Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

211results about How to "Effective shaping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

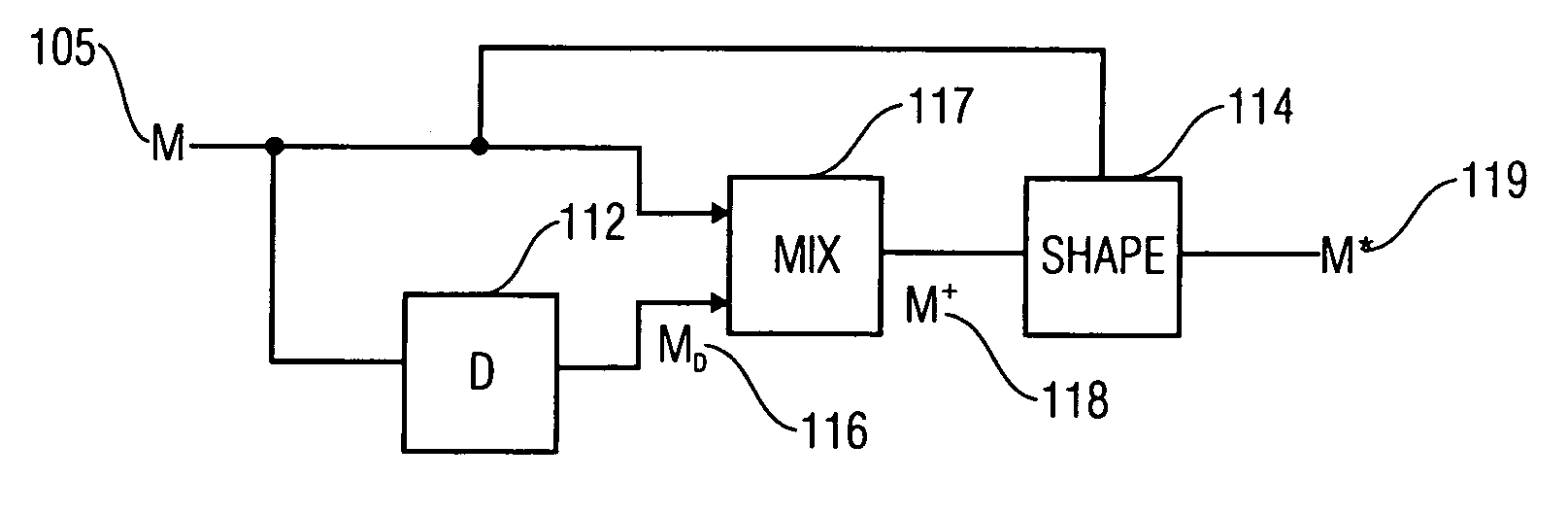

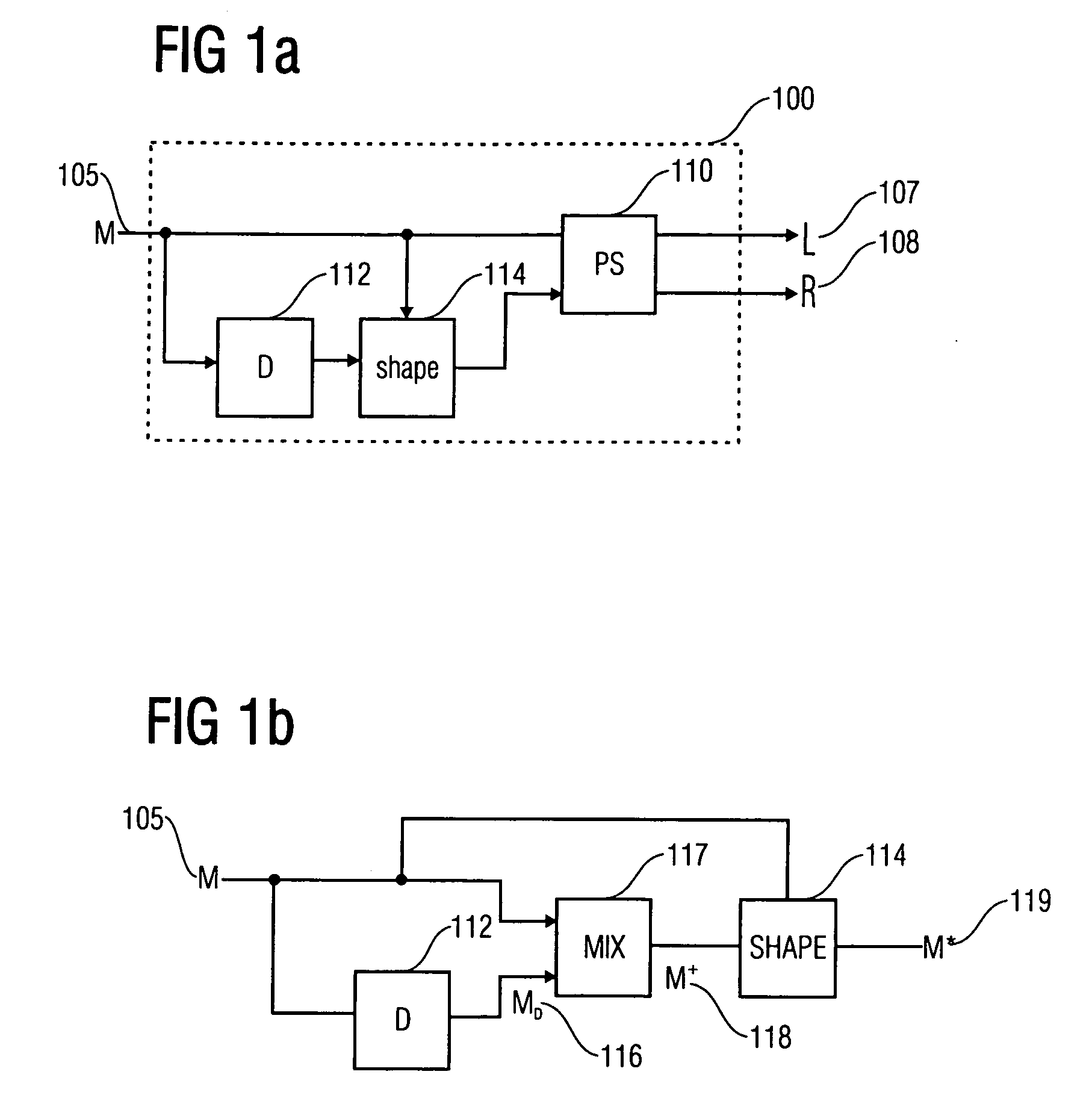

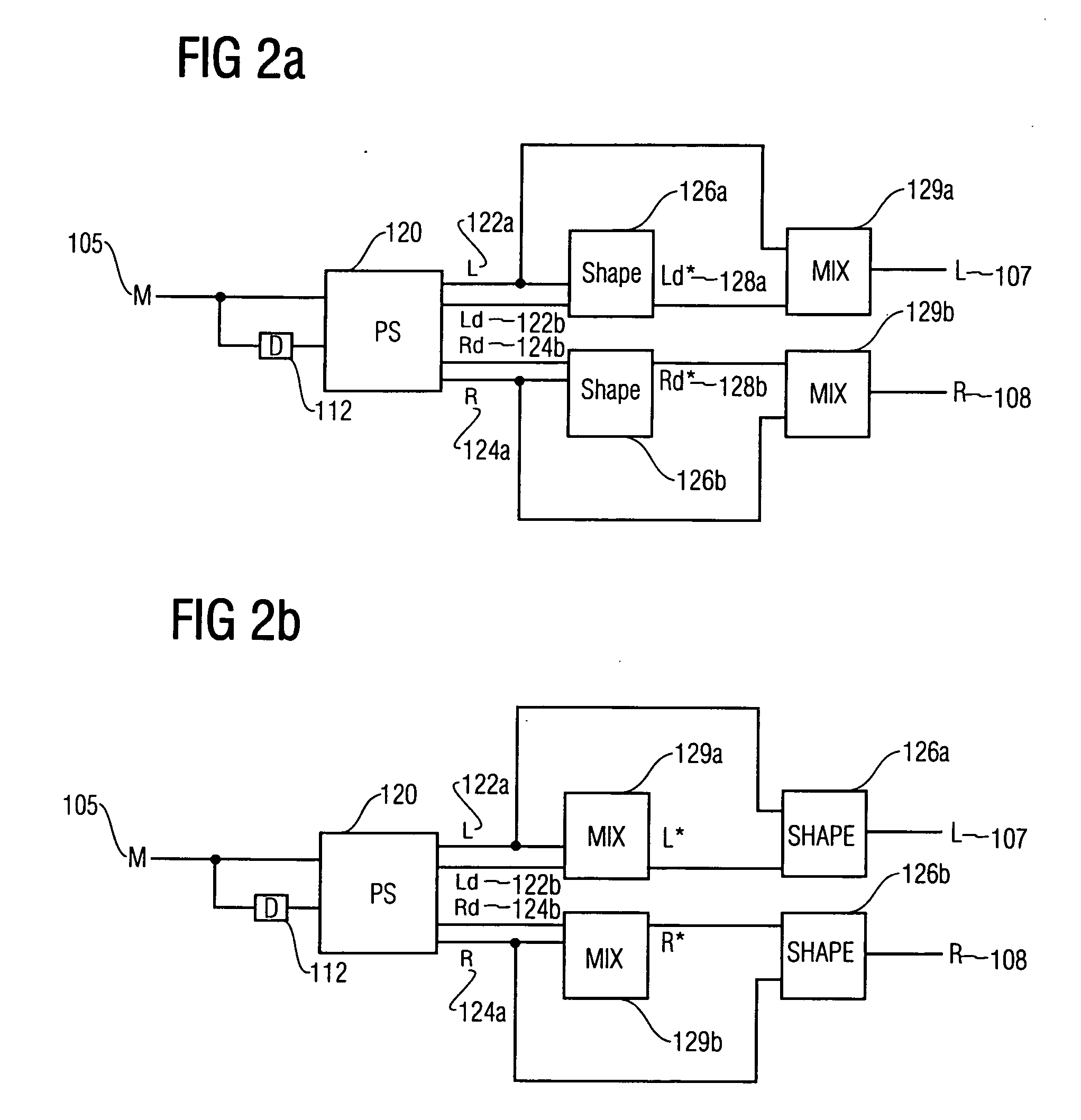

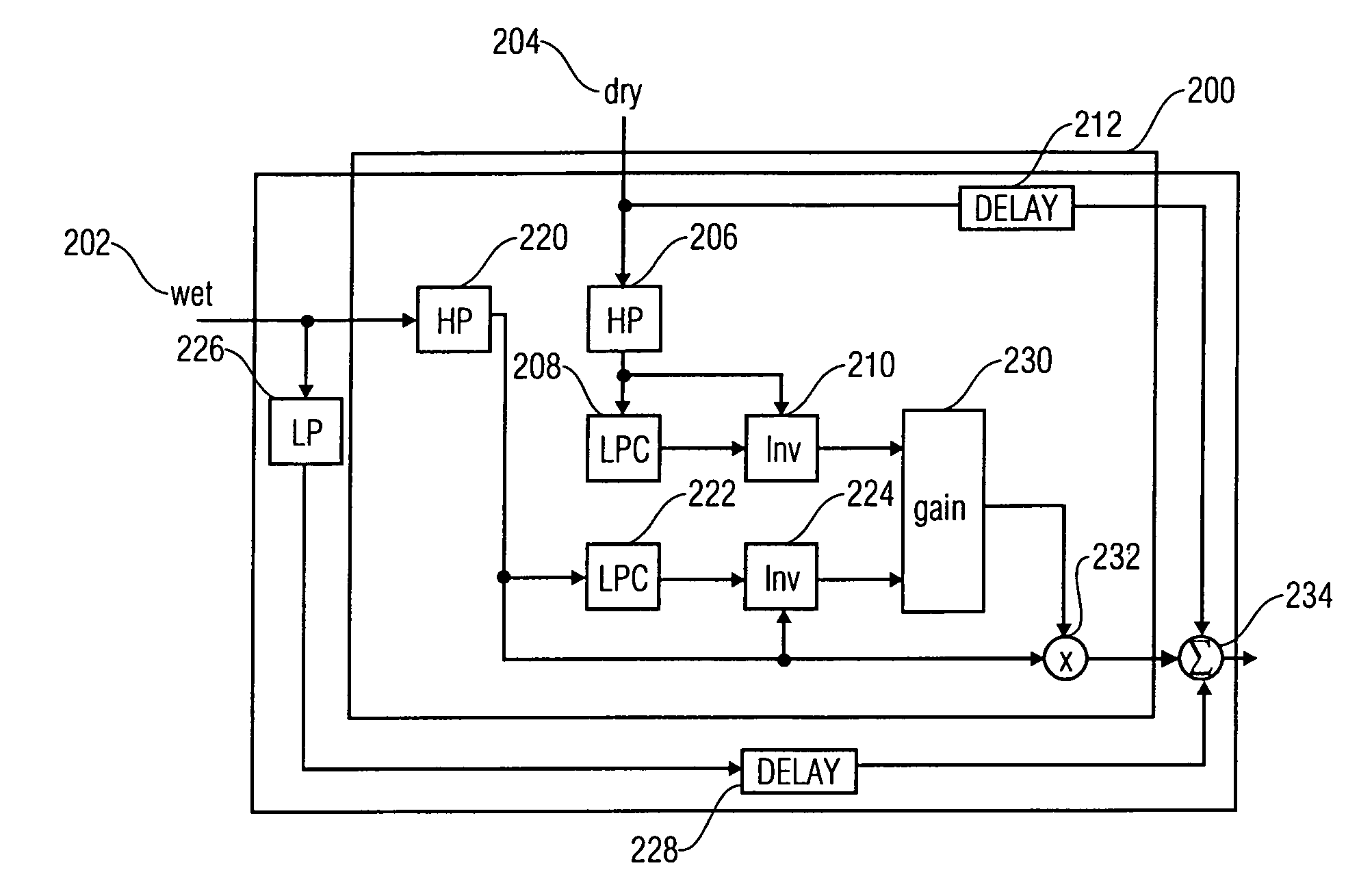

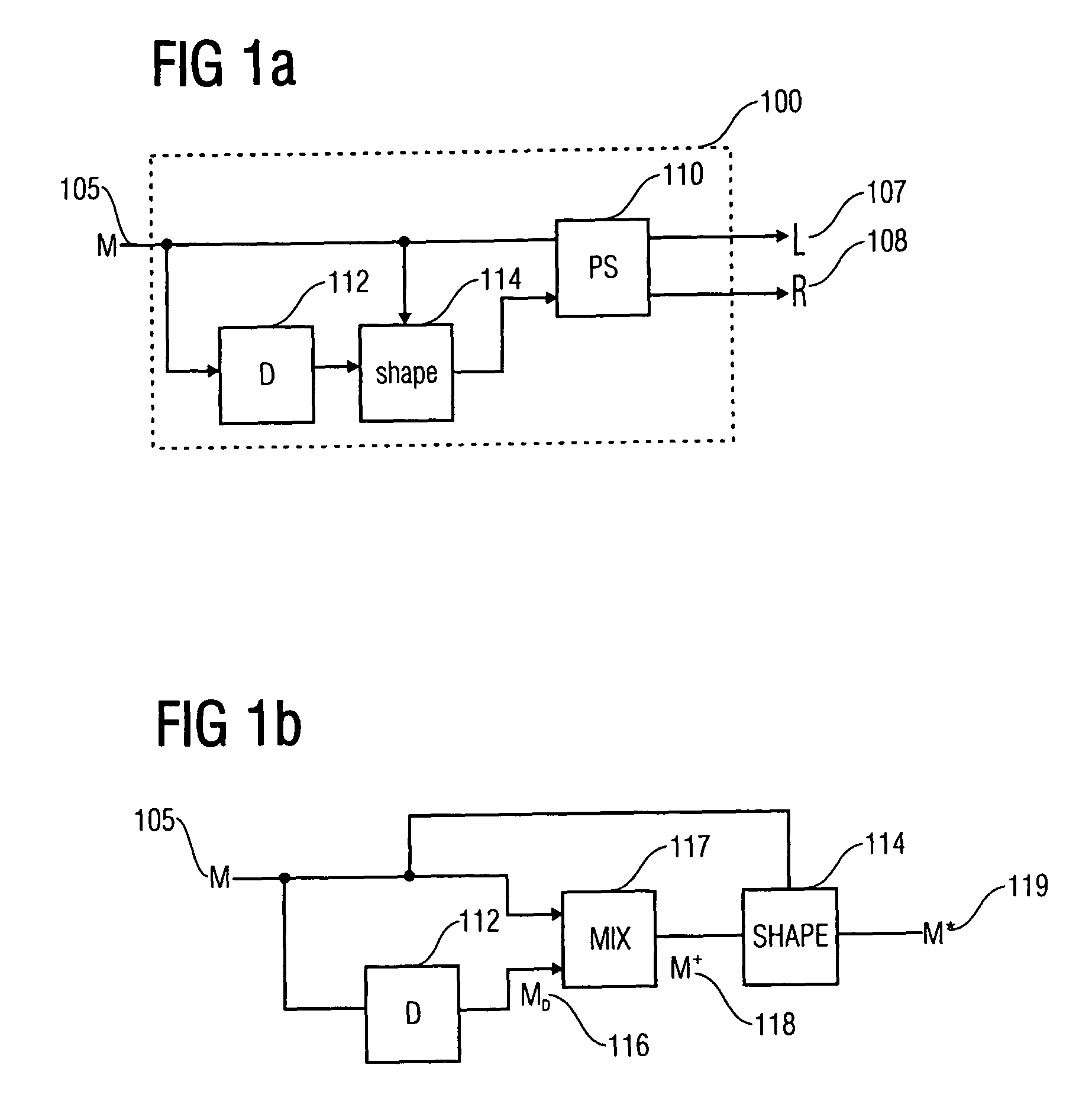

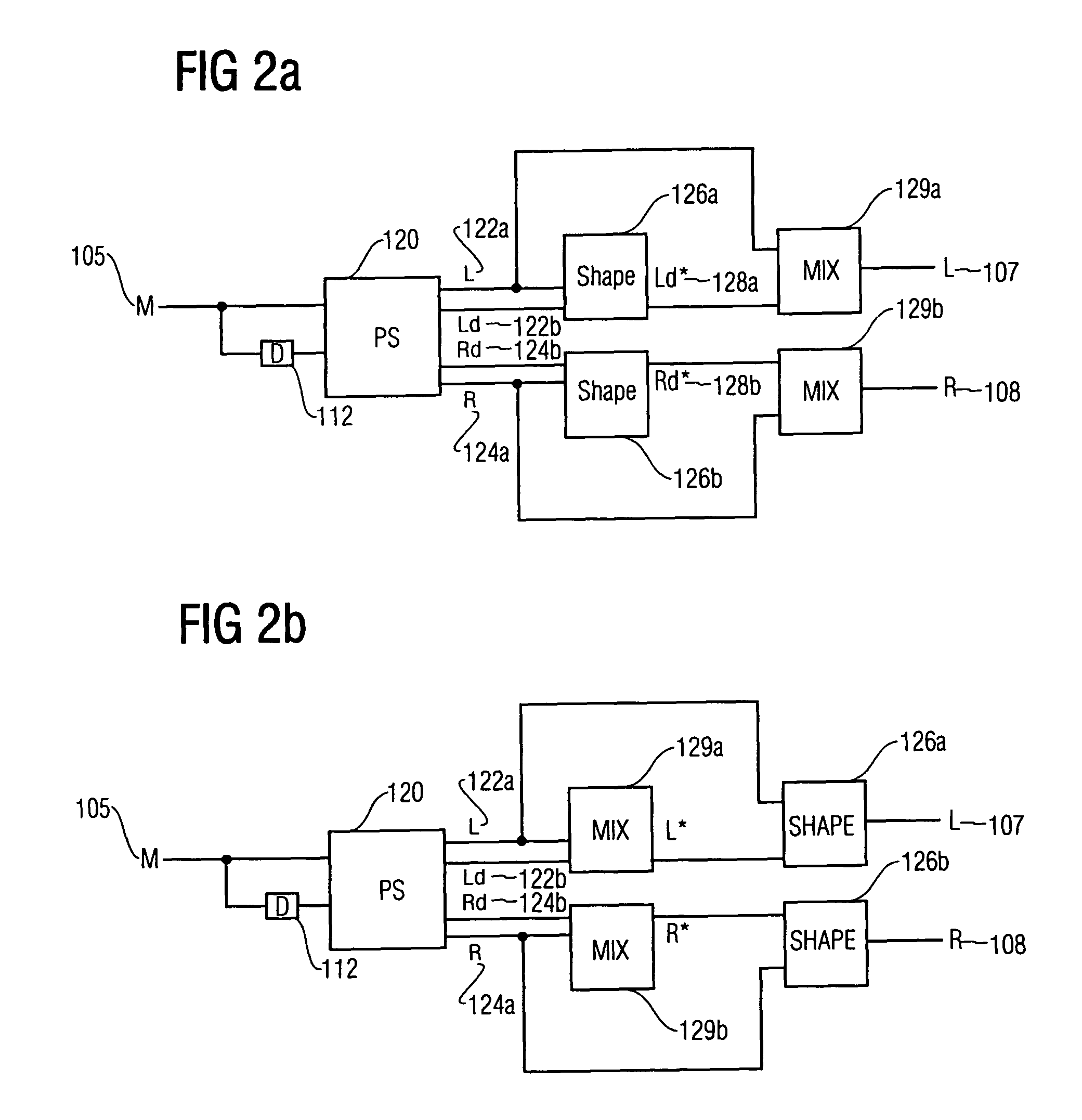

Envelope shaping of decorrelated signals

ActiveUS20060239473A1Avoid introducingEffective shapingSpeech analysisPseudo-stereo systemsFrequency spectrumDistortion

The envelope of a decorrelated signal derived from an original signal can be shaped without introducing additional distortion, when a spectral flattener is used to spectrally flatten the spectrum of the decorrelated signal and the original signal prior to using the flattened spectra for deriving a gain factor describing the energy distribution between the flattened spectra, and when the so derived gain factor is used by an envelope shaper to timely shape the envelope of the decorrelated signal.

Owner:DOLBY INT AB +1

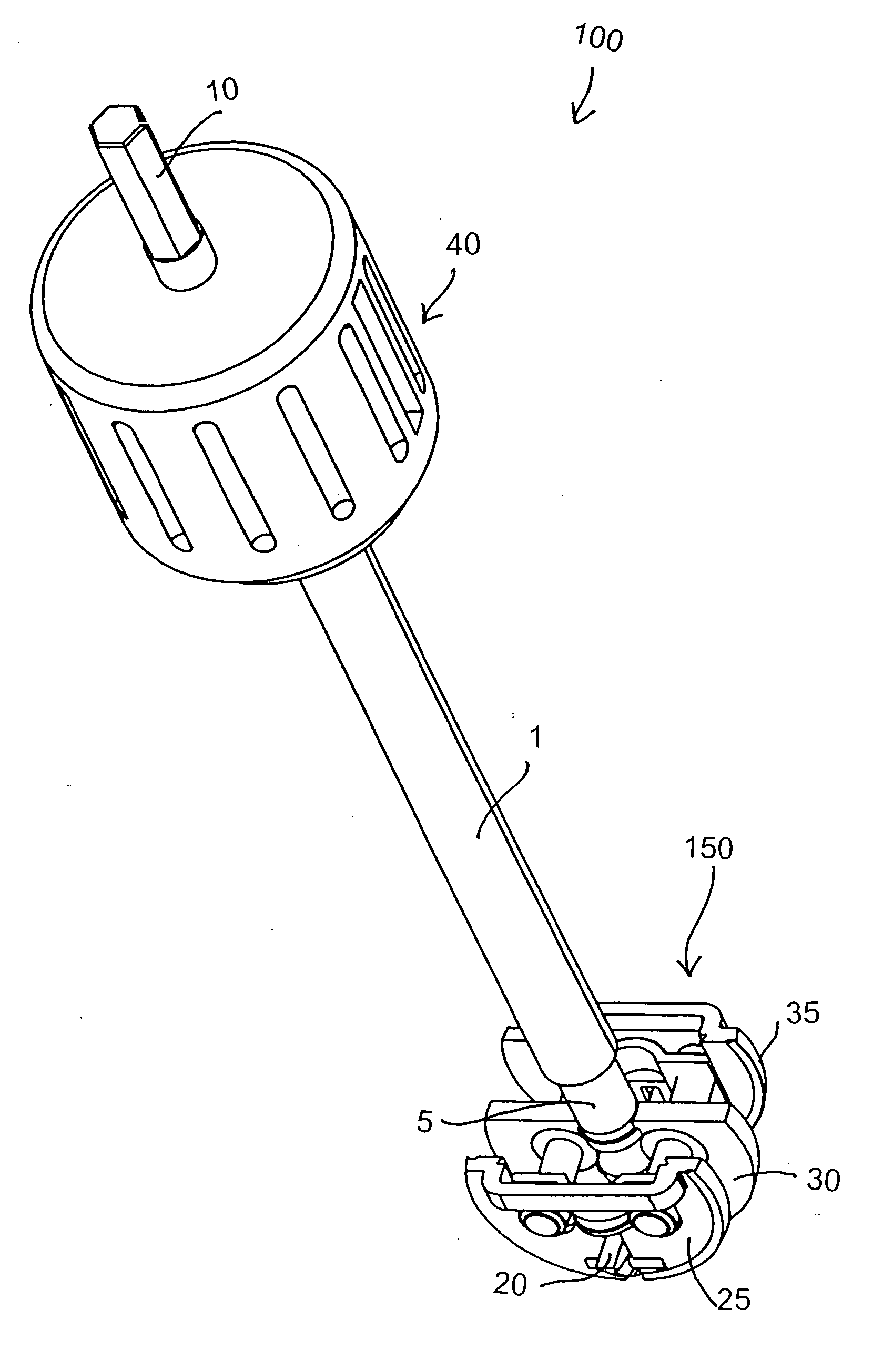

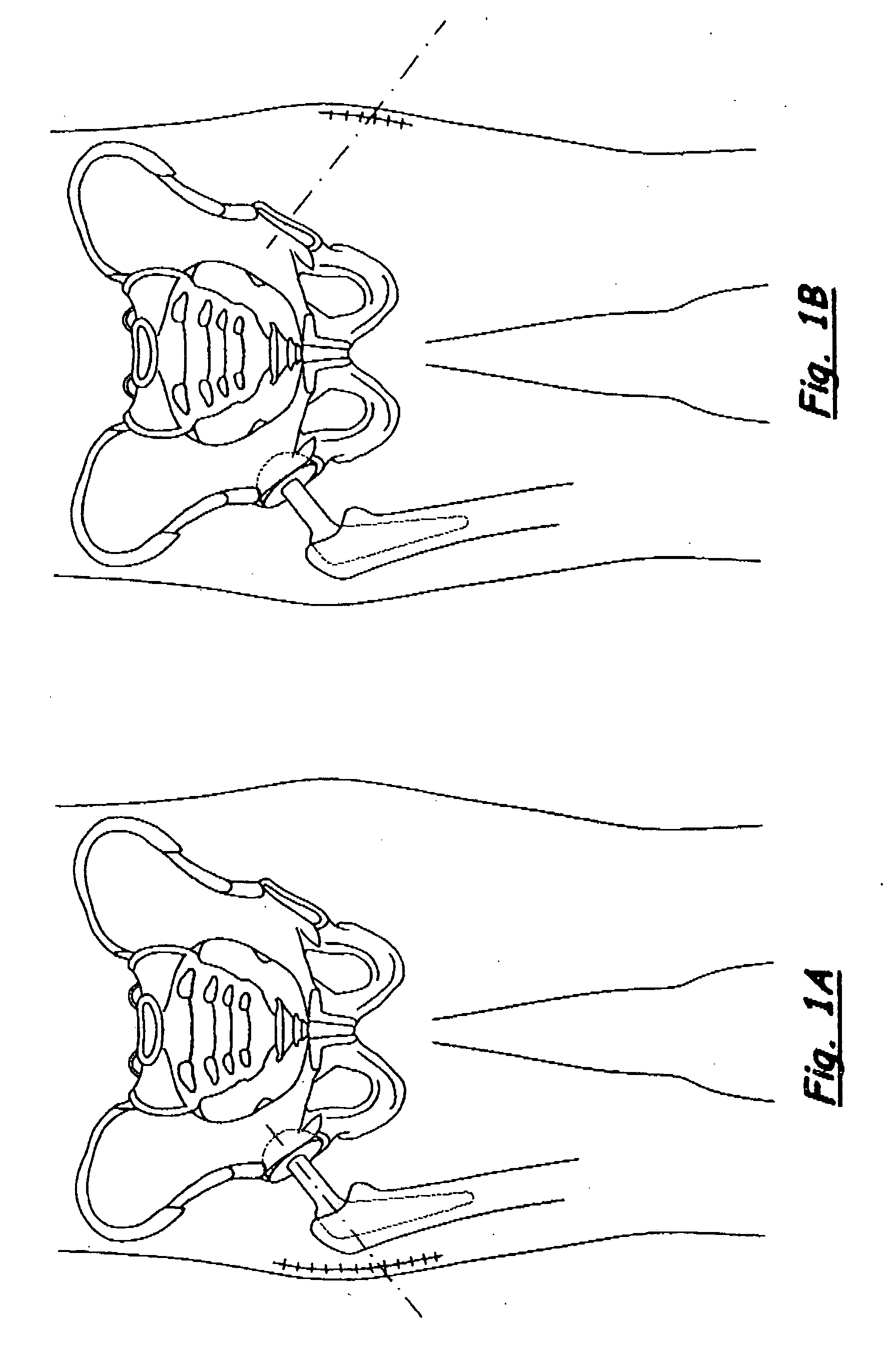

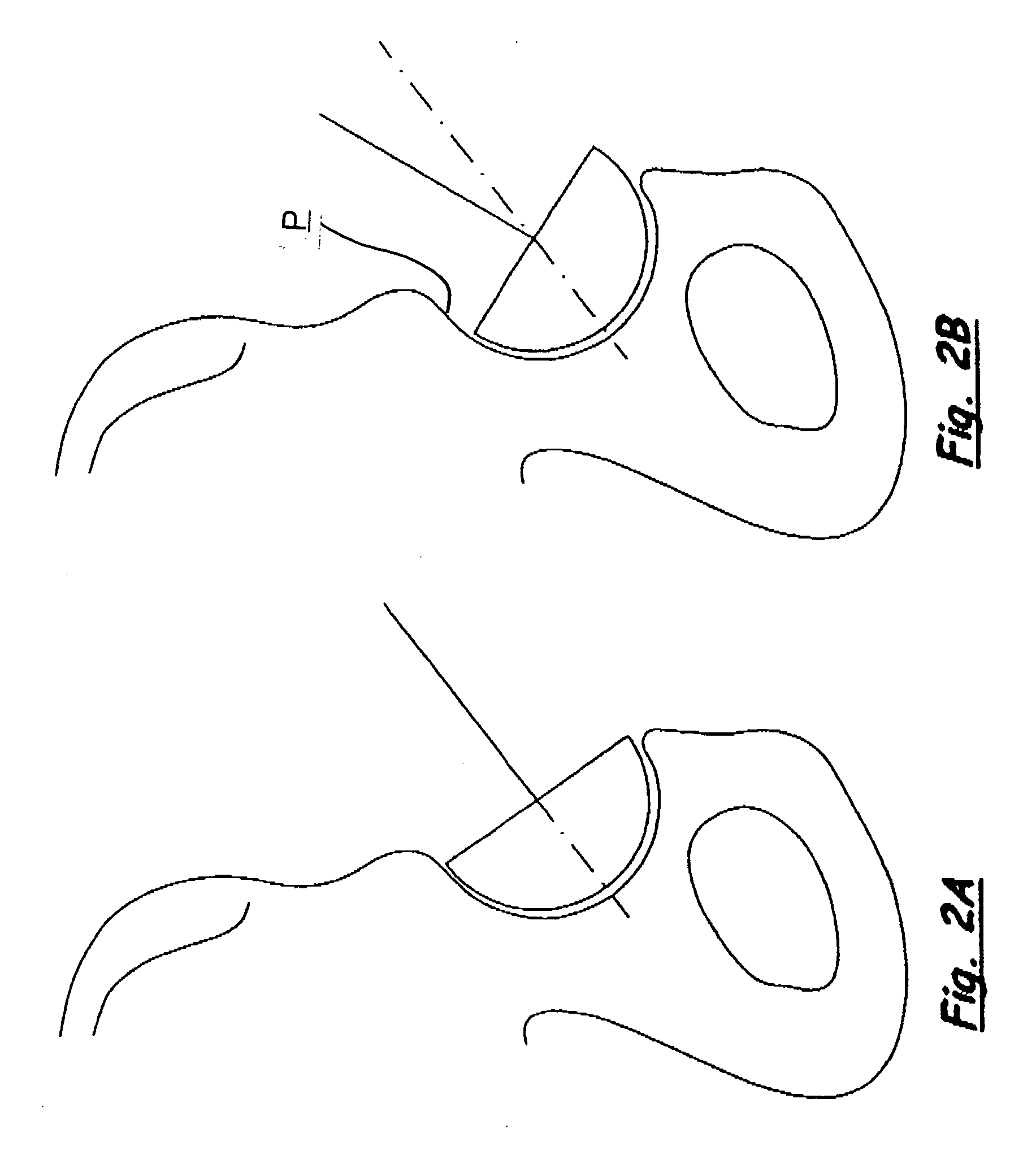

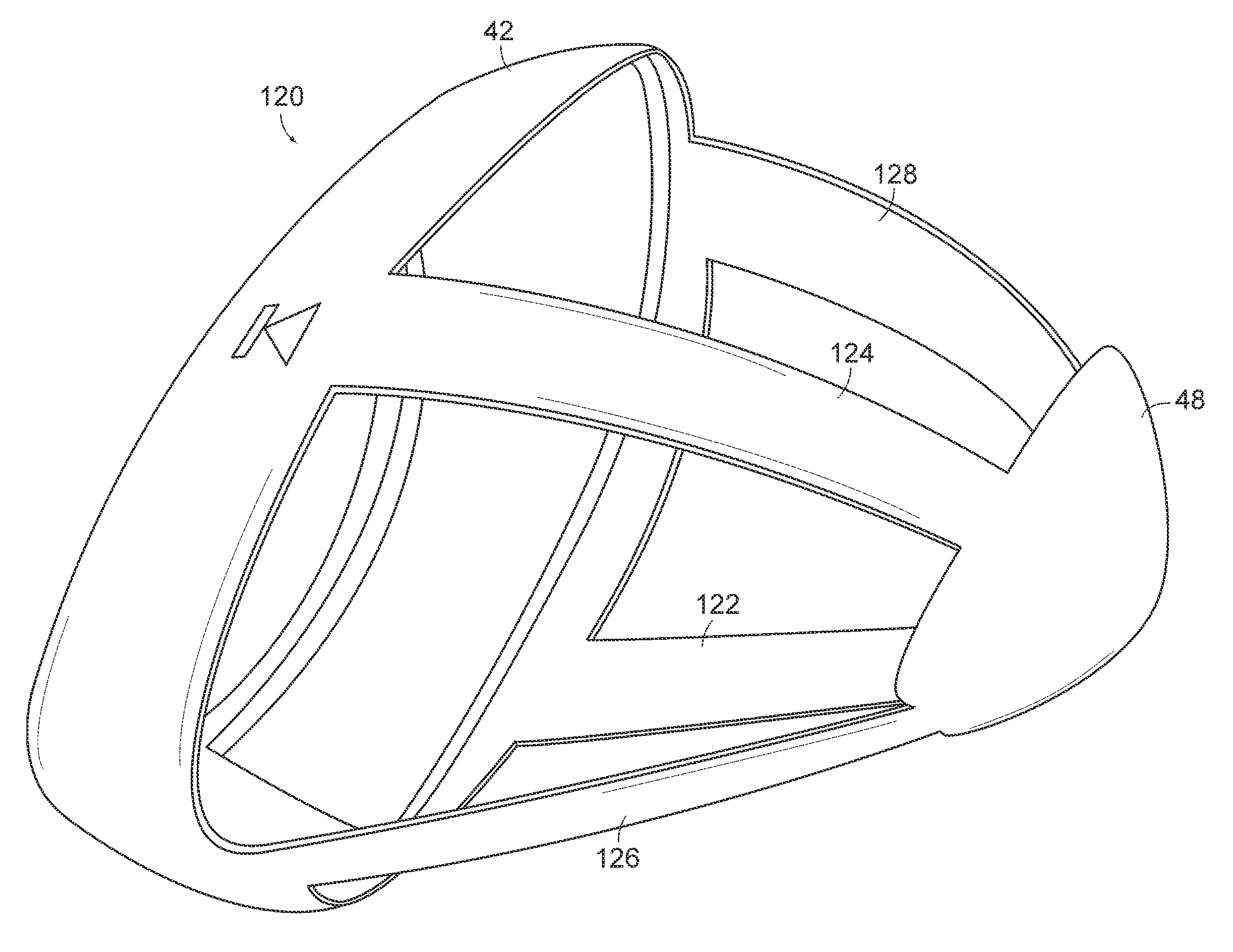

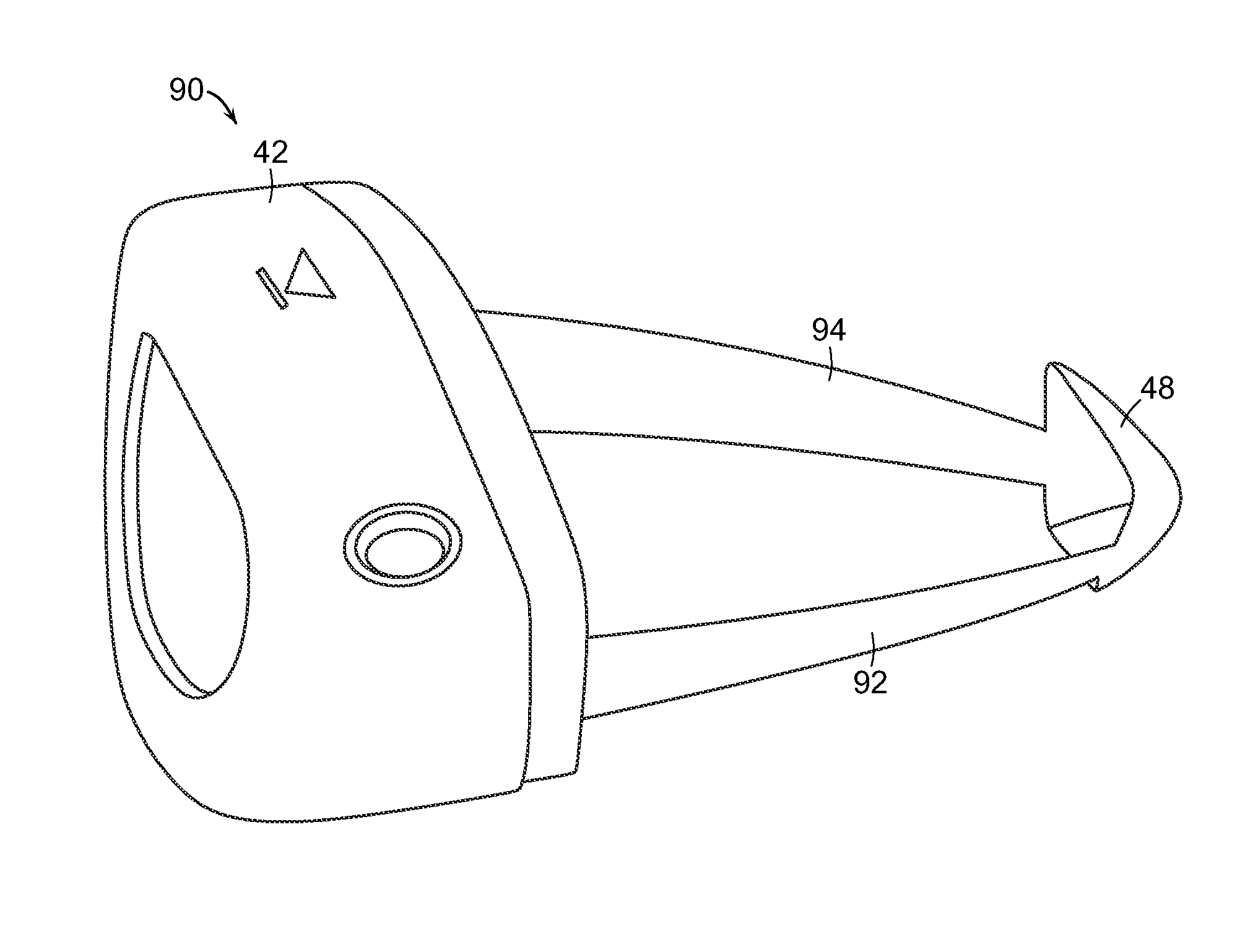

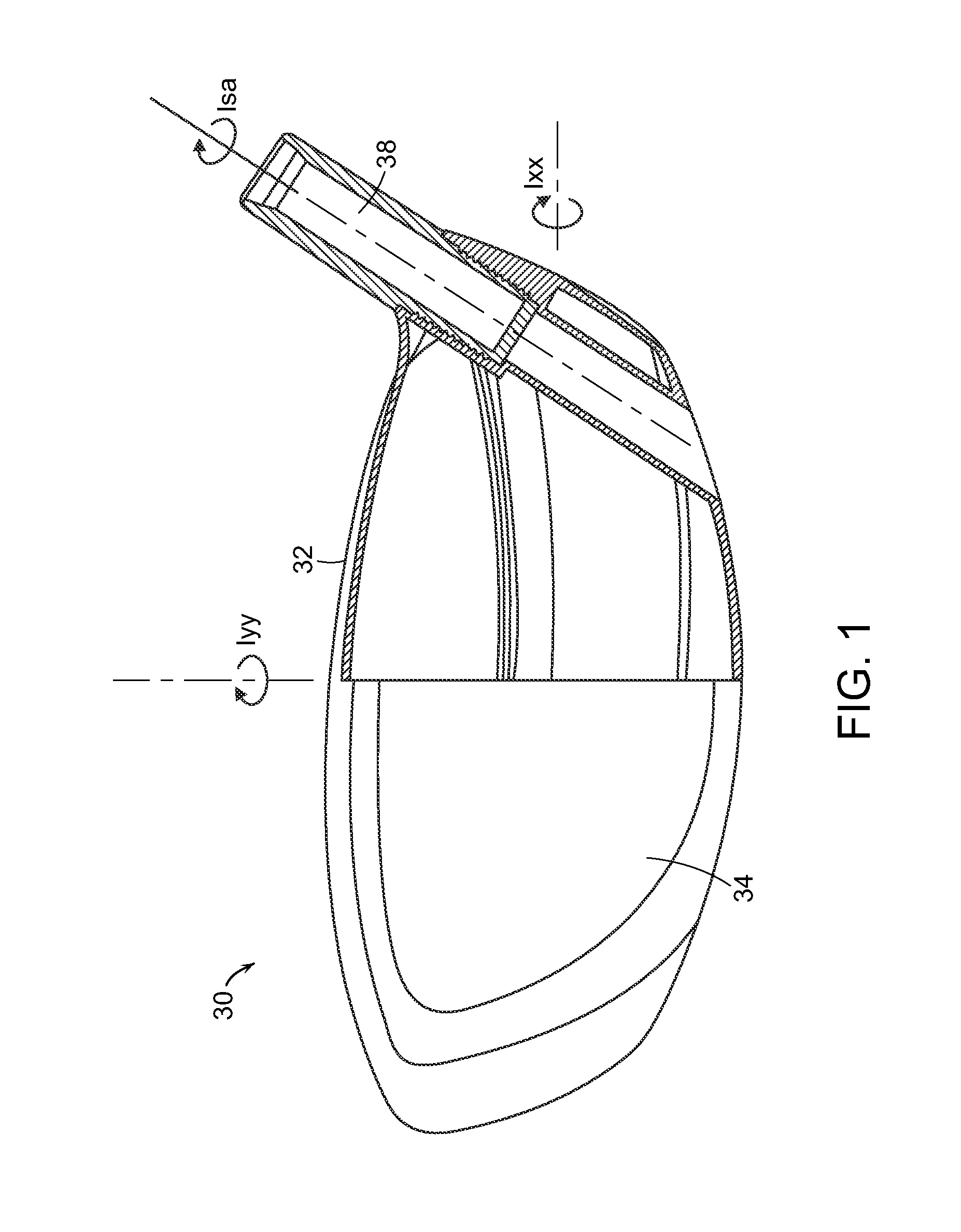

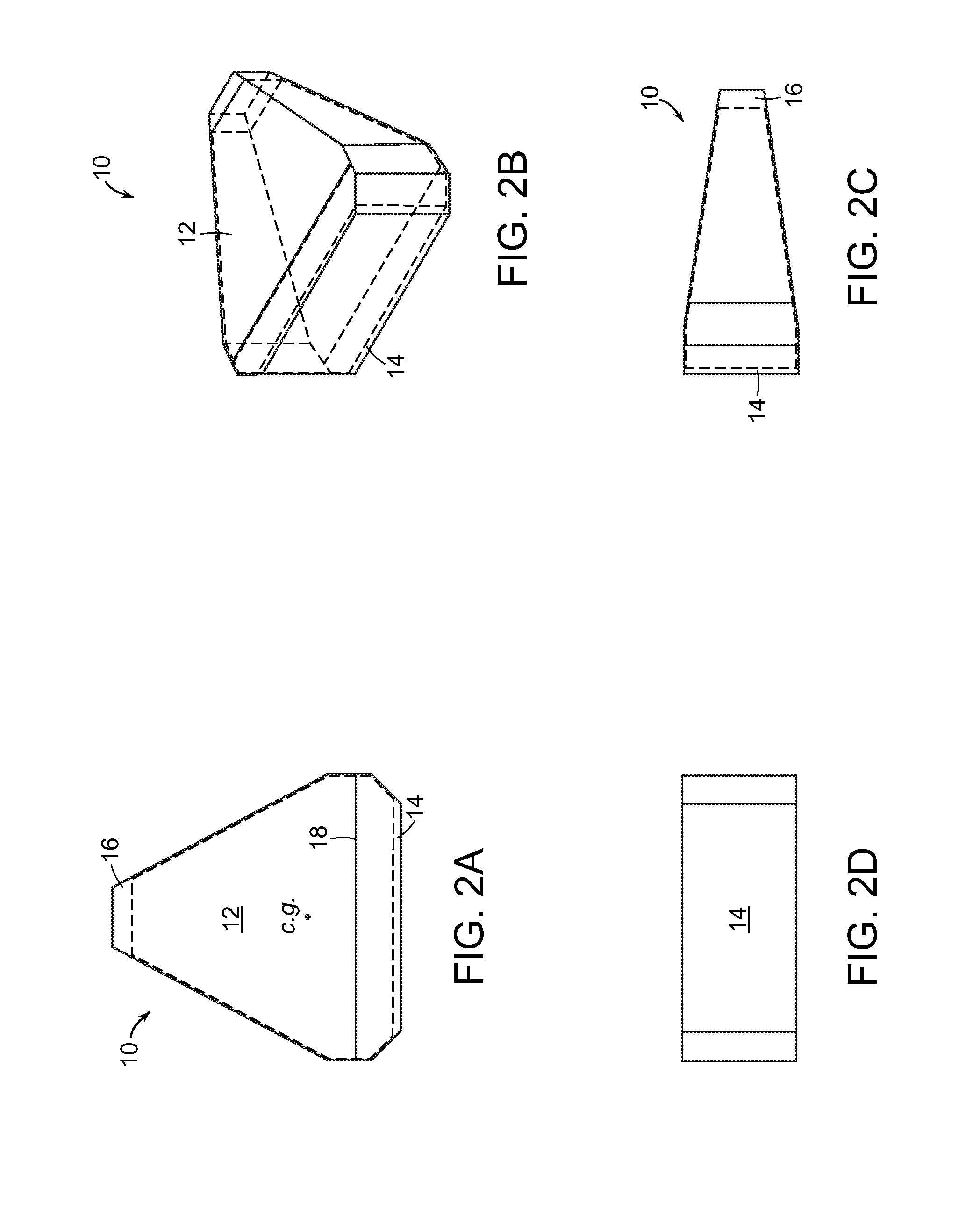

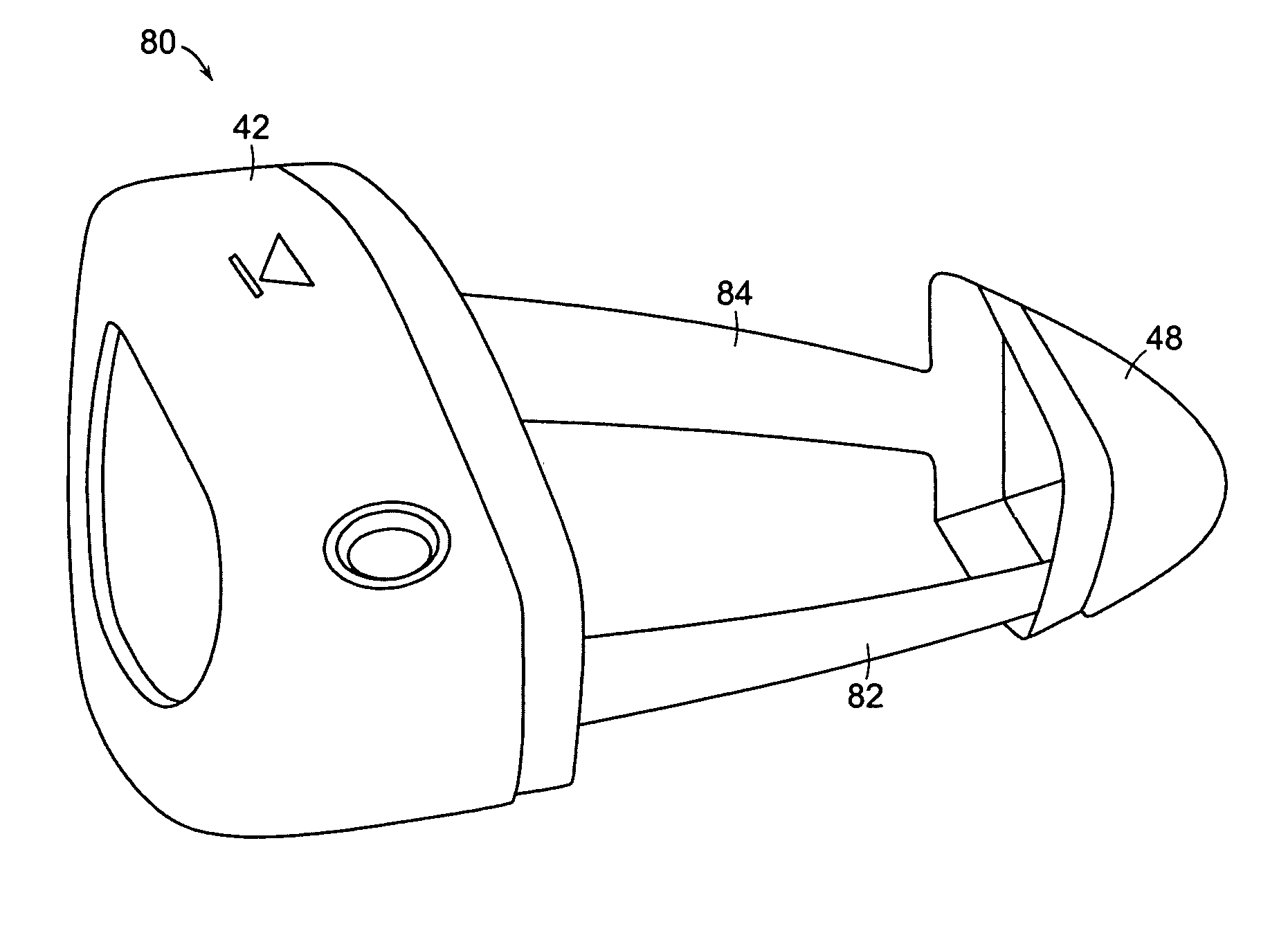

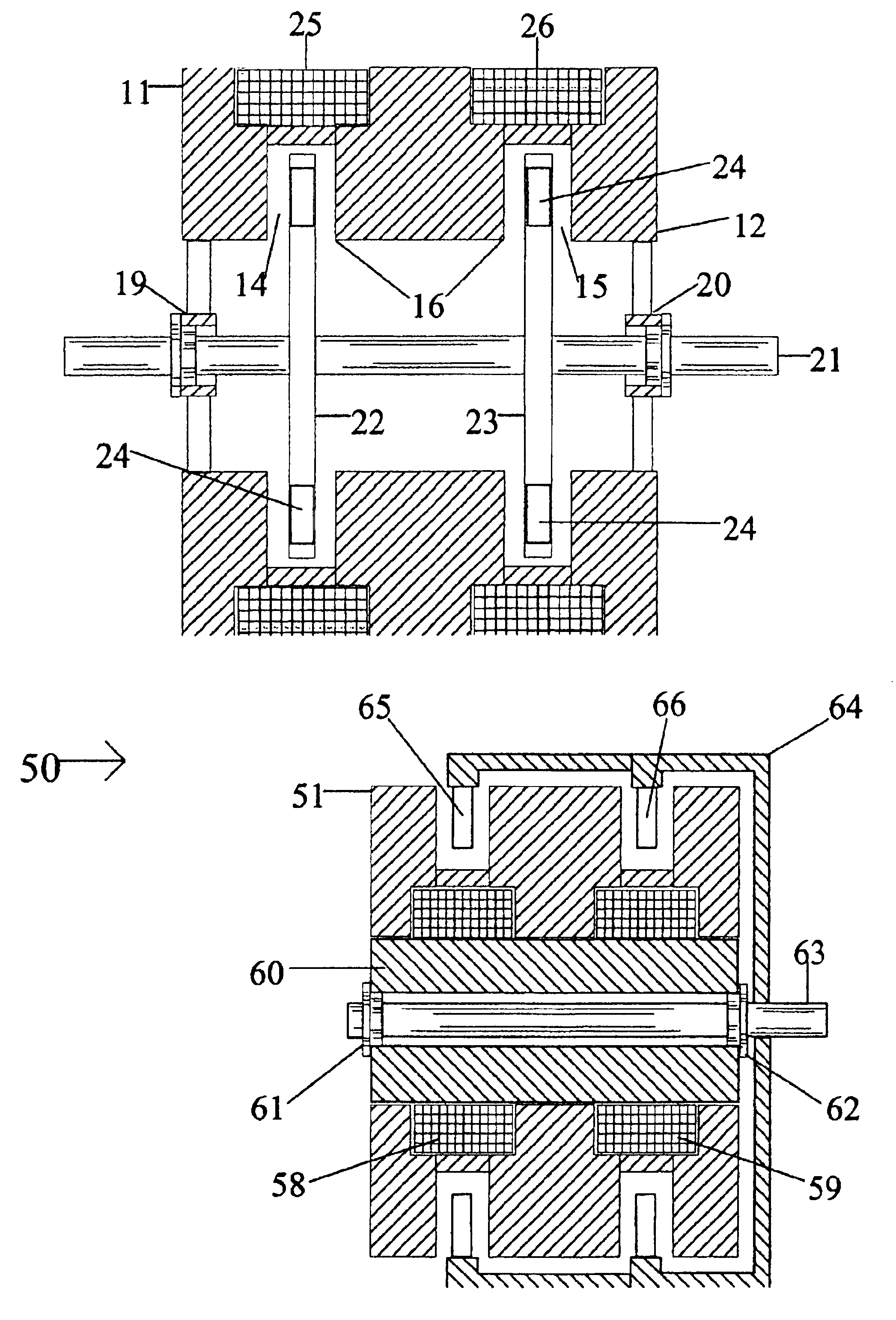

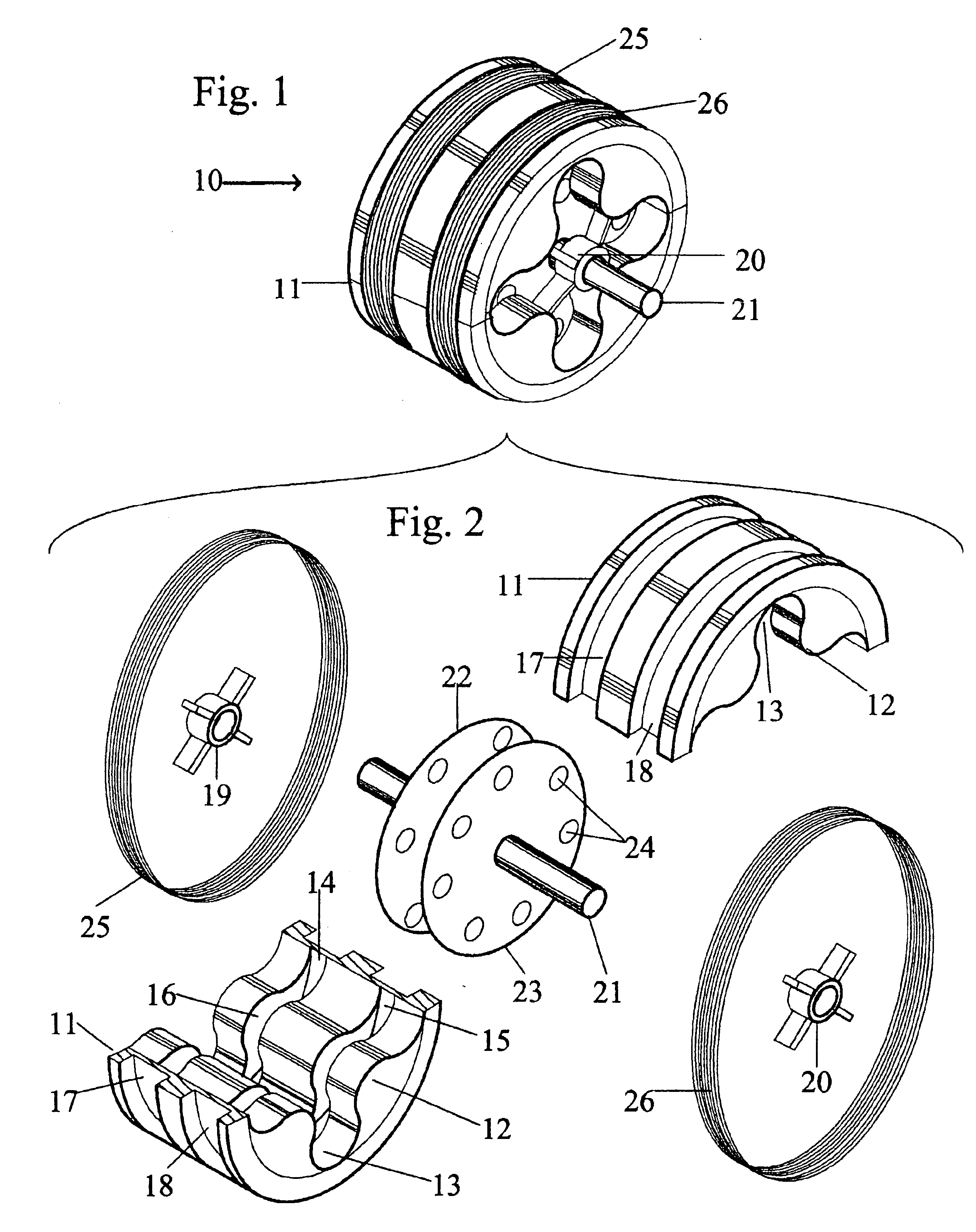

Expandable reaming device

InactiveUS20060276797A1Increase the effective diameterGood flexibilitySurgerySurgical drillProsthesis

An expanding reamer for reaming or cutting a concave surface, for example, for reaming an acetabulum in preparation for implanting a prosthetic component, such as an acetabular cup or socket, during a hip arthroplasty. The reamer includes a rotating shaft cooperating with a surgical drill or other power source at one end and rotating a reamer head at the other end, and a system adapted to expand one or more blades on the reamer head. In a preferred version, the reamer head comprises a plurality of generally circular, preferably substantially flat and parallel blades, the outer blades of which are radially expandable as segments of a cutting sphere to enlarge the effective diameter of the reamer head. A transverse blade may guide expansion of the blades to move upwards as well as outward to maintain a nearly perfect cutting sphere across a range of diameters. Upon rotation of the reamer head, the blades form a portion of an effective cutting sphere that is preferably greater-than-180-degrees in order to allow greater flexibility in placement of the shaft of the reamer relative to the surface being reamed, for example, relative to the center of axis of the acetabulum.

Owner:BOTIMER GARY

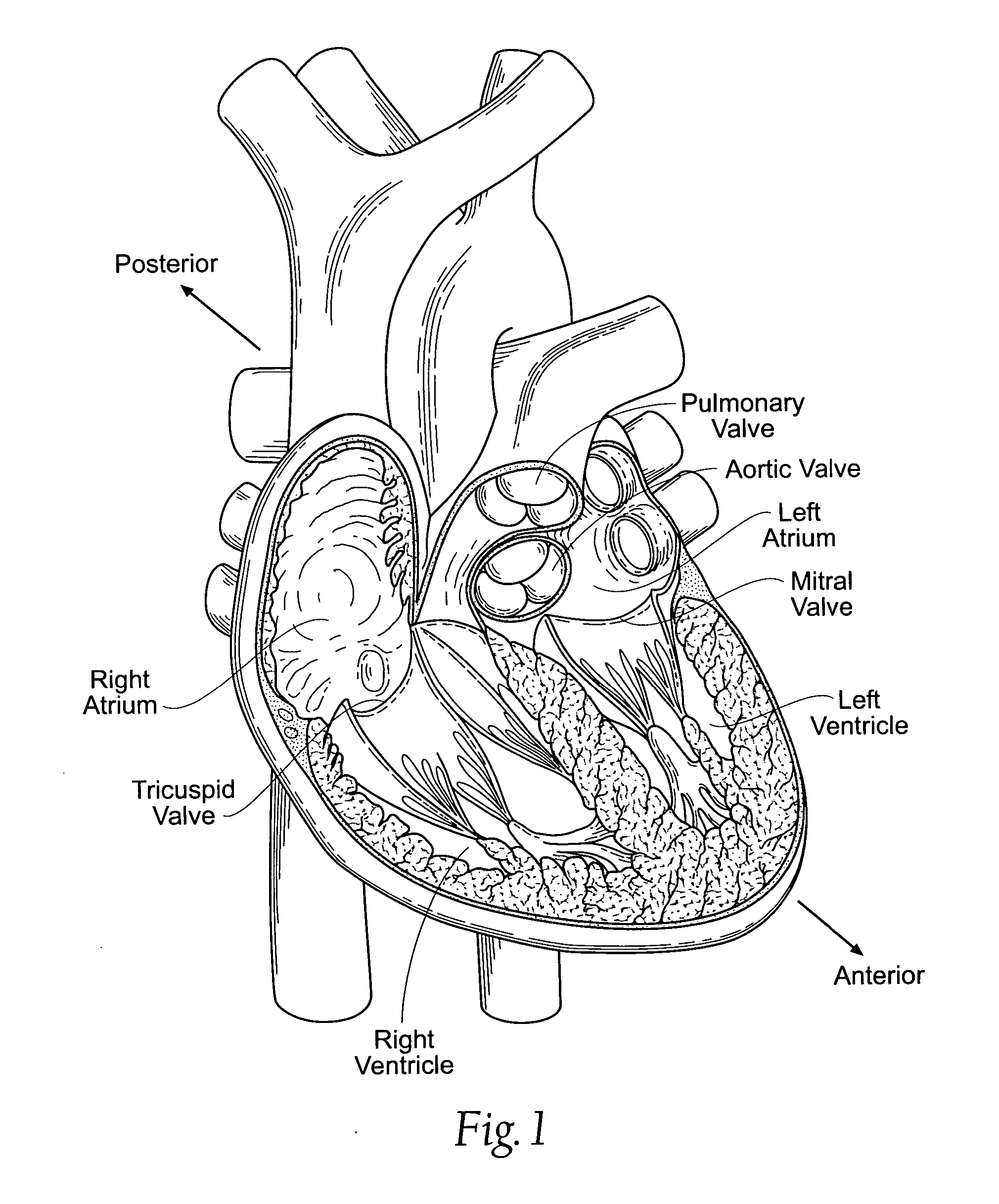

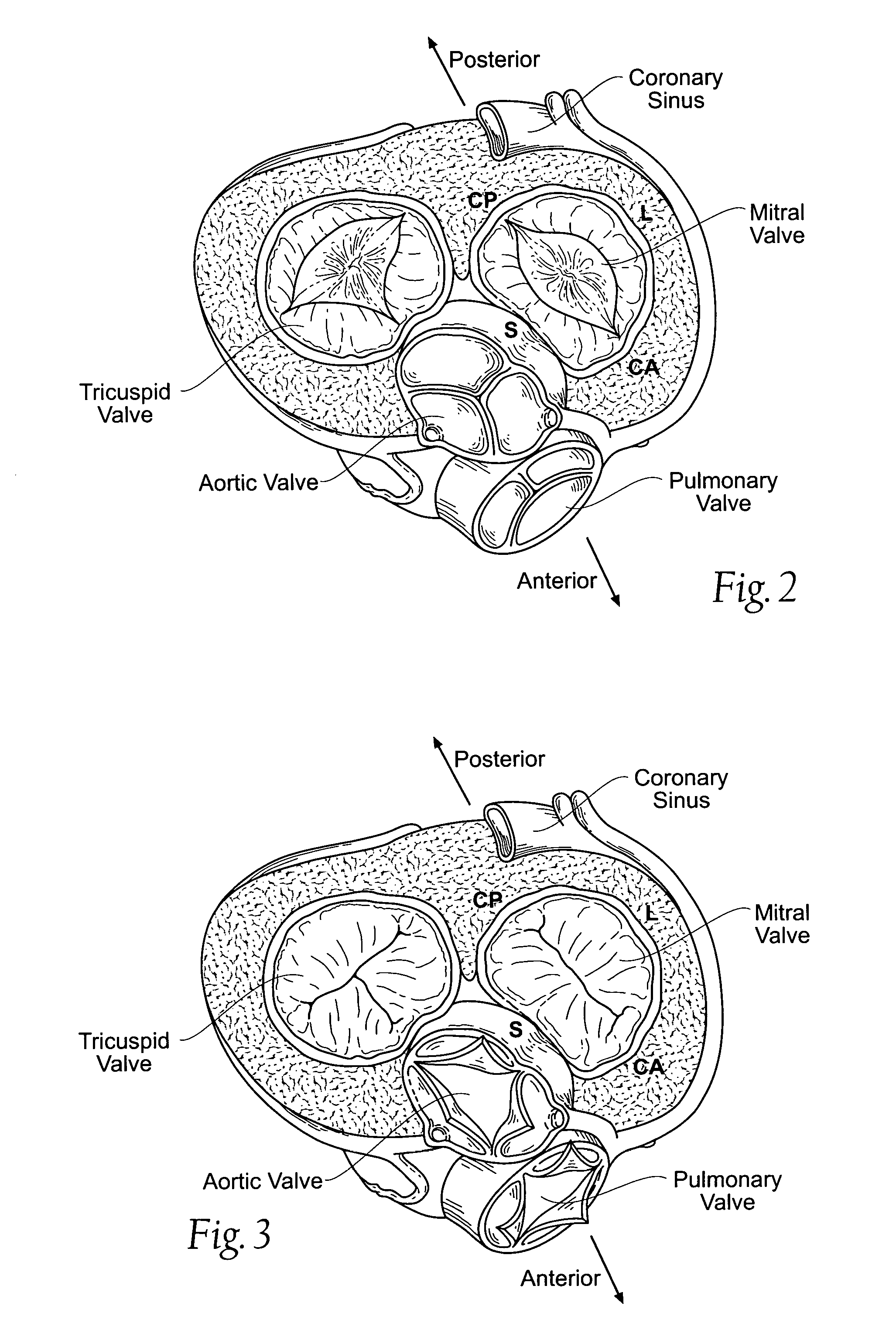

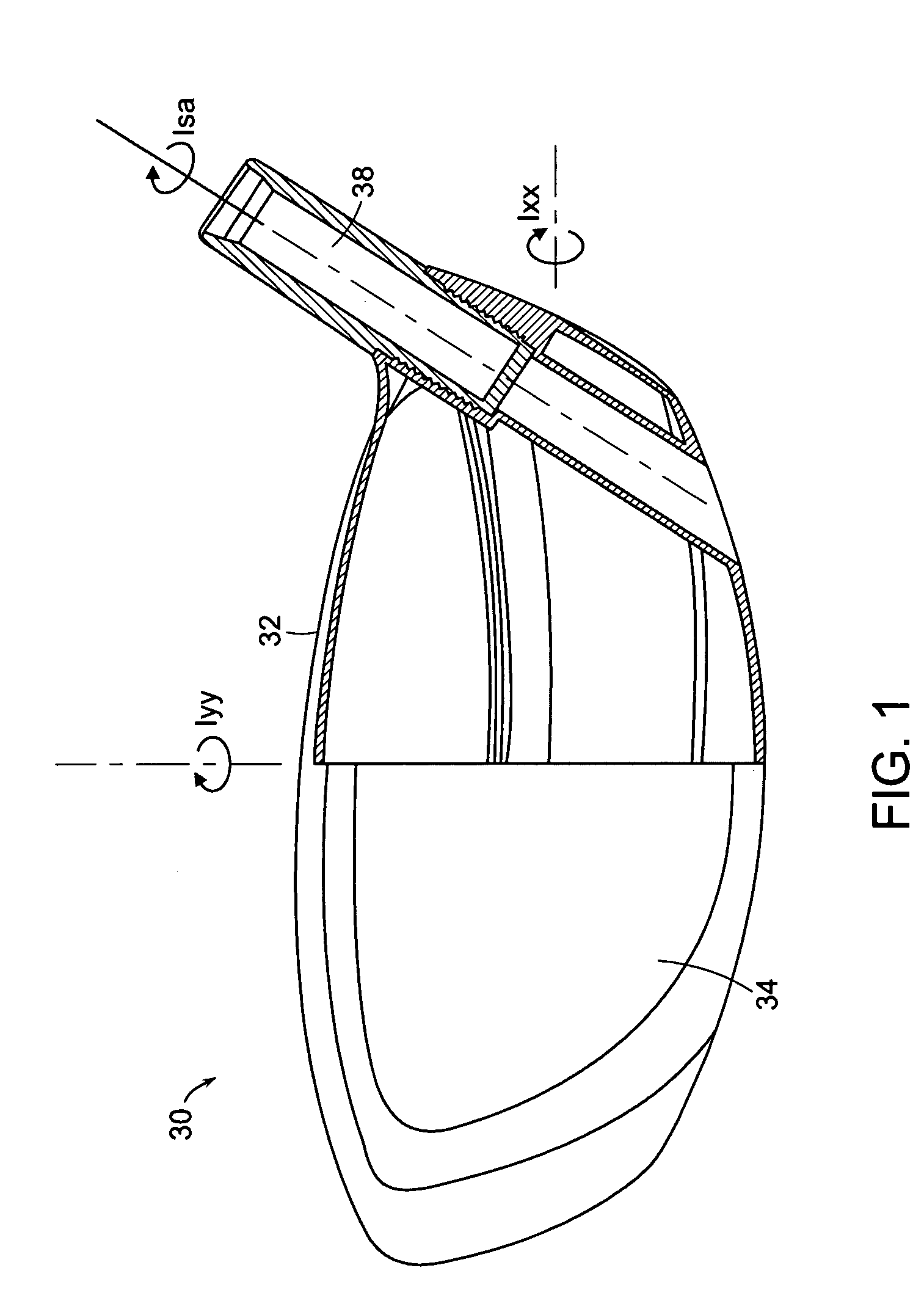

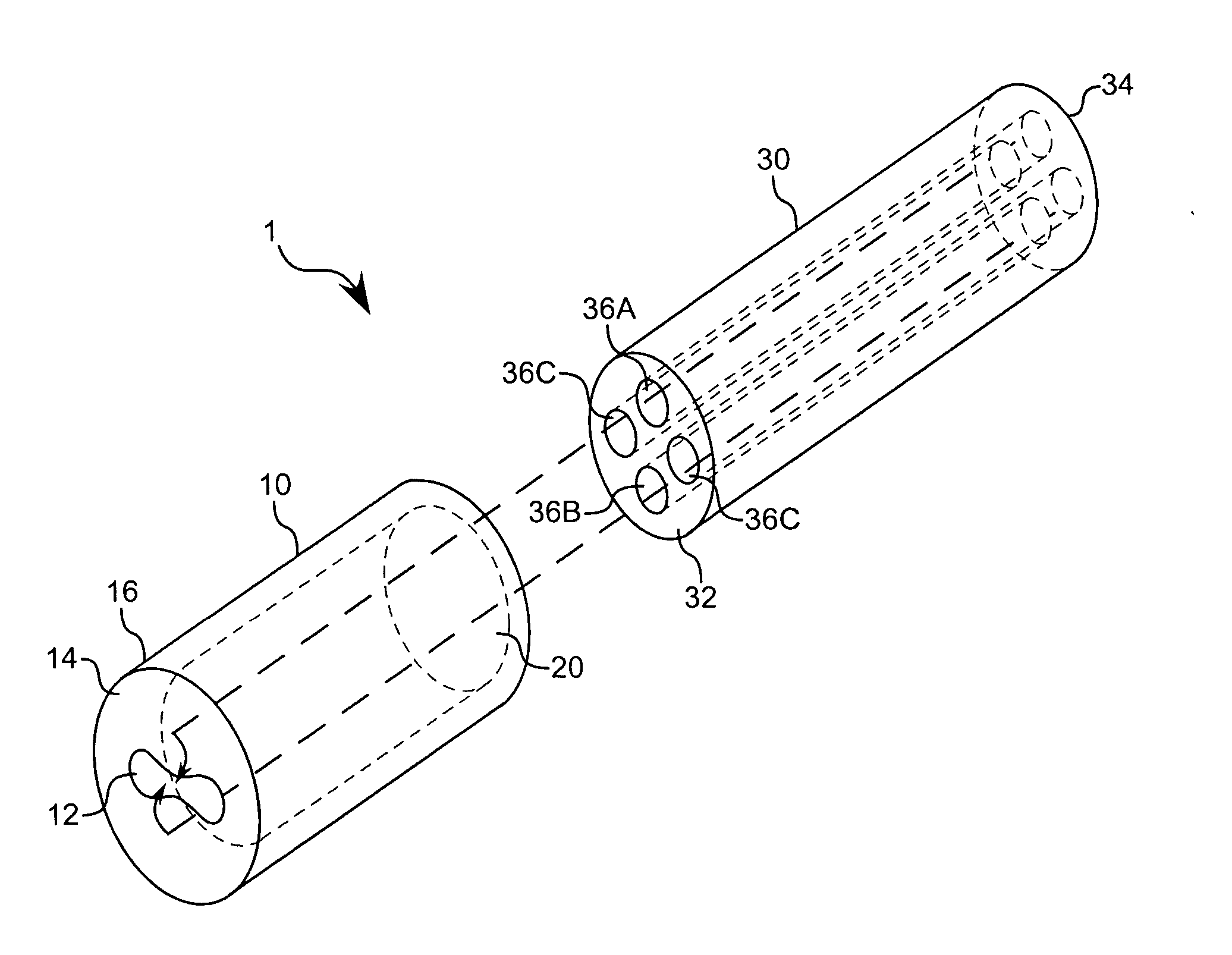

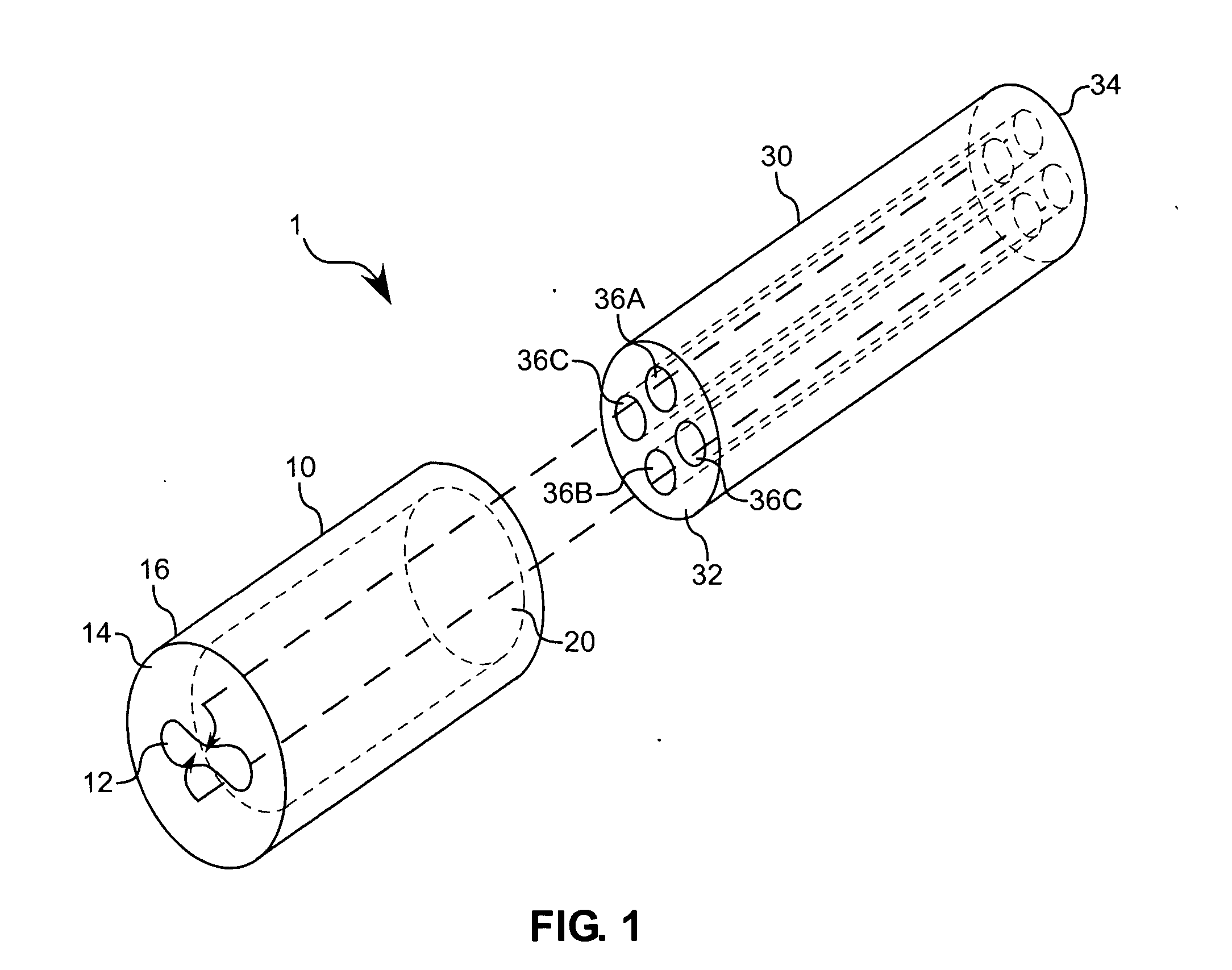

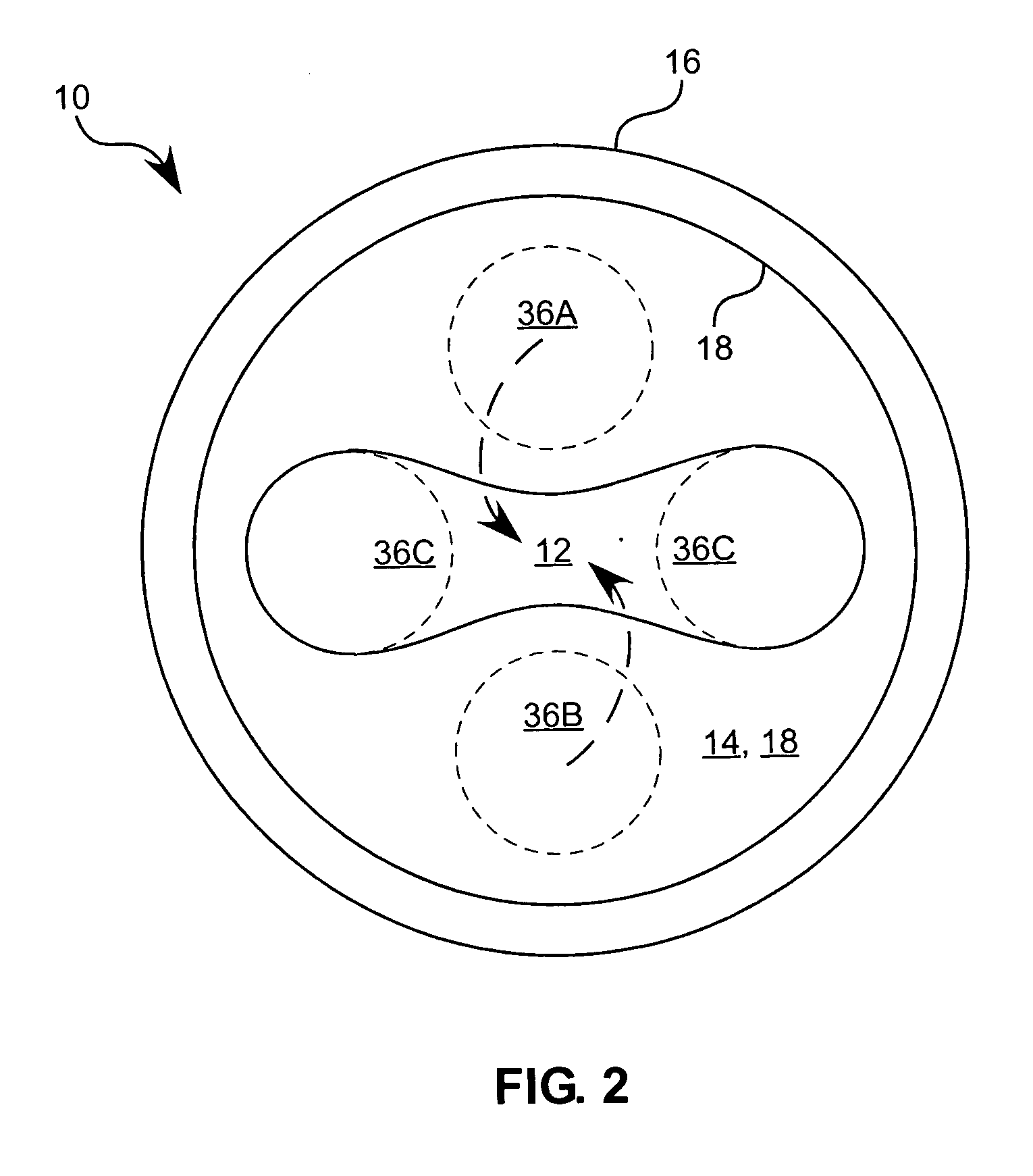

Devices, systems, and methods for reshaping a heart valve annulus

InactiveUS20060106456A9Reduce the amount requiredRecovery functionDiagnosticsAnnuloplasty ringsRetrograde FlowBiomedical engineering

Devices, systems, and methods employ an implant that is sized and configured to attach to the annulus of a dysfunctional heart valve annulus. In use, the implant extends across the major axis of the annulus above and / or along the valve annulus. The implant reshapes the major axis dimension and / or other surrounding anatomic structures. The implant restores to the heart valve annulus and leaflets a more functional anatomic shape and tension. The more functional anatomic shape and tension are conducive to coaptation of the leaflets, which, in turn, reduces retrograde flow or regurgitation. The implant improves function to the valve, without surgically cinching, resecting, and / or fixing in position large portions of a dilated annulus, or without the surgical fixation of ring-like structures.

Owner:VENTURE LENDING & LEASING IV

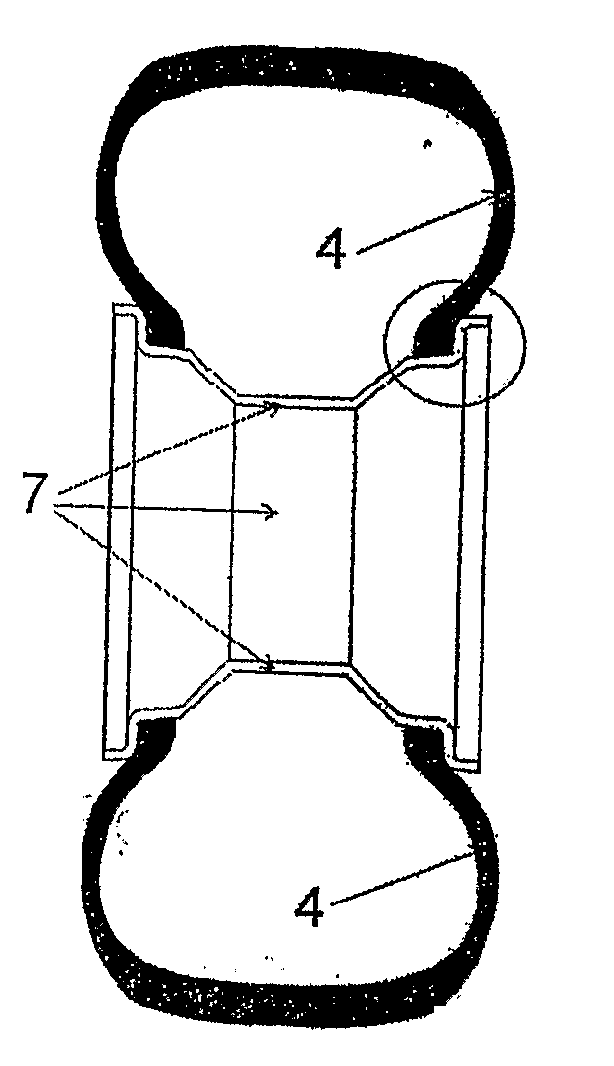

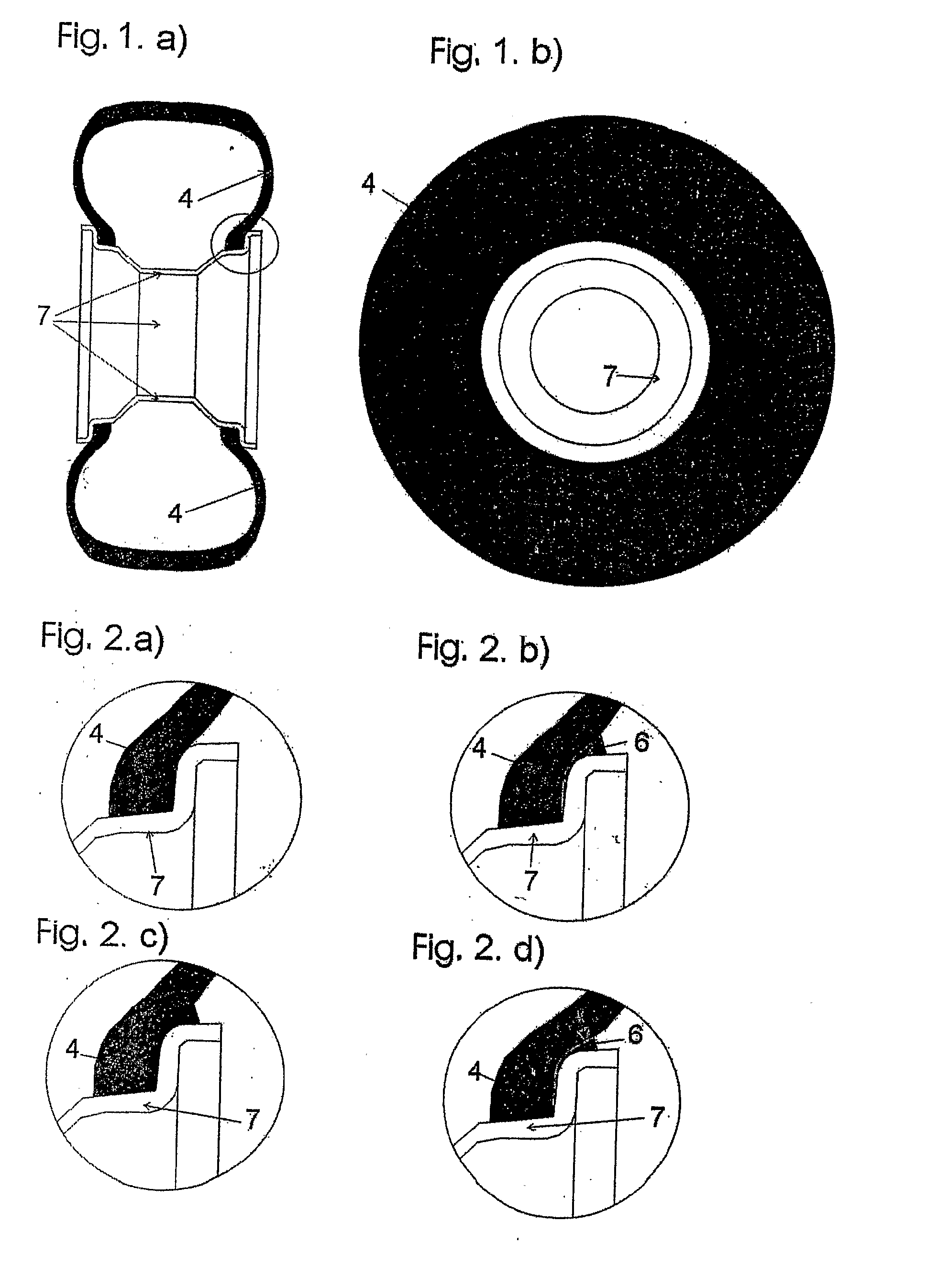

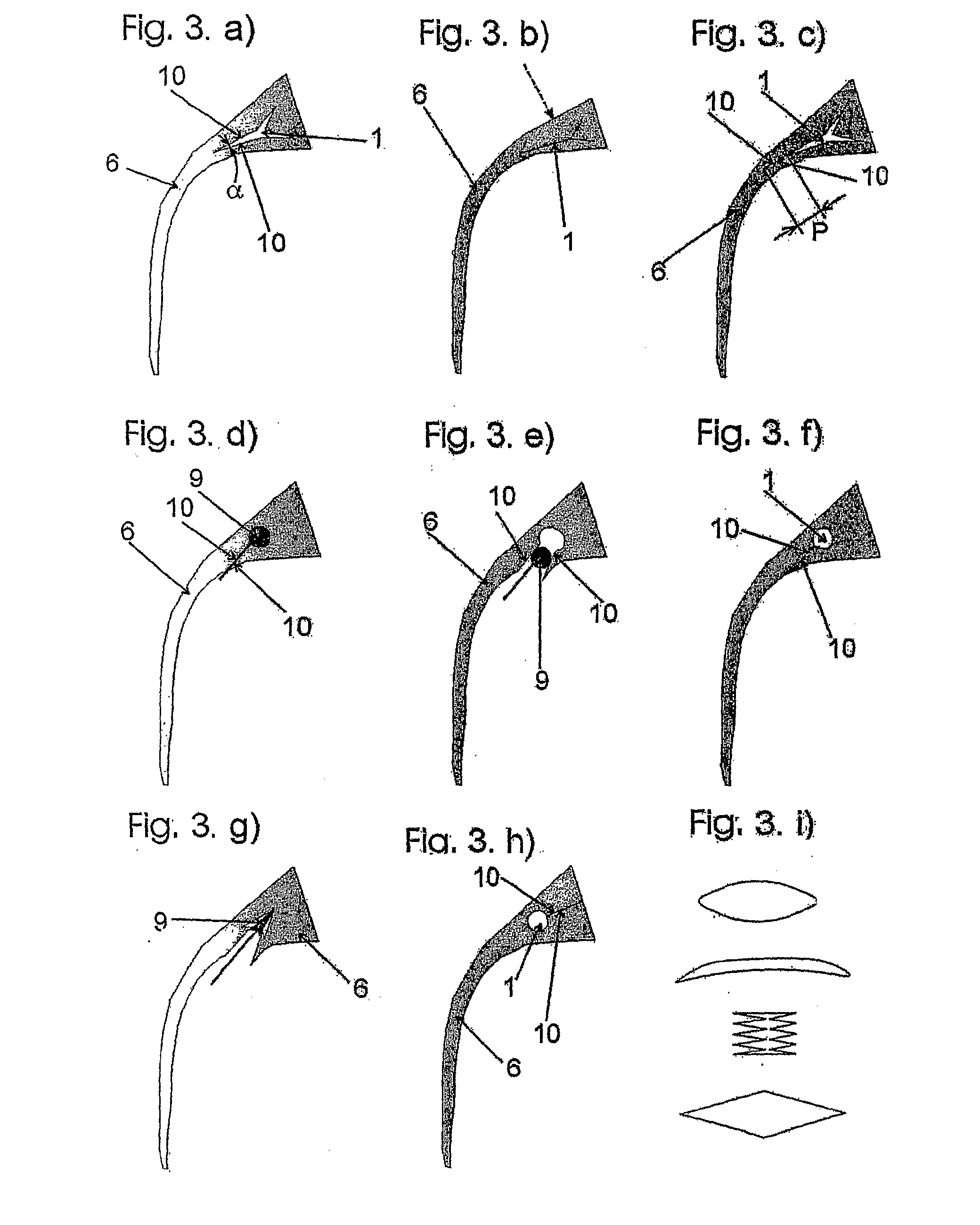

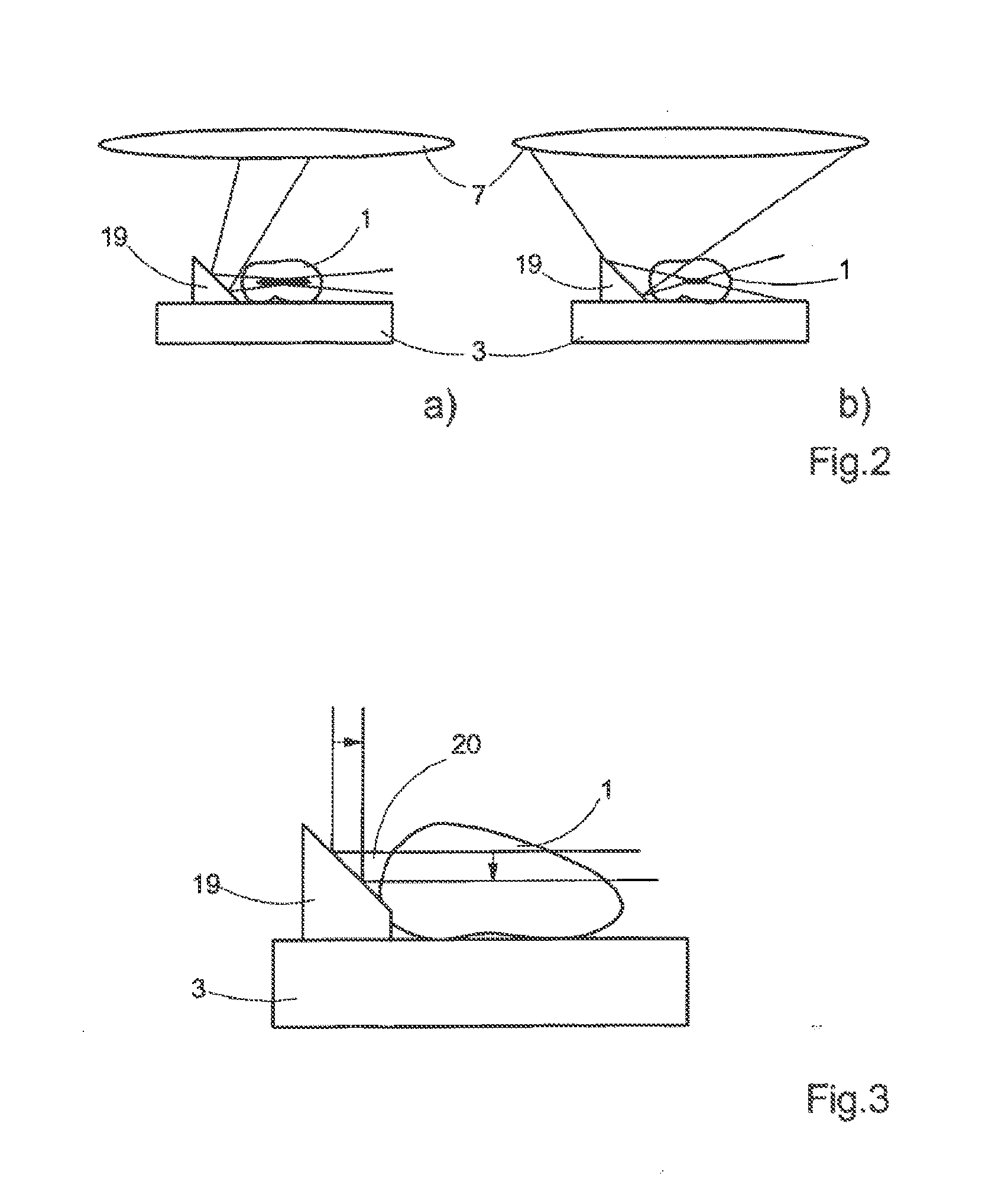

Chamber of a peristaltic pump for tire pressure adjustment

InactiveUS20090294006A1Effective shapingReduced service lifeTyresTyre beadsTire beadPeristaltic pump

A chamber (1) that works as a peristaltic pump for the pressure correction in the tire (4), which is a part of the tire (4) or of an ancillary structure (6) placed between the rim (7) and the tire bead (4) and is connected with the tire (4) internal space at one end and with the external environment at the other end. The chamber (1) is in the shape of a curved hollow channel, where at least one enclosing wall is at least partially formed by at least a pair of surfaces (10) coplanar with the longitudinal direction of the chamber (1). When the tire is mounted on the rim, the pair of surfaces (10) are pressed together thus hermetically closing the chamber (1). When the chamber (1) is closed during rotation of the wheel, the surfaces (10) can slightly slide on one another taking internal wall tensions onto themselves thus decreasing the possibility of wall damage through ripping. A method of producing the chamber (1) is also disclosed.

Owner:CODA INNOVATIONS SRO

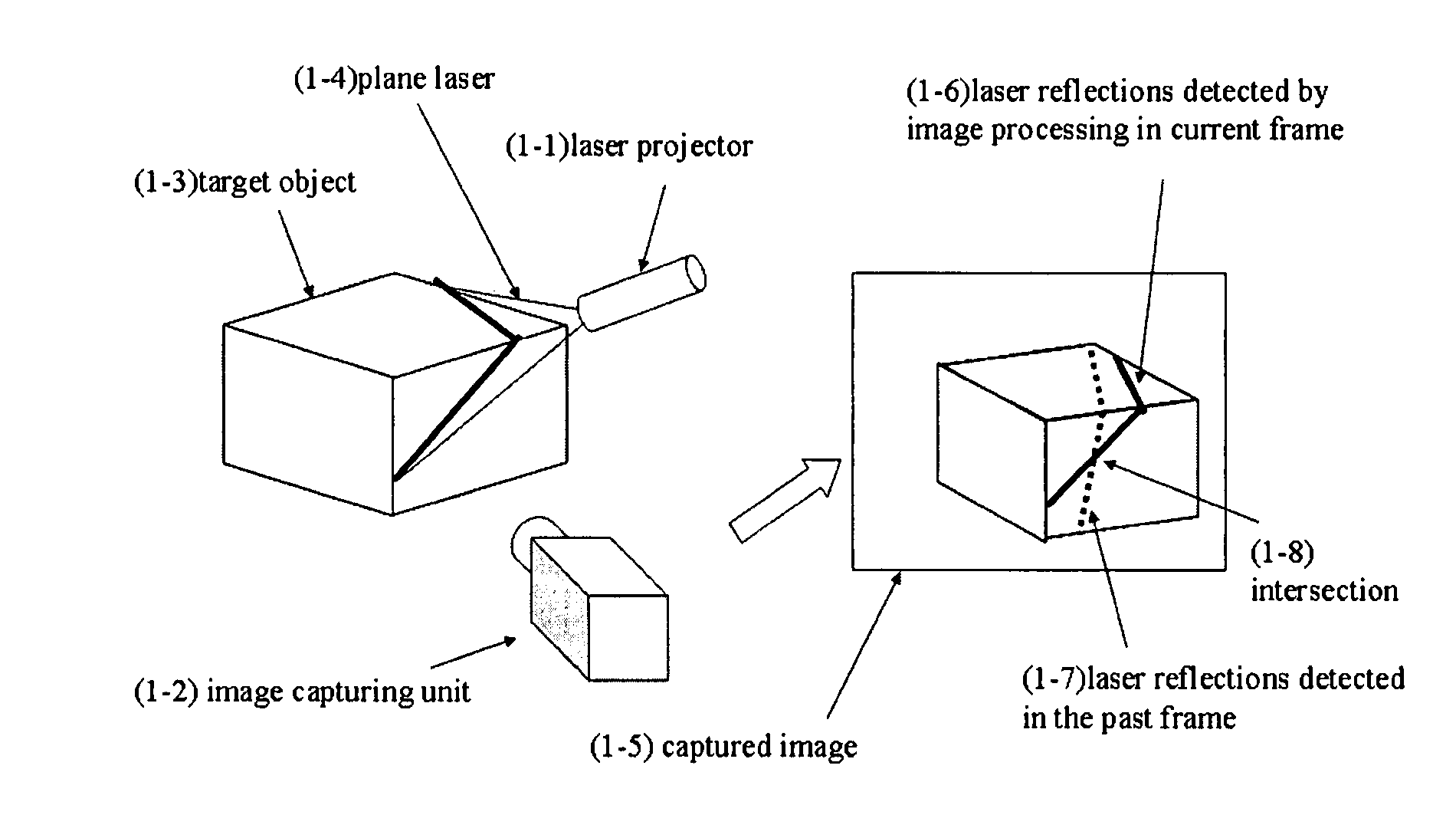

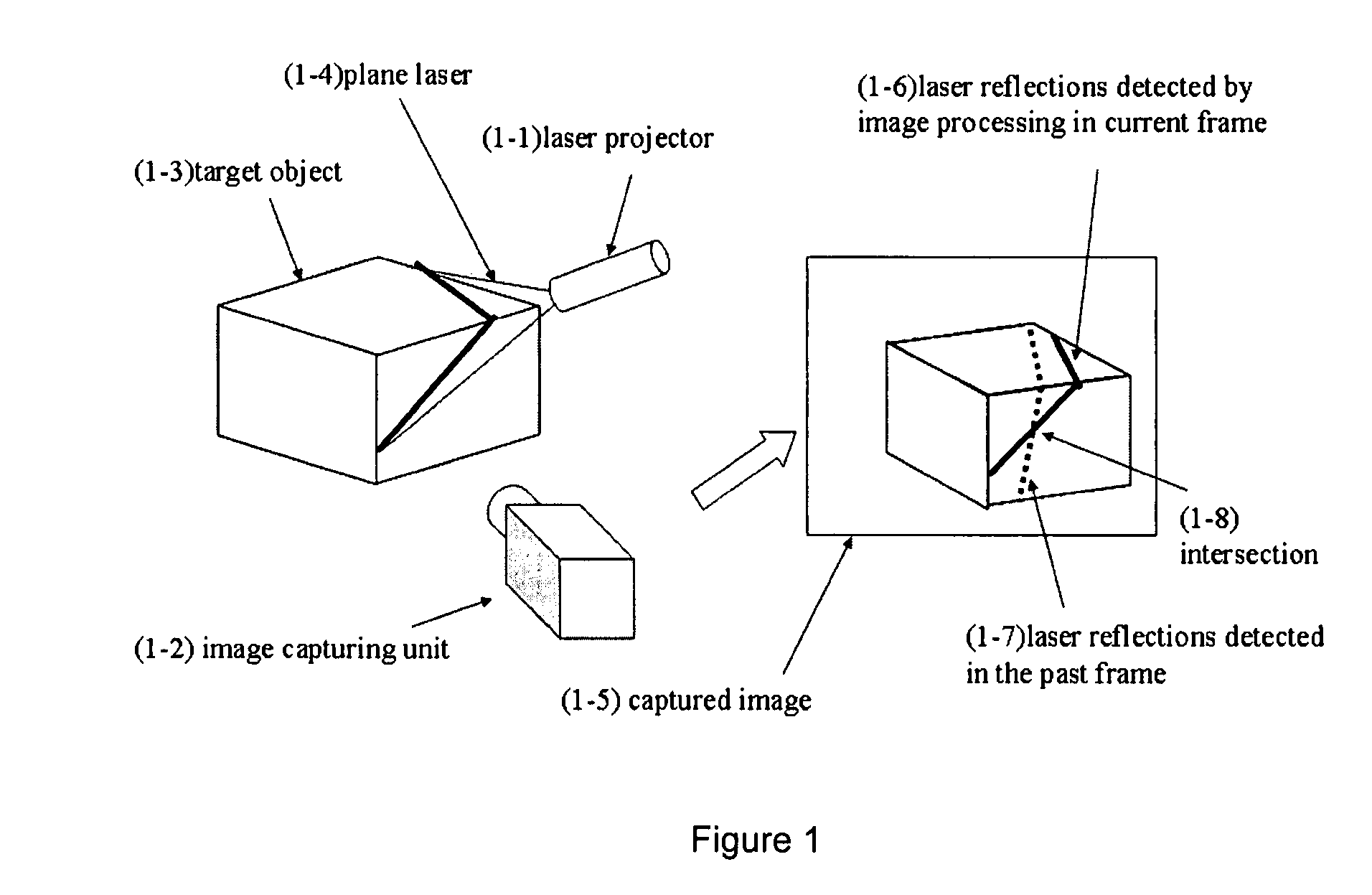

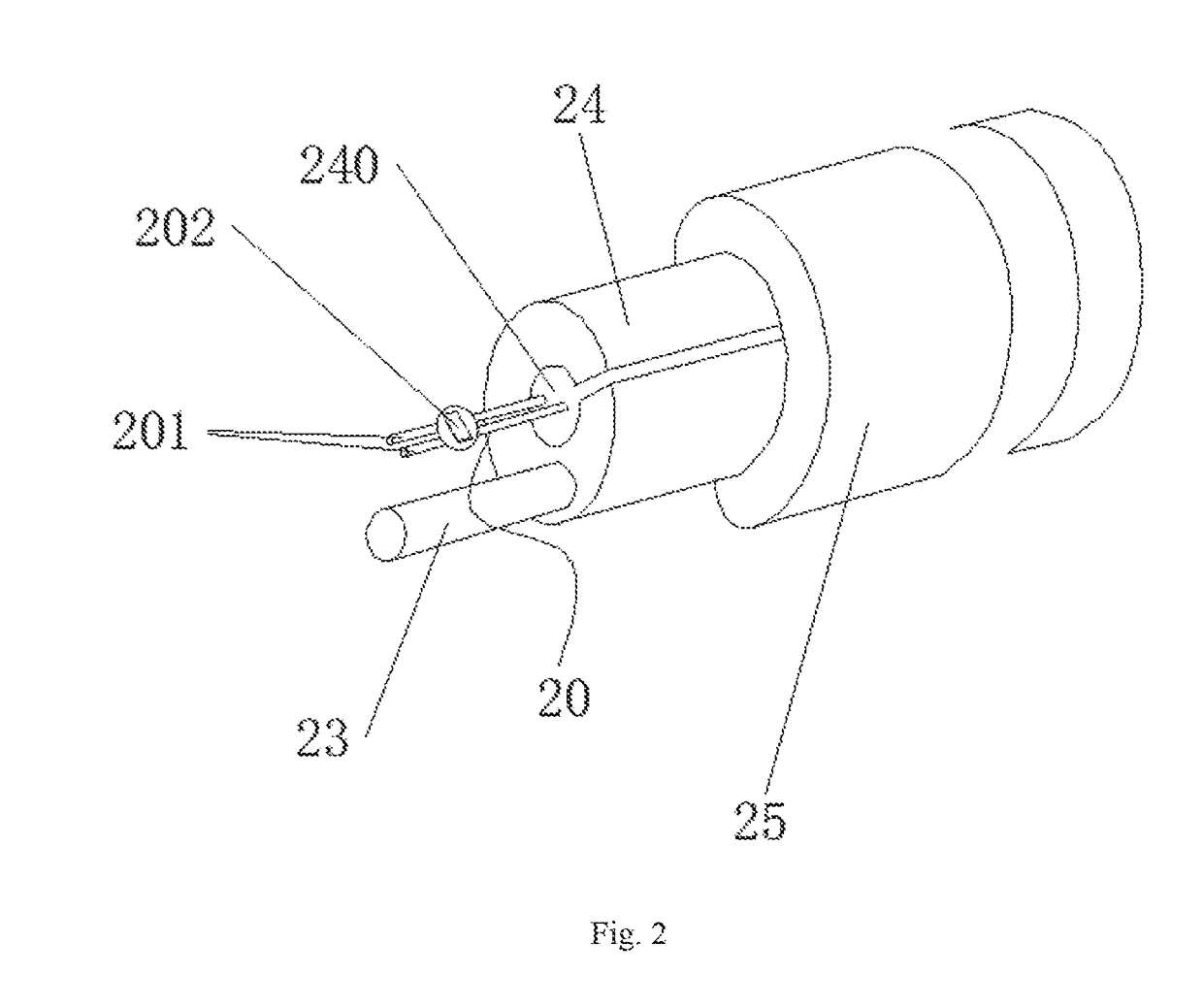

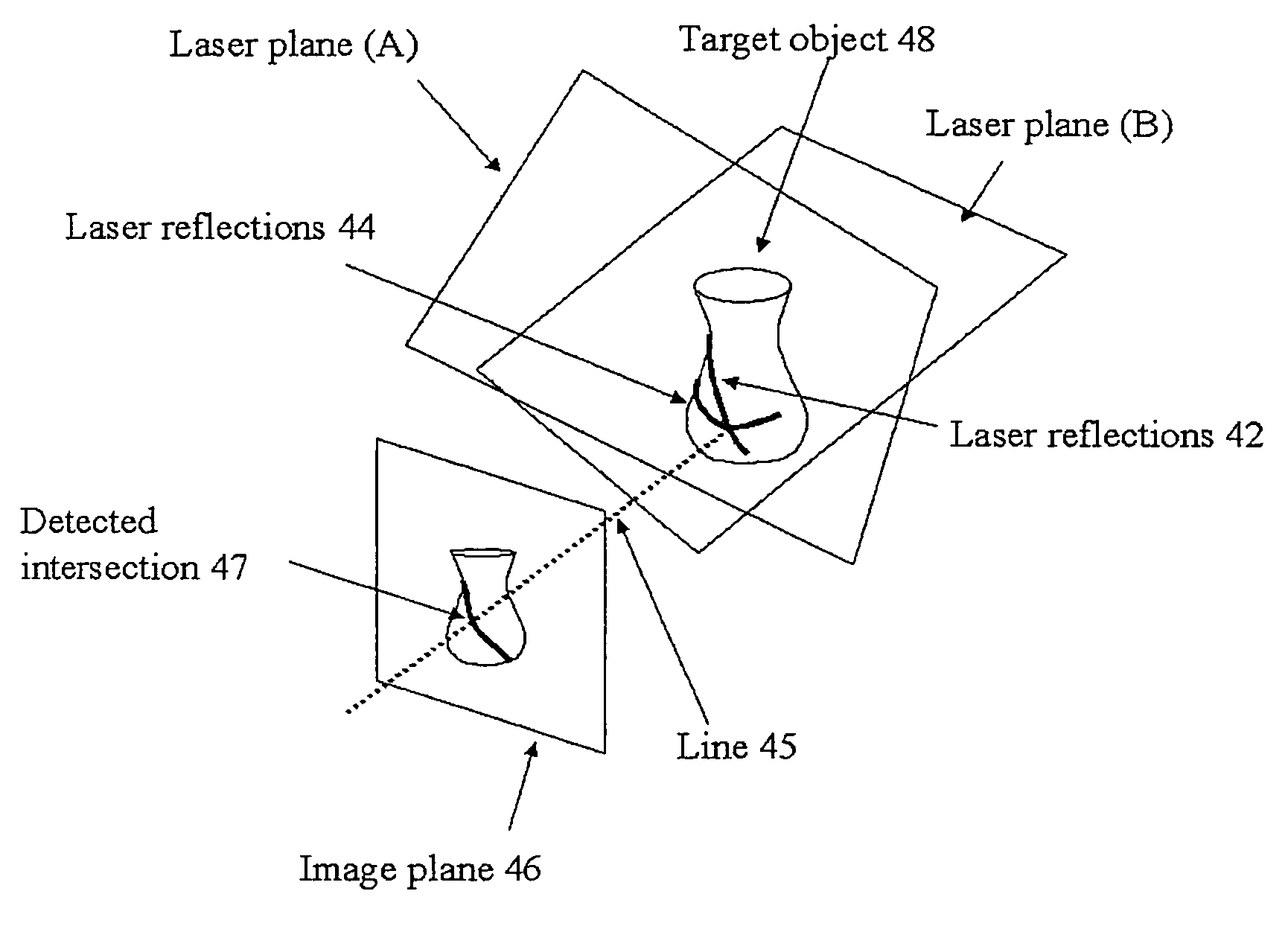

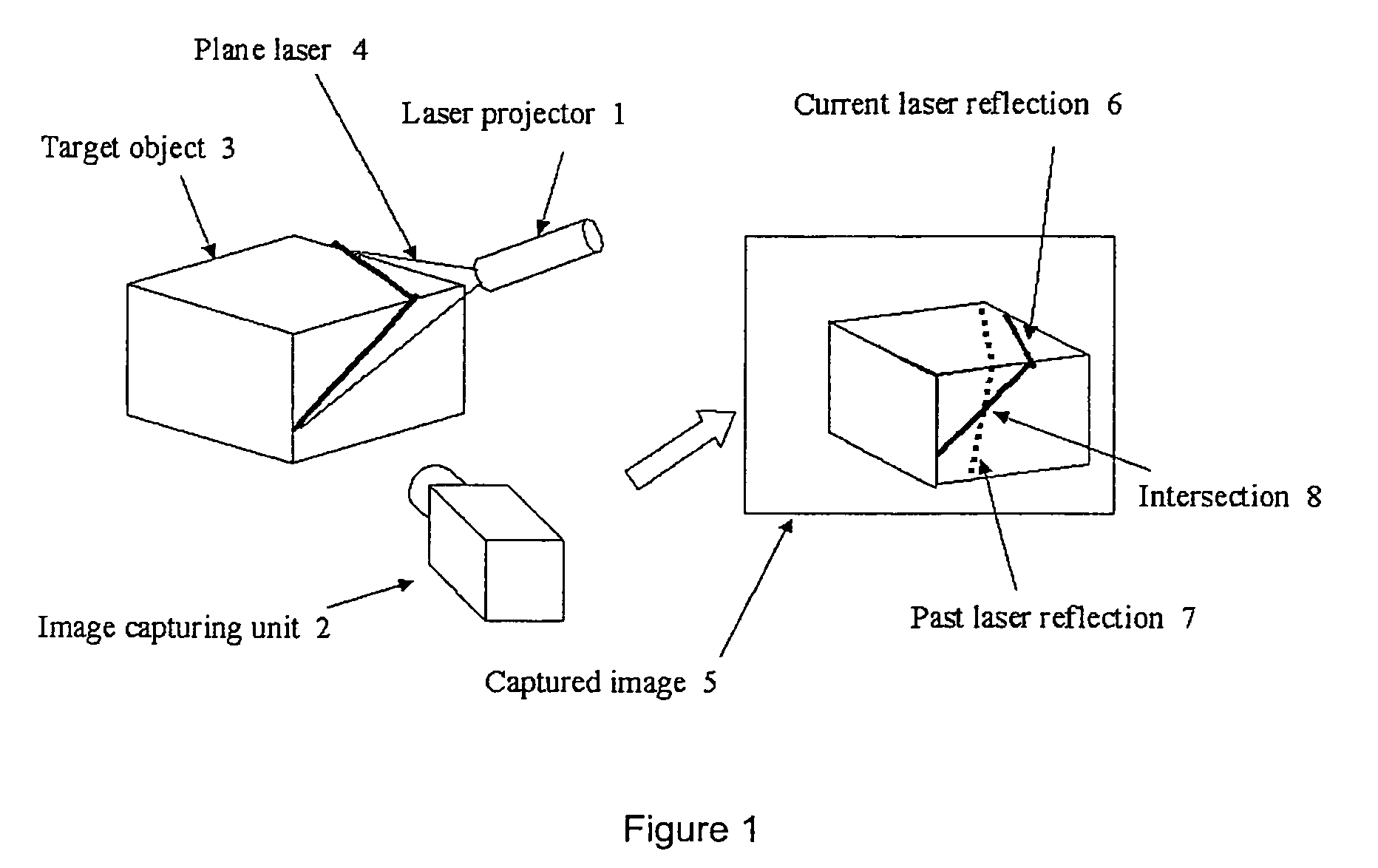

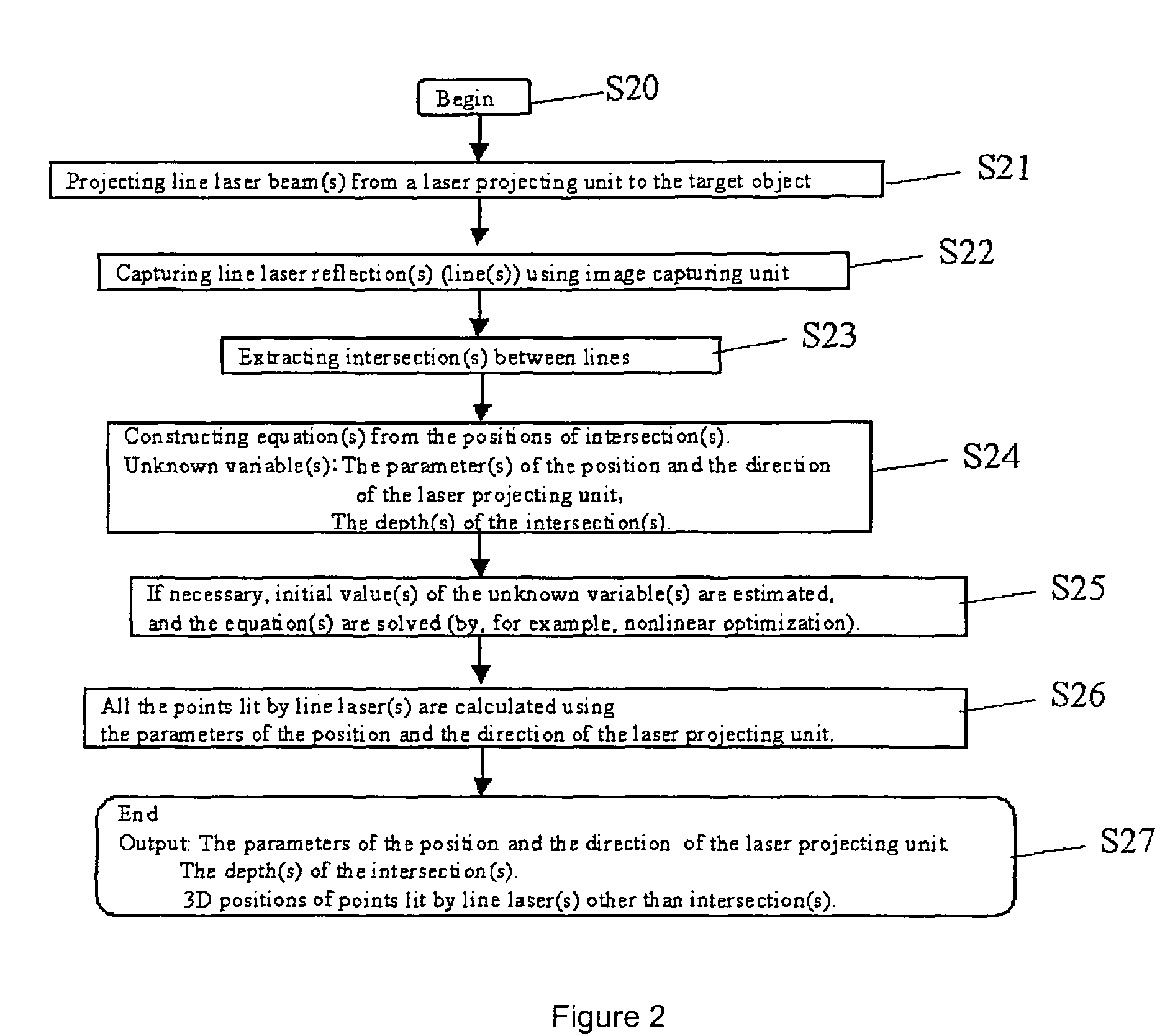

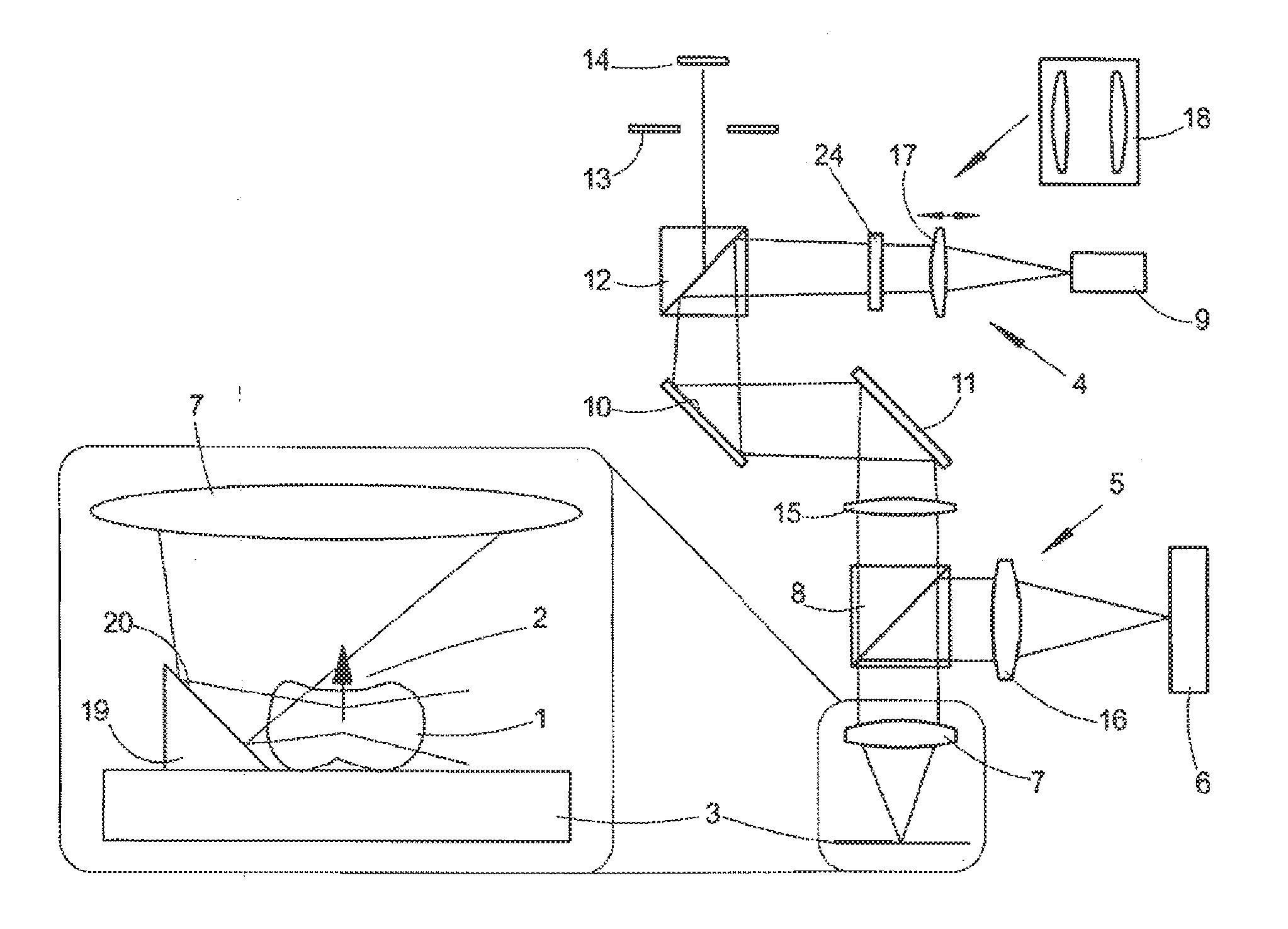

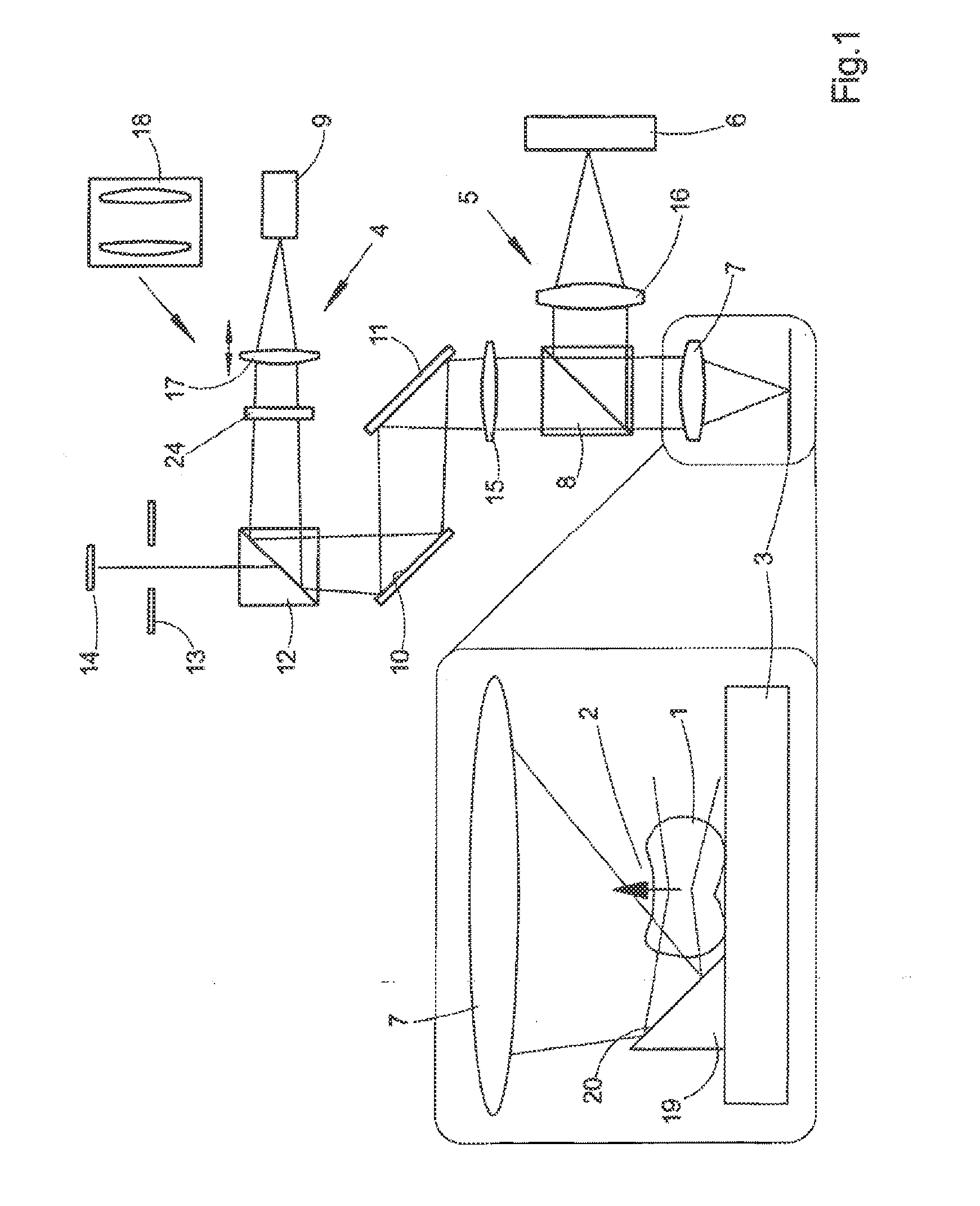

Three-dimensional shape measuring method and apparatus for the same

InactiveUS20090040532A1Improve practicalityImprove accuracyUsing optical meansTriangulationLight beam

A three-dimensional shape measuring apparatus includes a line laser light source (1) and an image capturing device (2). A three-dimensional shape measuring method and apparatus is characterized by irradiating a line laser beam to an object (3) to be measured from a laser projecting device, imaging points (6) irradiated with the laser beam by the image capturing device (2, detecting points on taken images as intersections (8), each of the points being detected from the taken images and being detected as a common point where line laser beams pass, deriving equations including the positions of the laser planes and the three-dimensional positions of the intersections as unknowns based on the detected intersections, determining the three-dimensional positions of the intersections and the positions of the laser planes by solving the derived equations as simultaneous equations, calculating by triangulation the three-dimensional positions of the points irradiated with the laser beams other than the intersections by using the positions of laser planes, and obtaining the three-dimensional shape of the object by repeating the series of processes.

Owner:TECHNODREAM21

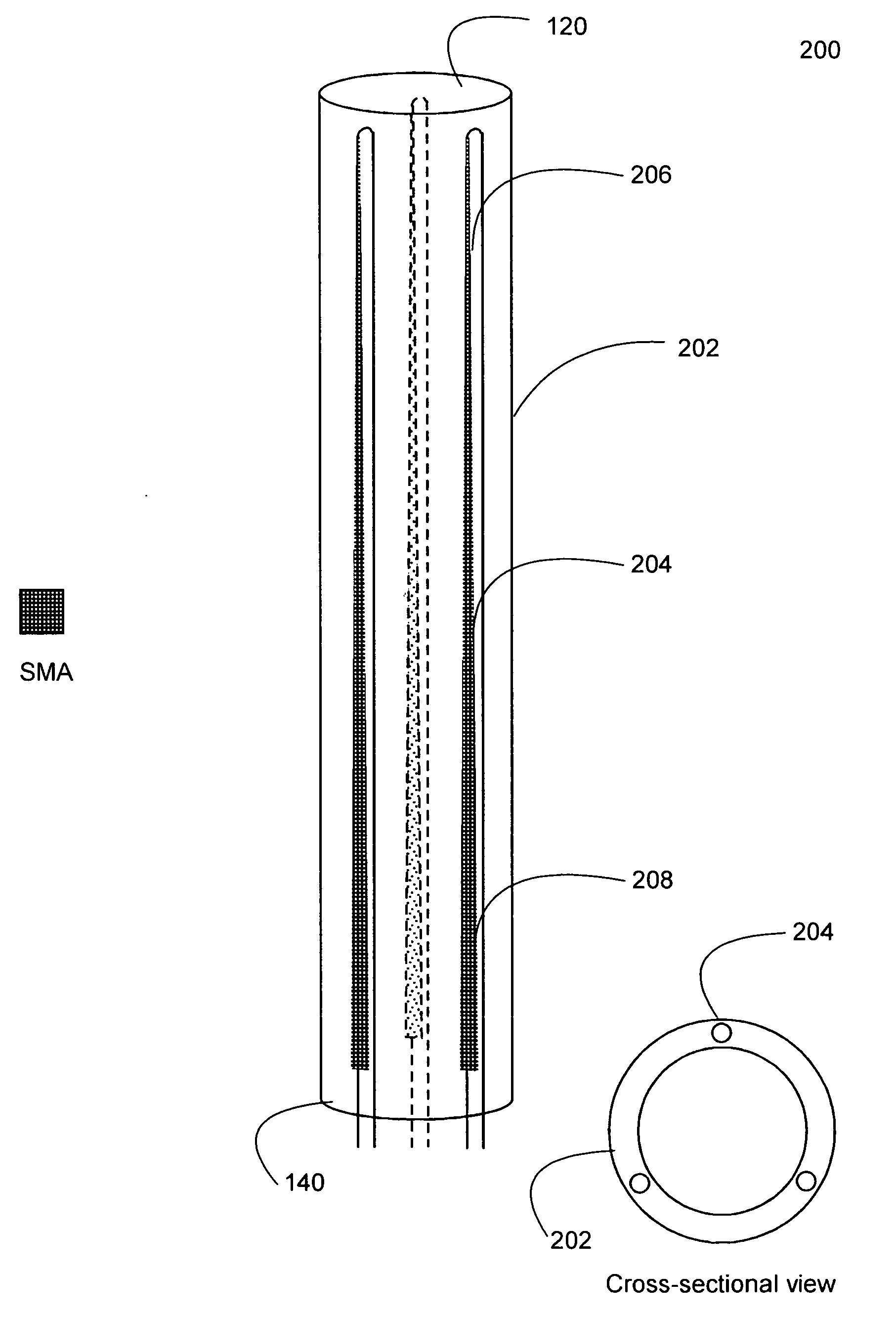

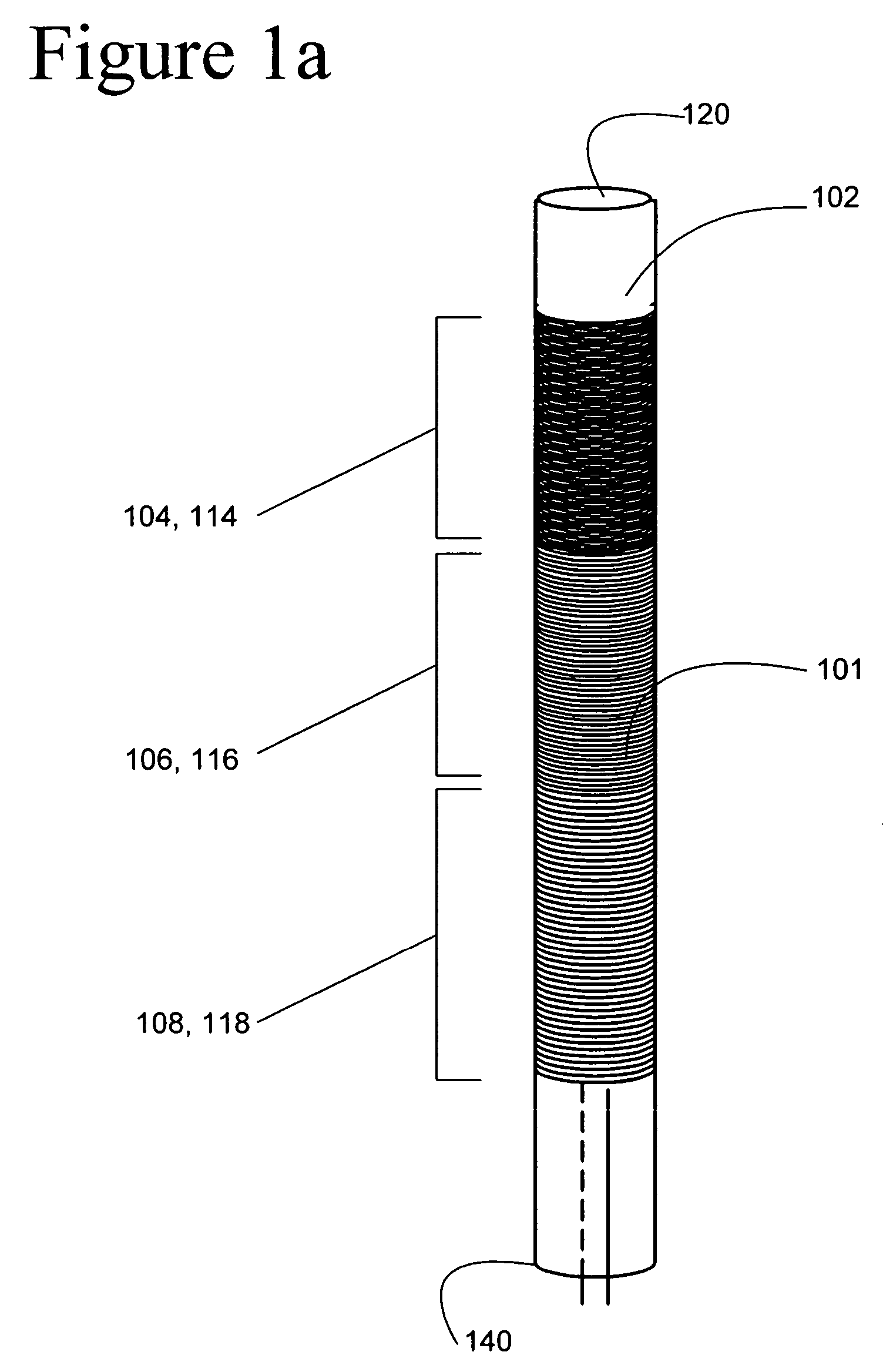

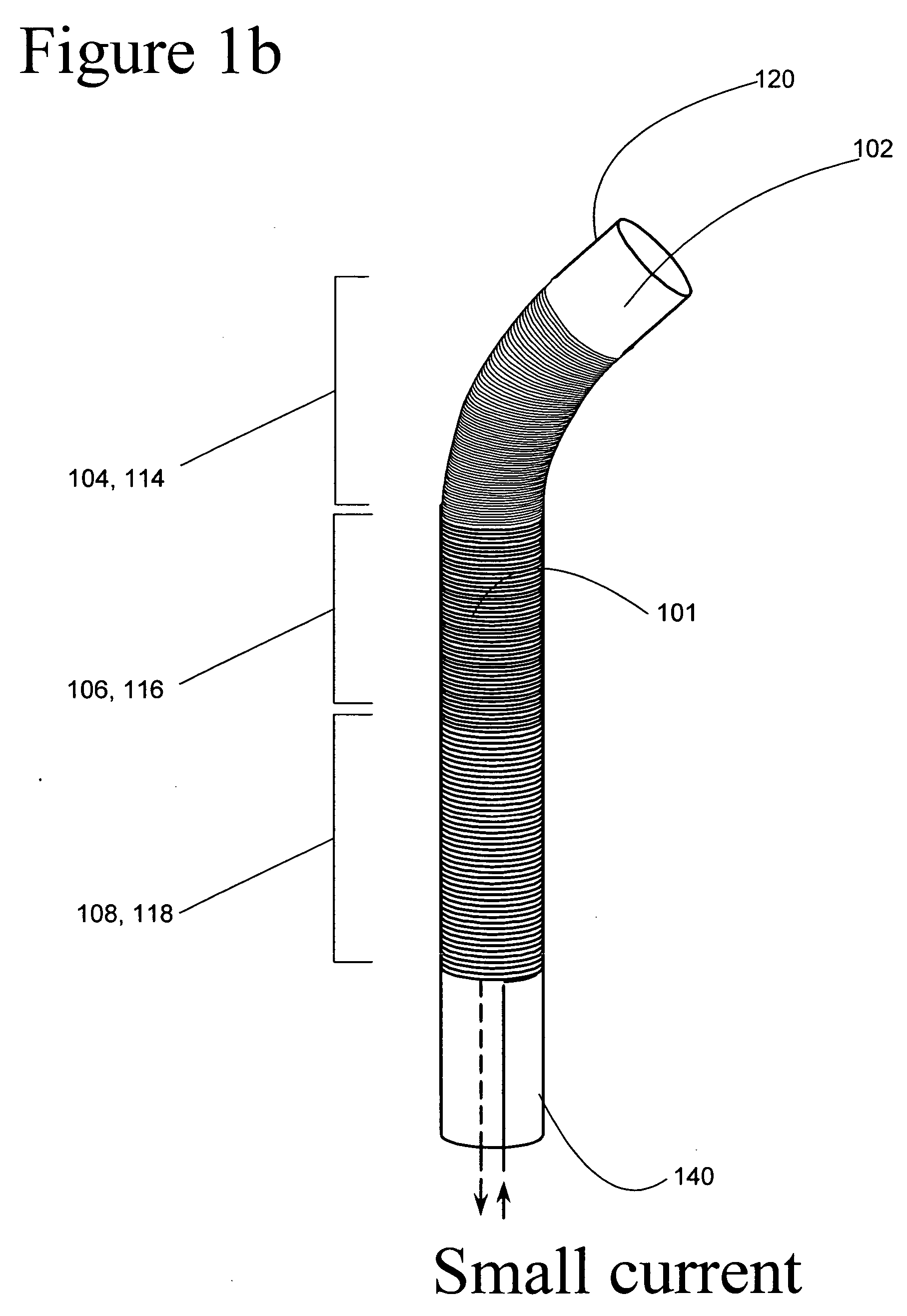

Steerable devices

InactiveUS20060064055A1Effective shapingImprove versatilityGuide wiresMedical devicesGuide tubeBiomedical engineering

The present invention provides steerable devices, such as catheters, having length, a proximal end, and a distal end that includes at least one shape memory structure incorporated into the device and configured such that graded or stepped bending of the shape memory structure may be achieved by variably heating the shape memory structure along some or all of the length of the shape memory structure to one or more transformation temperatures associated with the shape memory material either gradually or in steps, and driving devices providing the drive signal and / or energy to heat the shape memory structure to enable graded or stepped control thereof.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

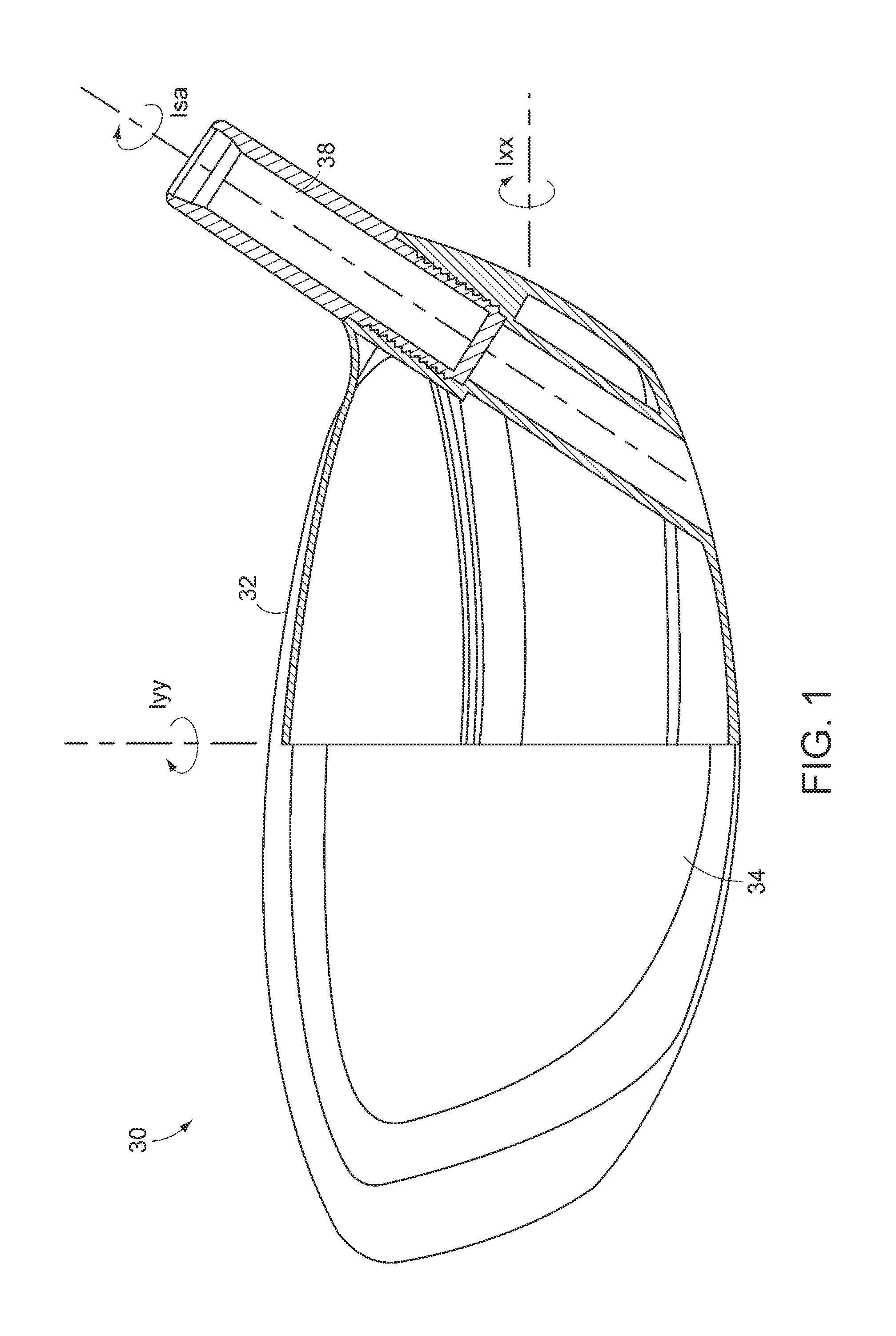

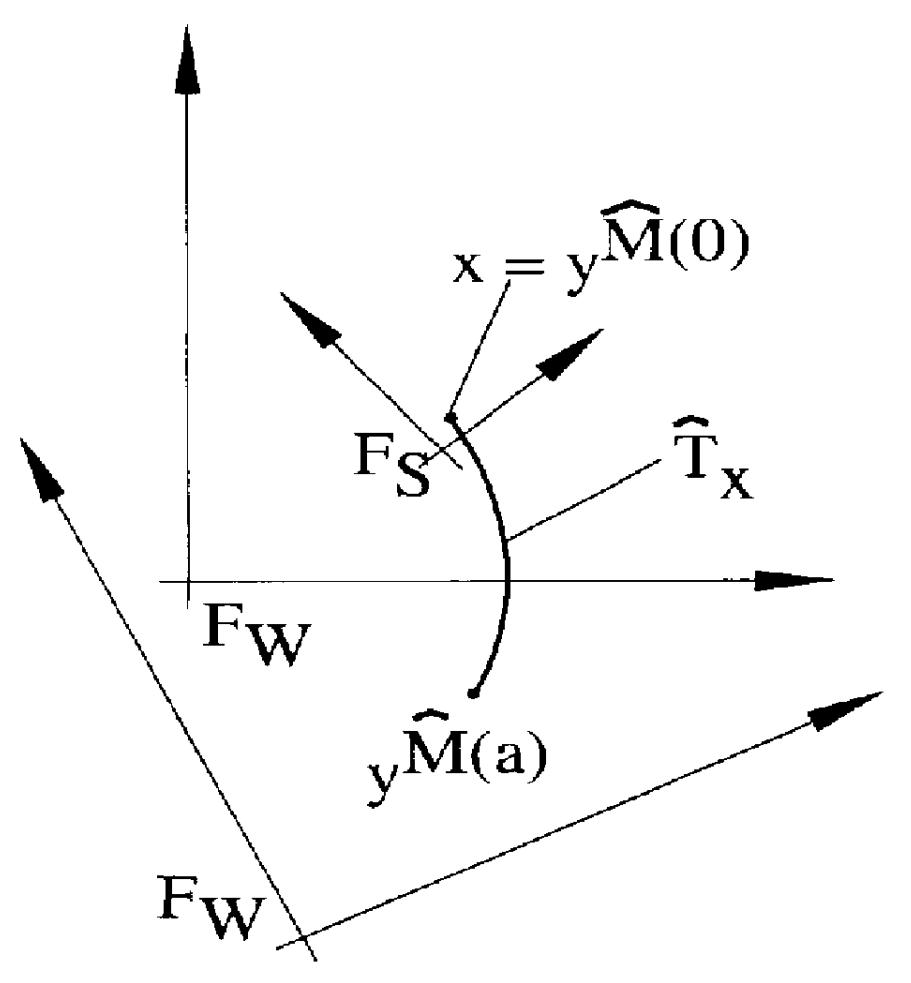

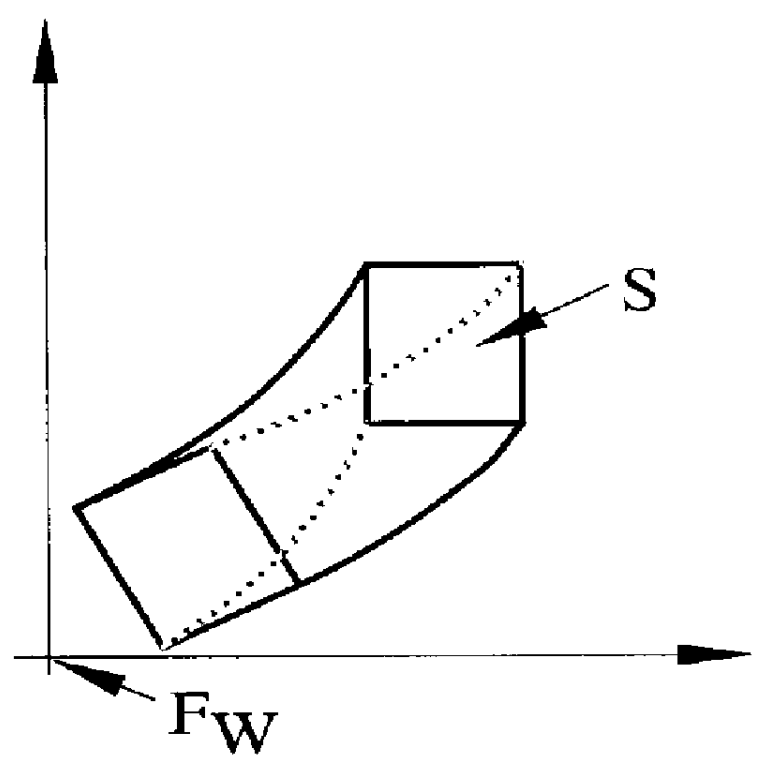

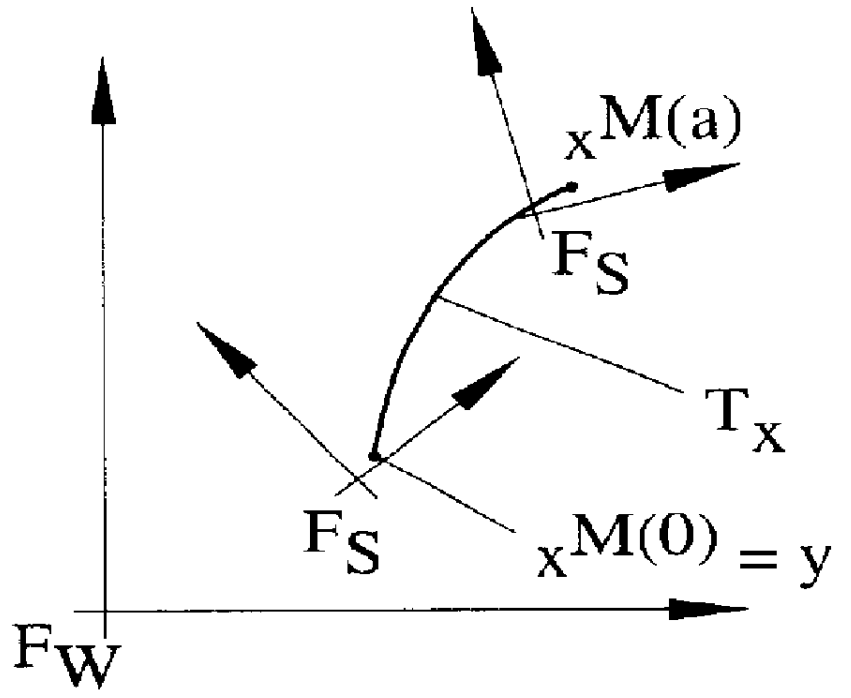

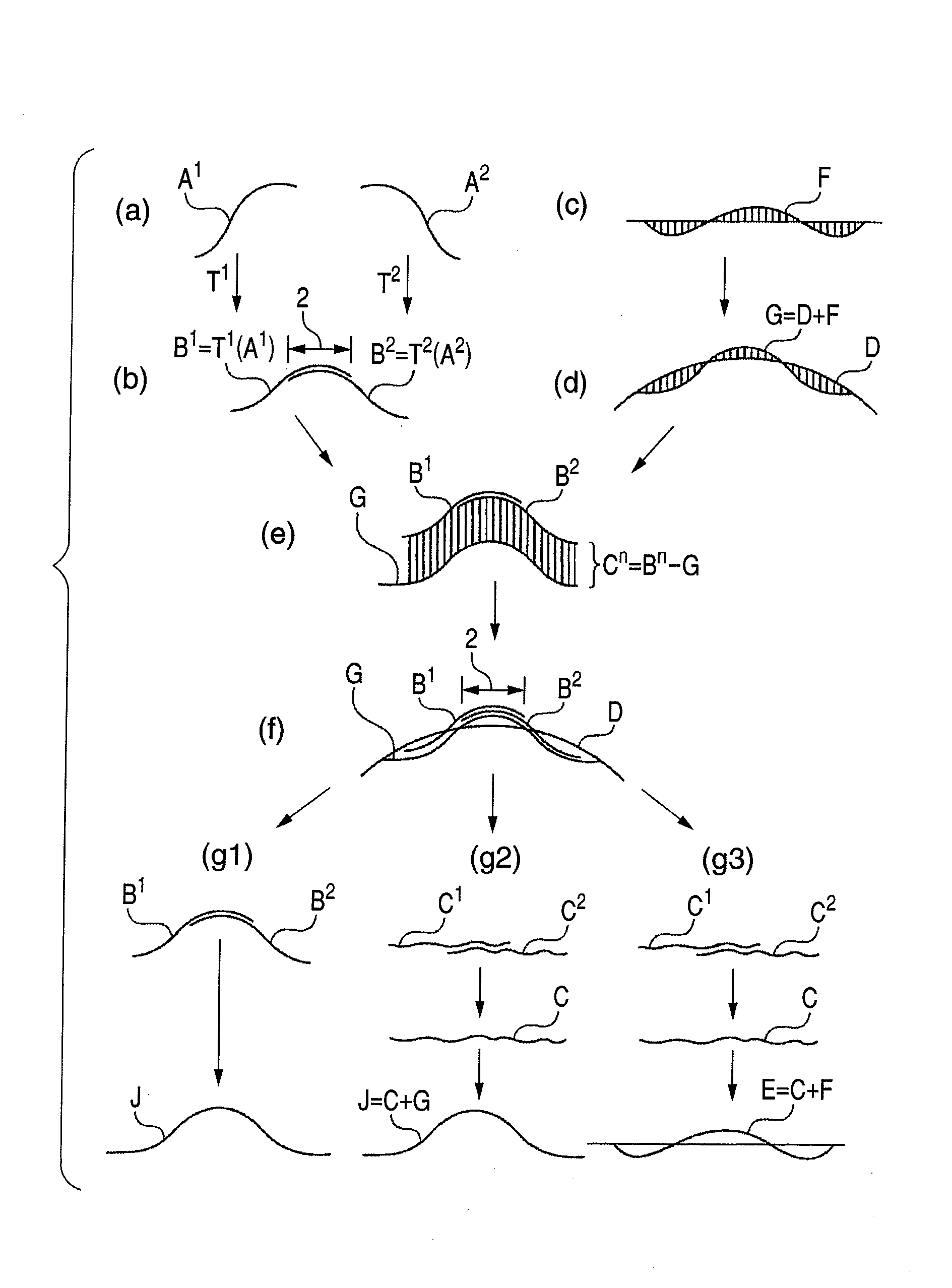

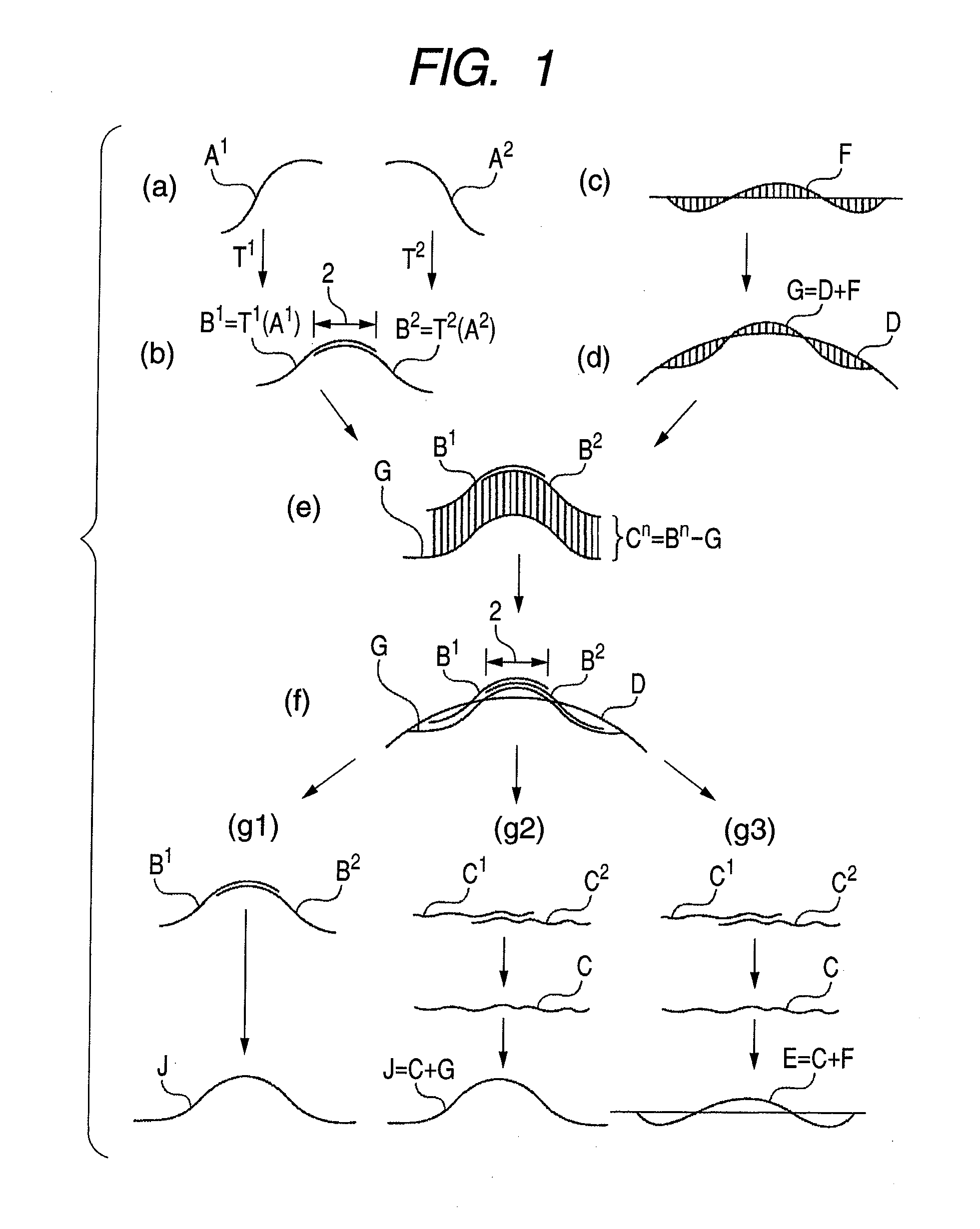

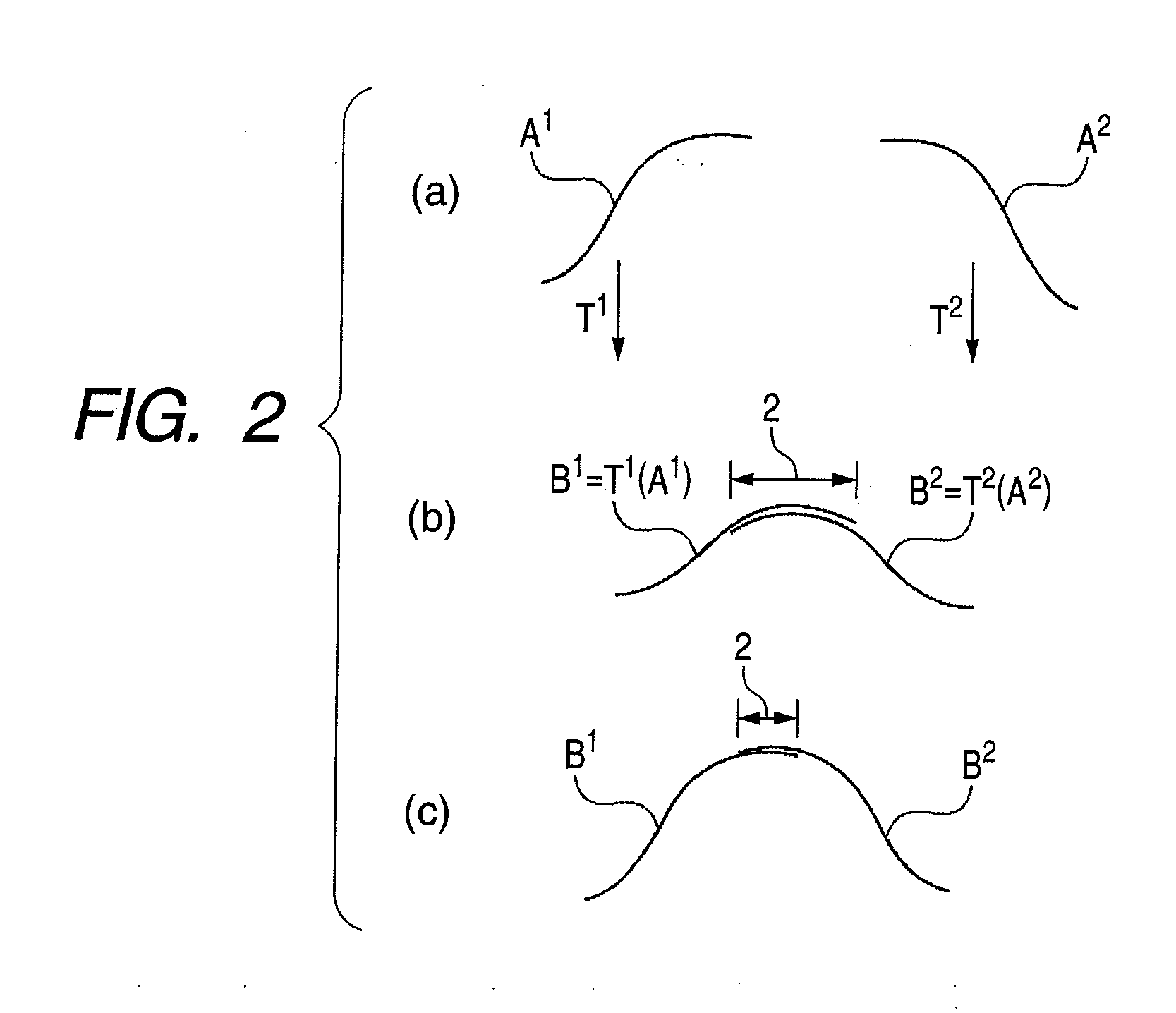

Methods and apparatus for shaping moving geometric shapes

InactiveUS6044306AEffective shapingCathode-ray tube indicatorsSpecial data processing applicationsEngineeringMechanical components

Disclosed are methods for determining the largest subset of points that remains within a set of points S (i.e., shape S) when S is subjected to a motion M. These methods, which are generally designated herein as unsweep (or formalistically unsweep(S,M)), can be implemented (preferably by computer) for a variety of practical purposes, for example mechanical parts design. In this instance, simply by knowing the motion to be experienced by a part and the envelope wherein the part must fit during motion, unsweep can define the largest part that fits within the envelope according to the given motion. While direct part shape output is obtained, no part shape needs to be proposed beforehand, and thus the design process is no longer an iterative process of proposing shapes and correcting them in the case of interference. Further, unsweep is related to the known sweep function and can be used to obtain sweeps as well as unsweeps.

Owner:SHAPIRO VADIM

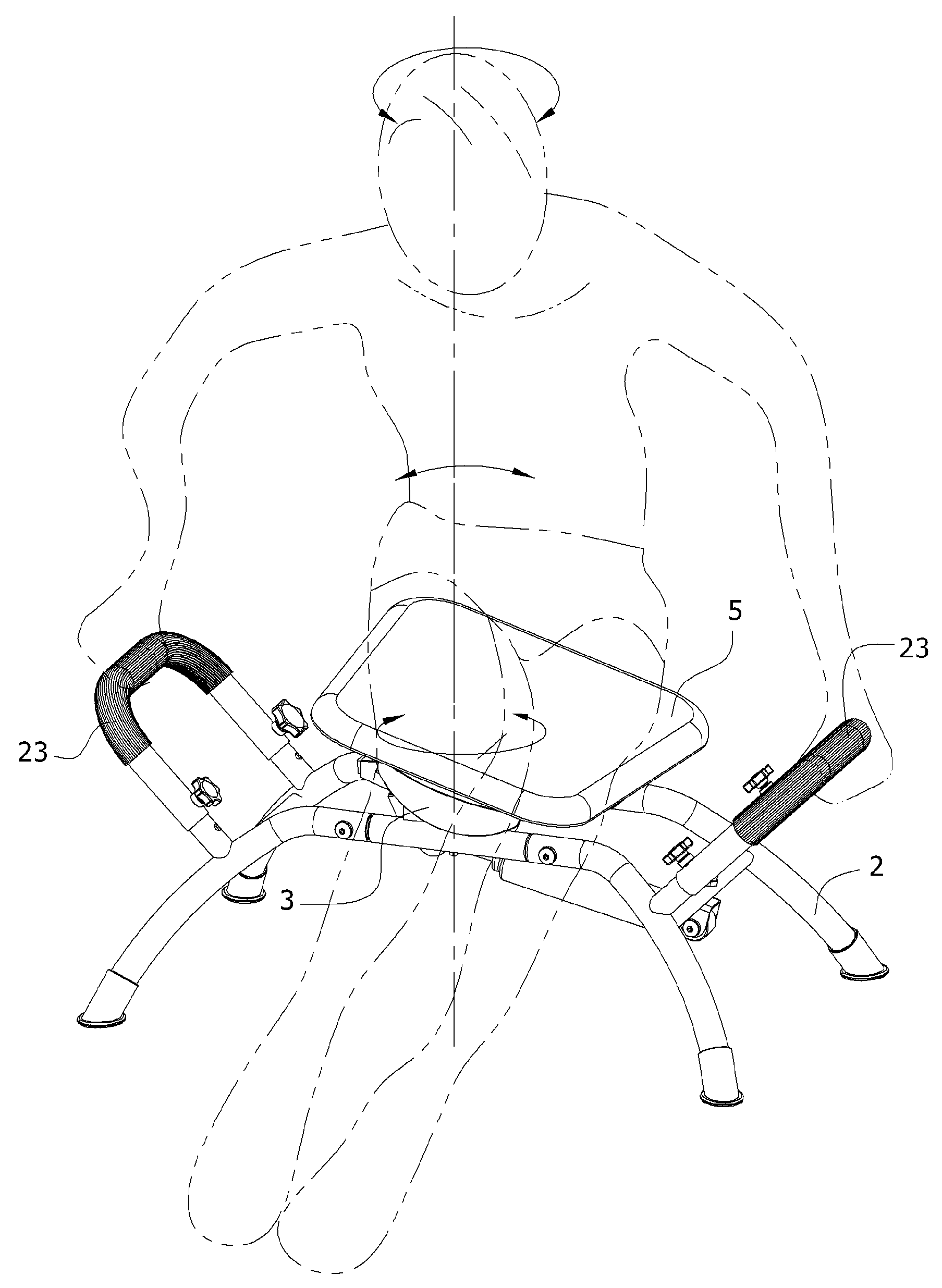

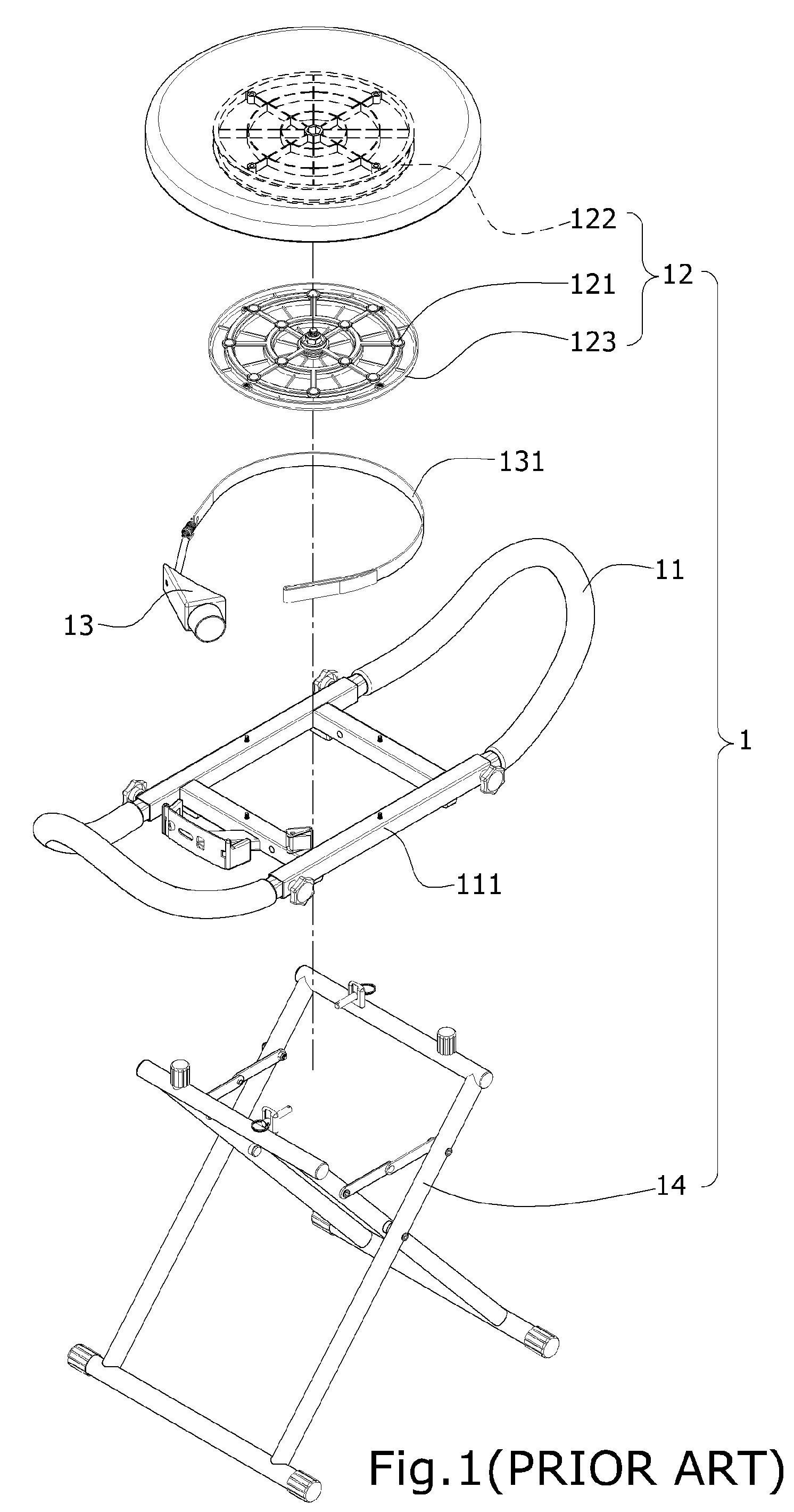

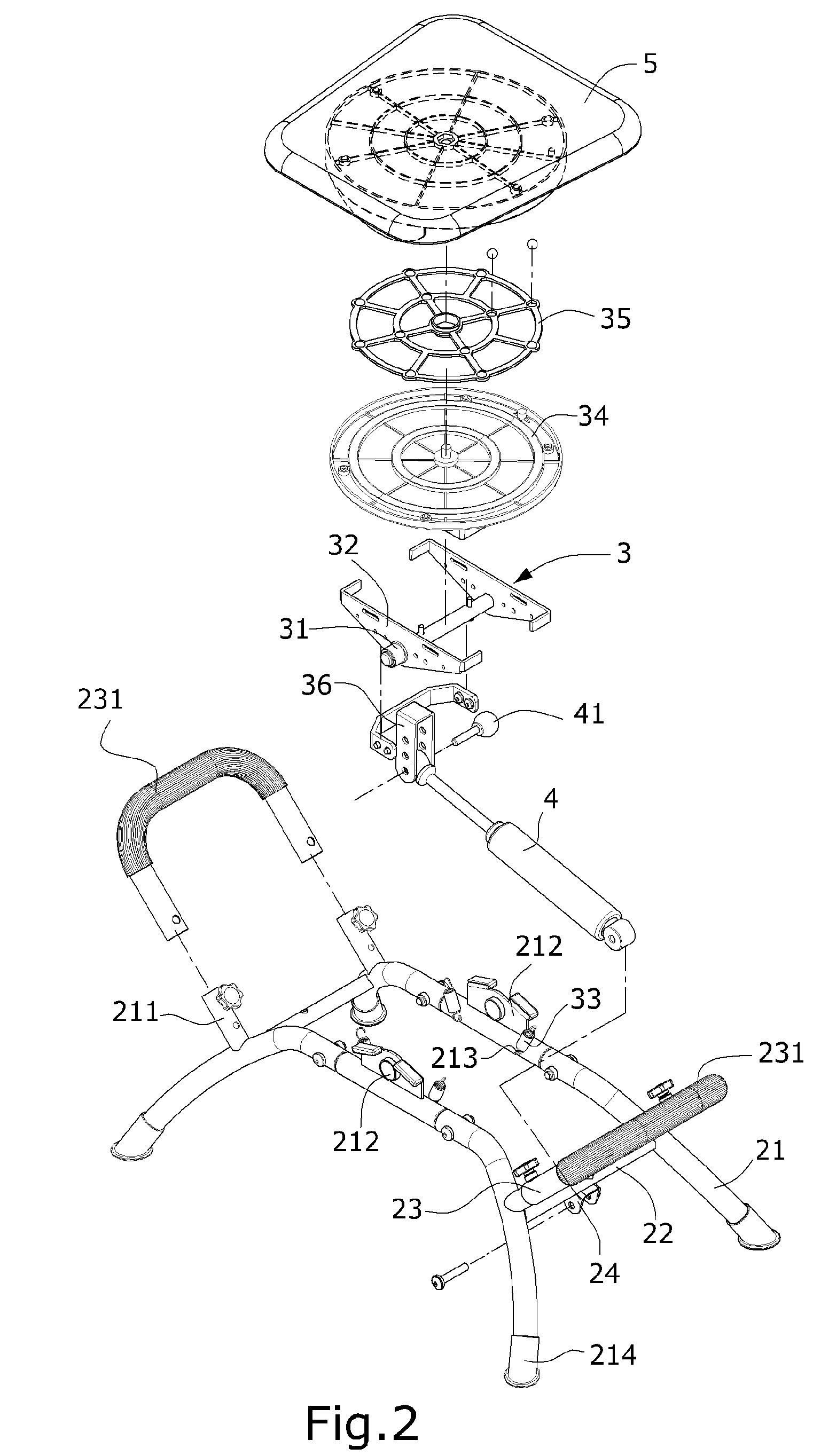

Swing rotary fitness apparatus

InactiveUS7625323B1Increase exerciseGood shaping effectResilient force resistorsSpace saving gamesEngineeringLumbar

A swing rotary fitness apparatus is described. A swing base is axially disposed at a center of a bracket having a pair of handles. A pound-force adjuster is disposed between the swing base and the bracket, and elastic elements for restoration are disposed between the swing base and the bracket. In addition, a rotatable seat is disposed on the swing base. When a user rides on the seat, the user exerts a force by lumbar muscles, so as to generate a circumferential motion of synchronous swing and rotation, which increases amplitude of twisting lumbar muscles greatly and thus improves an effect of exercising the waist.

Owner:XIAMEN KANG SOU FITNESS

Envelope shaping of decorrelated signals

ActiveUS7983424B2Avoid introducingEffective shapingSpeech analysisPseudo-stereo systemsDistortionGain factor

The envelope of a decorrelated signal derived from an original signal can be shaped without introducing additional distortion, when a spectral flattener is used to spectrally flatten the spectrum of the decorrelated signal and the original signal prior to using the flattened spectra for deriving a gain factor describing the energy distribution between the flattened spectra, and when the so derived gain factor is used by an envelope shaper to timely shape the envelope of the decorrelated signal.

Owner:DOLBY INT AB +1

Devices, systems, and methods for reshaping a heat valve annulus

ActiveUS20090306622A1Recovery functionReshape the heart valve annulusDiagnosticsAnnuloplasty ringsSystoleSurgical department

Devices, systems, and methods employ an implant that is sized and configured to attach to the annulus of a dysfunctional heart valve annulus. In use, the implant extends across the major axis of the annulus above and / or along the valve annulus. The implant reshapes the major axis dimension and / or other surrounding anatomic structures. The implant restores to the heart valve annulus and leaflets a more functional anatomic shape and tension. The more functional anatomic shape and tension are conducive to coaptation of the leaflets during systole, which, in turn, reduces regurgitation. The implant improves function to the valve, without surgically cinching, resecting, and / or fixing in position large portions of a dilated annulus, or without the surgical fixation of ring-like structures.

Owner:MVRX INC +1

Axial flux motor with active flux shaping

InactiveUS6897595B1Increased motive forceEffective alignmentMagnetic circuit rotating partsMagnetic circuit stationary partsMotor shaftMagnetic core

An improved electric motor design wherein the interior surface of the stator has a plurality of corrugations intersected by annular grooves formed therein and a corresponding number of rotor disks having permanent magnets secured to their outer surface, the permanent magnets being positioned to rotate within the grooves. The magnets alternate in polarity about each disk as well as being offset about the circumference from disk to disk so that one disk set will align with the pole face created by the intersection of the corrugations and the adjacent annular grooves and the other disk set will be offset from the corrugations and pole faces. Alternately energizing coils positioned within a plurality of notches formed in the outer surface of the stator with alternating current causes the magnets and their associated disks to reposition themselves in a manner that causes the motor shaft to rotate as well as shaping the core flux field for more efficient use, thereby increasing motor torque.

Owner:CHIARENZA KEVIN J

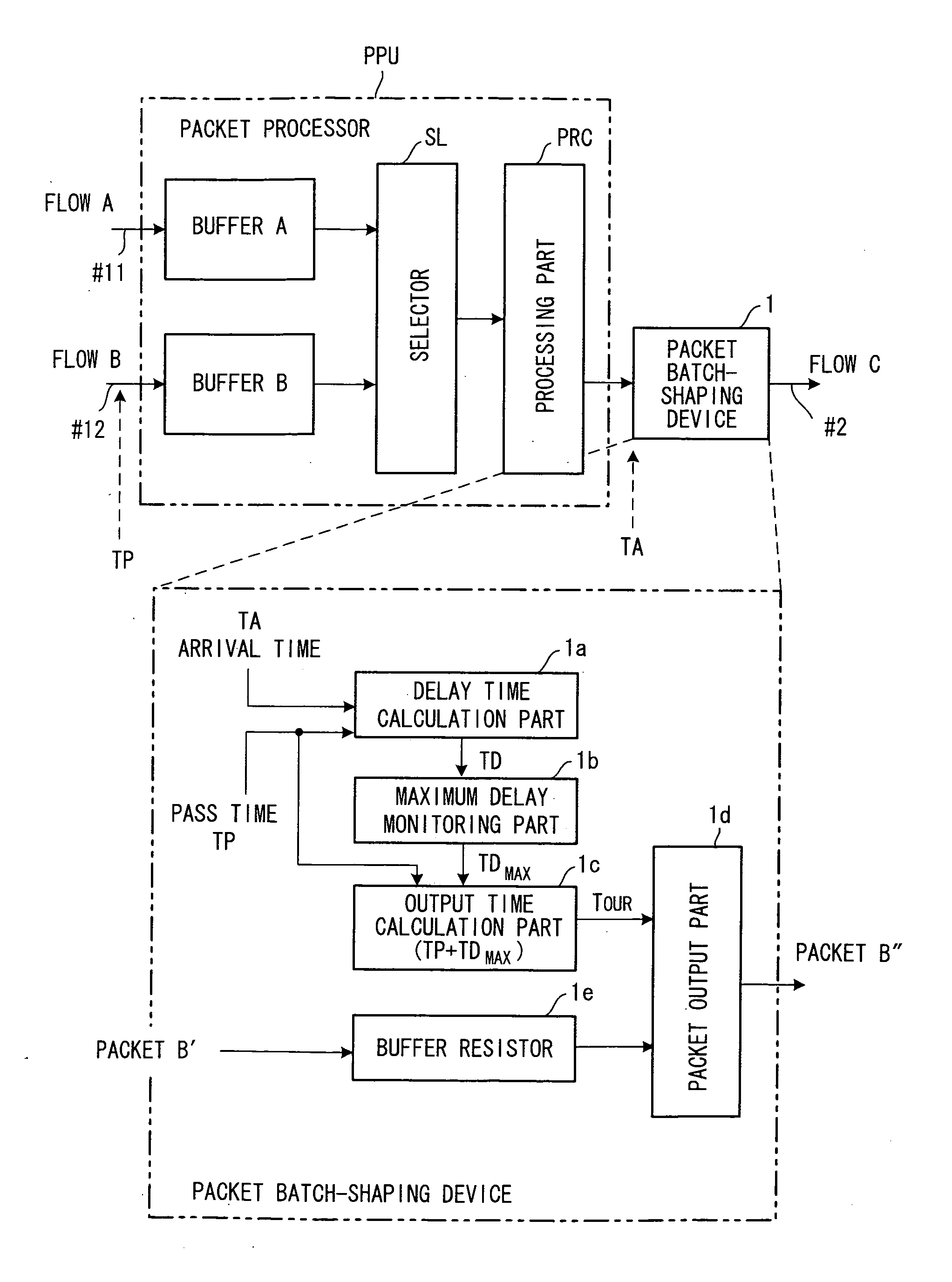

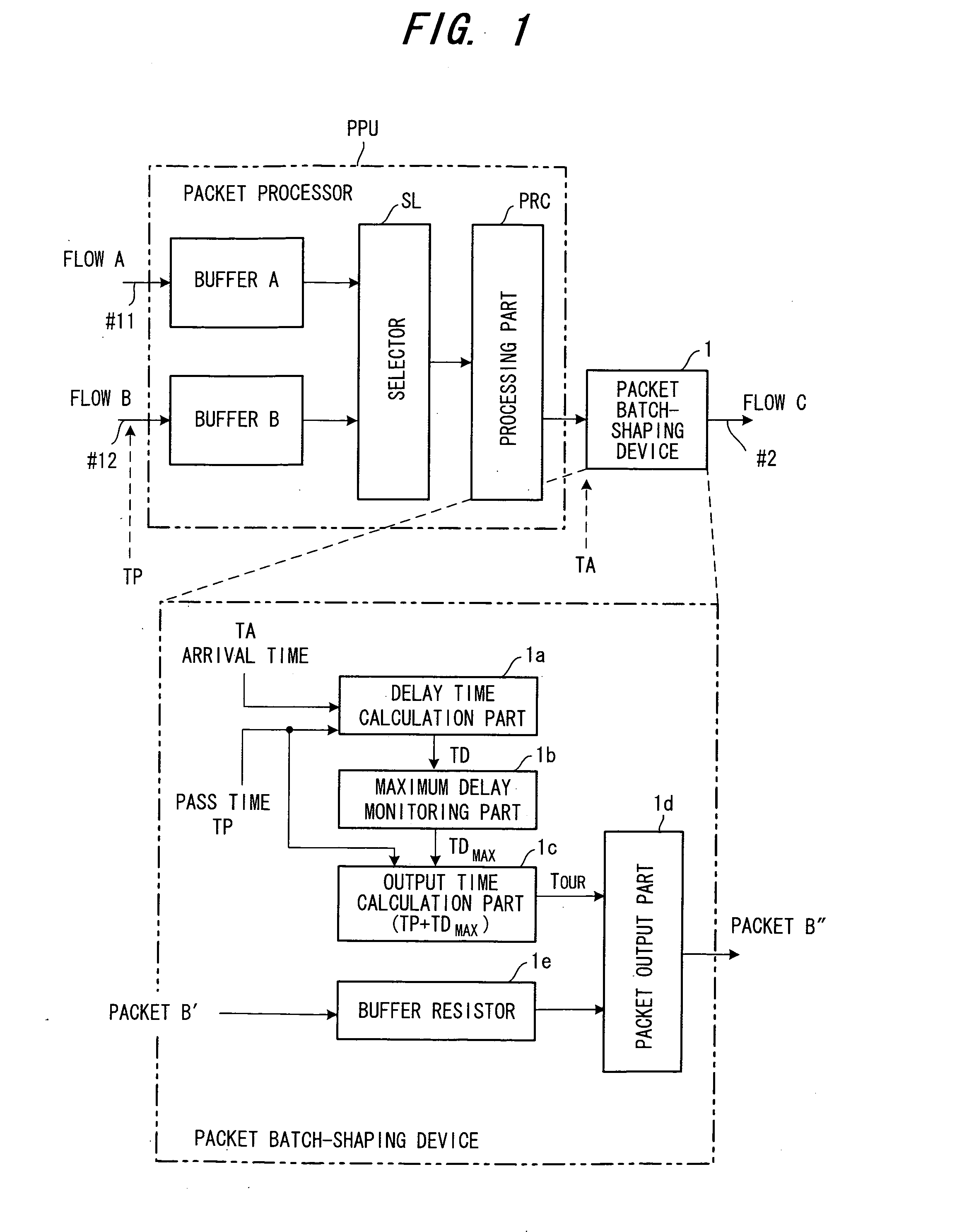

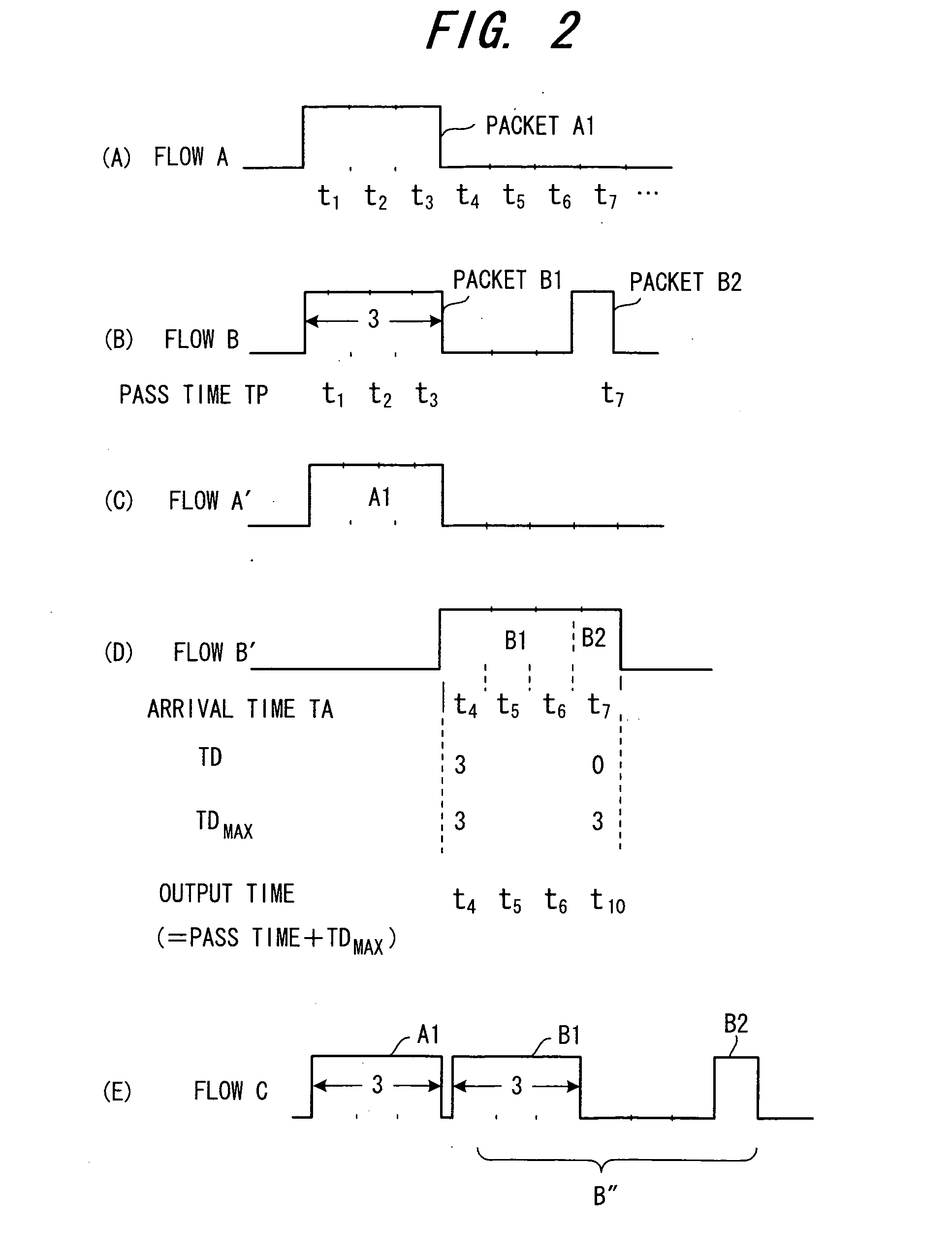

Packet shaping device, router, band control device and control method

InactiveUS20050249115A1Efficiently shapedSuppresses growthError preventionTransmission systemsTime differenceDelayed time

A packet shaping device for the purpose of shaping a packet in which burst has grown in a router to an original packet without the burst growth is disclosed. The packet shaping device monitors an arrival time TA of each packet on which a pass time TP is recorded when the packet passes a prescribed pass point and calculates a delay time TD which is a time difference between the pass time TP and the arrival time TA. Then, the packet shaping device obtains a maximum delay time TDmax among the delay times, and delays and sends all the arrived packets in such that the delay time of all the arrived packets is equivalent to the maximum delay time.

Owner:FUJITSU LTD

Devices, systems, and methods for reshaping a heart valve annulus

ActiveUS9861475B2Recovery functionReshape the heart valve annulusDiagnosticsAnnuloplasty ringsSystoleHeart valve

Devices, systems, and methods employ an implant that is sized and configured to attach to the annulus of a dysfunctional heart valve annulus. In use, the implant extends across the major axis of the annulus above and / or along the valve annulus. The implant reshapes the major axis dimension and / or other surrounding anatomic structures. The implant restores to the heart valve annulus and leaflets a more functional anatomic shape and tension. The more functional anatomic shape and tension are conducive to coaptation of the leaflets during systole, which, in turn, reduces regurgitation. The implant improves function to the valve, without surgically cinching, resecting, and / or fixing in position large portions of a dilated annulus, or without the surgical fixation of ring-like structures.

Owner:MVRX INC +1

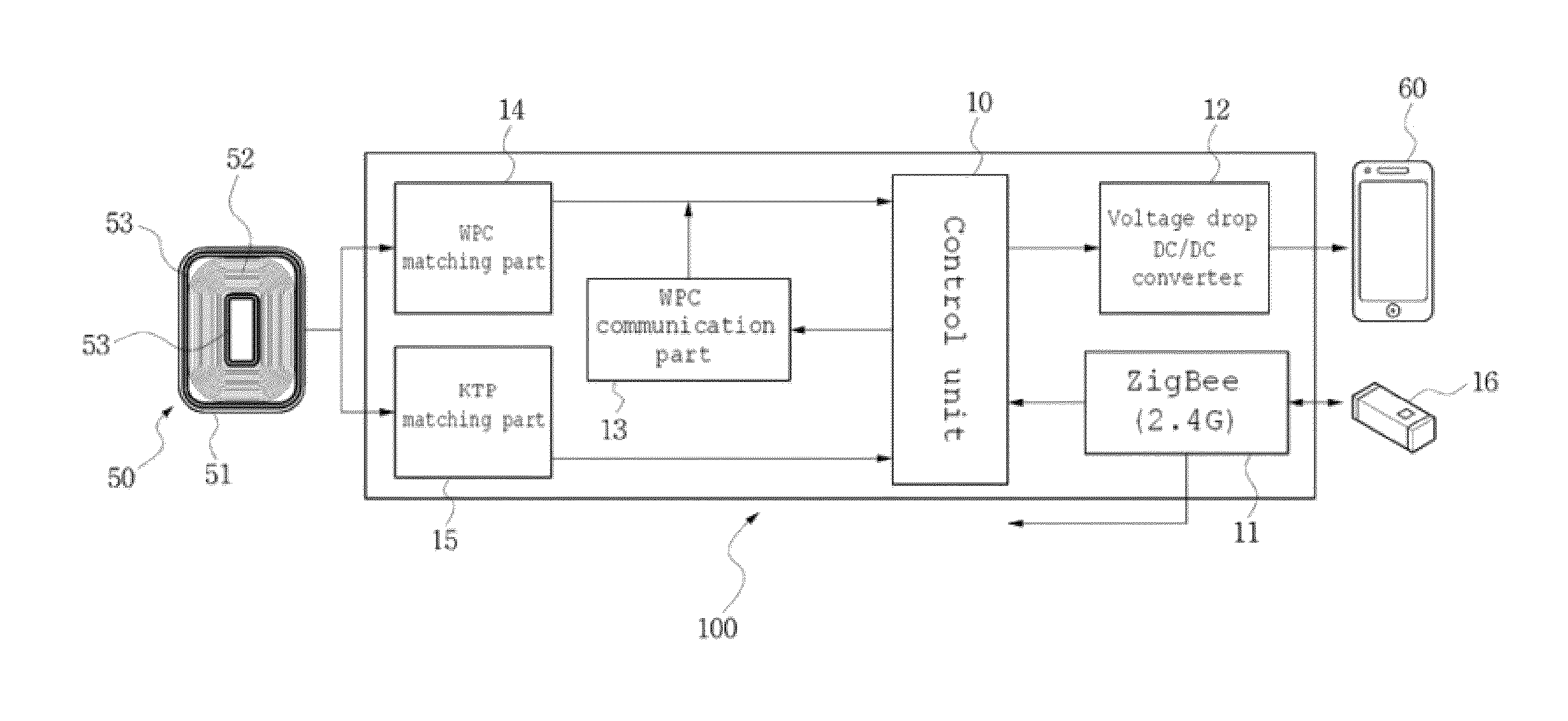

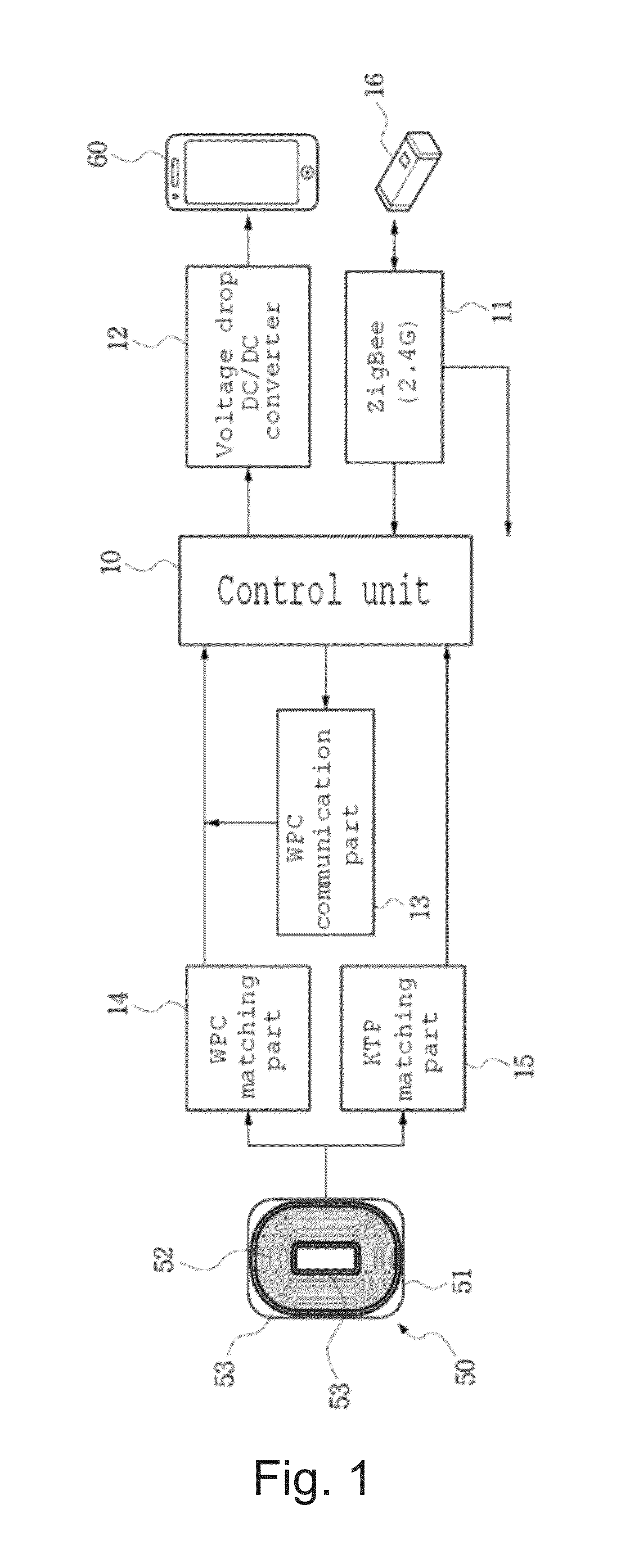

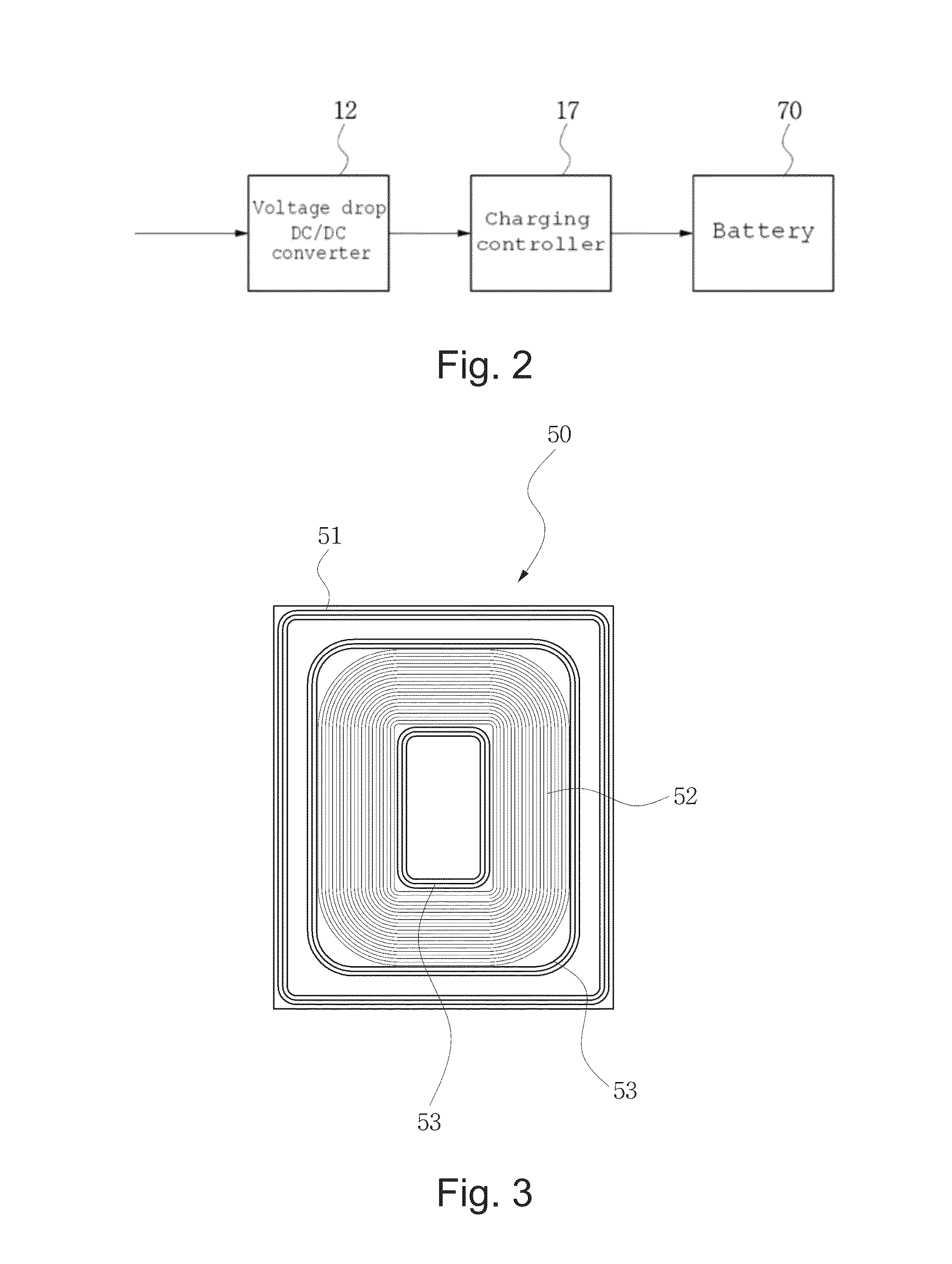

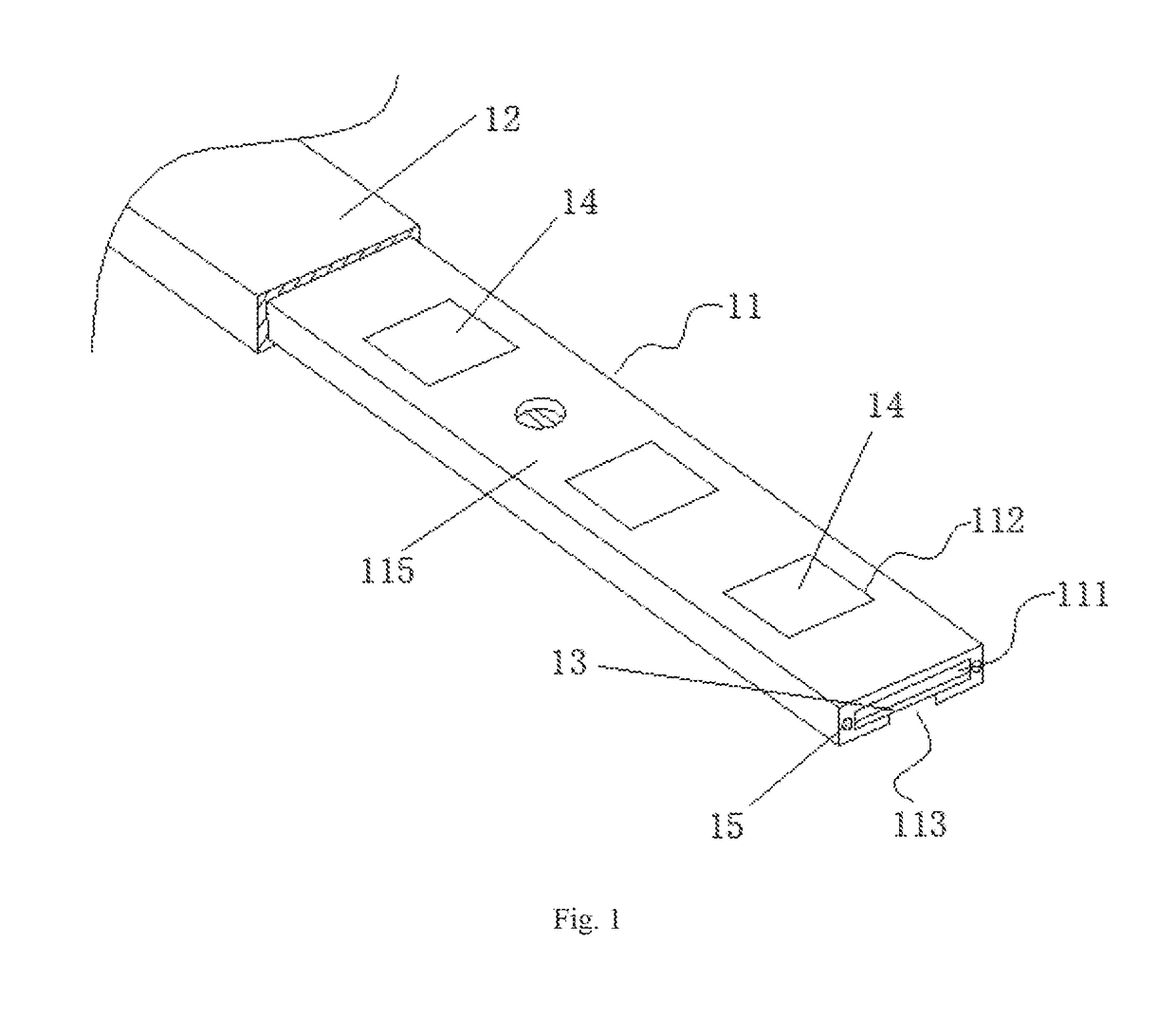

Receiver for wireless charging system

ActiveUS9413191B2Improve magnetic field efficiencyImprove receiving efficiencyLoop antennas with ferromagnetic coreNear-field transmissionContact typeEngineering

A receiver for a wireless charging system, capable of receiving power energy using non-contact type magnetic induction, includes a coil capable of receiving the power energy and a part for generating a predetermined output power from the power energy received by the coil, a portable terminal, an NFC coil further provided outside of the coil, and a ferrite sheet further provided at the coil and the NFC coil.

Owner:SAMSUNG ELECTRONICS CO LTD

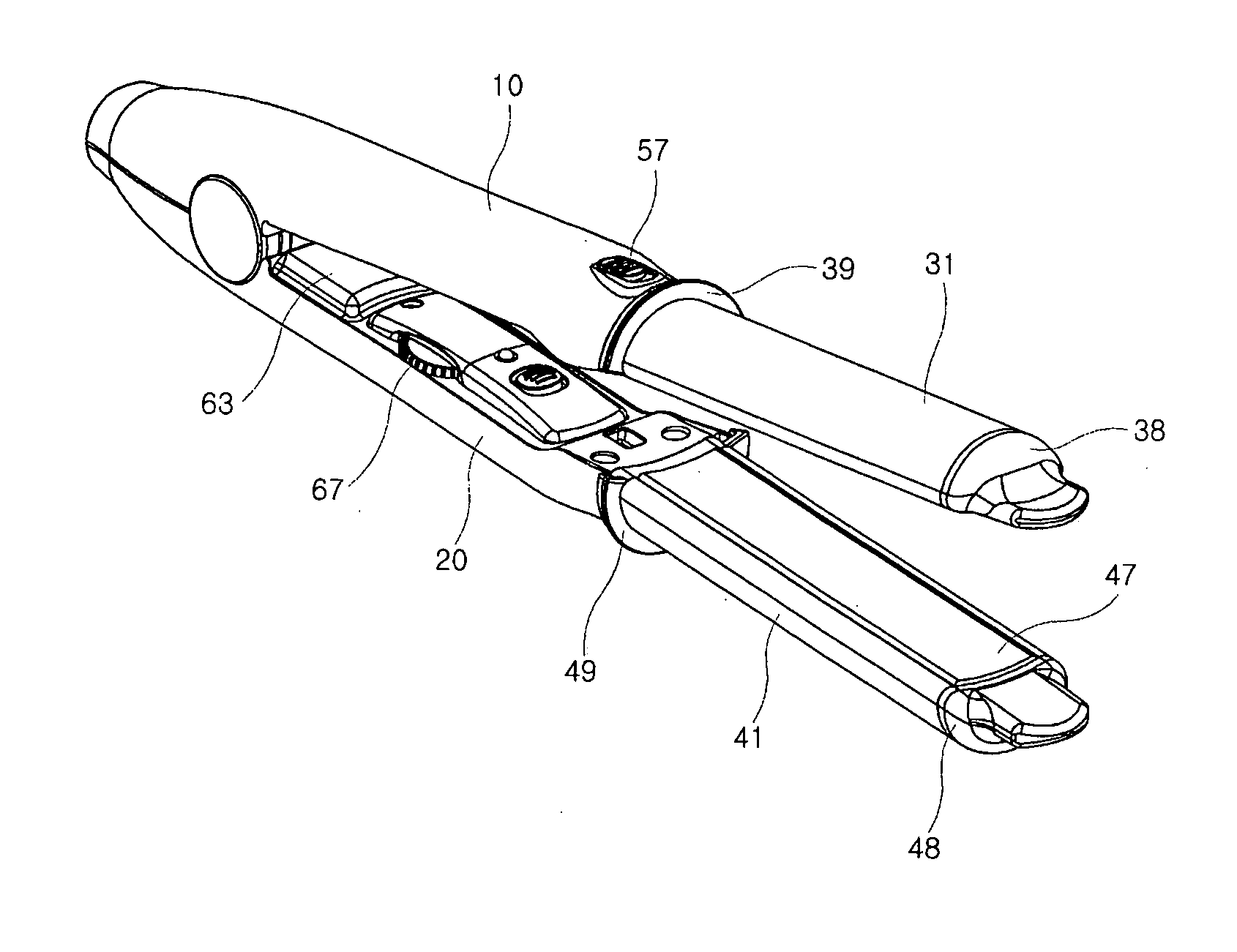

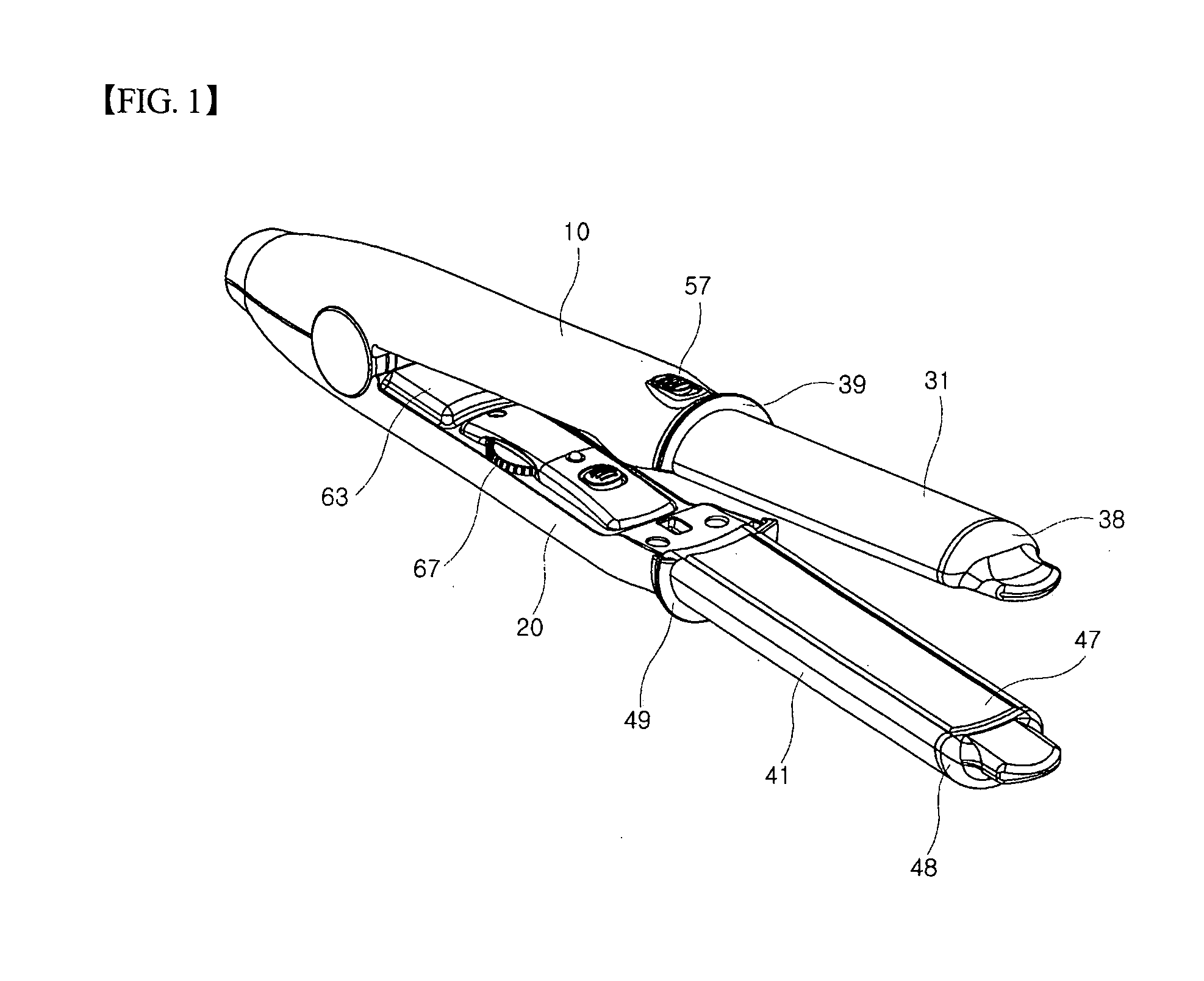

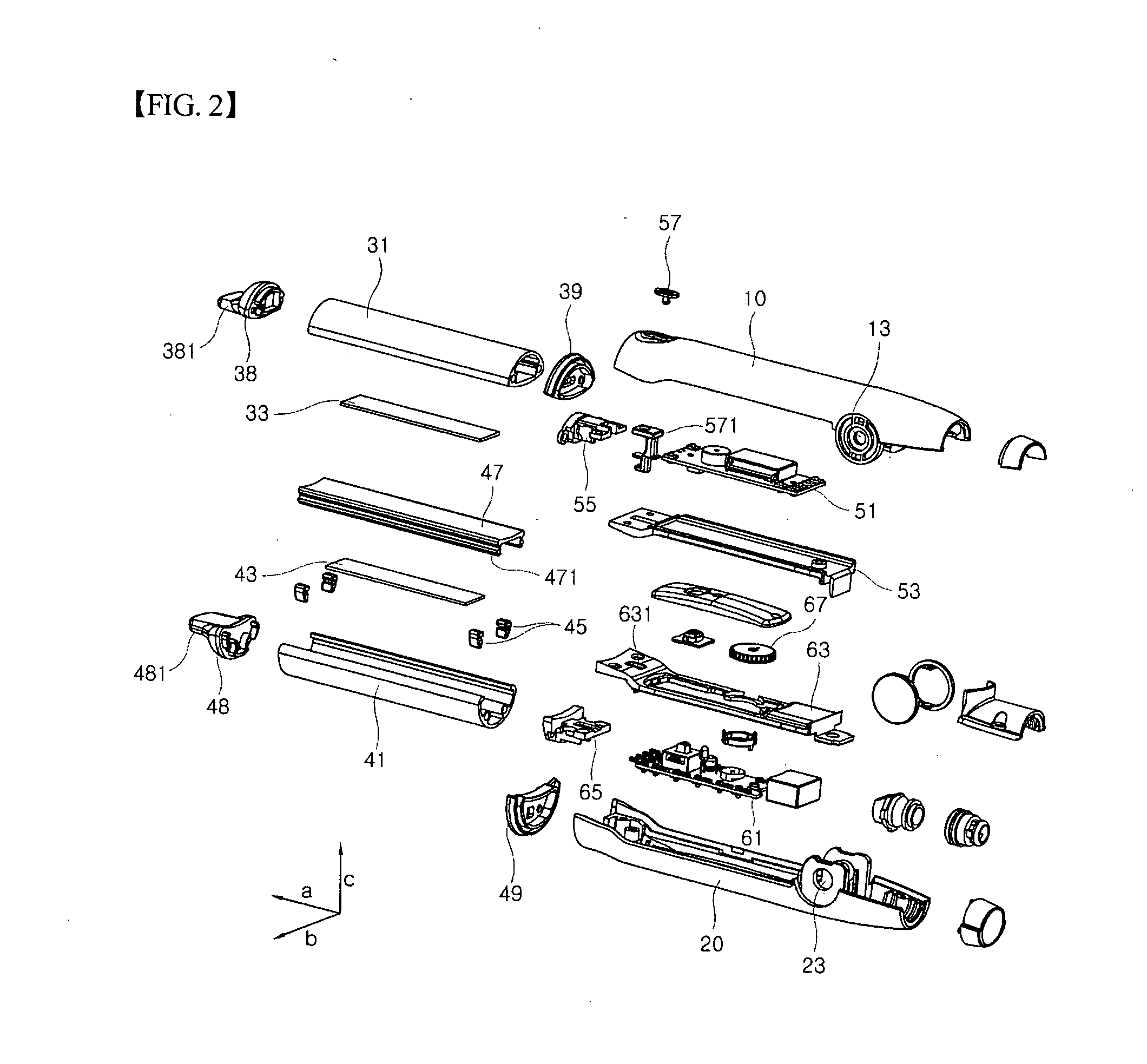

Hair iron

InactiveUS20110174331A1Efficiently shapedEffective shapingCurling-ironsCurling-tongsAngular rangeEngineering

A hair iron includes upper and lower casings defining a grip portion and coupled to each other at a first end with an elastic coupler such that the casings in the side of a second end opposite to the first end are pivotable within a certain angular range about the first end, an upper heater block extending in a longitudinal direction of the upper casing and coupled on the second end of the upper casing which is not coupled with the lower casing, a lower heater block extending in a longitudinal direction of the lower casing and coupled on the second end of the lower casing which is not coupled with the upper casing.

Owner:GHD KOREA INC

Randomly bendable and shapable LED light bar

ActiveUS20170328527A1Reduce manufacturing difficultyPrevent looseningSolid-state devicesLight effect designsEngineeringLED lamp

A randomly bendable and shapeable LED light bar is provided, including a plurality of LED light strings in parallel, a shaping metal rod and an insulating wrapping layer, wherein each LED light string includes two fine leads in parallel and a plurality of LED light emitting units; an anode and a cathode of each LED light emitting unit are welded / soldered with the two fine leads; the two fine leads are electrically connected with an anode and a cathode of a power supply; the plurality of LED light strings are parallel to the shaping metal rod and are both wrapped by the insulating wrapping layer. Compared with the prior art, the randomly bendable and shapeable LED light bar disclosed is relatively flexible, can be formed into various rich shapes, and is convenient to mount and shape, reliable in light emission, relatively high in practicability and relatively wide in application range.

Owner:YANG YI +2

Device and method for mixing and dispensing fluid components of a multicomponent composition

Provided are devices and methods for dispensing a multicomponent composition comprised of a mixture of a plurality of different fluid components. A diffuser surface is placed downstream from a plurality of inlets. An outlet extends through the diffuser surface. At least one inlet placed in fluid communication with a source of a pressurized carrier fluid, and each of a plurality of inlets is placed in fluid communication with a source of a different fluid component. Once the diffuser surface receives fluid components, each received fluid component is directed toward the outlet for mixing and dispensing therethrough by the pressurized carrier fluid from the carrier fluid inlet. Typically, the fluid components are maintained in a different flow path on the diffuser surface before mixing.

Owner:ANGIOTECH PHARMA US

Three-dimensional shape measuring method and apparatus for the same

A three-dimensional shape measuring apparatus includes a line laser light source (1) and an image capturing device (2). A three-dimensional shape measuring method and apparatus is characterized by irradiating a line laser beam to an object (3) to be measured from a laser projecting device, imaging points (6) irradiated with the laser beam by the image capturing device (2, detecting points on taken images as intersections (8), each of the points being detected from the taken images and being detected as a common point where line laser beams pass, deriving equations including the positions of the laser planes and the three-dimensional positions of the intersections as unknowns based on the detected intersections, determining the three-dimensional positions of the intersections and the positions of the laser planes by solving the derived equations as simultaneous equations, calculating by triangulation the three-dimensional positions of the points irradiated with the laser beams other than the intersections by using the positions of laser planes, and obtaining the three-dimensional shape of the object by repeating the series of processes.

Owner:TECHNODREAM21

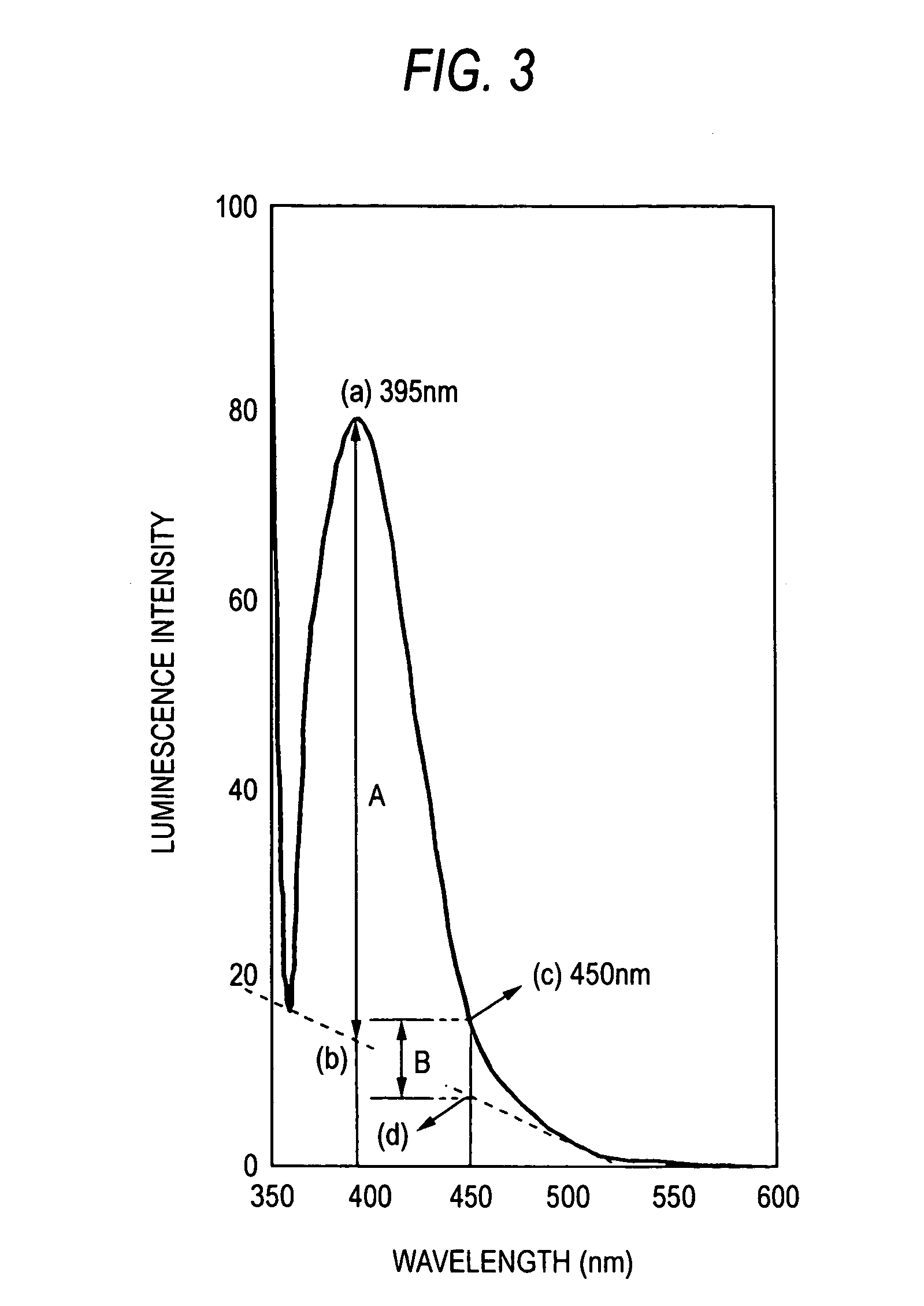

Polyester resin

InactiveUS20070065649A1High transparencyLess transparency fluctuationSynthetic resin layered productsUltravioletPack material

The invention is a polyester resin mainly comprising a terephthalic acid component and a glycol component, wherein the fluorescence spectrum obtained by irradiating the polyester resin with excited light having a wavelength of 343 nm has a fluorescence intensity at 450 nm (B0) of 20 or lower. The resin makes it possible to efficiently produce a shaped article, especially a heat-resistant blow-molded article, that has excellent transparency and a moderate and stable crystallization rate and excellent heat-resistance dimensional stability, and is prevented from emitting fluorescence when irradiated with UV rays, and which is excellent in long-run continuous workability with no mold contamination, and which provides a wrapping material having excellent flavor retentiveness.

Owner:TOYOBO CO LTD

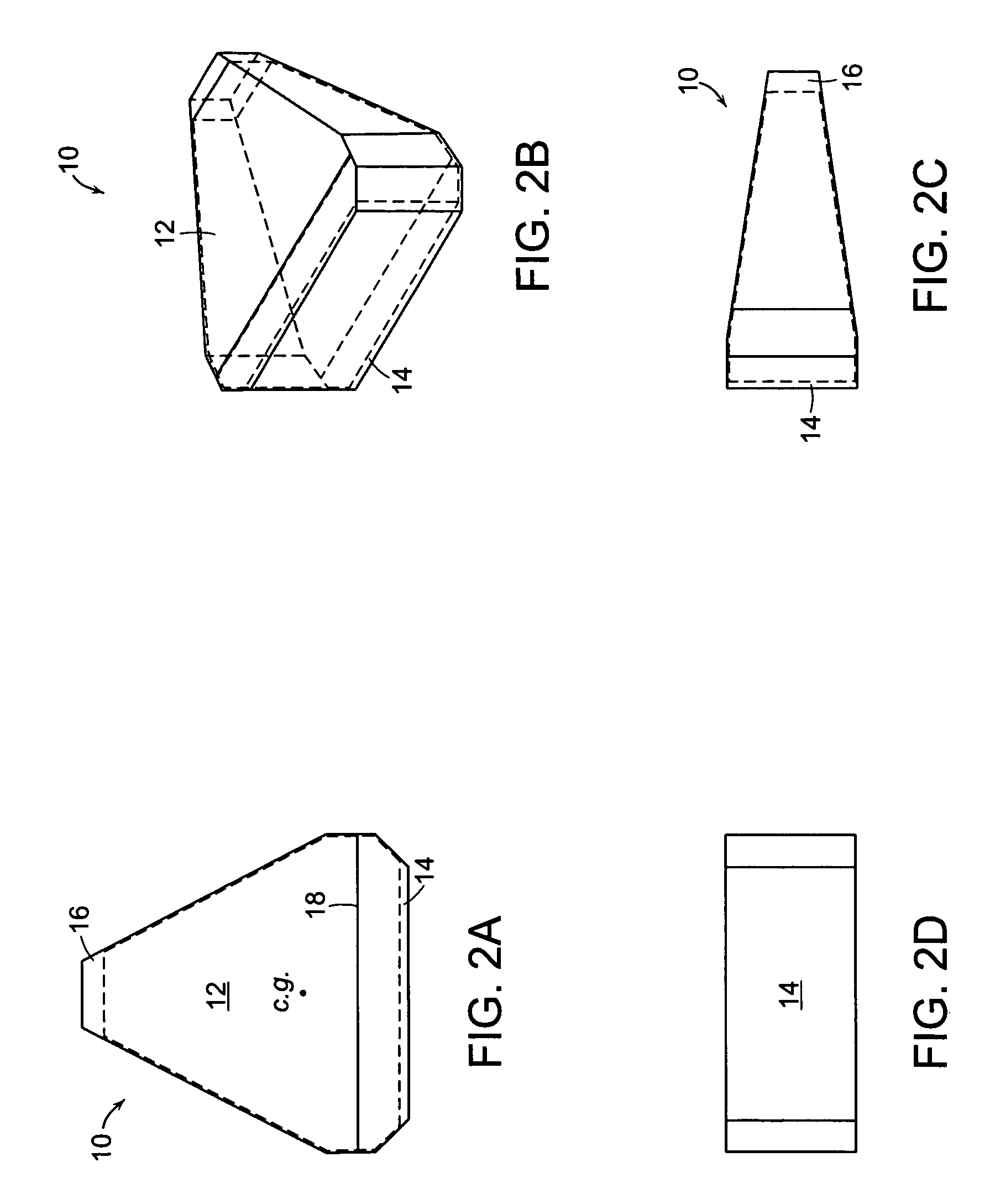

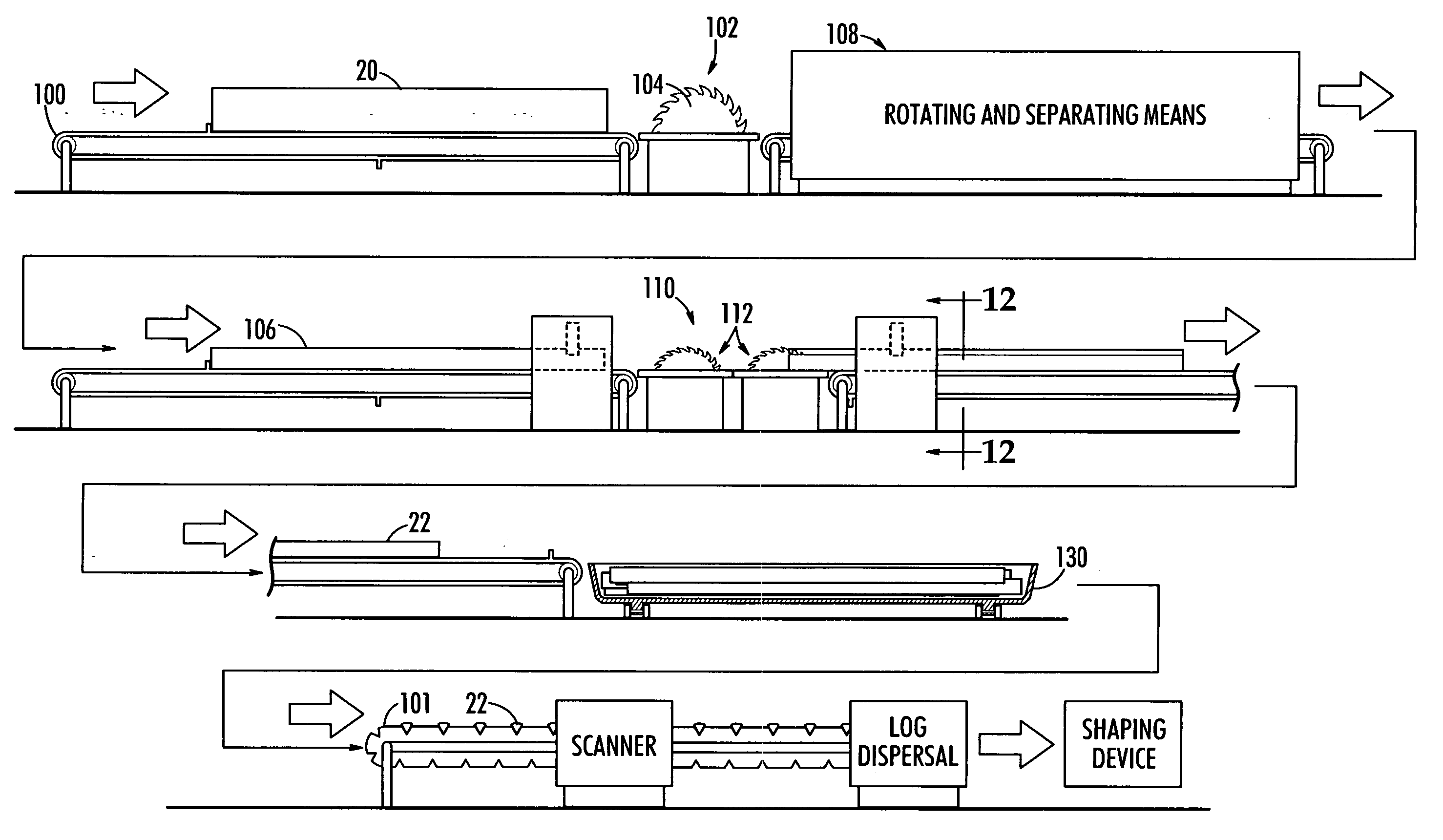

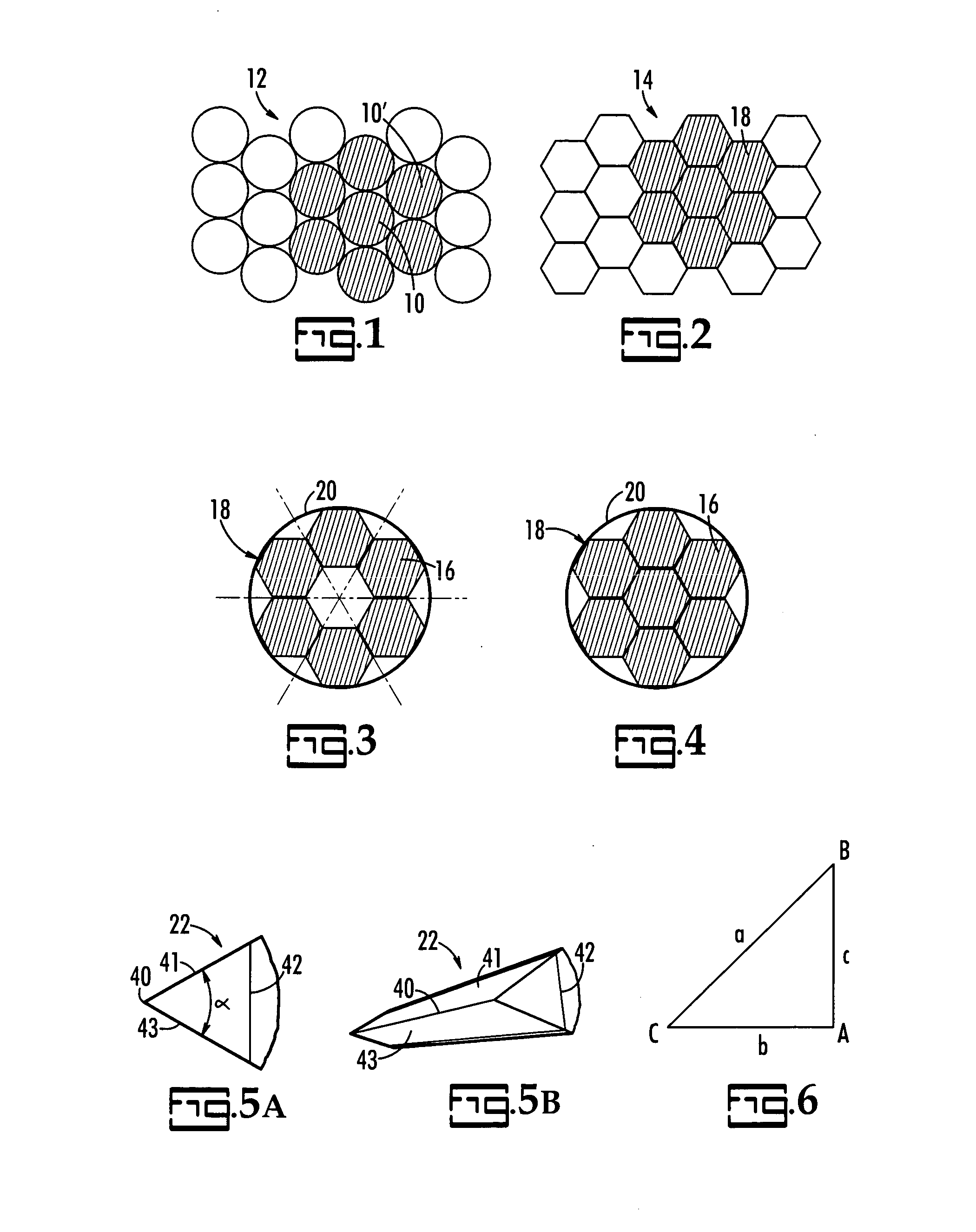

Radial sawing method

InactiveUS20050034786A1Efficient configurationReduce quality problemsWood splittingMulti-purpose machinesIsoetes triquetraEngineering

A radial sawing method for cutting a log into six sections. Each resulting section has a triangular wedge shape, such that in cross-section, an angle of approximately sixty-degrees (60°) at the interior edge of the log section is formed. The approximately 60° angle can be the point of an equilateral triangle. After the log has been formed into six pieces that are relatively equivalent in size and shape, each respective piece can then be fed into additional sawing machines for additional processing, such as to form symmetrically shaped pieces, include a circle, a square, a hexagon, an octagon, or other polygon pieces.

Owner:DARGAN SAMUEL G

Mold for achieving in-mold rapid forming and quenching

The invention provides a mold for achieving in-mold rapid forming and quenching. The mold comprises an upper mold, a binder ring and a lower mold, the upper mold is composed of an inner solid mold core and a thin-walled skin, and interconnected grooves are formed between the inner solid mold core and the thin-walled skin. In the forming stage, no heat insulation material such as filler or fillinggas exists in the grooves, and a low-temperature medium is introduced into the grooves in the quenching stage. The mold has the advantages that the forming and quenching processes are relatively independent and have little influence on each other, the skin is small in wall thickness and small in heat capacity, the grooves are filled with the heat insulation materials, the problem that a hot plateblank and a cold mold are rapidly cooled after making contact during forming can be avoided, and rapid cooling and quenching of the formed hot plate blank can be achieved. The mold core is prepared from common mold materials through common machining equipment, the mold manufacturing period is short, and the cost is low. The mold can be used for achieving rapid forming and quenching of metal materials of different types and thicknesses.

Owner:DALIAN UNIV OF TECH +1

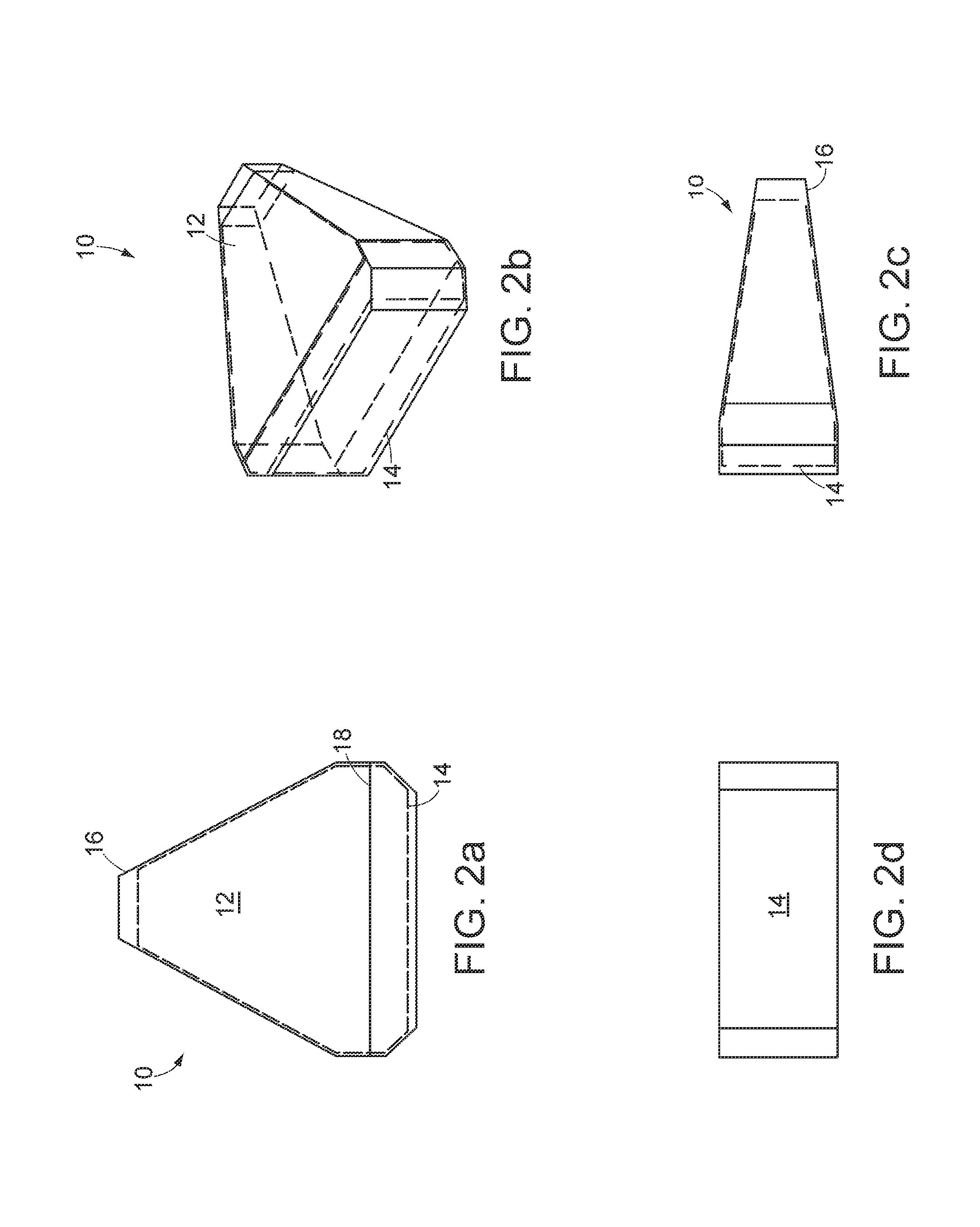

Shape measurement method of synthetically combining partial measurements

InactiveUS20090306931A1Accurately determineEffective shapingFeeler-pin gaugesMechanical counters/curvatures measurementsAlgorithmTransformation parameter

Coordinate transformation parameters are adopted at the time of synthetically combining partial measurement data so as to eliminate the setting error that can get in when a workpiece is set in position on a measuring machine. Then, a shape parameter is adopted to estimate the approximate error shape of the entire workpiece and the approximate error shape is removed from the measurement data. As a result, the residuals are reduced if the measurement data are those of three-dimensional sequences of points. Differences are small when small residuals are compared so that the mismatch is reduced. According to the present invention, the entire measurement data can be synthetically combined without using the conventional concept of overlap.

Owner:CANON KK

Microscope

ActiveUS20150226670A1Easy to checkFacilitates integration of SPIM technologyMicroscopesFluorescence/phosphorescenceExcitation beamBeam splitting

A microscope including a sample carrier configured to support a sample. Excitation light illuminates the sample via an excitation beam path, Detection light from the sample is guided to detection means via a detection beam oath. Through an objective arranged along the optical axis, excitation light is guided in direction of the sample carrier and detection light coming from the sample is guided in direction of the detection means. Beam-splitting means separate excitation light and detection light. Also provided are means for generating a light sheet from excitation tight, and means for illuminating the sample with this light sheet. The light sheet lies in a plane at a nonzero angle to the optical axis. The means for illuminating the sample include an optical-deflecting device arranged on or at the sample carrier, which deflects excitation light from the objective into the plane of the light sheet via an optically active surface.

Owner:CARL ZEISS MICROSCOPY GMBH

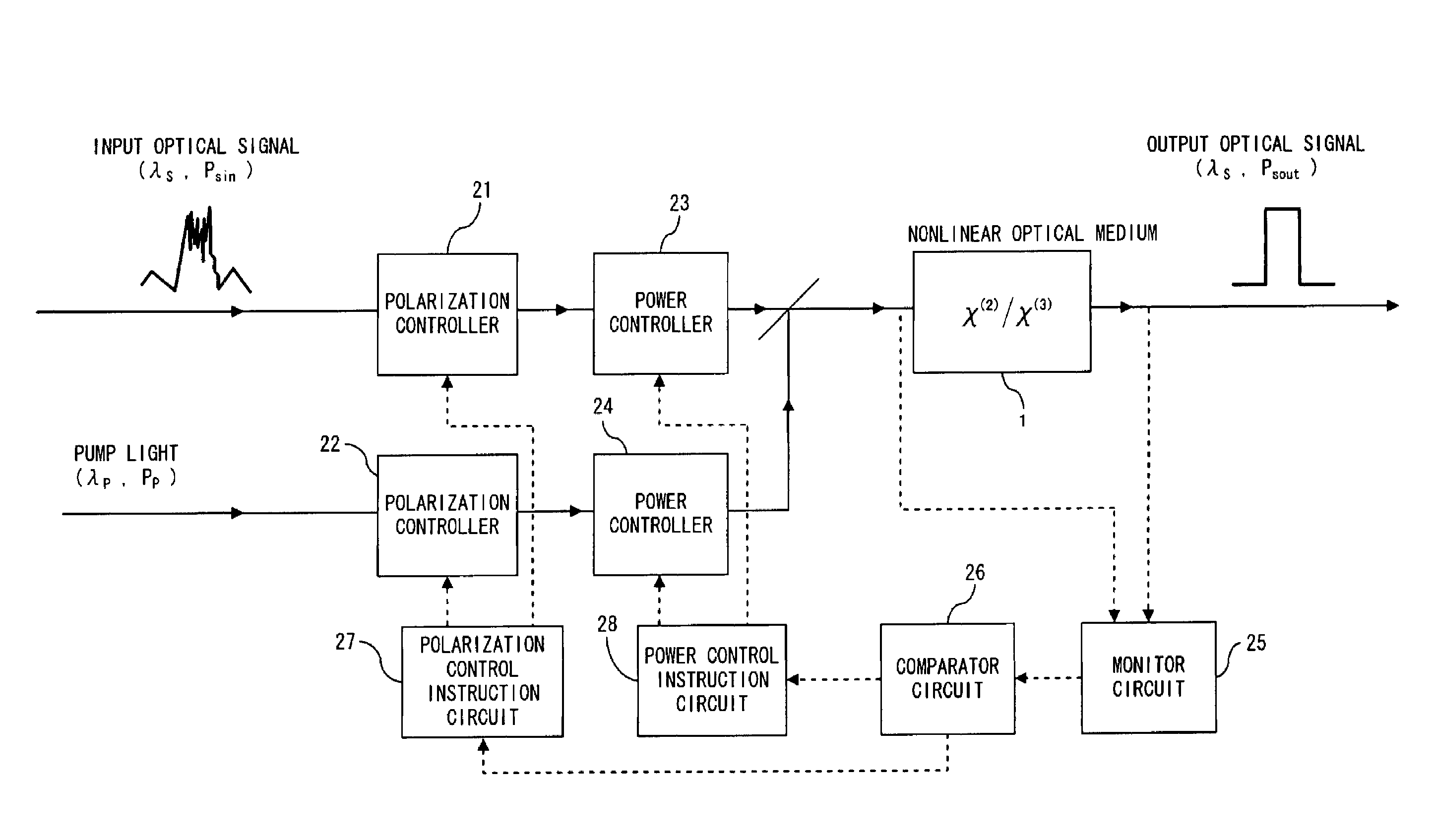

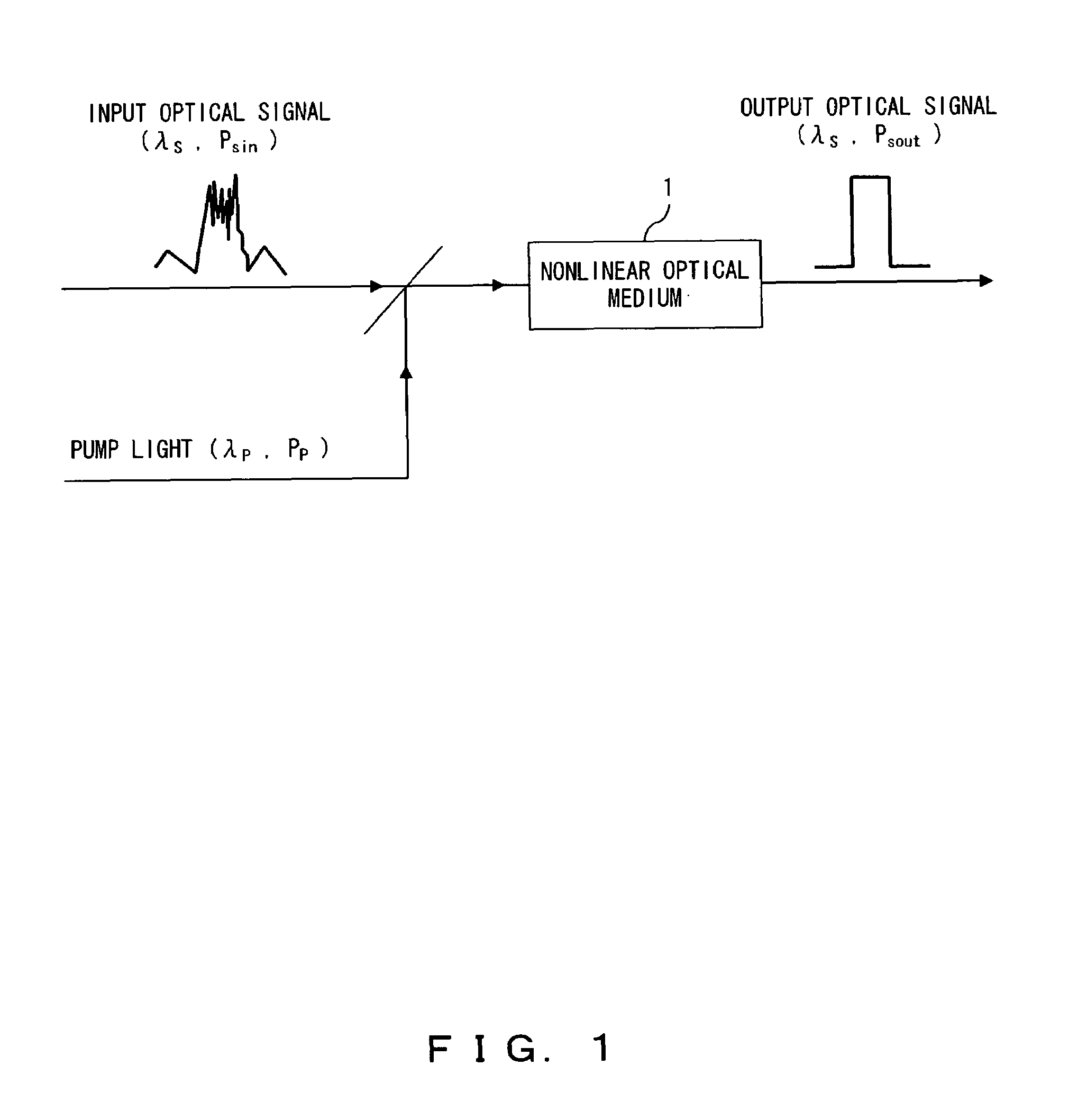

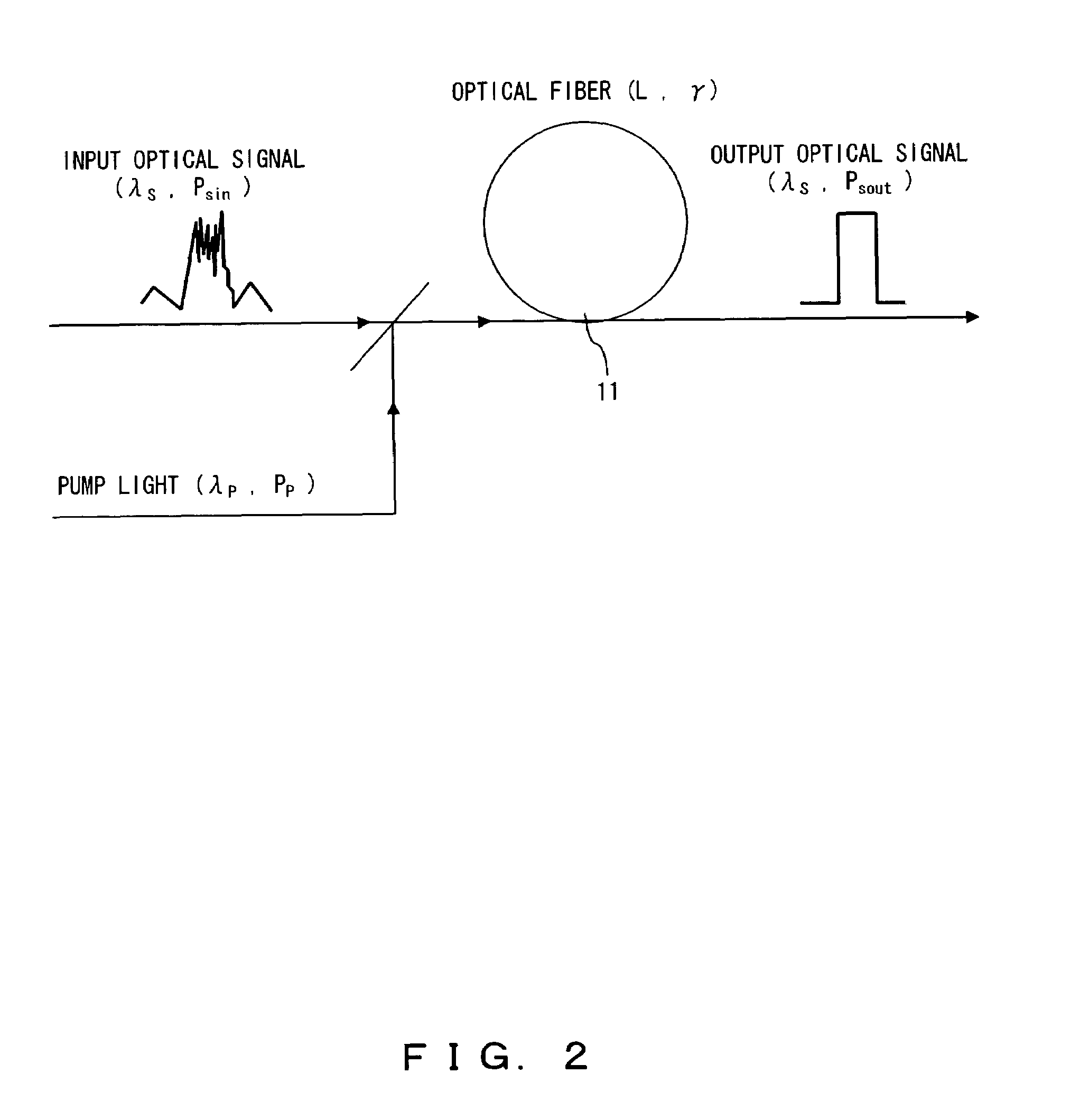

Optical signal waveform shaping apparatus

InactiveUS7450298B2Efficiently shapedSuppresses “ 1 ” level noiseLaser detailsElectromagnetic transmissionPower controllerWaveform shaping

An optical signal and pump light are input to a nonlinear optical medium. In the nonlinear optical medium, the optical signal is amplified with a nonlinear effect caused by the pump light. A monitor circuit monitors parametric gain in the nonlinear optical medium. A first power controller increases input power of the optical signal so that the gain reaches saturation. A second power controller controls input power of the pump light so as to obtain a desired gain.

Owner:FUJITSU LTD

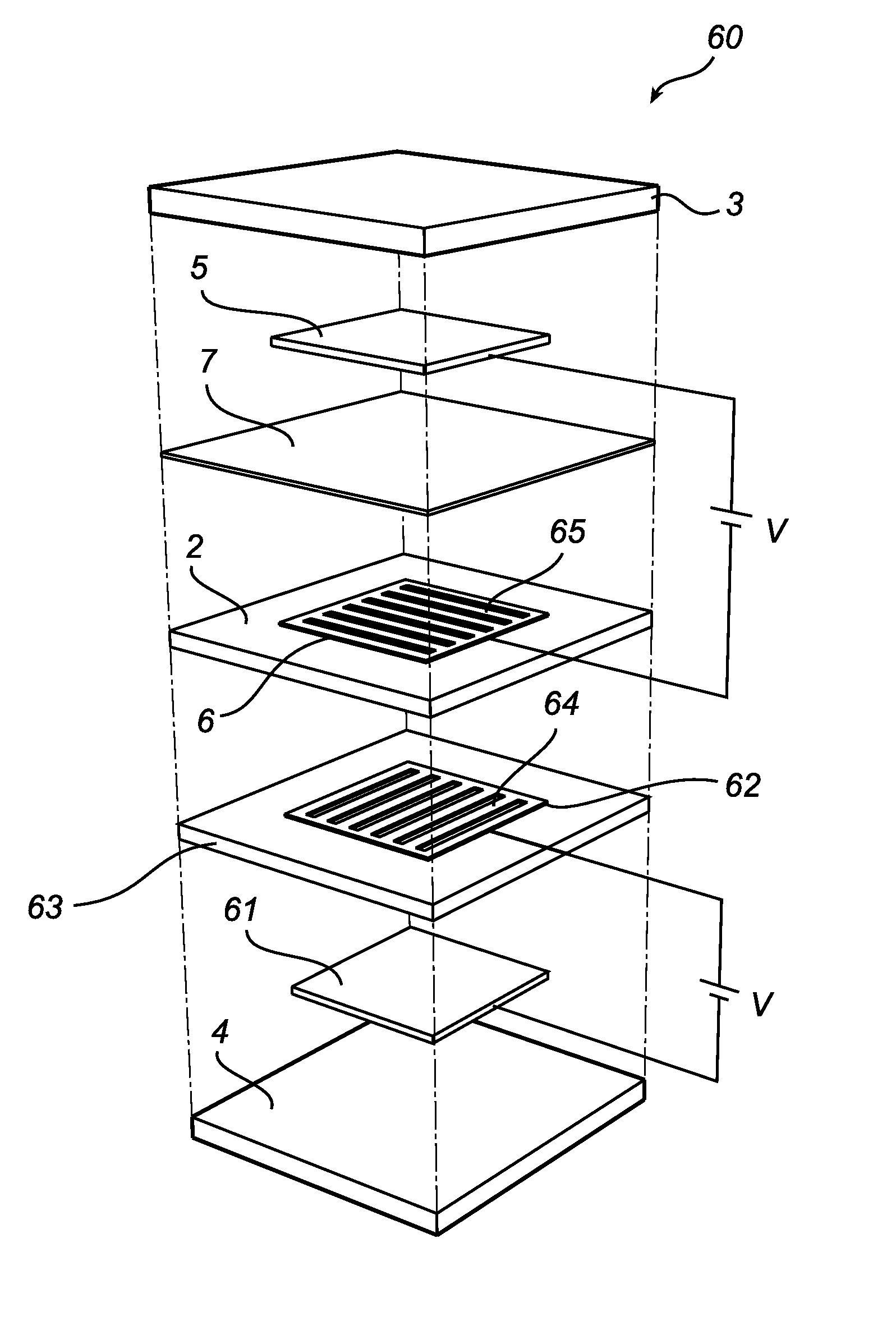

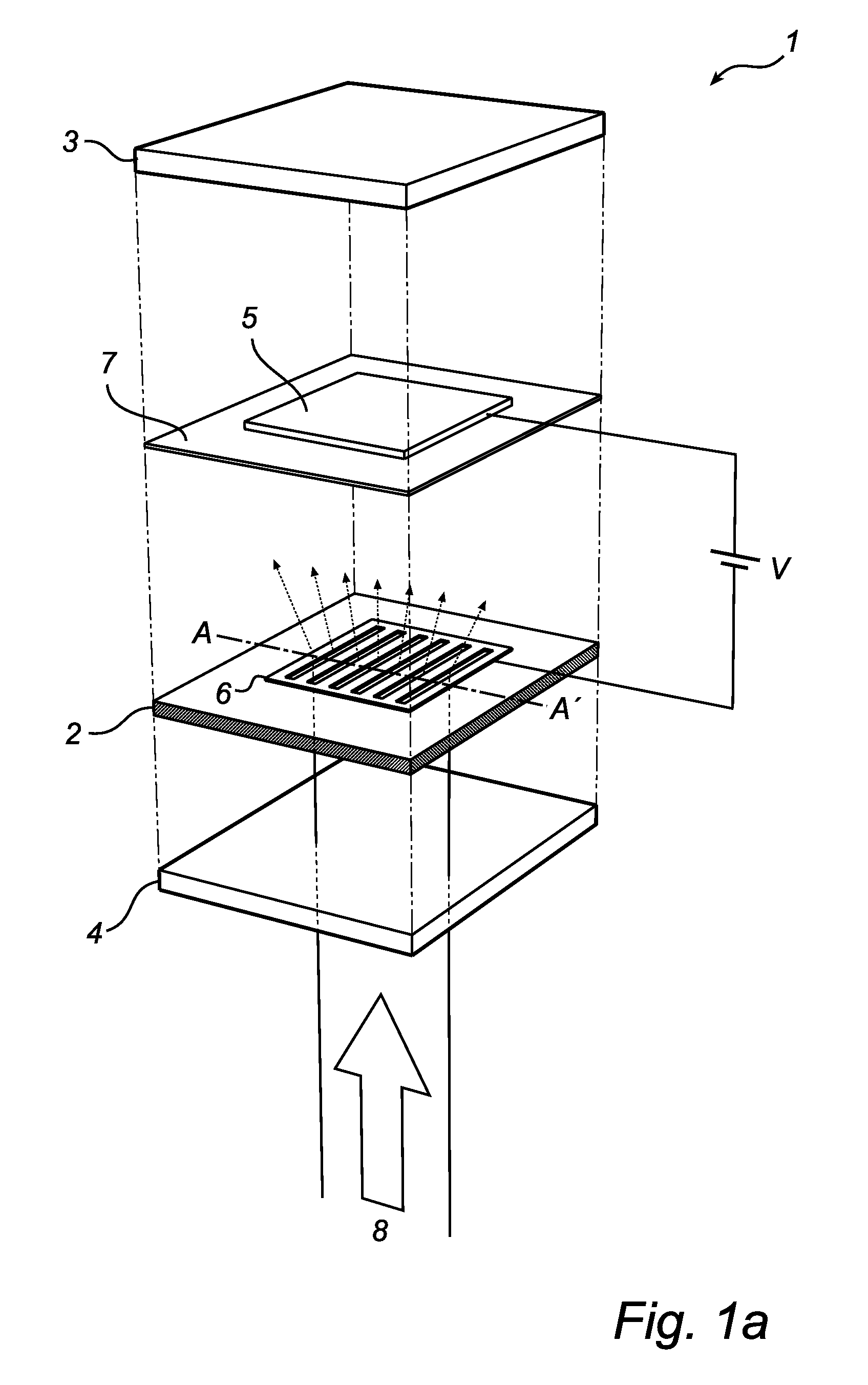

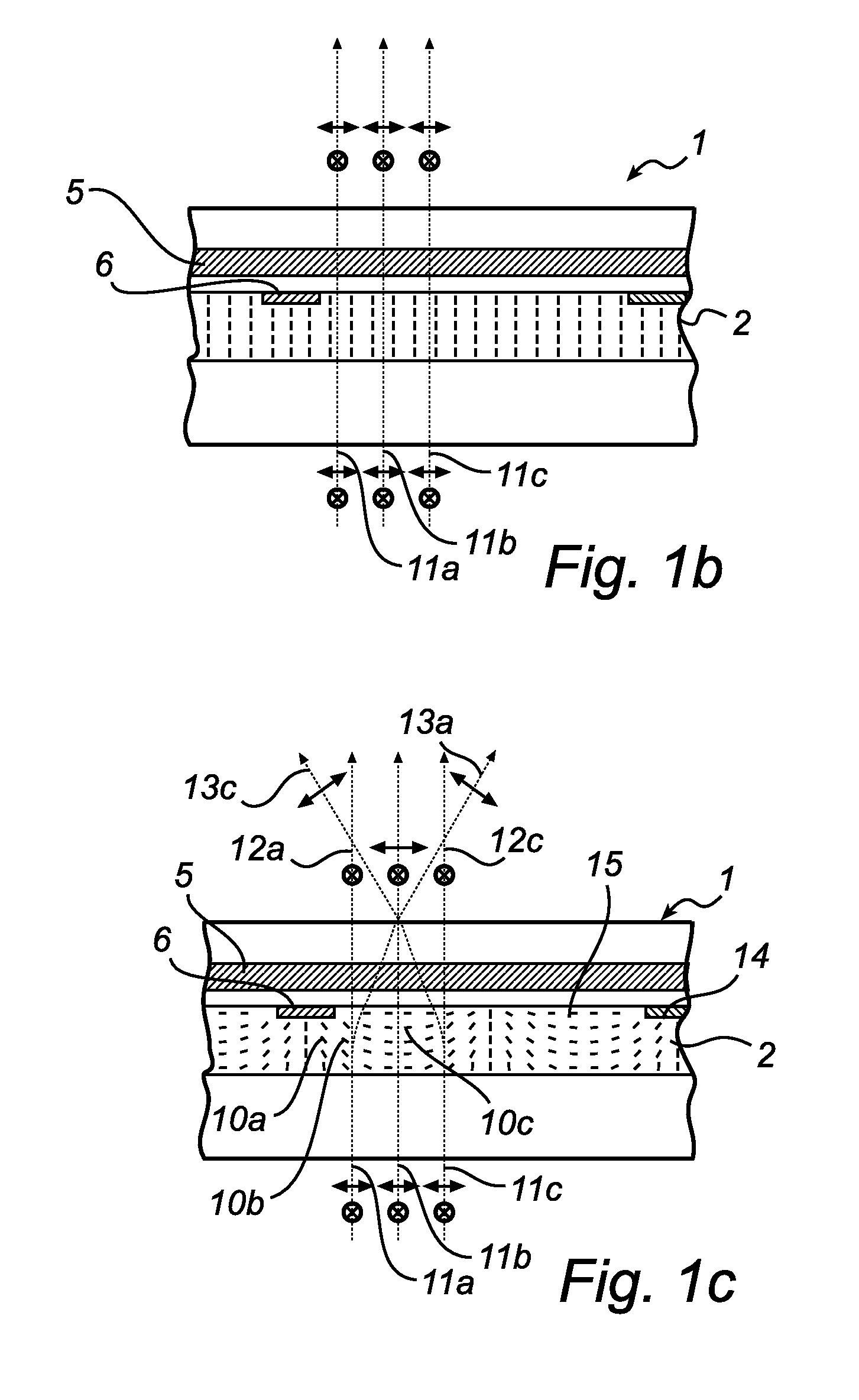

Beam shaping device

InactiveUS20100208185A1Effective shapingLow viscosityNon-linear opticsElectrical conductorLight beam

A beam shaping device (1; 50; 60) comprising first (3) and second (4) substrates, a liquid crystal layer (2) sandwiched between the substrates, and a first electrode layer (5; 51) provided on a side of the first substrate (3) facing the liquid crystal layer (2). The beam shaping device is controllable between beam shaping states, each permitting passage of light through the beam shaping device, and further comprises an insulating layer (7) covering the first electrode layer (5; 51) and a second electrode layer (6; 53) provided on top of the insulating layer. The second electrode layer (6; 53) comprises a conductor pattern exposing a portion of the insulating layer (7). The beam shaping device is configured in such a way that application of a voltage (V) between the first (5; 51) and second (6; 53) electrode layers causes liquid crystal molecules comprised in a portion of the liquid crystal layer (2) corresponding to the exposed portion of the insulating layer to tilt in a plane perpendicular to the liquid crystal layer, resulting in a local refractive index gradient, thereby enabling shaping of a beam (8) of light passing through the beam shaping device.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Optical element with nanoparticles

Owner:ROHM & HAAS DENMARK FINANCE

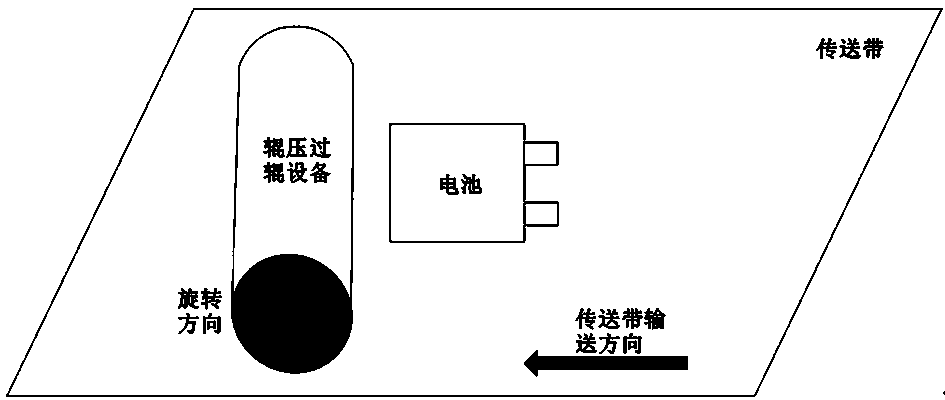

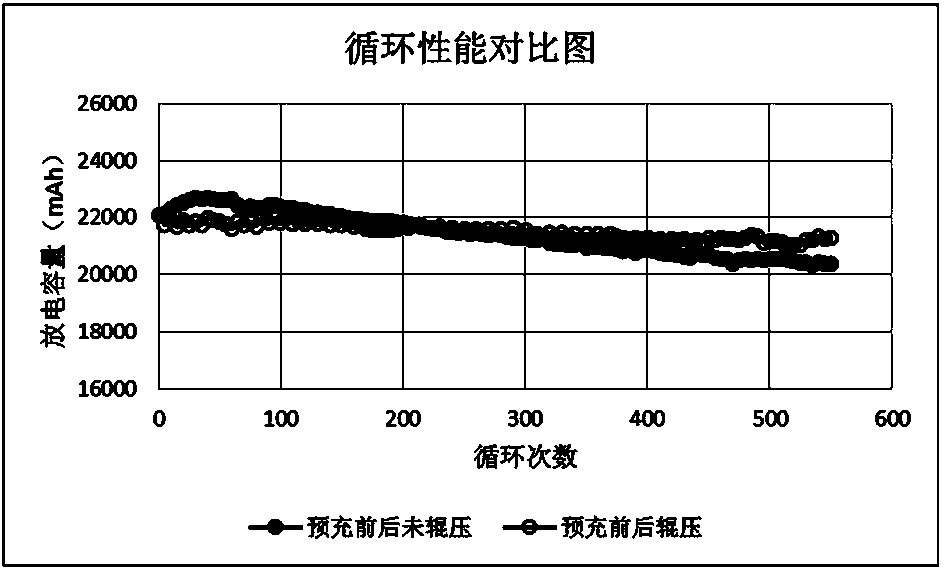

Novel control method for improving lithium ion soft-package laminated battery diaphragm fold

InactiveCN108155424AImprove performanceGuaranteed plastic effectFinal product manufactureSecondary cells charging/dischargingElectrical batteryPre-charge

The invention relates to a novel control method for improving lithium ion soft-package laminated battery diaphragm fold. The problem that the battery performance is influenced due to the fold of the soft-package laminated lithium ion battery diaphragm is solved. The control method comprises the following steps: laying down a battery after liquid injection, thereby ensuring that the electrolyte sufficiently infiltrates a pole piece; and then performing rolling on the lay-down battery, and controlling the pressure and speed of the rolling in the rolling process; pre-charging the battery after the rolling is ended; and performing secondary rolling on the completely pre-charged battery, further shaping the diaphragm, and releasing the gas to finish the secondary package. The contacting interface between a positive / negative pole piece and the diaphragm is better by comparing the lithium ion soft-package laminated battery prepared based on the control method with the battery without performing the rolling shaping, the dead lithium existing in the fold area caused by the diaphragm fold is avoided, thus the capacity of the positive / negative material is sufficiently played, and the batteryperformance is improved.

Owner:JIANGSU FRONT NEW ENERGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com