Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1337results about "Casting parameters measurement/indication devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

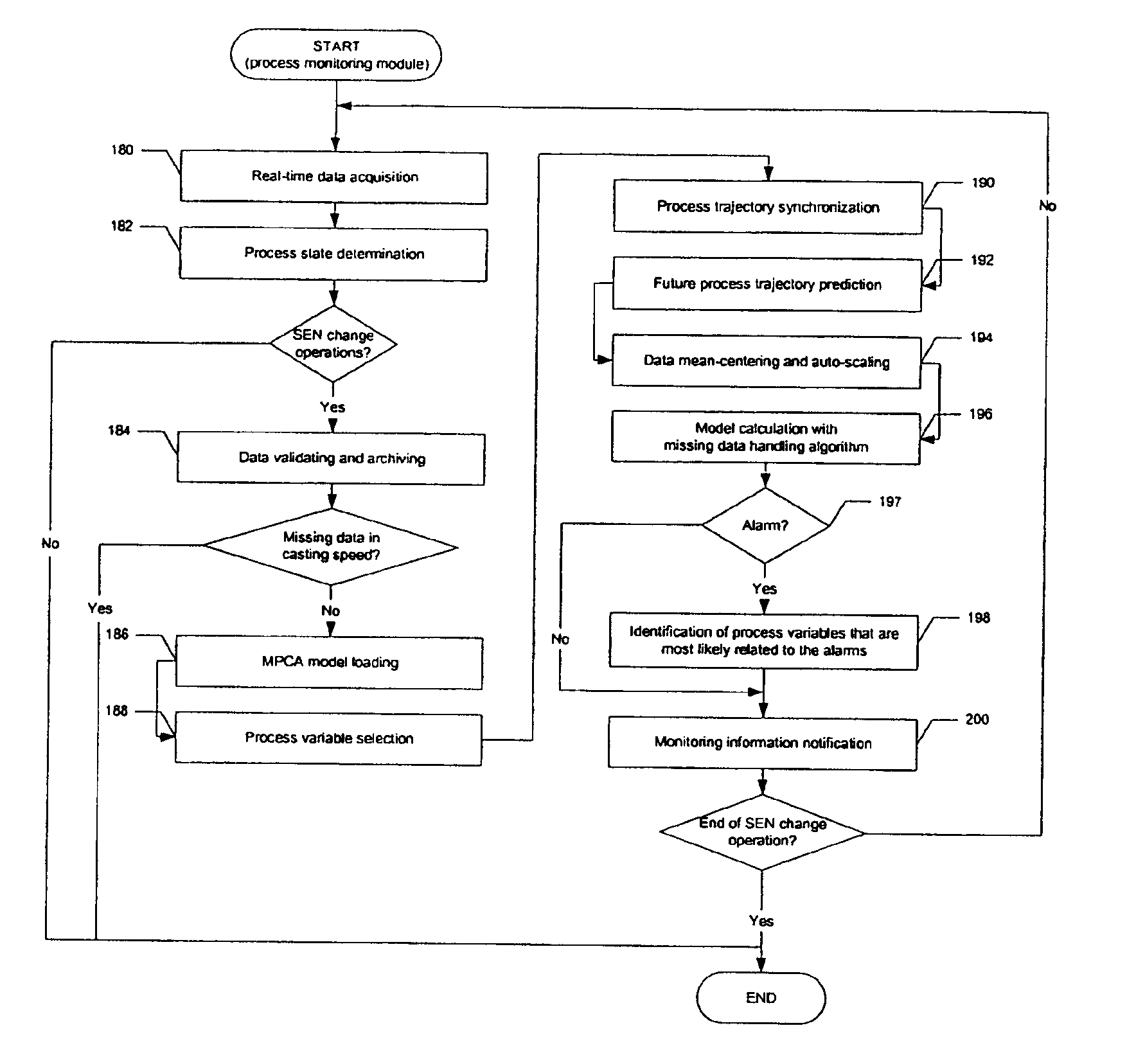

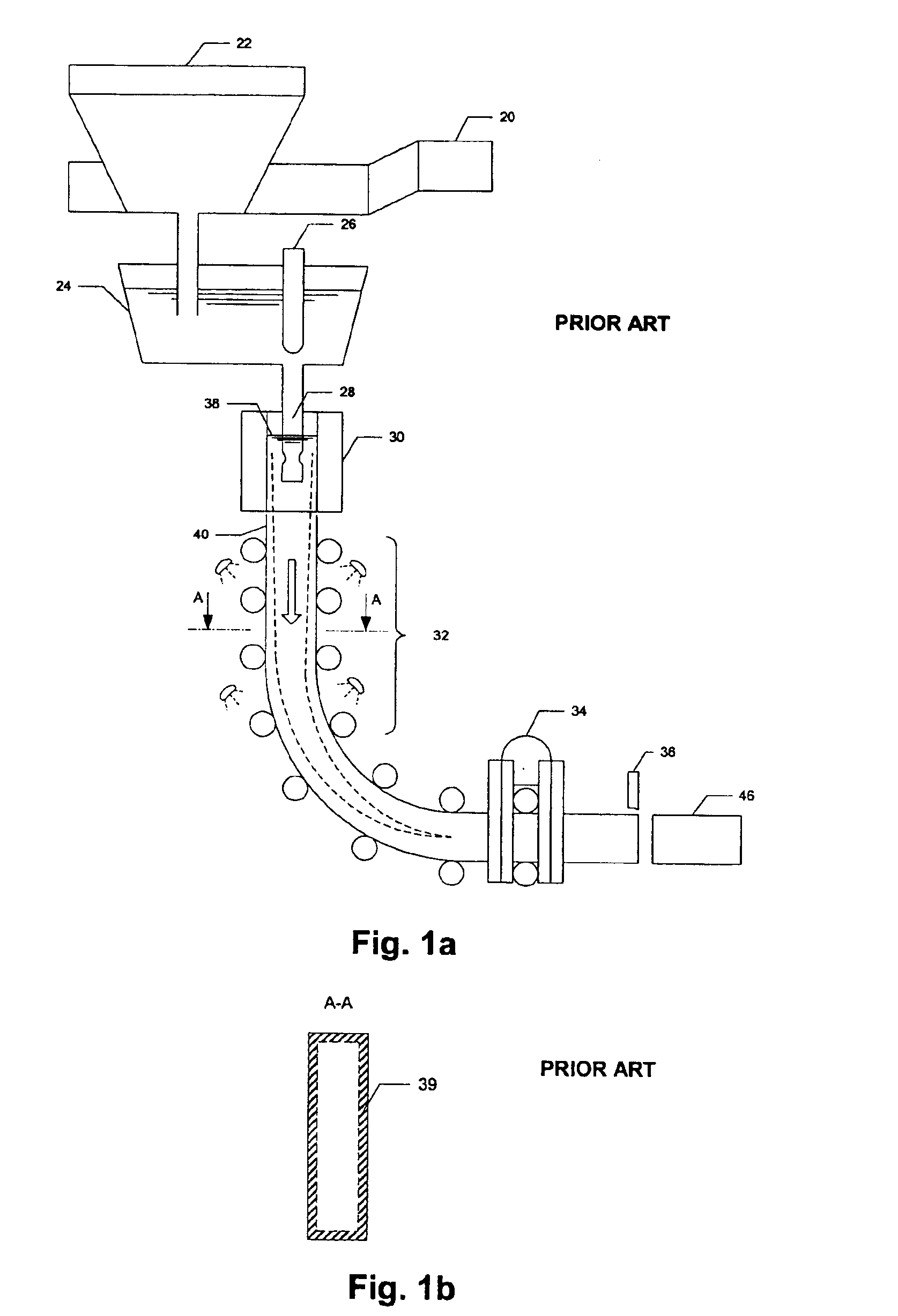

Real-time system and method of monitoring transient operations in continuous casting process for breakout prevention

ActiveUS6885907B1Testing/monitoring control systemsMoulding machine componentsPrincipal component analysisMultivariate statistical

A real-time system and method for online monitoring a transient operation in a continuous casting process. The transient operation refers to, but is not limited to, submerged entry nozzle changes, flying tundish changes, product grade changes, etc. This invention treats the aforementioned transient operations as batch processes and utilizes multiway principal component analysis to develop a multivariate statistical model to characterize normal process transitions based on carefully selected historical process data. Such a model is used by an online monitoring system to determine if a continuous caster transient operation is normal. This monitoring system can further be used to predict an impending breakout, one type of catastrophic process failures which may occur in a continuous casting process, during the transient operation. Process variables that are most likely related to the predicted breakout are identified by the system such that appropriate control actions can be taken to prevent an actual breakout occurrence.

Owner:DOFASCO INC

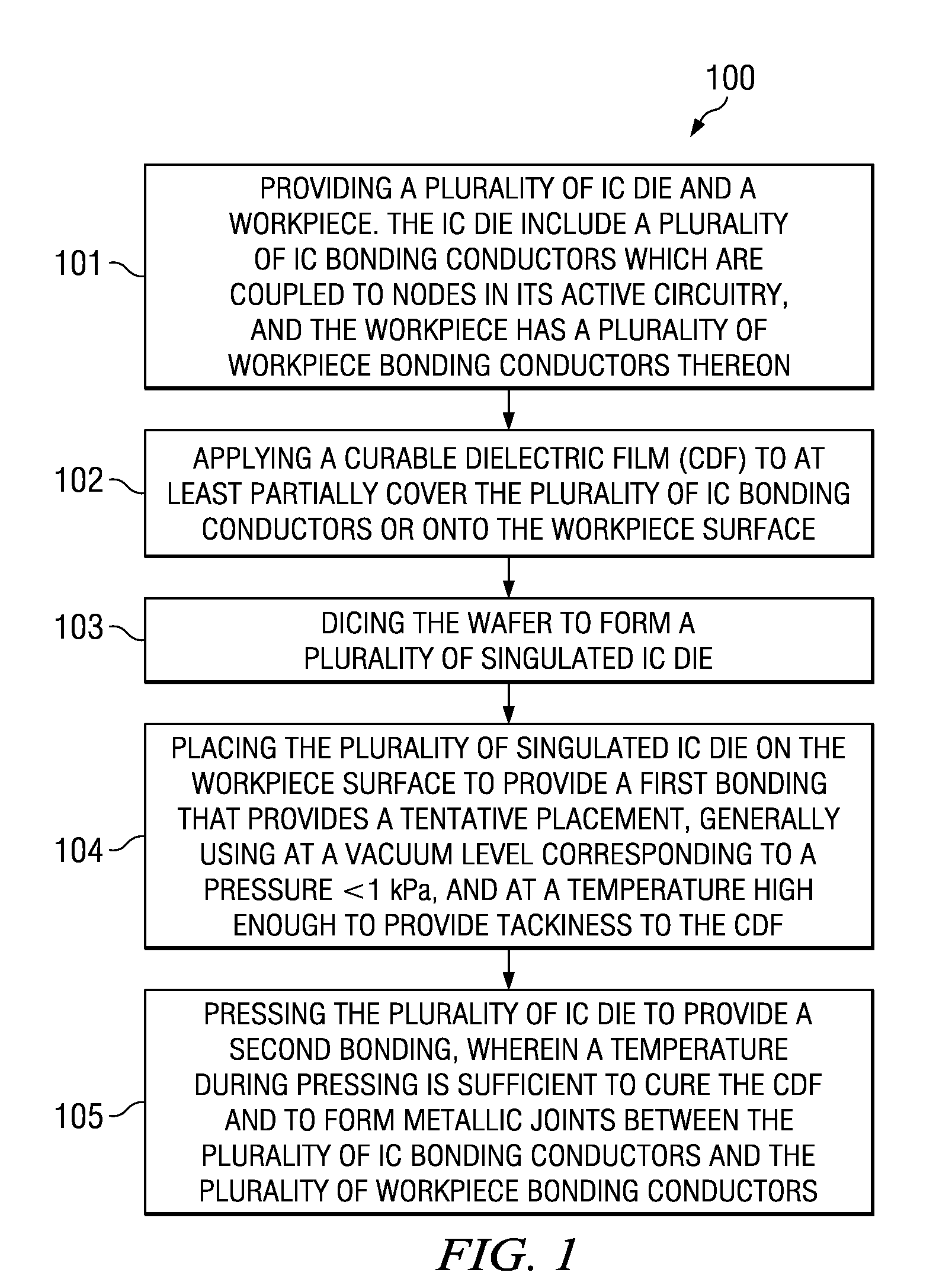

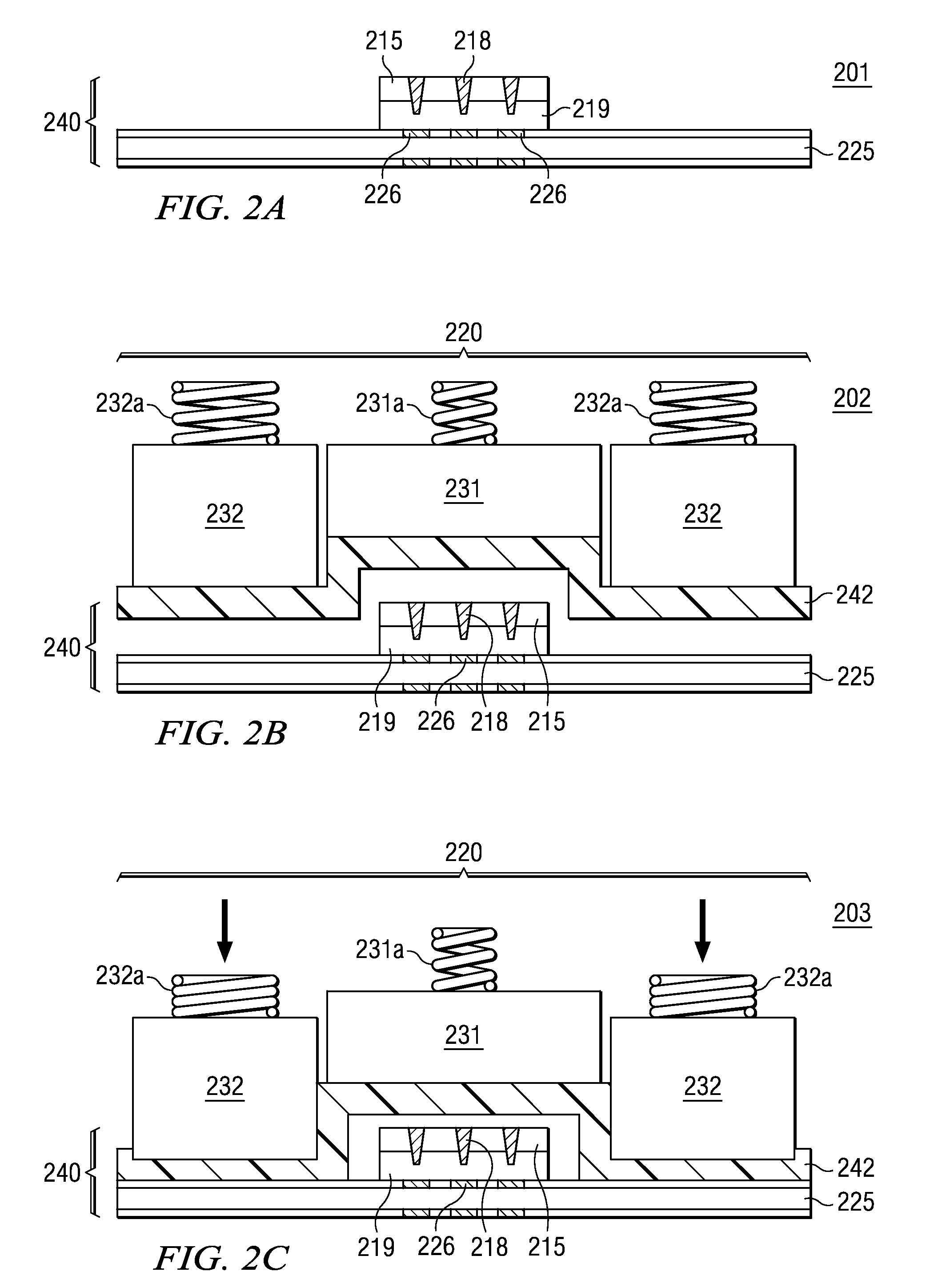

Combined metallic bonding and molding for electronic assemblies including void-reduced underfill

ActiveUS20090291524A1Small sizeReducing joint misalignmentCasting safety devicesSolid-state devicesElectrical conductorDielectric membrane

A method for forming electronic assemblies includes providing a plurality of IC die each having IC bonding conductors and a workpiece having workpiece bonding conductors. A curable dielectric film is applied to the IC bonding conductors or the workpiece surface. The plurality of IC die are placed on the workpiece surface so that the plurality of IC bonding conductors are aligned to and face the plurality of workpiece bonding conductors to provide a first bonding. The placing is performed at a vacuum level corresponding to a pressure <1 kPa, and at a temperature sufficient to provide tackiness to the curable dielectric film. The plurality of IC die are then pressed to provide a second bonding. A temperature during pressing cures the curable dielectric film to provide an underfill and forms metallic joints between the plurality of IC bonding conductors and the plurality of workpiece bonding conductors.

Owner:TEXAS INSTR INC

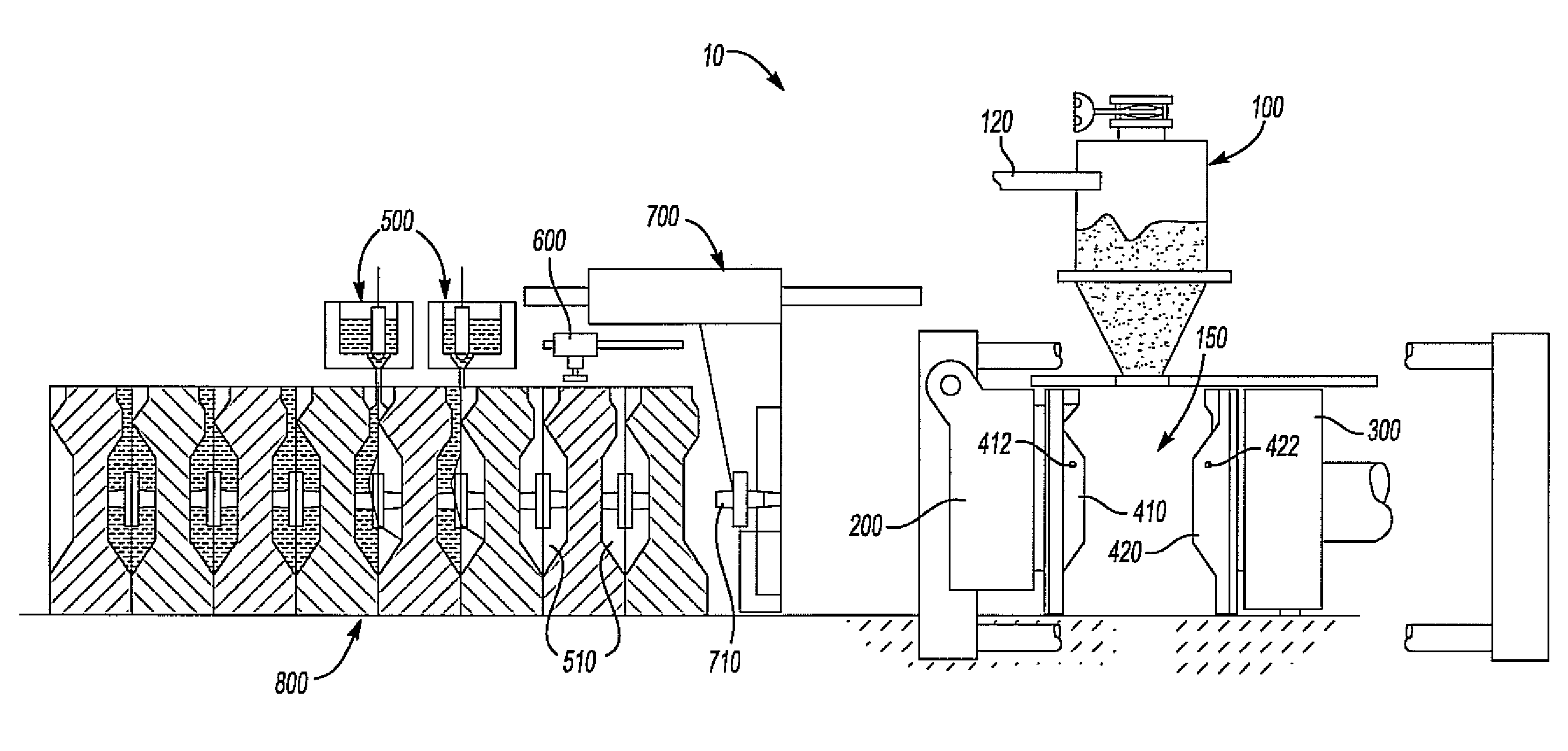

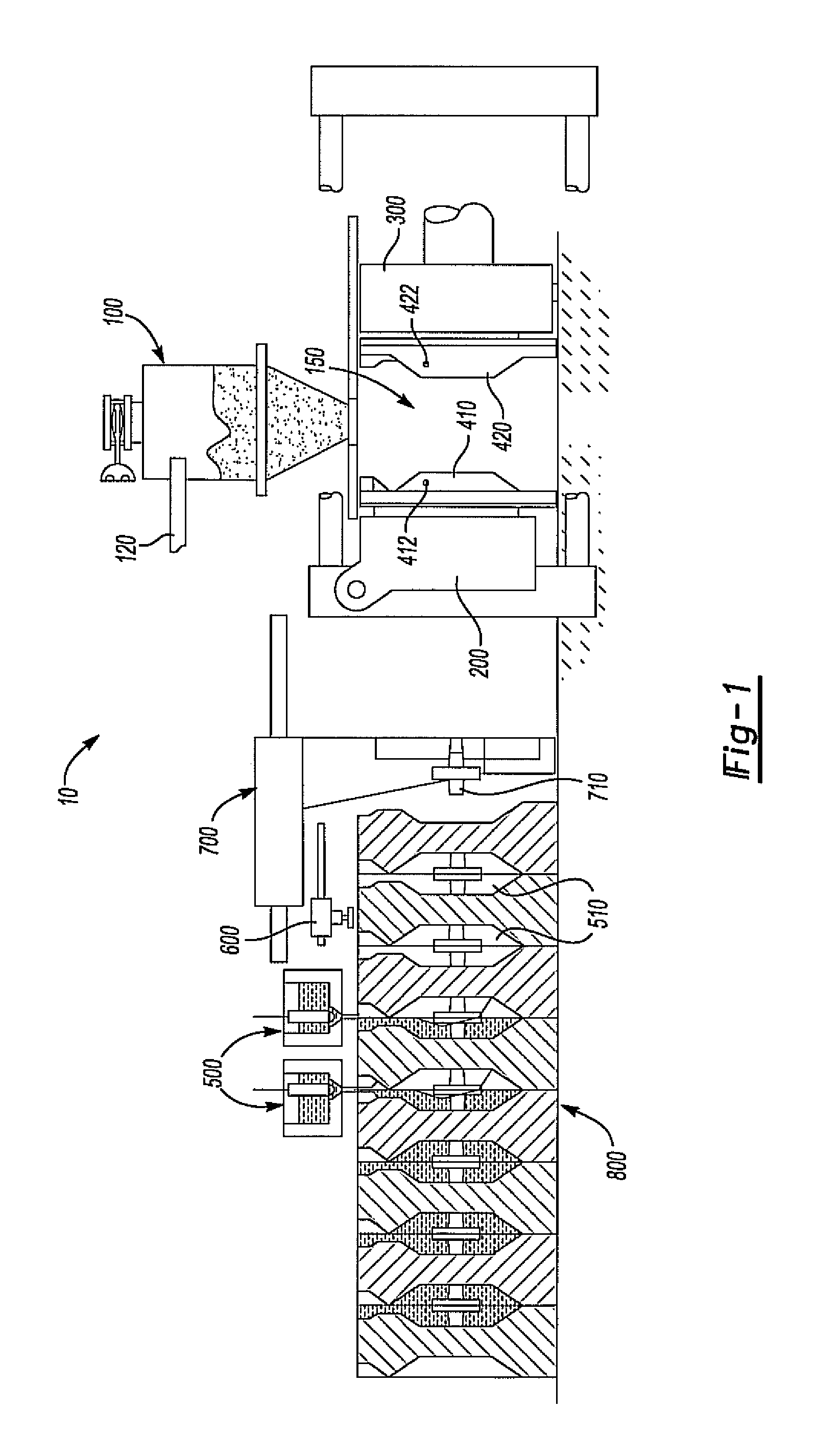

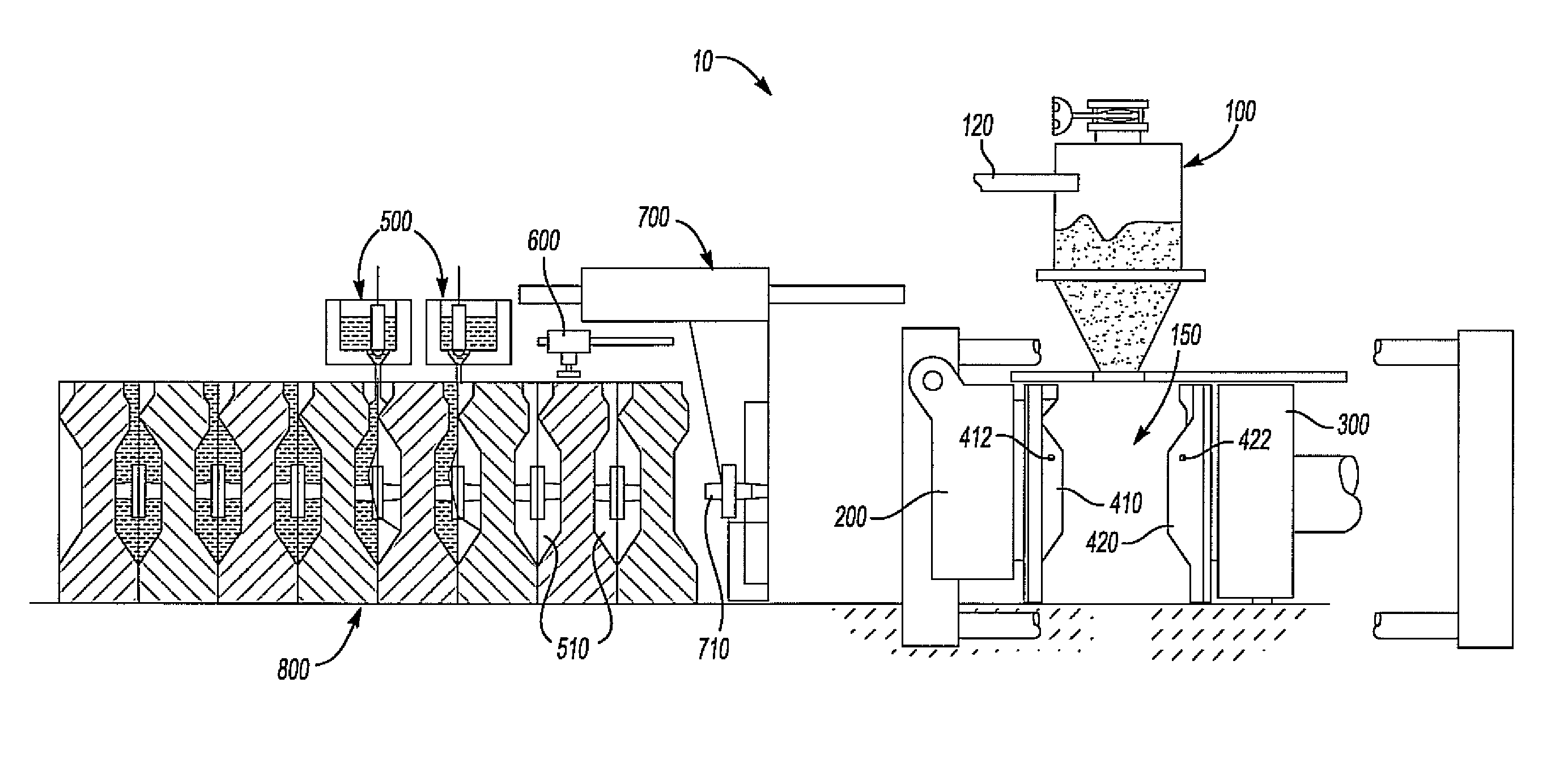

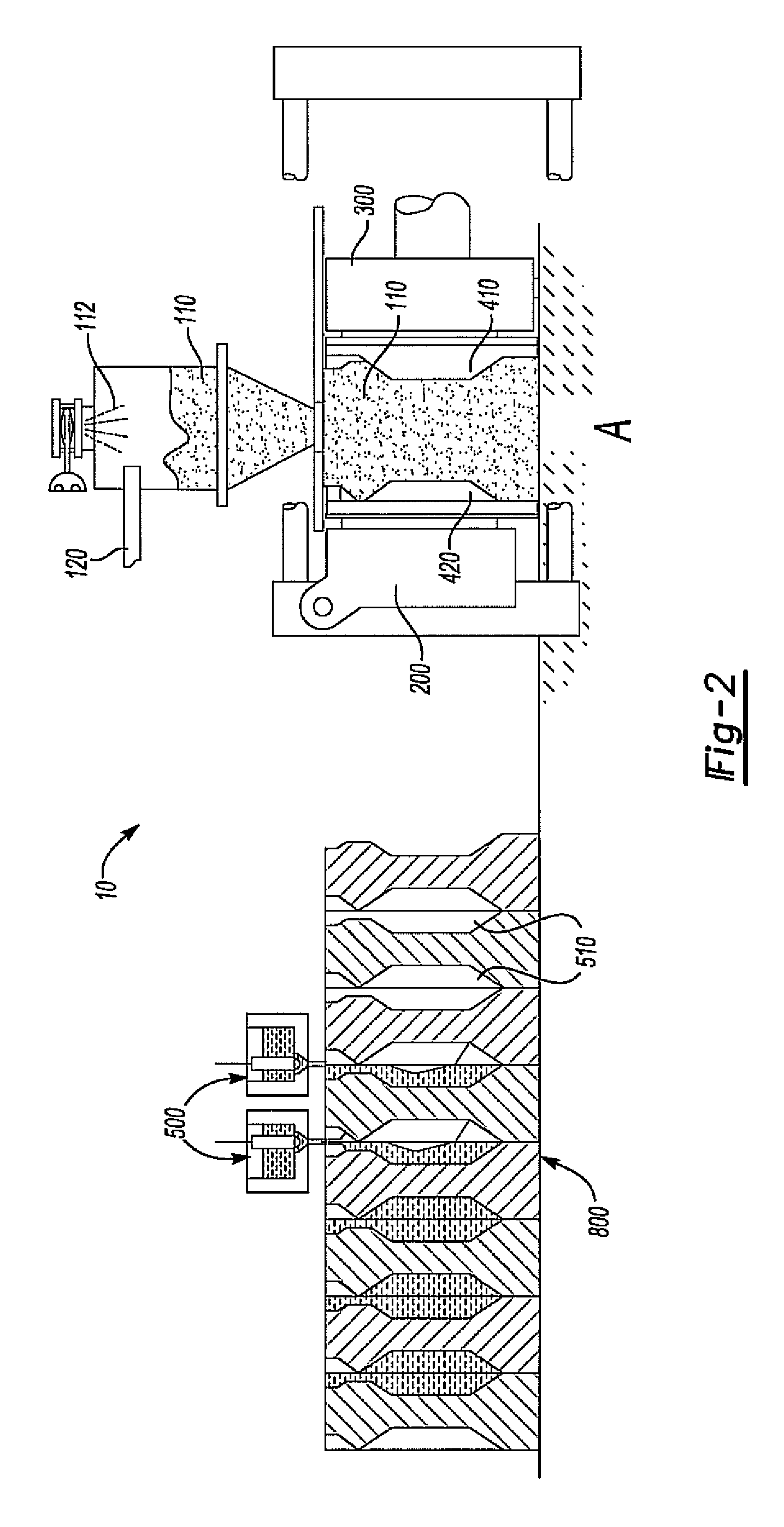

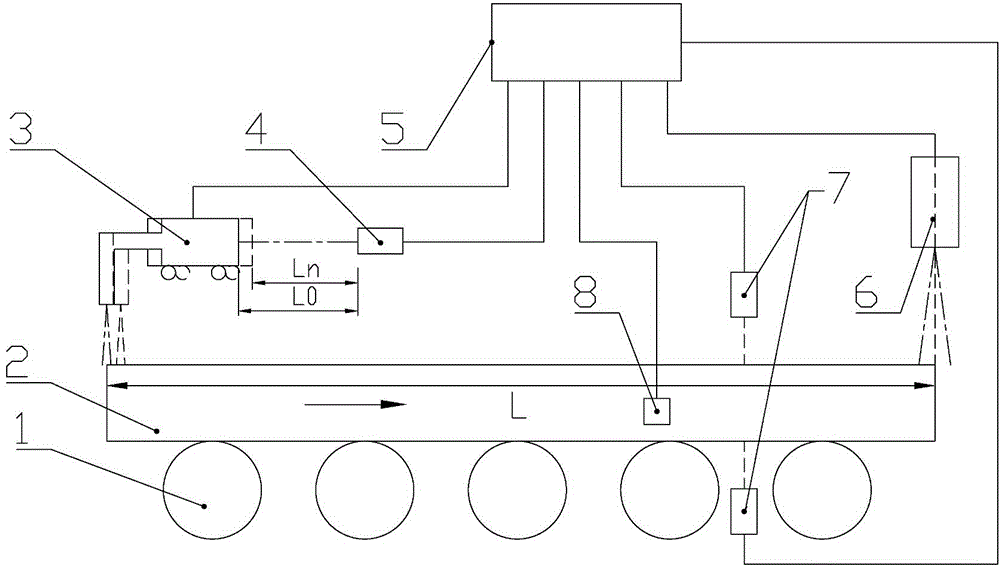

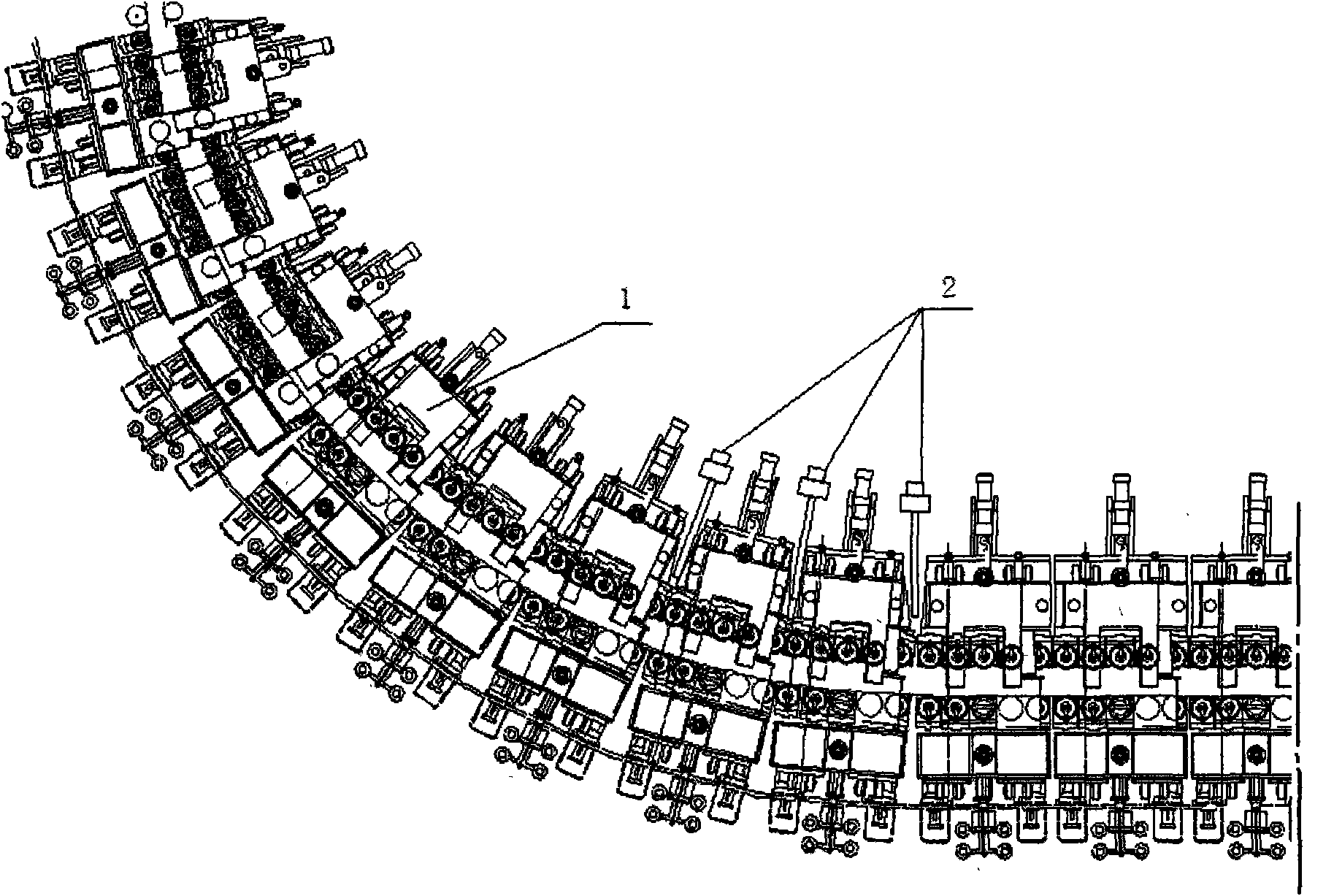

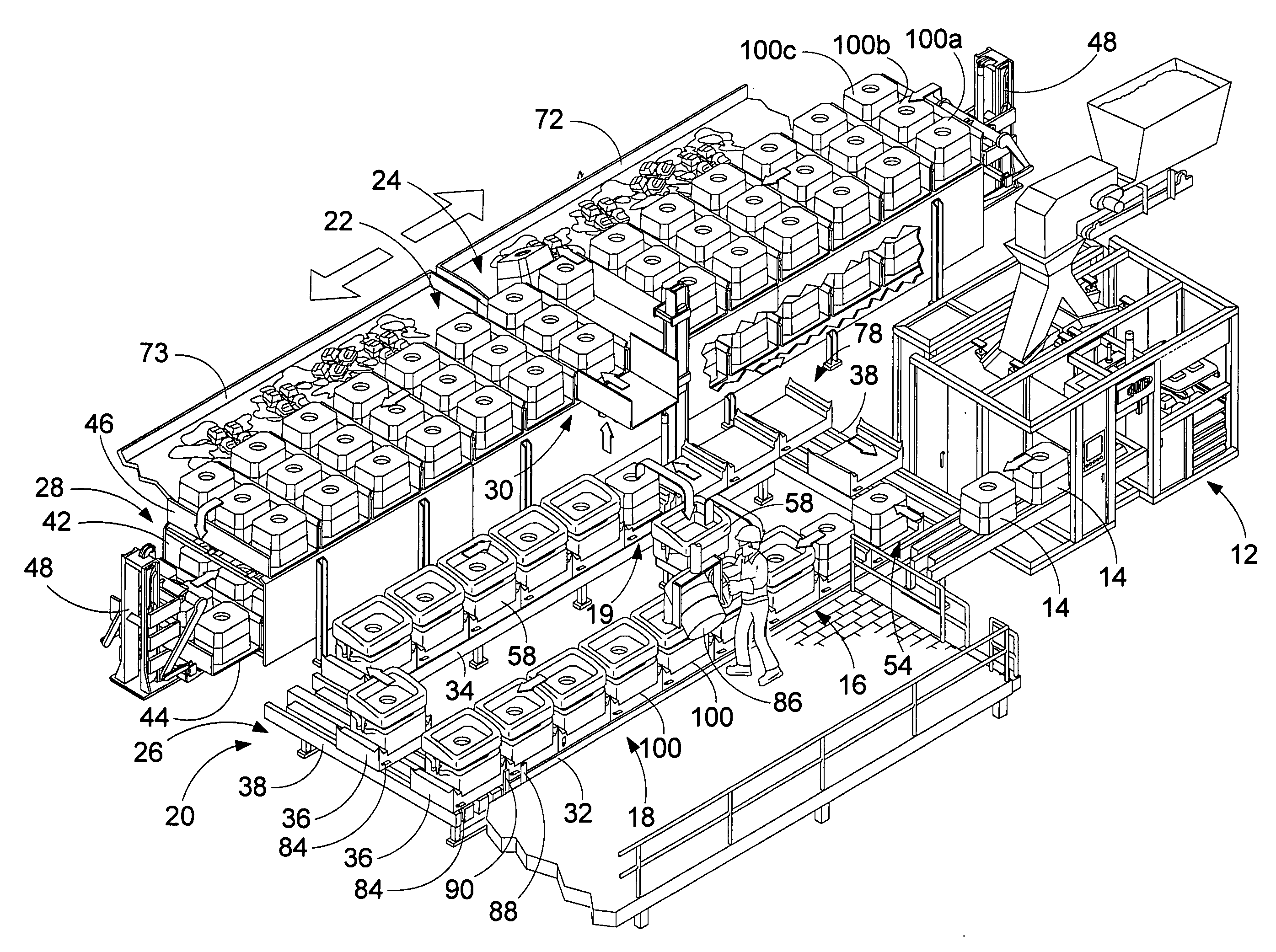

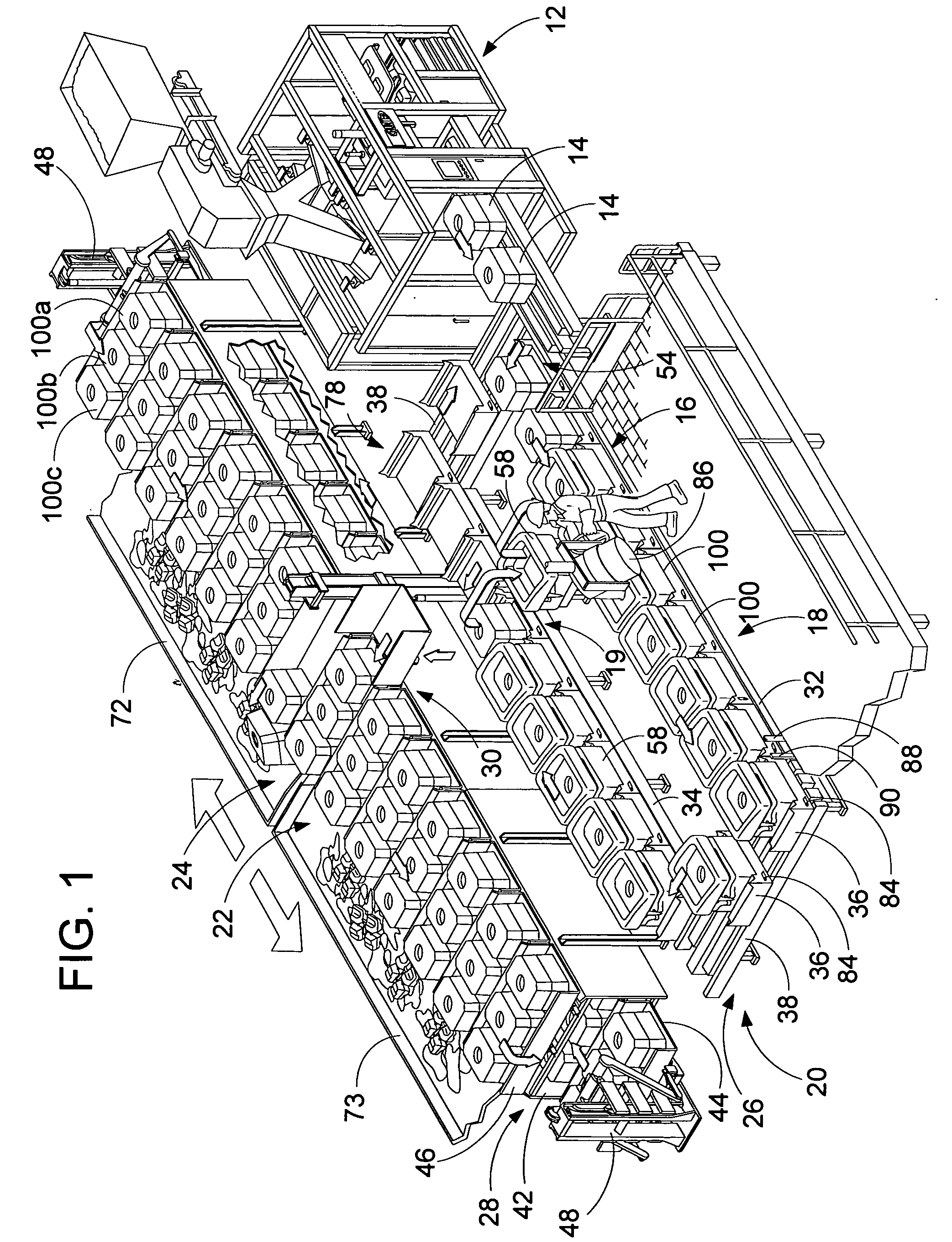

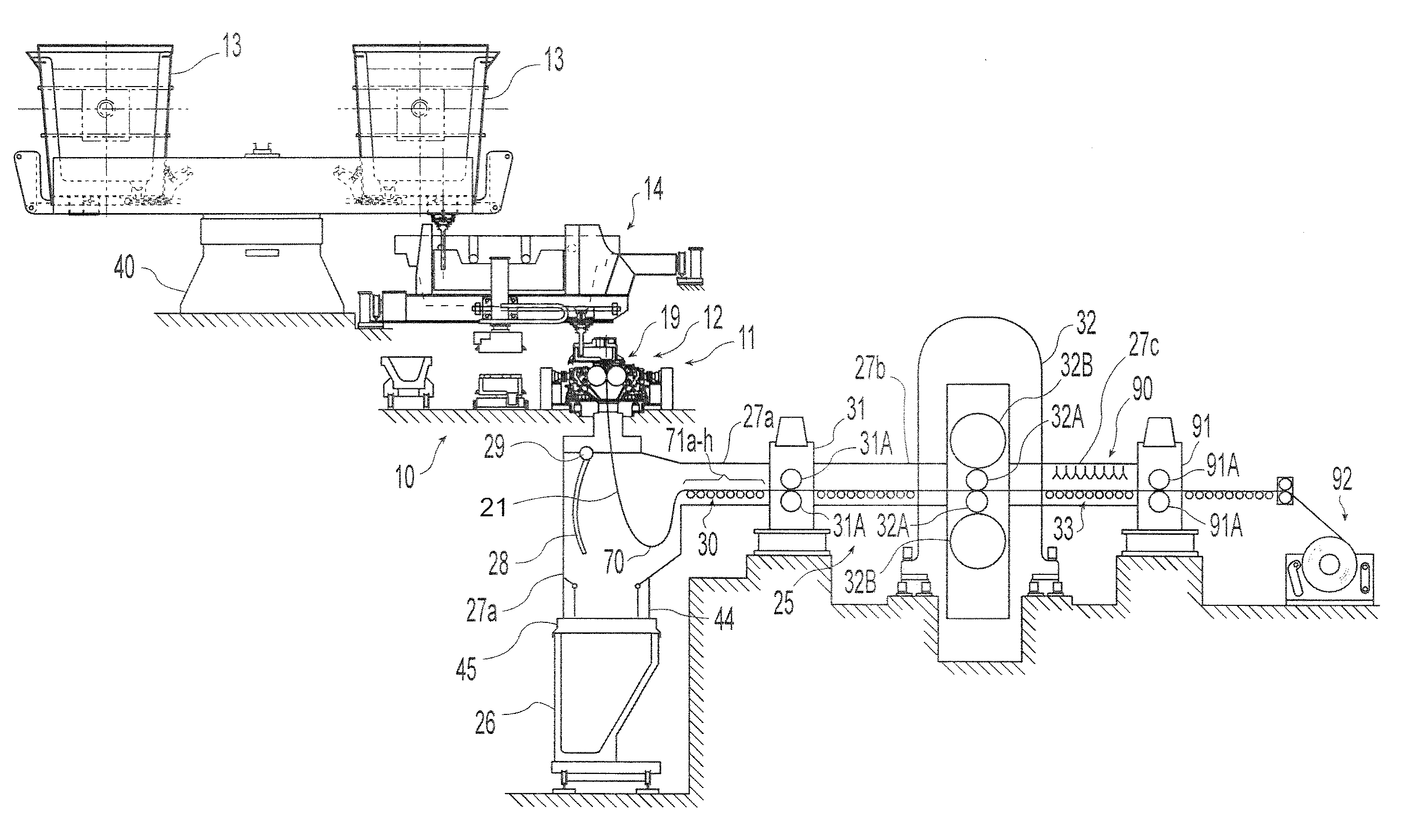

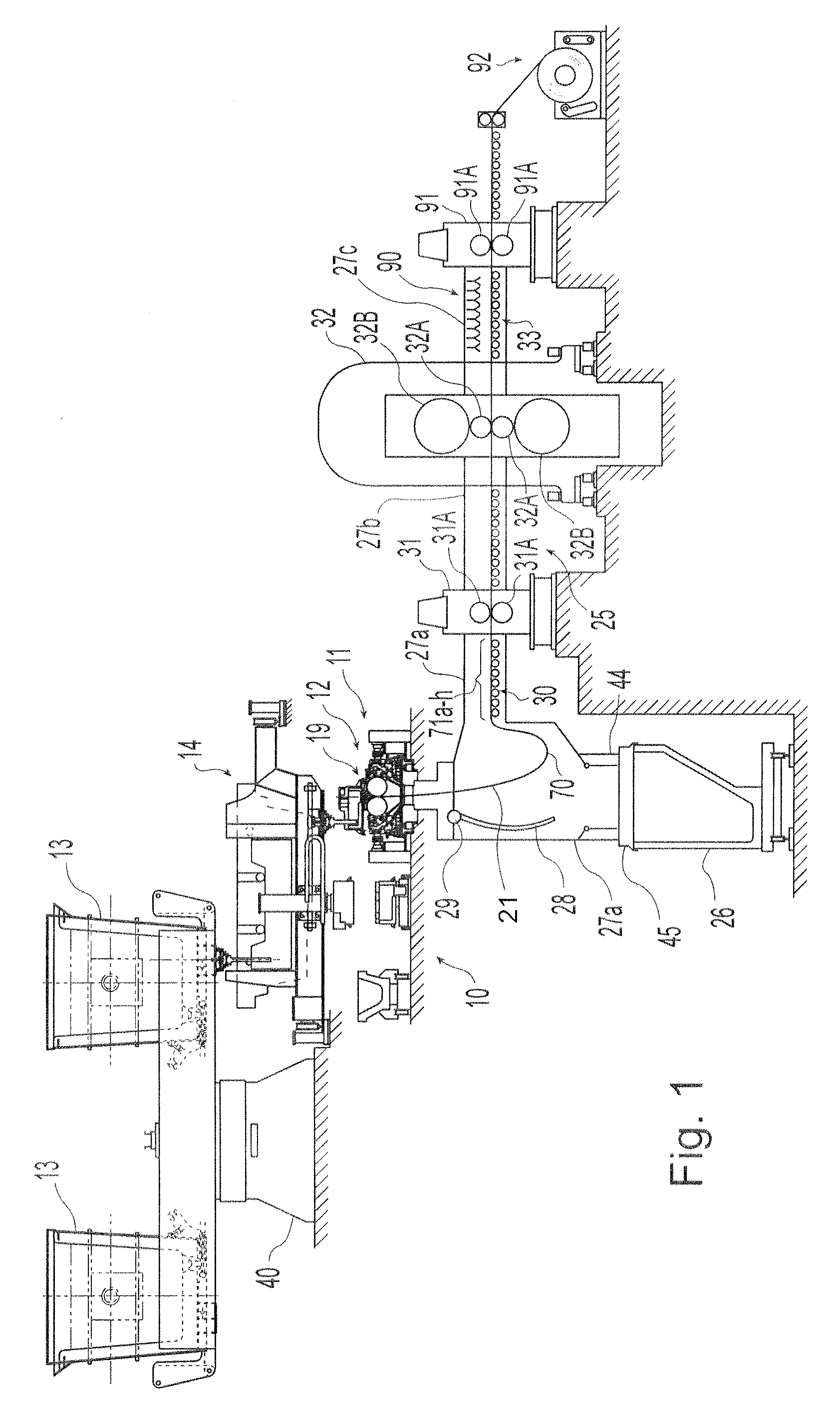

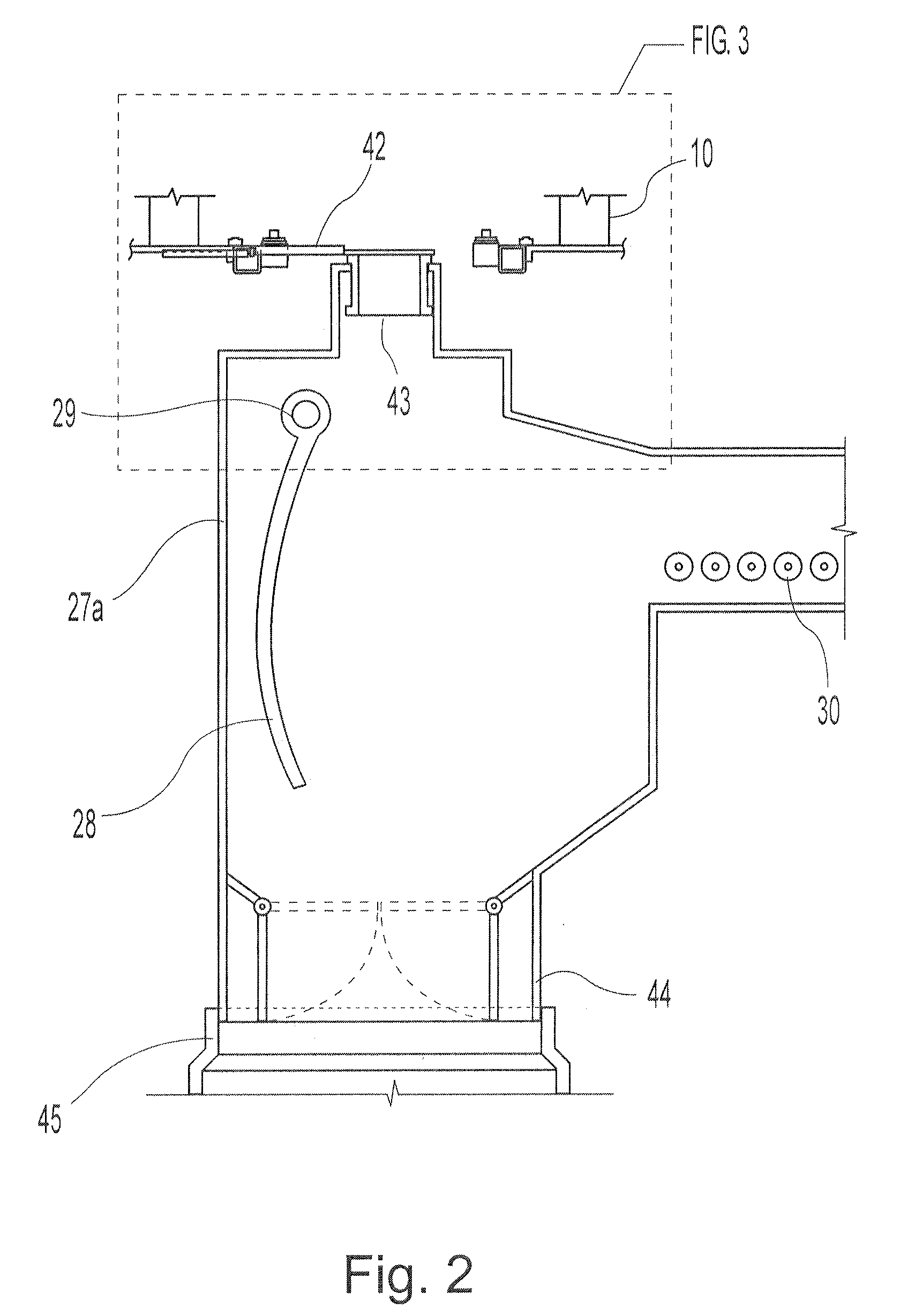

Molding and casting machine

ActiveUS20080135205A1Improved swing movementEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

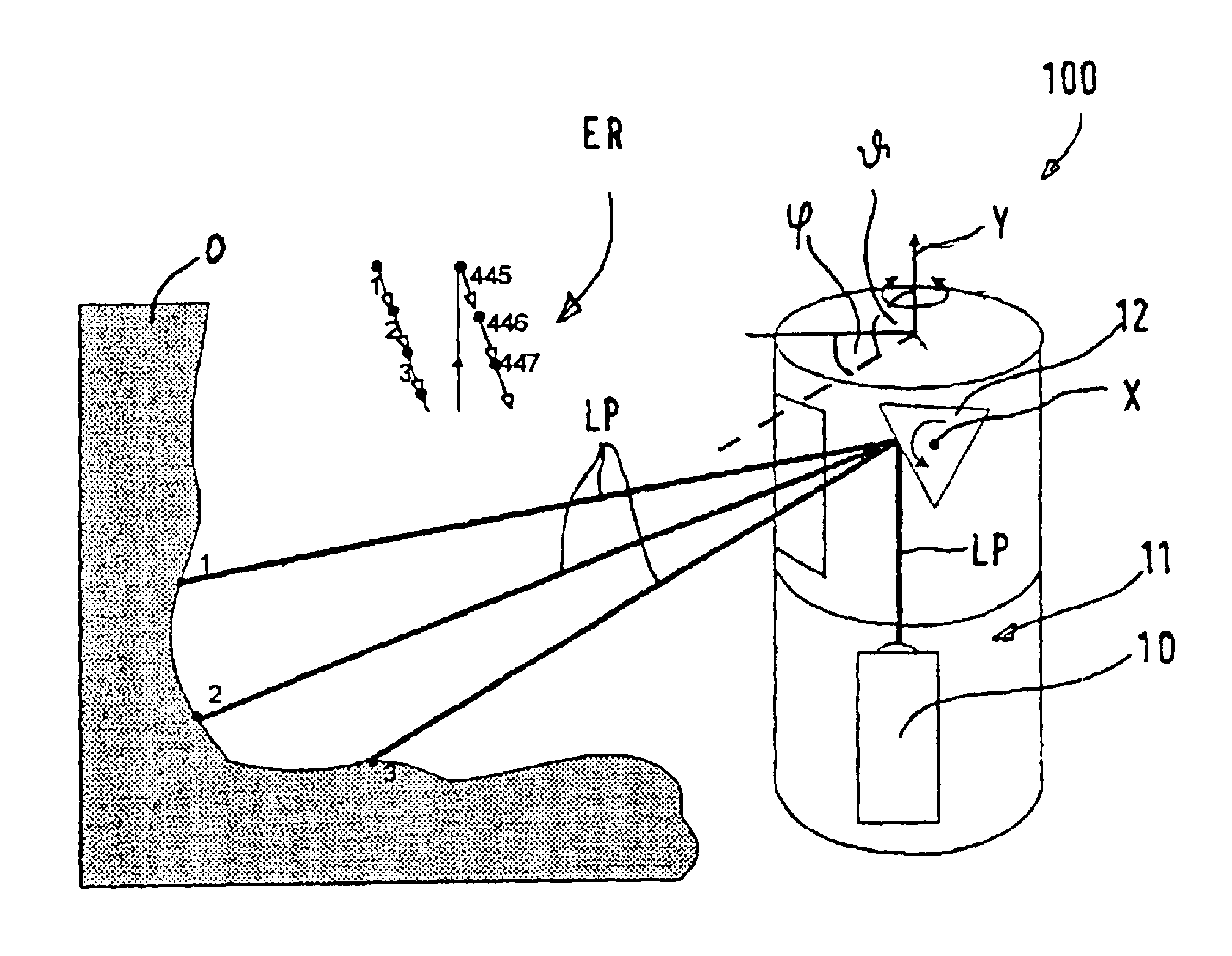

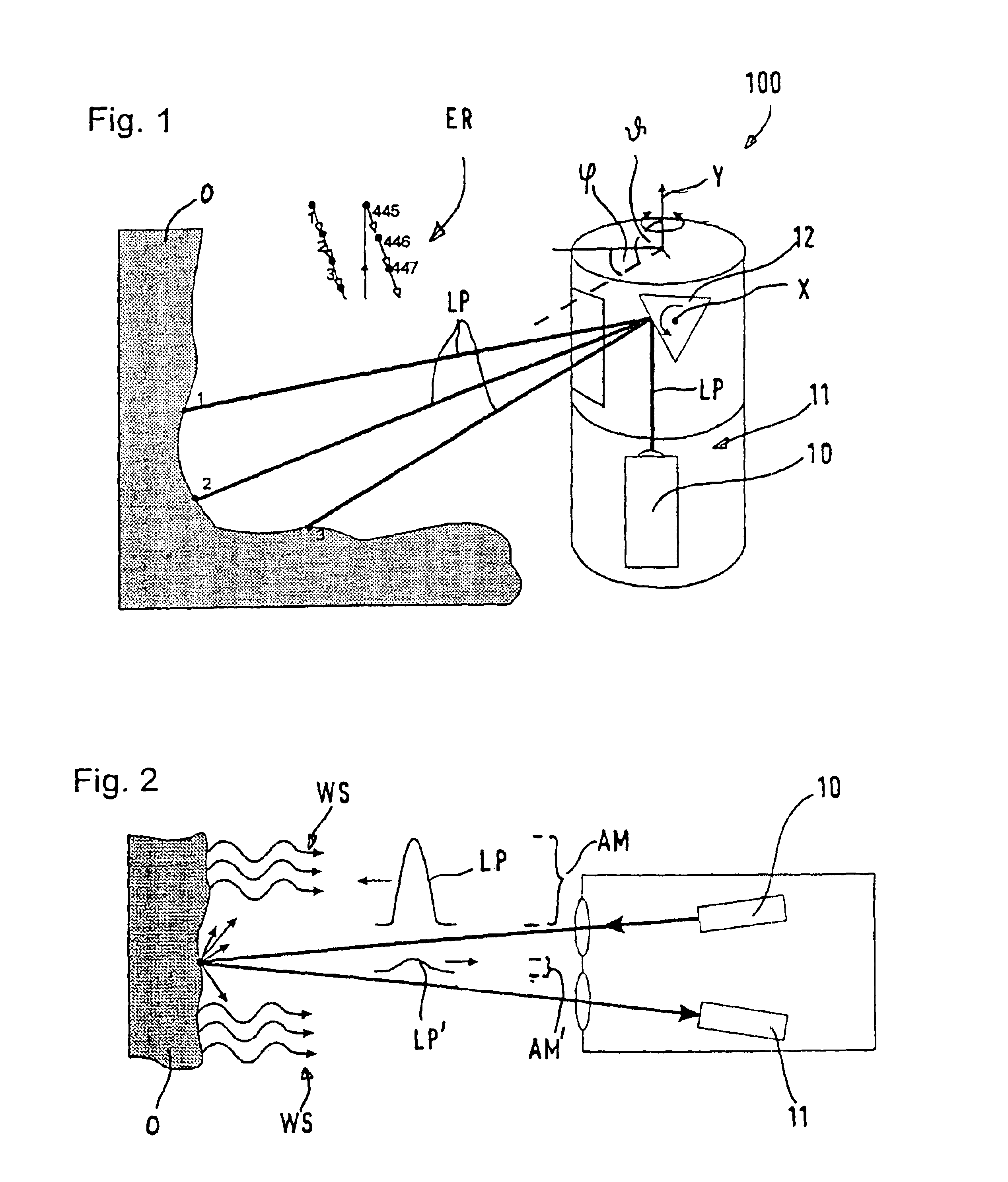

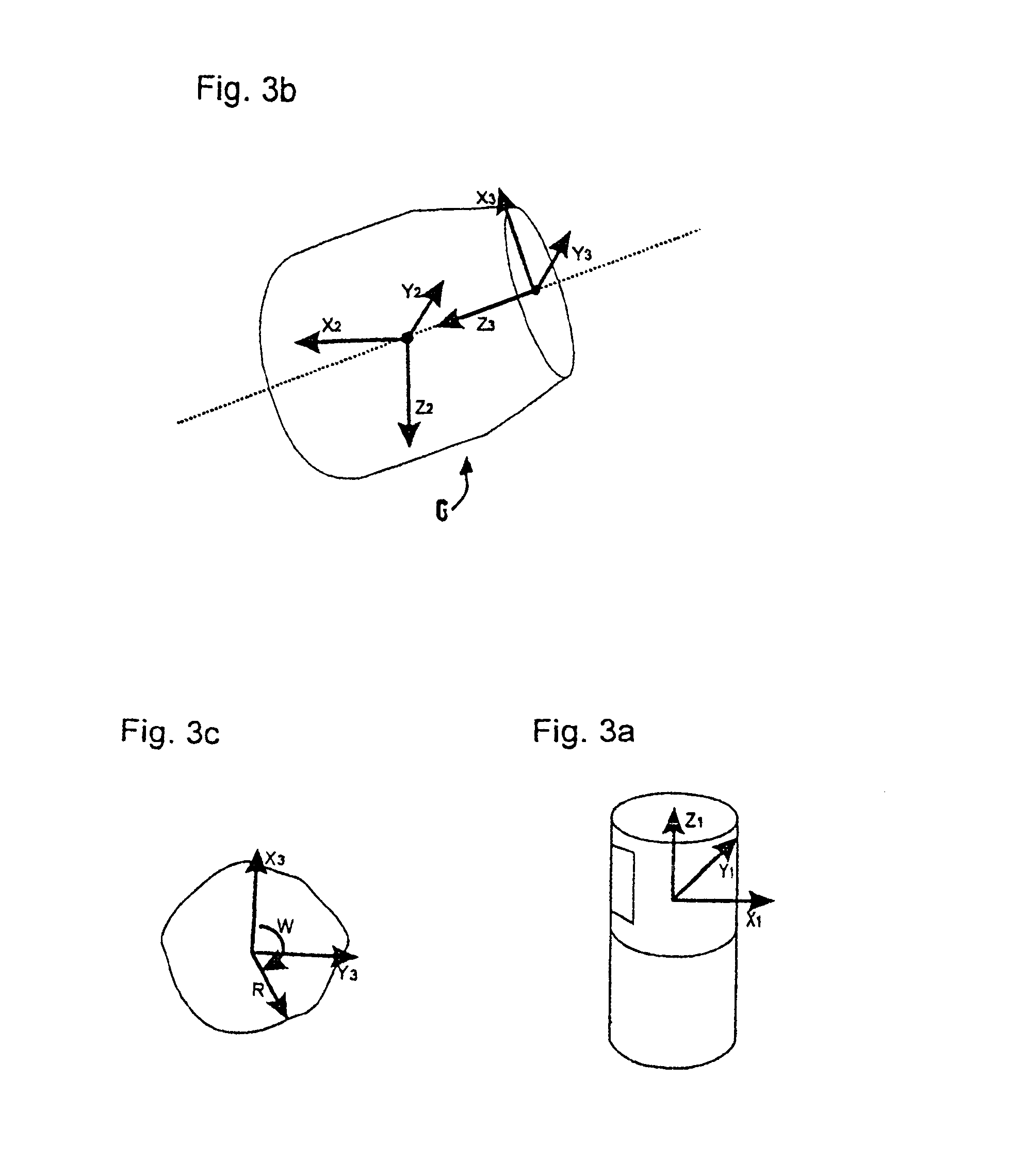

Measurement of the wear of the fireproof lining of a metallurgical vessel

According to the invention, a method for identifying and determining die position of a metallurgical vessel for measuring its fireproof lining using electromagnetic radiation, an operator is defined in relation to a two or three dimensional structure with a known shape and size. Distance values and corresponding measuring angles are determined in the area of the structure and measured distance value and corresponding measuring angles are used to scale the operator. The dimension and resolution of the operator in the pixel coordinates system and the anticipated values of the operator are adapted to the measured polar coordinates. A result value is then formed from the differences between the anticipated values of the operator and the measured values and the location of the structure that is sought is determined from the position of the minimum result value.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

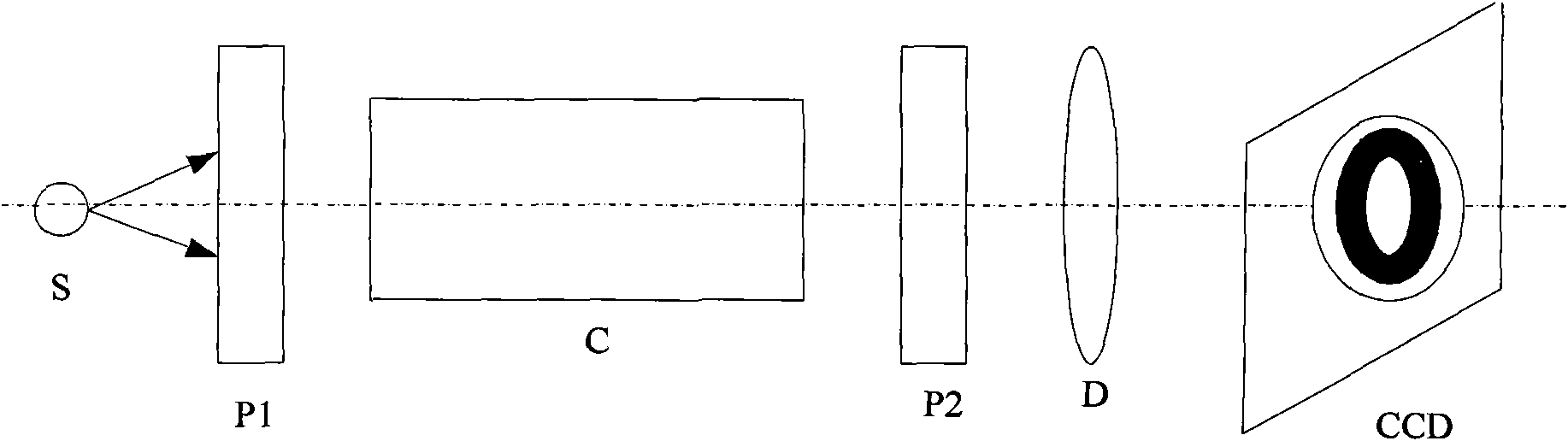

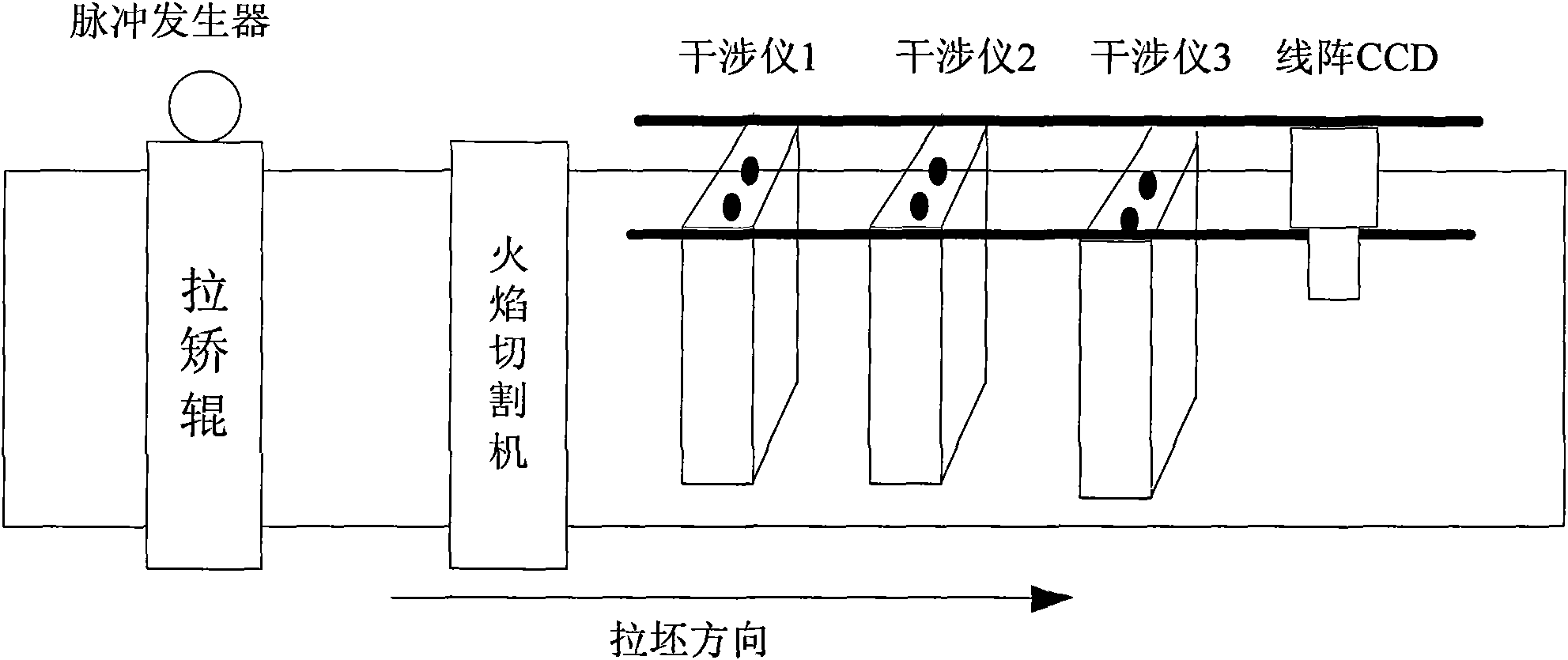

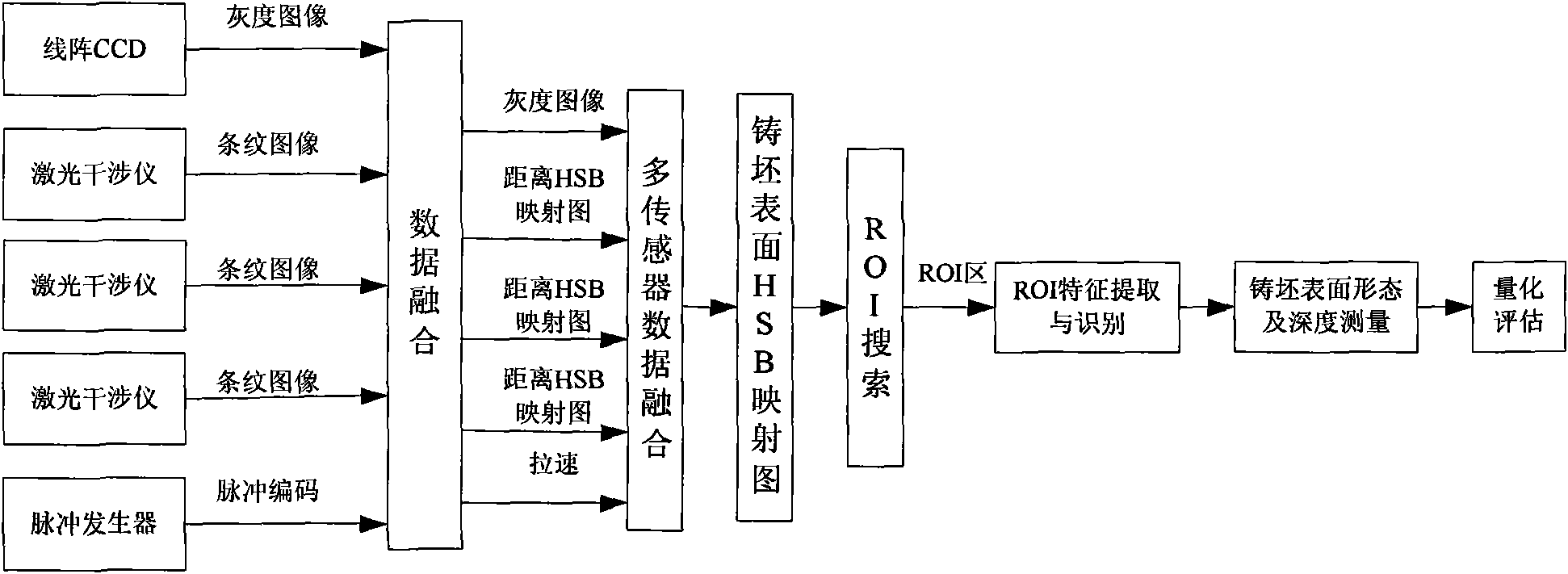

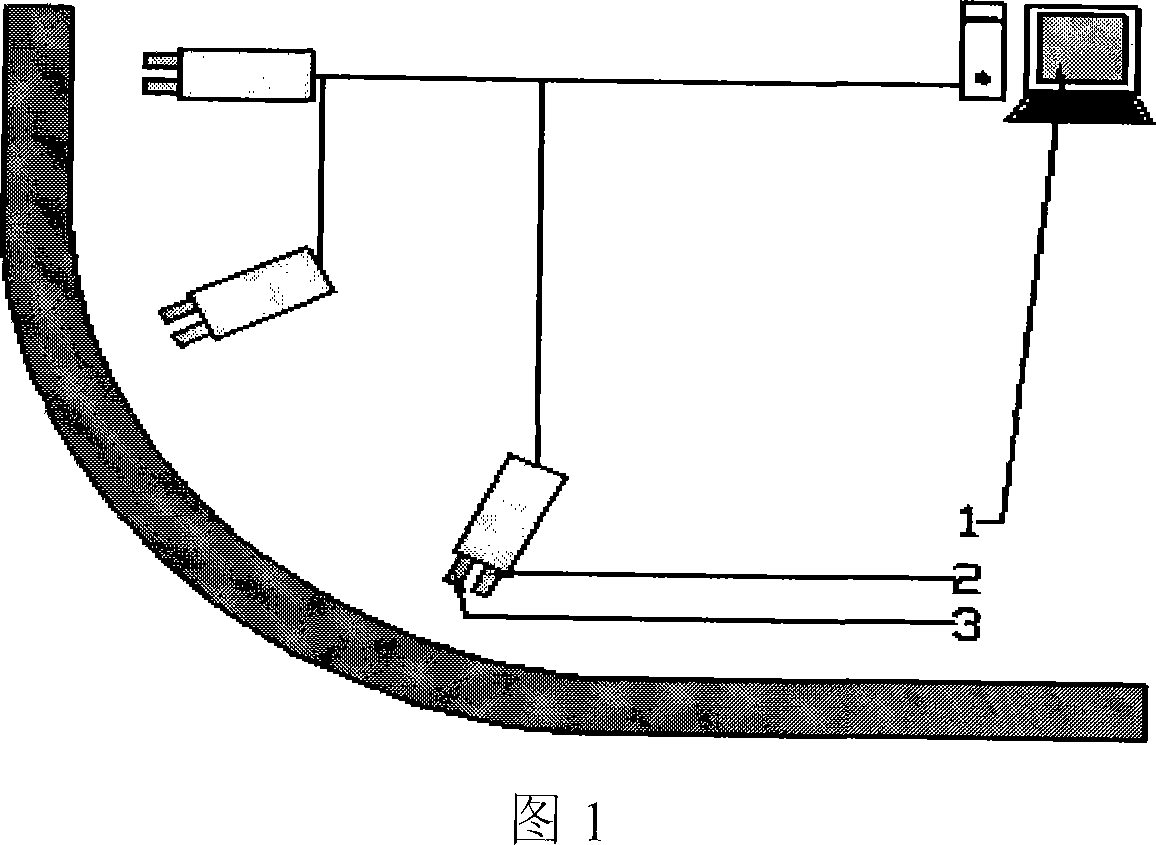

Surface defect form and depth on-line lossless detection method of high-temperature continuous casting blank

InactiveCN101655464ASuppress interferenceEnable digital assessmentMaterial analysis by optical meansUsing optical meansMetallurgyQuality assessment

The invention relates to a surface defect form and depth on-line lossless detection method of a high-temperature continuous casting blank, comprising the following steps: scanning the surface distanceof the transverse direction of the high-temperature continuous casting blank along a pulling-speed direction of the casting blank; measuring distance two-dimensional lattices on the running directionand the transverse direction of the casting blank; converting the distance two-dimensional lattices into a distance dimensional HSB two-dimensional diagram; and finally processing the HSB two-dimensional diagram to recognize the forms of surface defects and calculate the depths of the defects in a quantization mode. The method can effectively inhibit the interference of non-defect oxidative sheetiron in a defect form, realize the surface defect form and depth on-line detection of the continuous casting blank above 950 DEG C and evaluate the quality of the surface defects of the integral high-temperature continuous casting blank. The surface defect form and depth on-line lossless detection method has significances for increasing the automatic level of the surface detect detection of the high-temperature continuous casting blank, reducing the production cost, increasing the direct rolling and heat transmitting and loading rate of the continuous casting blank and has important guiding functions for developing a continuous casting blank quality forecast system, improving a continuous casting process technology and increasing the casting blank quality.

Owner:CHONGQING UNIV

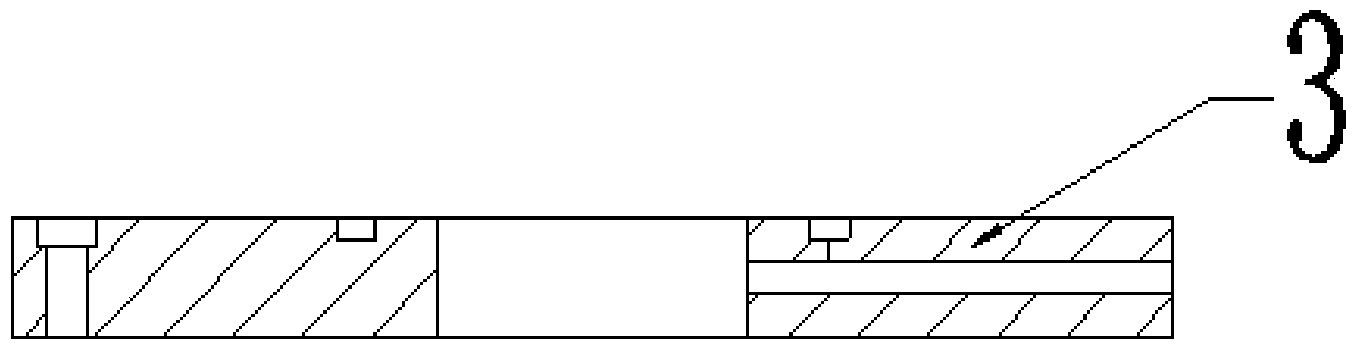

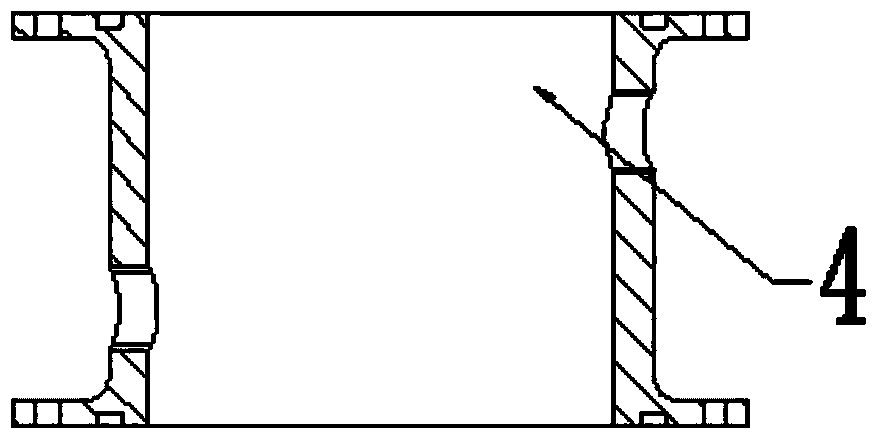

Method for preparing hollow steel ingot for protection ring of large power generator by adopting electroslag remelting

ActiveCN104164574AIncrease profitReduce heating timesCasting parameters measurement/indication devicesTransformerProtection ring

The invention discloses a method for preparing a hollow steel ingot for a protection ring of a large power generator by adopting electroslag remelting. The method comprises the following steps: (1) preparing consumable electrode groups; (2) melting slag into liquid molten slag; (3) inserting the consumable electrode groups into an electroslag remelting hollow ingot crystallizer; (4) starting two transformers; (5) injecting the liquid molten slag into the electroslag remelting hollow ingot crystallizer; (6) when the consumable electrode groups are in contact with the liquid molten slag, forming an electrifying loop among fake electrodes, the consumable electrode groups and a bottom water tank; (7) when the liquid molten slag is in contact with an upper section, forming a loop among the upper section, the bottom water tank and the transformers connected with the bottom water tank; (8) adjusting the output currents and voltages of the two transformers; (9) when a metal melt is in contact with a molten steel liquid level detection device, starting an ingot stripping device for ingot stripping; (10) exchanging the consumable electrode groups; and (11) inserting subsequent consumable electrode groups into the liquid molten slag, and repeating the steps (8 to 10) until the ingot stripping is finished.

Owner:NORTHEASTERN UNIV LIAONING

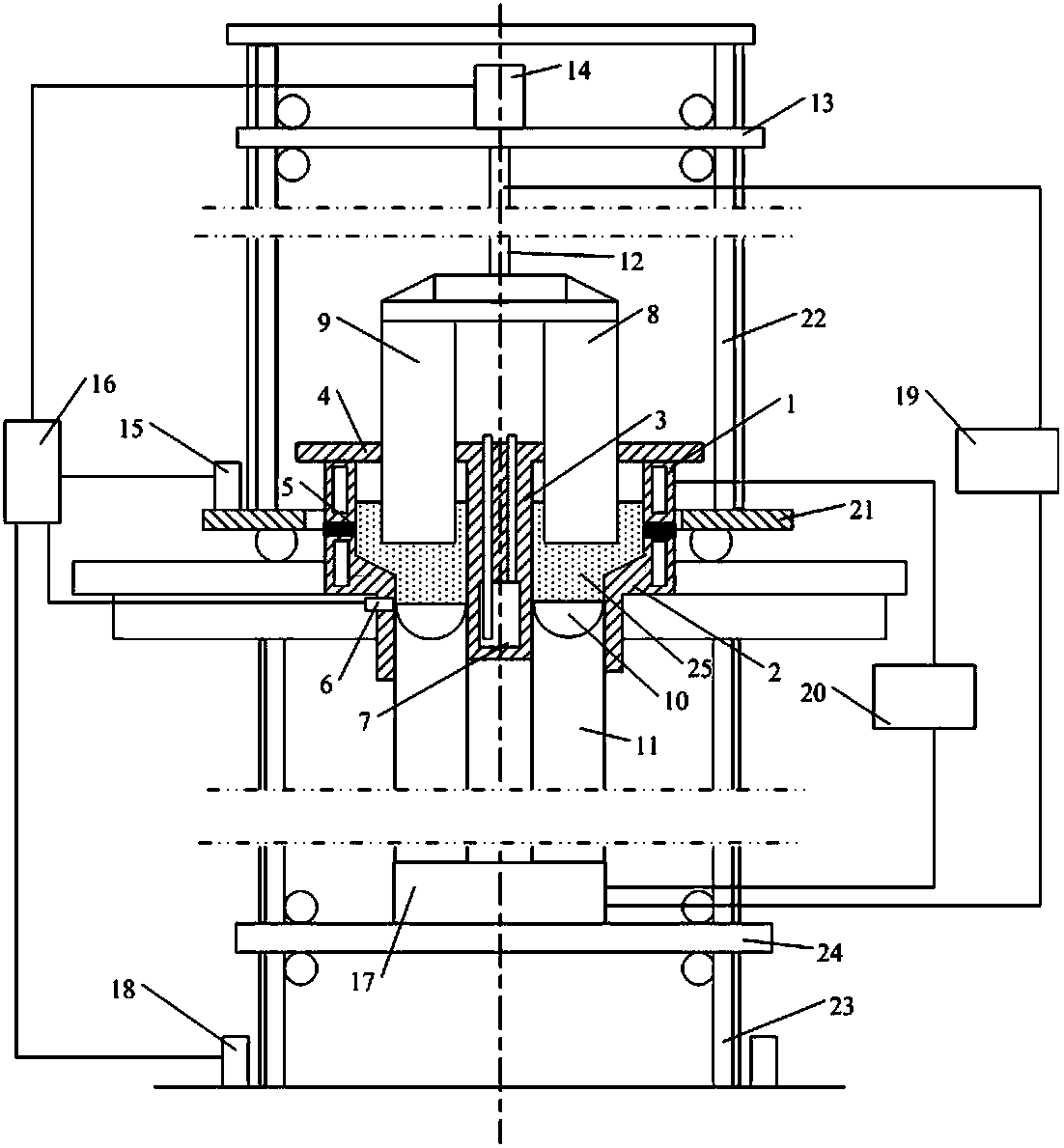

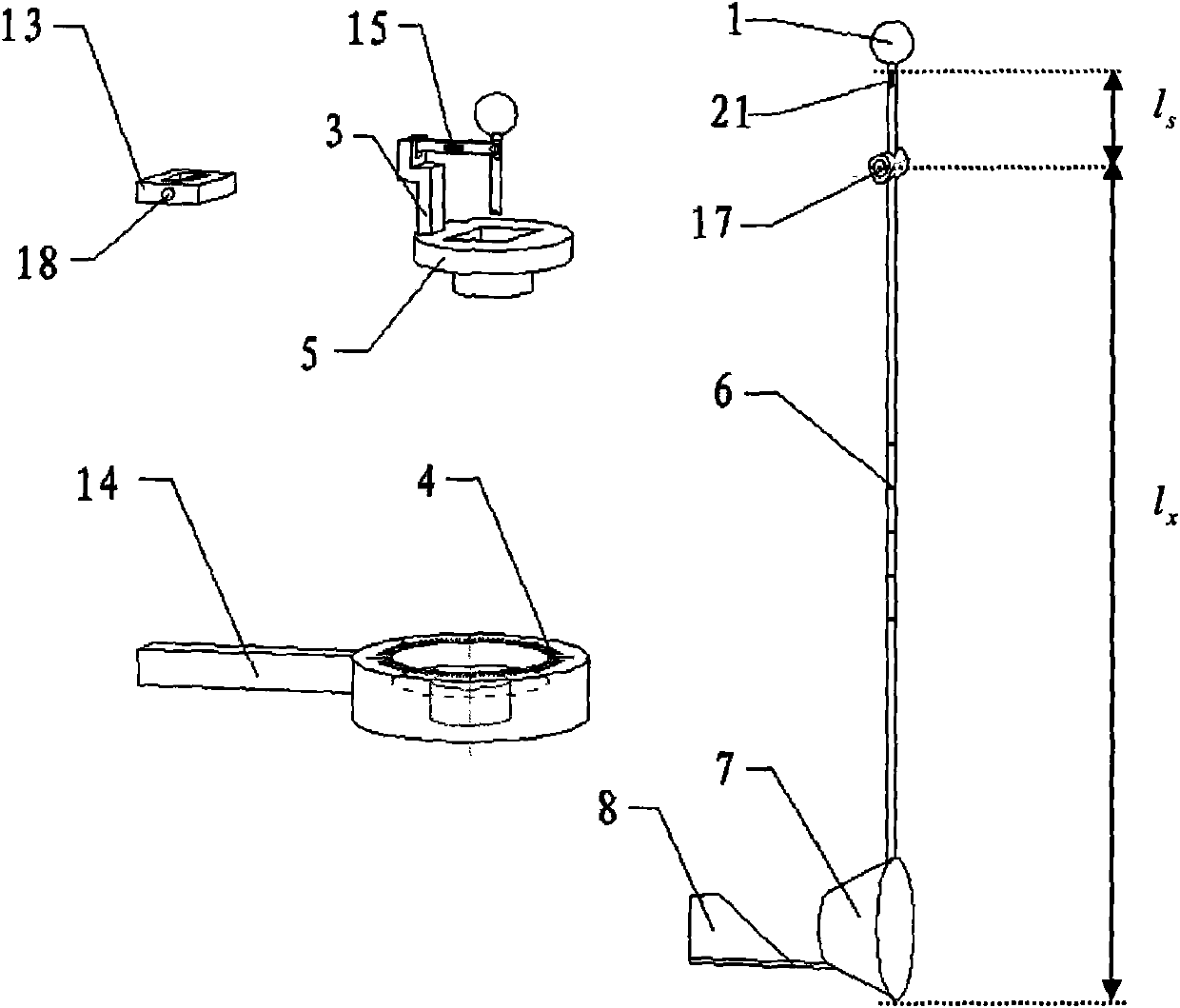

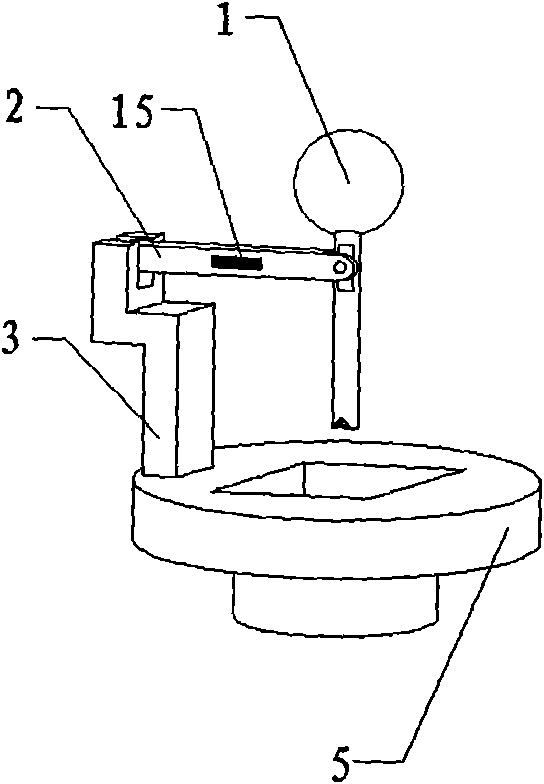

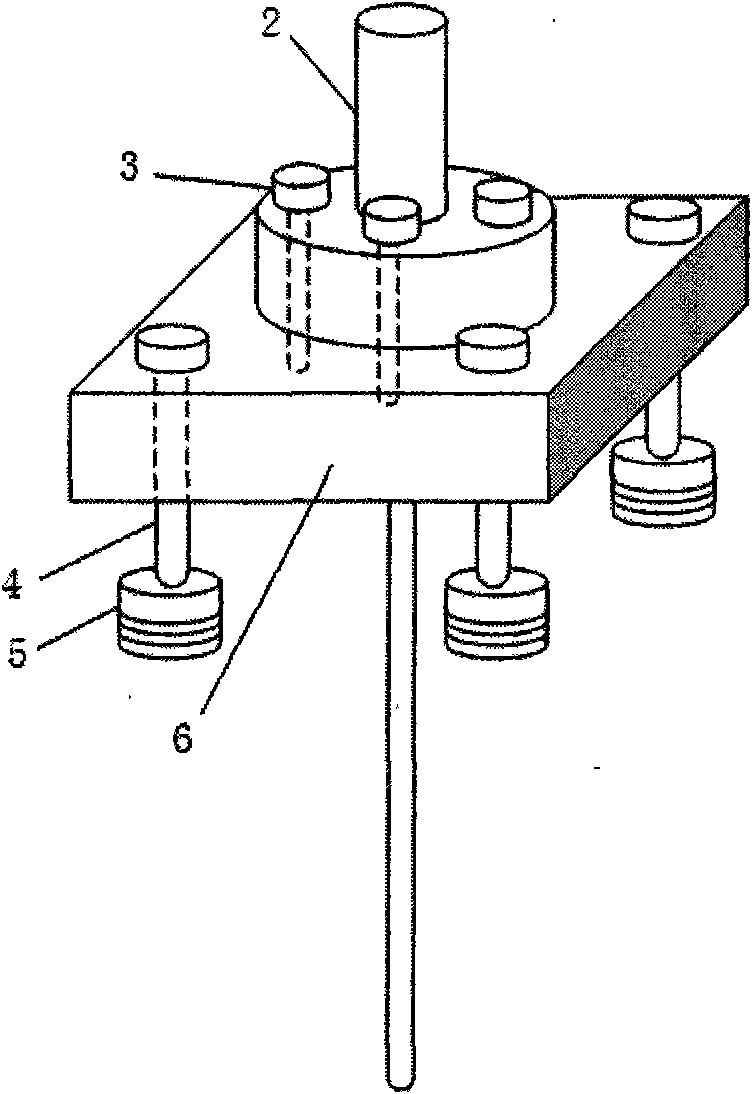

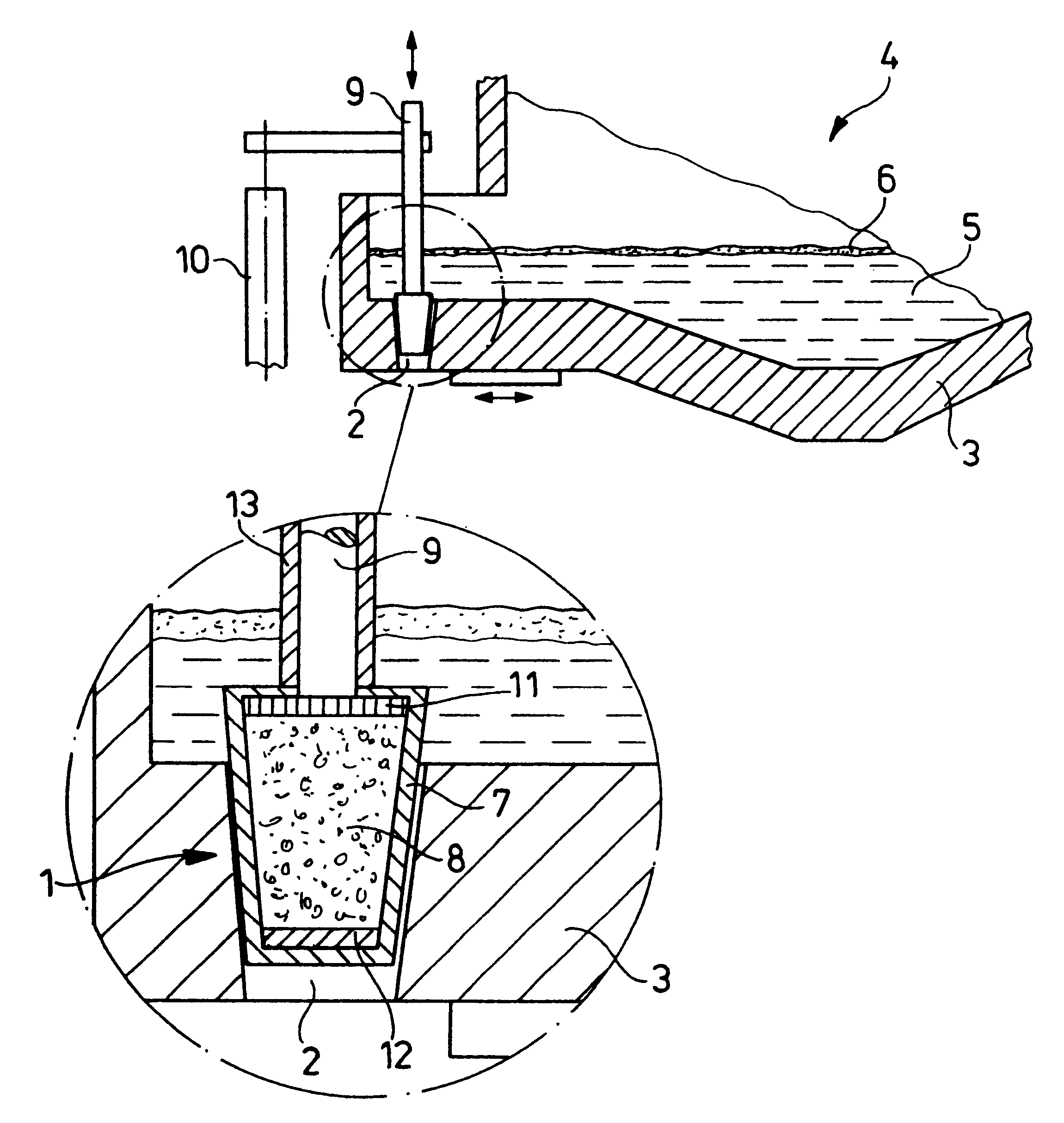

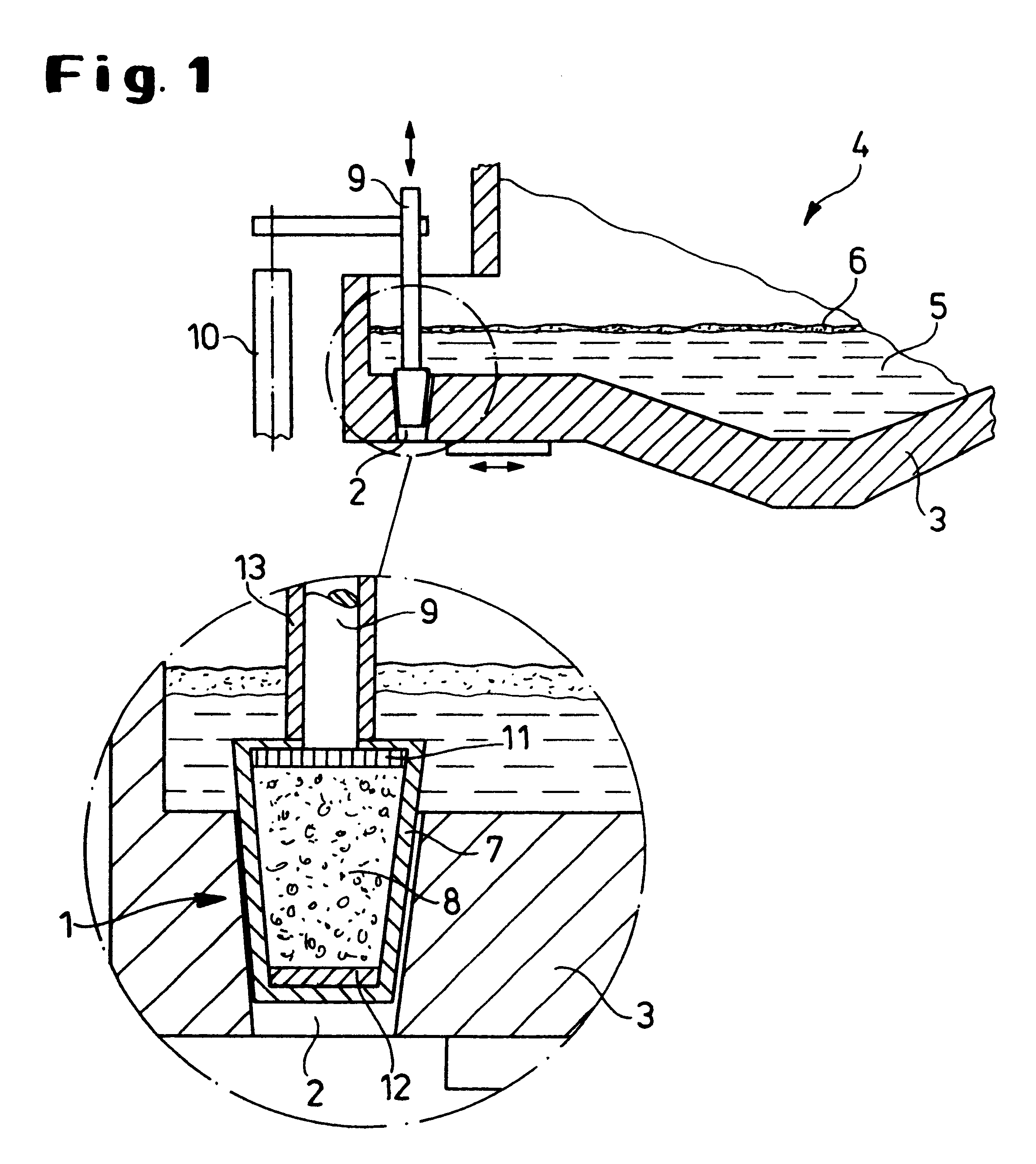

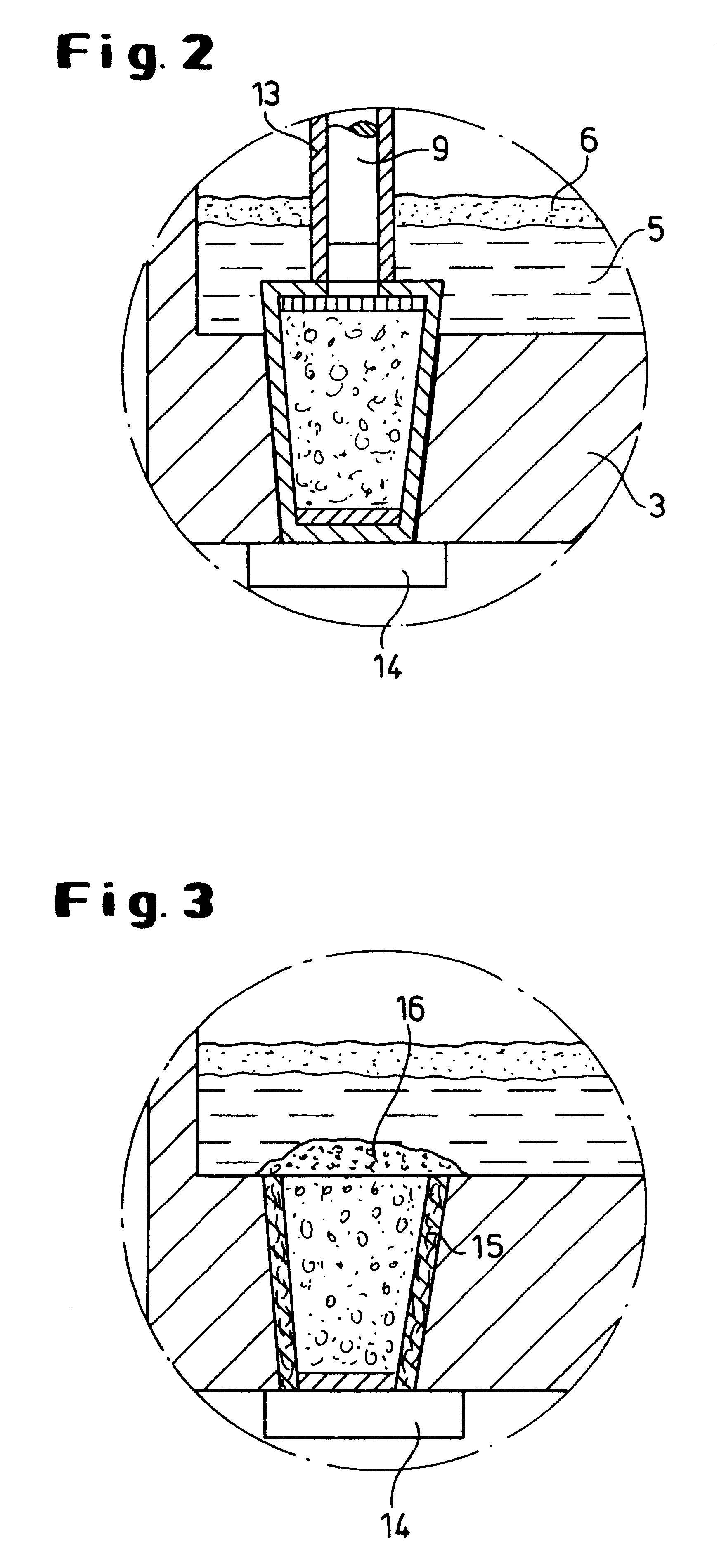

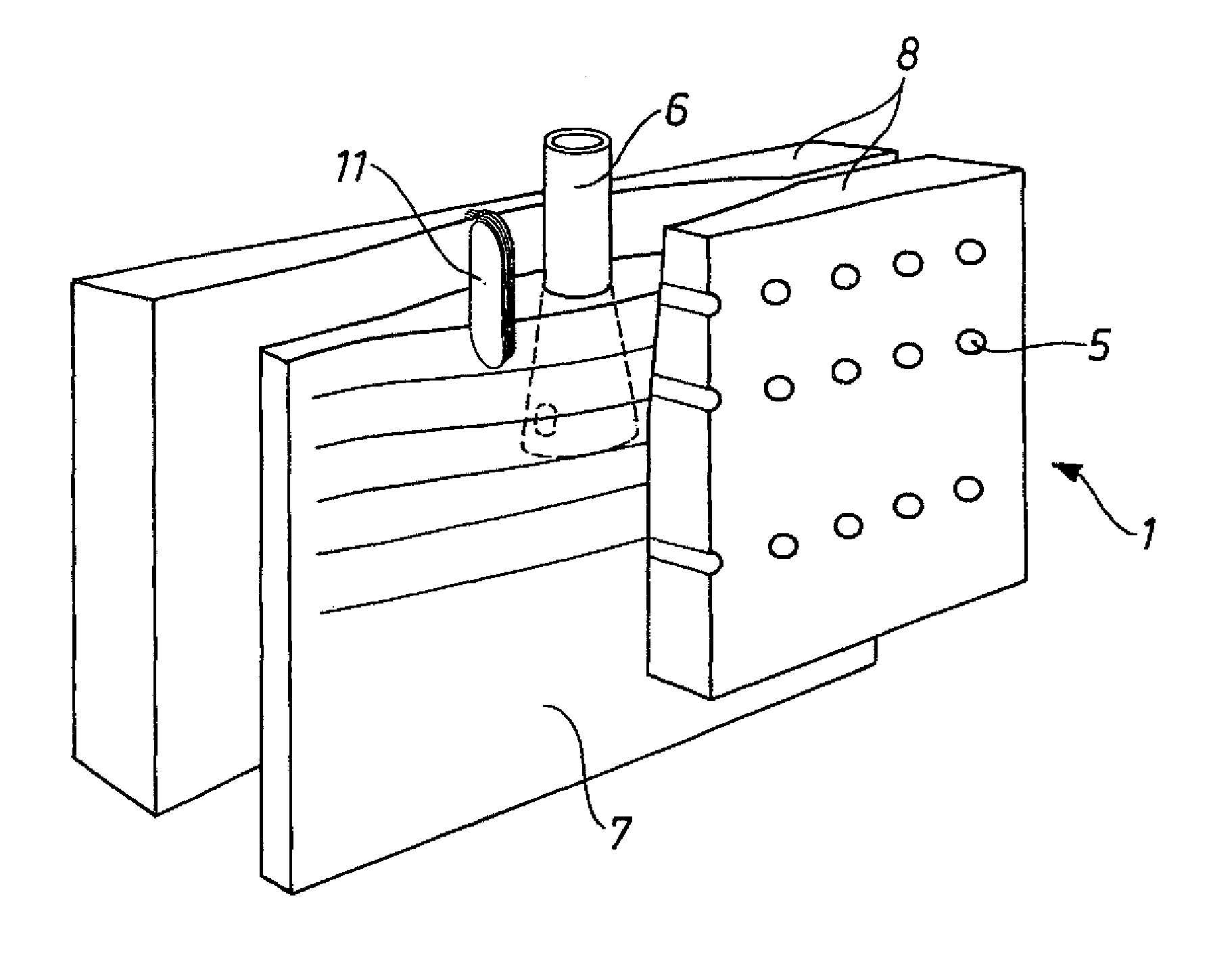

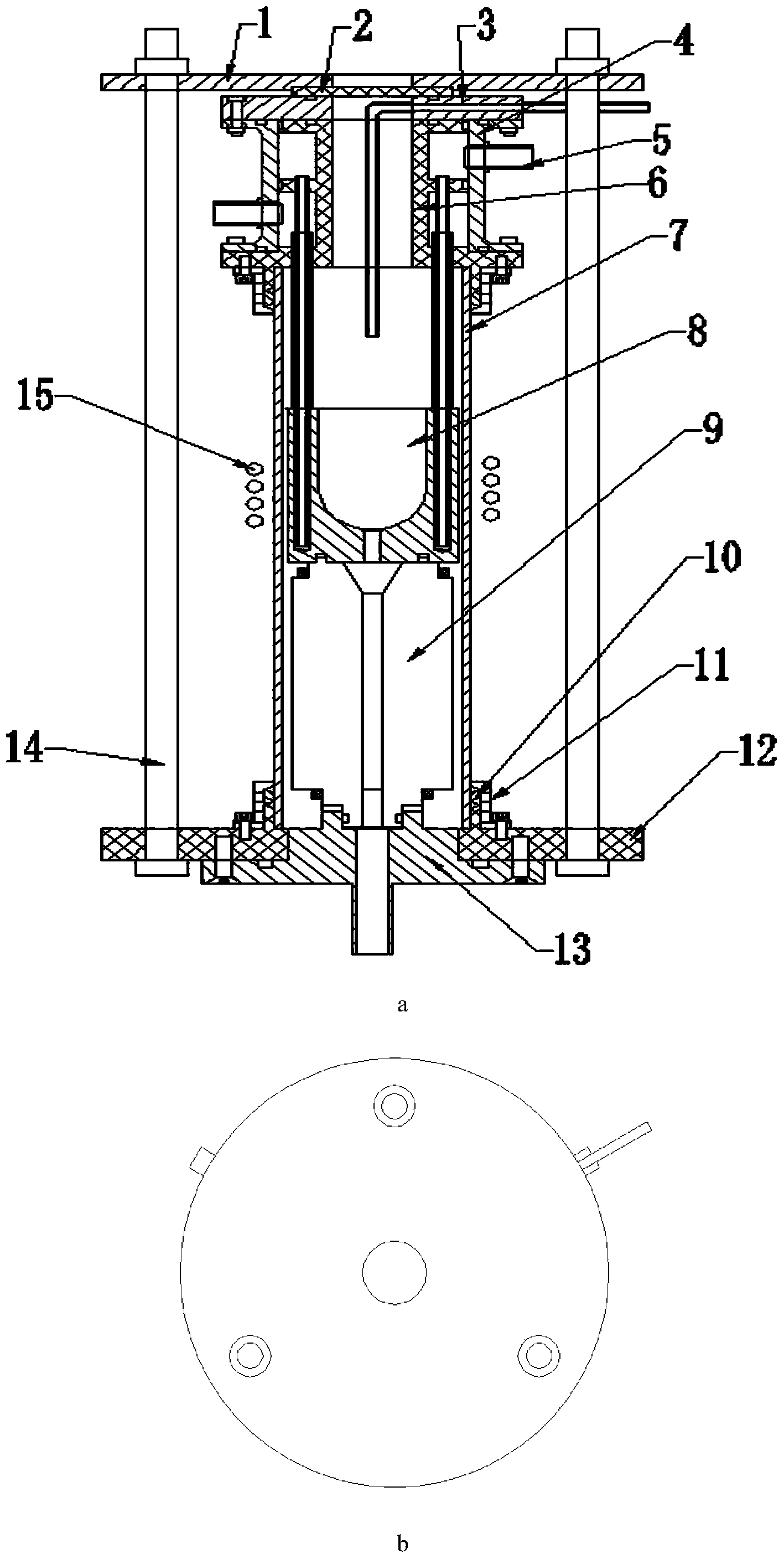

Device and method for detecting the flow state of molten steel in crystallizer

ActiveCN102019377ADetect flow velocityCheck liquidityCasting parameters measurement/indication devicesEngineeringMolten steel

The invention relates to a device and a method for detecting the flow state of molten steel in a crystallizer. The device comprises a funnel (7), a tail fin (8) and an indicator bar (6), wherein the funnel (7) is soaked in the molten steel (20) of a crystallizer and fixedly connected with the tail fin (8), the indicator bar (6) is fixedly connected with the upper part of the funnel (7) and can berotatably and axially supported on an indicator disc (5) through a rotating bearing (17), the indicator disc (5) can make planar rotation relative to a tray (4), the upper end of the indicator bar (6) which is rotatably and axially supported on the indicator disc (5) is connected with a pull rod (2) which is stuck to a stress strain foil (15), and a signal transmission line (16) is connected to asignal collector by the stress strain foil (15) on the pull rod (2). The device and the method of the invention can favorably detect the flow speed and the flow direction of the molten steel, provideevidence for adjusting the parameters of a steel casting process and further achieve the aims of improving the surface quality of casting blanks and reducing steel casting and bleeding accidents. Thedevice and the method of the invention have wide application prospects in the continuous casting production field.

Owner:BAOSHAN IRON & STEEL CO LTD

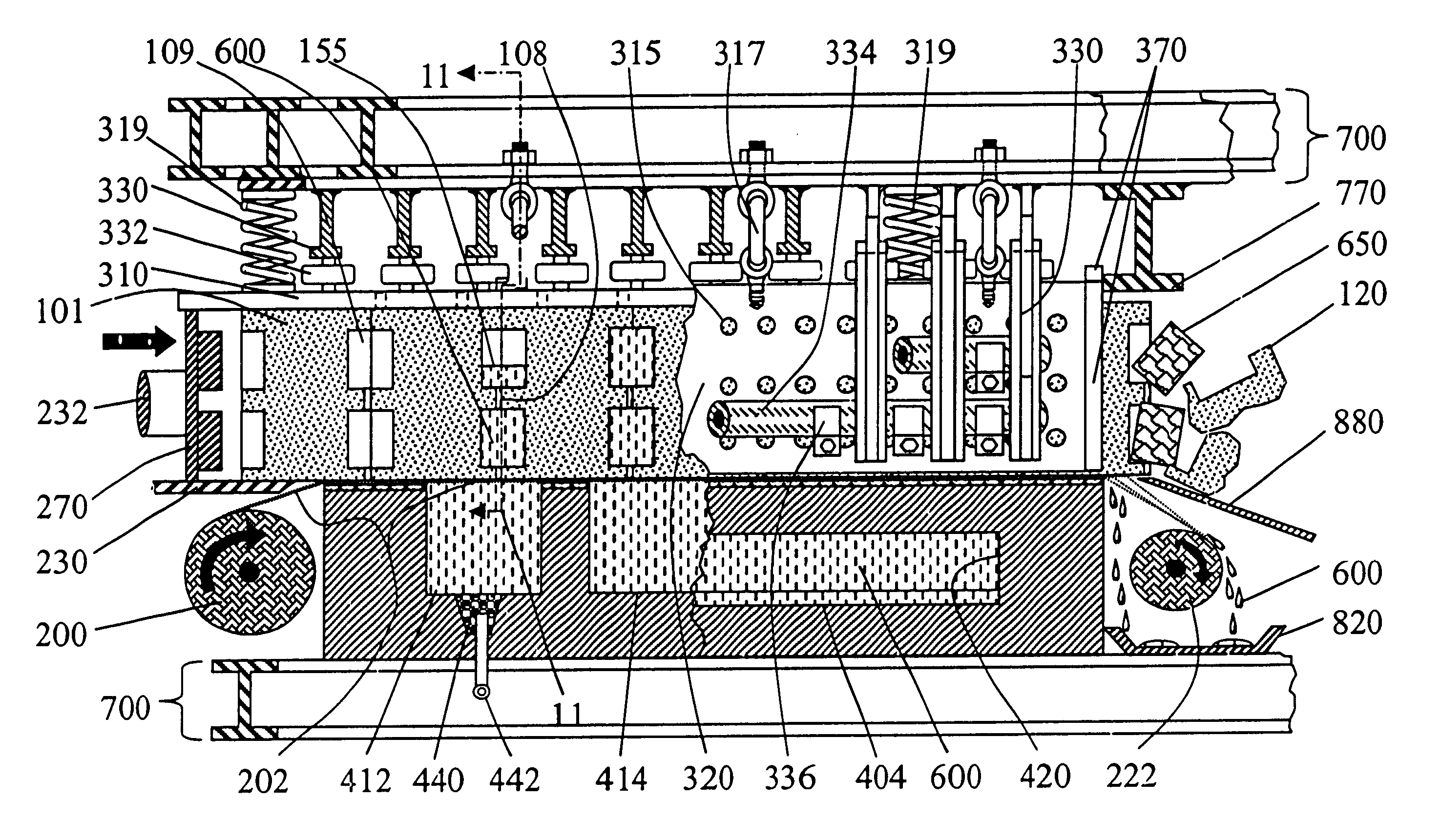

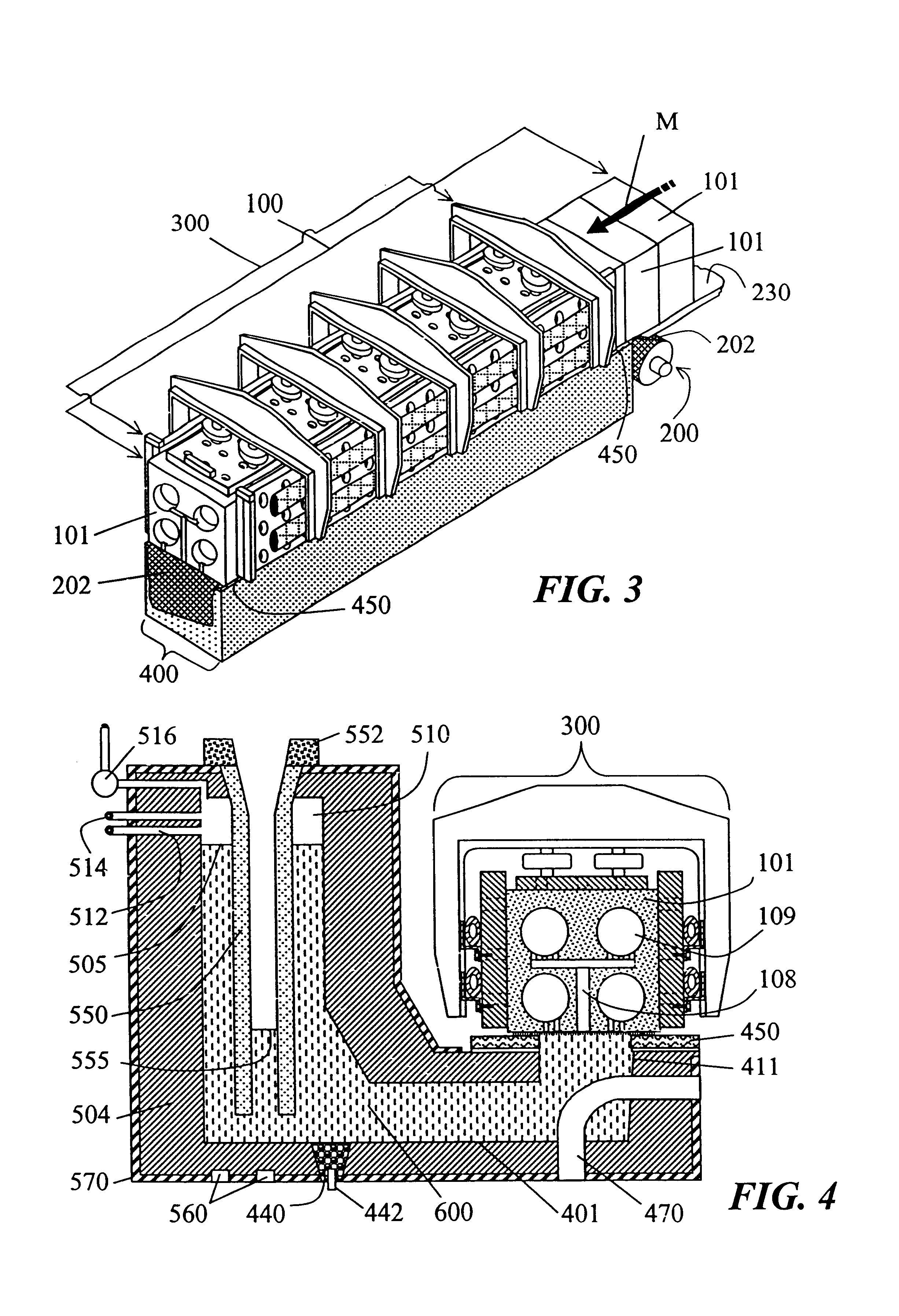

Molding and casting machine

ActiveUS7806161B2Easy to moveEasy to adjustPig casting plantsCasting safety devicesMolding machineSand casting

Disclosed is a sand casting molding machine for double indexing molds in a mold string. The machine can include a shot chamber having sand, a swingable squeeze head, a lateral squeeze head, a core setter, a mold hold down, a mold retention device and a mold string conveyor.

Owner:THYSSENKRUPP WAUPACA

Method and system for tracking and positioning continuous cast slabs

ActiveUS20080264598A1Keep in touchReduce thicknessCasting safety devicesMould controlling devicesControl signalComputer vision

A system and method for tracking and positioning a continuous cast strand in a casting plant. Lateral positions and, optionally, elevational positions of a cast strand are monitored by sensors as casting proceeds and are fed to a computer-based system as corresponding position information where the information is stored as associated data. The computer-based system processes the associated data and generates corresponding control signals which are used to control at least one correcting device to maintain desired orientation of the cast strand as casting proceeds.

Owner:NUCOR CORP

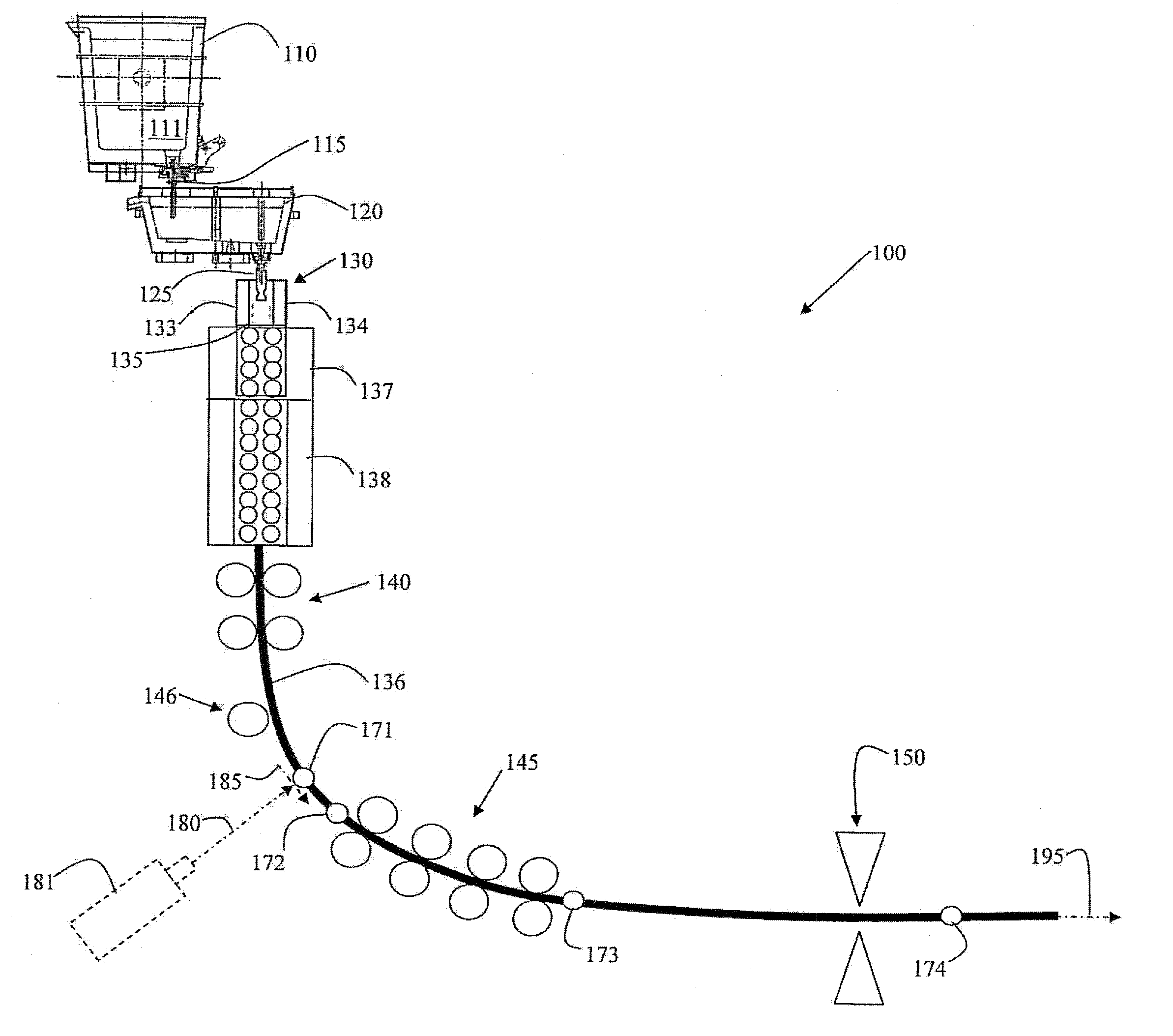

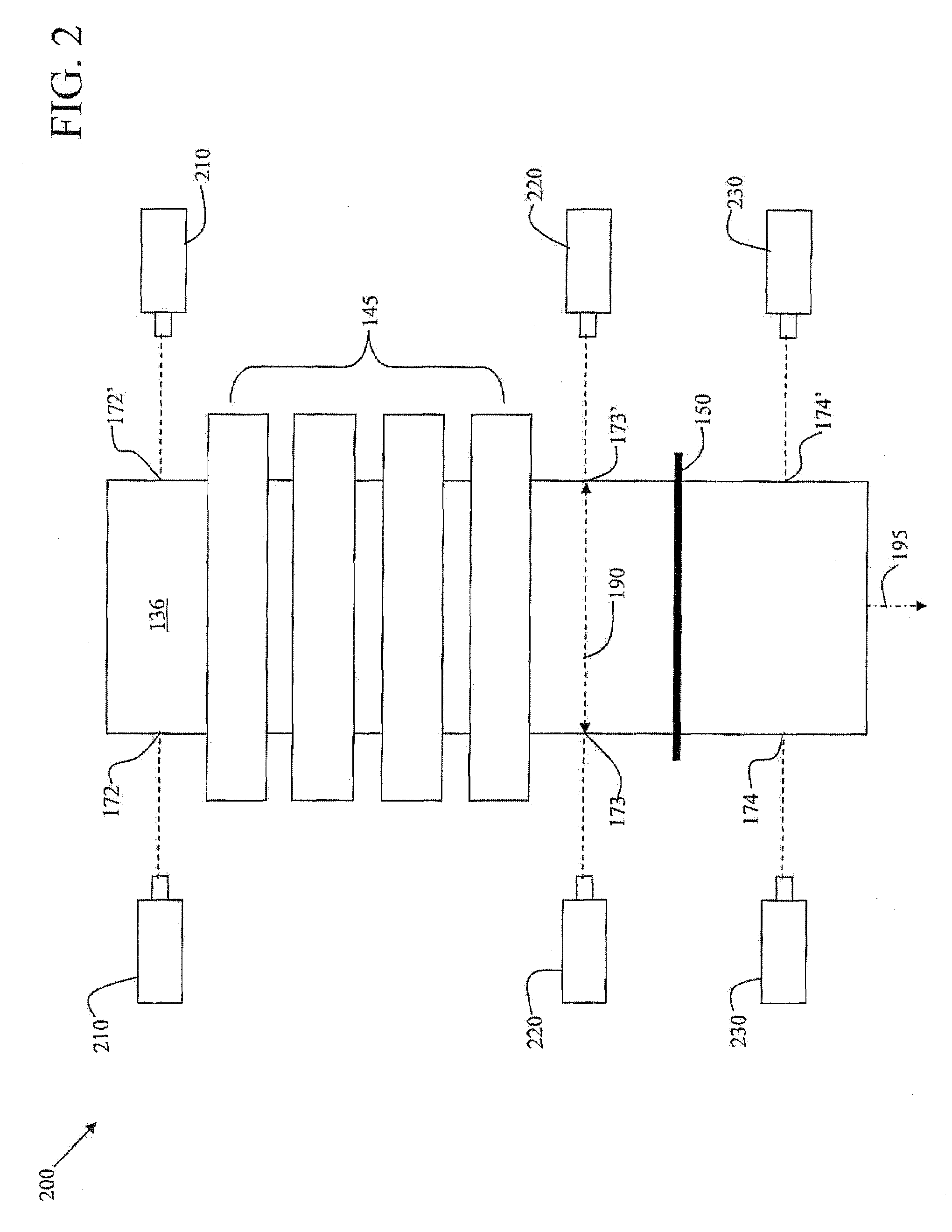

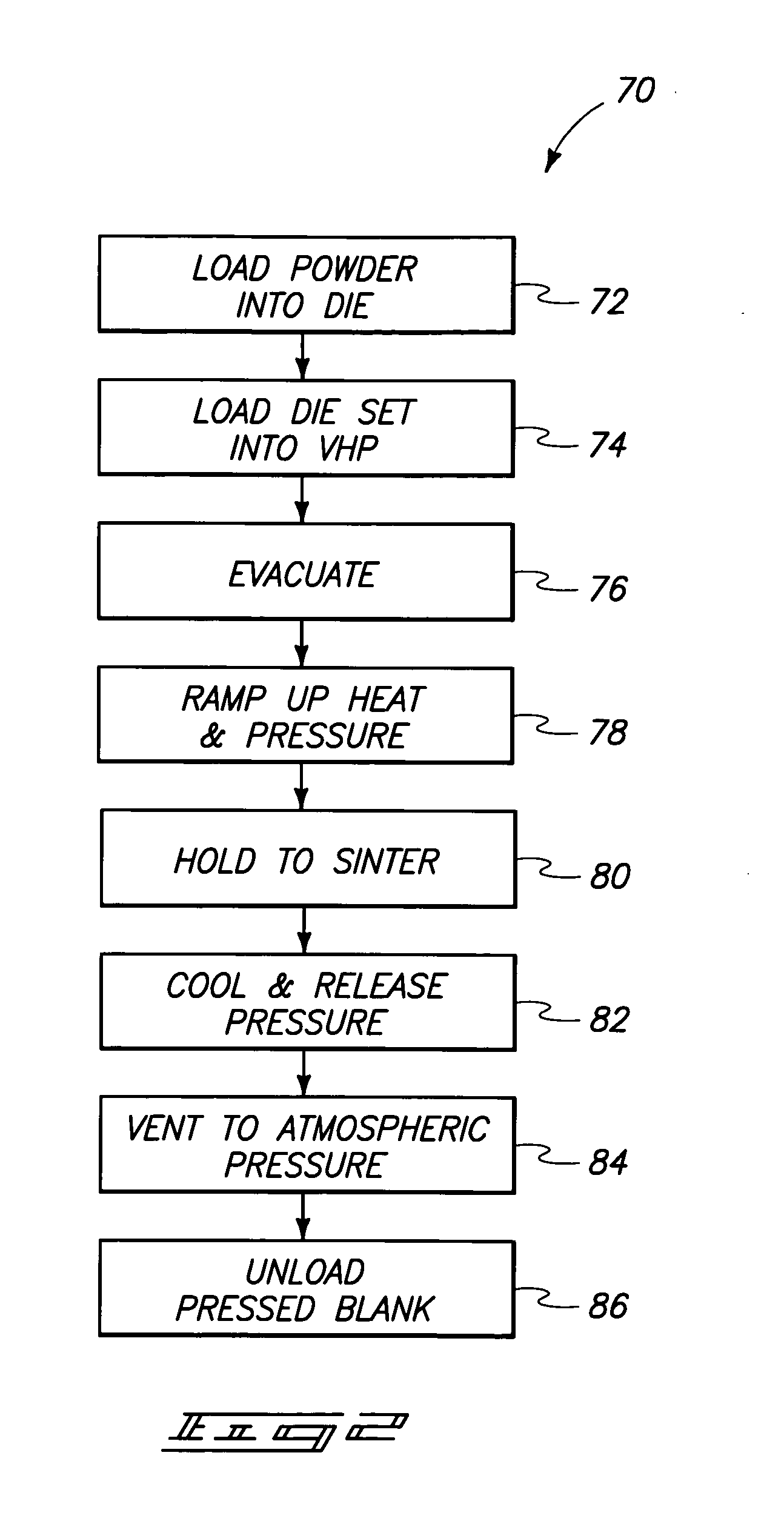

Automotive and aerospace materials in a continuous, pressurized mold filling and casting machine

Owner:HERRON DAVID J

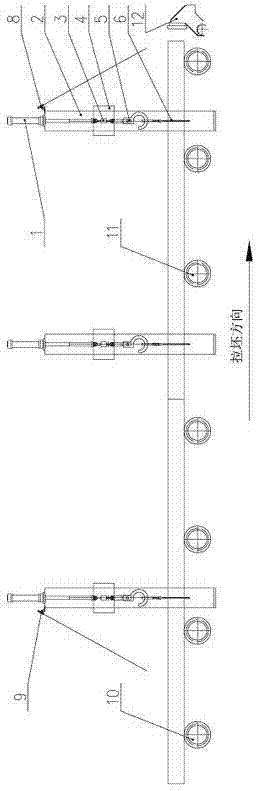

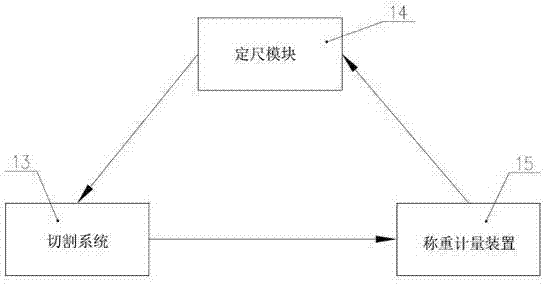

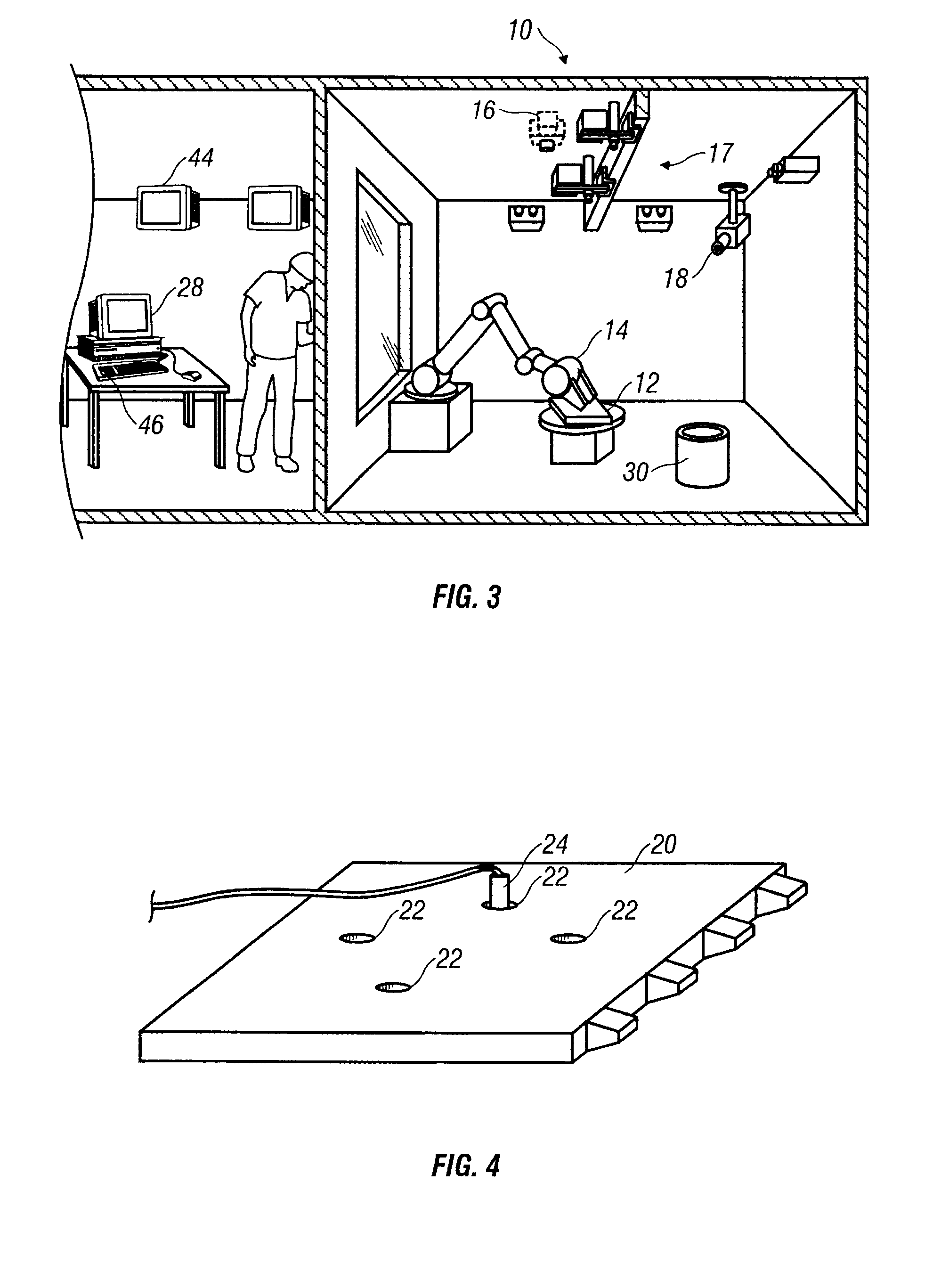

Online sizing and weighing system for multi-flow multi-sizing continuous casting slab

ActiveCN104117648AImprove adaptabilitySimple structureCasting parameters measurement/indication devicesControl systemClosed loop

The invention discloses an online sizing and weighing system for a multi-flow multi-sizing continuous casting slab. The online sizing and weighing system is adopted, the weight of each casting slab is measured precisely, the weight and the part of which the weight deviation is set are converted into a sizing length modification valve, the sizing length value is amended continuously, fixed-weight cutting is achieved, and the weight of the casting slab is controlled in a reasonable range; a sizing and weighing device set is arranged on each flow, all flows are independent mutually, and the ejection waiting time caused by the flow amount is shortened; according to different sizing lengths, a plurality of weighing devices are arranged on each flow, and the number of the weighing device depends on the longest sizing required by production; a closed-loop control system is adopted for the multi-flow multi-sizing online sizing system. The system is high in automatic degree and stable to work, all the flows are independent mutually, the ejection waiting time caused by the flow amount is shortened, the influence of the weighing process on the production is small, the casting slab after passing through a roll gang can pass through the weighing roller way smoothly, and the system is simple and practical.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

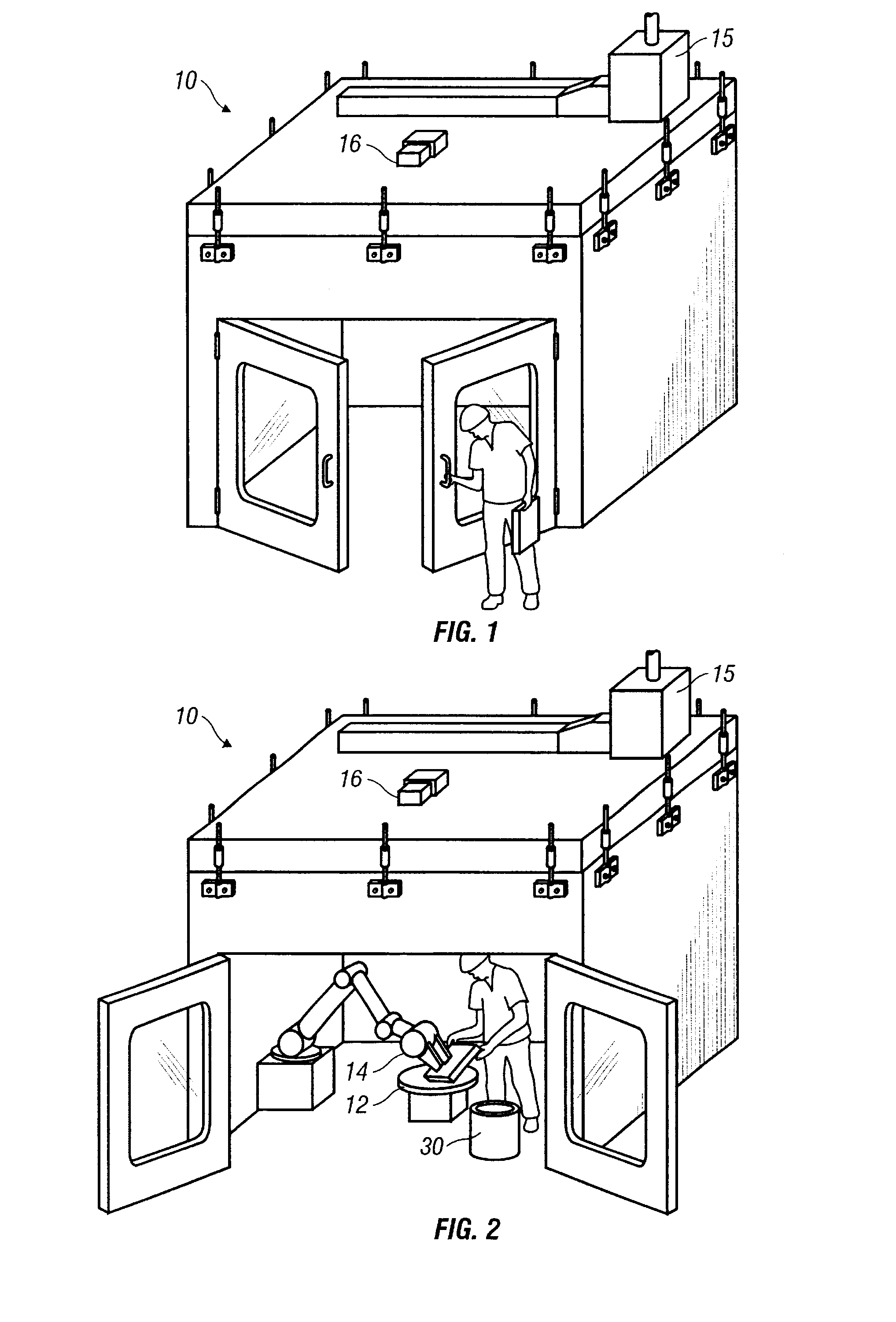

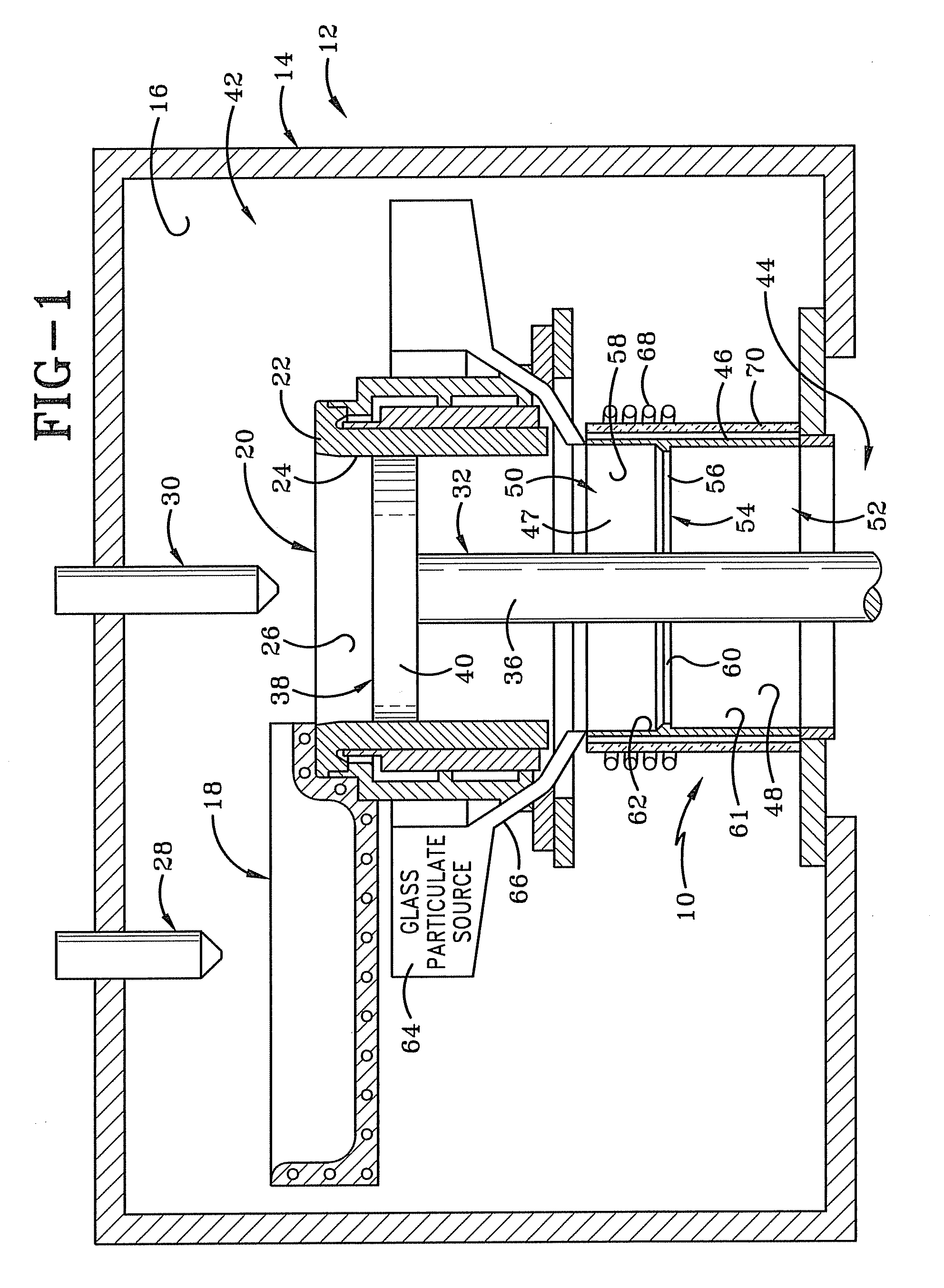

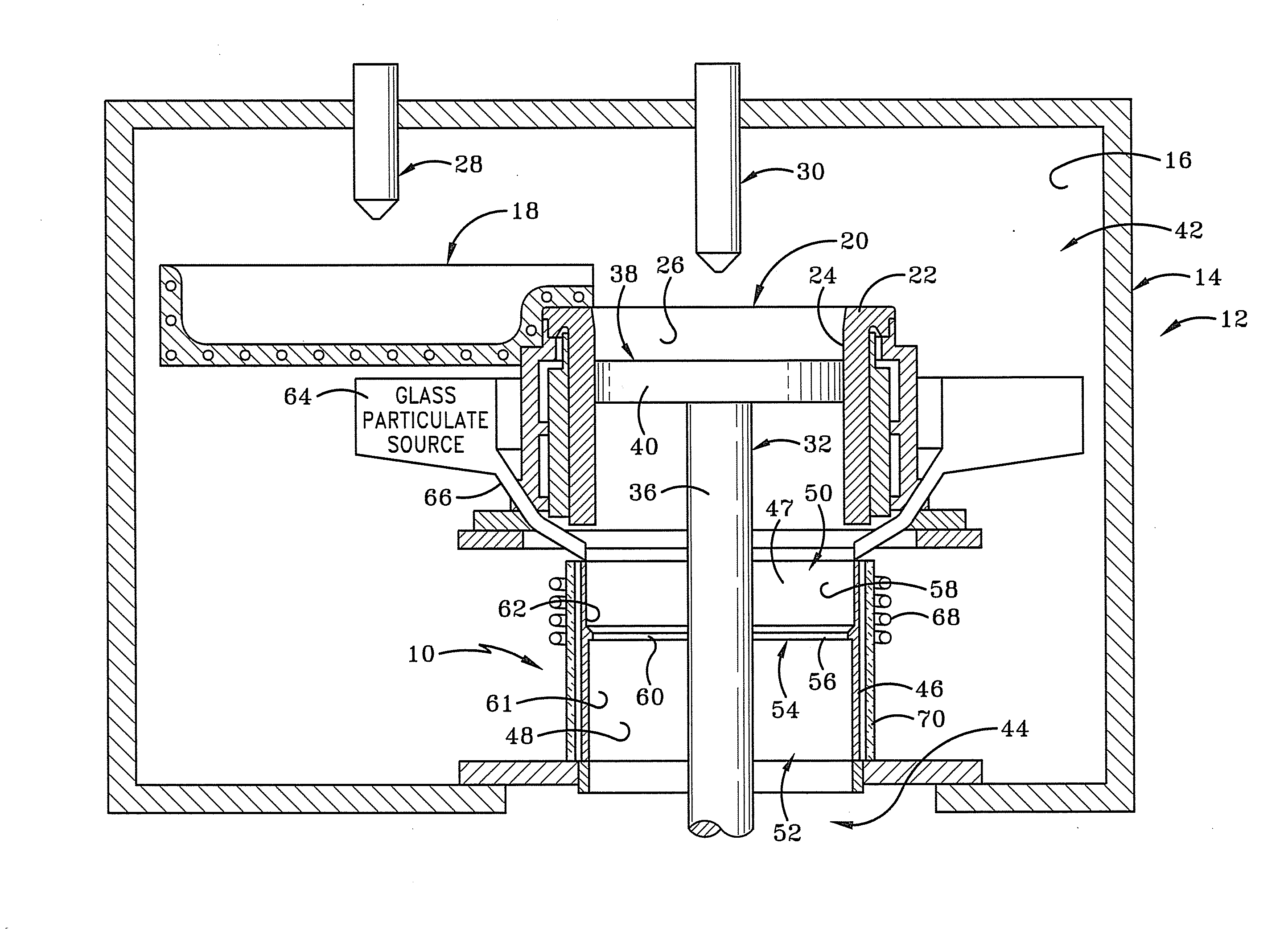

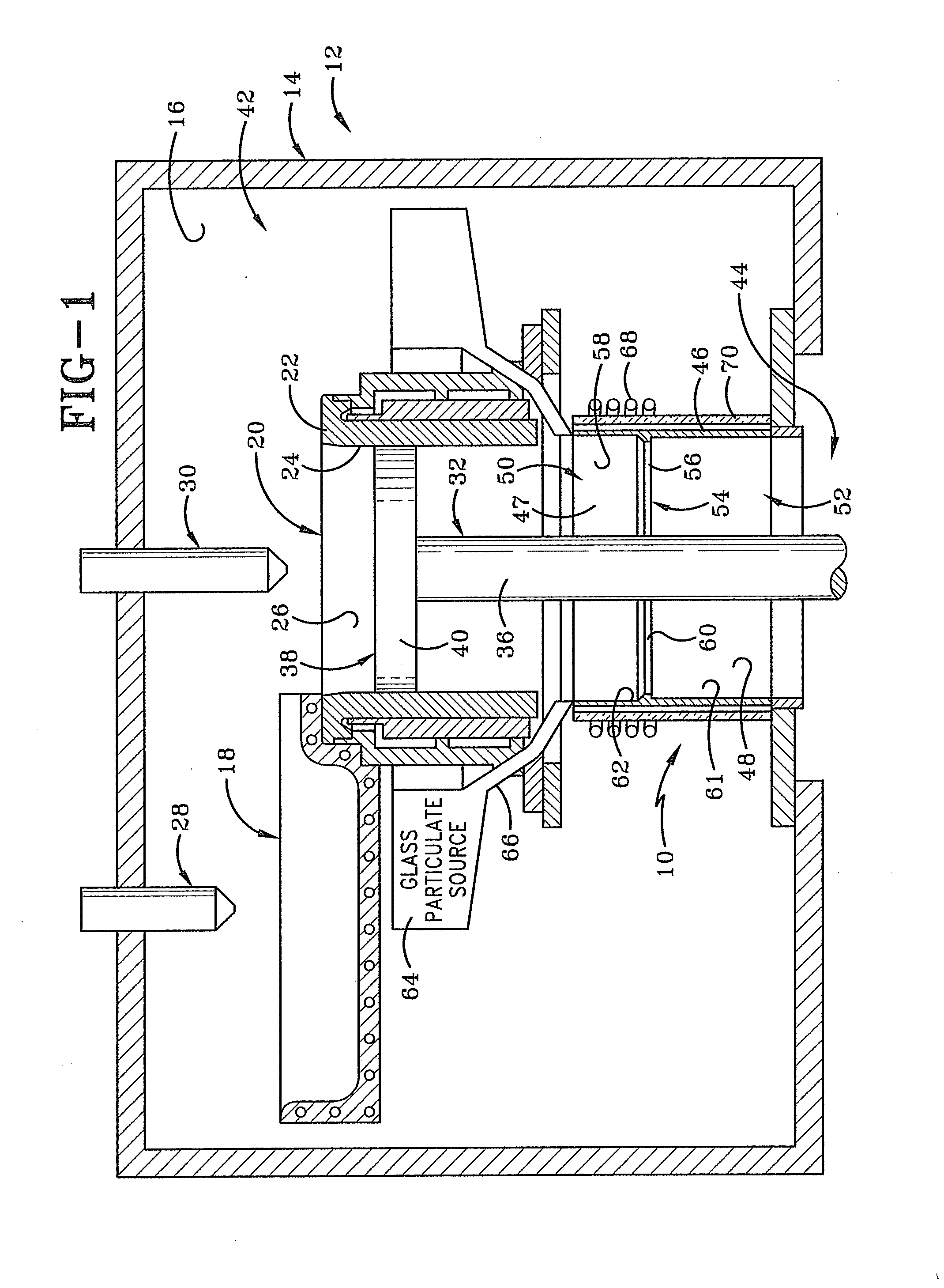

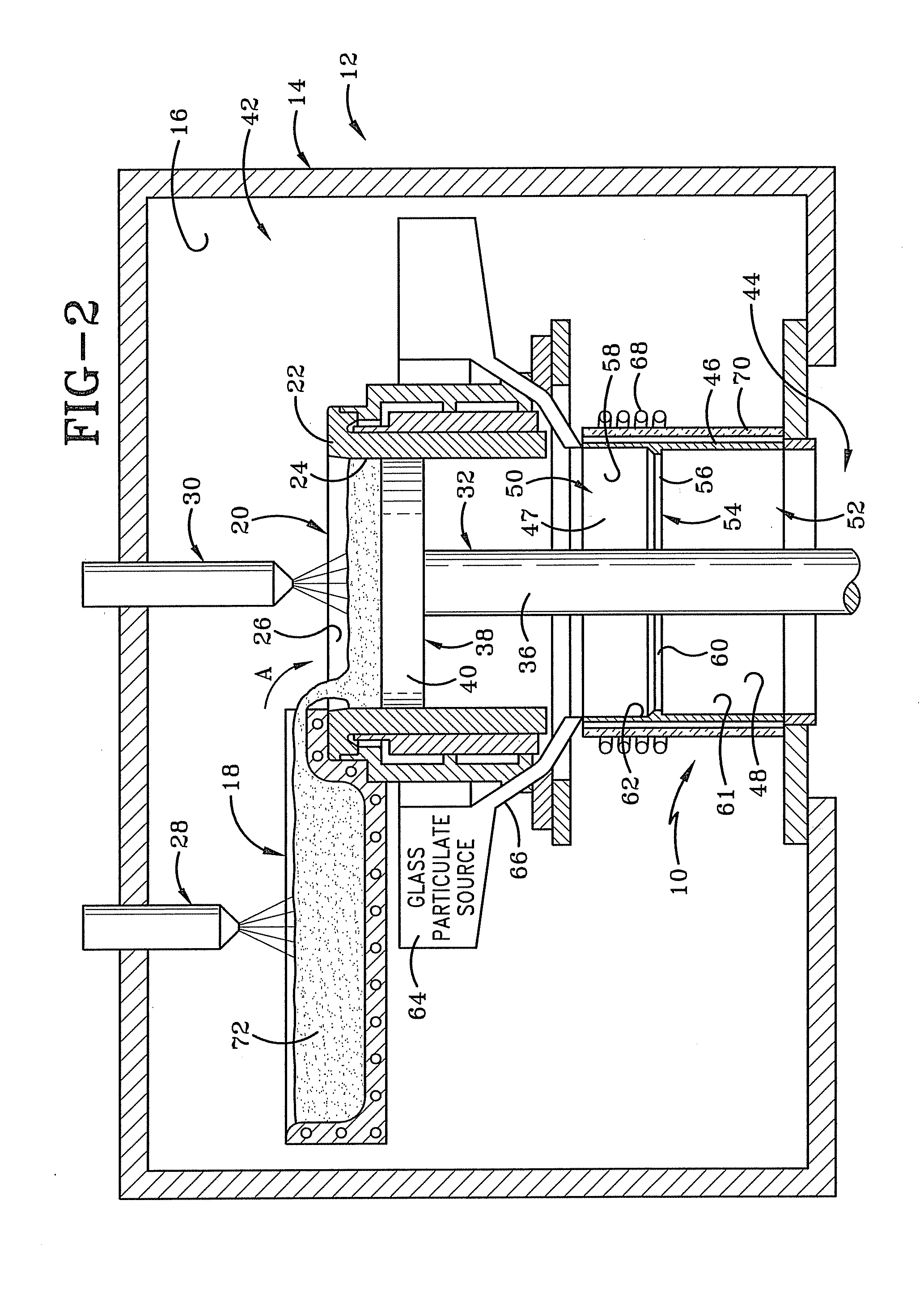

Automated spray form cell

InactiveUS6640878B2High sensitivityAccurate distributionMolten spray coatingCasting safety devicesStress inducedAutomotive industry

Owner:FORD MOTOR CO

Continuous casting billet online weight fixing system

InactiveCN105772655ARealize length measurementCalculate volumeCasting parameters measurement/indication devicesLaser rangingMetallurgy

The invention discloses a continuous casting billet online weight fixing system. The continuous casting billet online weight fixing system comprises continuous casting billets, a flame cutting device and a weight measuring device, the flame cutting device is used for cutting the continuous casting billets, and the weight measuring device is used for measuring the weights of the continuous casting billets. The weight measuring device comprises a computer, a length measuring module, a width measuring module and a thickness measuring module, wherein the length measuring module, the width measuring module and the thickness measuring module are electrically connected with the computer and used for measuring the lengths, the widths and the thicknesses of the continuous casting billets correspondingly. The computer calculates the real-time weights of the continuous casting billets by combining the measured sizes of the continuous casting billets according to the density information, obtained in advance, of the continuous casting billets and sends the real-time weights to the flame cutting device for fixed weight cutting of the continuous casting billets. The length measuring module comprises a laser range finder used for measuring the level at which the flame cutting device arrives at an original position so as to compensate and correct the measured lengths of the continuous casting billets. The continuous casting billet online weight fixing system can accurately calculate the real-time weights of the continuous casting billets for fixed weight cutting of the continuous casting billets, and therefore the weight deviation of the cut continuous casting billets is stabilized within an allowable range, and the requirement of efficient continuous casting production can be met.

Owner:HENGYANG RAMON SCI & TECH CO LTD

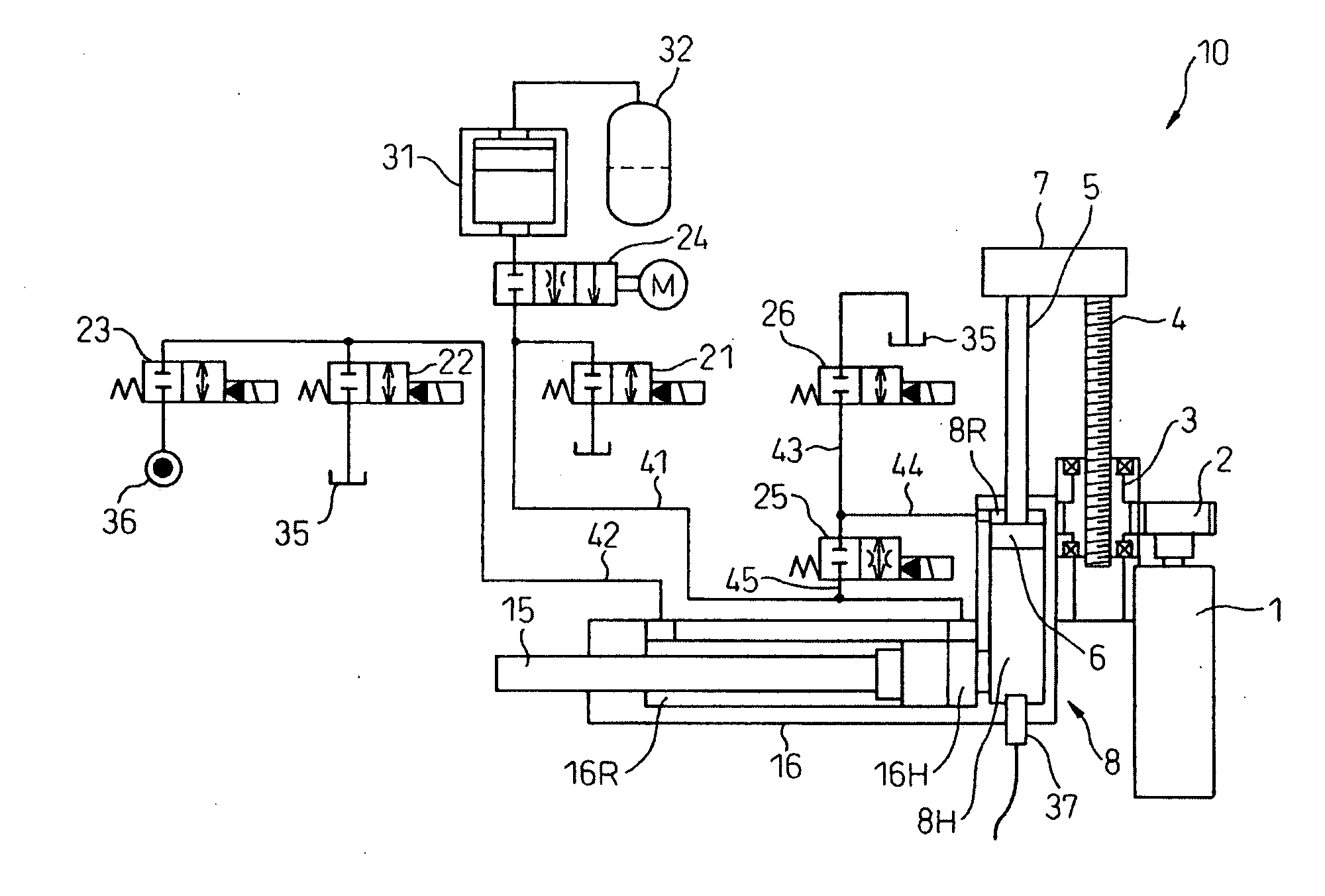

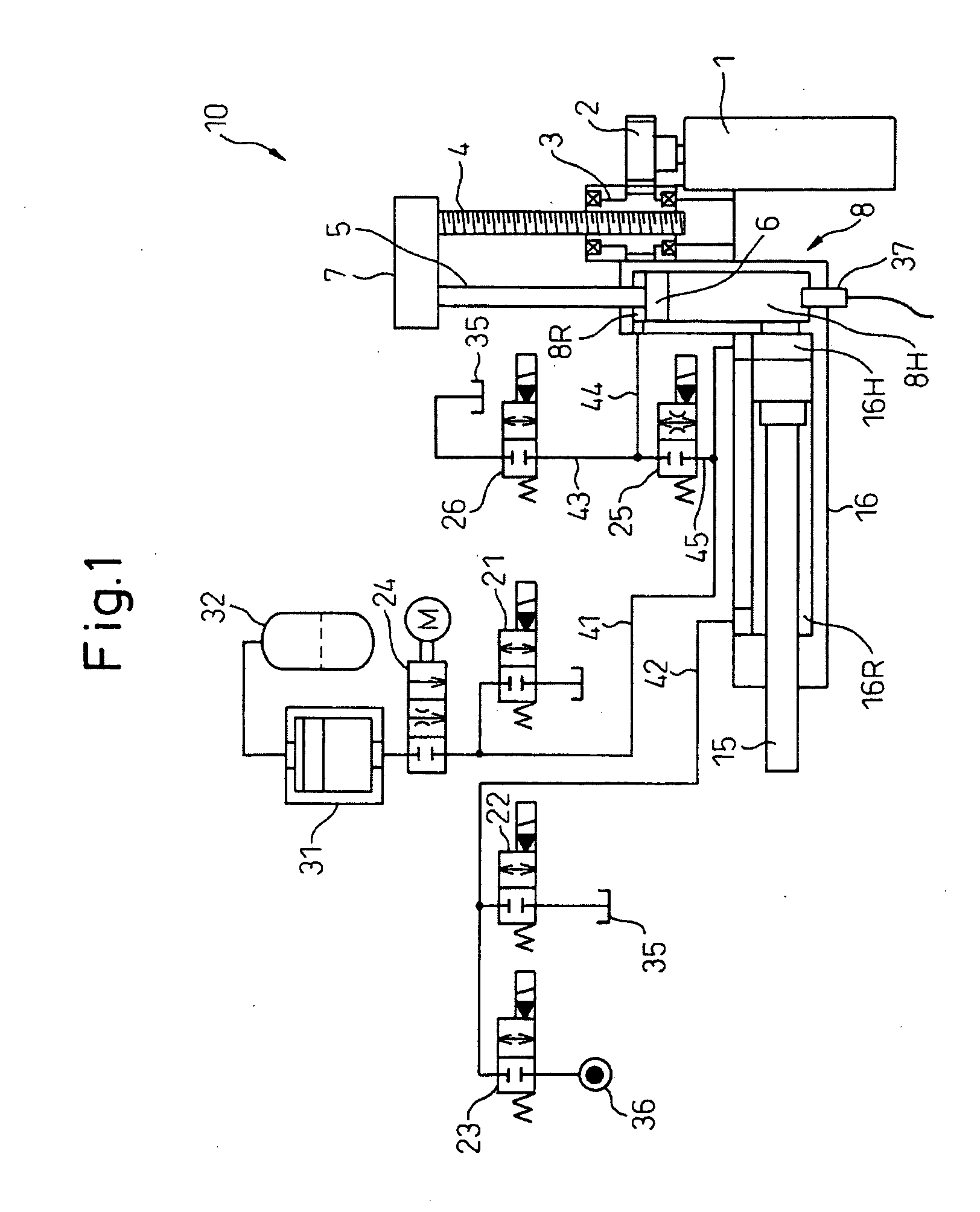

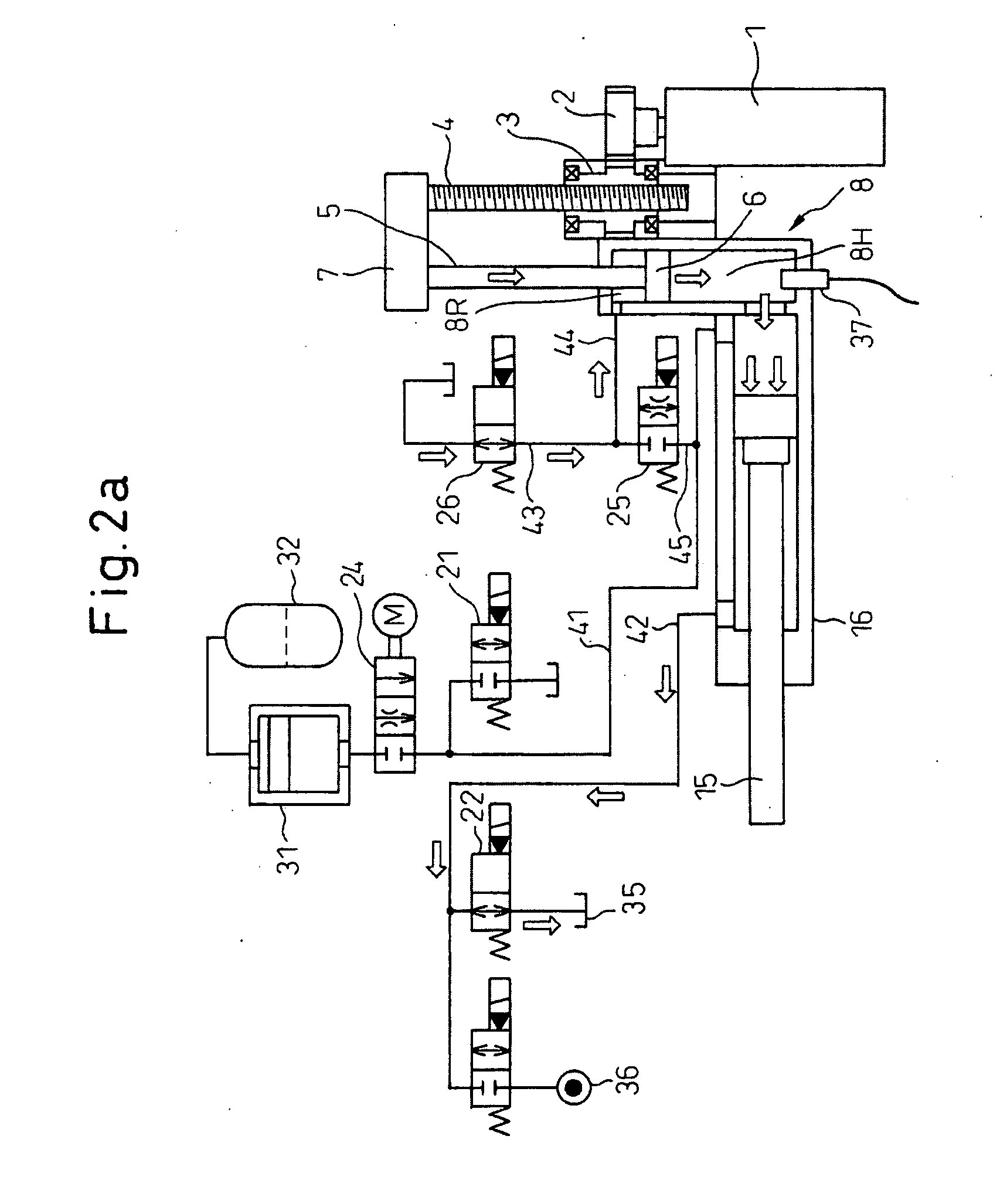

Injection device for die casting machine

InactiveUS20090242161A1Reducing necessary maximum torqueLower injection costsMoulding plantsCasting safety devicesHydraulic cylinderPower flow

In a hybrid injection system of a die casting machine, the occurrence of a large electric power loss can be prevented by avoiding a large current at a pressure-holding step and the size of a motor is reduced.In an injection system comprising an injection cylinder (16) housing an injection piston (15) for injecting molten metal to a mold and an electric booster (8) of hydraulic cylinder type, a head chamber (8H) to the electric booster communicates fluidly with a head chamber (16H) of the injection cylinder, causing a booster piston rod (5) to be housed in the electric booster (8) to move linearly and thus pressing under pressure to move the injection piston to perform injection molding. Because a stop valve (25) is provided in a pipe that causes the head chamber (16H) of the injection cylinder to communicate with a rod chamber (8R) of the booster (8), it is possible for the pressure of the hydraulic oil to act on a head area of the electric booster at a pressure-increasing step for increasing pressure of the molten metal, and for pressure of the hydraulic oil to act on a rod area of the electric booster at a pressure-holding step for holding pressure of the molten metal.

Owner:UBE MASCH CORP LTD

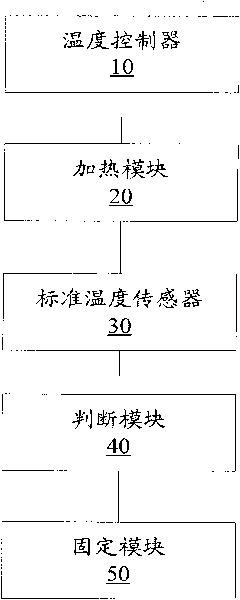

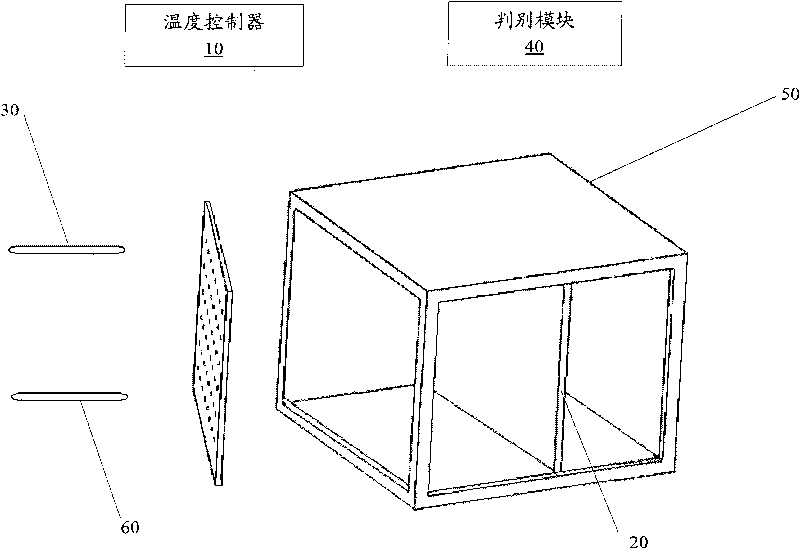

Temperature sensor detector

InactiveCN101706331AThermometer testing/calibrationCasting parameters measurement/indication devicesElectricityTemperature control

The invention provides a temperature sensor detector which comprises a temperature controller, a heating module, a standard temperature sensor, a judgment module and a fixing module, wherein the fixing module is used for fixing the standard temperature sensor and the temperature sensor to be detected; the standard temperature sensor and the temperature sensor to be detected are used for sensing the temperature of the heating module; the temperature controller is used for controlling the heating module to warm or cool according to set temperature; and the judgment module is respectively electrically connected with the standard temperature sensor and the temperature sensor to be detected, and is used for comparing the temperature sensor to be detected with the standard temperature sensor and judging whether the temperature sensor to be detected is qualified.

Owner:田陆

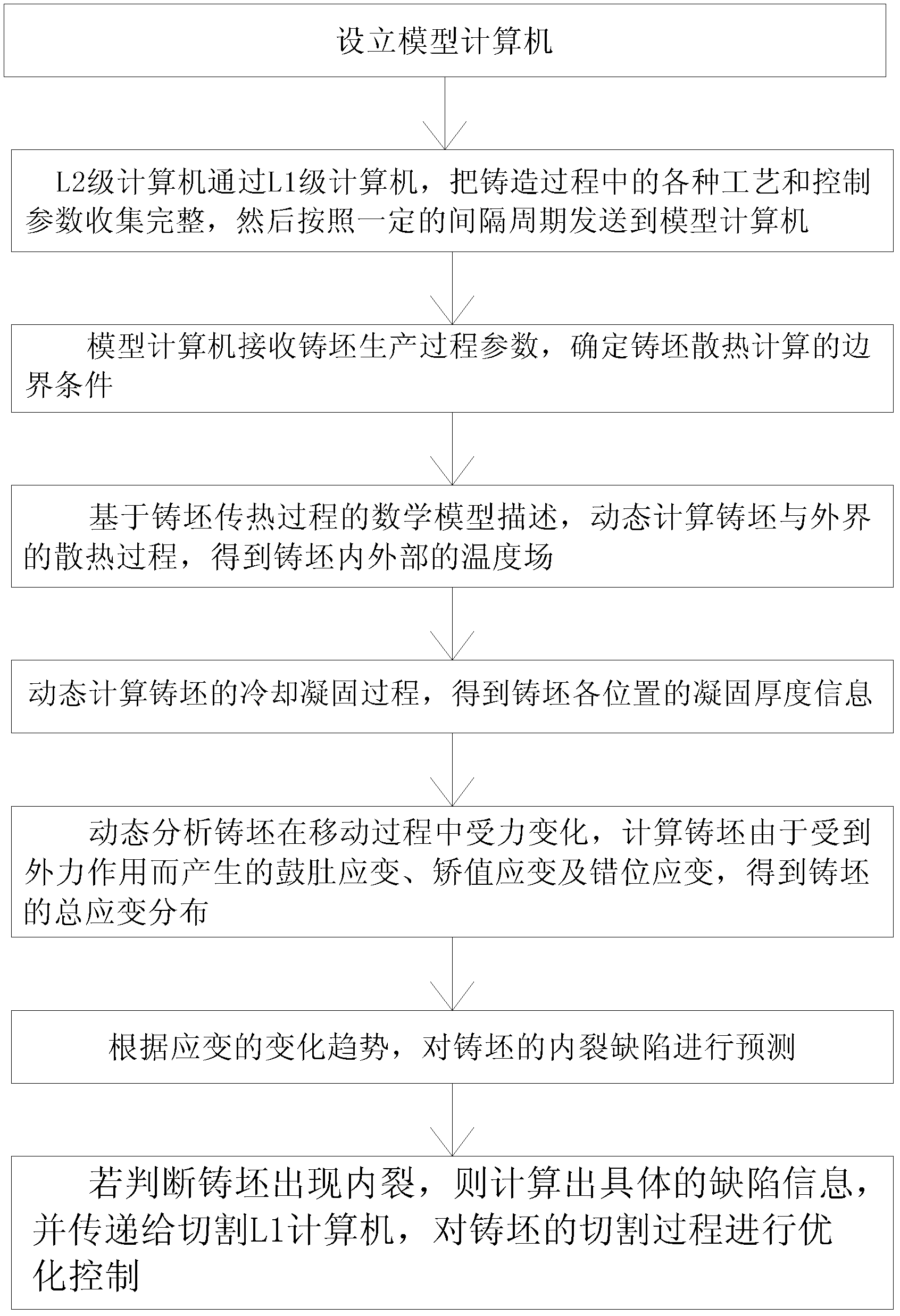

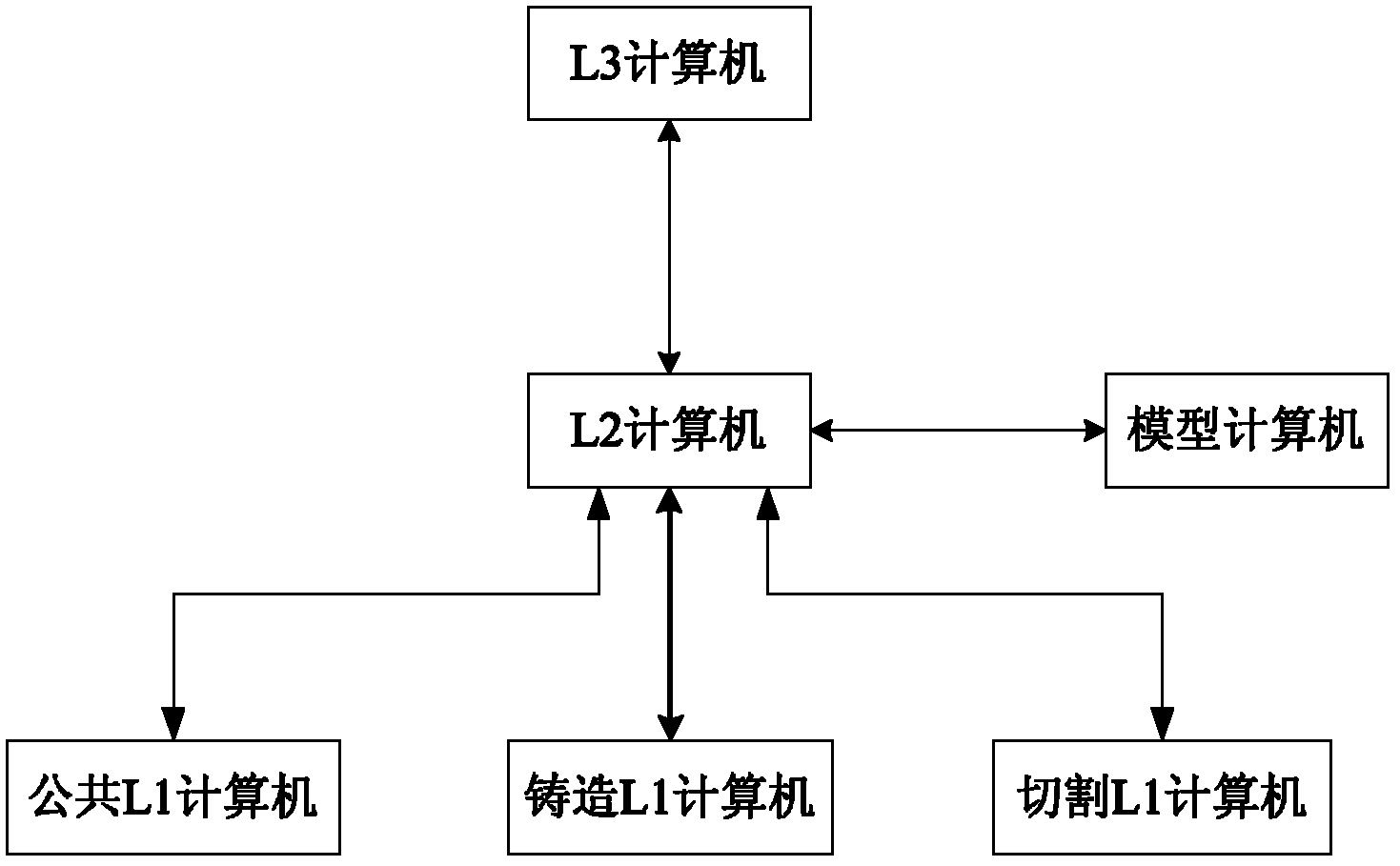

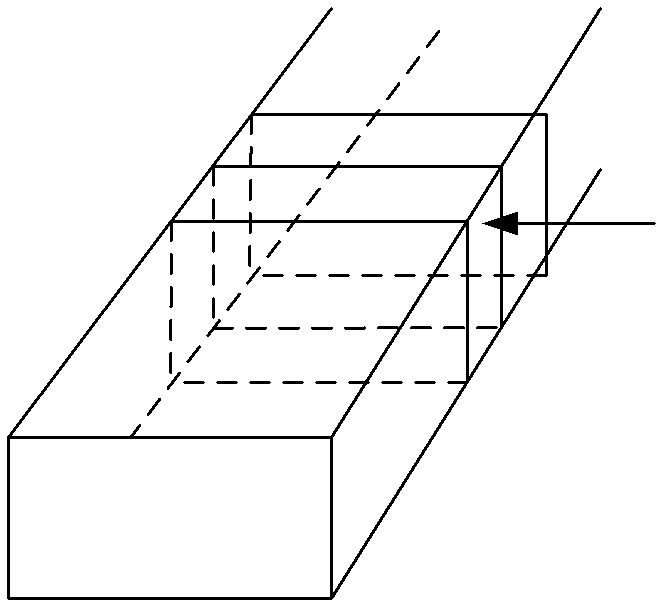

Online forecasting method for internal crack defect of casting blank

ActiveCN102527971AStrong real-timeGood online synchronization performanceCasting parameters measurement/indication devicesEconomic benefitsQuality control

An online forecasting method for an internal crack defect of a casting blank belongs to the field of metal casting and comprises a network composed of a computer of L3, a computer of L2 and a computer of L1 and data transmission among the computers, wherein on the basis of the existing computer of L2 or the same control level, a model computer is arranged to obtain the internal stress strain information of the casting blank by real-time online analog computation of cooling and solidifying process of the casting blank, and then forecasts the internal crack defect of the casting blank in real time according to the variation tendency of the strain; then the quality information of the casting blank in the production process is timely transmitted to the cutting computer of L1 which is used for optimizing and controlling the cutting process of the casting blank with the defect; the quality control accuracy of a product and the product percent of pass are increased, the percent of pass and the commercial grade of the product are increased, and the whole economic benefit of an enterprise is further increased. Therefore, the online forecasting method for the internal crack defect of the casting blank can be widely applied to optimizing / control field of the cutting process of the casting blank during the production of slab continuous casting.

Owner:BAOSHAN IRON & STEEL CO LTD

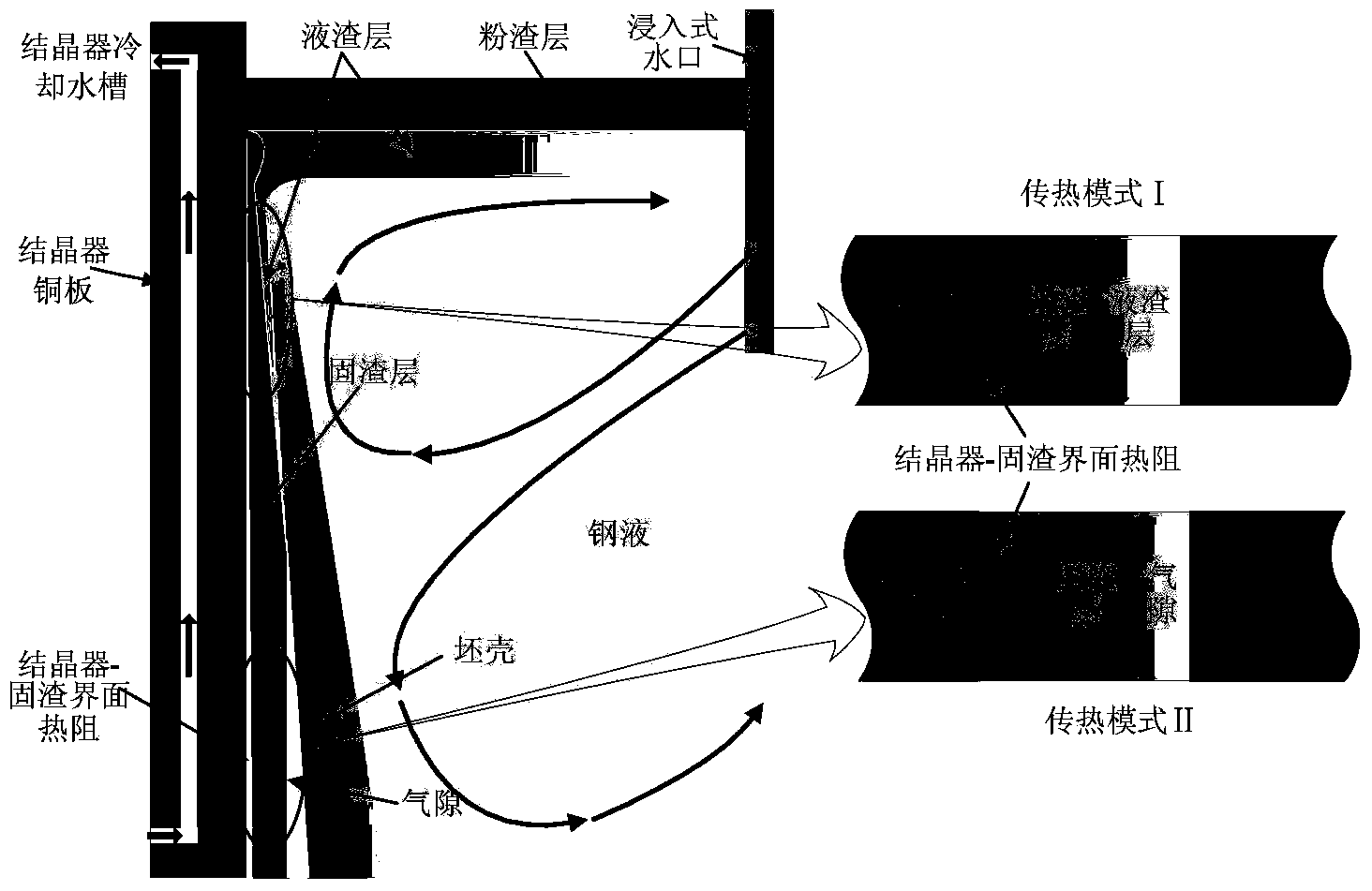

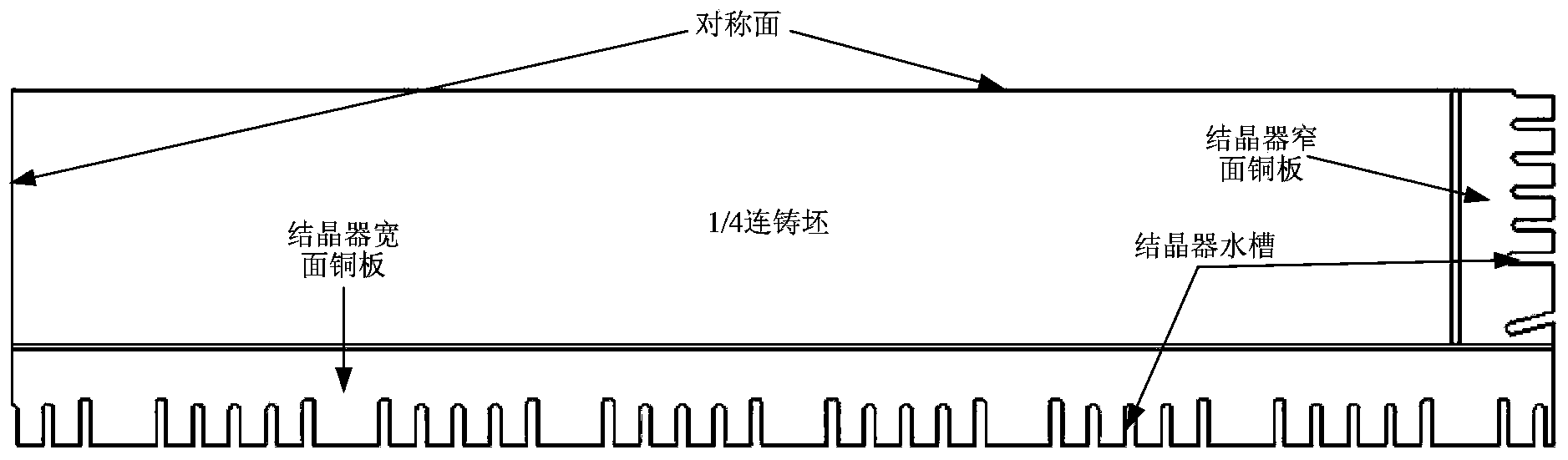

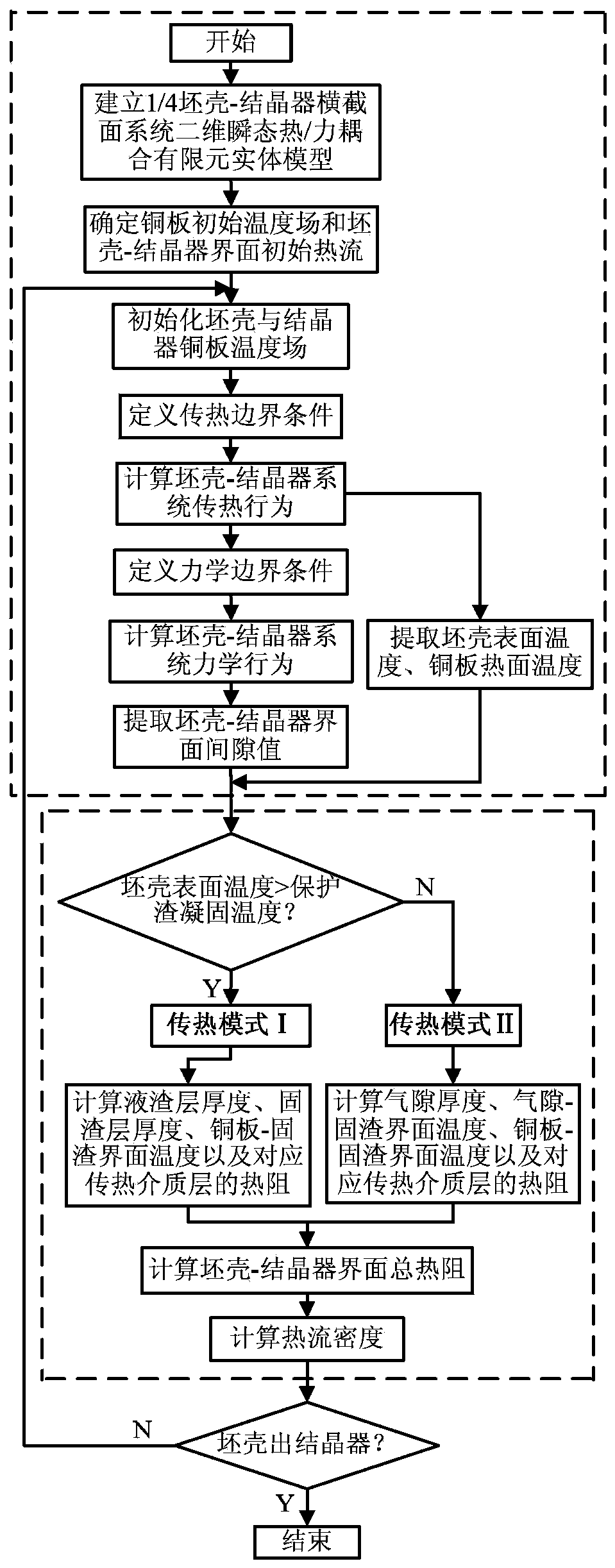

Method for determining heat flux density of continuous casting crystallizer based on flux film and air gap dynamic distribution

InactiveCN103433448AEasy to getImprove universalityCasting parameters measurement/indication devicesElement modelHeat flux

The invention belongs to the field of metallurgy continuous casting process numerical analog simulation, and discloses a method for determining heat flux density of a continuous casting crystallizer based on flux film and air gap dynamic distribution. According to a crystallizer copper plate structure and the size of the section of a continuous casting, a two-dimensional transient heat / force coupling finite element model with a 1 / 4 blank shell-crystallizer cross section system as a computation object is built, and the temperature of the surface of the blank shell, the temperature of the hot surface of a copper plate and the width of the clearance of a blank shell-crystallizer interface are determined. If the temperature of the surface of the blank shell is higher than the solidification temperature of casting powder, the heat resistor of the blank shell-crystallizer interface is formed by connecting a melt cinder layer, a solidification slug layer and a crystallizer-solidification slug interface heat resistor in series. If the temperature of the surface of the blank shell is smaller than or equal to the solidification temperature of the casting powder, the heat resistor of the blank shell-crystallizer interface is formed by connecting an air gap layer, a solidification slug layer and a crystallizer-solidification slug interface heat resistor in series. The method has good universality, and is suitable for determining the heat flux density of all existing continuous casting machine types and sectional crystallizers.

Owner:NORTHEASTERN UNIV

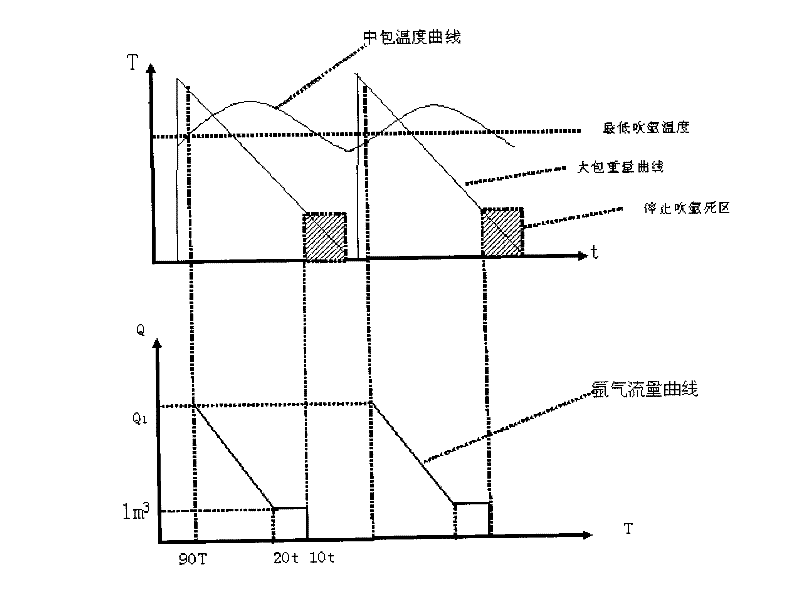

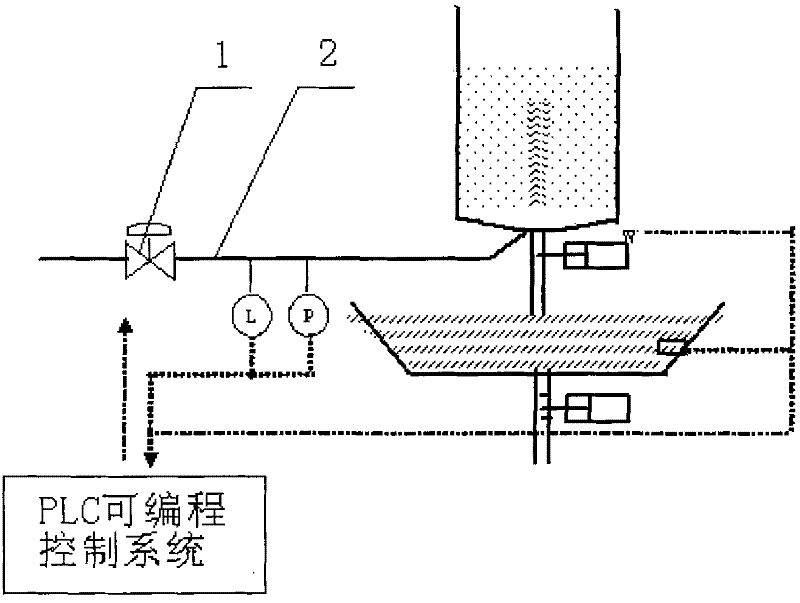

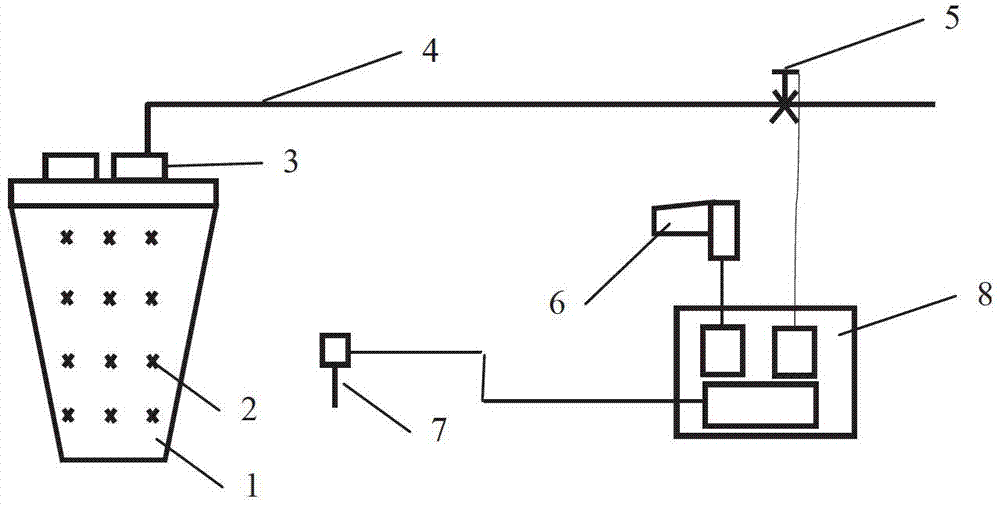

Method and device for automatically controlling argon blowing quantity for steel ladle of continuous casting machine

ActiveCN102126000AImprove purityReduce slag inclusionProgramme control in sequence/logic controllersCasting parameters measurement/indication devicesControl systemProgrammable logic controller

The invention relates to a method and a device for automatically controlling argon blowing quantity for a steel ladle of a continuous casting machine. In the method, by designing an argon blowing curve, argon quantity in the steel ladle can be effectively adjusted based on weight of molten steel in the steel ladle so as to control argon blowing quantity, thus achieving the optimum argon blowing effect. The device comprises an adjusting valve, an argon pipeline, a flow detection device, a pressure detection device and a PLC (programmable logic controller) control system, wherein, the argon pipeline is equipped with the adjusting valve, the flow detection device for gas flow detection and the pressure detection device; and the adjusting valve, the flow detection device and the pressure detection device are respectively connected with the PLC control system. The method and the device have the advantages of improving purity of the molten steel and reducing slag inclusion by a large-ladle argon blowing mode, maintaining even temperature during the casting process of the molten steel in the large ladle, preventing the molten steel from being mixed into a middle ladle owing to eddy effect in the case of low level, enhancing argon blowing effect and reducing temperature loss.

Owner:ANGANG STEEL CO LTD

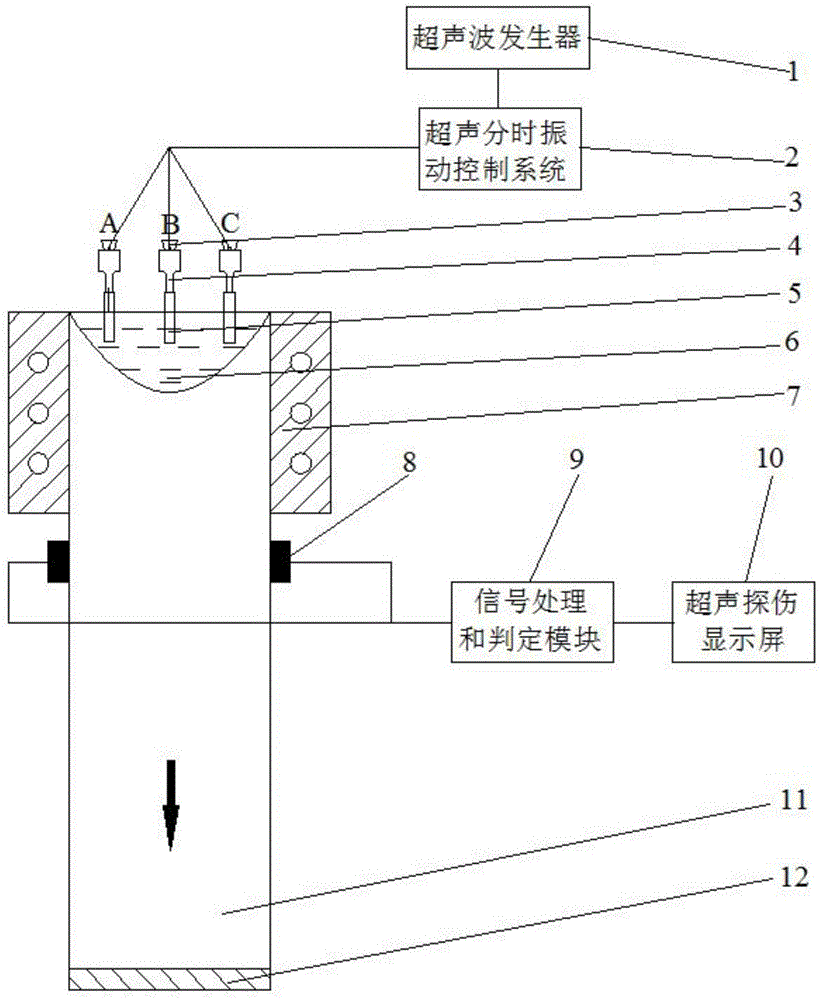

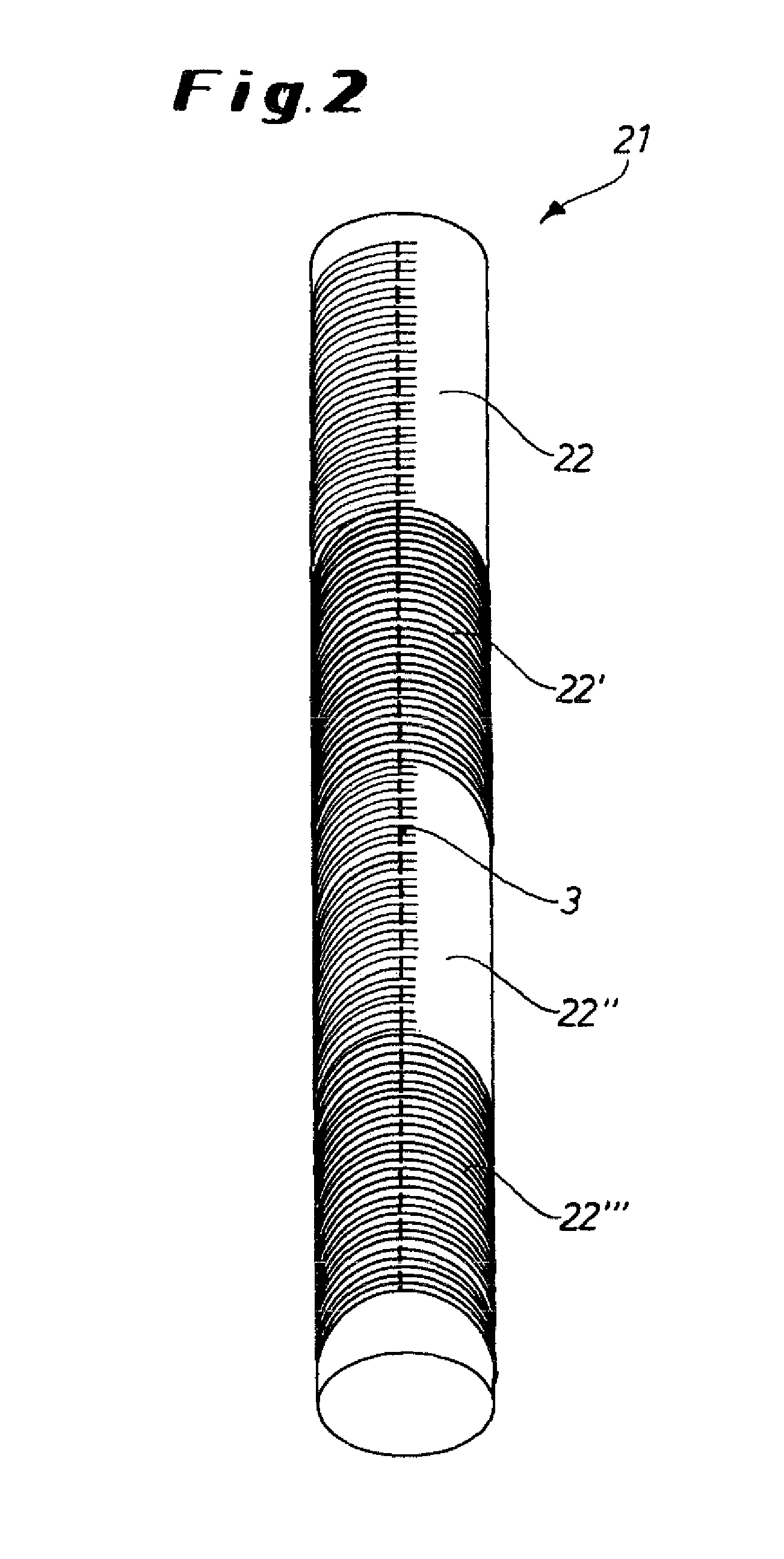

Magnesium alloy bar power ultrasonic semi-continuous casting and flaw detection device and method

InactiveCN105522131ALow costImprove efficiencyCasting parameters measurement/indication devicesVibration controlTransformer

The invention provides a magnesium alloy bar power ultrasonic semi-continuous casting and flaw detection device and method. The magnesium alloy bar power ultrasonic semi-continuous casting and flaw detection device comprises a power ultrasonic generating device, an ultrasonic flaw detection processing system and a vertical direct water-cooling semi-continuous casting machine. The power ultrasonic generating device comprises an ultrasonic generator, an ultrasonic time-sharing vibration control system and three ultrasonic transmitting assemblies with the same specification. Each ultrasonic transmitting assembly comprises an ultrasonic transducer, an ultrasonic amplitude transformer and a tool head. The ultrasonic flaw detection processing system comprises an ultrasonic receiving sensor, a signal processing and determination module and an ultrasonic flaw detection display screen. The ultrasonic transmitting assemblies are inserted into molten magnesium alloy at the same time, and controlled by the ultrasonic time-sharing vibration control system to transmit power ultrasound at intervals, and the molten magnesium alloy solidifies under the action of an ultrasonic field so that fine-grain cast bars can be obtained. Ultrasonic waves transmitted by the ultrasonic transmitting assemblies serve as a signal source, the waveforms of the ultrasonic waves are processed through the ultrasonic receiving sensor and the signal processing and determination module, and the internal flaw conditions of the cast bars are determined according to prompts on the ultrasonic flaw detection display screen.

Owner:JILIN UNIV

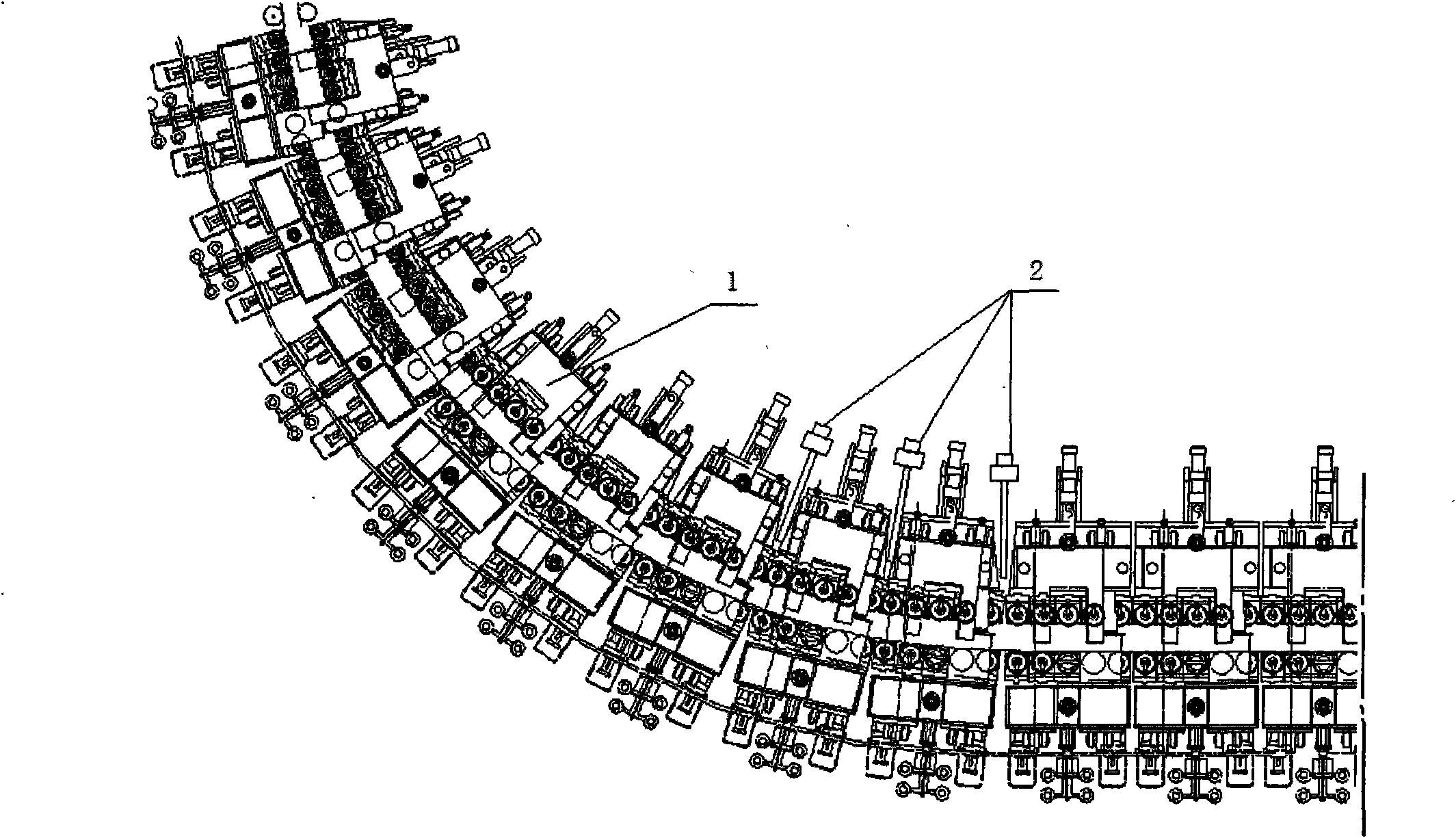

Method and device for measuring thickness of continuous casting shell

ActiveCN101992281AReasonable designGood measurement effectCasting parameters measurement/indication devicesShootEngineering

The invention relates to a method and a device for measuring the thickness of a continuous casting shell. Shoot nails are centralized on a set position by using at least two continuously arranged shoot nail guns, accurately calculating and controlling the shooting time every time so as to accurately measure the thickness of the casting shell at any time after analysis. The invention has the advantages of high measurement precision, simple and convenient operation, simple structure, convenient production, reasonable design in the measurement method and accurate analysis result. The thickness of a condensed casting shell of an actual casting blank can be followed and measured, and the measurement result provides sufficient basis for casting process personnel to analyze the production and the quality. The invention is particularly suitable for measuring the thickness of the casting shell of an arc-shaped continuous casting machine.

Owner:ANGANG STEEL CO LTD

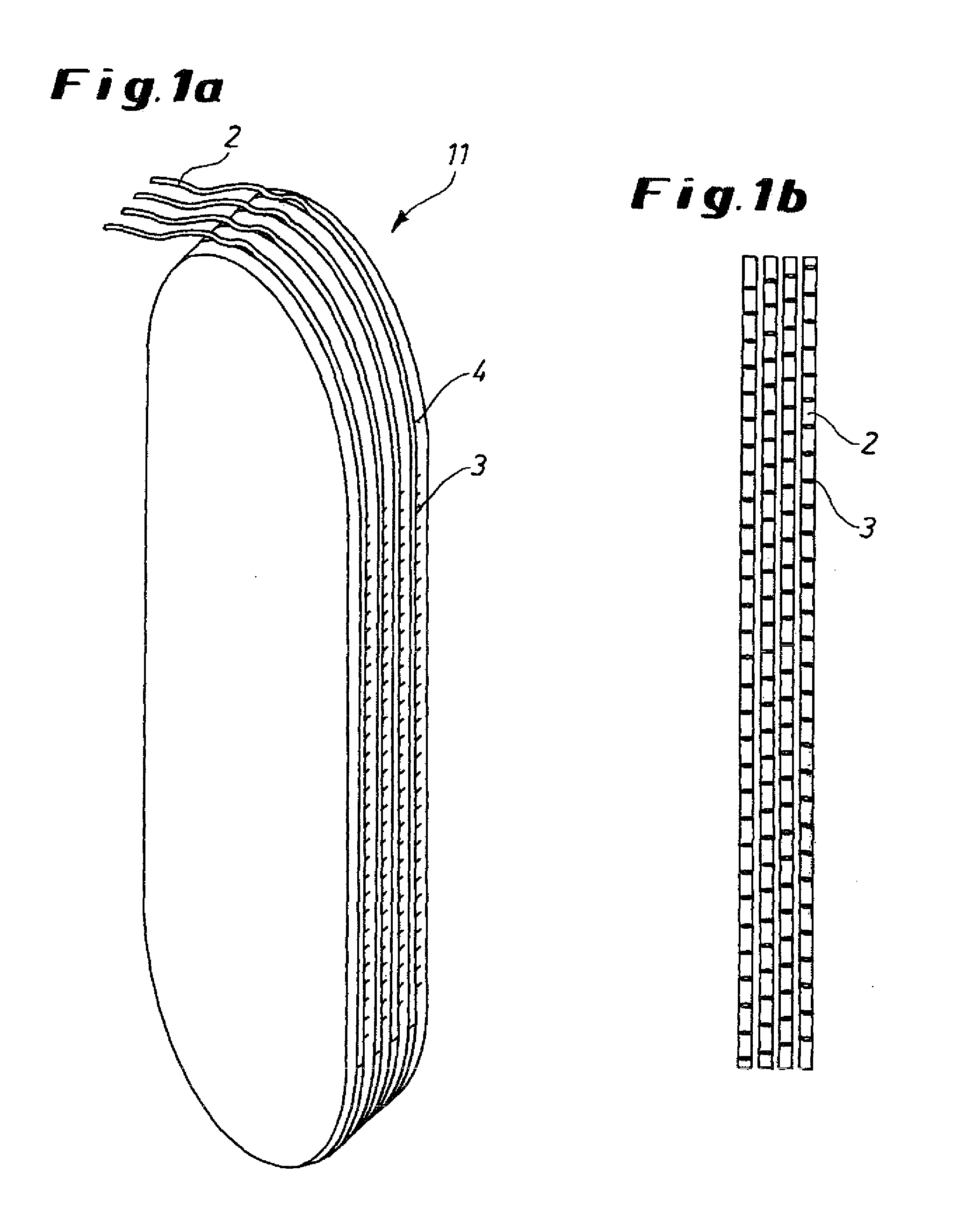

Continuous casting sealing method

A casting furnace for manufacturing a metal casting comprises an interior chamber and a secondary chamber through which the metal casting passes from the interior chamber into external atmosphere. A seal along the secondary chamber surrounds and seals against the metal casting to separate the interior chamber from the external atmosphere in a manner which allows for an extended period of continuous casting. A force producing mechanism typically forces the seal against the metal casting. Multiple seals may be used sequentially to increase the duration of the sealing capability and the continuous casting process.

Owner:HOWMET AEROSPACE INC

Continuous casting sealing method

ActiveUS20100282427A1Easy to moveCasting safety devicesMoulding machine componentsInterior spaceMaterials science

A casting furnace for manufacturing a metal casting comprises an interior chamber and a secondary chamber through which the metal casting passes from the interior chamber into external atmosphere. A seal along the secondary chamber surrounds and seals against the metal casting to separate the interior chamber from the external atmosphere in a manner which allows for an extended period of continuous casting. A force producing mechanism typically forces the seal against the metal casting. Multiple seals may be used sequentially to increase the duration of the sealing capability and the continuous casting process.

Owner:HOWMET AEROSPACE INC

Method and device for sealing a tap hole in metallurgical containers

InactiveUS6471911B1High puritySimple and inexpensiveMelt-holding vesselsMolten metal pouring equipmentsCardboardMaterials science

In a method for sealing a tap opening in a metallurgical container a plug with a plug sleeve and a refractory flowable material is provided having a metal rod or pipe surrounded by a protective pipe connected thereto. The plug sleeve and the protective pipe are made of a material resistant to a molten mass of metal in the metallurgical container only for a short period of time. The material is a temporarily heat-insulating material which cokes within the molten mass of metal and is cardboard or wood. The time of introduction of the plug sleeve is controlled based on measured parameters of the molten mass. The plug is introduced into the tap opening by guiding the plug with the metal rod or pipe through the molten mass in the metallurgical container. The plug sleeve changes by temperature action of the molten mass of metal such that the flowable material is distributed in the tap opening and seals the tap opening. The tap opening is then closed from the exterior of the metallurgical container and the plug sleeve in the tap opening as well as the protective pipe are coked and destroyed.

Owner:SMS DEMAG AG

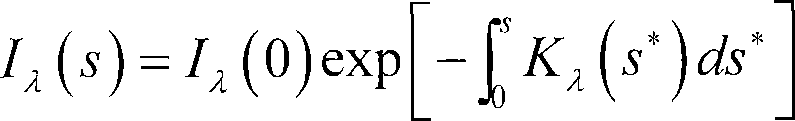

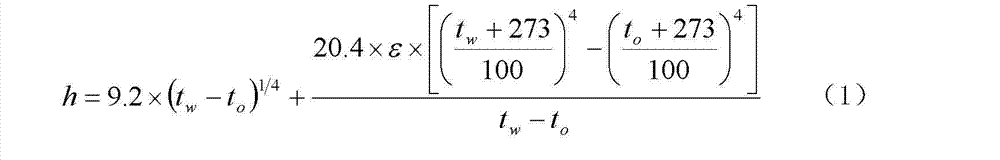

Method for measuring surface temperature of high-temperature casting billet within water fog medium

InactiveCN101162171AAccurate temperatureTemperature correctionRadiation pyrometryParticle suspension analysisFront edgeMaterials science

The present invention discloses a method for measuring the surface temperature of a high-temperature casting blank in water-fog medium; the water-fog concentration of the surface of the high-temperature casting blank is measured and transmitted to a remote computer through an air water-fog concentration sensor; the attenuation coefficient K lambda of water-fog medium to radiant energy in the water-fog concentration is gained by the remote computer through the relation curve between the attenuation coefficients of the water-fog medium and the radiant energy; temperature data tested by a thermodetector are modified by the attenuation coefficient K lambda and the emissivity of filam on the surface of the casting blank and the real temperature of the surface of the casting blank in the water-fog medium can be measured in real-time; the gain of accurate temperature has an important support on the application of continuous casting front-edge technology such as electromagnetic mixing, secondary cooling dynamic control and so on in dynamic slight press and has very important significance on improving the quality of casting blank and the whole level of continuous casting.

Owner:CHONGQING UNIV

Casting level measurement in a mold by means of a fiber optic measuring method

InactiveUS20110167905A1Increase the number ofHigh densityMachines/enginesLubrication indication devicesFiberLevel measurement

The invention provides a method for the cast level measurement in a mold by means of sensors for fiber optic temperature detection, which are disposed in the mold copper plate at the height of the casting level. The invention further comprises respective sensors. Fiber optic cables are disposed in said sensors, which allow simple, reliable and highly locally resolved temperature monitoring at the height of the casting level by means of a suitable temperature analysis system. By means of the temperatures determined by the sensors, a conclusion can be made as to the exact height of the casting level. Furthermore, the shape of the casting level shaft may be determined by means of which further parameters of the casting process become accessible.

Owner:SMS DEMAG AG

Smelting and casting method and casting device of titanium-based amorphous composite material

ActiveCN103834822AFast fillAvoid pollutionCasting parameters measurement/indication devicesAlloyElectromagnetic induction

The invention discloses a smelting and casting method and a casting device of a titanium-based amorphous composite material. The smelting and casting method has the advantages that the force effect in the electromagnetic induction principle is utilized, alloy in a crucible is suspended in the air for smelting, so that the pollution caused by contact with the crucible is avoided and the control for the alloy heating state is realized; when the smelting process is finished, a heating power supply is switched off, an electromagnetic valve for suction casting or spray casting is opened, so that the rapid mold-filling of alloy solution is realized; in the spray-casting process, the control to the spray-casting speed is realized by changing the level of the air pressure in a gas storage tank, and further the amorphous composite material with different microscopic structures is prepared by controlling the solidification process; the defects in the prior art are overcome, the large-size titanium-based amorphous composite material is obtained by integrating the prior art, the stable control of the process to the organization structure is realized by adjusting process parameters such as temperature, temperature holding time, circular heating times and casting speed, and an ideal optimized design structure is obtained.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Foundry mold handling system with multiple dump outputs and method

ActiveUS20050109478A1Problem can be addressedPig casting plantsCasting safety devicesFoundryControl system

A mold handling system for carrying and transporting sand molds comprises a mold handling conveyor with multiple mold exits to provide different outputs for the sand molds. The mold handling system may include flags which can be used to mark selected molds to segregate the sand molds into different groups. A control system responds to flag sensors and tracks the molds to selectively control output of sand molds through the mold exits. Methods of handling sand molds using a mold handling system are also disclosed.

Owner:HUNTER AUTOMATED MACHINERY

Method and device for rapidly and accurately detecting and controlling baking temperature of ladle

ActiveCN102886500AImprove temperature measurement environmentExtended service lifeMelt-holding vesselsRadiation pyrometryProportion integration differentiationFeedback controller

The invention relates to the temperature measurement field of a high temperature furnace in steel and colored metallurgy industry, in particular to a method and a device for rapidly and accurately detecting and controlling the baking temperature of a ladle. The method and the device are characterized in that a dotty temperature value of the outer surface of the ladle is measured by an infrared temperature measurement instrument, the temperature value of each point of the inner surface of the ladle is calculated by a heat transfer model, the transient temperatures of the inner surface of the ladle at the different depths are calculated by the temperature of the outer surface of the ladle and a convection radiation heat transfer coefficient, a baking air-fuel ratio is adjusted by a proportion integration differentiation (PID) temperature feedback controller so as to realize the automatic baking of the ladle; when the transient temperatures in the ladle reach target values, a heat insulation program is automatically transferred. Compared with the previous technology, the method and the device provided by the invention have beneficial effects that the structure is compact, simple and reasonable, and easy to operate, the temperature measurement environment of the ladle baking is greatly improved, and the service life of the temperature measurement instrument is lengthened, and simultaneously, the accuracy of the temperature measurement is improved, so that a basic data is provided for the accuracy control of thermal regulation of the ladle baking.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

Apparatus for continuous strip casting

InactiveUS20100000705A1Promote oxidationImprove scaleCasting safety devicesMould controlling devicesStrip steelEngineering

An apparatus for continuously casting thin strip includes a caster having a pair of casting rolls having a nip there between capable of delivering cast strip downwardly from the nip and an first enclosure capable of forming a protective atmosphere into which the strip can be formed in loop to extend over a plurality of rollers into pinch rolls with the strip having a strain of less than 0.4%, which may be provided by a plurality of rollers at entry of the strip into the pinch rolls to carry the strip into the pinch rolls, with at least a first entry roller having a diameter between 200 and 650 millimeters and being below a majority of other rollers.

Owner:NUCOR CORP

Alloy casting apparatuses and chalcogenide compound synthesis methods

A chalcogenide compound synthesis method includes homogeneously mixing solid particles and, during the mixing, imparting kinetic energy to the particle mixture, heating the particle mixture, alloying the elements, and forming alloyed particles containing the compound. Another chalcogenide compound synthesis method includes, under an inert atmosphere, melting the particle mixture in a heating vessel, removing the melt from the heating vessel, placing the melt in a quenching vessel, and solidifying the melt. The solidified melt is reduced to alloyed particles containing the compound. An alloy casting apparatus includes an enclosure, a heating vessel, a flow controller, a collection pan and an actively cooled quench plate. The heating vessel has a bottom-pouring orifice and a pour actuator. The flow controller operates the pour actuator from outside the enclosure. The quench plate is positioned above a bottom of the collection pan and below the bottom-pouring orifice.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com