Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2445results about "Auxillary equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

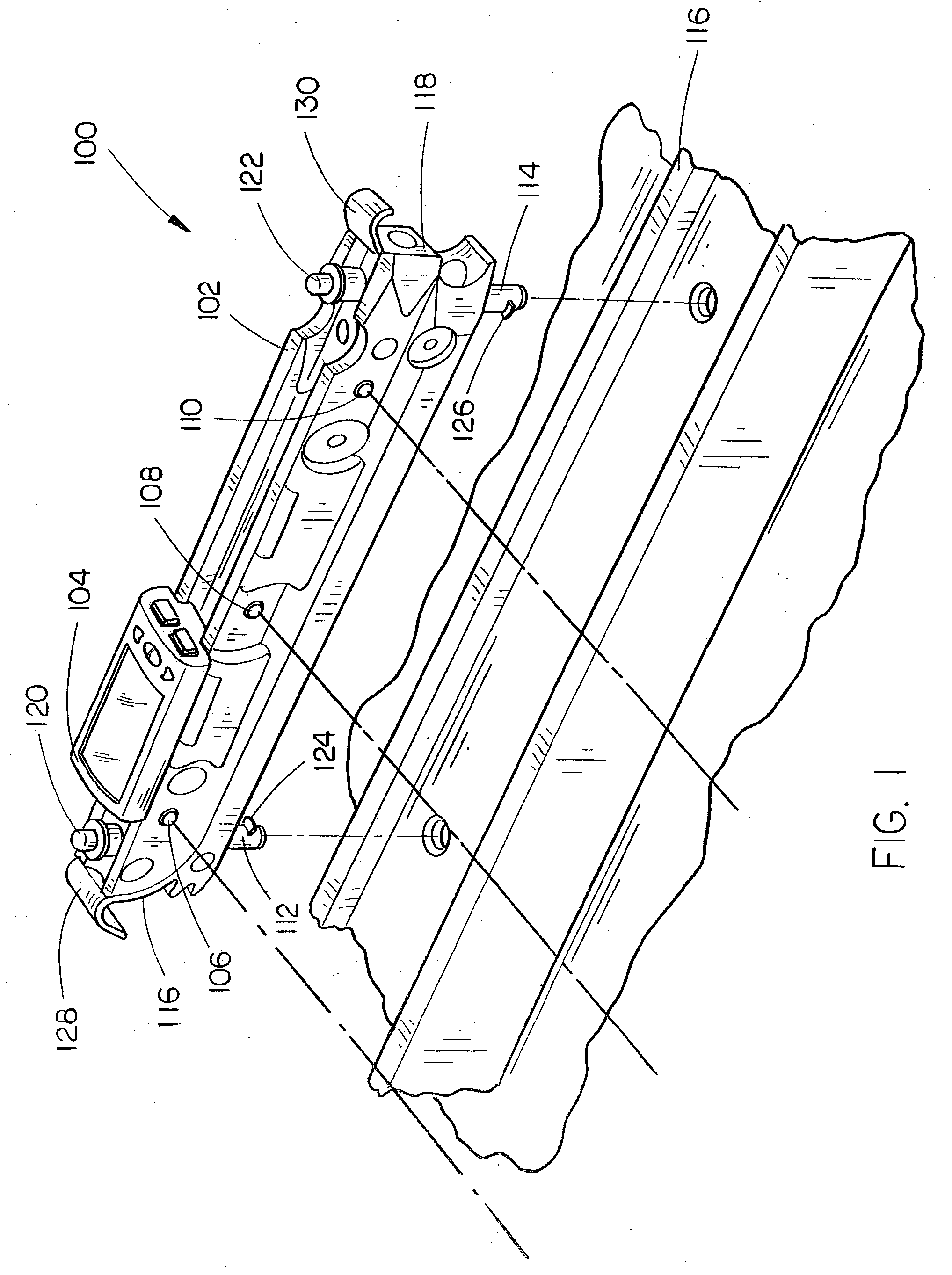

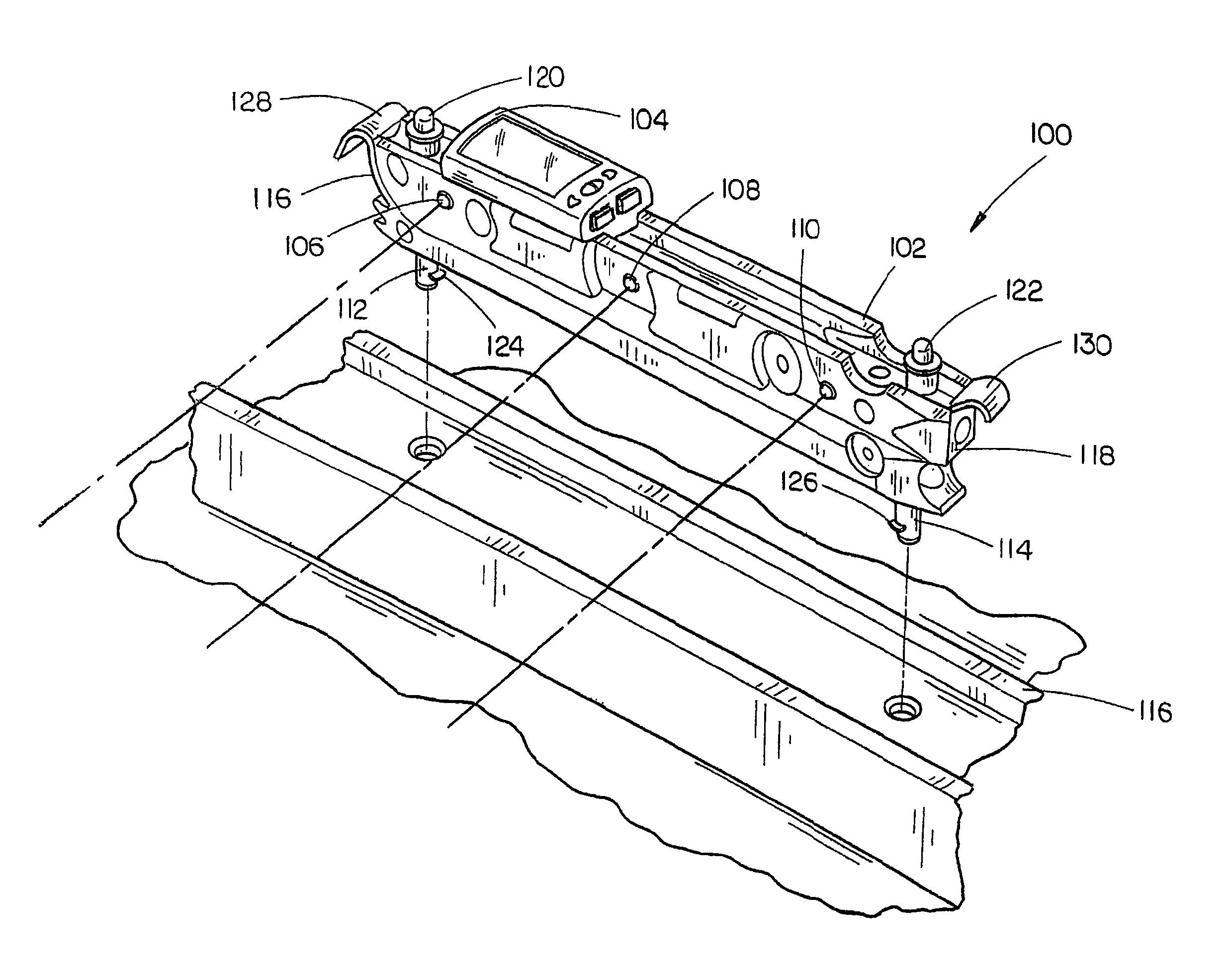

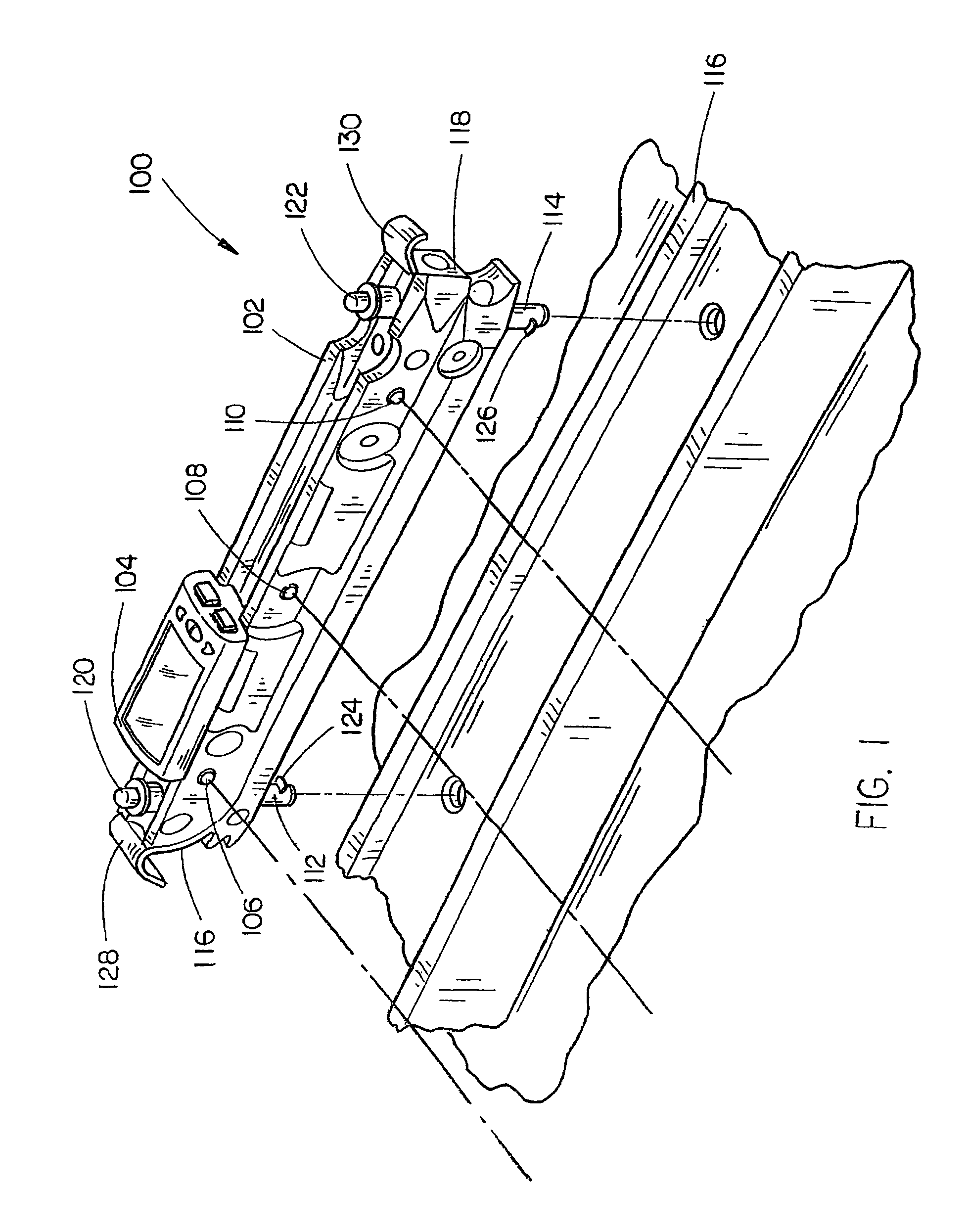

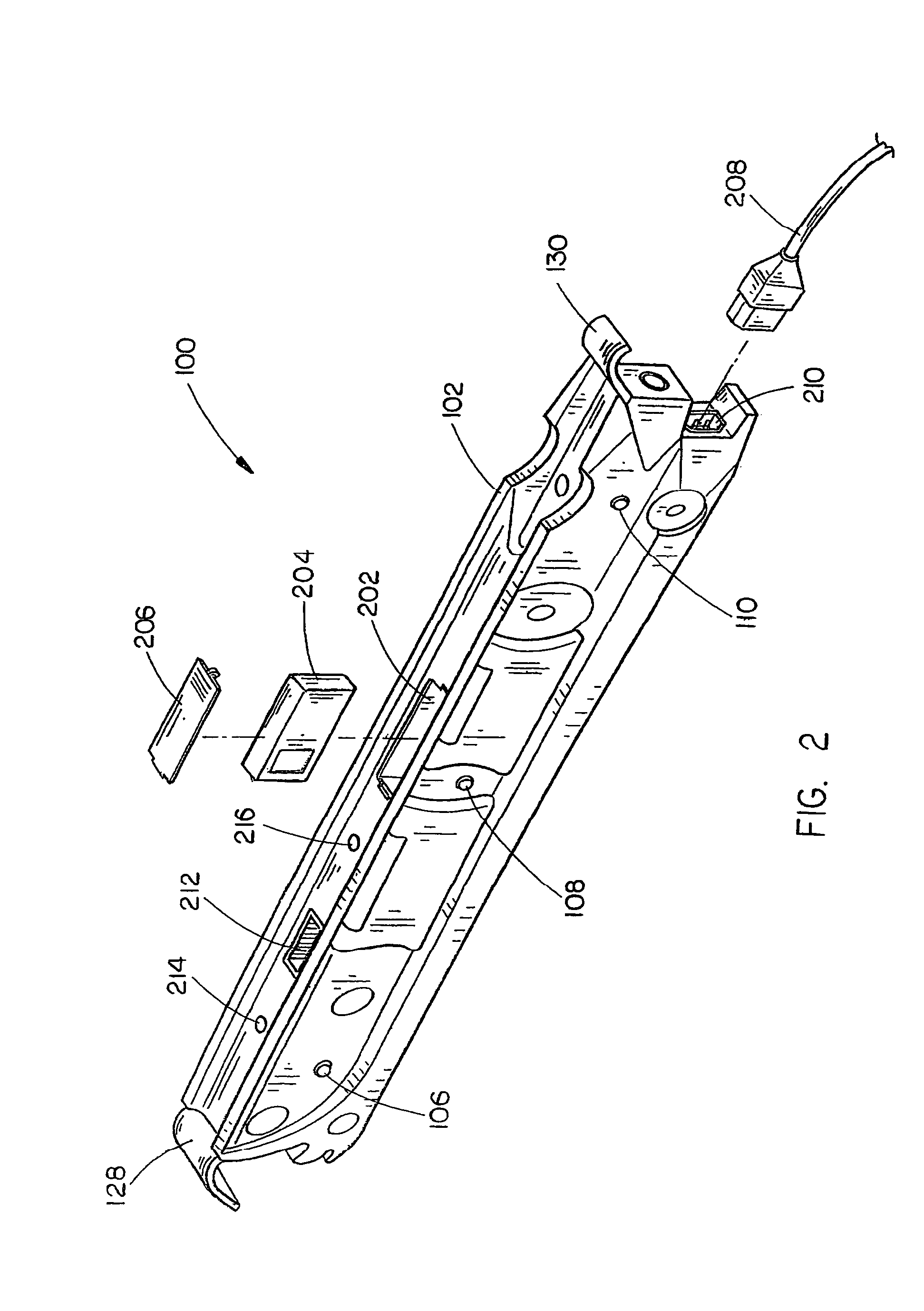

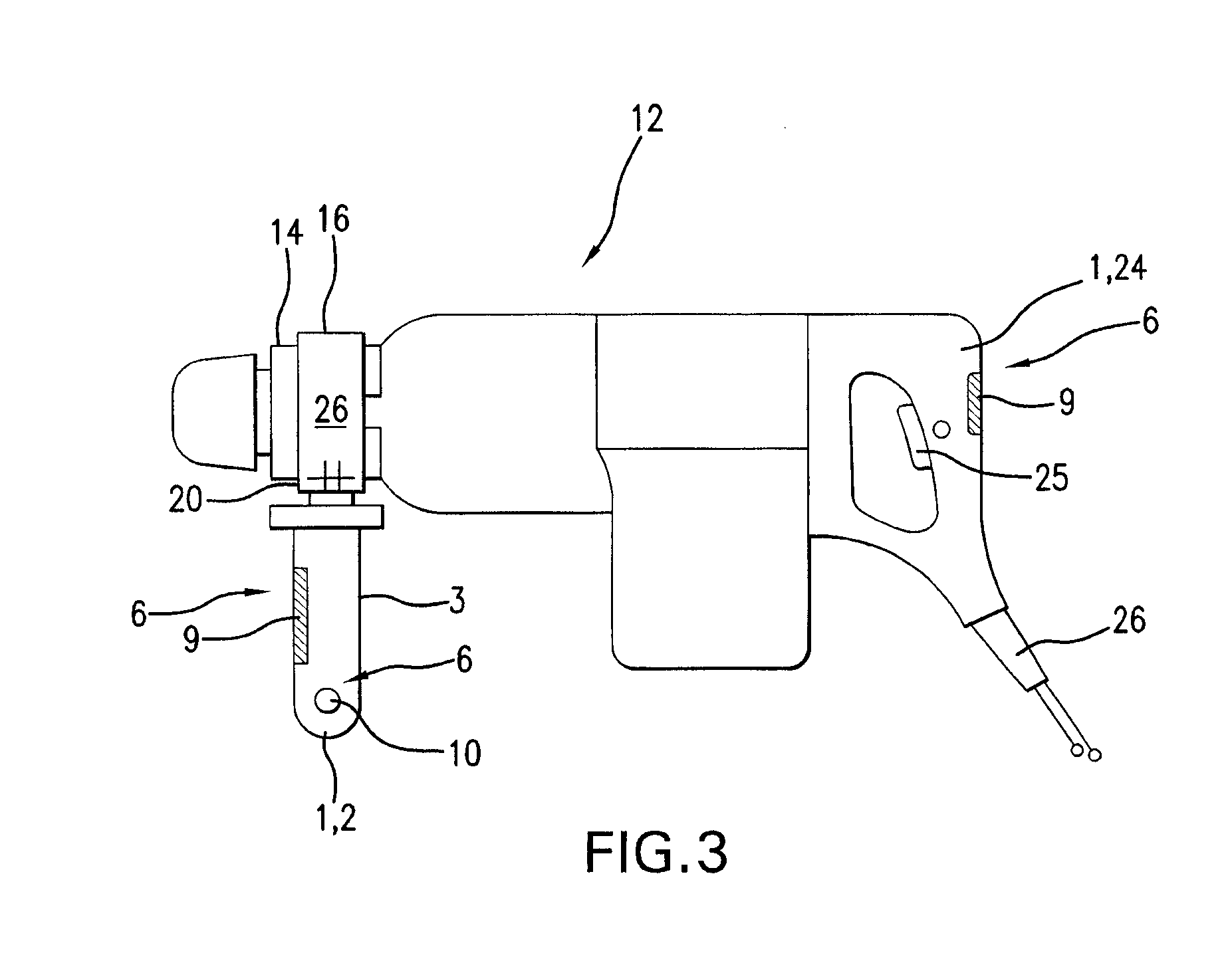

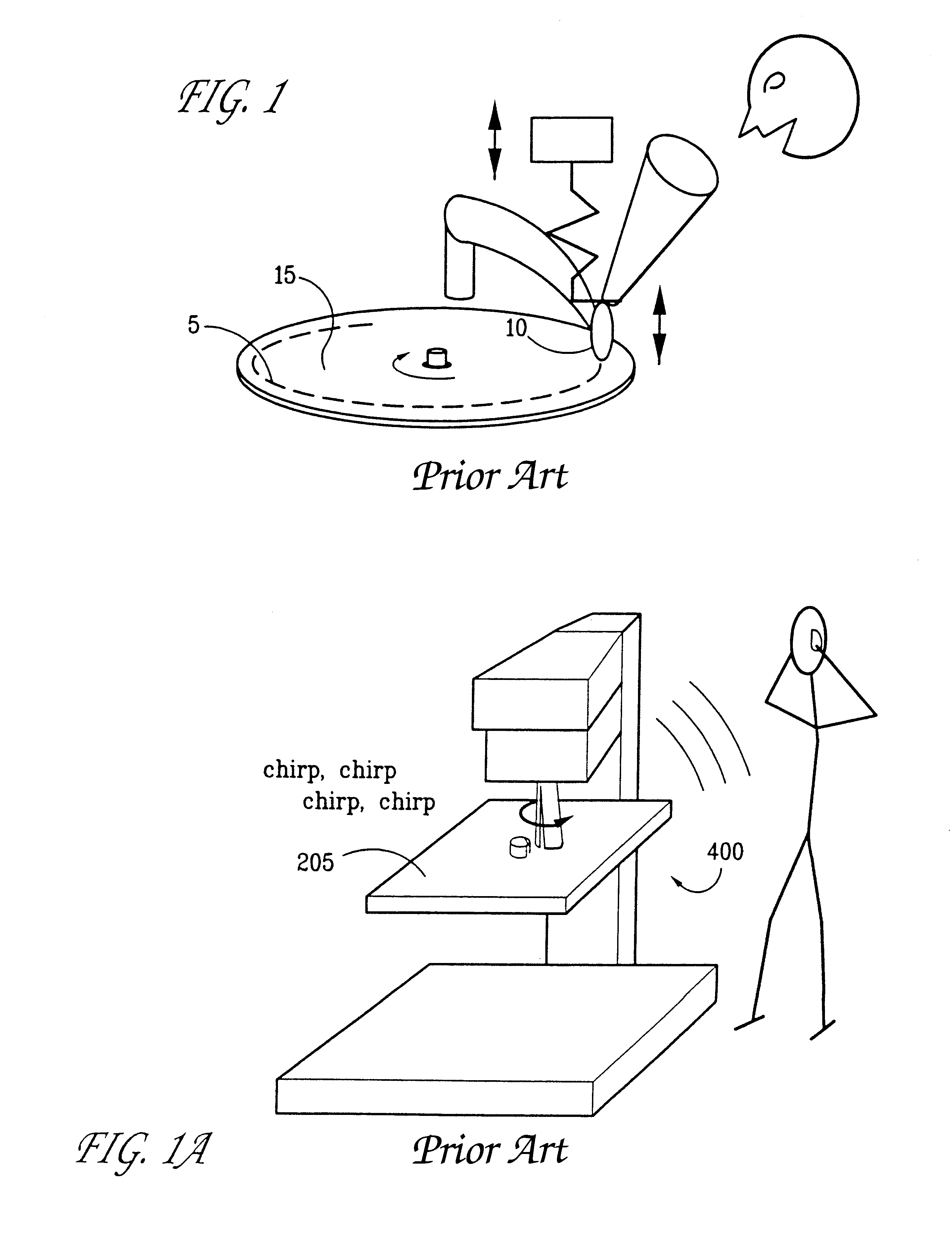

Power tool control system

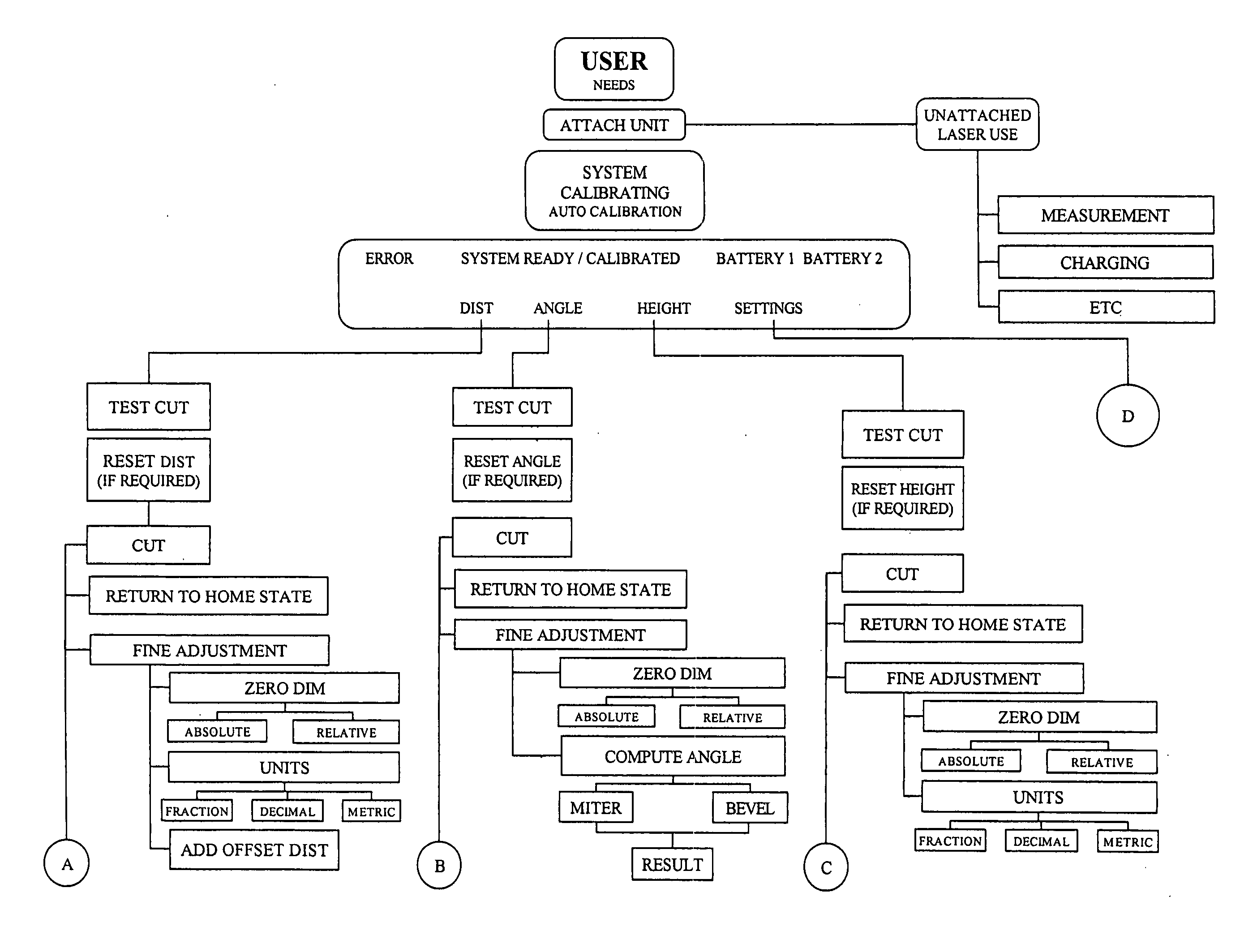

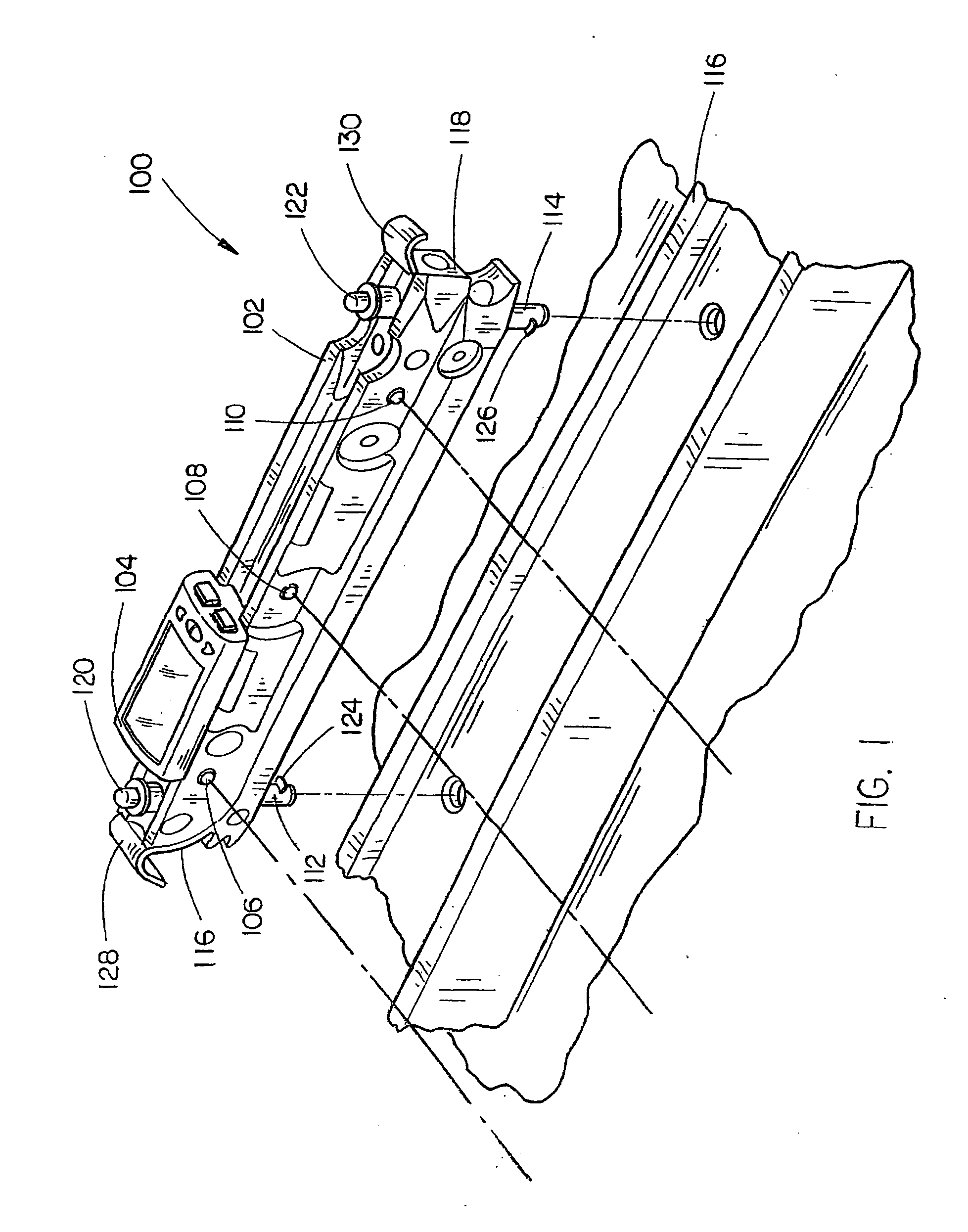

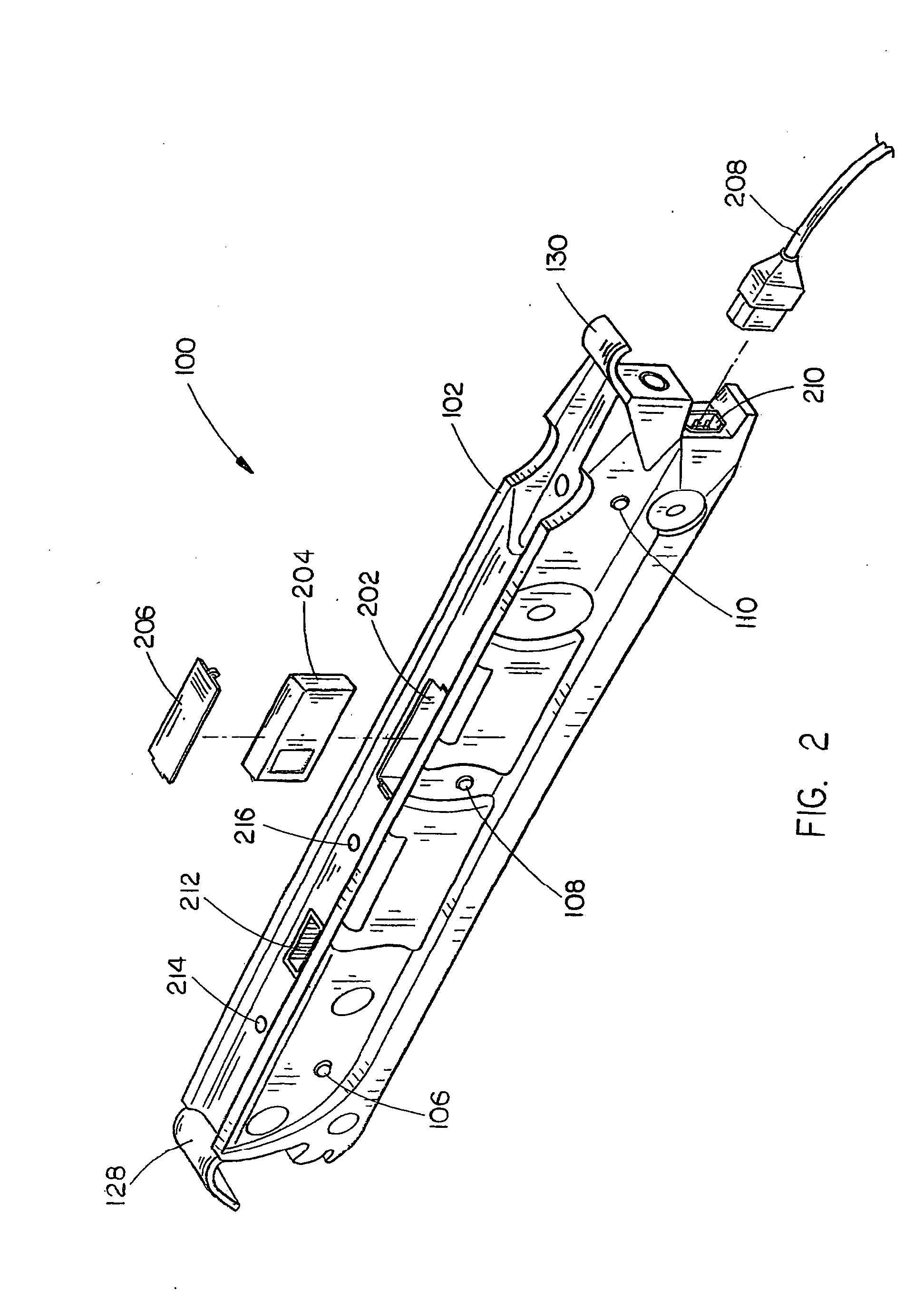

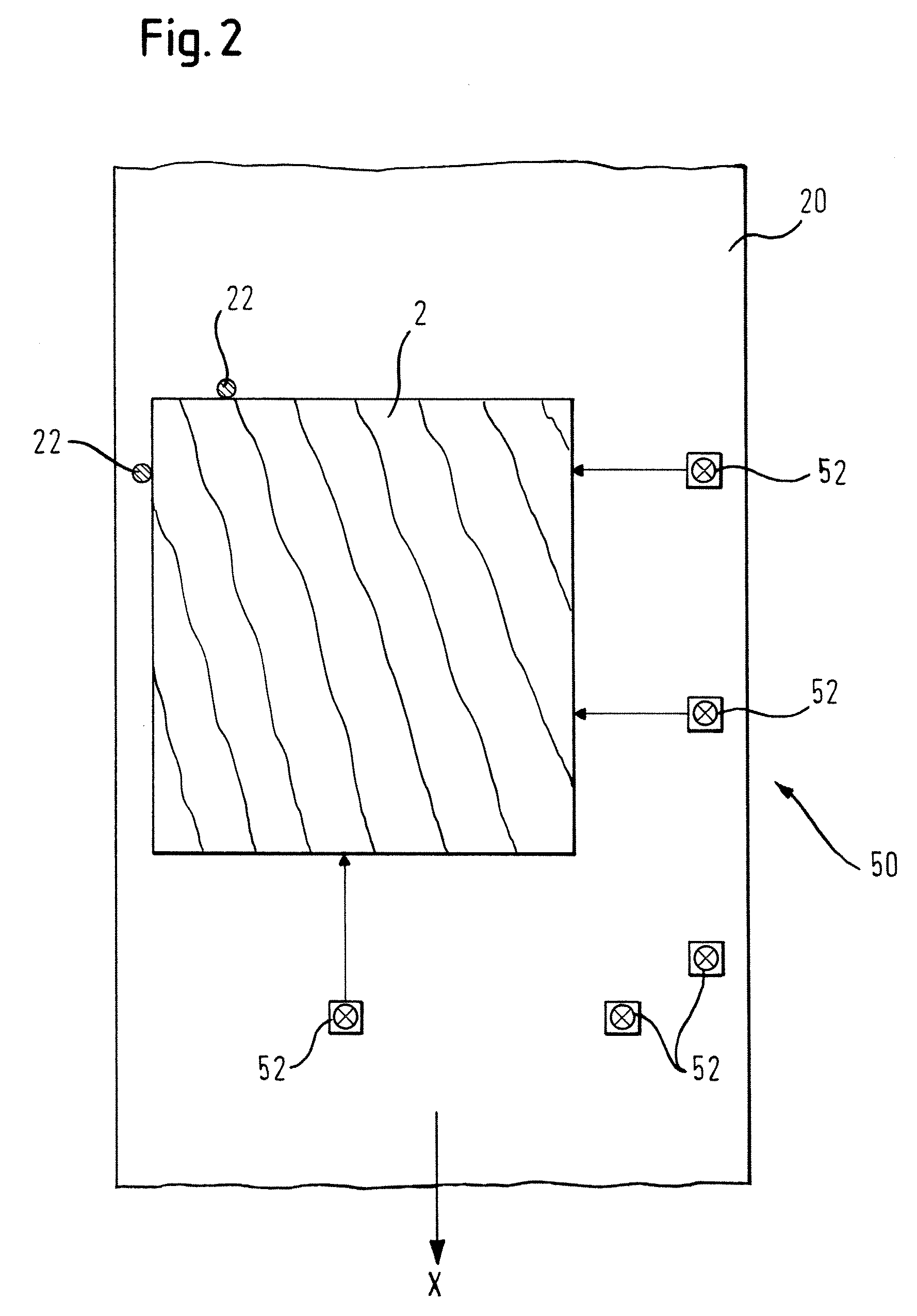

InactiveUS20060076385A1Quality improvementWell formedStapling toolsDrilling/boring measurement devicesUser needsGraphics

A power tool control system allows a user to operate a power tool through a graphical user interface communicatively coupled with a non-contact measurement and alignment device. The graphical user interface correlates user engageable selectors with a logically related menu of power tool setting options displayed on a display screen in a high quality and easily readable format. The non-contact measurement and alignment device uses one or more lasers to determine power tool settings and establish proper alignment based on user needs. The power tool control system further enables stud detection and visual indication of stud location.

Owner:BLACK & DECKER INC

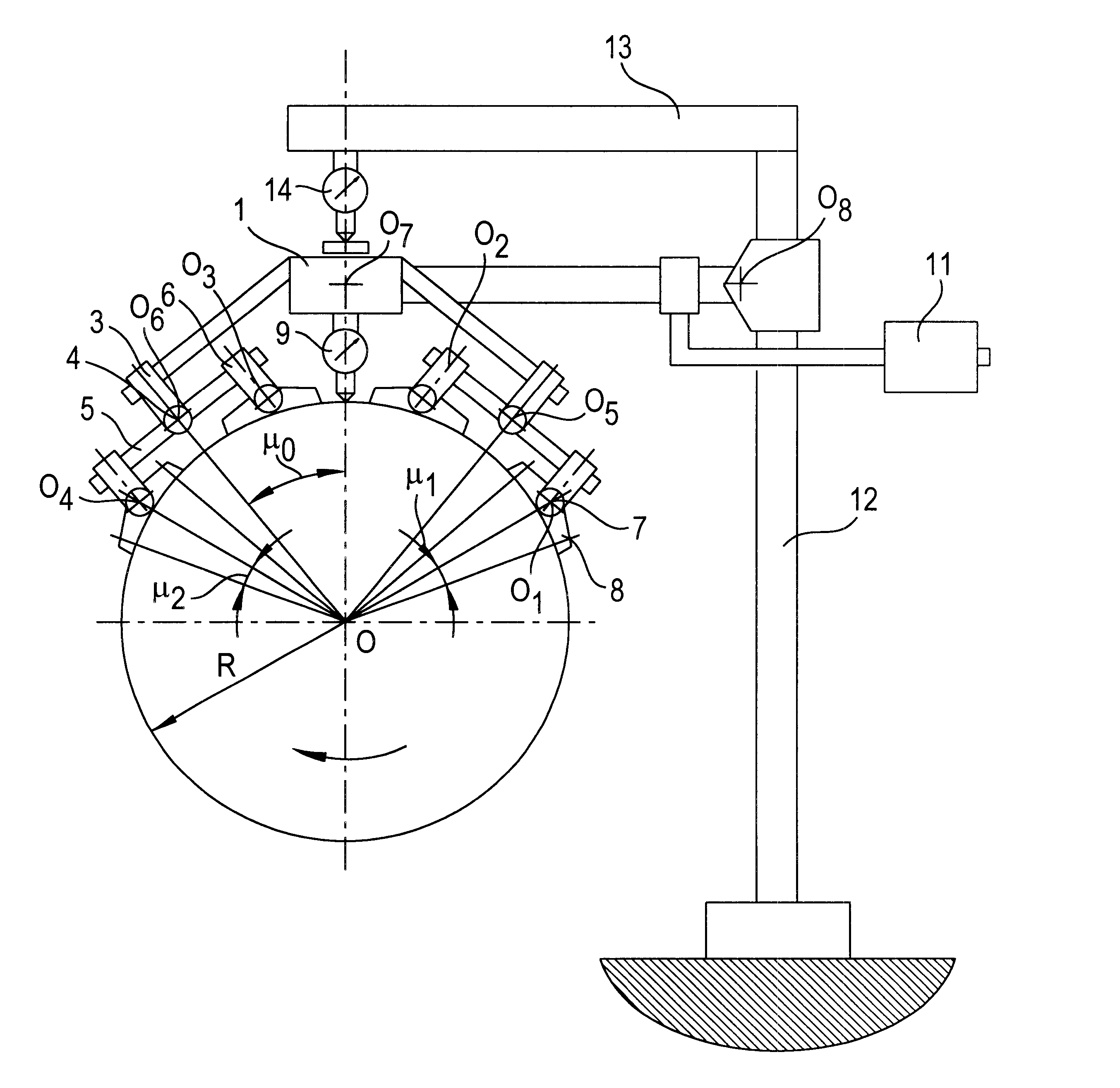

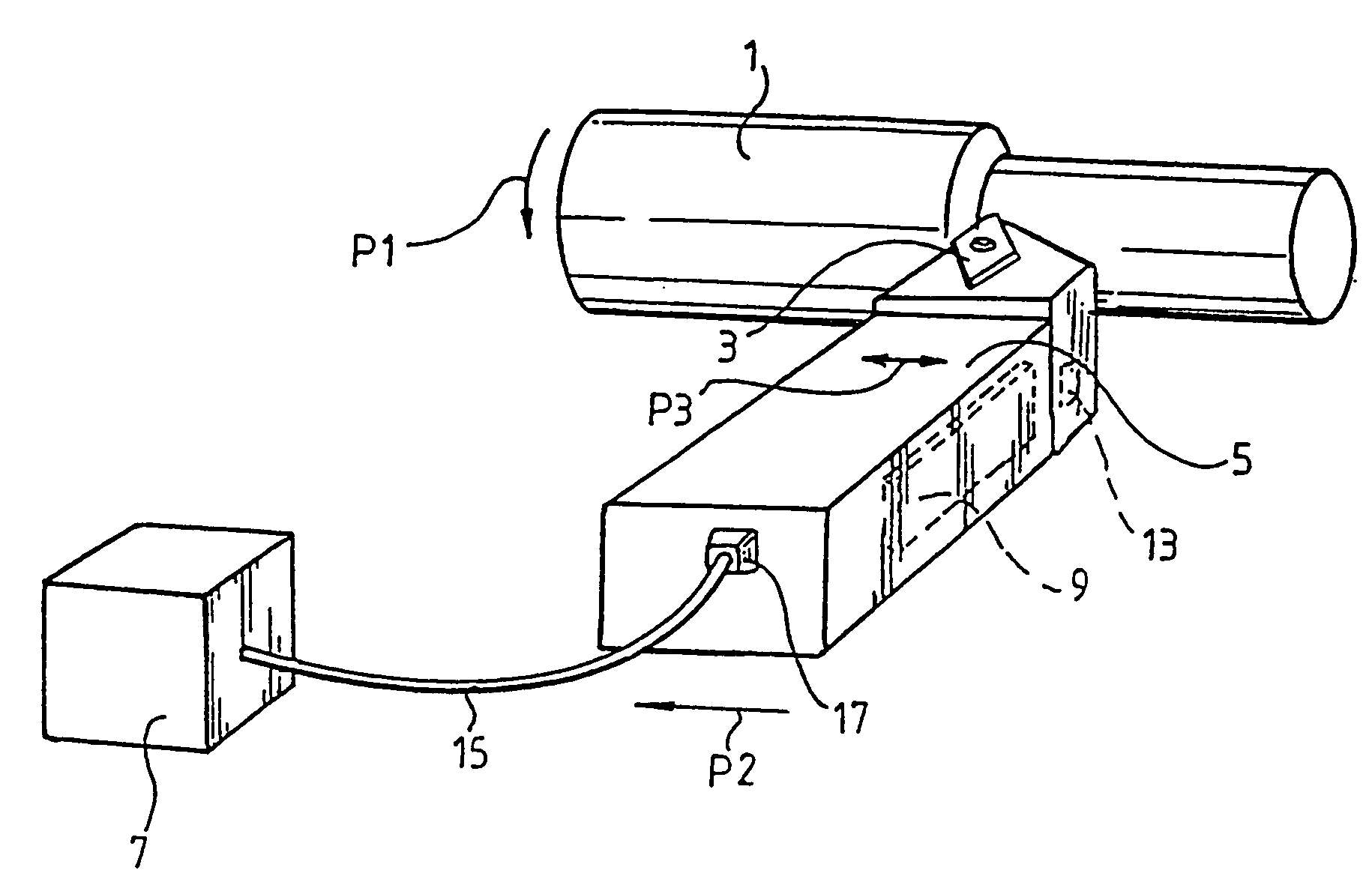

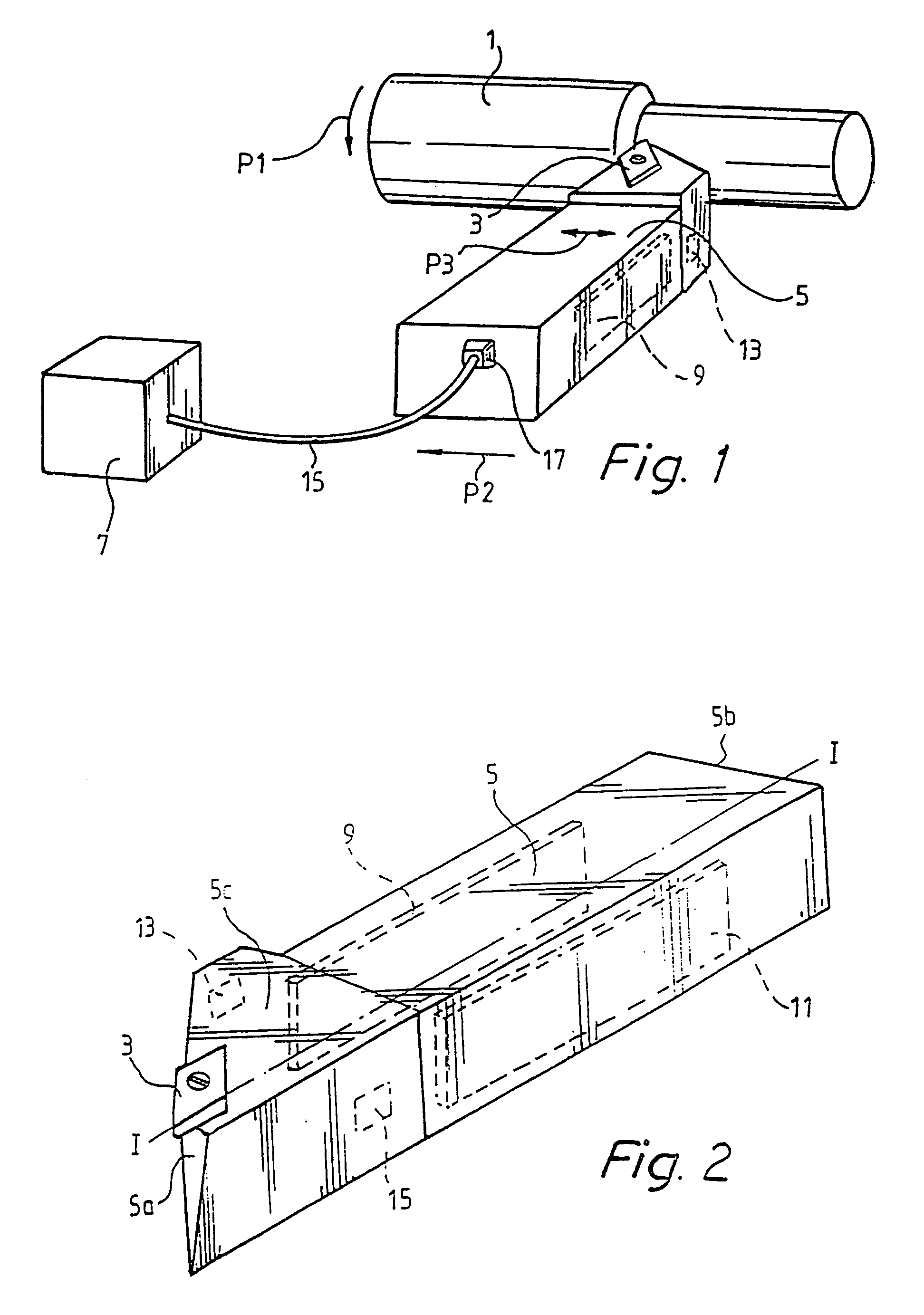

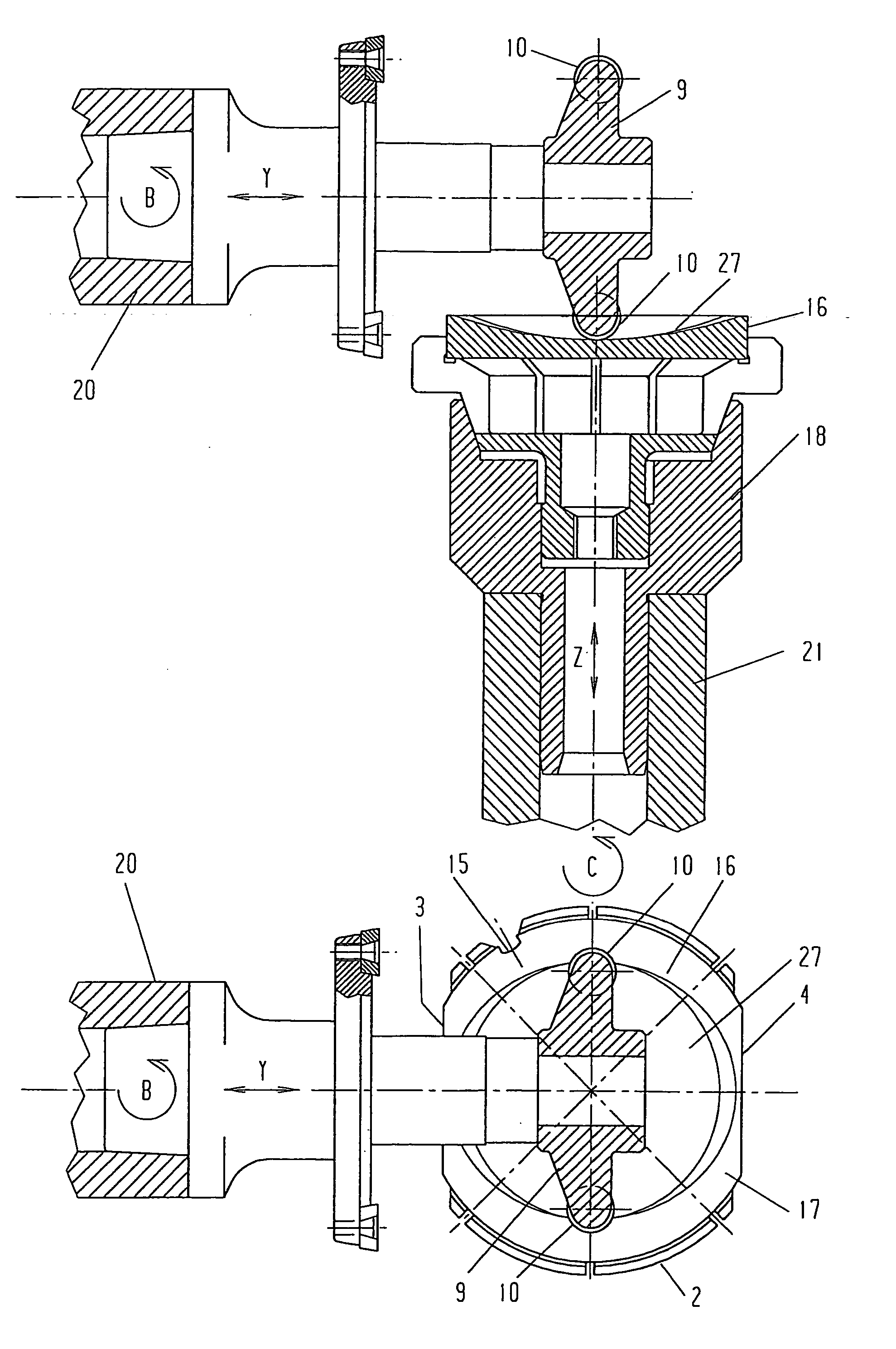

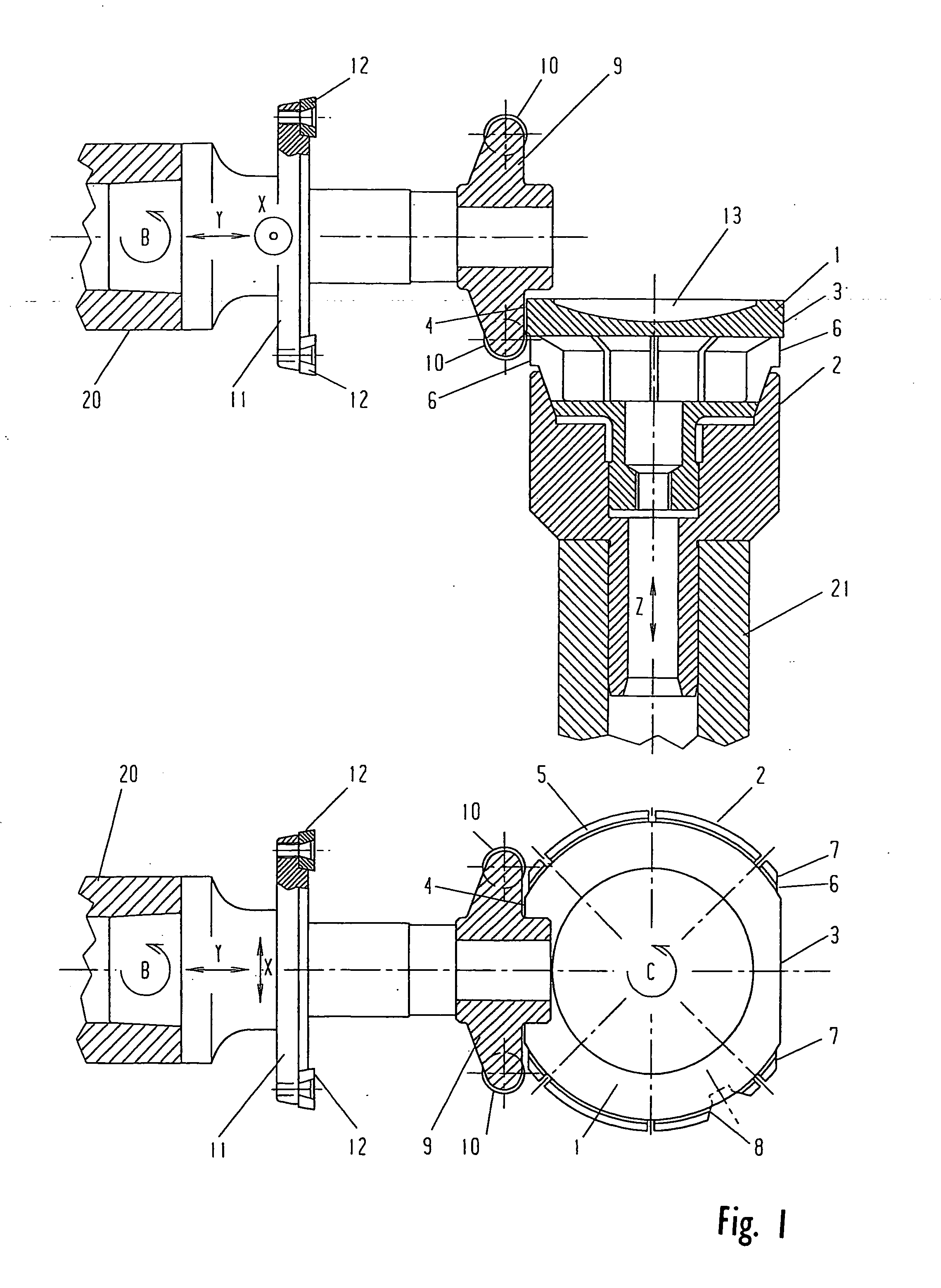

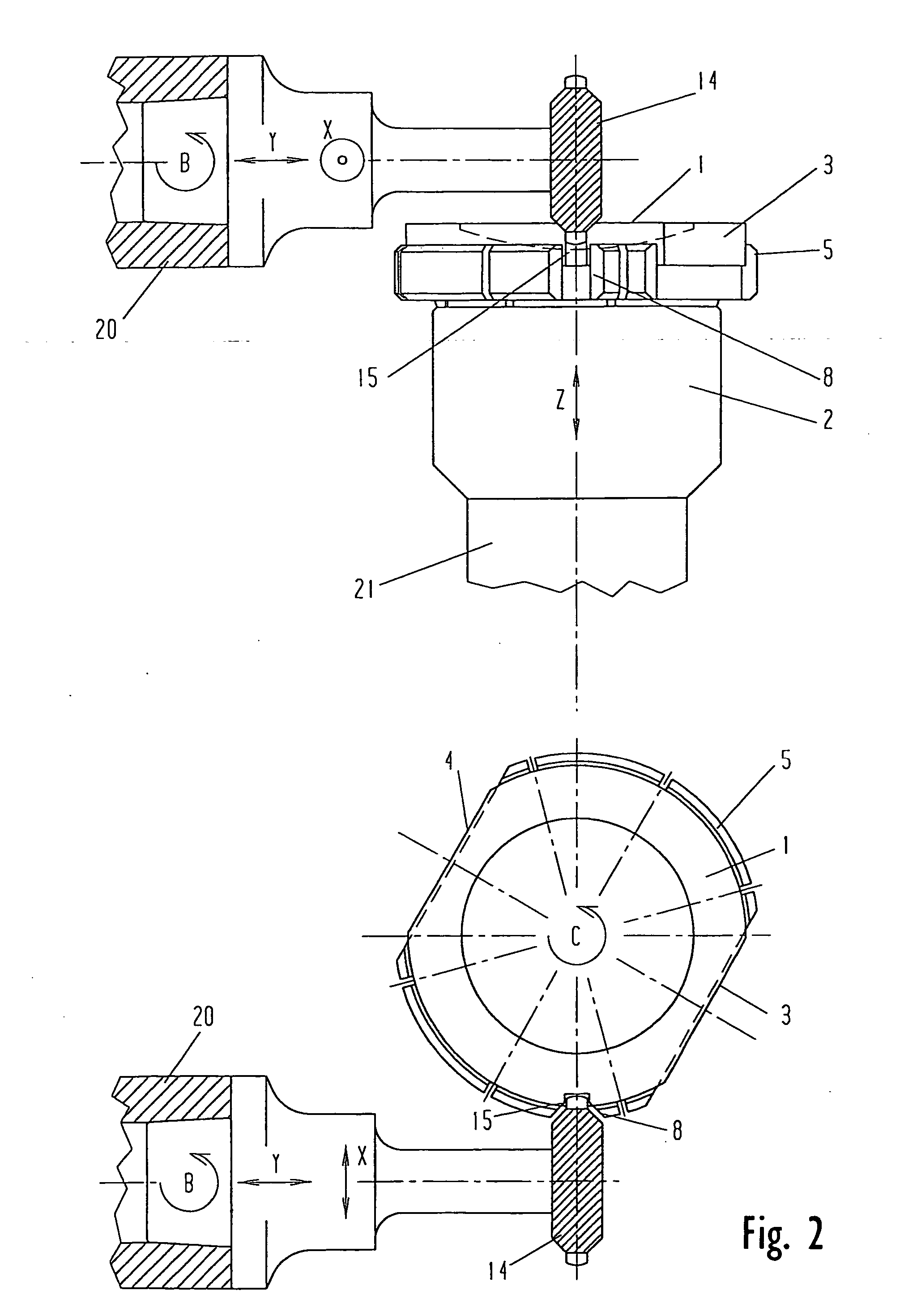

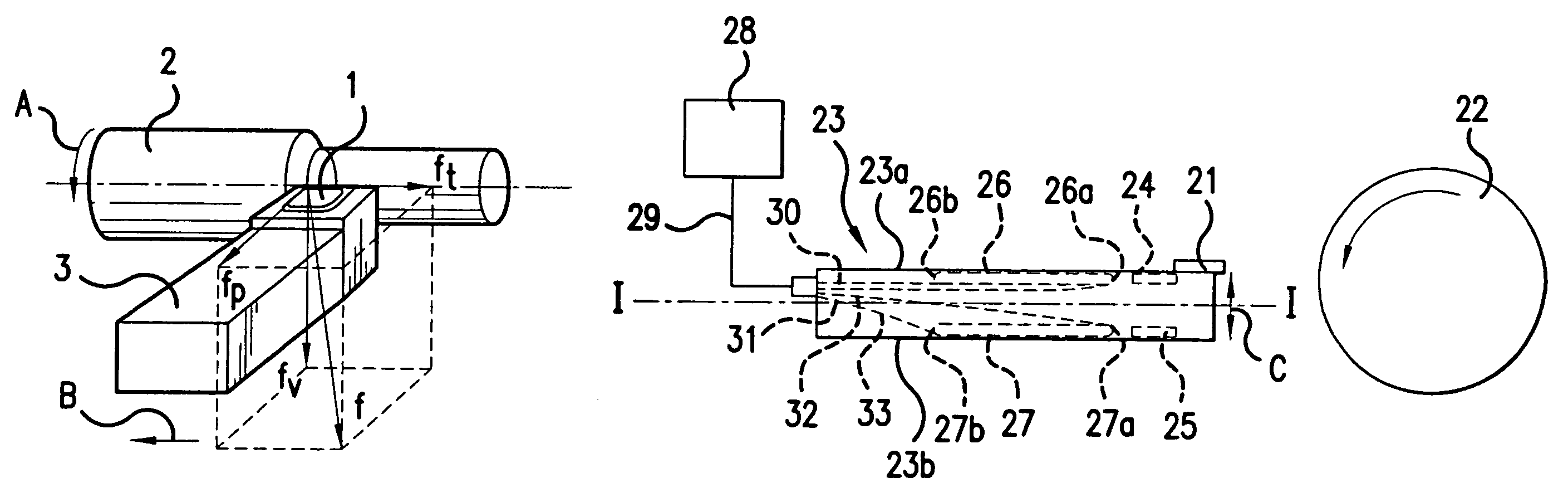

Device and method for measuring shape deviations of a cylindrical workpiece and correcting steadying element and correcting follower for use therewith

InactiveUS6568096B1Accurate measurementPrecise processingLathesAngles/taper measurementsShape deviationEngineering

A device and method for measuring deviations in shape of a generally cylindrical workpiece is disclosed. The device enables measurement of a number of shape-defining parameters while the workpiece is positioned in a machine tool, so that the workpiece does not have to be removed from the machine tool in order for the measurements to be taken. A steadying rest, for use on machine tools to hold a workpiece, especially one having a longitudinal central axis that is rotationally unsymmetrical or unstable with respect to the machining tool, in position to enable measurement of the shape defining parameters and shape deviations while the workpiece is mounted on the machine tool, is also disclosed.

Owner:OBSCHESTVO S OGRANICHENNOI OTVETABTVENNOSTIJU TEKHNOMASH

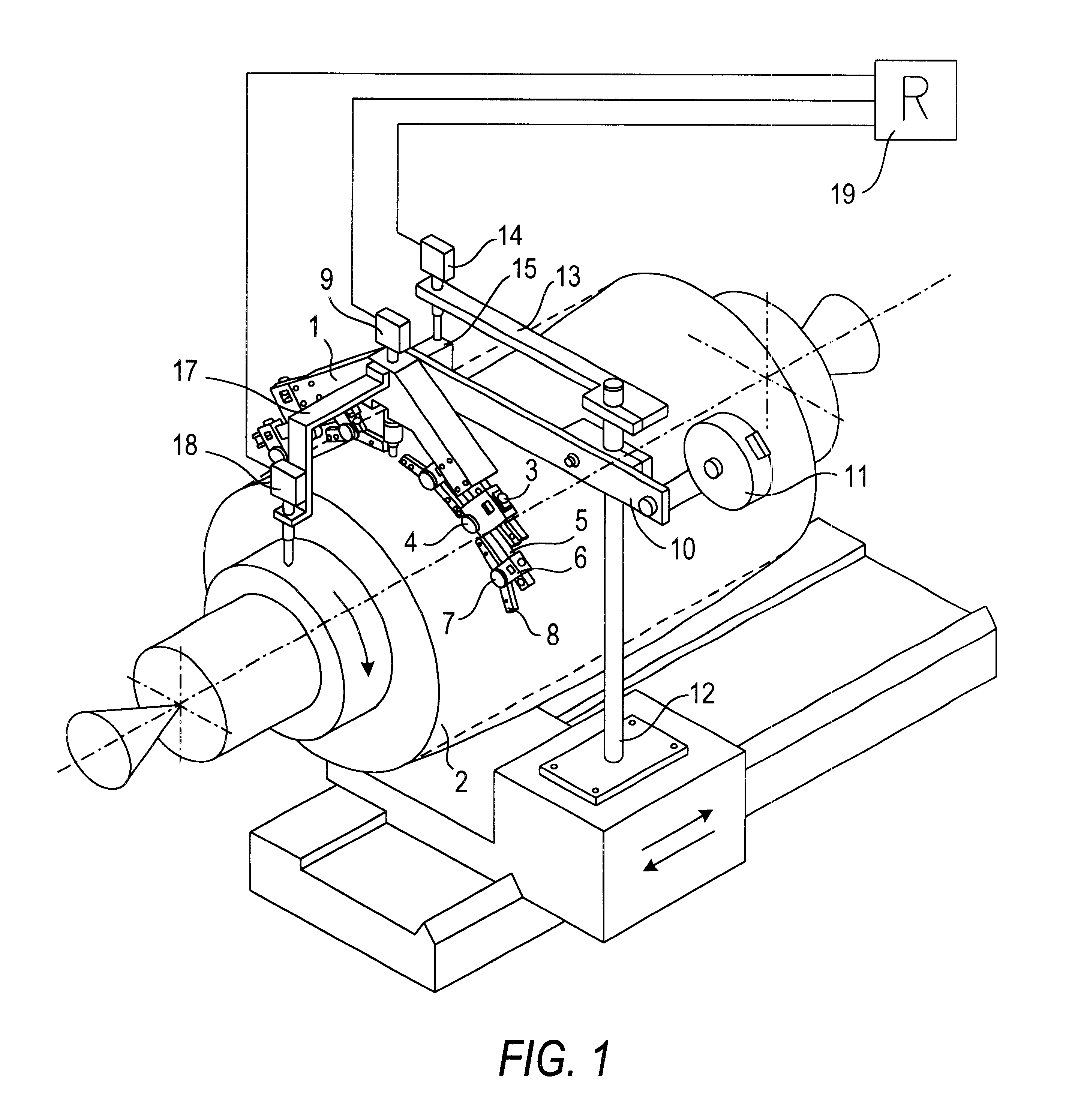

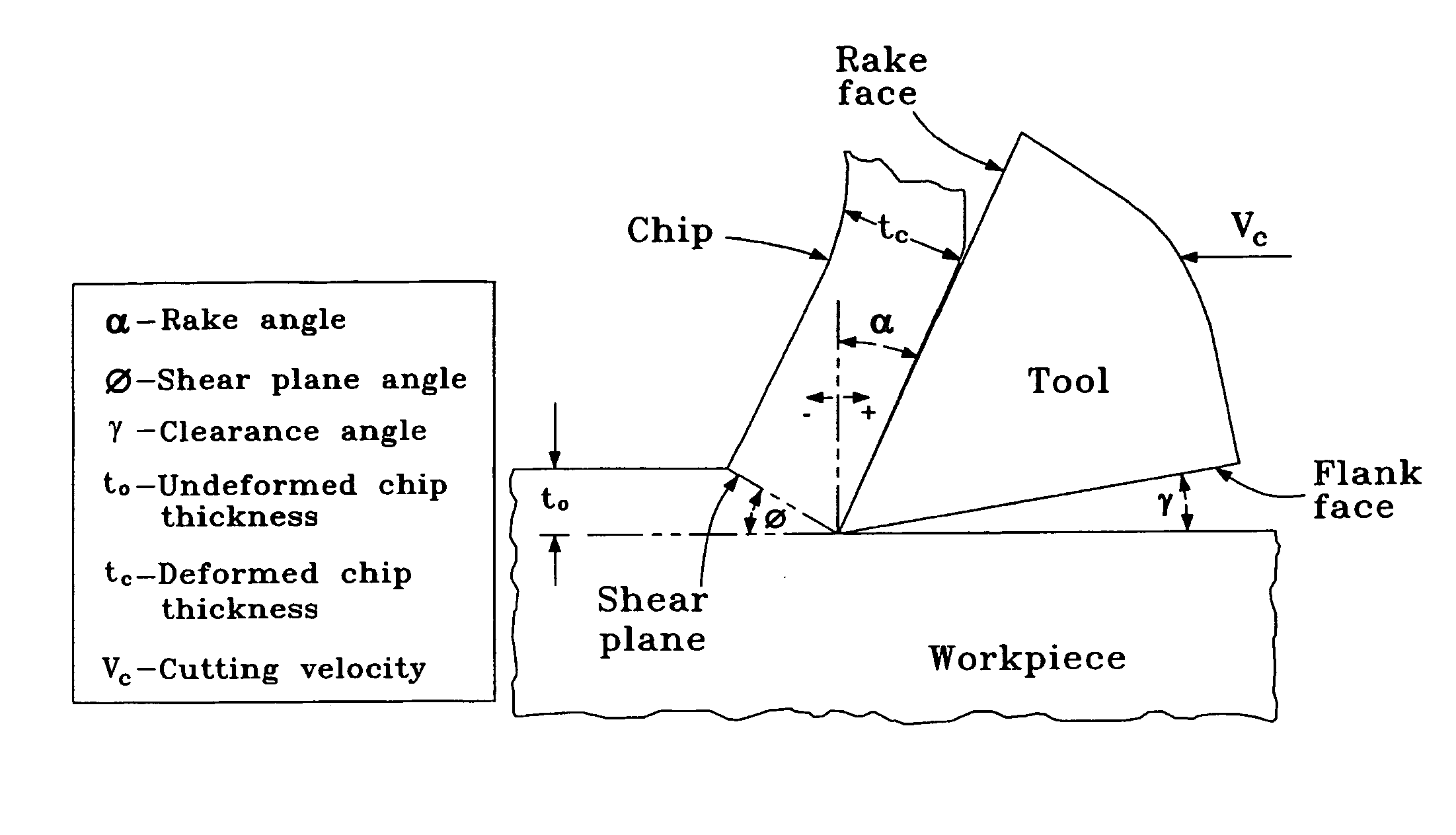

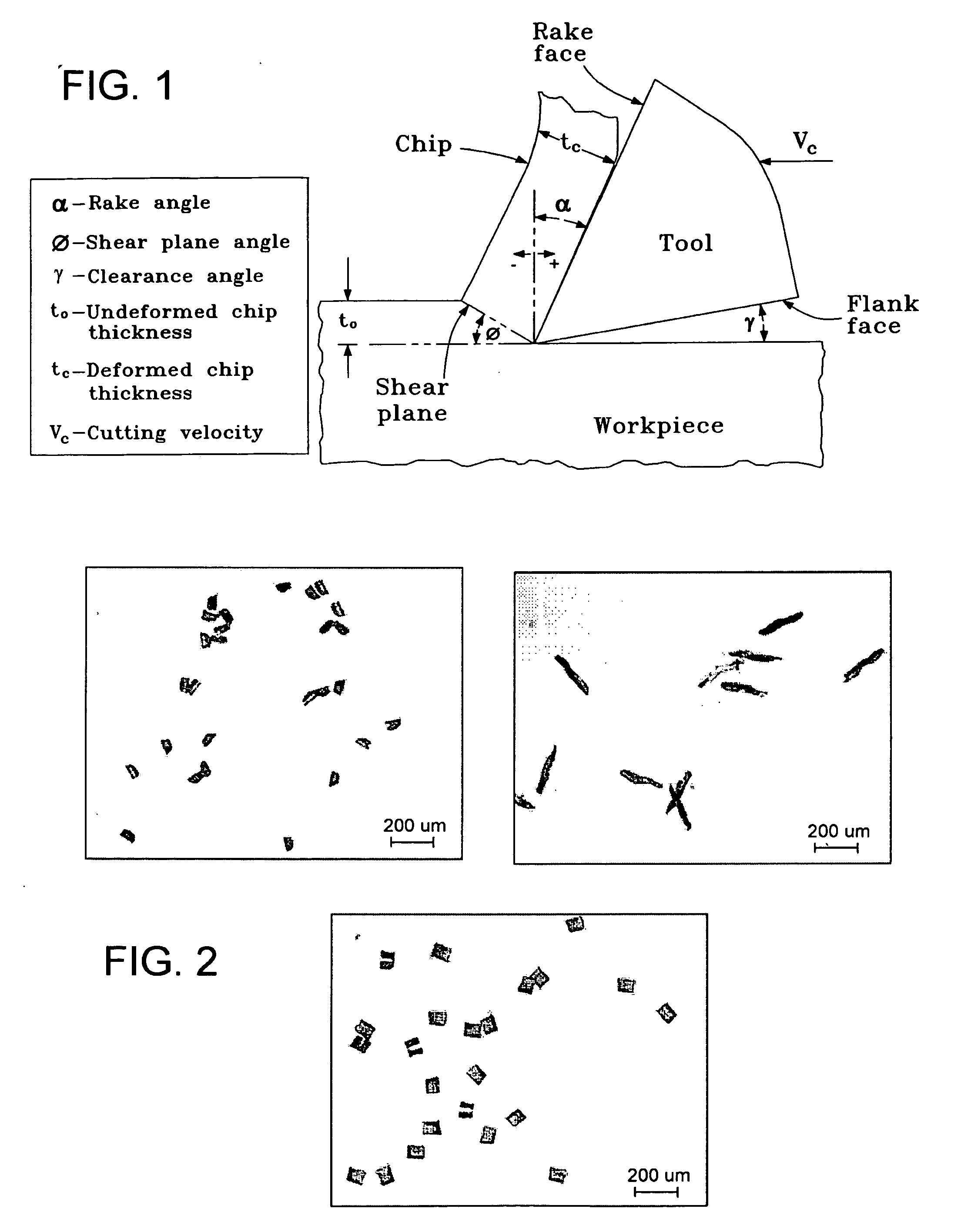

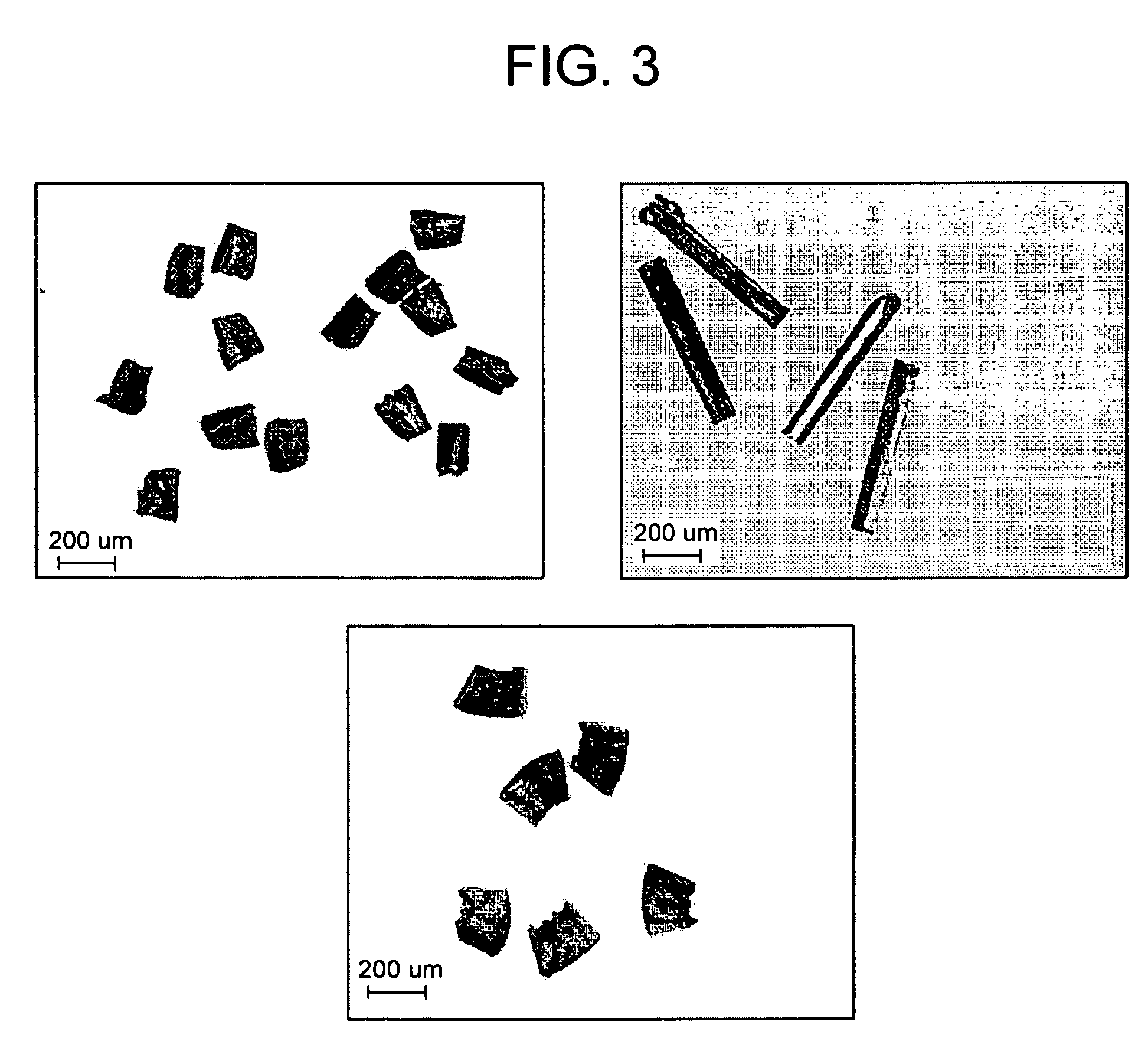

Methods and systems for chip breaking in turning applications using CNC toolpaths

ActiveUS20090107308A1Reduce the temperatureEnhances ability implementProgramme controlLathesNumerical controlEngineering

The present invention provides methods and systems for chip breaking, controlling cutting tool wear, and the like in turning, boring, and other applications, including: engaging a workpiece with a cutting tool in a feed direction along a toolpath, superimposing an oscillation in the feed direction on the toolpath, and dynamically or non-dynamically varying the oscillation superimposed in the feed direction on the toolpath such that interrupted cuts and chips of a predetermined length or less are produced. These systems take full advantage of computer numerical control (CNC) methodologies.

Owner:JUNIVERSITI OF NORT KAROLINA EHT SHARLOTT +1

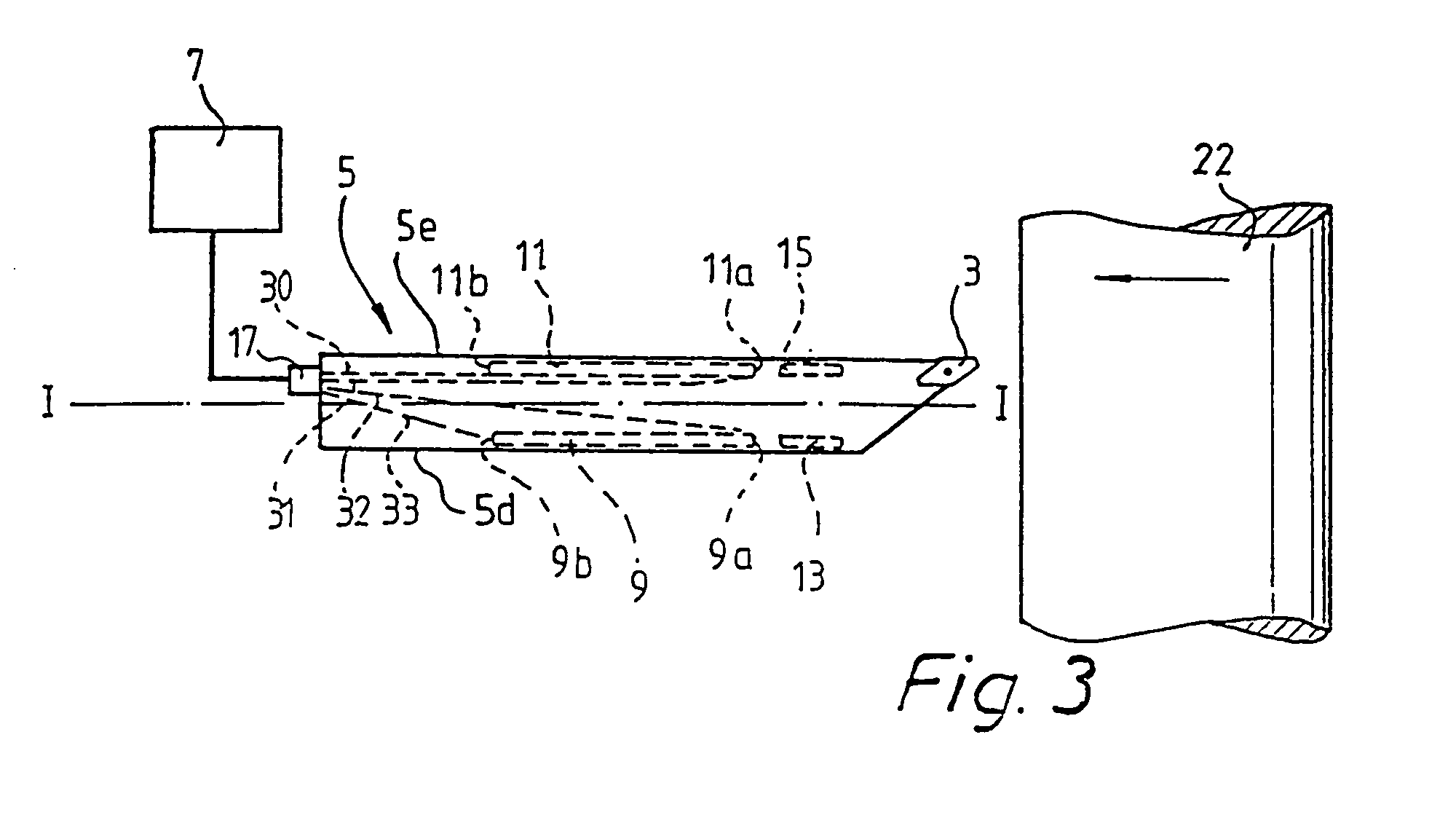

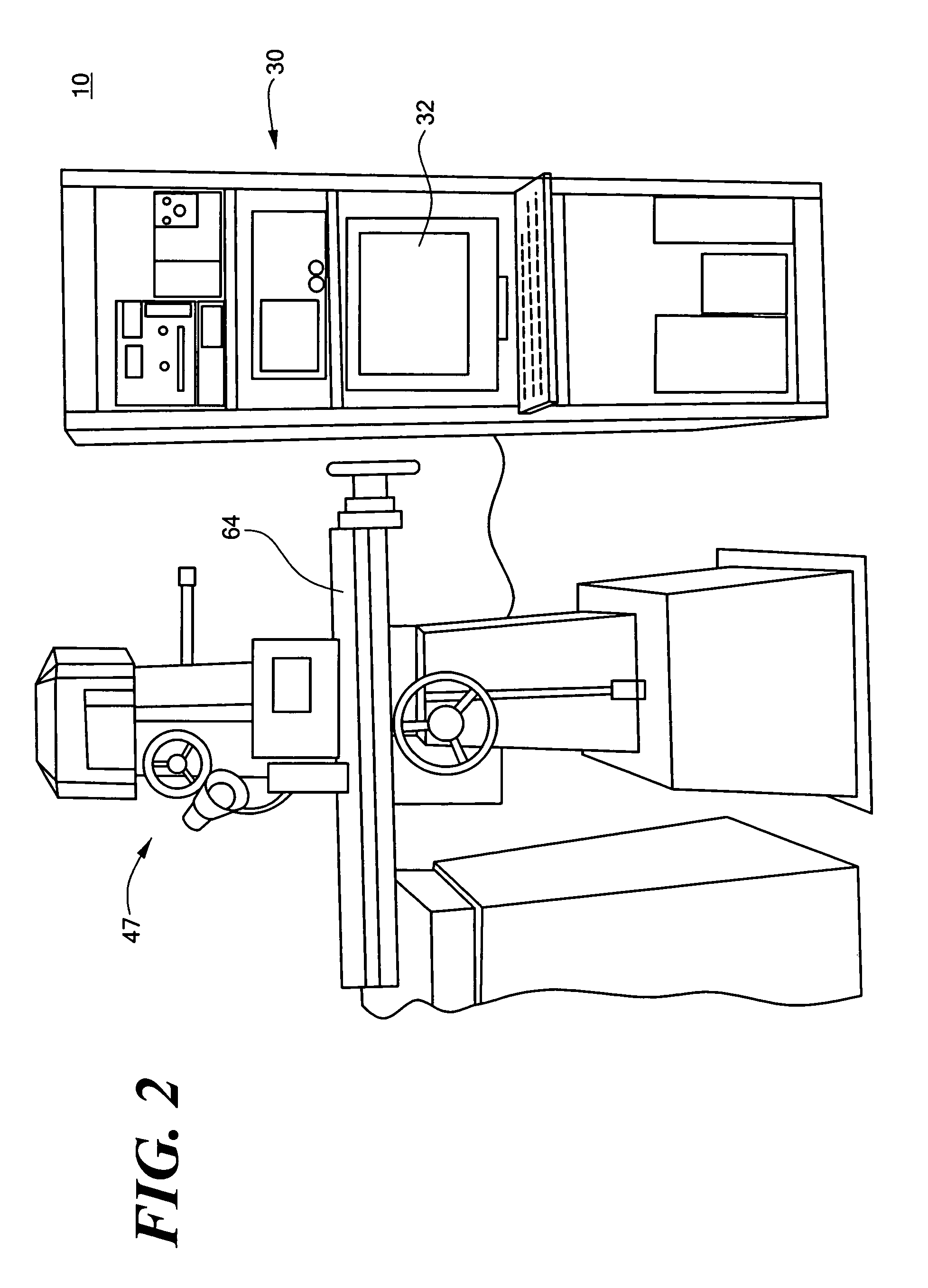

Power tool control system

InactiveUS8004664B2Quality improvementWell formedStapling toolsDrilling/boring measurement devicesGraphical user interfaceControl system

A power tool control system includes a non-contact measurement and alignment device operative with the power tool and enabled to establish various readings, such as power tool settings. A graphical user interface communicatively coupled with the non-contact measurement and alignment device enables user control over and display of the readings from the non-contact measurement and alignment device.

Owner:CHANG TYPE INDAL

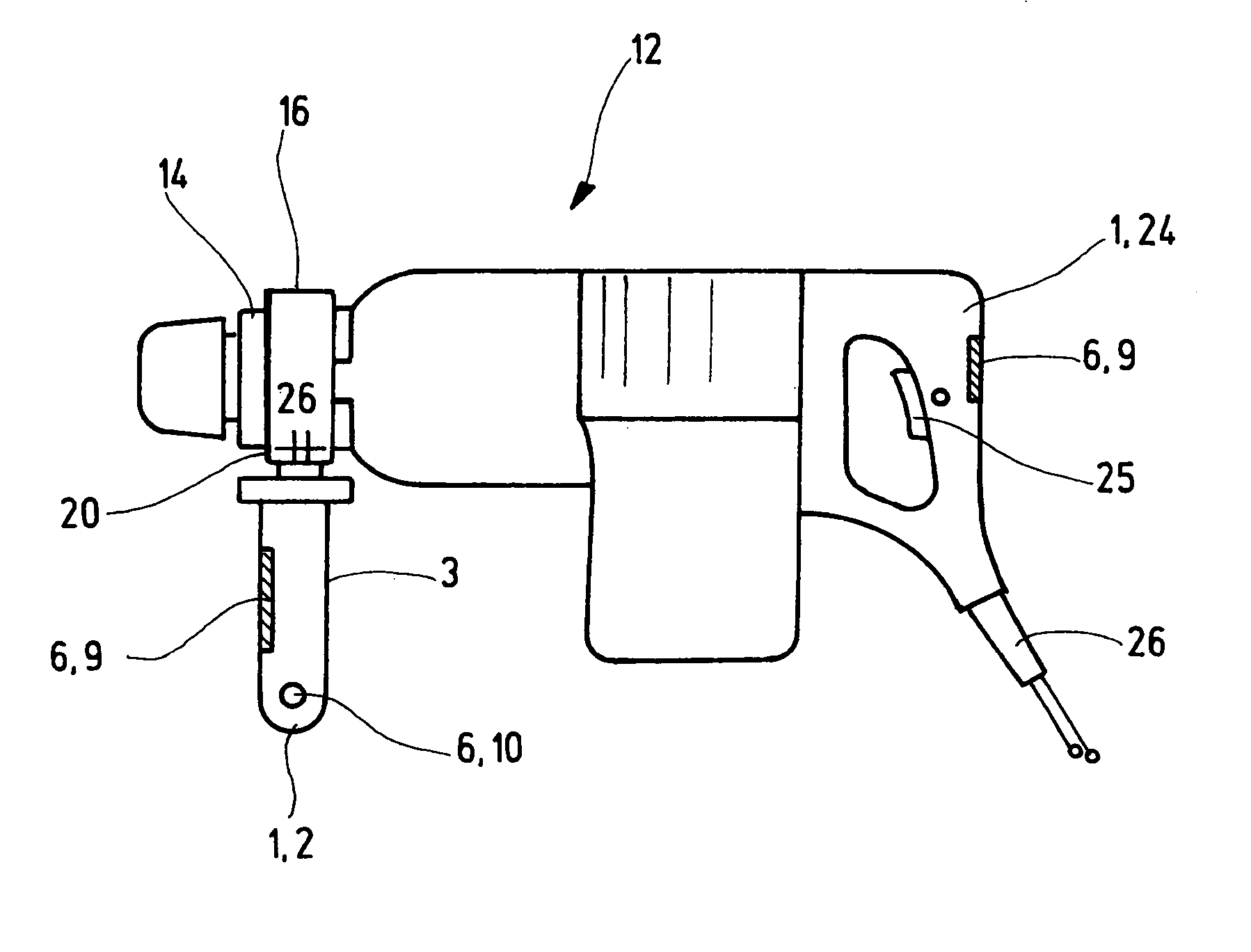

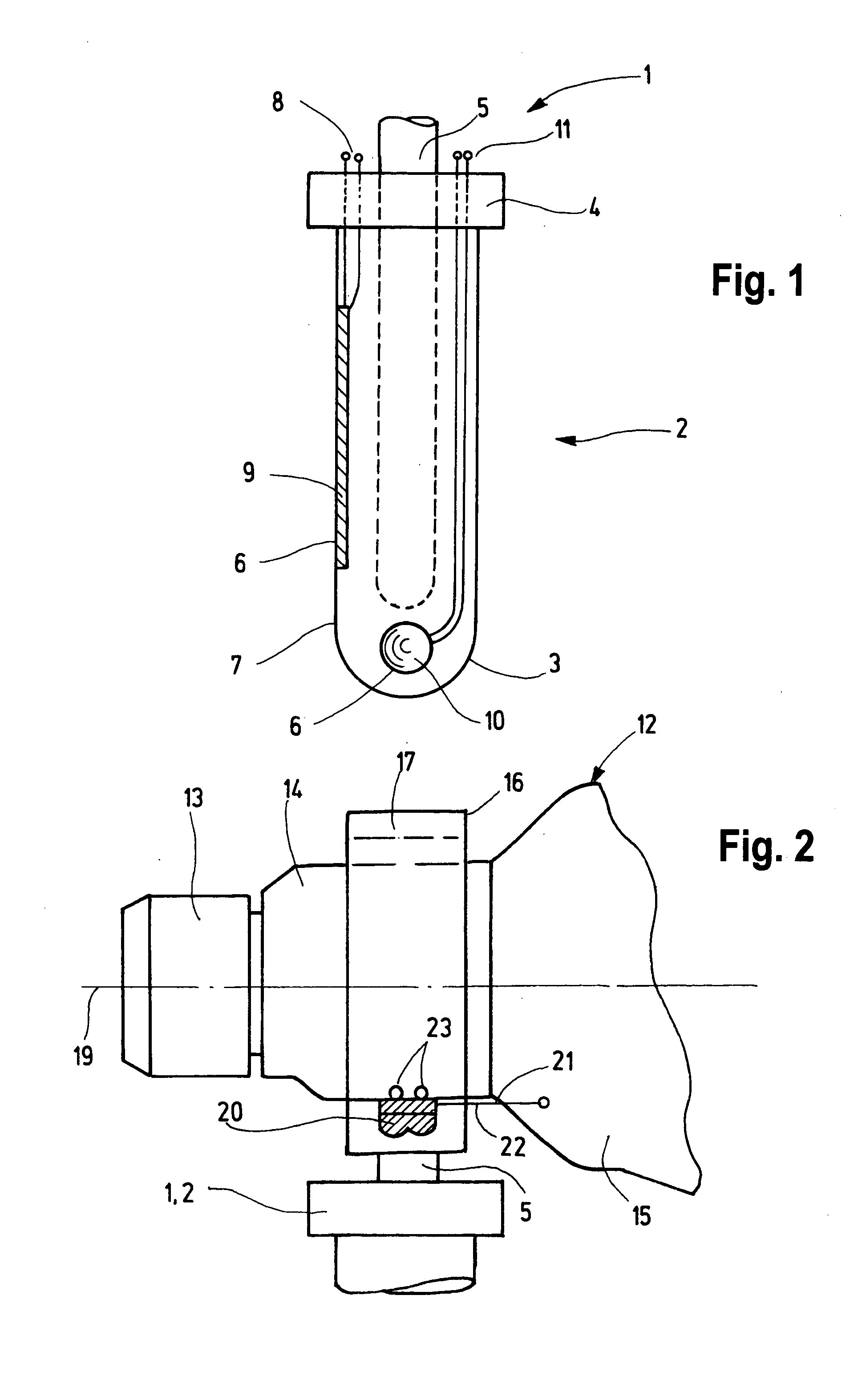

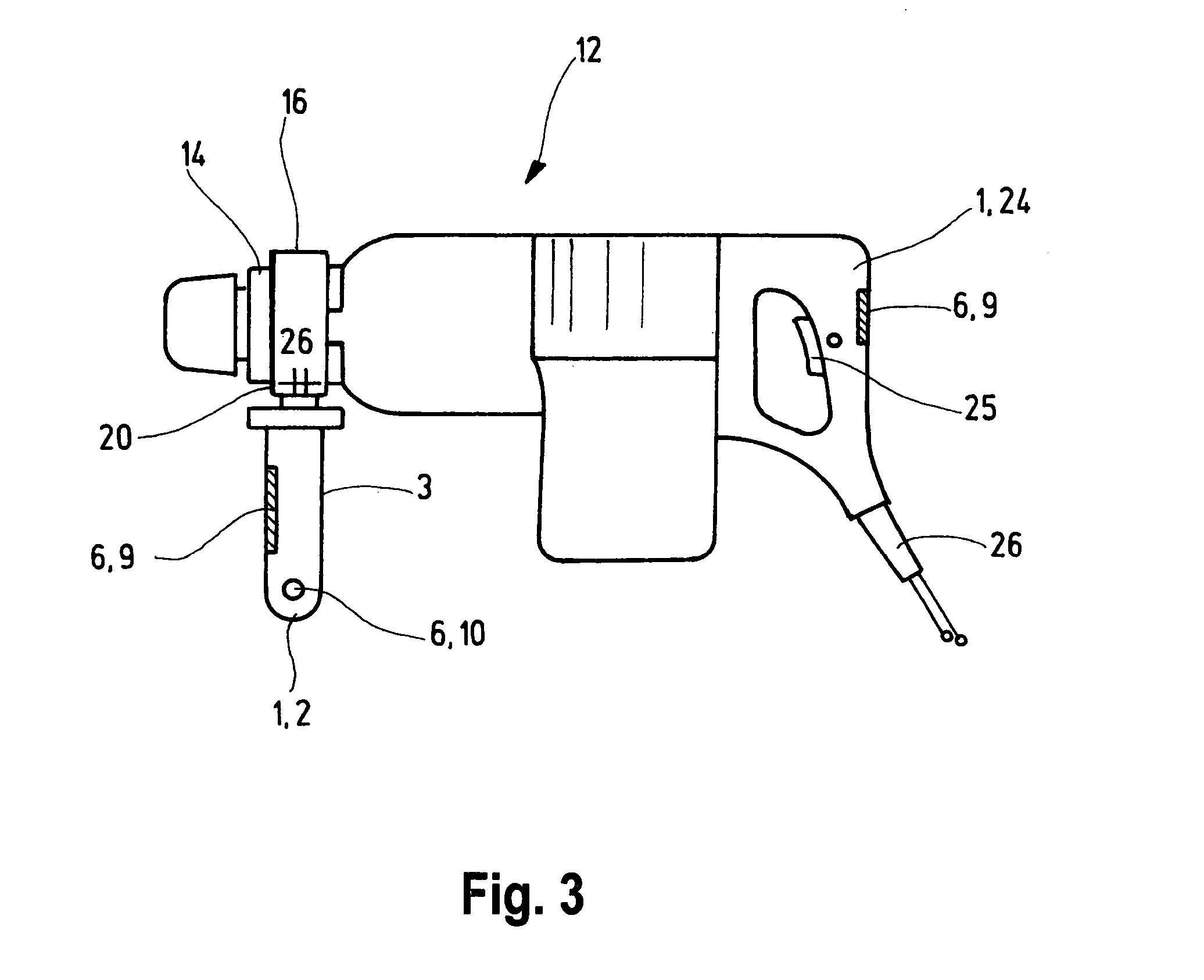

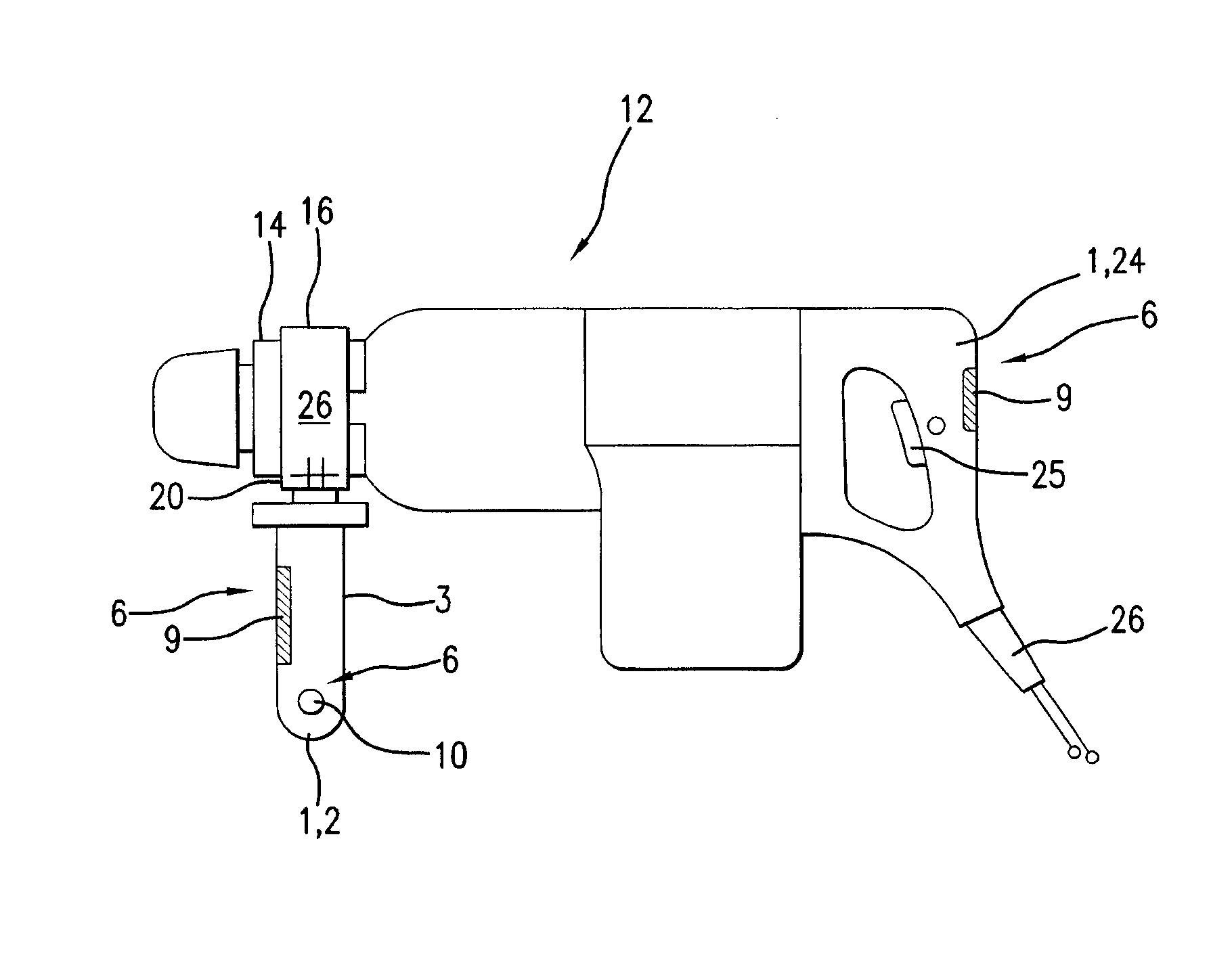

Handle with detecting unit

ActiveUS20050161241A1Fast powerQuick stopDerricks/mastsAuxillary equipmentSoftware engineeringPower tool

Owner:ROBERT BOSCH GMBH

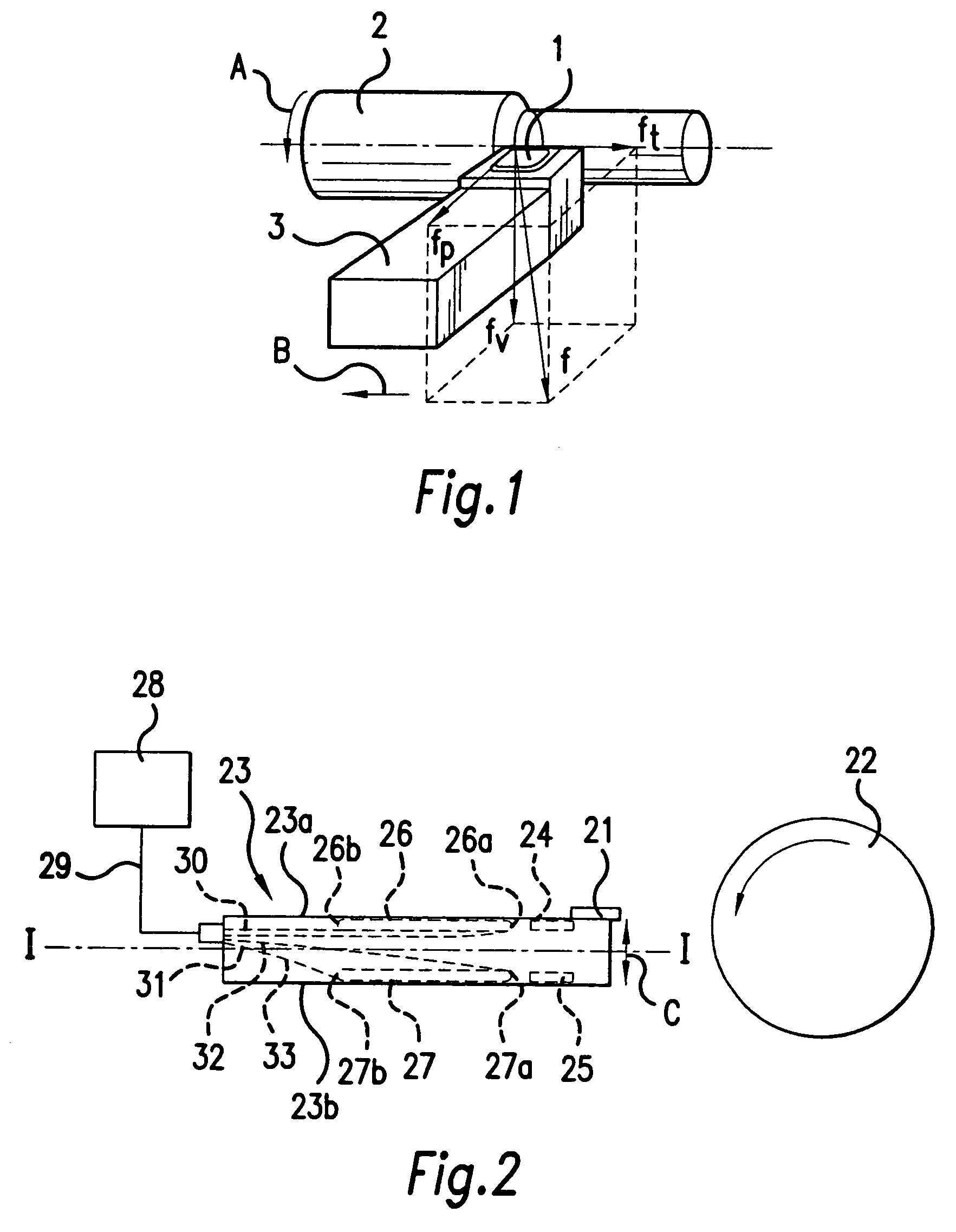

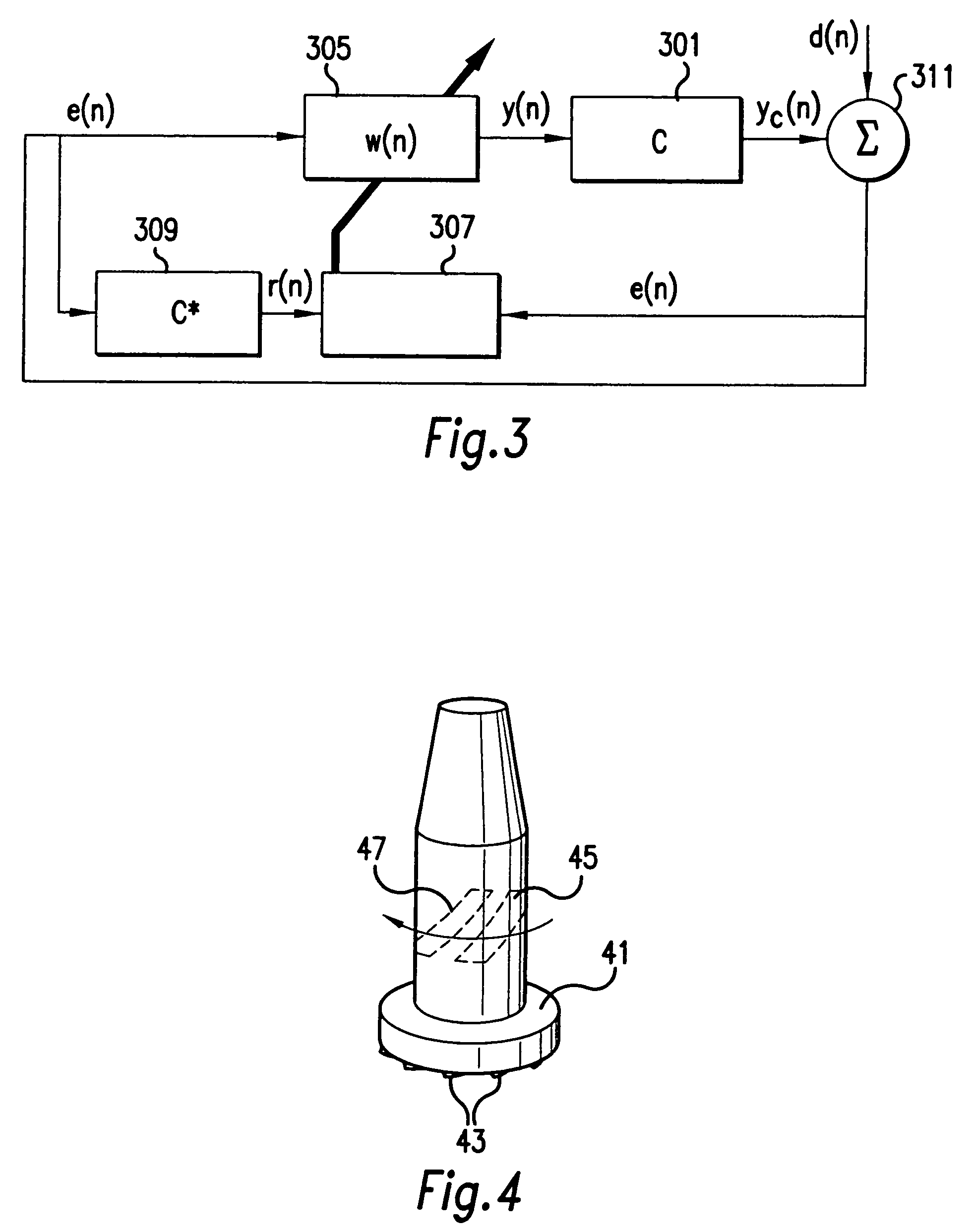

Method and device for controlling a turning operation

InactiveUS6925915B1Improve surface smoothnessLathesAutomatic/semiautomatic turning machinesControl systemActuator

A device increases the surface smoothness of a turned surface. The device comprising a control system with a control unit and an actuator connectible to the control unit and connectible with a tool holder. The actuator in adapted to impart a vibrating motion in the lateral direction to the tool holder. A method will also increase the surface smoothness of a turned surface, comprising the step of controlling the vibrations of the tool holder during turning. The method also comprises the step of imparting a vibrating motion in the lateral direction to the tool holder. Moreover, a turning lathe and a turning tool holder which like the device are designed to generate vibrating motion in the lateral direction.

Owner:STAFFANSBODA CIE

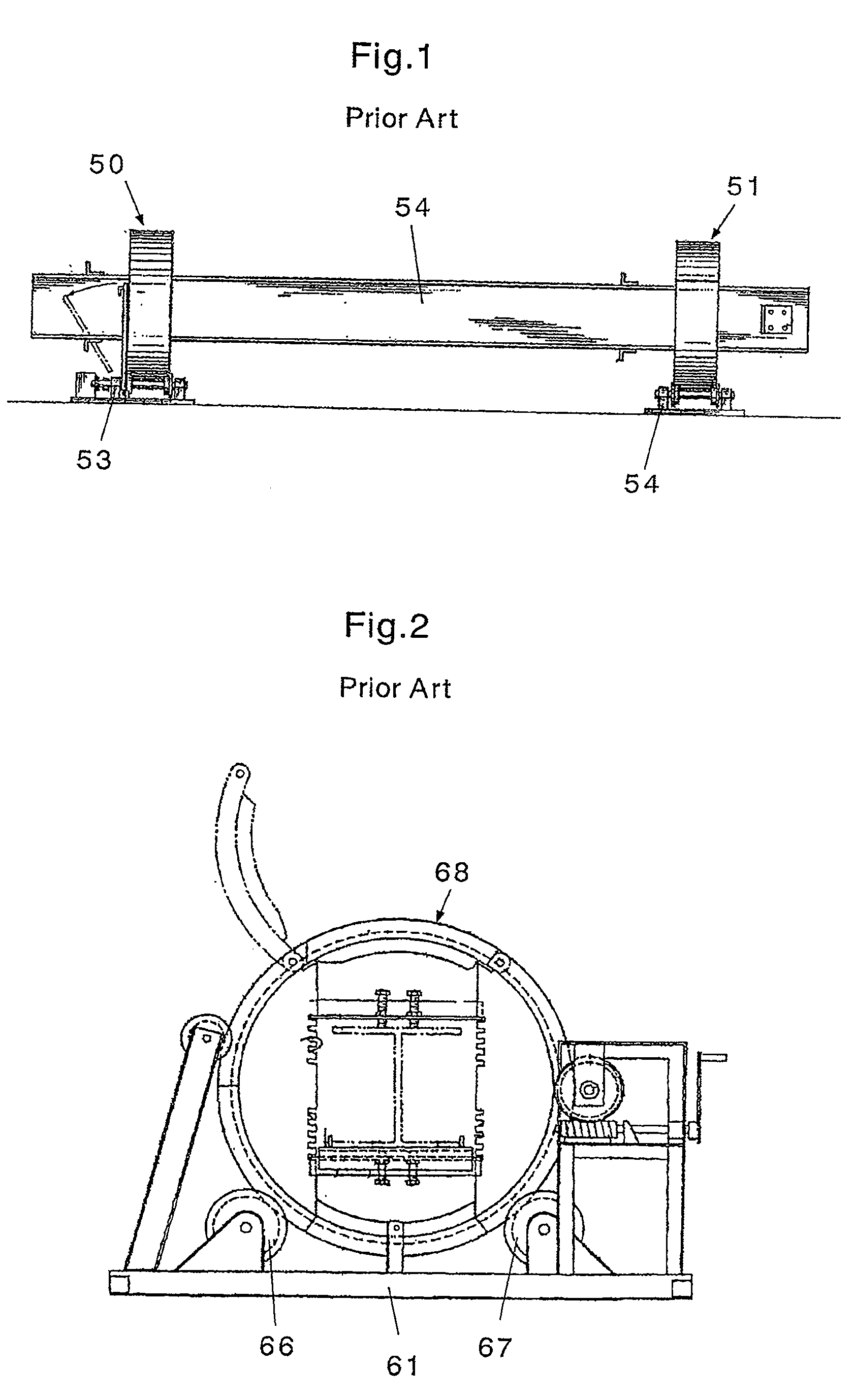

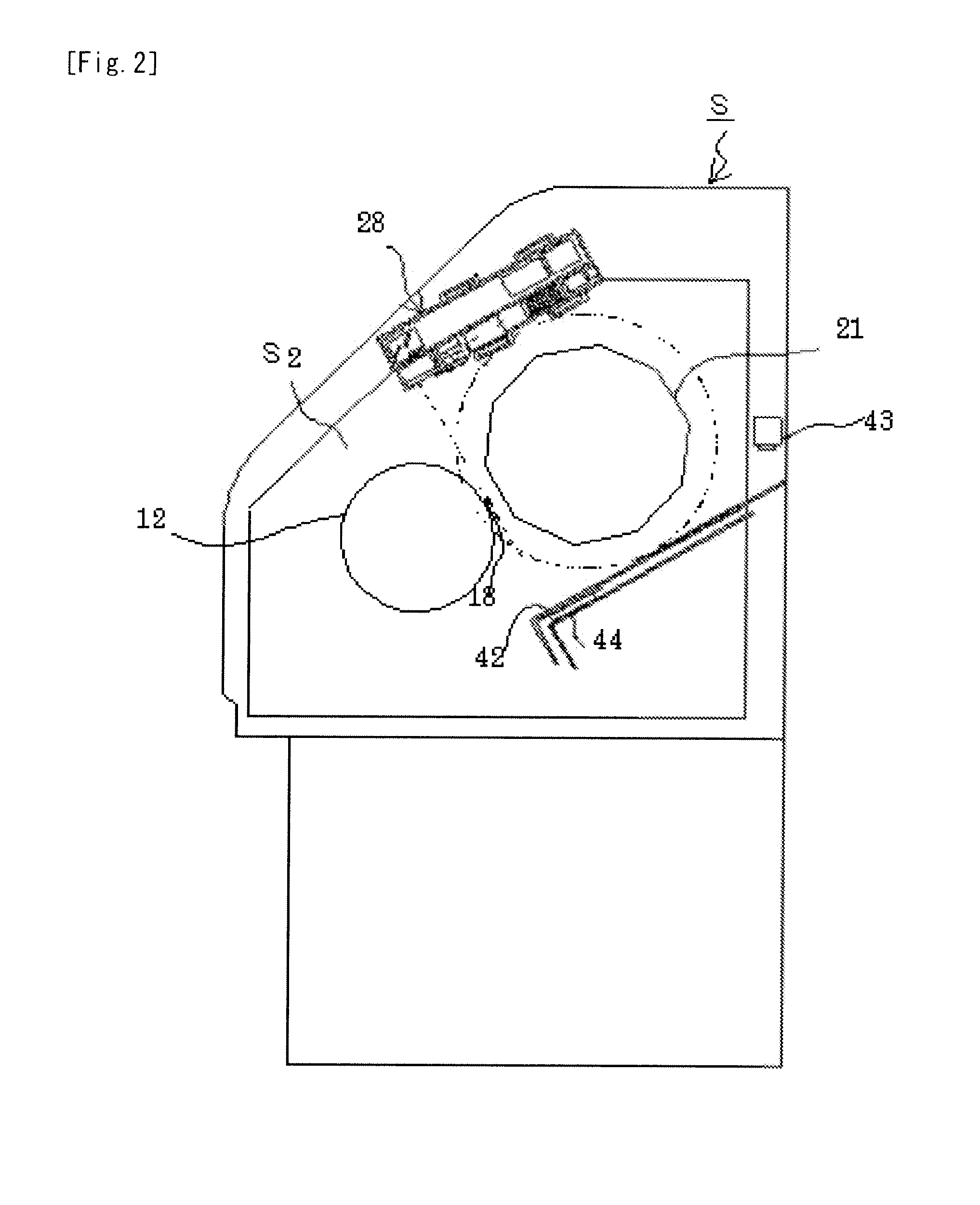

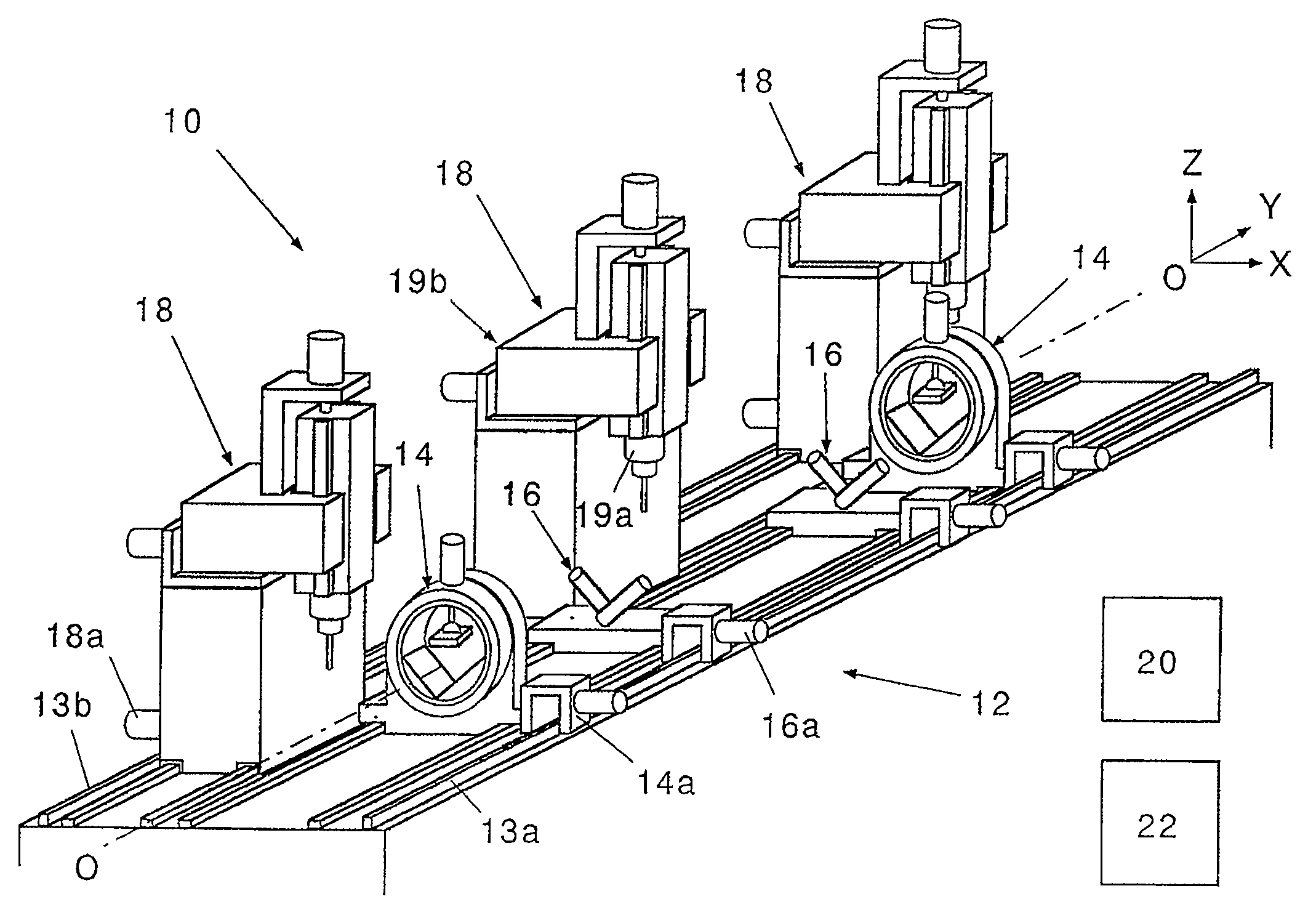

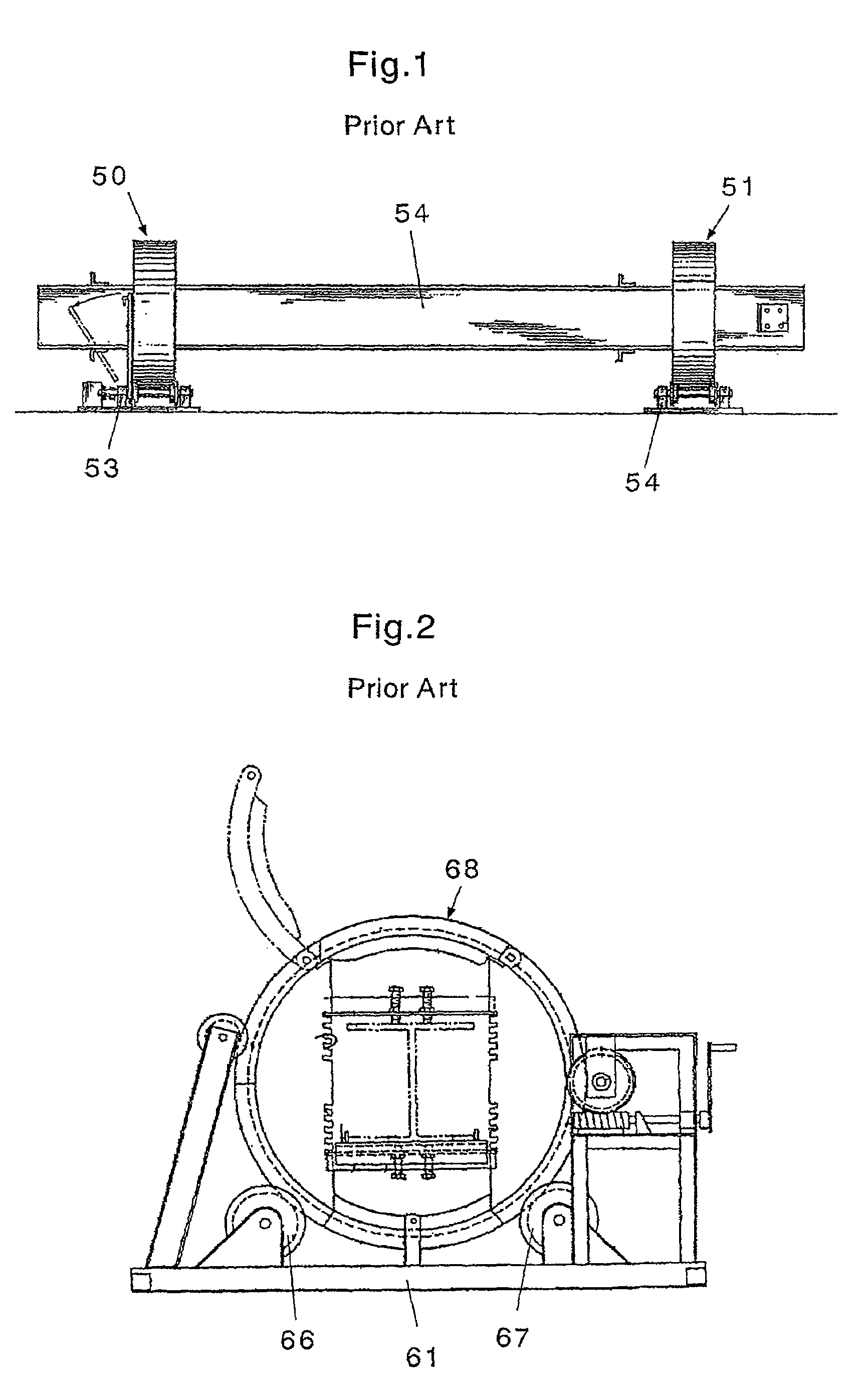

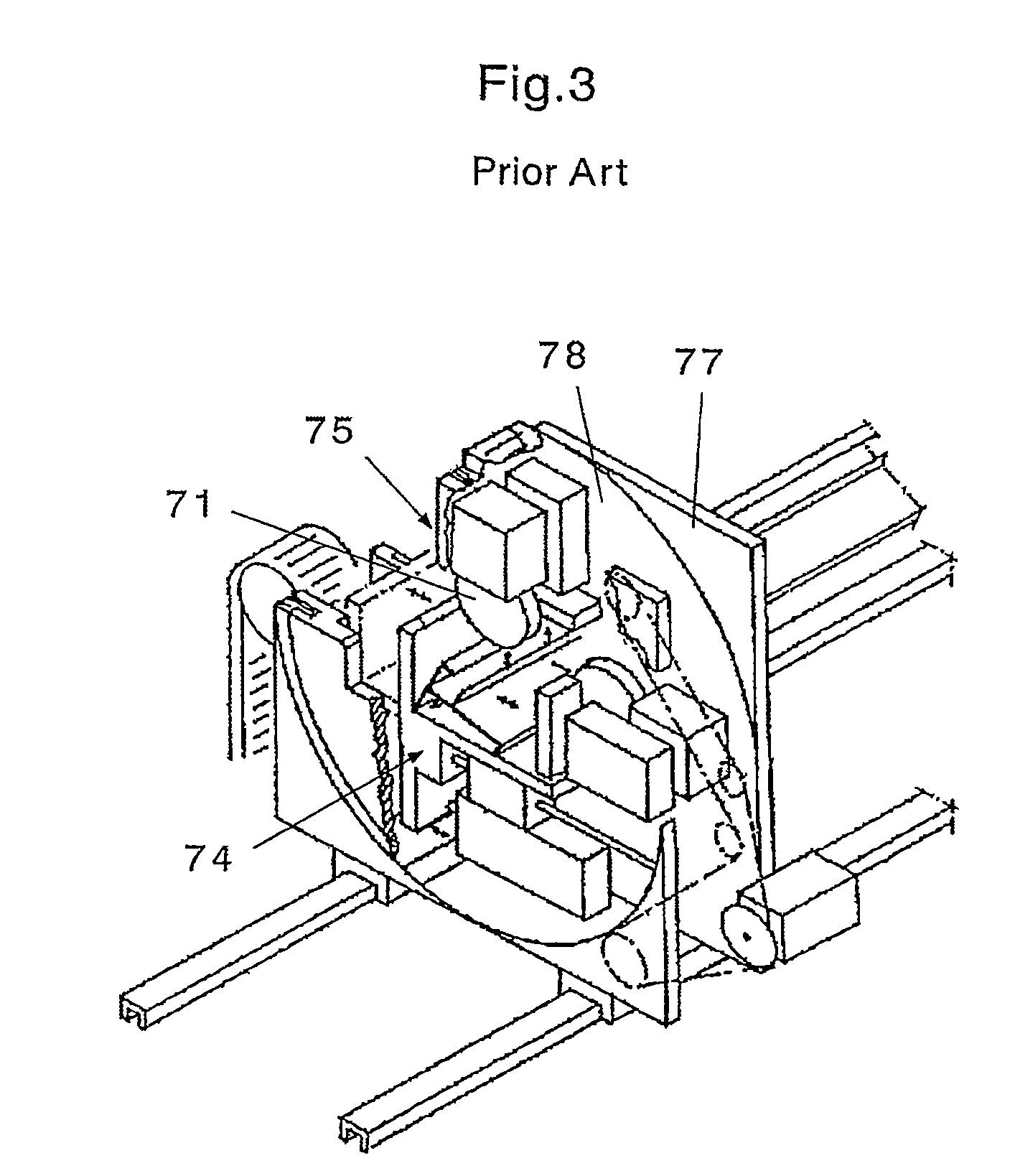

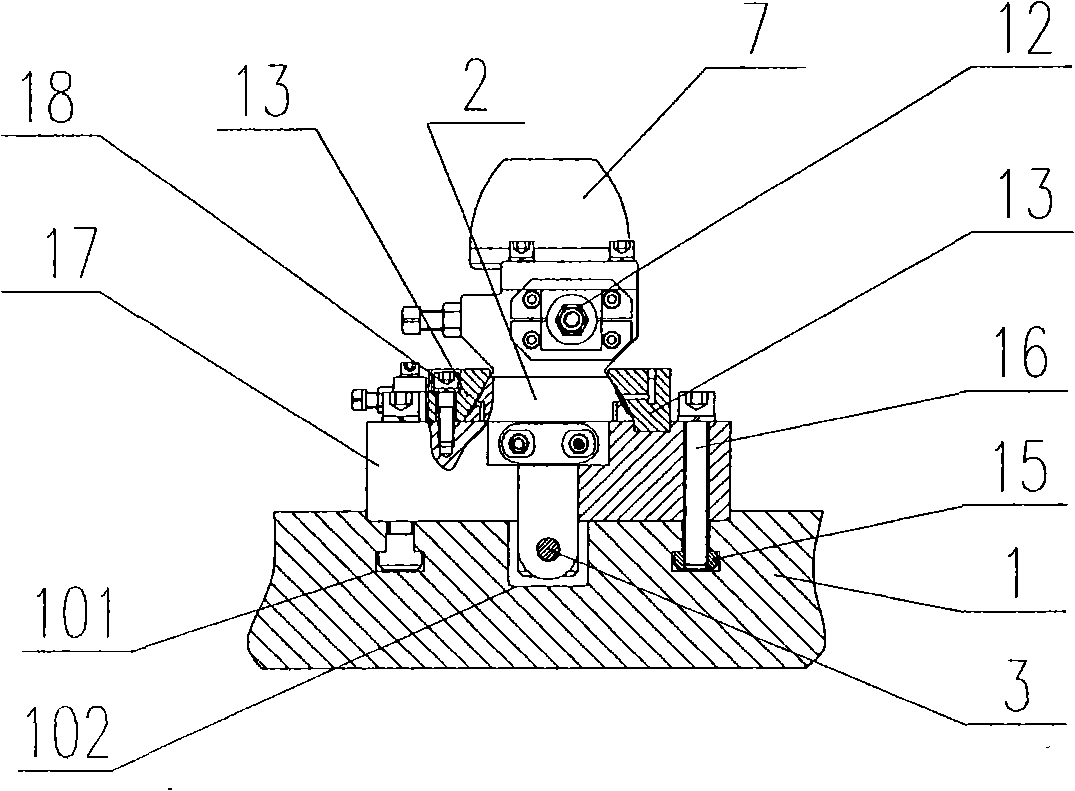

Apparatus and method for machining long workpiece

There are provided a base frame 12 positioned below a horizontal axis O; a pair of clamp units 14 positioned at the two ends above the base frame; a pair of support units 16 that horizontally support the long workpiece in two locations, and that are capable of moving vertically; and machining units 18 that are capable of machining the long workpiece. The two clamp units 14 are capable of moving from the outside toward the inside, which support the long workpiece in two locations, and rotate around the horizontal axis O in synchronization with each other.

Owner:IMAX CO LTD

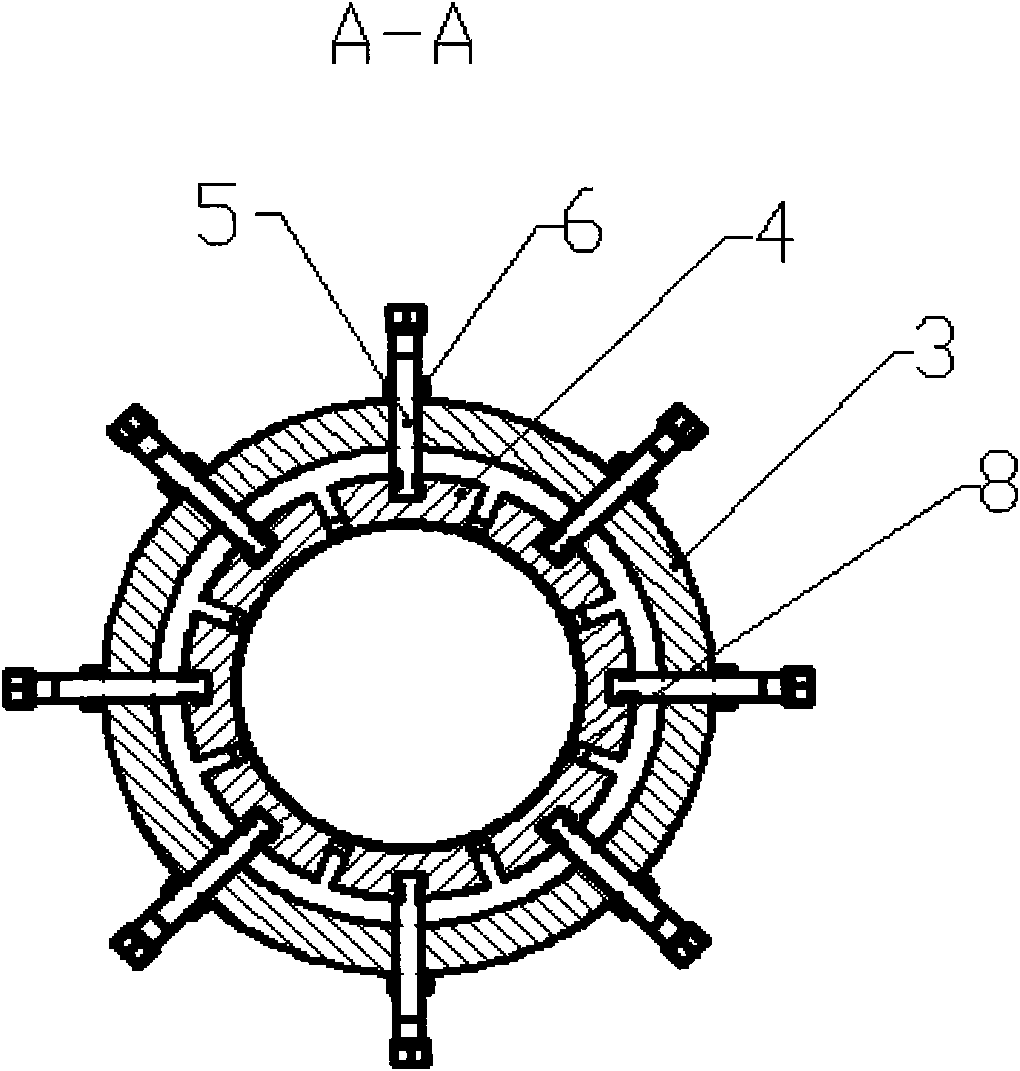

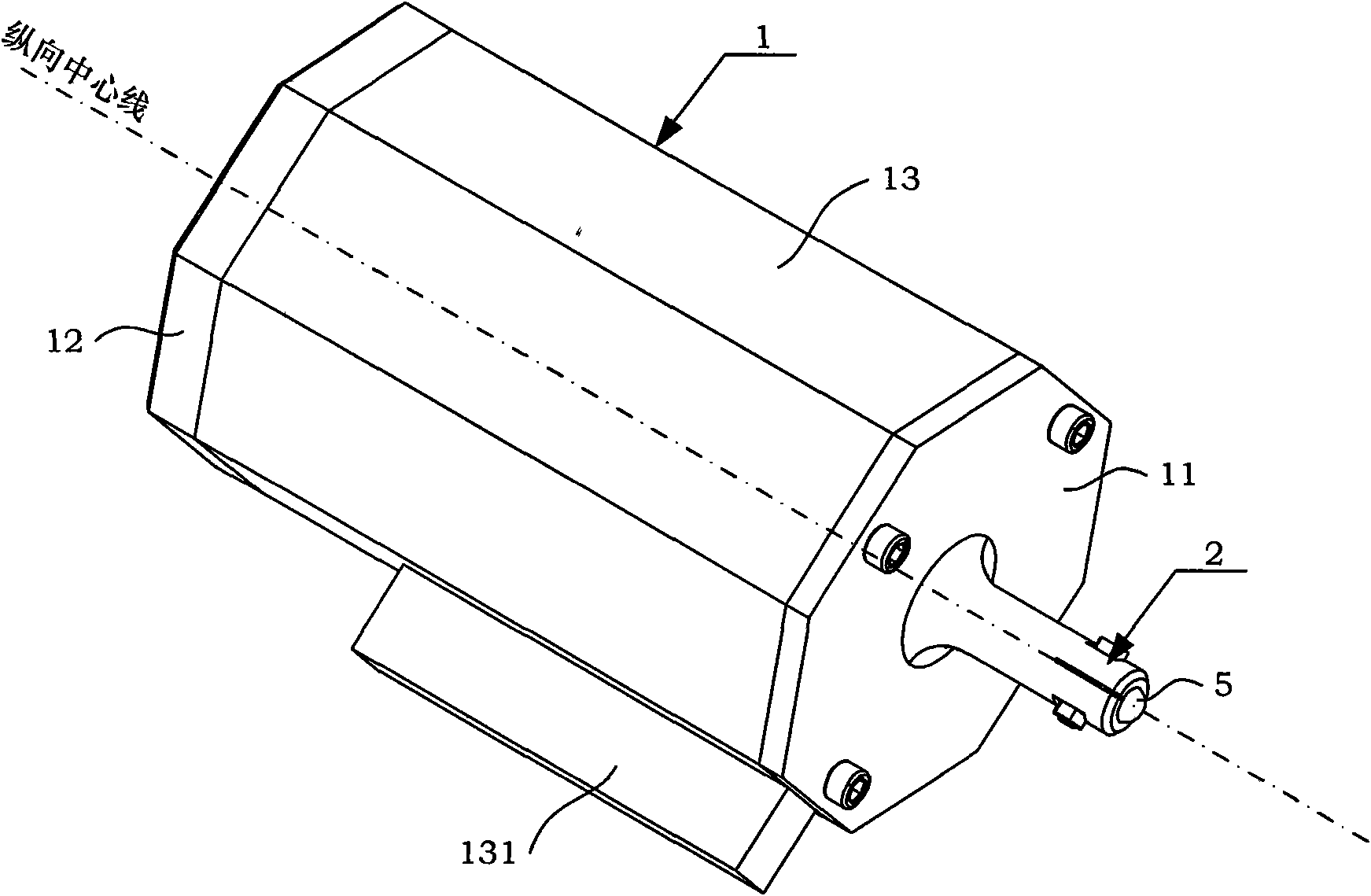

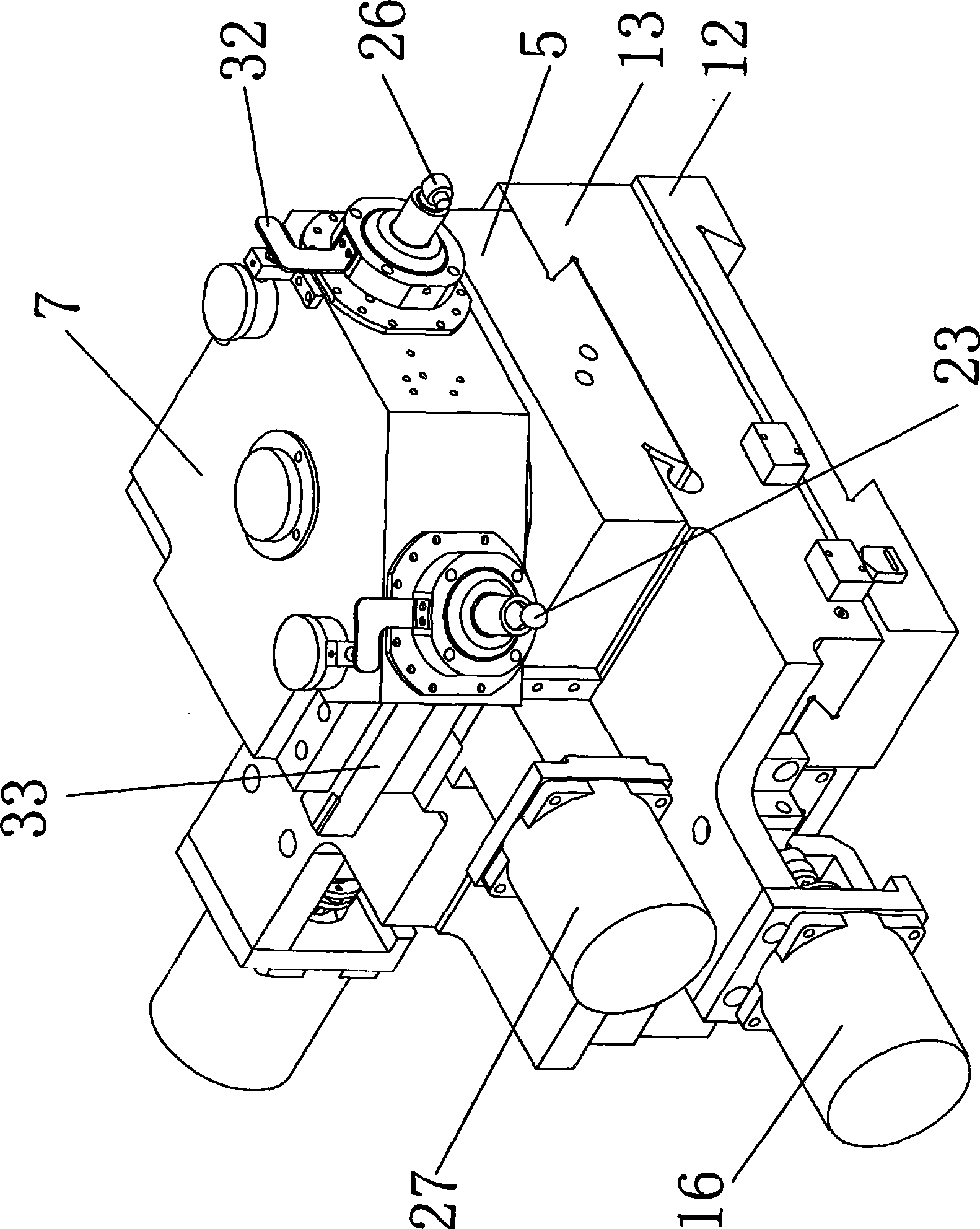

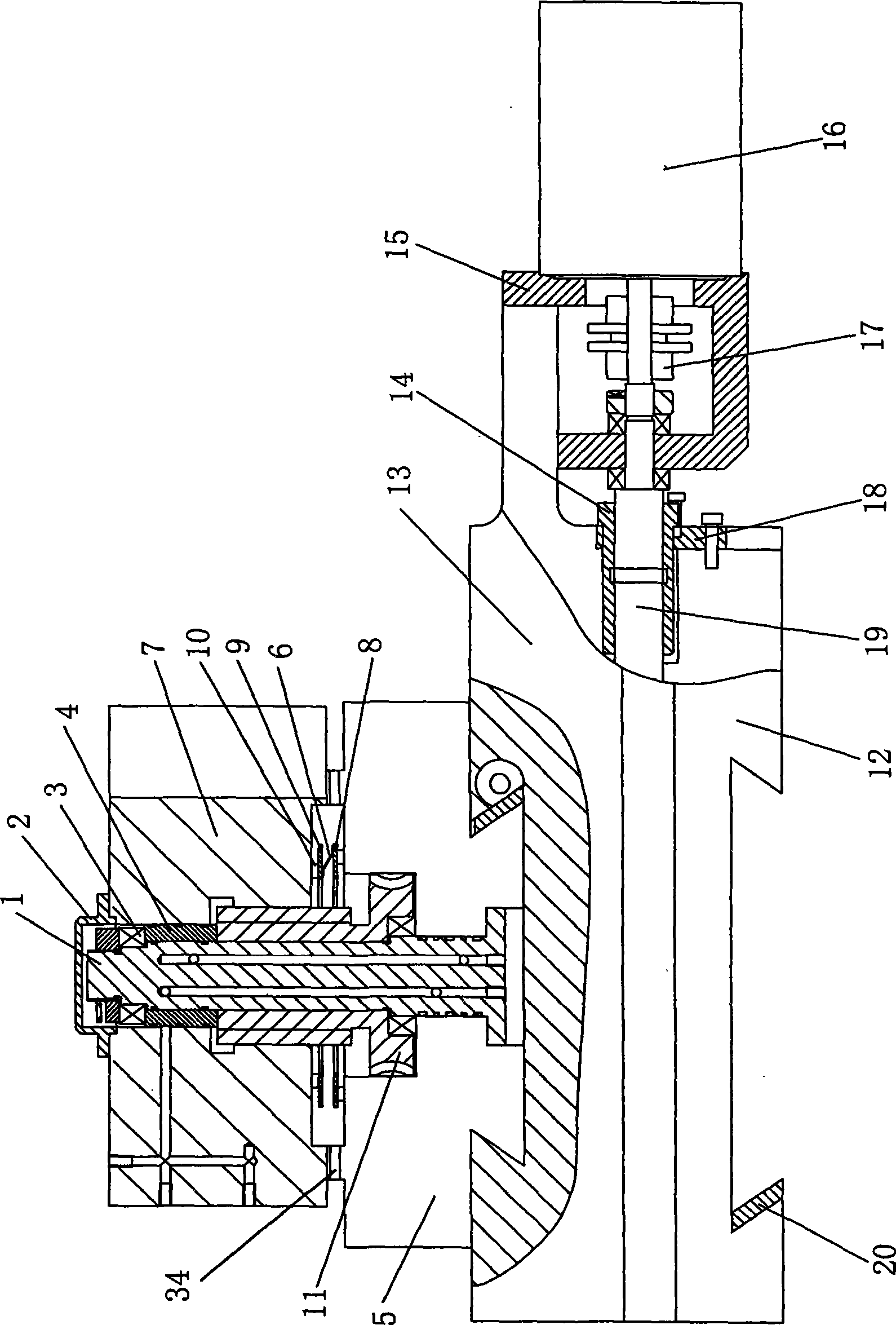

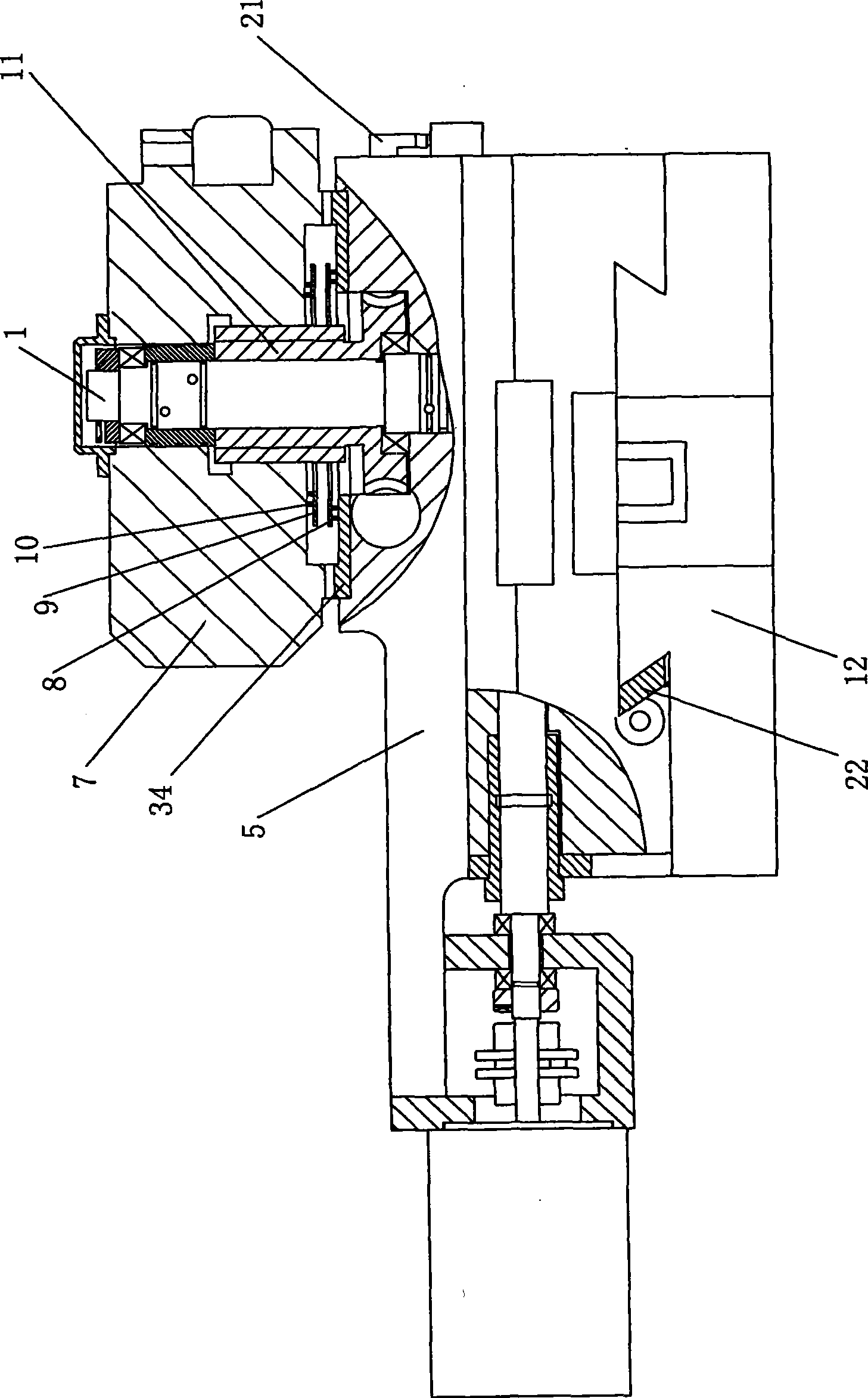

Processing method and technological equipment for cylindrical thin and long thin-walled workpiece

InactiveCN102049695AReduce distortionReduce the impact of machining accuracyAuxillary equipmentPositioning apparatusBall bearingEngineering

The invention relates to a processing method and technological equipment for a cylindrical thin and long thin-walled workpiece, which comprises positioning technological equipment and aligning technological equipment, wherein the positioning technological equipment consists of a connecting cylinder, a connecting flange, a positioning cylinder, a compression block, a compression screw, a stop nut and a connection screw; and the aligning technological equipment consists of an aligning technological equipment bottom plate, a bearing pedestal, a core shaft and a ball bearing. The processing method of the invention comprises a processing method suitable for manual operation of ordinary lathe and a processing method for operation of a hydraulic clamping center rest. The invention has the advantages that the deformation of the cylindrical thin and long thin-walled workpiece brought by clamping can be effectively reduced, the influence of workpiece clamping force on the workpiece processing precision is reduced, the processing quality is improved, the processing procedure is simplified, the processing time is shortened, the processing efficiency is improved, the high-quality product rate reaches 100%, the cost is saved at the same time, and the effect in batch production is more obvious.

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Power tool control system

InactiveUS20060106482A1Quality improvementWell formedStapling toolsDrilling/boring measurement devicesGraphicsGraphical user interface

A power tool control system includes a non-contact measurement and alignment device operative with the power tool and enabled to establish various readings, such as power tool settings. A graphical user interface communicatively coupled with the non-contact measurement and alignment device enables user control over and display of the readings from the non-contact measurement and alignment device.

Owner:CHANG TYPE INDAL

Handle with detecting unit

A handle for an electric hand tool, which in use, is detachably connected to the hand tool as an auxiliary handle (2), includes at least one detection device (6), which communicates with at least one regulating and / or control element in the electric hand tool through a contactless signal transmission device.

Owner:ROBERT BOSCH GMBH

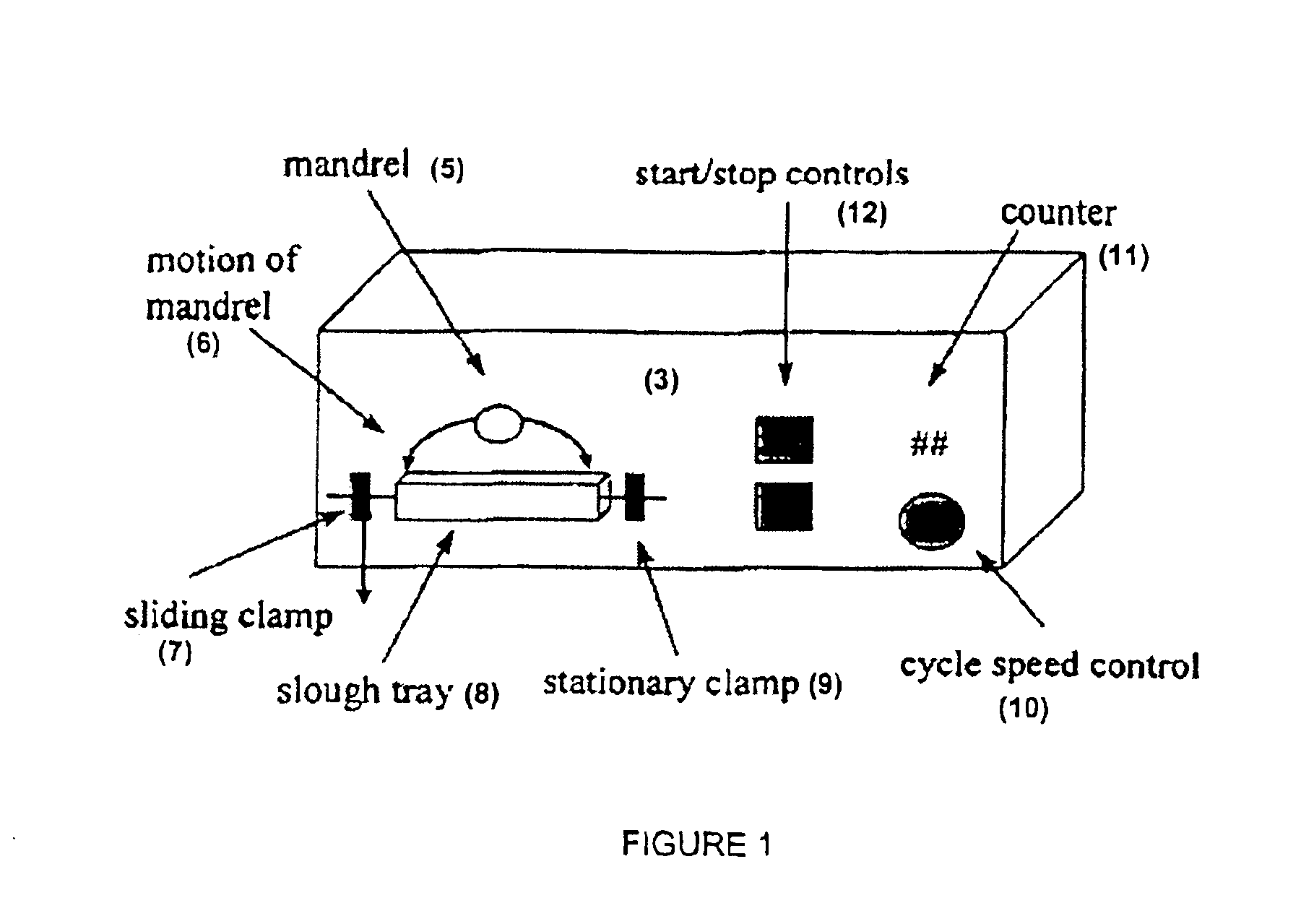

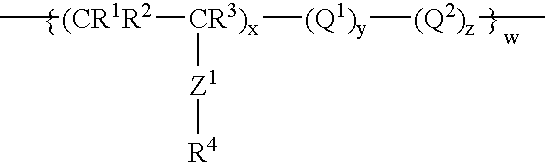

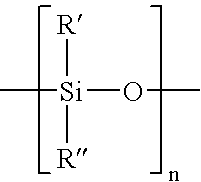

Hydrophobically modified cationic acrylate copolymer/polysiloxane blends and use in tissue

InactiveUS6951598B2Simple structureLow levelNatural cellulose pulp/paperMechanical working/deformationFiberVitrification

The present invention is a soft tissue sheet. The tissue sheet comprises papermaking fibers and a polysiloxane composition. The polysiloxane composition comprises a polysiloxane and a compatible synthetic resin binder having a glass transition temperature of about 100° C. or less.

Owner:KIMBERLY-CLARK WORLDWIDE INC

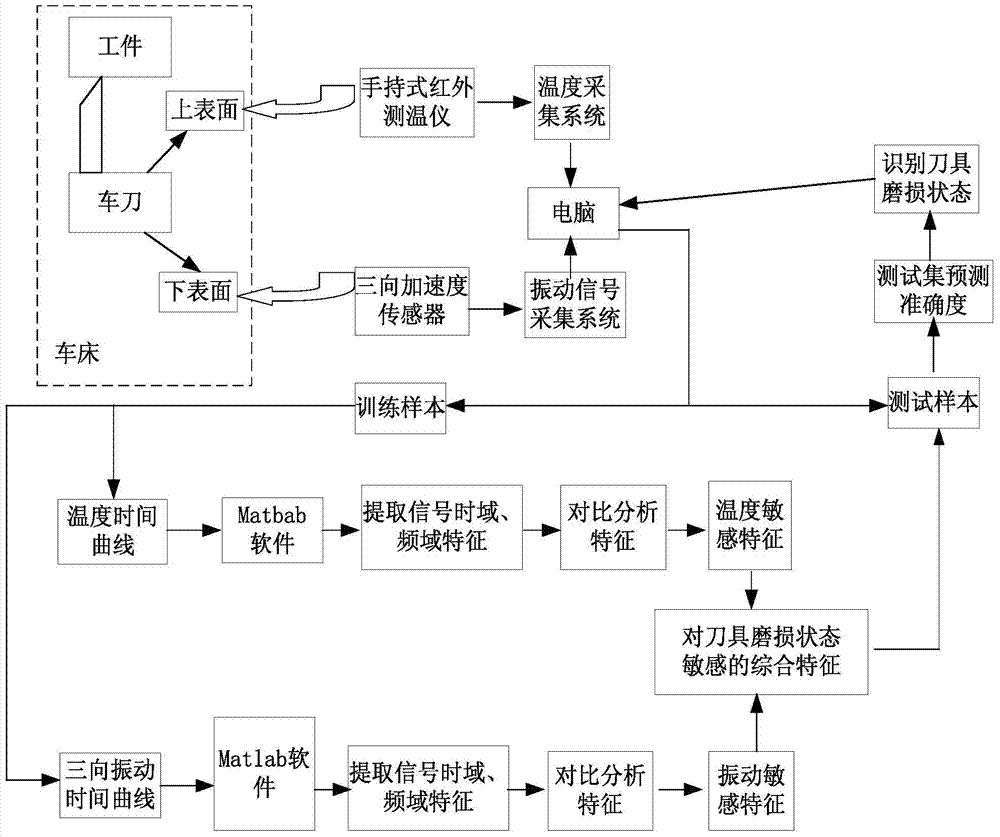

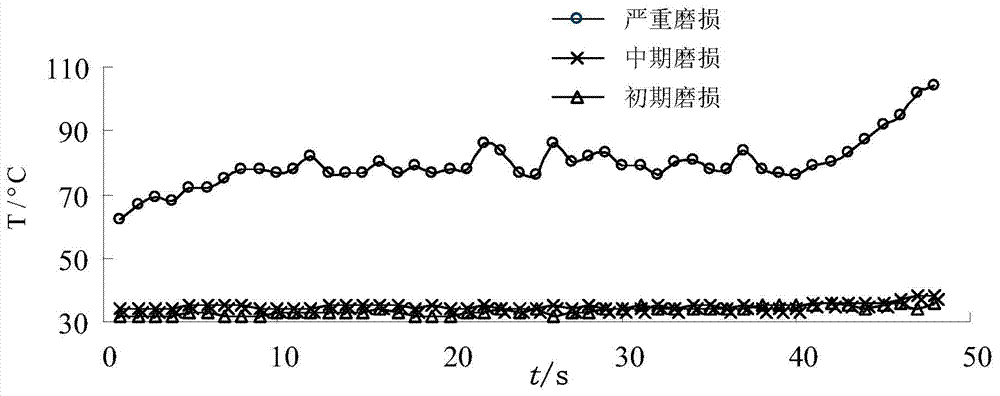

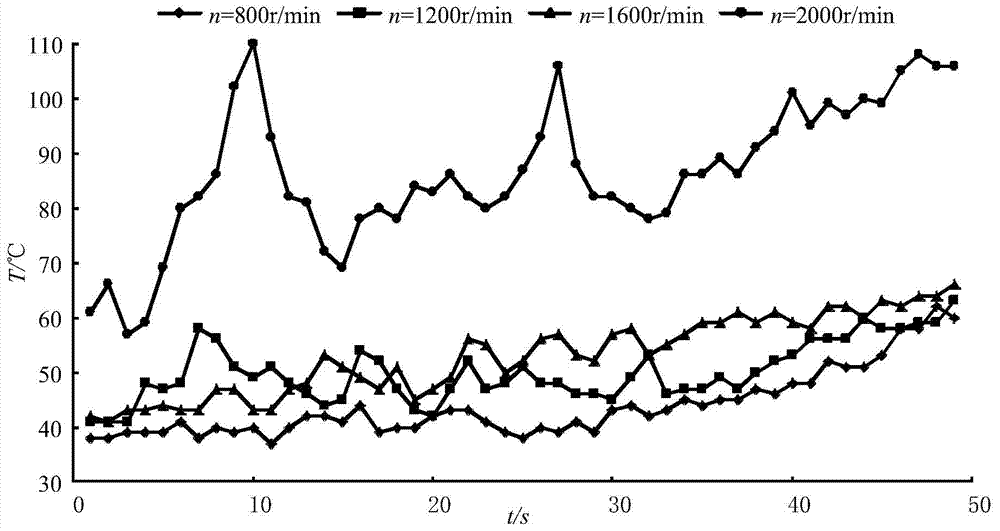

Turning cutter wear state monitoring system

InactiveCN104741638AEffective identification of wear statusEasy to set upAuxillary equipmentMeasurement/indication equipmentsPilot systemMonitoring system

The invention discloses a turning cutter wear state monitoring system. The turning cutter wear state monitoring system comprises a signal collecting system and a cutter wear state identifying system; the signal collecting system comprises a temperature collecting system and a vibration signal collecting system, wherein the temperature collecting system collects temperature of a cutter point of a rake face of the cutter, and the vibration signal collecting system collects a three-dimensional vibrating signal at the lower surface of a cutter handle corresponding to the utter point of the rake face of the cutter; after pretreating the signal collected by the signal collecting system, the sensitive characteristic of the cutter wear state is obtained and transmitted to the well-trained cutter wear state identifying system; thus the wear state of the cutter is judged through the cutter wear state identifying system. The turning cutter wear state monitoring system is simple and applicable, and is convenient to operate; moreover, the sensor in use is relatively universal in use, moderate in cost, and easy to build up a testing system; the turning cutter wear state monitoring system can largely reduce the monitoring cost, effectively identify the wear state of the cutter and reduce the cutter waste.

Owner:XUZHOU NORMAL UNIVERSITY

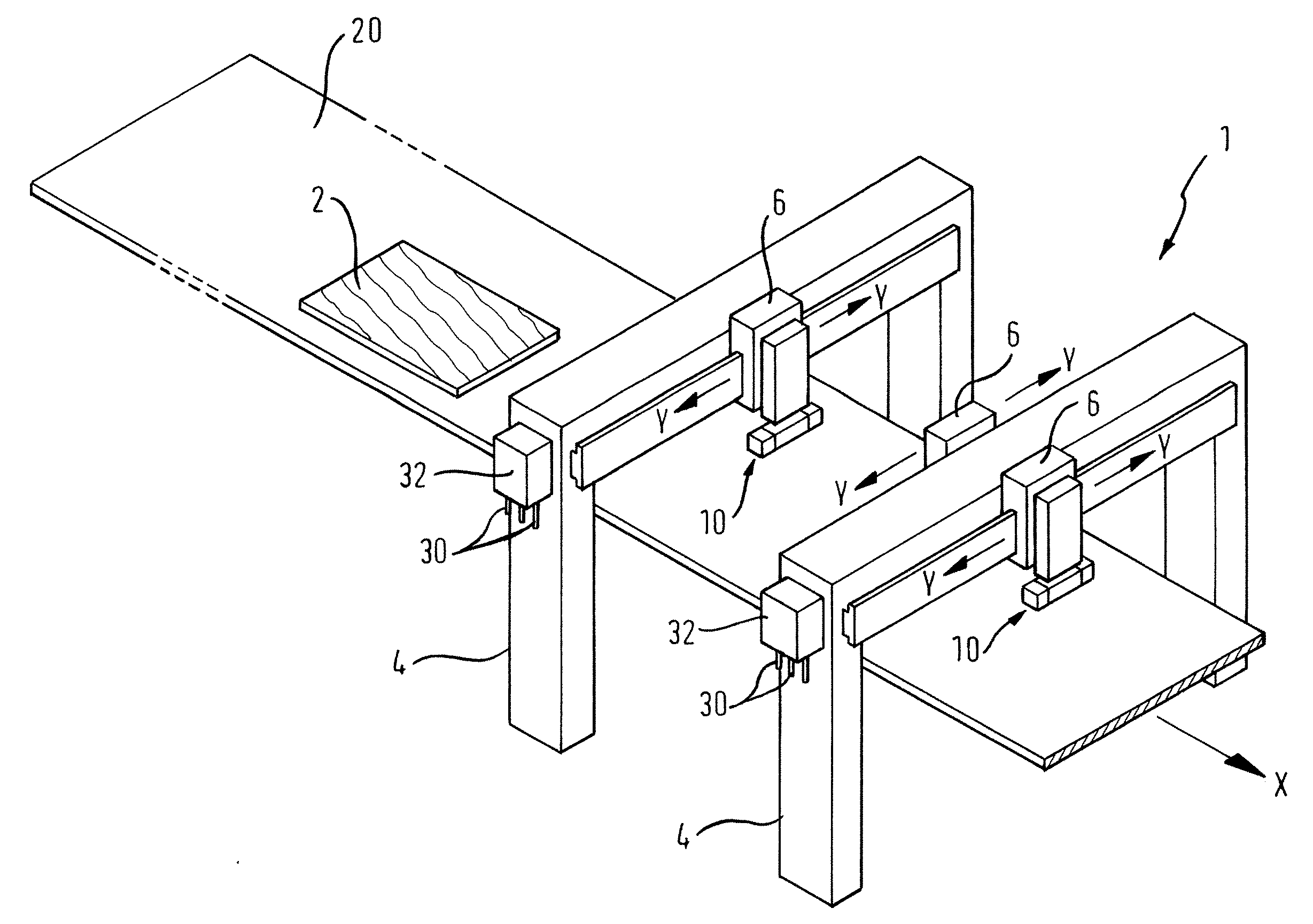

Device For Refining Workpieces

InactiveUS20090120249A1Easy to insertSimple designLathesTailstocks/centresRelative motionEngineering

The invention relates to a device for refining workpieces, which preferably consist at least partially of wood, wood materials or the like, having an ink-jet printing means having a plurality of nozzles from which drops of ink can be expelled, a workpiece carrier means for carrying the workpiece to be patterned, a conveyor device for bringing about a relative movement between the workpiece to be refined and the printing means. The device according to the invention is characterised in that it further has at least one machining means for machining the workpiece.

Owner:HOMAG HOLZBEARBEITUNGSSYST

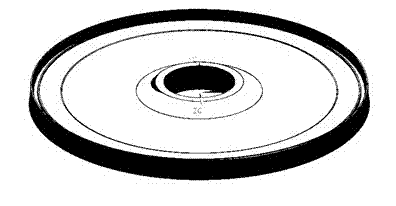

Method and device for producing ophthalmic lenses and other shaped bodies with optically active surfaces

ActiveUS20060073771A1Inhibit thermal stressSmall possible weightRevolution surface grinding machinesOptical surface grinding machinesCircular discEngineering

The invention concerns a method for producing ophthalmic lenses that uses plastic blanks in the form of flat, round discs. The outer edge of said plastic blanks is clamped and the desired final surface geometry and surface quality of the front faces of the lens are subsequently produced by a machining process using grinders and / or lathes and by smoothing and polishing processes. During machining, a thicker annular region is retained on the outer circumference of the workpiece. The annular region clamps or arranges the workpiece during machining and transport operations and stabilizes the lens for additional machining. Shaped pieces for identifying the machining axes are attached to the annular region. The lens is provided with fine markings to characterize the lens that has been produced, with the lens then being separated from the region.

Owner:OPTOTECH OPTIKMASCHEN +1

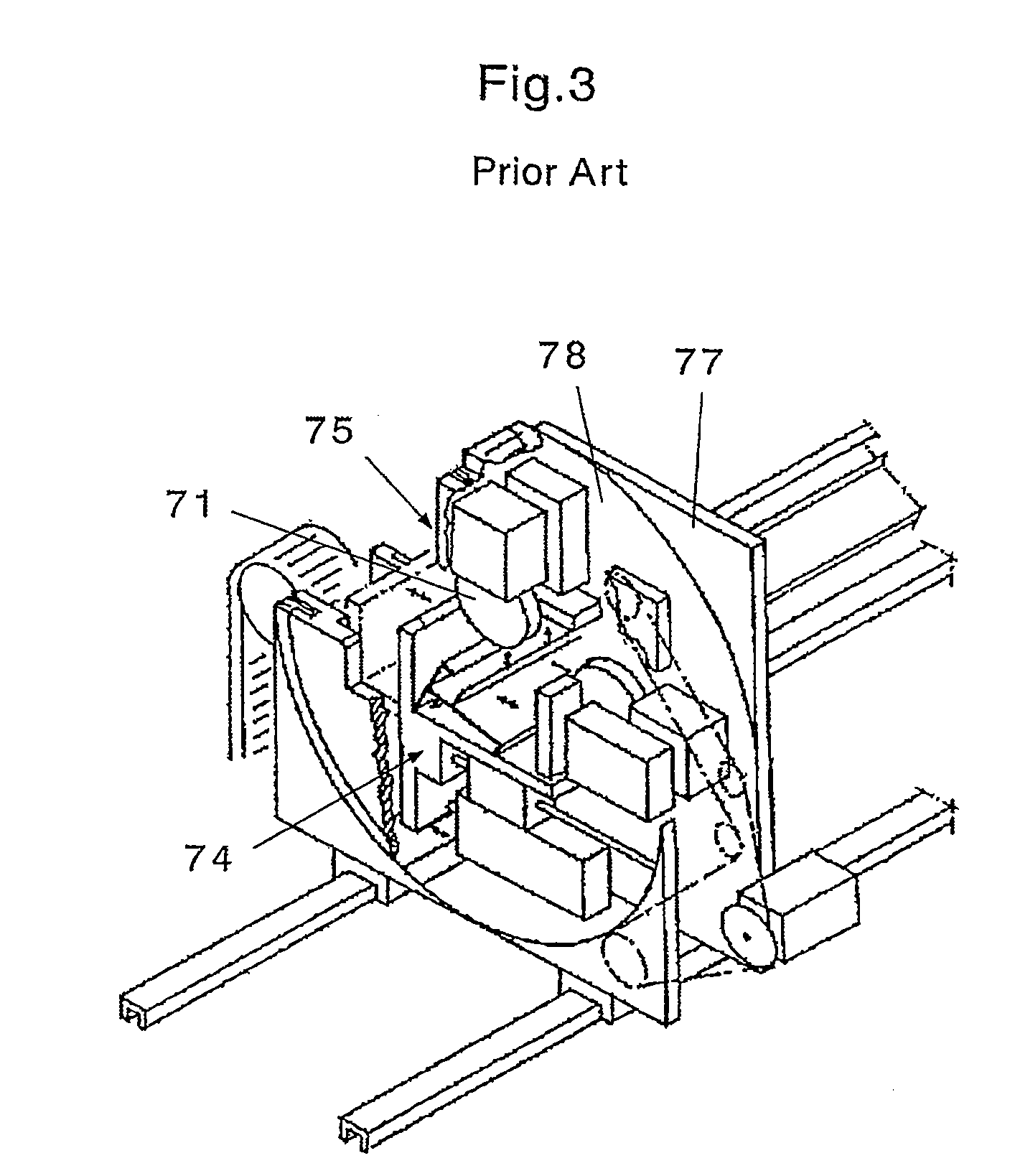

Tool holder assembly and method for modulation-assisted machining

ActiveUS20060251480A1Accurately and repeatably obtainedLarge deformationTransportation and packagingAuxillary equipmentMachining processTool holder

A tool holder assembly and method for intentionally inducing modulation in a machining process. The tool holder assembly is configured for mounting in a tool block on a machining apparatus and includes a tool holder body configured to be secured to the tool block of the machining apparatus, a tool holder mounted on the tool holder body and configured for securing a cutting tool thereto, and a device for imposing a superimposed modulation on the tool holder so as to move the cutting tool relative to the tool holder body and thereby relative to the tool. The tool holder assembly is useful in a process for producing chips having a desired shape and size, and particularly to a method of controllably producing nanocrystalline chips.

Owner:PURDUE RES FOUND INC

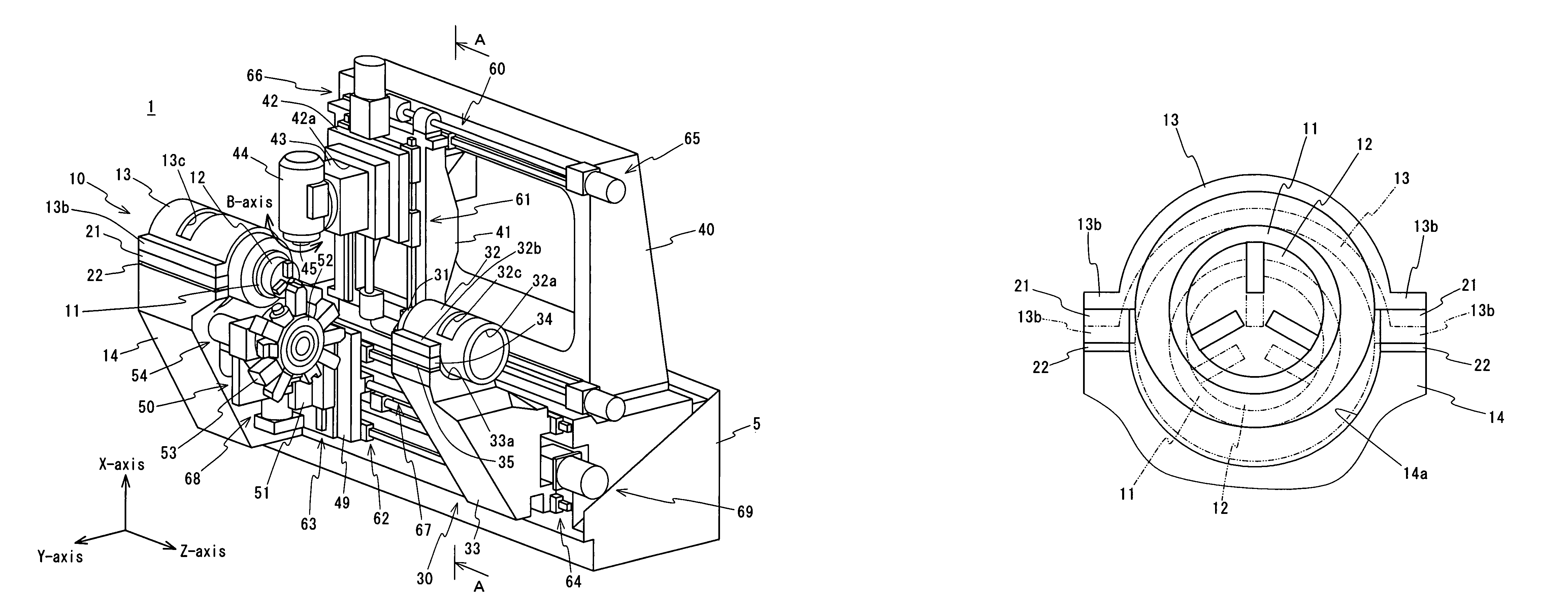

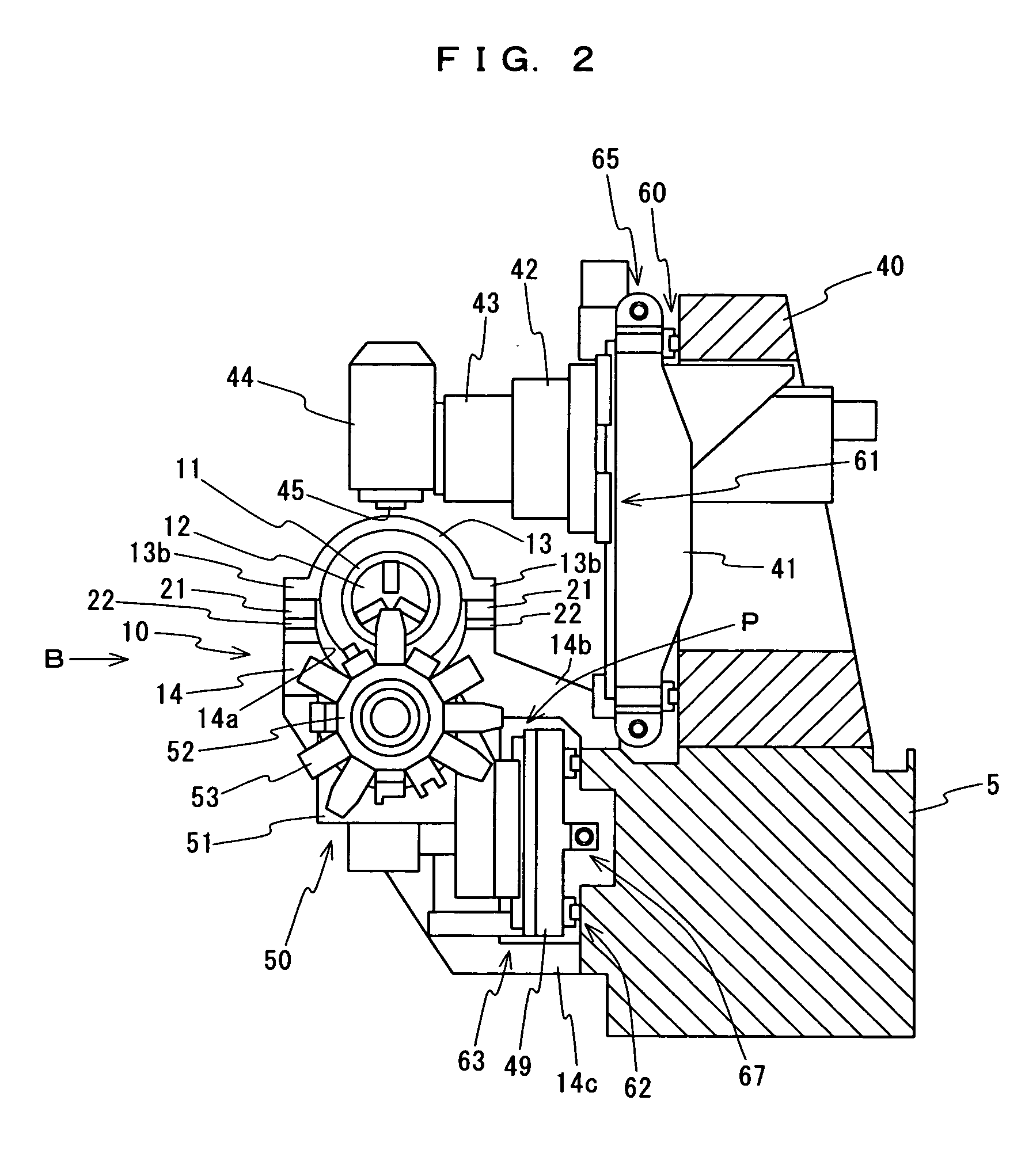

Lathe

InactiveUS7039992B2Improve accuracyHigh precision machiningAutomatic/semiautomatic turning machinesAuxillary equipmentEngineeringMechanical engineering

A lathe 1 comprises a bed 5, a headstock 10 having a housing 13 and a support base 14, a main spindle 11, a first tool rest 44, and a second tool rest 50. The support base 14 is formed so as to have a concave portion 14a on the upper portion thereof and so that the upper portion protrudes toward the second tool rest 50. The tool rest body 51 of the second tool rest 50 is configured so as to be movable into and out of a space formed downward from the upper portion of the support base 14. The housing 13 has a holding hole 13a for rotatably holding the main spindle 11, and installation portions 13b. The installation portions 13b are supported on the support base 14 in a state wherein a predetermined clearance is provided between the housing 13 and the concave portion 14a.

Owner:DMG MORI CO LTD

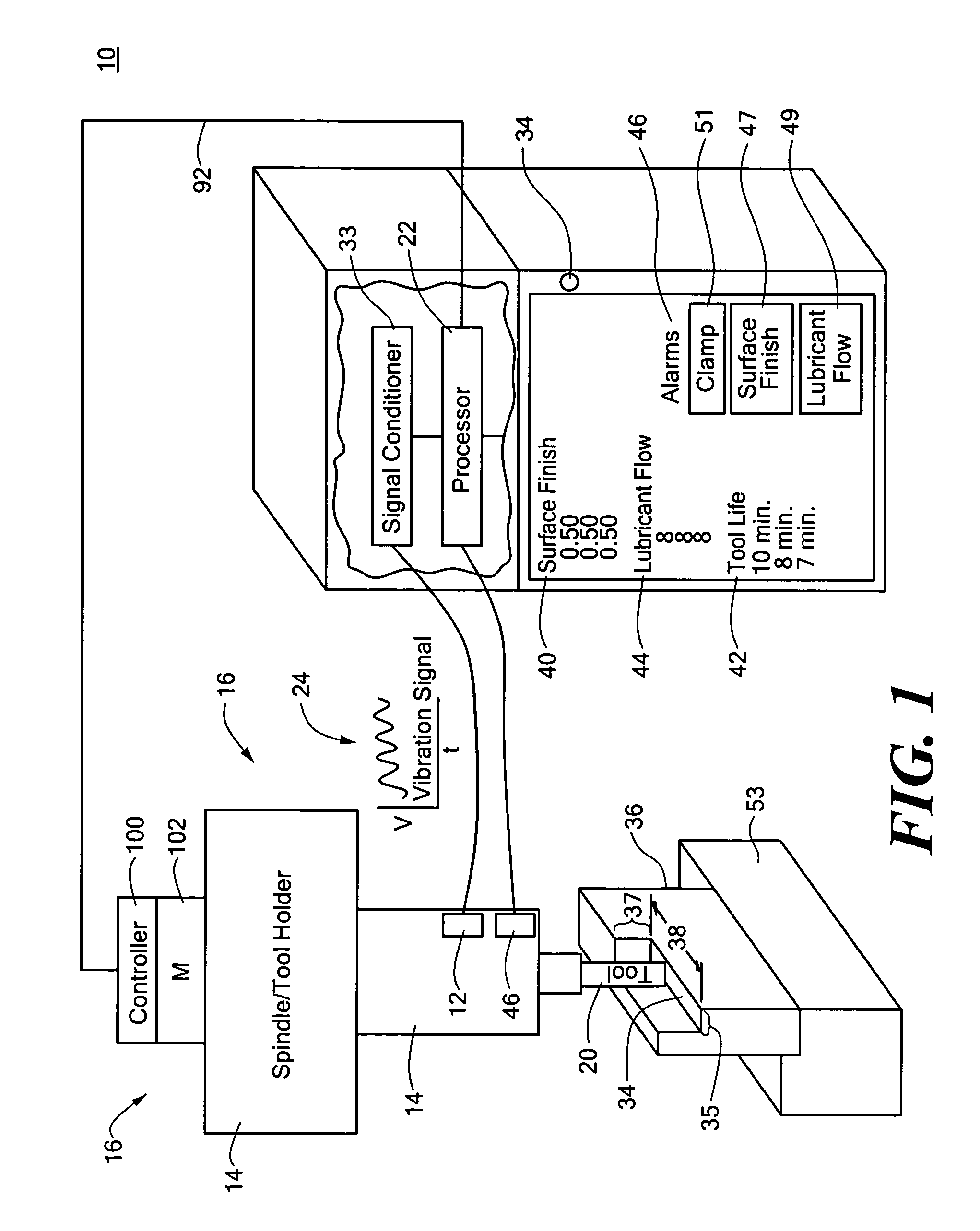

Dynamical instrument for machining

InactiveUS7341410B2Improve operational capabilitiesAccurate surface finishLathesVibration measurement in solidsEngineeringMachining

A dynamical instrument for machining comprising a sensor responsive to a non-rotating part of a machine proximate the tool of the machine for outputting a vibration signal, and a processor responsive to the sensor output configured to calculate a plurality of signature quantities which characterize the dynamics of the vibration signal and correlate the signature quantities to detect parameters associated with the operation of the machine.

Owner:FOSTER-MILLER

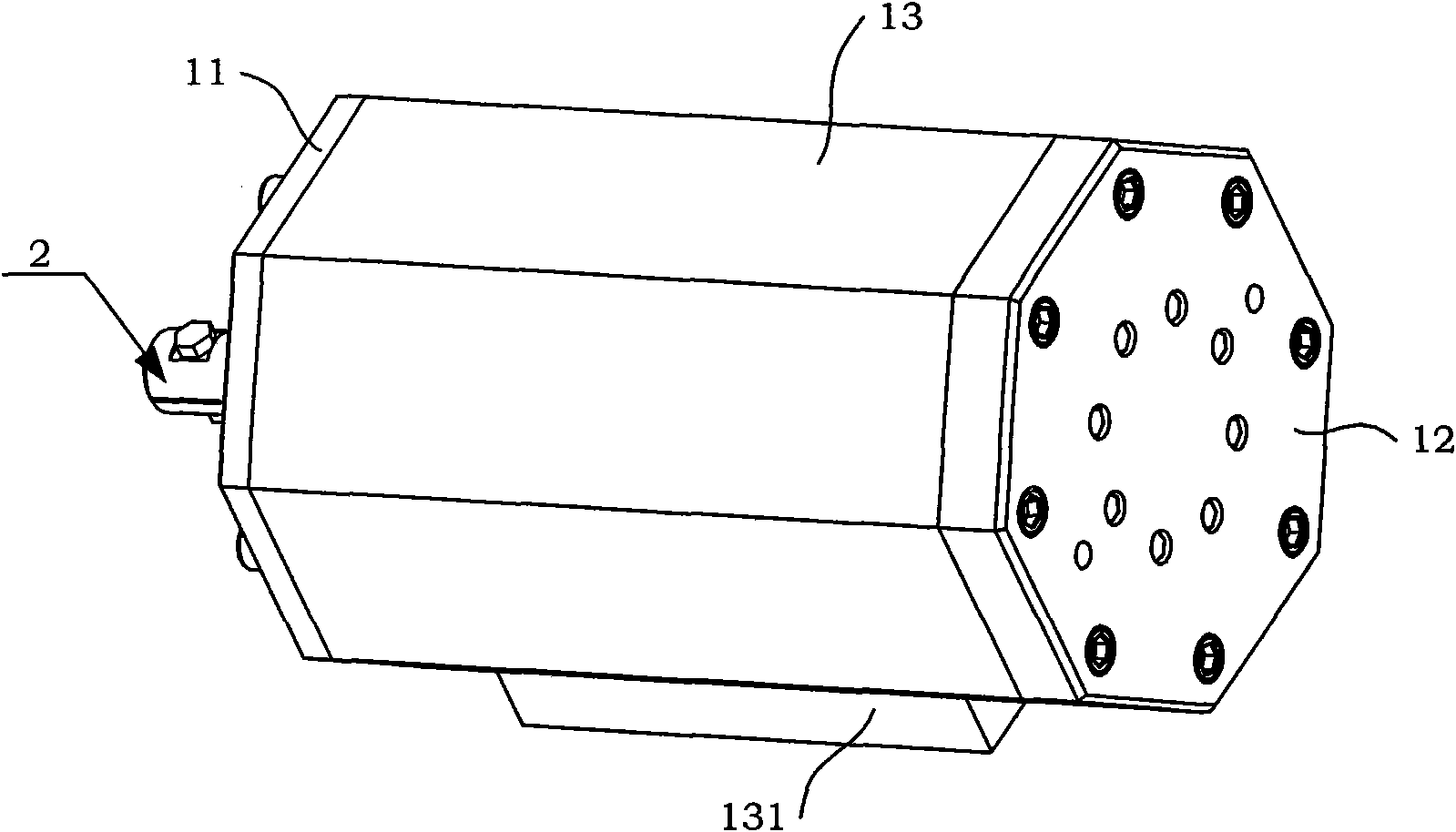

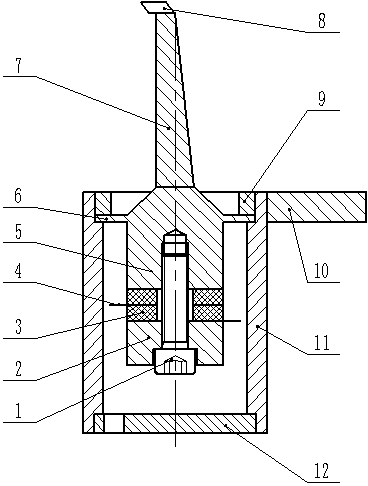

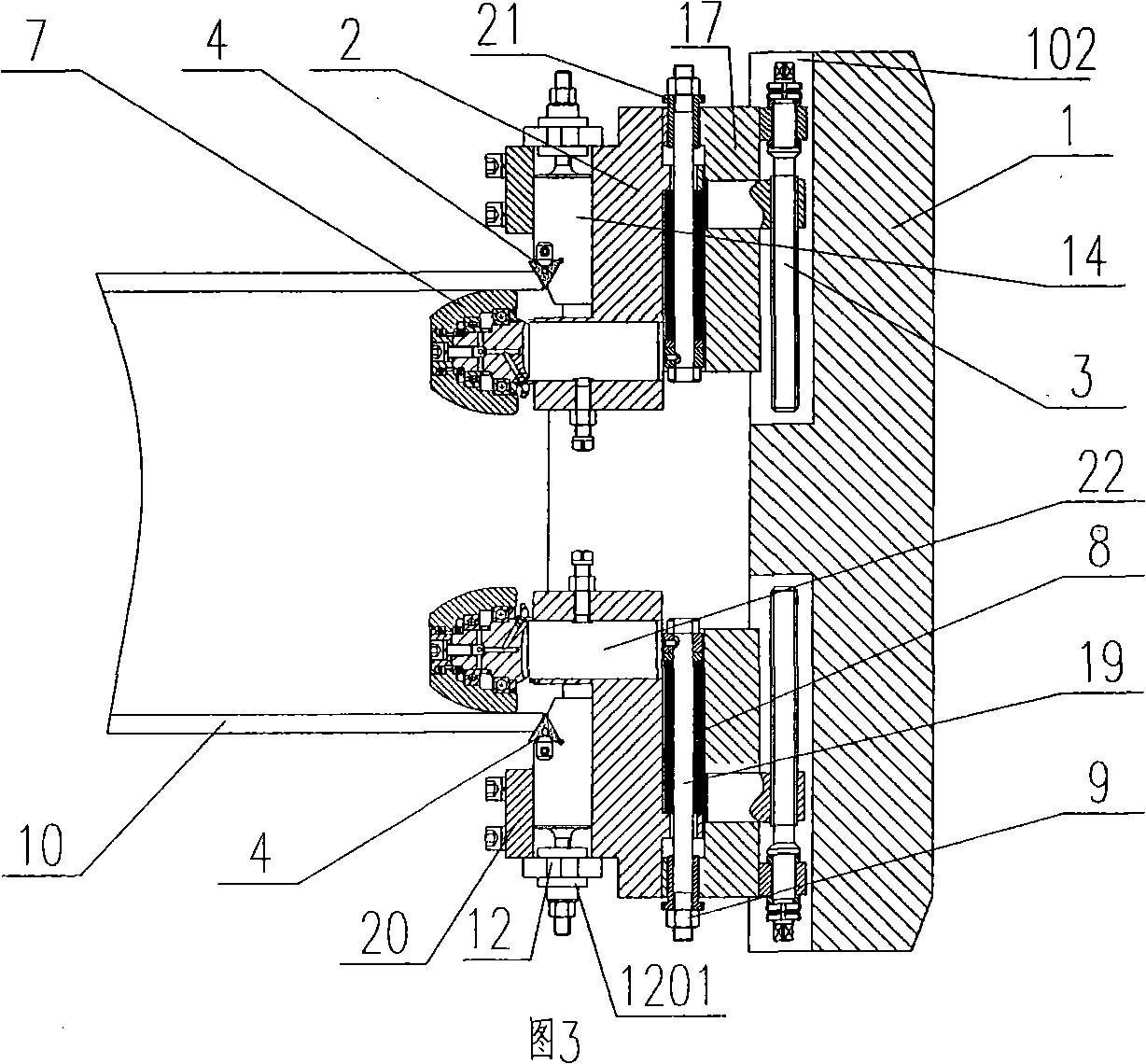

Ultraphonic elliptical vibration and extrusion processing device based on double-excitation longitudinal bending elliptical energy converter

InactiveCN101633048AExtended service lifeReduce or even avoid sliding frictionAuxillary equipmentMechanical vibrations separationEllipseEnergy converter

The invention discloses an ultraphonic elliptical vibration and extrusion processing device based on a double-excitation longitudinal bending elliptical energy converter, comprising a shell assembly, a vibration assembly, a sliding assembly and a pressure assembly, wherein the sliding assembly is sleeved on the excircle surface of the vibration assembly; the pressure assembly is arranged on the tail part of the vibration assembly; and the assembled vibration assembly, the sliding assembly and the pressure assembly are arranged in the shell assembly. The structure of the ultraphonic elliptical vibration and extrusion processing device is designed by combining a flexible extrusion requirement with a langevin energy converter principle, when the ultraphonic elliptical vibration and extrusion processing device is adopted to carry out extrusion processing, the double-excitation longitudinal bending elliptical energy converter of the ultraphonic elliptical vibration and extrusion processing device can drive a cutter to cautiously take longitudinal bending elliptical vibration, tracks of the longitudinal bending elliptical vibration are tangent with tracks of the turning motion of a workpiece and is reverse to the turning direction of the workpiece, when the turning speed of the longitudinal bending elliptical vibration is equal or approximately equal to the turning speed of the workpiece, the cutter is equivalent to make pure rolling on the surface of the workpiece so that relative sliding between the cutter and the processing surface disappears, and the mechanical abrasion caused by sliding friction is effectively prevented, and the purpose of prolonging the service life of the cutter is achieved.

Owner:BEIHANG UNIV

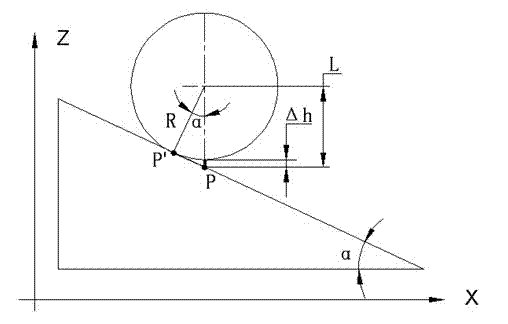

On-line measuring method for radials profile of compressor disc-like part of engine

InactiveCN102814512AAvoid errorsHas measurement limitationsAuxillary equipmentMeasurement/indication equipmentsReworkProcessing

The invention belongs to the field of automatic detection, particularly relates to an on-line measuring method for the radials profile of a compressor disc-like part of an engine. The method comprises the following steps that the measuring path of a measuring head is planned; the radius of sphere of the measuring head is corrected; characteristic points on the profile of a compressor disc are selected as measuring points; the motion program of the measuring head is edited; the motion track of the measuring head is optimized in virtual simulation software; the motion program of the measuring head is run; the measuring head traverses all the measuring points; the mean value of the measured values of the measuring points after errors are compensated is compared with the design theoretical value of the compressor disc part; when the measured values are within the design tolerance zone scope of the part, the processing size of the measured compressor disc part is considered to be qualified; otherwise, the processing and measurement are carried out again, until the size of the part is qualified. According to the method, a traditional manufacturing mode in the current industry that a design characteristic is matched with a set of measuring tooling is changed, so that the tooling manufacturing cost and the rework hours are saved, the one-time qualified rate of product processing is improved, the new product development cycle is shortened and the production cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

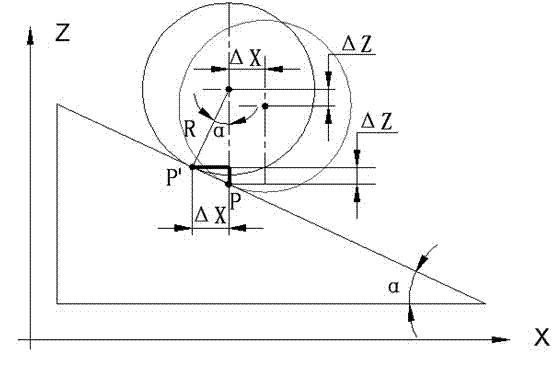

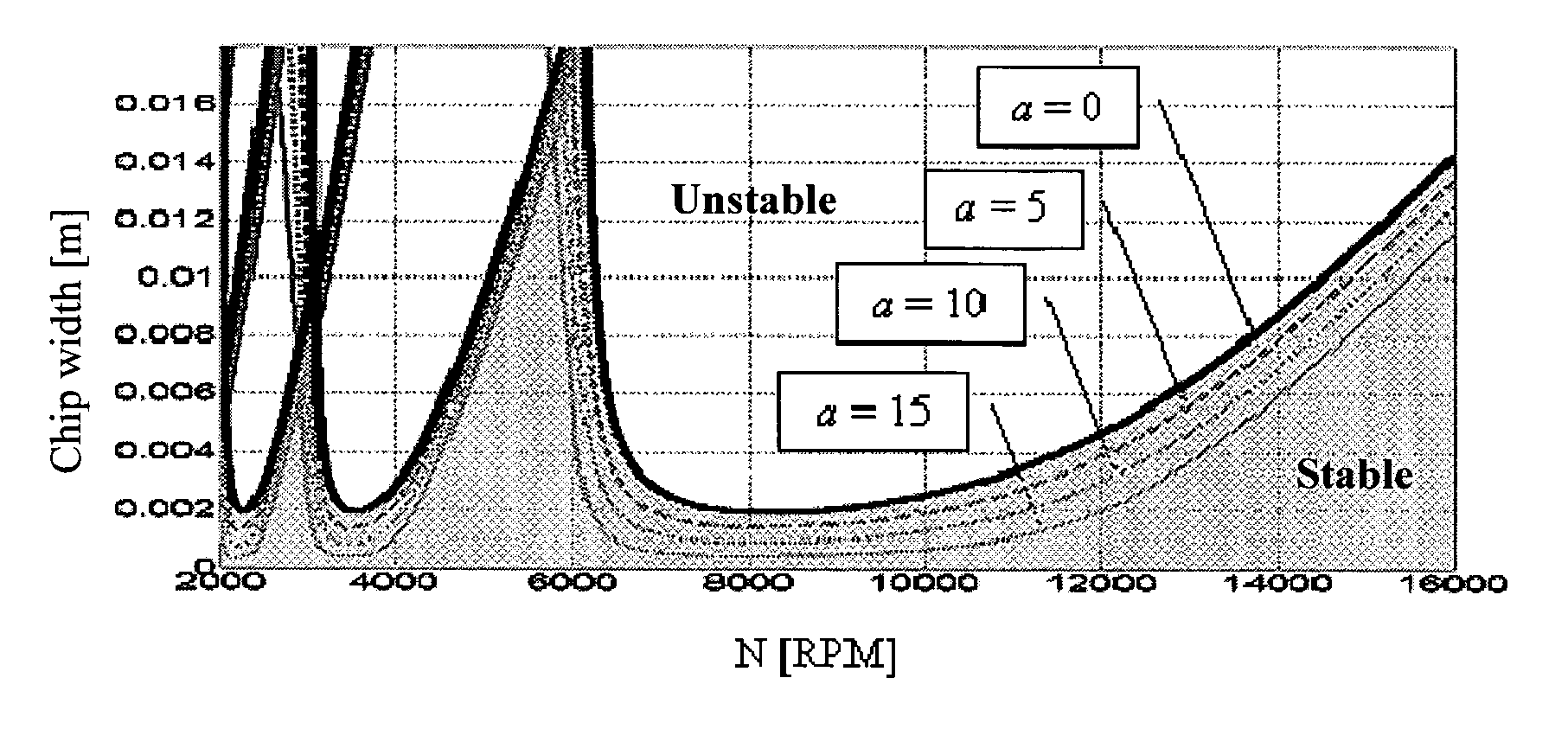

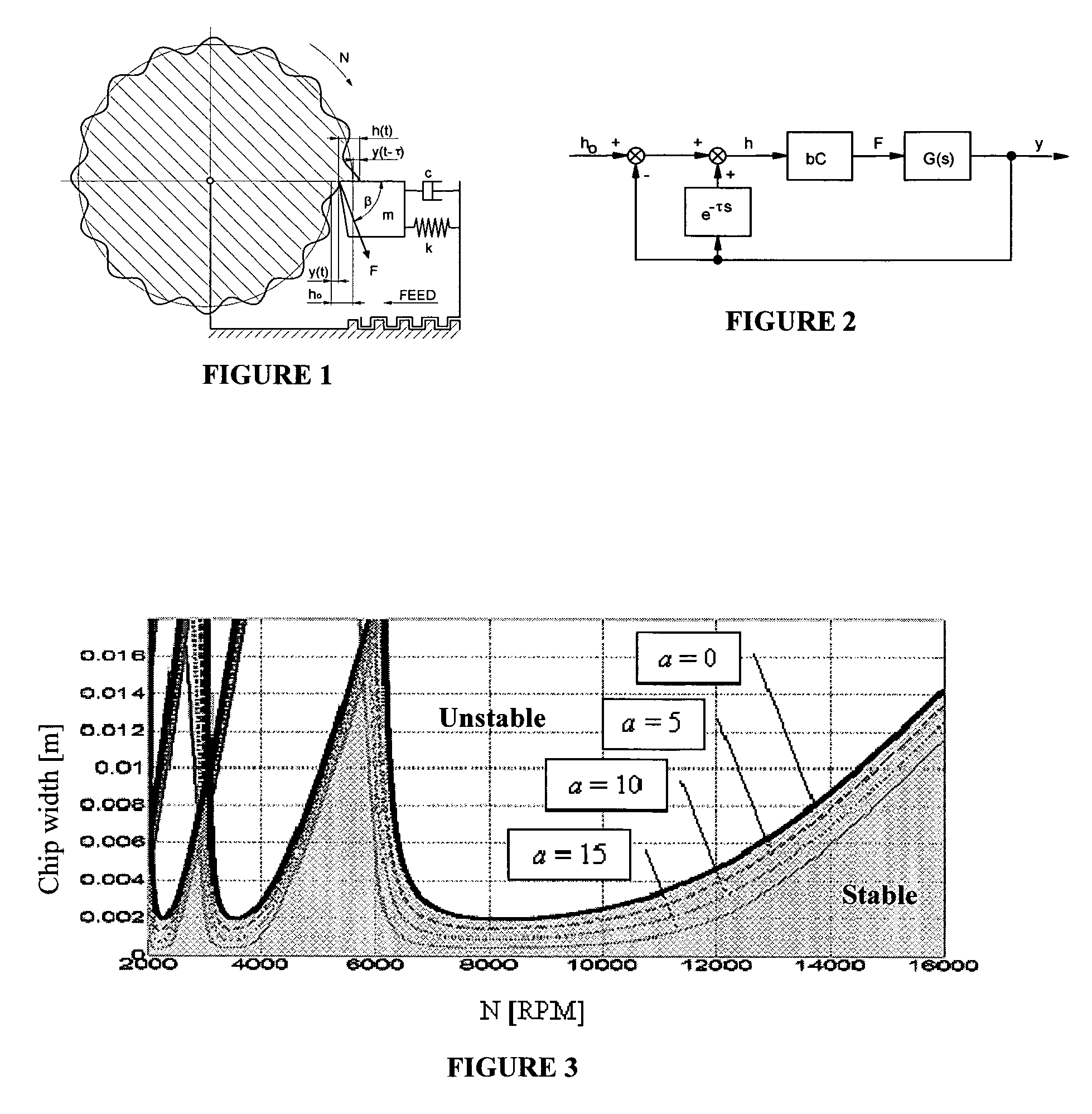

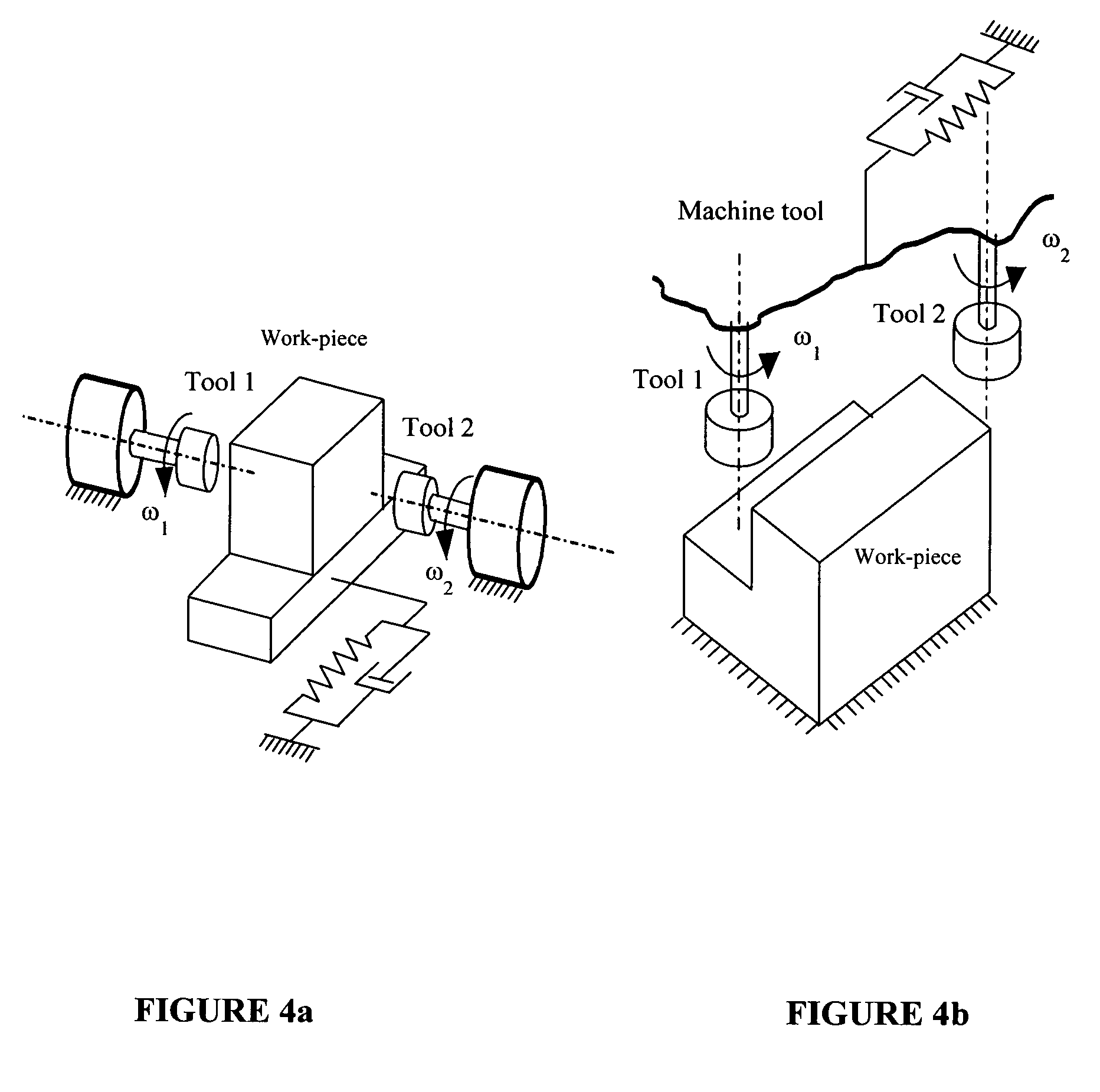

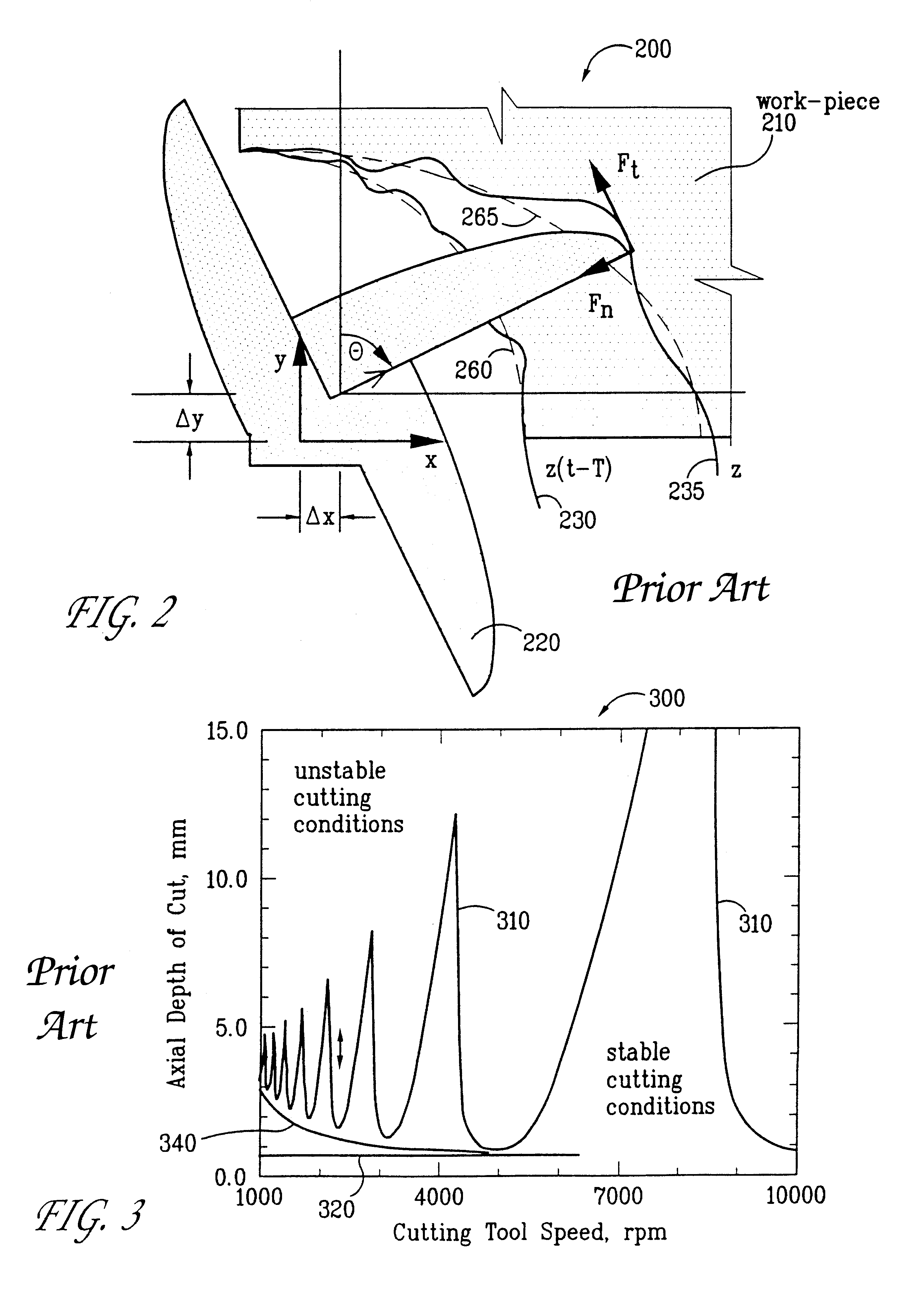

System and method for chatter stability prediction and control in simultaneous machining applications

InactiveUS20060271231A1Reducing and controlling machine tool chatterReduce controlProgramme controlLathesMilling cutterMachined surface

Systems and methods are provided for use in assessing the stability of simultaneous machining (SM) dynamics (which is also known as parallel machining). In SM, multiple cutters, which are generally driven by multiple spindles at different speeds, operate on the same work-piece. In an alternative implementation of SM, single milling cutters with non-uniformly distributed cutter flutes operate on a work-piece. When SM is optimized in the sense of maximizing the rate of metal removal constrained with or by the machined surface quality, “chatter instability” phenomenon appears. The present disclosure declares the complete stability picture of SM chatter within a mathematical framework of multiple time-delay systems (MTDS). A cluster treatment of characteristic roots (CTCR) procedure determines the regions of stability completely in the domain of the spindle speeds for varying chip thickness, thereby replicating the well-known “stability lobes” concept of STM for simultaneous machining.

Owner:UNIV OF CONNECTICUT

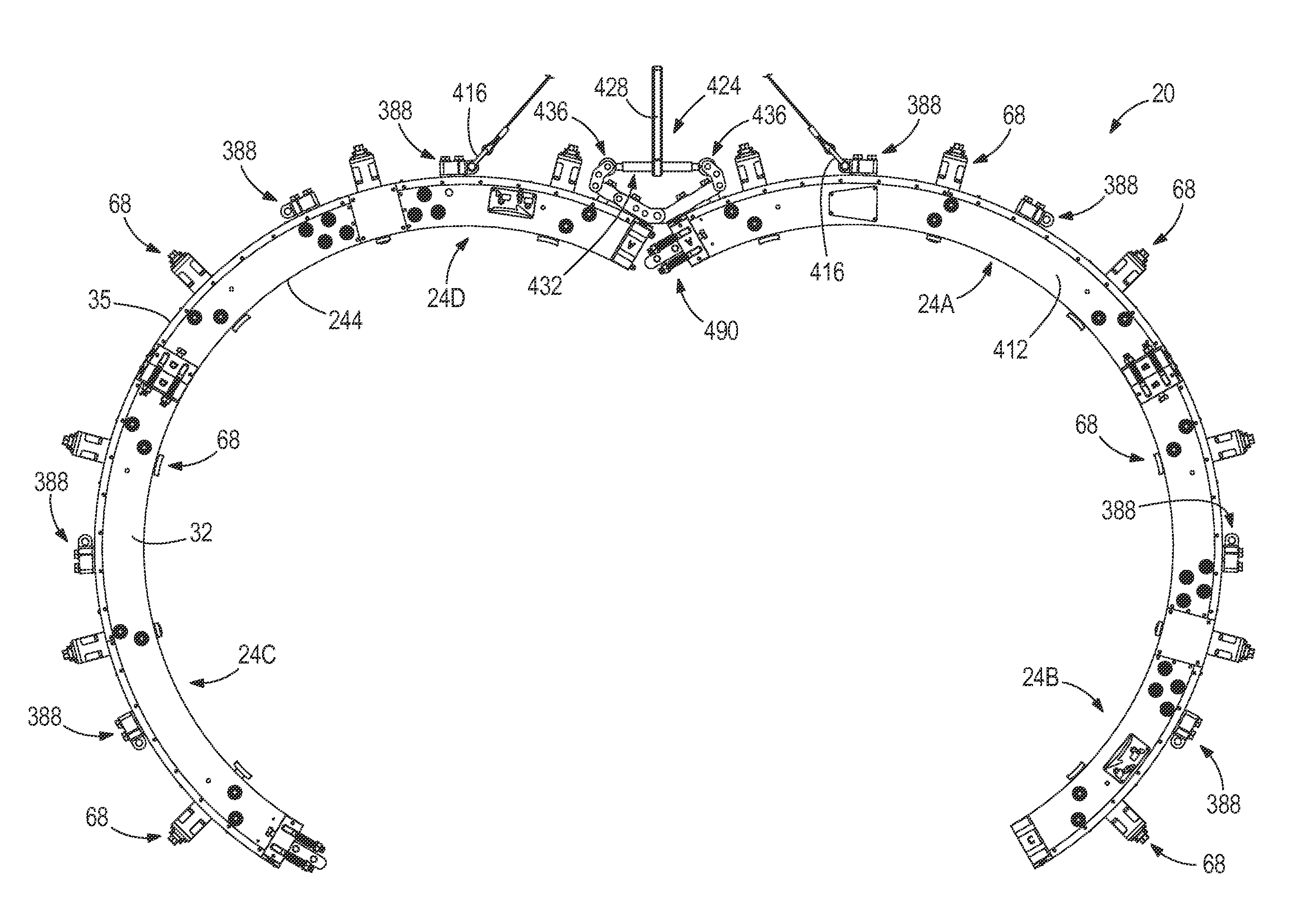

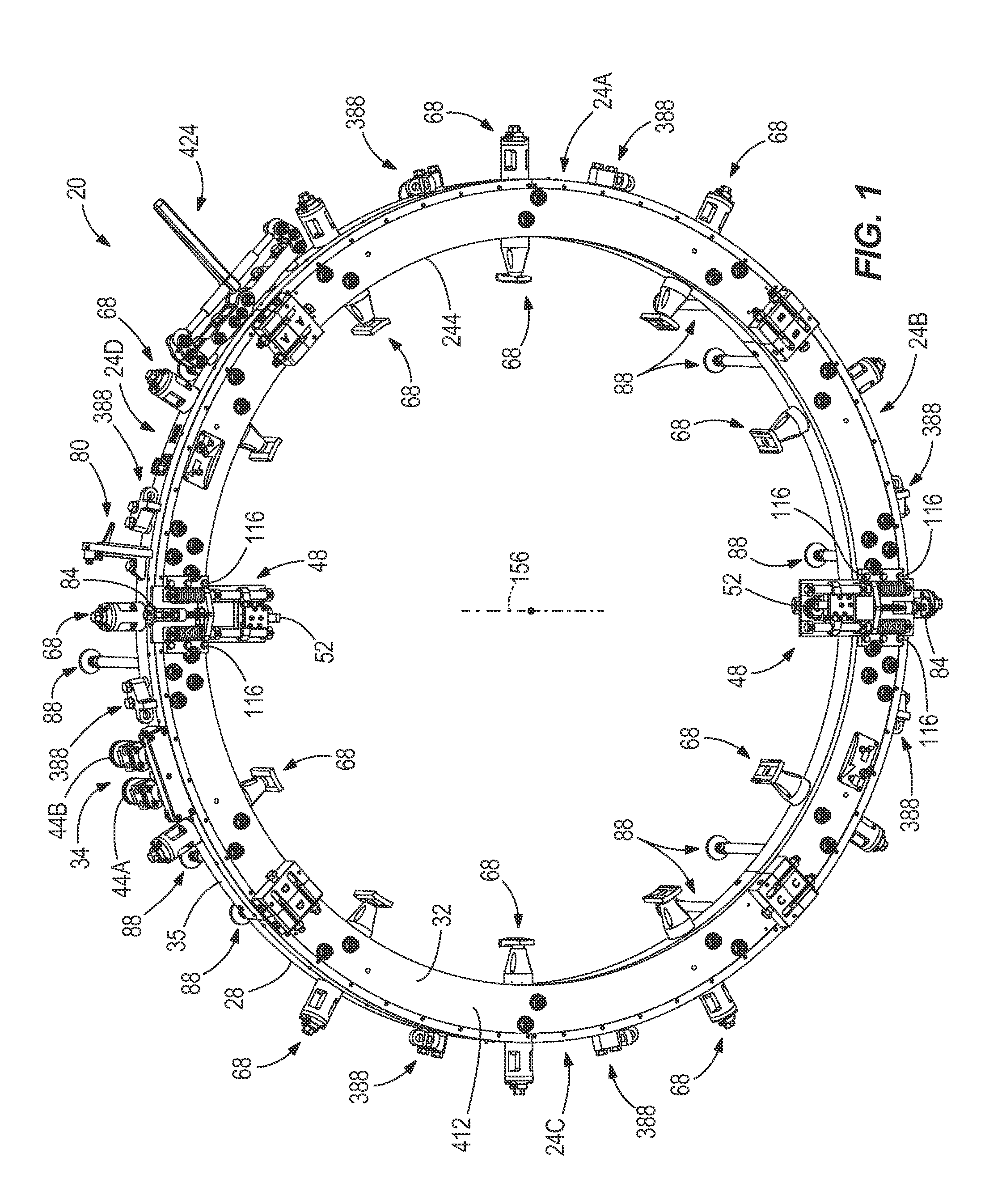

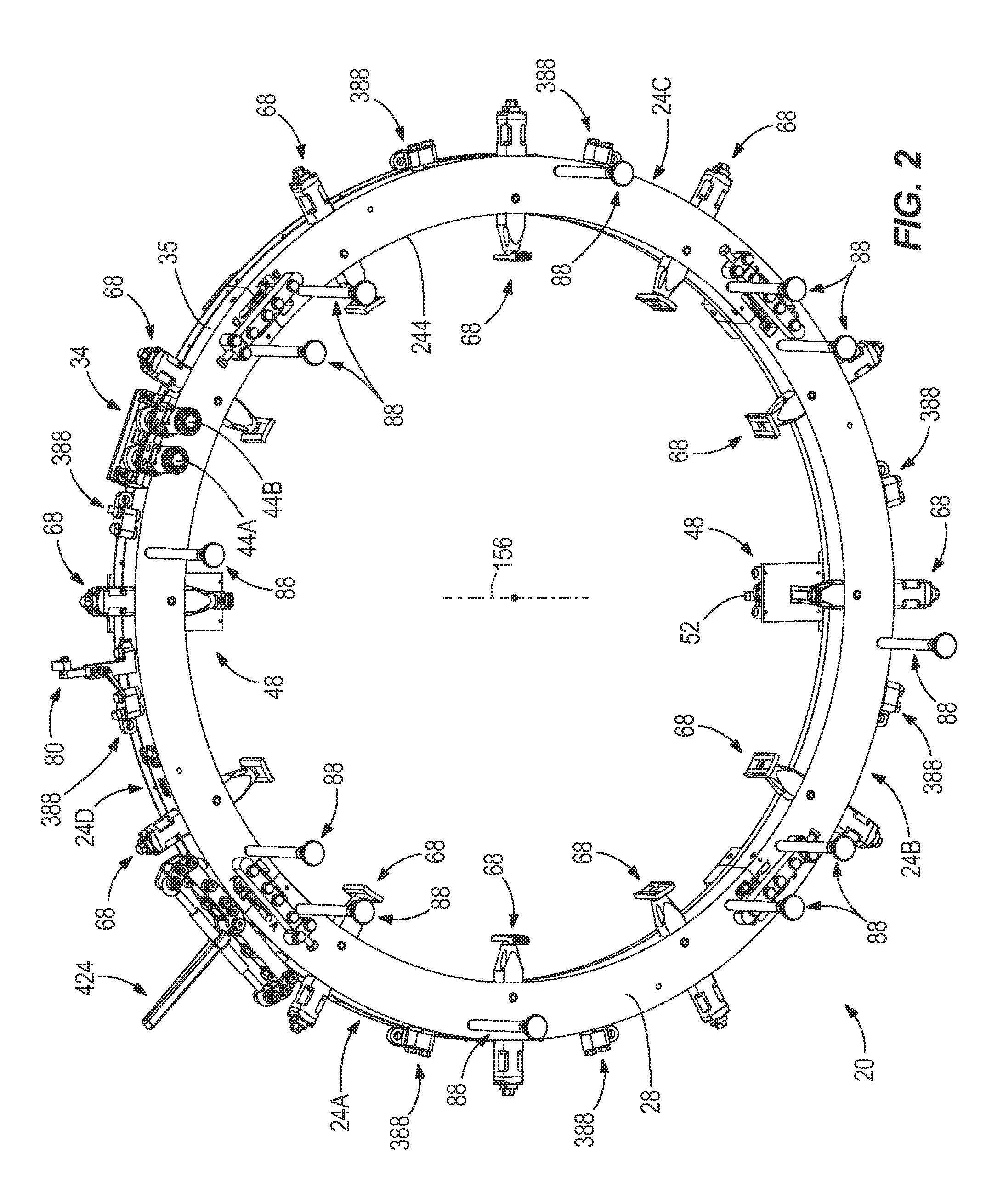

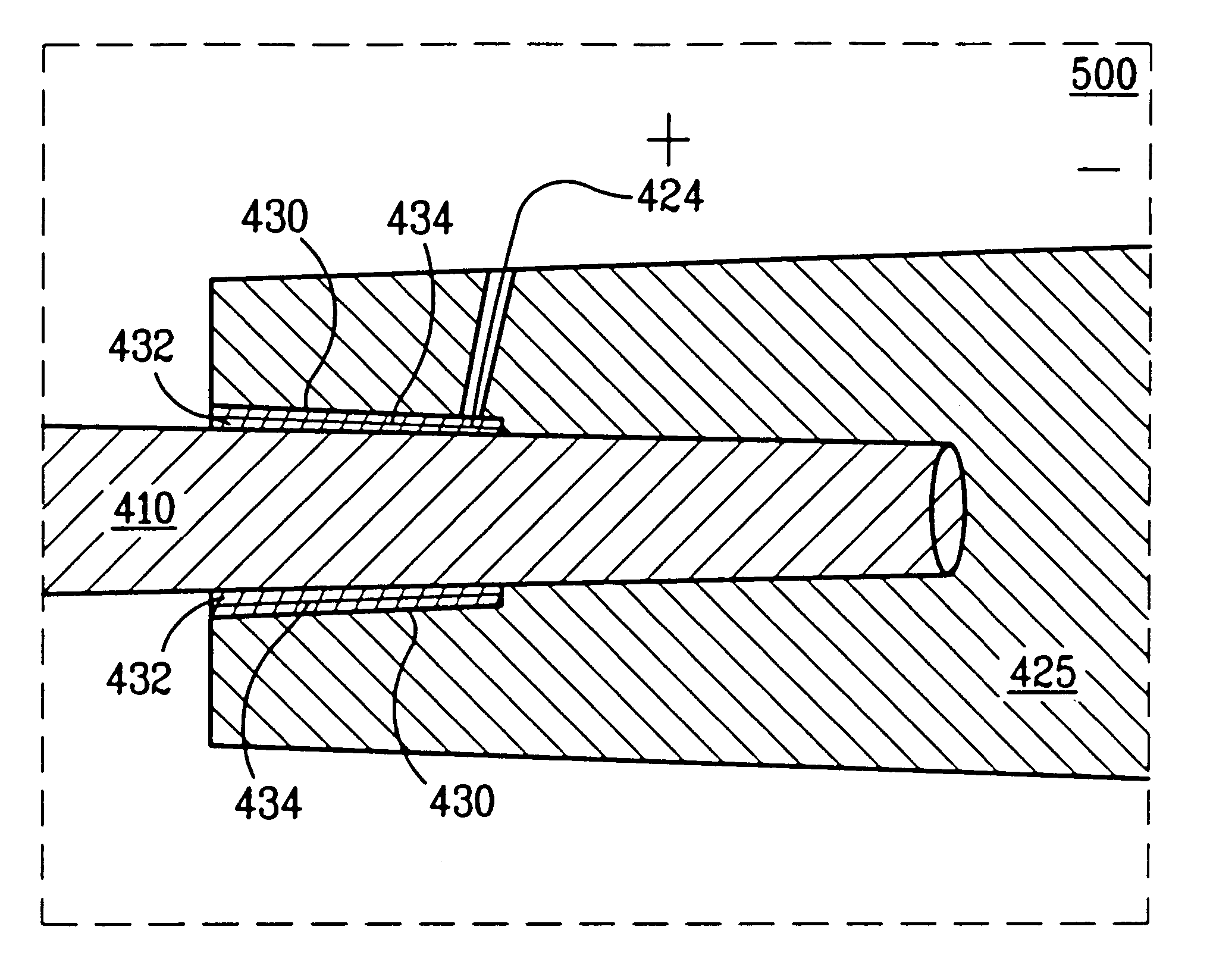

Pipe machining apparatuses and methods of operating the same

Pipe machining apparatuses are provided. In some aspects, a pipe machining apparatus may include a hinge to allow two sections of the pipe machining apparatus to move relative to one another. In another aspect, a support member may be provided to support a pipe machining apparatus on a surface. In a further aspect, a support member may be provided that allows lifting of a pipe machining apparatus in either a horizontal position or a vertical position.

Owner:ILLINOIS TOOL WORKS INC

Method and device for vibration control

A device and method for vibration control in a machine for cutting, said machine comprising a cutting tool supported by a tool holder. The device comprises a control unit and converting means which are connectible to the control unit and comprise a vibration sensor and an actuator. The actuator comprises an active element which converts an A.C. voltage supplied by the control unit to the actuator into dimensional changes. Said active element is adapted to be embedded in the body of the tool holder and in such manner that said dimensional changes impart bending to the body of the tool holder.

Owner:STAFFANSBODA CIE

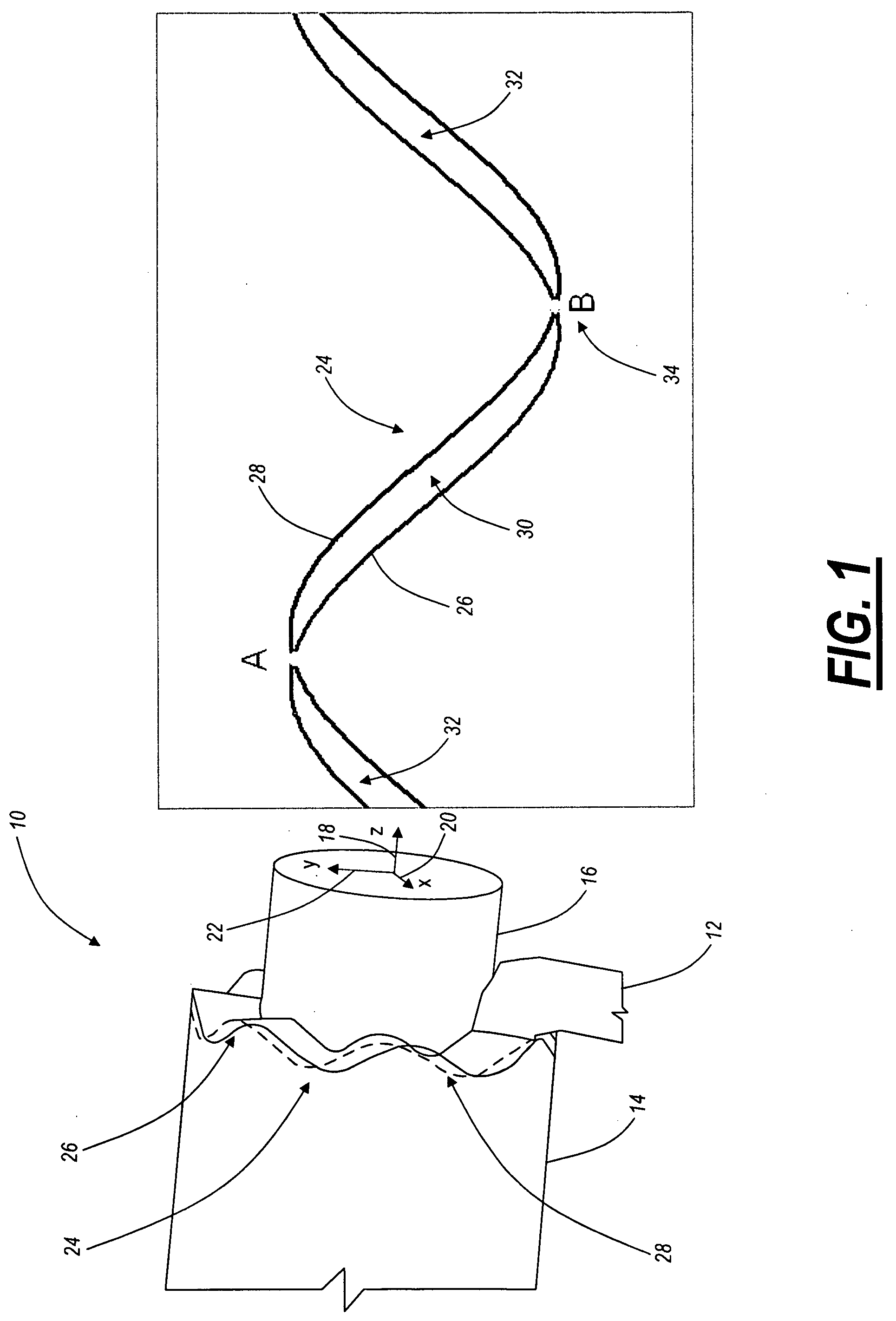

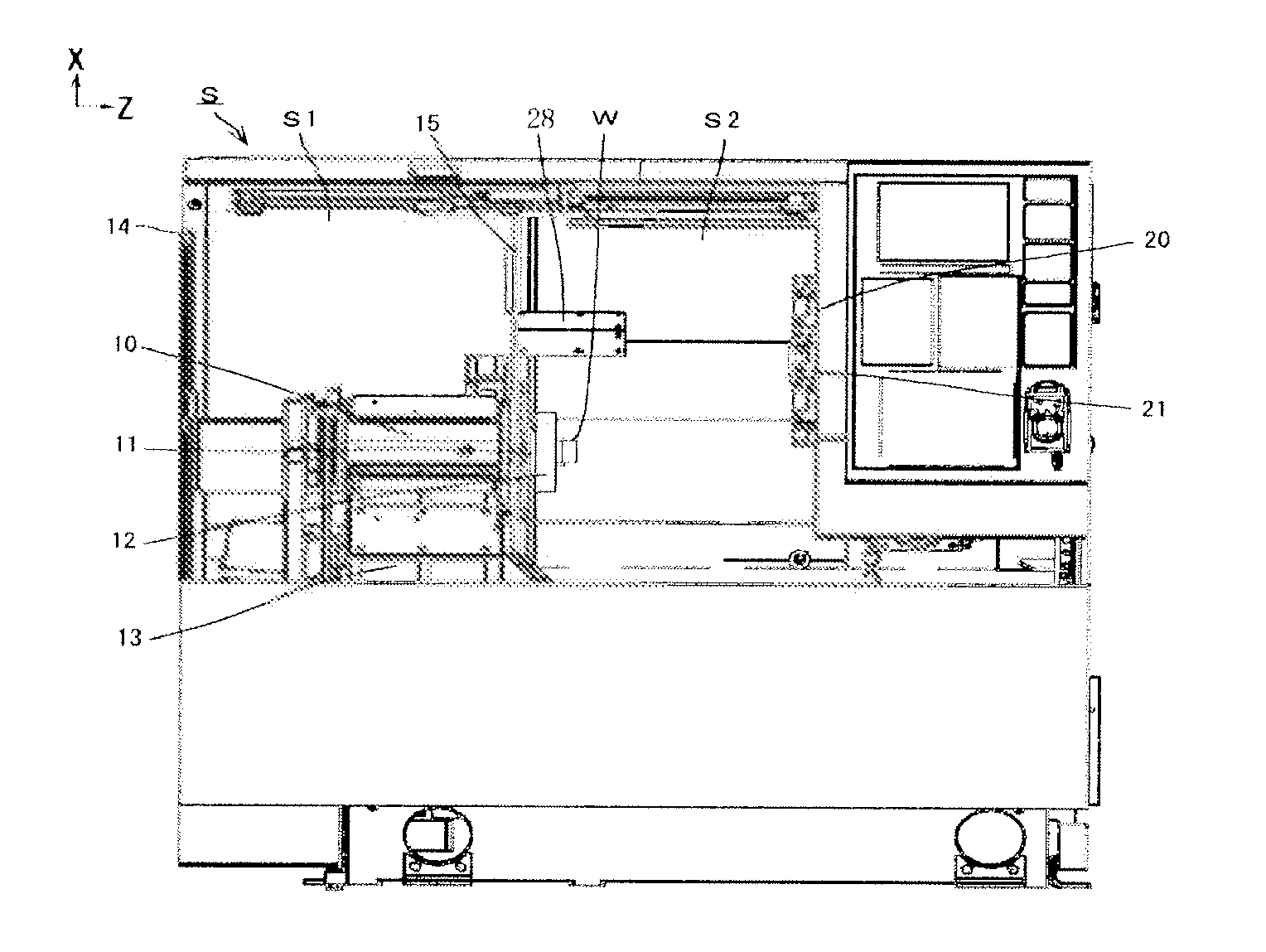

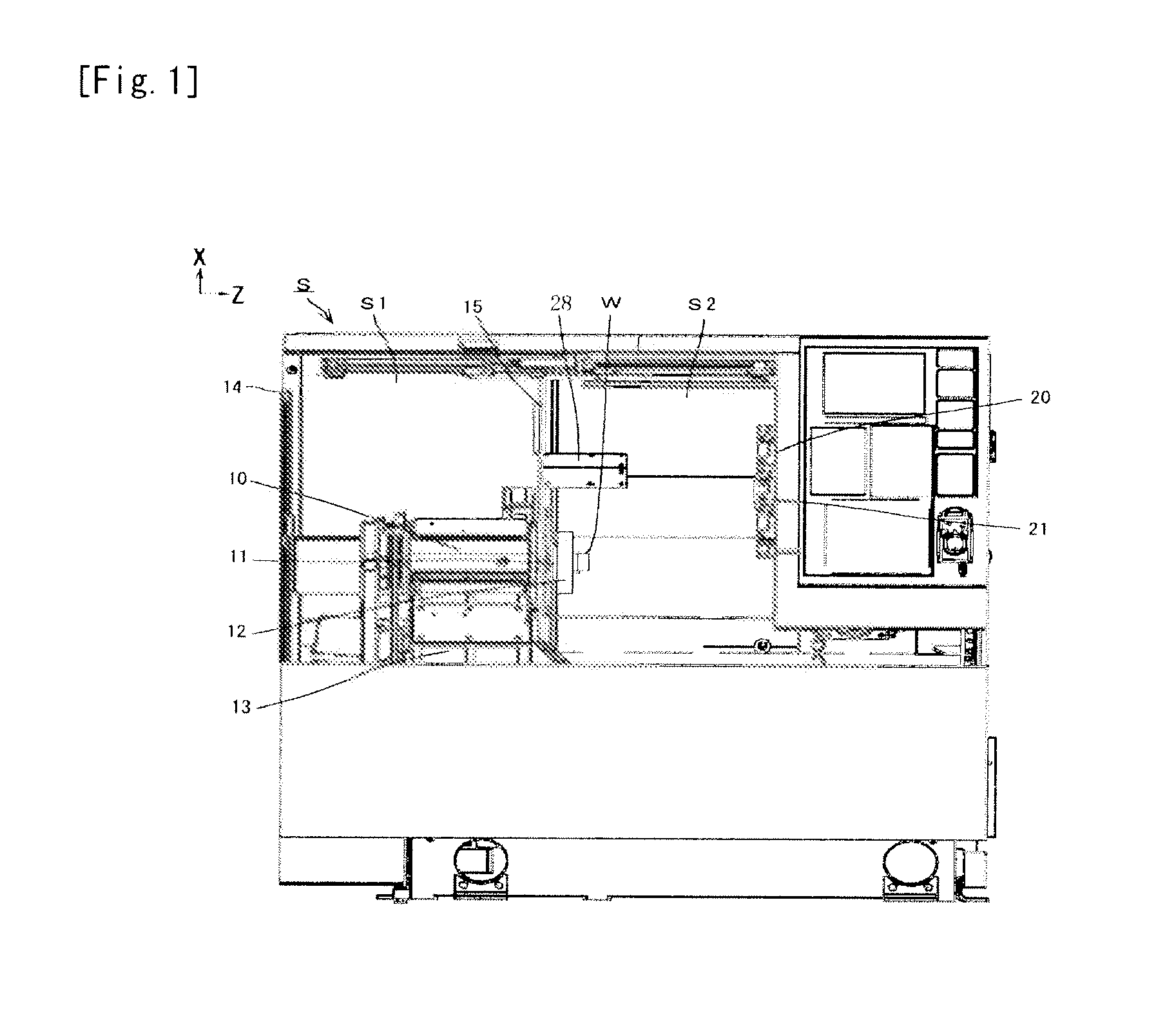

Measuring apparatus and measuring method thereof, apparatus for correcting processing position of cutting machine and method thereof for correcting processing position, and imaging apparatus and cutting machine comprising the same

ActiveUS20120038763A1Easy to measureAccurate measurementTelevision system detailsThermometers using material expansion/contactionEngineeringThermal expansion

Provided is an apparatus and a method thereof which can detect a displacement amount of a cutting tool with respect to a workpiece with high accuracy and can correct a processing position with high accuracy. Accordingly, a turret gauge 46 is comprised of an invar body 47 and a gauge main body 48 with a different thermal expansion coefficient. A point A of the gauge main body 48 and a leading edge 47A of the invar body are imaged in a state of viewing the whole thereof at a time of an initialization and a calibration cycle (CS), and a temperature of the gauge main body 48 is detected by comparing each image data. Furthermore, the length between the point A and a point B of the gauge main body 48 at the time of the CS is obtained based on the image data. The actual length is compared with a theoretical length between the point A and the point B at a temperature of the gauge main body 48 at the time of the CS, and consideration is given to the comparison. Therefore, a heat displacement amount of a ball screw can be accurately detected, the displacement of a processing position of a cutting tool can be corrected with high accuracy, and processing accuracy of a workpiece can be improved.

Owner:FUJI CORP

Numerical control supersonic machining apparatus for general lathe

InactiveCN101503755AReduce labor intensitySolve the problem that complex surfaces such as arcs cannot be processedAuxillary equipmentMechanical vibrations separationNumerical controlPatch panel

The invention provides a digital control ultrasonic processing device for a common lathe. The device comprises a pedestal, an intermediate guide rail, an upper support plate and a rotary tool rest, wherein the bottom surface of the pedestal is provided with a dovetail groove; the intermediate guide rail is arranged on the pedestal through a vertical guide rail; the upper support plate is arranged on the intermediate guide rail through a horizontal guide rail; an intermediate shaft is arranged inside the upper support plate; the rotary tool rest is arranged on the intermediate shaft; a patch panel and an electric brush panel are arranged between the rotary tool rest and the upper support plate; an electric brush is connected between the patch panel and the electric brush panel; a lead screw feeding mechanism is arranged on the intermediate guide rail and the upper support plate; a tool rest automatic tool change mechanism is arranged between the upper support plate and the rotary tool rest; a lathe tool, a round amplitude transformer and an external circular amplitude transformer are arranged on the rotary tool rest; and a processing tool bit is arranged on the two amplitude transformers and connected with an energy converter respectively. The digital control ultrasonic processing device for the common lathe has high efficiency and high processing precision and can complete turning, ultrasonic processing of the external circular face and ultrasonic processing of the crown face by clamping for one time.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

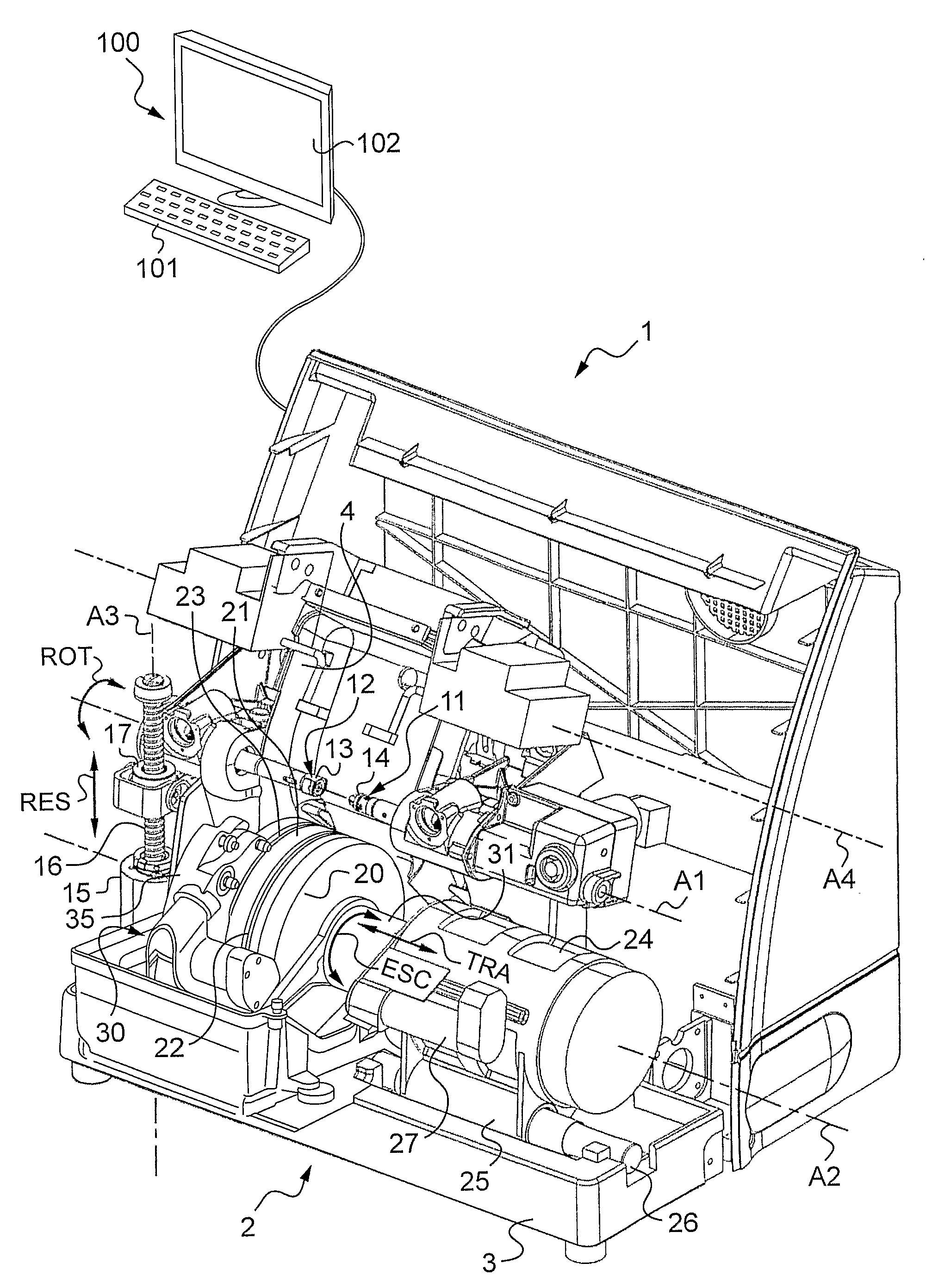

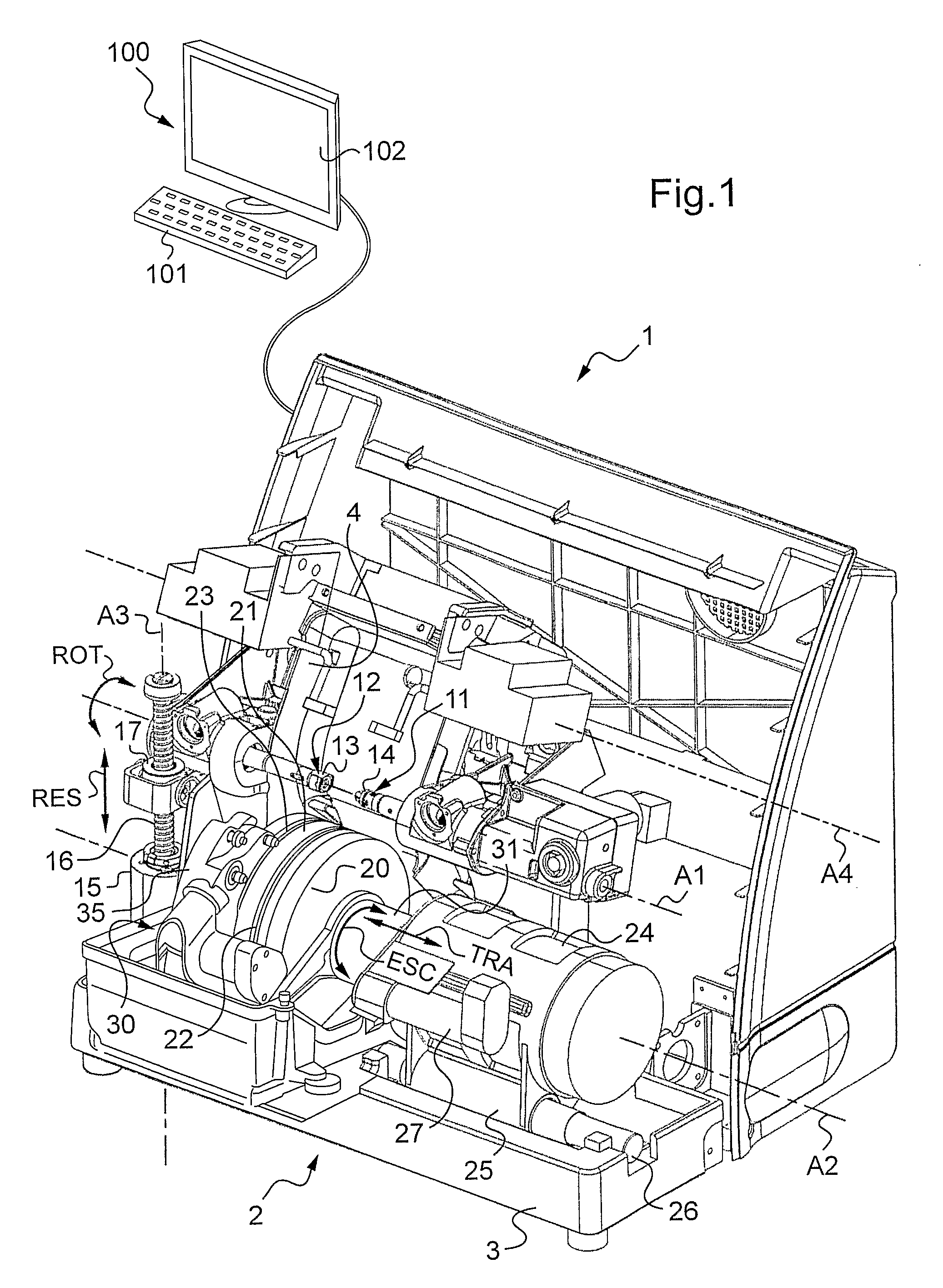

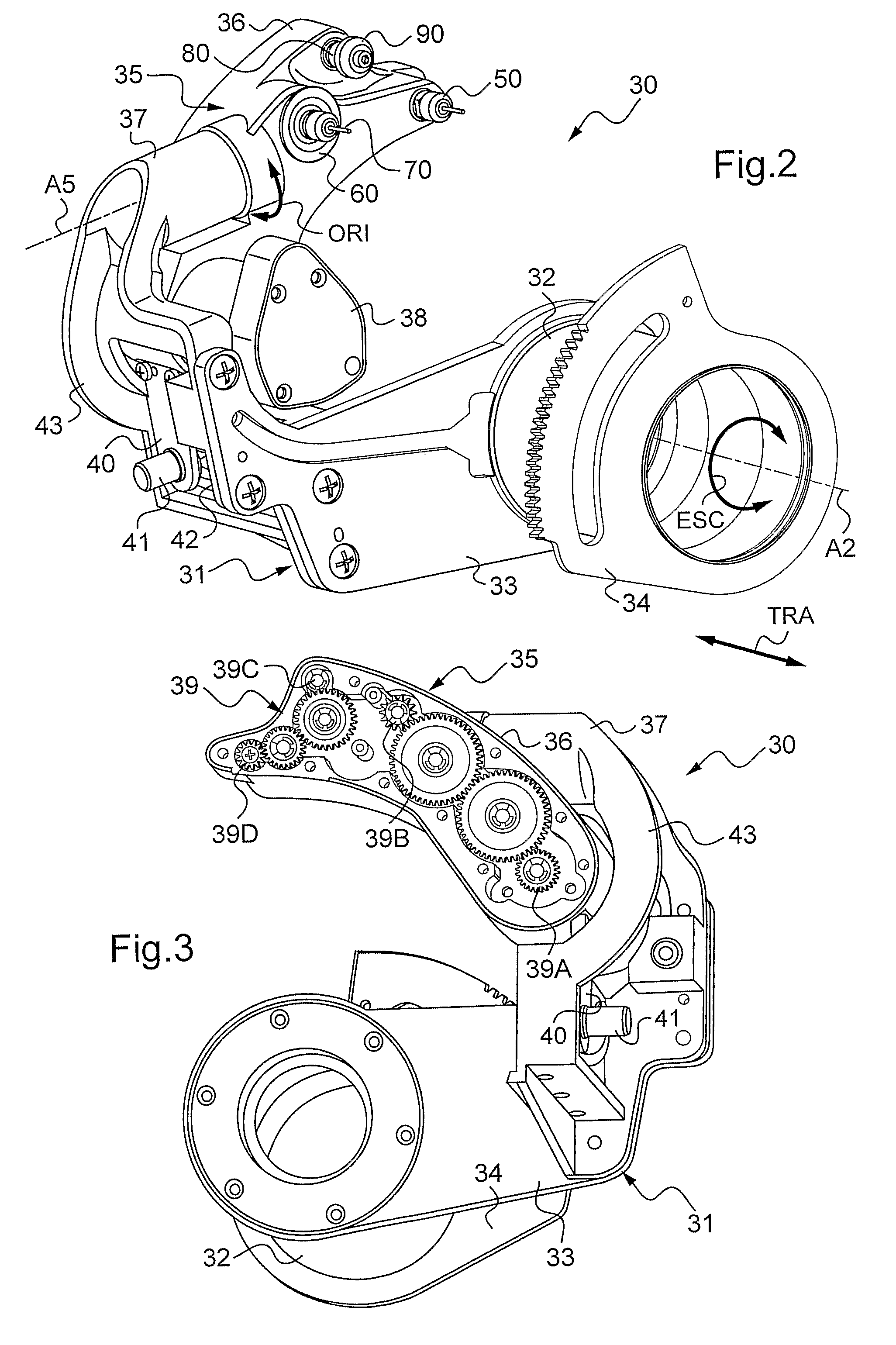

Device for machining ophthalmic lenses, the device having a plurality of machining tools placed on a swivel module

ActiveUS20100093265A1Easy maintenanceImprove accuracyEdge grinding machinesPolishing machinesEngineeringEye lens

A device (1) for machining an ophthalmic lens includes a support for the ophthalmic lens and for driving it in rotation about a blocking axis (A1), a machining module (35) that can be swiveled relative to the support and driving the lens in rotation and that is suitable for pivoting about a swivel axis that is not parallel to the blocking axis of the lens, and at least one drill tool mounted to rotate on the machining module about a first axis of rotation. The machining device includes at least one other machining tool mounted to rotate on the machining module about another axis of rotation that is distinct from the first axis of rotation and that is stationary relative to the first axis of rotation.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Apparatus and method for machining long workpiece

There are provided a base frame 12 positioned below a horizontal axis O; a pair of clamp units 14 positioned at the two ends above the base frame; a pair of support units 16 that horizontally support the long workpiece in two locations, and that are capable of moving vertically; and machining units 18 that are capable of machining the long workpiece. The two clamp units 14 are capable of moving from the outside toward the inside, which support the long workpiece in two locations, and rotate around the horizontal axis O in synchronization with each other.

Owner:IMAX CO LTD

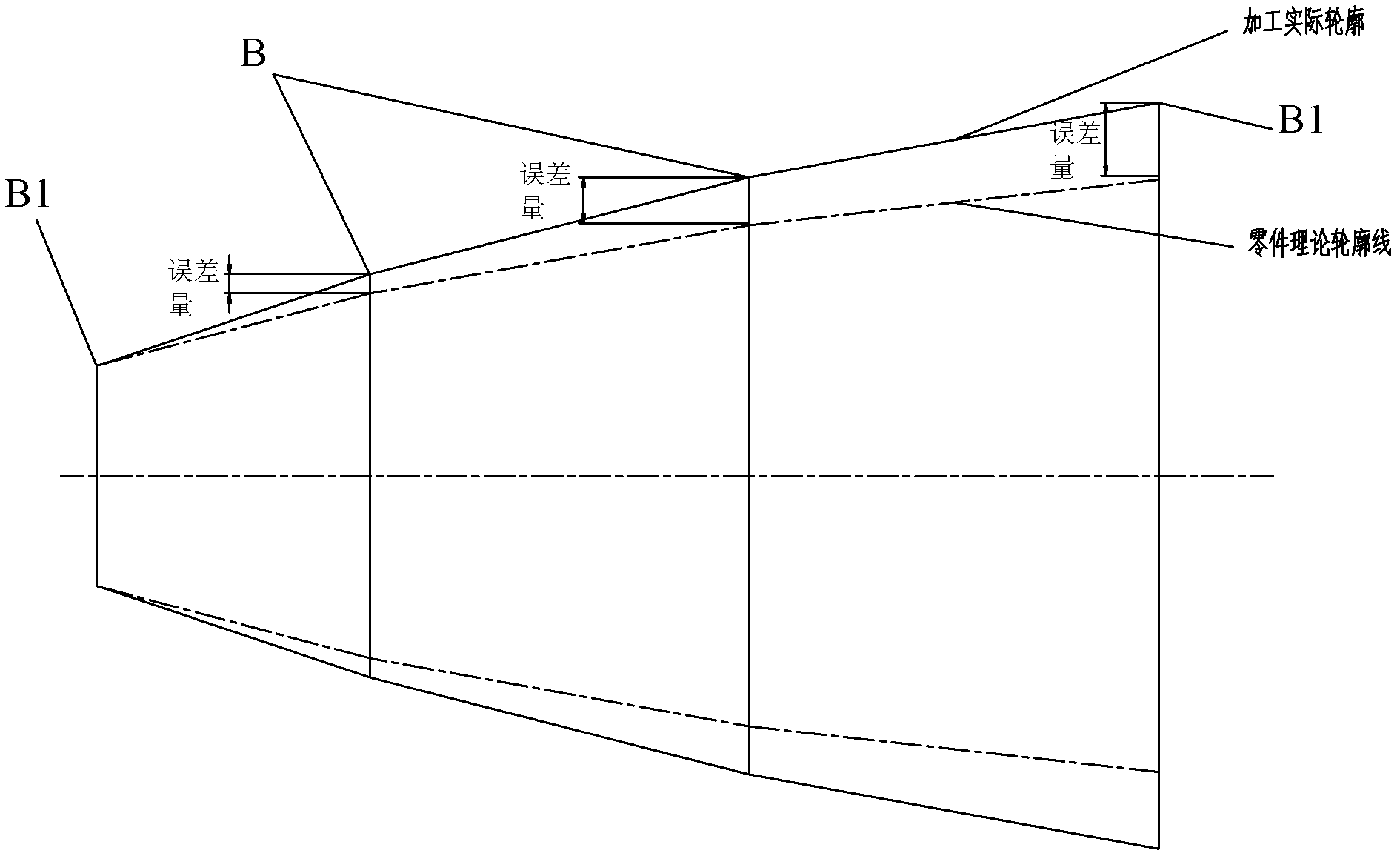

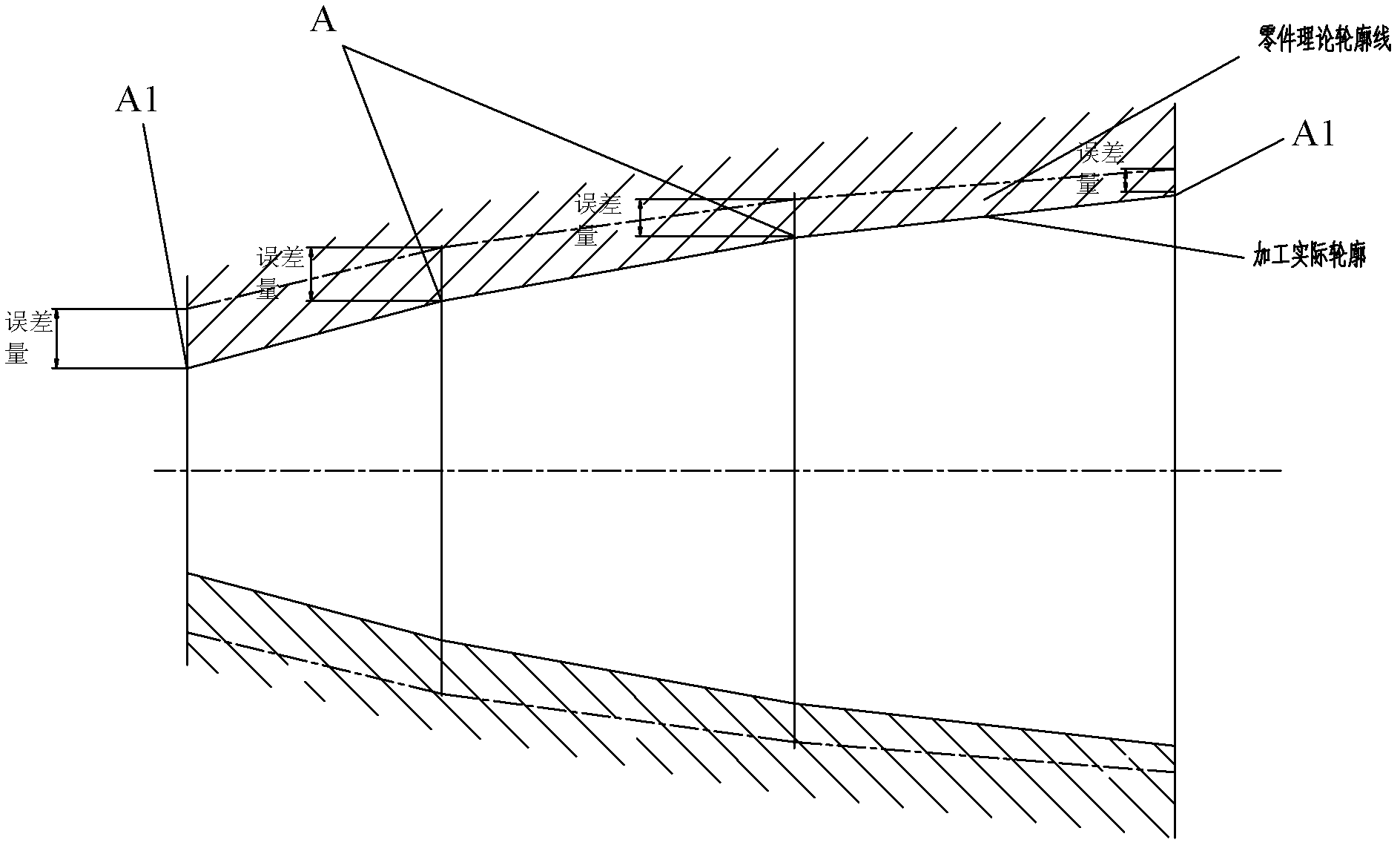

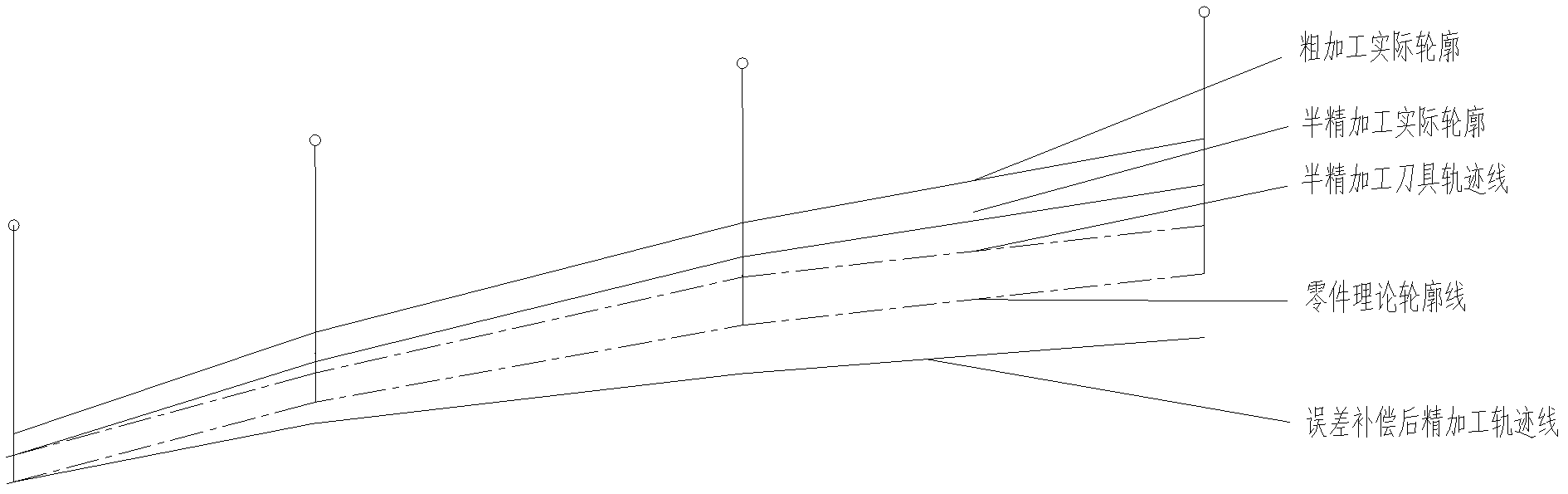

Self-adaptive compensation method for detecting turning error of large part of rotary body

ActiveCN102430765AImprove machining accuracyAvoid machining errorsAuxillary equipmentTurning machinesSelf adaptiveLine segment

The invention discloses a self-adaptive compensation method for detecting the turning error of a large part of a rotary body, comprising the steps of: rough machining the part of the rotary body; measuring the radius of intersection of two adjacent contour line segments on an axial section of an inner hole of the part of the rotary body and en extent of error delta 1 of the radius of the two end points by a probe, performing semifinishing for the rough machined part of the rotary body, performing semifinishing for the semifinishing lathe tool by machining trajectory intersection and two end points with theoretical machining radius which is X1-delta 1 / 2, measuring the actual radiuses of the intersection (A) and two end points (A1) in the step 2) after semifinishing to obtain an extent of error delta1' of semifinishing; performing finish machining, wherein that finish machining lathe tool, the main shaft rotary speed of the tool and the feeding speed are identical to those of semifinishing. In the process of finish machining, a numerical control system of the lathe compensates the extent of error delta 1' of semifinishing. The invention solves the problem that in the machining process the machining error caused by tool wear exists, thereby greatly improving the machining precision of the large part of the rotary body.

Owner:HUBEI SANJIANG SPACE XIANFENG ELECTRONICS&INFORMATION CO LTD

Method and apparatus for suppressing regenerative instability and related chatter in machine tools

Methods of and apparatuses for mitigating chatter vibrations in machine tools or components thereof. Chatter therein is suppressed by periodically or continuously varying the stiffness of the cutting tool (or some component of the cutting tool), and hence the resonant frequency of the cutting tool (or some component thereof). The varying of resonant frequency of the cutting tool can be accomplished by modulating the stiffness of the cutting tool, the cutting tool holder, or any other component of the support for the cutting tool. By periodically altering the impedance of the cutting tool assembly, chatter is mitigated. In one embodiment, a cyclic electric (or magnetic) field is applied to the spindle quill which contains an electro-rheological (or magneto-rheological) fluid. The variable yield stress in the fluid affects the coupling of the spindle to the machine tool structure, changing the natural frequency of oscillation. Altering the modal characteristics in this fashion disrupts the modulation of current tool vibrations with previous tool vibrations recorded on the workpiece surface.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

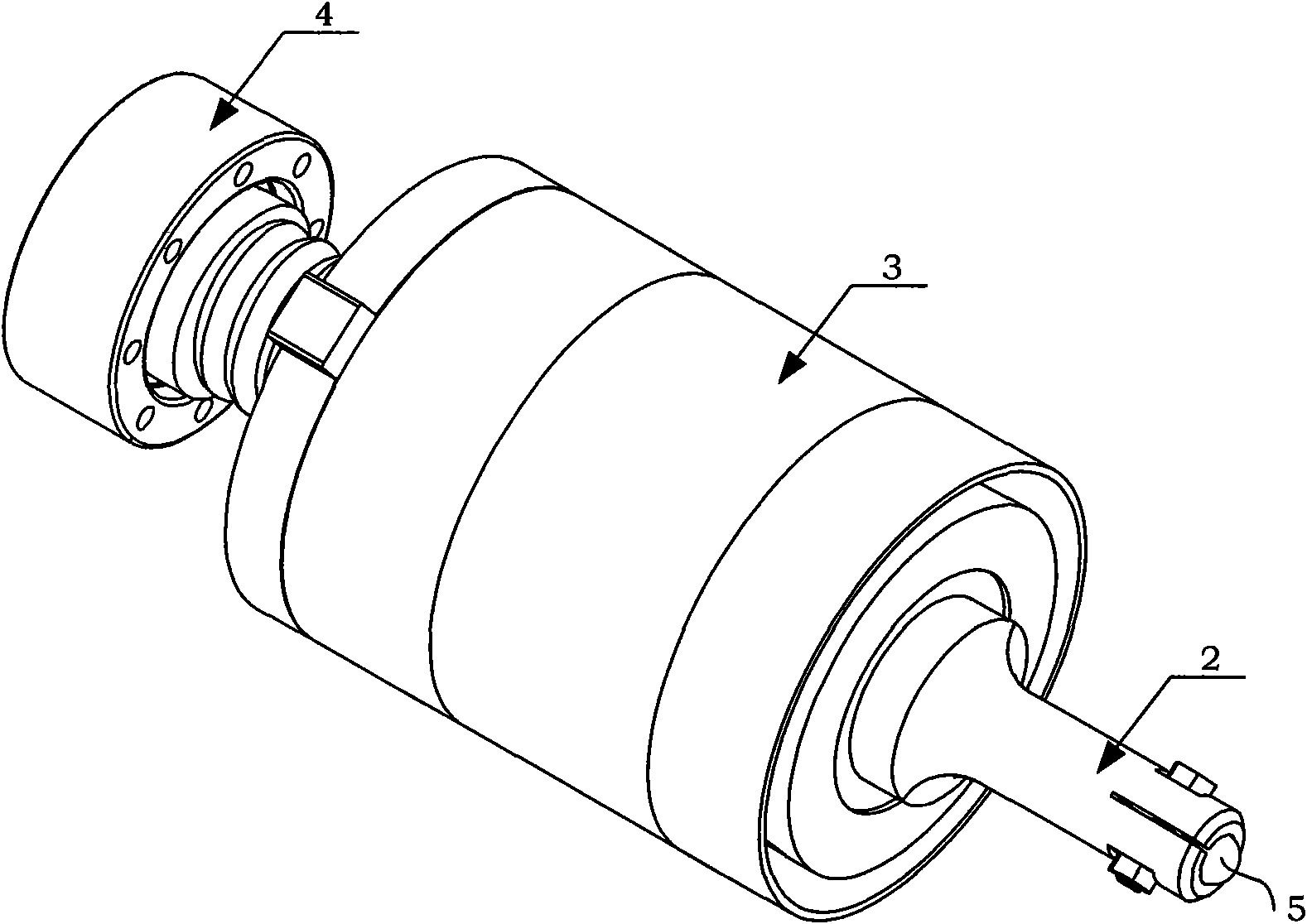

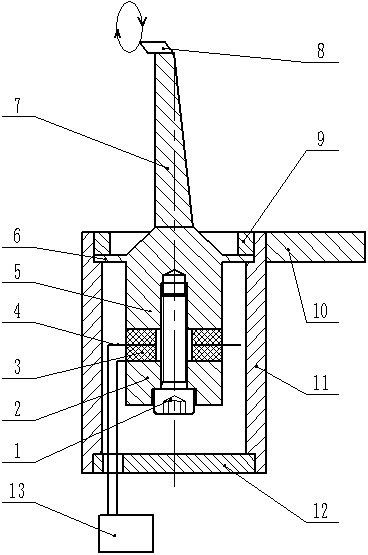

Single-driven ultrasonic elliptical vibration turning device

ActiveCN103447557AAffect work performanceLarge power capacityAuxillary equipmentMechanical vibrations separationTransducerUltrasonic vibration

The invention discloses a single-driven ultrasonic elliptical vibration turning device, comprising a shell unit, an ultrasonic vibration transducer, an elliptical vibration mode converter and a cutter, wherein the ultrasonic vibration transducer is arranged in the shell unit; the cutter is arranged on the front end of the elliptical vibration mode converter; the shell unit comprises an upper cover plate, a support plate, an external sleeve and a lower cover plate; the ultrasonic vibration transducer comprises a bolt, a rear cover plate, piezoelectric ceramic pieces, an electrode slice and a front cover plate; the rear cover plate, the piezoelectric ceramic pieces, the electrode slice and the front cover plate are sheathed on the bolt in sequence; the rear cover plate and the front cover plate enable the rear cover plate, the piezoelectric ceramic pieces, the electrode slice and the front cover plate to be linked and pressed through the bolt; the elliptical vibration mode converter is arranged on the front end of the front cover plate and is of an oblique wedge-shaped structure; the elliptical vibration mode converter can enable longitudinal ultrasonic vibration generated by the ultrasonic vibration transducer to be converted to the longitudinal-flexural composite ultrasonic elliptical vibration of the end of the elliptical vibration mode converter and the cutter.

Owner:SUZHOU UNIV OF SCI & TECH

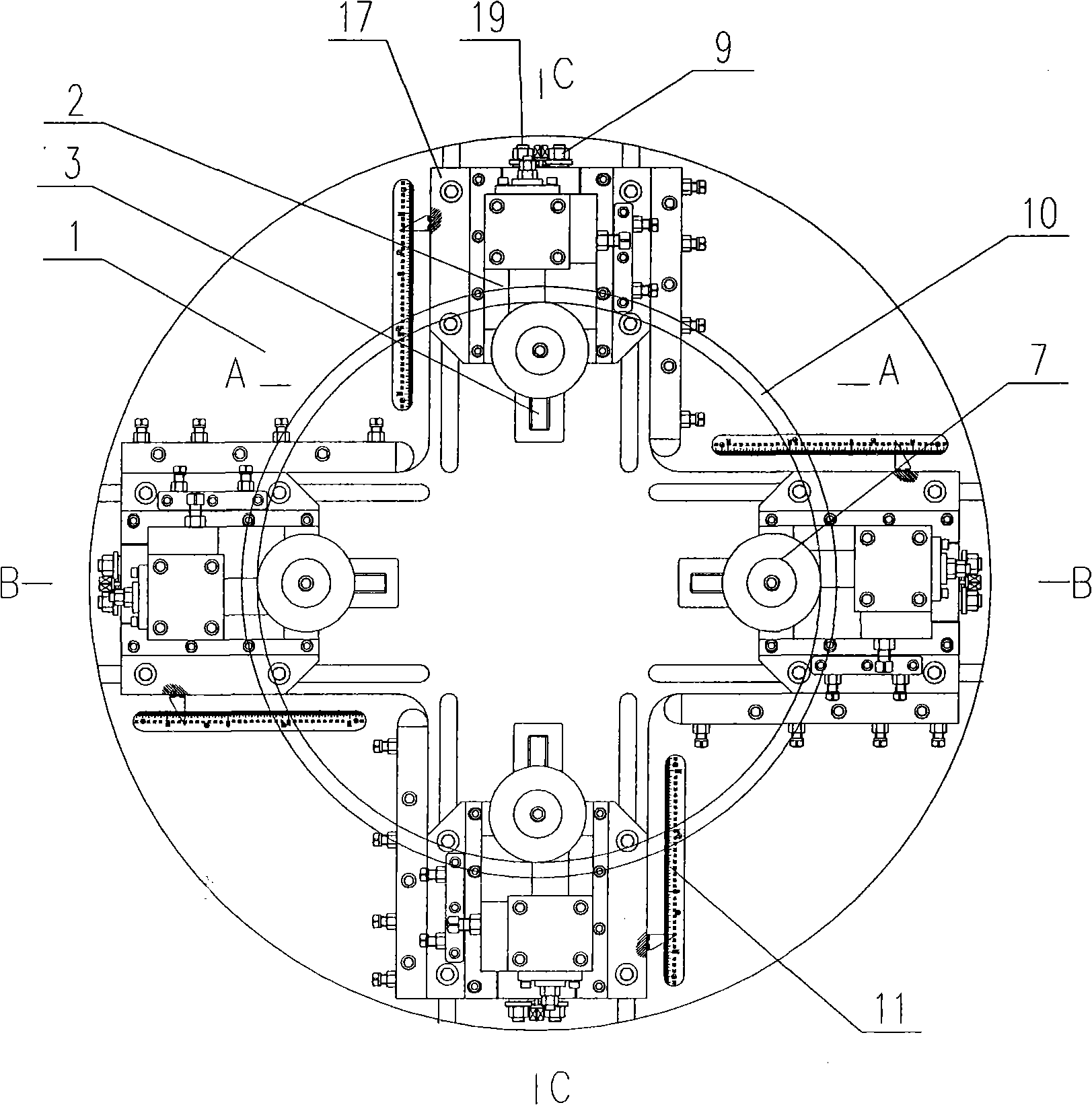

Adjustment method of inner-profile radial floating tool rest and tool

InactiveCN101357404AEat evenlyUniform turningAuxillary equipmentCopying process control systemsProduction lineEngineering

The invention relates to an internal profile modeling tool apron which is used in a steel pipe flat-end-face chamfering device in a large-dimensional and straightly welded seam pipe production line and floats along the radial direction; the tool apron comprises a cutter head, of which the end face are symmetrically provided with four sliding base bodies along the radial direction; each sliding base body is provided with a floating tool apron by a connecting screw rod; a cutter is vertical to the side wall of a steel pipe and arranged on the outer end of the floating tool apron, namely, the end far from an axis; the rear part of the cutter is provided with screw threads which are connected with a cutter adjusting mechanism; the end faces and the middle part of the sliding base bodies are provided with a spring slots; a plurality of dish-shape springs are sheathed on the connecting screw rod and arranged in the spring slots; the outer end of the connecting screw rod is provided with a spring adjusting nut; floating stroke adjusting nuts are arranged on the connecting screw rod and at the inner end of the spring adjusting nut; a profile modeling rolling is arranged at the inner end of the floating tool apron and rolls against the interior wall of the steel pipe; the position of the cutter and the steel pipe wall are relatively fixed, thereby simultaneous penetration of four cutters on the cutter head, even turning, no easy collision of the cutters and high production efficiency are ensured. The invention also relates to an adjusting method of the cutters.

Owner:TIANSHUI METALFORMING MACHINE TOOL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com