Nanometer modified plant fiber spun filament

A nano-modified, plant fiber technology, applied in the field of spinning materials, can solve the problems of non-degradable environment of chemical synthetic fiber bristles, natural bristles easily breed bacteria, difficult to clean, etc., and achieve sufficient raw material sources, enhanced adsorption, and improved degradation. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

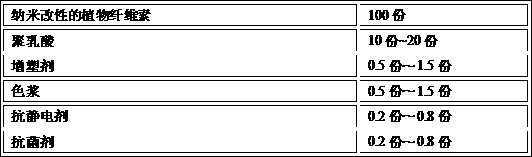

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: Preparation of nano-modified plant cellulose

[0047] (1) Enzymolysis: Cut natural plant fiber materials (jute, loofah or other natural fiber materials) into fibers with a length of 0.5~3cm, cook them in an electric heating constant temperature water bath, and stir them magnetically for 30 minutes. After the stirring is completed, filter them with suction , and dried in an oven at 105±3°C to obtain dried natural plant fibers. Enzymolyze with a compound enzyme composed of pectinase: laccase: hemicellulase, and enzymolyze at a temperature of 55±3°C for 12 hours to obtain enzymatically hydrolyzed plant fibers. The ratio of pectinase: laccase: hemicellulase in the compound enzyme is 1:2:2, and the amount of compound enzyme added is 5% of the mass of natural plant fiber material.

[0048] (2) Dissolution: Inactivate the natural plant fiber after enzymolysis at 95°C for 10 minutes, then filter the plate and frame, wash the filter residue and dry it at 50±3°C fo...

Embodiment 2

[0054] Embodiment 2: Preparation of nano-modified plant cellulose

[0055] (1) Enzymolysis: Cut natural plant fiber materials (jute, loofah or other natural fiber materials) into fibers with a length of 0.5~3cm, cook them in an electric heating constant temperature water bath, and stir them magnetically for 30 minutes. After the stirring is completed, filter them with suction , and dried in an oven at 110±3°C to obtain dried natural plant fibers. Use pectinase: laccase: hemicellulase compound enzyme to enzymolyze, and enzymolyze for 10 h at a temperature of 45±3°C to obtain enzymatically hydrolyzed plant fibers; in the compound enzyme, pectinase: laccase : The ratio of hemicellulase is 1:0.5:0.5, and the amount of compound enzyme added is 8% of the mass of natural plant fiber material.

[0056] (2) Dissolution: Inactivate the natural plant fiber after enzymolysis at 95°C for 10 minutes, then filter the plate and frame, wash the filter residue and dry it at 50°C~60°C for 5 hou...

Embodiment 3

[0061] Embodiment 3: the preparation of nano-modified plant cellulose

[0062] (1) Enzymolysis: Cut natural plant fiber materials (jute, loofah or other natural fiber materials) into fibers with a length of 0.5~3cm, cook them in an electric heating constant temperature water bath, and stir them magnetically for 30 minutes. After the stirring is completed, filter them with suction , and dried in an oven at 110±3°C to obtain dried natural plant fibers. Use pectinase: laccase: hemicellulase to enzymolyze the compound enzyme, and enzymolyze it for 24 hours at a temperature of 50±3°C to obtain the enzymatically hydrolyzed plant fiber; in the compound enzyme, pectinase: laccase : The ratio of hemicellulase is 1:0.5:0.5, and the amount of compound enzyme added is 1% of the mass of natural plant fiber material.

[0063] (2) Dissolution: Inactivate the natural plant fiber after enzymolysis at 95°C for 10 minutes, then filter the plate and frame, wash the filter residue and dry it at 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com