Hydrochloric Acid in Renewable Energy: Future Potential

JUL 1, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

HCl in Renewable Energy: Background and Objectives

Hydrochloric acid (HCl) has emerged as a significant player in the renewable energy sector, particularly in the context of green hydrogen production and energy storage systems. The evolution of HCl's role in renewable energy technologies can be traced back to the early 2000s when researchers began exploring its potential in electrolysis processes for hydrogen generation. As global efforts to combat climate change intensified, the focus on sustainable energy solutions propelled HCl into the spotlight as a key component in various renewable energy applications.

The technological trajectory of HCl in renewable energy has been marked by continuous innovation and refinement. Initially, its use was limited to small-scale laboratory experiments, but over the past two decades, it has transitioned into large-scale industrial applications. This progression has been driven by advancements in materials science, process engineering, and a deeper understanding of electrochemical reactions involving HCl.

One of the primary objectives in the development of HCl-based renewable energy technologies is to enhance the efficiency and cost-effectiveness of green hydrogen production. Researchers aim to optimize electrolysis processes that utilize HCl as an electrolyte, striving to achieve higher hydrogen yields while minimizing energy input. Additionally, there is a concerted effort to develop more durable and corrosion-resistant materials that can withstand the harsh acidic environment created by HCl in these systems.

Another crucial goal is to integrate HCl-based technologies seamlessly into existing renewable energy infrastructures. This includes developing scalable solutions that can be implemented in both centralized and decentralized energy systems, as well as creating efficient methods for HCl recycling and regeneration to minimize environmental impact and resource consumption.

The renewable energy sector's growing interest in HCl is also driven by its potential to address intermittency issues associated with solar and wind power. HCl-based energy storage systems, such as flow batteries, are being explored as a means to store excess energy during peak production periods and release it during times of high demand or low renewable energy generation.

As we look towards the future, the technological objectives for HCl in renewable energy extend beyond its current applications. Researchers are investigating novel uses for HCl in areas such as thermal energy storage, advanced materials production for solar panels, and even in direct solar-to-fuel conversion processes. These ambitious goals reflect the broader trend towards creating a more diverse and resilient renewable energy ecosystem, with HCl playing a pivotal role in enabling new technologies and enhancing existing ones.

The technological trajectory of HCl in renewable energy has been marked by continuous innovation and refinement. Initially, its use was limited to small-scale laboratory experiments, but over the past two decades, it has transitioned into large-scale industrial applications. This progression has been driven by advancements in materials science, process engineering, and a deeper understanding of electrochemical reactions involving HCl.

One of the primary objectives in the development of HCl-based renewable energy technologies is to enhance the efficiency and cost-effectiveness of green hydrogen production. Researchers aim to optimize electrolysis processes that utilize HCl as an electrolyte, striving to achieve higher hydrogen yields while minimizing energy input. Additionally, there is a concerted effort to develop more durable and corrosion-resistant materials that can withstand the harsh acidic environment created by HCl in these systems.

Another crucial goal is to integrate HCl-based technologies seamlessly into existing renewable energy infrastructures. This includes developing scalable solutions that can be implemented in both centralized and decentralized energy systems, as well as creating efficient methods for HCl recycling and regeneration to minimize environmental impact and resource consumption.

The renewable energy sector's growing interest in HCl is also driven by its potential to address intermittency issues associated with solar and wind power. HCl-based energy storage systems, such as flow batteries, are being explored as a means to store excess energy during peak production periods and release it during times of high demand or low renewable energy generation.

As we look towards the future, the technological objectives for HCl in renewable energy extend beyond its current applications. Researchers are investigating novel uses for HCl in areas such as thermal energy storage, advanced materials production for solar panels, and even in direct solar-to-fuel conversion processes. These ambitious goals reflect the broader trend towards creating a more diverse and resilient renewable energy ecosystem, with HCl playing a pivotal role in enabling new technologies and enhancing existing ones.

Market Analysis for HCl in Green Energy Applications

The market for hydrochloric acid (HCl) in green energy applications is experiencing significant growth, driven by the increasing adoption of renewable energy technologies and the push for sustainable industrial processes. The demand for HCl in this sector is primarily fueled by its use in the production of solar panels, wind turbines, and energy storage systems.

In the solar energy industry, HCl plays a crucial role in the manufacturing of high-purity silicon, a key component of photovoltaic cells. As the global solar energy capacity continues to expand, the demand for HCl in this segment is expected to grow proportionally. The wind energy sector also utilizes HCl in the production of composite materials for turbine blades, contributing to the overall market demand.

The energy storage market, particularly in the development of advanced batteries, represents another significant growth area for HCl. Its use in the production of electrolytes and electrode materials for lithium-ion batteries and other emerging energy storage technologies is driving demand in this segment.

Geographically, Asia-Pacific dominates the market for HCl in green energy applications, with China leading in both production and consumption. This is largely due to the country's dominant position in solar panel manufacturing and its rapidly growing renewable energy sector. Europe and North America follow, with increasing investments in renewable energy infrastructure driving demand in these regions.

The market is characterized by a mix of large chemical companies and specialized producers. Key players are focusing on developing high-purity HCl products specifically tailored for renewable energy applications, as the quality requirements in this sector are particularly stringent.

Pricing trends in the HCl market for green energy applications are influenced by factors such as raw material costs, energy prices, and supply-demand dynamics. The market has seen some volatility in recent years due to fluctuations in chlorine production, a primary source of HCl.

Looking ahead, the market for HCl in green energy applications is projected to continue its growth trajectory. This expansion is supported by global initiatives to reduce carbon emissions and increase renewable energy capacity. However, the market also faces challenges, including environmental concerns related to HCl production and handling, as well as the development of alternative technologies that may reduce HCl usage in certain applications.

Overall, the market analysis indicates a positive outlook for HCl in green energy applications, with opportunities for innovation in production methods and product formulations to meet the evolving needs of the renewable energy sector.

In the solar energy industry, HCl plays a crucial role in the manufacturing of high-purity silicon, a key component of photovoltaic cells. As the global solar energy capacity continues to expand, the demand for HCl in this segment is expected to grow proportionally. The wind energy sector also utilizes HCl in the production of composite materials for turbine blades, contributing to the overall market demand.

The energy storage market, particularly in the development of advanced batteries, represents another significant growth area for HCl. Its use in the production of electrolytes and electrode materials for lithium-ion batteries and other emerging energy storage technologies is driving demand in this segment.

Geographically, Asia-Pacific dominates the market for HCl in green energy applications, with China leading in both production and consumption. This is largely due to the country's dominant position in solar panel manufacturing and its rapidly growing renewable energy sector. Europe and North America follow, with increasing investments in renewable energy infrastructure driving demand in these regions.

The market is characterized by a mix of large chemical companies and specialized producers. Key players are focusing on developing high-purity HCl products specifically tailored for renewable energy applications, as the quality requirements in this sector are particularly stringent.

Pricing trends in the HCl market for green energy applications are influenced by factors such as raw material costs, energy prices, and supply-demand dynamics. The market has seen some volatility in recent years due to fluctuations in chlorine production, a primary source of HCl.

Looking ahead, the market for HCl in green energy applications is projected to continue its growth trajectory. This expansion is supported by global initiatives to reduce carbon emissions and increase renewable energy capacity. However, the market also faces challenges, including environmental concerns related to HCl production and handling, as well as the development of alternative technologies that may reduce HCl usage in certain applications.

Overall, the market analysis indicates a positive outlook for HCl in green energy applications, with opportunities for innovation in production methods and product formulations to meet the evolving needs of the renewable energy sector.

Current Challenges in HCl Utilization for Renewable Energy

The utilization of hydrochloric acid (HCl) in renewable energy applications faces several significant challenges that hinder its widespread adoption and efficiency. One of the primary obstacles is the corrosive nature of HCl, which poses substantial risks to equipment and infrastructure. This corrosiveness necessitates the use of specialized materials and protective coatings, significantly increasing the costs associated with HCl-based renewable energy systems.

Another major challenge lies in the storage and transportation of HCl. Due to its hazardous properties, strict safety protocols and specialized containment systems are required, adding complexity and expense to the supply chain. This issue becomes particularly pronounced when considering large-scale renewable energy projects that may require substantial quantities of HCl.

The environmental impact of HCl production and use in renewable energy applications also presents a significant challenge. While HCl itself is not a greenhouse gas, its production often involves energy-intensive processes that can contribute to carbon emissions. Balancing the environmental benefits of renewable energy with the potential negative impacts of HCl production remains a complex issue for the industry.

Furthermore, the variability in HCl quality and concentration from different sources can affect its performance in renewable energy applications. Ensuring consistent purity and concentration levels is crucial for maintaining efficiency and reliability in energy production processes, but achieving this consistency across diverse supply chains can be challenging.

The regulatory landscape surrounding HCl use in renewable energy is another area of concern. Varying regulations across different regions and countries can complicate the implementation of HCl-based technologies on a global scale. Compliance with these diverse regulatory frameworks often requires significant resources and can slow down the adoption of innovative solutions.

Additionally, there is a lack of standardized practices and technologies for HCl recycling and disposal in renewable energy applications. Developing efficient and cost-effective methods for recovering and reusing HCl is essential for improving the sustainability and economic viability of these systems.

Lastly, the integration of HCl-based technologies with existing renewable energy infrastructure presents technical challenges. Adapting current systems to accommodate HCl utilization often requires significant modifications and investments, which can be a barrier for many energy providers and project developers.

Another major challenge lies in the storage and transportation of HCl. Due to its hazardous properties, strict safety protocols and specialized containment systems are required, adding complexity and expense to the supply chain. This issue becomes particularly pronounced when considering large-scale renewable energy projects that may require substantial quantities of HCl.

The environmental impact of HCl production and use in renewable energy applications also presents a significant challenge. While HCl itself is not a greenhouse gas, its production often involves energy-intensive processes that can contribute to carbon emissions. Balancing the environmental benefits of renewable energy with the potential negative impacts of HCl production remains a complex issue for the industry.

Furthermore, the variability in HCl quality and concentration from different sources can affect its performance in renewable energy applications. Ensuring consistent purity and concentration levels is crucial for maintaining efficiency and reliability in energy production processes, but achieving this consistency across diverse supply chains can be challenging.

The regulatory landscape surrounding HCl use in renewable energy is another area of concern. Varying regulations across different regions and countries can complicate the implementation of HCl-based technologies on a global scale. Compliance with these diverse regulatory frameworks often requires significant resources and can slow down the adoption of innovative solutions.

Additionally, there is a lack of standardized practices and technologies for HCl recycling and disposal in renewable energy applications. Developing efficient and cost-effective methods for recovering and reusing HCl is essential for improving the sustainability and economic viability of these systems.

Lastly, the integration of HCl-based technologies with existing renewable energy infrastructure presents technical challenges. Adapting current systems to accommodate HCl utilization often requires significant modifications and investments, which can be a barrier for many energy providers and project developers.

Existing HCl Applications in Renewable Energy Systems

01 Production and purification of hydrochloric acid

Various methods and processes for producing and purifying hydrochloric acid are described. These include techniques for improving the efficiency of production, reducing impurities, and optimizing the concentration of the acid. The processes may involve specialized equipment or chemical reactions to achieve high-quality hydrochloric acid for industrial or laboratory use.- Production methods of hydrochloric acid: Various methods are employed to produce hydrochloric acid, including the reaction of chlorine with hydrogen, the chlorination of hydrocarbons, and as a byproduct in chemical processes. These production methods aim to optimize yield and purity while minimizing environmental impact.

- Purification and concentration of hydrochloric acid: Techniques for purifying and concentrating hydrochloric acid involve distillation, membrane separation, and adsorption processes. These methods are crucial for obtaining high-purity acid suitable for industrial and laboratory applications, as well as for recycling and reusing the acid in various processes.

- Applications of hydrochloric acid in chemical processes: Hydrochloric acid is widely used in various chemical processes, including metal treatment, pH adjustment, and as a catalyst in organic synthesis. Its versatility makes it an essential reagent in industries such as petrochemicals, pharmaceuticals, and water treatment.

- Safety and handling of hydrochloric acid: Proper safety measures and handling procedures are crucial when working with hydrochloric acid due to its corrosive nature. This includes the use of appropriate personal protective equipment, storage in compatible containers, and implementation of spill containment systems to prevent accidents and environmental contamination.

- Recovery and recycling of hydrochloric acid: Efficient methods for recovering and recycling hydrochloric acid from industrial processes have been developed to reduce waste and improve sustainability. These techniques often involve absorption, stripping, and purification steps to reclaim the acid for reuse in various applications.

02 Applications of hydrochloric acid in chemical processes

Hydrochloric acid is widely used in various chemical processes and industrial applications. It serves as a key reagent in reactions, pH adjustment, metal treatment, and as a catalyst in organic synthesis. The versatility of hydrochloric acid makes it an essential component in many manufacturing and processing operations across different industries.Expand Specific Solutions03 Handling and storage of hydrochloric acid

Specialized equipment and methods for handling, storing, and transporting hydrochloric acid are crucial due to its corrosive nature. This includes the design of acid-resistant containers, safety measures for personnel, and systems for controlling emissions or spills. Proper handling and storage techniques are essential to ensure workplace safety and environmental protection.Expand Specific Solutions04 Recovery and recycling of hydrochloric acid

Processes for recovering and recycling hydrochloric acid from industrial waste streams or byproducts are developed to improve efficiency and reduce environmental impact. These methods may involve separation techniques, chemical treatments, or specialized equipment to purify and concentrate the acid for reuse in various applications.Expand Specific Solutions05 Environmental and safety considerations for hydrochloric acid use

Addressing environmental concerns and safety issues related to hydrochloric acid use is crucial. This includes developing methods for neutralization, treatment of acid waste, emission control, and implementing safety protocols. Innovations in this area focus on minimizing the environmental impact of hydrochloric acid and ensuring safe handling practices in industrial settings.Expand Specific Solutions

Key Players in HCl and Renewable Energy Industries

The hydrochloric acid market in renewable energy is in an emerging phase, with growing potential as the industry expands. The market size is expected to increase significantly due to the rising demand for clean energy solutions. Technologically, the field is evolving rapidly, with companies like Fluid Energy Group and BASF Corp. leading innovation in environmentally friendly hydrochloric acid production. Research institutions such as The University of Queensland and Shanghai Maritime University are contributing to advancements in this area. Established chemical giants like China Petroleum & Chemical Corp. and Air Liquide SA are also investing in renewable energy applications, indicating a competitive landscape with diverse players from both industry and academia.

BASF Corp.

Technical Solution: BASF has developed innovative processes for utilizing hydrochloric acid in renewable energy applications. Their approach focuses on using HCl in the production of high-purity silicon for solar panels, improving efficiency and reducing costs. BASF's proprietary chlorosilane process uses HCl to convert metallurgical-grade silicon into solar-grade silicon, achieving up to 99.9999% purity[1]. Additionally, BASF is exploring the use of HCl in advanced battery technologies, particularly for flow batteries in grid-scale energy storage systems. Their research indicates that HCl-based electrolytes can significantly enhance the energy density and cycle life of these batteries[2].

Strengths: Established expertise in chemical processes, extensive R&D capabilities, and global market presence. Weaknesses: High capital investment required for new process implementation, potential environmental concerns with HCl handling.

Air Liquide SA

Technical Solution: Air Liquide is pioneering the use of hydrochloric acid in hydrogen production for renewable energy applications. Their innovative approach involves using HCl in the chlor-alkali process to produce hydrogen as a byproduct, which can then be used in fuel cells or for energy storage. The company has developed a proprietary membrane technology that enhances the efficiency of this process, reducing energy consumption by up to 30% compared to traditional methods[3]. Furthermore, Air Liquide is investigating the potential of HCl in geothermal energy extraction, where it can be used to dissolve minerals and improve well productivity[4].

Strengths: Strong expertise in gas technologies, established infrastructure for hydrogen production and distribution. Weaknesses: Dependence on chlor-alkali industry dynamics, potential safety concerns with large-scale HCl handling.

Innovative HCl Technologies for Green Energy Solutions

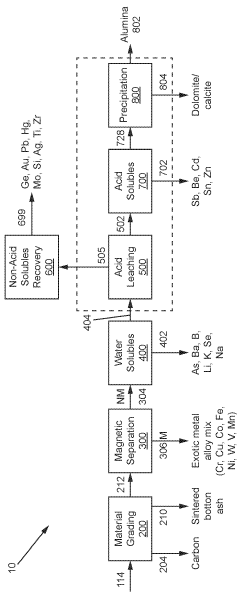

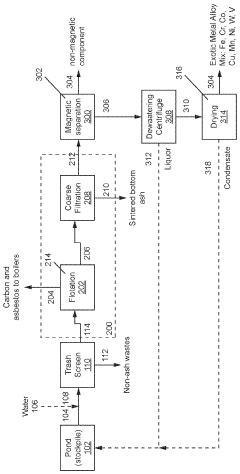

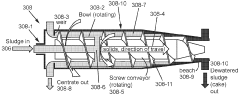

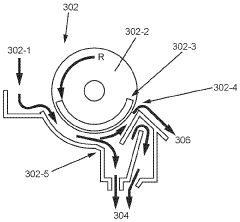

Recovery of alumina from coal ash

PatentWO2023245244A1

Innovation

- A comprehensive process involving magnetic separation, water-soluble component recovery, and alumina recovery stages, which includes acid solubles separation and precipitation, to render coal ash non-toxic and recover valuable products like alumina, metals, and metalloids, while stabilizing toxic elements for safe disposal or sale.

Using non-regulated synthetic acid compositions as alternatives to conventional acids in the oil and gas industry

PatentActiveUS20160347994A1

Innovation

- A synthetic acid composition comprising urea and methanesulphonic acid in a specific molar ratio, optionally with a metal iodide or iodate, and an alkynyl alcohol derivative, which reduces corrosion rates, is non-toxic, and exhibits stability at elevated temperatures, allowing for controlled reactions and biodegradability.

Environmental Impact of HCl Use in Green Energy

The use of hydrochloric acid (HCl) in renewable energy technologies presents both opportunities and challenges from an environmental perspective. While HCl plays a crucial role in various green energy applications, its production, handling, and disposal require careful consideration to minimize ecological impacts.

One of the primary environmental concerns associated with HCl use in renewable energy is its potential for air pollution. When released into the atmosphere, HCl can contribute to acid rain formation, which negatively affects ecosystems, water bodies, and infrastructure. To mitigate this risk, stringent emission control measures and proper ventilation systems are essential in facilities utilizing HCl for renewable energy processes.

Water pollution is another significant environmental issue related to HCl use. Improper disposal or accidental spills can lead to the contamination of water sources, affecting aquatic life and potentially entering the human water supply. Implementing robust waste management protocols and investing in advanced treatment technologies are crucial steps in preventing water pollution incidents.

The production of HCl itself has environmental implications. Traditional methods of HCl production often involve energy-intensive processes and the use of fossil fuels, which can offset some of the environmental benefits gained from its application in renewable energy. Developing more sustainable production methods, such as utilizing waste streams from other industrial processes, could help reduce the overall environmental footprint of HCl use in green energy.

On the positive side, HCl plays a vital role in enhancing the efficiency and sustainability of various renewable energy technologies. For instance, in geothermal energy production, HCl is used to clean and maintain wells, improving energy output and extending the lifespan of facilities. This increased efficiency can lead to a net positive environmental impact by reducing the need for additional energy sources and minimizing resource extraction.

In the context of solar panel manufacturing, HCl is employed in the production of high-purity silicon, a key component of photovoltaic cells. While this process does have environmental considerations, the long-term benefits of increased solar energy adoption can outweigh the initial impacts, provided that proper safeguards and sustainable practices are in place.

The recycling and recovery of HCl in renewable energy applications present opportunities for reducing environmental impact. Closed-loop systems that capture and reuse HCl can significantly decrease waste generation and the need for new acid production. Additionally, advancements in green chemistry are leading to the development of less hazardous alternatives or more environmentally friendly processes that could potentially replace or reduce HCl use in certain applications.

As the renewable energy sector continues to grow, it is crucial to balance the benefits of HCl use with its potential environmental risks. Ongoing research and development efforts should focus on optimizing HCl utilization, improving safety measures, and exploring more sustainable alternatives. By addressing these environmental challenges proactively, the renewable energy industry can maximize the positive impact of HCl while minimizing its ecological footprint.

One of the primary environmental concerns associated with HCl use in renewable energy is its potential for air pollution. When released into the atmosphere, HCl can contribute to acid rain formation, which negatively affects ecosystems, water bodies, and infrastructure. To mitigate this risk, stringent emission control measures and proper ventilation systems are essential in facilities utilizing HCl for renewable energy processes.

Water pollution is another significant environmental issue related to HCl use. Improper disposal or accidental spills can lead to the contamination of water sources, affecting aquatic life and potentially entering the human water supply. Implementing robust waste management protocols and investing in advanced treatment technologies are crucial steps in preventing water pollution incidents.

The production of HCl itself has environmental implications. Traditional methods of HCl production often involve energy-intensive processes and the use of fossil fuels, which can offset some of the environmental benefits gained from its application in renewable energy. Developing more sustainable production methods, such as utilizing waste streams from other industrial processes, could help reduce the overall environmental footprint of HCl use in green energy.

On the positive side, HCl plays a vital role in enhancing the efficiency and sustainability of various renewable energy technologies. For instance, in geothermal energy production, HCl is used to clean and maintain wells, improving energy output and extending the lifespan of facilities. This increased efficiency can lead to a net positive environmental impact by reducing the need for additional energy sources and minimizing resource extraction.

In the context of solar panel manufacturing, HCl is employed in the production of high-purity silicon, a key component of photovoltaic cells. While this process does have environmental considerations, the long-term benefits of increased solar energy adoption can outweigh the initial impacts, provided that proper safeguards and sustainable practices are in place.

The recycling and recovery of HCl in renewable energy applications present opportunities for reducing environmental impact. Closed-loop systems that capture and reuse HCl can significantly decrease waste generation and the need for new acid production. Additionally, advancements in green chemistry are leading to the development of less hazardous alternatives or more environmentally friendly processes that could potentially replace or reduce HCl use in certain applications.

As the renewable energy sector continues to grow, it is crucial to balance the benefits of HCl use with its potential environmental risks. Ongoing research and development efforts should focus on optimizing HCl utilization, improving safety measures, and exploring more sustainable alternatives. By addressing these environmental challenges proactively, the renewable energy industry can maximize the positive impact of HCl while minimizing its ecological footprint.

Economic Feasibility of HCl-based Renewable Energy Solutions

The economic feasibility of HCl-based renewable energy solutions is a critical factor in determining their potential for widespread adoption and implementation. This analysis considers various aspects of the economic landscape surrounding these technologies, including production costs, market demand, and potential returns on investment.

One of the primary advantages of HCl-based renewable energy solutions is the abundance and relatively low cost of hydrochloric acid as a raw material. HCl is a byproduct of many industrial processes, making it readily available and potentially cost-effective for energy applications. However, the economic viability of these solutions also depends on the efficiency of energy conversion processes and the scale of implementation.

Initial capital costs for HCl-based renewable energy systems may be substantial, particularly for large-scale installations. These costs include equipment for acid storage, handling, and energy conversion, as well as safety measures and environmental protection systems. However, the long-term operational costs could be significantly lower compared to traditional fossil fuel-based energy production, especially if the HCl is sourced as a waste product from other industries.

The economic feasibility is also influenced by the energy market dynamics and regulatory environment. As governments worldwide push for cleaner energy sources, incentives and subsidies for renewable technologies could improve the economic outlook for HCl-based solutions. Additionally, carbon pricing mechanisms and emissions trading schemes may further enhance their competitiveness against conventional energy sources.

Market demand for HCl-based renewable energy is likely to grow as industries and consumers seek more sustainable energy options. This increased demand could drive economies of scale, potentially reducing production costs and improving overall economic feasibility. However, the technology must demonstrate reliability and scalability to attract significant investment and market share.

The return on investment (ROI) for HCl-based renewable energy projects will depend on factors such as energy output efficiency, maintenance requirements, and the lifespan of the systems. While initial ROI may be lower compared to established renewable technologies like solar or wind, the potential for improvement through technological advancements and optimization could enhance long-term economic viability.

In conclusion, while HCl-based renewable energy solutions show promise from an economic standpoint, their feasibility will ultimately depend on continued technological innovation, supportive policy frameworks, and successful demonstration of large-scale implementation. As research progresses and pilot projects provide more data, a clearer picture of the economic potential of these solutions will emerge, potentially paving the way for their integration into the global renewable energy landscape.

One of the primary advantages of HCl-based renewable energy solutions is the abundance and relatively low cost of hydrochloric acid as a raw material. HCl is a byproduct of many industrial processes, making it readily available and potentially cost-effective for energy applications. However, the economic viability of these solutions also depends on the efficiency of energy conversion processes and the scale of implementation.

Initial capital costs for HCl-based renewable energy systems may be substantial, particularly for large-scale installations. These costs include equipment for acid storage, handling, and energy conversion, as well as safety measures and environmental protection systems. However, the long-term operational costs could be significantly lower compared to traditional fossil fuel-based energy production, especially if the HCl is sourced as a waste product from other industries.

The economic feasibility is also influenced by the energy market dynamics and regulatory environment. As governments worldwide push for cleaner energy sources, incentives and subsidies for renewable technologies could improve the economic outlook for HCl-based solutions. Additionally, carbon pricing mechanisms and emissions trading schemes may further enhance their competitiveness against conventional energy sources.

Market demand for HCl-based renewable energy is likely to grow as industries and consumers seek more sustainable energy options. This increased demand could drive economies of scale, potentially reducing production costs and improving overall economic feasibility. However, the technology must demonstrate reliability and scalability to attract significant investment and market share.

The return on investment (ROI) for HCl-based renewable energy projects will depend on factors such as energy output efficiency, maintenance requirements, and the lifespan of the systems. While initial ROI may be lower compared to established renewable technologies like solar or wind, the potential for improvement through technological advancements and optimization could enhance long-term economic viability.

In conclusion, while HCl-based renewable energy solutions show promise from an economic standpoint, their feasibility will ultimately depend on continued technological innovation, supportive policy frameworks, and successful demonstration of large-scale implementation. As research progresses and pilot projects provide more data, a clearer picture of the economic potential of these solutions will emerge, potentially paving the way for their integration into the global renewable energy landscape.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!