How to Enhance Biodegradability Rate of PLA in Landfills?

JUN 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

PLA Biodegradability Background and Objectives

Polylactic acid (PLA) has emerged as a promising biodegradable polymer, gaining significant attention in recent years due to its potential to address the growing environmental concerns associated with conventional plastics. Derived from renewable resources such as corn starch or sugarcane, PLA offers a more sustainable alternative to petroleum-based plastics. The development of PLA can be traced back to the 1920s, but it wasn't until the late 20th century that advancements in production techniques made it commercially viable.

The biodegradability of PLA is a key factor driving its adoption across various industries, including packaging, textiles, and medical applications. However, the rate at which PLA biodegrades in landfill conditions has been a subject of ongoing research and debate. While PLA can decompose relatively quickly under controlled composting conditions, its degradation in typical landfill environments is significantly slower, often taking several years to decades.

This discrepancy between ideal and real-world biodegradation rates presents a critical challenge for the widespread adoption of PLA as a truly sustainable material. The primary objective of enhancing PLA biodegradability in landfills is to bridge this gap, ensuring that PLA products can break down within a reasonable timeframe under various environmental conditions.

Recent technological advancements have focused on improving PLA's biodegradation rate through various strategies, including the development of new PLA blends, the incorporation of biodegradation-enhancing additives, and the modification of PLA's molecular structure. These efforts aim to create PLA materials that maintain their desirable properties during use but degrade more rapidly once disposed of in landfill conditions.

The evolution of PLA technology is closely tied to broader trends in sustainable materials and circular economy principles. As global awareness of plastic pollution grows, there is an increasing demand for materials that can offer the functionality of traditional plastics without their long-term environmental impact. This has led to a surge in research and development activities focused on enhancing PLA's performance, including its biodegradability in diverse environments.

Looking ahead, the trajectory of PLA biodegradability research is expected to continue its upward trend, with a focus on developing more robust and versatile solutions. The ultimate goal is to create PLA materials that can biodegrade efficiently across a wide range of conditions, from industrial composting facilities to home composting systems and landfills, thereby maximizing their environmental benefits and minimizing their ecological footprint.

The biodegradability of PLA is a key factor driving its adoption across various industries, including packaging, textiles, and medical applications. However, the rate at which PLA biodegrades in landfill conditions has been a subject of ongoing research and debate. While PLA can decompose relatively quickly under controlled composting conditions, its degradation in typical landfill environments is significantly slower, often taking several years to decades.

This discrepancy between ideal and real-world biodegradation rates presents a critical challenge for the widespread adoption of PLA as a truly sustainable material. The primary objective of enhancing PLA biodegradability in landfills is to bridge this gap, ensuring that PLA products can break down within a reasonable timeframe under various environmental conditions.

Recent technological advancements have focused on improving PLA's biodegradation rate through various strategies, including the development of new PLA blends, the incorporation of biodegradation-enhancing additives, and the modification of PLA's molecular structure. These efforts aim to create PLA materials that maintain their desirable properties during use but degrade more rapidly once disposed of in landfill conditions.

The evolution of PLA technology is closely tied to broader trends in sustainable materials and circular economy principles. As global awareness of plastic pollution grows, there is an increasing demand for materials that can offer the functionality of traditional plastics without their long-term environmental impact. This has led to a surge in research and development activities focused on enhancing PLA's performance, including its biodegradability in diverse environments.

Looking ahead, the trajectory of PLA biodegradability research is expected to continue its upward trend, with a focus on developing more robust and versatile solutions. The ultimate goal is to create PLA materials that can biodegrade efficiently across a wide range of conditions, from industrial composting facilities to home composting systems and landfills, thereby maximizing their environmental benefits and minimizing their ecological footprint.

Market Analysis for Biodegradable Plastics

The biodegradable plastics market has experienced significant growth in recent years, driven by increasing environmental concerns and regulatory pressures to reduce plastic waste. Polylactic acid (PLA), a biodegradable polymer derived from renewable resources, has emerged as a key player in this market. The global biodegradable plastics market was valued at approximately $4.1 billion in 2020 and is projected to reach $7.8 billion by 2025, growing at a CAGR of 13.7% during the forecast period.

PLA, in particular, has gained traction due to its versatility and relatively low production costs compared to other biodegradable alternatives. The PLA market is expected to grow from $786 million in 2020 to $1.8 billion by 2025, with a CAGR of 18.1%. This growth is primarily driven by increased adoption in packaging, food service, and agricultural applications.

The market for biodegradable plastics, including PLA, is influenced by several factors. Consumer awareness and demand for eco-friendly products have been steadily increasing, with 66% of global consumers willing to pay more for sustainable goods. Government regulations and initiatives aimed at reducing plastic waste have also played a crucial role in market growth. For instance, the European Union's Single-Use Plastics Directive has accelerated the adoption of biodegradable alternatives in the region.

However, the market faces challenges, particularly in the area of end-of-life management. While PLA is biodegradable, its degradation rate in landfills is relatively slow, typically taking several months to years to fully decompose. This has led to increased focus on enhancing PLA's biodegradability in landfill conditions, creating a significant market opportunity for improved formulations and additives.

The packaging industry remains the largest consumer of biodegradable plastics, accounting for 47% of the market share in 2020. Food packaging, in particular, has seen rapid adoption of PLA due to its food-safe properties and compostability. The agricultural sector is another key growth area, with biodegradable mulch films gaining popularity as an environmentally friendly alternative to conventional plastic films.

Geographically, Europe leads the biodegradable plastics market, followed by North America and Asia-Pacific. Europe's market dominance is attributed to stringent regulations and high consumer awareness. However, Asia-Pacific is expected to witness the highest growth rate in the coming years, driven by increasing industrialization, population growth, and government initiatives promoting sustainable materials.

In conclusion, the market analysis for biodegradable plastics, particularly PLA, indicates a strong growth trajectory. However, addressing the challenge of enhancing PLA's biodegradability rate in landfills presents a significant opportunity for innovation and market differentiation. Companies that can develop effective solutions to this problem are likely to gain a competitive edge in this rapidly evolving market.

PLA, in particular, has gained traction due to its versatility and relatively low production costs compared to other biodegradable alternatives. The PLA market is expected to grow from $786 million in 2020 to $1.8 billion by 2025, with a CAGR of 18.1%. This growth is primarily driven by increased adoption in packaging, food service, and agricultural applications.

The market for biodegradable plastics, including PLA, is influenced by several factors. Consumer awareness and demand for eco-friendly products have been steadily increasing, with 66% of global consumers willing to pay more for sustainable goods. Government regulations and initiatives aimed at reducing plastic waste have also played a crucial role in market growth. For instance, the European Union's Single-Use Plastics Directive has accelerated the adoption of biodegradable alternatives in the region.

However, the market faces challenges, particularly in the area of end-of-life management. While PLA is biodegradable, its degradation rate in landfills is relatively slow, typically taking several months to years to fully decompose. This has led to increased focus on enhancing PLA's biodegradability in landfill conditions, creating a significant market opportunity for improved formulations and additives.

The packaging industry remains the largest consumer of biodegradable plastics, accounting for 47% of the market share in 2020. Food packaging, in particular, has seen rapid adoption of PLA due to its food-safe properties and compostability. The agricultural sector is another key growth area, with biodegradable mulch films gaining popularity as an environmentally friendly alternative to conventional plastic films.

Geographically, Europe leads the biodegradable plastics market, followed by North America and Asia-Pacific. Europe's market dominance is attributed to stringent regulations and high consumer awareness. However, Asia-Pacific is expected to witness the highest growth rate in the coming years, driven by increasing industrialization, population growth, and government initiatives promoting sustainable materials.

In conclusion, the market analysis for biodegradable plastics, particularly PLA, indicates a strong growth trajectory. However, addressing the challenge of enhancing PLA's biodegradability rate in landfills presents a significant opportunity for innovation and market differentiation. Companies that can develop effective solutions to this problem are likely to gain a competitive edge in this rapidly evolving market.

Current PLA Degradation Challenges in Landfills

Polylactic acid (PLA), a biodegradable polymer derived from renewable resources, faces significant challenges in achieving efficient degradation within landfill environments. The primary obstacle lies in the anaerobic conditions prevalent in landfills, which significantly slow down the biodegradation process of PLA. Unlike composting facilities that maintain optimal conditions for microbial activity, landfills lack the necessary oxygen, moisture, and temperature controls to facilitate rapid PLA breakdown.

The chemical structure of PLA, consisting of long chains of lactic acid monomers, requires specific environmental conditions and microbial enzymes for effective degradation. In landfills, the absence of these factors leads to extended degradation periods, often spanning several decades. This prolonged persistence contradicts the intended environmental benefits of using biodegradable plastics and poses challenges for waste management strategies.

Another critical issue is the variability in PLA composition and additives used in different products. These variations can significantly affect the material's degradation rate and behavior in landfill conditions. Some additives, while enhancing certain properties of PLA products, may inadvertently inhibit biodegradation processes, further complicating the disposal and breakdown of these materials.

The lack of standardized testing methods for assessing PLA degradation in landfill-like conditions presents an additional challenge. Current biodegradability standards often focus on composting environments, which differ substantially from landfill conditions. This discrepancy makes it difficult to accurately predict and evaluate the long-term behavior of PLA in real-world landfill scenarios.

Furthermore, the heterogeneous nature of landfill waste creates micro-environments with varying pH levels, moisture content, and microbial populations. These diverse conditions can lead to inconsistent degradation rates across a single landfill site, making it challenging to implement uniform strategies for enhancing PLA biodegradability.

The limited microbial diversity in landfills, particularly in terms of organisms capable of efficiently breaking down PLA, is another significant hurdle. Unlike natural soil environments or composting facilities, landfills often lack the rich microbial ecosystems necessary for rapid polymer degradation. This deficiency in specialized microorganisms further contributes to the slow breakdown of PLA materials.

Addressing these challenges requires a multifaceted approach, combining innovations in PLA formulation, waste management practices, and landfill design. Developing PLA variants that are more susceptible to degradation under anaerobic conditions, incorporating biodegradation-enhancing additives, and exploring methods to introduce beneficial microorganisms into landfill environments are potential avenues for improving PLA's end-of-life performance in these challenging settings.

The chemical structure of PLA, consisting of long chains of lactic acid monomers, requires specific environmental conditions and microbial enzymes for effective degradation. In landfills, the absence of these factors leads to extended degradation periods, often spanning several decades. This prolonged persistence contradicts the intended environmental benefits of using biodegradable plastics and poses challenges for waste management strategies.

Another critical issue is the variability in PLA composition and additives used in different products. These variations can significantly affect the material's degradation rate and behavior in landfill conditions. Some additives, while enhancing certain properties of PLA products, may inadvertently inhibit biodegradation processes, further complicating the disposal and breakdown of these materials.

The lack of standardized testing methods for assessing PLA degradation in landfill-like conditions presents an additional challenge. Current biodegradability standards often focus on composting environments, which differ substantially from landfill conditions. This discrepancy makes it difficult to accurately predict and evaluate the long-term behavior of PLA in real-world landfill scenarios.

Furthermore, the heterogeneous nature of landfill waste creates micro-environments with varying pH levels, moisture content, and microbial populations. These diverse conditions can lead to inconsistent degradation rates across a single landfill site, making it challenging to implement uniform strategies for enhancing PLA biodegradability.

The limited microbial diversity in landfills, particularly in terms of organisms capable of efficiently breaking down PLA, is another significant hurdle. Unlike natural soil environments or composting facilities, landfills often lack the rich microbial ecosystems necessary for rapid polymer degradation. This deficiency in specialized microorganisms further contributes to the slow breakdown of PLA materials.

Addressing these challenges requires a multifaceted approach, combining innovations in PLA formulation, waste management practices, and landfill design. Developing PLA variants that are more susceptible to degradation under anaerobic conditions, incorporating biodegradation-enhancing additives, and exploring methods to introduce beneficial microorganisms into landfill environments are potential avenues for improving PLA's end-of-life performance in these challenging settings.

Existing PLA Biodegradability Enhancement Methods

01 Factors affecting PLA biodegradation rate

The biodegradation rate of PLA is influenced by various factors, including environmental conditions (temperature, humidity, pH), molecular weight, crystallinity, and the presence of additives. Understanding these factors is crucial for predicting and controlling the biodegradability of PLA-based products.- Factors affecting PLA biodegradation rate: The biodegradation rate of PLA is influenced by various factors, including environmental conditions (temperature, humidity, pH), molecular weight, crystallinity, and the presence of additives. Understanding these factors is crucial for controlling and predicting the biodegradability of PLA-based products.

- Enhancing PLA biodegradability: Methods to enhance PLA biodegradability include blending with other biodegradable polymers, incorporating natural fibers or fillers, and using specific additives or compatibilizers. These approaches can accelerate the degradation process and improve the overall environmental performance of PLA-based materials.

- Biodegradation testing methods for PLA: Various testing methods are employed to assess the biodegradation rate of PLA, including composting tests, soil burial tests, and enzymatic degradation assays. These methods help in evaluating the material's performance under different environmental conditions and provide valuable data for product development and regulatory compliance.

- PLA modifications for controlled biodegradation: Modifications to PLA structure and composition can be made to control its biodegradation rate. This includes copolymerization with other monomers, adjusting the stereochemistry of the polymer, and incorporating specific functional groups. These modifications allow for tailoring the biodegradation rate to suit specific applications and end-of-life scenarios.

- Industrial applications considering PLA biodegradability: The biodegradability rate of PLA is a crucial factor in various industrial applications, including packaging, agriculture, and biomedical fields. Understanding and optimizing the biodegradation rate is essential for developing sustainable products that meet performance requirements while ensuring proper end-of-life management.

02 Enhancing PLA biodegradability

Methods to enhance PLA biodegradability include blending with other biodegradable polymers, incorporating natural fibers or fillers, and using specific additives or compatibilizers. These approaches can accelerate the degradation process and improve the overall environmental performance of PLA-based materials.Expand Specific Solutions03 Biodegradation testing methods for PLA

Various testing methods are employed to assess the biodegradation rate of PLA, including composting tests, soil burial tests, and enzymatic degradation assays. These methods help in evaluating the material's performance under different environmental conditions and provide valuable data for product development and regulatory compliance.Expand Specific Solutions04 PLA modifications for controlled biodegradation

Modifications to PLA structure and composition can be made to control its biodegradation rate. This includes copolymerization with other monomers, surface treatments, and the development of multi-layer structures. These modifications allow for tailoring the biodegradation rate to specific application requirements.Expand Specific Solutions05 Industrial applications considering PLA biodegradability

The biodegradability rate of PLA is a crucial factor in various industrial applications, including packaging, agriculture, and biomedical fields. Understanding and optimizing the biodegradation rate is essential for developing sustainable products that meet performance requirements while ensuring proper end-of-life disposal.Expand Specific Solutions

Key Players in Biodegradable Plastics Industry

The biodegradability enhancement of PLA in landfills is a growing concern in the bioplastics industry, currently in its growth phase. The market for biodegradable plastics is expanding, driven by environmental regulations and consumer awareness. Technologically, the field is advancing but still maturing. Companies like Total Research Corp, Sichuan University, and Centre National de la Recherche Scientifique are at the forefront of research. Universities such as Cornell and Michigan Molecular Institute are contributing significant academic insights. Industrial players like LG Chem Ltd. and PTT Global Chemical Plc are investing in practical applications. The collaboration between academia and industry is accelerating progress, with a focus on improving PLA's degradation rate in landfill conditions.

Arctic Biomaterials Oy

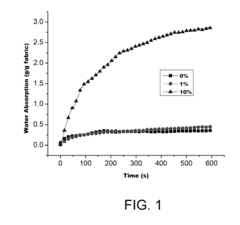

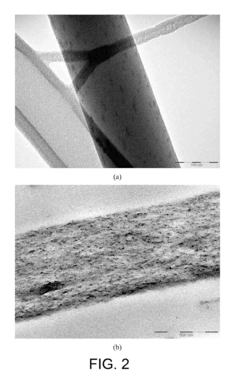

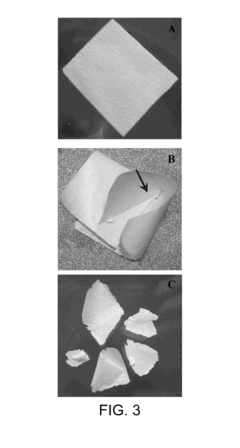

Technical Solution: Arctic Biomaterials Oy has developed a proprietary technology called ArcBiox® to enhance the biodegradability of PLA in landfills. This technology involves incorporating specific additives and modifiers into the PLA matrix during the manufacturing process. These additives act as catalysts, accelerating the hydrolysis of PLA chains and promoting microbial activity. The company has also implemented a unique processing technique that creates a more porous structure in the PLA material, increasing its surface area and allowing for faster water penetration and subsequent degradation.

Strengths: Significantly faster biodegradation rate compared to standard PLA; maintains mechanical properties during use. Weaknesses: Potentially higher production costs; limited data on long-term environmental impact.

Sulapac Oy

Technical Solution: Sulapac Oy has developed a innovative biodegradable material that combines wood chips and biodegradable polymers, including modified PLA. Their technology focuses on creating a microplastic-free alternative that biodegrades rapidly in various environments, including landfills. The company's approach involves carefully selecting and blending different types of wood particles with specially formulated biodegradable binders. This unique composition allows for enhanced water absorption and microbial access, leading to accelerated biodegradation. Additionally, Sulapac has incorporated natural enzymes and microorganisms into their material, which actively break down the polymer chains when exposed to landfill conditions.

Strengths: Rapid biodegradation without leaving microplastics; versatile applications in packaging and consumer goods. Weaknesses: Higher cost compared to traditional plastics; limited availability of raw materials.

Innovative PLA Degradation Acceleration Techniques

Biodegradable chemical delivery system

PatentActiveUS20110275520A1

Innovation

- A polymeric material system comprising a hydrophobic polymeric matrix and a hydrophilic second polymeric material, where the latter forms nanocomposite fibers with PLA, enhancing degradation rates and allowing controlled release of compounds like pesticides through varying the composition and form of the polymeric material.

Method for degradation of a plastic-containing waste

PatentPendingUS20230278083A1

Innovation

- A method involving mixing plastic-containing waste with bacteria in a digesting apparatus with a high surface-to-volume ratio, using Geobacillus bacteria and other microorganisms, to achieve rapid biodegradation of PLA and other biodegradable plastics on-site, reducing the need for industrial processing.

Environmental Impact Assessment of PLA Disposal

The environmental impact assessment of PLA disposal in landfills is crucial for understanding the overall sustainability of this biodegradable polymer. PLA, or polylactic acid, is often marketed as an eco-friendly alternative to traditional plastics. However, its performance in landfill environments requires careful evaluation to determine its true environmental footprint.

In landfill conditions, PLA's biodegradation rate is significantly slower than in controlled composting environments. This is primarily due to the lack of optimal temperature, moisture, and microbial activity in landfills. Studies have shown that PLA can take several decades to fully degrade in landfill conditions, which is considerably longer than initially anticipated.

The slow degradation of PLA in landfills has several environmental implications. Firstly, it contributes to the accumulation of plastic waste, albeit temporarily. This accumulation can lead to soil and water pollution, as well as potential harm to wildlife if the waste escapes containment. Additionally, the slow breakdown of PLA may result in the release of methane, a potent greenhouse gas, if anaerobic conditions prevail in the landfill.

However, compared to conventional plastics, PLA still offers some environmental benefits even in landfill scenarios. Unlike petroleum-based plastics, PLA is derived from renewable resources, typically corn or sugarcane. This reduces the carbon footprint associated with its production. Furthermore, when PLA eventually degrades, it does not leave behind toxic residues or microplastics, which are persistent environmental pollutants associated with traditional plastics.

The leachate produced during PLA degradation in landfills is another factor to consider. While PLA leachate is generally less harmful than that of conventional plastics, it can still contribute to the overall chemical load in landfill leachate systems. This necessitates proper management and treatment of landfill runoff to minimize potential impacts on surrounding ecosystems and groundwater.

To mitigate the environmental impact of PLA disposal in landfills, several strategies can be employed. Improving waste sorting and diversion systems to ensure PLA products are directed to industrial composting facilities rather than landfills is crucial. Additionally, enhancing landfill designs to create more favorable conditions for PLA biodegradation, such as better moisture control and aeration, could accelerate the breakdown process and reduce long-term environmental impacts.

In conclusion, while PLA offers environmental advantages over traditional plastics, its disposal in landfills presents challenges that require careful consideration and management. Continued research into enhancing PLA's biodegradability in landfill conditions, coupled with improved waste management practices, is essential to maximize the environmental benefits of this biodegradable polymer.

In landfill conditions, PLA's biodegradation rate is significantly slower than in controlled composting environments. This is primarily due to the lack of optimal temperature, moisture, and microbial activity in landfills. Studies have shown that PLA can take several decades to fully degrade in landfill conditions, which is considerably longer than initially anticipated.

The slow degradation of PLA in landfills has several environmental implications. Firstly, it contributes to the accumulation of plastic waste, albeit temporarily. This accumulation can lead to soil and water pollution, as well as potential harm to wildlife if the waste escapes containment. Additionally, the slow breakdown of PLA may result in the release of methane, a potent greenhouse gas, if anaerobic conditions prevail in the landfill.

However, compared to conventional plastics, PLA still offers some environmental benefits even in landfill scenarios. Unlike petroleum-based plastics, PLA is derived from renewable resources, typically corn or sugarcane. This reduces the carbon footprint associated with its production. Furthermore, when PLA eventually degrades, it does not leave behind toxic residues or microplastics, which are persistent environmental pollutants associated with traditional plastics.

The leachate produced during PLA degradation in landfills is another factor to consider. While PLA leachate is generally less harmful than that of conventional plastics, it can still contribute to the overall chemical load in landfill leachate systems. This necessitates proper management and treatment of landfill runoff to minimize potential impacts on surrounding ecosystems and groundwater.

To mitigate the environmental impact of PLA disposal in landfills, several strategies can be employed. Improving waste sorting and diversion systems to ensure PLA products are directed to industrial composting facilities rather than landfills is crucial. Additionally, enhancing landfill designs to create more favorable conditions for PLA biodegradation, such as better moisture control and aeration, could accelerate the breakdown process and reduce long-term environmental impacts.

In conclusion, while PLA offers environmental advantages over traditional plastics, its disposal in landfills presents challenges that require careful consideration and management. Continued research into enhancing PLA's biodegradability in landfill conditions, coupled with improved waste management practices, is essential to maximize the environmental benefits of this biodegradable polymer.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics plays a crucial role in shaping the development, production, and disposal of materials like PLA in landfills. As concerns about plastic pollution grow, governments worldwide are implementing stricter regulations to promote the use of biodegradable alternatives and ensure their proper management.

In the United States, the Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims and specify the disposal conditions under which the material will biodegrade.

The European Union has taken a more comprehensive approach with its Packaging and Packaging Waste Directive, which sets targets for the recovery and recycling of packaging materials. This directive also includes specific requirements for biodegradable packaging, mandating that such materials must not hinder the recycling process of conventional plastics.

Many countries have implemented certification systems for biodegradable plastics. For instance, the ASTM D6400 standard in the United States and the EN 13432 standard in Europe set specific criteria for the biodegradability and compostability of plastics. These standards typically require materials to biodegrade within a specified timeframe under controlled composting conditions.

Regulations also address the end-of-life management of biodegradable plastics. Some jurisdictions have mandated separate collection and processing of compostable materials, while others have incorporated biodegradable plastics into existing waste management systems. However, the lack of uniformity in these regulations across different regions poses challenges for manufacturers and consumers alike.

To enhance the biodegradability rate of PLA in landfills, regulatory frameworks are evolving to encourage research and development in this area. Some governments are offering incentives for companies that develop innovative solutions to improve the biodegradation of plastics in various environments, including landfills.

Furthermore, there is a growing trend towards extended producer responsibility (EPR) policies, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. These policies are likely to drive innovation in biodegradable plastic technologies and improve end-of-life management strategies.

As the regulatory landscape continues to evolve, it is expected that more stringent and harmonized standards for biodegradable plastics will emerge. This will likely include specific requirements for biodegradation in landfill conditions, potentially leading to advancements in PLA formulations and disposal methods that enhance its biodegradability rate in such environments.

In the United States, the Federal Trade Commission (FTC) has established guidelines for environmental marketing claims, including those related to biodegradability. These guidelines require manufacturers to provide scientific evidence supporting their biodegradability claims and specify the disposal conditions under which the material will biodegrade.

The European Union has taken a more comprehensive approach with its Packaging and Packaging Waste Directive, which sets targets for the recovery and recycling of packaging materials. This directive also includes specific requirements for biodegradable packaging, mandating that such materials must not hinder the recycling process of conventional plastics.

Many countries have implemented certification systems for biodegradable plastics. For instance, the ASTM D6400 standard in the United States and the EN 13432 standard in Europe set specific criteria for the biodegradability and compostability of plastics. These standards typically require materials to biodegrade within a specified timeframe under controlled composting conditions.

Regulations also address the end-of-life management of biodegradable plastics. Some jurisdictions have mandated separate collection and processing of compostable materials, while others have incorporated biodegradable plastics into existing waste management systems. However, the lack of uniformity in these regulations across different regions poses challenges for manufacturers and consumers alike.

To enhance the biodegradability rate of PLA in landfills, regulatory frameworks are evolving to encourage research and development in this area. Some governments are offering incentives for companies that develop innovative solutions to improve the biodegradation of plastics in various environments, including landfills.

Furthermore, there is a growing trend towards extended producer responsibility (EPR) policies, which hold manufacturers accountable for the entire lifecycle of their products, including disposal. These policies are likely to drive innovation in biodegradable plastic technologies and improve end-of-life management strategies.

As the regulatory landscape continues to evolve, it is expected that more stringent and harmonized standards for biodegradable plastics will emerge. This will likely include specific requirements for biodegradation in landfill conditions, potentially leading to advancements in PLA formulations and disposal methods that enhance its biodegradability rate in such environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!