Urea-free active dye printing color paste and printing technology thereof

A technology of reactive dyes and printing pastes, which can be used in dyeing, textiles and papermaking, and can solve the problems of rising prices and printing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

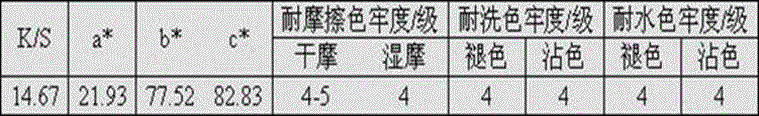

Embodiment 1

[0020] The urea-free reactive dye printing paste of the present embodiment is made from the raw materials of the following weight ratio: reactive red K-2G 1%, PEG 200 0.5%, glycerin 0.5%, sodium bicarbonate 2% , anti-staining salt S 1%, thickener PTF-RT 5%, the balance is water.

[0021] The printing process of the urea-free reactive dye printing paste of the present embodiment to cotton fabrics, the steps are as follows: Weigh the PEG 200 and glycerin of the formula amount, add an appropriate amount of water to fully dissolve it, and then add the formula amount of anti-staining salt S , fully stirred to dissolve the anti-staining salt S to obtain a mixture A; weigh the reactive dye of the formula amount, add a small amount of distilled water to make a paste, pour it into the mixture A, and stir fully to dissolve the reactive dye to obtain a mixture B; then Mixture B is slowly added to the diluted thickener PTF-RT in the formula amount, pour the remaining water, stir well, add...

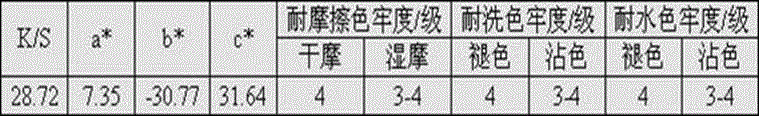

Embodiment 2

[0023] The urea-free reactive dye printing paste of the present embodiment is made from the raw materials of the following weight ratio: reactive red K-2BP 1.5%, reactive red M-8B 0.5%, PEG 200 0.5%, glycerin 1%, sodium bicarbonate 2%, anti-staining salt S 1%, thickener PTF-RT 6%, the balance is water.

[0024] The printing process of the urea-free reactive dye printing paste of the present embodiment to cotton fabrics, the steps are as follows: use reactive red K-2BP 1.5%, reactive red M-8B 0.5%, PEG 200 0.5%, glycerin 1%, Sodium bicarbonate 2%, resist salt S 1%, thickener PTF-RT 6%, the balance is water printing paste (preparation method is the same as Example 1) to print on cotton fabrics, and then dry at 90°C for 6min , steamed at 105°C for 7 minutes, and then post-treatment. The post-treatment process includes cold water washing, hot water washing, neutral soap washing, hot water washing, cold water washing, and drying.

Embodiment 3

[0026] The urea-free reactive dye printing color paste of the present embodiment is made from the raw materials of the following weight ratio: reactive yellow K-RN 3%, PEG 200 1%, glycerin 1%, sodium bicarbonate 2.5% , anti-staining salt S 1%, thickener PTF-RT 4%, the balance is water.

[0027] The printing process of the urea-free reactive dye printing paste of the present embodiment to cotton fabrics, the steps are as follows: use reactive yellow K-RN 3%, PEG 200 1%, glycerin 1%, sodium bicarbonate 2.5%, resist Salt S 1%, thickener PTF-RT 4%, the balance is water printing paste (preparation method is the same as Example 1) to print on cotton fabrics, then dry at 80°C for 7min, steam at 102°C for 10min, and then Carry out post-processing, the post-processing process includes cold water washing, hot water washing, neutral soap washing, hot water washing, cold water washing, and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com