Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1097results about How to "Efficient preparation method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

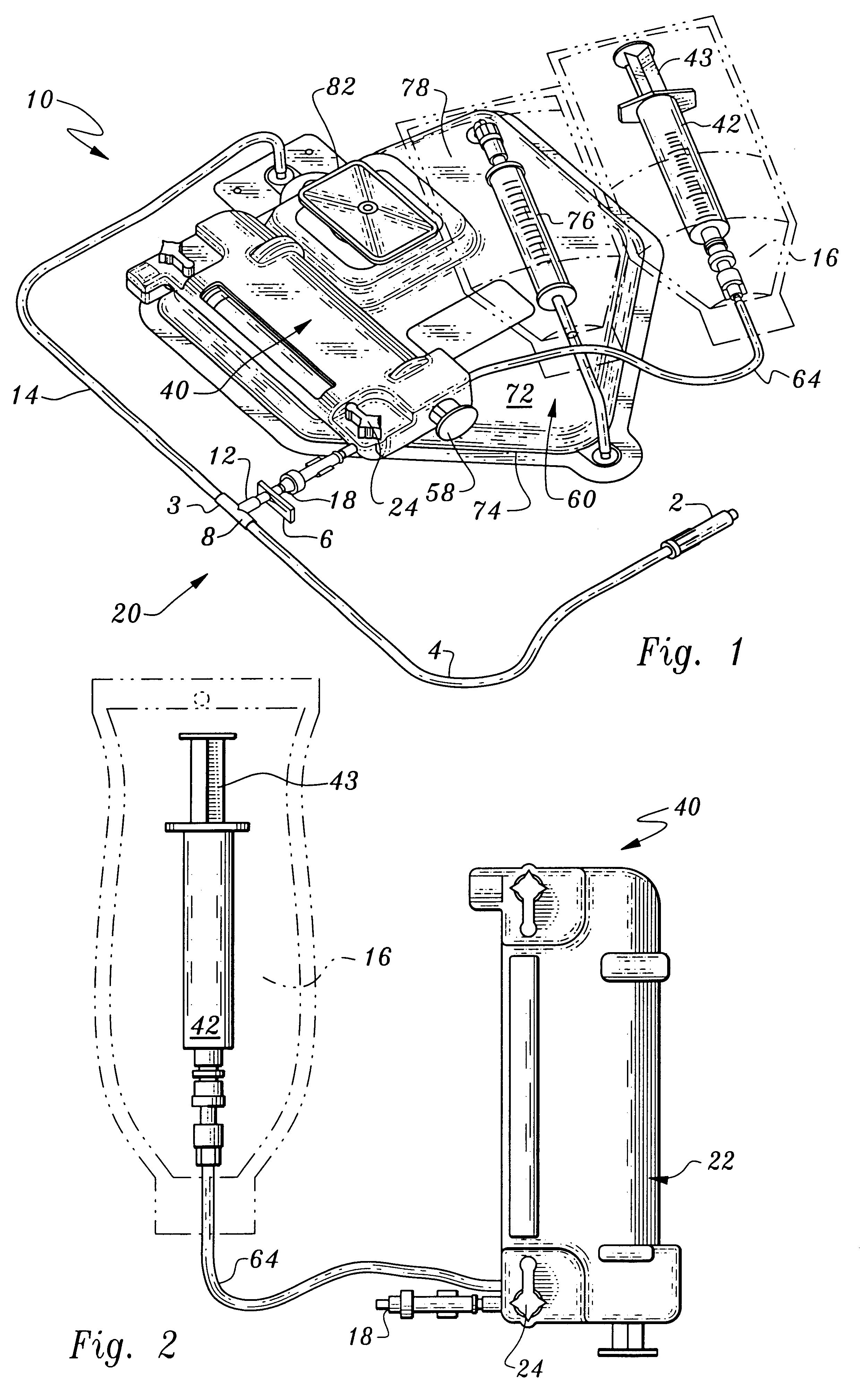

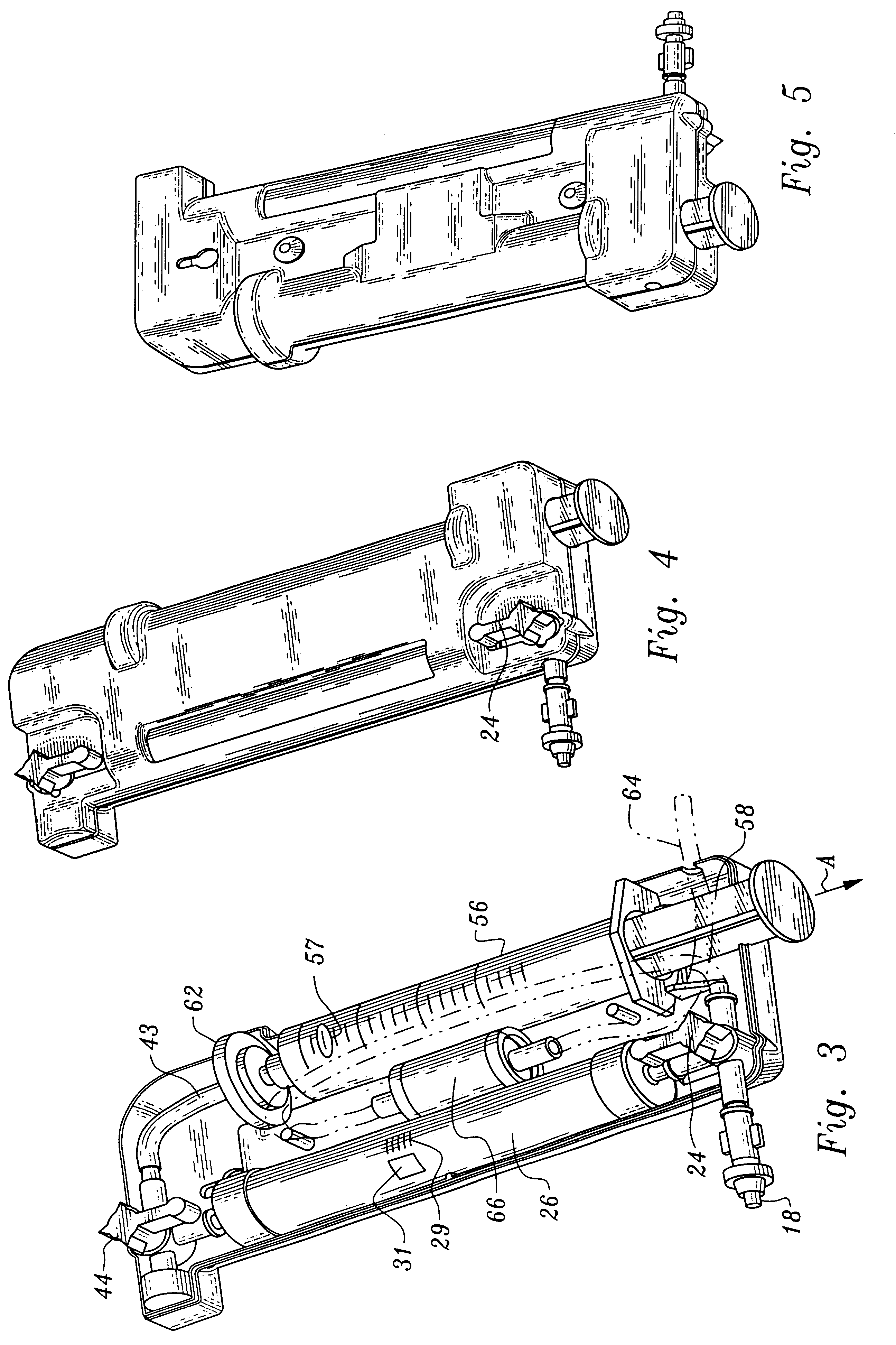

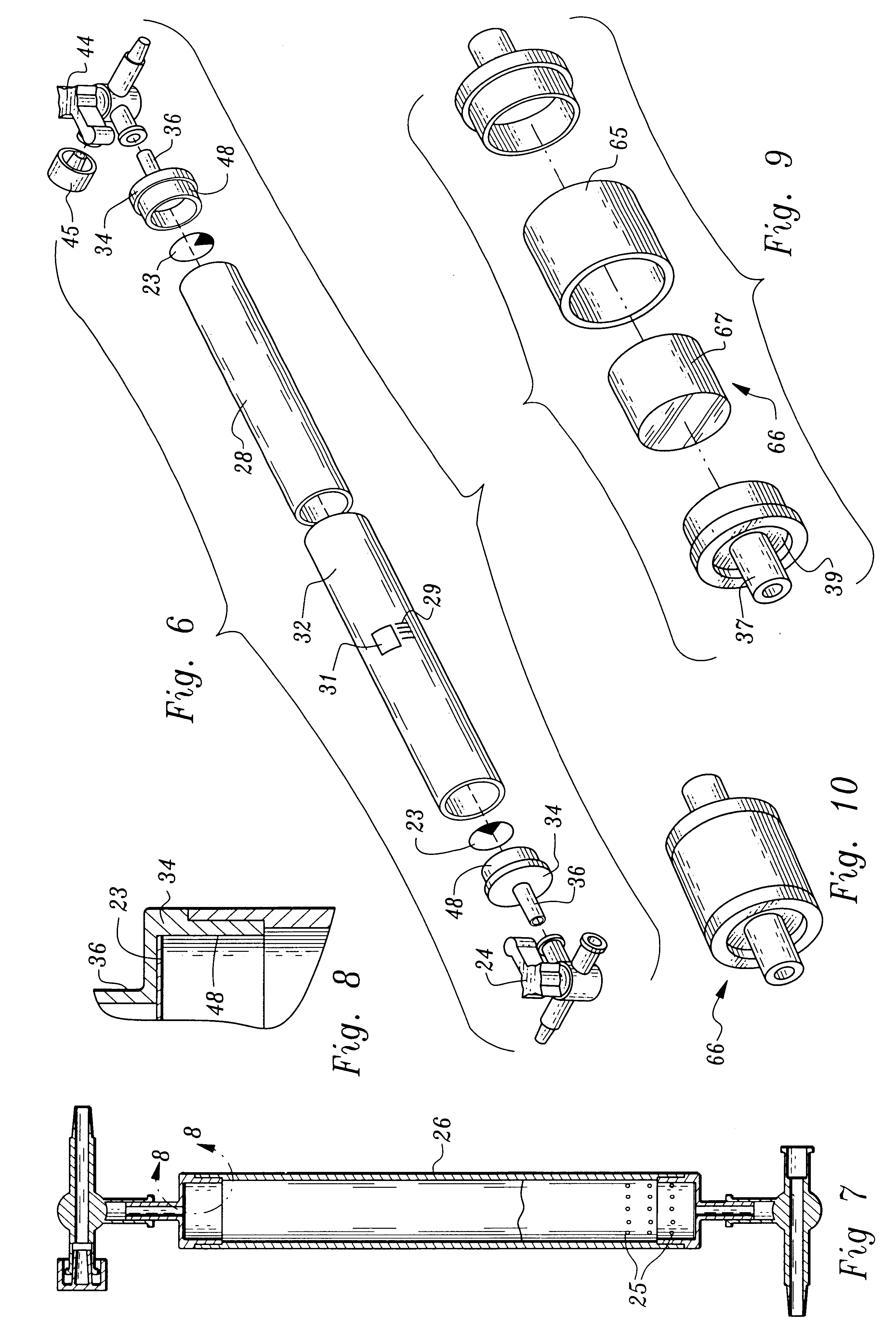

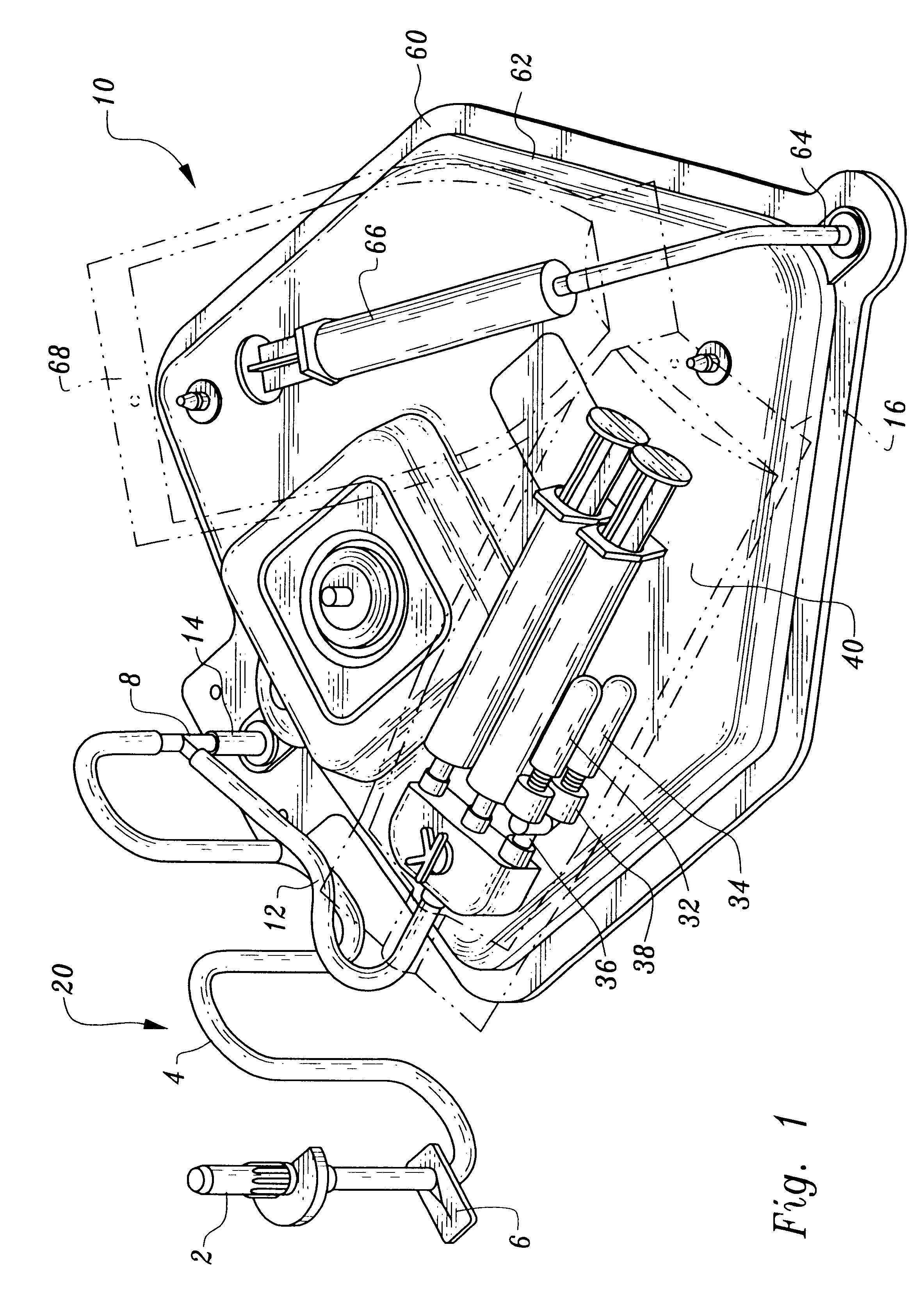

Method for preparing thrombin for use in a biological glue

InactiveUS6472162B1Derive fast acting, stable autologous thrombinSimple preparatory procedureBioreactor/fermenter combinationsBiological substance pretreatmentsTissue sealantDonors plasma

A sterile method for preparing stable thrombin component from a single donor's plasma in which the thrombin component and the clotting and adhesive proteins component are harvested simultaneously from the same donor plasma in less than one hour. The combined components provide an improved biological hemostatic agent and tissue sealant by virtue of its freedom from the risk of contaminating viruses or bacteria from allogenic human or bovine blood sources. The thrombin provides polymerization of the clotting and adhesive proteins in less than five seconds, and is sufficiently stable to provide that fast clotting over a six hour period. Further, the clotting times can be predictably lengthened by diluting the thrombin with saline.

Owner:ASAHI KASEI MEDICAL CO LTD

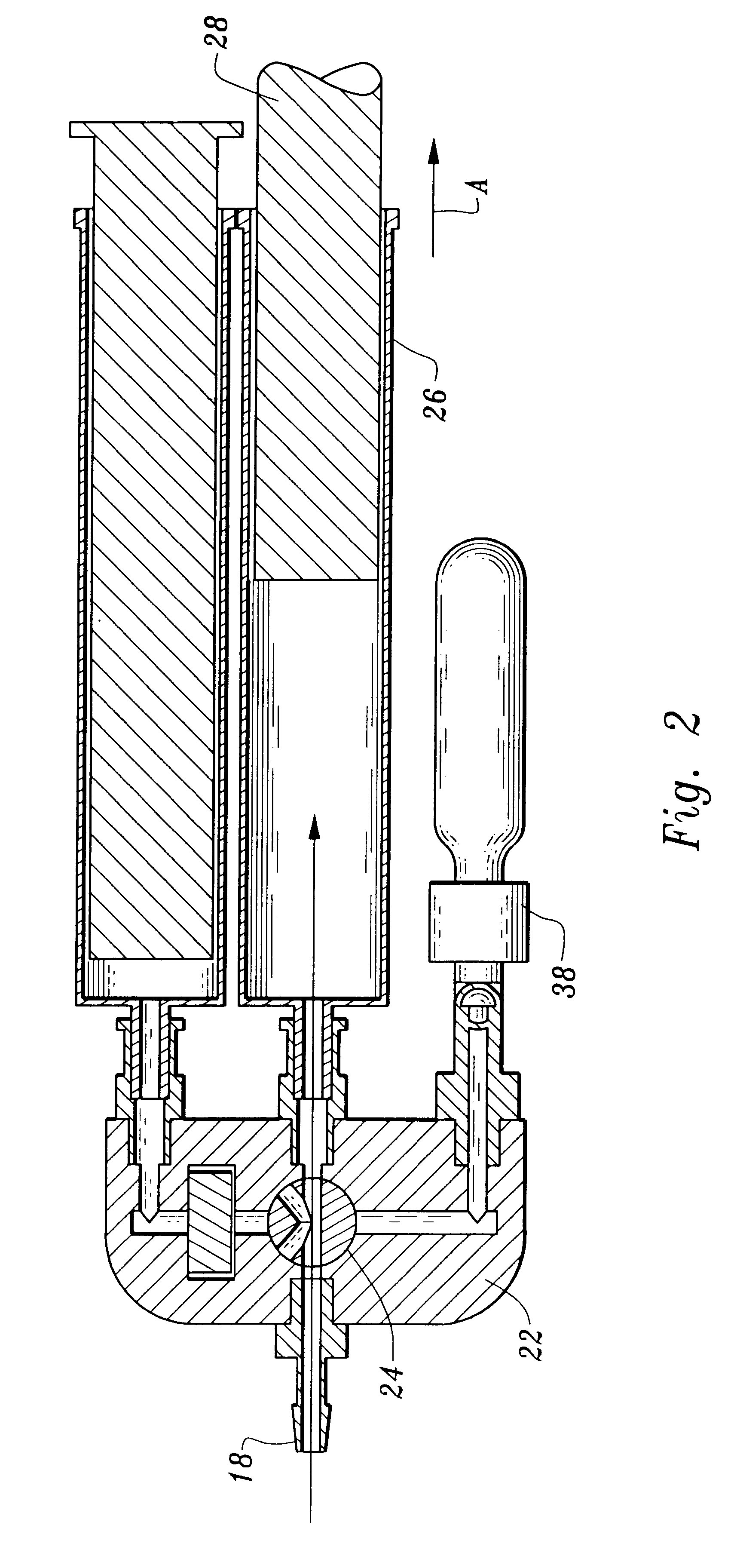

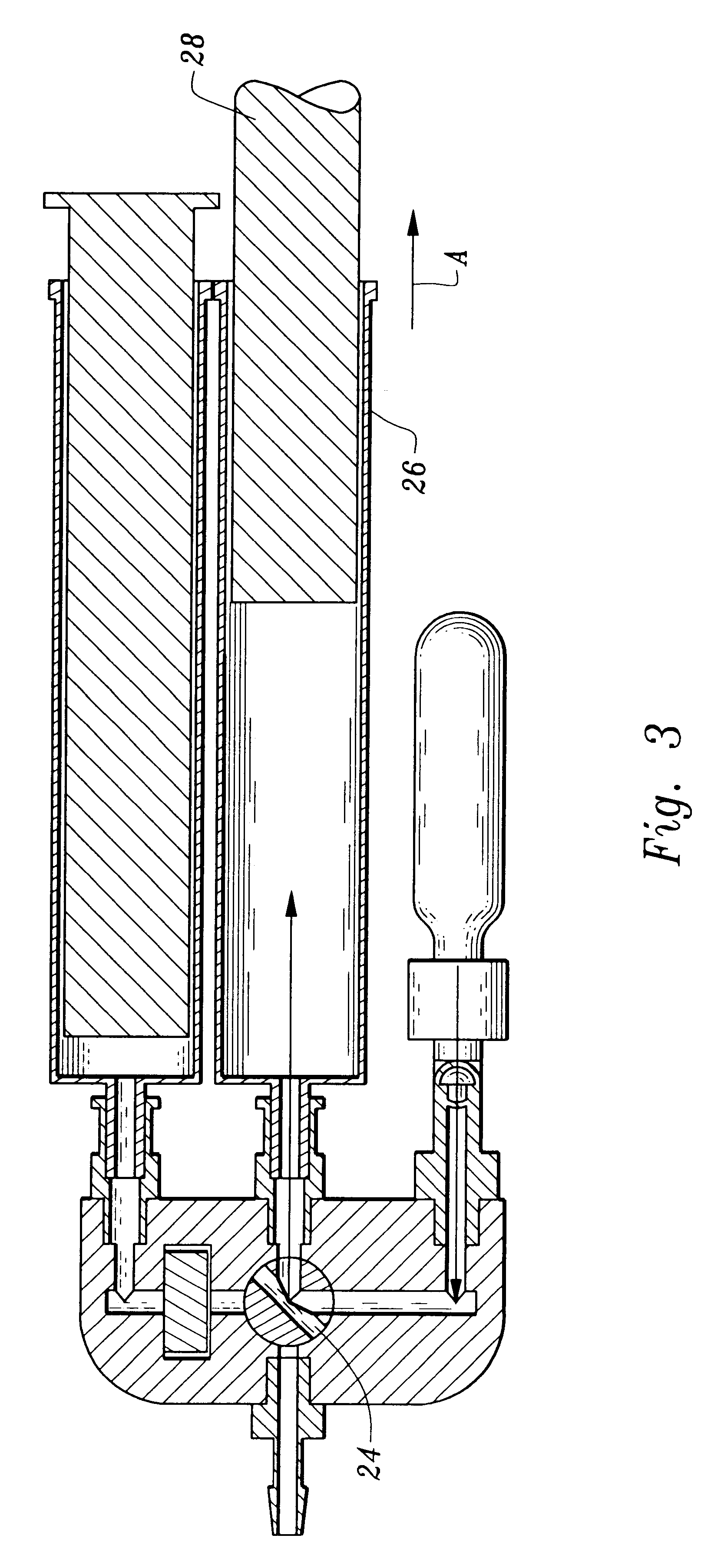

Apparatus and method of preparation of stable, long term thrombin from plasma and thrombin formed thereby

InactiveUS6274090B1Derive fast acting, stable autologous thrombinSimple preparatory procedureImmobilised enzymesBioreactor/fermenter combinationsTissue sealantDonors plasma

A sterile method for preparing stable thrombin component from a single donor's plasma in which the thrombin component is harvested simultaneously from the clotting and adhesive proteins component from the same donor plasma in less than one hour. The combined components provide an improved biological hemostatic agent and tissue sealant by virtue of its freedom from the risk of contaminating viruses or bacteria from allogenic human or bovine blood sources. The thrombin provides polymerization of the clotting and adhesive proteins in less than five seconds, and is sufficiently stable to provide that fast clotting over a six hour period. Further, the clotting times can be predictably lengthened by diluting the thrombin with saline.

Owner:ASAHI KASEI MEDICAL CO LTD

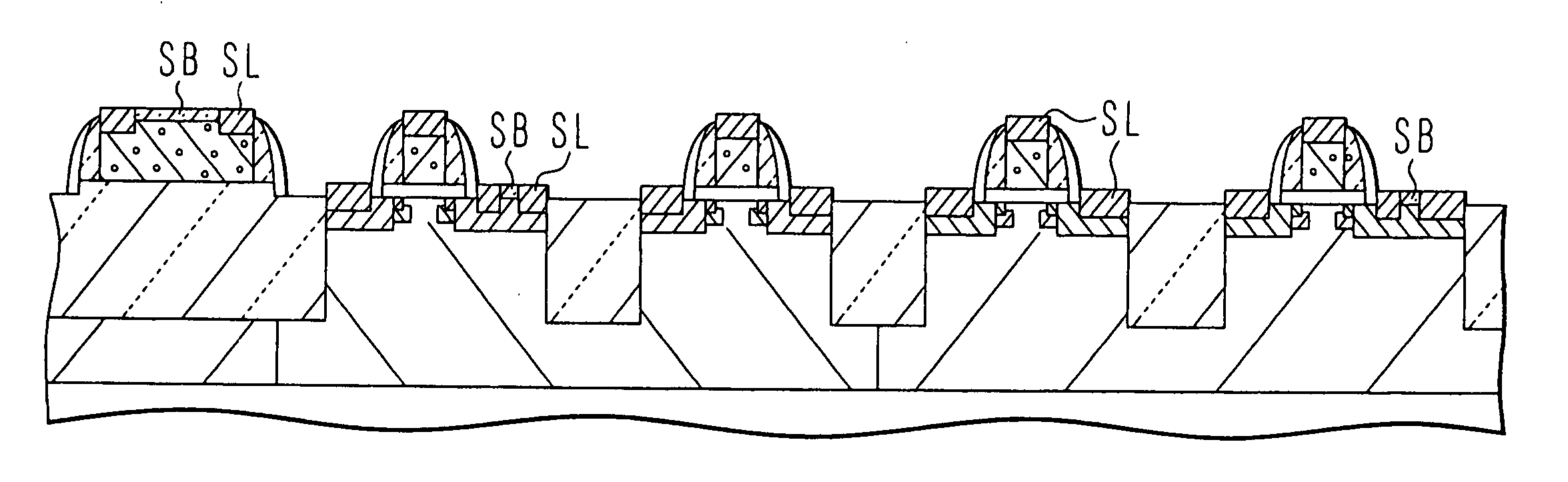

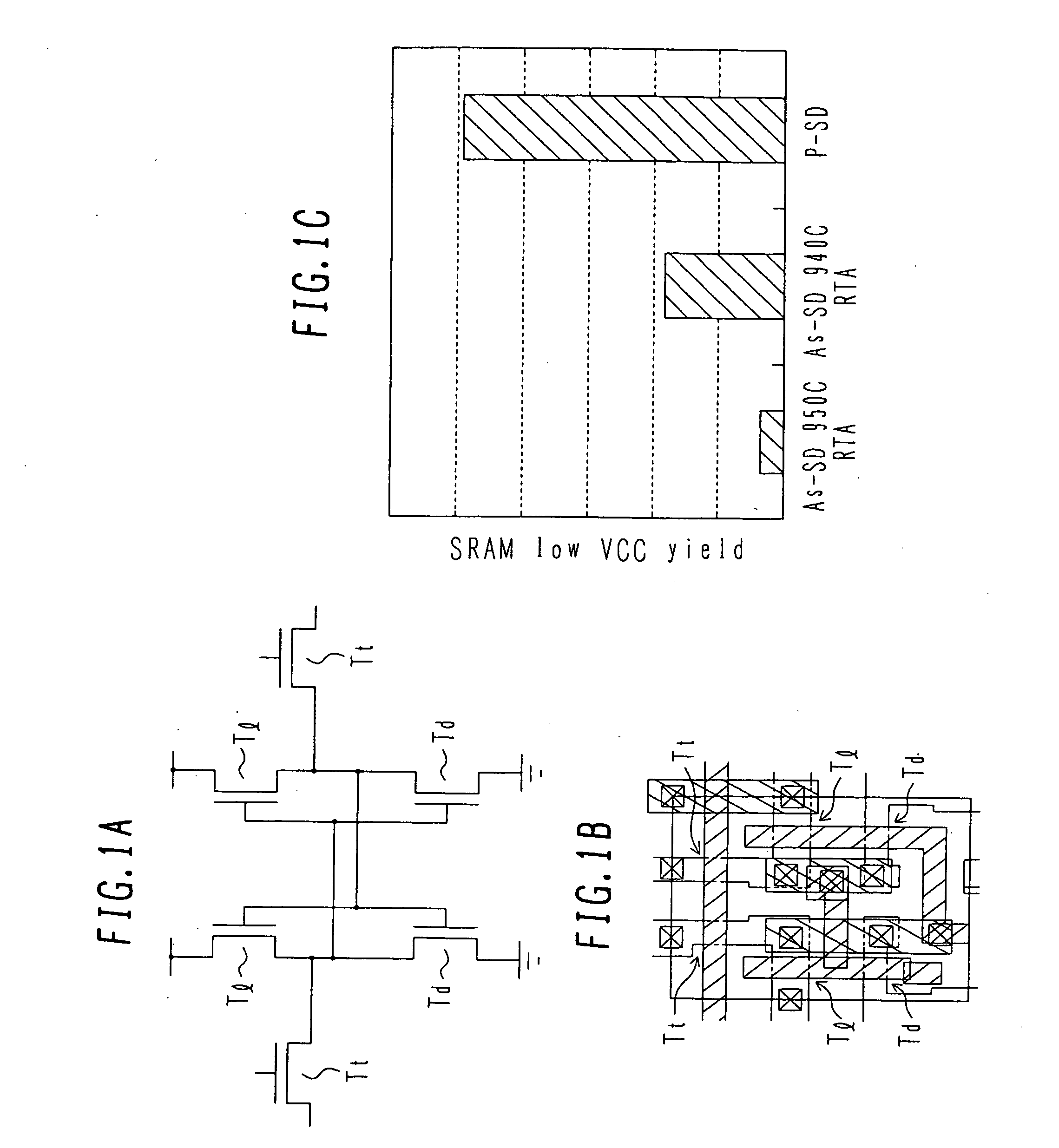

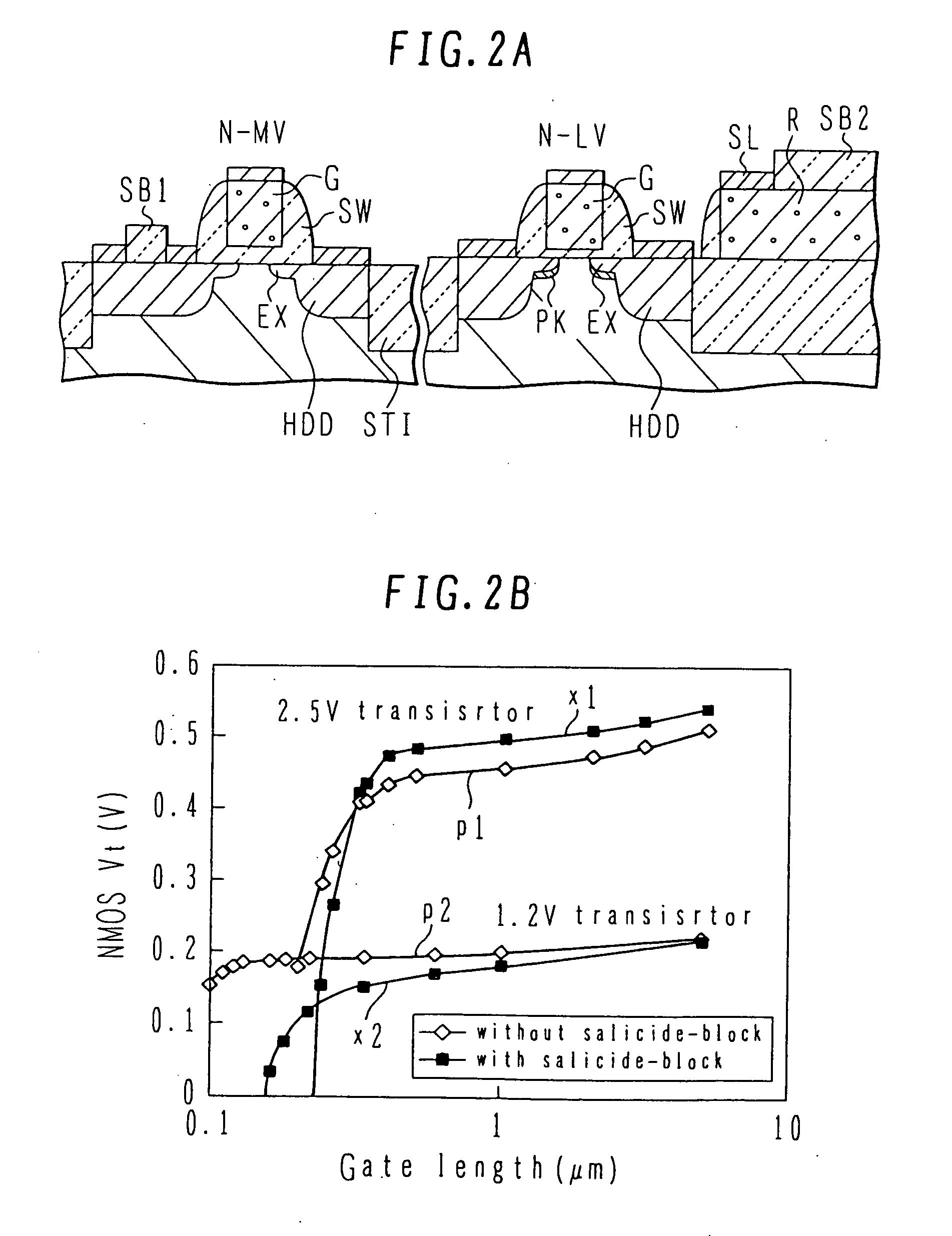

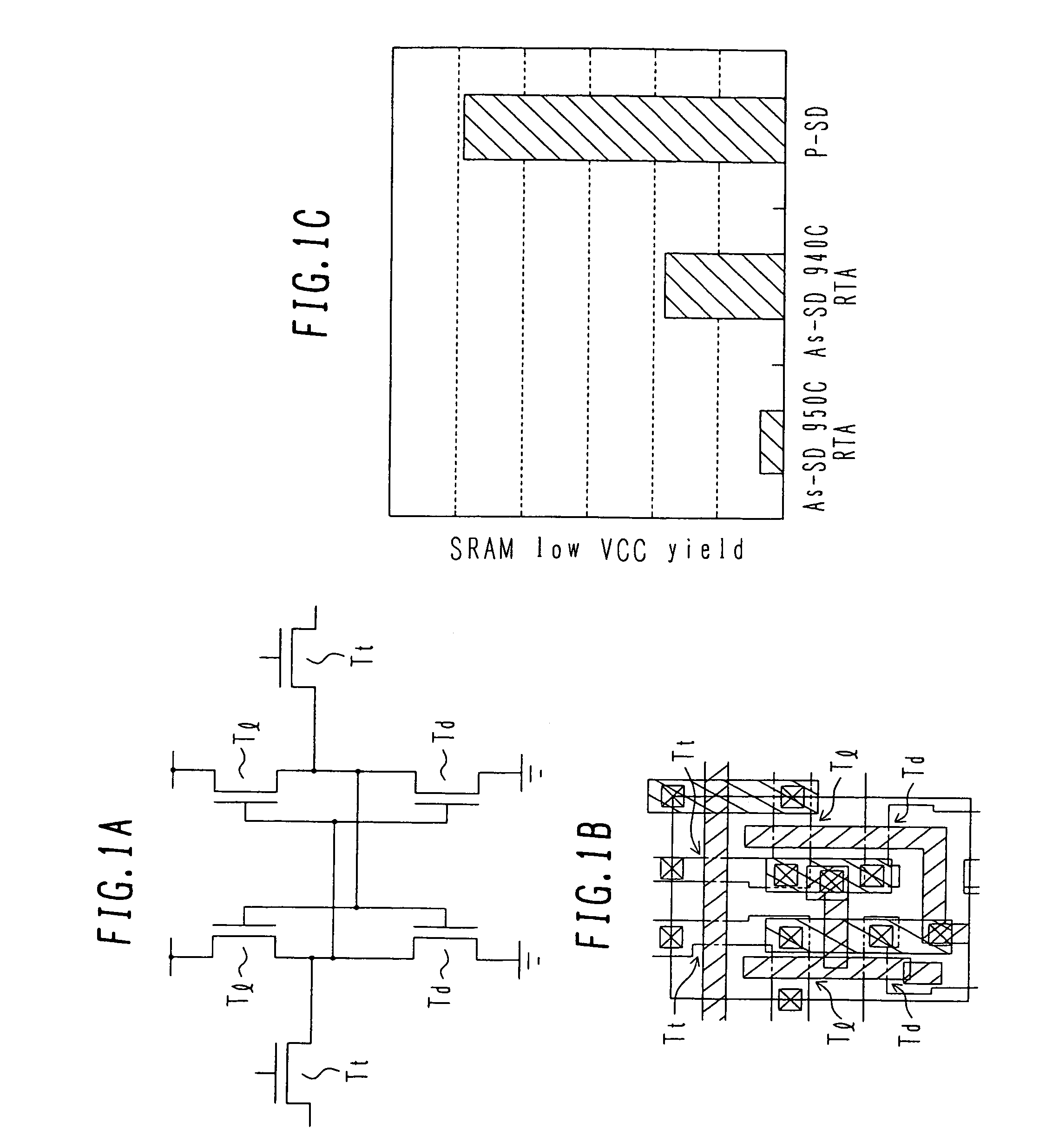

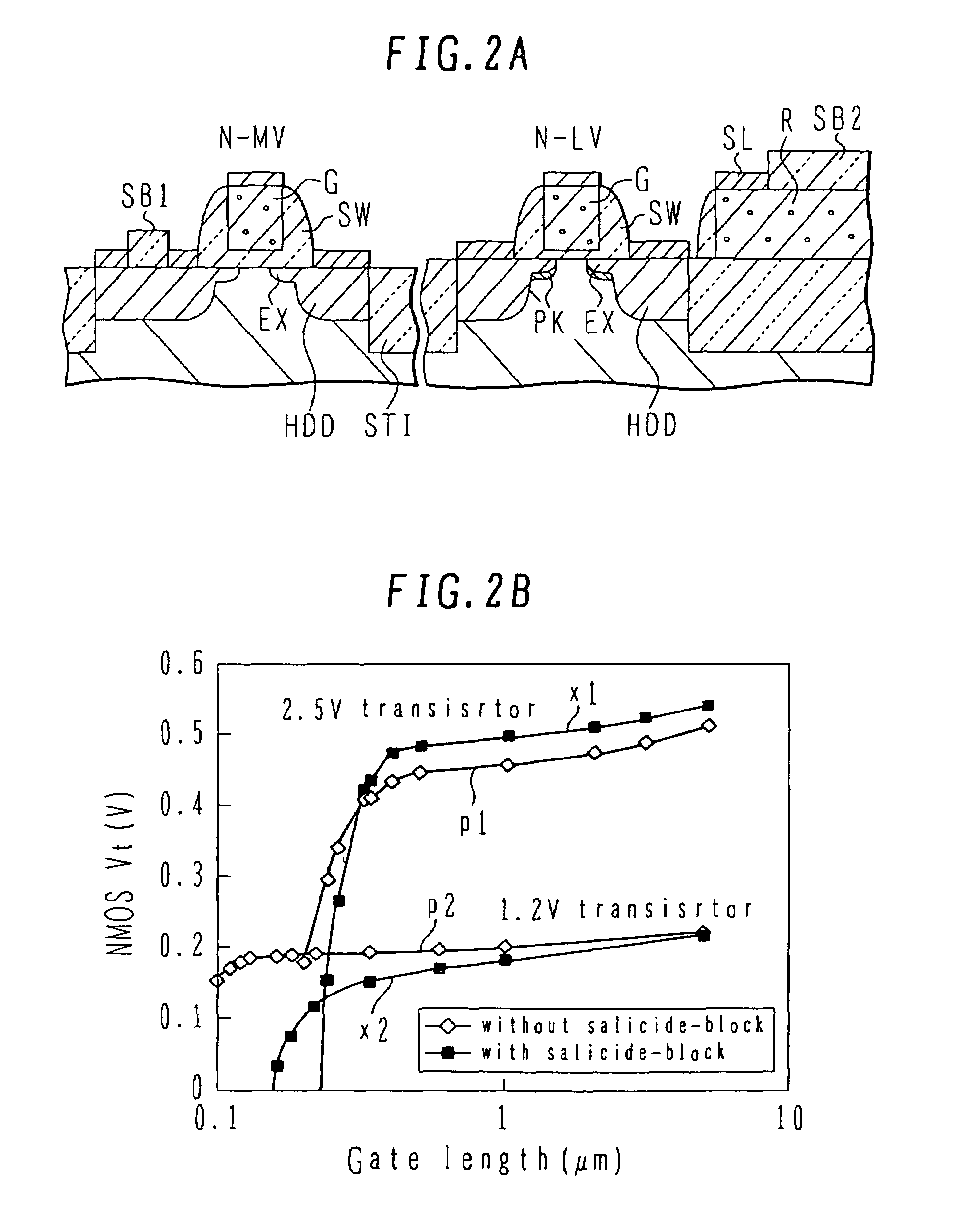

Semiconductor device and its manufacturing method

InactiveUS20050227440A1Simple processEfficient preparation methodTransistorSolid-state devicesDevice materialMetal silicide

A semiconductor device manufacturing method includes, forming isolation region having an aspect ratio of 1 or more in a semiconductor substrate, forming a gate insulating film, forming a silicon gate electrode and a silicon resistive element, forming side wall spacers on the gate electrode, heavily doping a first active region with phosphorus and a second active region and the resistive element with p-type impurities by ion implantation, forming salicide block at 500° C. or lower, depositing a metal layer covering the salicide block, and selectively forming metal silicide layers. The method may further includes, forming a thick and a thin gate insulating films, and performing implantation of ions of a first conductivity type not penetrating the thick gate insulating film and oblique implantation of ions of the opposite conductivity type penetrating also the thick gate insulating film before the formation of side wall spacers.

Owner:FUJITSU LTD

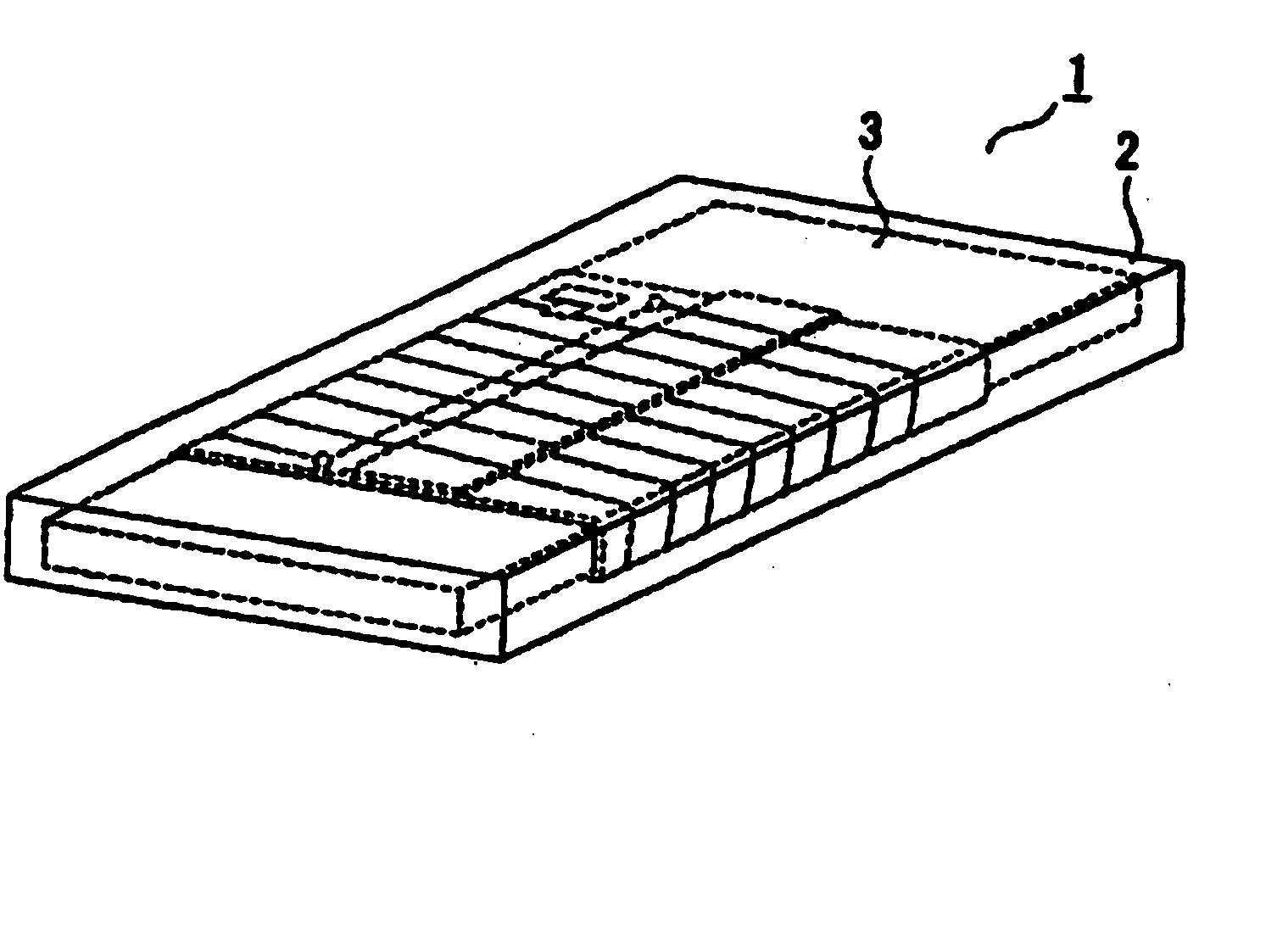

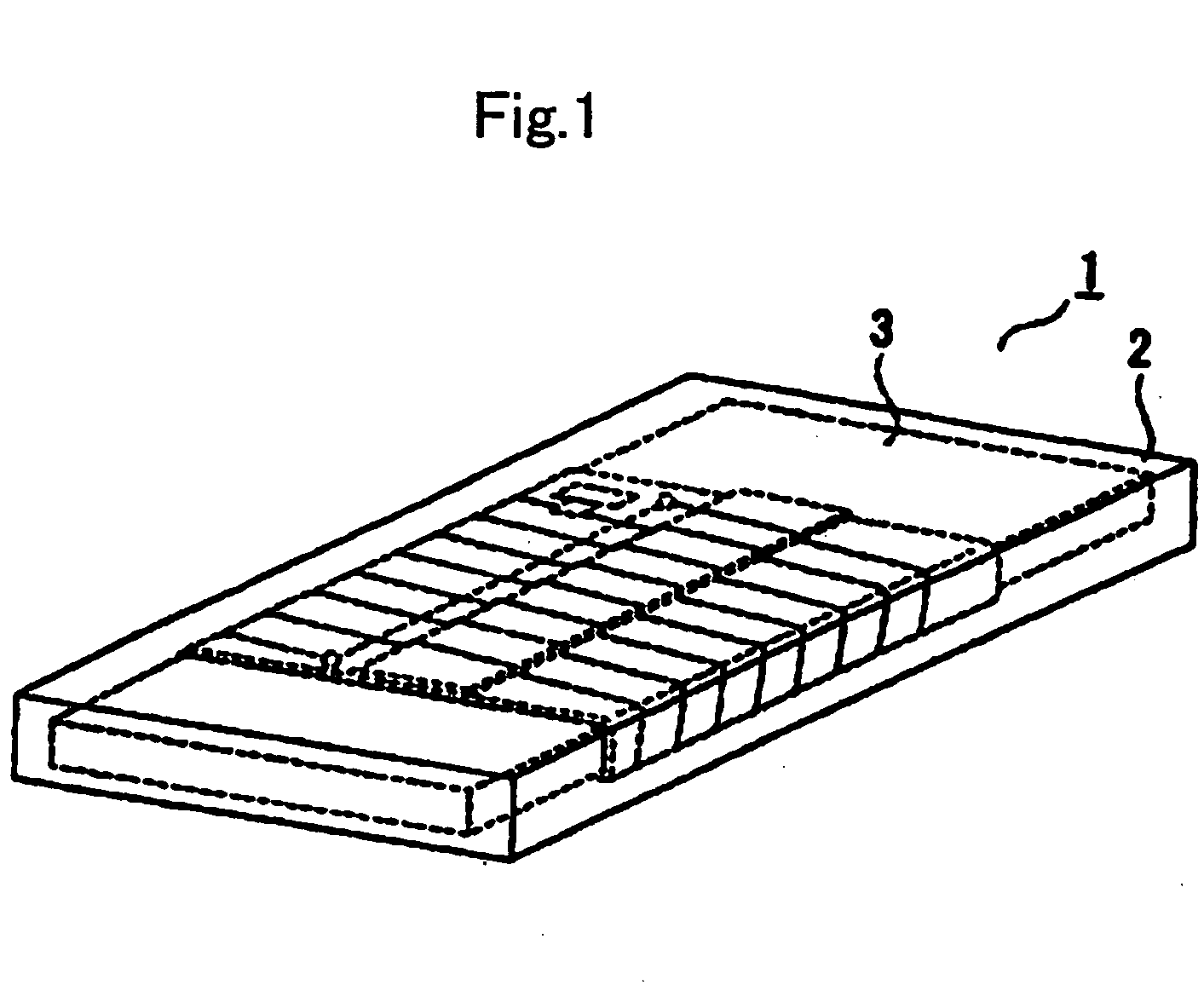

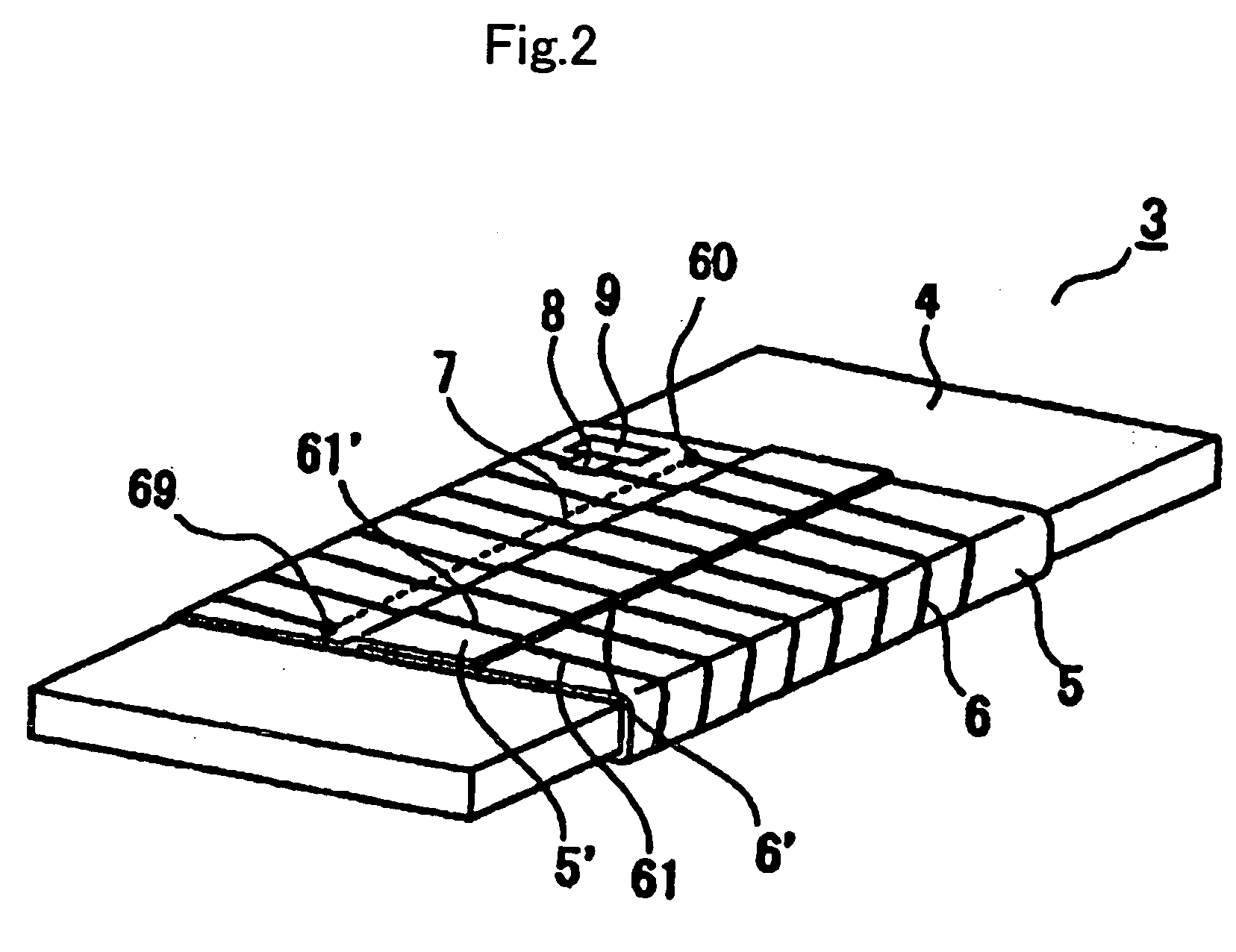

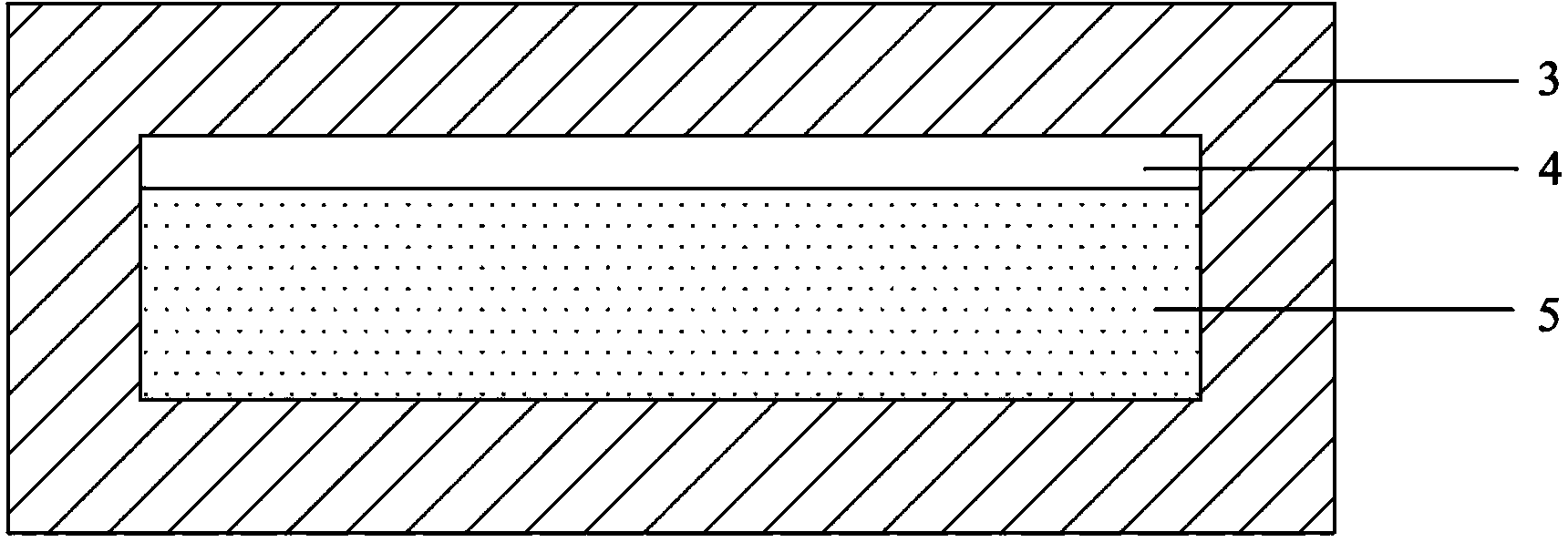

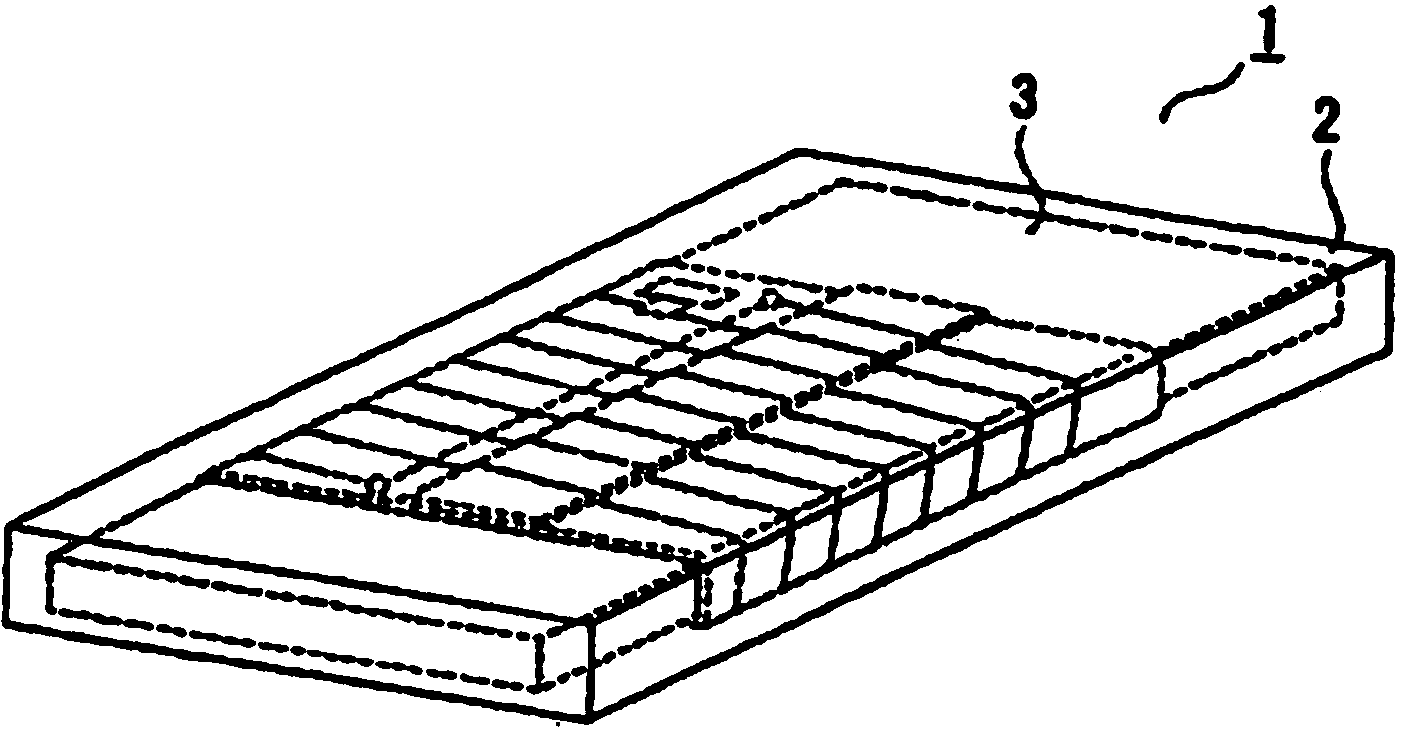

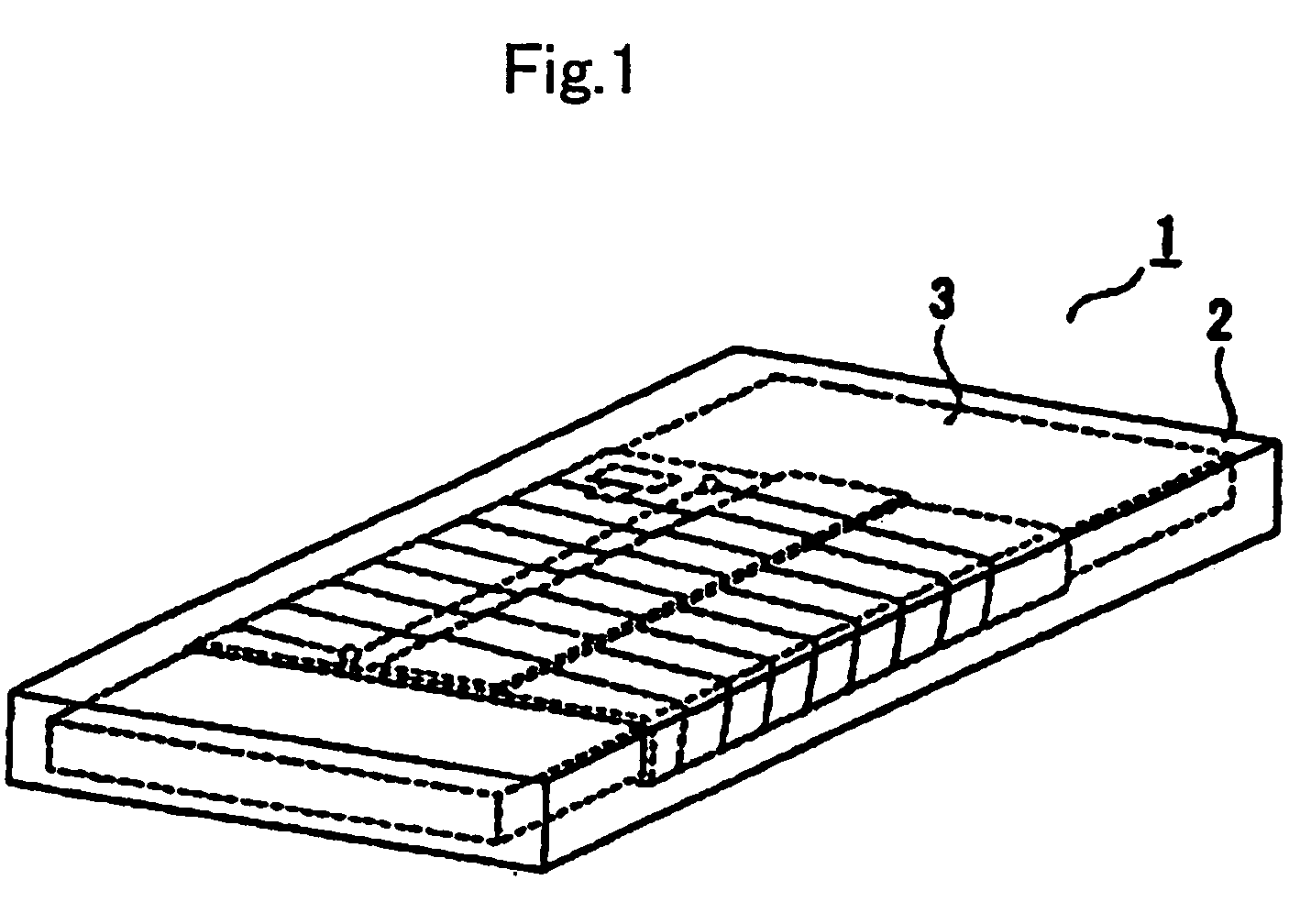

RFID tag and its manufacturing method

InactiveUS20050179552A1Efficient measurementIncrease in costLoop antennas with ferromagnetic coreLine/current collector detailsElectrical conductorEngineering

An RFID tag which is provided with a coil-shaped antenna such that a conductor is placed on the periphery of a magnetic core, the RFID comprising: the magnetic core, an FPC wound on the periphery of the magnetic core, two or more linear conductor patterns formed in parallel with one another on the FPC, an IC that is connected to the linear conductor patterns and disposed on the FPC, a crossover pattern that electrically connects one end and the other end of outermost linear conductor patterns among the linear conductor patterns formed in parallel with one another, where in the two or more linear conductor patterns, adjacent linear conductor patterns in a joint portion in the wound FPC are electrically connected in respective start edges and end edges.

Owner:FURUKAWA ELECTRIC CO LTD

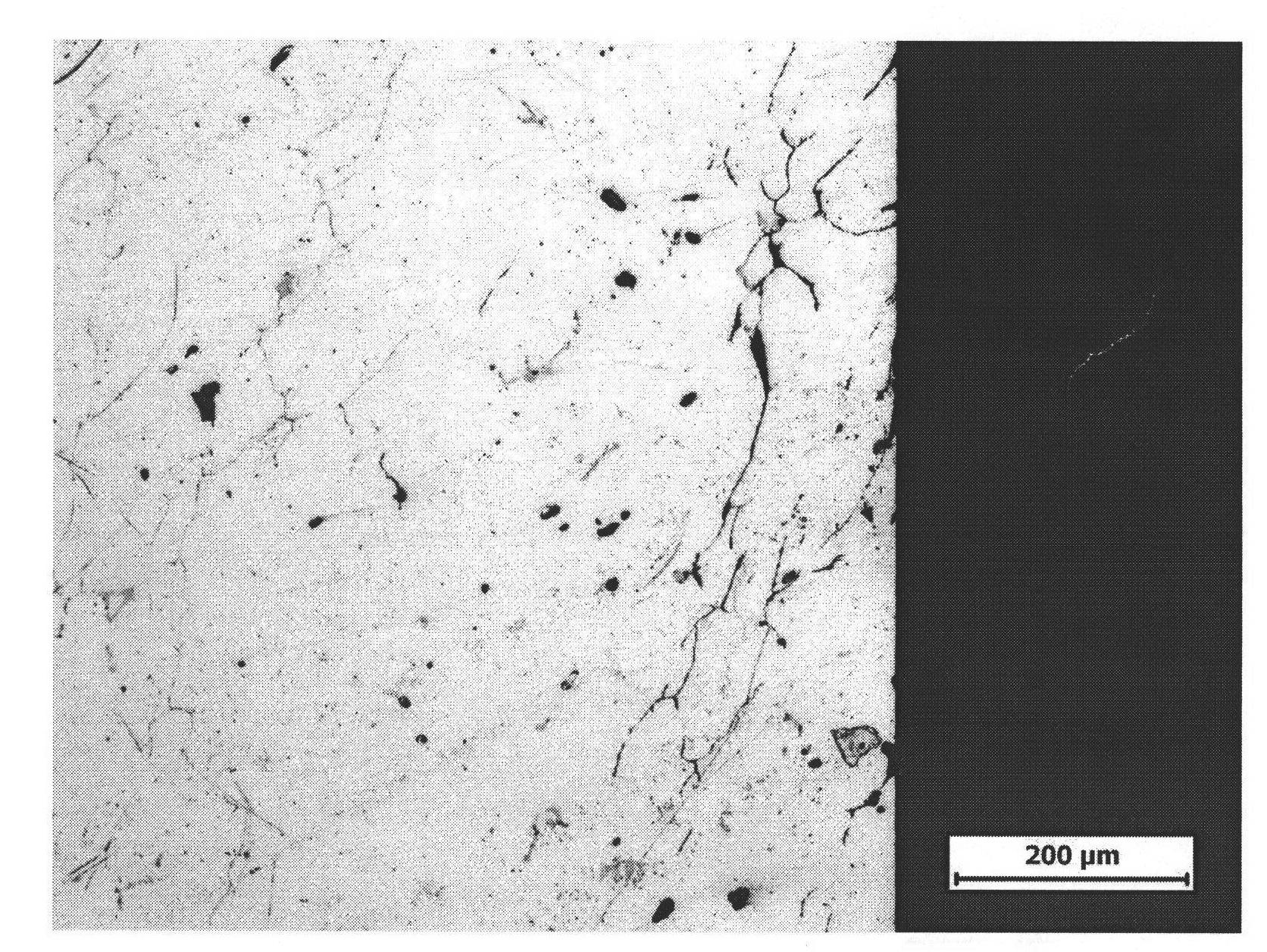

Method for preparing polymer porous nanofiber through mixed phase separation

InactiveCN102517673AWide range of applicationsEasy to prepareFilament/thread formingArtificial filaments from cellulose derivativesElectrospinningWater treatment

The invention discloses a method for preparing polymer porous nanofiber through mixed phase separation. The diameter of the prepared polymer porous nanofiber is between 300nm and 900nm, and the aperture is 1 to 120nm. The preparation method for the polymer porous nanofiber comprises the following steps of: mixing a polymer, an additive and a solvent according to certain proportion; heating and stirring the mixture until the mixture is completely dissolved and forms transparent solution; performing electrostatic spinning on the solution; depositing primarily generated fibers in ice-water bath or the water bath with the temperature of 0 to 20 DEG C, wherein thermally induced phase separation and nonsolvent induced phase separation are caused; and extracting residual solvent and additive through post treatment to obtain the polymer porous nanofiber. The preparation method is simple and highly effective and is convenient to perform; and polymer porous nanofibers with different diameters and porosities can be prepared by adjusting the conditions of electrostatic spinning. The method has enormous application prospect in aspects, such as high-tech composite materials, water treatment, catalyst carriers, electrode materials and the like.

Owner:ZHEJIANG UNIV

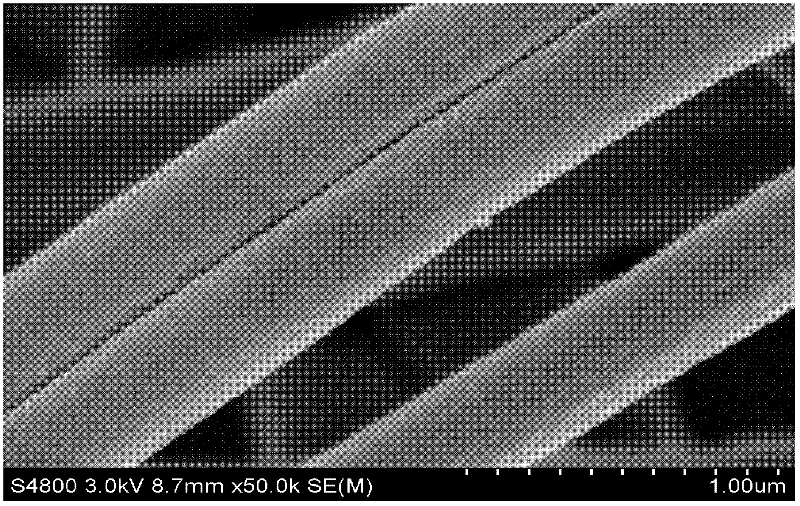

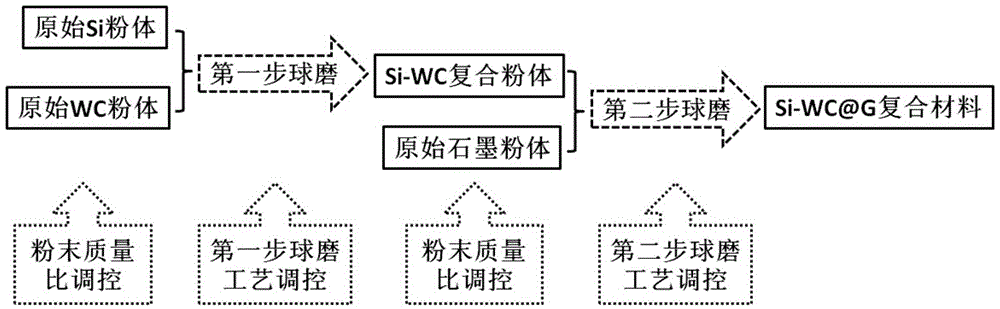

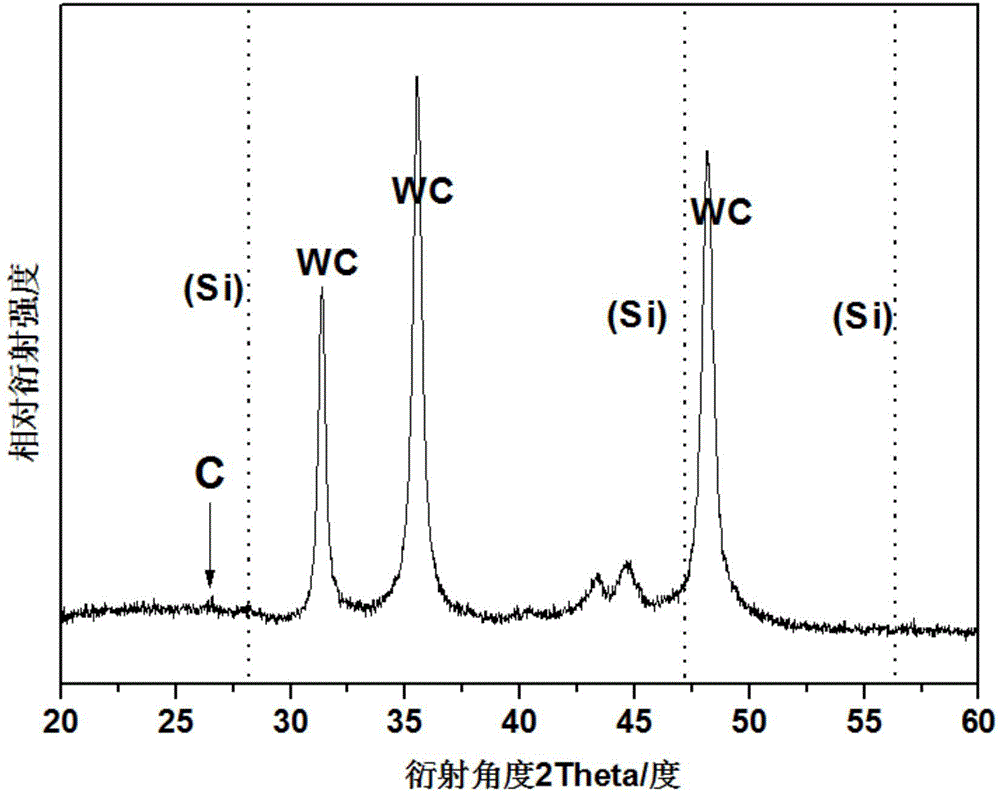

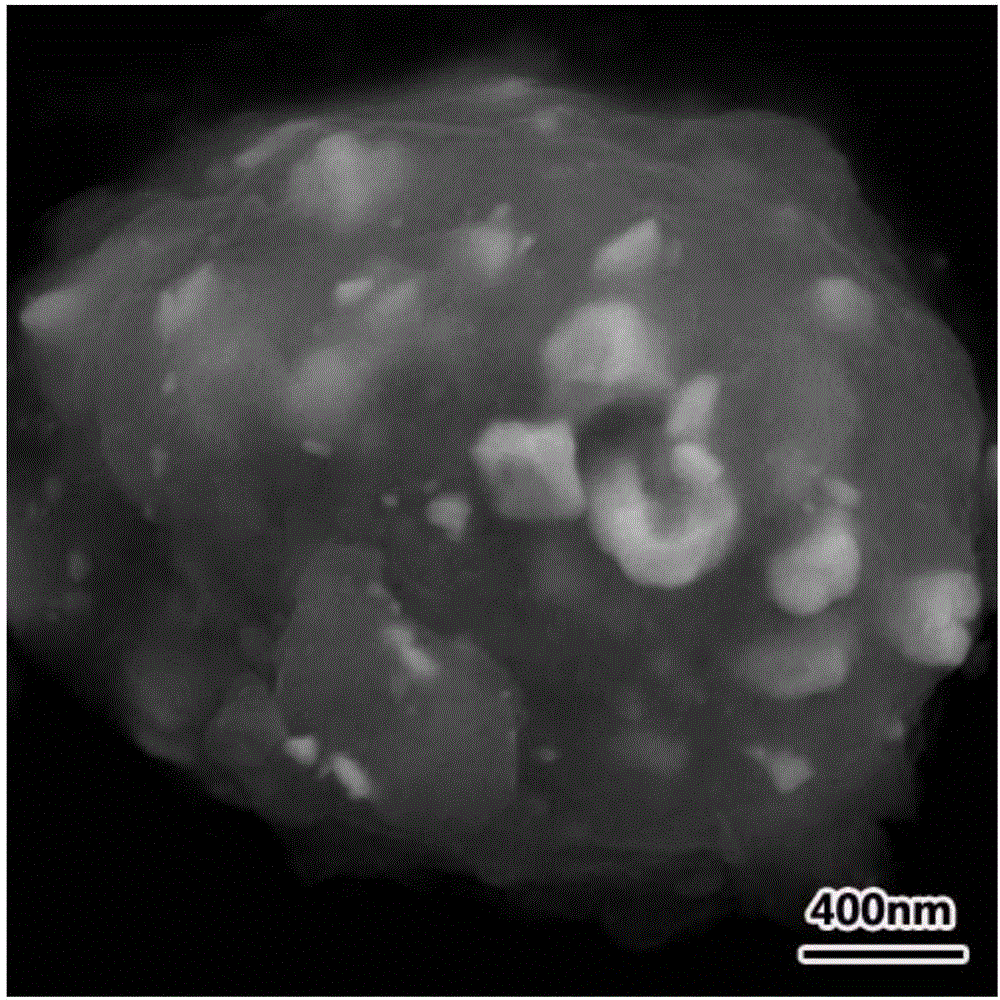

Anode material for lithium-ion battery and preparation method of anode material

InactiveCN104577081ALow priceSufficient raw materialsMaterial nanotechnologyCell electrodesThin layerLithium electrode

The invention discloses an anode material for a lithium-ion battery and a preparation method of the anode material. The material is structurally characterized by adopting a core-shell structure and comprises an active and stable core formed by uniformly dispersing submicron-grade multi-scale tungsten carbide particles in an amorphous silicon substrate and a highly-conductive shell coated with a thin-layer graphene sheet formed by stripping. The preparation method is a two-step ball-milling method, during ball milling in the first step, the tungsten carbide particles can fully play a milling assisting role to efficiently refine original coarse silicon; during ball milling in the second step, the graphene sheet formed by stripping ordinary graphite can stabilize the structure and improve the electrical conductivity. Therefore, the prepared anode material for the lithium-ion battery has the advantages of stable structure, good cycle performance, excellent rate performance and the like.

Owner:SOUTH CHINA UNIV OF TECH

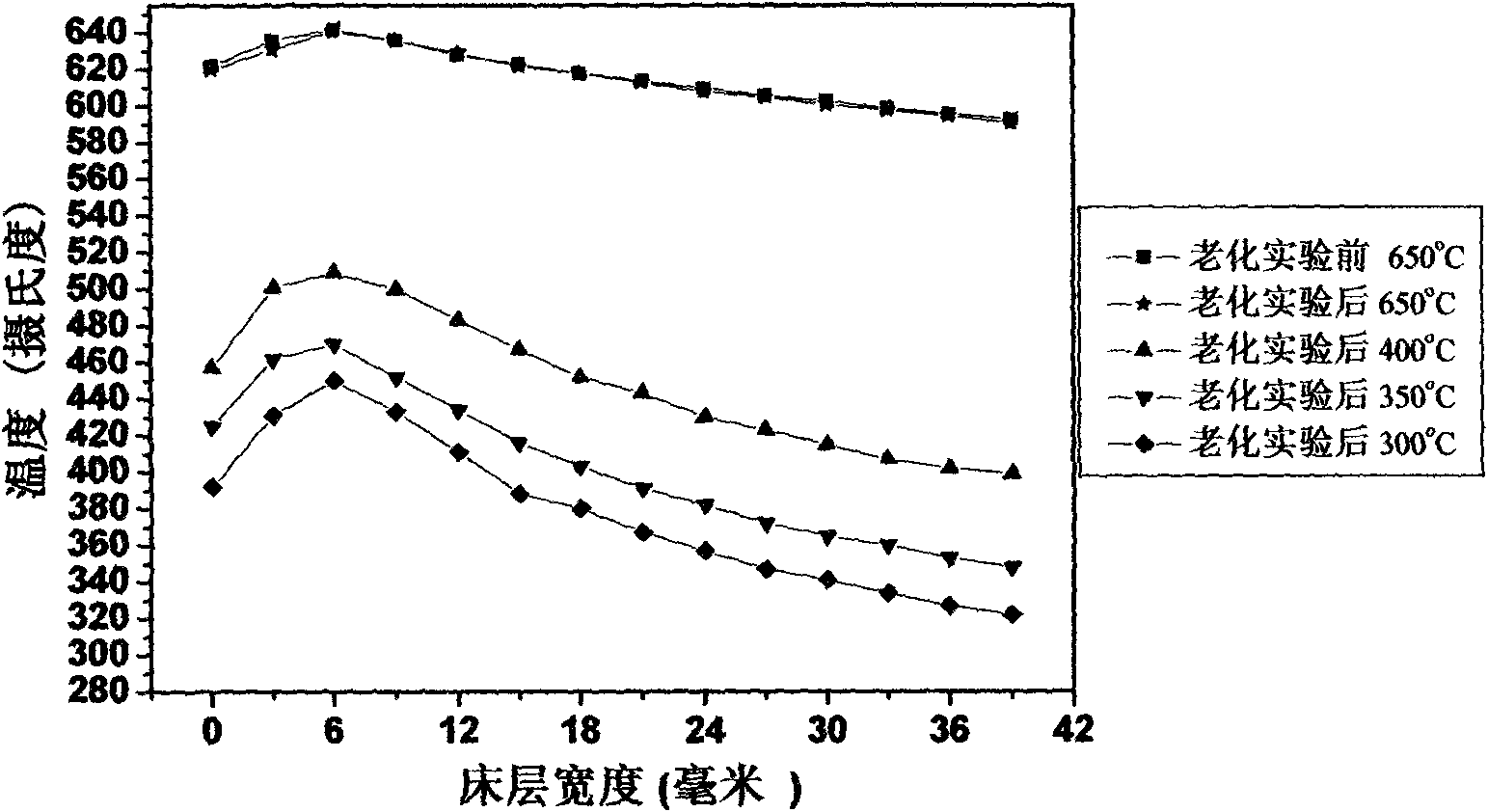

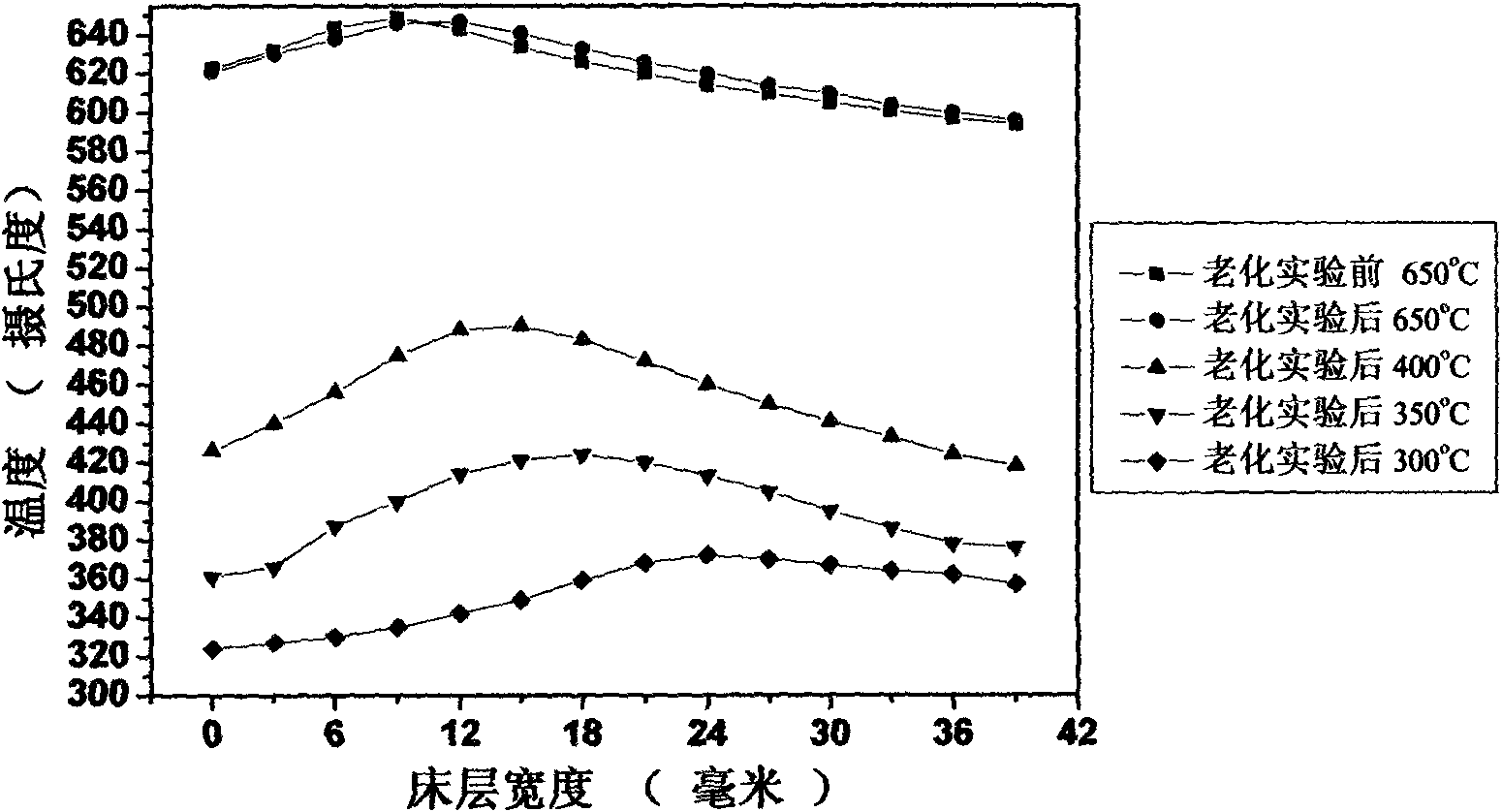

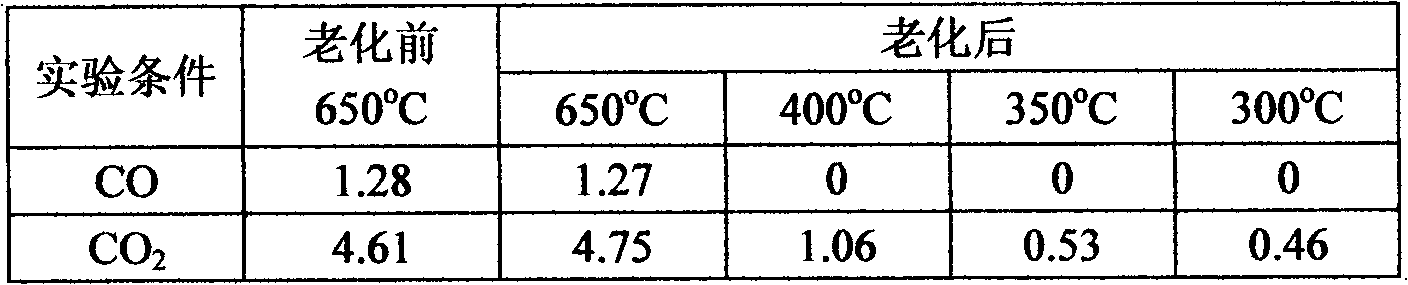

Wide-temperature full methanation catalyst and preparation method thereof

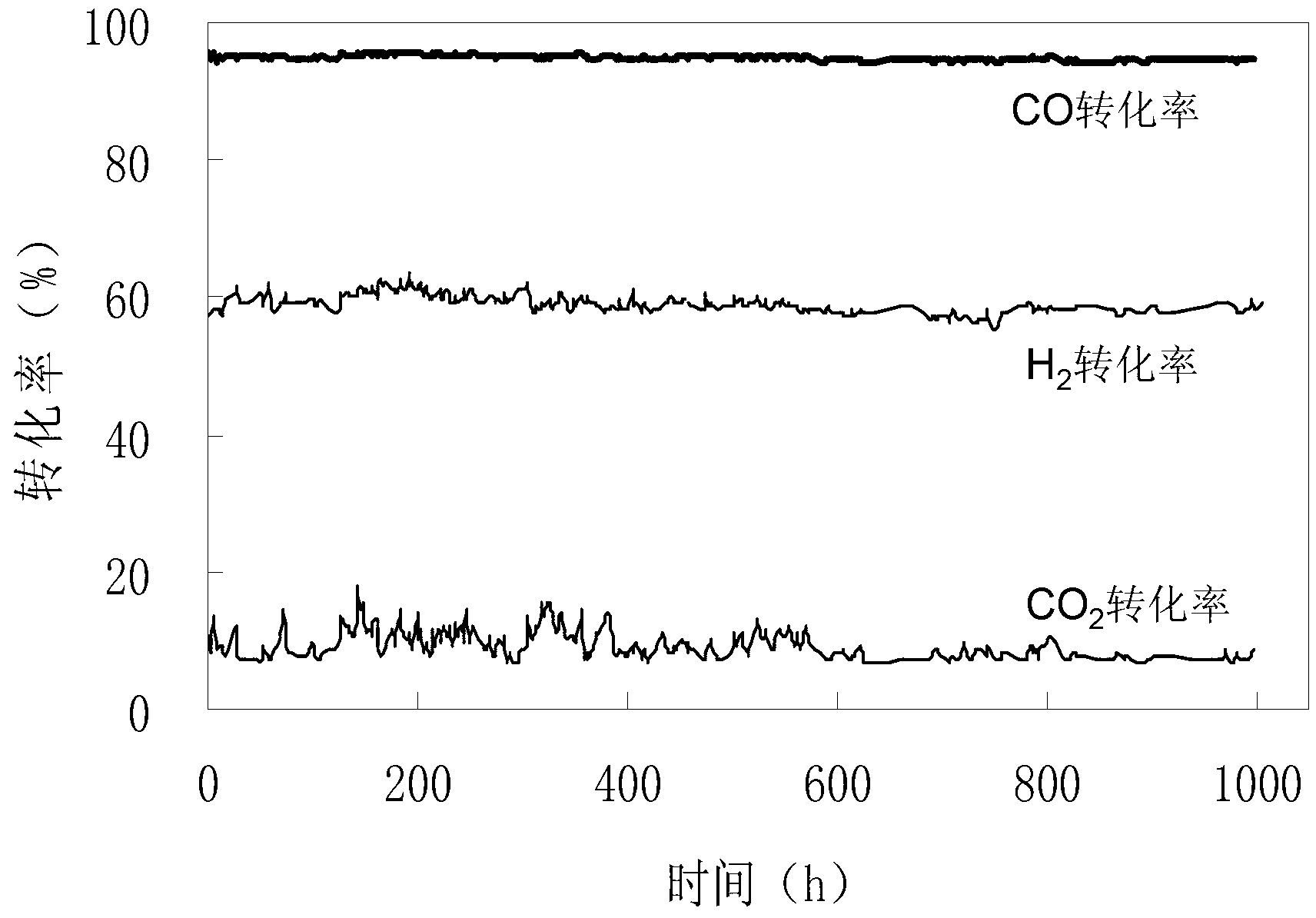

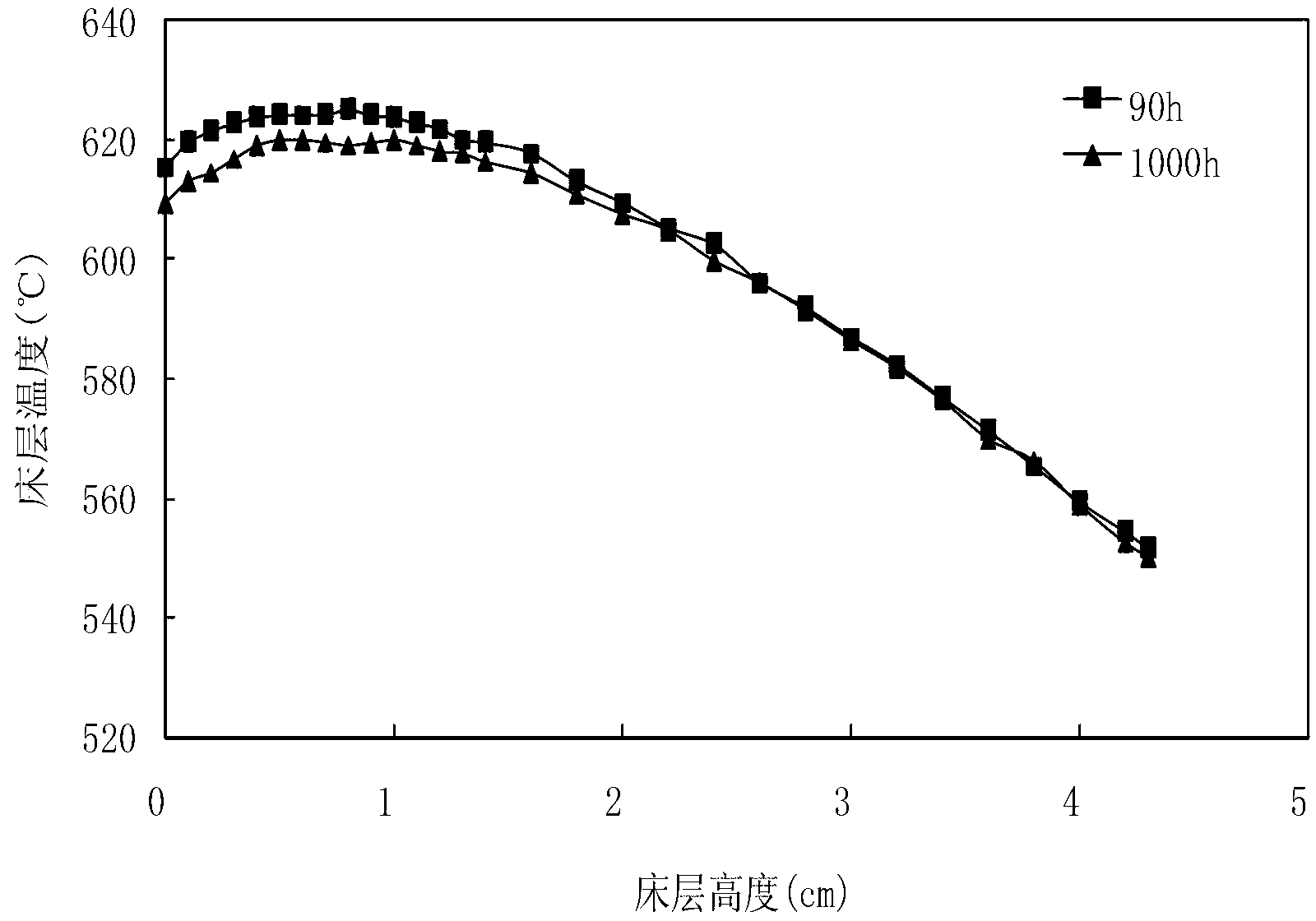

ActiveCN102029162AEfficient preparation methodEasy to prepareHydrocarbon from carbon oxidesCatalyst activation/preparationPtru catalystMethanation

The invention provides a wide-temperature full methanation catalyst and a preparation method thereof. The methanation catalyst is characterized in that: nickel is used as a main active ingredient, a composition formed by zirconium oxide and one or more of aluminum oxide and nickel-aluminum compounds is used as a main carrier, and lanthanum oxide is used as a cocatalyst; and a catalyst precursor is prepared by using a chemical precipitation process, and the catalyst precursor is reduced into the catalyst by filtering, washing, roasting, forming and re-roasting. The methanation catalyst has excellent catalytic activity and stability in a use range of between 260 and 750 DEG C, and fully meets the requirements of a full methanation process of synthesis gas on high temperature resistance, high hydrothermal stability and low-temperature high activity of the catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

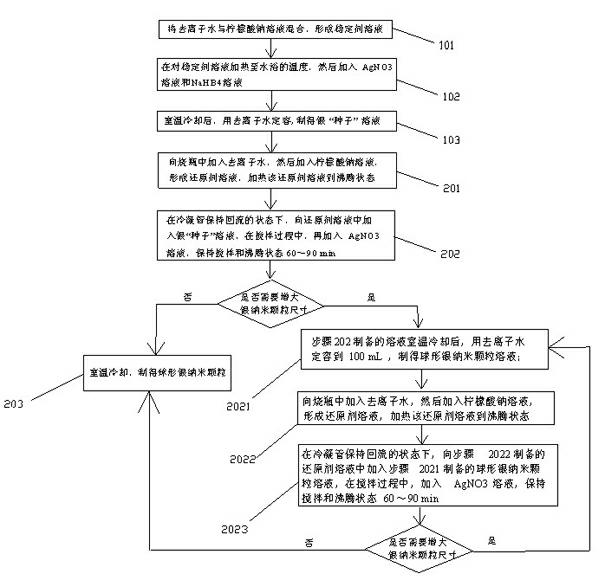

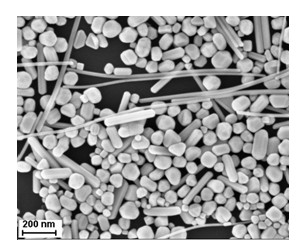

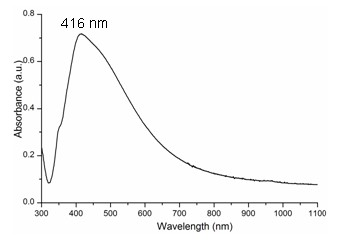

Water phase preparation method of spherical silver nanoparticle with adjustable size

The invention discloses a water phase preparation method of a spherical silver nanoparticle with adjustable size, which comprises the following steps of: 10, preparing a silver seed solution : 101, mixing deionized water with a sodium citrate solution, and obtaining a stabilizer solution after stirring; 102, heating the stabilizer solution to the temperature of water bath, adding an AgNO3 solution, and then adding a NaHB4 solution; and 103, utilizing the deionized water to obtain a constant volume after cooling at room temperature, and obtaining the silver seed solution; 20, preparing the spherical silver nanoparticle: 201, adding deionized water to a flask, then adding sodium citrate solution to obtain a reducer solution, and heating the reducer solution to a boiling state; 202, adding the silver seed solution to the reducer solution, and then adding the AgNO3 solution; and 203, cooling at room temperature to obtain the spherical silver nanoparticle. The preparation method can be used for preparing the spherical silver nanoparticle with favorable monodispersity, and the size of the spherical silver nanoparticle can be adjusted.

Owner:THE SECOND AFFILIATED HOSPITAL OF NANJING MEDICAL UNIV

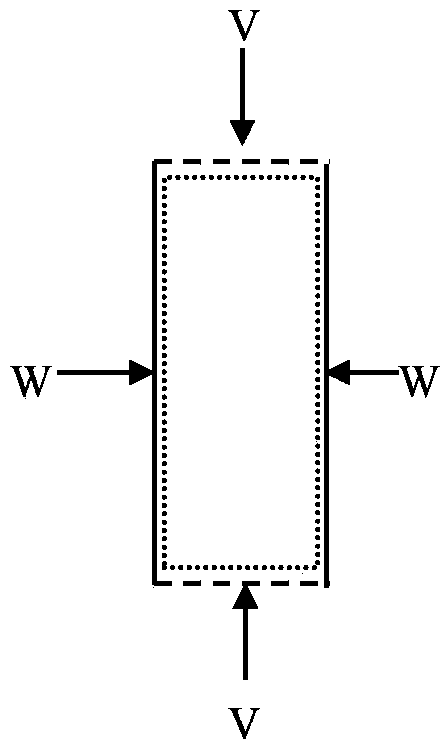

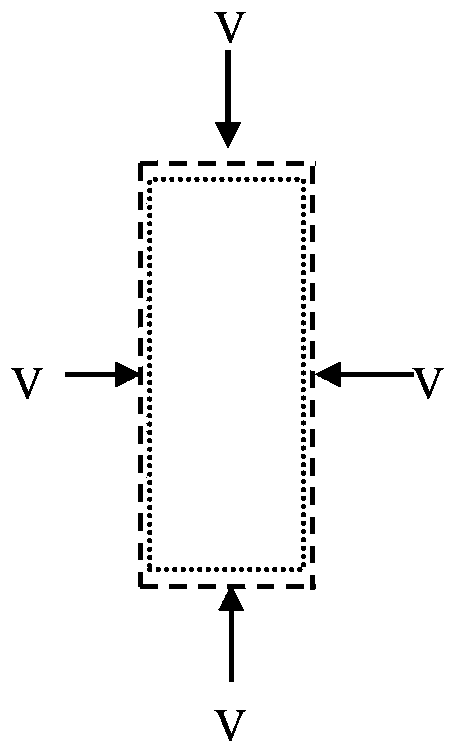

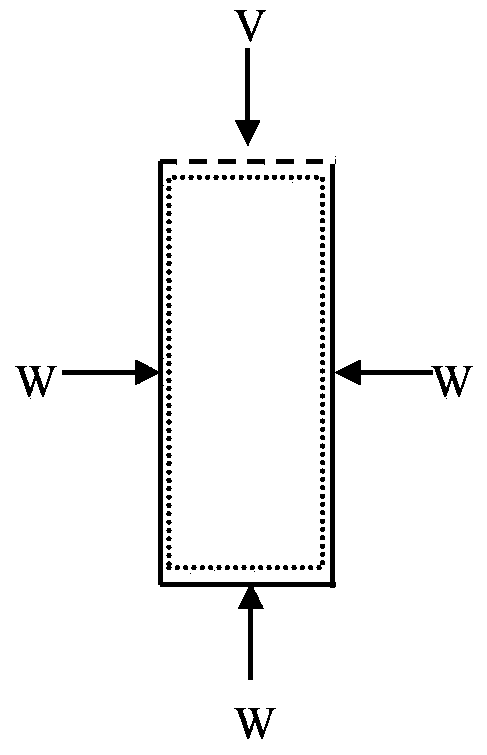

Arc battery cell, arc single cell, arc cell combination structure and manufacturing method

InactiveCN103401024ARealize a variety of designsNo internal short circuitFinal product manufactureElectrolyte accumulators manufactureElectrical batteryBattery cell

The invention discloses an arc battery cell, an arc single cell, an arc cell combination structure and a manufacturing method. According to the invention, the battery cell is required to be bent in the perpendicular direction of a connecting line of opposite open ends, the limit in the arc bending direction is performed, so that the external bending acting force cannot damage an internal structure of the battery, the defects of internal short circuit, increase of the internal resistance, reduction of capacity, unstable size and the like cannot be caused, and the batch production of cells is easy to realized. The bending degree of the battery cell is larger, and the manufactured single cell and cell combination structure can be combined and matched variously, so that diversified designs of the cell product are achieved. The manufacturing method of the battery cell is obtained by adjusting a conventional manufacturing method of the cell, the cell is not required to be heated during bending, and accordingly, the manufacturing method is simpler, practical, efficient and low in manufacturing cost.

Owner:GUANGZHOU FULLRIVER BATTERY NEW TECH

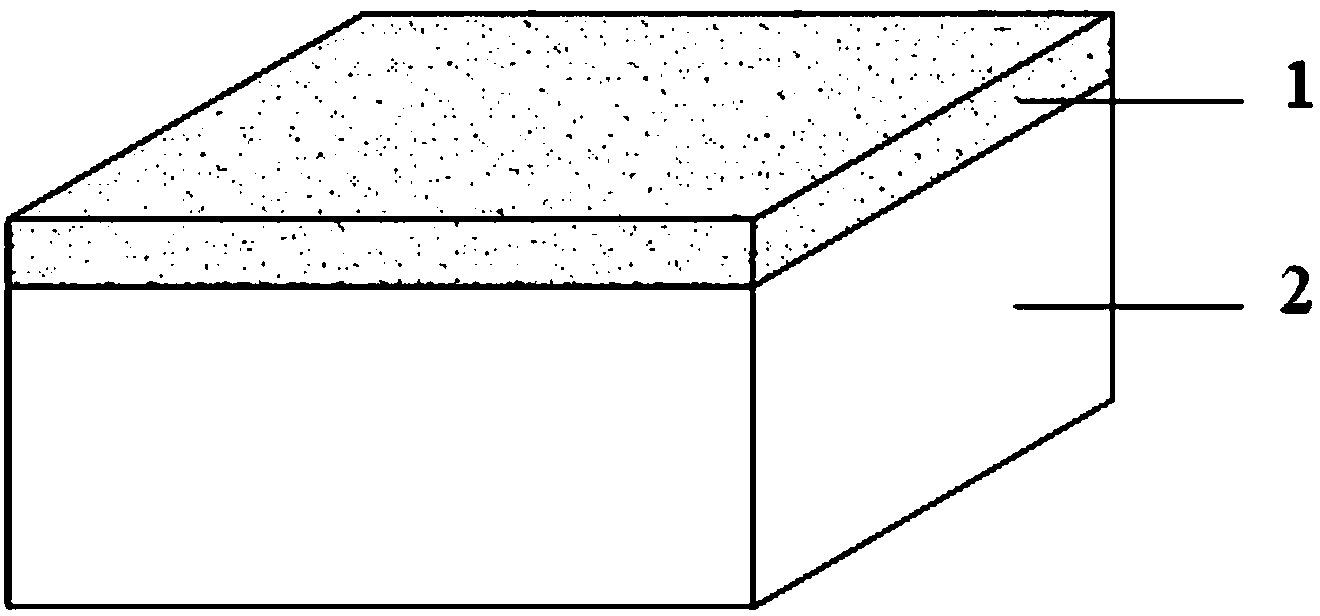

Aluminum silicon carbide composite material with laser welding layer and preparing method of aluminum silicon carbide composite material

ActiveCN103367270AImprove thermal conductivityReduce bloatSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationCarbide silicon

The invention discloses an aluminum silicon carbide composite material with a laser welding layer and a preparing method of the aluminum silicon carbide composite material. The composite material is composed of the laser welding layer and an aluminum silicon carbide layer, the laser welding layer is composed of pure aluminum or aluminum alloy comprising silicon and aluminum, the volume fraction of the silicon in the aluminum alloy is a, the volume fraction of the aluminum in the aluminum alloy is b, the a is greater than 0 and less than or equal to 30%, and the b is greater than or equal to 30% and less than 100%. The aluminum silicon carbide layer is composed of silicon carbide and pure aluminum or aluminum alloy, and the volume fraction of the silicon carbide ranges from 30% to 70%. The preparing method comprises the steps that silicon carbide pelleting powder is prepared firstly, then silicon carbide preformed parts are prepared, and the aluminum silicon carbide composite material with the laser welding layer is prepared in the vacuum pressure impregnation method finally. The aluminum silicon carbide composite material is good in weldability and gas tightness, high in heat conductivity, low in coefficient of thermal expansion, simple in preparing method, efficient and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

Semiconductor device and its manufacturing method

InactiveUS7414292B2Simple processEfficient preparation methodTransistorSolid-state devicesMetal silicideImpurity

A semiconductor device manufacturing method includes, forming isolation region having an aspect ratio of 1 or more in a semiconductor substrate, forming a gate insulating film, forming a silicon gate electrode and a silicon resistive element, forming side wall spacers on the gate electrode, heavily doping a first active region with phosphorus and a second active region and the resistive element with p-type impurities by ion implantation, forming salicide block at 500° C. or lower, depositing a metal layer covering the salicide block, and selectively forming metal silicide layers. The method may further includes, forming a thick and a thin gate insulating films, and performing implantation of ions of a first conductivity type not penetrating the thick gate insulating film and oblique implantation of ions of the opposite conductivity type penetrating also the thick gate insulating film before the formation of side wall spacers.

Owner:FUJITSU LTD

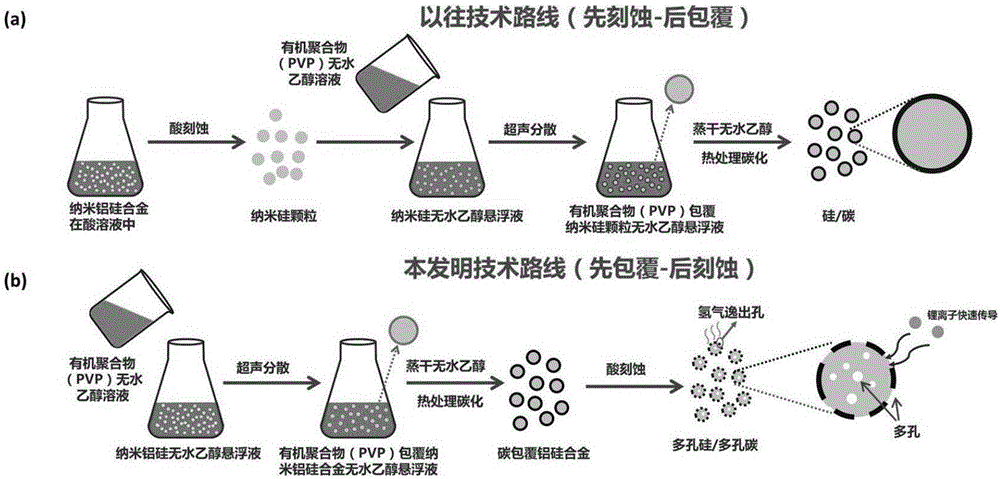

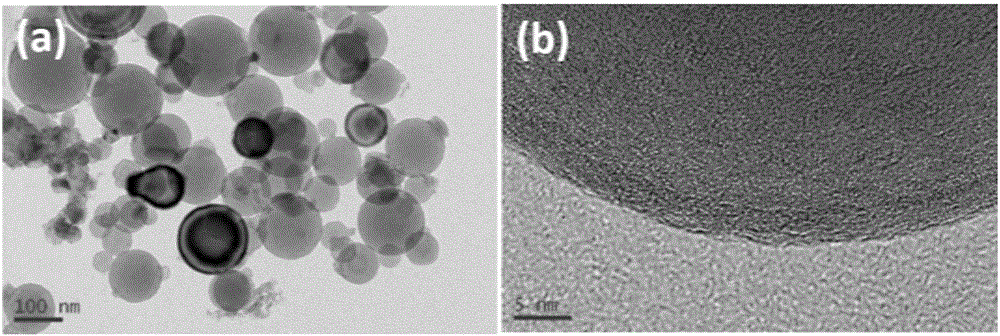

Nano silicon/porous carbon composite anode material of lithium ion batteries as well as preparation method and application of composite anode material

The invention discloses a nano silicon / porous carbon composite anode material of lithium ion batteries as well as a preparation method and an application of the composite anode material. The composite anode material is a core-shell structure material consisting of a porous nano silicon particle core and a porous carbon layer shell. The preparation method of the composite anode material comprises the steps as follows: carbonization treatment is performed after an organic polymer layer is coated on the surface of aluminum-silicon alloy powder, aluminum is removed by performing acid etching on a carbonization product, pore forming is performed on a carbon layer, and thus the nano silicon / porous carbon composite anode material is obtained. The preparation method is simple and low in cost, the mass production requirement is met, and the prepared composite anode material can be used for preparing the lithium ion battery and shows high capacity and excellent cycle and rate performance.

Owner:CENT SOUTH UNIV

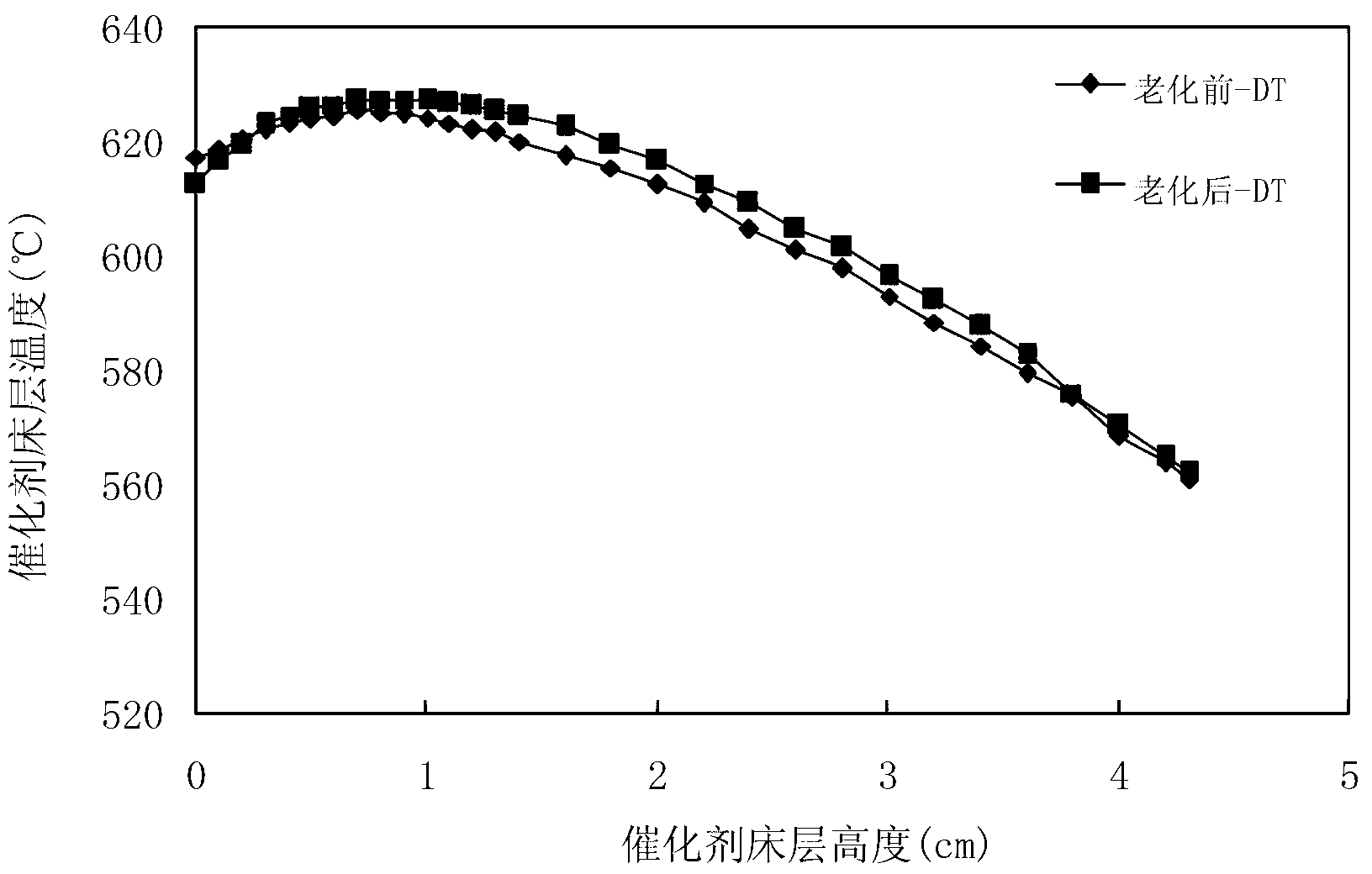

Completely-methanated catalyst as well as preparation method and application thereof

ActiveCN103071507AImprove activity and high temperature hydrothermal stabilityHigh activityGaseous fuelsCatalyst activation/preparationActive componentNatural gas

The invention provides a completely-methanated catalyst as well as a preparation method and an application thereof. The preparation method comprises the following steps of: respectively mixing precursors of an active component, a first auxiliary agent and a second auxiliary agent and dissolving into water to prepare a solution I; adding a precipitating agent into water to be dissolved to respectively prepare a solution II and a solution II'; adding a precursor of a carrier into the water to be dissolved to prepare a solution III or a solution III'; adding the solution I into the solution II to carry out precipitation to obtain a precipitating system I; adding the solution II' into the solution III to carry out the precipitation to obtain a precipitating system II or adding an acidic solution into the solution III' to peptize to obtain the precipitating system II; and then mixing the precipitating system I with the precipitating system II. According to the completely-methanated catalyst as well as the preparation method and the application thereof, the catalyst is prepared by applying a sub-step reverse precipitating method; and the catalyst has the characteristics of high activity and high safety and is suitable for being applied to a high-temperature or low-temperature completely-methanated reaction process for synthesizing natural gas by coal gasification through methanation.

Owner:DATANG INT CHEM TECH RESINST

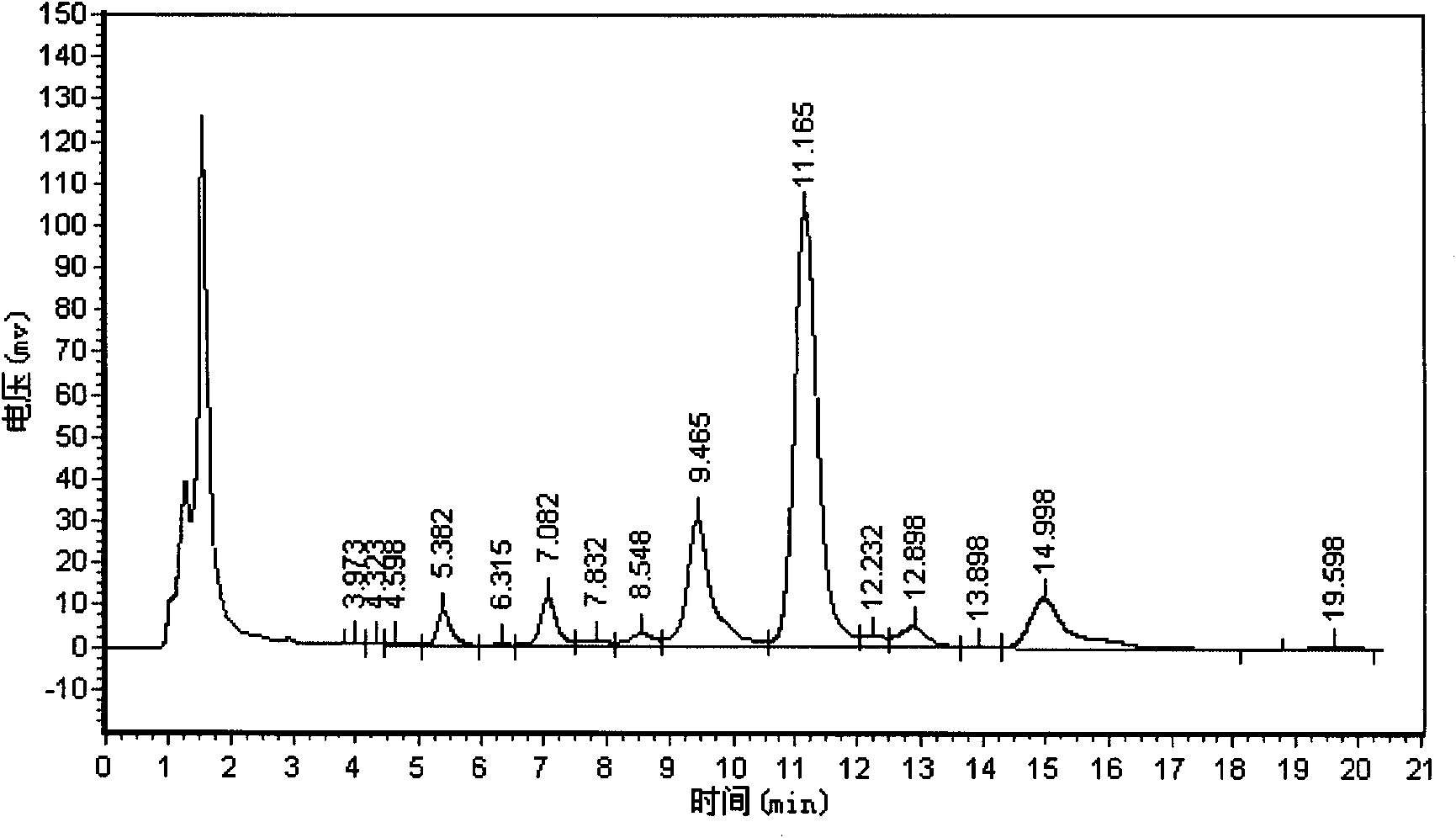

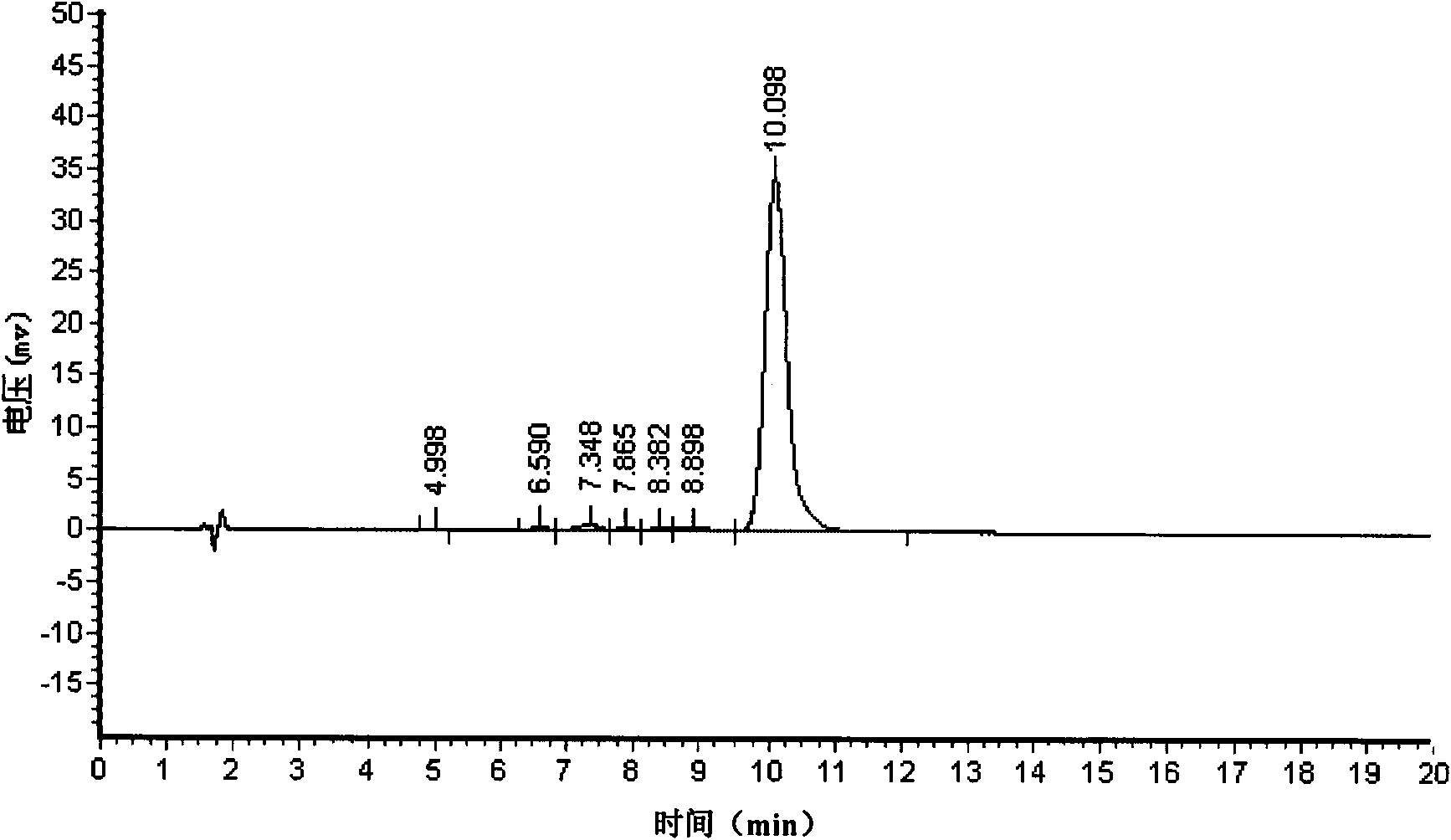

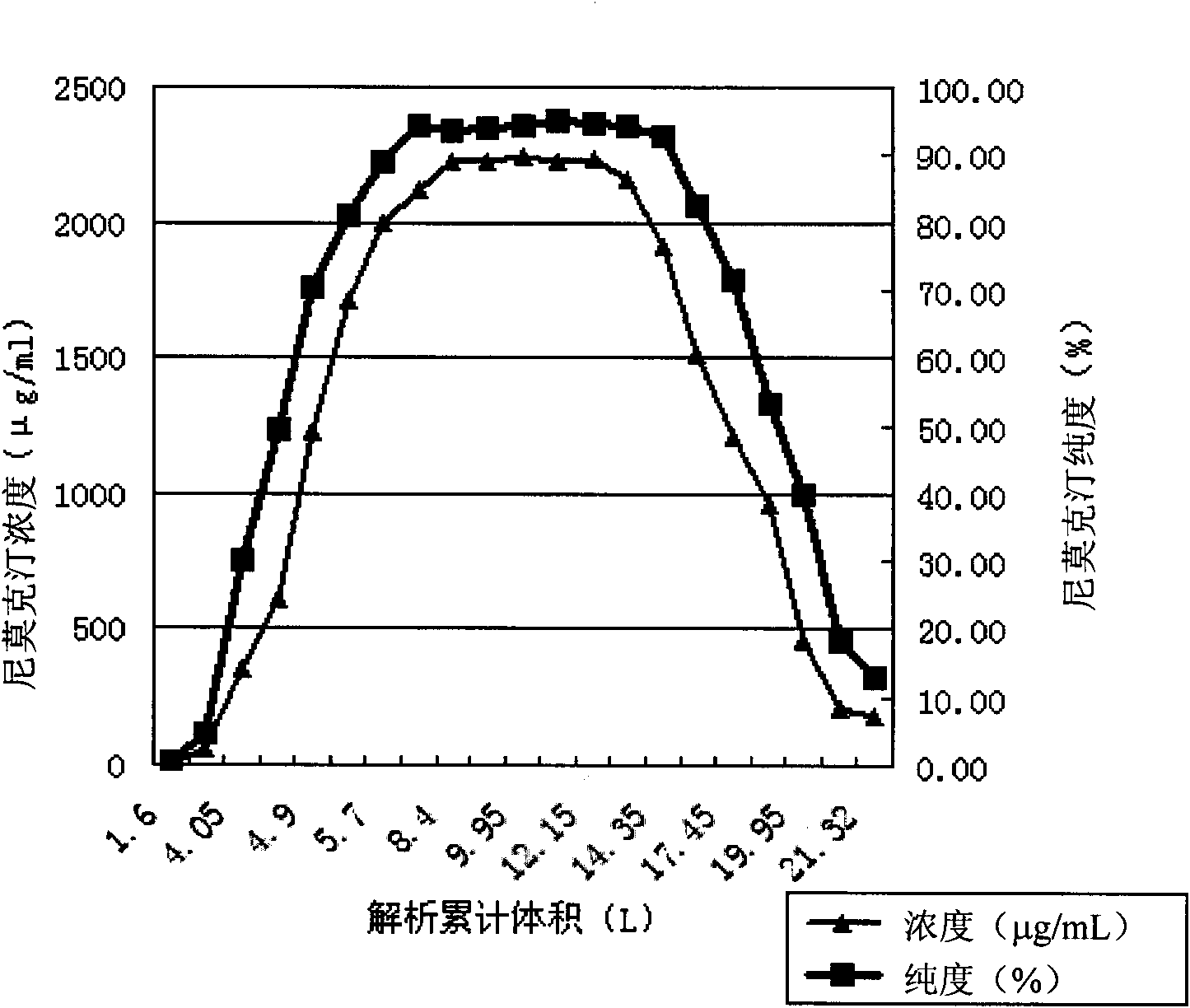

Preparation method of nemadectin

ActiveCN102336796ASimple processLow costSugar derivativesMicroorganism based processesSolventNemadectin

The invention discloses a preparation method of nemadectin. According to the invention, a fermentation broth used for producing nemadectin is directly dried by spraying, such that solid powder is obtained; the solid powder is extracted by using an organic solvent, the extract is filtered, and nemadectin in the extract is absorbed by using macroporous resin; nemadectin absorbed by macroporous resin is then eluted; and the eluent is extracted, concentrated, and dried, such that a nemadectin pure product is obtained. According to the invention, a direct spray-drying method is adopted upon the fermentation broth, and the obtained dried solid fermentation bacterium powder is transportation-tolerant, and is easy to store. With the method provided by the invention, the producing of nemadectin degradation product is reduced, the bacterium powder is easy to extract, and the consumption of the extraction solvent is low. The technology is simple, the cost is low, and the method is easy to operate. With the method, the prepared nemadectin has a high HPLC purity of above 90%.

Owner:CHONGQING DAXIN PHARMA +2

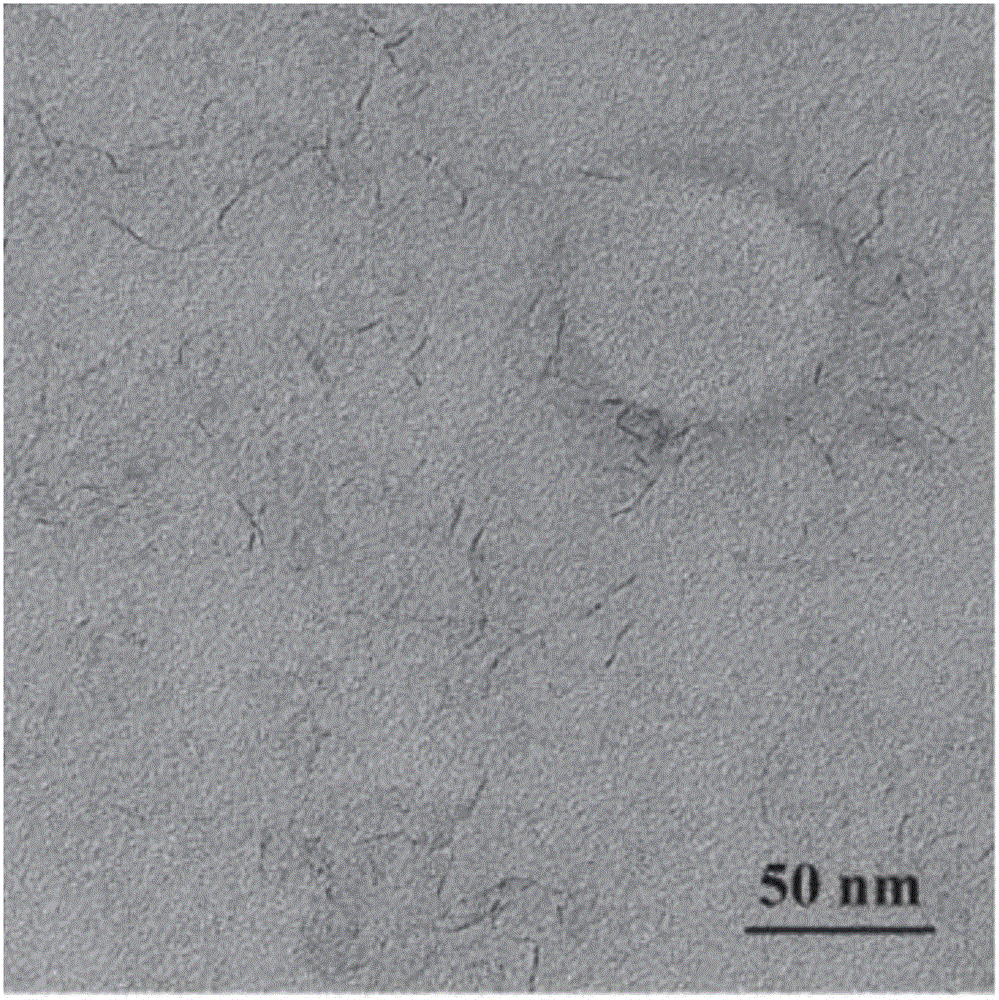

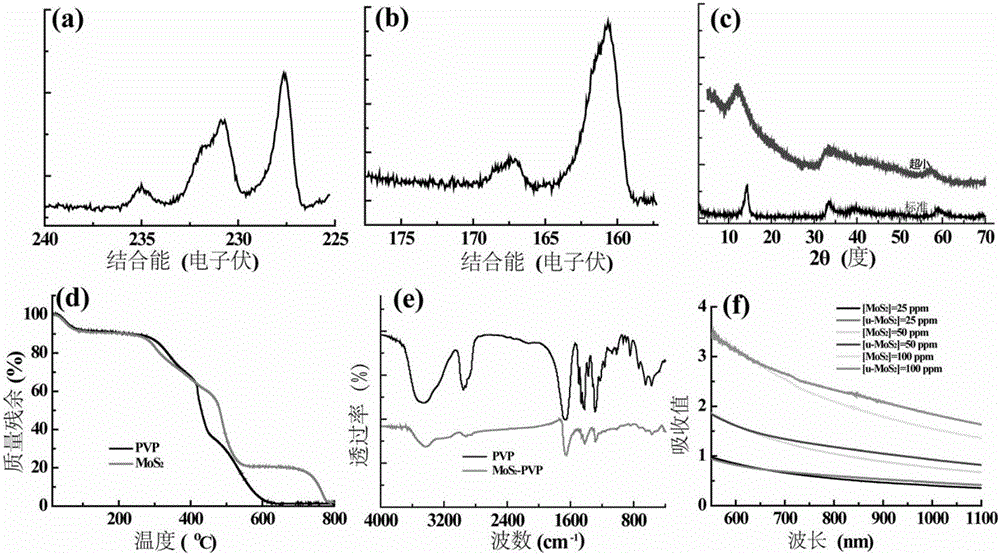

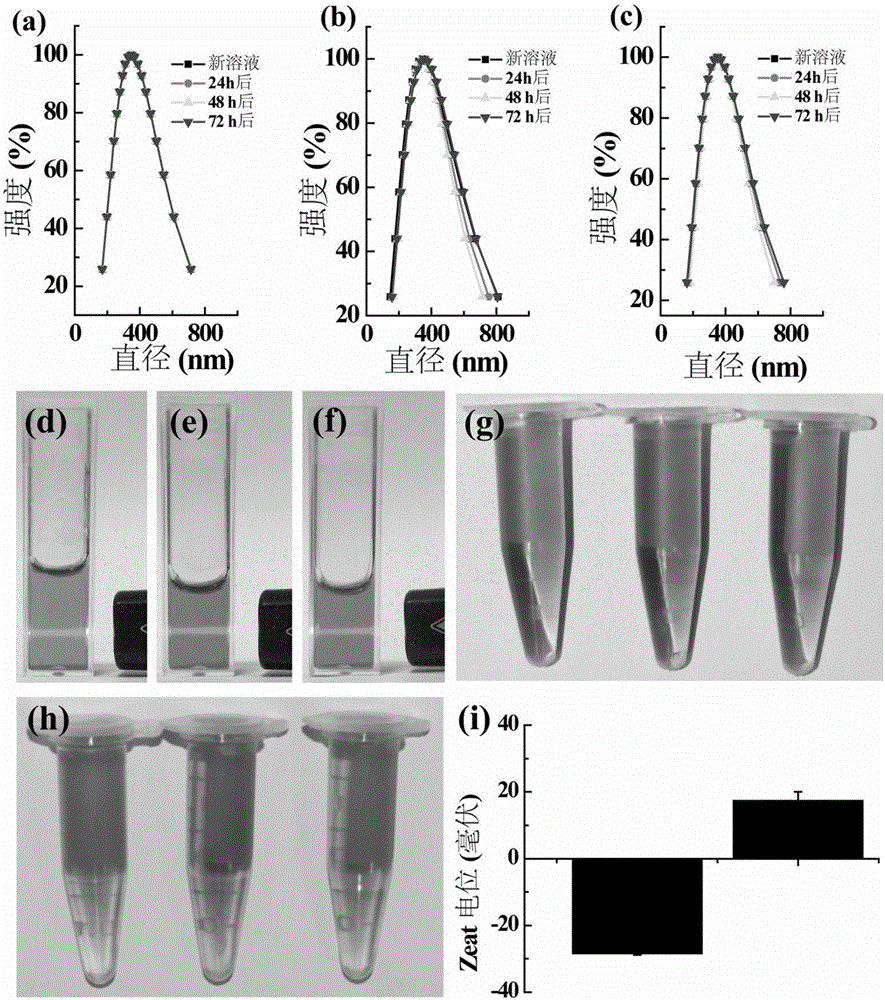

Ultra-small MoS2 nanosheet as well as preparation method and application thereof

InactiveCN106075438AImprove colloidal stabilityGood biocompatibilityEnergy modified materialsEchographic/ultrasound-imaging preparationsSulfurDistilled water

The invention discloses an ultra-small MoS2 nanosheet. The surface of the MoS2 nanosheet is modified with polyvinylpyrrolidone, and the diameter of the modified MoS2 nanosheet ranges from 15 nm to 25 nm. The invention further discloses a preparation method of the ultra-small MoS2 nanosheet. The preparation method comprises the following steps: a sulfur source and a molybdenum source are dissolved in water and stirred until the resources are completely dissolved; polyvinylpyrrolidone is dissolved in the solution of the sulfur source and the molybdenum source; the solution is transferred into a stainless steel reaction kettle with a polyphenyl lining for closed reaction, a reaction product is washed with an ethanolamine water solution and distilled water, and the ultra-small MoS2 nanosheet with the surface modified with polyvinylpyrrolidone is obtained. The invention further provides an application of the ultra-small MoS2 nanosheet as a photo-thermal conversion material. The ultra-small MoS2 nanosheet has good colloid stability, photo-thermal conversion capacity and photo-acoustic imaging capacity and has broad application prospect in the fields of tumor treatment and the like.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

RFID tag and its manufacturing method

InactiveUS7126482B2Increase in cost and sizeEfficient preparationLoop antennas with ferromagnetic coreLine/current collector detailsElectrical conductorMagnetic core

An RFID tag which is provided with a coil-shaped antenna such that a conductor is placed on the periphery of a magnetic core, the RFID comprising: the magnetic core, an FPC wound on the periphery of the magnetic core, two or more linear conductor patterns formed in parallel with one another on the FPC,an IC that is connected to the linear conductor patterns and disposed on the FPC, a crossover pattern that electrically connects one end and the other end of outermost linear conductor patterns among the linear conductor patterns formed in parallel with one another, where in the two or more linear conductor patterns, adjacent linear conductor patterns in a joint portion in the wound FPC are electrically connected in respective start edges and end edges.

Owner:FURUKAWA ELECTRIC CO LTD

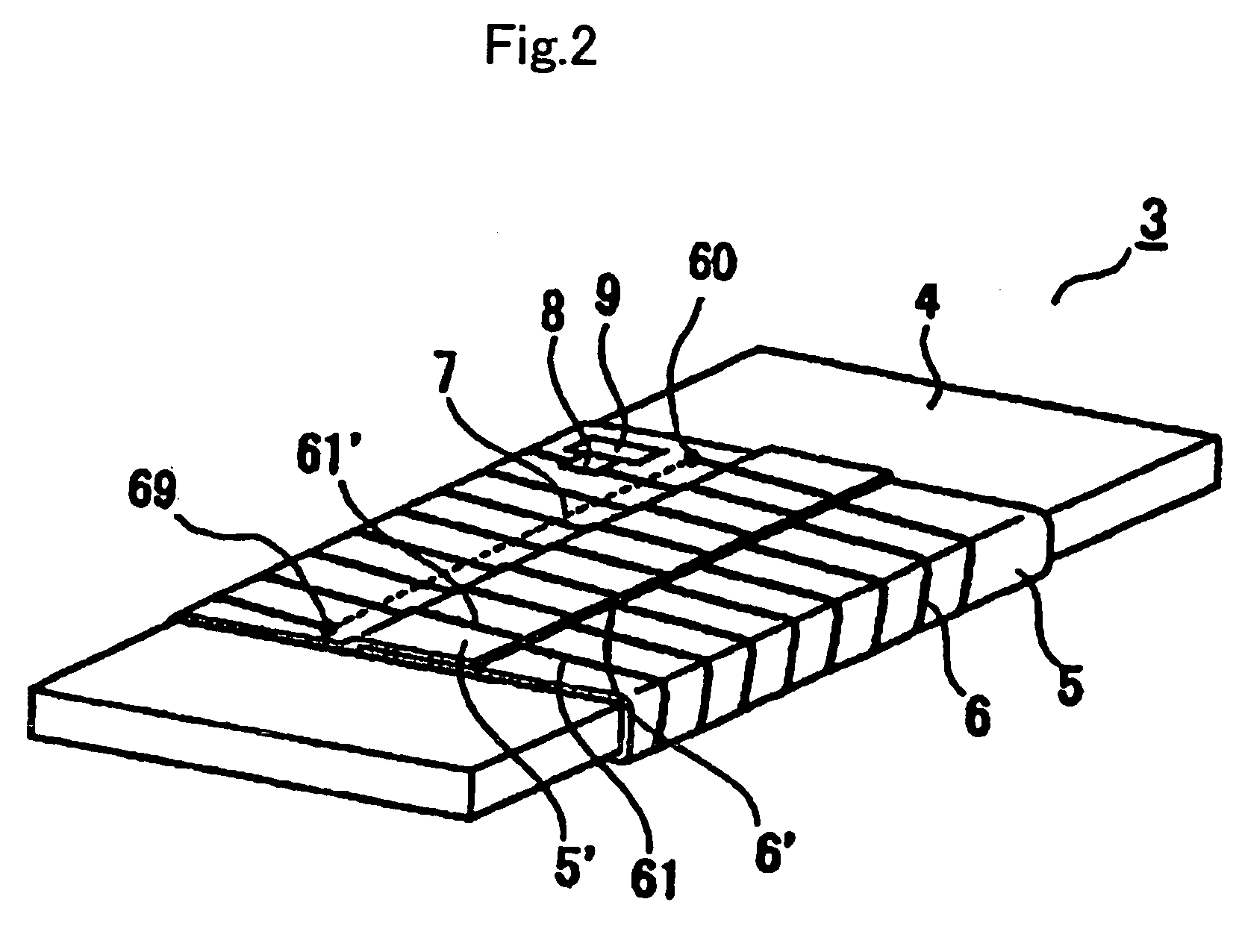

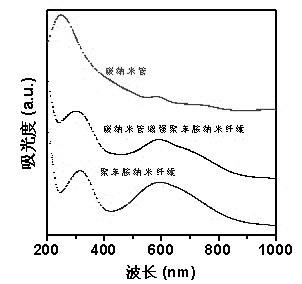

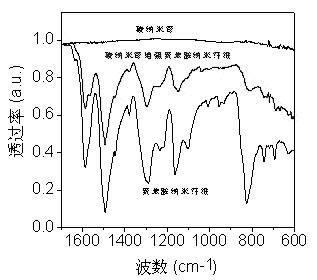

Carbon nano tube reinforced polyaniline nano-fiber and preparing method thereof

InactiveCN102558554AConductivity controllableOvercome the technical problem of not being able to conduct electricity under alkaline conditionsFiberPolymer science

The invention discloses carbon nano tube reinforced polyaniline nano-fiber and a preparing method thereof. The preparing method includes steps of: adding aniline monomers and carbon nano tubes into dilute acid for ultrasound treatment to obtain carbon nano tube and aniline monomer blend solution; dissolving initiators into ethanol to form initiator solution and dissolving oxidants in dilute acid to form oxidant solution; and adding the initiator solution into the carbon nano tube and aniline monomer blend solution, then adding the oxidant solution, severely swinging for a moment, performing centrifugation, washing, redispersion and the like after standing reaction is complete so as to finally obtain the carbon nano tube reinforced polyaniline nano-fiber. The preparing method is simple, efficient and high in controllability. The carbon nano tubes can be uniformly dispersed on a polyaniline matrix. The mean diameter of the obtained carbon nano tube reinforced polyaniline nano-fiber is 30-60 nm, the length is 1-2 mu m, and electric conductivity is 10(-8)-10(2) S / cm, and the carbon nano tube reinforced polyaniline nano-fiber can be used in the application fields such as sensors, actuating devices, ultra-capacitors, electrochromatic windows, functional coatings and ultrafiltration membranes.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Bioactive bacterial cellulose-zein composite film and preparation method thereof

ActiveCN104225669AEfficient preparation methodNo pollution in the processCosmetic preparationsFlexible coversChemistryOxidation resistant

The invention discloses a bioactive bacterial cellulose-zein composite film and a preparation method thereof. The method comprises the following steps: preparing and purifying a bacterial cellulose film; uniformly stirring the purified bacterial cellulose in distilled water, shearing by using a high-speed shearing machine, and homogenizing by high pressure microfluidization to obtain a nano-fiber dispersion liquid; dissolving zein and water-insoluble bioactive substances in an ethanol-water solution to obtain an alcoholic solution; dissolving sodium caseinate in water, stirring and adding the solution into the alcoholic solution to obtain a mixed solution; removing the ethanol, and centrifuging to obtain bioactive molecule enriched zein nanoparticles; mixing the nano-fiber dispersion liquid and the bioactive molecule enriched zein nanopartiles, uniformly stirring, and carrying out ultrasonic treatment; and sucking and filtering in vacuum, and quickly forming a film; and drying. The composite film material has the advantages of excellent mechanical performance, biocompatibility and biodegradability, and has managed bioactivities of bacteria resistance, oxidation resistance and the like.

Owner:SOUTH CHINA UNIV OF TECH

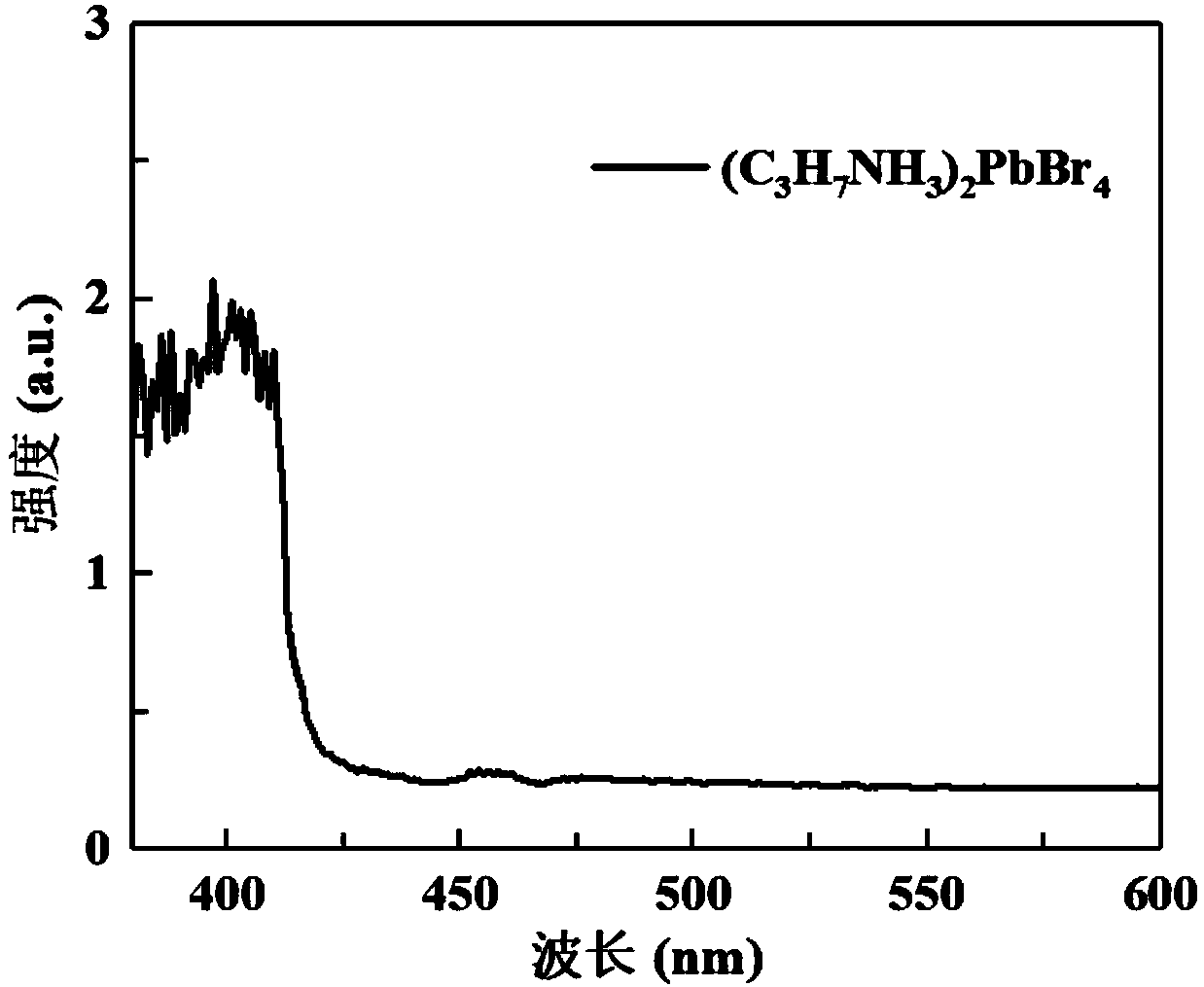

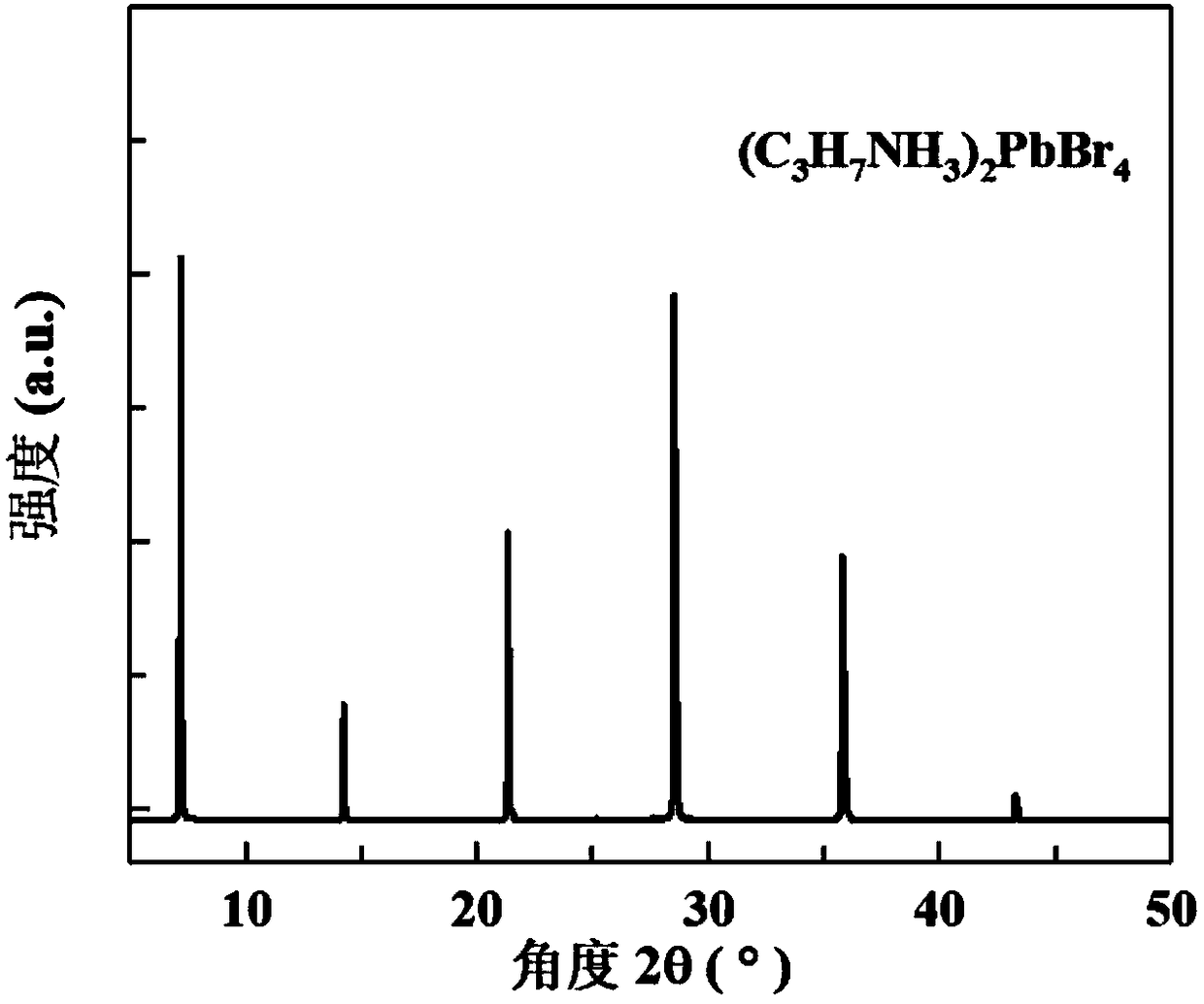

Two-dimensional perovskite single-crystal material and preparation method thereof

ActiveCN108560056ALow water and oxygen requirementsShort preparation cyclePolycrystalline material growthFrom normal temperature solutionsChlorobenzeneEvaporation

The invention relates to a two-dimensional perovskite single-crystal and a preparation method thereof. The chemical composition of the two-dimensional perovskite single-crystal material is A2PbBr4, wherein A is C4H9NH3+ or C3H7NH3+. Lead bromide and ammonium bromide with the ratio being 1:2 are adopted as raw materials, dimethylformamide is adopted as a solvent, chlorobenzene or a mixture of chlorobenzene and acetonitrile are adopted as an anti-solvent, and due to the anti-solvent mixing evaporation method, the large-size two-dimensional perovskite single-crystal is prepared under the room temperature atmosphere environment. The method is low in environment condition requirement, simple in process, applicable to preparing large-size crystal. The two-dimensional perovskite single-crystal has the good application prospect in the photoelectric field, and the efficient and simple preparation method has the great potential for single-crystal commercialization application.

Owner:WUHAN UNIV

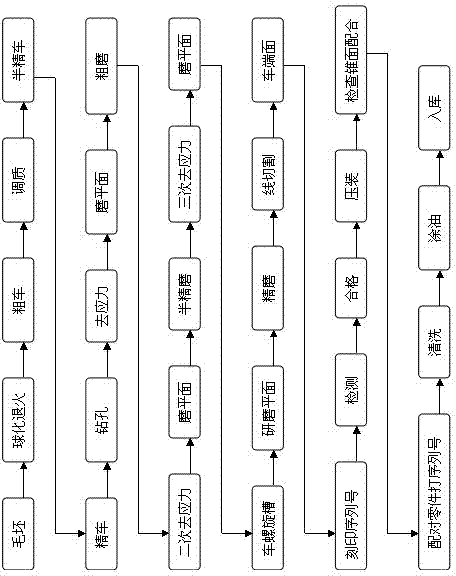

Machining technology for high-precision outer conical surface thin wall sleeve

InactiveCN103495844AMeet the technical requirements of high-precision outer tapered thin-walled sleevesReduce distortionNumerical controlEngraving

The invention relates to the technical field of high-precision part machining process, in particular to a machining technology for a high-precision outer conical surface thin wall sleeve. The machining technology includes the following technology processes of workblank preparing, spheroidizing annealing, rough turning, thermal refining, semi-finish turning, finish turning, hole drilling, distressing, plane grinding, rough grinding, secondary distressing, plane grinding, spiral groove turning, plane lapping, accurate grinding, wire-electrode cutting, end face turning, serial number engraving, detecting, qualified product obtaining, press fitting, conical surface fit detecting, part matching and serial number printing, cleaning, lubricating oil coating and warehousing. A double-end vertical type numerical control grinder is adopted as a finishing machine, and through the machining methods of rough grinding and accurate grinding or rough grinding, semi-accurate grinding and accurate grinding, the technical requirements of the high-precision outer conical surface thin wall sleeve can be met; through the corresponding distressing heating processing technology, residual stress in the machining process is removed, deformation in the machining process can be reduced, the yield of products is improved, and finally the good manufacturing method of the high-precision outer conical surface thin wall sleeve is provided.

Owner:CRRC QISHUYAN CO LTD

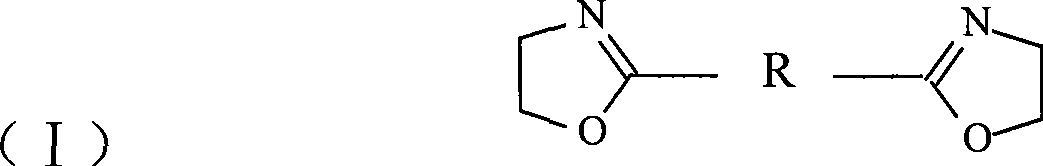

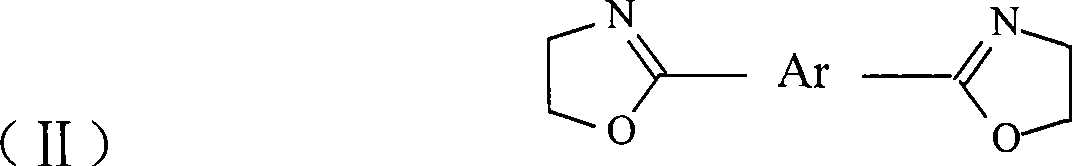

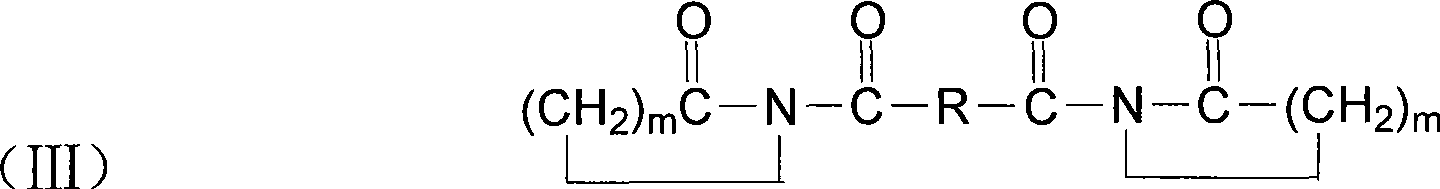

Method for preparing high molecular weight biodegradable polyester by combined chain extension

The invention relates to a method for preparing biodegradable polyester. Firstly, melt polycondensation is conducted through diol and dicarboxylic acid and a low molecular weight polyester prepolymer with number average molecular weight between 2, 000 and 20, 000 or intrinsic viscosity below 0.64dL / g is prepared; binary oxadiazoline and diacyl bis-caprolactamate are combined to extend chain, and chain extension is carried out at a certain temperature; and the biodegradable polyester is obtained. The number average molecular weight of polybutylene adipate (PBA) can reach up to 39, 000 and the intrinsic viscosity to 1.13dL / g. For poly (butylene succinate) (PBS) with relatively high melting point, the intrinsic viscosity after chain extension is up to 0.99dL / g.

Owner:BEIJING UNIV OF CHEM TECH

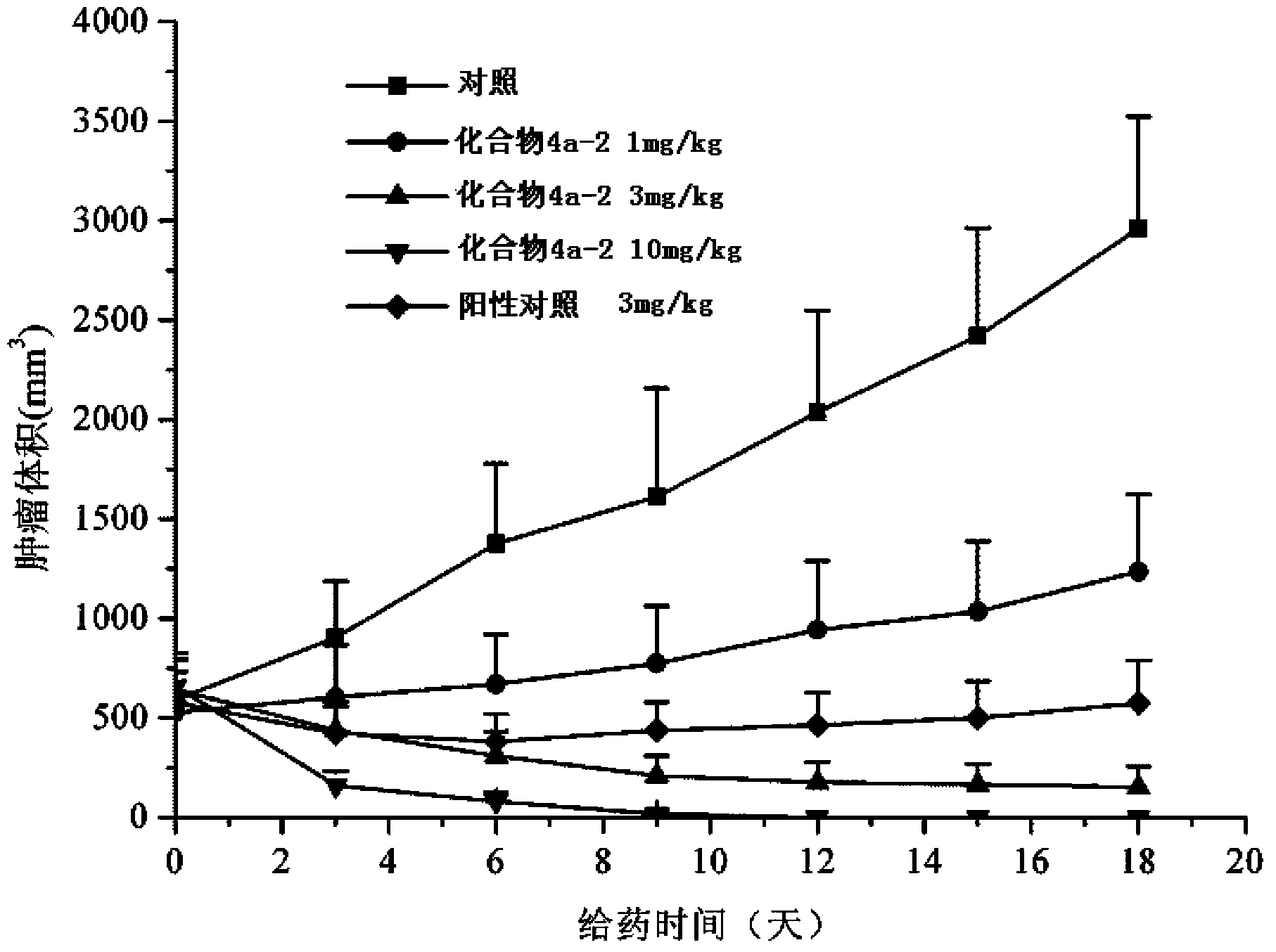

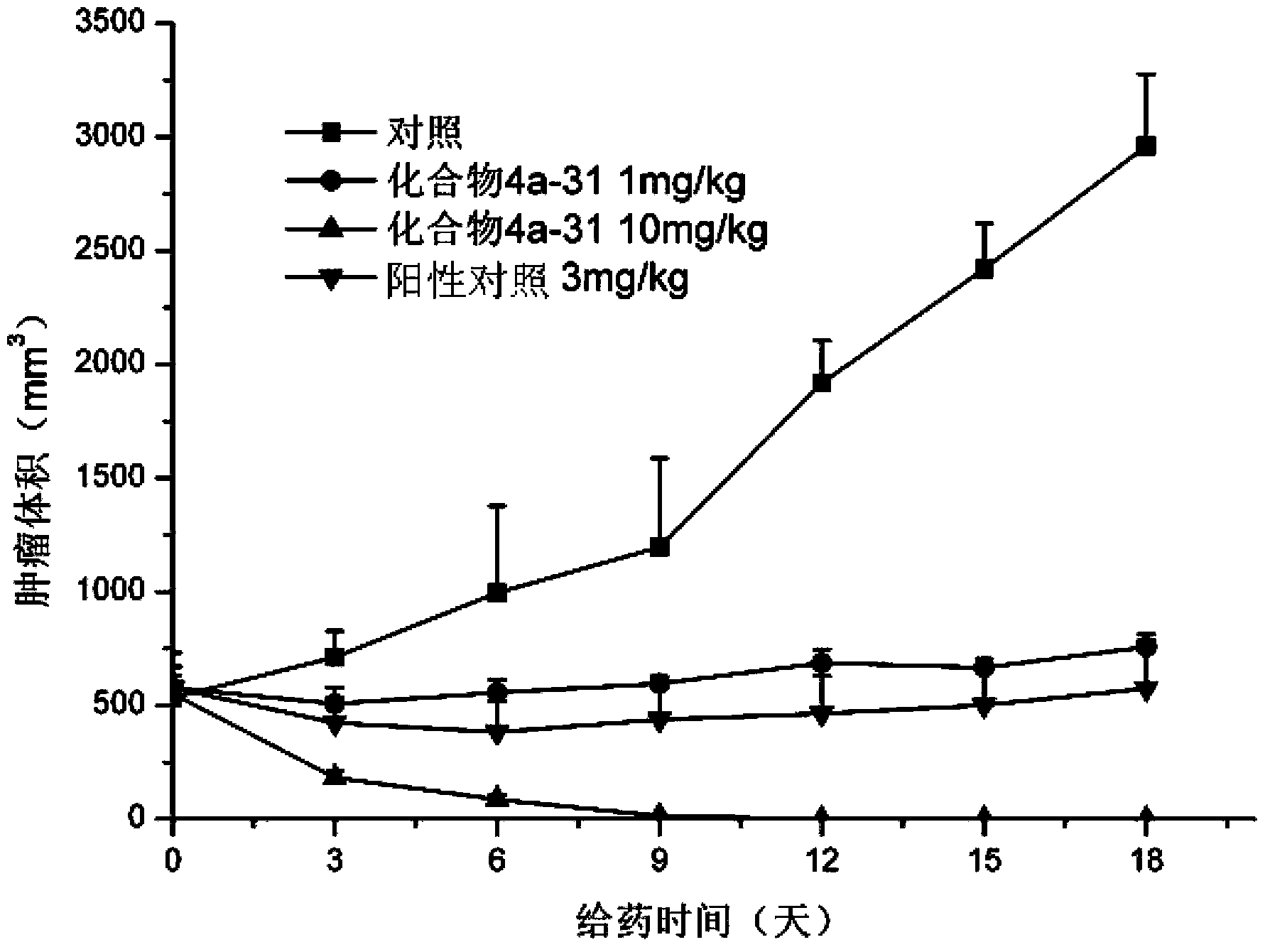

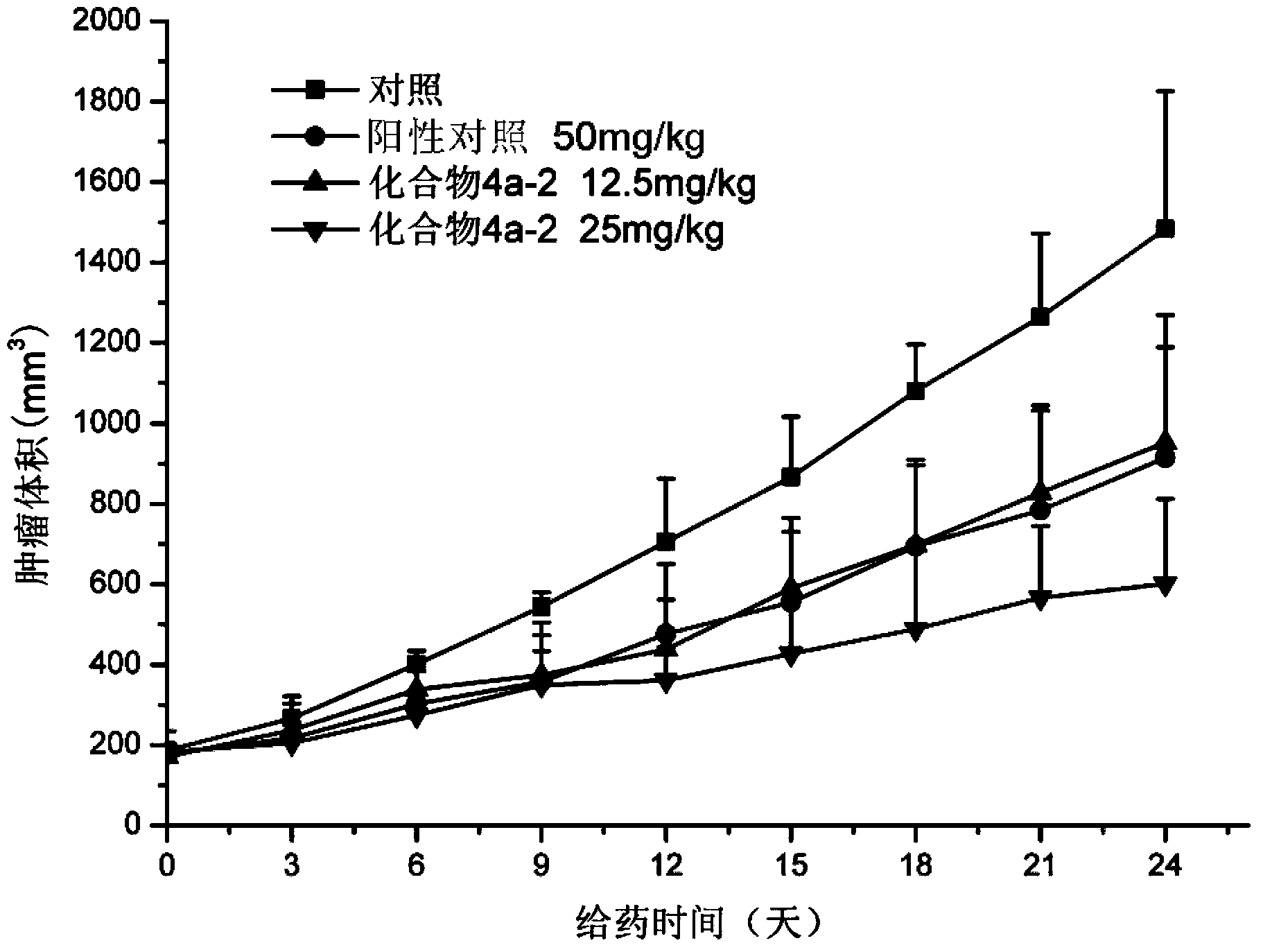

Pyrazolopyrimidine derivative, its preparation method, and its use in preparation of medicines

ActiveCN103570723AStrong inhibitory activityEasy to prepareOrganic active ingredientsOrganic chemistryAutoimmune conditionAutoimmune disease

Owner:GUANGXI WUZHOU PHARMA GRP

Preparation method of graphene composite nonwoven cloth

ActiveCN108301201ALong-lasting anti-miteWith far infrared effectBiochemical fibre treatmentLight resistant fibresGrapheneNonwoven fabric

The invention relates to a preparation method of graphene composite nonwoven cloth. The preparation method comprises the following steps: A1, preparing nonwoven cloth from common fiber; A2, mixing a graphene raw material with active carbon, water, an antioxidant, stearate and glue, and uniformly stirring the materials to form spraying liquid; A3, uniformly spraying the spraying liquid formed in Step A2 onto the nonwoven cloth prepared in Step A1, and drying and rolling the nonwoven cloth to prepare the graphene composite nonwoven cloth. The preparation method has the following beneficial effects: 1, the graphene-containing spraying liquid is sprayed onto the common nonwoven cloth, so that the long-acting anti-mite, antibacterial and antiultraviolet graphene composite nonwoven cloth havinga far infrared effect can be obtained; 2, the preparation method disclosed by the invention is simple and efficient, and can be widely applied to industrial production to prepare facial mask cloth, antibacterial costumes, antibacterial underwear, antibacterial socks, gauze masks, bedroom supplies and the like.

Owner:NANTONG QIANGSHENG GRAPHENE TECH CO LTD

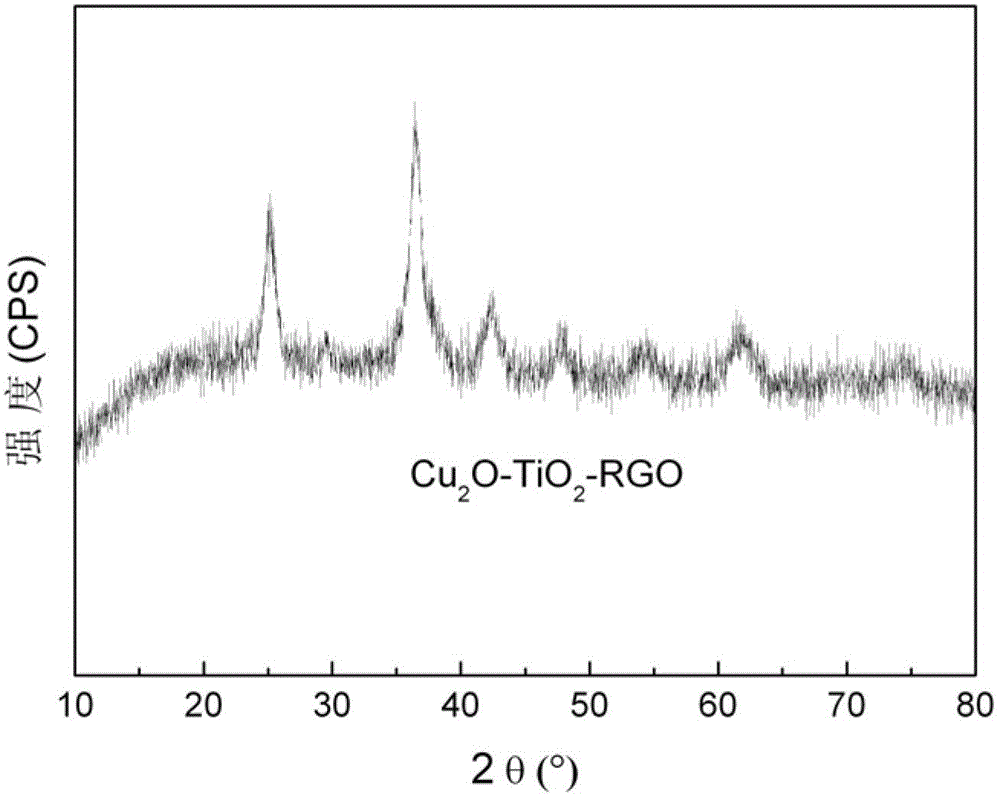

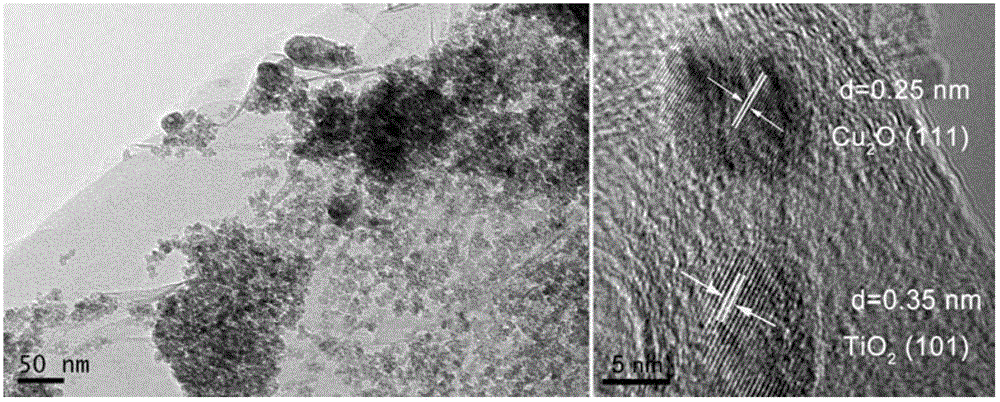

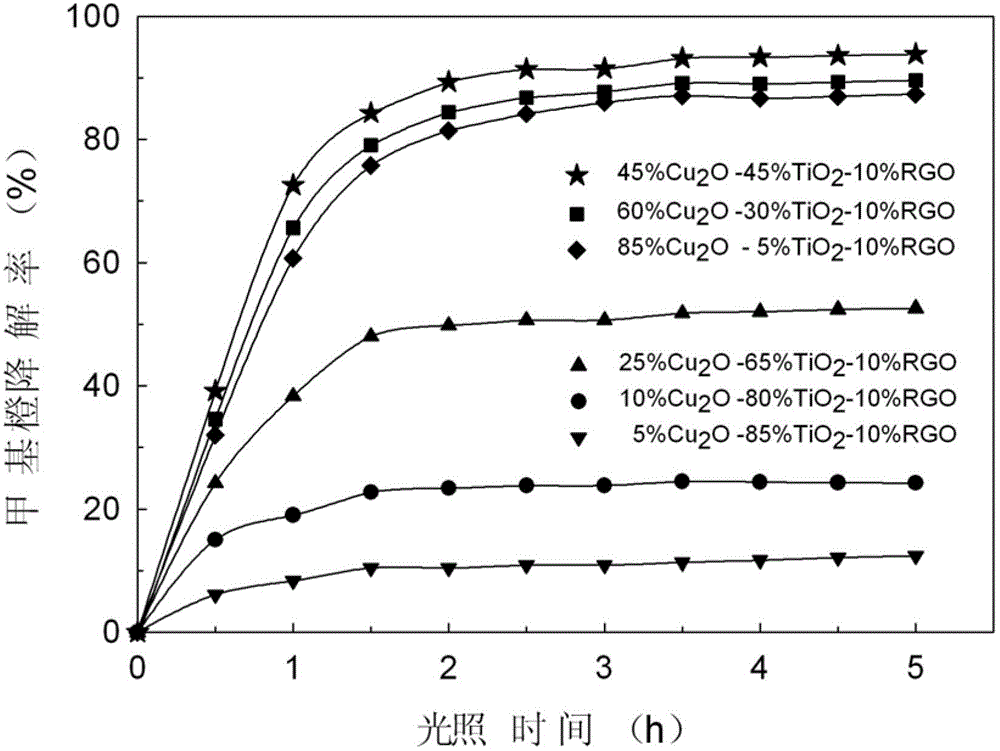

Cu2O-TiO2/reduced graphene oxide ternary complex, and preparation method and applications thereof

ActiveCN103331159AEfficient preparation methodDispersed particle separationHydrogen productionPollutantCompound s

The invention discloses a Cu2O-TiO2 / reduced graphene oxide (RGO) ternary complex, and a preparation method and applications thereof. The preparation method of the ternary complex comprises the following steps: preparing graphene oxide (GO) through a Hummers method, preparing a TiO2 / RGO binary complex through a hydrothermal method, and preparing the Cu2O-TiO2 / RGO ternary complex through precipitating and reducing processes. The preparation method has the advantages of simplicity, low cost and benefiting for the industrialized production; and the prepared ternary complex has a high catalysis activity in a visible region as a visible-light-induced photocatalyst, has a high catalysis efficiency, is especially suitable for degrading organic pollutants in a solution, and can be used for photo-decomposing water to produce hydrogen and degrading volatile organic pollutants in air as the visible-light-induced photocatalyst.

Owner:CENT SOUTH UNIV

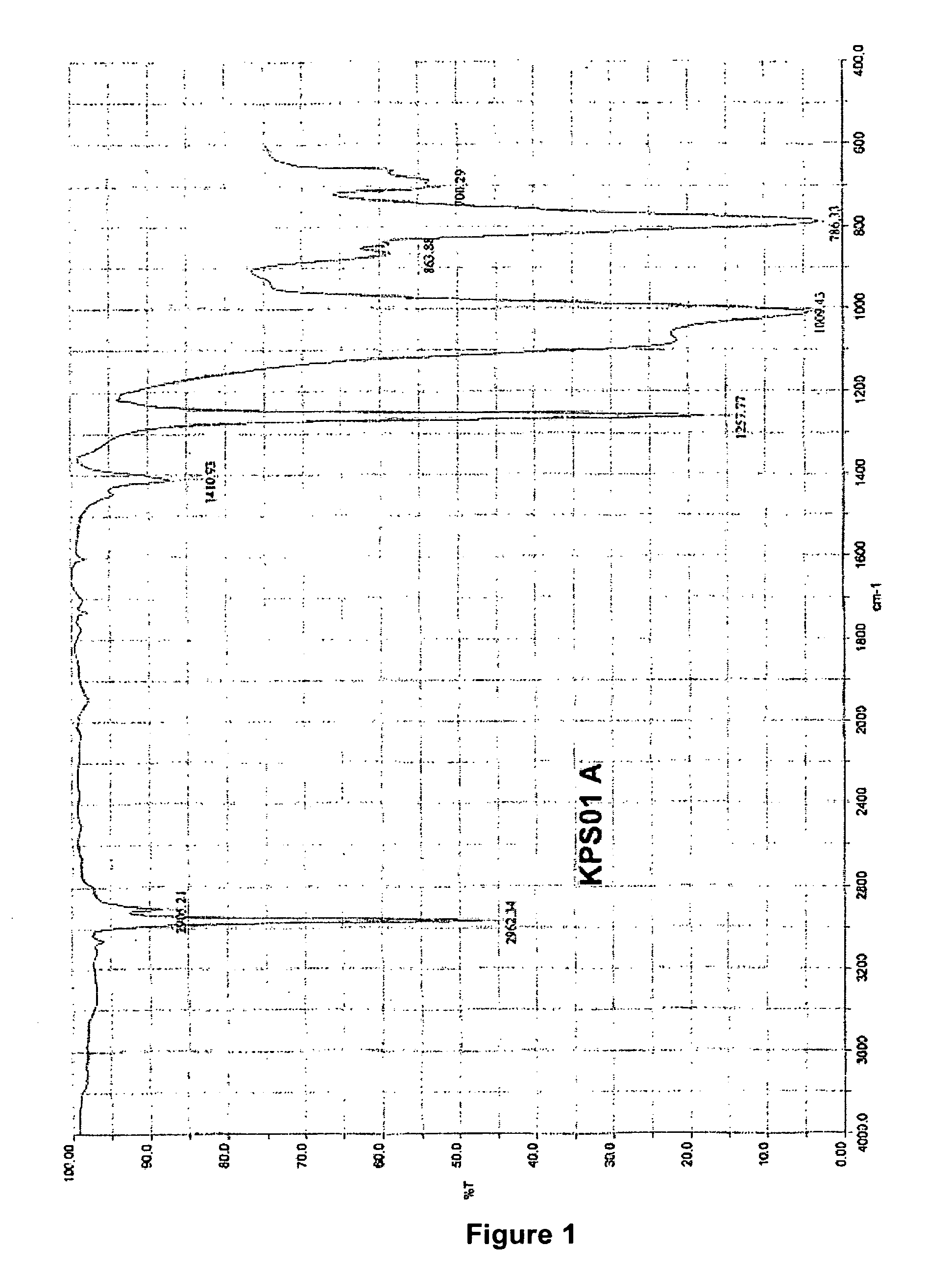

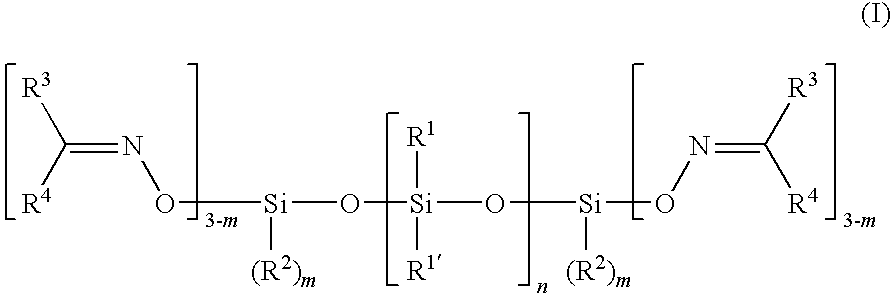

Silicone composition

ActiveUS20100063190A1Simple and rapid preparationFast chemical reactionPretreated surfacesSpecial tyresHigh adhesionSilicone

The present invention relates to silicone compositions which comprise at least one ketoximosilane-terminated polydiorganosiloxane and also at least one alkoxysilane. These compositions are neutrally crosslinking and combine a low odour with high adhesion and good storage stability.

Owner:SIKA TECH AG

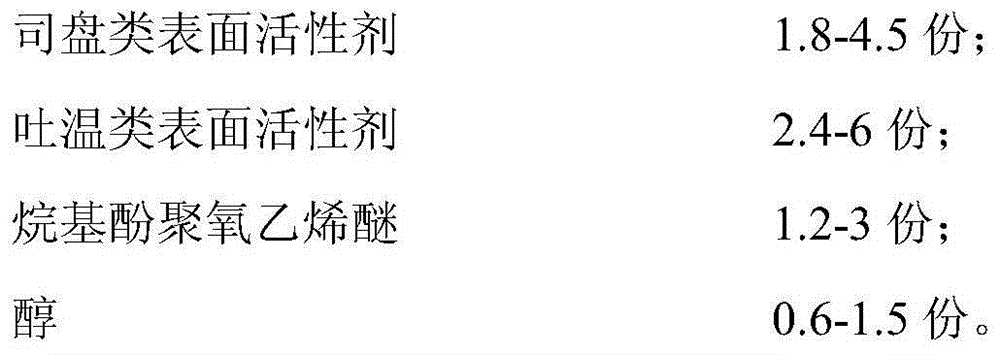

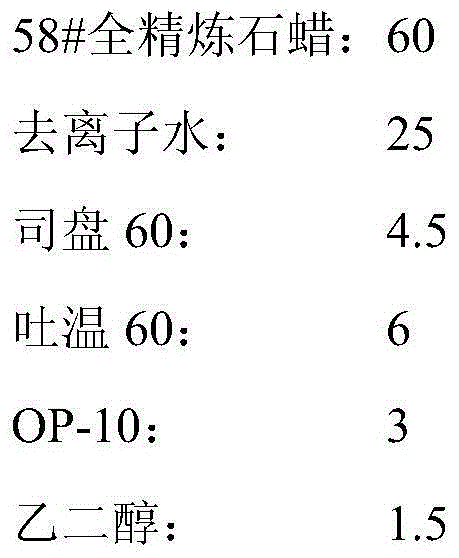

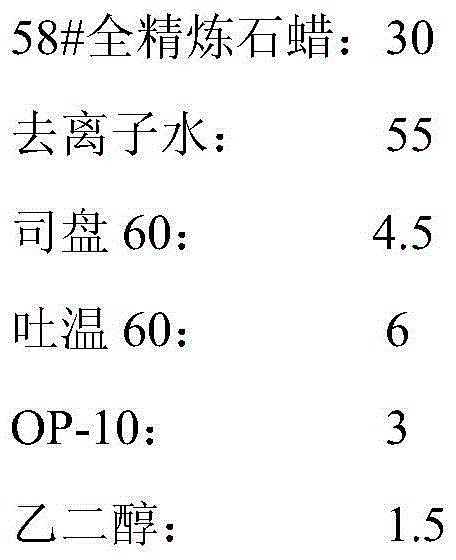

Emulsified paraffin for wood processing and preparation method thereof

The invention belongs to the technical field of chemical engineering, and particularly relates to emulsified paraffin for wood processing and a preparation method thereof. The emulsified paraffin for wood processing is prepared from paraffin, a compound emulsifier and water, wherein the compound emulsifier is a mixture of a Span type surfactant, a Tween type surfactant, alkylphenol polyoxyethylene and alcohol. The emulsified paraffin disclosed by the invention is non-toxic and tasteless, good in dispersibility, good in stability, acid-resistant and alkali-resistant; in the wood processing industry, the emulsified paraffin can completely substitute paraffin to be used as a waterproof and dampproof auxiliary, and is simple to use, low in cost and good in effect, compared with the paraffin; the preparation method is simple and feasible; the three wastes cannot be generated in the preparation process; the preparation method is environment-friendly and efficient.

Owner:CHINA PETROLEUM & CHEM CORP

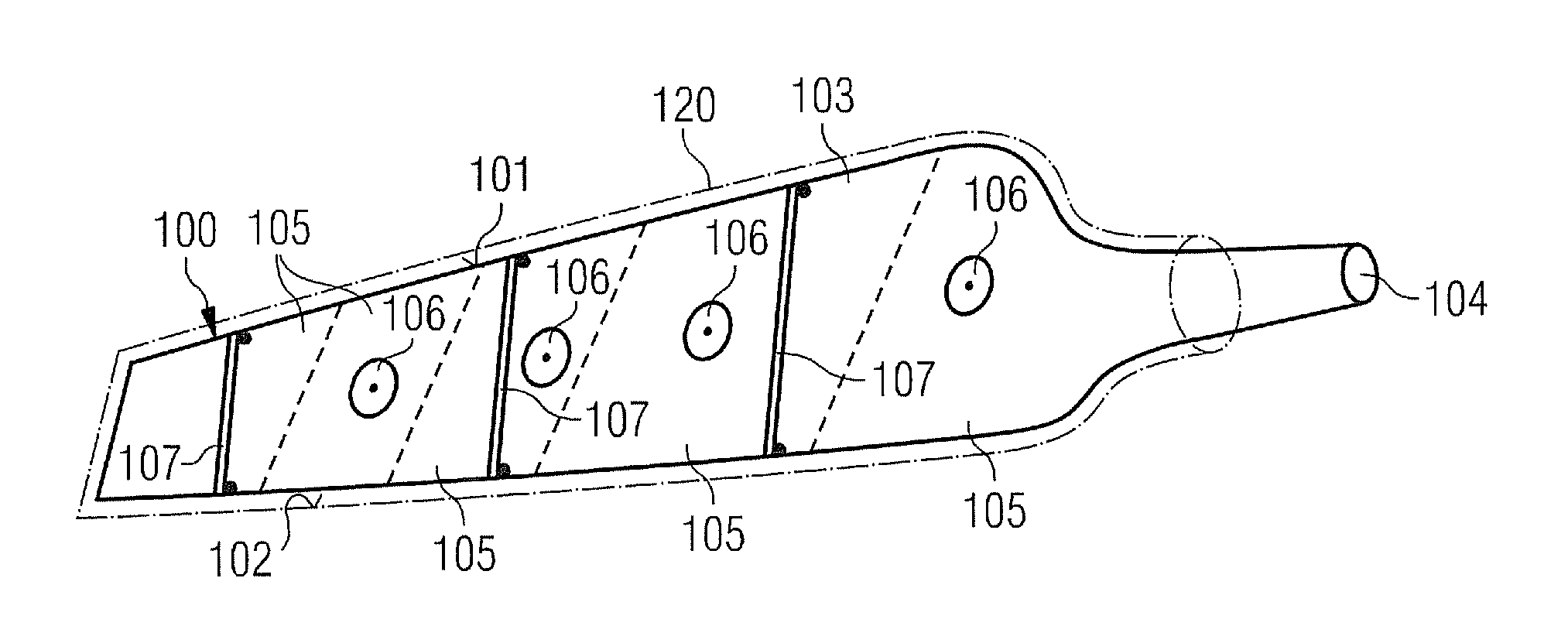

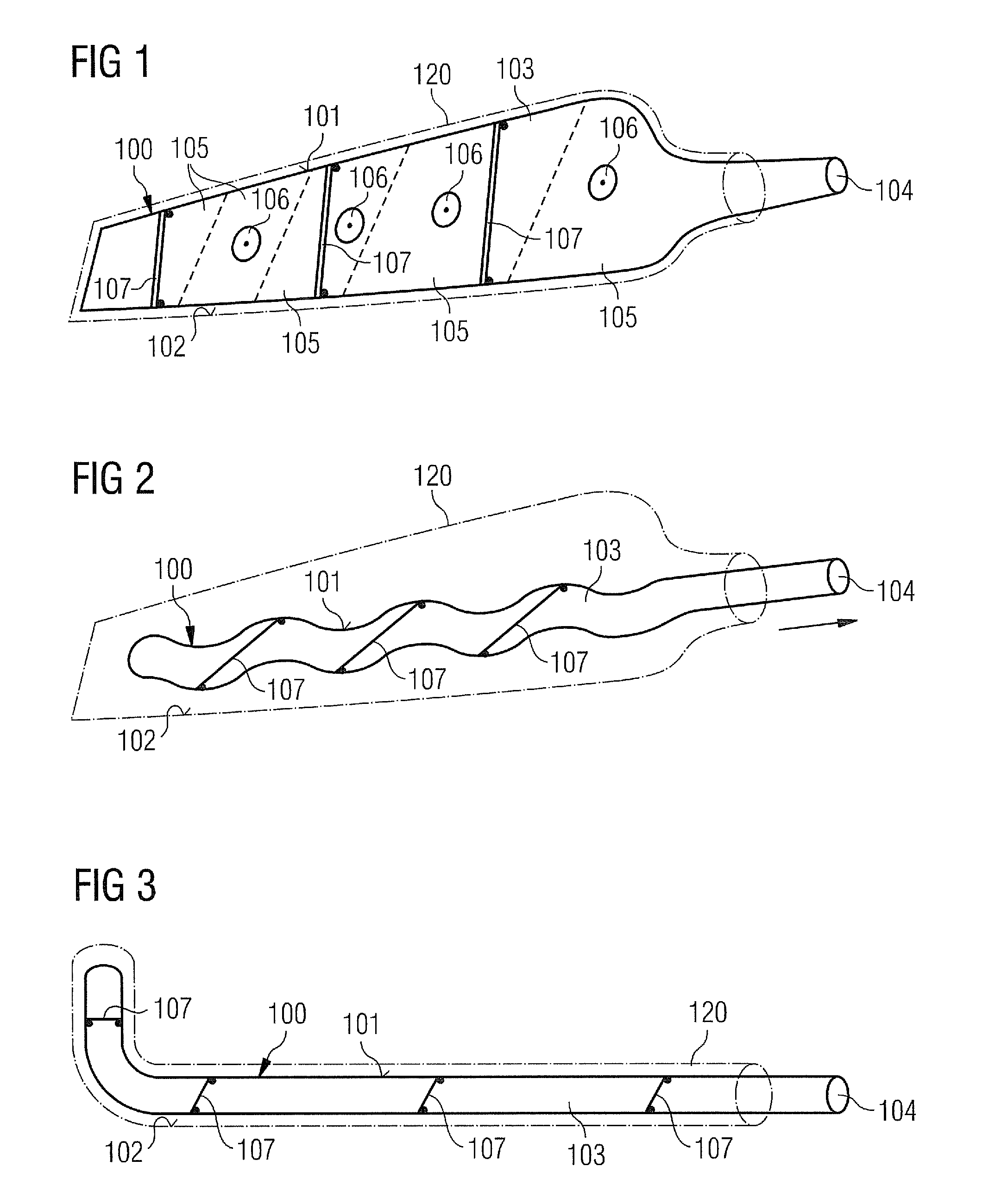

Inflatable dorn

ActiveUS8919754B2Easy to handleEfficient preparation methodLabelling non-rigid containersFinal product manufactureFiber-reinforced compositeTurbine

A mandrel for producing a fiber-reinforced composite part, in particular a blade for a wind turbine is disclosed. The mandrel includes an expandable body with an outer surface onto which a fiber material of the fiber-reinforced composite part is layable out. The expandable body is expandable in an expanded state, wherein in the expanded state the outer surface forms an interior shape of the fiber-reinforced composite part to be produced. Moreover, the expandable body is collapsible in a collapsed state.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

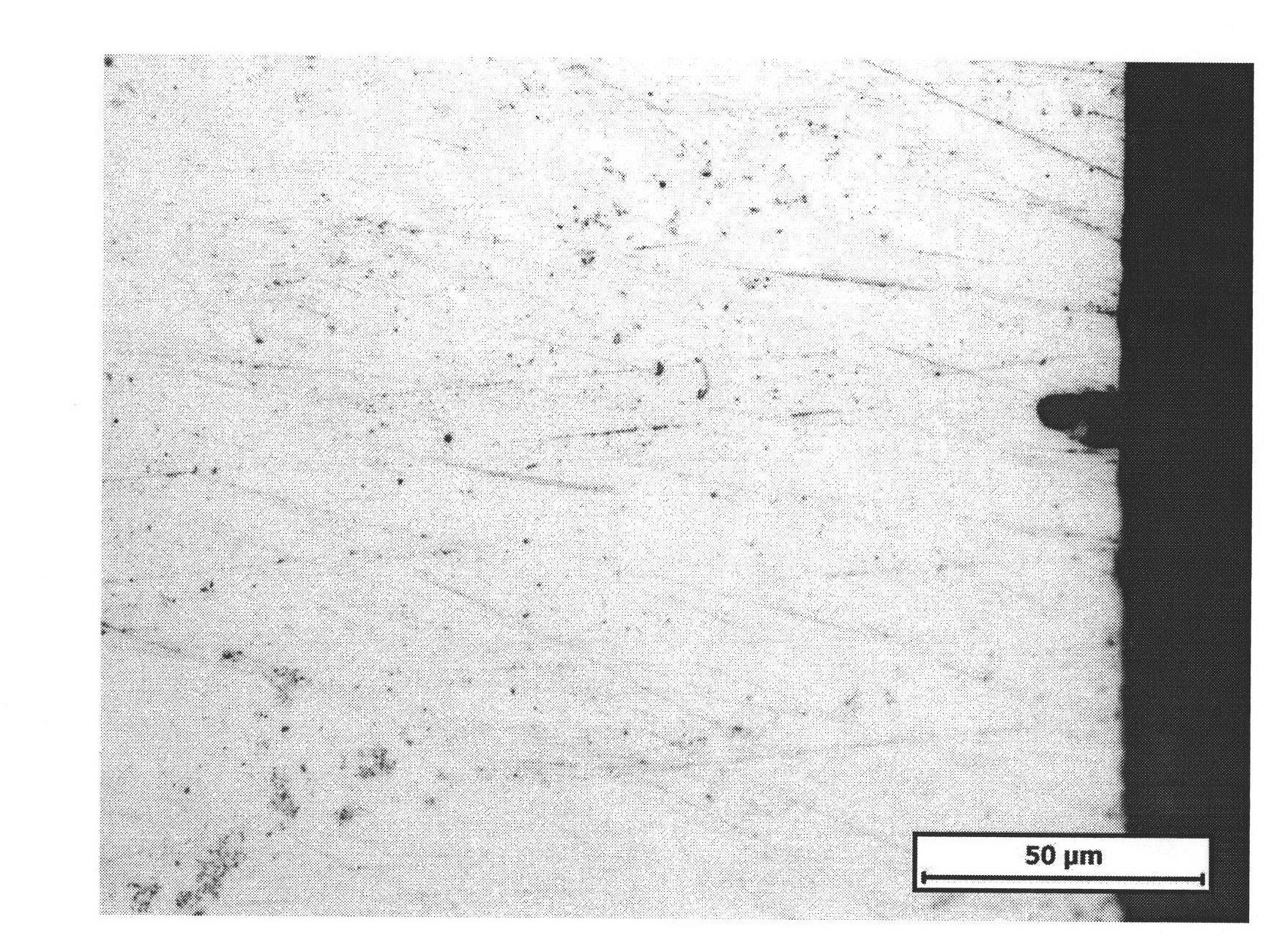

Aluminum alloy 7085 microalloyed with strontium and preparation method thereof

The invention discloses an aluminum alloy 7085 microalloyed with strontium, which is formed by microalloying aluminum alloy 7085 with a small amount of strontium. The alloy mainly comprises Al, Zn, Mg, Cu, Zr and Sr, wherein the mass percent of Zn is 7.0-7.95%, the mass percent of Mg is 1.41-1.80%, the mass percent of Cu is 1.50-1.59%, the mass percent of Zr is 0.138-0.148%, the mass percent of Sr is 0.0228-0.0237%, and the balance is Al and a small amount of impurity elements. The preparation process flow of the alloy is as follows: melting pure Al, sequentially adding Al-Cu intermediate alloy, Al-Sr intermediate alloy, Al-Zr intermediate alloy, pure Zn and pure Mg, melting, adding hexachloroethane for refining, standing and maintaining the temperature for 5-10 minutes, and then casting into ingots; and carrying out post treatments of annealing, stamping and soilid solution ageing on the alloy ingots formed by casting. The invention has the advantages of high rigidity, good exfoliation corrosion resistance and wide application range.

Owner:JIANGSU UNIV

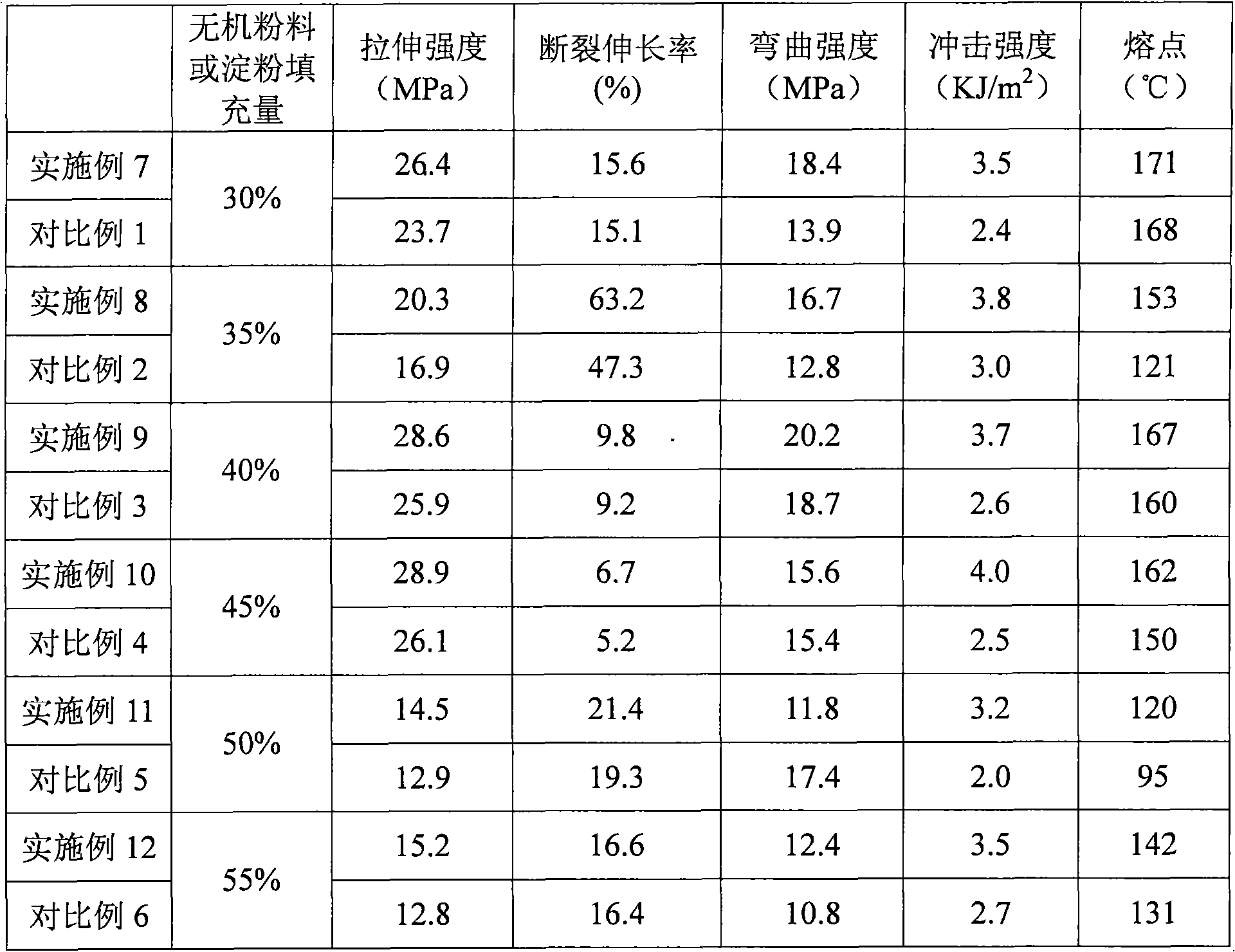

Completely biodegradable material filling master batch and preparation method thereof

The invention discloses a completely biodegradable material filling master batch and a preparation method thereof. The completely biodegradable material filling master batch is characterized by comprising the following components in percentage by weight: 5-35 percent of completely biodegradable material based carrier, 60-90 percent of filler and 1-10 percent of auxiliary agent. The excellent completely biodegradable material filling master batch has great filling amount in a completely biodegradable material, remarkable cost advantage and good mechanical performance, has good dispersibility after adding, improves the heat resistance and stability of a biodegradable material and effectively improves the processing environment, and is a good completely biodegradable material filling master batch.

Owner:SHENZHEN ECOMANN BIOTECH

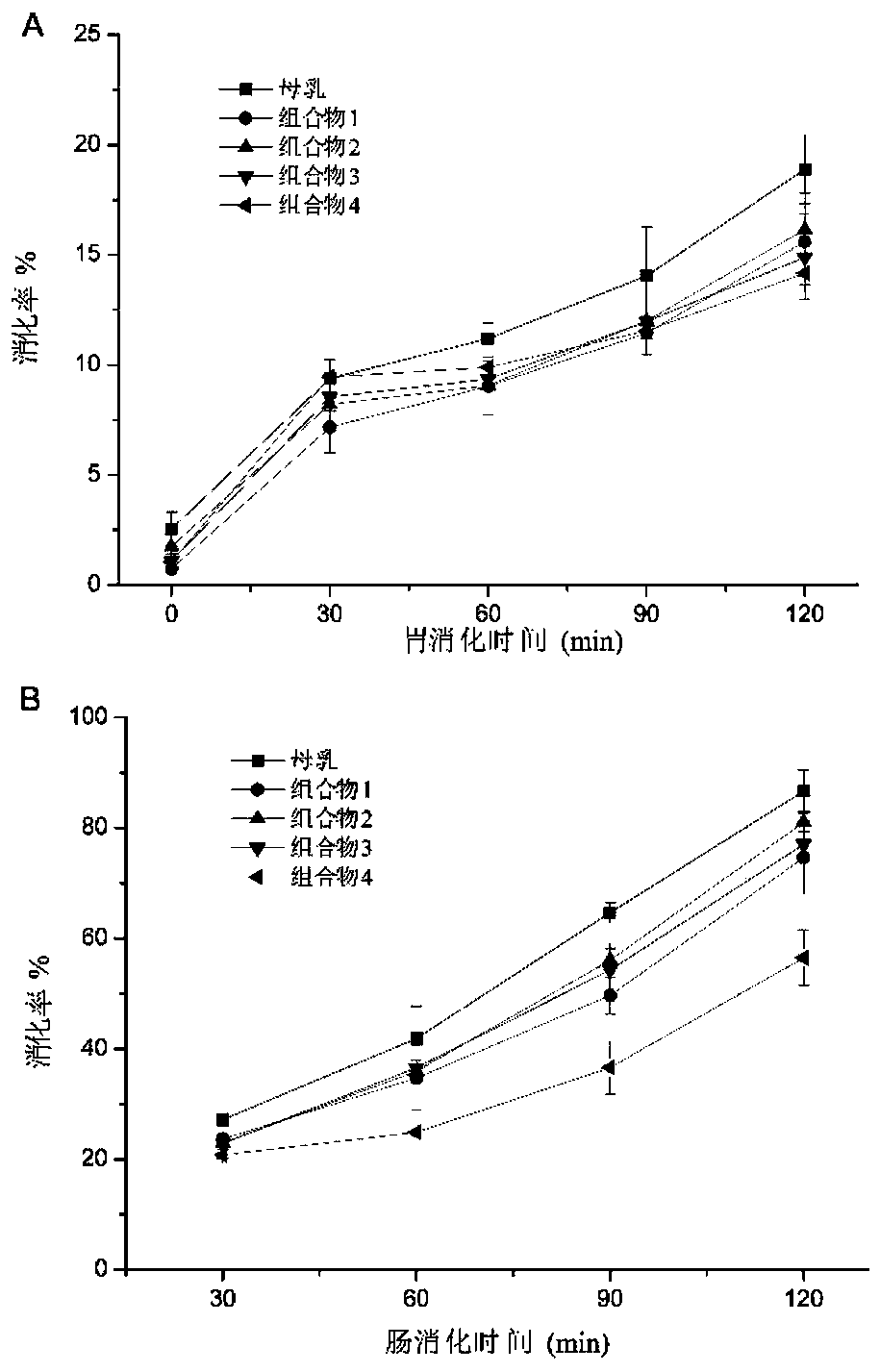

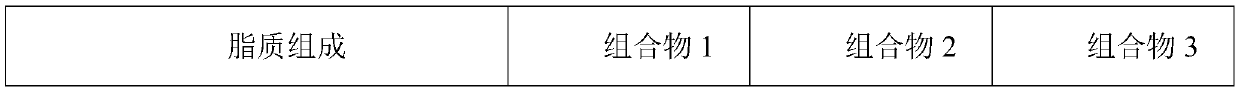

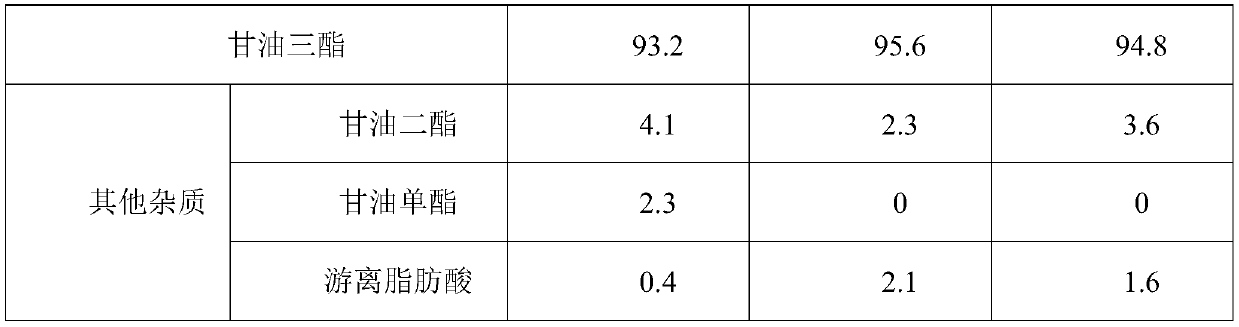

Grease composition comprising medium-long carbon chain triglycerides and preparation method of grease composition

ActiveCN109907126AImprove digestion and absorptionMeet lipid requirementsFermentationEdible oils/fatsTriglycerideCarbon chain

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com