Computational Modeling of Laminar Flow Patterns

JUL 10, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Laminar Flow Modeling Background and Objectives

Laminar flow modeling has been a cornerstone in fluid dynamics research for decades, playing a crucial role in understanding and predicting fluid behavior in various engineering applications. The study of laminar flow patterns dates back to the early 20th century, with pioneering work by Ludwig Prandtl on boundary layer theory. Since then, the field has evolved significantly, driven by advancements in computational power and numerical methods.

The primary objective of computational modeling of laminar flow patterns is to accurately simulate and predict fluid behavior in low Reynolds number regimes. This involves developing mathematical models and numerical algorithms that can capture the intricate details of fluid motion without the complexities introduced by turbulence. Such models are essential for a wide range of applications, from microfluidics to aerospace engineering.

Over the years, the focus of laminar flow modeling has shifted from analytical solutions to more sophisticated computational approaches. Early models relied heavily on simplifying assumptions and were limited to basic geometries. However, with the advent of computational fluid dynamics (CFD) and high-performance computing, researchers can now tackle increasingly complex problems with greater accuracy.

The evolution of laminar flow modeling has been marked by several key milestones. These include the development of the Navier-Stokes equations, which form the foundation of fluid dynamics, and the introduction of finite difference and finite element methods for numerical solutions. More recently, spectral methods and lattice Boltzmann techniques have emerged as powerful tools for simulating laminar flows in complex geometries.

Current trends in laminar flow modeling focus on improving the accuracy and efficiency of numerical simulations. This includes the development of high-order methods, adaptive mesh refinement techniques, and parallel computing algorithms. Additionally, there is a growing interest in coupling laminar flow models with other physical phenomena, such as heat transfer, chemical reactions, and multiphase flows.

Looking ahead, the field of computational modeling of laminar flow patterns is poised for further advancements. Emerging technologies, such as machine learning and quantum computing, hold promise for revolutionizing the way we approach fluid dynamics simulations. These innovations may lead to more accurate predictions, faster computation times, and the ability to tackle even more complex flow problems.

In conclusion, the computational modeling of laminar flow patterns remains a vibrant and essential area of research. As we continue to push the boundaries of what is possible in fluid dynamics simulations, we can expect to see significant improvements in our ability to understand and predict laminar flow behavior across a wide range of applications.

The primary objective of computational modeling of laminar flow patterns is to accurately simulate and predict fluid behavior in low Reynolds number regimes. This involves developing mathematical models and numerical algorithms that can capture the intricate details of fluid motion without the complexities introduced by turbulence. Such models are essential for a wide range of applications, from microfluidics to aerospace engineering.

Over the years, the focus of laminar flow modeling has shifted from analytical solutions to more sophisticated computational approaches. Early models relied heavily on simplifying assumptions and were limited to basic geometries. However, with the advent of computational fluid dynamics (CFD) and high-performance computing, researchers can now tackle increasingly complex problems with greater accuracy.

The evolution of laminar flow modeling has been marked by several key milestones. These include the development of the Navier-Stokes equations, which form the foundation of fluid dynamics, and the introduction of finite difference and finite element methods for numerical solutions. More recently, spectral methods and lattice Boltzmann techniques have emerged as powerful tools for simulating laminar flows in complex geometries.

Current trends in laminar flow modeling focus on improving the accuracy and efficiency of numerical simulations. This includes the development of high-order methods, adaptive mesh refinement techniques, and parallel computing algorithms. Additionally, there is a growing interest in coupling laminar flow models with other physical phenomena, such as heat transfer, chemical reactions, and multiphase flows.

Looking ahead, the field of computational modeling of laminar flow patterns is poised for further advancements. Emerging technologies, such as machine learning and quantum computing, hold promise for revolutionizing the way we approach fluid dynamics simulations. These innovations may lead to more accurate predictions, faster computation times, and the ability to tackle even more complex flow problems.

In conclusion, the computational modeling of laminar flow patterns remains a vibrant and essential area of research. As we continue to push the boundaries of what is possible in fluid dynamics simulations, we can expect to see significant improvements in our ability to understand and predict laminar flow behavior across a wide range of applications.

Market Applications of Laminar Flow Simulations

Laminar flow simulations have found extensive applications across various industries, driving innovation and optimization in product design and process efficiency. In the automotive sector, these simulations play a crucial role in enhancing aerodynamics, leading to improved fuel efficiency and reduced emissions. Automotive manufacturers utilize computational fluid dynamics (CFD) to model airflow around vehicles, optimizing body shapes and reducing drag coefficients. This application has resulted in significant advancements in electric vehicle range and overall performance.

The aerospace industry heavily relies on laminar flow simulations for aircraft design and optimization. By modeling airflow over wings and fuselage surfaces, engineers can develop more efficient wing profiles and reduce skin friction drag. This has led to the development of natural laminar flow (NLF) airfoils and hybrid laminar flow control (HLFC) systems, contributing to substantial fuel savings and extended flight ranges for commercial and military aircraft.

In the field of biomedical engineering, laminar flow simulations have revolutionized the design of medical devices and the understanding of physiological processes. Computational modeling of blood flow in arteries and veins has enabled the development of more effective stents, heart valves, and artificial organs. These simulations also aid in predicting the behavior of drug delivery systems and optimizing the design of microfluidic devices for diagnostic applications.

The energy sector has benefited greatly from laminar flow simulations, particularly in the design of wind turbines and solar thermal systems. Wind farm operators use these simulations to optimize turbine blade designs and placement, maximizing energy capture while minimizing wake effects. In solar thermal power plants, laminar flow models help engineers design more efficient heat transfer systems, improving overall plant efficiency and reducing costs.

In the chemical and process industries, laminar flow simulations are essential for designing and optimizing reactors, heat exchangers, and mixing systems. These models enable engineers to predict reaction kinetics, heat transfer rates, and mixing efficiencies, leading to improved product quality and reduced energy consumption. The pharmaceutical industry, in particular, relies on these simulations for the design of bioreactors and chromatography columns, enhancing drug production processes.

The HVAC (Heating, Ventilation, and Air Conditioning) industry utilizes laminar flow simulations to design more efficient and comfortable indoor environments. By modeling airflow patterns in buildings, engineers can optimize ventilation systems, reduce energy consumption, and improve indoor air quality. This application has become increasingly important in the context of sustainable building design and the need for energy-efficient solutions in urban environments.

The aerospace industry heavily relies on laminar flow simulations for aircraft design and optimization. By modeling airflow over wings and fuselage surfaces, engineers can develop more efficient wing profiles and reduce skin friction drag. This has led to the development of natural laminar flow (NLF) airfoils and hybrid laminar flow control (HLFC) systems, contributing to substantial fuel savings and extended flight ranges for commercial and military aircraft.

In the field of biomedical engineering, laminar flow simulations have revolutionized the design of medical devices and the understanding of physiological processes. Computational modeling of blood flow in arteries and veins has enabled the development of more effective stents, heart valves, and artificial organs. These simulations also aid in predicting the behavior of drug delivery systems and optimizing the design of microfluidic devices for diagnostic applications.

The energy sector has benefited greatly from laminar flow simulations, particularly in the design of wind turbines and solar thermal systems. Wind farm operators use these simulations to optimize turbine blade designs and placement, maximizing energy capture while minimizing wake effects. In solar thermal power plants, laminar flow models help engineers design more efficient heat transfer systems, improving overall plant efficiency and reducing costs.

In the chemical and process industries, laminar flow simulations are essential for designing and optimizing reactors, heat exchangers, and mixing systems. These models enable engineers to predict reaction kinetics, heat transfer rates, and mixing efficiencies, leading to improved product quality and reduced energy consumption. The pharmaceutical industry, in particular, relies on these simulations for the design of bioreactors and chromatography columns, enhancing drug production processes.

The HVAC (Heating, Ventilation, and Air Conditioning) industry utilizes laminar flow simulations to design more efficient and comfortable indoor environments. By modeling airflow patterns in buildings, engineers can optimize ventilation systems, reduce energy consumption, and improve indoor air quality. This application has become increasingly important in the context of sustainable building design and the need for energy-efficient solutions in urban environments.

Current Challenges in Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) has made significant strides in recent years, yet several challenges persist in accurately modeling complex flow phenomena, particularly in the realm of laminar flow patterns. One of the primary obstacles is the high computational cost associated with resolving fine-scale structures in laminar flows, especially in scenarios involving intricate geometries or multi-phase interactions.

The accurate representation of boundary layers remains a critical challenge in CFD simulations of laminar flows. Traditional mesh-based methods often struggle to capture the steep velocity gradients near solid boundaries without excessive grid refinement, leading to increased computational demands. This issue is particularly pronounced in applications such as microfluidics or biological flows, where the accurate prediction of wall shear stress is crucial.

Another significant challenge lies in the modeling of interfacial phenomena in multi-phase laminar flows. The precise tracking of fluid-fluid interfaces, including surface tension effects and contact line dynamics, continues to pose difficulties for existing numerical methods. This challenge is particularly relevant in applications such as droplet dynamics, coating processes, and microfluidic devices.

The treatment of moving boundaries and fluid-structure interaction in laminar flow simulations presents another area of ongoing research. Accurately capturing the coupling between fluid motion and structural deformation, while maintaining numerical stability and efficiency, remains a complex task. This challenge is particularly evident in biomedical applications, such as blood flow in flexible vessels or the dynamics of microorganisms in viscous fluids.

Furthermore, the development of robust and efficient numerical schemes for simulating non-Newtonian fluids in laminar flow regimes continues to be an active area of research. Many industrial and biological fluids exhibit complex rheological behaviors, such as shear-thinning or viscoelasticity, which can significantly impact flow patterns. Accurately capturing these non-linear material responses while ensuring numerical stability and convergence remains a challenge for CFD practitioners.

The integration of machine learning techniques with traditional CFD approaches presents both opportunities and challenges in the modeling of laminar flows. While data-driven methods show promise in reducing computational costs and improving predictive accuracy, challenges remain in ensuring the physical consistency and generalizability of these hybrid models, particularly for complex laminar flow scenarios.

Lastly, the validation and uncertainty quantification of CFD simulations for laminar flows continue to be critical challenges. The lack of comprehensive experimental data for many complex flow scenarios, coupled with the inherent uncertainties in model parameters and boundary conditions, necessitates the development of robust validation methodologies and uncertainty propagation techniques specific to laminar flow simulations.

The accurate representation of boundary layers remains a critical challenge in CFD simulations of laminar flows. Traditional mesh-based methods often struggle to capture the steep velocity gradients near solid boundaries without excessive grid refinement, leading to increased computational demands. This issue is particularly pronounced in applications such as microfluidics or biological flows, where the accurate prediction of wall shear stress is crucial.

Another significant challenge lies in the modeling of interfacial phenomena in multi-phase laminar flows. The precise tracking of fluid-fluid interfaces, including surface tension effects and contact line dynamics, continues to pose difficulties for existing numerical methods. This challenge is particularly relevant in applications such as droplet dynamics, coating processes, and microfluidic devices.

The treatment of moving boundaries and fluid-structure interaction in laminar flow simulations presents another area of ongoing research. Accurately capturing the coupling between fluid motion and structural deformation, while maintaining numerical stability and efficiency, remains a complex task. This challenge is particularly evident in biomedical applications, such as blood flow in flexible vessels or the dynamics of microorganisms in viscous fluids.

Furthermore, the development of robust and efficient numerical schemes for simulating non-Newtonian fluids in laminar flow regimes continues to be an active area of research. Many industrial and biological fluids exhibit complex rheological behaviors, such as shear-thinning or viscoelasticity, which can significantly impact flow patterns. Accurately capturing these non-linear material responses while ensuring numerical stability and convergence remains a challenge for CFD practitioners.

The integration of machine learning techniques with traditional CFD approaches presents both opportunities and challenges in the modeling of laminar flows. While data-driven methods show promise in reducing computational costs and improving predictive accuracy, challenges remain in ensuring the physical consistency and generalizability of these hybrid models, particularly for complex laminar flow scenarios.

Lastly, the validation and uncertainty quantification of CFD simulations for laminar flows continue to be critical challenges. The lack of comprehensive experimental data for many complex flow scenarios, coupled with the inherent uncertainties in model parameters and boundary conditions, necessitates the development of robust validation methodologies and uncertainty propagation techniques specific to laminar flow simulations.

Existing Computational Methods for Laminar Flow

01 Flow measurement and analysis techniques

Various methods and devices are used to measure and analyze laminar flow patterns. These include advanced sensors, imaging systems, and computational algorithms that can detect and characterize flow characteristics in real-time. Such techniques are crucial for understanding and optimizing fluid dynamics in various applications.- Flow measurement and analysis techniques: Various methods and devices are used to measure and analyze laminar flow patterns. These include advanced sensors, imaging systems, and computational algorithms that can detect, visualize, and quantify flow characteristics in real-time. Such techniques are crucial for understanding and optimizing fluid dynamics in various applications.

- Laminar flow control in fluid systems: Techniques for controlling and maintaining laminar flow in fluid systems are essential in many industries. This involves designing specialized components, such as nozzles, channels, and barriers, to guide fluid flow and minimize turbulence. Precise control of flow parameters helps improve efficiency and performance in various processes.

- Laminar flow applications in manufacturing: Laminar flow patterns play a crucial role in manufacturing processes, particularly in areas such as coating, printing, and material deposition. Controlled laminar flow enables uniform application of substances, precise patterning, and improved product quality. Various technologies have been developed to leverage laminar flow in industrial settings.

- Modeling and simulation of laminar flow: Advanced computational methods and software tools are used to model and simulate laminar flow patterns. These simulations help in predicting flow behavior, optimizing system designs, and troubleshooting issues before physical implementation. Such modeling techniques are valuable in research, engineering, and product development across various industries.

- Laminar flow in environmental and biological systems: The study of laminar flow patterns is important in environmental and biological contexts, such as air and water quality management, microfluidics for medical diagnostics, and understanding natural phenomena. Research in this area focuses on how laminar flow affects particle transport, mixing, and separation in various scales and conditions.

02 Laminar flow control in fluid systems

Techniques for controlling and maintaining laminar flow in fluid systems are essential for many industrial and scientific applications. This includes the design of specialized nozzles, channels, and other flow-directing components that help to reduce turbulence and maintain smooth, predictable fluid movement.Expand Specific Solutions03 Laminar flow applications in manufacturing

Laminar flow patterns are utilized in various manufacturing processes to improve efficiency and product quality. This includes applications in coating technologies, material deposition, and precision machining where controlled, uniform fluid flow is critical to achieving desired results.Expand Specific Solutions04 Computational modeling of laminar flow

Advanced computational methods are employed to model and simulate laminar flow patterns. These models help in predicting flow behavior, optimizing system designs, and understanding complex fluid dynamics without the need for extensive physical testing.Expand Specific Solutions05 Laminar flow in microfluidic devices

The study and application of laminar flow patterns in microfluidic devices is crucial for developing lab-on-a-chip technologies, medical diagnostics, and miniaturized chemical analysis systems. At these small scales, laminar flow properties can be exploited for precise fluid manipulation and control.Expand Specific Solutions

Key Players in CFD Software and Research

The computational modeling of laminar flow patterns is a mature field within fluid dynamics, with significant applications across various industries. The market is characterized by established players and ongoing research, indicating a stable growth phase. Key competitors include major oil and gas companies like Chevron, Schlumberger, and ExxonMobil, alongside academic institutions such as ETH Zurich and Hohai University. These organizations are investing in advanced modeling techniques to optimize fluid flow in diverse applications, from petroleum engineering to environmental studies. The technology's maturity is evident in its widespread adoption, yet continuous refinement and integration with emerging technologies like AI and machine learning suggest potential for further market expansion and innovation.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed advanced computational modeling techniques for laminar flow patterns in oil and gas reservoirs. Their approach combines high-resolution numerical simulations with machine learning algorithms to predict and optimize fluid flow in porous media. The company utilizes finite element methods and computational fluid dynamics (CFD) to model complex geometries and multiphase flows[1]. Their models incorporate detailed rock properties, fluid characteristics, and reservoir conditions to provide accurate predictions of flow behavior at various scales. Schlumberger's technology also integrates real-time data from downhole sensors to continuously refine and update flow models, enabling adaptive reservoir management strategies[3].

Strengths: Industry-leading expertise in reservoir simulation, access to vast amounts of field data, and integration with other oilfield services. Weaknesses: High computational requirements and potential limitations in unconventional reservoirs.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed computational modeling capabilities for laminar flow patterns tailored to the unique characteristics of Chinese oil and gas fields. Their approach combines traditional numerical methods with artificial intelligence to improve the accuracy and efficiency of flow simulations[5]. Sinopec's models incorporate detailed geological data and can simulate complex fractured reservoirs common in China. The company has also developed specialized modules for modeling enhanced oil recovery processes, including polymer flooding and CO2 injection[6]. Sinopec's technology integrates with their in-house reservoir management software to provide end-to-end solutions for field development planning and optimization.

Strengths: Specialized knowledge of Chinese reservoirs, integration with field operations, and focus on enhanced oil recovery. Weaknesses: Potential limitations in applicability to non-Chinese reservoirs and less international exposure.

Innovative Algorithms in Laminar Flow Modeling

Computer simulation of physical processes including modeling of laminar-to-turbulent transition

PatentActiveUS20170109464A1

Innovation

- The method involves performing separate calculations for laminar and turbulent boundary layer flows, selecting appropriate wall-shear stress values based on turbulence intensity, and using a lattice Boltzmann approach to model fluid flow dynamics, allowing for accurate determination of flow regimes and corresponding wall-shear stress assignment on a per-facet basis.

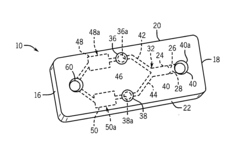

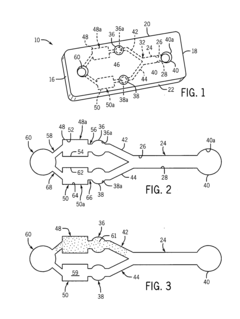

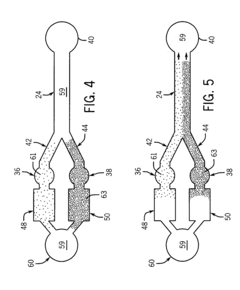

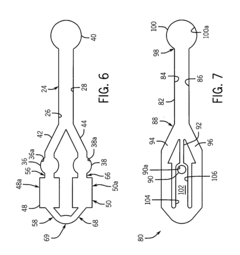

Method And Device For Controlled Laminar Flow Patterning Within A Channel

PatentActiveUS20130276890A1

Innovation

- A microfluidic device with a channel network that includes a main channel and input channels with fluidic resistances, buffering channels, and a fluidic capacitor, utilizing surface tension-generated pressures to achieve controlled laminar flow by depositing buffer and sample fluids through input ports, allowing for asynchronous loading and synchronized flow paths.

Validation and Verification Methodologies

Validation and verification methodologies play a crucial role in ensuring the accuracy and reliability of computational models for laminar flow patterns. These methodologies involve a systematic approach to assess the model's performance against experimental data and theoretical predictions.

One of the primary validation techniques is the comparison of computational results with experimental measurements. This process typically involves conducting controlled experiments in wind tunnels or hydraulic flumes to obtain precise flow data. The experimental setup must be carefully designed to replicate the conditions simulated in the computational model. Key parameters such as velocity profiles, pressure distributions, and shear stress measurements are collected and compared with the model's predictions.

Verification methods focus on assessing the mathematical correctness and numerical accuracy of the computational model. This includes grid convergence studies, where the model is run with increasingly refined mesh resolutions to ensure that the solution converges to a consistent result. Additionally, code verification techniques, such as the method of manufactured solutions, are employed to confirm that the governing equations are solved correctly.

Uncertainty quantification is another essential aspect of validation and verification. This involves identifying and quantifying various sources of uncertainty in both the computational model and experimental data. Statistical methods, such as Monte Carlo simulations or polynomial chaos expansions, are often used to propagate these uncertainties through the model and assess their impact on the final results.

Benchmark problems play a significant role in the validation process. These are well-documented cases with known analytical solutions or high-quality experimental data. By simulating these benchmark problems, researchers can evaluate the performance of their computational models across a range of flow conditions and geometries.

Inter-code comparisons are also valuable for verification purposes. This involves running the same simulation using different computational fluid dynamics (CFD) codes or numerical methods and comparing the results. Discrepancies between different codes can highlight potential issues in implementation or numerical schemes.

Sensitivity analysis is another crucial component of the validation process. This involves systematically varying input parameters and assessing their impact on the model's output. This helps identify which parameters have the most significant influence on the results and guides further refinement of the model.

Finally, the development and adherence to best practices and guidelines for CFD simulations are essential for ensuring consistent and reliable results. These guidelines often cover aspects such as mesh quality, boundary condition specification, and solver settings, which are critical for accurate laminar flow modeling.

One of the primary validation techniques is the comparison of computational results with experimental measurements. This process typically involves conducting controlled experiments in wind tunnels or hydraulic flumes to obtain precise flow data. The experimental setup must be carefully designed to replicate the conditions simulated in the computational model. Key parameters such as velocity profiles, pressure distributions, and shear stress measurements are collected and compared with the model's predictions.

Verification methods focus on assessing the mathematical correctness and numerical accuracy of the computational model. This includes grid convergence studies, where the model is run with increasingly refined mesh resolutions to ensure that the solution converges to a consistent result. Additionally, code verification techniques, such as the method of manufactured solutions, are employed to confirm that the governing equations are solved correctly.

Uncertainty quantification is another essential aspect of validation and verification. This involves identifying and quantifying various sources of uncertainty in both the computational model and experimental data. Statistical methods, such as Monte Carlo simulations or polynomial chaos expansions, are often used to propagate these uncertainties through the model and assess their impact on the final results.

Benchmark problems play a significant role in the validation process. These are well-documented cases with known analytical solutions or high-quality experimental data. By simulating these benchmark problems, researchers can evaluate the performance of their computational models across a range of flow conditions and geometries.

Inter-code comparisons are also valuable for verification purposes. This involves running the same simulation using different computational fluid dynamics (CFD) codes or numerical methods and comparing the results. Discrepancies between different codes can highlight potential issues in implementation or numerical schemes.

Sensitivity analysis is another crucial component of the validation process. This involves systematically varying input parameters and assessing their impact on the model's output. This helps identify which parameters have the most significant influence on the results and guides further refinement of the model.

Finally, the development and adherence to best practices and guidelines for CFD simulations are essential for ensuring consistent and reliable results. These guidelines often cover aspects such as mesh quality, boundary condition specification, and solver settings, which are critical for accurate laminar flow modeling.

High-Performance Computing in CFD

High-performance computing (HPC) has become an indispensable tool in the field of Computational Fluid Dynamics (CFD), particularly for modeling complex laminar flow patterns. The increasing demand for higher accuracy and resolution in CFD simulations has driven the need for more powerful computational resources. HPC systems, with their massive parallel processing capabilities, have revolutionized the way researchers and engineers approach CFD problems.

In the context of laminar flow modeling, HPC enables the simulation of larger and more intricate flow domains with unprecedented detail. This is crucial for applications such as aerodynamics, microfluidics, and biomedical engineering, where understanding the nuances of laminar flow behavior is essential. HPC clusters allow for the distribution of computational tasks across multiple nodes, significantly reducing the time required to solve complex fluid dynamics equations.

One of the key advantages of HPC in CFD is the ability to perform high-resolution simulations that capture fine-scale flow structures. This is particularly important in laminar flow regimes, where small perturbations can have significant effects on the overall flow behavior. By leveraging HPC resources, researchers can implement advanced numerical methods and turbulence models that were previously impractical due to computational limitations.

The integration of HPC with CFD has also facilitated the development of more sophisticated algorithms for mesh generation and adaptive refinement. These techniques are crucial for accurately resolving boundary layers and other critical regions in laminar flow simulations. HPC systems enable the dynamic adjustment of mesh resolution during runtime, ensuring optimal computational efficiency while maintaining high accuracy in areas of interest.

Furthermore, HPC has opened new avenues for uncertainty quantification and sensitivity analysis in laminar flow modeling. By running multiple simulations with varying parameters, researchers can gain deeper insights into the robustness of their models and the influence of different factors on flow behavior. This approach is particularly valuable in design optimization processes, where understanding the sensitivity of flow patterns to geometric or boundary condition changes is essential.

As HPC continues to evolve, emerging technologies such as GPU acceleration and quantum computing promise to further enhance the capabilities of CFD simulations. These advancements will likely lead to even more accurate and efficient modeling of laminar flow patterns, pushing the boundaries of what is possible in fluid dynamics research and engineering applications.

In the context of laminar flow modeling, HPC enables the simulation of larger and more intricate flow domains with unprecedented detail. This is crucial for applications such as aerodynamics, microfluidics, and biomedical engineering, where understanding the nuances of laminar flow behavior is essential. HPC clusters allow for the distribution of computational tasks across multiple nodes, significantly reducing the time required to solve complex fluid dynamics equations.

One of the key advantages of HPC in CFD is the ability to perform high-resolution simulations that capture fine-scale flow structures. This is particularly important in laminar flow regimes, where small perturbations can have significant effects on the overall flow behavior. By leveraging HPC resources, researchers can implement advanced numerical methods and turbulence models that were previously impractical due to computational limitations.

The integration of HPC with CFD has also facilitated the development of more sophisticated algorithms for mesh generation and adaptive refinement. These techniques are crucial for accurately resolving boundary layers and other critical regions in laminar flow simulations. HPC systems enable the dynamic adjustment of mesh resolution during runtime, ensuring optimal computational efficiency while maintaining high accuracy in areas of interest.

Furthermore, HPC has opened new avenues for uncertainty quantification and sensitivity analysis in laminar flow modeling. By running multiple simulations with varying parameters, researchers can gain deeper insights into the robustness of their models and the influence of different factors on flow behavior. This approach is particularly valuable in design optimization processes, where understanding the sensitivity of flow patterns to geometric or boundary condition changes is essential.

As HPC continues to evolve, emerging technologies such as GPU acceleration and quantum computing promise to further enhance the capabilities of CFD simulations. These advancements will likely lead to even more accurate and efficient modeling of laminar flow patterns, pushing the boundaries of what is possible in fluid dynamics research and engineering applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!