Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

298results about How to "Guaranteed qualified" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

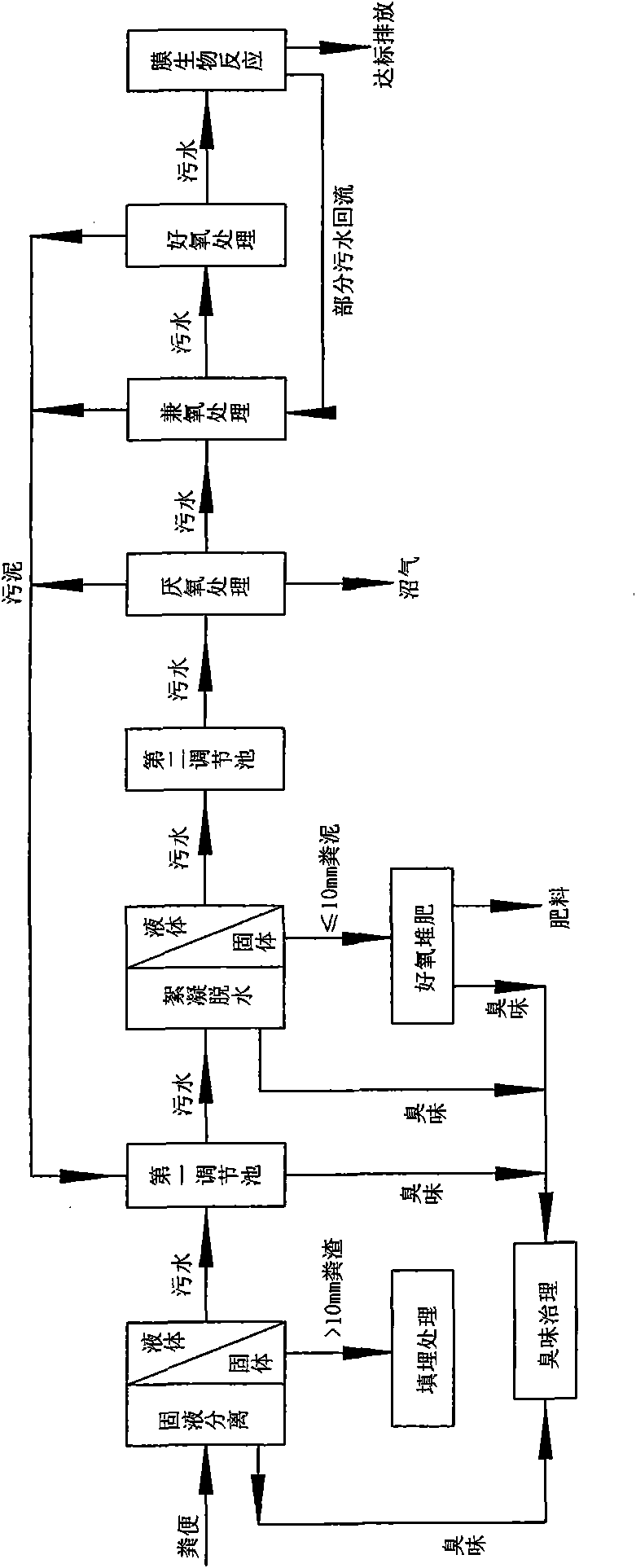

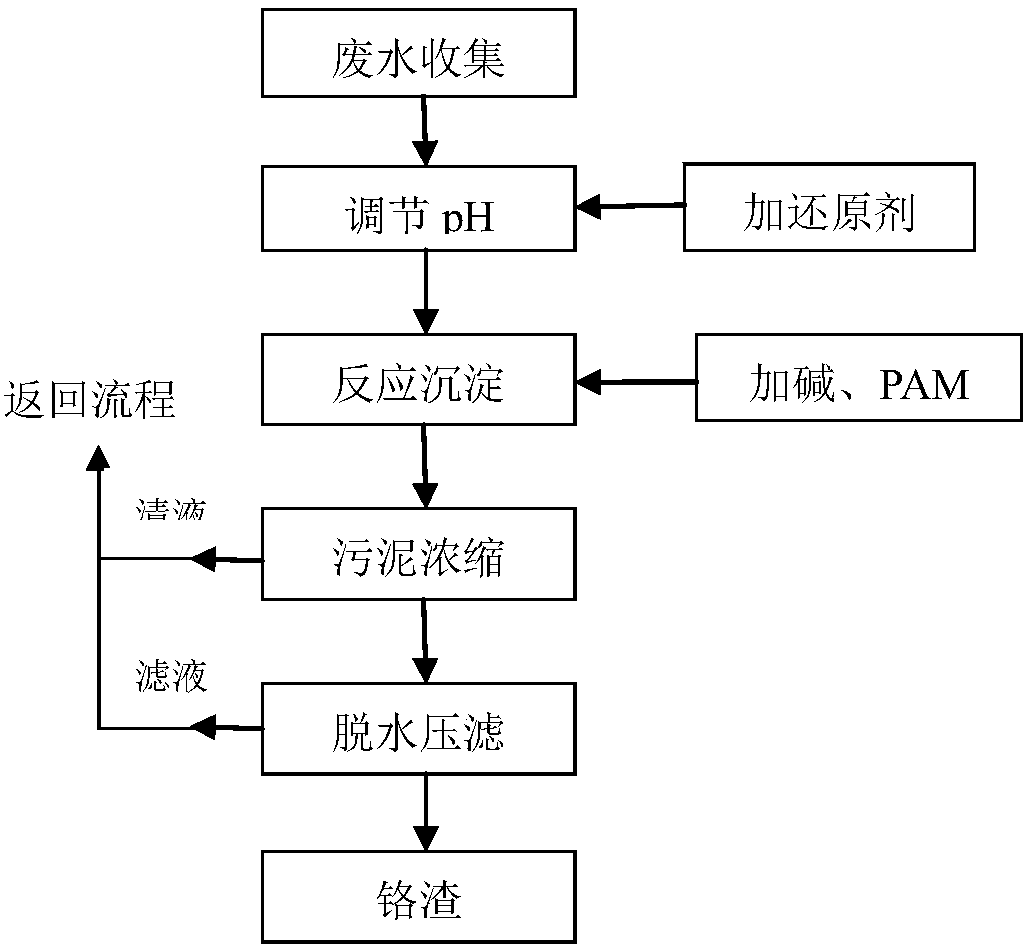

Excrement centralized processing method

ActiveCN101654318AAvoid cloggingCOD removalBio-organic fraction processingSludge treatment by de-watering/drying/thickeningFlocculationFeces

The invention relates to an excrement centralized processing method, comprising the steps of solid-liquid separation, flocculation water removing, aerobic compost treatment, anaerobic sewage treatment, facultative anaerobic sewage treatment, aerobic sewage treatment, membrane anaerobic reacting sewage treatment and odor treatment. Treated with the processing method of the invention, the urban night soil is 100% decontaminated, is 99.7% minimized and the excrement sludge is completely changed into resource.

Owner:北京昊业怡生科技有限公司

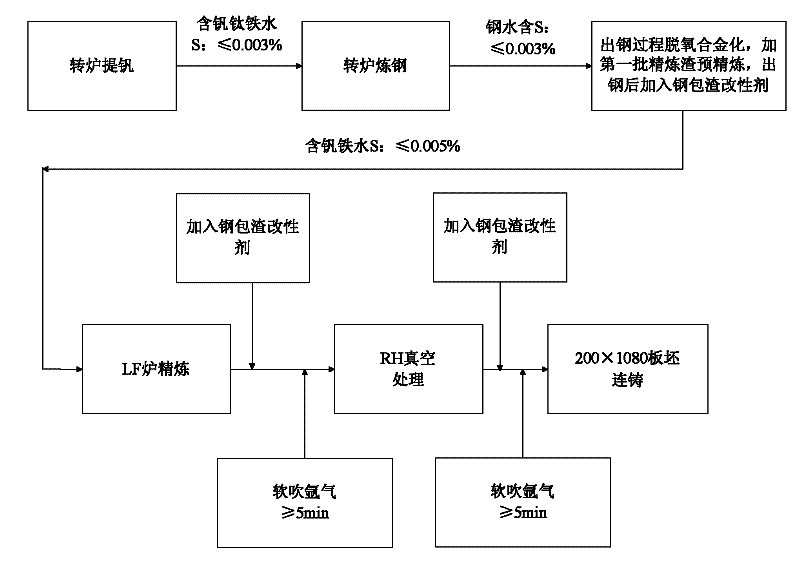

High phosphorus and low sulfur non-oriented electrical steel and its smelting method

ActiveCN102260822AGuaranteed qualifiedSolve the technical difficulties of smeltingElectrical steelSulfur

The invention belongs to the technical field of metallurgy and particularly relates to high-phosphorus low-sulfur non-oriented electrical steel and a smelting method thereof. The technical problem to be solved is to improve resistivity of the electrical steel without influencing the magnetism of the electrical steel. For solving the problem, the invention adopts a technical scheme which is to provide high-phosphorus low-sulfur non-oriented electrical steel. The high-phosphorus low-sulfur non-oriented electrical steel comprises the following ingredients in percentage by weight: 0 to 0.0050 percent of carbon, 0.30 to 1.0 percent of silicon, 0.15 to 0.35 percent of manganese, 0.030 to 0.08 percent of phosphorus, 0 to 0.005 percent of sulfur, less than or equal to 0.0050 percent of aluminum and the balance of ferrum. A production process for the electrical steel is suitable for producing the high-phosphorus low-sulfur non-oriented electrical steel by taking vanadium titanium-containing molten iron as a raw material, and has a good application prospect.

Owner:PANZHIHUA IRON AND STEEL +3

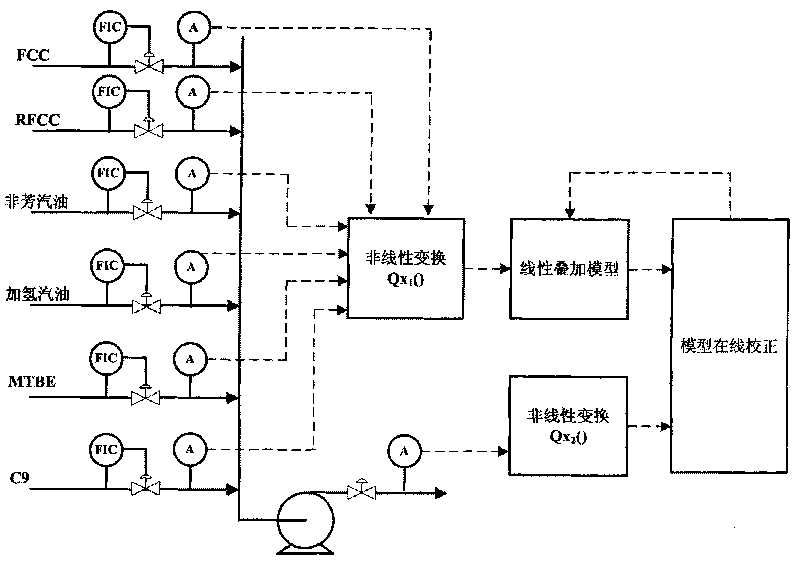

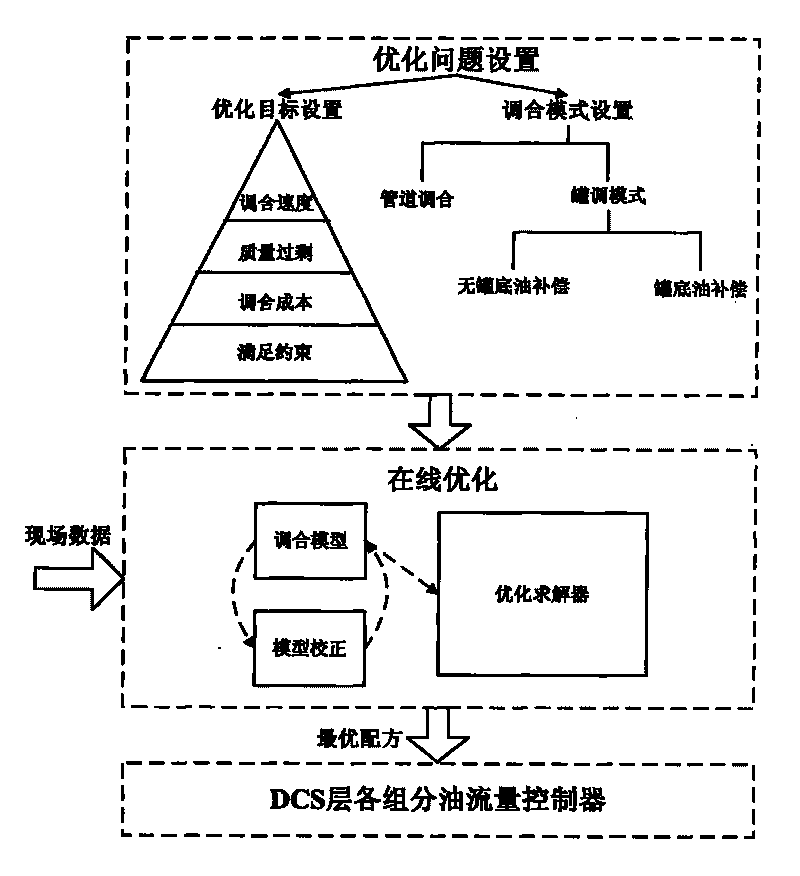

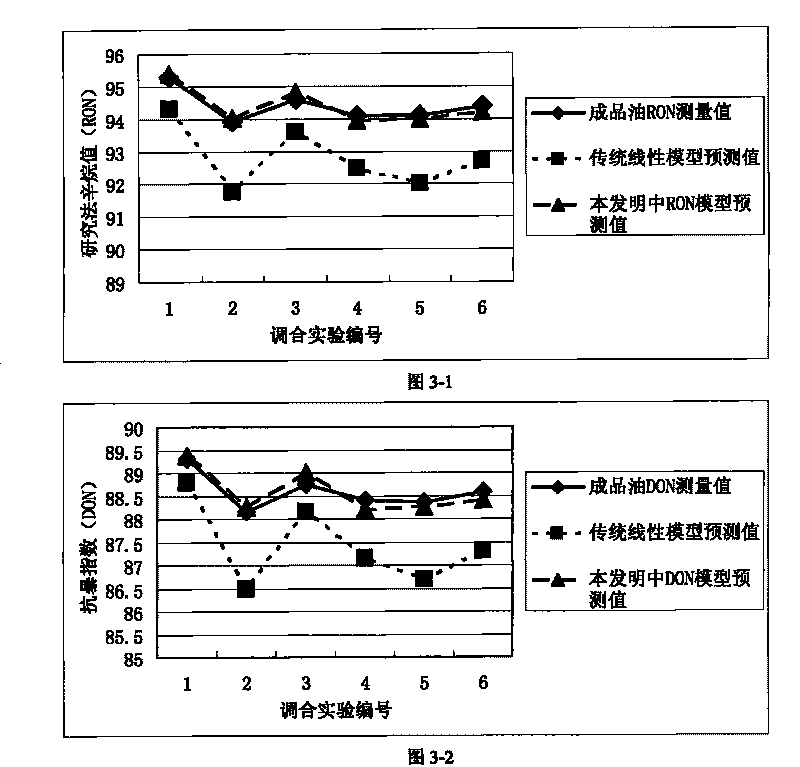

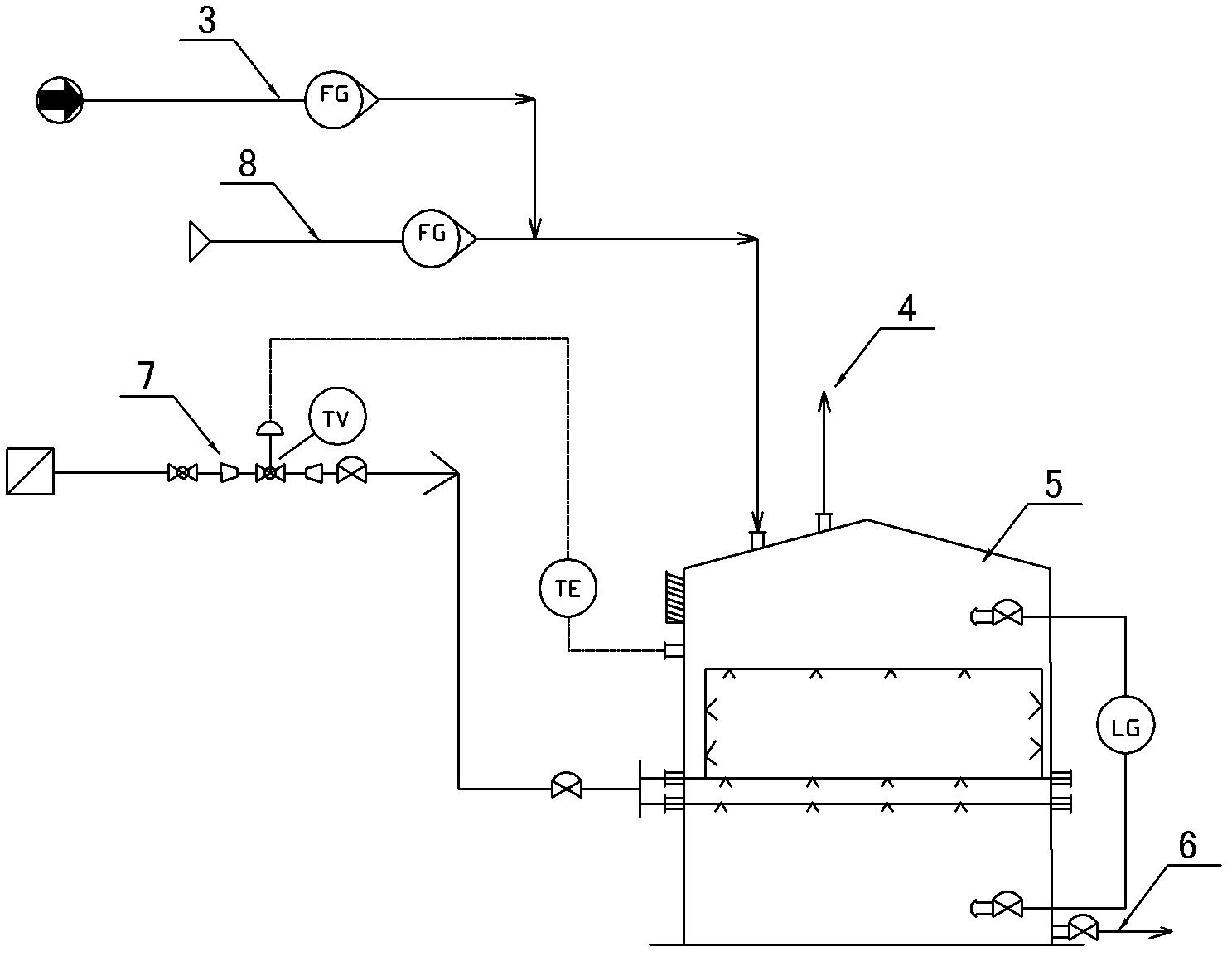

Gasoline online blending method

The invention discloses a gasoline online blending method, wherein the method comprises: linear and nonlinear mathematic models based on real-time flow quantity and quality indicators of processed oil and constituent oils constituting the processed oil, an online real-time auto-correction method for gasoline blending mathematic models and a real-time optimization technique which is developed based on the mathematic model. By adopting the gasoline online blending method in the invention, the problems of low success rate of products produced by a traditional intermittent vessel type blending method, long blending time, high blending cost and more excess of quality can be solved, and an optimal blending formulation can be offered in real-time to satisfy a plurality of requirements related to quality and cost when the products of the constituent oils fluctuate, thus enhancing the benefit of an oil plant remarkably.

Owner:EAST CHINA UNIV OF SCI & TECH

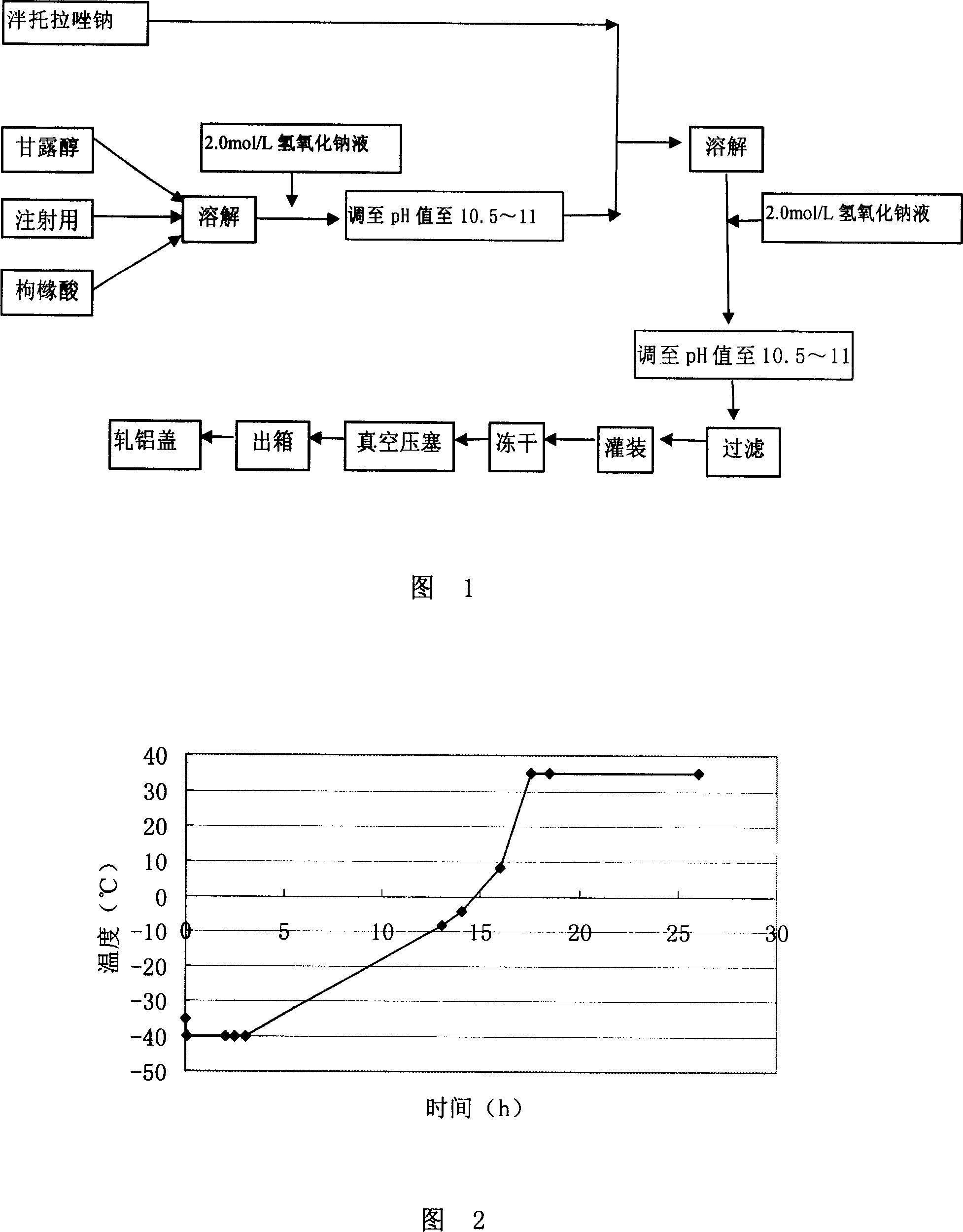

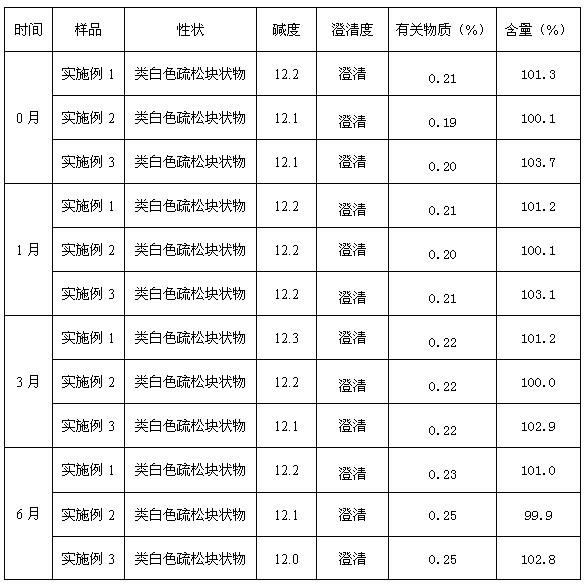

Pantoprazole sodium freeze dried injection and preparation method thereof

InactiveCN101011397AReduce dosageIncrease dosagePowder deliveryOrganic active ingredientsInorganic saltsFreeze-drying

The invention relates to a method for preparing batoracosodium freeze dried, whose pH value is 9.5-11.5. And the invention comprises 1 deal of batoracosodium, 0.5-1 deals of supporting agent, 0-0.06 deals of weak-acid strong-alkali salt, and some inorganic alkali. And the preparation comprises that 1, preparing materials; 2, dissolving the supporting agent and weak-acid strong-alkali salt via injection water, using inorganic salt to adjust the pH value to 9.5-11.5, adding batoracosodium, dissolving and using inorganic salt to adjust the pH value to 9.5-11.5; 3, filtering; 4, freezing and drying to obtain the final product. The invention can be used treat peptic ulcer, ulcer bleed, or the like.

Owner:LIVZON PHARM GRP INC

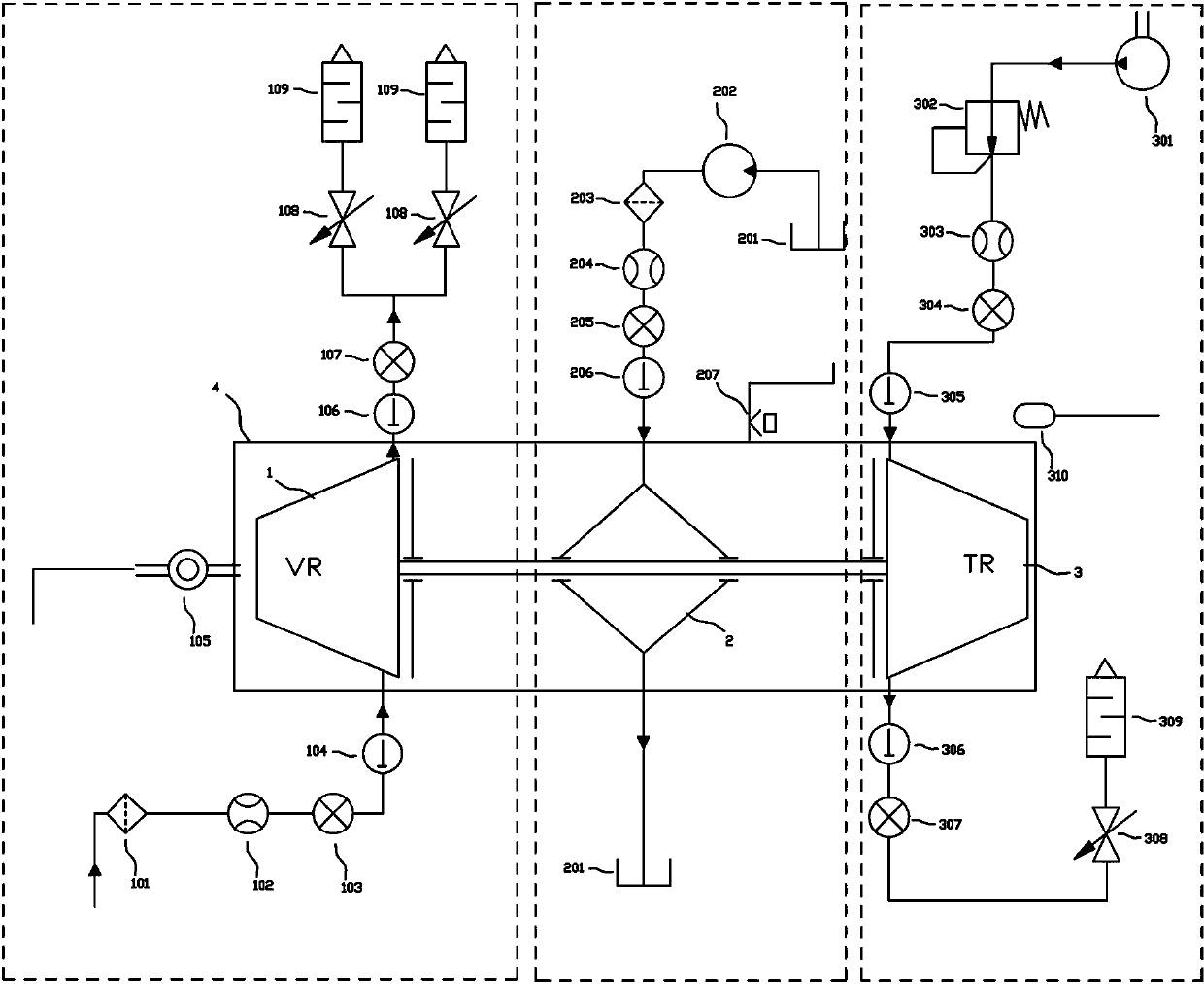

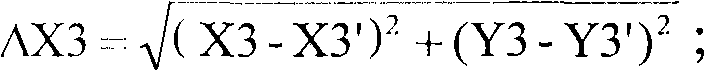

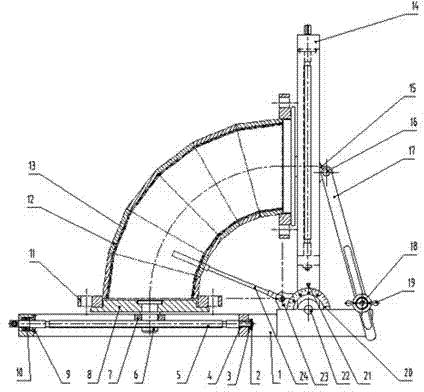

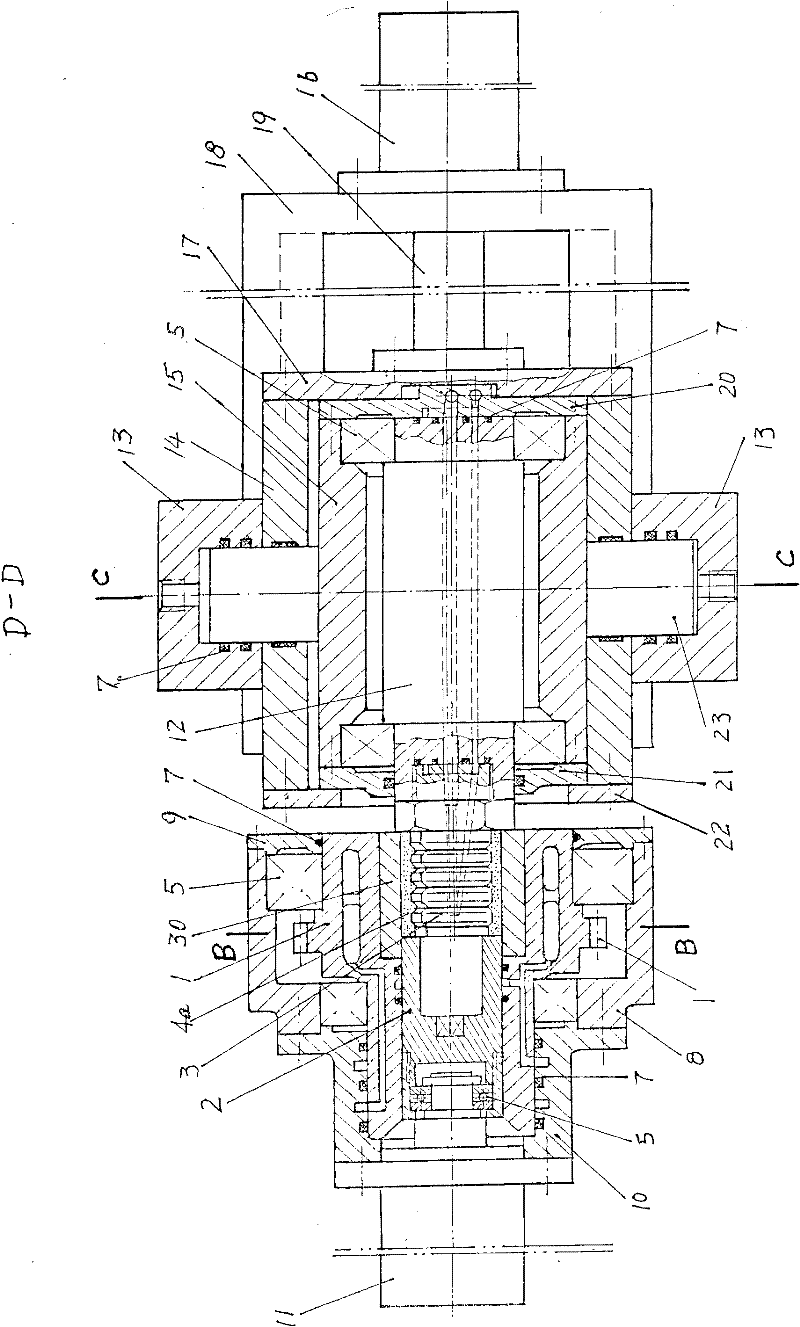

Online detecting device and method for turbocharger

ActiveCN103424253ADetection time is shortGuaranteed qualifiedInternal-combustion engine testingMachine part testingImpellerTurbocharger

The invention discloses an online detecting device for a turbocharger. The device comprises a bearing lubrication system, a compressor end test system, a turbine end test system, a vibrating sensor (207) which is in contact with a casing of the turbocharger, a noise sensor (310) which is close to a turbine end of the turbocharger and a velocity sensor (105) which is close to an impeller of a compressor end of the turbocharger. The invention also discloses a method for using the online detecting device for the turbocharger to perform online detection on the turbocharger. The method can be used for detecting whether the flow of lubricating oil, the temperature of the lubricating oil, the pressure of the lubricating oil, the starting torque, the turbine end air outlet, the turbine end air inlet, the compressor end air outlet, the compressor end air inlet, the vibration and the noise are qualified or not. According to the online detecting device and the method, the consumed detection time is short, the cleanliness of the inside of the turbocharger is not influenced, and each turbocharger can be detected to guarantee that each turbocharger leaving the factory is qualified.

Owner:BORGWARNER AUTOMOTIVE COMPONENTS (NINGBO) CO LTD

Standard laminated plate and manufacturing method thereof

ActiveCN102098884AImprove pass rateGuaranteed qualifiedMultilayer circuit manufacturePass rateEngineering

The invention discloses a standard laminated plate and a manufacturing method thereof, which aim to improve the passing rate of laminated plates. The method comprises the following steps of: setting a test part on core plates for lamination and manufacture; stacking a plurality of the core plates and performing laminating operation to obtain the laminated plate; according to the position of the test part of a plurality of the core plates, mechanically drilling the corresponding position of the laminated plate to obtain mechanical holes; performing interlayer offset detection on the mechanically drilled laminated plate to judge whether the laminated plate is qualified. The technical scheme of the invention ensures that the standard laminated plate is the qualified laminate plate, thereby improving the passing rate of the laminated plates which are manufactured in batch by taking the standard laminated plate as the standard, and reducing the rejection rate of the laminated plates manufactured in batch.

Owner:新方正控股发展有限责任公司 +1

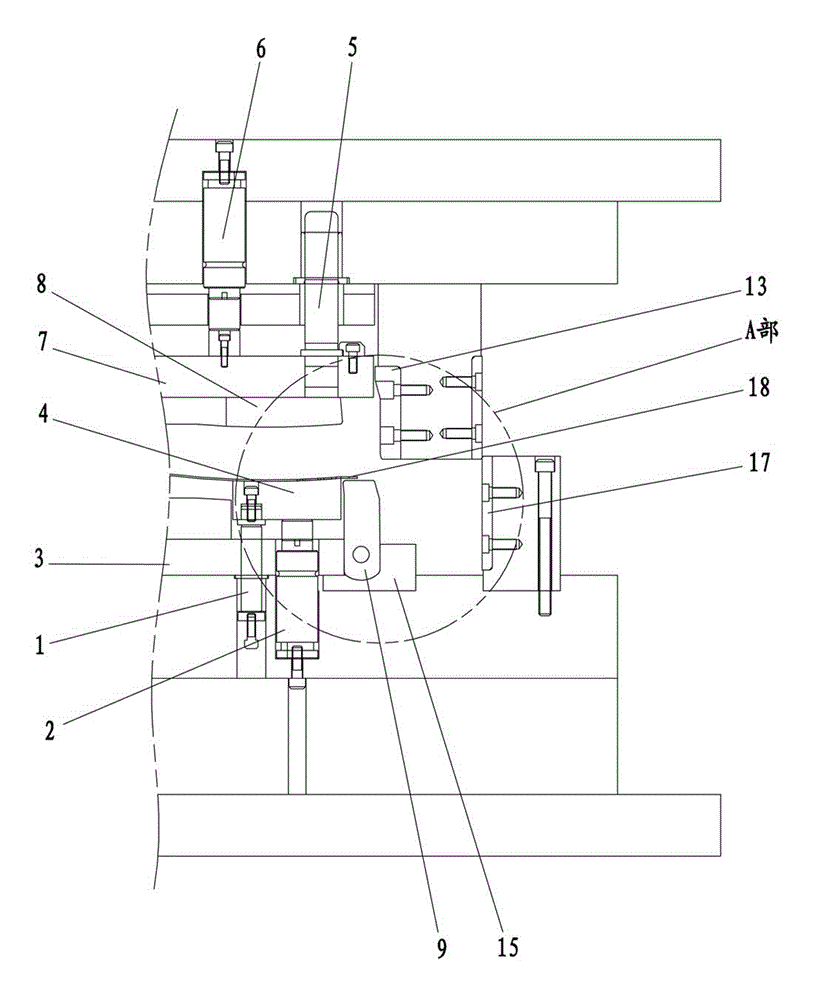

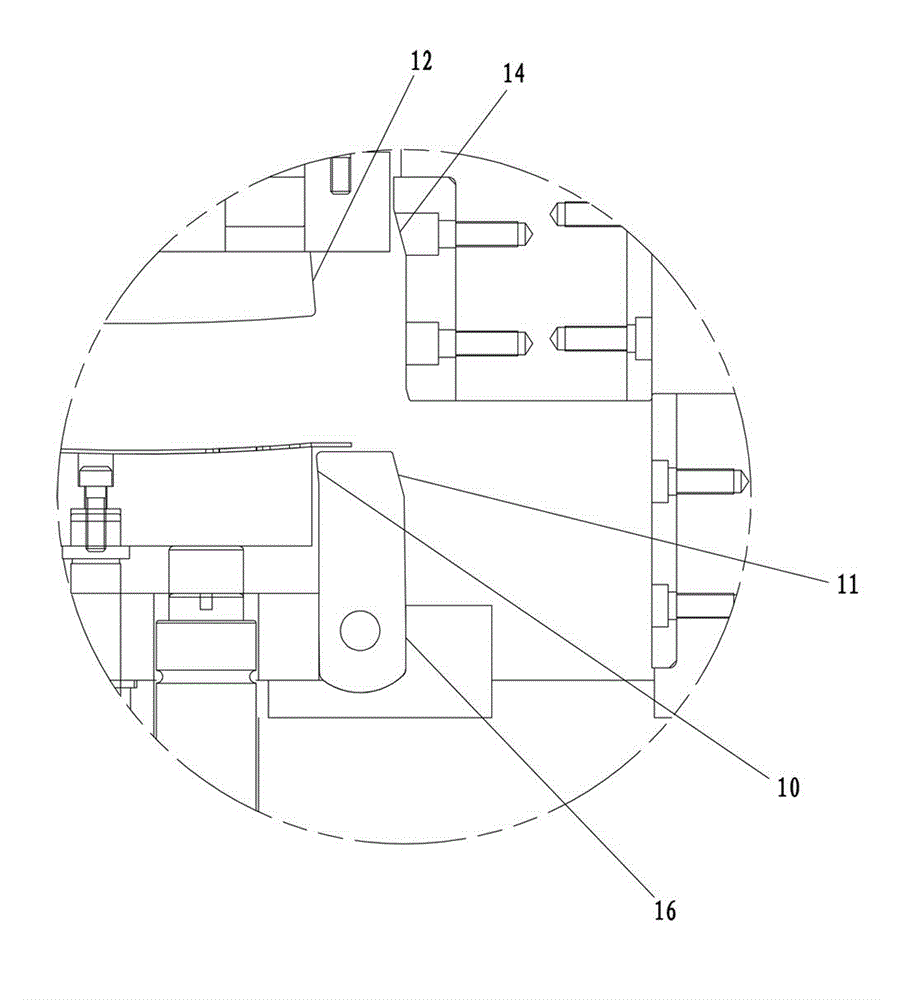

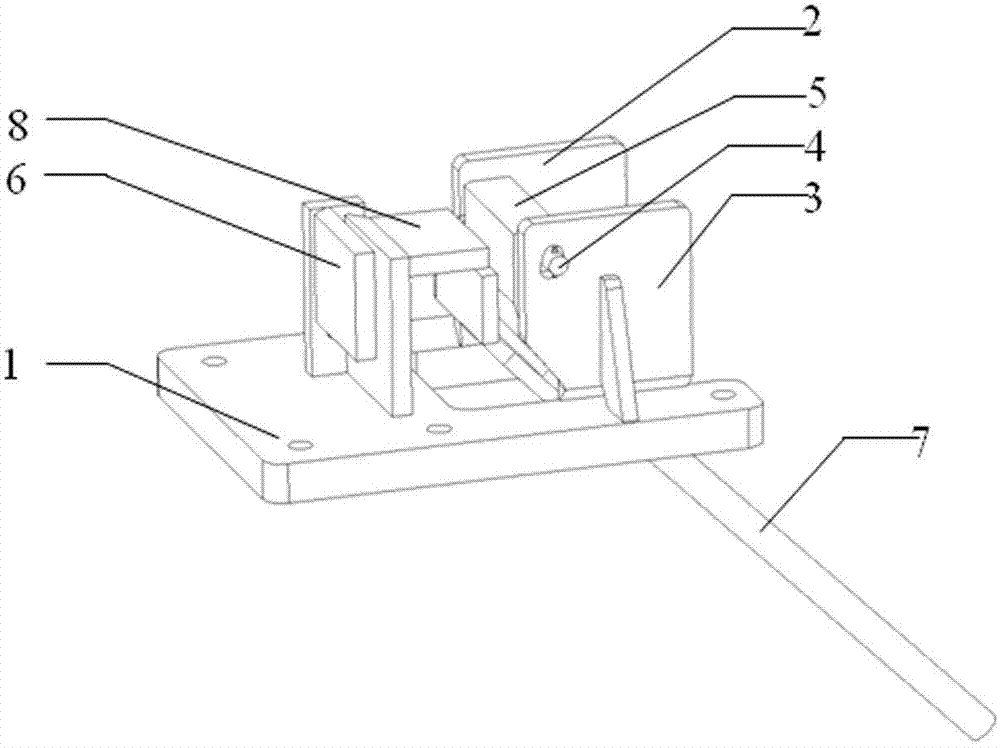

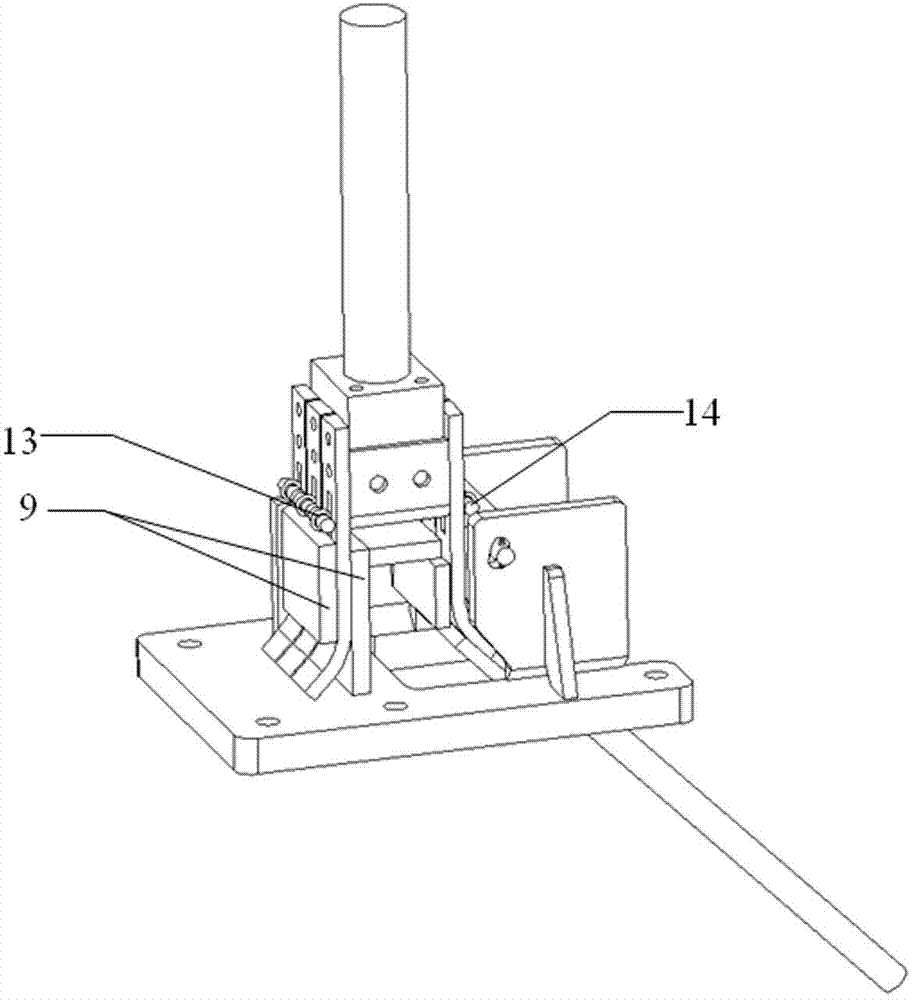

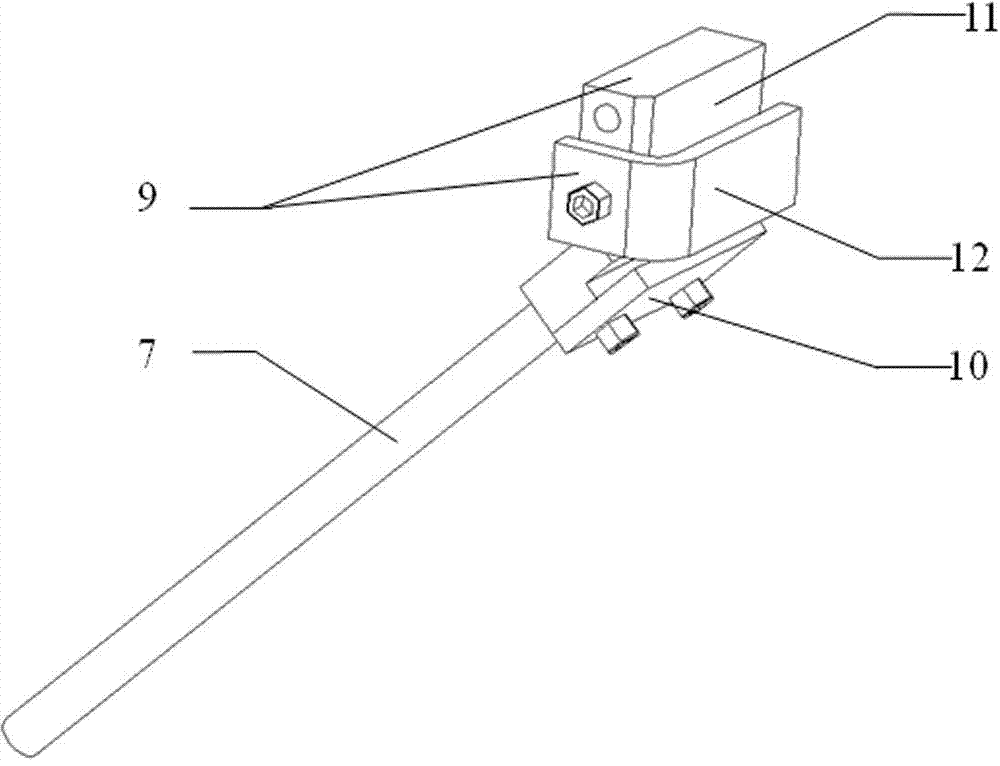

Multi-specification combined elbow welding tool and welding method for same

ActiveCN103692128AImprove quality and efficiencyIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesLocking mechanismEngineering

The invention discloses a multi-specification combined elbow welding tool, which comprises a base and an upper seat, wherein the base is connected with the upper seat in a rotating way; a screw rod is arranged on the base, and is also connected with a positioning flange on the base through a connecting nut; the structure of the upper seat is the same as that of the base; a positioning seat is also arranged on the base; a positioning shifting fork is connected to the positioning seat through a pin shaft; a locking mechanism is arranged on the positioning shifting fork and the base; an angle adjustment mechanism is also arranged between the base and the upper seat. According to the multi-specification combined elbow welding tool, the size and the angle of a finished product elbow is directly determined through the tool, and flanges and elbow pieces are placed on the tool for integral assembly-welding, so that the angle and the size of the elbow can be ensured, and the finished product elbow can be ensured to be qualified.

Owner:NANJING MEISHAN METALLURGY DEV

Lansoprazole nano-particle frozen preparation for injection and preparation method thereof

ActiveCN102198106APromote absorptionImprove bioavailabilityPowder deliveryOrganic active ingredientsLansoprazoleSulfite salt

The invention discloses a lansoprazole nano-particle frozen preparation for injection capable of simultaneously improving the stability and dissolubility, and a preparation method thereof. The preparation comprises the following components in parts by weight: 20-40 parts of lansoprazole, 5-50 parts of dextran, 5-40 parts of sodium sulfite, 5-60 parts of solubilizer, 10-100 parts of nano-carrier material and 10-100 parts of freeze drying excipient. The preparation method comprises the steps of: adding the dextran, the solubilizer and the sodium sulfite into a liquid preparation tank, adding water for injection and stirring until dissolved, regulating the pH value, adding the lansoprazole and the nano-carrier material, continuing to stir evenly, adding the freeze drying excipient and stirring until dissolved, supplementing the water for injection to the full dose, decoloring, finely filtering, subpackaging and freeze drying to obtain the frozen preparation.

Owner:WUHAN PUSHENG PHARMA

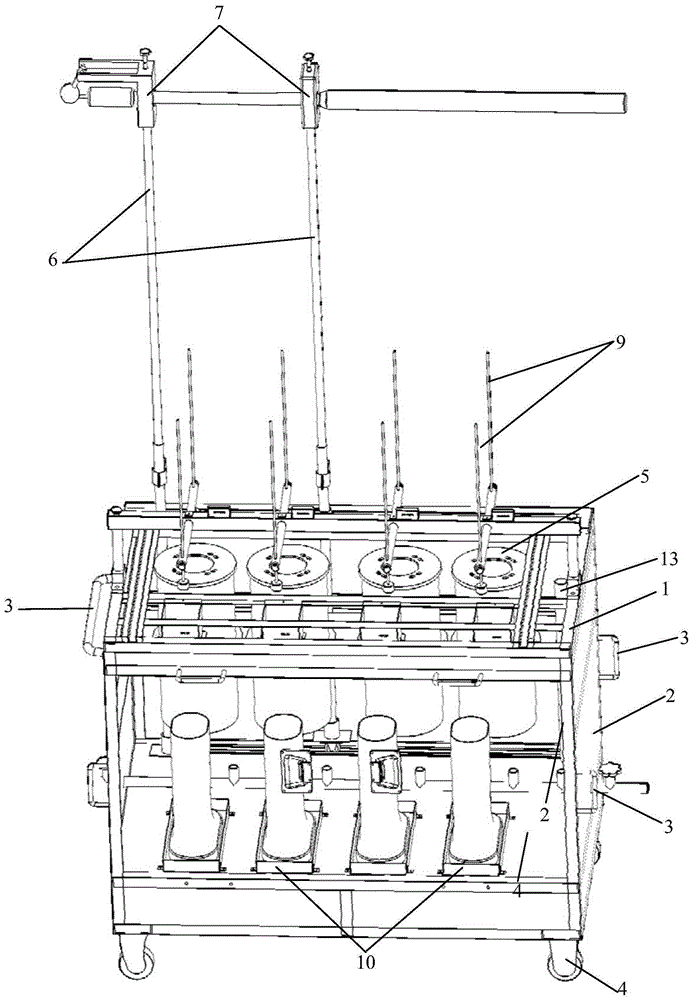

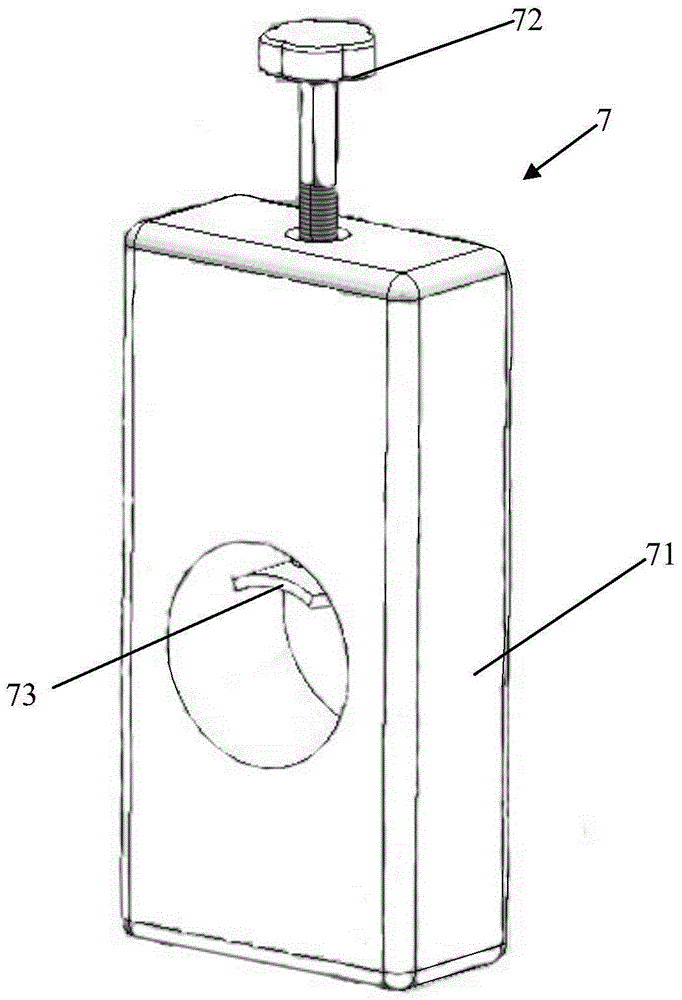

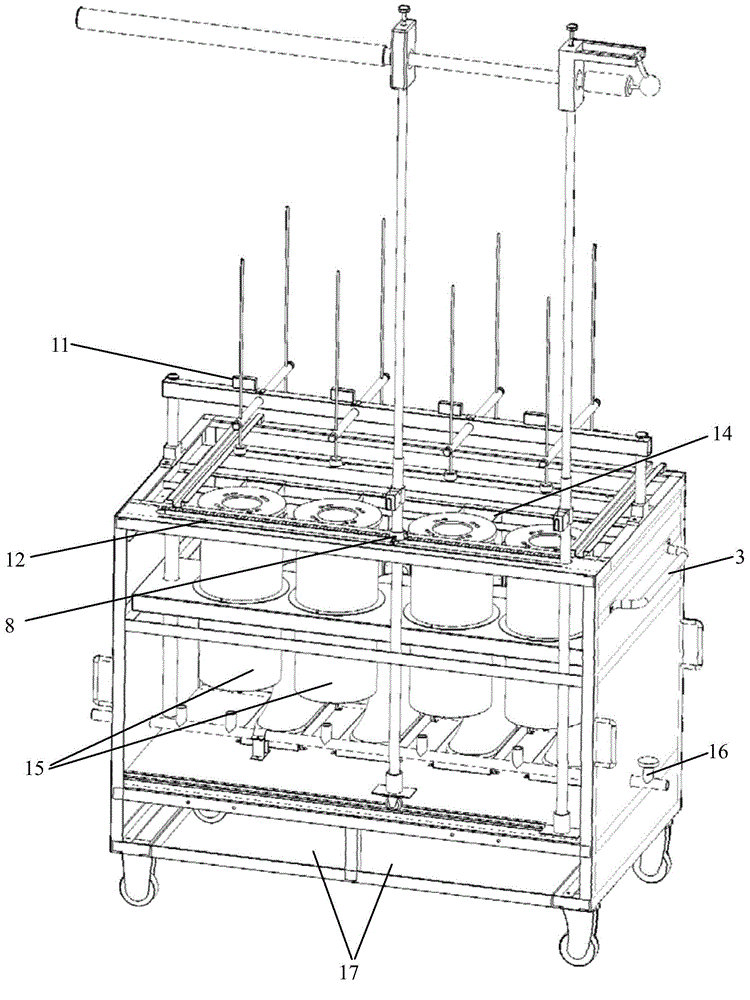

Portable insulation safety tool power-frequency voltage-withstand dolly

ActiveCN104880655ASave on fuel costsReduce labor costsTesting dielectric strengthTime of useRubber mat

The invention relates to a portable insulation safety tool power-frequency voltage-withstand dolly, comprising a dolly portion, a clamping portion, a conductive portion, a measuring portion, and a storage portion. The portable insulation safety tool power-frequency voltage-withstand dolly can satisfy power-frequency voltage-withstand test requirements of insulating gloves, insulating boots, an insulating rods, an electroscope, a grounding wire, an insulating septum, an insulating rubber mat, and other various safety tools. The dolly saves large amount of manpower and material resources, reduces occurrence of safety accidents, and has good economical benefits and social benefits. Because of application of the test dolly, the number of times of use of the dolly to carry tools is reduced, and the dolly brings about considerable environmental benefits.

Owner:江苏省电力公司太仓市供电公司

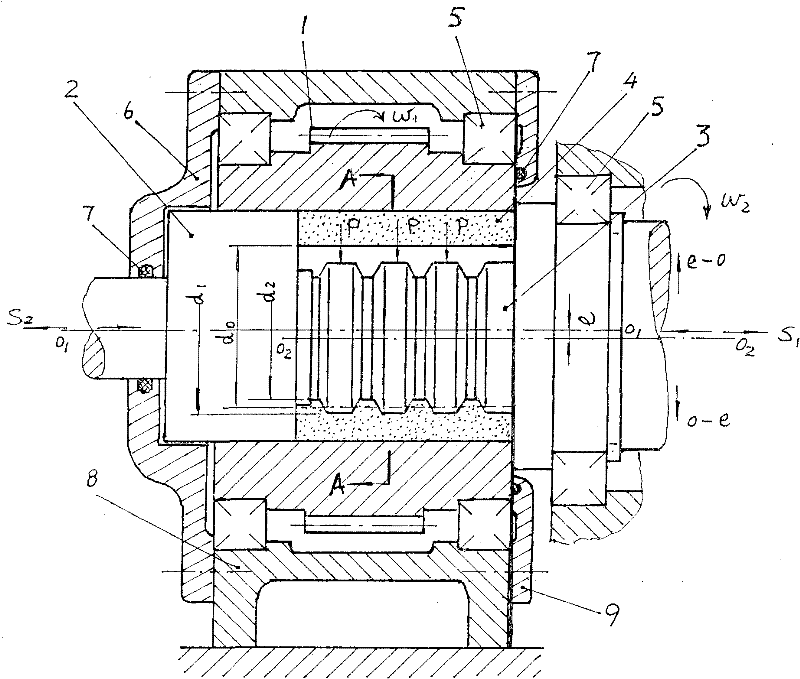

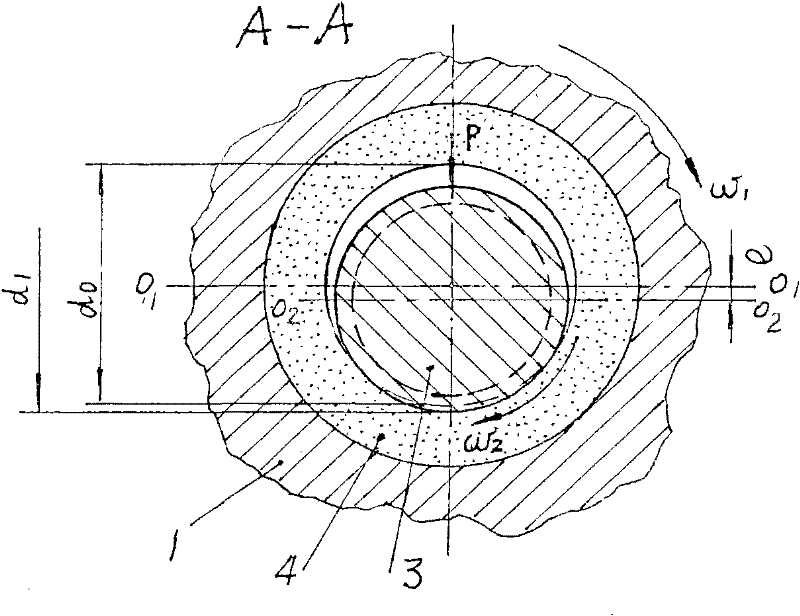

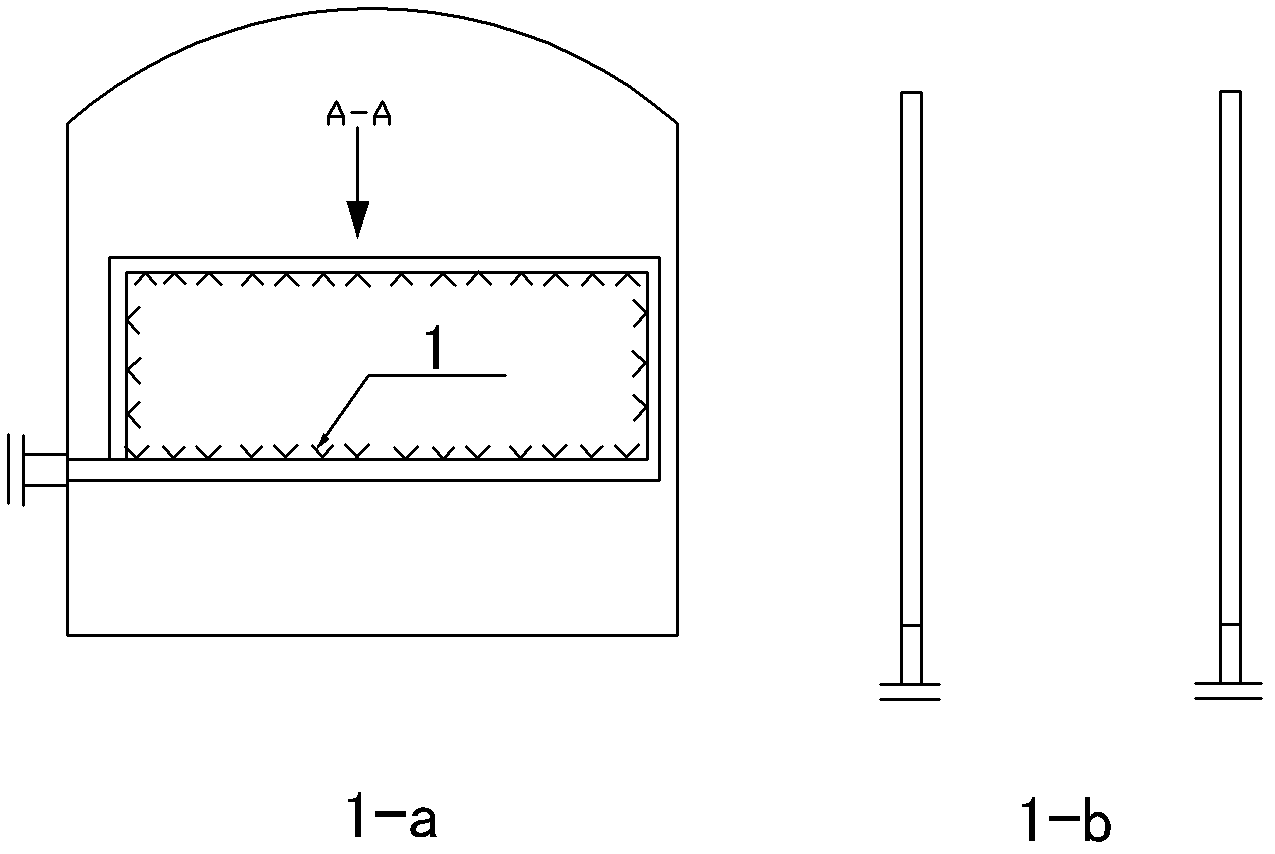

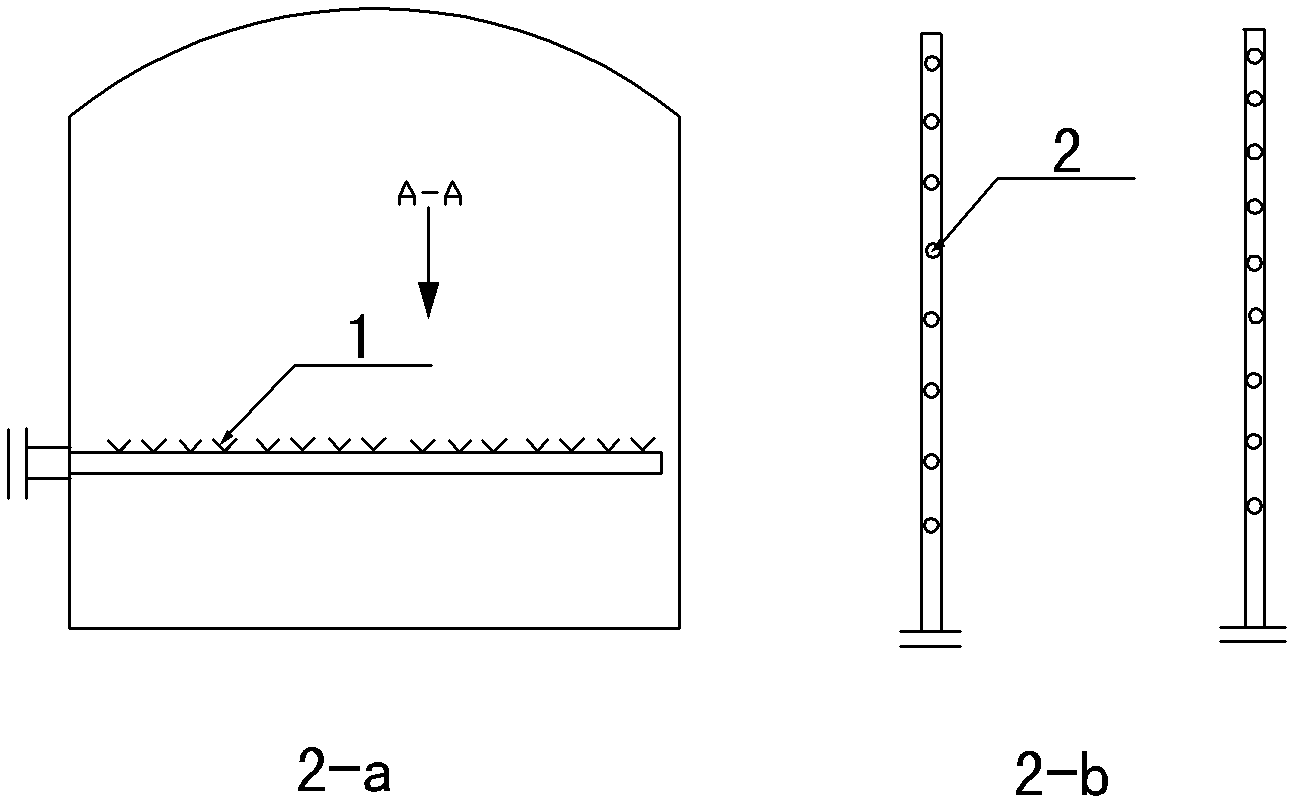

Compound mill

The invention discloses a compound mill. A roller (1) is positioned on a base (8) through bearings (5), a cylindrical space is arranged inside the roller (1), one end of the roller (1) is closed by a stopper (2), the other end of the roller (1) is firstly provided with a tubular blank (4) and extends into a roll shaft (3) with an annular groove, a die comprises the roller (1), the stopper (2) and the roll shaft (3), the roller (1) drives the blank (4) to rotate at an angular speed 1 under the drive of external force, friction force is generated between the roll shaft (3) and the blank (4) by means of pressure P, and the roll shaft (3) rotates at an angular speed 2 and further has the functions of axial reciprocation and radial reciprocation. When the axis O2-O2 of the roll shaft (3) is misaligned with the axis O1-O1 of the roller, the blank (4) is embedded by the aid of offset, and the inner wall of the blank (4) is broached and shrunk in compound milling and extrusion, so that the blank (4) becomes a qualified workpiece with an external cylindrical surface and an internal annular groove. Afterwards, the roll shaft (3) radially returns, stops rotating and axially returns, the stopper advances (pushes the workpiece out of the roller) and returns, all technical processes for machining one workpiece are continued to be completed rapidly and automatically by means of mechanical, electrical and hydraulic integration, production efficiency is improved, labor intensity is reduced, chipless machining is realized, and metal materials are saved.

Owner:袁正敏

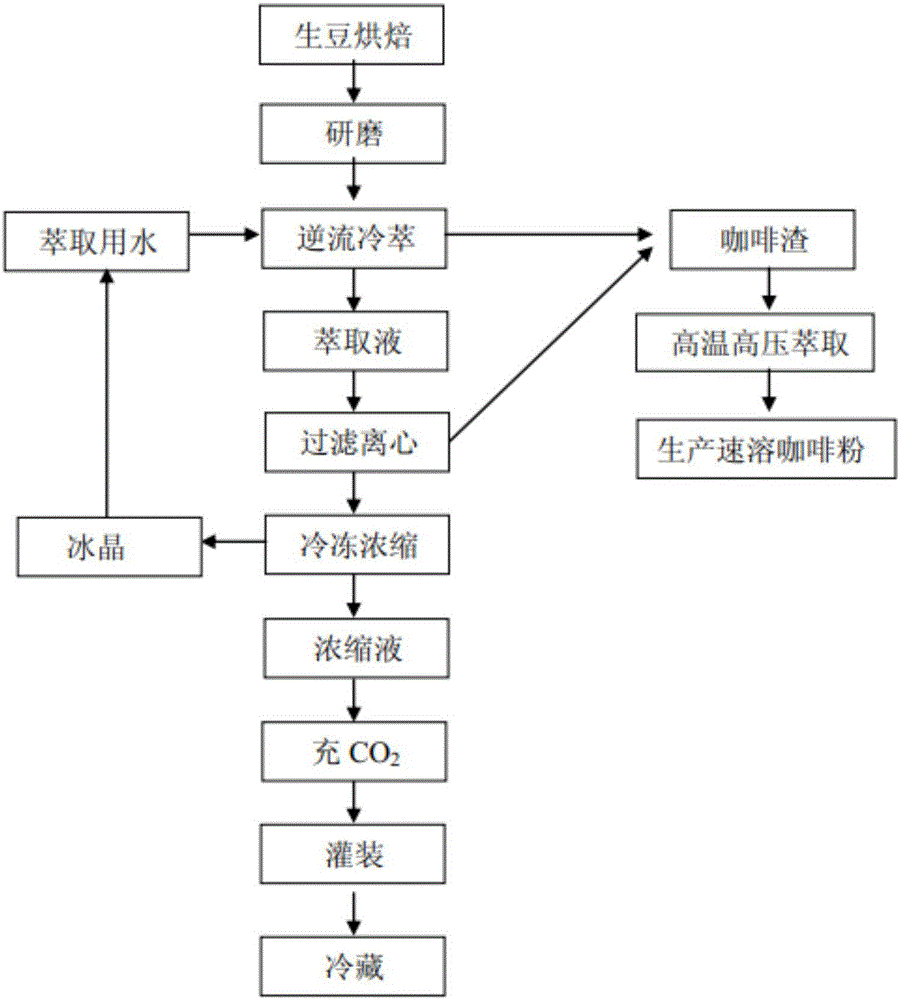

Method for producing high quality coffee concentrated solution

The invention discloses a method for producing high quality coffee concentrated solution. The method comprises the following steps of raw bean baking, grinding, countercurrent cold extraction, filtration centrifugation, freeze concentration, CO2 filling, filling and cold storage. The product is rich in coffee aroma, mellow in taste, pure in flavor and good in stability. Low temperature non-thermal processing technologies and CO2 filling are effectively combined, and the low temperature non-thermal processing technologies such as countercurrent cold extraction and freeze concentration are adopted to process the coffee concentrated solution, so that volatile aroma and active ingredients of coffee can be stored completely. The CO2 filling technology is adopted to isolate oxygen to prevent oil oxidation in the coffee concentrated solution and oxidation browning of nutrient substances, growth and reproduction of microorganisms are restrained, and even the microorganisms die due to damage of growth conditions. The low temperature non-thermal processing technologies and the CO2 filling are effectively combined, so that not only is the high quality of the coffee concentrated solution guaranteed, but also the stability problem of the coffee concentrated solution is effectively solved, the guarantee period of the coffee concentrated solution is prolonged, and the industrial production of the coffee concentrated solution is achieved.

Owner:DAMIN FOODSTUFF ZHANGZHOU CO LTD

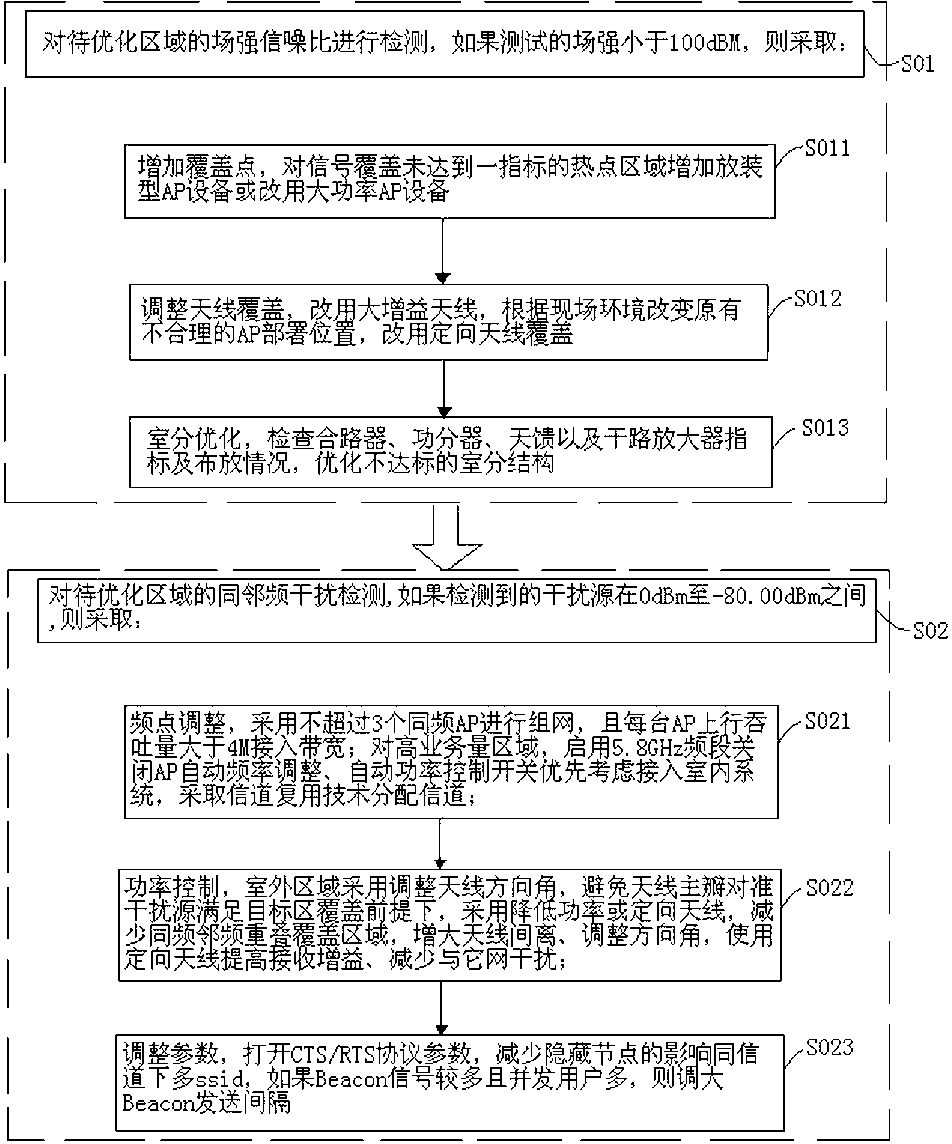

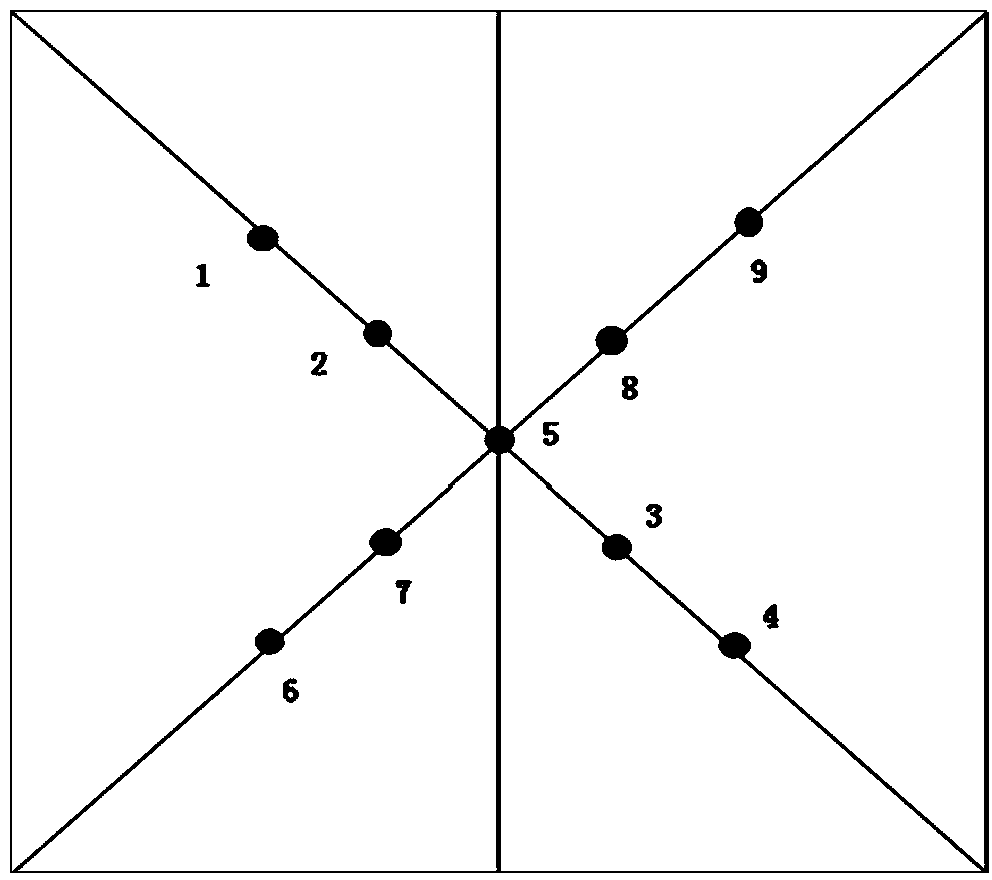

Wireless fidelity (WIFI) network optimization based on complex environment

ActiveCN103002481AGuaranteed qualifiedLittle satisfactionEnergy efficient ICTWireless communicationAdjacent-channel interferenceMultiplexing

The invention relates to wireless fidelity (WIFI) network optimization based on a complex environment. The WIFI network optimization is characterized by comprising a step S01 of detecting the field intensity signal to noise ratio of a to-be-optimized area, and if the measured field intensity is smaller than 100dBM, adding covering points, adding mounted type access point (AP) devices or using high-power AP devices for hot spot areas where signal coverage does not meet an index; a step S02 of detecting the same adjacent channel interference of the to-be-optimized area, and if a detected interference source is between 0dBm and 80.00dBm, performing frequency point adjustment, adopting no more than 3 common-frequency APs to perform networking, and enabling upstream throughput of each AP to be larger than 4M access bandwidth; for a high-business-volume area, starting a 5.8GHz frequency band to close AP automatic frequency regulation and automatic power control switches to give priority to access to an indoor system, and adopting a channel multiplexing technology to allocate channels. The WIFI network optimization can be achieved, a wireless access device can cover all areas expected to be covered, and the capability of adequately bearing an expected load is provided.

Owner:福建省邮电工程有限公司

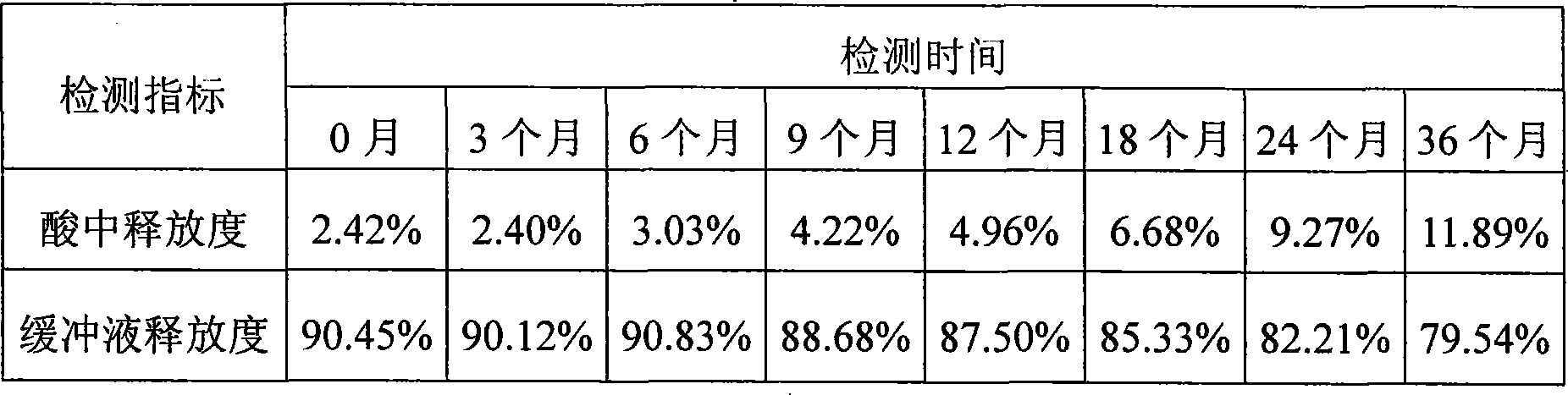

Erythromycin enteric-coated capsule and preparation thereof

ActiveCN101239051ASmooth releaseLittle change in releaseAntibacterial agentsOrganic active ingredientsBiotechnologyMicrobiology

The invention provides an erythromycin enteric-coated capsule and the preparation method. The invention is characterized in that: the component ratio of the enteric-coated liquid of the enteric-pellets capsules contained in the enteric-coated capsules counted by weight percentage is that: polyacrylic resin: II: 1, diethyl phthalate: 0.07 to 0.1, Tween-80:0.08 to 0.12, castor oil: 0.08 to 0.12, ethanol whose concentration is bigger than or equal to 95%: 12 to 14; all are counted as weight percentage. The invention conquers defects in the prior art, elevates the product quality, keeps the releasing degree of the product stable and guarantees the quality as well as healing effect of the product during the period of validity, and also the preparation is simple and convenient, the work efficiency is high and the quality of the products is quite well.

Owner:TIANSHENG PHARMA GROUP

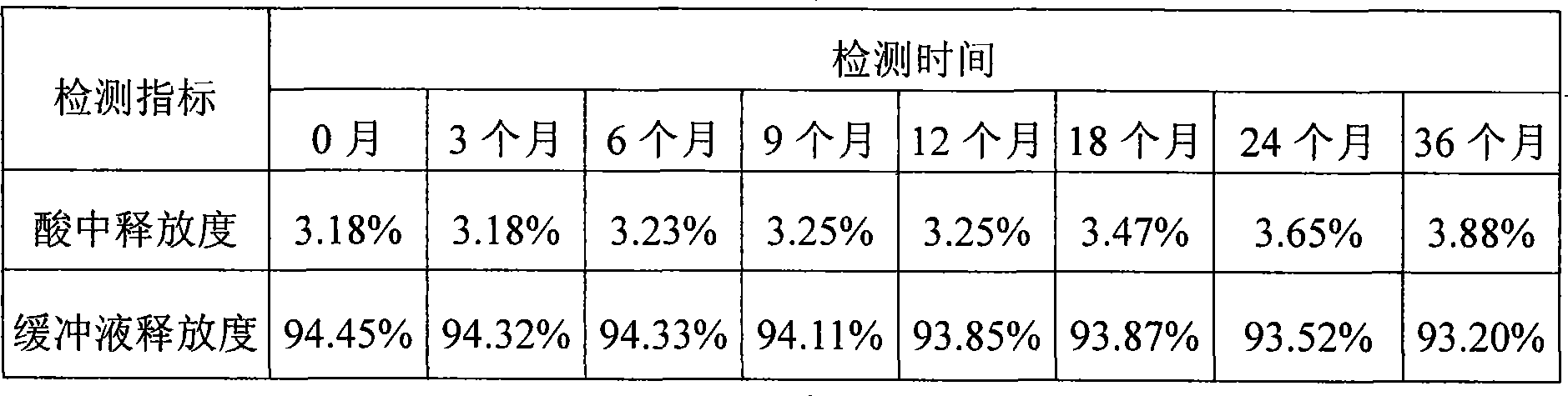

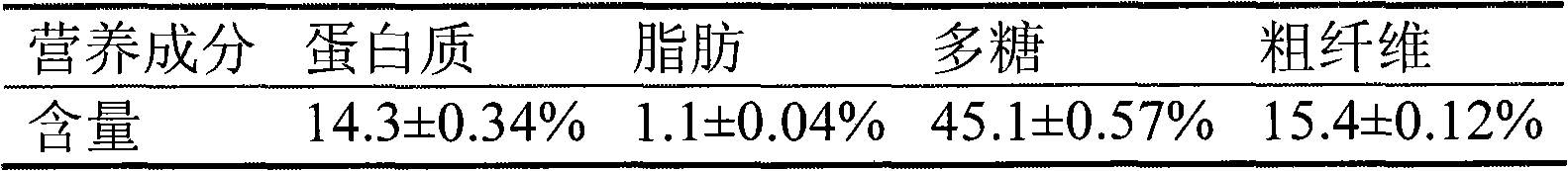

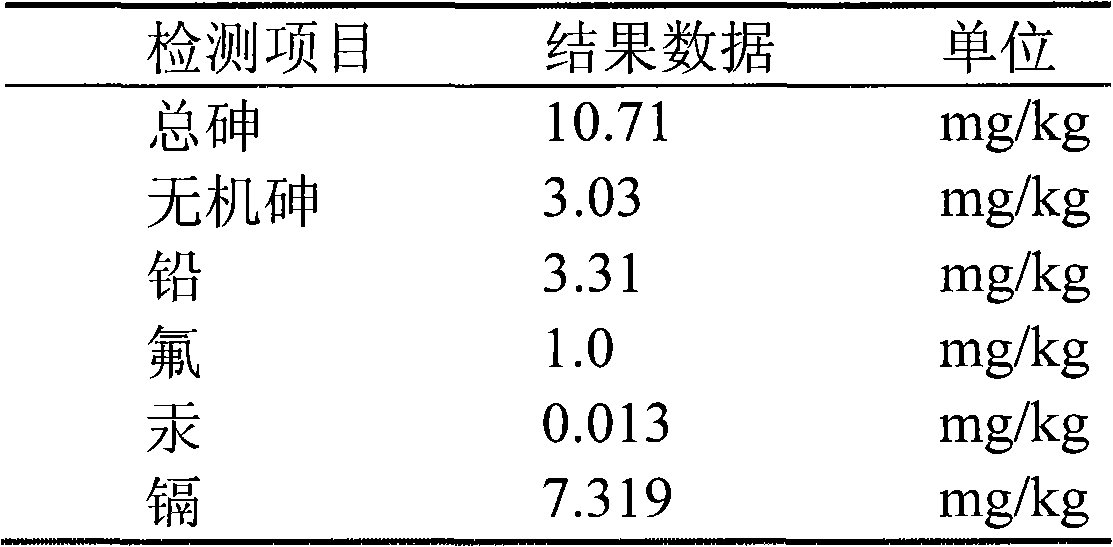

Preparation method of pure powder particles of enteromorpha feed additive

The invention relates to animal feed, in particular to a preparation method of pure powder particles of an enteromorpha feed additive. The preparation method comprises the following steps of: (1) primarily processing to remove impurities; (2) drying enteromorpha; (3) crushing the enteromorpha; (4) tempering; (5) pelletizing; and (6) cooling and drying to obtain the finished product of enteromorpha feed. The invention product has rich nutrition and good product quality.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

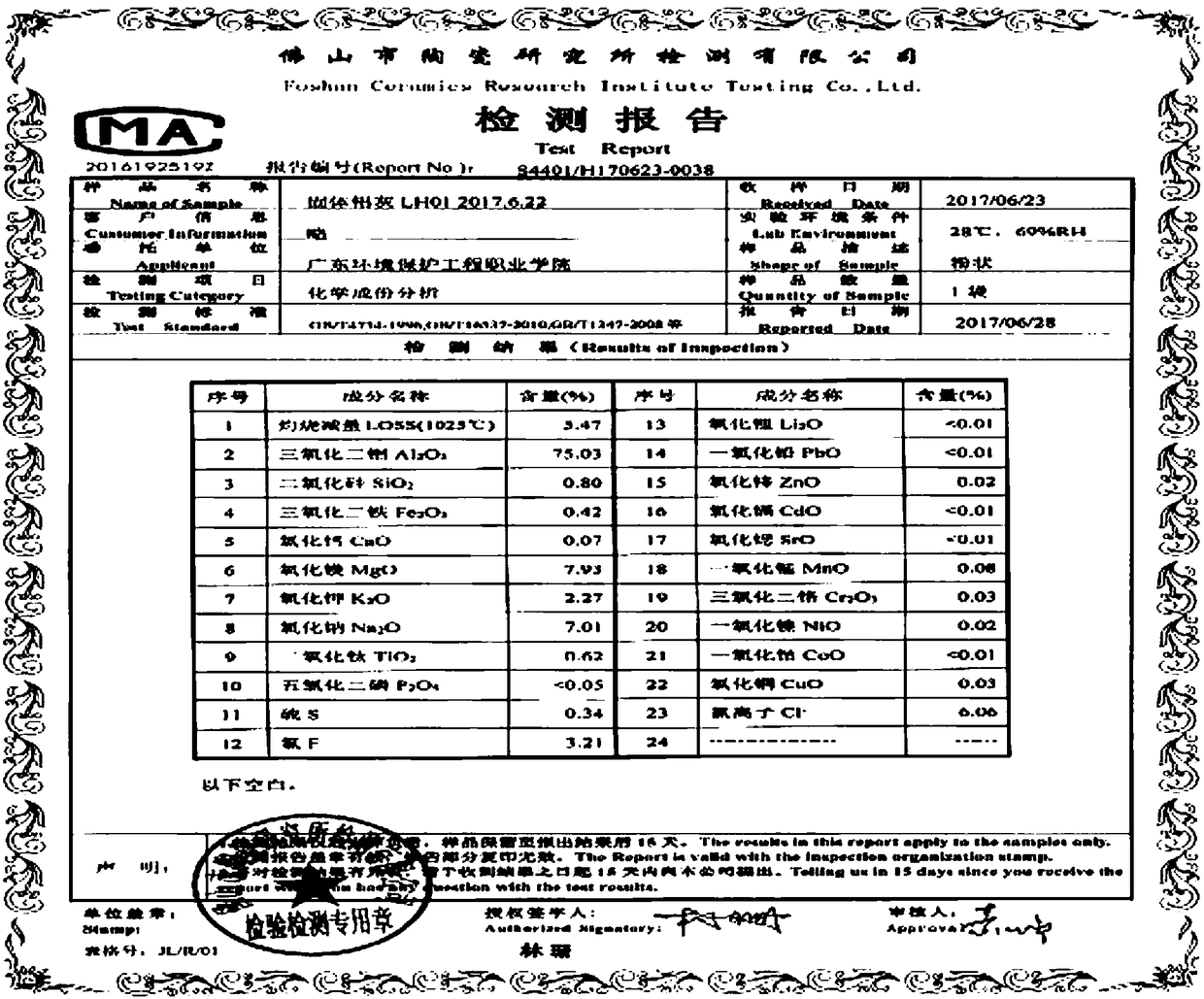

Oil removing and chromizing chemical agent compatibility and pollution reduction sprinkling system for slag reducing of aluminum industry

ActiveCN108166011ANot easy to hang ashNo precipitationMetallic material coating processesSlagZero emission

The invention discloses an oil removing and chromizing chemical agent compatibility and pollution reduction sprinkling system for slag reducing of the aluminum industry. An oil removing groove, a first non-flowing water washing groove set, a chromizing groove, a second non-flowing water washing groove set, a sprinkling groove and a drainage groove are included; an aluminum material sequentially passes through the oil removing groove, the first non-flowing water washing groove set, the chromizing groove, the second non-flowing water washing groove set, the sprinkling groove and the drainage groove; the oil removing groove and the second non-flowing water washing groove set are both communicated with the first non-flowing water washing groove set; oil removing liquid exists in the oil removing groove; chromizing liquid exists in the chromizing groove; the oil removing liquid and the chromizing liquid are mutually compatible; a first pump is further included; the sprinkling groove and thedrainage groove are both communicated with the second non-flowing water washing groove set through the first pump; and the first pump is used for pumping water in the sprinkling groove and the drainage groove into the second non-flowing water washing groove set. We pay attention to compatibility of selected components on the oil removing liquid for the first time. The oil removing and chromizingchemical agent compatibility and pollution reduction sprinkling system for slag reducing of the aluminum industry achieves waste water and waste slag zero emission during spraying and chromizing treatment and production water saving.

Owner:FOSHAN SANSHUI XIONGYING INNOVATION CENT FOR ALUMINUM SURFACE TECH

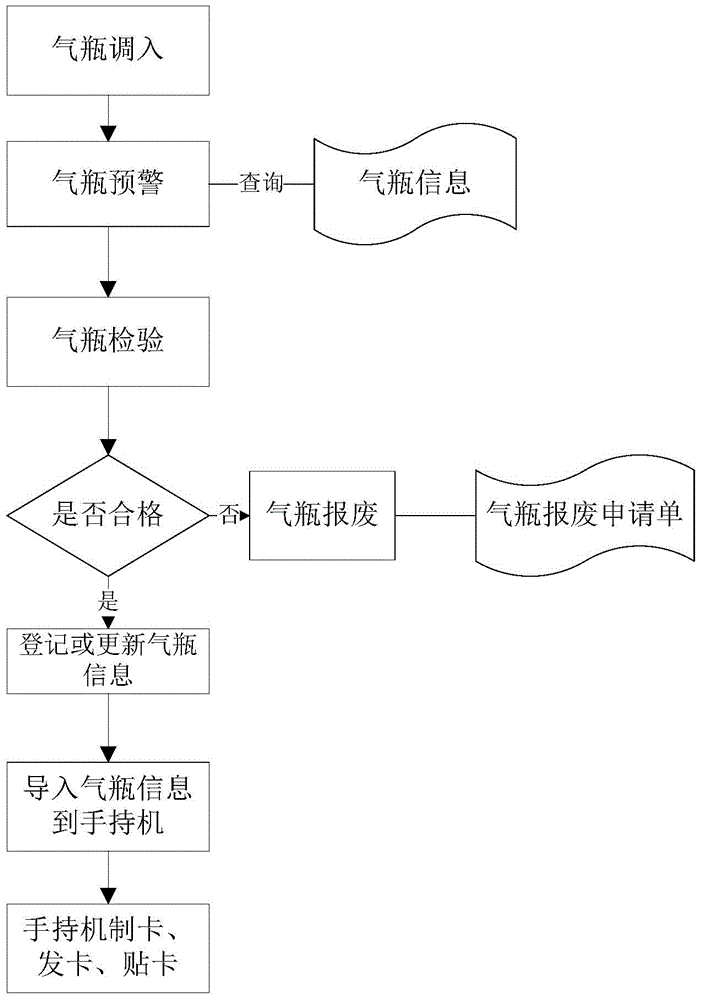

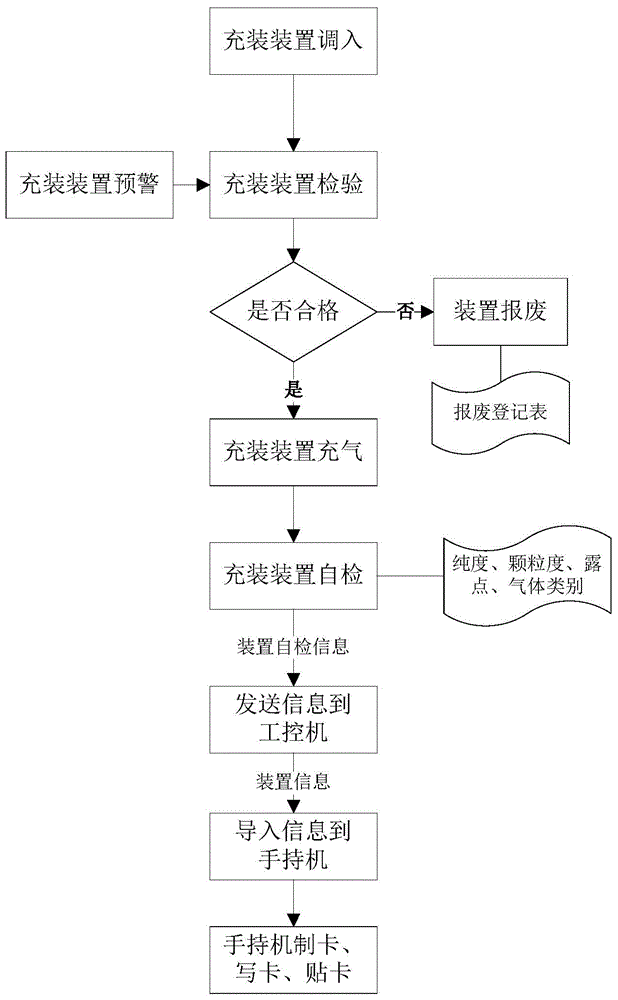

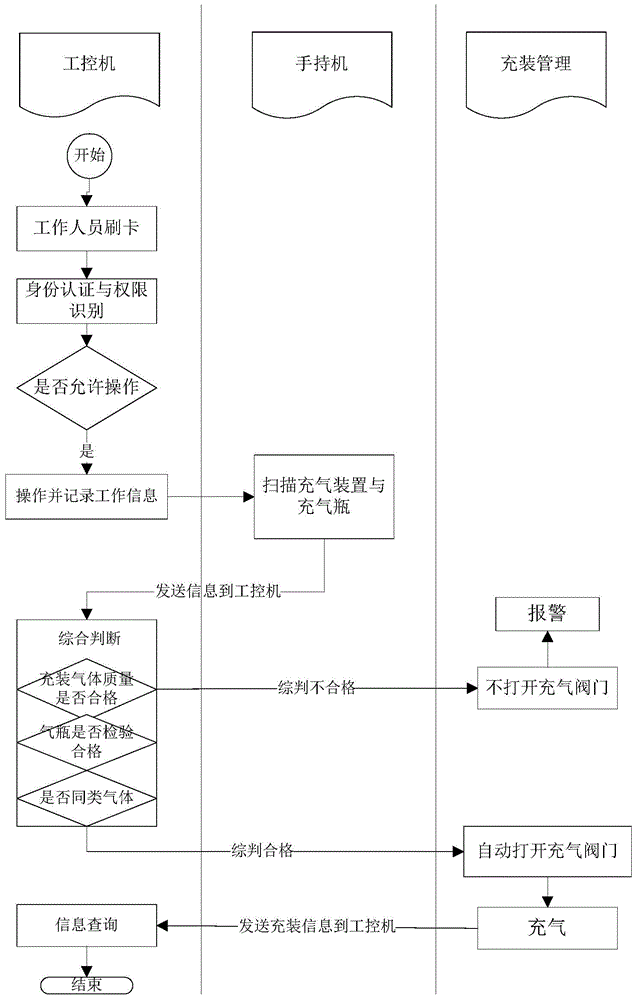

Gas cylinder safety supervision system and method

ActiveCN104021515ARealize automatic collectionImplement updateData processing applicationsGas cylinderProduct gas

The invention belongs to the technical field of communications and discloses a gas cylinder safety supervision system and a gas cylinder safety supervision method. A gas cylinder, a pressure gage and a safety valve are detected and supervised through radio frequency identification (RFID) electronic tags on the gas cylinder, the pressure gage and the safety valve, and the used products are qualified and do not exceed the period to serve or serve in spite of illness. Moreover, mixed loading and wrong loading accidents in the process of canning gases are avoided, and a safety supervision effect of charging the gas cylinder is finally achieved.

Owner:CHENGDU JIUZHOU ELECTRONIC INFORMATION SYSTEM CO LTD

90-degree bending mechanism for sheet metal stamping die

The invention provides a 90-degree bending mechanism for a sheet metal stamping die; the 90-degree bending mechanism comprises a lower floating block, a pressing plate, and a male bending unit, wherein the lower floating block is connected with a lower die through a lower pull rod and a lower nitrogen spring; the pressing plate is connected with an upper die through an upper pull rod and an upper nitrogen spring, and the male bending unit is used for 90-degree bending; the male bending unit is arranged at the lower die and is located beside the lower floating block; the pressing plate corresponds to the lower floating block and is arranged above the lower floating block; the male bending unit is hinged at the lower die in a form of capable of rotating inwards the die; an outwards convex inner inclined surface is arranged at an inner side of the top part of the male bending unit; an inwards concave outer inclined surface is arranged at an outer surface of the top part of the male bending unit; an outer side surface of the pressing plate is of an inwards concave inclined surface shape, and specifically is of an avoiding inclined surface used for avoiding the male bending unit; the bending mechanism provided by the invention is novel in structure; when performing the 90-degrees bending to a sheet metal component by using the bending mechanism, negative angle bending used for compensating bending springback is achieved on the basis of the 90-degree bending is finished by using one set of stamping die via one stamping process, so that a 90-degree bending angle is ensured to be qualified, and die cost is saved, and meanwhile, a stamping process is reduced.

Owner:XIANGXIN AUTOMOTIVE COMPONENT TOOL & DIE

Method for increasing chlorate decomposition efficiency

ActiveCN102634813AHeating evenlyImprove chlorate decomposition abilityElectrolysis componentsSaline waterDecomposition

The invention relates to a method for increasing chlorate decomposition efficiency, which belongs to the technical field of preparation of ion film caustic soda. The method is realized by means of improving the structures of steam heating tubes in a chlorate decomposition tank and adjusting parameters of a decomposition process. The steam heating tubes are arranged in double layers, the steam heating tubes on the lower layer upwards spray gas, the steam heating tubes on the upper layer downwards spray gas, and steam nozzles are uniformly arranged on the steam heating tubes. The process parameters include that the mass ratio of light salt brine for decomposing chlorate to outflow light salt brine of an electrolyzer is 1:1.4-1.6; preacid of the light salt brine after the light salt brine decomposes the chlorate is controlled in a range from 25g / l to 32g / l; and the temperature of the light salt brine in the chlorate decomposition tank ranges from 94 DEG C to 97 DEG C. Uniformity of the temperature in the chlorate decomposition tank is improved, decomposition stability is ensured, chlorate decomposition rate reaches 82-95%, and the content of the chlorate in the salt brine of a device is ensured to be qualified and stable.

Owner:SHANDONG DONGYUE FLUO SILICON MATERIALS CO LTD

Steel for boron-containing prestressed steel wires and steel strands and smelting process thereof

ActiveCN103834848AGuaranteed qualifiedQuality improvementManufacturing convertersProcess efficiency improvementSmelting processBoron containing

The invention belongs to the technical field of smelting, and particularly relates to a smelting process of steel for boron-containing prestressed steel wires and steel strands. The process comprises the following steps: preparing molten iron, waste steel and raw iron serving as raw materials; during smelting of a revolving furnace, adding slag charge, performing the operation of raising high carbon content and post blowing, controlling the end point C over 0.4 percent, and controlling the end point P below 0.015 percent; during steel tapping of the revolving furnace, adding silicon carbide, lime and an alloy serving as deoxidizing materials in sequence along with the steel flow; during refining, deoxidizing the top of the slag by adopting the silicon carbide, wherein the target refining final alkalinity is 1.7; after refining, performing soft argon blowing at the bottom of a steel ladle; during continuous casting, feeding Xibao special high-carbon steel protection slag to a crystallizer; and electromagnetically stirring the crystallizer, casting at a low superheat degree, performing forced cooling during secondary cooling, and electromagnetically stirring at the tail end. By adopting the smelted steel for the boron-containing prestressed steel wires and the steel strands, qualification of chemical components can be ensured. During pulling and twisting of parent metal, the fracture times due to generic defects, sundries and carbon segregation on the surface of a casting blank can be reduced effectively.

Owner:ZENITH STEEL GROUP CORP

Aluminum alloy pipe for coal mine column and preparation method thereof

Aluminium alloy tubes for pillar for coal mine and a method for preparation, relate to the tubes and a method for preparing the same. The invention solves the problem that the existing tubes for pillar for coal mine have low bearing capacity. The tubes of the invention comprises, based on weight percentage, Si of 0-0.04%, Fe of 0-0.04%, Cu of 0.55-0.99%, Mn of 0.15-0.35%, Mg of 2.6-2.9%, Zn of 4.60-5.20%, and the residuel of Al. The method includes: 1) hollow cast ingot made of, based on weight percentage, Si of 0-0.04%, Fe of 0-0.04%, Cu of 0.55-0.99%, Mn of 0.15-0.35%, Mg of 2.6-2.9%, Zn of 4.60-5.20%, and the residuel of Al; 2) extruding to form hollow tubes; 3) quenching the extruding formed hollow seamless tubes; 4) hot treatment and roller straightening to produce aluminium alloy tubes for pillar for coal mine. The tubes produced by the method of the invention have tensile strength of 470 Mpa, yield strength of 420 Mpa, while wear property and service life of the tubes are improved.

Owner:NORTHEAST LIGHT ALLOY CO LTD

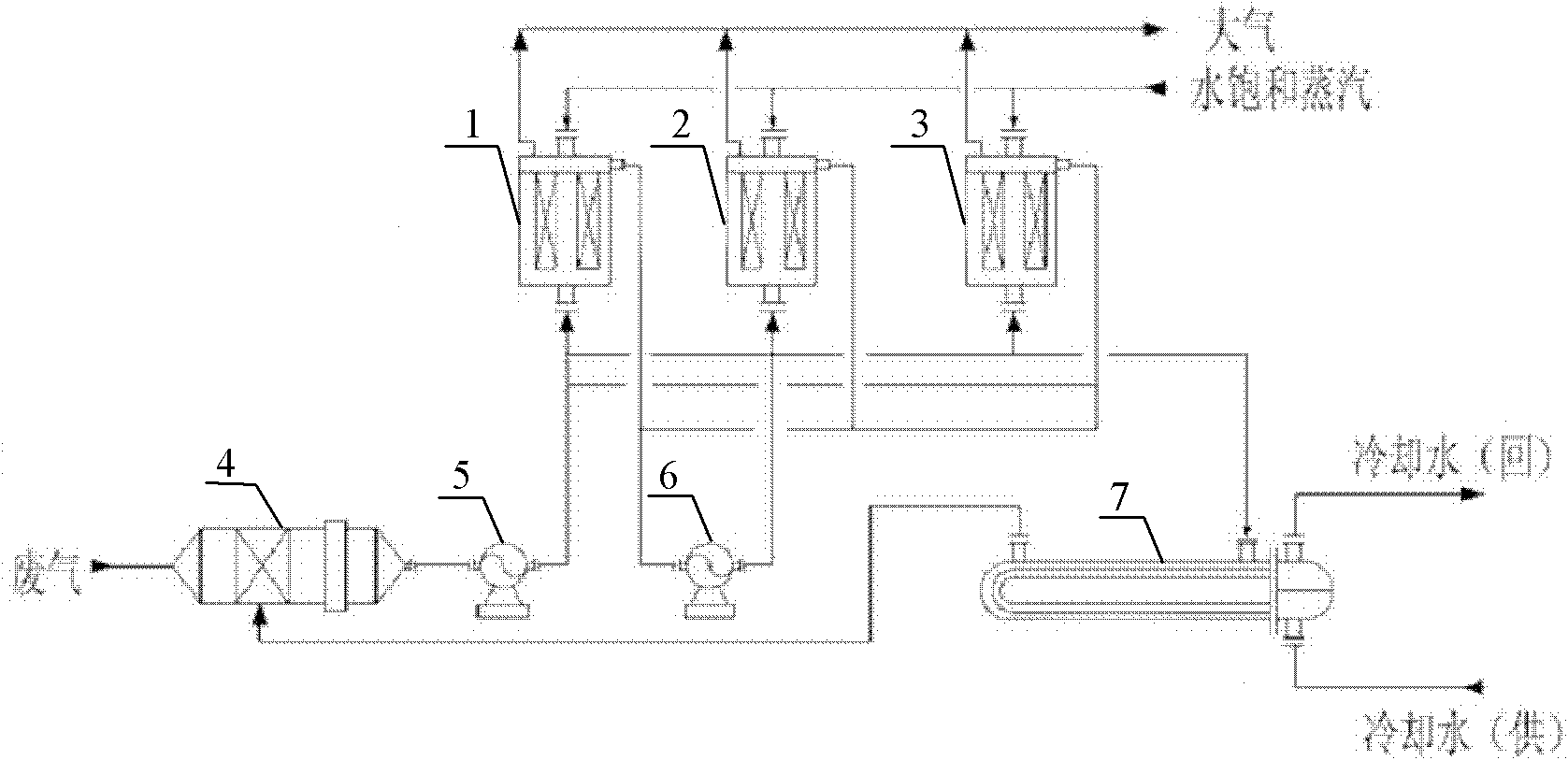

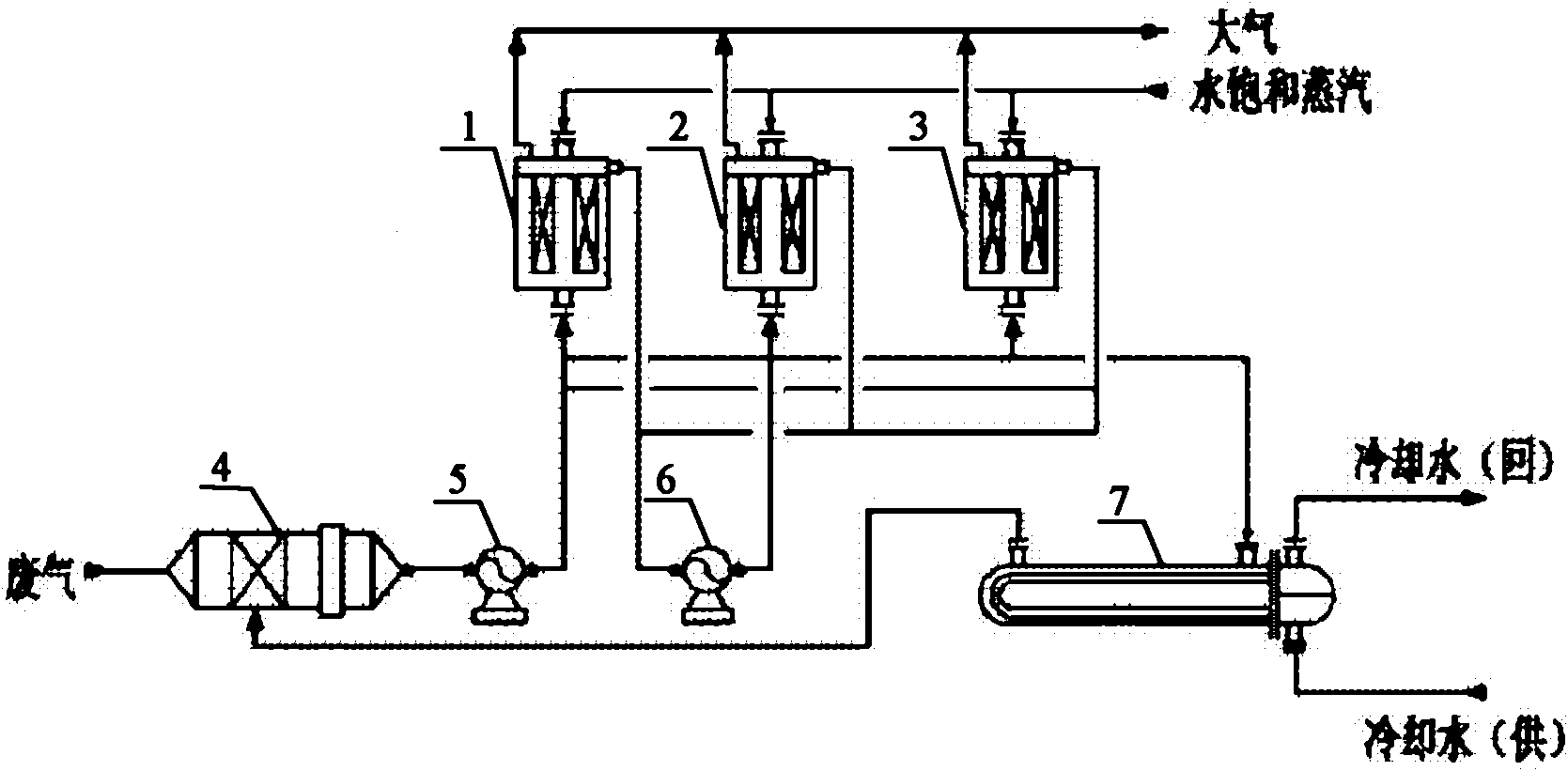

A treatment method for waste gas in chemical acrylamide production

The invention relates to a method for processing waste gas in acrylamide production by a chemical method. In the method, a waste gas is fed into a waste gas precooler to cool the waste gas to be 10-30 DEG C.; the cooled waste gas is fed into a waste gas adsorber which is formed by serial connection of three adsorbers; a medium filled in the adsorber is powdery active carbon, granular active carbon or fibrous active carbon; two of the three adsorbers simultaneously work online in a serial connection manner; the adsorbed waste gas is discharged into atmosphere directly; and the other adsorber resolves the acrylamide adsorbed on the adsorbing medium by using saturated steam; after being cooled by a recovered acrylamide cooler, the resolved acrylamide and the steam are recycled; the three adsorbers perform adsorption resolving operations in turn and switch automatically. The waste gas processed by the method can reach the environmental protection emission standard, and post-treatments such as burning or oxidation and the like are not needed; investment and process consumption are reduced; a greatest amount of acrylamide is recovered; and aims of saving energy and reducing emission are fulfilled.

Owner:PETROCHINA CO LTD

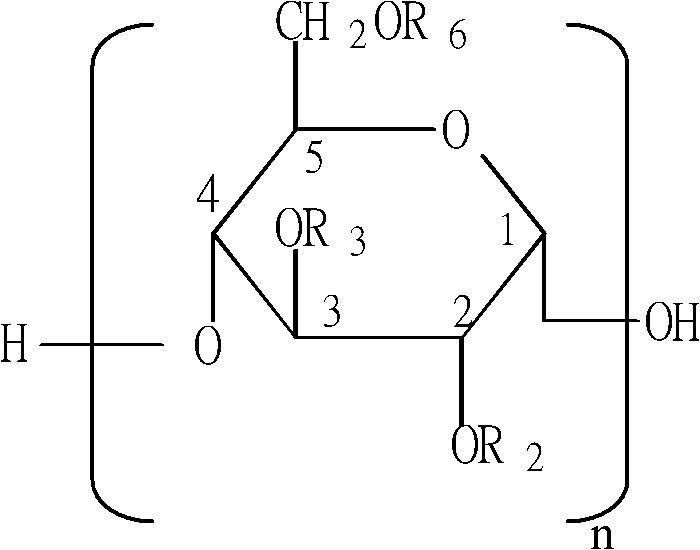

A clean production method of medium molecular weight hydroxyethyl starch

The invention provides a clean production method of medium molecular weight hydroxyethyl starch, in particular to a clean production method in the refining process of chemical raw materials hydroxyethyl starch 200 / 0.5 and hydroxyethyl starch 130 / 04 used for plasma expanders. Bacterial endotoxin is the key toxic substance leading to clinical infusion pyrogenic reaction. The bacterial endotoxin in the raw material drug of hydroxyethyl starch exceeds the limit, which can easily lead to the limit of bacterial endotoxin in the final product of the preparation, hydroxyethyl starch injection, and the unqualified rate increases. The method of the invention is controlled by necessary process conditions such as clean air spray drying under clean conditions, microbial control under high temperature conditions, and on-line cleaning and disinfection of equipment, so that the quality of the bacterial endotoxin index of the obtained final product is obviously better than the current national drug quality standards. At the same time, it provides the necessary conditions for the direct preparation method of raw materials without microfiltration, which is helpful for the qualification of the insoluble particle index of the preparation, shortens the process flow of the final preparation, and reduces the probability of pollution.

Owner:WUHAN HUST LIFE SCI & TECH

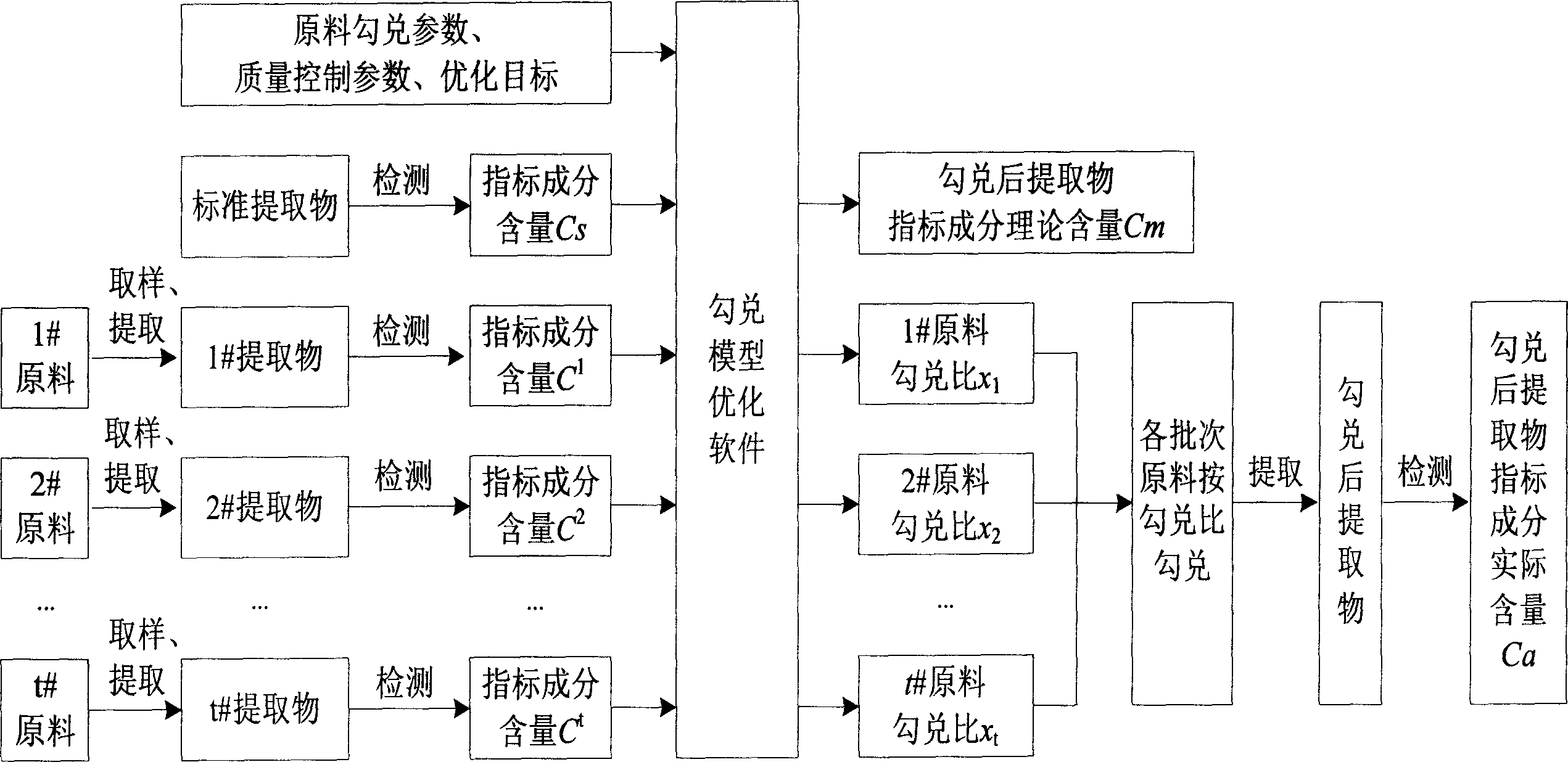

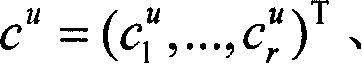

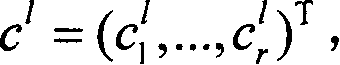

Method for preparing Chinese herbs or natural product to make extract component stable

The present invention relates to a method for blending Chinese medicinal material or natural product to make its extract component content be stable. Said method includes the following steps: 1), defining target component and its content of Chinese medicinal material or natural product standard extract; 2), defining relative deviation range of its target component content when its extract quality is acceptable after the Chinese medicinal material or natural product is blended; 3), sampling and extracting every batch of Chinese medicinal material or natural product to be blended, determining its target component content; 4), defining blending parameter, quality control parameter and blending target of Chinese medicinal material or natural product so as to form constrained optimization problem; 5), resolving constrained optimization problem to obtain optimum blending ratio; and 6), mixing Chinese medicinal material or natural product according to optimum blending ratio, making extraction so as to obtain the extract whose target component content is acceptable. Said method can be extensively used in production process of Chinese medicine, natural product, biological product, wine, beverage, health-care product, flavouring product, edible oil, fuel oil, gas and feed, etc.

Owner:TSINGHUA UNIV

Water treatment method for reducing chlorpyrifos pollution

InactiveCN102040298AEfficient removalAvoid cloggingMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationActivated carbonAluminium chlorohydrate

The invention discloses a water treatment method for reducing chlorpyrifos pollution, relates to the water treatment method, and solves the problems of blockage of a filter tank and low removal efficiency which are caused by an oxidation method or a filter process for removing chlorpyrifos in water by using powdered activated carbon. The method comprises the following steps of: 1, adding wood powdered activated carbon emulsion into a water intake of water to be treated to keep the wood powdered activated carbon content in the water at 10 to 60mg / L; 2, adding a polyaluminium chloride coagulant after the water treated in the step 1 passes through a stable pressure well and before the water passes through a reaction tank; and 3, sterilizing the water which is treated in the step 2 and passes through the reaction tank, a sedimentation tank and a sand filter tank to obtain outlet water. By the method, the chlorpyrifos in the water (the removal rate of the chlorpyrifos in the water is more than 89 percent) can be effectively removed; meanwhile, the problems of blockage of the filter tank and floating residues in the water which are caused by the adsorbed powdered activated carbon in the filter process are solved, and the quality of the outlet water is improved.

Owner:HARBIN INST OF TECH

Smelting method for improving quality of 20CrMnTi gear steel continuous casting molten steel

InactiveCN108300833ASmelting success guaranteeShorten smelting timeElectric furnaceProcess efficiency improvementManganeseChromium Alloys

The invention discloses a smelting method for improving quality of 20CrMnTi gear steel continuous casting molten steel. The smelting method comprises the following steps that 1, 30% or above of molteniron is added into a LF refining electric furnace; 2, lime is added as a slag material, and it is guaranteed that in the whole smelting process of the electric furnace, foaming slag submerged arc operation is adopted; 3, the C content of the tapped molten steel is controlled to be greater than or equal to 0.05%, the P content of the tapped molten steel is controlled to be less than or equal to 0.010%, and the temperature is controlled to be higher than 1630 DEG C; 4, silicon and manganese alloy and medium carbon and chromium alloy are added to a steel ladle before tapping, and baking is conducted; 5, tapping side deoxidation is conducted; 6, the tapping time of a tapping hole of the electric furnace is controlled to be longer than 110 seconds; 7, after tapping is completed, argon gas blowing is quickly adjusted to soft blowing; and 8, the deoxidation rules are that aluminum residue balls and calcium carbide are added before tapping, and silicon-calcium-barium and aluminum-iron-steel are added after 20 tons of the molten steel is tapped, wherein the tapping time is 140+ / -10 seconds. By means of the smelting method, the smelting process is optimized; chemical components, the aluminum content and deoxidation are strictly controlled, so that the smelting time of the refining furnace is shortened; quality of the molten steel and quality of a continuous casting blank are improved; and it is guaranteed that the continuous casting, purity, the grain size and the banded structure of the steel are all qualified.

Owner:XINJIANG BAYI IRON & STEEL

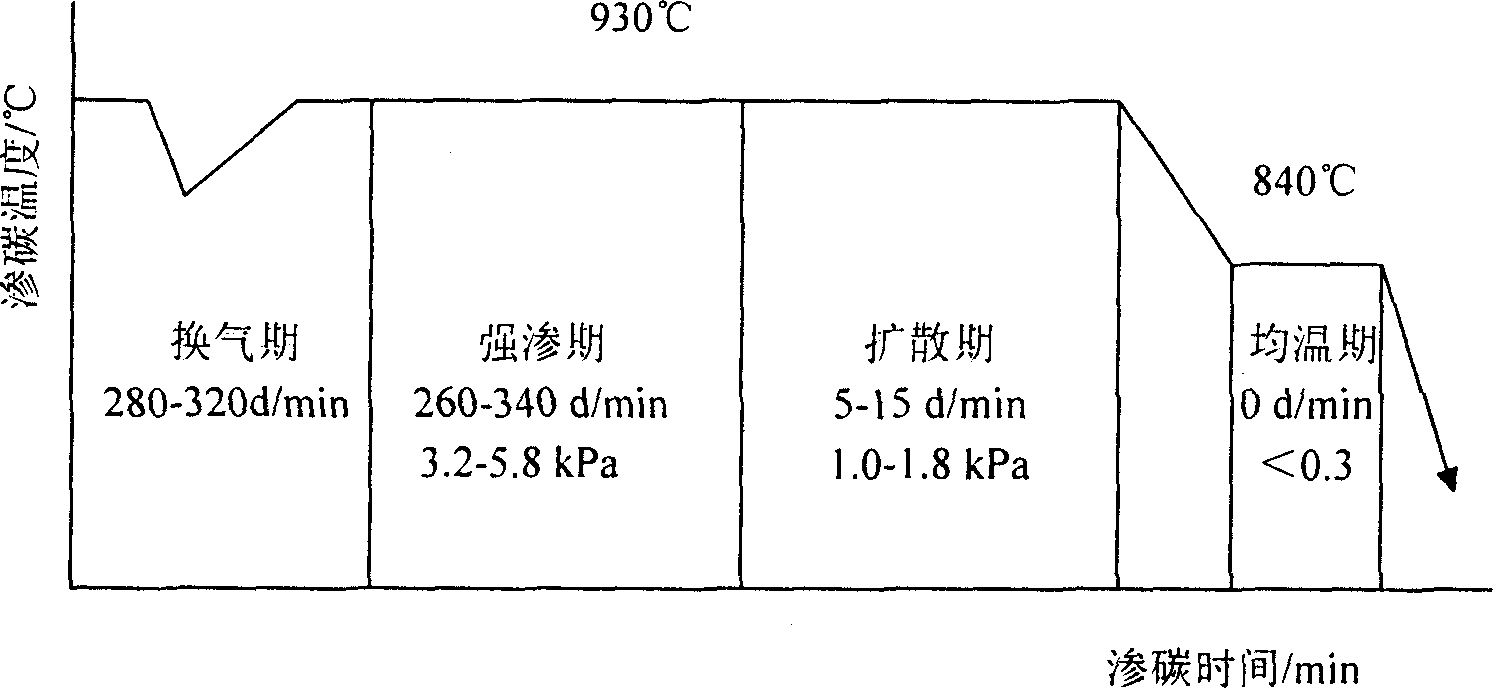

Whole process variable pressure controlled carburation method

InactiveCN1624189AGuaranteed depthMeet other requirements such as metallographic structureSolid state diffusion coatingPositive pressureKerosene

A carbonizing method with variable-pressure control in whole procedure for high carbonizing quality features that above the carbonizing furnace, the high-flow kerosene drip method is used to increase the positive pressure in furnace for generating high-activity high-carbon atmosphere and high furnace pressure, which can speed up the carbonizing on the surface of workpiece, and the furnace pressure can be regulated for controlling the carbonized depth, hardness and metallographic structure of workpiece.

Owner:ZHONGYUAN ENGINEERING COLLEGE

Rapid production process of organic fertilizer

ActiveCN102180718AShorten fermentation timeProlong fermentation timeBio-organic fraction processingOrganic fertiliser preparationWork in processOrganic fertilizer

The invention discloses a rapid production process of an organic fertilizer, which includes the following steps: (1) pre-fermentation that specifically includes the following working procedures: (1-1) mixing of raw materials and auxiliary materials, (1-2) drying and (1-3) pre-fermentation; (2) fermentation; (3) sampling and testing that are conducted according to NY525-2002 standards, and follow-up operation after testing results are qualified; (4) grinding and screening, namely grinding and screening semi-finished products sampled and tested to be qualified, and putting the semi-finished products into a warehouse for the semi-finished products; (5) post-fermentation: piling up the semi-finished products with moisture content dropping to 25-30% wt, and conducting post-fermentation while preventing the rain; (6) packaging, namely mechanical or manual packaging, sealing and palletizing; and (7) loading and delivery, namely mechanical or manual loading of packaged products, and delivery.The rapid production process of the organic fertilizer can ensure high drying efficiency of the raw materials, the auxiliary materials and the semi-finished products, has the advantages of low energyconsumption, deodorization, and good effect in killing flies and maggots, and saves fermentation time.

Owner:北京养鸡业协会 +1

Tool special for assembling and disassembling contact finger of disconnecting switch

The invention discloses a tool special for assembling and disassembling a contact finger of a disconnecting switch. The tool comprises a bottom plate, a first upright plate, a second upright plate, a rotating shaft, a first contact finger clamping device, a handle, a second contact finger clamping device and a toothed plate baffle plate, wherein the first upright plate and the second upright plate are fixedly and oppositely arranged on the two sides of the right side of the bottom plate; the rotating shaft penetrates through the first upright plate and the second upright plate; the first contact finger clamping device is sleeved on the rotating shaft; the handle is fixedly arranged on the first contact finger clamping device; the second contact finger clamping device is fixedly arranged on the left side of the bottom plate; the toothed plate baffle plate is arranged between the first contact finger clamping device and the second contact finger clamping device; the first contact finger clamping device and the second contact finger clamping device are provided with clamping components used for clamping the contact finger; and when the handle is rotated, the first contact finger clamping device can be rotated along the rotating shaft. By adopting the tool, the cooperation among the contact finger, a compression spring, a pin and a toothed plate can be enhanced, and an opening of the contact finger can be pressed open with less effort.

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD MAINTENANCE CO +2

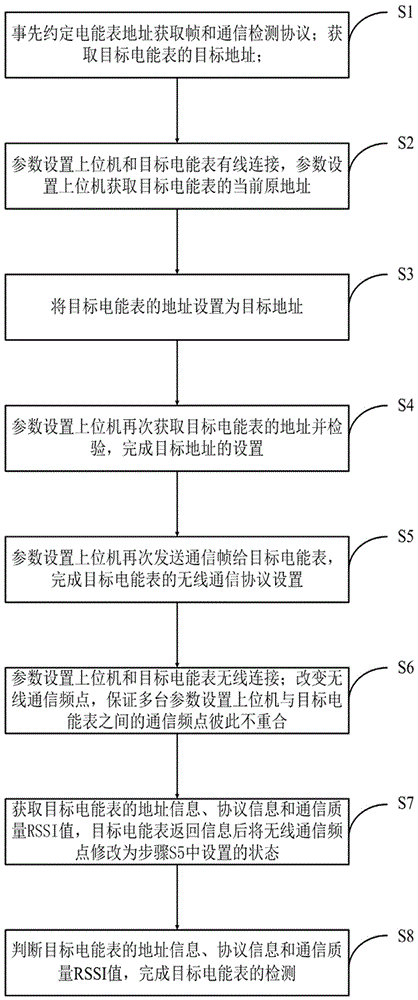

Parameter setting and detection method for electric energy meter batch production

ActiveCN105763376AGuaranteed reliabilityGuaranteed qualifiedTransmission monitoringData switching networksElectricity meterWireless communication protocol

The invention discloses a parameter setting and detection method for electric energy meter batch production. The method comprises steps: an electric energy meter address acquisition frame and a communication detection protocol are appointed, and a target address of a target electric energy meter is acquired; the current original address of the electric energy meter is acquired; the address of the target electric energy meter is set to be the target address; setting of a wireless communication protocol for the target electric energy meter is completed; a wireless communication frequency point is set; the address information, the protocol information and the communication quality RSSI value of the target electric energy meter are acquired, and the target electric energy meter changes the wireless communication frequency point to be in the state set in the fourth step; and detection on the target electric energy meter is completed. Parameter setting is changed into wired communication setting, communication frequency points of multiple production lines are staggered, a communication method of adding the communication quality RSSI value on the basis of the existing communication protocol is provided, electric energy meter parameter setting can be completed quickly and successfully, the leaving-factory parameter and the communication circuit of the electric energy meter can be ensured to be qualified, the cost is low, and the reliability is high.

Owner:WASION GROUP HLDG

Method for producing oxidized pellets from gold ore tailings and limonite

The invention provides a method for producing oxidized pellets by using gold ore tailing and limonite. The method comprises the following steps of: mixing 40 percent by weight of powder of the gold ore tailing, 30 percent by weight of powder of the limonite and 30 percent by weight of powder of magnetite respectively to prepare green pellets; preheating in a chain grate; feeding in a rotary kiln to fire and shape; and finally, cooling through a circular cooler to prepare oxidized pellets, wherein the iron content of the pellet finished product reaches 53 percent. In the method, by rationally proportioning the gold ore tailing, the limonite and the magnetite and rationally setting process parameters, and prolonging the time of the green pellets at a low-temperature section of 200-400 DEG Cof the chain grate, the strength of the green pellets is improved, the cracking temperature of the green pellets during preheating is also increased by 45-50 DEG C, qualified green pellets are obtained, and the green pellets are finally fired through the rotary kiln to prepare the final oxidized pellets.

Owner:山东瑞拓球团工程技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com