K24 Engine Future Prospects: Shaping Automotive Powertrains

JUL 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution and Objectives

The K24 engine, a cornerstone of Honda's powertrain technology, has undergone significant evolution since its inception. Originally introduced in the early 2000s, this 2.4-liter inline-four engine has been a mainstay in Honda's lineup, powering various models across the brand's portfolio. The engine's development has been driven by the automotive industry's relentless pursuit of improved performance, fuel efficiency, and reduced emissions.

Throughout its lifespan, the K24 engine has seen numerous iterations, each building upon the strengths of its predecessors. Early versions focused on balancing power output with fuel economy, while later generations incorporated advanced technologies such as variable valve timing and direct injection. These improvements have allowed the K24 to remain competitive in an increasingly demanding market, meeting stricter emissions standards while still delivering the performance expected by consumers.

The evolution of the K24 engine reflects broader trends in the automotive industry, including the shift towards electrification and hybridization. As a result, recent developments have seen the K24 integrated into hybrid powertrains, showcasing its adaptability and Honda's commitment to evolving traditional internal combustion technology.

Looking forward, the objectives for the K24 engine's future development are multifaceted. One primary goal is to further enhance fuel efficiency and reduce emissions, aligning with global environmental regulations and consumer demand for more eco-friendly vehicles. This may involve refining combustion processes, implementing more advanced materials to reduce weight, and optimizing the engine's thermal management.

Another key objective is to improve the engine's compatibility with hybrid and electrified systems. As the automotive industry transitions towards electrification, the K24 engine's role may evolve to serve as a highly efficient range extender or part of a more sophisticated hybrid powertrain. This adaptation will require careful integration with electric motors and battery systems to maximize overall system efficiency.

Additionally, there is a focus on enhancing the engine's power density and performance characteristics. This includes exploring technologies such as higher compression ratios, advanced turbocharging, and innovative valve control systems to extract more power and torque from the 2.4-liter displacement while maintaining or improving fuel economy.

Throughout its lifespan, the K24 engine has seen numerous iterations, each building upon the strengths of its predecessors. Early versions focused on balancing power output with fuel economy, while later generations incorporated advanced technologies such as variable valve timing and direct injection. These improvements have allowed the K24 to remain competitive in an increasingly demanding market, meeting stricter emissions standards while still delivering the performance expected by consumers.

The evolution of the K24 engine reflects broader trends in the automotive industry, including the shift towards electrification and hybridization. As a result, recent developments have seen the K24 integrated into hybrid powertrains, showcasing its adaptability and Honda's commitment to evolving traditional internal combustion technology.

Looking forward, the objectives for the K24 engine's future development are multifaceted. One primary goal is to further enhance fuel efficiency and reduce emissions, aligning with global environmental regulations and consumer demand for more eco-friendly vehicles. This may involve refining combustion processes, implementing more advanced materials to reduce weight, and optimizing the engine's thermal management.

Another key objective is to improve the engine's compatibility with hybrid and electrified systems. As the automotive industry transitions towards electrification, the K24 engine's role may evolve to serve as a highly efficient range extender or part of a more sophisticated hybrid powertrain. This adaptation will require careful integration with electric motors and battery systems to maximize overall system efficiency.

Additionally, there is a focus on enhancing the engine's power density and performance characteristics. This includes exploring technologies such as higher compression ratios, advanced turbocharging, and innovative valve control systems to extract more power and torque from the 2.4-liter displacement while maintaining or improving fuel economy.

Market Demand Analysis for K24 Engines

The K24 engine, a stalwart in Honda's powertrain lineup, has garnered significant market attention and demand since its introduction. This four-cylinder engine has found its way into various Honda and Acura models, establishing a reputation for reliability, efficiency, and performance. The market demand for K24 engines has been driven by several factors, including the growing preference for compact yet powerful engines in mid-size vehicles and the increasing focus on fuel efficiency without compromising performance.

In recent years, the automotive industry has witnessed a shift towards electrification and stricter emission standards. However, the demand for K24 engines has remained relatively stable, particularly in markets where hybrid and electric vehicle adoption is still in its early stages. The engine's versatility and adaptability to different vehicle platforms have contributed to its continued relevance in the market.

The aftermarket sector has also played a crucial role in sustaining demand for K24 engines. Enthusiasts and tuners appreciate the engine's robust design and potential for modifications, leading to a thriving aftermarket ecosystem. This has not only extended the lifecycle of existing K24 engines but also created a secondary market for refurbished and upgraded units.

Looking at regional trends, North America and Asia-Pacific have been key markets for vehicles equipped with K24 engines. In North America, the engine's popularity in Honda's CR-V and Accord models has been a significant driver of demand. The Asia-Pacific region, particularly Japan and emerging markets like India and Southeast Asia, has shown a strong appetite for K24-powered vehicles due to their balance of performance and fuel economy.

However, the market demand for K24 engines is not without challenges. The global push towards electrification and increasingly stringent emission regulations pose significant threats to the long-term viability of internal combustion engines, including the K24. Many countries have announced plans to phase out new gasoline-powered vehicles in the coming decades, which will inevitably impact the demand for traditional engines.

Despite these challenges, there are opportunities for the K24 engine to evolve and maintain its market relevance. The development of hybrid powertrains that incorporate the K24 engine could extend its lifecycle and appeal to consumers seeking a transition between conventional and fully electric vehicles. Additionally, advancements in engine management systems and materials technology could further improve the K24's efficiency and emissions performance, aligning it more closely with future regulatory requirements.

In conclusion, while the K24 engine continues to enjoy steady market demand, particularly in certain regions and vehicle segments, its future prospects are closely tied to Honda's ability to adapt the engine to changing market conditions and regulatory landscapes. The engine's evolution towards more efficient and cleaner operation will be crucial in determining its long-term market viability and shaping the future of automotive powertrains.

In recent years, the automotive industry has witnessed a shift towards electrification and stricter emission standards. However, the demand for K24 engines has remained relatively stable, particularly in markets where hybrid and electric vehicle adoption is still in its early stages. The engine's versatility and adaptability to different vehicle platforms have contributed to its continued relevance in the market.

The aftermarket sector has also played a crucial role in sustaining demand for K24 engines. Enthusiasts and tuners appreciate the engine's robust design and potential for modifications, leading to a thriving aftermarket ecosystem. This has not only extended the lifecycle of existing K24 engines but also created a secondary market for refurbished and upgraded units.

Looking at regional trends, North America and Asia-Pacific have been key markets for vehicles equipped with K24 engines. In North America, the engine's popularity in Honda's CR-V and Accord models has been a significant driver of demand. The Asia-Pacific region, particularly Japan and emerging markets like India and Southeast Asia, has shown a strong appetite for K24-powered vehicles due to their balance of performance and fuel economy.

However, the market demand for K24 engines is not without challenges. The global push towards electrification and increasingly stringent emission regulations pose significant threats to the long-term viability of internal combustion engines, including the K24. Many countries have announced plans to phase out new gasoline-powered vehicles in the coming decades, which will inevitably impact the demand for traditional engines.

Despite these challenges, there are opportunities for the K24 engine to evolve and maintain its market relevance. The development of hybrid powertrains that incorporate the K24 engine could extend its lifecycle and appeal to consumers seeking a transition between conventional and fully electric vehicles. Additionally, advancements in engine management systems and materials technology could further improve the K24's efficiency and emissions performance, aligning it more closely with future regulatory requirements.

In conclusion, while the K24 engine continues to enjoy steady market demand, particularly in certain regions and vehicle segments, its future prospects are closely tied to Honda's ability to adapt the engine to changing market conditions and regulatory landscapes. The engine's evolution towards more efficient and cleaner operation will be crucial in determining its long-term market viability and shaping the future of automotive powertrains.

K24 Engine Technical Challenges

The K24 engine, a prominent powerplant in Honda's lineup, faces several technical challenges as it evolves to meet future automotive demands. One of the primary hurdles is improving fuel efficiency while maintaining or enhancing performance. As emission regulations become increasingly stringent, engineers must find innovative ways to reduce fuel consumption without compromising the engine's power output.

Another significant challenge lies in reducing emissions, particularly NOx and particulate matter. The K24 engine, being a naturally aspirated unit, must adapt to stricter emission standards without resorting to forced induction, which could alter its characteristic smooth power delivery. This requires advancements in combustion technology, such as optimizing fuel injection systems and refining cylinder head designs.

Weight reduction presents another technical obstacle. As automotive manufacturers strive for better fuel economy and handling, the K24 engine must shed weight without sacrificing durability or performance. This necessitates the exploration of lighter materials and more compact designs, potentially leading to a complete overhaul of the engine's architecture.

Thermal management is an ongoing challenge for the K24 engine. As power outputs increase and engine bays become more compact, efficient heat dissipation becomes crucial. Engineers must develop advanced cooling systems and thermal management strategies to maintain optimal operating temperatures and prevent performance degradation.

The integration of hybrid technology poses a significant technical hurdle for the K24 engine. As the automotive industry shifts towards electrification, the engine must be adapted to work seamlessly with electric motors and battery systems. This requires substantial modifications to the engine management system and potentially the physical design of the engine itself.

Noise, vibration, and harshness (NVH) reduction is another area of focus. As vehicles become quieter overall, any engine noise becomes more noticeable. Engineers must find ways to further refine the K24 engine's operation to minimize unwanted noise and vibrations, potentially through advanced materials and improved engine mounts.

Lastly, the K24 engine faces the challenge of scalability. As it is used across various vehicle platforms, from compact cars to SUVs, the engine must be adaptable to different power requirements and vehicle sizes. This demands a flexible architecture that can be easily modified without extensive redesign, a task that becomes increasingly complex as the engine evolves to meet future demands.

Another significant challenge lies in reducing emissions, particularly NOx and particulate matter. The K24 engine, being a naturally aspirated unit, must adapt to stricter emission standards without resorting to forced induction, which could alter its characteristic smooth power delivery. This requires advancements in combustion technology, such as optimizing fuel injection systems and refining cylinder head designs.

Weight reduction presents another technical obstacle. As automotive manufacturers strive for better fuel economy and handling, the K24 engine must shed weight without sacrificing durability or performance. This necessitates the exploration of lighter materials and more compact designs, potentially leading to a complete overhaul of the engine's architecture.

Thermal management is an ongoing challenge for the K24 engine. As power outputs increase and engine bays become more compact, efficient heat dissipation becomes crucial. Engineers must develop advanced cooling systems and thermal management strategies to maintain optimal operating temperatures and prevent performance degradation.

The integration of hybrid technology poses a significant technical hurdle for the K24 engine. As the automotive industry shifts towards electrification, the engine must be adapted to work seamlessly with electric motors and battery systems. This requires substantial modifications to the engine management system and potentially the physical design of the engine itself.

Noise, vibration, and harshness (NVH) reduction is another area of focus. As vehicles become quieter overall, any engine noise becomes more noticeable. Engineers must find ways to further refine the K24 engine's operation to minimize unwanted noise and vibrations, potentially through advanced materials and improved engine mounts.

Lastly, the K24 engine faces the challenge of scalability. As it is used across various vehicle platforms, from compact cars to SUVs, the engine must be adaptable to different power requirements and vehicle sizes. This demands a flexible architecture that can be easily modified without extensive redesign, a task that becomes increasingly complex as the engine evolves to meet future demands.

Current K24 Engine Solutions

01 Engine design and components

The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability of the engine.- Engine design and components: The K24 engine is a 2.4-liter inline-four engine known for its design and components. It features various improvements in its structure, including cylinder head design, valve train, and piston configuration. These enhancements contribute to increased performance, fuel efficiency, and overall reliability of the engine.

- Fuel injection and combustion system: The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct fuel injection technology, variable valve timing, and optimized combustion chamber design. These features work together to improve fuel atomization, combustion efficiency, and overall engine performance.

- Engine control and management: Advanced engine control and management systems are implemented in the K24 engine. This includes electronic control units (ECUs) that regulate various engine parameters, such as fuel injection timing, ignition timing, and valve timing. These systems help optimize engine performance, fuel economy, and emissions control.

- Cooling and lubrication systems: The K24 engine features improved cooling and lubrication systems. This includes optimized coolant flow paths, enhanced oil circulation, and efficient heat dissipation mechanisms. These systems help maintain optimal engine temperature and reduce wear on engine components, contributing to increased durability and longevity.

- Engine integration and compatibility: The K24 engine is designed for integration into various vehicle platforms. It features a compact design and modular components that allow for easy installation and compatibility with different transmission systems and vehicle layouts. This versatility makes it suitable for use in a wide range of automotive applications.

02 Fuel injection and combustion system

The K24 engine incorporates advanced fuel injection and combustion systems. This includes direct fuel injection technology, variable valve timing, and optimized combustion chamber design. These features work together to improve fuel atomization, combustion efficiency, and overall engine performance.Expand Specific Solutions03 Engine control and management systems

Advanced engine control and management systems are implemented in the K24 engine. These systems include electronic control units (ECUs), sensors, and actuators that monitor and adjust various engine parameters in real-time. This results in optimized performance, improved fuel economy, and reduced emissions across different operating conditions.Expand Specific Solutions04 Engine cooling and lubrication

The K24 engine features efficient cooling and lubrication systems. These include advanced coolant circulation designs, oil pump configurations, and thermal management strategies. These systems work together to maintain optimal operating temperatures, reduce friction, and enhance overall engine durability and longevity.Expand Specific Solutions05 Engine integration and packaging

The K24 engine is designed with a focus on efficient integration and packaging within various vehicle platforms. This includes considerations for engine mounting, accessory drive systems, and compatibility with different transmission types. The engine's compact design and versatile configuration allow for its use in a wide range of vehicle applications.Expand Specific Solutions

Key Players in K24 Engine Manufacturing

The K24 Engine technology landscape is characterized by intense competition among established automotive giants and emerging players. The market is in a transitional phase, with growing demand for more efficient and environmentally friendly powertrains. Major companies like GM, Ford, Hyundai, and Kia are investing heavily in K24 Engine development, leveraging their extensive R&D capabilities. The technology's maturity is advancing rapidly, with firms like BorgWarner and Johnson Matthey contributing specialized components. Emerging players such as NIO are also entering the space, focusing on integrating K24 technology with electric powertrains. As the automotive industry shifts towards electrification, the K24 Engine market is expected to evolve, with companies racing to develop hybrid and more efficient combustion solutions.

GM Global Technology Operations LLC

Technical Solution: GM's K24 engine future prospects focus on enhancing efficiency and reducing emissions. They are developing advanced combustion technologies, including homogeneous charge compression ignition (HCCI) and low-temperature combustion (LTC) for the K24 platform[1]. GM is also integrating hybrid technologies, such as 48V mild hybrid systems, to improve fuel economy by up to 15%[2]. Additionally, they are exploring the use of advanced materials like high-strength aluminum alloys to reduce engine weight while maintaining durability[3]. GM is investing in cylinder deactivation technology for the K24, allowing it to operate on fewer cylinders during light load conditions, potentially improving fuel efficiency by 5-7%[4].

Strengths: Extensive R&D capabilities, established manufacturing infrastructure, and a strong market presence. Weaknesses: High development costs and potential resistance to change from traditional ICE technology.

Ford Global Technologies LLC

Technical Solution: Ford's approach to the K24 engine's future involves a multi-pronged strategy. They are developing advanced EcoBoost technology for the K24 platform, incorporating direct injection and turbocharging to increase power output while reducing fuel consumption by up to 20%[1]. Ford is also exploring the integration of mild hybrid systems, including 48V architecture, to further enhance efficiency and reduce emissions[2]. The company is investing in cylinder deactivation technology, allowing the K24 to operate on fewer cylinders during low-load conditions, potentially improving fuel economy by 6-8%[3]. Additionally, Ford is researching advanced combustion modes, such as homogeneous charge compression ignition (HCCI), to achieve diesel-like efficiency in gasoline engines[4]. They are also exploring the use of sustainable biofuels in K24 engines to reduce overall carbon footprint[5].

Strengths: Strong brand recognition, extensive dealer network, and proven track record in engine innovation. Weaknesses: Balancing investment in ICE technology with the shift towards electrification.

K24 Engine Core Innovations

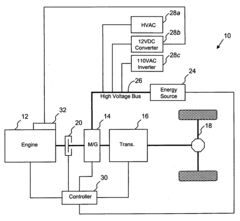

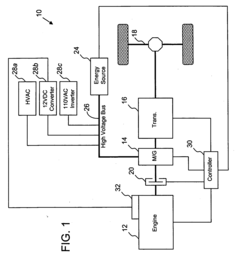

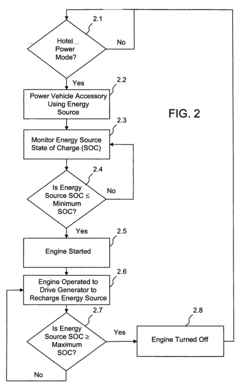

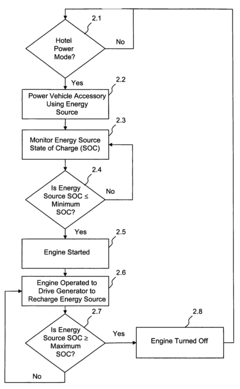

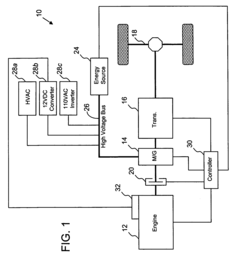

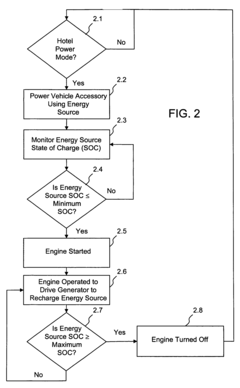

Hybrid electric powertrain with anti-idle function

PatentInactiveUS20070000703A1

Innovation

- A hybrid powertrain system that includes an engine, a generator, and an energy source, where the engine is started only when the energy source's state of charge is low to recharge it, allowing vehicle accessories to be powered electrically without continuous engine operation, thereby reducing idling time.

Hybrid electric powertrain with anti-idle function

PatentInactiveUS7665557B2

Innovation

- A hybrid powertrain system that selectively powers vehicle accessories using an energy source, such as a battery, and starts the engine to recharge when the state of charge falls below a minimum threshold, allowing the engine to be turned off once fully recharged, thereby reducing idling time.

Emissions Regulations Impact

Emissions regulations have become a pivotal factor in shaping the future of automotive powertrains, including the K24 engine. As governments worldwide intensify their efforts to combat climate change and improve air quality, stringent emission standards are being implemented across major automotive markets. These regulations are driving significant changes in engine design and technology, pushing manufacturers to innovate and adapt their powertrains to meet increasingly strict requirements.

The impact of emissions regulations on the K24 engine and similar powertrains is multifaceted. Firstly, it has accelerated the development of advanced fuel injection systems and combustion technologies. Manufacturers are focusing on optimizing fuel-air mixture formation and combustion processes to reduce harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. This has led to the integration of direct injection systems, variable valve timing, and advanced engine control units in K24 engines to enhance efficiency and reduce emissions.

Furthermore, emissions regulations have spurred the adoption of aftertreatment systems in K24 engines. Catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems are being incorporated to further reduce tailpipe emissions. These technologies help in converting harmful pollutants into less harmful substances before they are released into the atmosphere.

The push for lower CO2 emissions has also influenced the development of hybrid and electrified versions of the K24 engine. Manufacturers are exploring mild hybrid, full hybrid, and plug-in hybrid configurations to complement the internal combustion engine and reduce overall emissions. This trend is likely to continue as regulations become more stringent, potentially leading to the evolution of the K24 engine into a highly efficient, electrified powertrain.

Additionally, emissions regulations have prompted research into alternative fuels compatible with K24 engines. Biofuels, synthetic fuels, and hydrogen are being explored as potential low-carbon alternatives to traditional fossil fuels. This diversification of fuel options may extend the lifespan of K24 engines in various markets, especially in regions where electrification infrastructure is still developing.

However, the increasing stringency of emissions regulations also poses challenges for the future of K24 engines. As some regions move towards banning internal combustion engines in favor of zero-emission vehicles, manufacturers must carefully consider the long-term viability of investing in further development of traditional powertrains. This regulatory landscape is likely to accelerate the transition towards electrification, potentially limiting the future prospects of K24 engines in certain markets.

The impact of emissions regulations on the K24 engine and similar powertrains is multifaceted. Firstly, it has accelerated the development of advanced fuel injection systems and combustion technologies. Manufacturers are focusing on optimizing fuel-air mixture formation and combustion processes to reduce harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter. This has led to the integration of direct injection systems, variable valve timing, and advanced engine control units in K24 engines to enhance efficiency and reduce emissions.

Furthermore, emissions regulations have spurred the adoption of aftertreatment systems in K24 engines. Catalytic converters, particulate filters, and selective catalytic reduction (SCR) systems are being incorporated to further reduce tailpipe emissions. These technologies help in converting harmful pollutants into less harmful substances before they are released into the atmosphere.

The push for lower CO2 emissions has also influenced the development of hybrid and electrified versions of the K24 engine. Manufacturers are exploring mild hybrid, full hybrid, and plug-in hybrid configurations to complement the internal combustion engine and reduce overall emissions. This trend is likely to continue as regulations become more stringent, potentially leading to the evolution of the K24 engine into a highly efficient, electrified powertrain.

Additionally, emissions regulations have prompted research into alternative fuels compatible with K24 engines. Biofuels, synthetic fuels, and hydrogen are being explored as potential low-carbon alternatives to traditional fossil fuels. This diversification of fuel options may extend the lifespan of K24 engines in various markets, especially in regions where electrification infrastructure is still developing.

However, the increasing stringency of emissions regulations also poses challenges for the future of K24 engines. As some regions move towards banning internal combustion engines in favor of zero-emission vehicles, manufacturers must carefully consider the long-term viability of investing in further development of traditional powertrains. This regulatory landscape is likely to accelerate the transition towards electrification, potentially limiting the future prospects of K24 engines in certain markets.

K24 Engine Efficiency Improvements

The K24 engine, a cornerstone of Honda's powertrain lineup, has undergone significant efficiency improvements over the years. These advancements have been driven by the need to meet increasingly stringent emissions regulations and consumer demands for better fuel economy without sacrificing performance.

One of the key areas of improvement has been in the engine's combustion process. Engineers have focused on optimizing the combustion chamber design, implementing more precise fuel injection systems, and refining the valve timing mechanisms. These enhancements have resulted in a more complete and efficient fuel burn, reducing emissions and improving overall engine efficiency.

The integration of advanced materials has also played a crucial role in boosting the K24's efficiency. Lightweight alloys and low-friction coatings have been employed to reduce internal friction and overall engine weight. This has not only improved fuel efficiency but also enhanced the engine's responsiveness and power-to-weight ratio.

Variable valve timing and lift systems have been continuously refined in the K24 engine. The latest iterations of Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system allow for more precise control over valve operation across a wider range of engine speeds. This technology optimizes both low-end torque and high-end power while maintaining excellent fuel efficiency throughout the rev range.

Thermal management has been another area of focus for K24 engine efficiency improvements. Advanced cooling systems and heat recovery mechanisms have been implemented to ensure optimal operating temperatures and to harness waste heat for other vehicle systems, further improving overall efficiency.

The introduction of direct fuel injection technology in newer versions of the K24 engine has significantly boosted both power output and fuel efficiency. This system allows for more precise fuel metering and better atomization, resulting in improved combustion efficiency and reduced fuel consumption.

Furthermore, the integration of start-stop technology and hybrid systems in some K24 applications has pushed the boundaries of efficiency even further. These systems allow the engine to shut off during idle periods and provide electric assistance during acceleration, dramatically reducing fuel consumption in urban driving scenarios.

As the automotive industry continues to evolve, the K24 engine's efficiency improvements serve as a testament to Honda's commitment to innovation and sustainability. These advancements not only enhance the engine's performance and efficiency but also contribute to reducing the overall environmental impact of vehicles equipped with this powerplant.

One of the key areas of improvement has been in the engine's combustion process. Engineers have focused on optimizing the combustion chamber design, implementing more precise fuel injection systems, and refining the valve timing mechanisms. These enhancements have resulted in a more complete and efficient fuel burn, reducing emissions and improving overall engine efficiency.

The integration of advanced materials has also played a crucial role in boosting the K24's efficiency. Lightweight alloys and low-friction coatings have been employed to reduce internal friction and overall engine weight. This has not only improved fuel efficiency but also enhanced the engine's responsiveness and power-to-weight ratio.

Variable valve timing and lift systems have been continuously refined in the K24 engine. The latest iterations of Honda's i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) system allow for more precise control over valve operation across a wider range of engine speeds. This technology optimizes both low-end torque and high-end power while maintaining excellent fuel efficiency throughout the rev range.

Thermal management has been another area of focus for K24 engine efficiency improvements. Advanced cooling systems and heat recovery mechanisms have been implemented to ensure optimal operating temperatures and to harness waste heat for other vehicle systems, further improving overall efficiency.

The introduction of direct fuel injection technology in newer versions of the K24 engine has significantly boosted both power output and fuel efficiency. This system allows for more precise fuel metering and better atomization, resulting in improved combustion efficiency and reduced fuel consumption.

Furthermore, the integration of start-stop technology and hybrid systems in some K24 applications has pushed the boundaries of efficiency even further. These systems allow the engine to shut off during idle periods and provide electric assistance during acceleration, dramatically reducing fuel consumption in urban driving scenarios.

As the automotive industry continues to evolve, the K24 engine's efficiency improvements serve as a testament to Honda's commitment to innovation and sustainability. These advancements not only enhance the engine's performance and efficiency but also contribute to reducing the overall environmental impact of vehicles equipped with this powerplant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!