K24 Engine Tuning: Perfecting Air-Fuel Mixtures

JUL 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

K24 Engine Evolution

The K24 engine, a marvel of Honda's engineering prowess, has undergone significant evolution since its inception in 2001. Initially designed for the Honda Accord, this 2.4-liter inline-four engine has become a cornerstone of Honda's powertrain lineup, finding its way into various models across the Honda and Acura brands.

The K24's journey began with the K24A1 variant, which produced a modest 160 horsepower. As emissions regulations tightened and performance demands increased, Honda continuously refined the engine. The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology marked a significant milestone in the K24's evolution, allowing for improved fuel efficiency without sacrificing power.

Throughout its lifespan, the K24 has seen numerous iterations, each bringing incremental improvements. The K24A2 and K24A4 variants, for instance, incorporated balance shafts to reduce vibration, enhancing overall engine smoothness. The K24Z series, introduced in the mid-2000s, saw further refinements in valve timing and lift, resulting in increased power output and improved fuel economy.

One of the most significant leaps came with the K24W, which introduced direct fuel injection. This technology allowed for more precise fuel delivery, contributing to both power gains and emissions reductions. The latest K24V7 variant, found in vehicles like the 10th generation Honda Accord, represents the pinnacle of K24 development, boasting impressive power figures while meeting stringent emissions standards.

Throughout its evolution, the K24 engine has maintained its reputation for reliability and tunability. The aftermarket community has embraced the K24, developing a wide array of performance parts and tuning solutions. This has led to the engine becoming a popular choice for engine swaps and high-performance builds, further cementing its legacy in the automotive world.

The K24's evolution also reflects broader trends in engine development, such as the push for increased efficiency and reduced emissions. Honda's continuous refinement of the K24 demonstrates the company's commitment to meeting these challenges while still delivering engaging performance. As the automotive industry shifts towards electrification, the K24's journey serves as a testament to the enduring appeal and adaptability of internal combustion engines.

The K24's journey began with the K24A1 variant, which produced a modest 160 horsepower. As emissions regulations tightened and performance demands increased, Honda continuously refined the engine. The introduction of i-VTEC (intelligent Variable Valve Timing and Lift Electronic Control) technology marked a significant milestone in the K24's evolution, allowing for improved fuel efficiency without sacrificing power.

Throughout its lifespan, the K24 has seen numerous iterations, each bringing incremental improvements. The K24A2 and K24A4 variants, for instance, incorporated balance shafts to reduce vibration, enhancing overall engine smoothness. The K24Z series, introduced in the mid-2000s, saw further refinements in valve timing and lift, resulting in increased power output and improved fuel economy.

One of the most significant leaps came with the K24W, which introduced direct fuel injection. This technology allowed for more precise fuel delivery, contributing to both power gains and emissions reductions. The latest K24V7 variant, found in vehicles like the 10th generation Honda Accord, represents the pinnacle of K24 development, boasting impressive power figures while meeting stringent emissions standards.

Throughout its evolution, the K24 engine has maintained its reputation for reliability and tunability. The aftermarket community has embraced the K24, developing a wide array of performance parts and tuning solutions. This has led to the engine becoming a popular choice for engine swaps and high-performance builds, further cementing its legacy in the automotive world.

The K24's evolution also reflects broader trends in engine development, such as the push for increased efficiency and reduced emissions. Honda's continuous refinement of the K24 demonstrates the company's commitment to meeting these challenges while still delivering engaging performance. As the automotive industry shifts towards electrification, the K24's journey serves as a testament to the enduring appeal and adaptability of internal combustion engines.

Market Demand Analysis

The market demand for K24 engine tuning, particularly in perfecting air-fuel mixtures, has seen significant growth in recent years. This surge is driven by several factors, including the increasing popularity of Honda and Acura vehicles equipped with K24 engines, the growing aftermarket performance industry, and the rising interest in optimizing engine efficiency and power output.

The K24 engine, known for its reliability and potential for performance enhancement, has become a favorite among automotive enthusiasts and tuners. As emissions regulations tighten globally, there is a growing demand for tuning solutions that can improve engine performance while maintaining or even reducing emissions. This has led to a focus on perfecting air-fuel mixtures, which plays a crucial role in achieving both power gains and cleaner exhaust outputs.

The aftermarket performance industry has responded to this demand by developing a wide range of products and services specifically tailored for K24 engine tuning. These include programmable engine control units (ECUs), high-flow fuel injectors, advanced air intake systems, and specialized tuning software. The market for these products has expanded beyond traditional performance-oriented consumers to include everyday drivers seeking improved fuel efficiency and smoother engine operation.

Racing and motorsports have also contributed significantly to the market demand for K24 engine tuning. Many amateur and professional racing series feature vehicles powered by K24 engines, driving innovation in tuning techniques and technologies. This racing pedigree has further enhanced the appeal of K24 tuning among enthusiasts, creating a trickle-down effect in the consumer market.

The trend towards electric and hybrid vehicles has, paradoxically, intensified interest in optimizing internal combustion engines like the K24. Many consumers and manufacturers are looking to extract maximum efficiency and performance from existing gasoline engines before transitioning to alternative powertrains. This has created a niche market for advanced tuning solutions that can bridge the gap between traditional and future propulsion technologies.

Furthermore, the rise of online communities and social media platforms dedicated to automotive performance has amplified the visibility and desirability of K24 engine tuning. These platforms serve as hubs for sharing knowledge, experiences, and results, further driving market demand and fostering innovation in tuning techniques.

As the automotive industry continues to evolve, the market for K24 engine tuning, especially in the realm of air-fuel mixture optimization, is expected to remain robust. The combination of performance potential, reliability, and the large existing fleet of K24-equipped vehicles ensures a sustained demand for tuning products and services in the foreseeable future.

The K24 engine, known for its reliability and potential for performance enhancement, has become a favorite among automotive enthusiasts and tuners. As emissions regulations tighten globally, there is a growing demand for tuning solutions that can improve engine performance while maintaining or even reducing emissions. This has led to a focus on perfecting air-fuel mixtures, which plays a crucial role in achieving both power gains and cleaner exhaust outputs.

The aftermarket performance industry has responded to this demand by developing a wide range of products and services specifically tailored for K24 engine tuning. These include programmable engine control units (ECUs), high-flow fuel injectors, advanced air intake systems, and specialized tuning software. The market for these products has expanded beyond traditional performance-oriented consumers to include everyday drivers seeking improved fuel efficiency and smoother engine operation.

Racing and motorsports have also contributed significantly to the market demand for K24 engine tuning. Many amateur and professional racing series feature vehicles powered by K24 engines, driving innovation in tuning techniques and technologies. This racing pedigree has further enhanced the appeal of K24 tuning among enthusiasts, creating a trickle-down effect in the consumer market.

The trend towards electric and hybrid vehicles has, paradoxically, intensified interest in optimizing internal combustion engines like the K24. Many consumers and manufacturers are looking to extract maximum efficiency and performance from existing gasoline engines before transitioning to alternative powertrains. This has created a niche market for advanced tuning solutions that can bridge the gap between traditional and future propulsion technologies.

Furthermore, the rise of online communities and social media platforms dedicated to automotive performance has amplified the visibility and desirability of K24 engine tuning. These platforms serve as hubs for sharing knowledge, experiences, and results, further driving market demand and fostering innovation in tuning techniques.

As the automotive industry continues to evolve, the market for K24 engine tuning, especially in the realm of air-fuel mixture optimization, is expected to remain robust. The combination of performance potential, reliability, and the large existing fleet of K24-equipped vehicles ensures a sustained demand for tuning products and services in the foreseeable future.

Current Tuning Challenges

K24 engine tuning faces several significant challenges in achieving optimal air-fuel mixtures. One of the primary issues is the complexity of modern engine management systems. These systems incorporate numerous sensors and actuators, making it difficult to fine-tune individual parameters without affecting others. Tuners must navigate through intricate software and hardware interactions to achieve the desired results.

Another challenge lies in the variability of fuel quality and environmental conditions. K24 engines, like many others, are designed to operate across a wide range of conditions, from cold starts to high-temperature, high-load scenarios. Tuners must account for these variations while maintaining performance and efficiency, which often requires compromises in the tuning process.

The stock ECU (Engine Control Unit) limitations present another hurdle. Many factory ECUs have restricted access to certain parameters or may not allow for the level of customization required for advanced tuning. This often necessitates the use of aftermarket ECUs or piggyback systems, which can introduce compatibility issues and increase the complexity of the tuning process.

Emissions regulations pose a significant challenge in K24 engine tuning. Strikers emissions standards require tuners to balance performance gains with legal compliance, often leading to trade-offs between power output and emissions control. This balancing act becomes increasingly difficult as regulations tighten, particularly in regions with stringent emissions testing.

The pursuit of higher power outputs in K24 engines often leads to increased thermal loads, which can cause issues with engine reliability and longevity. Tuners must carefully manage air-fuel ratios, ignition timing, and boost pressures (in turbocharged applications) to prevent engine damage while maximizing performance. This delicate balance requires extensive knowledge and experience to achieve successfully.

Lastly, the integration of modern features such as direct injection and variable valve timing in some K24 variants adds layers of complexity to the tuning process. These technologies, while beneficial for efficiency and performance, introduce additional variables that must be carefully controlled and optimized. Tuners must develop strategies to leverage these features effectively while maintaining the desired air-fuel mixture across the engine's operating range.

Another challenge lies in the variability of fuel quality and environmental conditions. K24 engines, like many others, are designed to operate across a wide range of conditions, from cold starts to high-temperature, high-load scenarios. Tuners must account for these variations while maintaining performance and efficiency, which often requires compromises in the tuning process.

The stock ECU (Engine Control Unit) limitations present another hurdle. Many factory ECUs have restricted access to certain parameters or may not allow for the level of customization required for advanced tuning. This often necessitates the use of aftermarket ECUs or piggyback systems, which can introduce compatibility issues and increase the complexity of the tuning process.

Emissions regulations pose a significant challenge in K24 engine tuning. Strikers emissions standards require tuners to balance performance gains with legal compliance, often leading to trade-offs between power output and emissions control. This balancing act becomes increasingly difficult as regulations tighten, particularly in regions with stringent emissions testing.

The pursuit of higher power outputs in K24 engines often leads to increased thermal loads, which can cause issues with engine reliability and longevity. Tuners must carefully manage air-fuel ratios, ignition timing, and boost pressures (in turbocharged applications) to prevent engine damage while maximizing performance. This delicate balance requires extensive knowledge and experience to achieve successfully.

Lastly, the integration of modern features such as direct injection and variable valve timing in some K24 variants adds layers of complexity to the tuning process. These technologies, while beneficial for efficiency and performance, introduce additional variables that must be carefully controlled and optimized. Tuners must develop strategies to leverage these features effectively while maintaining the desired air-fuel mixture across the engine's operating range.

Air-Fuel Mixture Solutions

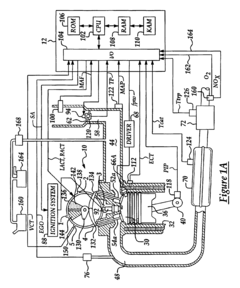

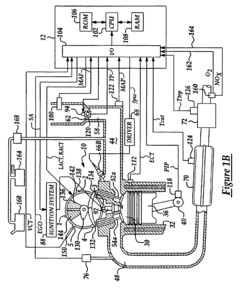

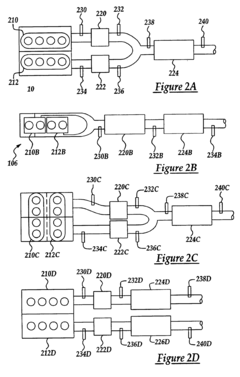

01 Air-fuel mixture control systems

Various systems and methods for controlling the air-fuel mixture in engines, including the K24 engine. These systems typically involve sensors, electronic control units, and fuel injection systems to optimize the air-fuel ratio for improved performance and efficiency.- Air-fuel mixture control systems: Various systems and methods for controlling the air-fuel mixture in engines, including the K24 engine. These systems typically involve sensors, electronic control units, and fuel injection systems to optimize the air-fuel ratio for improved performance and efficiency.

- Fuel injection optimization: Techniques for optimizing fuel injection in engines, focusing on precise control of fuel delivery timing and quantity. These methods aim to improve combustion efficiency, reduce emissions, and enhance overall engine performance.

- Exhaust gas recirculation (EGR) systems: Implementation of EGR systems in engines to reduce emissions and improve fuel efficiency. These systems recirculate a portion of the exhaust gas back into the combustion chamber, affecting the air-fuel mixture and combustion characteristics.

- Engine management systems: Advanced engine management systems that integrate various sensors and control modules to optimize air-fuel mixture, ignition timing, and other parameters. These systems often use adaptive learning algorithms to fine-tune engine performance under different operating conditions.

- Carburetor improvements: Enhancements to carburetor designs for better air-fuel mixture control in engines. While less common in modern engines, these improvements can still be relevant for certain applications or older engine designs.

02 Fuel injection optimization

Techniques for optimizing fuel injection in engines, focusing on precise control of fuel delivery timing and quantity. These methods aim to improve combustion efficiency, reduce emissions, and enhance overall engine performance.Expand Specific Solutions03 Exhaust gas recirculation (EGR) systems

Implementation of EGR systems in engines to reduce emissions and improve fuel efficiency. These systems recirculate a portion of the exhaust gas back into the combustion chamber, affecting the air-fuel mixture and combustion process.Expand Specific Solutions04 Engine management systems

Advanced engine management systems that integrate various sensors and control modules to optimize air-fuel mixture, ignition timing, and other parameters. These systems aim to improve overall engine performance, fuel efficiency, and emissions control.Expand Specific Solutions05 Carburetor improvements

Enhancements to carburetor designs for better air-fuel mixture control in engines. These improvements focus on achieving more precise fuel metering, better atomization, and improved mixture distribution across different engine operating conditions.Expand Specific Solutions

Key Aftermarket Players

The K24 engine tuning market is in a mature stage, with established players and a well-defined competitive landscape. The global automotive engine tuning market size is estimated to be in the billions of dollars, driven by performance enthusiasts and racing applications. Technologically, K24 tuning has reached a high level of sophistication, with companies like Honda, Toyota, and Nissan leading in engine development and aftermarket tuning solutions. Specialized tuning firms and parts manufacturers such as Vitesco Technologies and Continental Automotive also play significant roles in advancing K24 performance optimization techniques. The market continues to evolve with innovations in fuel injection, turbocharging, and engine management systems from major automotive suppliers like Bosch and Denso.

Toyota Motor Corp.

Technical Solution: Toyota's approach to engine tuning, particularly relevant to K24-like engines, involves their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. This system combines direct and port fuel injection to optimize air-fuel mixtures across various engine loads and speeds[4]. Toyota employs advanced ECU programming with adaptive learning capabilities to continuously refine fuel mapping based on driving conditions and environmental factors[5]. The company also utilizes VVT-i (Variable Valve Timing with intelligence) technology to adjust valve timing, improving volumetric efficiency and enabling precise control over the air-fuel ratio throughout the engine's operating range[6].

Strengths: Dual injection system offers flexibility in mixture control, robust ECU programming for consistent performance. Weaknesses: System complexity may lead to higher production costs, potential for carbon buildup in direct injection components.

Robert Bosch GmbH

Technical Solution: Bosch, as a leading automotive supplier, has developed advanced engine management systems applicable to K24 engine tuning. Their Motronic system integrates electronic throttle control, direct fuel injection, and variable valve timing to achieve optimal air-fuel mixtures[7]. Bosch's engine control units (ECUs) utilize sophisticated algorithms and high-speed processors to make real-time adjustments to fuel delivery and ignition timing based on multiple sensor inputs[8]. The company's latest systems incorporate machine learning techniques to adapt to individual driving styles and engine wear over time, ensuring consistent performance and efficiency[9].

Strengths: Cutting-edge sensor technology, highly adaptable ECU software, extensive experience in diverse engine applications. Weaknesses: Premium pricing may limit adoption in lower-cost vehicles, potential over-reliance on electronic systems.

Advanced Tuning Techniques

A method of maintaining ideal air-fuel mixture and a system

PatentActiveIN738MUM2012A

Innovation

- A system comprising an oxygen sensor, Engine Management Unit (EMU), a reconditioning chamber, and an oxygen injector that senses oxygen content and mass flow rate, activating a control valve to inject oxygen when necessary to maintain the ideal air-fuel ratio, ensuring complete combustion and reducing emissions.

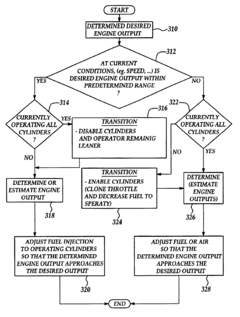

Method to improve fuel economy in lean burn engines with variable-displacement-like characteristics

PatentInactiveUS6758185B2

Innovation

- A method for operating an engine by determining desired output, transitioning between modes where all cylinders combust a fuel-air mixture and some cylinders induce air with no fuel, allowing higher load operation and leaner air-fuel ratios for improved stability and efficiency, enabling smoother idle operation and increased fuel economy.

Emissions Regulations Impact

Emissions regulations have significantly impacted K24 engine tuning, particularly in the pursuit of perfecting air-fuel mixtures. These regulations, implemented by various governmental bodies worldwide, aim to reduce harmful emissions from internal combustion engines, including those found in vehicles equipped with K24 engines.

The stringent nature of these regulations has necessitated a shift in engine tuning practices. Traditionally, tuners focused primarily on maximizing power output and fuel efficiency. However, with the advent of stricter emissions standards, they must now balance these objectives with the need to minimize pollutants such as carbon monoxide, nitrogen oxides, and unburned hydrocarbons.

One of the key challenges in K24 engine tuning under these regulations is maintaining optimal air-fuel ratios across various operating conditions. Emissions standards often require engines to run leaner mixtures, which can potentially compromise performance and reliability. Tuners must now employ advanced strategies to ensure compliance while still delivering satisfactory engine performance.

The implementation of more sophisticated engine management systems has been crucial in meeting these regulatory demands. Modern K24 engine control units (ECUs) incorporate complex algorithms that continuously adjust fuel injection and ignition timing based on real-time sensor data. This allows for more precise control over the air-fuel mixture, enabling tuners to optimize engine performance within the constraints of emissions regulations.

Catalytic converter efficiency has become a critical factor in K24 engine tuning. Emissions regulations have led to the development of more advanced catalytic converters, which require specific exhaust gas compositions to function effectively. Tuners must carefully calibrate air-fuel mixtures to ensure that the catalytic converter operates at peak efficiency, further complicating the tuning process.

The introduction of on-board diagnostics (OBD) systems has added another layer of complexity to K24 engine tuning. These systems monitor various engine parameters and emissions-related components, alerting drivers and technicians to potential issues that could lead to increased emissions. Tuners must ensure that their modifications do not trigger OBD fault codes or compromise the system's ability to accurately monitor emissions performance.

As emissions regulations continue to evolve, K24 engine tuners face ongoing challenges in adapting their techniques. The trend towards increasingly strict standards has spurred innovation in tuning methodologies and technologies. This includes the development of more advanced mapping techniques, the use of artificial intelligence in engine calibration, and the integration of real-world driving data into tuning processes.

The stringent nature of these regulations has necessitated a shift in engine tuning practices. Traditionally, tuners focused primarily on maximizing power output and fuel efficiency. However, with the advent of stricter emissions standards, they must now balance these objectives with the need to minimize pollutants such as carbon monoxide, nitrogen oxides, and unburned hydrocarbons.

One of the key challenges in K24 engine tuning under these regulations is maintaining optimal air-fuel ratios across various operating conditions. Emissions standards often require engines to run leaner mixtures, which can potentially compromise performance and reliability. Tuners must now employ advanced strategies to ensure compliance while still delivering satisfactory engine performance.

The implementation of more sophisticated engine management systems has been crucial in meeting these regulatory demands. Modern K24 engine control units (ECUs) incorporate complex algorithms that continuously adjust fuel injection and ignition timing based on real-time sensor data. This allows for more precise control over the air-fuel mixture, enabling tuners to optimize engine performance within the constraints of emissions regulations.

Catalytic converter efficiency has become a critical factor in K24 engine tuning. Emissions regulations have led to the development of more advanced catalytic converters, which require specific exhaust gas compositions to function effectively. Tuners must carefully calibrate air-fuel mixtures to ensure that the catalytic converter operates at peak efficiency, further complicating the tuning process.

The introduction of on-board diagnostics (OBD) systems has added another layer of complexity to K24 engine tuning. These systems monitor various engine parameters and emissions-related components, alerting drivers and technicians to potential issues that could lead to increased emissions. Tuners must ensure that their modifications do not trigger OBD fault codes or compromise the system's ability to accurately monitor emissions performance.

As emissions regulations continue to evolve, K24 engine tuners face ongoing challenges in adapting their techniques. The trend towards increasingly strict standards has spurred innovation in tuning methodologies and technologies. This includes the development of more advanced mapping techniques, the use of artificial intelligence in engine calibration, and the integration of real-world driving data into tuning processes.

Performance vs Efficiency

The balance between performance and efficiency is a critical consideration in K24 engine tuning, particularly when perfecting air-fuel mixtures. This delicate equilibrium requires careful optimization to achieve the desired outcomes for both power output and fuel economy.

Performance-oriented tuning typically aims to maximize horsepower and torque, often at the expense of fuel efficiency. This approach involves enriching the air-fuel mixture, which provides more fuel for combustion and helps prevent detonation under high-load conditions. A richer mixture can lead to improved throttle response, increased power across the RPM range, and enhanced engine cooling. However, this comes at the cost of reduced fuel economy and potentially increased emissions.

On the other hand, efficiency-focused tuning prioritizes fuel economy and emissions reduction. This strategy often involves leaning out the air-fuel mixture to achieve more complete combustion and minimize fuel waste. Lean mixtures can result in improved fuel efficiency, lower emissions, and potentially increased engine longevity due to reduced carbon buildup. However, excessively lean mixtures can lead to higher combustion temperatures, increased risk of detonation, and reduced power output.

The challenge lies in finding the optimal point where performance and efficiency intersect. Modern engine management systems and advanced tuning techniques allow for dynamic adjustment of air-fuel ratios based on various operating conditions. For example, a K24 engine might run a leaner mixture during cruising for improved efficiency, then switch to a richer mixture under high-load situations for maximum power and engine protection.

Factors such as compression ratio, camshaft profiles, and intake/exhaust flow characteristics also play crucial roles in determining the ideal air-fuel mixture for different scenarios. Tuners must consider these variables alongside the desired balance between performance and efficiency when optimizing the K24 engine.

Ultimately, the goal is to achieve a harmonious blend of power and economy that suits the specific application and user requirements. This may involve compromises in certain areas but should result in an overall package that delivers satisfactory performance without excessive fuel consumption or emissions.

Performance-oriented tuning typically aims to maximize horsepower and torque, often at the expense of fuel efficiency. This approach involves enriching the air-fuel mixture, which provides more fuel for combustion and helps prevent detonation under high-load conditions. A richer mixture can lead to improved throttle response, increased power across the RPM range, and enhanced engine cooling. However, this comes at the cost of reduced fuel economy and potentially increased emissions.

On the other hand, efficiency-focused tuning prioritizes fuel economy and emissions reduction. This strategy often involves leaning out the air-fuel mixture to achieve more complete combustion and minimize fuel waste. Lean mixtures can result in improved fuel efficiency, lower emissions, and potentially increased engine longevity due to reduced carbon buildup. However, excessively lean mixtures can lead to higher combustion temperatures, increased risk of detonation, and reduced power output.

The challenge lies in finding the optimal point where performance and efficiency intersect. Modern engine management systems and advanced tuning techniques allow for dynamic adjustment of air-fuel ratios based on various operating conditions. For example, a K24 engine might run a leaner mixture during cruising for improved efficiency, then switch to a richer mixture under high-load situations for maximum power and engine protection.

Factors such as compression ratio, camshaft profiles, and intake/exhaust flow characteristics also play crucial roles in determining the ideal air-fuel mixture for different scenarios. Tuners must consider these variables alongside the desired balance between performance and efficiency when optimizing the K24 engine.

Ultimately, the goal is to achieve a harmonious blend of power and economy that suits the specific application and user requirements. This may involve compromises in certain areas but should result in an overall package that delivers satisfactory performance without excessive fuel consumption or emissions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!