How Smart Sensors Enhance Monitoring of Battery Acid Levels

AUG 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Smart Sensor Evolution

The evolution of smart sensors for monitoring battery acid levels has been marked by significant technological advancements over the past few decades. Initially, basic analog sensors were used to measure voltage and current, providing limited information about battery health. These early sensors lacked the ability to communicate data in real-time or perform complex analysis.

As digital technology progressed, the second generation of sensors emerged, incorporating microprocessors and basic communication capabilities. These sensors could measure multiple parameters simultaneously, such as temperature, voltage, and specific gravity, offering a more comprehensive view of battery conditions. However, data interpretation still largely relied on human expertise.

The third generation saw the integration of wireless communication technologies, enabling remote monitoring and data collection. This breakthrough allowed for continuous monitoring of large battery banks in industrial settings, improving maintenance schedules and reducing downtime. Sensors became smaller, more energy-efficient, and capable of storing historical data for trend analysis.

The current generation of smart sensors represents a quantum leap in capabilities. These sensors leverage advanced materials science, miniaturization techniques, and artificial intelligence to provide unprecedented accuracy and predictive capabilities. Modern smart sensors can detect minute changes in electrolyte composition, identify early signs of degradation, and even predict potential failures before they occur.

Machine learning algorithms embedded in these sensors can analyze vast amounts of data in real-time, adapting to specific battery chemistries and usage patterns. This allows for highly personalized monitoring and maintenance strategies, significantly extending battery life and improving overall system reliability.

The latest developments in smart sensor technology focus on non-invasive monitoring techniques, such as ultrasonic measurements and spectroscopic analysis. These methods allow for accurate assessment of battery health without the need for physical contact with the electrolyte, reducing the risk of contamination and improving safety in hazardous environments.

Looking ahead, the next generation of smart sensors is expected to incorporate self-healing capabilities and energy harvesting technologies. These advancements will enable sensors to operate autonomously for extended periods, further reducing maintenance requirements and improving the overall efficiency of battery monitoring systems.

As digital technology progressed, the second generation of sensors emerged, incorporating microprocessors and basic communication capabilities. These sensors could measure multiple parameters simultaneously, such as temperature, voltage, and specific gravity, offering a more comprehensive view of battery conditions. However, data interpretation still largely relied on human expertise.

The third generation saw the integration of wireless communication technologies, enabling remote monitoring and data collection. This breakthrough allowed for continuous monitoring of large battery banks in industrial settings, improving maintenance schedules and reducing downtime. Sensors became smaller, more energy-efficient, and capable of storing historical data for trend analysis.

The current generation of smart sensors represents a quantum leap in capabilities. These sensors leverage advanced materials science, miniaturization techniques, and artificial intelligence to provide unprecedented accuracy and predictive capabilities. Modern smart sensors can detect minute changes in electrolyte composition, identify early signs of degradation, and even predict potential failures before they occur.

Machine learning algorithms embedded in these sensors can analyze vast amounts of data in real-time, adapting to specific battery chemistries and usage patterns. This allows for highly personalized monitoring and maintenance strategies, significantly extending battery life and improving overall system reliability.

The latest developments in smart sensor technology focus on non-invasive monitoring techniques, such as ultrasonic measurements and spectroscopic analysis. These methods allow for accurate assessment of battery health without the need for physical contact with the electrolyte, reducing the risk of contamination and improving safety in hazardous environments.

Looking ahead, the next generation of smart sensors is expected to incorporate self-healing capabilities and energy harvesting technologies. These advancements will enable sensors to operate autonomously for extended periods, further reducing maintenance requirements and improving the overall efficiency of battery monitoring systems.

Battery Acid Monitoring Market

The battery acid monitoring market has experienced significant growth in recent years, driven by the increasing adoption of smart sensors and advanced monitoring technologies. This market segment is primarily fueled by the rising demand for efficient and reliable battery management systems across various industries, including automotive, telecommunications, and renewable energy storage.

The global battery acid monitoring market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including the rapid expansion of electric vehicle (EV) production, the growing need for uninterrupted power supply in critical infrastructure, and the increasing focus on renewable energy integration.

In the automotive sector, the surge in EV sales has created a substantial demand for advanced battery monitoring systems. As battery performance and longevity are crucial factors in EV adoption, manufacturers are investing heavily in smart sensor technologies to enhance battery acid level monitoring and overall battery health management.

The telecommunications industry represents another significant market for battery acid monitoring solutions. With the ongoing rollout of 5G networks and the expansion of data centers, there is an increased need for reliable backup power systems. Smart sensors play a vital role in ensuring the optimal performance and longevity of these backup batteries, driving the demand for sophisticated monitoring technologies.

The renewable energy sector, particularly in solar and wind power applications, has also contributed to the growth of the battery acid monitoring market. As energy storage becomes increasingly important for grid stability and off-grid solutions, the need for accurate and real-time monitoring of battery acid levels has become paramount.

Geographically, North America and Europe currently lead the battery acid monitoring market, owing to their advanced automotive industries and early adoption of renewable energy technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing EV production, and government initiatives promoting clean energy adoption.

Key players in the battery acid monitoring market include established sensor manufacturers, battery management system providers, and emerging startups specializing in IoT-based monitoring solutions. These companies are continuously innovating to develop more accurate, reliable, and cost-effective smart sensor technologies for battery acid level monitoring.

As the market continues to evolve, there is a growing trend towards the integration of artificial intelligence and machine learning algorithms in battery monitoring systems. These advanced technologies enable predictive maintenance, optimize battery performance, and extend battery life, further driving the demand for smart sensor solutions in the battery acid monitoring market.

The global battery acid monitoring market is expected to continue its upward trajectory, with a compound annual growth rate (CAGR) projected to remain strong over the next five years. This growth is attributed to several factors, including the rapid expansion of electric vehicle (EV) production, the growing need for uninterrupted power supply in critical infrastructure, and the increasing focus on renewable energy integration.

In the automotive sector, the surge in EV sales has created a substantial demand for advanced battery monitoring systems. As battery performance and longevity are crucial factors in EV adoption, manufacturers are investing heavily in smart sensor technologies to enhance battery acid level monitoring and overall battery health management.

The telecommunications industry represents another significant market for battery acid monitoring solutions. With the ongoing rollout of 5G networks and the expansion of data centers, there is an increased need for reliable backup power systems. Smart sensors play a vital role in ensuring the optimal performance and longevity of these backup batteries, driving the demand for sophisticated monitoring technologies.

The renewable energy sector, particularly in solar and wind power applications, has also contributed to the growth of the battery acid monitoring market. As energy storage becomes increasingly important for grid stability and off-grid solutions, the need for accurate and real-time monitoring of battery acid levels has become paramount.

Geographically, North America and Europe currently lead the battery acid monitoring market, owing to their advanced automotive industries and early adoption of renewable energy technologies. However, the Asia-Pacific region is expected to witness the fastest growth in the coming years, driven by rapid industrialization, increasing EV production, and government initiatives promoting clean energy adoption.

Key players in the battery acid monitoring market include established sensor manufacturers, battery management system providers, and emerging startups specializing in IoT-based monitoring solutions. These companies are continuously innovating to develop more accurate, reliable, and cost-effective smart sensor technologies for battery acid level monitoring.

As the market continues to evolve, there is a growing trend towards the integration of artificial intelligence and machine learning algorithms in battery monitoring systems. These advanced technologies enable predictive maintenance, optimize battery performance, and extend battery life, further driving the demand for smart sensor solutions in the battery acid monitoring market.

Smart Sensor Challenges

The implementation of smart sensors for monitoring battery acid levels presents several significant challenges that need to be addressed. One of the primary obstacles is the harsh and corrosive environment in which these sensors must operate. Battery acid is highly corrosive, which can quickly degrade traditional sensing materials and components. This necessitates the development of sensors with advanced materials that can withstand prolonged exposure to acidic conditions while maintaining accuracy and reliability.

Another challenge lies in the miniaturization of sensor technology. As batteries become more compact and energy-dense, the space available for sensors becomes increasingly limited. This requires innovative design approaches to create sensors that are not only small enough to fit within modern battery configurations but also capable of delivering precise measurements without compromising performance.

Power consumption is a critical concern in smart sensor development for battery monitoring. The sensors must operate with minimal energy draw to avoid significantly impacting the battery's overall performance and lifespan. Achieving a balance between sensor functionality and power efficiency remains a complex engineering challenge, particularly for long-term monitoring applications.

Data accuracy and consistency pose additional challenges. Fluctuations in temperature, pressure, and other environmental factors can affect sensor readings, potentially leading to false alarms or missed critical events. Developing algorithms and calibration techniques that can compensate for these variables and provide reliable data across diverse operating conditions is crucial for effective battery management.

Connectivity and data transmission present further hurdles. Smart sensors need to communicate their readings effectively, often in real-time, to battery management systems or monitoring devices. This requires robust wireless communication protocols that can function reliably within the confines of a battery pack, where signal interference and physical barriers may be present.

The integration of smart sensors with existing battery management systems (BMS) also presents compatibility challenges. Ensuring seamless interaction between new sensor technologies and established BMS architectures requires careful consideration of communication protocols, data formats, and system architectures.

Lastly, the cost-effectiveness of implementing smart sensor technology on a large scale remains a significant challenge. While the benefits of enhanced monitoring are clear, the additional expense of incorporating advanced sensors into every battery unit must be justified by tangible improvements in performance, safety, and longevity. Striking the right balance between sensor sophistication and economic viability is essential for widespread adoption in commercial applications.

Another challenge lies in the miniaturization of sensor technology. As batteries become more compact and energy-dense, the space available for sensors becomes increasingly limited. This requires innovative design approaches to create sensors that are not only small enough to fit within modern battery configurations but also capable of delivering precise measurements without compromising performance.

Power consumption is a critical concern in smart sensor development for battery monitoring. The sensors must operate with minimal energy draw to avoid significantly impacting the battery's overall performance and lifespan. Achieving a balance between sensor functionality and power efficiency remains a complex engineering challenge, particularly for long-term monitoring applications.

Data accuracy and consistency pose additional challenges. Fluctuations in temperature, pressure, and other environmental factors can affect sensor readings, potentially leading to false alarms or missed critical events. Developing algorithms and calibration techniques that can compensate for these variables and provide reliable data across diverse operating conditions is crucial for effective battery management.

Connectivity and data transmission present further hurdles. Smart sensors need to communicate their readings effectively, often in real-time, to battery management systems or monitoring devices. This requires robust wireless communication protocols that can function reliably within the confines of a battery pack, where signal interference and physical barriers may be present.

The integration of smart sensors with existing battery management systems (BMS) also presents compatibility challenges. Ensuring seamless interaction between new sensor technologies and established BMS architectures requires careful consideration of communication protocols, data formats, and system architectures.

Lastly, the cost-effectiveness of implementing smart sensor technology on a large scale remains a significant challenge. While the benefits of enhanced monitoring are clear, the additional expense of incorporating advanced sensors into every battery unit must be justified by tangible improvements in performance, safety, and longevity. Striking the right balance between sensor sophistication and economic viability is essential for widespread adoption in commercial applications.

Current Smart Sensor Solutions

01 Smart sensors for pH monitoring

Advanced sensors designed to measure and monitor acid levels in various environments. These sensors utilize innovative technologies to provide accurate and real-time data on pH levels, enabling better control and management of acidic conditions in industrial processes, environmental monitoring, and other applications.- Smart sensors for pH monitoring: Advanced sensors designed to measure and monitor acid levels in various environments. These sensors utilize innovative technologies to provide accurate and real-time data on pH levels, enabling better control and management of acidic conditions in industrial processes, environmental monitoring, and other applications.

- Integrated sensor systems for acid detection: Comprehensive sensor systems that incorporate multiple components for detecting and analyzing acid levels. These systems may include data processing units, communication modules, and specialized algorithms to interpret sensor readings and provide actionable insights on acid concentrations and trends.

- Wireless acid level monitoring solutions: Wireless sensor networks and IoT-enabled devices for remote monitoring of acid levels. These solutions allow for continuous data collection and transmission, enabling real-time monitoring and alerts for acid level fluctuations in various industrial and environmental settings.

- Smart sensors with predictive maintenance capabilities: Intelligent sensor systems that not only measure acid levels but also incorporate predictive maintenance features. These sensors can analyze historical data, detect patterns, and predict potential issues related to acid levels, allowing for proactive maintenance and reducing downtime in industrial processes.

- Miniaturized smart sensors for acid detection: Compact and highly sensitive smart sensors designed for precise acid level detection in confined spaces or specialized applications. These miniaturized sensors may utilize advanced materials and fabrication techniques to achieve high accuracy and reliability in measuring acid concentrations.

02 Integration of acid level sensors in smart systems

Incorporation of acid level sensors into larger smart systems and networks. This integration allows for improved data collection, analysis, and automated responses to changes in acid levels. Such systems can be applied in manufacturing, agriculture, and environmental monitoring to enhance efficiency and safety.Expand Specific Solutions03 Power management for acid level sensing devices

Development of power-efficient solutions for acid level sensing devices. These innovations focus on optimizing battery life, implementing energy harvesting techniques, and improving overall power management to ensure long-term operation of sensors in remote or hard-to-reach locations.Expand Specific Solutions04 Data processing and analysis for acid level measurements

Advanced algorithms and data processing techniques for analyzing acid level measurements. These methods improve the accuracy of readings, filter out noise, and provide meaningful insights from raw sensor data. They can also predict trends and anomalies in acid levels, enabling proactive management and maintenance.Expand Specific Solutions05 Wireless communication for acid level sensors

Implementation of wireless communication technologies in acid level sensing systems. This enables remote monitoring, real-time data transmission, and integration with IoT platforms. Wireless capabilities enhance the flexibility and scalability of acid level monitoring solutions across various industries and applications.Expand Specific Solutions

Key Industry Players

The smart sensor market for battery acid level monitoring is in a growth phase, driven by increasing demand for advanced battery management systems. The market size is expanding rapidly, with significant potential in automotive, industrial, and energy storage sectors. Technological maturity varies among key players, with companies like Microchip Technology, Siemens AG, and GS Yuasa Corp leading in sensor development and integration. Emerging players such as Silver Power Systems and Dreamtech Co., Ltd. are introducing innovative solutions, while established firms like Ericsson and Cisco Technology are leveraging their expertise in IoT and connectivity to enhance smart sensor capabilities. The competitive landscape is diverse, with a mix of specialized battery manufacturers, technology giants, and niche sensor developers vying for market share.

Microchip Technology, Inc.

Technical Solution: Microchip Technology has developed advanced smart sensor solutions for battery acid level monitoring. Their approach integrates miniaturized electrochemical sensors with low-power microcontrollers to provide real-time, accurate measurements of battery electrolyte levels and composition. The system employs proprietary algorithms to compensate for temperature variations and electrolyte stratification, ensuring reliable data across diverse operating conditions[1]. Microchip's smart sensors feature wireless connectivity options, enabling remote monitoring and integration with battery management systems (BMS). The company has also implemented machine learning techniques to predict battery health and optimize charging cycles based on historical acid level data[3].

Strengths: High accuracy, low power consumption, and seamless integration with existing BMS. Weaknesses: May require periodic calibration and can be more expensive than traditional monitoring methods.

Siemens AG

Technical Solution: Siemens AG has pioneered an innovative smart sensor technology for battery acid level monitoring, leveraging their expertise in industrial automation and IoT. Their solution incorporates multi-parameter sensing, including acid density, temperature, and conductivity measurements, to provide a comprehensive view of battery health. Siemens' smart sensors utilize advanced signal processing techniques and AI-driven analytics to filter out noise and detect subtle changes in acid levels that may indicate potential issues[2]. The system is designed with a modular architecture, allowing for easy integration with various battery types and sizes. Siemens has also developed a cloud-based platform that aggregates data from multiple sensors, enabling predictive maintenance and fleet-wide battery management for large-scale industrial applications[4].

Strengths: Comprehensive multi-parameter sensing, scalable for large industrial applications, and strong data analytics capabilities. Weaknesses: May be overly complex for smaller-scale implementations and potentially higher initial investment costs.

Innovative Acid Level Detection

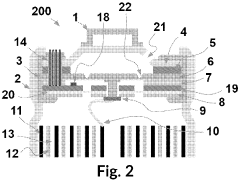

Smart battery with system for monitoring the state of health in real time

PatentWO2023128744A1

Innovation

- Integration of a multi-sensor device within the battery, comprising a multi-pixel metal oxide gas sensor, pressure sensor, temperature sensor, and humidity sensor, connected to an ASIC and a protection circuit, which transmits data via I²C protocol and uses Zigbee wireless technology for communication, enabling real-time state of health monitoring and adaptive charging protocols.

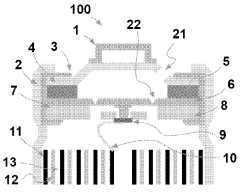

Method and device for measuring the variation in the acid concentration or base concentration of aqueous solutions

PatentInactiveEP1161677A1

Innovation

- A device using a dimensionally stable tube with an ion exchange thread that expands based on acid concentration, measured via a spring force and electrical output, allowing continuous monitoring of sulfuric acid concentration, compensated for temperature and stratification effects, and integrated with a battery management system.

Regulatory Compliance

The regulatory landscape surrounding battery acid level monitoring is complex and multifaceted, with various standards and guidelines in place to ensure safety, environmental protection, and operational efficiency. In the context of smart sensors for battery acid level monitoring, compliance with these regulations is crucial for manufacturers, operators, and end-users alike.

One of the primary regulatory bodies overseeing this area is the Occupational Safety and Health Administration (OSHA) in the United States. OSHA has established specific guidelines for the handling and maintenance of lead-acid batteries, including requirements for proper monitoring of electrolyte levels. Smart sensors must be designed and implemented in a way that meets or exceeds these standards, providing accurate and reliable data to ensure worker safety and prevent hazardous situations.

Environmental regulations also play a significant role in the development and deployment of smart sensor technology for battery acid monitoring. The Environmental Protection Agency (EPA) has set forth strict guidelines for the handling and disposal of battery acid, as well as for the prevention of spills and leaks. Smart sensors that can detect and alert operators to potential leaks or abnormal acid levels can greatly assist in maintaining compliance with these environmental regulations.

In the automotive industry, the United Nations Economic Commission for Europe (UNECE) has established regulations specifically addressing electric vehicle battery safety, including requirements for monitoring systems. These regulations have been adopted by many countries and regions, making compliance essential for global market access. Smart sensors used in electric vehicle batteries must adhere to these standards to ensure the safety and reliability of the vehicles.

The International Electrotechnical Commission (IEC) has developed standards for secondary batteries and battery installations, including specifications for monitoring systems. IEC 62619, for example, provides safety requirements for secondary lithium cells and batteries for use in industrial applications. Smart sensor technologies must be designed to meet these international standards to ensure global acceptance and interoperability.

For telecommunications and data center applications, where large-scale battery backup systems are common, organizations like the Telecommunications Industry Association (TIA) have established standards for battery monitoring and management. These standards often require continuous monitoring of battery parameters, including acid levels, making smart sensors an integral part of regulatory compliance in these sectors.

As the technology for smart sensors continues to evolve, regulatory bodies are likely to update and refine their standards to keep pace with these advancements. Manufacturers and implementers of smart sensor solutions for battery acid monitoring must stay informed of these regulatory changes and ensure that their products remain compliant. This may involve regular software updates, recertification processes, or even hardware modifications to meet new requirements.

One of the primary regulatory bodies overseeing this area is the Occupational Safety and Health Administration (OSHA) in the United States. OSHA has established specific guidelines for the handling and maintenance of lead-acid batteries, including requirements for proper monitoring of electrolyte levels. Smart sensors must be designed and implemented in a way that meets or exceeds these standards, providing accurate and reliable data to ensure worker safety and prevent hazardous situations.

Environmental regulations also play a significant role in the development and deployment of smart sensor technology for battery acid monitoring. The Environmental Protection Agency (EPA) has set forth strict guidelines for the handling and disposal of battery acid, as well as for the prevention of spills and leaks. Smart sensors that can detect and alert operators to potential leaks or abnormal acid levels can greatly assist in maintaining compliance with these environmental regulations.

In the automotive industry, the United Nations Economic Commission for Europe (UNECE) has established regulations specifically addressing electric vehicle battery safety, including requirements for monitoring systems. These regulations have been adopted by many countries and regions, making compliance essential for global market access. Smart sensors used in electric vehicle batteries must adhere to these standards to ensure the safety and reliability of the vehicles.

The International Electrotechnical Commission (IEC) has developed standards for secondary batteries and battery installations, including specifications for monitoring systems. IEC 62619, for example, provides safety requirements for secondary lithium cells and batteries for use in industrial applications. Smart sensor technologies must be designed to meet these international standards to ensure global acceptance and interoperability.

For telecommunications and data center applications, where large-scale battery backup systems are common, organizations like the Telecommunications Industry Association (TIA) have established standards for battery monitoring and management. These standards often require continuous monitoring of battery parameters, including acid levels, making smart sensors an integral part of regulatory compliance in these sectors.

As the technology for smart sensors continues to evolve, regulatory bodies are likely to update and refine their standards to keep pace with these advancements. Manufacturers and implementers of smart sensor solutions for battery acid monitoring must stay informed of these regulatory changes and ensure that their products remain compliant. This may involve regular software updates, recertification processes, or even hardware modifications to meet new requirements.

Environmental Impact Assessment

The implementation of smart sensors for monitoring battery acid levels has significant environmental implications. These advanced sensing technologies contribute to more efficient battery management, which in turn leads to reduced environmental impact across various sectors.

Smart sensors enable real-time, accurate monitoring of battery acid levels, allowing for timely maintenance and preventing premature battery failures. This extended battery lifespan reduces the frequency of battery replacements, thereby decreasing the overall demand for new batteries. Consequently, this leads to a reduction in the environmental burden associated with battery production, including resource extraction, manufacturing processes, and transportation.

Furthermore, the precise monitoring capabilities of smart sensors contribute to optimized battery performance, resulting in improved energy efficiency. This enhanced efficiency translates to reduced energy consumption and, by extension, lower greenhouse gas emissions from power generation. In applications such as electric vehicles and renewable energy storage systems, this efficiency gain can have a substantial positive impact on overall carbon footprints.

The implementation of smart sensors also mitigates the risk of acid spills and leaks, which can have severe environmental consequences. By providing early detection of potential issues, these sensors help prevent contamination of soil and water resources, protecting local ecosystems and biodiversity.

In industrial settings, smart sensors facilitate more effective recycling processes for batteries. Accurate information about battery condition and composition enables more efficient sorting and recycling, maximizing the recovery of valuable materials and minimizing waste. This closed-loop approach contributes to the circular economy and reduces the environmental impact of battery disposal.

Moreover, the data collected by smart sensors can be leveraged to improve battery design and manufacturing processes. This iterative improvement cycle leads to the development of more environmentally friendly batteries with longer lifespans and improved recyclability, further reducing the overall environmental footprint of battery technologies.

The adoption of smart sensors for battery acid level monitoring also promotes a shift towards predictive maintenance strategies. This proactive approach not only extends battery life but also reduces the need for emergency replacements and unscheduled downtime, which often involve resource-intensive and potentially polluting activities.

In conclusion, the environmental impact assessment of smart sensors for battery acid level monitoring reveals a multifaceted positive influence on sustainability. From extending battery life and improving energy efficiency to enhancing recycling processes and preventing environmental contamination, these technologies play a crucial role in mitigating the environmental challenges associated with battery usage across various industries.

Smart sensors enable real-time, accurate monitoring of battery acid levels, allowing for timely maintenance and preventing premature battery failures. This extended battery lifespan reduces the frequency of battery replacements, thereby decreasing the overall demand for new batteries. Consequently, this leads to a reduction in the environmental burden associated with battery production, including resource extraction, manufacturing processes, and transportation.

Furthermore, the precise monitoring capabilities of smart sensors contribute to optimized battery performance, resulting in improved energy efficiency. This enhanced efficiency translates to reduced energy consumption and, by extension, lower greenhouse gas emissions from power generation. In applications such as electric vehicles and renewable energy storage systems, this efficiency gain can have a substantial positive impact on overall carbon footprints.

The implementation of smart sensors also mitigates the risk of acid spills and leaks, which can have severe environmental consequences. By providing early detection of potential issues, these sensors help prevent contamination of soil and water resources, protecting local ecosystems and biodiversity.

In industrial settings, smart sensors facilitate more effective recycling processes for batteries. Accurate information about battery condition and composition enables more efficient sorting and recycling, maximizing the recovery of valuable materials and minimizing waste. This closed-loop approach contributes to the circular economy and reduces the environmental impact of battery disposal.

Moreover, the data collected by smart sensors can be leveraged to improve battery design and manufacturing processes. This iterative improvement cycle leads to the development of more environmentally friendly batteries with longer lifespans and improved recyclability, further reducing the overall environmental footprint of battery technologies.

The adoption of smart sensors for battery acid level monitoring also promotes a shift towards predictive maintenance strategies. This proactive approach not only extends battery life but also reduces the need for emergency replacements and unscheduled downtime, which often involve resource-intensive and potentially polluting activities.

In conclusion, the environmental impact assessment of smart sensors for battery acid level monitoring reveals a multifaceted positive influence on sustainability. From extending battery life and improving energy efficiency to enhancing recycling processes and preventing environmental contamination, these technologies play a crucial role in mitigating the environmental challenges associated with battery usage across various industries.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!