Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

726results about "Aqueous dispersions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

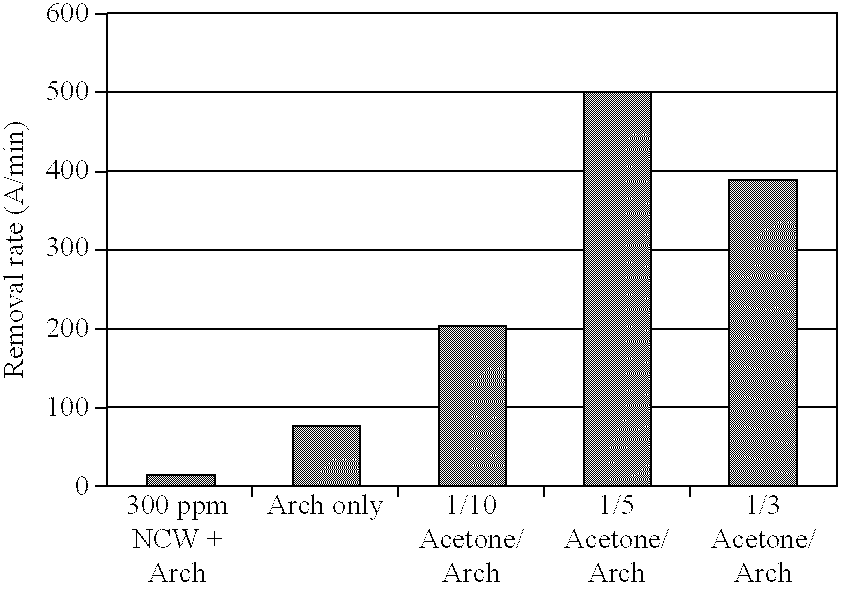

Additives to CMP slurry to polish dielectric films

A method and composition for planarizing a substrate. The composition includes one or more chelating agents, one or more oxidizers, one or more corrosion inhibitors, a polar solvent, and deionized water. The composition may further comprise one or more surfactants, one or more agents to adjust the pH and / or abrasive particles. The method comprises planarizing a substrate using a composition including a polar solvent.

Owner:APPLIED MATERIALS INC

Catalyst attached to solid and used to promote free radical formation in CMP formulations

InactiveUS7029508B2Promote formationFacilitates and accelerates reactionOther chemical processesAbrasion apparatusCompound (substance)Free Radical Formation

The present invention provides a composition for chemical-mechanical polishing which comprises at least one abrasive particle having a surface at least partially coated by a activator. The activator comprises a metal other than a metal of Group 4(b), Group 5(b) or Group 6(b). The composition further comprises at least one oxidizing agent. The composition is believed to be effective by virtue of the interaction between the activator coated on the surface of the abrasive particles and the oxidizing agent, at the activator surface, to form free radicals. The invention further provides a method that employs the composition in the polishing of a feature or layer, such as a metal film, on a substrate surface. The invention additionally provides a substrate produced this method.

Owner:VERSUM MATERIALS US LLC

Surface modified colloidal abrasives, including stable bimetallic surface coated silica sols for chemical mechanical planarization

A composition and an associated method for chemical mechanical planarization (or other polishing) are described. The composition includes a surface-modified abrasive modified with at least one stabilizer and at least one catalyst differing from the at least one stabilizer. The composition can further include a medium containing the abrasive and an oxidizing agent (e.g., hydrogen peroxide), wherein the at least one catalyst is adapted to catalyze oxidation of a substrate by the oxidizing agent. Preferably, the abrasive is alumina, titania, zirconia, germania, silica, ceria and / or mixtures thereof, the stabilizer includes B, W and / or Al, and the catalyst is Cu, Fe, Mn, Ti, W and / or V. Both the stabilizer and the catalyst are immobilized on the abrasive surface. The method includes applying the composition to a substrate to be polished, such as substrates containing W, Cu and / or dielectrics.

Owner:VERSUM MATERIALS US LLC

Aqueous dispersion for chemical mechanical polishing

InactiveUS6527818B2Pigmenting treatmentOther chemical processesColloidal silicaOXALIC ACID DIHYDRATE

There is provided an aqueous dispersion for CMP with an excellent balance between chemical etching and mechanical polishing performance. The aqueous dispersion for CMP of the invention is characterized by comprising an abrasive, water and a heteropolyacid. Another aqueous dispersion for CMP according to the invention is characterized by comprising an abrasive, water, a heteropolyacid and an organic acid. Yet another aqueous dispersion for CMP according to the invention is characterized by comprising colloidal silica with a primary particle size of 5-100 nm, water and a heteropolyacid. Preferred for the heteropolyacid is at least one type selected from among silicomolybdic acid, phosphorotungstic acid, silicotungstic acid, phosphoromolybdic acid and silicotungstomolybdic acid. Preferred for the organic acid is at least one selected from among oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, maleic acid, fumaric acid, phthalic acid, malic acid, tartaric acid and citric acid.

Owner:JSR CORPORATIOON

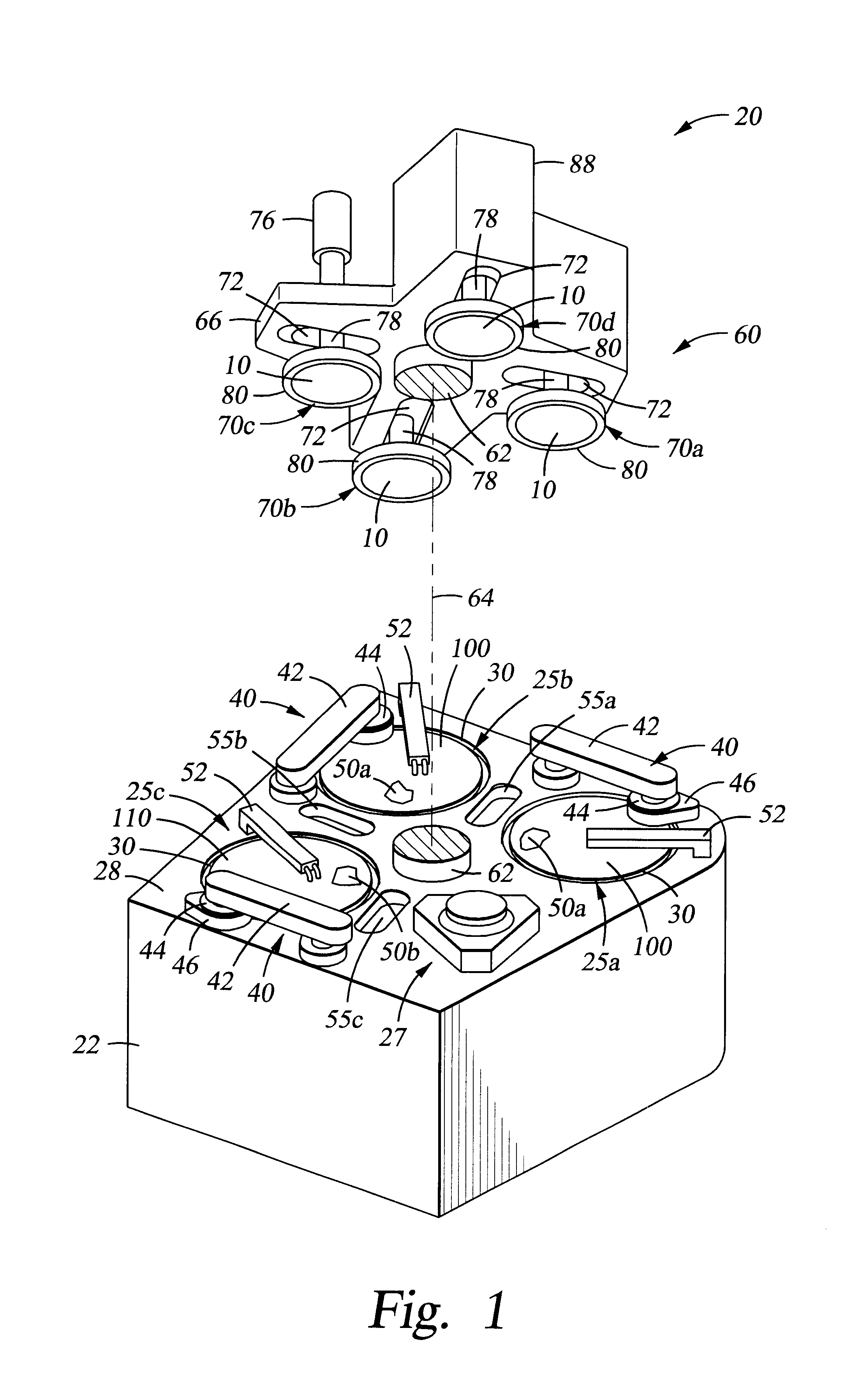

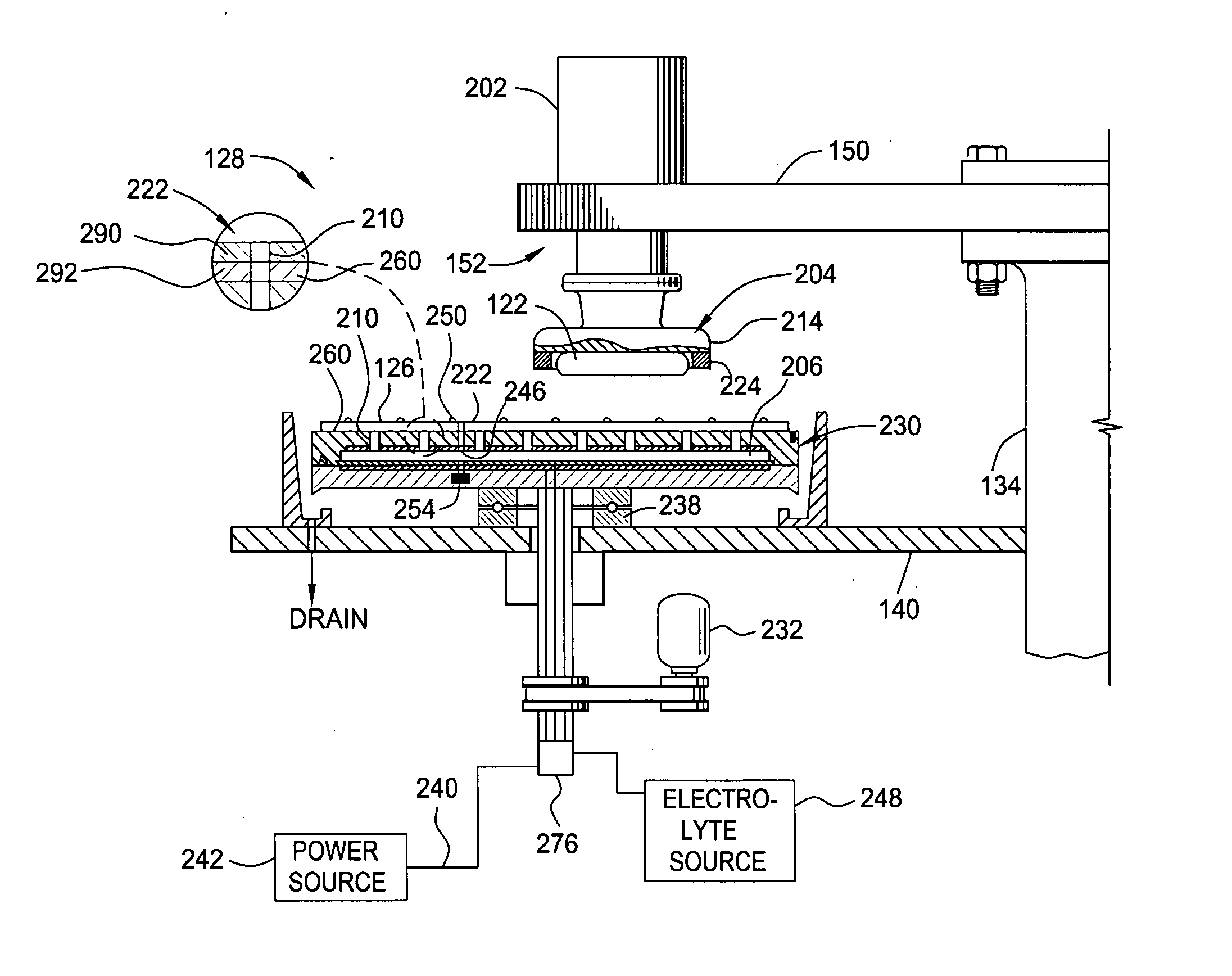

Electrolyte composition and treatment for electrolytic chemical mechanical polishing

Owner:APPLIED MATERIALS INC

Abrasive composition containing organic particles for chemical mechanical planarization

The present invention is drawn to a composition comprising abrasive particles comprising an organic resin for chemical mechanical planarization (CMP), which can be widely used in the semiconductor industry. The abrasive composition is an aqueous slurry comprising abrasive particles comprising an organic resin, wherein the slurry is held at a pH in the range of 2-12. An attractive feature of the inventive abrasive composition is that it can be tailored to selectively remove different components from the surface. The inventive abrasive composition also provides efficient polishing rates and good surface quality when used in CMP applications.

Owner:DYNEA AUSTRIA

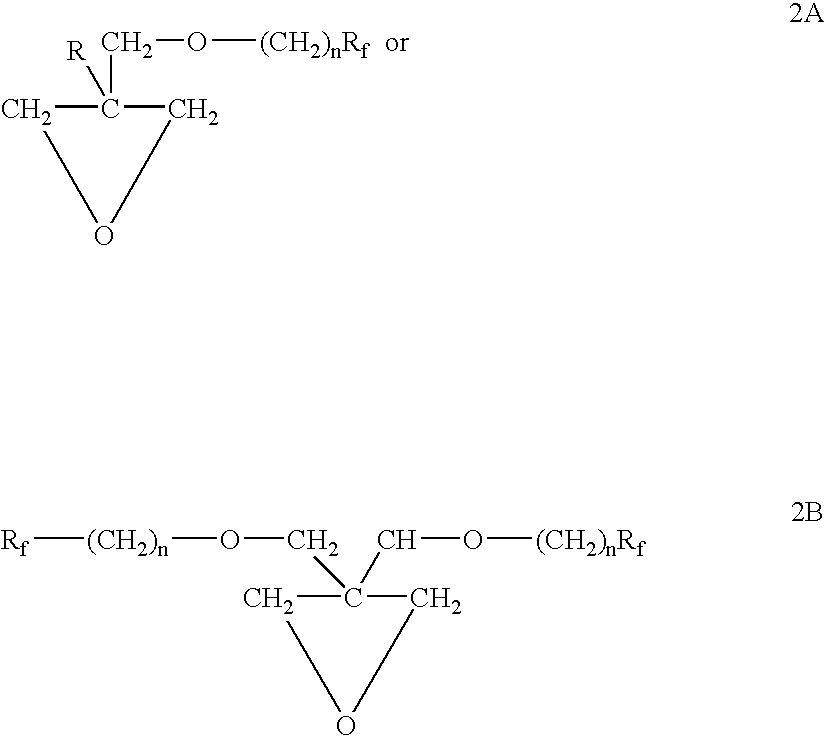

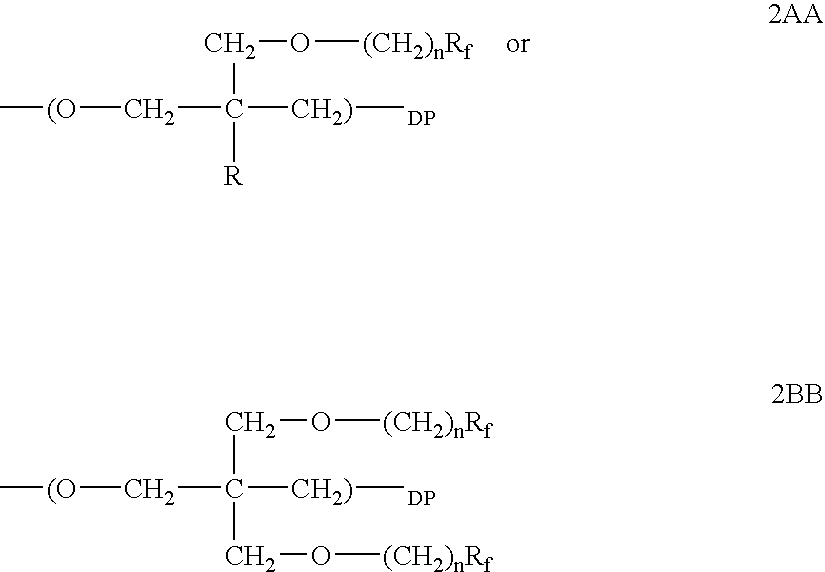

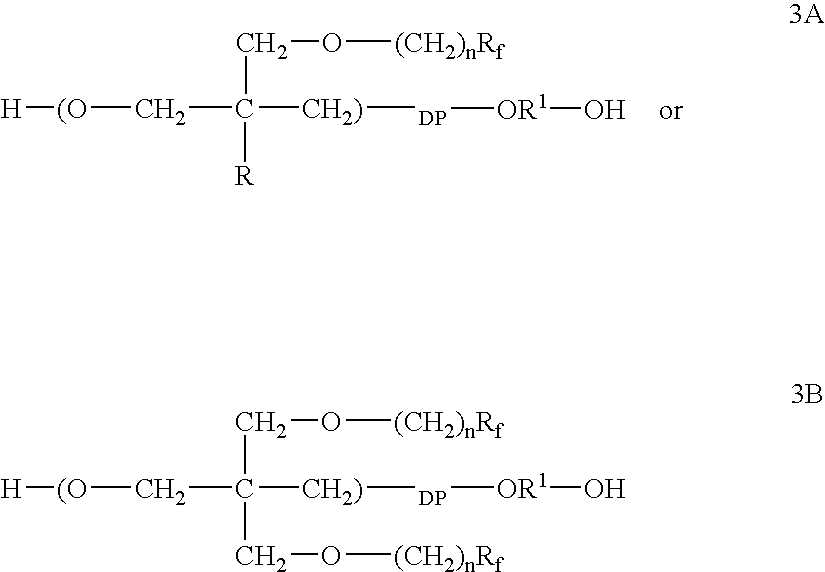

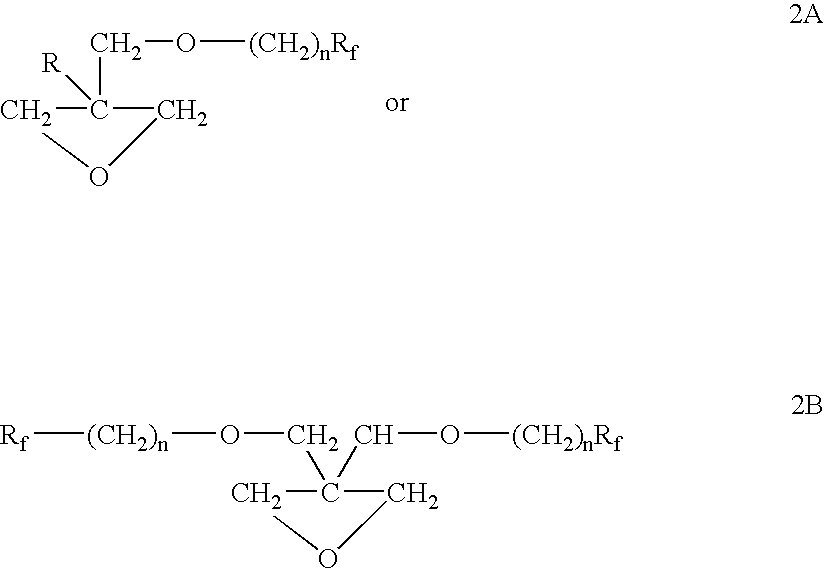

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

InactiveUS20040242804A1Good optical performanceHigh glossTransportation and packagingMixingPolymeric surfacePolymer science

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or ether side chain containing from about 1 to about 20 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:DEUT BANK AG NEW YORK BRANCH AS SUCCESSOR AGENT

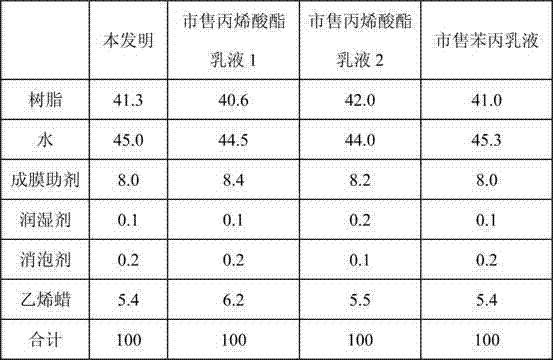

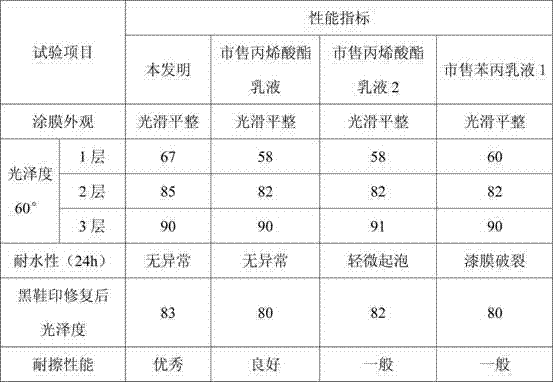

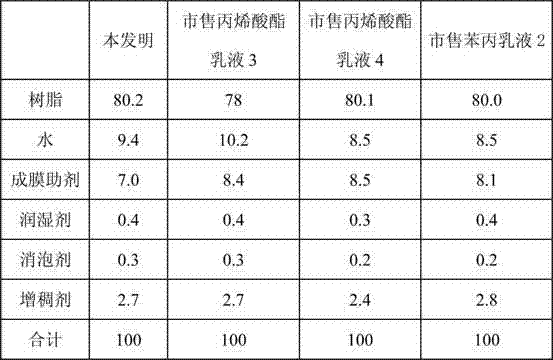

Room temperature self-crosslinking acrylic ester emulsion

InactiveCN102585072AHigh glossImprove wear resistanceAqueous dispersionsCoatingsMethacrylateFunctional monomer

The invention discloses a room temperature self-crosslinking acrylic ester emulsion. The emulsion comprises deionized water, an initiator, an emulsifier, a vinyl aromatic compound, carboxyl-containing olefin monomers, alkyl acrylate unsaturated monomers of C4-C12, methacrylate unsaturated monomers of C4-C20 and functional monomers. The emulsion is prepared with an emulsion polymerization method by adding a pH regulator, a curing agent and a metallic cross linker. The emulsion has the advantages of high glossiness, good abrasive resistance, water resistance and alcohol resistance, has good dryness under high humidity, can be applied to different coating fields and is also suitable for floor wax formulas of polishing-free wax, spray cleaning, cleaning wax polish and the like. The emulsion can be applied to various rigid base materials such as PVC (Polyvinyl Chloride), boards and composite boards and has good balance between detergent resistance and removability.

Owner:NANJING REGAL POLYMER

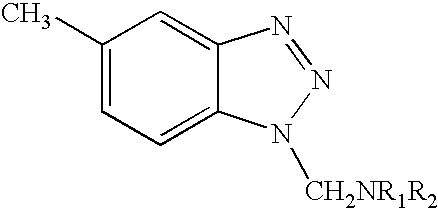

Polishing fluid and polishing method

ActiveUS20050181609A1Increase chanceSuperior in dimensional accuracy and electric characteristicOther chemical processesSemiconductor/solid-state device manufacturingDevice materialSlurry

A polishing slurry including an oxidant, a metal oxide dissolver, a metal inhibitor and water and having a pH from 2 to 5. The metal oxide dissolver contains one or more types selected from one or more acids (A-group) selected from acids of which the dissociation constant (pKa) of a first dissociable acid group is less than 3.7 and from which five acids of lactic acid, phthalic acid, fumaric acid, maleic acid and aminoacetic acid are excluded, ammonium salts of the A-group and esters of the A-group, and one or more types selected from one or more acids (B-group) selected from acids of which the dissociation constant (pKa) of a first dissociable acid group is 3.7 or more and the five acids, ammonium salts of the B-group and esters of the B-group. The metal inhibitor contains one or more types selected from the group consisting of aromatic compounds having a triazole skeleton and one or more types selected from the group consisting of aliphatic compounds having a triazole skeleton and compounds having any one of pyrimidine skeleton, imidazole skeleton, guanidine skeleton, thiazole skeleton and pyrazole skeleton. The polishing slurry having a high metal-polishing rate, reducing etching rate and polishing friction, results in the production, with high productivity, of semiconductor devices reduced in dishing and erosion in metal wiring.

Owner:HITACHI CHEM CO LTD

Composition and associated methods for chemical mechanical planarization having high selectivity for metal removal

InactiveUS6893476B2Pigmenting treatmentOther chemical processesInorganic particleInorganic particles

A composition and associated methods for chemical mechanical planarization (or other polishing) are described. The composition may comprise an abrasive and a dispersed hybrid organic / inorganic particle. The composition may further comprise an alkyne compound. Two different methods for chemical mechanical planarization are disclosed. In one method (Method A), the CMP slurry composition employed in the method comprises comprise an abrasive and a dispersed hybrid organic / inorganic particle. In another method (Method B), the CMP slurry composition employed in the method comprises comprise an abrasive and an alkyne compound. The composition may further comprise an oxidizing agent in which case the composition is particularly useful in conjunction with the associated methods (A and B) for metal CMP applications (e.g., tungsten CMP).

Owner:VERSUM MATERIALS US LLC

Chemical mechanical polishing compositions and methods relating thereto

ActiveUS20060000151A1Inorganic/elemental detergent compounding agentsPigmenting treatmentNonferrous metalCompound (substance)

The present invention provides an aqueous composition useful for CMP of a semiconductor wafer containing a metal comprising oxidizer, inhibitor for a nonferrous metal, complexing agent for the nonferrous metal, modified cellulose, 0.001 to 10% by weight copolymer blends of a first copolymer and a second copolymer and balance water.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Catalytic composition for chemical-mechanical polishing, method of using same, and substrate treated with same

InactiveUS7014669B2Facilitates and accelerates reactionPigmenting treatmentOther chemical processesCompound (substance)Oxidizing agent

The present invention provides a composition for chemical-mechanical polishing which comprises at least one abrasive particle having a surface at least partially coated by a catalyst. The catalyst comprises a metal other than a metal of Group 4(b), Group 5(b) or Group 6(b). The composition further comprises at least one oxidizing agent. The composition is believed to be effective by virtue of the interaction between the catalyst coated on the surface of the abrasive particles and the oxidizing agent, at the catalyst surface. The invention further provides a method that employs the composition in the polishing of a feature or layer, such as a metal film, on a substrate surface. The invention additionally provides a substrate produced this method.

Owner:VERSUM MATERIALS US LLC

Cellulose-containing polishing compositions and methods relating thereto

An aqueous composition is useful for chemical mechanical polishing of a patterned semiconductor wafer containing a nonferrous metal. The composition comprises an oxidizer, an inhibitor for the nonferrous metal, 0.001 to 15 weight percent of a water soluble modified cellulose, non-saccaride water soluble polymer, 0 to 15 weight percent phosphorus compound, 0.005 to 10 weight percent of a water miscible organic solvent, and water.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

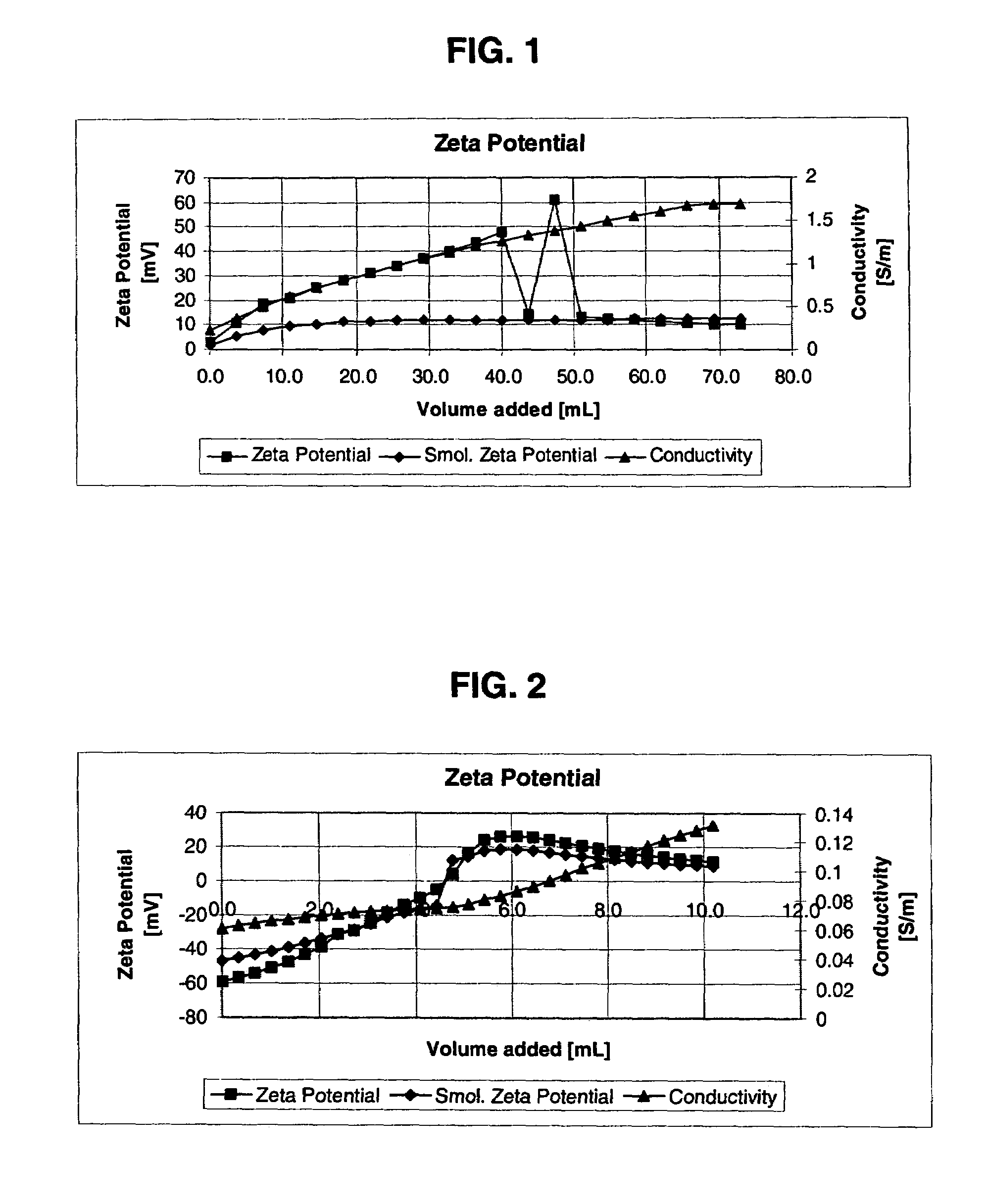

Electrolyte with good planarization capability, high removal rate and smooth surface finish for electrochemically controlled copper CMP

InactiveUS6863797B2Machining working mediaElectrolysis componentsSurface finishElectrical resistance and conductance

Electrolyte compositions and methods for planarizing a surface of a substrate using the electrolyte compositions are provided. In one aspect, an electrolyte composition includes one or more chelating agents, one or more corrosion inhibitors, and one or more pH adjusting agents. In another aspect, an electrolyte composition includes one or more chelating agents, two or more corrosion inhibitors, and one or more pH adjusting agents. In another aspect, an electrolyte composition includes one or more chelating agents, one or more corrosion inhibitors, one or more pH adjusting agents, and one or more electrically resistive additives.

Owner:APPLIED MATERIALS INC

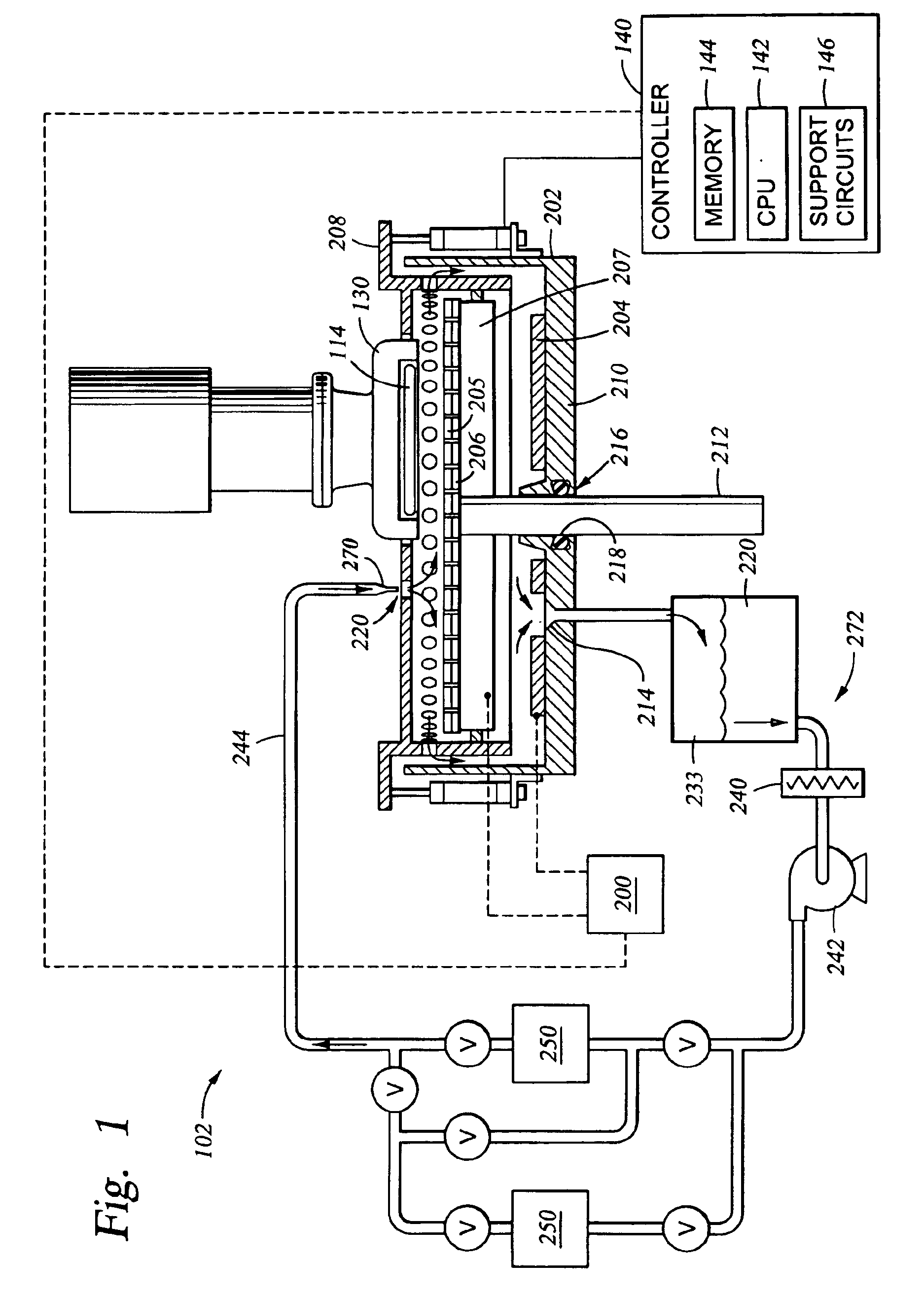

Method and composition for polishing a substrate

InactiveUS20060175298A1Decorative surface effectsSemiconductor/solid-state device manufacturingSolventSubstrate surface

Polishing compositions and methods for removing barrier materials from a substrate surface are provided. In one aspect, a composition is provided for removing at least a barrier material from a substrate surface including an acid based electrolyte system, one or more chelating agents, one or more pH adjusting agents to provide a pH between about 3 and about 11, and a solvent. The composition may be used in an electrochemical mechanical planarization process. The polishing compositions and methods described herein improve the effective removal rate of barrier materials from the substrate surface with a reduction in planarization type defects.

Owner:APPLIED MATERIALS INC

Selective polishing with slurries containing polyelectrolytes

InactiveUS6824579B2Increase polishing rate selectivityPigmenting treatmentOther chemical processesCationic polyelectrolytesSlurry

Owner:VERSUM MATERIALS US LLC

Method and composition for electro-chemical-mechanical polishing

InactiveUS20060163083A1Electrolysis componentsSemiconductor/solid-state device manufacturingCompound (substance)Copper

Owner:IBM CORP

Cerium oxide abrasive and method of polishing substrates

InactiveUS6863700B2Increase chanceNot be smoothly removedPigmenting treatmentOther chemical processesMetallurgyX-ray

A cerium oxide abrasive slurry having, dispersed in a medium, cerium oxide particles whose primary particles have a median diameter of from 30 nm to 250 nm, a maximum particle diameter of 600 nm or smaller, and a specific surface area of from 7 to 45 m2 / g, and slurry particles have a median diameter of from 150 nm to 600 nm. The cerium oxide particles have structural parameter Y, representing an isotropic microstrain obtained by an X-ray Rietvelt method (with RIETAN-94), of from 0.01 to 0.70, and structural parameter X, representing a primary particle diameter obtained by an X-ray Rietvelt method (with RIETAN-94), of from 0.08 to 0.3. The cerium oxide abrasive slurry is made by a method of obtaining particles by firing at a temperature of from 600° C. to 900° C. and then pulverizing, then dispersing the resulting cerium oxide particles in a medium.

Owner:HITACHI CHEM CO LTD

Polishing composition

A polishing composition for chemical mechanical polishing of semiconductor wafers having a copper metal circuit includes, an aqueous composition having a pH of under 5.0, and polyacrylic acid having a number average molecular weight of about 20,000-150,000, or blends of high and low number average molecular weight polyacrylic acids.

Owner:RODEL HLDG INC

Polymeric surfactants derived from cyclic monomers having pendant fluorinated carbon groups

InactiveUS7022801B2Good optical performanceHigh glossTransportation and packagingMixingPolymeric surfacePolymer science

A fluorine containing polymer which acts as a wetting, flow or leveling agent, and has at least one polar group. The polymer has at least one pendant or ether side chain containing from about 1 to about 20 carbon atoms with at least 25% of the hydrogen atoms being replaced by fluorine atoms. The fluorinated polymers unexpectedly impart wetting, flow or leveling properties to a variety of coatings while producing little foam.

Owner:OMNOVA SOLUTIONS INC

Tantalum barrier removal solution

InactiveUS7491252B2Pigmenting treatmentSoap detergents with inorganic compounding agentsGuanidine derivativesNonferrous metal

A chemical mechanical planarization solution is useful for removing tantalum barrier materials. The solution includes by weight percent 0 to 25 oxidizer, 0 to 15 inhibitor for a nonferrous metal and 0 to 20 complexing agent for the nonferrous metal, 0.01 to 12 tantalum removal agent selected from the group consisting of formamidine, formamidine salts, formamidine derivatives, guanidine derivatives, guanidine salts and mixtures thereof, 0 to 5 abrasive, 0 to 15 total particles selected from the group consisting of polymeric particles and polymer-coated coated particles and balance water. The solution has a tantalum nitride to TEOS selectivity of at least 3 to 1 as measured with a microporous polyurethane polishing pad pressure measure normal to a wafer less than 20.7 kPa.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Fluorochemical free aqueous coating compositions and methods of use thereof

InactiveUS20050215678A1Avoid healthGood wettingAqueous dispersionsPhosphorus organic compoundsOrganic phosphatesFluoride

Fluorochemical free aqueous coating compositions are disclosed. The compositions comprise a film-forming polymer and an organophosphate surfactant. The compositions exhibit superior wetting and leveling properties compared to fluoroaining sulfur based surfactants. Inventive compositions are particularly suitable for use as floor finishes. Methods of makinge aqueous coating compositions are also described.

Owner:JOHNSONDIVERSEY INC

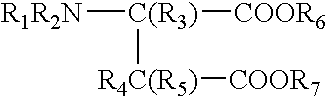

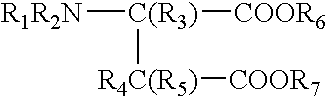

Tunable composition and method for chemical-mechanical planarization with aspartic acid/tolyltriazole

InactiveUS7153335B2Pigmenting treatmentOther chemical processesChemical compoundTriazole derivatives

A composition and associated method for chemical mechanical planarization (or other polishing) are described which afford high tantalum to copper selectivity in copper CMP and which are tunable (in relation to polishing performance). The composition comprises an abrasive and an N-acyl-N-hydrocarbonoxyalkyl aspartic acid compound and / or a tolyltriazole derivative.

Owner:VERSUM MATERIALS US LLC

Siloxane automotive protectant compositions

InactiveUS6221433B1Group 4/14 element organic compoundsPlastic/resin/waxes insulatorsParticulatesEmulsion

Gloss and ease of application of sprayable aqueous organopolysiloxane vinyl protectant emulsions are both improved by the addition of a gloss-improving additive. Protectants may be formulated to achieve higher gloss with the same amount of active organopolysiloxane or the same or higher gloss with less organopolysiloxane. Preferred gloss-improving additives are water soluble organic viscosifiers and / or minor amounts of inorganic, viscosity-increasing particulate solids.

Owner:WACKER SILICONES

Polishing composition

InactiveUS20030154659A1High polishing removal rateLow hazePigmenting treatmentOther chemical processesCelluloseColloidal silica

A polishing composition for polishing a semiconductor wafer includes comprises water, an abrasive that is preferably colloidal silica, water-soluble cellulose having a molecular weight of at least about 1,000,000 and an alkaline compound that is preferably ammonia. Tetra methyl ammonium hydroxide may also be added to the polishing composition.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Chemical Mechanical Polishing Slurry Composition for Polishing Phase-Change Memory Device and Method for Polishing Phase-Change Memory Device Using the Same

InactiveUS20090001339A1Increase chanceMinimize occurrenceOther chemical processesSolid-state devicesHigh ratePhase-change memory

Owner:CHEIL IND INC

Composition and associated methods for chemical mechanical planarization having high selectivity for metal removal

A composition and associated methods for chemical mechanical planarization (or other polishing) are described. The composition may comprise an abrasive and a dispersed hybrid organic / inorganic particle. The composition may further comprise an alkyne compound. Two different methods for chemical mechanical planarization are disclosed. In one method (Method A), the CMP slurry composition employed in the method comprises comprise an abrasive and a dispersed hybrid organic / inorganic particle. In another method (Method B), the CMP slurry composition employed in the method comprises comprise an abrasive and an alkyne compound. The composition may further comprise an oxidizing agent in which case the composition is particularly useful in conjunction with the associated methods (A and B) for metal CMP applications (e.g., tungsten CMP).

Owner:VERSUM MATERIALS US LLC

High-rate barrier polishing composition

InactiveUS7300480B2Pigmenting treatmentSoap detergents with inorganic compounding agentsHigh rateNonferrous metal

The solution is useful for removing a barrier material from a semiconductor substrate. The solution comprises, by weight percent, 0.01 to 25 oxidizer, 0 to 15 inhibitor for a nonferrous metal, 0 to 15 abrasive, 0 to 20 complexing agent for the nonferrous metal, 0.01 to 12 barrier removal agent and balance water. The barrier removal agent is selected from the group comprising imine derivative compounds, hydrazine derivative compounds and mixtures thereof.

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

Chemical mechanical polishing compositions for copper and associated materials and method of using same

A CMP composition containing a rheology agent, e.g., in combination with oxidizing agent, chelating agent, inhibiting agent, abrasive and solvent. Such CMP composition advantageously increases the materials selectivity in the CMP process and is useful for polishing surfaces of copper elements on semiconductor substrates, without the occurrence of dishing or other adverse planarization deficiencies in the polished copper.

Owner:ADVANCED TECH MATERIALS INC

Method for grinding soft crisp functional crystal

InactiveCN101376228AAvoid scratchesPrevent embeddingSupport wheelsAqueous dispersionsHigh surfaceGrinding wheel

A soft brittle functional crystal grinding and machining method belongs to the technical field of soft brittle functional crystal machining, and particularly relates to a soft brittle functional crystal ultra-precision grinding and machining method for a semiconductor and a photoelectric crystal. The method is characterized in that a micro-powder diamond segmental variable speed feed and a soft abrasion grinding wheel chemical mechanical grinding method are adopted to machine the soft brittle function crystal. During the crude grinding period and the accurate grinding period, the feeding speed of the grinding wheel is firstly high and then low. A grinding fluid is de-ionized water. A soft abrasive agent grinding wheel is adopted to conduct the chemical mechanical grinding. The soft abrasive agent is a macromolecule polymer or waterproof resin. A filler is NaHCO3 or a refined naphthalene foaming agent. The chemical and mechanical grinding fluid is adopted as a reaction fluid and a cooling fluid. The grinding fluid mainly contains lactic acid, acetic acid and de-ionized water. The pH value of the grinding fluid is 2-4. The invention has the advantages of high grinding and machining efficiency, low machining cost and high surface precision. In addition, no surface / sub-surface damage is caused to the surface of a workpiece, such as small scratches, embedment of free abrasive agent, plastic deformation, residual stress, and the like.

Owner:DALIAN UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com