Yellow-gray quick-drying anti-corrosive paint for galvanized stainless pipe fitting and preparation method thereof

A technology of stainless steel and anti-corrosion paint, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor corrosion resistance, easy peeling of spray film and paint layer, poor adhesion, etc., to improve anti-corrosion performance, increase anti-rust and Corrosion resistance, the effect of increasing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

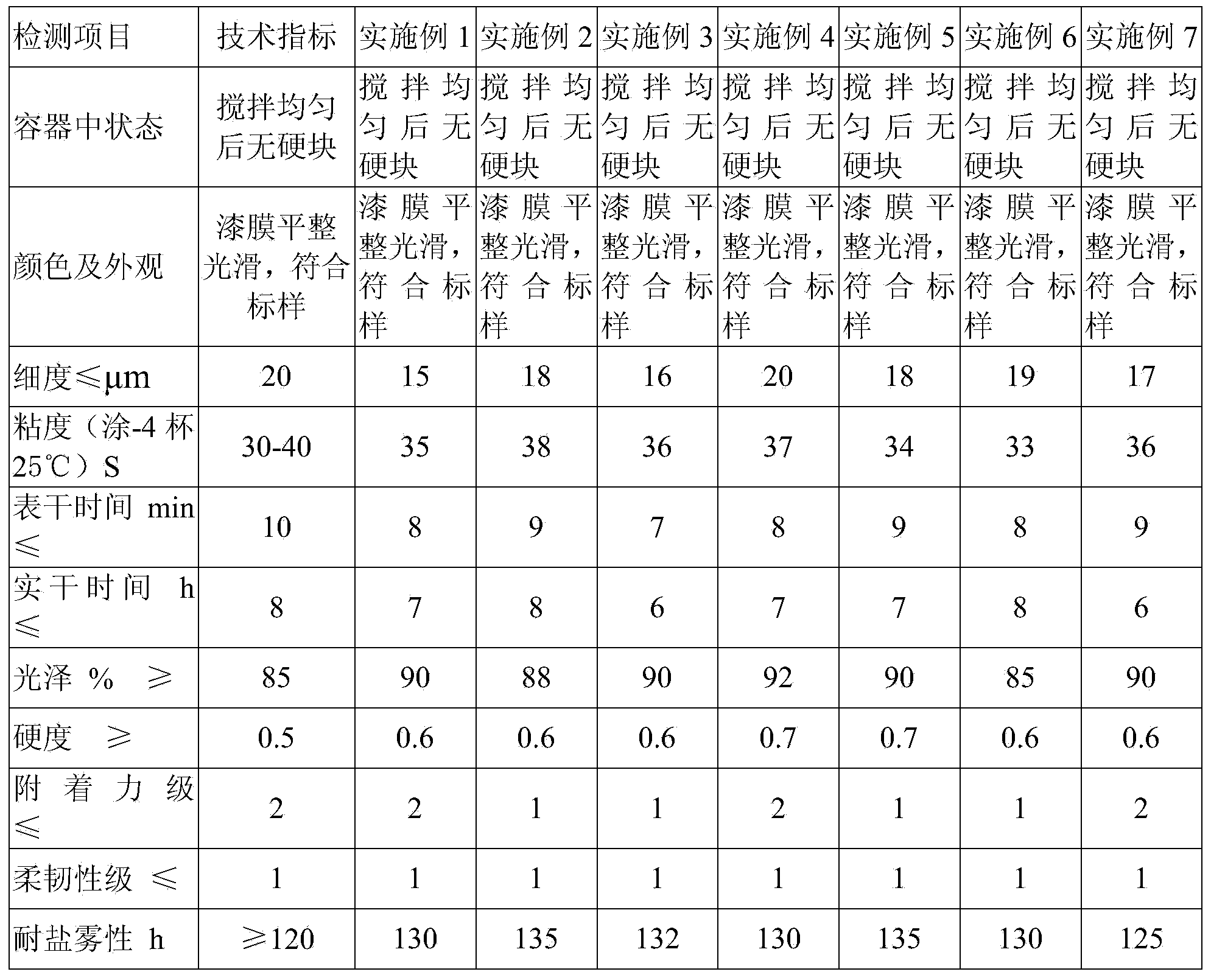

Examples

preparation example Construction

[0017] A method for preparing a yellow-gray quick-drying anti-corrosion paint for galvanized stainless steel pipe fittings, comprising the following steps:

[0018] 1) Add the acrylic resin into the material preparation tank, and start the disperser to stir;

[0019] 2) Slowly add dispersant, titanium dioxide, medium chrome yellow, high-pigment carbon black and 1 / 3 xylene under stirring, and grind until the fineness is less than 20 μm after stirring evenly;

[0020] 3) Take it to the paint mixing tank, add modified resin, leveling agent, adhesion aid, preservative, butyl acetate and the remaining xylene, stir well, and it is ready.

[0021] In the following examples, the technical indicators of the acrylic resin used are as follows:

[0022] serial number

project

technical indicators

1

Exterior

clear transparent liquid

2

Viscosity (format tube) S

20-30

[0023] 3

Finenessum≤

15

4

Colorimetric...

Embodiment 1

[0028] The invention provides a yellow-gray quick-drying anti-corrosion paint for galvanized stainless steel pipe fittings, which is prepared from the following components in weight percentage: 39% of acrylic resin, 13% of modified resin, 11% of titanium dioxide, and 4% of medium chrome yellow %, high pigment carbon black 0.25%, dispersant 0.75%, leveling agent 0.4%, adhesion aid 1.4%, preservative 0.7%, butyl acetate 13% and xylene 16.5%.

[0029] The above-mentioned preparation method for the yellow-gray quick-drying anticorrosion paint for galvanized stainless steel pipe fittings comprises the following steps:

[0030] 1) Add the acrylic resin into the material preparation tank, and start the disperser to stir;

[0031] 2) Slowly add dispersant, titanium dioxide, medium chrome yellow, high-pigment carbon black and 1 / 3 xylene under stirring, and grind until the fineness is less than 20 μm after stirring evenly;

[0032] 3) Take it to the paint mixing tank, add modified resi...

Embodiment 2

[0034] This embodiment provides a yellow gray quick-drying anti-corrosion paint for galvanized stainless steel pipe fittings, which is made from the following components in percentage by weight: 38% acrylic resin, 14% modified resin, 10% titanium dioxide, medium chrome yellow 5%, high pigment carbon black 0.2%, dispersant 0.6%, leveling agent 0.2%, adhesion aid 1.5%, preservative 0.5%, butyl acetate 12% and xylene 18%.

[0035] The above-mentioned preparation method for the yellow-gray quick-drying anticorrosion paint for galvanized stainless steel pipe fittings comprises the following steps:

[0036] 1) Add the acrylic resin into the material preparation tank, and start the disperser to stir;

[0037] 2) Slowly add dispersant, titanium dioxide, medium chrome yellow, high-pigment carbon black and 1 / 3 xylene under stirring, and grind until the fineness is less than 20 μm after stirring evenly;

[0038] 3) Take it to the paint mixing tank, add modified resin, leveling agent, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com