled at 80 r / min to stir at a constant speed;

[0035] (2) Add reducing agent: when the reaction temperature reaches 60 °C, close the steam valve, add reducing agent 4 according to the molar ratio of ferric ion and reducing agent in the solution is 1.5:1, reducing agent 4 is reduced iron powder, when the solution When the color changes from light yellow to yellow-green, it can be considered that the reduced iron powder is completely dissolved. At this time, the Fe in the ...

Embodiment 2

[0041] Such as figure 1 Shown:

[0042] Utilize the waste water produced by chlorinated benzene to prepare the technique of iron oxide black, concrete steps are as follows:

[0043] (1) Feed waste acid water: check the liquid level of washing waste water tank 1, feed waste acid water into titanium reactor 3, stop feeding waste acid water when the liquid level reaches 80% of the volume of reactor 3, and open the steam valve , the steam pressure is controlled at 0.2 MPa, and the stirring speed is controlled to rotate and stir at a rotating speed of 50 r / min;

[0044] (2) Add reducing agent: when the reaction temperature reaches 80 °C, close the steam valve, add reducing agent 4 according to the molar ratio of ferric ion and reducing agent in the solution is 2.5:1, reducing agent 4 is reduced iron powder, when the solution When the color changes from light yellow to yellow-green, it can be considered that the reduced iron powder is completely dissolved. At this time, the Fe in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com