Tungsten Breakthroughs In Artificial Intelligence Hardware

Tungsten AI Hardware Evolution and Objectives

Tungsten has emerged as a promising material for advancing artificial intelligence (AI) hardware, marking a significant evolution in the field. The journey of tungsten in AI hardware began with its initial application in traditional computing systems, where its high melting point and excellent thermal conductivity made it valuable for heat management. As AI algorithms became more complex and demanding, the need for specialized hardware accelerators grew, leading researchers to explore novel materials and architectures.

The evolution of tungsten in AI hardware has been driven by the increasing demand for more efficient and powerful computing solutions. Early experiments with tungsten-based components in neural network processors showed potential for improved performance and energy efficiency. This sparked a wave of research and development efforts focused on optimizing tungsten's properties for AI-specific applications.

One of the key objectives in tungsten AI hardware development has been to leverage its unique electronic properties to create more efficient synaptic connections in artificial neural networks. Researchers have been working on developing tungsten-based memristors, which can mimic the behavior of biological synapses, potentially leading to more brain-like computing architectures.

Another important goal has been to utilize tungsten's thermal properties to address the heat dissipation challenges in high-performance AI chips. As AI models grow larger and more complex, managing heat becomes critical for maintaining performance and reliability. Tungsten's superior thermal conductivity offers promising solutions for next-generation AI hardware designs.

The evolution of tungsten in AI hardware also aims to improve the scalability and integration density of AI chips. By exploiting tungsten's properties at the nanoscale, researchers are exploring ways to create more compact and powerful AI processors, enabling the development of edge AI devices with enhanced capabilities.

As the field progresses, the objectives for tungsten AI hardware continue to expand. Current research is focused on developing novel tungsten-based materials and structures that can support neuromorphic computing paradigms, potentially revolutionizing the way AI computations are performed. Additionally, efforts are underway to combine tungsten with other advanced materials to create hybrid solutions that can address the multifaceted challenges of next-generation AI hardware.

The evolution of tungsten in AI hardware represents a convergence of materials science, electrical engineering, and computer architecture. By setting ambitious objectives and pushing the boundaries of what's possible with tungsten, researchers and engineers are paving the way for more efficient, powerful, and intelligent computing systems that could transform various industries and applications in the coming years.

Market Demand for Advanced AI Chips

The market demand for advanced AI chips has been experiencing exponential growth, driven by the rapid expansion of artificial intelligence applications across various industries. As AI technologies become more sophisticated and pervasive, the need for high-performance, energy-efficient hardware solutions has become paramount. This surge in demand is particularly evident in sectors such as data centers, edge computing, autonomous vehicles, and consumer electronics.

The global AI chip market is projected to reach significant valuations in the coming years, with major tech companies and startups alike investing heavily in research and development. This growth is fueled by the increasing adoption of AI in business operations, the rise of cloud computing services, and the proliferation of AI-enabled devices in everyday life.

One of the key drivers of market demand is the need for more powerful and efficient processors to handle complex AI workloads. Traditional CPUs and GPUs are often insufficient for the computational requirements of advanced AI algorithms, leading to a growing interest in specialized AI accelerators and neural processing units (NPUs). These custom-designed chips offer superior performance and energy efficiency for AI tasks, making them highly sought after in the market.

The demand for AI chips is also being propelled by the trend towards edge computing, where AI processing is performed closer to the data source rather than in centralized cloud servers. This shift requires compact, low-power AI chips that can operate effectively in resource-constrained environments, opening up new market opportunities for chip manufacturers.

In the data center segment, the demand for AI chips is particularly strong, as companies seek to optimize their infrastructure for AI workloads. Cloud service providers and large enterprises are investing in AI-specific hardware to improve the performance and efficiency of their AI services, driving the need for more advanced chip solutions.

The automotive industry represents another significant market for AI chips, with the development of autonomous vehicles requiring powerful onboard AI processing capabilities. As self-driving technology advances, the demand for specialized AI hardware in this sector is expected to grow substantially.

Consumer electronics is yet another area driving demand for AI chips, with smartphones, smart home devices, and wearables incorporating increasingly sophisticated AI features. This trend is creating a market for smaller, more power-efficient AI chips that can enable on-device AI processing without compromising battery life or performance.

As the AI landscape continues to evolve, the market demand for advanced AI chips is likely to remain strong, with ongoing innovations in chip design and manufacturing processes playing a crucial role in meeting the growing needs of AI applications across various industries.

Current Challenges in Tungsten-based AI Hardware

Despite significant advancements in AI hardware, tungsten-based solutions face several critical challenges that hinder their widespread adoption and optimal performance. One of the primary obstacles is the high power consumption associated with tungsten-based AI accelerators. As AI models grow increasingly complex, the energy demands of these hardware components escalate, leading to concerns about efficiency and sustainability in large-scale deployments.

Another significant challenge lies in the thermal management of tungsten-based AI hardware. The high operating temperatures generated during intensive computational tasks can potentially compromise the longevity and reliability of these systems. Developing effective cooling solutions that can dissipate heat efficiently without adding substantial bulk or cost to the hardware remains a pressing issue for researchers and engineers in this field.

The integration of tungsten-based components with existing silicon-based architectures presents yet another hurdle. Ensuring seamless compatibility and optimal performance when combining these different materials and technologies requires innovative design approaches and sophisticated manufacturing processes. This integration challenge extends to the development of software frameworks and tools that can fully leverage the unique capabilities of tungsten-based AI hardware.

Scalability is also a key concern for tungsten-based AI solutions. As the demand for AI processing power continues to grow exponentially, scaling up tungsten-based hardware to meet these requirements while maintaining cost-effectiveness and performance efficiency poses significant technical and economic challenges. This includes addressing issues related to chip design, interconnect technologies, and system-level architectures.

Furthermore, the manufacturing processes for tungsten-based AI hardware components are still evolving. Achieving consistent quality, yield, and cost-effectiveness in production remains a challenge, particularly when compared to more established silicon-based manufacturing techniques. Overcoming these production hurdles is crucial for the widespread adoption of tungsten-based AI hardware solutions.

Lastly, the industry faces challenges in standardization and ecosystem development for tungsten-based AI hardware. The lack of widely accepted standards and a robust ecosystem of tools, libraries, and frameworks specifically optimized for tungsten-based architectures hampers their adoption and integration into existing AI workflows. Addressing these ecosystem challenges is essential for creating a supportive environment that encourages innovation and accelerates the development of tungsten-based AI hardware solutions.

Existing Tungsten AI Hardware Solutions

01 Tungsten deposition methods

Various methods for depositing tungsten on substrates, including chemical vapor deposition (CVD) and atomic layer deposition (ALD). These techniques are used to create thin films of tungsten for applications in semiconductor manufacturing and other industries.- Tungsten deposition and film formation: Various methods and processes for depositing tungsten and forming tungsten films on substrates. This includes techniques such as chemical vapor deposition (CVD), atomic layer deposition (ALD), and physical vapor deposition (PVD) to create thin tungsten layers for semiconductor applications.

- Tungsten-based alloys and composites: Development of tungsten-based alloys and composite materials for improved properties such as strength, hardness, and thermal stability. These materials find applications in various industries including aerospace, defense, and electronics.

- Tungsten in semiconductor manufacturing: Use of tungsten in semiconductor manufacturing processes, including its application as interconnects, gate electrodes, and barrier layers. This involves techniques for patterning, etching, and integrating tungsten into complex semiconductor structures.

- Tungsten-based lighting and electron emission: Applications of tungsten in lighting technologies and electron emission devices. This includes the use of tungsten filaments in incandescent lamps and as cathodes in various electronic devices, exploiting its high melting point and electron emission properties.

- Recycling and processing of tungsten: Methods for recycling and processing tungsten from various sources, including scrap materials and ores. This involves techniques for extracting, purifying, and recovering tungsten to meet the growing demand for this valuable metal in various industries.

02 Tungsten etching processes

Techniques for selectively etching tungsten layers in semiconductor fabrication. These processes are crucial for creating precise patterns and structures in integrated circuits and other microelectronic devices.Expand Specific Solutions03 Tungsten-based alloys and composites

Development of tungsten alloys and composite materials with enhanced properties for various applications. These materials combine tungsten with other elements to improve characteristics such as strength, hardness, and thermal stability.Expand Specific Solutions04 Tungsten in lighting applications

Use of tungsten in lighting technologies, particularly in filaments for incandescent and halogen lamps. This includes innovations in tungsten wire production and lamp design to improve efficiency and longevity.Expand Specific Solutions05 Tungsten in electronic components

Applications of tungsten in electronic components, such as interconnects, electrodes, and heat sinks. These components leverage tungsten's high melting point, excellent electrical conductivity, and thermal properties for improved device performance.Expand Specific Solutions

Key Players in Tungsten AI Chip Industry

The artificial intelligence hardware market, particularly in tungsten-based technologies, is in a dynamic growth phase. The industry is witnessing significant advancements, with major players like Intel, Samsung, and TSMC leading the charge. The market size is expanding rapidly, driven by increasing demand for high-performance AI chips. Technologically, the field is progressing from experimental stages to more mature applications, with companies like Applied Materials and GLOBALFOUNDRIES pushing the boundaries of tungsten integration in AI hardware. Universities such as Tsinghua and Central South University are contributing to fundamental research, while established semiconductor firms like Fujitsu and Infineon Technologies are translating these breakthroughs into commercial products, indicating a collaborative ecosystem spanning academia and industry.

Applied Materials, Inc.

Taiwan Semiconductor Manufacturing Co., Ltd.

Core Innovations in Tungsten AI Chip Design

- The implementation of tungsten feed-throughs that contact the gate shield, n+ source, and p+ substrate, utilizing a reduced area and improved processing techniques such as CVD titanium, Ti-nitride, and tungsten plug processing to form deep trenches, allowing for low resistance and compact design.

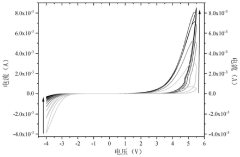

- Design an artificial non-spiking interneuron device, using a structure composed of heavily doped p-type or n-type silicon, CuOx materials and metal layers. The resistance state of the device is changed by applying different voltage signals to simulate the information filtering of non-spiking neurons. , amplification and adaptive response.

Environmental Impact of Tungsten AI Chips

The environmental impact of tungsten AI chips is a critical consideration as artificial intelligence hardware continues to advance. Tungsten, a rare metal with unique properties, has emerged as a promising material for AI chip manufacturing. However, its extraction and processing pose significant environmental challenges.

Tungsten mining operations often involve open-pit mining, which can lead to extensive land disturbance and habitat destruction. The extraction process requires substantial energy consumption and water usage, contributing to increased carbon emissions and potential water scarcity in mining regions. Additionally, the chemical processes used to refine tungsten ore can generate hazardous waste, including heavy metals and acidic byproducts, which may contaminate soil and water sources if not properly managed.

The production of tungsten AI chips also raises concerns about electronic waste (e-waste) management. As AI hardware evolves rapidly, older chips may become obsolete, leading to increased e-waste generation. Tungsten's high melting point and chemical stability make it challenging to recycle, potentially resulting in the accumulation of non-biodegradable waste in landfills.

On the other hand, tungsten's unique properties offer potential environmental benefits in AI chip design. Its high thermal conductivity and resistance to wear can lead to more efficient and longer-lasting chips, potentially reducing the frequency of hardware replacements and associated e-waste. Furthermore, tungsten's ability to operate at higher temperatures may enable the development of more energy-efficient AI systems, potentially lowering overall power consumption and associated carbon emissions in data centers and edge computing devices.

To mitigate the environmental impact of tungsten AI chips, several strategies can be implemented. Sustainable mining practices, such as water recycling and habitat restoration, can help minimize the ecological footprint of tungsten extraction. Investing in recycling technologies specifically designed for tungsten-based electronics can improve the circularity of AI hardware. Additionally, designing AI chips with modular components that allow for easier upgrades and repairs could extend their lifespan and reduce e-waste generation.

As the demand for AI hardware continues to grow, balancing the technological benefits of tungsten with its environmental implications will be crucial. Industry stakeholders, policymakers, and researchers must collaborate to develop sustainable practices throughout the lifecycle of tungsten AI chips, from responsible sourcing to efficient manufacturing and effective end-of-life management.

Tungsten AI Hardware Manufacturing Processes

The manufacturing processes for tungsten-based AI hardware have seen significant advancements in recent years, driven by the increasing demand for high-performance computing in artificial intelligence applications. These processes involve several critical steps, each requiring precision and advanced technologies to ensure the production of reliable and efficient AI hardware components.

The first stage in the manufacturing process typically involves the preparation of tungsten raw materials. This includes purification and refinement of tungsten ore to achieve the high levels of purity required for AI hardware applications. Advanced techniques such as zone refining and chemical vapor deposition are often employed to produce ultra-pure tungsten suitable for use in AI chips.

Once the raw materials are prepared, the next step involves the fabrication of tungsten-based components. This process often utilizes advanced lithography techniques, including extreme ultraviolet (EUV) lithography, to create intricate patterns on tungsten substrates. The use of EUV lithography allows for the production of smaller and more densely packed transistors, which is crucial for improving the performance of AI hardware.

Following the patterning process, various deposition techniques are employed to build up the layers of the AI chip. These may include physical vapor deposition (PVD) and chemical vapor deposition (CVD) methods, which are used to deposit thin films of tungsten and other materials onto the substrate. The precise control of these deposition processes is essential for achieving the desired electrical and thermal properties of the AI hardware components.

Etching is another critical step in the manufacturing process, where excess material is selectively removed to create the final structure of the AI chip. Advanced plasma etching techniques are often used to achieve high aspect ratio features and precise control over the etching process. This step is particularly important for creating the complex interconnects and vias that are essential for the functionality of AI hardware.

The integration of tungsten components with other materials, such as silicon and various insulators, is a crucial aspect of the manufacturing process. This integration often involves advanced bonding techniques and careful management of thermal and mechanical stresses to ensure the reliability and longevity of the final AI hardware product.

Quality control and testing are integral parts of the manufacturing process, with various inspection and characterization techniques employed throughout the production line. These may include electron microscopy, X-ray diffraction, and electrical testing to ensure that the tungsten-based AI hardware meets the stringent performance and reliability requirements of modern AI applications.

In conclusion, the manufacturing processes for tungsten AI hardware involve a complex interplay of advanced materials science, precision engineering, and cutting-edge fabrication technologies. As the field of AI continues to evolve, these manufacturing processes are likely to see further refinements and innovations to meet the ever-increasing demands for more powerful and efficient AI hardware solutions.