Advances in PLA‑Based Smart Materials

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Smart Materials Background and Objectives

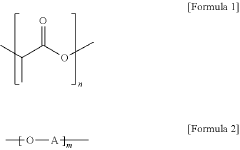

Poly(lactic acid) (PLA) has emerged as a promising biodegradable and biocompatible polymer, gaining significant attention in the field of smart materials. The evolution of PLA-based smart materials represents a convergence of sustainability and advanced functionality, addressing the growing demand for environmentally friendly solutions in various industries.

The development of PLA-based smart materials can be traced back to the early 2000s when researchers began exploring ways to enhance the properties of PLA beyond its inherent biodegradability. Initial efforts focused on improving mechanical properties and thermal stability, laying the foundation for more advanced applications. As the field progressed, scientists started incorporating responsive elements into PLA matrices, giving rise to materials capable of reacting to external stimuli such as temperature, pH, light, or electrical fields.

The technological trajectory of PLA smart materials has been driven by the need to overcome limitations in traditional polymers while meeting the increasing demand for sustainable alternatives. This has led to the exploration of various modification techniques, including blending, copolymerization, and nanocomposite formation, to impart smart functionalities to PLA-based systems.

Recent advancements have seen the integration of shape memory properties, self-healing capabilities, and stimuli-responsive behaviors into PLA materials. These innovations have opened up new possibilities in fields such as biomedical engineering, packaging, and smart textiles. For instance, shape memory PLA composites have shown potential in minimally invasive medical devices, while self-healing PLA materials are being investigated for sustainable packaging solutions.

The primary objectives in the development of PLA-based smart materials include enhancing their responsiveness to environmental cues, improving their mechanical and thermal properties, and expanding their range of applications. Researchers aim to create multifunctional materials that can adapt to changing conditions, self-repair, or perform specific tasks on demand, all while maintaining the biodegradability and biocompatibility inherent to PLA.

Looking ahead, the field of PLA smart materials is poised for further growth and innovation. Key areas of focus include the development of more sophisticated stimuli-responsive systems, the exploration of novel fabrication techniques such as 3D printing of smart PLA composites, and the integration of PLA-based smart materials with emerging technologies like Internet of Things (IoT) sensors for advanced monitoring and control applications.

As environmental concerns continue to drive material science research, PLA-based smart materials are expected to play a crucial role in the transition towards more sustainable and intelligent material solutions across various sectors. The ongoing research and development in this field aim to bridge the gap between eco-friendly materials and high-performance smart technologies, paving the way for a new generation of sustainable and responsive materials.

The development of PLA-based smart materials can be traced back to the early 2000s when researchers began exploring ways to enhance the properties of PLA beyond its inherent biodegradability. Initial efforts focused on improving mechanical properties and thermal stability, laying the foundation for more advanced applications. As the field progressed, scientists started incorporating responsive elements into PLA matrices, giving rise to materials capable of reacting to external stimuli such as temperature, pH, light, or electrical fields.

The technological trajectory of PLA smart materials has been driven by the need to overcome limitations in traditional polymers while meeting the increasing demand for sustainable alternatives. This has led to the exploration of various modification techniques, including blending, copolymerization, and nanocomposite formation, to impart smart functionalities to PLA-based systems.

Recent advancements have seen the integration of shape memory properties, self-healing capabilities, and stimuli-responsive behaviors into PLA materials. These innovations have opened up new possibilities in fields such as biomedical engineering, packaging, and smart textiles. For instance, shape memory PLA composites have shown potential in minimally invasive medical devices, while self-healing PLA materials are being investigated for sustainable packaging solutions.

The primary objectives in the development of PLA-based smart materials include enhancing their responsiveness to environmental cues, improving their mechanical and thermal properties, and expanding their range of applications. Researchers aim to create multifunctional materials that can adapt to changing conditions, self-repair, or perform specific tasks on demand, all while maintaining the biodegradability and biocompatibility inherent to PLA.

Looking ahead, the field of PLA smart materials is poised for further growth and innovation. Key areas of focus include the development of more sophisticated stimuli-responsive systems, the exploration of novel fabrication techniques such as 3D printing of smart PLA composites, and the integration of PLA-based smart materials with emerging technologies like Internet of Things (IoT) sensors for advanced monitoring and control applications.

As environmental concerns continue to drive material science research, PLA-based smart materials are expected to play a crucial role in the transition towards more sustainable and intelligent material solutions across various sectors. The ongoing research and development in this field aim to bridge the gap between eco-friendly materials and high-performance smart technologies, paving the way for a new generation of sustainable and responsive materials.

Market Analysis for PLA-Based Smart Products

The market for PLA-based smart materials and products is experiencing significant growth, driven by increasing environmental concerns and the demand for sustainable, biodegradable alternatives across various industries. The global smart materials market, which includes PLA-based products, is projected to reach substantial value in the coming years, with a compound annual growth rate (CAGR) outpacing many traditional material sectors.

In the packaging industry, PLA-based smart materials are gaining traction due to their biodegradability and potential for active and intelligent packaging solutions. These materials can incorporate sensors or indicators that respond to environmental changes, providing real-time information about product freshness or package integrity. The food and beverage sector, in particular, is showing strong interest in these innovations to reduce food waste and improve consumer safety.

The healthcare and pharmaceutical industries are also key markets for PLA-based smart products. Smart drug delivery systems utilizing PLA-based materials are being developed to provide controlled release of medications, potentially improving treatment efficacy and patient compliance. Additionally, PLA-based smart materials are being explored for tissue engineering and regenerative medicine applications, offering biocompatible and programmable scaffolds for cell growth and tissue repair.

In the consumer electronics sector, PLA-based smart materials are finding applications in wearable devices and flexible electronics. These materials offer the potential for biodegradable electronic components, addressing the growing issue of electronic waste. The automotive industry is also exploring PLA-based smart materials for lightweight, eco-friendly components that can adapt to changing conditions, such as temperature-responsive surfaces or impact-absorbing structures.

The construction industry presents another significant market opportunity for PLA-based smart materials. Self-healing concrete incorporating PLA-based microcapsules is being developed to increase the longevity of infrastructure. Smart coatings and insulation materials based on PLA are also gaining attention for their potential to improve energy efficiency in buildings.

Despite the promising market outlook, challenges remain in scaling up production and reducing costs to compete with traditional materials. However, as regulations on plastic use become stricter and consumer demand for sustainable products grows, the market for PLA-based smart materials is expected to expand rapidly. Companies investing in research and development of these materials are likely to gain a competitive edge in the evolving landscape of smart, sustainable materials.

In the packaging industry, PLA-based smart materials are gaining traction due to their biodegradability and potential for active and intelligent packaging solutions. These materials can incorporate sensors or indicators that respond to environmental changes, providing real-time information about product freshness or package integrity. The food and beverage sector, in particular, is showing strong interest in these innovations to reduce food waste and improve consumer safety.

The healthcare and pharmaceutical industries are also key markets for PLA-based smart products. Smart drug delivery systems utilizing PLA-based materials are being developed to provide controlled release of medications, potentially improving treatment efficacy and patient compliance. Additionally, PLA-based smart materials are being explored for tissue engineering and regenerative medicine applications, offering biocompatible and programmable scaffolds for cell growth and tissue repair.

In the consumer electronics sector, PLA-based smart materials are finding applications in wearable devices and flexible electronics. These materials offer the potential for biodegradable electronic components, addressing the growing issue of electronic waste. The automotive industry is also exploring PLA-based smart materials for lightweight, eco-friendly components that can adapt to changing conditions, such as temperature-responsive surfaces or impact-absorbing structures.

The construction industry presents another significant market opportunity for PLA-based smart materials. Self-healing concrete incorporating PLA-based microcapsules is being developed to increase the longevity of infrastructure. Smart coatings and insulation materials based on PLA are also gaining attention for their potential to improve energy efficiency in buildings.

Despite the promising market outlook, challenges remain in scaling up production and reducing costs to compete with traditional materials. However, as regulations on plastic use become stricter and consumer demand for sustainable products grows, the market for PLA-based smart materials is expected to expand rapidly. Companies investing in research and development of these materials are likely to gain a competitive edge in the evolving landscape of smart, sustainable materials.

Current Challenges in PLA Smart Material Development

Despite the promising potential of PLA-based smart materials, several significant challenges currently hinder their widespread adoption and development. One of the primary obstacles is the inherent brittleness of PLA, which limits its applicability in scenarios requiring high flexibility or impact resistance. This characteristic restricts the use of PLA-based smart materials in applications such as wearable electronics or dynamic structural components.

Another major challenge lies in the thermal instability of PLA at elevated temperatures. The relatively low glass transition temperature of PLA (around 60°C) can lead to undesirable shape changes or loss of mechanical properties in smart material applications that involve temperature fluctuations. This thermal sensitivity narrows the operational temperature range of PLA-based smart materials, limiting their use in high-temperature environments.

The biodegradability of PLA, while advantageous in many contexts, poses challenges in maintaining long-term stability and performance of smart materials. Controlling the degradation rate and ensuring consistent smart functionality over extended periods remains a significant hurdle, particularly in applications requiring prolonged material integrity.

Furthermore, achieving precise control over the shape memory effect in PLA-based materials presents ongoing difficulties. The shape recovery process can be slow and incomplete, especially in complex geometries or under varying environmental conditions. Enhancing the speed, accuracy, and repeatability of shape memory responses is crucial for expanding the practical applications of these smart materials.

The integration of multiple smart functionalities within a single PLA-based material system also remains challenging. Combining properties such as shape memory, self-healing, and sensing capabilities without compromising the overall material performance requires sophisticated material design and processing techniques that are still under development.

Lastly, scaling up the production of PLA-based smart materials from laboratory to industrial levels presents significant challenges. Ensuring consistent quality, reproducibility, and cost-effectiveness in large-scale manufacturing processes is essential for commercial viability but remains difficult to achieve with current technologies.

Another major challenge lies in the thermal instability of PLA at elevated temperatures. The relatively low glass transition temperature of PLA (around 60°C) can lead to undesirable shape changes or loss of mechanical properties in smart material applications that involve temperature fluctuations. This thermal sensitivity narrows the operational temperature range of PLA-based smart materials, limiting their use in high-temperature environments.

The biodegradability of PLA, while advantageous in many contexts, poses challenges in maintaining long-term stability and performance of smart materials. Controlling the degradation rate and ensuring consistent smart functionality over extended periods remains a significant hurdle, particularly in applications requiring prolonged material integrity.

Furthermore, achieving precise control over the shape memory effect in PLA-based materials presents ongoing difficulties. The shape recovery process can be slow and incomplete, especially in complex geometries or under varying environmental conditions. Enhancing the speed, accuracy, and repeatability of shape memory responses is crucial for expanding the practical applications of these smart materials.

The integration of multiple smart functionalities within a single PLA-based material system also remains challenging. Combining properties such as shape memory, self-healing, and sensing capabilities without compromising the overall material performance requires sophisticated material design and processing techniques that are still under development.

Lastly, scaling up the production of PLA-based smart materials from laboratory to industrial levels presents significant challenges. Ensuring consistent quality, reproducibility, and cost-effectiveness in large-scale manufacturing processes is essential for commercial viability but remains difficult to achieve with current technologies.

Existing PLA Smart Material Solutions

01 PLA-based smart materials with shape memory properties

Development of PLA-based materials with shape memory capabilities, allowing them to change shape or recover their original form in response to external stimuli such as temperature or light. These materials have potential applications in various fields including biomedical devices, packaging, and aerospace.- PLA-based smart materials with shape memory properties: Development of PLA-based smart materials that exhibit shape memory properties. These materials can change their shape in response to external stimuli such as temperature, and return to their original shape under specific conditions. This technology has applications in various fields including biomedical devices and packaging.

- PLA composites with enhanced mechanical properties: Creation of PLA-based composites by incorporating various fillers or reinforcing agents to improve mechanical properties such as strength, stiffness, and toughness. These composites maintain the biodegradability of PLA while offering enhanced performance for applications in automotive, construction, and consumer goods industries.

- Electrically conductive PLA-based materials: Development of electrically conductive PLA-based materials by incorporating conductive fillers or through surface modifications. These smart materials can be used in flexible electronics, sensors, and electromagnetic shielding applications while maintaining the biodegradability of PLA.

- PLA-based materials with self-healing properties: Creation of PLA-based smart materials with self-healing capabilities. These materials can repair damage autonomously or with minimal external intervention, extending the lifespan of products and improving their durability. Applications include protective coatings, automotive parts, and consumer electronics.

- Stimuli-responsive PLA-based drug delivery systems: Development of PLA-based smart materials for controlled drug delivery systems. These materials can respond to specific stimuli such as pH, temperature, or light to release drugs in a targeted and controlled manner. This technology has significant potential in the pharmaceutical and biomedical fields for improving therapeutic efficacy and reducing side effects.

02 PLA composites with enhanced mechanical properties

Creation of PLA-based composites by incorporating reinforcing agents or blending with other polymers to improve mechanical strength, toughness, and durability. These enhanced materials can be used in applications requiring higher performance than traditional PLA, such as automotive parts or consumer goods.Expand Specific Solutions03 Biodegradable PLA-based smart materials for medical applications

Development of biodegradable PLA-based smart materials specifically designed for medical applications, such as drug delivery systems, tissue engineering scaffolds, and implantable devices. These materials can respond to biological stimuli and degrade safely in the body over time.Expand Specific Solutions04 PLA-based smart materials with self-healing properties

Innovation in PLA-based materials that can self-heal when damaged, potentially through the incorporation of microcapsules containing healing agents or the use of reversible chemical bonds. These materials could extend the lifespan of products and reduce waste in various industries.Expand Specific Solutions05 Electrically conductive PLA-based smart materials

Development of PLA-based materials with electrical conductivity through the incorporation of conductive fillers or surface modifications. These materials can be used in smart packaging, flexible electronics, or sensors while maintaining biodegradability.Expand Specific Solutions

Key Players in PLA Smart Material Industry

The field of PLA-based smart materials is in a growth phase, with increasing market size and technological advancements. The global market for these materials is expanding rapidly, driven by demand for sustainable and multifunctional materials. Technologically, the sector is progressing from basic biodegradable applications to more sophisticated smart functionalities. Companies like NatureWorks LLC and Toray Industries, Inc. are leading in PLA production, while research institutions such as Sichuan University and Zhejiang University are pushing boundaries in smart material development. Collaborations between industry players like BYD Co., Ltd. and academic institutions are accelerating innovation, particularly in areas such as shape memory and self-healing properties. The involvement of diverse entities, from established corporations to specialized startups, indicates a competitive and dynamic landscape with significant potential for further technological breakthroughs.

Toray Industries, Inc.

Technical Solution: Toray Industries has developed advanced PLA-based smart materials with enhanced properties. Their technology focuses on improving the thermal and mechanical properties of PLA through the incorporation of nanofillers and the development of novel processing techniques. They have successfully created PLA composites with shape memory properties, allowing for programmable shape changes in response to external stimuli such as temperature or pH. Additionally, Toray has developed PLA-based materials with self-healing capabilities, utilizing reversible cross-linking mechanisms to repair micro-cracks and extend the material's lifespan.

Strengths: Extensive experience in polymer science, strong R&D capabilities, and a wide range of applications across industries. Weaknesses: Higher production costs compared to traditional plastics, and potential limitations in extreme environmental conditions.

Lubrizol Advanced Materials, Inc.

Technical Solution: Lubrizol Advanced Materials has developed innovative PLA-based smart materials with a focus on enhancing performance and functionality. Their technology includes the development of PLA blends and composites with improved impact resistance and flexibility. They have created PLA-based materials with advanced flame-retardant properties, making them suitable for use in electronics and automotive applications. Lubrizol has also developed smart PLA materials with controlled degradation rates, allowing for tailored biodegradability in various environments. Additionally, they have introduced PLA-based materials with enhanced processability, enabling easier manufacturing and broader application potential.

Strengths: Diverse product portfolio, strong technical expertise in material science, and global presence. Weaknesses: Potential challenges in scaling up production and competition from established petrochemical-based materials.

Core Innovations in PLA Smart Materials

Renewable, biodegradable poly(lactic acid) composites with improved thermal properties

PatentWO2015048589A1

Innovation

- A composite comprising PLA and microground cellulosic filler, with the microground cellulosic size ranging from 10 to 250 μm, is used to achieve an HDT greater than or equal to 85°C, which is 100% compostable and biosourced, eliminating the need for expensive additives and ensuring cost-effectiveness.

Poly(lactic acid) resin composition and molded product comprising same

PatentActiveUS20200283622A1

Innovation

- A polylactic acid resin composition incorporating a hard segment with polylactic acid repeating units, a soft segment with polyurethane polyol repeating units linked via a urethane bond, and a poly-D-lactic acid (PDLA) resin as a nucleating agent, along with talc, to enhance crystallinity and crystallization rate.

Environmental Impact of PLA Smart Materials

The environmental impact of PLA-based smart materials is a crucial consideration in their development and application. PLA, or polylactic acid, is a biodegradable polymer derived from renewable resources, making it an attractive option for environmentally conscious applications. However, the integration of smart functionalities into PLA materials introduces new complexities in terms of their ecological footprint.

One of the primary advantages of PLA-based smart materials is their potential for reduced environmental impact compared to traditional petroleum-based plastics. The biodegradability of PLA offers a significant benefit in terms of end-of-life disposal, potentially reducing plastic waste accumulation in landfills and oceans. However, the addition of smart components, such as sensors or actuators, may complicate the biodegradation process and require specialized recycling or disposal methods.

The production of PLA-based smart materials also presents environmental considerations. While PLA itself is derived from renewable resources like corn or sugarcane, the energy-intensive processes required for its production and the cultivation of these crops can contribute to greenhouse gas emissions and land use changes. The incorporation of smart functionalities may further increase the energy and resource requirements during manufacturing.

The durability and lifespan of PLA-based smart materials play a crucial role in their overall environmental impact. If these materials can effectively replace less sustainable alternatives and maintain functionality over extended periods, they may contribute to a reduction in resource consumption and waste generation. However, if the smart components degrade more rapidly than the PLA matrix, it could lead to premature disposal and increased waste.

Recycling and recovery of PLA-based smart materials present both challenges and opportunities. While PLA can be composted or recycled under specific conditions, the presence of electronic components or other smart additives may complicate these processes. Developing effective methods for separating and recycling the various components of these materials is essential for minimizing their environmental footprint.

The potential for PLA-based smart materials to enable more efficient and sustainable practices in various applications should also be considered. For instance, smart packaging made from these materials could help reduce food waste by monitoring freshness, or smart textiles could optimize energy use in clothing. These indirect environmental benefits may offset some of the impacts associated with their production and disposal.

As research in this field progresses, life cycle assessments (LCAs) will be crucial in comprehensively evaluating the environmental impact of PLA-based smart materials. These assessments should consider all stages of the material's life, from raw material extraction to end-of-life disposal, to provide a holistic understanding of their ecological implications and guide future developments towards more sustainable solutions.

One of the primary advantages of PLA-based smart materials is their potential for reduced environmental impact compared to traditional petroleum-based plastics. The biodegradability of PLA offers a significant benefit in terms of end-of-life disposal, potentially reducing plastic waste accumulation in landfills and oceans. However, the addition of smart components, such as sensors or actuators, may complicate the biodegradation process and require specialized recycling or disposal methods.

The production of PLA-based smart materials also presents environmental considerations. While PLA itself is derived from renewable resources like corn or sugarcane, the energy-intensive processes required for its production and the cultivation of these crops can contribute to greenhouse gas emissions and land use changes. The incorporation of smart functionalities may further increase the energy and resource requirements during manufacturing.

The durability and lifespan of PLA-based smart materials play a crucial role in their overall environmental impact. If these materials can effectively replace less sustainable alternatives and maintain functionality over extended periods, they may contribute to a reduction in resource consumption and waste generation. However, if the smart components degrade more rapidly than the PLA matrix, it could lead to premature disposal and increased waste.

Recycling and recovery of PLA-based smart materials present both challenges and opportunities. While PLA can be composted or recycled under specific conditions, the presence of electronic components or other smart additives may complicate these processes. Developing effective methods for separating and recycling the various components of these materials is essential for minimizing their environmental footprint.

The potential for PLA-based smart materials to enable more efficient and sustainable practices in various applications should also be considered. For instance, smart packaging made from these materials could help reduce food waste by monitoring freshness, or smart textiles could optimize energy use in clothing. These indirect environmental benefits may offset some of the impacts associated with their production and disposal.

As research in this field progresses, life cycle assessments (LCAs) will be crucial in comprehensively evaluating the environmental impact of PLA-based smart materials. These assessments should consider all stages of the material's life, from raw material extraction to end-of-life disposal, to provide a holistic understanding of their ecological implications and guide future developments towards more sustainable solutions.

Standardization of PLA Smart Material Testing

The standardization of PLA smart material testing is crucial for ensuring consistent and reliable evaluation of these advanced materials. Current testing methods for PLA-based smart materials often lack uniformity, leading to challenges in comparing results across different research groups and industries. To address this issue, several key areas require standardization.

Mechanical property testing is a primary focus for standardization efforts. This includes developing standardized protocols for tensile strength, flexural strength, and impact resistance tests specifically tailored to PLA smart materials. These tests must account for the unique properties of PLA, such as its biodegradability and potential for shape memory effects.

Thermal characterization is another critical area for standardization. Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) methods need to be adapted to accurately measure the thermal properties of PLA smart materials, including glass transition temperature, melting point, and thermal degradation behavior. Standardized procedures for sample preparation and testing conditions are essential for obtaining reproducible results.

Electrical and electromagnetic property testing standards are particularly important for PLA smart materials with conductive or piezoelectric properties. Standardized methods for measuring electrical conductivity, dielectric strength, and piezoelectric coefficients need to be established, taking into account the unique challenges posed by PLA-based composites.

Biodegradability testing is a crucial aspect of PLA smart materials that requires standardization. Current biodegradation tests often vary in their methodologies, making it difficult to compare results across different studies. Standardized protocols for assessing biodegradation rates and environmental impact are necessary to ensure consistent evaluation of these materials' eco-friendly properties.

Shape memory and self-healing capabilities are distinctive features of many PLA smart materials. Standardized testing methods for evaluating shape recovery ratios, recovery speeds, and self-healing efficiencies are needed to accurately assess and compare the performance of different PLA-based smart materials.

Durability and aging tests are essential for understanding the long-term performance of PLA smart materials. Standardized accelerated aging protocols that simulate various environmental conditions can help predict the materials' behavior over time and assess their suitability for different applications.

To achieve these standardization goals, collaboration between academic institutions, industry partners, and standardization bodies is crucial. Organizations such as ASTM International and ISO are working towards developing comprehensive testing standards for bioplastics and smart materials. However, the rapid advancement in PLA smart material technology necessitates continuous updating and refinement of these standards to keep pace with new developments in the field.

Mechanical property testing is a primary focus for standardization efforts. This includes developing standardized protocols for tensile strength, flexural strength, and impact resistance tests specifically tailored to PLA smart materials. These tests must account for the unique properties of PLA, such as its biodegradability and potential for shape memory effects.

Thermal characterization is another critical area for standardization. Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA) methods need to be adapted to accurately measure the thermal properties of PLA smart materials, including glass transition temperature, melting point, and thermal degradation behavior. Standardized procedures for sample preparation and testing conditions are essential for obtaining reproducible results.

Electrical and electromagnetic property testing standards are particularly important for PLA smart materials with conductive or piezoelectric properties. Standardized methods for measuring electrical conductivity, dielectric strength, and piezoelectric coefficients need to be established, taking into account the unique challenges posed by PLA-based composites.

Biodegradability testing is a crucial aspect of PLA smart materials that requires standardization. Current biodegradation tests often vary in their methodologies, making it difficult to compare results across different studies. Standardized protocols for assessing biodegradation rates and environmental impact are necessary to ensure consistent evaluation of these materials' eco-friendly properties.

Shape memory and self-healing capabilities are distinctive features of many PLA smart materials. Standardized testing methods for evaluating shape recovery ratios, recovery speeds, and self-healing efficiencies are needed to accurately assess and compare the performance of different PLA-based smart materials.

Durability and aging tests are essential for understanding the long-term performance of PLA smart materials. Standardized accelerated aging protocols that simulate various environmental conditions can help predict the materials' behavior over time and assess their suitability for different applications.

To achieve these standardization goals, collaboration between academic institutions, industry partners, and standardization bodies is crucial. Organizations such as ASTM International and ISO are working towards developing comprehensive testing standards for bioplastics and smart materials. However, the rapid advancement in PLA smart material technology necessitates continuous updating and refinement of these standards to keep pace with new developments in the field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!