Method for separating iron and aluminum from red mud and/or iron-containing solid waste

A technology for separation of iron and solid-liquid separation, applied in the field of separation of iron and aluminum, can solve the problems of the comprehensive utilization rate of red mud not exceeding 10%, the corrosion of heat storage materials and reaction materials, and the lack of macro utilization technology. Potential for industrial applications, low equipment requirements, mild effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

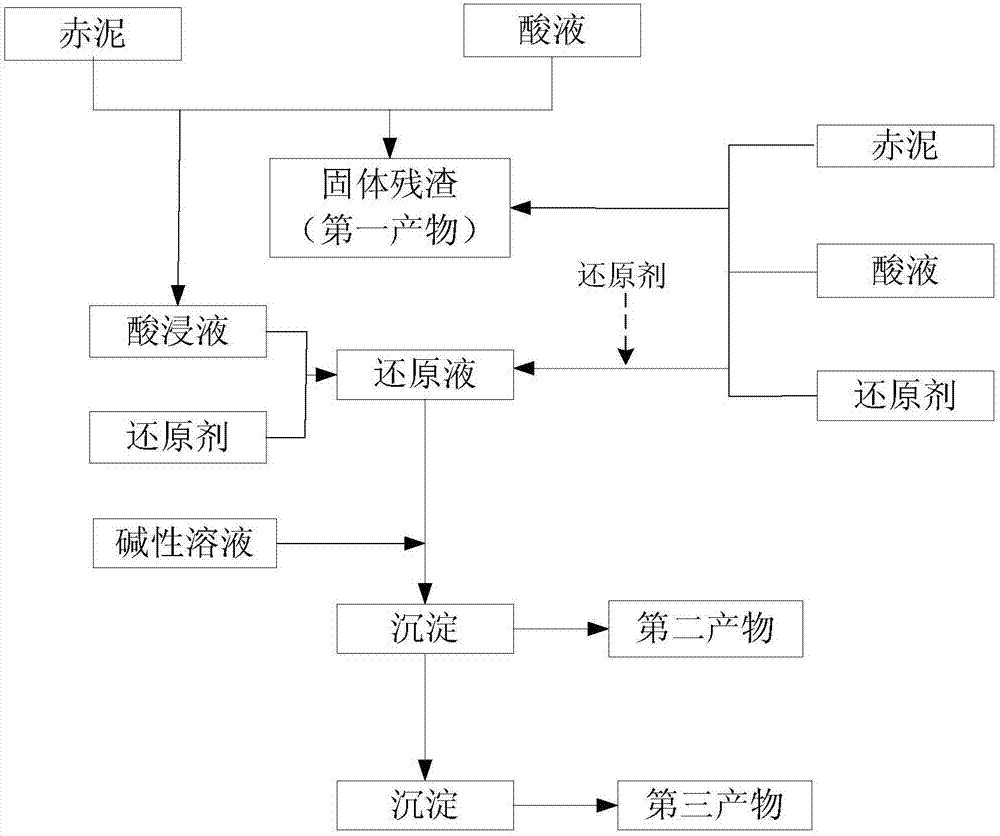

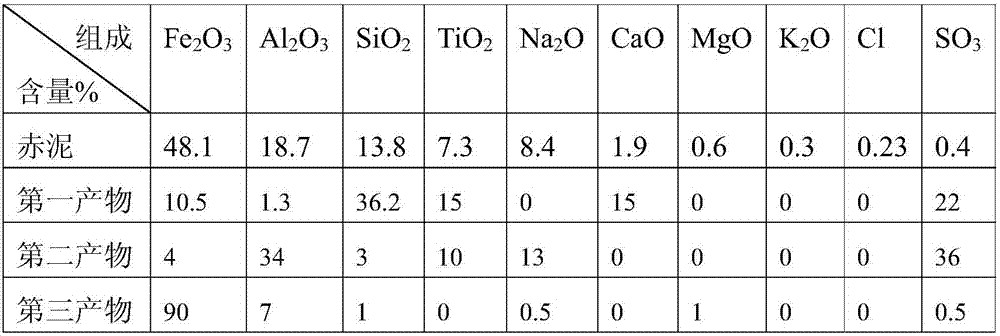

[0068] The process of separating aluminum and iron by acidolysis and fractional precipitation of red mud includes the following steps:

[0069] (1) React 1kg of red mud and 4kg of 50wt% sulfuric acid at 170°C for 10h to obtain a slurry;

[0070] (2) the slurry is separated to obtain 0.3kg of reaction residue (first product) and acidic solution;

[0071] (3) Add 200g of reduced iron powder to the acidic solution, the reaction is complete at 50°C, and the yellow solution turns into a green solution;

[0072] (4) Add 10wt% ammonia aqueous solution dropwise in the solution, control the pH value at 4.5, obtain a colloidal slurry containing off-white, after centrifugation, obtain the corresponding colloidal precipitation and transparent solution;

[0073] (5) After the colloid precipitation obtained in step (4) is dried and calcined, 0.4kg of the second product is obtained;

[0074] (6) Add ammonia solution dropwise to the transparent solution obtained by separation in step (4), a...

Embodiment 2

[0085] The process of separating aluminum and iron by acidolysis and fractional precipitation of red mud includes the following steps:

[0086] (1) 1kg of red mud, 3kg of 80wt% sulfuric acid and 1kg of paraformaldehyde were reacted at 70°C for 12h to obtain a slurry;

[0087] (2) separating the slurry to obtain a reaction residue (first product) and an acidic solution;

[0088] (3) Add dropwise 10wt% sodium hydroxide aqueous solution in the solution, control the pH value at 4.5, obtain the off-white colloidal slurry, after centrifugation, obtain the corresponding colloidal precipitation and transparent solution;

[0089] Steps (4), (5) and (6) are the same as steps (5), (6) and (7) in Example 1 in turn.

[0090] The masses of the first product, the second product and the third product obtained in this example were 0.4kg, 0.3kg and 0.3kg respectively.

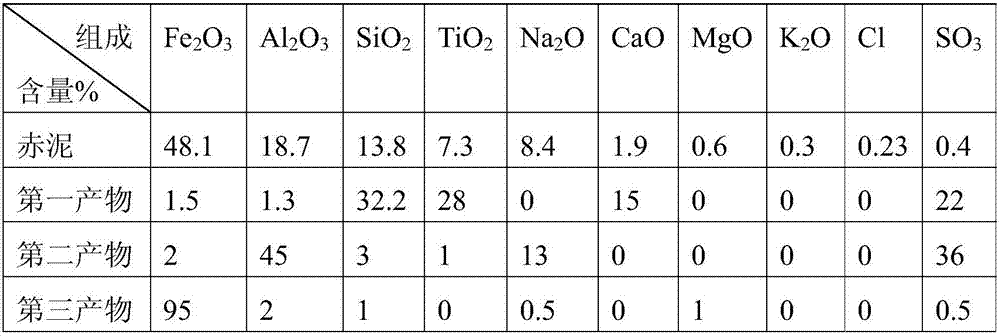

[0091] The composition of red mud and each product is as shown in Table 2 in this embodiment:

[0092] Table 2 Composition ...

Embodiment 3

[0105] The process of separating aluminum and iron by acidolysis and fractional precipitation of red mud includes the following steps:

[0106] (1) React 1kg of red mud and 3kg of 30wt% hydrochloric acid at 130°C for 12h to obtain a slurry;

[0107] (2) Slurry is separated to obtain 0.3kg of reaction residue (first product) and acidic solution;

[0108] (3) Add 0.2kg of aluminum powder to the acidic solution, and the reaction is complete at 30°C, changing from a yellow solution to a green solution;

[0109] (4) Add dropwise 10wt% potassium hydroxide aqueous solution in the solution, control the pH value at 4.5, obtain the off-white colloidal slurry, after centrifugation, obtain the corresponding colloidal precipitation and transparent solution;

[0110] Steps (5), (6) and (7) are sequentially the same as steps (5), (6) and (7) in Example 1.

[0111] The masses of the first product, the second product and the third product obtained in this example were 0.3kg, 0.6kg and 0.4kg ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com