Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about "Cellulosic sausage casings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fibre-Reinforced Film, Process for Producing the Same, and Use for Food Packaging

InactiveUS20100227164A1Excellently suitableSynthetic resin layered productsNon-macromolecular organic additionFiberPolyol

The present invention is directed to a fibre-reinforced film comprising a paper-reinforced alginate film containing polyhydric alcohol. Further, the invention is directed to a process for producing the fibre-reinforced film, and the use thereof for packaging food products, particularly meat products to be cooked and smoked.

Owner:VISKOTEEPAK BELGIUM NV

Flavor release casing

InactiveUS20060057258A1Simple preparation processUnique flavorThermoplastic sausage casingsMonolayer sausage casingsFlavouring agentFood flavor

The present invention relates to shirred, nonfibrous casings internally coated with compositions of concentrated oil-based natural flavorants which transfer to foodstuffs, such as sausage meats, encased during cooking, resulting in foodstuffs flavored by the internal casing coating.

Owner:VISCASE CORP

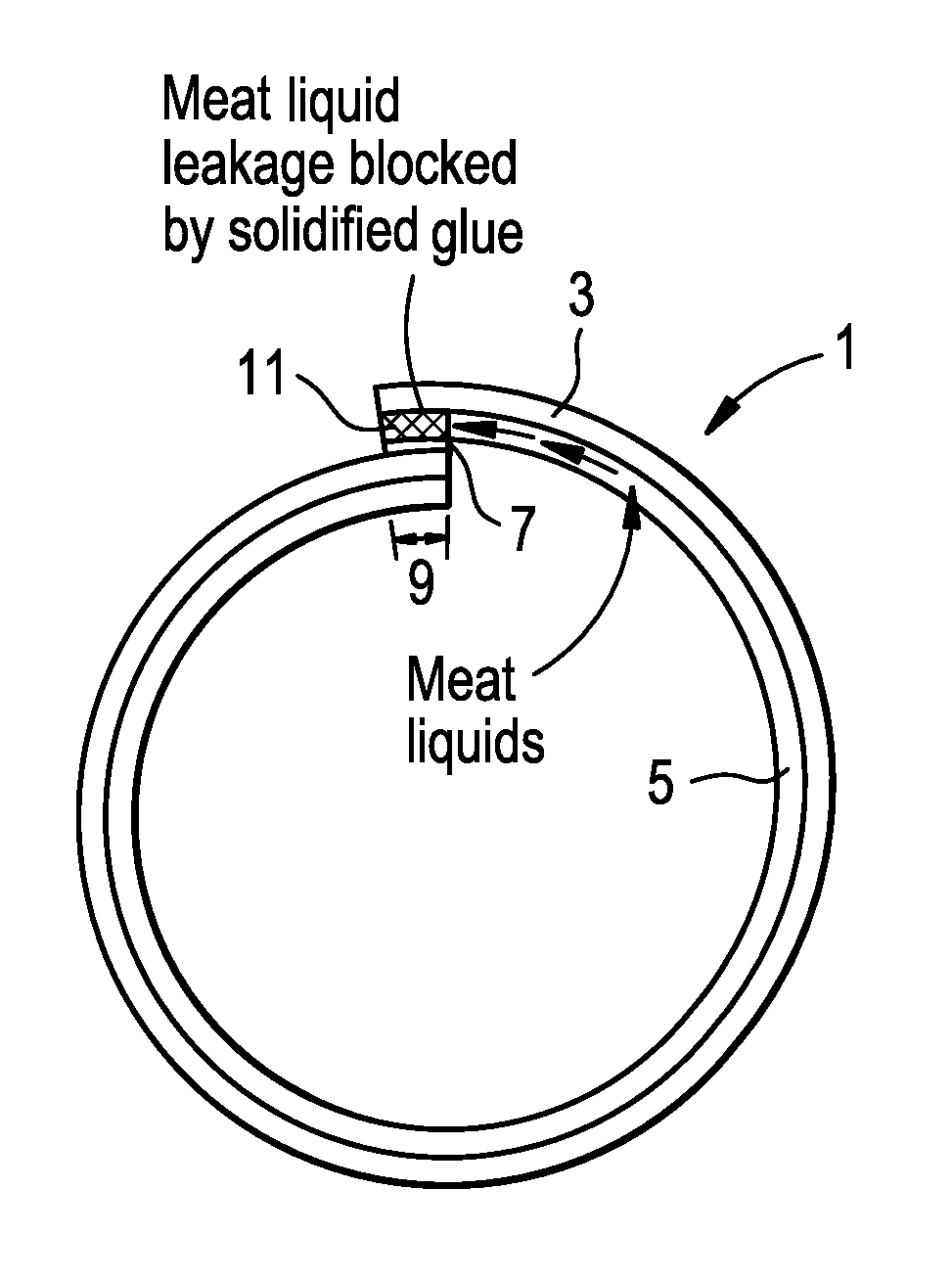

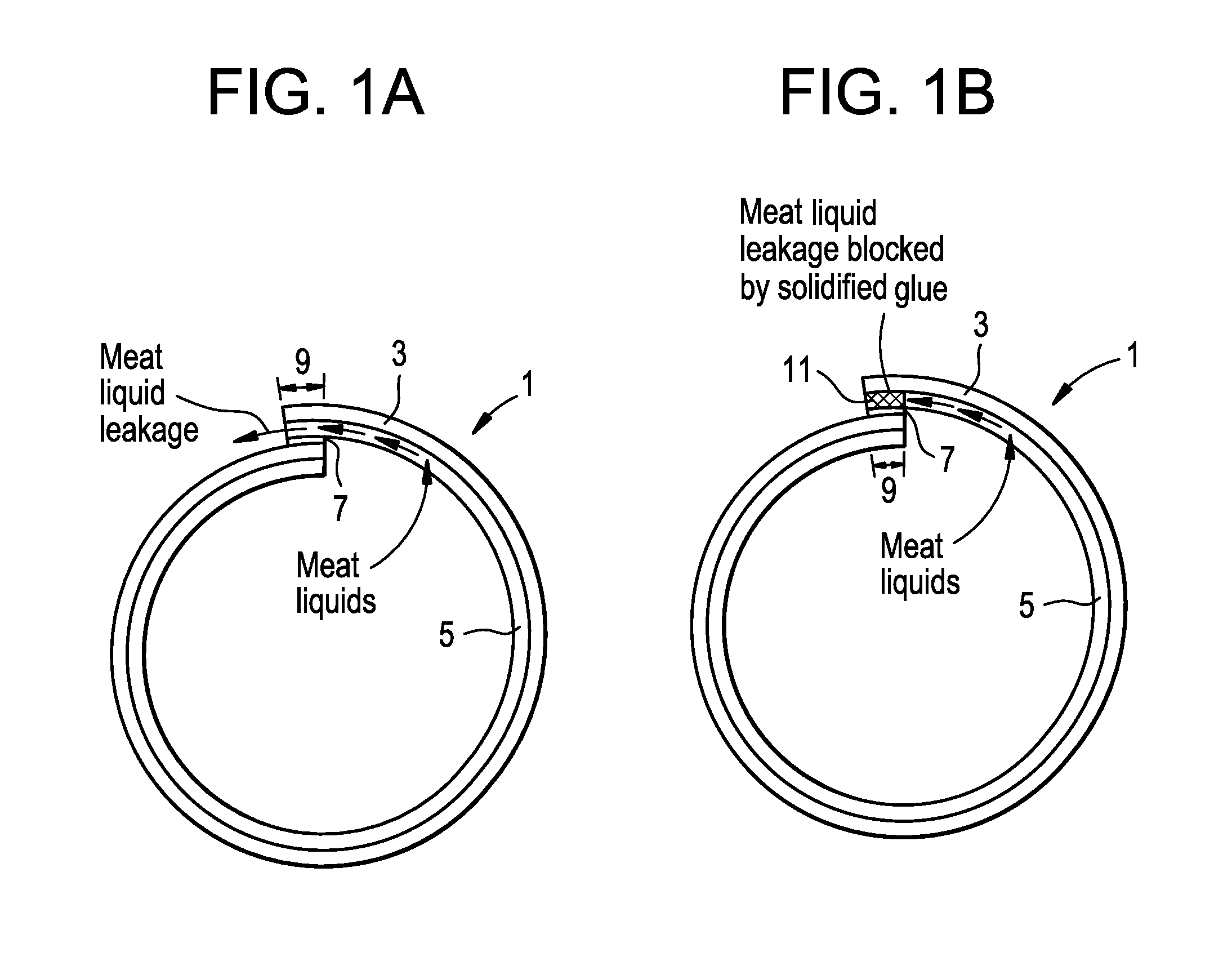

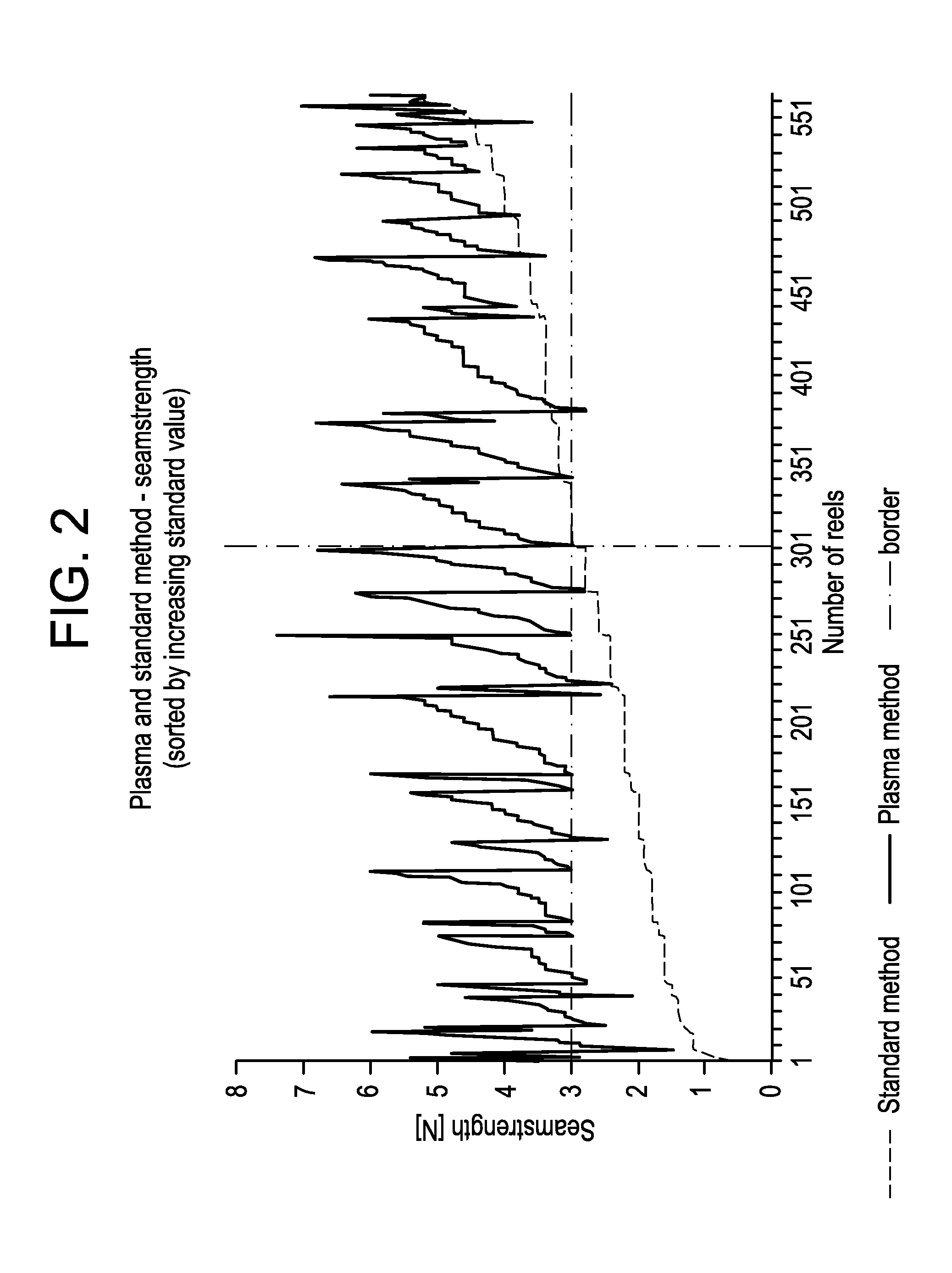

Tubular Food Casing Having a Smoke-permeable Glued Seam

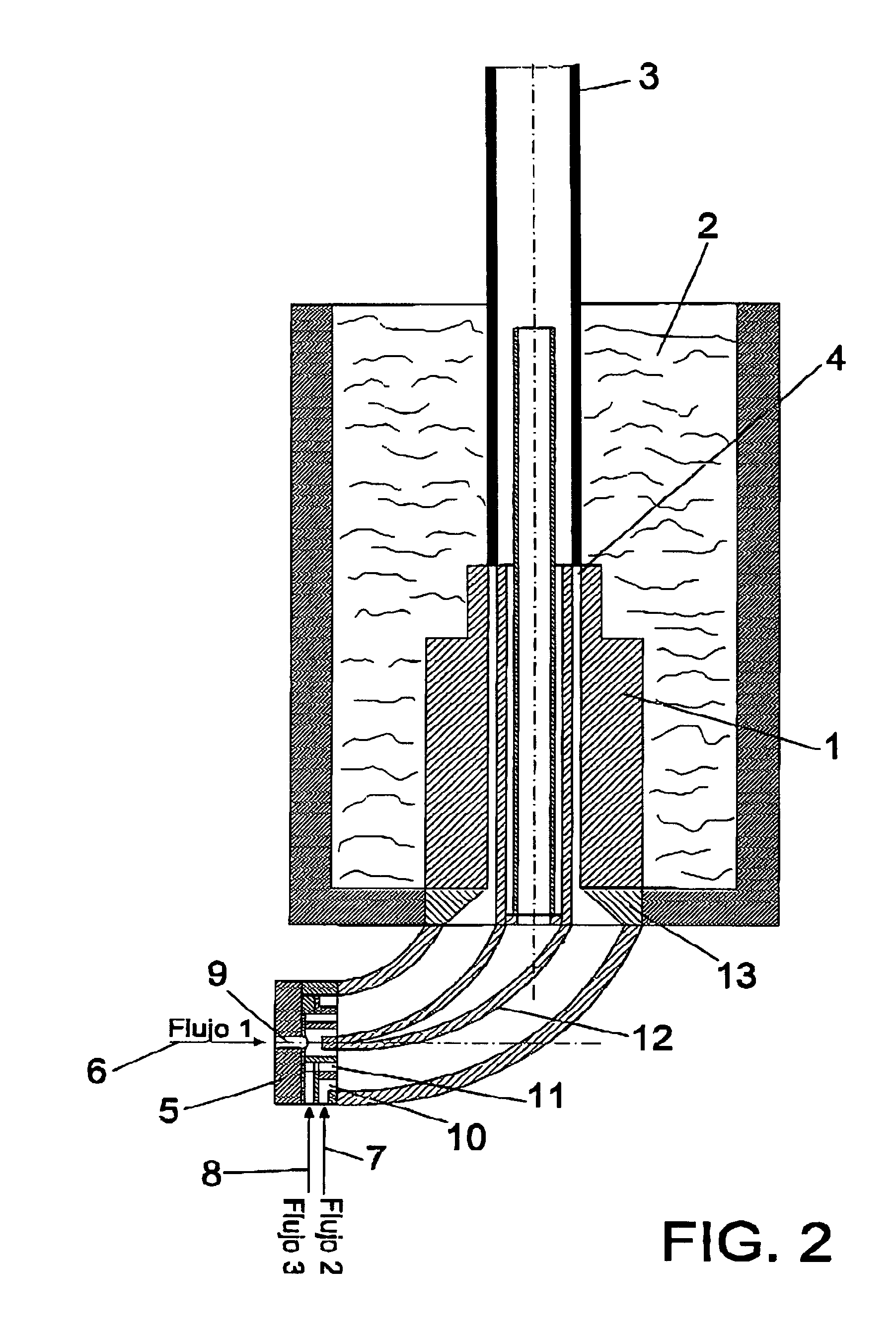

A food casing is described with or without flat reinforcement insert and a smoke-permeable costing, preferably of protein, cellulose or acrylic. The insert is preferably a consolidated nonwoven or spunbonded nonwoven, a woven fabric, loop-formingly knitted fabric, laid fabric or loop-drawingly knitted fabric. The flat strip is glued to form a tube using a smoke-permeable gluing medium, preferably blood, plasma, protein, or other proteins. The food casing is preferably used as artificial sausage casing or cheese casing.

Owner:KALLE AG

Additive delivery laminate and packaging article comprising same

InactiveUS20060051465A1Ready-for-oven doughsThermoplastic sausage casingsPolymer scienceWater insoluble

An additive delivery laminate is suitable for packaging a food product which is cooked in the package, with an additive transferring from the laminate to the food product. The additive delivery laminate has a substrate and an additive delivery layer. The additive delivery layer contains a water-insoluble thermoplastic polymer, a polymer toughening agent, and additive granules containing a colorant, flavorant, and / or odorant. The polymer toughening agent is present in a blend with the water-insoluble thermoplastic polymer. Polyisobutylene is a preferred water-insoluble thermoplastic polymer, and hydrogenated wood rosin is a preferred polymer toughening agent. The polymer toughening agent decreases the tendency of the water-insoluble thermoplastic polymer to form legs or transfer to the food product upon stripping the laminate from the food product after cooking and transfer to the additive to the food product.

Owner:CRYOVAC ILLC

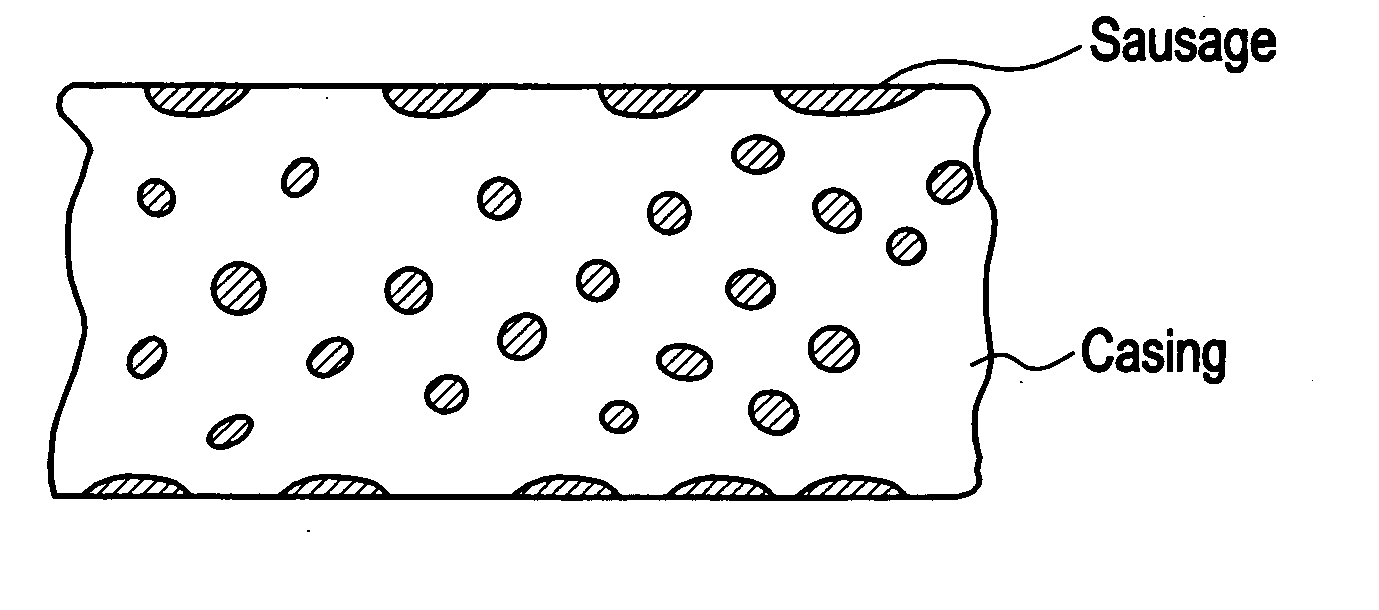

Edible cellulosic casings and compositions, and methods of formation

PendingUS20220132871A1Climate change adaptationCellulosic sausage casingsPolymer sciencePolysaccharide

Edible cellulosic casings comprise cellulose and at least one modifier comprising at least one polysaccharide. The at least one modifier is substantially evenly distributed with the cellulose throughout a casing material of the edible cellulosic casing. A composition useful for an edible cellulosic casing comprises regenerated cellulose and at least one non-cellulose hydrophilic polysaccharide dispersed in the regenerated cellulose. The regenerated cellulose composes at least 50 wt. % of the composition. A method for forming an edible cellulosic casing comprises forming a cellulose solution and forming a modifier solution comprising at least one polysaccharide dissolved therein. The modifier and cellulose solutions are mixed to form a mixture from which the edible cellulosic casing is made. Edible cellulosic casings, as disclosed, may be consumed along with an encased foodstuff or other material for ingestion.

Owner:VISCASE CORP

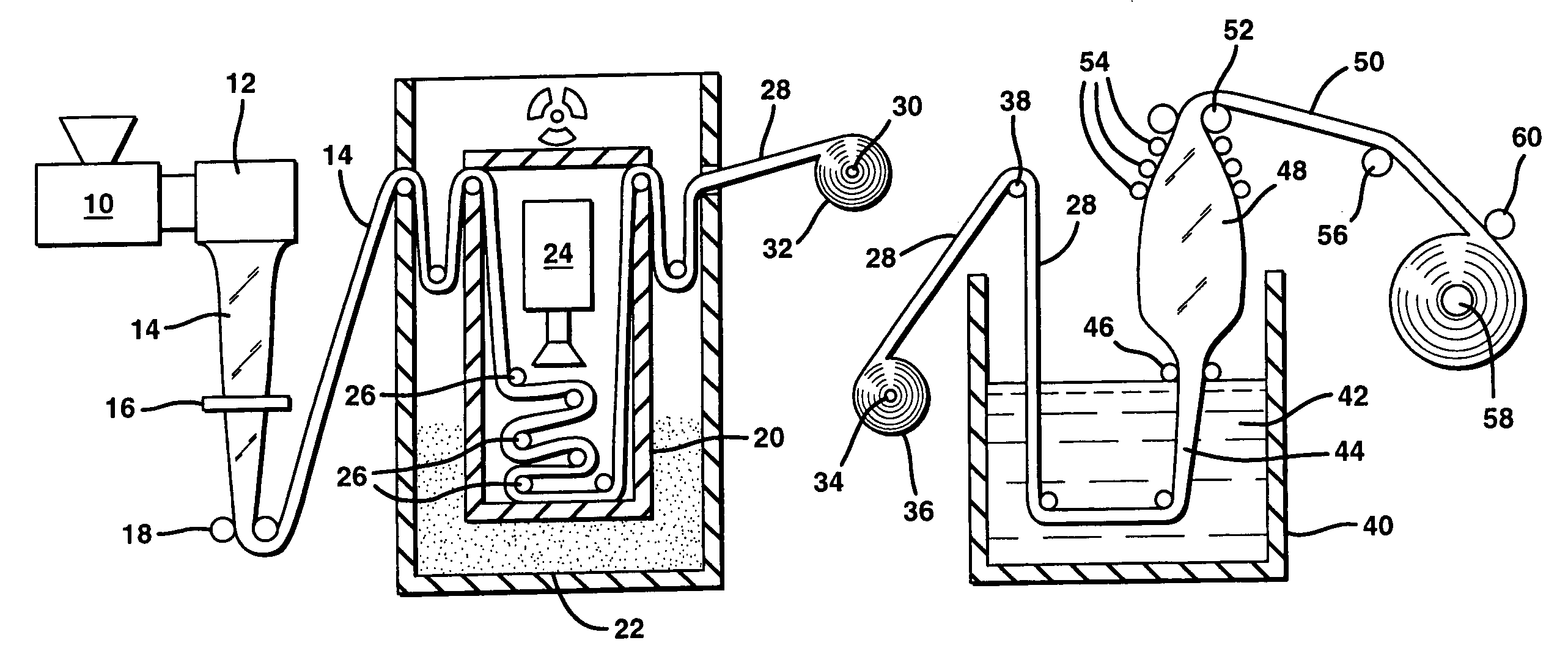

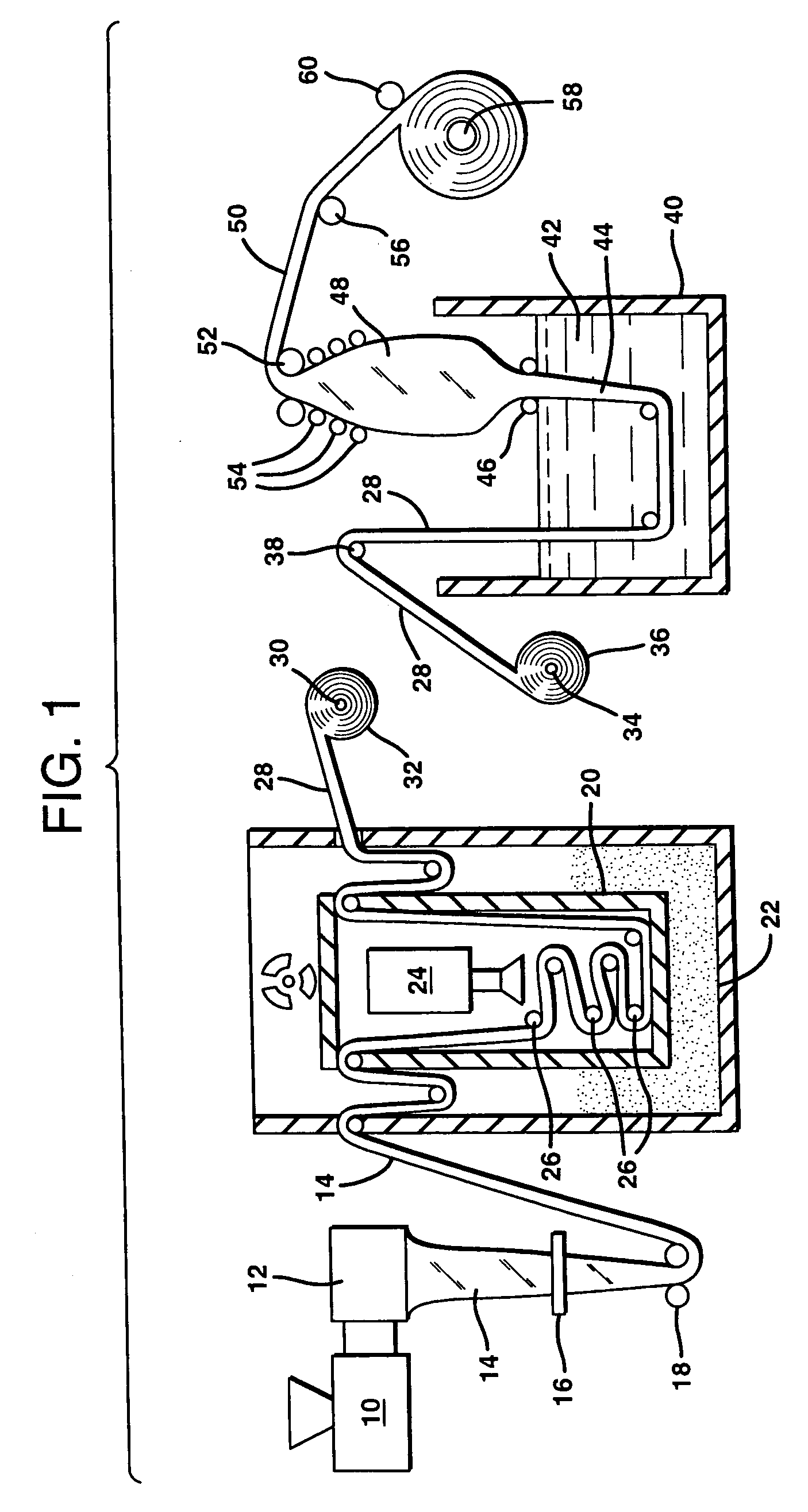

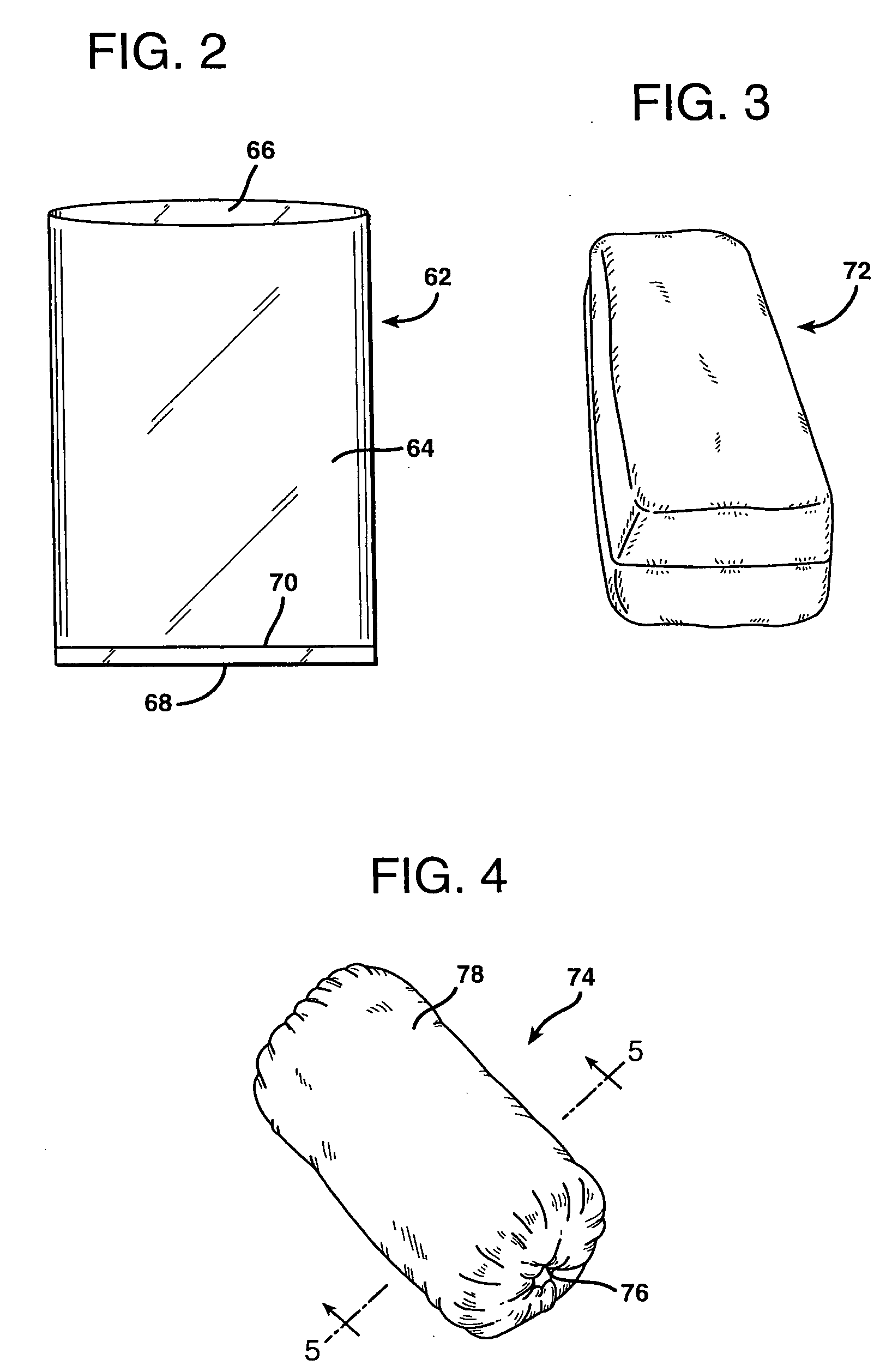

Process For Producing A Composite Food Casing

InactiveUS20100255230A1Avoid entanglementThermoplastic sausage casingsMultilayer sausage casingsPulp and paper industry

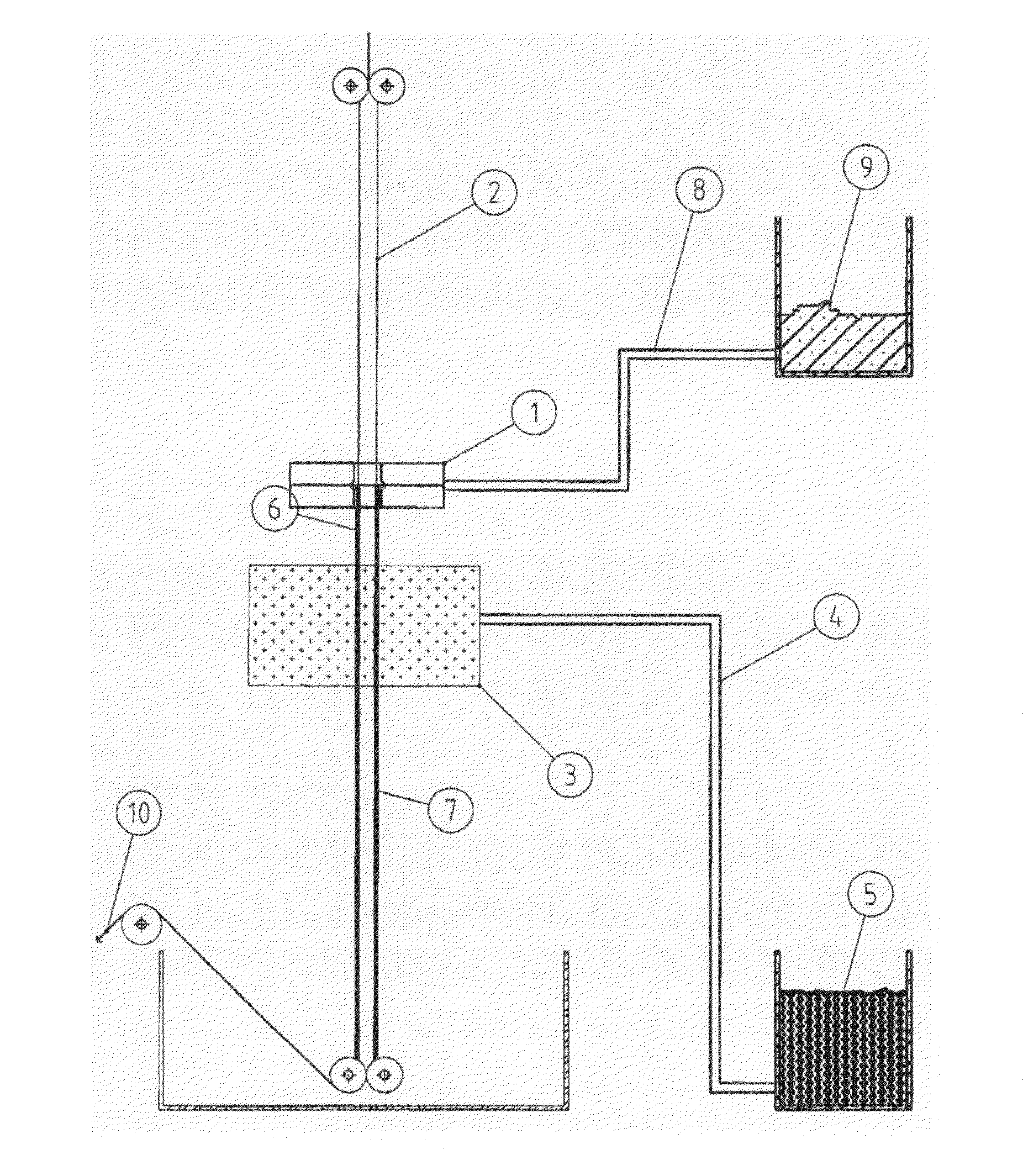

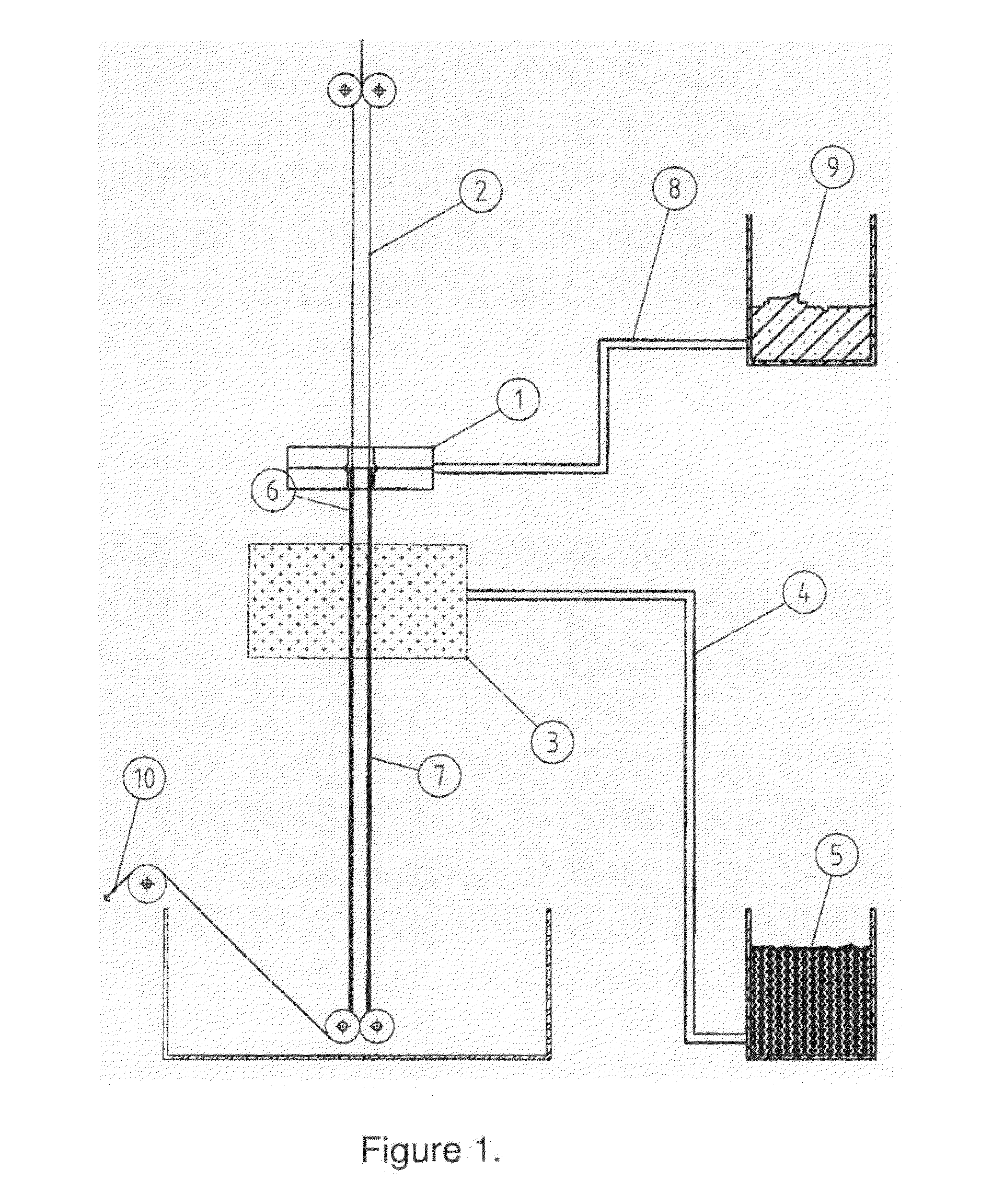

The invention relates to a process for producing a composite casing shirred to a caterpillar, said process comprising steps of pulling an outer casing over the inner casing, and optionally a net between the inner and outer casings, or over the outer casing, and finally shining the composite casing thus obtained to give a compact tube, which is cut to yield caterpillars.

Owner:VISKOTEEPAK BELGIUM NV

Food Casings with Modified Adhesion and Release Properties and Methods of Manufacture

ActiveUS20120052223A1Improve adhesionFacilitated releaseMultilayer sausage casingsPretreated surfacesFiberWet strength

The invention relates to a multilayer fibrous reinforced food casing comprising a fibrous reinforced layer located between an inside layer and an outer layer; the inside layer comprising an adhesion promoter comprising one or more of protein coagulants, proteins, glyoxals, glutaraldehyde, caseins, gelatines, wet strengths resins and any mixtures thereof; and the outer layer comprising a peeling agent comprising one or more of polyalkylene glycols and any mixtures thereof or the inside layer comprising a peeling agent comprising one or more of polyalkylene glycols and any mixtures thereof or the outer layer and the inside layer comprising a peeling agent comprising one or more of polyalkylene glycols and any mixtures thereof.

Owner:VISKOTEEPAK BELGIUM NV

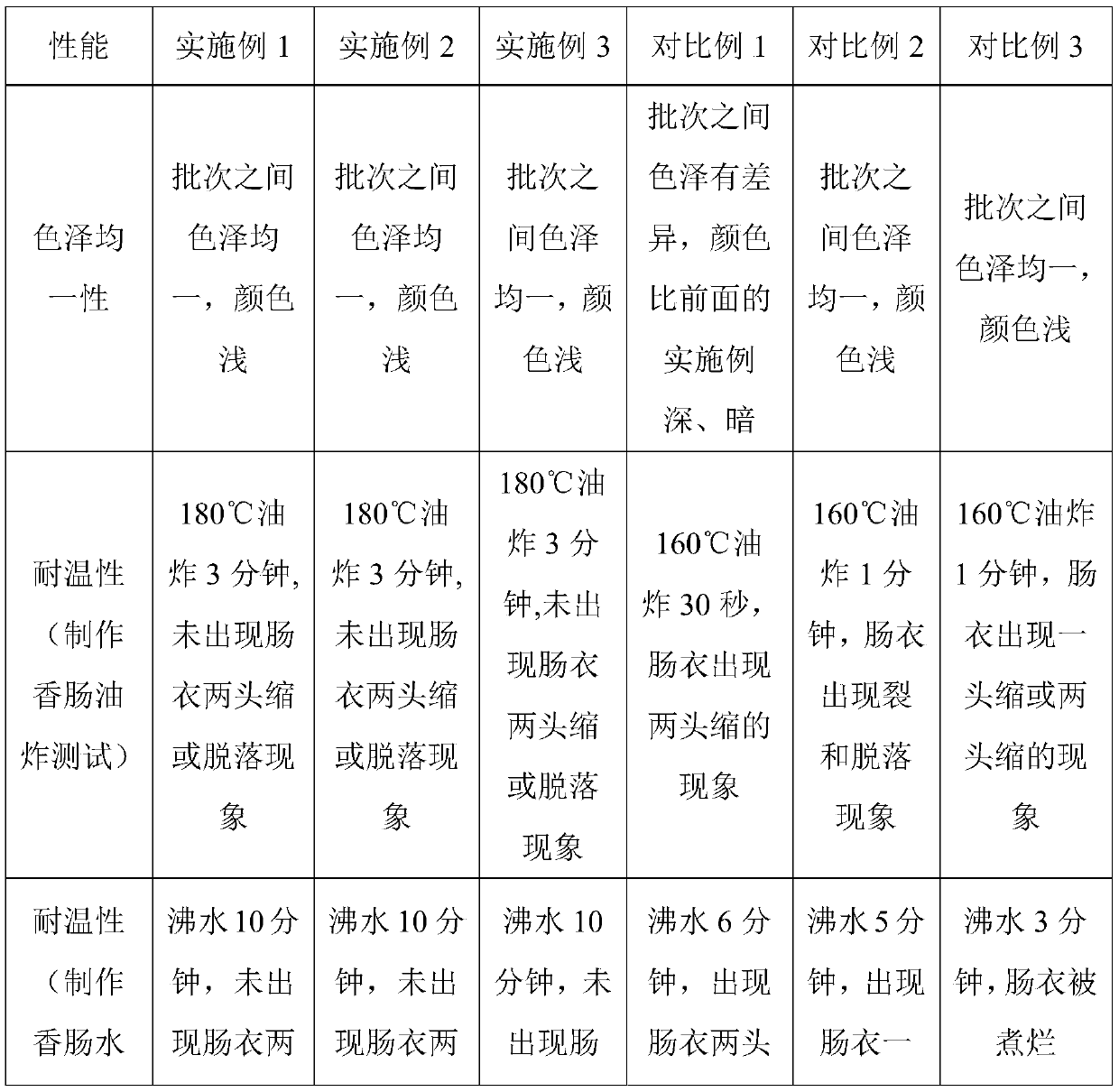

Production process of boiled/fried collagen casing

ActiveCN110140747AIncrease the degree of cross-linkingWeave evenlyTextile casingsCellulosic sausage casingsFiberPolyol

The invention relates to the technical field of casing production, in particular to a production process of a boiled / fried collagen casing. In the process of extracting collagen fibers, small molecular polyols, a strong oxidant and ferric ions are added into a semi-finished product after ash washing to carry out pretreatment, and then acidification is carried out. The method performs pretreatmenton the semi-finished product after ash washing, increases the crosslinking degree in the collagen casing; a collagen group is obtained by adding proper auxiliary materials and collagen fibers; the casing blowing process is improved by optimizing the process parameters and adjusting the process steps; and the crosslinking further occurs among collagen molecules and in the molecules by optimizing the technological parameters of a sleeve shrinkage curing process. The process is simple and feasible; the prepared casing has good temperature resistance, pressure resistance and mechanical properties;and the casing is uniform and beautiful in color, stable in quality and beneficial to industrial production.

Owner:山东海奥斯生物科技股份有限公司

Slip Resistant Tubular Food Casing Comprising Cellulose or Fibre-Reinforced Cellulose

InactiveUS20090081343A1Improve skid resistanceImproved grip propertyLayered productsVacuum evaporation coatingCelluloseSurface modified

The invention relates to slip resistant seamless packaging casings and more particularly to slip resistant seamless tubular food casings comprising cellulose or cellulose hydrate and having the surface modified with particles or fibres of food compatible material. The invention also relates to a method for the manufacture of said slip resistant tubular food casing having the surface modified with particles or fibres of food compatible material, and to the use of the obtained slip resistant seamless tubular food casing.

Owner:VISKOTEEPAK BELGIUM NV

Tubular Food Casing Having Glued, Permanently Elastic Longitudinal Seam

InactiveUS20080069985A1Improve mechanical propertiesUniform propertySynthetic resin layered productsPretreated surfacesFiberEngineering

A description is given of a tubular food casing having a glued, permanently elastic longitudinal seam based on a flat fibrous material coated with acrylic, collagen and / or a protein derived therefrom. The seam is generated using a reactive hotmelt glue. The glued seam is resistant to boiling for a long time and also exhibits sufficient stability thereafter. The insert is preferably a textile material, a concolidated nonwoven or spunbonded nonwoven, a woven fabric, loop-forming knitted fabric, laid fabric, loop-drawingly knitted fabric or a fiber paper. It is coated in the flat state. The coated longitudinal strip is cut into strips according to the diameter of the casing to be produced and glued using a PUR hotmelt glue to form the tube. The food casing is preferably used as artificial sausage casing or for wrapping cheese or fish.

Owner:KALLE AG

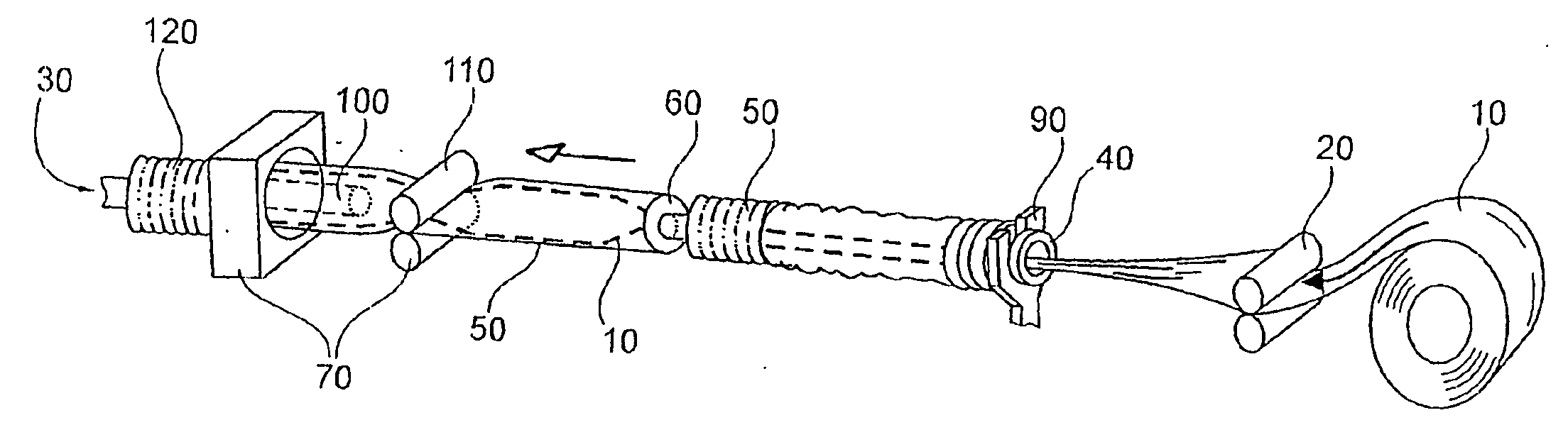

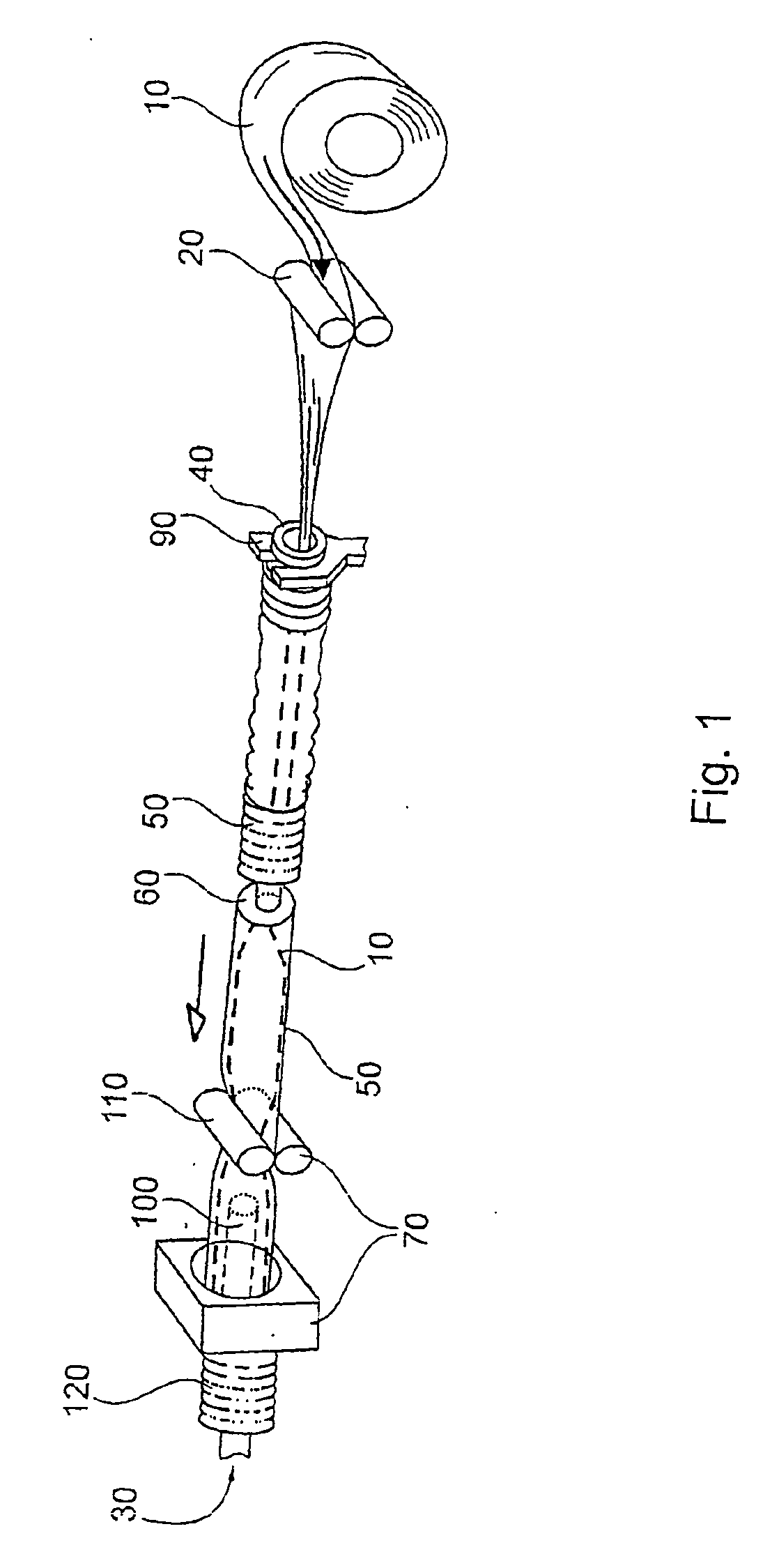

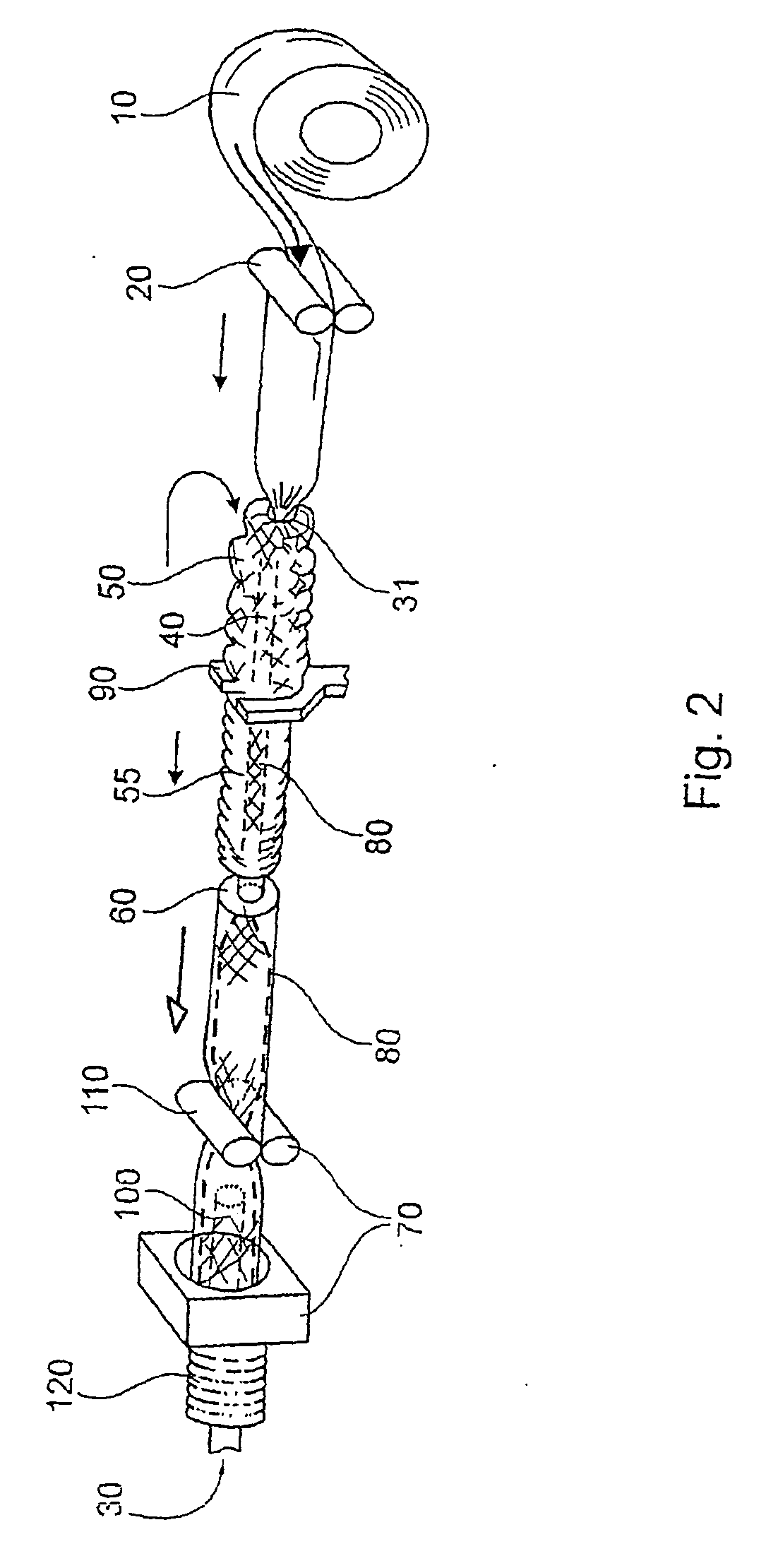

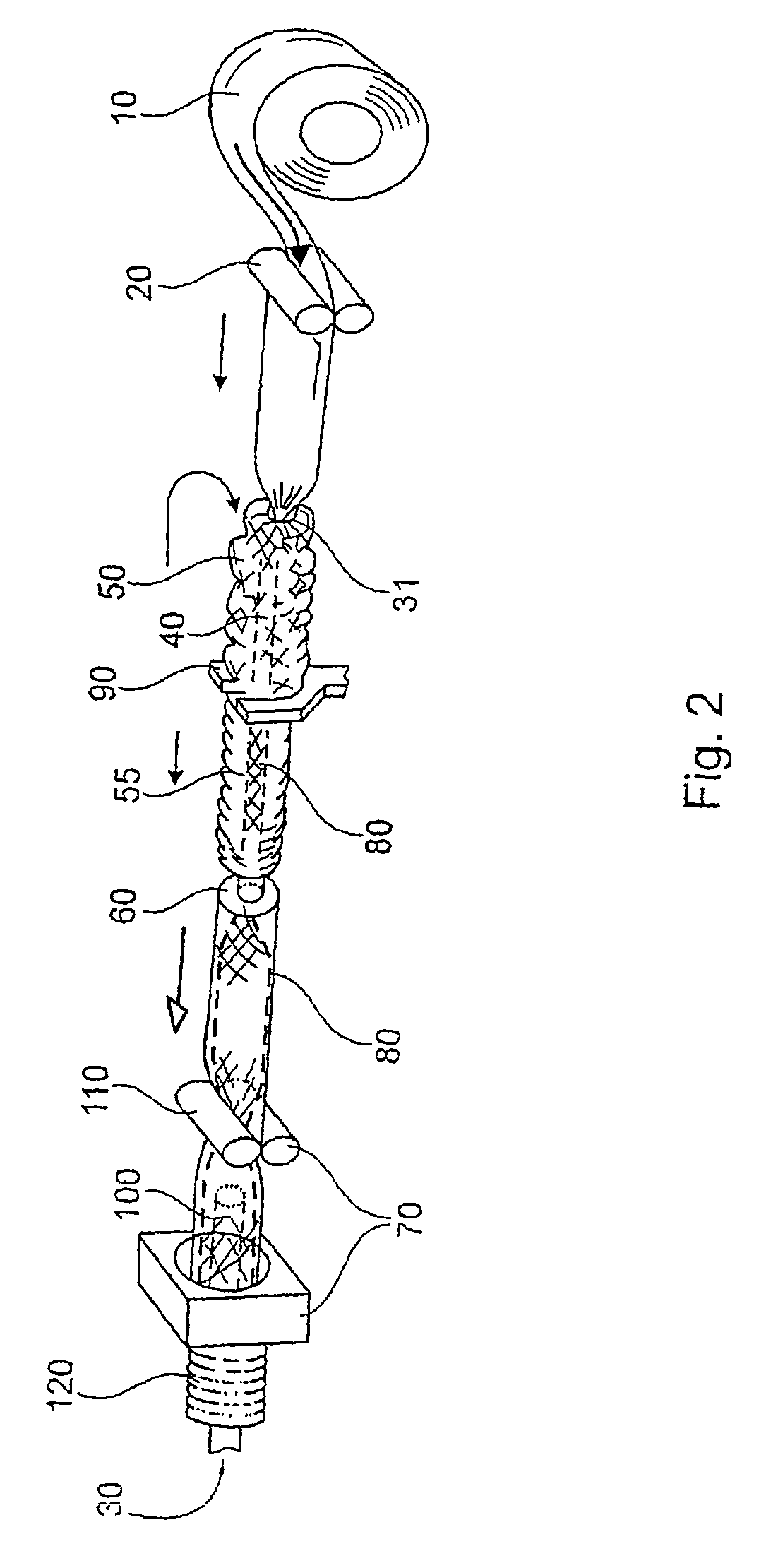

Process for producing a composite food casing

InactiveUS8226457B2Thermoplastic sausage casingsMultilayer sausage casingsPulp and paper industryCaterpillar

The invention relates to a process for producing a composite casing shirred to a caterpillar, said process comprising steps of pulling an outer casing over the inner casing, and optionally a net between the inner and outer casings, or over the outer casing, and finally shirring the composite casing thus obtained to give a compact tube, which is cut to yield caterpillars.

Owner:VISKOTEEPAK BELGIUM NV

Laser-perforated food casings based on fiber reinforced cellulose

The present invention relates to a perforated food casing based on fiber-reinforced cellulose, which includes a plurality of openings, the maximum diameter of said openings being less than 0.18 mm and the minimum diameter of the openings being such that air and water vapor trapped between the casing wall and the sausage meat are able to quickly escape.

Owner:KALLE AG

Artificial food casing comprising a traceability code, method for manufacturing and method of tracing thereof

The invention relates to an artificial food casing comprising a marking with a traceability code, wherein the marking comprises an ultraviolet-detectable component.

Owner:VISKOTEEPAK BELGIUM NV

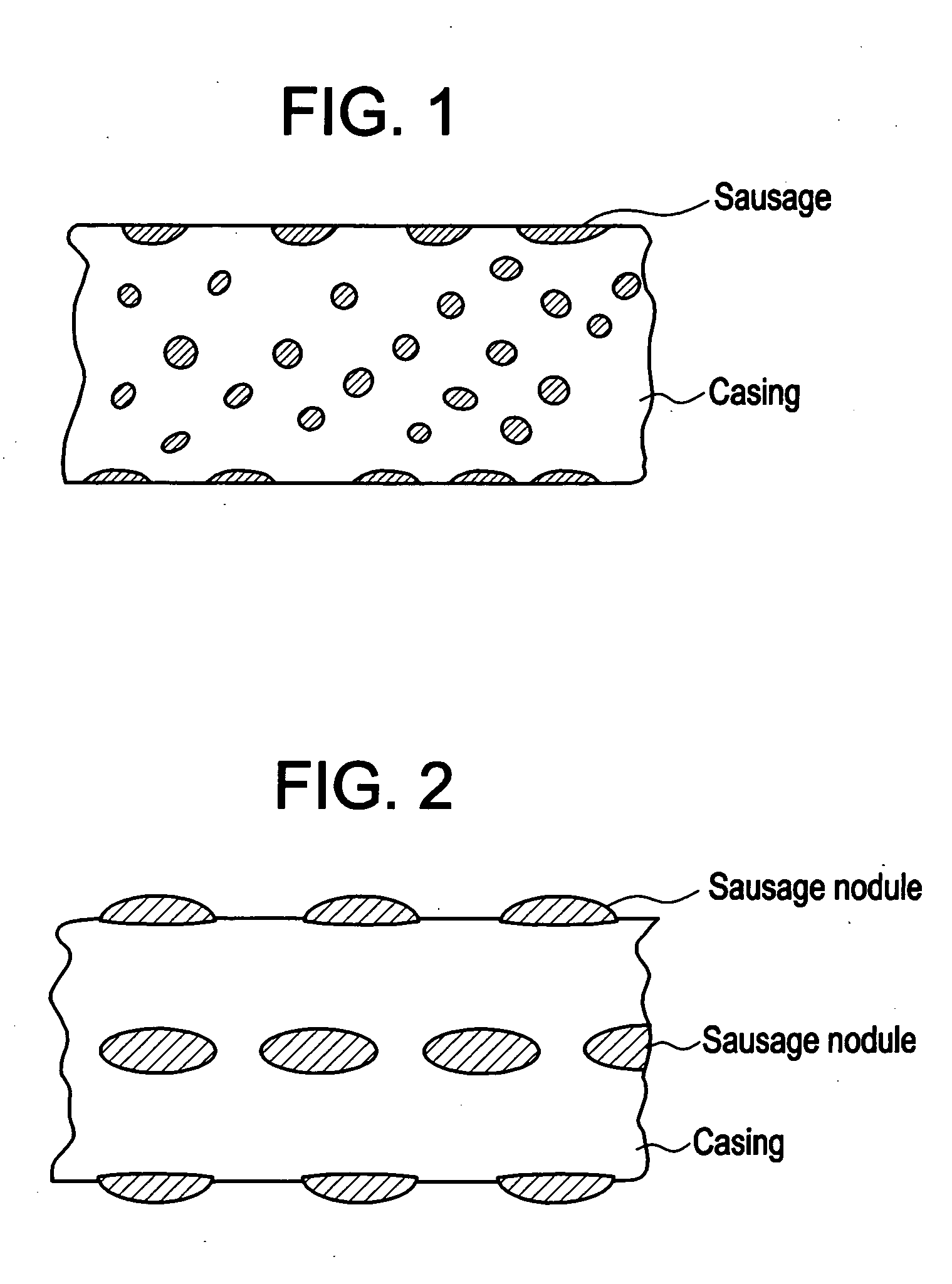

Textured non-porous barrier transfer casing

ActiveUS20200037623A1Sufficient barrier effectPreventing contamination of environmentThermoplastic sausage casingsOrganic chemistryPolymer sciencePolyolefin

The present invention provides a functional additive transferring (co)extruded thermoplastic food casing having a water vapor barrier and / or oxygen barrier effect wherein an inside surface of the thermoplastic food casing has a textured surface which forms a three-dimensional pattern of higher and lower retaining capacity for a functional additive, wherein the thermoplastic food casing having a textured surface in case of a monolayer casing or an inner layer comprising the inside surface having a textured surface in case of a multilayer casing comprises as a main component at least one thermoplastic polymer material selected from the group consisting of (co)polyamides, (co)polyolefins, (co)polyester and vinylidenchloride (co)polymers, wherein the (co)extruded thermoplastic food casing does not comprise a net and / or a material forming a net or any other three dimensional structure on its outside surface, wherein the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity is in a range of from 1 to 100 μm, wherein the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 191 to 2000 μm, provided that the thickness difference between the average thickness in the areas having higher retaining capacity and the average thickness in the areas having a lower retaining capacity is in a range of from 160 to 1950 μm and that a ratio of the average thickness of the thermoplastic food casing in the areas having a higher retaining capacity and the average thickness of the thermoplastic food casing in the areas having a lower retaining capacity is in a range of from 0.002 to 0.25.

Owner:VISCOFAN

Preparation method of nanocellulose reinforced collagen casing

InactiveCN112931578AQuality improvementImprove mechanical propertiesCellulosic sausage casingsSausage casings by extrusionFiberPolymer science

The invention discloses a preparation method of a nanocellulose reinforced collagen casing, which comprises the following steps: (1) cleaning and splitting the inner layer of cow leather to obtain split leather; (2) carrying out alkali treatment on split leather, conducting cutting to form blocks, and conducting soaking until the pH is neutral; (3) soaking the neutral cow leather in hydrochloric acid, and conducting swelling; (4) scraping collagen fibers on the swelled cow leather, using the collagen fibers to prepare a collagen suspension, and adjusting the pH value of the collagen suspension; (5) preparing nano cellulose by using a physical method, a chemical method or a biological method; (6) adding the nanocellulose suspension into the collagen suspension to obtain a mixed solution A; (7) adding glycerol into the mixed solution A, uniformly conducting stirring to obtain mucilage, and conducting refrigerating; and (8) extruding and spraying the refrigerated mucilage out of a tube, conducting drying, carrying out immobilization treatment, conducting curing and qualitative treatment, and conducting packaging to obtain the casing. By utilizing the advantages of high length-diameter ratio, larger specific surface area and the like of the nanocellulose, the mechanical property of the casing can be improved when the nanocellulose is applied to preparation of the casing.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Biopolymer-based flexible-tube type food casing with internal impregnation

A biopolymer-based food casing having an impregnation on the side facing the food is provided. The impregnation includes at least one hydrophobic, synthetic, organic polymer. By taloring the impregnation, the peelability of the casing may be adjusted to correspond to the type of food contained within the casing. The casing is used, especially, as an artificial sausage casing for raw sausage, scalded-emulsion sausage or cooked-meat sausage.

Owner:KALLE AG

Preparation method of nanofiber membrane and application of nanofiber membrane in cellulose casing

ActiveCN114605683AImprove shrinkageNo wrinklesSmokable sausage casingsBiaxially oriented sausage casingsCellulosePolymer science

The invention discloses a preparation method of a nanofiber membrane and application of the nanofiber membrane in cellulose casings, and belongs to the field of polysaccharide and derivatives thereof, the preparation method comprises the steps of alkalization and squeezing of pulp, crushing and aging, yellowing, preparation of viscose and membrane preparation. The nanofiber membrane disclosed by the invention is used as the casing, has good contractibility, can contract along with meat stuffing after being smoked, does not have wrinkles, and has the maximum shrinkage rate of 7.4-7.6%; the nanofiber membrane disclosed by the invention is used as a casing, the casing cannot burst in a frozen anhydrous state, and the longitudinal tensile strength is 6.49-6.53 kN / m and the transverse tensile strength is 5.19-5.23 kN / m in a state that the temperature is-20 DEG C and the water content is 0.5%.

Owner:WEIFANG WEISEN FIBER NEW MATERIAL CO LTD

Pigmented and internally impregnated fibrous cellulose sausage casing

ActiveUS7854976B2Spot formation is preventedWide molecular weight distributionLiquid surface applicatorsWood working apparatusCelluloseCollagen hydrolysates

The invention relates to a double-viscosed fibrous cellulose sausage casing having a pigmented outer cellulose hydrate layer and an impregnated internal cellulose hydrate layer. The impregnation of the internal cellulose hydrate layer includes a collagen hydrolysate and the outer cellulose hydrate layer includes at least one white pigment, preferably having titanium dioxide pigments. The invention further relates to a method for producing the fibrous cellulose sausage casing and also to its use as artificial sausage casing.

Owner:KALLE AG

Readily peelable cellulose-based sausage casing

InactiveUS20060233983A1Reduce adhesionFlexible pipesCellulosic sausage casingsCellulosePolyvinyl alcohol

A tubular sausage casing based on cellulose hydrate and exhibits low adhesion to the filling is disclosed. The casing has a coating applied to its inside, the coating comprising a water-soluble polyvinyl alcohol and water-soluble cellulose ether. In an additional embodiment the coating further contains at least one member selected from the group consisting of oil and fatty diketene. A process for the preparation of the casing is also disclosed.

Owner:CASETECH

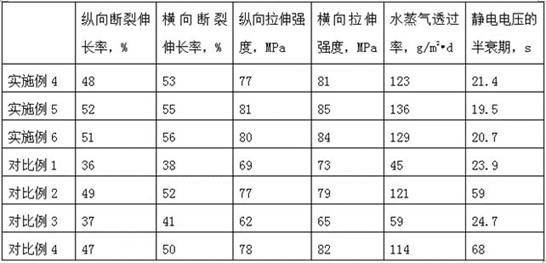

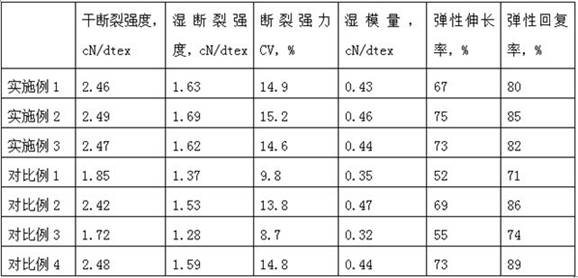

Preparation method of cellulose mucilage glue and application of cellulose mucilage glue in cellulose casing

ActiveCN114517338AImprove toughnessHigh strengthArtificial filaments from viscoseTextile/flexible product manufactureCellulosePolymer science

The invention discloses a preparation method of cellulose viscose and application of the cellulose viscose in cellulose casings, and belongs to the technical field of viscose, the preparation method of the cellulose viscose comprises the steps of viscose solution preparation, viscose solution modification, spinning and post-treatment; the application of the cellulose mucilage glue in the cellulose casing comprises the steps of weaving forming, sizing, primary drying, washing sizing and secondary drying. While the toughness, antistatic property and spinnability of the cellulose casing are improved, the water vapor permeability, wet modulus, dimensional stability, elasticity, wear resistance and acid and alkali resistance of the cellulose casing are improved.

Owner:WEIFANG WEISEN FIBER NEW MATERIAL CO LTD

High cling food casing

InactiveCN102326613ACellulosic sausage casingsThin material handlingWater vaporWater vapor permeation

Owner:VISCOFAN USA

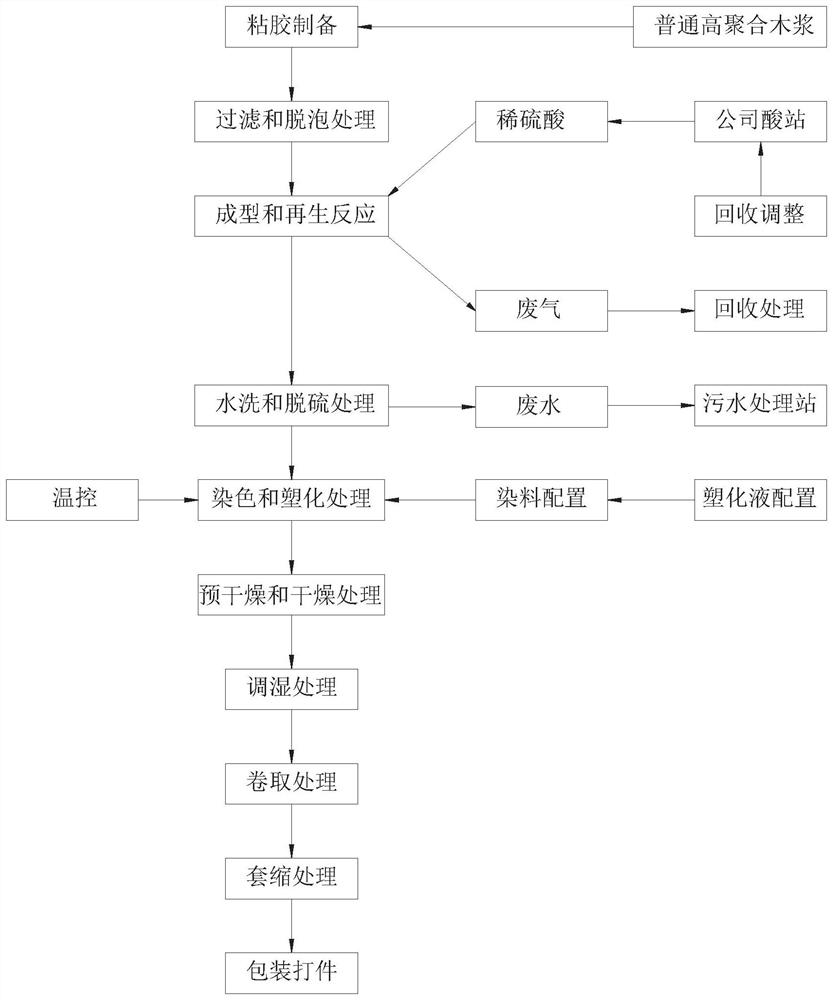

Production process of color-transferable biological cellulose casing

InactiveCN113647442AGood water permeabilityAdd flavorCellulosic sausage casingsCellulosePlasticulture

The invention discloses a production process of a color-transferable biological cellulose casing. The production process comprises the following steps: viscose preparation, filtering and defoaming treatment, forming and regeneration reaction, washing and desulfurization treatment, dyeing and plasticizing treatment, pre-drying and drying treatment, humidifying treatment, coiling treatment, shrinkage treatment, packaging and piece forming. The natural cellulose wood pulp (cotton pulp) is adopted as the raw material, the product can be naturally degraded, is green and pollution-free, is a green and environment-friendly food packaging material, has excellent water permeability and air permeability, can achieve a better smoking effect, is good in moisture retention performance, is better in flavor of the fumigated sausages, and in the steaming process of the sausages, the color of the surface of the casing can be transferred from the surface of the casing to the meat surface of the sausage, bright meat color required by customers is formed on the surface of the sausage, and unique fragrance is formed.

Owner:WEIFANG WEISEN FIBER NEW MATERIAL CO LTD

Artificial food casing comprising a traceability code, method for manufacturing and method of tracing thereof

Owner:VISKOTEEPAK BELGIUM NV

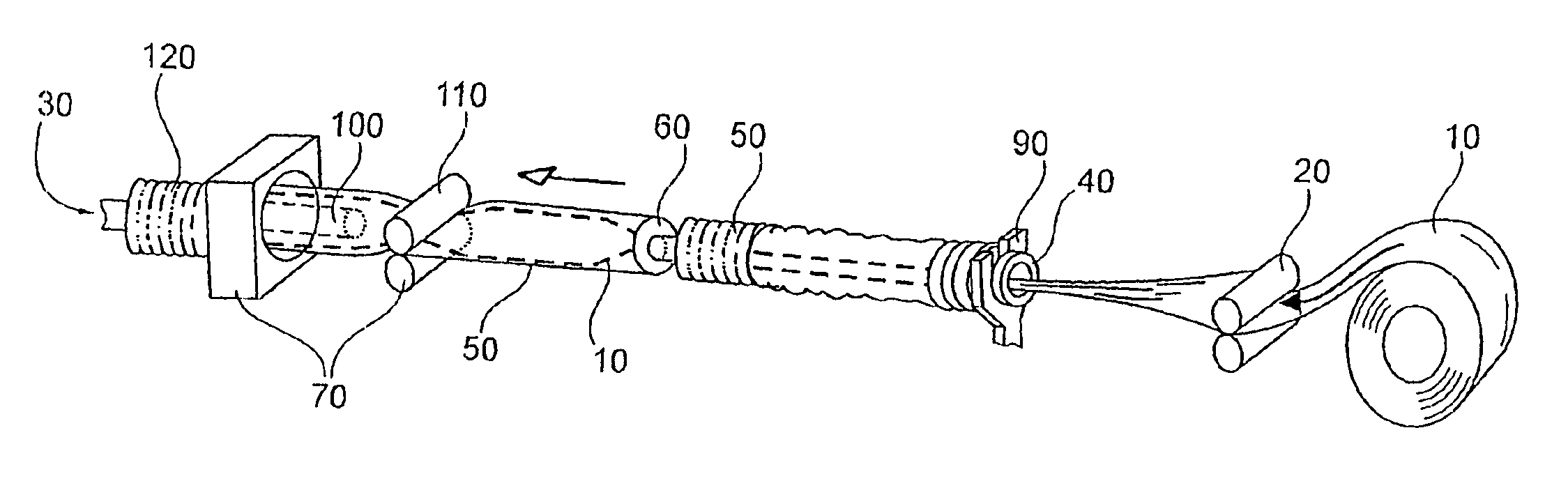

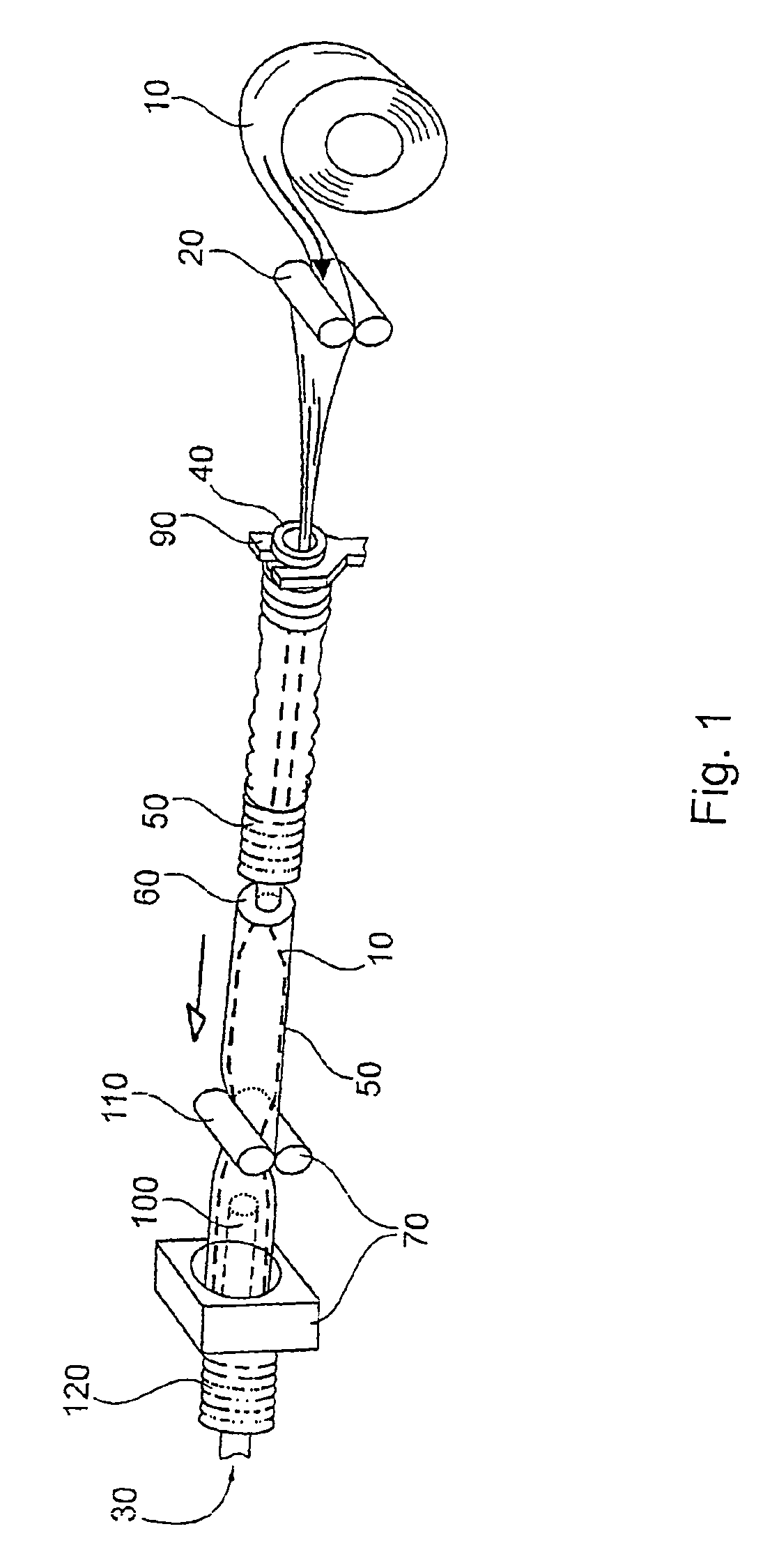

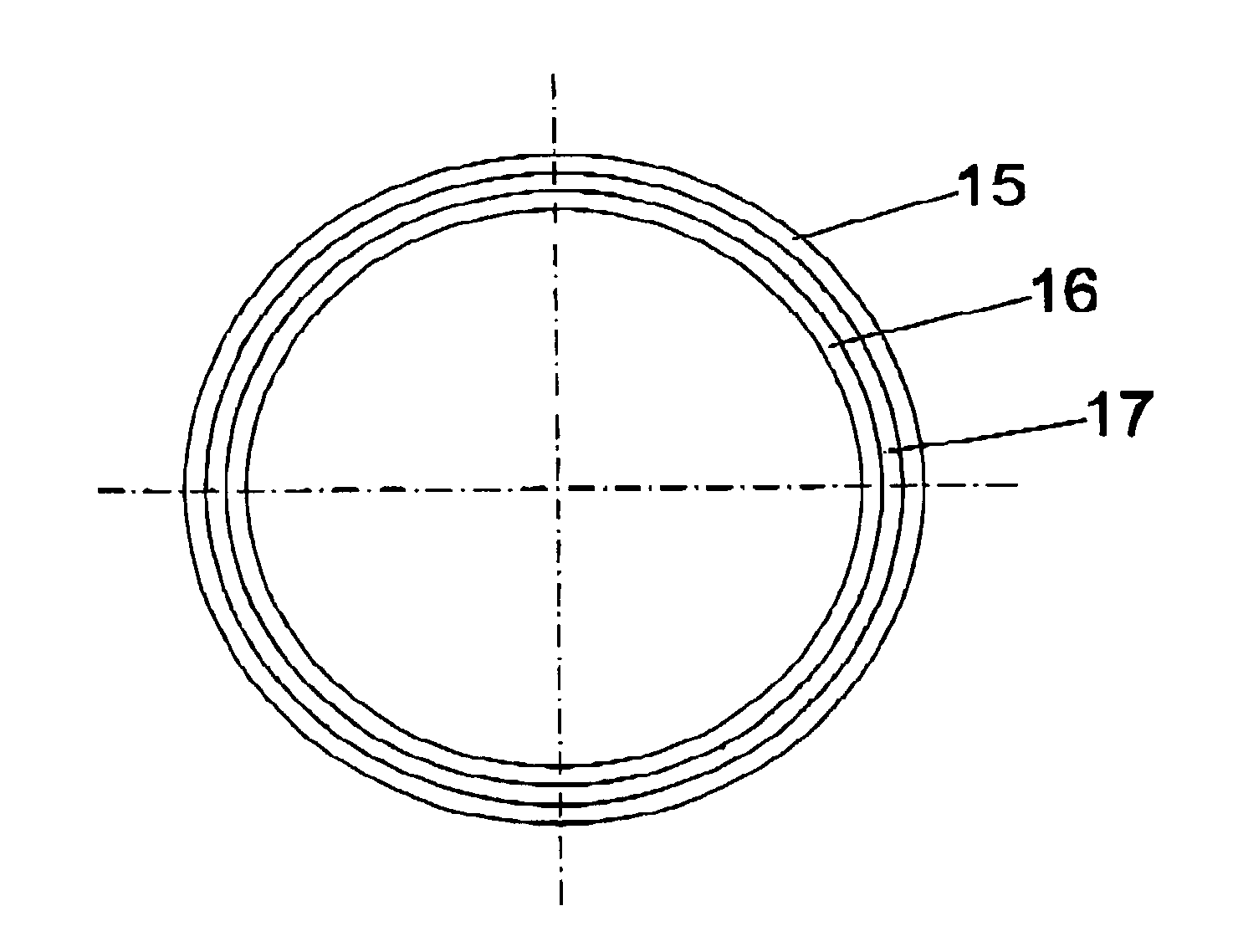

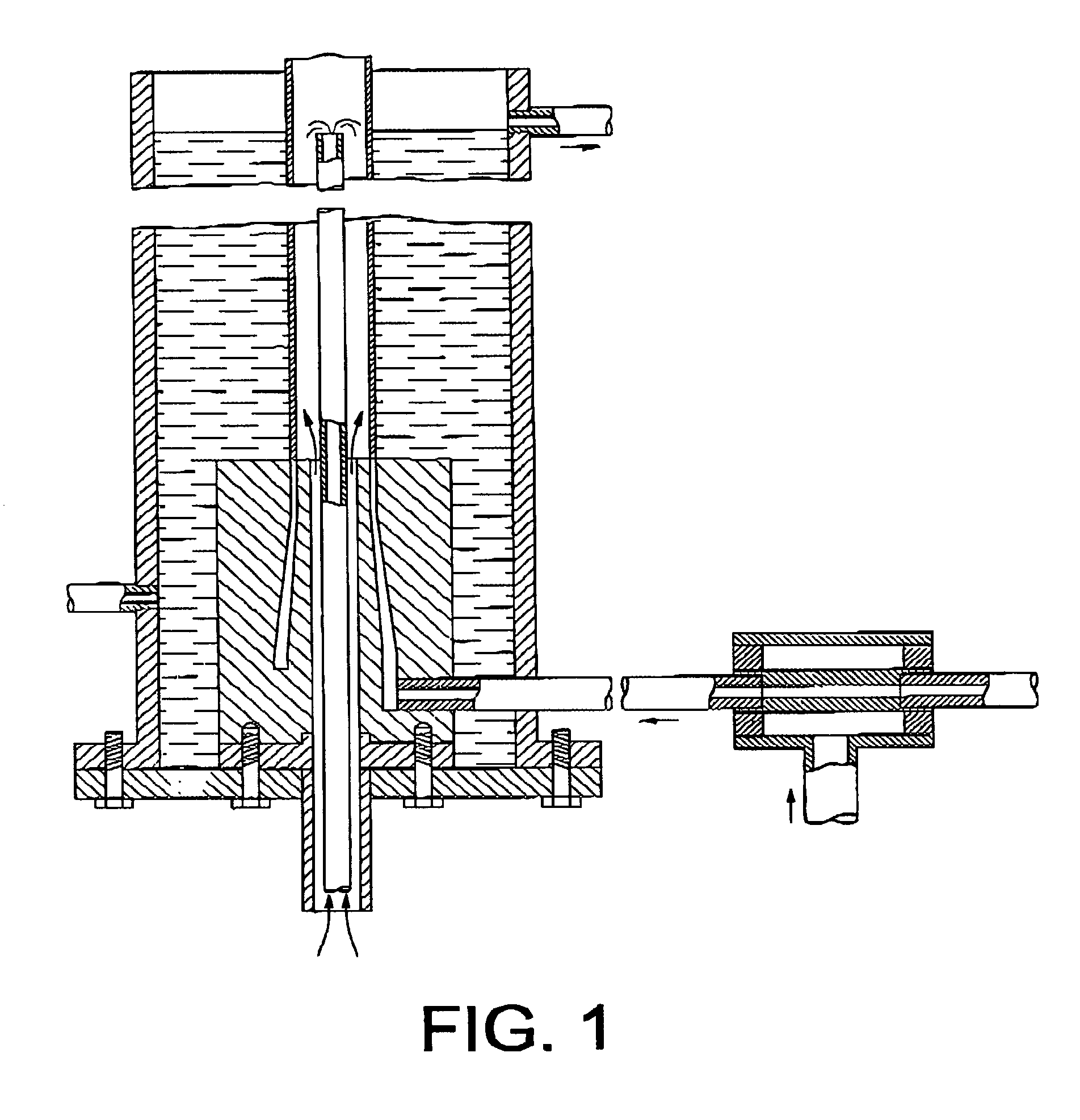

Multilayered cellulose casing, method of manufacture thereof and extrusion head for obtaining said casing

ActiveUS7622173B2Reduce the ratioEconomic advantageWrappers shrinkageLayered productsFlavoring extractEngineering

Cellulose casing for sausages, comprising at least three concentric layers of regenerated cellulose, of which the two layers in contact with the outside, that is, those with the greatest and smallest diameter respectively are made of colorless, transparent viscose, and in which the internal layer or layers are made of regenerated cellulose to which is added other substances such as pigments, fumes, flavor extracts, spices or plastic proteins.The object of the invention is a manufacturing method for the cellulose casing obtained by extrusion of at least three concentric layers of regenerated cellulose. Also object of the invention is the circular viscose extrusion head used in manufacturing the cellulose casing for sausages.

Owner:VISCOFAN INDA NAVARRA DE ENVOLTRAS CELULOSICAS

Tubular Food Casing Having Glued, Permanently Elastic Longitudinal Seam

ActiveUS20150181899A1High transfer functionImprove mechanical propertiesEnvelopes/bags making machineryWrappersFiberEngineering

A shirr-stable, tubular food casing having a glued, permanently elastic longitudinal seam based on a flat fibrous textile material coated with acrylic, collagen and / or a protein derived therefrom is provided. The seam is generated using a reactive hotmelt glue. The glued seam is resistant to boiling for a long time and also exhibits sufficient stability thereafter. Exemplary textile materials include a consolidated nonwoven or spunbonded nonwoven, a woven fabric, loop-formingly knitted fabric, laid fabric, loop-drawingly knitted fabric. To form the casing, the textile material is coated in the flat state. The coated textile material is cut into strips according to the diameter of the casing to be produced and glued using a reactive hotmelt glue, such as a PUR hotmelt glue, to form the tube. The food casing is preferably used as artificial sausage casing or for wrapping cheese or fish.

Owner:KALLE AG

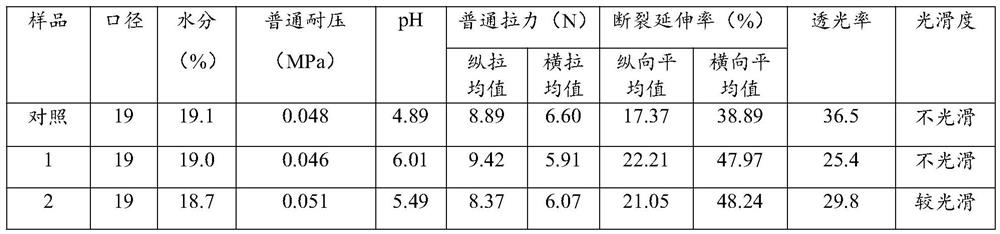

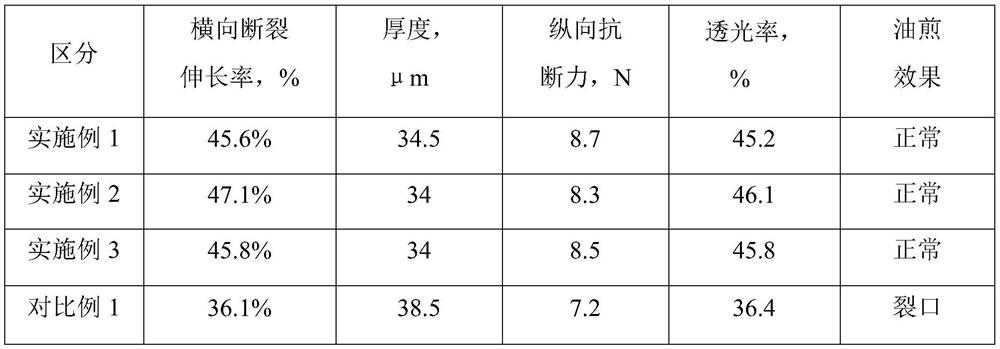

Preparation method of fresh collagen casing

PendingCN112471217AHigh elongation at breakThe overall thickness is thinCellulosic sausage casingsCelluloseFiber

The invention relates to a preparation method of a fresh collagen casing, and belongs to the technical field of casing preparation. The preparation method of the fresh collagen sausage casing comprises the following steps: (1) preparing the castrated bull skin with the age of 1-2 years, wherein the skin material isfull grain cow leather of 6-8 mm in thickness; (2) pickling the skin material for 40-90 days at the temperature of 10-20 DEG C; (3) carrying out ash washing, acidification and defibration on the pickled leather to obtain collagenous fibers; and (4) adding nano cellulose into the collagen fiber to obtain a collagen group, filtering and carding the material, and blowing the material to obtain the fresh collagen casing. The method is scientific, reasonable and simple and convenientto operate, and the prepared sausage casing is high in elongation at break, small in thickness, increased in breaking resistance value, high in light transmittance and good in effect when used for frying and baking.

Owner:山东海奥斯生物科技股份有限公司

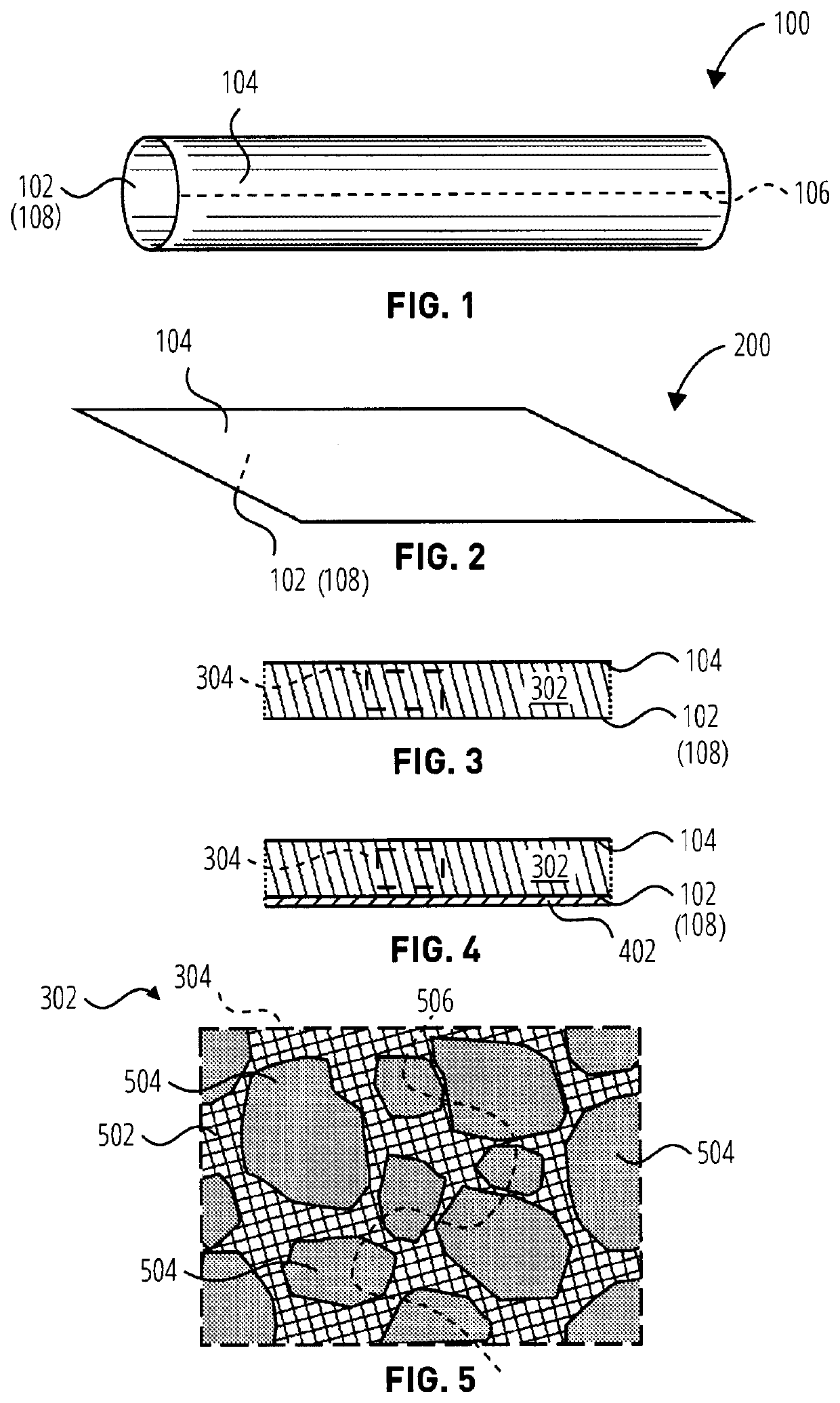

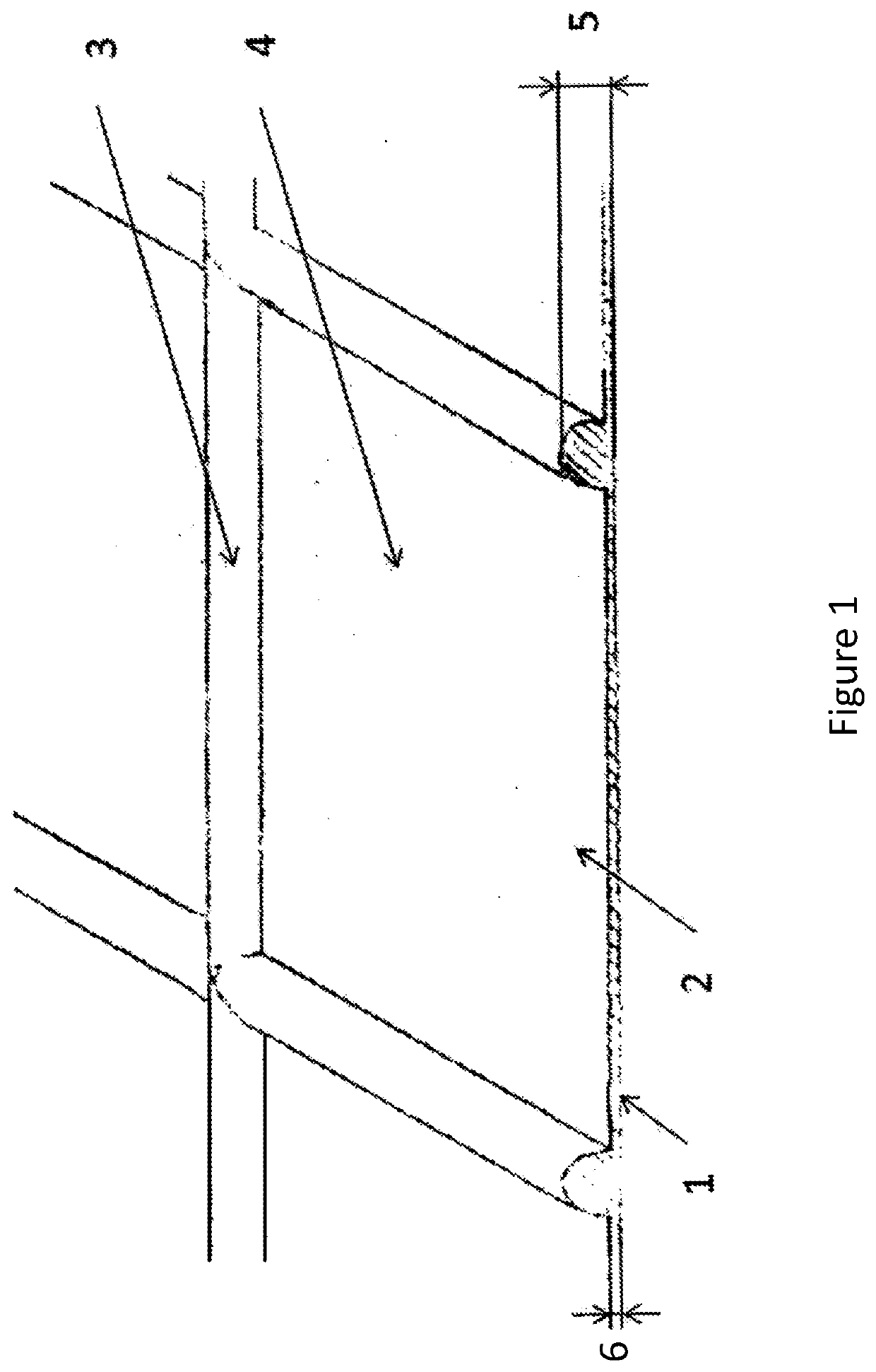

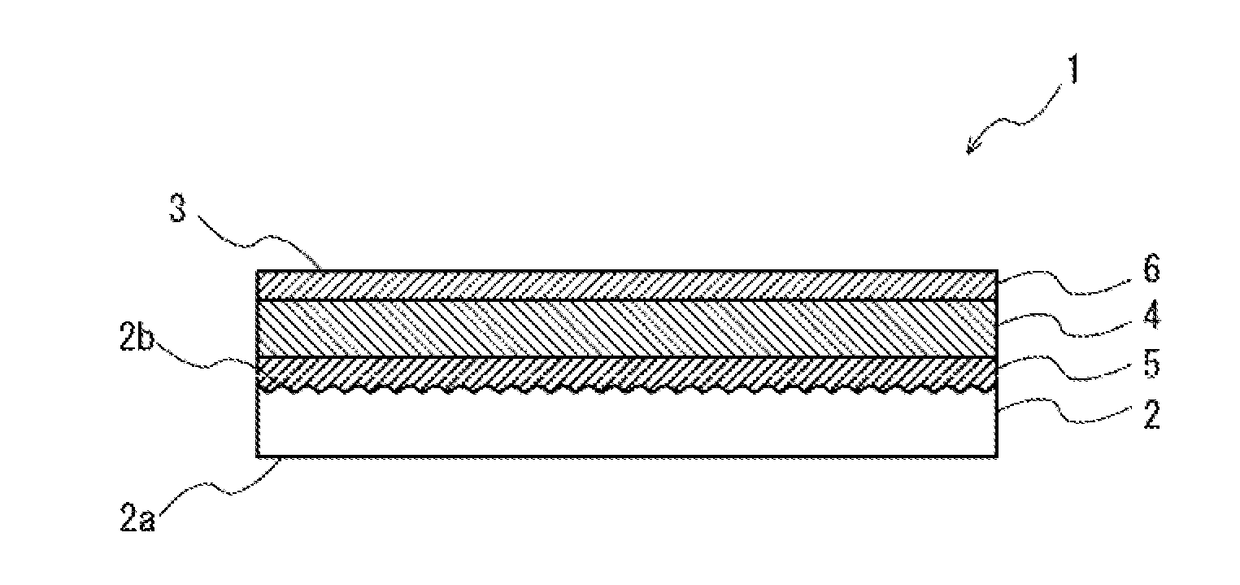

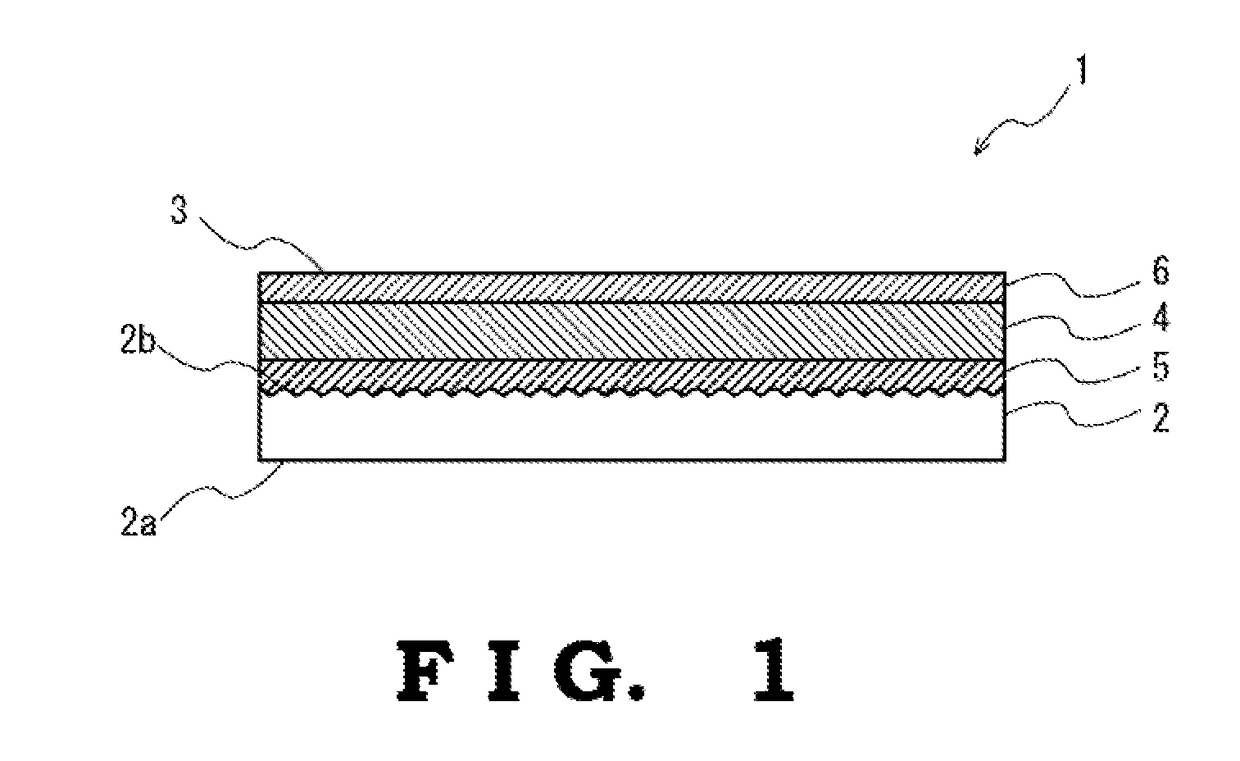

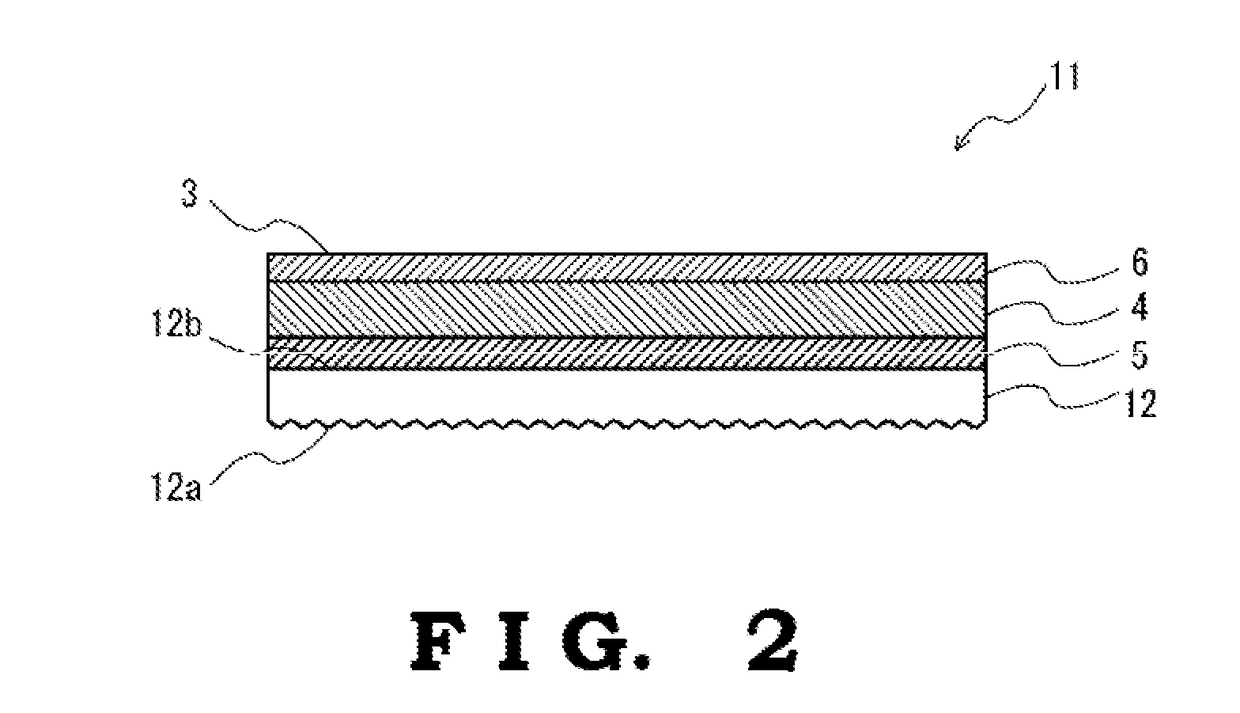

Paper material for fibrous casing, production method thereof, and fibrous casing

ActiveUS20170142988A1Improve performanceSynthetic resin layered productsPaper/cardboard layered productsFiberPulp and paper industry

Provided are a paper material for fibrous casing enabling a fibrous casing to deliver favorable performance, a production method thereof, and a fibrous casing employing the paper material for fibrous casing. The paper material for fibrous casing of the present invention is used as a food packaging material in heat processing of a foodstuff, and is formed from pulp as a principal component, with one face being a glossy face and another face being a matte face. The fibrous casing of the present invention comprises: a paper layer that is arranged as an innermost layer and formed from a paper material; and a synthetic resin layer that is overlaid on an outer face of the paper layer, the paper material being the paper material for fibrous casing. The matte face of the paper material is preferably directed inward. The glossy face of the paper material is also preferably directed inward.

Owner:DAIO PAPER CORP +1

Artificial food casing, method for removing and method for manufacturing thereof

ActiveUS9968103B2Easy to detectPrecise positioningThermoplastic sausage casingsPrintable sausage casingsEngineeringArtificial feeding

Owner:VISKOTEEPAK BELGIUM NV

Biopolymer-based flexible-tube type food casing with internal impregnation

A biopolymer-based food casing having an impregnation on the side facing the food is provided. The impregnation includes at least one hydrophobic, synthetic, organic polymer. By taloring the impregnation, the peelability of the casing may be adjusted to correspond to the type of food contained within the casing. The casing is used, especially, as an artificial sausage casing for raw sausage, scalded-emulsion sausage or cooked-meat sausage.

Owner:KALLE AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com