How to Safely Handle Hydrochloric Acid in Lab Environments?

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl Safety Background

Hydrochloric acid (HCl) is a strong, highly corrosive mineral acid widely used in various laboratory applications. Its safe handling is crucial due to its potential hazards, including severe burns, respiratory issues, and equipment damage. The history of HCl safety in laboratories dates back to the early days of chemistry, with significant advancements in safety protocols occurring throughout the 20th century.

In the early 1900s, laboratory safety practices were often rudimentary, with minimal protective equipment and inadequate ventilation systems. As industrial use of HCl increased, so did awareness of its dangers. The 1930s and 1940s saw the introduction of basic safety measures, such as rubber gloves and simple fume hoods, to mitigate risks associated with HCl handling.

The 1970s marked a turning point in laboratory safety, with the establishment of regulatory bodies like the Occupational Safety and Health Administration (OSHA) in the United States. These organizations set standards for chemical handling, including specific guidelines for HCl. This period also saw the development of more sophisticated personal protective equipment (PPE) and improved laboratory ventilation systems.

By the 1990s, comprehensive safety protocols for HCl handling had become standard in most laboratories. These included detailed risk assessments, mandatory safety training for personnel, and the implementation of emergency response procedures. The advent of digital technology in the 21st century further enhanced safety measures, with the introduction of electronic monitoring systems and improved data management for tracking chemical usage and exposure.

Today, safe handling of HCl in laboratory environments involves a multi-faceted approach. This includes the use of advanced PPE such as chemical-resistant gloves, goggles, and face shields, as well as specialized storage and containment systems. Modern laboratories are equipped with sophisticated fume hoods and ventilation systems designed to minimize exposure to HCl vapors.

Current safety protocols also emphasize proper training and education. Laboratory personnel are required to undergo regular safety briefings and practical training sessions on HCl handling. This includes instruction on proper dilution techniques, spill management, and emergency response procedures. Additionally, there is an increased focus on sustainable practices, with efforts to minimize HCl usage and explore safer alternatives where possible.

The evolution of HCl safety practices reflects broader trends in laboratory safety and environmental consciousness. As research continues to advance, so too do the methods and technologies used to ensure the safe handling of this potent acid, balancing its invaluable role in scientific research with the paramount importance of worker and environmental safety.

In the early 1900s, laboratory safety practices were often rudimentary, with minimal protective equipment and inadequate ventilation systems. As industrial use of HCl increased, so did awareness of its dangers. The 1930s and 1940s saw the introduction of basic safety measures, such as rubber gloves and simple fume hoods, to mitigate risks associated with HCl handling.

The 1970s marked a turning point in laboratory safety, with the establishment of regulatory bodies like the Occupational Safety and Health Administration (OSHA) in the United States. These organizations set standards for chemical handling, including specific guidelines for HCl. This period also saw the development of more sophisticated personal protective equipment (PPE) and improved laboratory ventilation systems.

By the 1990s, comprehensive safety protocols for HCl handling had become standard in most laboratories. These included detailed risk assessments, mandatory safety training for personnel, and the implementation of emergency response procedures. The advent of digital technology in the 21st century further enhanced safety measures, with the introduction of electronic monitoring systems and improved data management for tracking chemical usage and exposure.

Today, safe handling of HCl in laboratory environments involves a multi-faceted approach. This includes the use of advanced PPE such as chemical-resistant gloves, goggles, and face shields, as well as specialized storage and containment systems. Modern laboratories are equipped with sophisticated fume hoods and ventilation systems designed to minimize exposure to HCl vapors.

Current safety protocols also emphasize proper training and education. Laboratory personnel are required to undergo regular safety briefings and practical training sessions on HCl handling. This includes instruction on proper dilution techniques, spill management, and emergency response procedures. Additionally, there is an increased focus on sustainable practices, with efforts to minimize HCl usage and explore safer alternatives where possible.

The evolution of HCl safety practices reflects broader trends in laboratory safety and environmental consciousness. As research continues to advance, so too do the methods and technologies used to ensure the safe handling of this potent acid, balancing its invaluable role in scientific research with the paramount importance of worker and environmental safety.

Lab Demand Analysis

The demand for safe handling of hydrochloric acid in laboratory environments has grown significantly in recent years, driven by the expanding research and development activities across various industries. Hydrochloric acid, a strong and corrosive mineral acid, is widely used in chemical synthesis, analytical procedures, and industrial processes. Its versatility makes it indispensable in many laboratory applications, including pH adjustment, metal cleaning, and as a reagent in numerous chemical reactions.

In academic institutions, the demand for hydrochloric acid handling protocols has increased due to the growing emphasis on STEM education and research. Universities and colleges are expanding their chemistry and materials science programs, leading to a higher frequency of experiments involving hydrochloric acid. This trend necessitates robust safety measures and standardized handling procedures to protect students and researchers.

The pharmaceutical and biotechnology sectors have also contributed to the rising demand for safe hydrochloric acid handling practices. As drug discovery and development processes intensify, the use of hydrochloric acid in various stages of research and production has become more prevalent. This has led to an increased focus on developing and implementing stringent safety protocols in laboratory settings within these industries.

Environmental testing laboratories have seen a surge in demand for hydrochloric acid handling expertise. With growing concerns about water quality and environmental contamination, these labs frequently use hydrochloric acid in sample preparation and analysis. The need for accurate and safe handling procedures has become paramount to ensure reliable test results and protect laboratory personnel.

The semiconductor industry, a key driver of technological advancement, relies heavily on hydrochloric acid for wafer cleaning and etching processes. As the demand for more sophisticated electronic devices continues to grow, so does the need for safe and efficient hydrochloric acid handling in semiconductor fabrication facilities. This has led to increased investment in specialized equipment and training programs focused on acid safety.

In the realm of materials science and nanotechnology, hydrochloric acid plays a crucial role in the synthesis and modification of various materials. The expanding research in these fields has resulted in a higher demand for advanced safety measures and handling techniques, particularly when working with hydrochloric acid at the nanoscale level.

The chemical manufacturing industry, being a major consumer of hydrochloric acid, has also contributed to the increased focus on safe handling practices. As production scales up to meet global demand, the importance of implementing comprehensive safety protocols and training programs has become more pronounced. This has led to a growing market for specialized safety equipment and consultancy services related to hydrochloric acid handling.

Overall, the demand for safe hydrochloric acid handling in laboratory environments reflects the broader trends in scientific research, industrial innovation, and regulatory compliance. As industries continue to evolve and new applications for hydrochloric acid emerge, the emphasis on developing and implementing effective safety measures is expected to remain a top priority for laboratories across various sectors.

In academic institutions, the demand for hydrochloric acid handling protocols has increased due to the growing emphasis on STEM education and research. Universities and colleges are expanding their chemistry and materials science programs, leading to a higher frequency of experiments involving hydrochloric acid. This trend necessitates robust safety measures and standardized handling procedures to protect students and researchers.

The pharmaceutical and biotechnology sectors have also contributed to the rising demand for safe hydrochloric acid handling practices. As drug discovery and development processes intensify, the use of hydrochloric acid in various stages of research and production has become more prevalent. This has led to an increased focus on developing and implementing stringent safety protocols in laboratory settings within these industries.

Environmental testing laboratories have seen a surge in demand for hydrochloric acid handling expertise. With growing concerns about water quality and environmental contamination, these labs frequently use hydrochloric acid in sample preparation and analysis. The need for accurate and safe handling procedures has become paramount to ensure reliable test results and protect laboratory personnel.

The semiconductor industry, a key driver of technological advancement, relies heavily on hydrochloric acid for wafer cleaning and etching processes. As the demand for more sophisticated electronic devices continues to grow, so does the need for safe and efficient hydrochloric acid handling in semiconductor fabrication facilities. This has led to increased investment in specialized equipment and training programs focused on acid safety.

In the realm of materials science and nanotechnology, hydrochloric acid plays a crucial role in the synthesis and modification of various materials. The expanding research in these fields has resulted in a higher demand for advanced safety measures and handling techniques, particularly when working with hydrochloric acid at the nanoscale level.

The chemical manufacturing industry, being a major consumer of hydrochloric acid, has also contributed to the increased focus on safe handling practices. As production scales up to meet global demand, the importance of implementing comprehensive safety protocols and training programs has become more pronounced. This has led to a growing market for specialized safety equipment and consultancy services related to hydrochloric acid handling.

Overall, the demand for safe hydrochloric acid handling in laboratory environments reflects the broader trends in scientific research, industrial innovation, and regulatory compliance. As industries continue to evolve and new applications for hydrochloric acid emerge, the emphasis on developing and implementing effective safety measures is expected to remain a top priority for laboratories across various sectors.

HCl Handling Challenges

Handling hydrochloric acid (HCl) in laboratory environments presents several significant challenges due to its corrosive and hazardous nature. One of the primary concerns is the potential for chemical burns and tissue damage upon contact with skin or eyes. Even brief exposure can cause severe irritation and injury, necessitating immediate and thorough decontamination procedures.

Inhalation of HCl vapors poses another critical challenge. The fumes can cause respiratory distress, coughing, and in severe cases, pulmonary edema. This risk is particularly pronounced when working with concentrated solutions or heating HCl, as the release of vapors increases significantly under these conditions. Proper ventilation and the use of fume hoods are essential but can be challenging to maintain consistently in all laboratory settings.

The corrosive nature of HCl also presents challenges in terms of equipment and infrastructure. It can rapidly degrade many common laboratory materials, including certain metals, plastics, and rubbers. This necessitates careful selection of storage containers, transfer equipment, and personal protective equipment (PPE) that are specifically resistant to HCl. However, even HCl-resistant materials may degrade over time, requiring regular inspection and replacement.

Spill management is another significant challenge when handling HCl. Due to its high reactivity, spills can quickly lead to dangerous situations, including the release of toxic fumes and potential fire hazards when in contact with certain metals. Developing and maintaining effective spill response protocols, including the availability of appropriate neutralizing agents and absorbents, is crucial but can be complex to implement across diverse laboratory settings.

The storage of HCl presents its own set of challenges. It must be kept in a cool, well-ventilated area, away from incompatible substances such as strong bases, active metals, and oxidizing agents. In many laboratories, space constraints and the need to store multiple chemicals in proximity can make this challenging to achieve consistently.

Proper disposal of HCl and HCl-contaminated waste is another significant challenge. It cannot be simply neutralized and disposed of down the drain due to environmental regulations and potential damage to plumbing systems. Developing and adhering to proper disposal protocols that comply with local, state, and federal regulations can be complex and resource-intensive.

Lastly, ensuring that all laboratory personnel are adequately trained in the safe handling of HCl is an ongoing challenge. This includes not only initial safety training but also regular refresher courses and updates on best practices. The high turnover rate in many academic and research laboratories can make it difficult to maintain a consistently high level of awareness and competence in HCl handling procedures across all personnel.

Inhalation of HCl vapors poses another critical challenge. The fumes can cause respiratory distress, coughing, and in severe cases, pulmonary edema. This risk is particularly pronounced when working with concentrated solutions or heating HCl, as the release of vapors increases significantly under these conditions. Proper ventilation and the use of fume hoods are essential but can be challenging to maintain consistently in all laboratory settings.

The corrosive nature of HCl also presents challenges in terms of equipment and infrastructure. It can rapidly degrade many common laboratory materials, including certain metals, plastics, and rubbers. This necessitates careful selection of storage containers, transfer equipment, and personal protective equipment (PPE) that are specifically resistant to HCl. However, even HCl-resistant materials may degrade over time, requiring regular inspection and replacement.

Spill management is another significant challenge when handling HCl. Due to its high reactivity, spills can quickly lead to dangerous situations, including the release of toxic fumes and potential fire hazards when in contact with certain metals. Developing and maintaining effective spill response protocols, including the availability of appropriate neutralizing agents and absorbents, is crucial but can be complex to implement across diverse laboratory settings.

The storage of HCl presents its own set of challenges. It must be kept in a cool, well-ventilated area, away from incompatible substances such as strong bases, active metals, and oxidizing agents. In many laboratories, space constraints and the need to store multiple chemicals in proximity can make this challenging to achieve consistently.

Proper disposal of HCl and HCl-contaminated waste is another significant challenge. It cannot be simply neutralized and disposed of down the drain due to environmental regulations and potential damage to plumbing systems. Developing and adhering to proper disposal protocols that comply with local, state, and federal regulations can be complex and resource-intensive.

Lastly, ensuring that all laboratory personnel are adequately trained in the safe handling of HCl is an ongoing challenge. This includes not only initial safety training but also regular refresher courses and updates on best practices. The high turnover rate in many academic and research laboratories can make it difficult to maintain a consistently high level of awareness and competence in HCl handling procedures across all personnel.

Current HCl Protocols

01 Personal protective equipment for handling hydrochloric acid

Proper personal protective equipment (PPE) is crucial when handling hydrochloric acid. This includes acid-resistant gloves, goggles or face shields, and protective clothing. Respiratory protection may also be necessary in certain situations. Using appropriate PPE helps prevent skin contact, inhalation, and eye exposure to the corrosive acid.- Personal protective equipment for handling hydrochloric acid: Proper personal protective equipment (PPE) is crucial when handling hydrochloric acid. This includes acid-resistant gloves, goggles or face shields, and protective clothing. Respiratory protection may also be necessary in certain situations. Using appropriate PPE helps prevent skin contact, inhalation, and eye exposure to the corrosive acid.

- Storage and containment systems for hydrochloric acid: Safe storage of hydrochloric acid requires specialized containment systems. These may include corrosion-resistant tanks, secondary containment measures, and proper ventilation systems. Implementing appropriate storage solutions helps prevent leaks, spills, and potential chemical reactions that could lead to safety hazards.

- Neutralization and disposal methods for hydrochloric acid: Proper neutralization and disposal of hydrochloric acid are essential for safety and environmental protection. This may involve using alkaline substances to neutralize the acid before disposal or implementing specialized waste treatment processes. Correct disposal methods help prevent environmental contamination and potential harm to living organisms.

- Emergency response and first aid procedures: Establishing clear emergency response and first aid procedures is crucial when working with hydrochloric acid. This includes having readily available eyewash stations, safety showers, and spill containment kits. Training personnel in proper response techniques and immediate actions in case of exposure helps minimize potential injuries and damage.

- Handling and transportation safety measures: Implementing proper handling and transportation safety measures for hydrochloric acid is essential. This includes using appropriate containers, securing loads during transport, and following specific protocols for transferring the acid between containers or equipment. These measures help prevent accidents, spills, and potential chemical reactions during handling and transportation.

02 Storage and containment of hydrochloric acid

Safe storage of hydrochloric acid involves using corrosion-resistant containers and storing them in well-ventilated areas away from incompatible materials. Secondary containment systems should be in place to prevent spills from spreading. Proper labeling and regular inspections of storage areas are essential for maintaining safety.Expand Specific Solutions03 Emergency response and first aid for hydrochloric acid incidents

Emergency procedures for hydrochloric acid incidents include immediate flushing with water for skin or eye contact, removing contaminated clothing, and seeking medical attention. For spills, neutralization and proper disposal methods should be employed. Having emergency eyewash stations and safety showers nearby is crucial for rapid response.Expand Specific Solutions04 Ventilation and exposure control measures

Adequate ventilation is essential when working with hydrochloric acid to prevent the buildup of harmful vapors. This may include local exhaust ventilation systems or fume hoods. Regular air quality monitoring and the use of vapor suppression techniques can help minimize exposure risks in industrial settings.Expand Specific Solutions05 Safe handling and transportation procedures

Safe handling of hydrochloric acid involves using proper transfer techniques, avoiding splashing or aerosol formation, and never adding water to acid. For transportation, secure packaging, appropriate labeling, and adherence to hazardous materials regulations are crucial. Training personnel in safe handling procedures is essential to prevent accidents.Expand Specific Solutions

Key Safety Suppliers

The competitive landscape for safely handling hydrochloric acid in lab environments is characterized by a mature market with established players and ongoing innovation. The industry is in a stable growth phase, driven by increasing demand from research institutions, chemical manufacturers, and educational facilities. The global market size for laboratory safety equipment and chemicals is substantial, estimated in the billions of dollars. Technologically, the field is moderately mature, with companies like Covestro Deutschland AG, Fluid Energy Group Ltd., and Praxair Technology, Inc. leading in developing advanced containment systems, neutralization techniques, and personal protective equipment. Emerging players such as Annihilare Medical Systems, Inc. and Enlighten Innovations, Inc. are introducing novel approaches to acid handling and neutralization, indicating ongoing technological advancements in the sector.

Covestro Deutschland AG

Technical Solution: Covestro Deutschland AG has developed a holistic approach to safely handling hydrochloric acid in laboratory environments. Their strategy focuses on material innovation, particularly in the development of highly resistant polymers for protective equipment and storage containers[7]. They have created a line of smart PPE that incorporates sensors to detect acid exposure and alert users to potential hazards. Covestro's system also includes the use of advanced neutralization agents that can quickly and effectively neutralize acid spills while minimizing environmental impact[8]. Additionally, they have implemented a digital safety management system that tracks acid usage, monitors storage conditions, and provides real-time safety alerts to laboratory personnel[9].

Strengths: Innovative material science applications, smart PPE technology, and integrated digital safety management. Weaknesses: Potentially high initial investment costs and the need for specialized training to utilize advanced features effectively.

Fluid Energy Group Ltd.

Technical Solution: Fluid Energy Group Ltd. has pioneered a unique approach to hydrochloric acid safety in laboratories through the development of their "Green Acid" technology. This innovative solution involves reformulating hydrochloric acid to reduce its corrosivity and vapor pressure while maintaining its chemical effectiveness[10]. Their process includes the addition of proprietary inhibitors that significantly reduce the acid's aggressiveness towards metals and human tissue. Fluid Energy Group has also created a complementary line of handling equipment specifically designed for use with their modified acid, including specialized pumps, valves, and storage tanks that further enhance safety[11]. Their system includes a comprehensive training program that covers the specific properties and handling requirements of their Green Acid formulation.

Strengths: Reduced inherent hazards of the acid itself, specialized handling equipment, and potential for broader applications due to improved safety profile. Weaknesses: May not be suitable for all laboratory applications where standard hydrochloric acid properties are required, and potential for higher costs compared to conventional acid.

Innovative HCl Safety

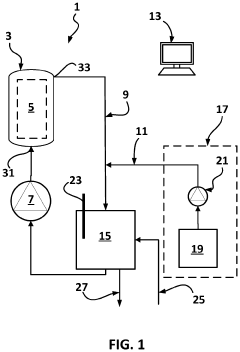

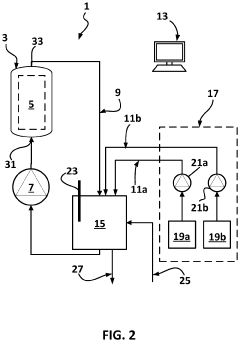

Apparatus and method for the electrolytic production of hypochlorous acid

PatentPendingUS20230313389A1

Innovation

- An apparatus and method using electrolysis of a sodium chloride solution with an acidic solution in a reaction loop, controlled by a system that monitors and adjusts pH to produce a stable HOCl solution, allowing for on-demand production with variable scale and remote monitoring.

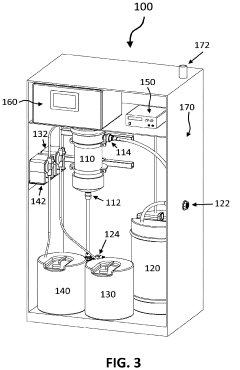

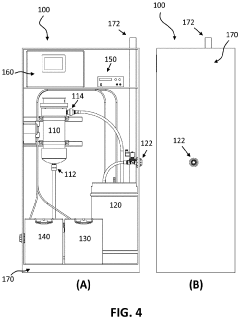

Mixing device

PatentActiveUS20180147548A1

Innovation

- A mixing device that produces fluidic vortices within a chamber with strategically placed apertures to stabilize HOCl, allowing for its production without electrolysis or chlorine gas, and using a weaker acid like acetic acid to control pH and proton concentration, enabling stable storage for several months.

Regulatory Compliance

Regulatory compliance is a critical aspect of safely handling hydrochloric acid in laboratory environments. The Occupational Safety and Health Administration (OSHA) in the United States has established specific guidelines for the use and storage of hydrochloric acid under the Hazard Communication Standard (HCS) and Laboratory Standard. These regulations require proper labeling, safety data sheets (SDS), and employee training on the hazards and safe handling procedures for hydrochloric acid.

The Environmental Protection Agency (EPA) also regulates the storage, use, and disposal of hydrochloric acid under the Resource Conservation and Recovery Act (RCRA). Laboratories must comply with strict waste management protocols, including proper containment, documentation, and disposal through licensed hazardous waste facilities.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of hydrochloric acid. This regulation mandates thorough risk assessments and the implementation of appropriate risk management measures for handling and storing the acid.

Many countries have adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which provides standardized hazard communication elements for hydrochloric acid. This system ensures consistent labeling and safety information across international borders, facilitating safer handling practices worldwide.

Local and state regulations may impose additional requirements for the safe handling of hydrochloric acid. These can include specific storage conditions, ventilation requirements, and emergency response procedures. Laboratories must stay informed about these local regulations and ensure full compliance to maintain a safe working environment.

Regulatory bodies often require regular inspections and audits to verify compliance with safety standards. Laboratories must maintain detailed records of acid usage, storage conditions, and disposal practices to demonstrate adherence to regulations during these inspections.

Compliance with these regulations not only ensures legal operation but also significantly reduces the risk of accidents, injuries, and environmental contamination. Laboratories should establish comprehensive safety management systems that incorporate all relevant regulatory requirements and best practices for handling hydrochloric acid.

Regular training and updates on regulatory changes are essential for maintaining compliance. Laboratories should designate responsible personnel to monitor regulatory developments and implement necessary changes in procedures and protocols promptly.

The Environmental Protection Agency (EPA) also regulates the storage, use, and disposal of hydrochloric acid under the Resource Conservation and Recovery Act (RCRA). Laboratories must comply with strict waste management protocols, including proper containment, documentation, and disposal through licensed hazardous waste facilities.

In the European Union, the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation governs the use of hydrochloric acid. This regulation mandates thorough risk assessments and the implementation of appropriate risk management measures for handling and storing the acid.

Many countries have adopted the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), which provides standardized hazard communication elements for hydrochloric acid. This system ensures consistent labeling and safety information across international borders, facilitating safer handling practices worldwide.

Local and state regulations may impose additional requirements for the safe handling of hydrochloric acid. These can include specific storage conditions, ventilation requirements, and emergency response procedures. Laboratories must stay informed about these local regulations and ensure full compliance to maintain a safe working environment.

Regulatory bodies often require regular inspections and audits to verify compliance with safety standards. Laboratories must maintain detailed records of acid usage, storage conditions, and disposal practices to demonstrate adherence to regulations during these inspections.

Compliance with these regulations not only ensures legal operation but also significantly reduces the risk of accidents, injuries, and environmental contamination. Laboratories should establish comprehensive safety management systems that incorporate all relevant regulatory requirements and best practices for handling hydrochloric acid.

Regular training and updates on regulatory changes are essential for maintaining compliance. Laboratories should designate responsible personnel to monitor regulatory developments and implement necessary changes in procedures and protocols promptly.

Environmental Impact

The environmental impact of hydrochloric acid (HCl) handling in laboratory environments is a critical consideration that extends beyond immediate safety concerns. HCl, being a strong mineral acid, poses significant risks to ecosystems and natural resources if not managed properly. When released into the environment, even in small quantities, it can cause severe damage to soil, water bodies, and air quality.

In aquatic ecosystems, HCl can dramatically alter the pH balance, leading to acidification of water bodies. This change can have devastating effects on aquatic life, including fish, amphibians, and microorganisms that are sensitive to pH changes. The acid can also mobilize heavy metals in sediments, making them more bioavailable and potentially toxic to aquatic organisms.

Soil contamination is another major concern when HCl is improperly disposed of or accidentally spilled. The acid can leach into the ground, altering soil chemistry and potentially rendering it infertile. This can have long-lasting impacts on plant life and soil microorganisms, disrupting local ecosystems and potentially affecting agricultural productivity in affected areas.

Air pollution is also a potential consequence of HCl mishandling. When the acid vaporizes, it can form an acidic mist that contributes to air quality degradation. This can lead to respiratory issues in humans and animals, as well as contribute to the formation of acid rain, which has far-reaching environmental consequences.

The production and transportation of HCl also have environmental implications. The manufacturing process can result in emissions and waste products that require careful management to minimize environmental impact. Additionally, the transportation of HCl poses risks of accidental spills during transit, which can have immediate and severe consequences for the surrounding environment.

To mitigate these environmental risks, laboratories must implement strict protocols for HCl handling, storage, and disposal. This includes using appropriate containment systems, such as secondary containment trays and acid-resistant storage cabinets, to prevent spills and leaks. Proper neutralization techniques should be employed before disposal, and all waste should be handled in accordance with local environmental regulations.

Furthermore, laboratories should prioritize the use of less hazardous alternatives where possible, and minimize the quantities of HCl used in experiments. Implementing recycling and recovery systems for HCl can also help reduce the overall environmental footprint of laboratory operations.

By understanding and addressing the potential environmental impacts of HCl, laboratories can play a crucial role in environmental stewardship while maintaining the necessary use of this important chemical in scientific research and industrial applications.

In aquatic ecosystems, HCl can dramatically alter the pH balance, leading to acidification of water bodies. This change can have devastating effects on aquatic life, including fish, amphibians, and microorganisms that are sensitive to pH changes. The acid can also mobilize heavy metals in sediments, making them more bioavailable and potentially toxic to aquatic organisms.

Soil contamination is another major concern when HCl is improperly disposed of or accidentally spilled. The acid can leach into the ground, altering soil chemistry and potentially rendering it infertile. This can have long-lasting impacts on plant life and soil microorganisms, disrupting local ecosystems and potentially affecting agricultural productivity in affected areas.

Air pollution is also a potential consequence of HCl mishandling. When the acid vaporizes, it can form an acidic mist that contributes to air quality degradation. This can lead to respiratory issues in humans and animals, as well as contribute to the formation of acid rain, which has far-reaching environmental consequences.

The production and transportation of HCl also have environmental implications. The manufacturing process can result in emissions and waste products that require careful management to minimize environmental impact. Additionally, the transportation of HCl poses risks of accidental spills during transit, which can have immediate and severe consequences for the surrounding environment.

To mitigate these environmental risks, laboratories must implement strict protocols for HCl handling, storage, and disposal. This includes using appropriate containment systems, such as secondary containment trays and acid-resistant storage cabinets, to prevent spills and leaks. Proper neutralization techniques should be employed before disposal, and all waste should be handled in accordance with local environmental regulations.

Furthermore, laboratories should prioritize the use of less hazardous alternatives where possible, and minimize the quantities of HCl used in experiments. Implementing recycling and recovery systems for HCl can also help reduce the overall environmental footprint of laboratory operations.

By understanding and addressing the potential environmental impacts of HCl, laboratories can play a crucial role in environmental stewardship while maintaining the necessary use of this important chemical in scientific research and industrial applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!