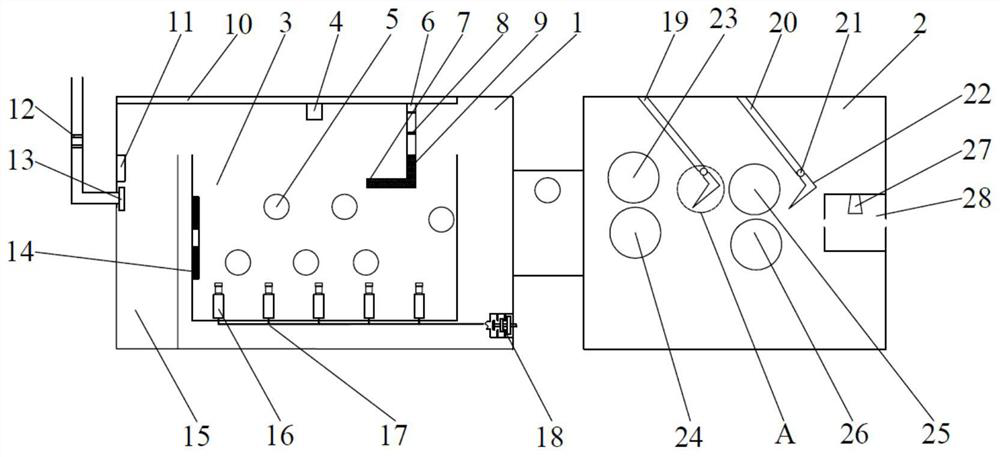

A polyester-cotton blended yarn sizing device and its process

A technology of polyester-cotton blending and yarn, which is applied in the processing of textile material equipment configuration, textile and papermaking, and textile material processing. Effect of small contact angle and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

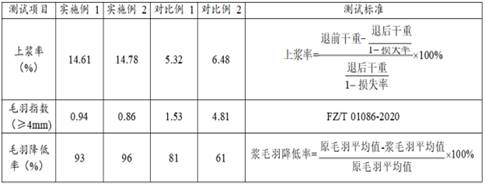

example 1

[0050] A) take by weighing a certain amount of starch and distilled water and be mixed with starch suspension, drip potassium hydroxide solution, regulate starch suspension Ph to 8, add a certain amount of propionic anhydride and n-propionic acid, described propionic anhydride: n-propionic acid weight Ratio is 1: 1, and described starch: propionic anhydride weight ratio is 14: 1, be warming up to 78~82 ℃, stirring reaction 75min, add hydrochloric acid after the reaction is finished and adjust pH to 7, after terminating the reaction, adopt ethanolic solution and distilled water Wash 2-3 times to obtain acrylamide grafted starch;

[0051] B) take by weighing the starch and urea of predetermined amount, described starch: urea mass ratio is 200: 13, adding massfraction is 2% ferric chloride solution as initiator, described starch, urea and described chlorine The bath ratio of the iron solution is 1:20, the temperature is raised to 160°C, the stirring is continued for 2 hours, an...

example 2

[0058] A) take by weighing a certain amount of starch and distilled water and be mixed with starch suspension, drip potassium hydroxide solution, regulate starch suspension Ph to 8, add a certain amount of propionic anhydride and n-propionic acid, described propionic anhydride: n-propionic acid weight Ratio is 1: 1, and described starch: propionic anhydride weight ratio is 15: 1, be warming up to 78~82 ℃, stirring reaction 75min, add hydrochloric acid after the reaction is finished and adjust pH to 7, after terminating the reaction, adopt ethanolic solution and distilled water Wash 2-3 times to obtain acrylamide grafted starch;

[0059] B) take by weighing predetermined amount of starch and urea, described starch: urea mass ratio is 200: 14, adding mass fraction is 2% ferric chloride solution as initiator, described starch, urea and described chlorine The bath ratio of the iron solution is 1:22, the temperature is raised to 160 ° C, and the stirring is continued for 2 h. After...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com