How to Harness Biodegradable Additives for LDPE?

LDPE Biodegradation Background and Objectives

Low-density polyethylene (LDPE) has been a cornerstone of the plastics industry since its introduction in the 1930s. Its versatility, durability, and low cost have made it ubiquitous in packaging, consumer goods, and various industrial applications. However, the very properties that make LDPE so useful also contribute to its environmental persistence, leading to growing concerns about plastic pollution and its long-term ecological impact.

The development of biodegradable additives for LDPE represents a significant technological evolution in addressing these environmental challenges. These additives aim to enhance the biodegradability of LDPE without compromising its desirable physical properties during its intended use. The primary objective is to create LDPE products that maintain their functionality but can break down more readily in natural environments after disposal.

The journey towards biodegradable LDPE began in earnest in the 1980s, with early attempts focusing on photodegradable additives. However, these solutions proved insufficient as they only fragmented the plastic rather than fully biodegrading it. The focus then shifted to truly biodegradable additives that could facilitate the breakdown of LDPE into environmentally benign components.

Current research and development efforts are centered on several key objectives. First, there is a push to develop additives that can accelerate the biodegradation process of LDPE under various environmental conditions, including soil, marine environments, and industrial composting facilities. Second, researchers are working to ensure that these additives do not negatively impact the processing or performance characteristics of LDPE during its useful life.

Another critical objective is to create biodegradable additives that are cost-effective and can be easily integrated into existing LDPE production processes. This is essential for widespread adoption in the industry. Additionally, there is a focus on developing additives that result in complete biodegradation, leaving no microplastic residues.

The technological trajectory in this field is moving towards more sophisticated, bio-based additives that can trigger controlled biodegradation. This includes exploring the potential of enzyme-based additives and the incorporation of naturally occurring biodegradable polymers. The ultimate goal is to create a new generation of LDPE products that offer the same performance as traditional LDPE but with significantly reduced environmental impact.

As the field progresses, there is also an increasing emphasis on understanding and optimizing the interaction between these biodegradable additives and various disposal environments. This includes studying the behavior of modified LDPE in different ecosystems and under varying conditions to ensure effective biodegradation in real-world scenarios.

Market Demand for Eco-Friendly Plastics

The demand for eco-friendly plastics has been steadily increasing in recent years, driven by growing environmental concerns and regulatory pressures. This trend is particularly evident in the market for Low-Density Polyethylene (LDPE), a widely used plastic in packaging and consumer goods. Consumers are becoming more environmentally conscious, leading to a shift in preferences towards sustainable and biodegradable alternatives.

The global market for biodegradable plastics is experiencing significant growth, with projections indicating a compound annual growth rate (CAGR) of over 10% in the coming years. This growth is largely attributed to the increasing adoption of biodegradable additives in conventional plastics like LDPE. These additives enhance the biodegradability of LDPE without significantly compromising its desirable properties, making it an attractive option for manufacturers and consumers alike.

Several industries are driving the demand for eco-friendly LDPE. The packaging industry, in particular, is at the forefront of this shift, as it faces mounting pressure to reduce plastic waste. Food and beverage companies are increasingly opting for biodegradable LDPE packaging to meet consumer expectations and comply with stricter environmental regulations. The agriculture sector is another significant market, with a growing demand for biodegradable mulch films and other agricultural plastics.

Retail and e-commerce sectors are also contributing to the rising demand for eco-friendly LDPE. As online shopping continues to grow, there's an increasing need for sustainable packaging solutions. Many retailers are now actively seeking biodegradable alternatives to traditional LDPE packaging materials for shipping and product protection.

The automotive industry is exploring the use of biodegradable LDPE in various applications, from interior components to packaging for spare parts. This shift is driven by both consumer preferences and regulatory requirements aimed at increasing the recyclability and biodegradability of automotive materials.

Despite the growing demand, challenges remain in the widespread adoption of biodegradable LDPE. Cost considerations are a significant factor, as biodegradable additives can increase the overall production costs. However, as technology advances and production scales up, these costs are expected to decrease, making eco-friendly LDPE more competitive with conventional options.

The market demand is also influenced by regional factors. Developed economies in North America and Europe are currently leading the adoption of biodegradable LDPE, driven by stringent environmental regulations and high consumer awareness. However, emerging economies in Asia-Pacific and Latin America are expected to show rapid growth in demand as environmental concerns gain prominence and regulations tighten.

Current Challenges in LDPE Biodegradation

Low-density polyethylene (LDPE) is a widely used plastic material known for its versatility and durability. However, its resistance to biodegradation poses significant environmental challenges. The current obstacles in LDPE biodegradation stem from its molecular structure and the lack of efficient biodegradation mechanisms in natural environments.

One of the primary challenges is the high molecular weight and strong carbon-carbon bonds in LDPE, which make it resistant to microbial attack. The long polymer chains and the absence of functional groups that microorganisms can easily recognize and break down contribute to its persistence in the environment. This structural stability, while beneficial for many applications, becomes problematic when LDPE products reach the end of their lifecycle.

Another significant hurdle is the hydrophobic nature of LDPE, which repels water and prevents the adhesion of microorganisms that could potentially degrade the material. This characteristic limits the surface area available for biodegradation and hinders the initial stages of microbial colonization, which are crucial for the breakdown process.

The lack of naturally occurring enzymes capable of efficiently breaking down LDPE presents another major challenge. While some microorganisms have shown limited ability to degrade LDPE, the process is extremely slow and inefficient in real-world conditions. This deficiency in biological catalysts significantly impedes the development of effective biodegradation strategies.

Environmental factors also play a role in the challenges of LDPE biodegradation. The material's resistance to weathering and its stability under various pH and temperature conditions make it difficult to initiate and sustain the degradation process in diverse ecosystems. This resilience contributes to the accumulation of LDPE waste in both terrestrial and aquatic environments.

The current recycling infrastructure and waste management systems are not adequately equipped to handle the volume of LDPE waste generated globally. The difficulty in separating LDPE from other plastic types and contaminants in mixed waste streams complicates recycling efforts and often leads to the material being landfilled or incinerated, further exacerbating environmental issues.

Regulatory challenges also exist, with inconsistent policies and standards regarding biodegradable plastics across different regions. This lack of harmonization creates confusion in the market and hinders the development and adoption of truly biodegradable LDPE alternatives.

Addressing these challenges requires a multifaceted approach, combining advances in material science, biotechnology, and environmental engineering. The development of biodegradable additives for LDPE must overcome these obstacles while maintaining the material's desirable properties for its intended applications.

Existing Biodegradable Additive Solutions for LDPE

01 Natural biodegradable additives

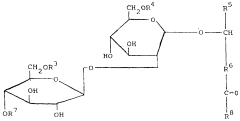

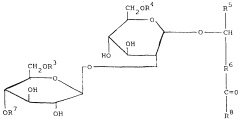

Incorporation of natural biodegradable additives such as starch, cellulose, or other plant-based materials into LDPE to enhance its biodegradability. These additives can be blended with LDPE during the manufacturing process, creating a more environmentally friendly plastic that can break down more easily in natural conditions.- Starch-based additives for LDPE biodegradability: Starch-based additives are incorporated into LDPE to enhance its biodegradability. These additives can be modified or blended with other materials to improve compatibility with LDPE and increase the overall biodegradation rate of the polymer. The starch-based additives act as a food source for microorganisms, promoting the breakdown of the plastic material.

- Pro-oxidant additives for LDPE degradation: Pro-oxidant additives are used to accelerate the oxidative degradation of LDPE. These additives typically include transition metal compounds that catalyze the oxidation process, leading to chain scission and eventual biodegradation. The pro-oxidants can be combined with other biodegradable additives to enhance the overall degradation process of LDPE.

- Enzyme-based additives for LDPE biodegradation: Enzyme-based additives are incorporated into LDPE to promote its biodegradation. These additives contain specific enzymes that can break down the polymer chains, making them more susceptible to microbial attack. The enzymes can be encapsulated or modified to ensure their stability and effectiveness within the LDPE matrix.

- Natural fiber additives for enhancing LDPE biodegradability: Natural fibers, such as cellulose, lignin, or plant-based materials, are used as additives to improve the biodegradability of LDPE. These fibers provide a pathway for moisture and microorganisms to penetrate the polymer matrix, facilitating the degradation process. The natural fibers can also improve the mechanical properties of the LDPE composites.

- Biodegradable polymer blends with LDPE: Biodegradable polymers, such as polylactic acid (PLA) or polyhydroxyalkanoates (PHA), are blended with LDPE to create partially biodegradable composites. These blends combine the desirable properties of LDPE with the biodegradability of the added polymers. Compatibilizers may be used to improve the miscibility and overall performance of the blends.

02 Pro-oxidant additives

Use of pro-oxidant additives in LDPE formulations to accelerate the oxidation process and subsequent biodegradation. These additives typically include transition metal compounds that catalyze the oxidation of the polymer chains, making them more susceptible to microbial attack and environmental degradation.Expand Specific Solutions03 Enzyme-based additives

Integration of enzyme-based additives or enzyme-producing microorganisms into LDPE to enhance biodegradability. These biological additives can help break down the polymer structure over time, facilitating the decomposition process in various environmental conditions.Expand Specific Solutions04 Photodegradable additives

Incorporation of photodegradable additives that make LDPE more susceptible to degradation when exposed to sunlight. These additives typically include light-sensitive compounds that initiate the breakdown of polymer chains upon exposure to UV radiation, accelerating the overall biodegradation process.Expand Specific Solutions05 Nanocomposite additives

Utilization of nanocomposite additives, such as nanoclays or metal oxide nanoparticles, to enhance the biodegradability of LDPE. These nanoparticles can improve the material's properties while also facilitating its breakdown in the environment by increasing the surface area available for microbial attack and oxidation processes.Expand Specific Solutions

Key Players in Biodegradable Plastics Industry

The market for biodegradable additives in LDPE is in a growth phase, driven by increasing environmental concerns and regulatory pressures. The global market size for biodegradable plastics is projected to reach $7.8 billion by 2025, with a CAGR of 20.7%. The technology is maturing, but still evolving, with companies like Bayer AG, BIOTEC, and Braskem SA leading in innovation. PetroChina and Sinopec are leveraging their petrochemical expertise to develop sustainable solutions, while specialized firms like Kingfa Sci. & Tech. and Wanhua Chemical Group are focusing on advanced polymer materials. The competitive landscape is diverse, with both established chemical giants and emerging players contributing to technological advancements in this field.

BIOTEC Biologische Naturverpackungen GmbH & Co. KG

Braskem SA

Core Innovations in LDPE Biodegradation Technology

- A biodegradation additive comprising animal flour and a biodegradable non-ionic or zwitterionic lipid surfactant, such as sophorolipid or lecithin, which stimulates indigenous microorganisms with a balanced nitrogen and phosphorus source, eliminating the need for emulsion formation and reducing toxicity concerns.

- A biodegradable antimicrobial polymer is developed by mixing Low-Density Polyethylene (LDPE) with waste material of paper tissue (WMPT) and adding cellulose and bentonite nanoparticles, along with antimicrobial agents to enhance mechanical properties and biodegradability, while incorporating nanocomposites for improved performance.

Environmental Impact Assessment

The incorporation of biodegradable additives into Low-Density Polyethylene (LDPE) presents a significant opportunity to mitigate the environmental impact of plastic waste. This assessment examines the potential effects of utilizing such additives on various ecological aspects.

Biodegradable additives in LDPE can substantially reduce the persistence of plastic waste in the environment. These additives accelerate the degradation process, allowing LDPE products to break down more rapidly under specific conditions. This can lead to a significant decrease in the accumulation of plastic waste in landfills, oceans, and terrestrial ecosystems.

The degradation of LDPE with biodegradable additives typically results in the production of carbon dioxide, water, and biomass. While this process does release greenhouse gases, the overall carbon footprint is generally lower compared to traditional LDPE that remains in the environment indefinitely. However, the exact environmental impact depends on the specific additives used and the conditions under which degradation occurs.

One potential concern is the effect of partially degraded LDPE particles on soil and aquatic ecosystems. As the plastic breaks down, it may release microplastics or leach chemicals into the surrounding environment. Research is ongoing to determine the long-term impacts of these byproducts on soil fertility, aquatic life, and food chains.

The use of biodegradable additives in LDPE can also influence waste management practices. While these materials may degrade more quickly in industrial composting facilities, they may not break down effectively in home composting systems or natural environments. This necessitates the development of appropriate waste collection and processing infrastructure to maximize the environmental benefits of biodegradable LDPE.

From a lifecycle perspective, the production of biodegradable additives and their incorporation into LDPE may require additional energy and resources. A comprehensive analysis of the entire production and disposal process is crucial to ensure that the environmental benefits outweigh any potential negative impacts associated with manufacturing.

The adoption of biodegradable LDPE could potentially reduce the reliance on fossil fuel-based plastics, leading to a decrease in oil consumption and associated environmental impacts. However, this shift must be balanced against the land use and agricultural impacts of producing bio-based additives, particularly if they compete with food crops for resources.

In conclusion, while the use of biodegradable additives in LDPE shows promise in reducing plastic pollution, a thorough understanding of their complete environmental impact is essential. Continued research and development are necessary to optimize these additives and ensure their implementation aligns with broader sustainability goals.

Regulatory Framework for Biodegradable Plastics

The regulatory framework for biodegradable plastics plays a crucial role in shaping the development and adoption of biodegradable additives for LDPE. As environmental concerns continue to grow, governments and international organizations have been implementing policies and standards to address plastic pollution and promote sustainable alternatives.

In the European Union, the EN 13432 standard sets the requirements for packaging recoverable through composting and biodegradation. This standard defines the characteristics that a material must have to be considered "compostable" and provides a framework for testing and certification. Similarly, the ASTM D6400 standard in the United States outlines specifications for compostable plastics.

Many countries have introduced regulations to restrict or ban single-use plastics, indirectly promoting the use of biodegradable alternatives. For instance, the EU Single-Use Plastics Directive, implemented in 2021, aims to reduce the impact of certain plastic products on the environment. This directive has spurred research and development in biodegradable additives for LDPE as a potential solution to meet regulatory requirements.

The regulatory landscape also includes labeling and certification requirements for biodegradable plastics. The ISO 14021 standard provides guidelines for environmental claims, including those related to biodegradability and compostability. Compliance with these standards is essential for manufacturers looking to market their biodegradable LDPE products.

However, the regulatory framework for biodegradable plastics is not without challenges. The lack of harmonization between different regional standards can create confusion and hinder global trade. Additionally, there are ongoing debates about the effectiveness of current standards in addressing real-world environmental conditions, as laboratory testing may not always reflect actual biodegradation rates in various ecosystems.

Regulatory bodies are also grappling with the need to differentiate between truly biodegradable materials and those that merely fragment into microplastics. This has led to increased scrutiny of oxo-degradable plastics, with some jurisdictions banning their use due to concerns about their environmental impact.

As the field of biodegradable additives for LDPE continues to evolve, regulators are working to keep pace with technological advancements. There is a growing emphasis on life cycle assessments and the development of more comprehensive standards that consider the entire environmental footprint of biodegradable plastics, from production to disposal.