Zirconia in Thermal Barrier Coatings: Innovative Strategies

Zirconia TBC Evolution

The evolution of Zirconia Thermal Barrier Coatings (TBCs) represents a significant advancement in high-temperature materials technology. Initially developed in the 1970s, Zirconia TBCs have undergone continuous refinement to meet the ever-increasing demands of gas turbine engines and other high-temperature applications.

In the early stages, the focus was on developing stable Zirconia compositions that could withstand extreme thermal cycling. The introduction of Yttria-stabilized Zirconia (YSZ) marked a crucial milestone, providing enhanced phase stability and improved thermal insulation properties. This development allowed for higher operating temperatures in turbine engines, leading to increased efficiency and performance.

The 1980s and 1990s saw significant advancements in deposition techniques. Electron Beam Physical Vapor Deposition (EB-PVD) emerged as a preferred method for applying TBCs, producing columnar microstructures that offered superior strain tolerance and durability. Concurrently, improvements in plasma spraying techniques enabled more cost-effective TBC applications for a broader range of components.

As the understanding of failure mechanisms deepened, researchers began to focus on enhancing the durability and reliability of Zirconia TBCs. This led to the development of multi-layer coating systems and the incorporation of additional elements to improve oxidation resistance and reduce sintering rates. The early 2000s saw the introduction of rare-earth doped Zirconia coatings, which demonstrated enhanced thermal cycling performance and reduced thermal conductivity.

Recent years have witnessed a shift towards nanostructured Zirconia TBCs. These coatings exhibit significantly lower thermal conductivity and improved mechanical properties compared to their conventional counterparts. Additionally, researchers have explored novel compositions, such as gadolinium zirconate and lanthanum zirconate, which offer potential advantages in terms of phase stability and resistance to calcium-magnesium-alumino-silicate (CMAS) infiltration.

The ongoing evolution of Zirconia TBCs is driven by the need for higher operating temperatures, longer component lifetimes, and improved reliability. Current research focuses on developing smart TBC systems with self-healing capabilities, as well as exploring the potential of functionally graded coatings to optimize performance across varying operational conditions.

As we look to the future, the integration of advanced manufacturing techniques, such as additive manufacturing, promises to revolutionize the design and application of Zirconia TBCs. These innovations may enable the creation of complex coating architectures with tailored properties, further pushing the boundaries of high-temperature materials technology.

Market Demand Analysis

The market demand for innovative strategies in Zirconia-based Thermal Barrier Coatings (TBCs) has been steadily increasing, driven by the growing need for high-performance materials in extreme temperature environments. The aerospace industry, particularly in the gas turbine engine sector, remains the primary driver of this demand. As aircraft engines continue to push the boundaries of operational temperatures to improve fuel efficiency and reduce emissions, the need for advanced TBCs becomes more critical.

The automotive sector is emerging as a significant market for Zirconia TBCs, especially in high-performance and racing vehicles. The application of these coatings in exhaust systems and engine components helps improve thermal management and overall engine efficiency. This trend is expected to expand into mainstream automotive production as manufacturers seek ways to meet stringent emissions standards and improve fuel economy.

In the energy sector, the demand for Zirconia TBCs is growing in power generation applications, particularly in gas turbines for electricity production. As the global focus shifts towards cleaner energy sources, the efficiency improvements offered by advanced TBCs become increasingly valuable. The ability of these coatings to withstand higher operating temperatures allows for more efficient combustion processes, reducing fuel consumption and emissions.

The industrial sector presents another expanding market for Zirconia TBCs. Applications in furnaces, chemical processing equipment, and other high-temperature industrial environments are driving demand for more durable and efficient thermal barrier solutions. The ability of Zirconia-based coatings to protect underlying materials from thermal degradation and corrosion is particularly valuable in these harsh operating conditions.

Market analysts project a compound annual growth rate (CAGR) for the global thermal barrier coatings market, with Zirconia-based coatings representing a significant portion of this growth. The increasing focus on material longevity, energy efficiency, and environmental regulations across various industries is expected to sustain this growth trajectory.

However, the market also faces challenges. The high cost of advanced Zirconia TBCs and the complexity of their application processes can be barriers to widespread adoption, particularly in cost-sensitive industries. Additionally, the ongoing research into alternative materials and coating technologies could potentially disrupt the current market dynamics for Zirconia-based TBCs.

Despite these challenges, the overall market outlook for innovative Zirconia TBC strategies remains positive. The continuous push for higher operating temperatures in various applications, coupled with the need for improved durability and efficiency, ensures a strong and growing demand for advanced Zirconia-based thermal barrier coating solutions across multiple industries.

Current Challenges

Zirconia-based thermal barrier coatings (TBCs) face several significant challenges in their current applications and development. One of the primary issues is the limited temperature capability of these coatings. While zirconia TBCs have significantly improved the operating temperatures of gas turbines, they are approaching their thermal limits. The melting point of zirconia (around 2700°C) sets an upper bound on its effectiveness at extreme temperatures.

Another critical challenge is the thermal cycling durability of zirconia TBCs. The repeated heating and cooling cycles in turbine operations cause thermal stresses, leading to coating degradation and potential failure. This issue is exacerbated by the mismatch in thermal expansion coefficients between the ceramic top coat and the metallic substrate, resulting in spallation and reduced coating lifespan.

The sintering of zirconia at high temperatures poses another significant problem. Prolonged exposure to elevated temperatures causes densification of the coating, reducing its strain tolerance and thermal insulation properties. This sintering effect compromises the coating's ability to accommodate thermal stresses and maintain its protective function over time.

Oxygen permeability through the zirconia coating is an ongoing concern. Despite its protective nature, zirconia TBCs are not completely impermeable to oxygen. This allows for some oxidation of the underlying bond coat and substrate, potentially leading to coating failure and reduced component life.

The phase stability of zirconia under extreme conditions is another challenge. Zirconia undergoes phase transformations at different temperatures, which can lead to volume changes and structural instability. Maintaining the desired tetragonal phase throughout the operating temperature range is crucial for coating performance and longevity.

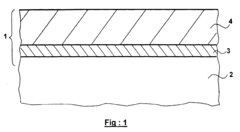

Erosion resistance is a persistent issue for zirconia TBCs, particularly in environments with particulate matter. The relatively soft nature of zirconia makes it susceptible to erosion damage from high-velocity particles, reducing coating thickness and effectiveness over time.

Lastly, the manufacturing and application processes for zirconia TBCs present their own set of challenges. Achieving consistent coating thickness, porosity, and microstructure across complex geometries remains difficult. Additionally, the high costs associated with advanced deposition techniques like electron beam physical vapor deposition (EB-PVD) limit widespread adoption in some industries.

Existing Zirconia TBCs

01 Zirconia-based thermal barrier coatings

Zirconia is widely used as a base material for thermal barrier coatings due to its excellent thermal insulation properties. These coatings are typically applied to components exposed to high temperatures, such as gas turbine engines, to protect the underlying substrate from heat damage. The coatings can be modified with various additives or stabilizers to enhance their performance and durability.- Zirconia-based thermal barrier coatings: Zirconia is widely used as a base material for thermal barrier coatings due to its excellent thermal insulation properties. These coatings are typically applied to components exposed to high temperatures, such as gas turbine engines, to protect the underlying substrate from heat damage. The coatings can be modified with various additives or stabilizers to enhance their performance and durability.

- Multi-layer thermal barrier systems: Advanced thermal barrier systems often employ multiple layers to optimize performance. These systems may include a bond coat, a ceramic top coat (often zirconia-based), and sometimes intermediate layers. Each layer serves a specific function, such as improving adhesion, providing thermal insulation, or enhancing durability. The multi-layer approach allows for tailored properties to meet specific application requirements.

- Deposition techniques for zirconia thermal barriers: Various deposition techniques are used to apply zirconia thermal barrier coatings, including plasma spraying, electron beam physical vapor deposition (EB-PVD), and sol-gel methods. Each technique offers different advantages in terms of coating microstructure, adhesion, and performance. The choice of deposition method can significantly impact the coating's thermal insulation properties and durability.

- Composition modifications for enhanced performance: Researchers continually explore modifications to zirconia-based thermal barrier compositions to enhance their performance. This includes doping with rare earth elements, creating composite structures, or developing novel ceramic formulations. These modifications aim to improve properties such as thermal cycling resistance, erosion resistance, and overall durability of the thermal barrier coatings.

- Testing and characterization of zirconia thermal barriers: Rigorous testing and characterization methods are essential for evaluating the performance of zirconia thermal barrier coatings. This includes thermal cycling tests, erosion resistance assessments, and microstructural analysis. Advanced characterization techniques such as electron microscopy and X-ray diffraction are used to understand the coating's structure and behavior under various conditions, helping to improve coating design and application processes.

02 Multi-layer thermal barrier systems

Advanced thermal barrier systems often employ multiple layers to optimize performance. These systems may include a bond coat, a ceramic top coat (often zirconia-based), and sometimes intermediate layers. Each layer serves a specific function, such as improving adhesion, providing thermal insulation, or enhancing durability. The multi-layer approach allows for tailored properties to meet specific application requirements.Expand Specific Solutions03 Deposition techniques for zirconia thermal barriers

Various deposition techniques are used to apply zirconia thermal barrier coatings, including plasma spraying, electron beam physical vapor deposition (EB-PVD), and sol-gel methods. Each technique offers different advantages in terms of coating microstructure, adhesion, and performance. The choice of deposition method can significantly impact the coating's thermal insulation properties and durability.Expand Specific Solutions04 Composition modifications for enhanced performance

Researchers continually explore modifications to zirconia-based thermal barrier compositions to enhance their performance. This includes doping with rare earth elements, creating composite structures, or developing novel ceramic compositions. These modifications aim to improve properties such as thermal cycling resistance, erosion resistance, and overall durability of the thermal barrier coatings.Expand Specific Solutions05 Testing and characterization of zirconia thermal barriers

Rigorous testing and characterization methods are essential for evaluating the performance of zirconia thermal barrier coatings. This includes thermal cycling tests, erosion resistance assessments, and microstructural analysis. Advanced techniques such as X-ray diffraction, electron microscopy, and thermal imaging are used to understand the coating's behavior under various conditions and to guide further improvements in coating design.Expand Specific Solutions

Key Industry Players

The development of innovative strategies for Zirconia in Thermal Barrier Coatings (TBCs) is in a mature yet evolving stage, with a growing market driven by aerospace and energy sectors. The global TBC market size is projected to reach significant growth, fueled by increasing demand for high-performance coatings. Technologically, the field is advancing rapidly, with companies like Praxair Technology, United Technologies Corp., and General Electric Company leading in research and development. Academic institutions such as Beihang University and Tsinghua University are contributing to fundamental research, while industry players like SNECMA SA and Mitsubishi Heavy Industries are focusing on practical applications. The competitive landscape is characterized by a mix of established aerospace giants and specialized materials companies, with ongoing efforts to enhance coating performance, durability, and cost-effectiveness.

SNECMA SA

Mitsubishi Heavy Industries, Ltd.

Core Zirconia Innovations

- A dispersion strengthened rare earth stabilized zirconia coating composition is formed by blending a first rare earth oxide stabilized zirconia powder with a second powder, such as yttria stabilized zirconia, ceria stabilized zirconia, or alumina, to enhance mechanical properties, with the rare earth oxide present in a minimum of 5.0 wt%, and deposited onto a substrate using techniques like plasma spraying.

- A new ceramic composition combining zirconia with dysprosium oxide, which stabilizes the zirconia and introduces point defects to reduce phonon thermal conductivity, is developed, along with a method involving a bonding sub-layer for deposition on superalloy parts.

Material Sustainability

The sustainability of zirconia in thermal barrier coatings (TBCs) is a critical consideration for long-term environmental and economic viability. Zirconia-based TBCs have demonstrated exceptional performance in high-temperature applications, particularly in gas turbine engines. However, their sustainability profile requires careful examination and innovative strategies for improvement.

One key aspect of zirconia's sustainability in TBCs is its durability and longevity. The extended lifespan of zirconia-based coatings reduces the frequency of replacement, thereby minimizing material consumption and waste generation. Ongoing research focuses on enhancing the thermal cycling resistance and erosion resistance of zirconia TBCs, which could further extend their operational life and improve overall sustainability.

The raw material sourcing for zirconia production presents both challenges and opportunities for sustainability. While zirconium is relatively abundant in the Earth's crust, its extraction and processing can have significant environmental impacts. Innovative strategies are being developed to optimize zirconia production processes, including the use of more environmentally friendly extraction methods and the exploration of alternative precursors.

Recycling and reuse of zirconia from spent TBCs is an emerging area of focus for improving material sustainability. Advanced recycling techniques are being investigated to recover zirconia from end-of-life components, potentially reducing the demand for virgin materials and minimizing waste. However, the complex nature of TBC systems, often involving multiple layers and contamination from service, presents technical challenges that require innovative solutions.

The energy efficiency of zirconia TBCs contributes significantly to their sustainability profile. By improving the thermal insulation of engine components, these coatings enable higher operating temperatures and increased engine efficiency. This translates to reduced fuel consumption and lower emissions over the lifecycle of the engine, aligning with broader sustainability goals in the aerospace and power generation sectors.

Innovative strategies for enhancing the sustainability of zirconia in TBCs include the development of nanostructured and functionally graded coatings. These advanced designs aim to optimize material usage while improving performance, potentially leading to thinner coatings with enhanced durability. Additionally, research into self-healing zirconia coatings shows promise for extending coating lifespans and reducing maintenance requirements.

The environmental impact of zirconia production and application in TBCs is an area requiring continued attention. Efforts are underway to reduce the carbon footprint of manufacturing processes, explore bio-inspired coating designs, and develop more environmentally benign deposition techniques. These initiatives aim to minimize the ecological impact of zirconia TBCs throughout their lifecycle, from production to disposal.

Performance Metrics

Performance metrics for zirconia-based thermal barrier coatings (TBCs) are crucial for evaluating their effectiveness and durability in high-temperature applications. The primary metrics include thermal conductivity, thermal expansion coefficient, phase stability, and erosion resistance.

Thermal conductivity is a key parameter, as TBCs are designed to reduce heat transfer to the underlying substrate. Zirconia-based coatings typically exhibit thermal conductivity values ranging from 1.0 to 2.0 W/mK at room temperature, with the goal of maintaining low conductivity at elevated temperatures. Advanced zirconia compositions and microstructural modifications aim to further reduce thermal conductivity, with some innovative strategies achieving values as low as 0.5 W/mK.

The thermal expansion coefficient of zirconia TBCs is another critical metric, as it affects the coating's ability to withstand thermal cycling without delamination. Ideally, the coefficient should closely match that of the metallic substrate to minimize thermal stresses. Yttria-stabilized zirconia (YSZ), a common TBC material, has a thermal expansion coefficient of approximately 10-11 × 10^-6 K^-1, which is compatible with many superalloy substrates.

Phase stability is essential for long-term performance of zirconia TBCs. The coating must maintain its desired crystal structure (typically tetragonal) throughout its operational temperature range to prevent detrimental phase transformations. Performance metrics related to phase stability include the temperature range of phase stability and the rate of phase transformation under cyclic thermal conditions.

Erosion resistance is a critical metric for TBCs exposed to particulate-laden gas streams. Zirconia-based coatings are evaluated based on their erosion rate, typically measured in grams of material lost per kilogram of erodent impact. Advanced zirconia compositions and microstructural designs aim to improve erosion resistance while maintaining other desirable properties.

Additional performance metrics for zirconia TBCs include bond strength, which measures the adhesion between the coating and the substrate, and thermal cycling resistance, which assesses the coating's ability to withstand repeated heating and cooling cycles without failure. These metrics are often evaluated through standardized testing procedures, such as furnace cycle tests and thermal shock tests, to simulate real-world operating conditions.