Preparation method of micro-nano holes in surface of nickel-containing iron-chromium alloy

A nickel-iron-chromium alloy and micro-nano-pore technology, which is applied in the direction of anodic oxidation, can solve the problems of unfavorable metal-resin composite materials, and achieve the effect of easy operation, low cost and simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

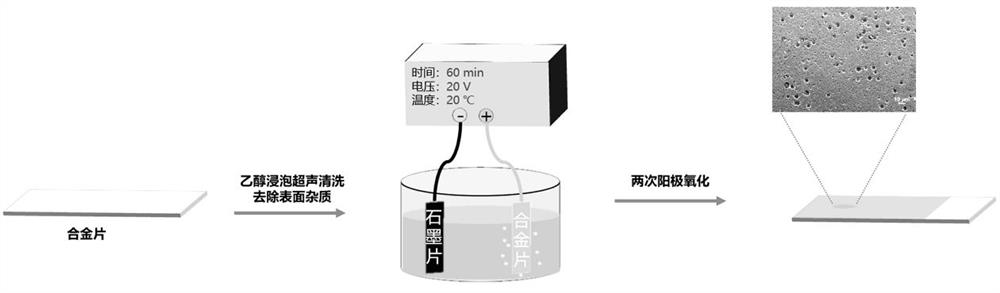

[0027] Method for preparing a micro-nanophoe having a nickel-chromium alloy surface, such as figure 1 As shown, including the following steps:

[0028] (1) Alloy surface pretreatment: The alloy was placed in acetone solution for 30 min, and the ethanol was mixed 60 ° C for 60 ° C.

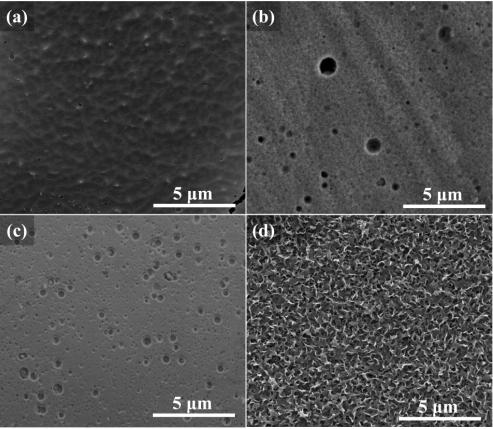

[0029] (2) The alloy surface once anodized: the alloy block obtained by step (1) as an anode, graphite sheet as a cathode, at 20 ° C, 0.1 mol / L fluoronicate / ethylene glycol electrolyte oxidation 60min, ethanol cleaning, and the surface is dried.

[0030] (3) Alloy surface secondary anode oxidation treatment: the alloy block obtained by the surface of the anode oxidation of the surface (2), will be used as an anode, in a 0.1 mol / L dihydrate dihydrogenate electrolytic solution with 20V voltage anode Oxidation 60min, ethanol washing, after drying, obtained the secondary anodized metal block.

Embodiment 2

[0032] Method for preparing a micro-nanophoe having a nickel-chromium alloy surface, such as figure 1 As shown, including the following steps:

[0033] (1) Alloy surface pretreatment: The alloy was placed in acetone solution for 30 min, and the ethanol was mixed 60 ° C for 60 ° C.

[0034] (2) The alloy surface once anodized: the alloy block obtained by step (1) as an anode, graphite sheet as a cathode, 20 ° C, 0.05 mol / L fluoride / ethylene glycol electrolyte oxidation 60min, ethanol cleaning, and the surface is dried.

[0035] (3) Alloy surface secondary anode oxidation treatment: the alloy block obtained by the surface of the anode oxidation of the surface (2), will be used as an anode, in a 0.1 mol / L dihydrate dihydrogenate electrolytic solution with 20V voltage anode Oxidation 60min, ethanol washing, after drying, obtained the secondary anodized metal block.

Embodiment 3

[0037] Method for preparing a micro-nanophoe having a nickel-chromium alloy surface, such as figure 1 As shown, including the following steps:

[0038] (1) Alloy surface pretreatment: The alloy was placed in acetone solution for 30 min, and the ethanol was mixed 60 ° C for 60 ° C.

[0039] (2) One anode oxidation of the alloy surface: the alloy block obtained by step (1) as an anode, graphite sheet as a cathode, at 20 ° C, 0.15 mol / L fluoride / ethylene glycol electrolyte oxidation 60min, ethanol cleaning, and the surface is dried.

[0040] (3) Alloy surface secondary anode oxidation treatment: the alloy block obtained by the surface of the anode oxidation of the surface (2), will be used as an anode, in a 0.1 mol / L dihydrate dihydrogenate electrolytic solution with 20V voltage anode Oxidation 60min, ethanol washing, after drying, obtained the secondary anodized metal block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com