Artificial joint made from zirconia-alumina composite ceramic

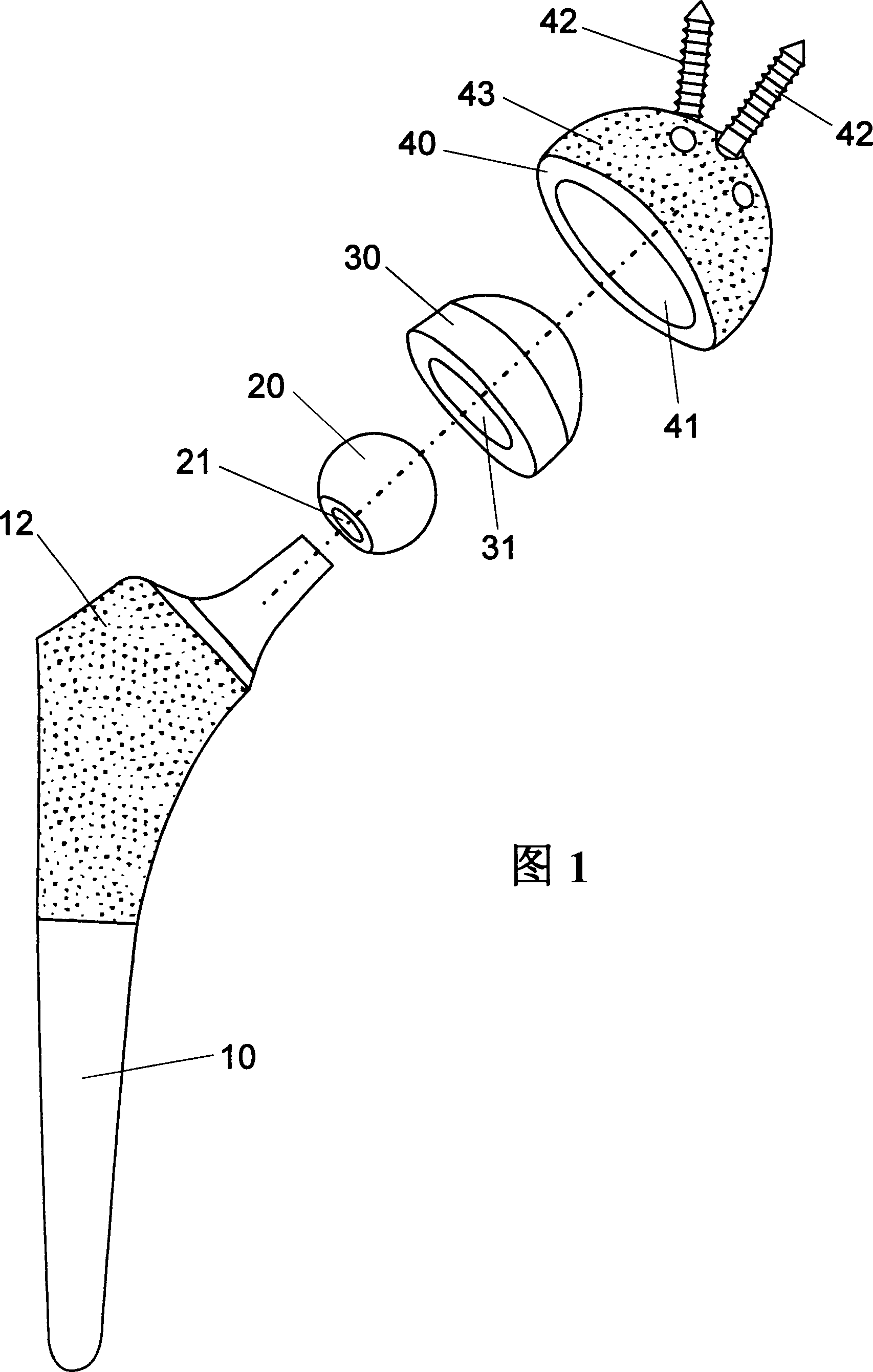

A technology of composite ceramics and artificial joints, applied in hip joints, internal bone synthesis, joint implants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (Example 1 and Comparative Examples 1-3)

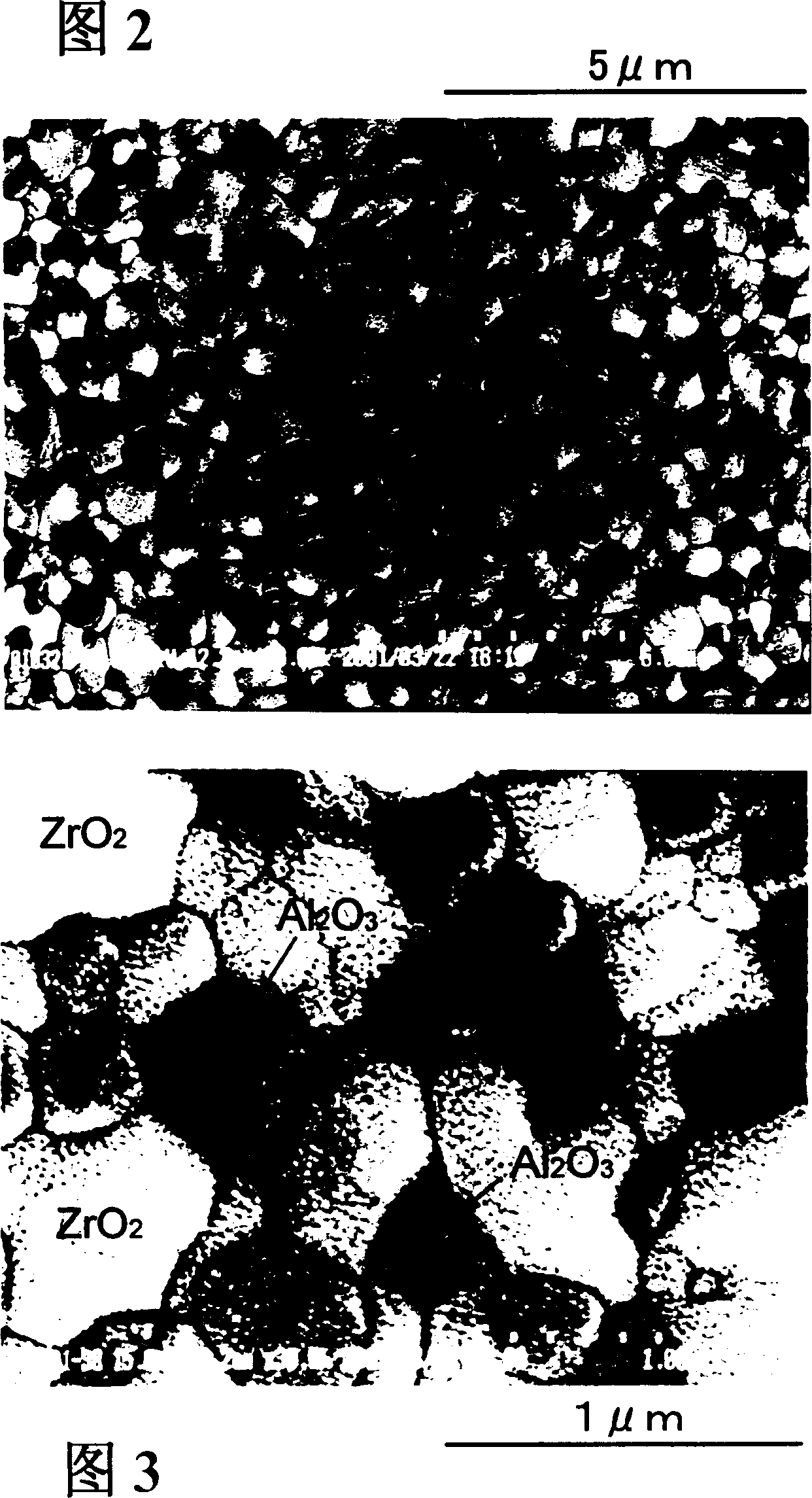

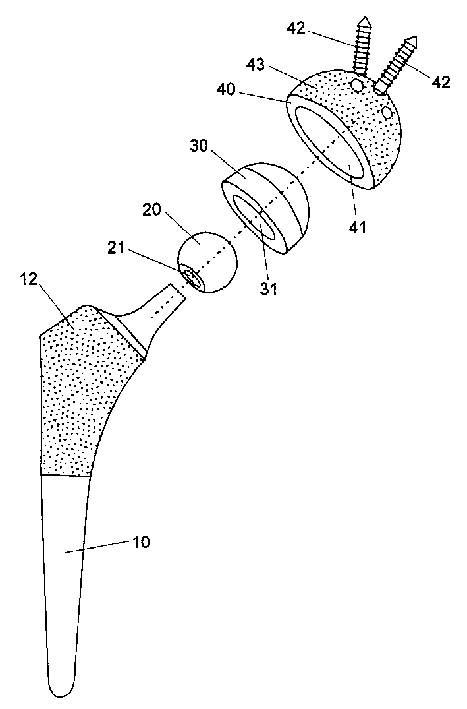

[0038] Tetragonal zirconia powder (amount of tetragonal zirconia: 98% by volume), which contained 10 mol% of ceria, 0.05 mol% of titania and 0.05 mol% of calcium oxide relative to the total amount of zirconia, was compared with The alumina powder was mixed with 30% by volume of the total volume of the zirconia-alumina composite ceramics to obtain a mixed powder. After the mixed powder was molded by unidirectional pressing and isostatic pressing to obtain a compact with a desired shape, the compact was pressurelessly sintered at 1400°C for 5 hours under atmospheric pressure. Thus, the zirconia-alumina composite ceramic of Example 1 having an average particle diameter of 0.22 μm was obtained. In order to evaluate the wear resistance and friction coefficient of this composite ceramic, a dial wear test was performed with distilled water as lubricant.

[0039] As a comparative example, an alumina sintered body having an average pa...

Embodiment 2-5

[0063] (embodiment 2-5 and comparative example 4)

[0064] Tetragonal zirconia powder (amount of tetragonal zirconia: 98% by volume), which contains 10 mol% of ceria and 0.05 mol% of titania relative to the total amount of zirconia, was compounded with zirconia-alumina 35% by volume of the total volume of the ceramics was mixed with alumina powder to obtain a mixed powder. After the mixed powder was molded by unidirectional pressing and isostatic pressing to obtain a compact of desired shape, as shown in Table 2, the compact was sintered without pressure for 5 hours at different temperatures and atmospheric pressure. Thus, the zirconia-alumina composite ceramics of Examples 2-5 and Comparative Example 4 were obtained. In Comparative Example 4, since the sintering temperature was 1600° C., the average grain size of the obtained composite ceramic was 1.65 μm, which was inconsistent with the composite ceramic of the present invention. After performing heat treatment and polishi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com