A kind of preparation method of interior wall paint with the function of eliminating formaldehyde

A technology for interior wall paint and formaldehyde elimination, applied in coatings and other directions, can solve problems such as safety and health hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

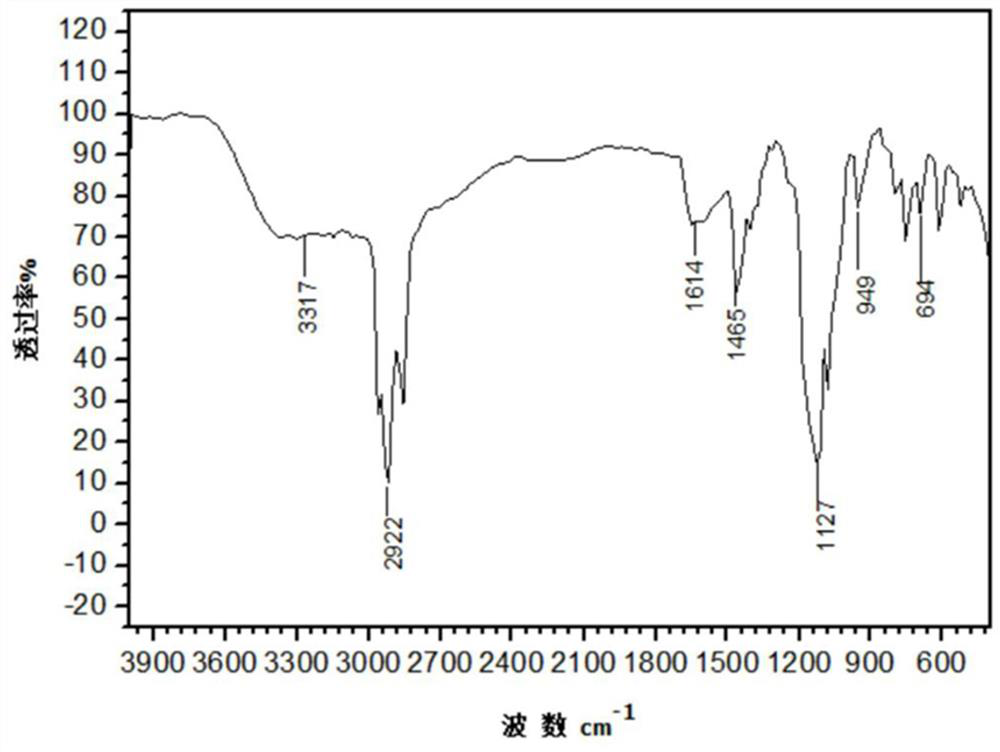

Image

Examples

Embodiment 1

[0031] A kind of preparation method of interior wall paint with the function of eliminating formaldehyde, its technical scheme is as follows:

[0032] According to the mass parts, add 0.5kg dispersant to 100kg deionized water, mix well and add 0.8kg wetting agent, mix well and add 55kg kaolin, 35kg limestone powder, 18kg silicon-based nickel-containing straw material and 15kg heavy Calcium carbonate powder, after stirring for 30 minutes at a speed of 2000 rpm in a high-speed disperser, add 5kg of film-forming aids and 0.8kg of leveling agent, continue to stir at a speed of 2000 rpm for 40 minutes, and then add 55kg of styrene-acrylic emulsion , and continue stirring at a speed of 1000 rpm for 20 minutes to obtain the interior wall paint with the function of eliminating formaldehyde.

[0033] The preparation method of the silicon-based nickel-containing straw material is as follows:

[0034] Step 1: Add 50 parts of straw powder and 6 parts of zinc chloride to 200 parts of hydr...

Embodiment 2

[0044] A kind of preparation method of interior wall paint with the function of eliminating formaldehyde, its technical scheme is as follows:

[0045] According to the mass parts, add 2.5kg dispersant to 130kg deionized water, mix well and add 1.6kg wetting agent, mix well and add 61kg kaolin, 42kg limestone powder, 25kg silicon-based nickel-containing straw material and 27kg heavy For calcium carbonate powder, stir for 40 minutes at a speed of 2500 rpm in a high-speed disperser, add 8kg of film-forming aids and 1.4kg of leveling agent, continue stirring for 50 minutes at a speed of 2500 rpm, and add 64kg of styrene-acrylic emulsion after completion , and continue stirring at a speed of 2000 rpm for 30 minutes to obtain the interior wall paint with the function of eliminating formaldehyde.

[0046] The preparation method of the silicon-based nickel-containing straw material is as follows:

[0047] Step 1: Add 58 parts of straw powder and 7 parts of zinc chloride to 270 parts ...

Embodiment 3

[0057] A kind of preparation method of interior wall paint with the function of eliminating formaldehyde, its technical scheme is as follows:

[0058] According to the mass parts, add 3.5kg dispersant to 150kg deionized water, mix well and add 2.6kg wetting agent, mix well and add 68kg kaolin, 48kg limestone powder, 32kg silicon-based nickel-containing straw material and 34kg heavy Calcium carbonate powder, after stirring for 60 minutes at a speed of 3000 rpm in a high-speed disperser, add 10kg of film-forming aids and 1.8kg of leveling agent, continue to stir at a speed of 3000 rpm for 60 minutes, and then add 72kg of styrene-acrylic emulsion , and continue stirring at a speed of 3000 rpm for 40 minutes to obtain the interior wall paint with the function of eliminating formaldehyde.

[0059] The preparation method of the silicon-based nickel-containing straw material is as follows:

[0060] Step 1: Add 70 parts of straw powder and 15 parts of zinc chloride to 300 parts of hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com