Preparation process of Al-Zn-Mg alloy profile for high-speed train body

A high-speed EMU and alloy profile technology, which is applied in the field of preparation of Al-Zn-Mg alloy profiles for high-speed EMU car bodies, can solve the problems of reduced fatigue performance stability, reduced stress corrosion resistance, and large performance differences. , to achieve the effects of ensuring performance stability, improving heat treatment accuracy, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

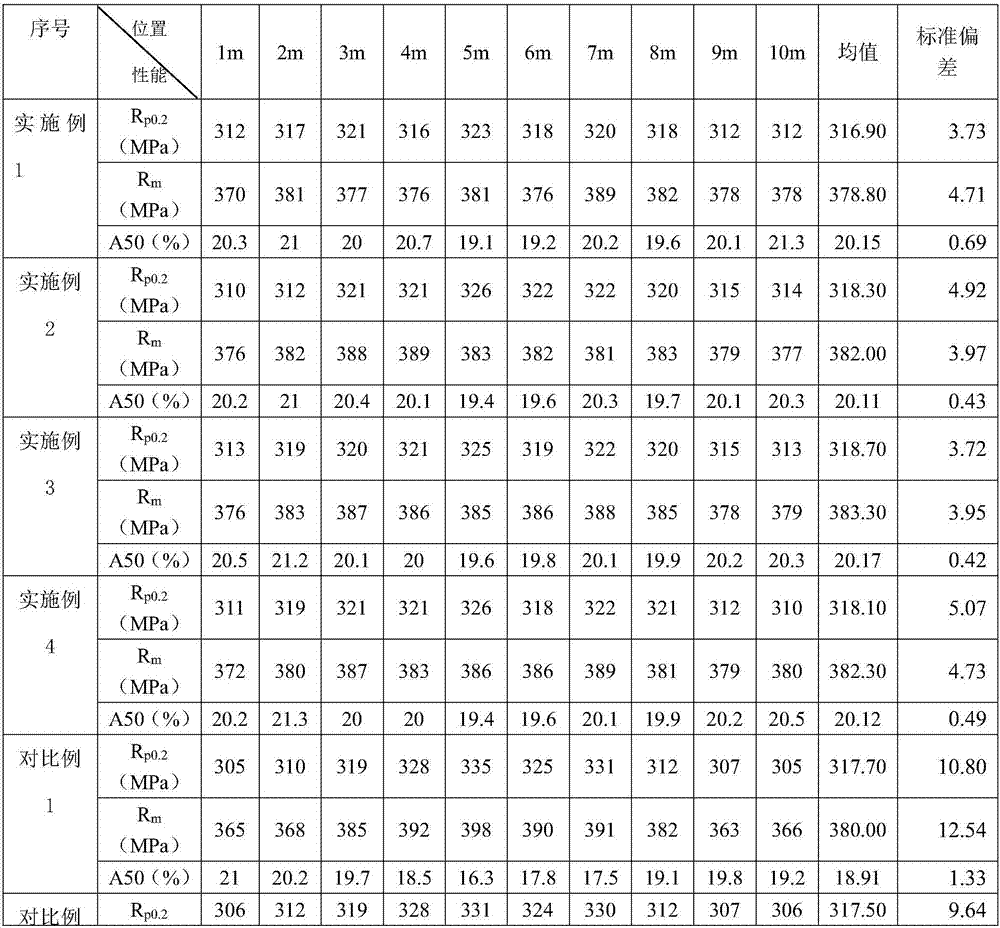

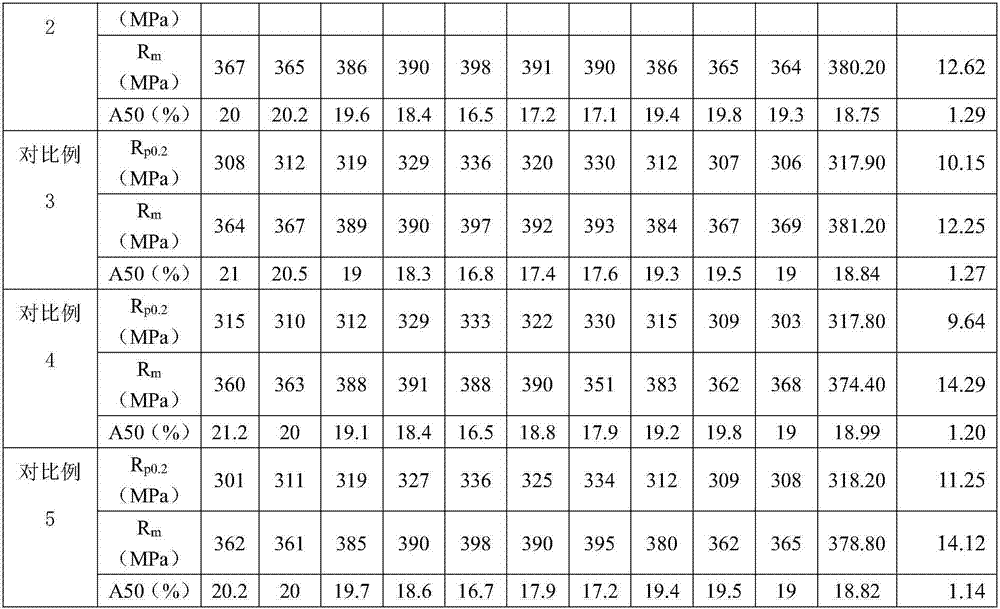

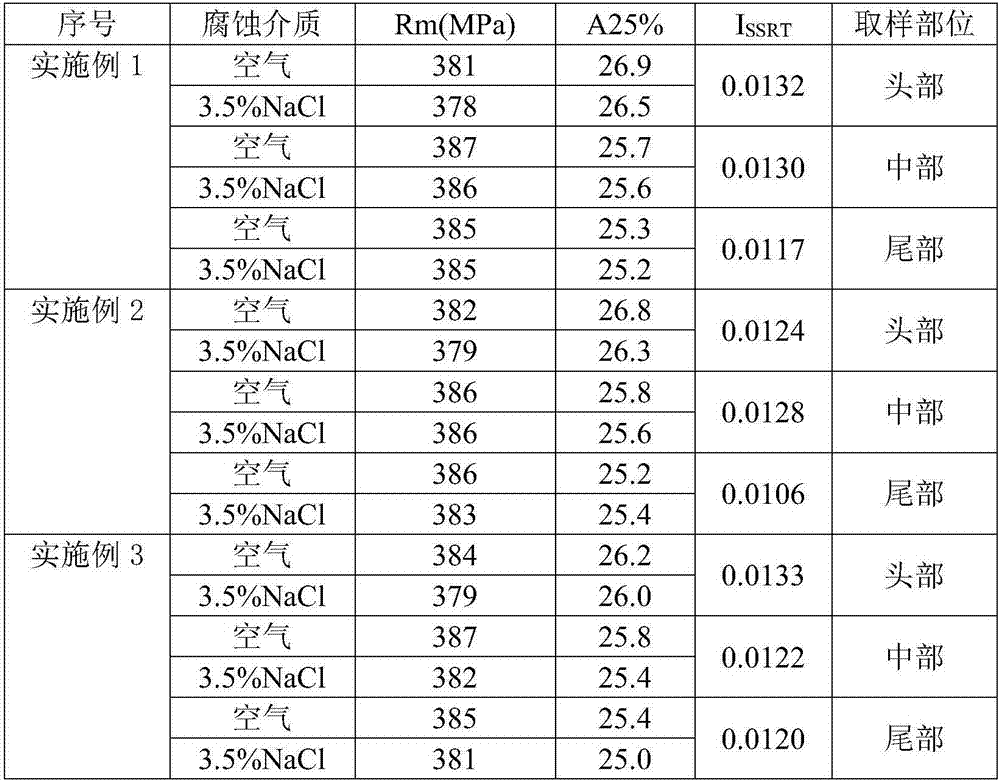

Examples

Embodiment 1

[0024] A preparation process for an Al-Zn-Mg alloy profile for a high-speed EMU car body, comprising the following steps:

[0025] (1) Extrusion: The mass percentage composition of each component with a length of 700mm includes: Mg: 0.8%, Zn: 3.0%, Si≤0.4%, Fe≤0.5%, Mn≤0.30%, Zr≤0.20%, Cr ≤ 0.20%, Cu ≤ 0.20%, Ti ≤ 0.05%, V ≤ 0.03%, Al-Zn-Mg alloy ingot with the balance of Al, heated in a heating furnace, Al-Zn-Mg alloy ingot is heated The heating temperature in the furnace is controlled at 400°C, and the temperature of the head of the Al-Zn-Mg alloy ingot is 2°C higher than that of the tail, and then it is extruded on the line, and the extrusion speed is controlled at 0.2m / min;

[0026] (2) Roller bottom continuous solution quenching: Put the Al-Zn-Mg alloy profile in step (1) into the roller hearth furnace, hold the temperature at 400°C, and the heat preservation accuracy is ±3°C, then perform continuous quenching, the quenching pressure 3.0bar, the quenching method is water...

Embodiment 2

[0032] A preparation process for an Al-Zn-Mg alloy profile for a high-speed EMU car body, comprising the following steps:

[0033] (1) Extrusion: The mass percentage composition of each component with a length of 1800mm includes: Mg: 2.2%, Zn: 6.0%, Si≤0.4%, Fe≤0.5%, Mn≤0.30%, Zr≤0.20%, The Al-Zn-Mg alloy ingot with Cr≤0.20% and the balance of Al is heated in a heating furnace. The heating temperature of the Al-Zn-Mg alloy ingot in the heating furnace is controlled at 510 ° C, and the Al-Zn -The temperature at the head of the Mg alloy ingot is 60°C higher than the temperature at the tail, and then it is extruded on the line, and the extrusion speed is controlled at 2.0m / min;

[0034] (2) Roller bottom continuous solution quenching: Put the Al-Zn-Mg alloy profile in step (1) into the roller hearth furnace, hold the temperature at 480°C, and the heat preservation accuracy is ±3°C, then perform continuous quenching, the quenching pressure It is 6.0bar, and the quenching method i...

Embodiment 3

[0040] A preparation process for an Al-Zn-Mg alloy profile for a high-speed EMU car body, comprising the following steps:

[0041] (1) Extrusion: The mass percentage composition of each component with a length of 800mm includes: Mg: 1.2%, Zn: 4.0%, Si≤0.4%, Fe≤0.5%, Zr≤0.20%, Cr≤0.20% , V ≤ 0.03%, Al-Zn-Mg alloy ingot with the balance of Al, heated in a heating furnace, the heating temperature of the Al-Zn-Mg alloy ingot in the heating furnace is controlled at 450 ° C, and the Al- The temperature at the head of the Zn-Mg alloy ingot is 25°C higher than the temperature at the tail, and then on-line extrusion, the extrusion speed is controlled at 1.5m / min;

[0042] (2) Roller bottom continuous solution quenching: Put the Al-Zn-Mg alloy profile in step (1) into the roller hearth furnace, hold the temperature at 450°C, and the heat preservation accuracy is ±3°C, then perform continuous quenching, the quenching pressure It is 4.0bar, and the quenching method is water mist quenchin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com