How To Increase Efficiency Of Tungsten Powders?

Tungsten Powder Evolution and Objectives

Tungsten powder has undergone significant evolution since its initial development in the early 20th century. The journey began with the production of coarse tungsten powders through chemical reduction methods, primarily for use in lighting filaments. As industrial demands grew, particularly in the fields of metallurgy and advanced materials, the focus shifted towards developing finer and more uniform tungsten powders.

The 1950s and 1960s saw the introduction of new production techniques, such as hydrogen reduction of tungsten oxides, which allowed for better control over particle size and morphology. This period marked a crucial turning point in tungsten powder technology, enabling the production of powders with enhanced sintering properties and improved mechanical characteristics in final products.

In recent decades, the evolution of tungsten powder has been driven by the need for higher performance in extreme environments, such as aerospace applications and nuclear reactors. This has led to the development of ultra-fine and nano-sized tungsten powders, which offer superior properties in terms of strength, ductility, and thermal stability.

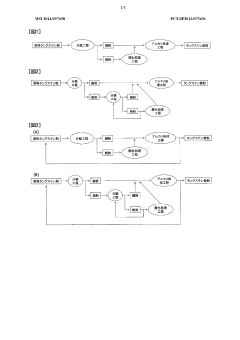

The current objectives in tungsten powder technology are multifaceted, focusing on increasing efficiency across various aspects of production and application. A primary goal is to optimize the powder production process to achieve higher yields and lower energy consumption. This involves refining reduction techniques, exploring novel precursor materials, and implementing advanced process control systems.

Another critical objective is to enhance the powder characteristics to improve the efficiency of subsequent manufacturing processes. This includes developing powders with tailored particle size distributions, controlled morphologies, and improved flow properties. Such advancements can significantly reduce sintering times, lower processing temperatures, and minimize material waste in additive manufacturing and other forming techniques.

Furthermore, there is a growing emphasis on developing tungsten powders with enhanced purity levels. This is particularly important for applications in electronics and medical devices, where even trace impurities can significantly affect performance. Achieving higher purity levels while maintaining cost-effectiveness is a key challenge that researchers and manufacturers are actively addressing.

Sustainability is also becoming an increasingly important objective in tungsten powder evolution. This involves developing more environmentally friendly production methods, improving recycling processes for tungsten scrap, and exploring ways to reduce the reliance on primary tungsten resources. These efforts aim to ensure a stable supply of tungsten powders while minimizing environmental impact.

Market Demand Analysis for High-Efficiency Tungsten Powders

The market demand for high-efficiency tungsten powders has been steadily increasing across various industries, driven by the unique properties and versatile applications of tungsten. The global tungsten market size was valued at USD 3.5 billion in 2020 and is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2021 to 2028. This growth is primarily attributed to the rising demand for tungsten powders in aerospace, automotive, electronics, and mining industries.

In the aerospace sector, high-efficiency tungsten powders are crucial for manufacturing components that require high temperature resistance and strength. The aerospace industry's continuous pursuit of lighter and more durable materials has led to increased adoption of tungsten-based alloys, driving the demand for advanced tungsten powders.

The automotive industry is another significant consumer of high-efficiency tungsten powders. With the growing emphasis on fuel efficiency and emission reduction, automakers are increasingly using tungsten in various applications, including engine components, exhaust systems, and catalytic converters. The shift towards electric vehicles has also created new opportunities for tungsten powders in battery technologies and electric motor components.

In the electronics sector, the demand for high-efficiency tungsten powders is fueled by the rapid growth of smartphones, tablets, and other electronic devices. Tungsten's excellent thermal and electrical conductivity properties make it an ideal material for heat sinks, interconnects, and other critical components in electronic devices.

The mining and construction industries continue to be significant consumers of tungsten powders, particularly in the production of cutting tools, drill bits, and wear-resistant coatings. As these industries expand and modernize, the demand for more efficient and durable tungsten-based tools is expected to rise.

Geographically, Asia Pacific dominates the tungsten powder market, accounting for over 50% of the global consumption. China, in particular, is the largest producer and consumer of tungsten powders. However, concerns over supply chain stability and geopolitical tensions have led to increased efforts in developing alternative sources and more efficient production methods in other regions, including North America and Europe.

The market trend is shifting towards the development of nano-sized tungsten powders, which offer enhanced properties and performance in various applications. This trend is driven by the growing demand for miniaturization in electronics and the need for more efficient materials in energy and aerospace applications.

In conclusion, the market demand for high-efficiency tungsten powders is robust and diverse, with significant growth potential across multiple industries. The ongoing technological advancements and the push for more sustainable and efficient materials are expected to further drive the demand for innovative tungsten powder solutions in the coming years.

Current State and Challenges in Tungsten Powder Production

The current state of tungsten powder production is characterized by a complex interplay of technological advancements and persistent challenges. Globally, the industry has made significant strides in improving production processes, yet efficiency remains a critical concern. Traditional methods, such as hydrogen reduction and carbothermal reduction, continue to dominate the market, but they are often energy-intensive and time-consuming.

One of the primary challenges facing the industry is the high energy consumption associated with tungsten powder production. The reduction process typically requires temperatures exceeding 800°C, leading to substantial energy costs and environmental concerns. This has prompted research into more energy-efficient methods, including microwave-assisted reduction and plasma processing, which show promise in reducing energy requirements and processing times.

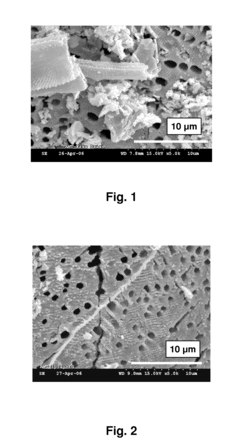

Another significant challenge is the control of particle size and morphology. Achieving uniform particle size distribution is crucial for the powder's performance in various applications, such as in the production of cemented carbides and additive manufacturing. Current production methods often result in a wide particle size range, necessitating additional processing steps like milling or classification, which can reduce overall yield and increase production costs.

The industry also grapples with raw material quality and availability. High-grade tungsten ores are becoming scarcer, forcing producers to work with lower-grade sources. This shift requires more sophisticated beneficiation and purification processes, adding complexity and cost to the production chain. Additionally, the geopolitical concentration of tungsten resources in a few countries poses supply chain risks and price volatility challenges for global manufacturers.

Environmental and health concerns present another set of challenges. The production of tungsten powder can generate hazardous waste and emissions, necessitating stringent control measures and compliance with increasingly strict environmental regulations. This has led to a growing focus on developing cleaner production technologies and recycling processes to minimize environmental impact and improve resource utilization.

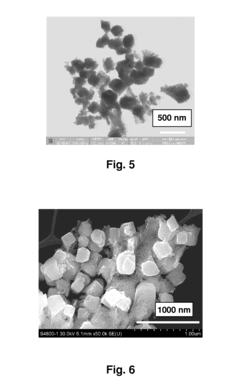

In terms of technological progress, recent years have seen advancements in ultra-fine powder production techniques. Methods such as chemical vapor deposition (CVD) and solution-based processes are being explored to produce nanoscale tungsten powders with enhanced properties. However, scaling these methods for industrial production while maintaining cost-effectiveness remains a significant challenge.

The industry is also witnessing a shift towards more automated and digitally integrated production systems. While this trend promises improved process control and efficiency, it requires substantial investment in equipment and workforce training. The integration of Industry 4.0 technologies, such as artificial intelligence and machine learning, for process optimization is still in its early stages in tungsten powder production.

Existing Methods for Enhancing Tungsten Powder Efficiency

01 Production methods for high-efficiency tungsten powders

Various methods are employed to produce high-efficiency tungsten powders, including chemical vapor deposition, plasma spheroidization, and mechanical alloying. These techniques aim to improve the powder's properties such as particle size distribution, purity, and morphology, which directly impact the efficiency of the final product.- Production methods for high-efficiency tungsten powders: Various methods are employed to produce high-efficiency tungsten powders, including chemical vapor deposition, plasma spheroidization, and mechanical alloying. These techniques aim to improve the powder's properties such as particle size distribution, purity, and morphology, which in turn enhance the efficiency of the final product.

- Optimization of tungsten powder characteristics: Researchers focus on optimizing tungsten powder characteristics such as particle size, shape, and surface area to improve efficiency. This includes developing methods to control these parameters during production and post-processing techniques to enhance the powder's performance in various applications.

- Tungsten powder additives and composites: The addition of other elements or compounds to tungsten powders can significantly improve their efficiency. This includes creating tungsten alloys or composites with enhanced properties such as improved thermal conductivity, wear resistance, or mechanical strength.

- Application-specific tungsten powder development: Tailoring tungsten powders for specific applications can greatly improve their efficiency. This involves developing powders with optimized properties for use in areas such as additive manufacturing, thermal management, or radiation shielding.

- Recycling and sustainable production of tungsten powders: Efforts to improve the efficiency of tungsten powder production include developing recycling methods and more sustainable production processes. This aims to reduce waste, lower production costs, and minimize environmental impact while maintaining or improving powder quality.

02 Optimization of tungsten powder characteristics

Enhancing the efficiency of tungsten powders involves optimizing characteristics such as particle size, shape, and surface area. Fine-tuning these properties can lead to improved sintering behavior, higher density, and better mechanical properties in the final product, ultimately increasing overall efficiency.Expand Specific Solutions03 Doping and alloying for enhanced performance

Incorporating dopants or alloying elements into tungsten powders can significantly improve their efficiency. These additions can enhance properties such as hardness, wear resistance, and thermal stability, leading to better performance in various applications, including cutting tools and high-temperature components.Expand Specific Solutions04 Advanced processing techniques for tungsten powders

Innovative processing techniques, such as spark plasma sintering, hot isostatic pressing, and additive manufacturing, are being developed to enhance the efficiency of tungsten powder-based products. These methods allow for better control over microstructure and properties, resulting in improved performance and efficiency.Expand Specific Solutions05 Recycling and sustainable production of tungsten powders

Efforts to improve the efficiency of tungsten powder production include developing sustainable recycling methods and optimizing resource utilization. These approaches aim to reduce environmental impact, lower production costs, and improve the overall efficiency of tungsten powder manufacturing and usage.Expand Specific Solutions

Key Players in Tungsten Powder Industry

The tungsten powder efficiency market is in a growth phase, driven by increasing demand in various industries. The market size is expanding, with a global reach and significant potential for further development. Technologically, the field is advancing rapidly, with companies like Kyocera Corp., Applied Materials, Inc., and Toshiba Corp. leading innovation. These major players, along with emerging companies such as Chongyi Zhangyuan Tungsten Co., Ltd. and Xiamen Golden Egret Special Alloy Co., Ltd., are investing heavily in R&D to improve powder efficiency. The technology maturity varies, with established methods being refined and new techniques emerging, indicating a dynamic and competitive landscape with opportunities for breakthrough advancements.

Applied Materials, Inc.

Chongyi Zhangyuan Tungsten Co., Ltd.

Innovative Approaches in Tungsten Powder Optimization

- A method involving heating tungsten-containing materials in a reducing atmosphere at specific temperature ranges to produce nanocrystalline tungsten powders without the need for milling, using ammonium paratungstate, ammonium metatungstate, or tungsten oxides, and controlling temperature and time to achieve crystallites less than 200 nm in size.

- A method involving classification of tungsten powder into fine and coarse particles, followed by oxidation treatment and alkaline aqueous solution processing to remove oxide films, achieving a high-yield production of tungsten powder with a small average particle size and large BET specific surface area suitable for capacitors.

Environmental Impact of Tungsten Powder Production

The production of tungsten powder has significant environmental implications that must be carefully considered and addressed. The extraction and processing of tungsten ore, primarily wolframite and scheelite, involve energy-intensive operations that contribute to greenhouse gas emissions. Mining activities can lead to habitat destruction, soil erosion, and water pollution if not properly managed. The use of chemicals in ore processing, such as acids for leaching, poses risks of contamination to soil and water resources.

Tungsten powder production often requires high temperatures and pressures, resulting in substantial energy consumption and associated carbon emissions. The reduction process, typically using hydrogen or carbon, can release harmful gases if not properly controlled. Additionally, the fine particulate nature of tungsten powder raises concerns about air quality and potential respiratory hazards for workers and nearby communities.

Water usage is another critical environmental factor in tungsten powder production. Large volumes of water are required for ore processing, cooling, and dust suppression. This can strain local water resources, particularly in water-scarce regions. Proper water management and recycling systems are essential to minimize consumption and prevent contamination of water bodies.

Waste management is a significant challenge in tungsten powder production. Tailings and slag from ore processing can contain heavy metals and other contaminants. Improper disposal of these wastes can lead to long-term environmental degradation and health risks. Implementing effective waste treatment and storage solutions is crucial to mitigate these impacts.

The environmental footprint of tungsten powder production extends beyond the immediate production site. Transportation of raw materials and finished products contributes to carbon emissions and air pollution. Furthermore, the energy-intensive nature of production often relies on fossil fuels, exacerbating climate change concerns.

To address these environmental challenges, the tungsten powder industry is increasingly focusing on sustainable practices. This includes developing more efficient extraction and processing technologies to reduce energy consumption and emissions. Closed-loop water systems and advanced waste treatment methods are being implemented to minimize resource use and environmental contamination. Additionally, there is growing interest in recycling tungsten from scrap materials to reduce the need for primary ore extraction and its associated environmental impacts.

Quality Control and Standardization in Tungsten Powder Industry

Quality control and standardization play crucial roles in enhancing the efficiency of tungsten powder production and ensuring consistent product quality. The tungsten powder industry has recognized the need for stringent quality control measures and standardized processes to meet the growing demands of various applications, including aerospace, electronics, and automotive sectors.

Implementing robust quality control systems is essential for maintaining the desired characteristics of tungsten powders, such as particle size distribution, purity, and morphology. Advanced analytical techniques, including laser diffraction, X-ray fluorescence spectroscopy, and scanning electron microscopy, are employed to assess these properties accurately. Regular testing and monitoring of production batches help identify and address any deviations from specified parameters promptly.

Standardization efforts in the tungsten powder industry focus on establishing uniform testing methods, specifications, and terminology. International organizations, such as ASTM International and ISO, have developed standards for tungsten powders, covering aspects like chemical composition, physical properties, and sampling procedures. These standards facilitate communication between suppliers and customers, ensuring consistency in product quality across different manufacturers.

Process standardization is another critical aspect of improving efficiency in tungsten powder production. By implementing standardized operating procedures (SOPs) throughout the manufacturing process, companies can minimize variations and optimize resource utilization. This includes standardizing raw material selection, processing parameters, and packaging methods.

Statistical process control (SPC) techniques are increasingly adopted to monitor and control the production process in real-time. By analyzing key process variables and product characteristics, manufacturers can identify trends, detect anomalies, and make data-driven decisions to maintain consistent quality and improve overall efficiency.

Automation and digitalization initiatives are transforming quality control practices in the tungsten powder industry. Advanced sensors, machine vision systems, and artificial intelligence algorithms are being integrated into production lines to enable continuous monitoring and rapid detection of quality issues. These technologies not only enhance the accuracy and speed of quality control but also contribute to reducing human errors and improving overall process efficiency.

Supplier quality management is another critical component of quality control in the tungsten powder industry. Establishing strong partnerships with suppliers and implementing rigorous supplier qualification processes ensure the consistency and reliability of raw materials. This, in turn, contributes to the overall quality and efficiency of tungsten powder production.

As the industry continues to evolve, there is a growing emphasis on developing and implementing industry-wide best practices for quality control and standardization. Collaborative efforts between manufacturers, research institutions, and regulatory bodies are driving the development of more comprehensive and effective quality management systems tailored to the specific needs of the tungsten powder industry.