Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

115results about How to "Increase boost pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

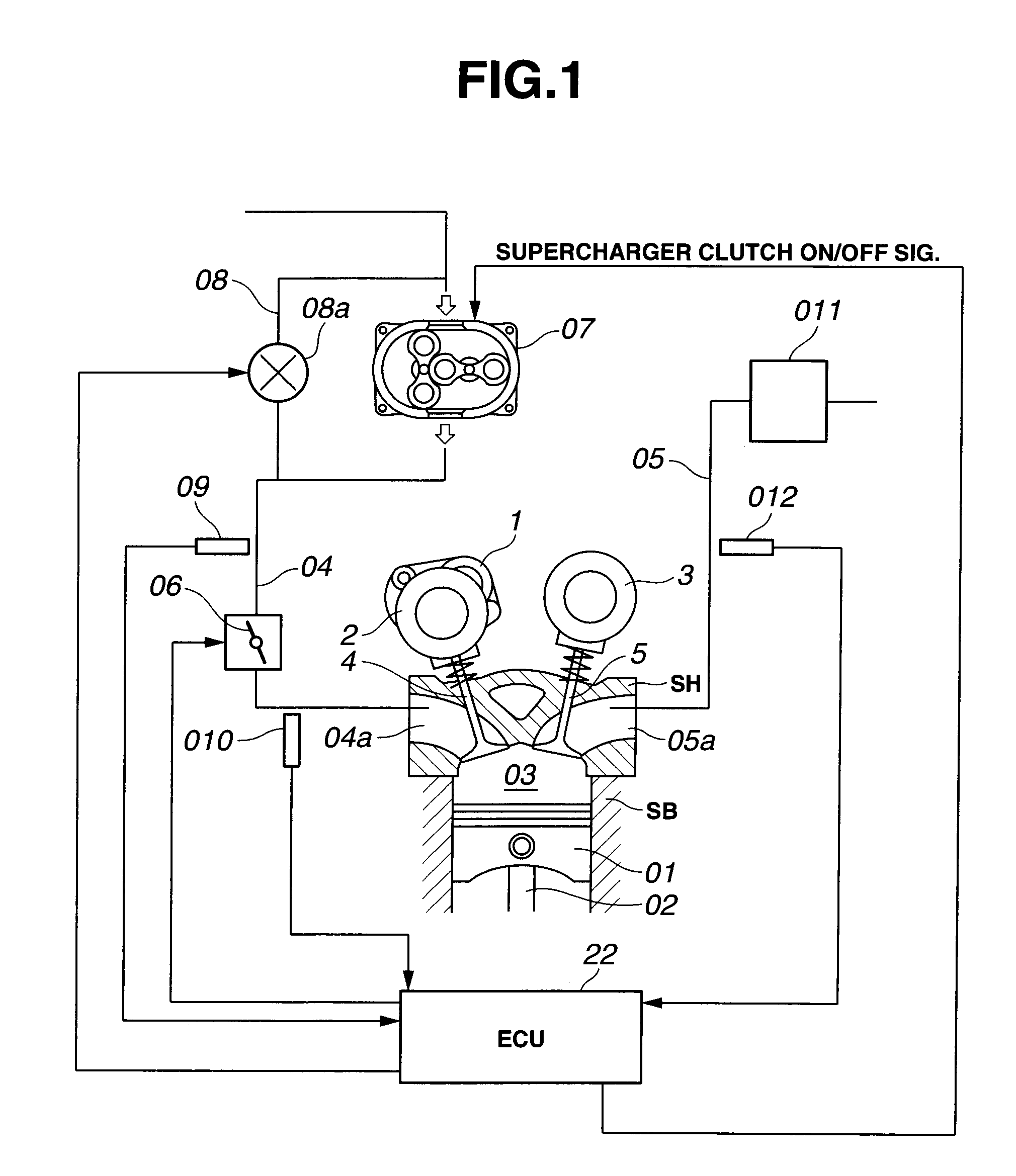

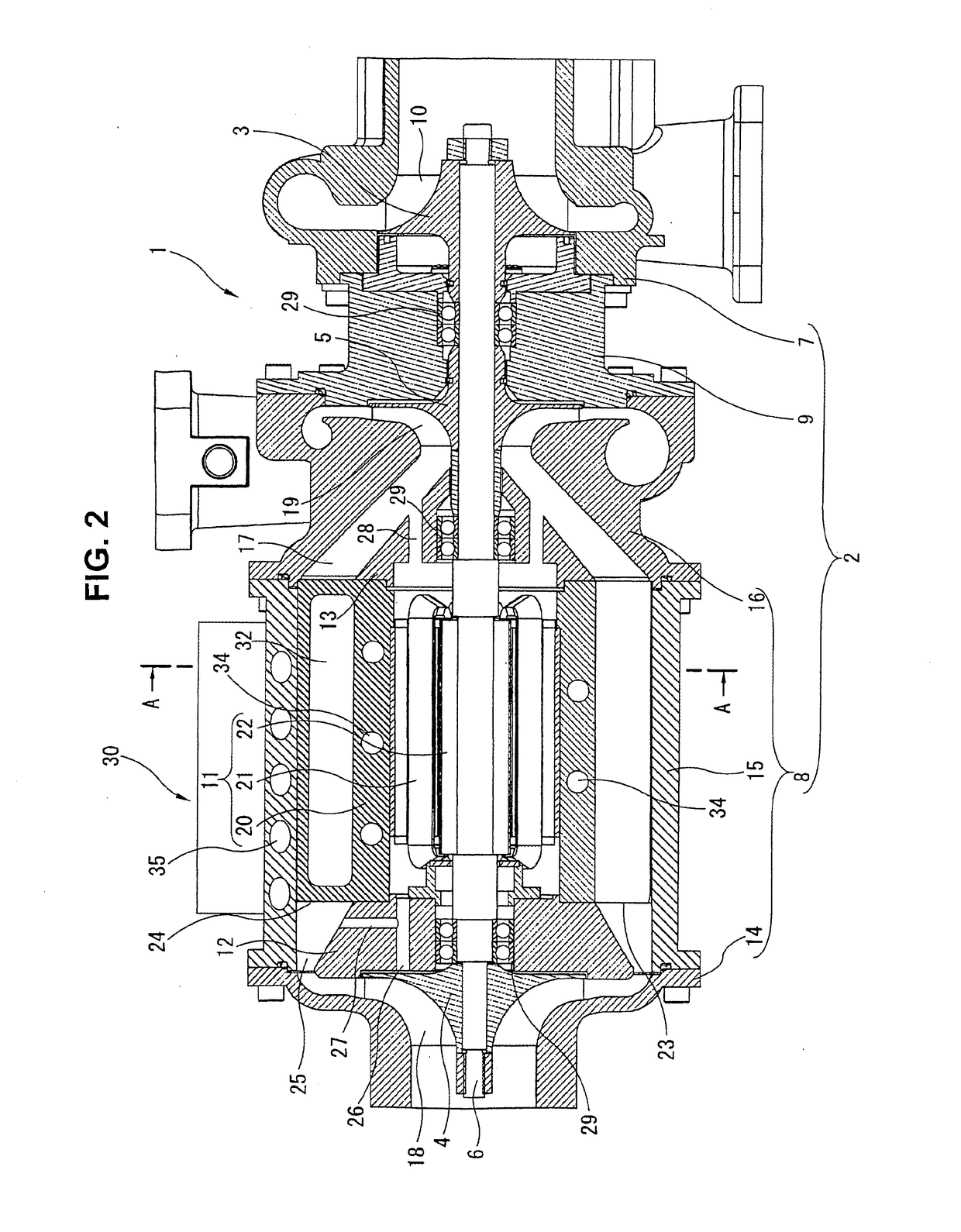

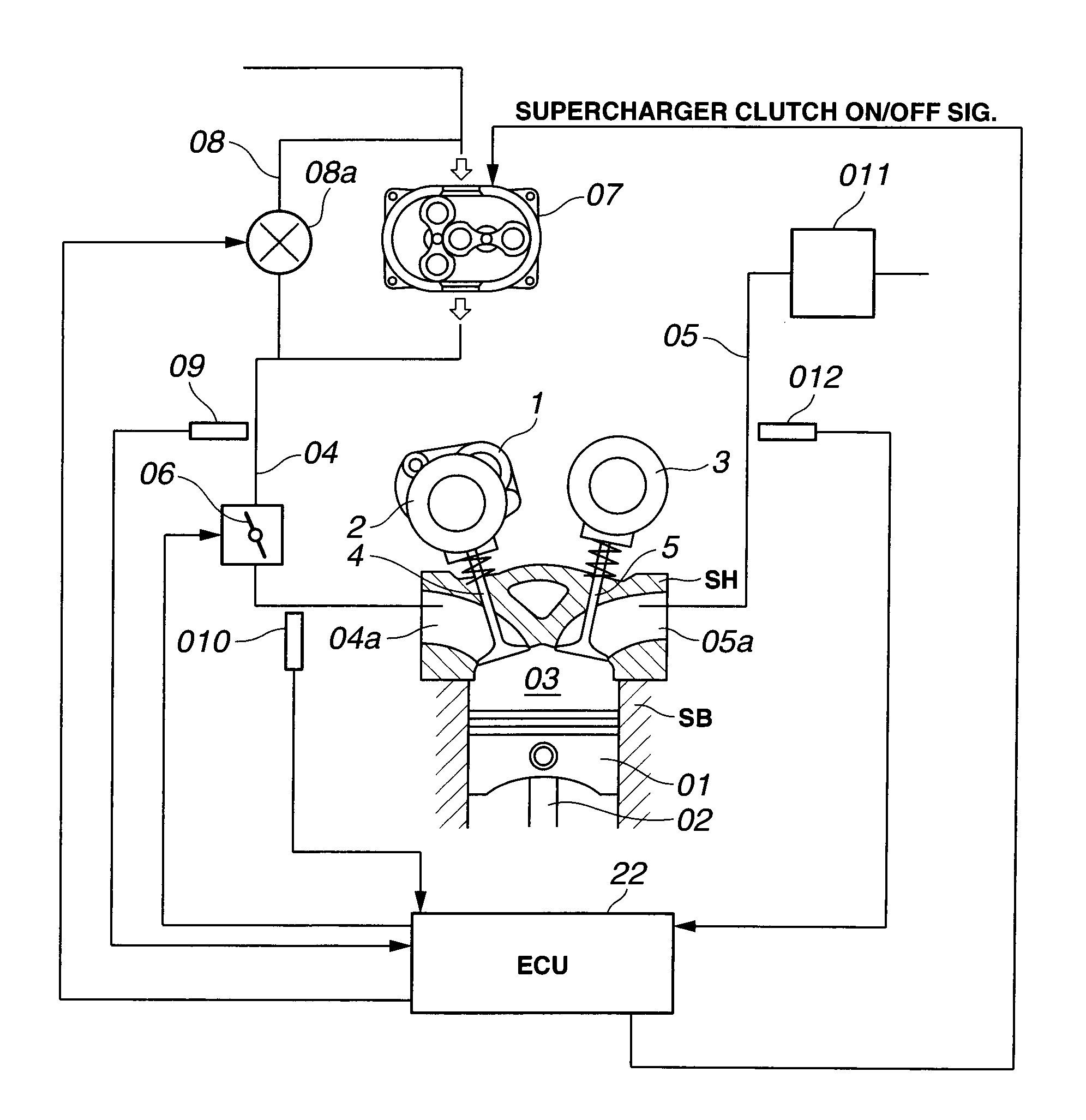

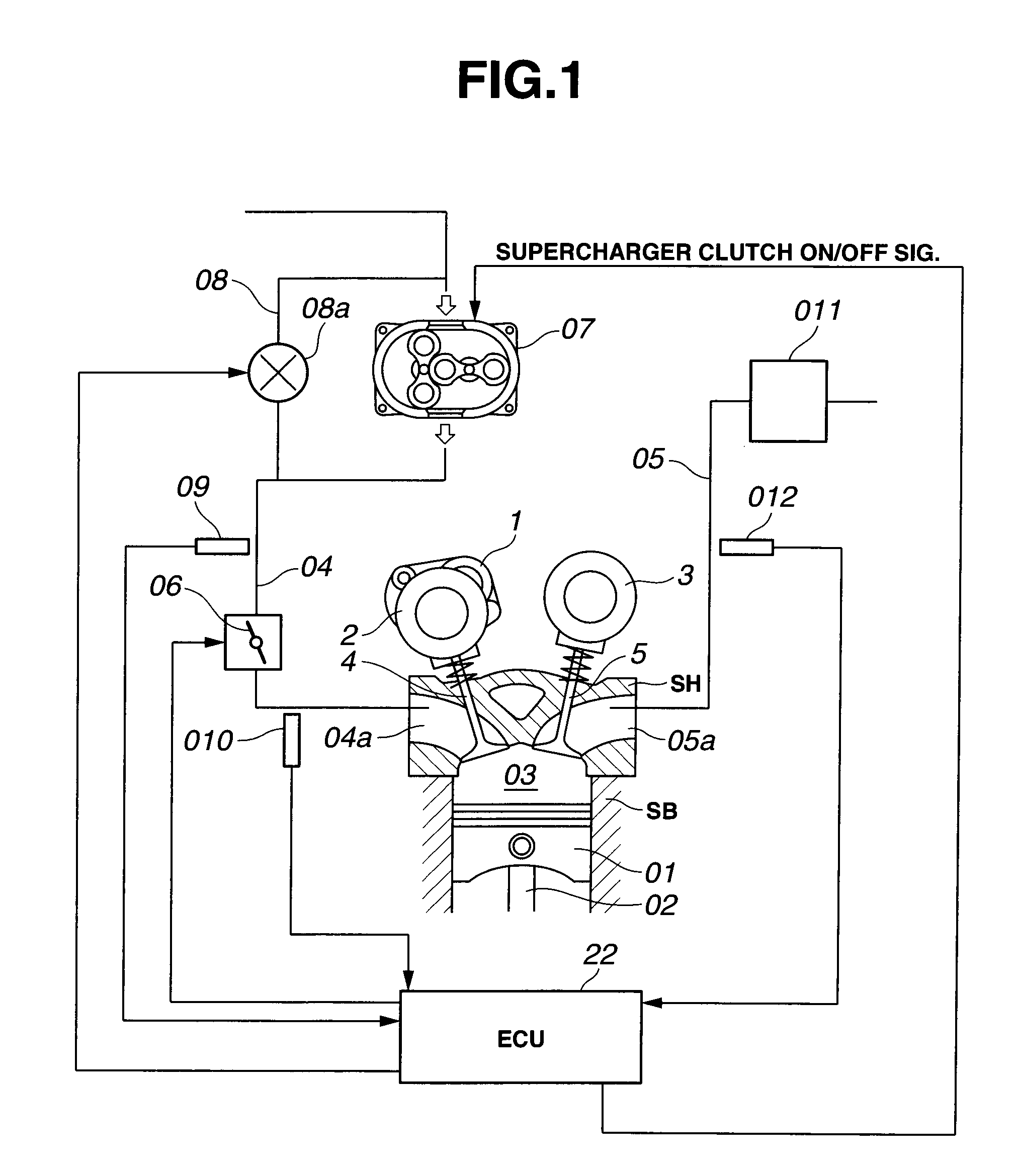

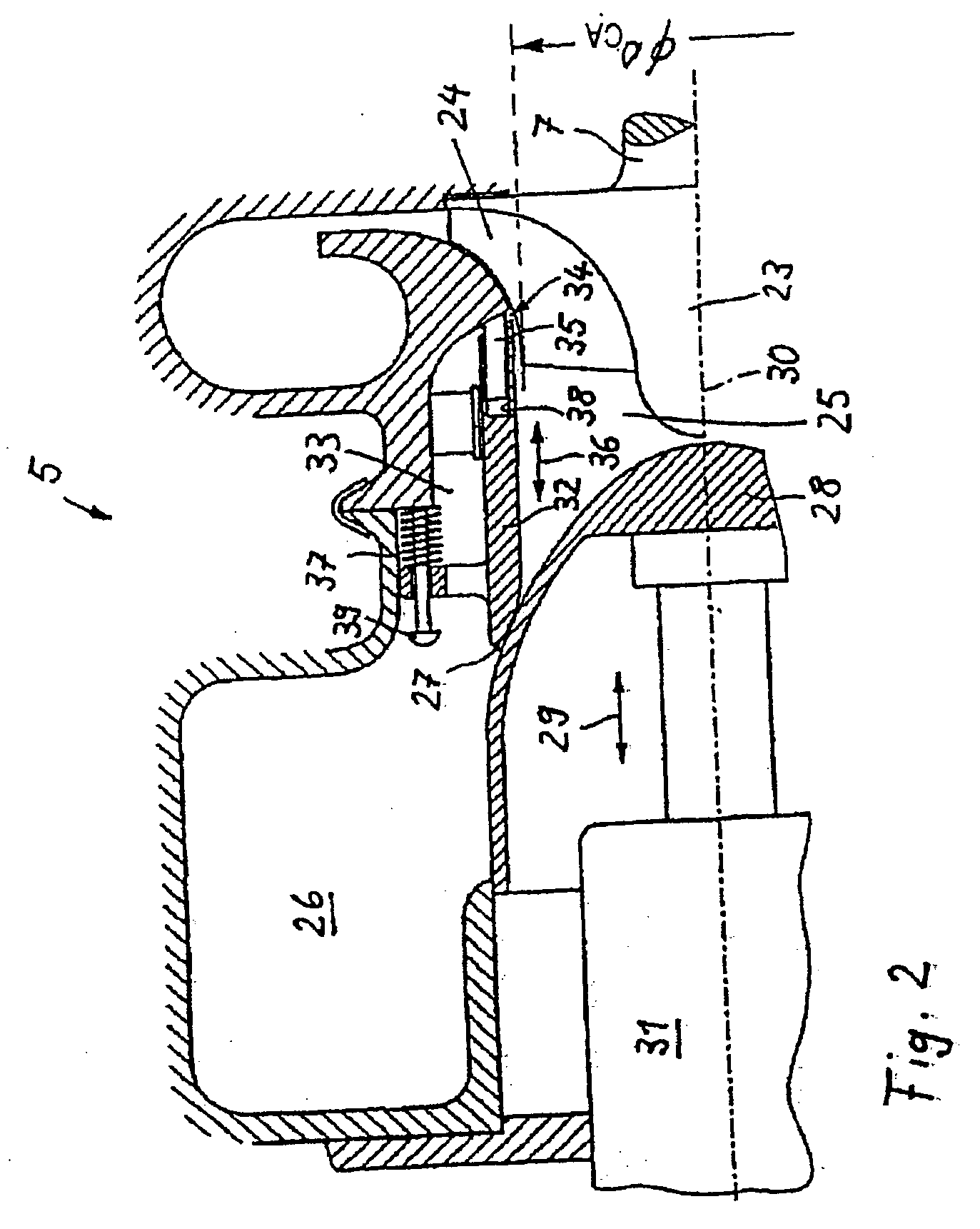

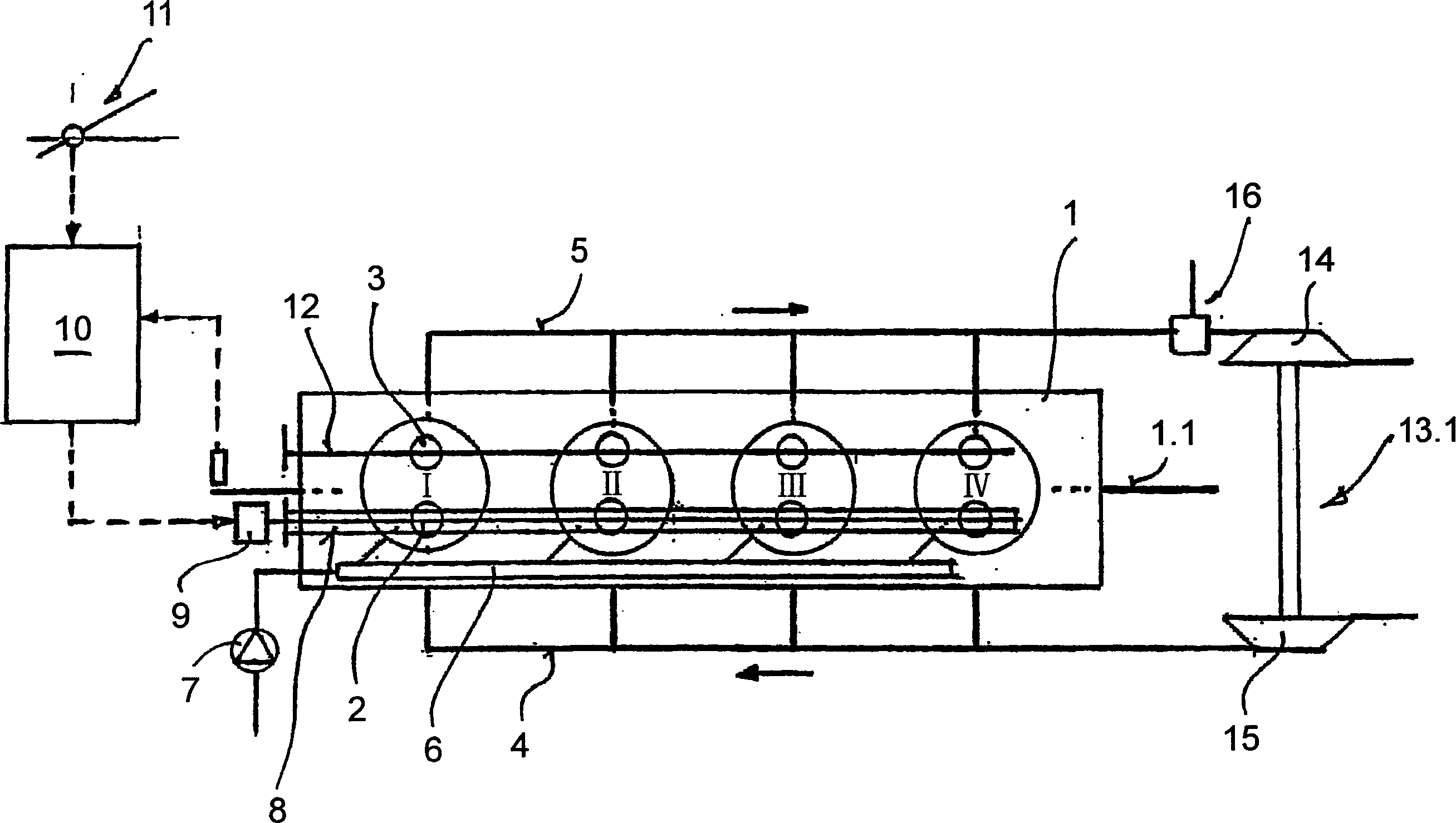

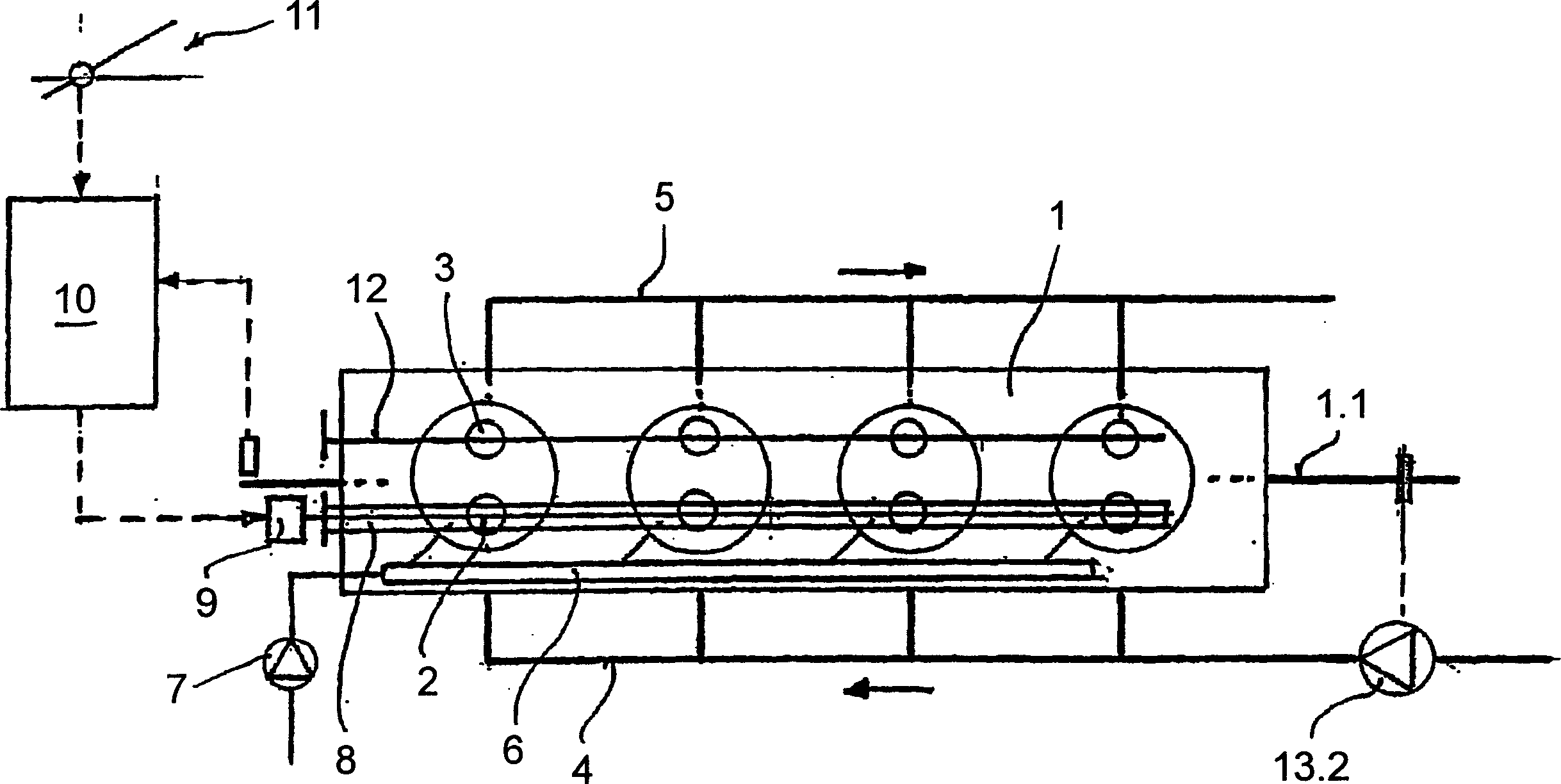

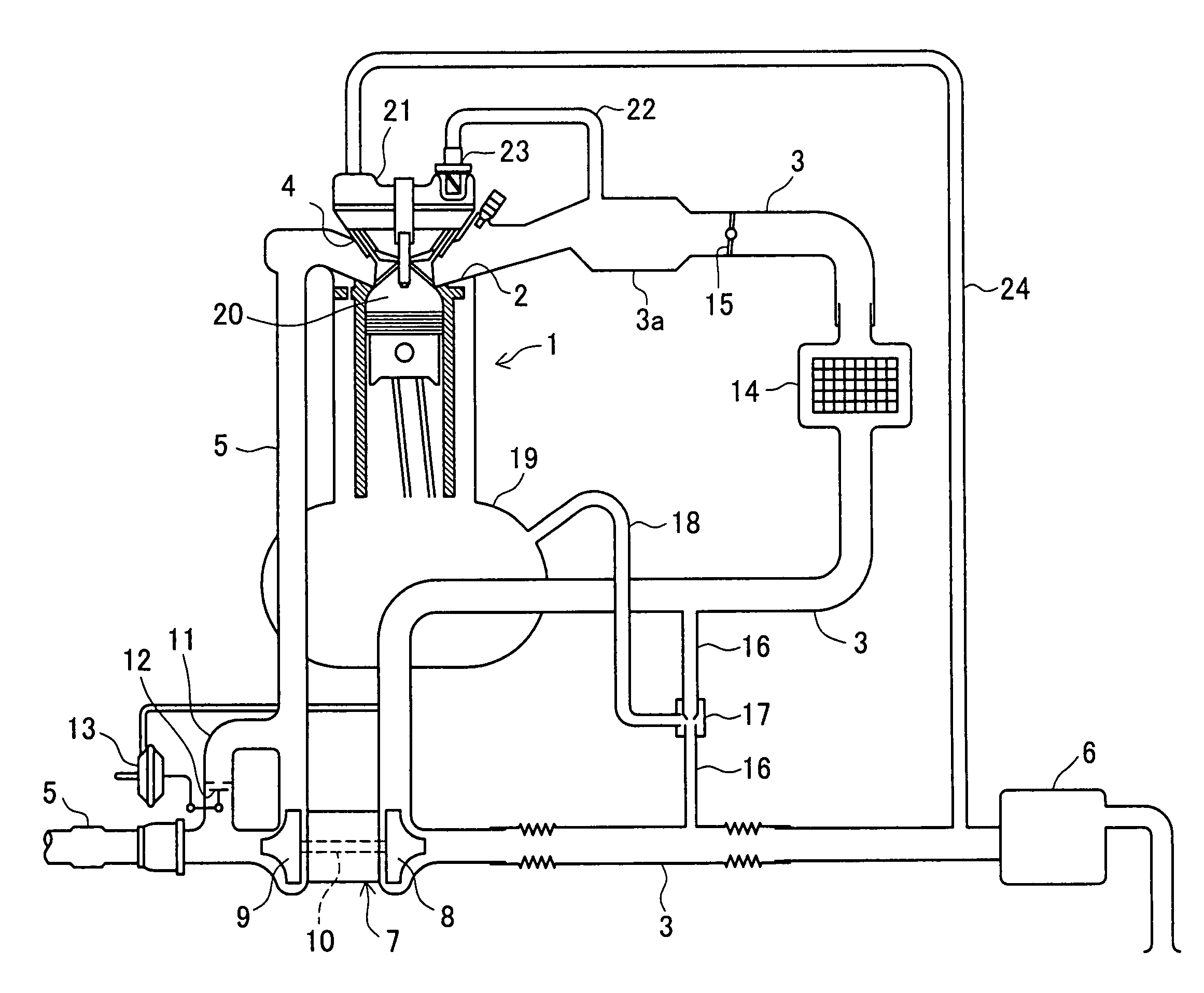

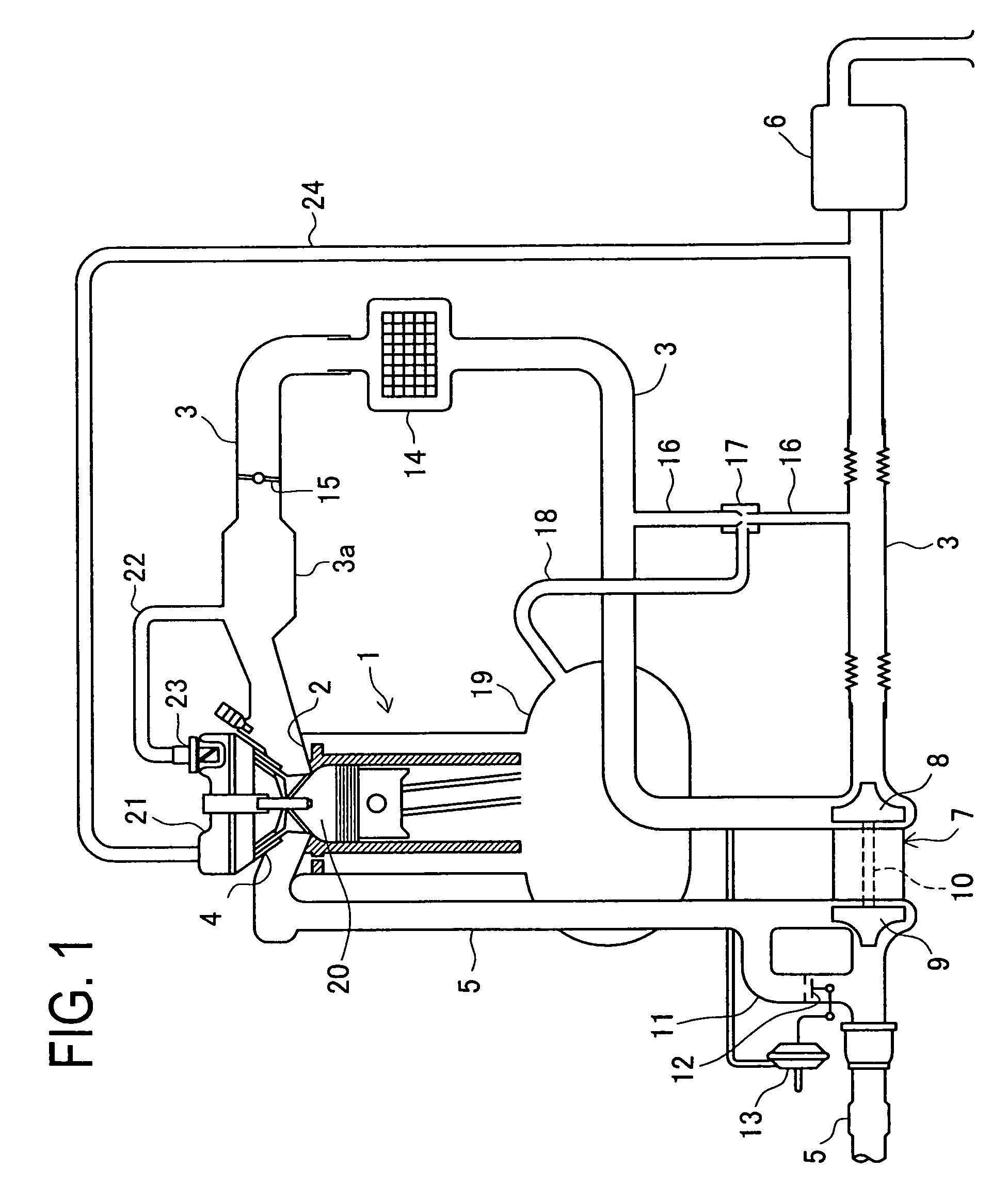

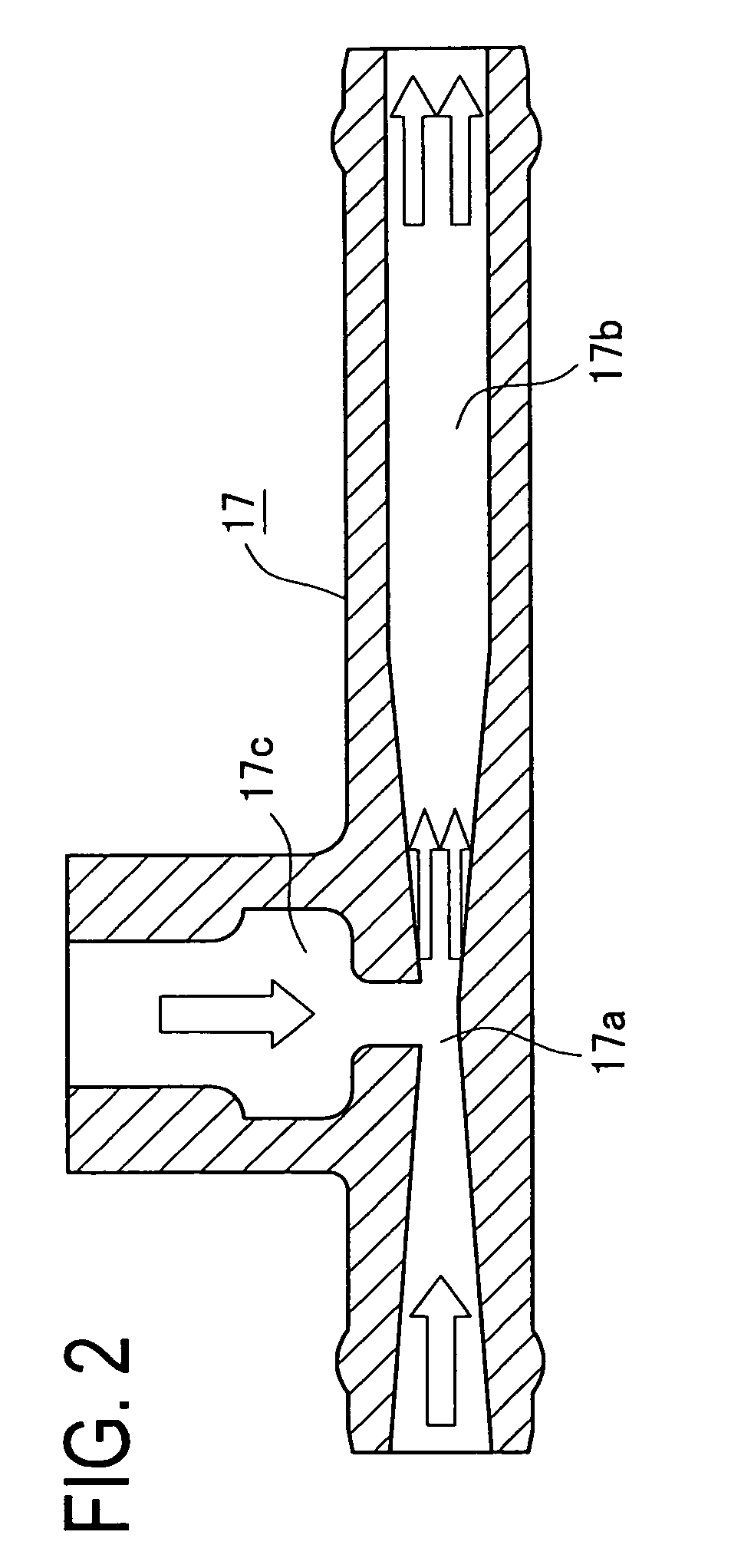

Blowby gas returning apparatus

ActiveUS20090308364A1Increase intake resistanceIncrease boost pressureNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerEngineering

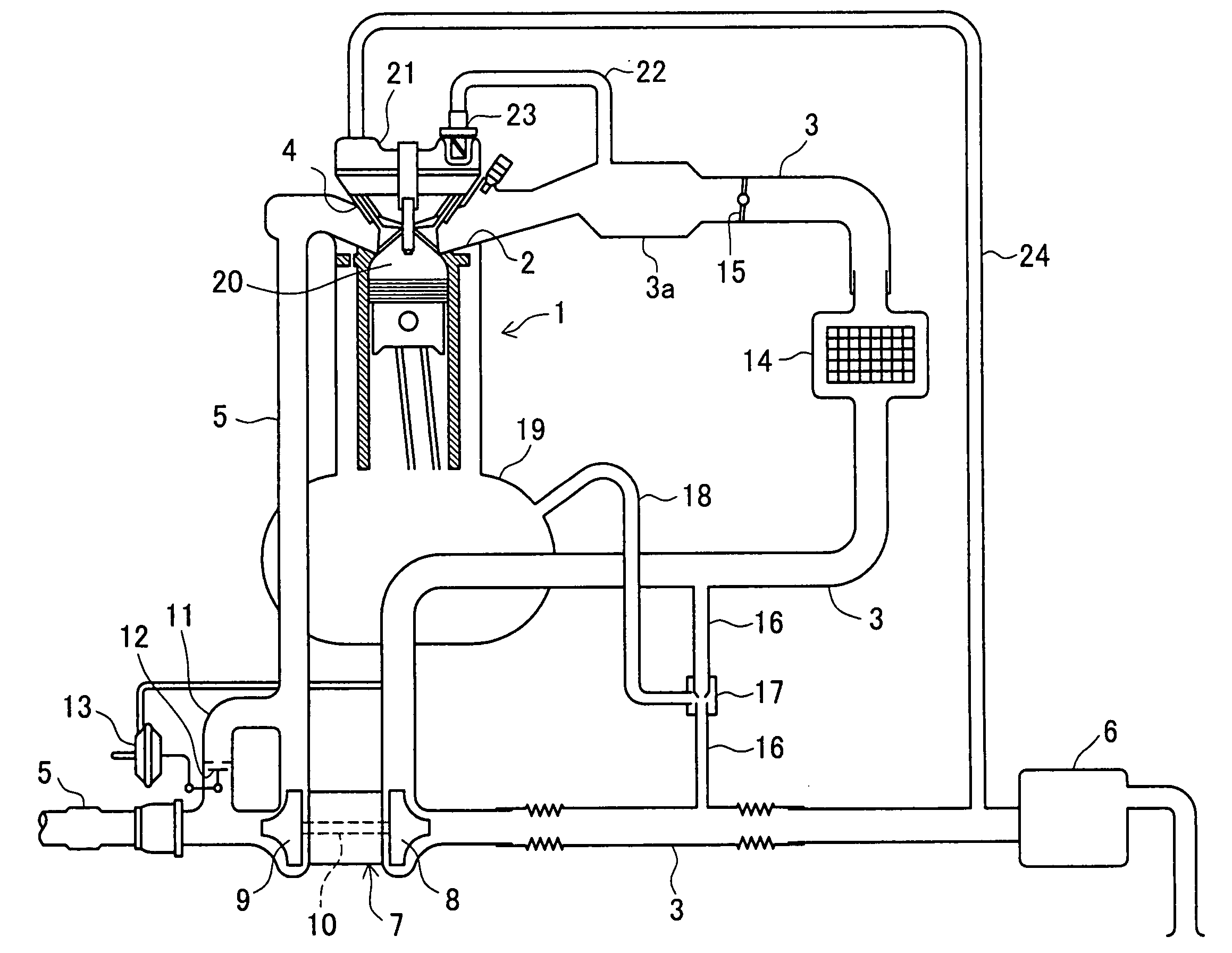

A blowby gas returning apparatus is mounted in an engine provided with a turbocharger in an intake passage and provided with a blowby gas returning passage for flowing blowby gas generated in the engine to return to the engine. This apparatus comprises an intake bypass passage connecting an upstream side and a downstream side of the intake passage with respect to the turbocharger, and a jet pump for generating negative pressure in the intake bypass passage. An exit of the first blowby gas returning passage is connected to the intake bypass passage through the jet pump. The apparatus further includes a second blowby gas returning passage connecting the intake passage downstream of the throttle valve to a head cover. In the head cover, a PCV valve is placed at an entrance of the second blowby gas returning passage.

Owner:AISAN IND CO LTD

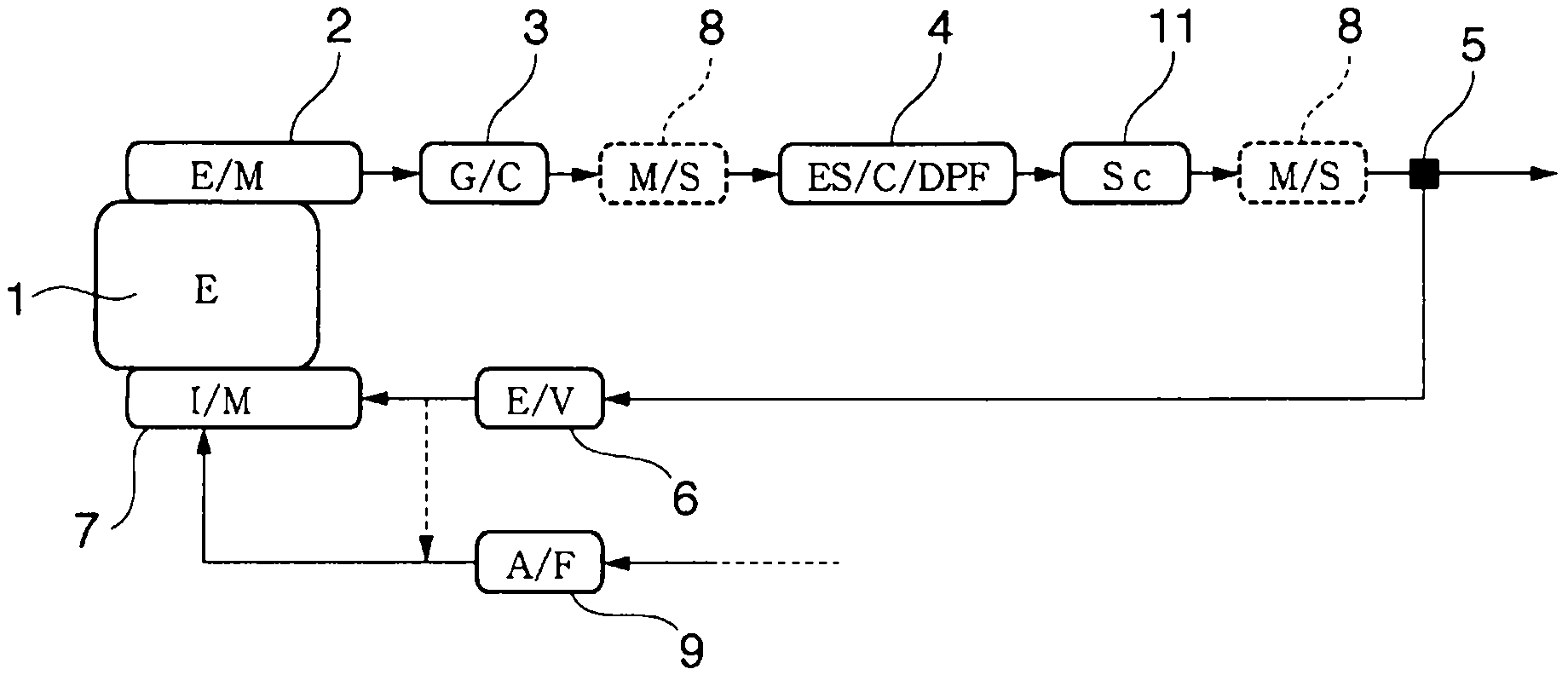

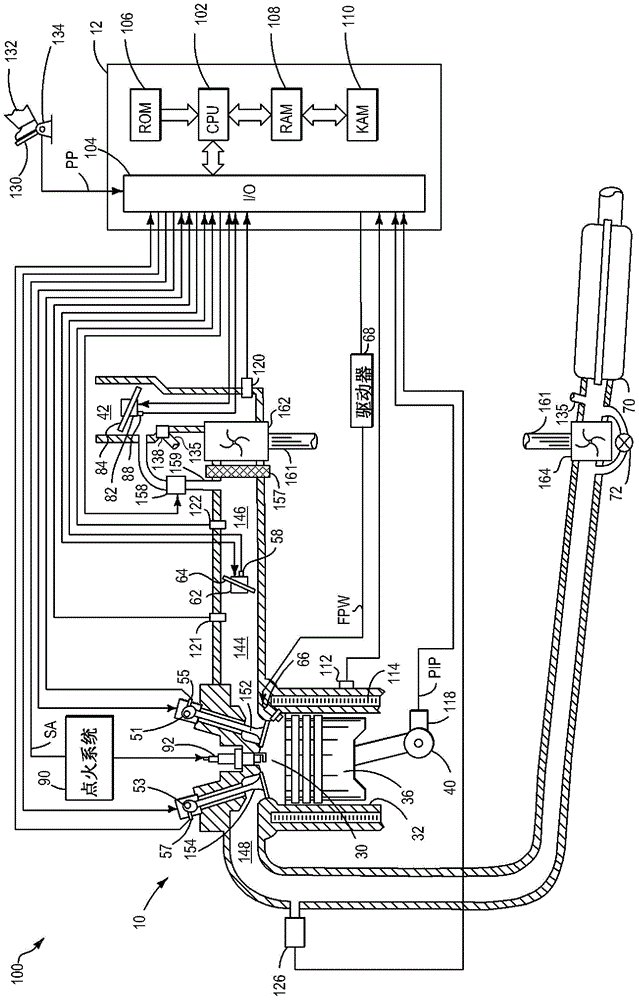

Method and Apparatus for Controlling an Internal Combustion Engine

InactiveUS20090007564A1Increase fuel consumptionSave fuelElectrical controlInternal combustion piston enginesExternal combustion engineTurbocharger

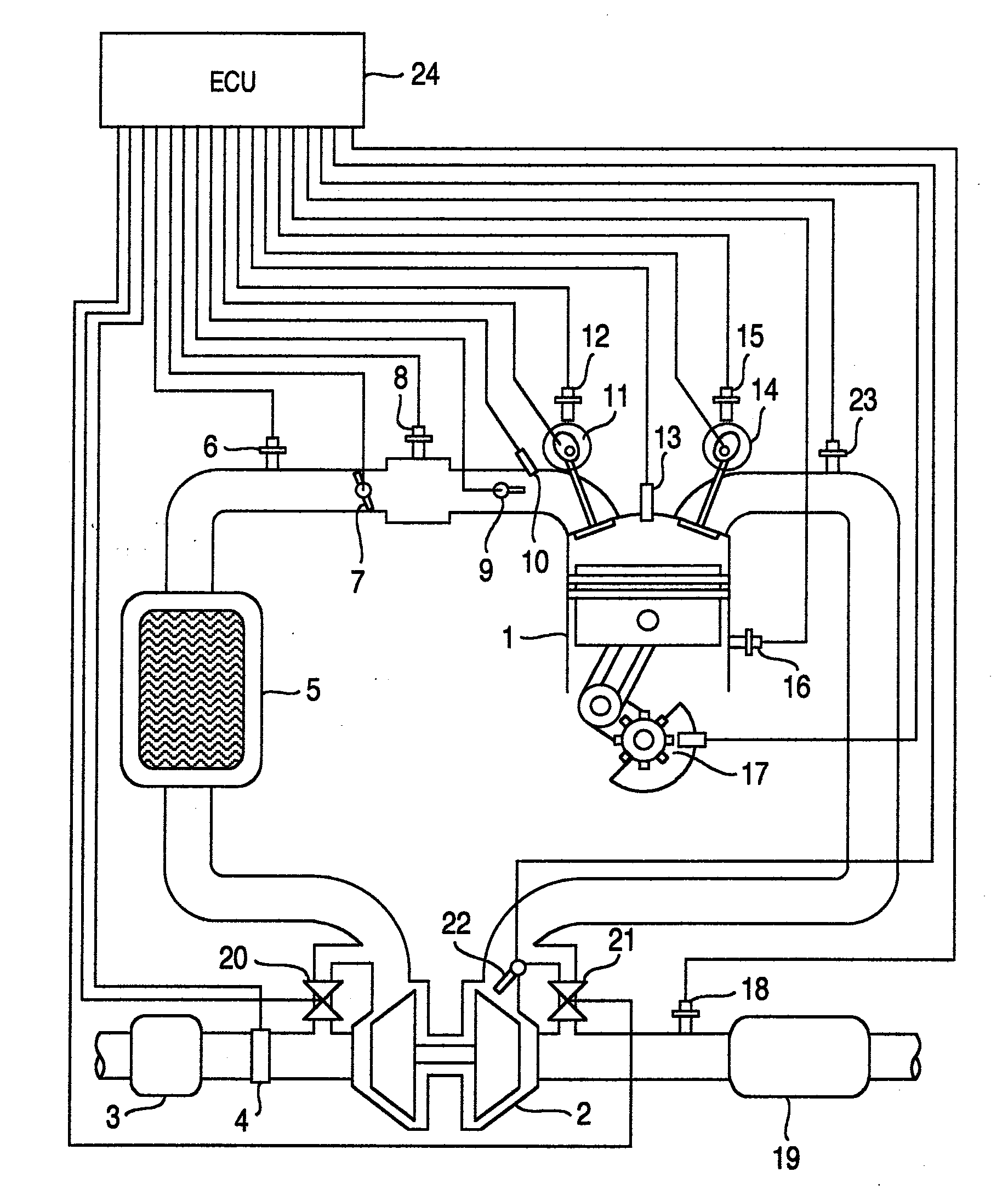

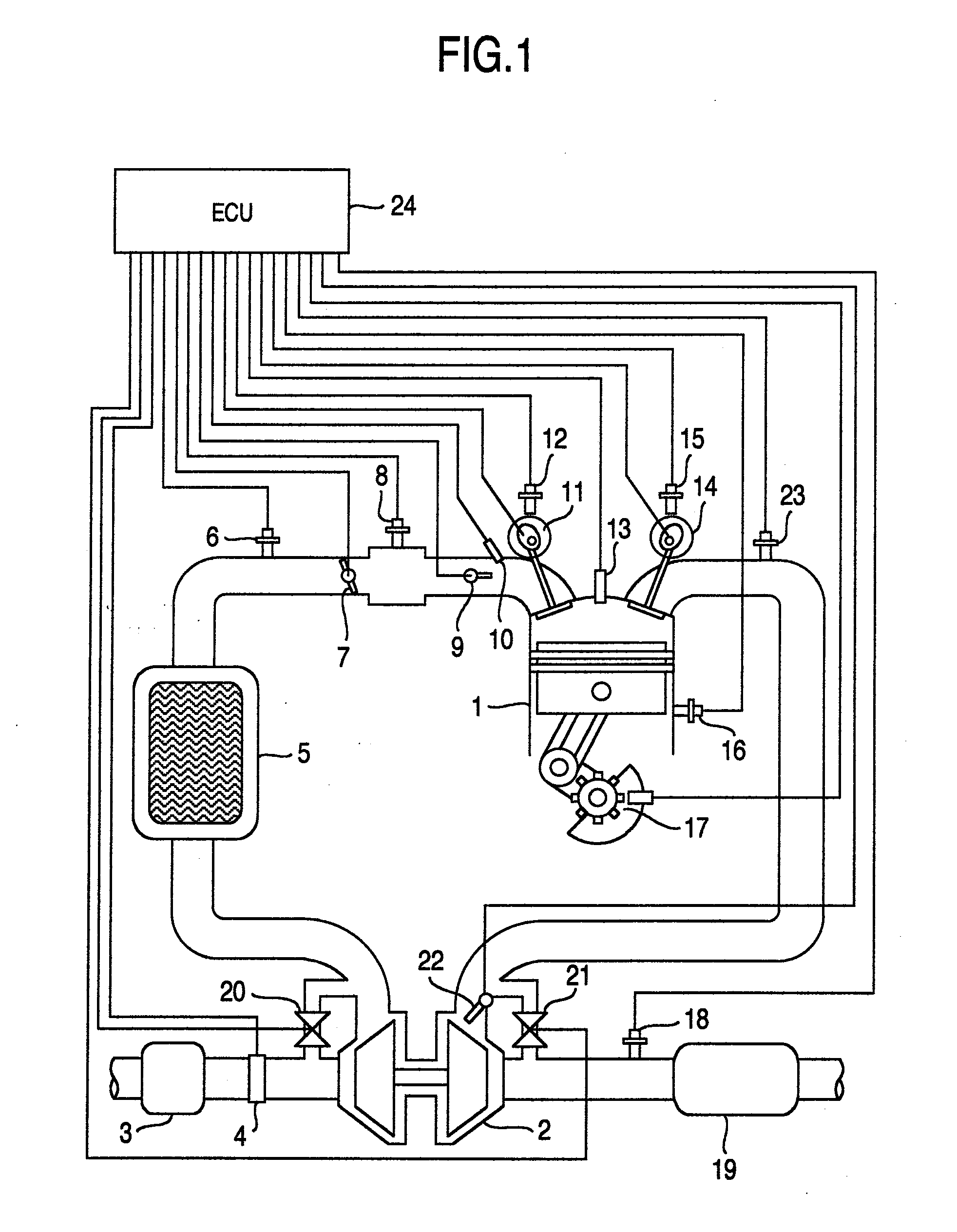

A control device for an internal combustion engine, which comprise a turbocharger, of which turbo flow rate is made variable, and an intake valve provided with a variable valve mechanism and in which mirror cycle is performed, the control device comprising: device, which calculates an intake air quantity per unit time and an intake air quantity per cycle on the basis of torque required to the internal combustion engine; device, which controls the turbocharger so that with the intake air quantity per unit time, supercharging pressure is further increased in that range, in which a ratio of supercharging pressure and exhaust pressure is equal to or less than a predetermined value; and device, which controls the variable valve mechanism on the basis of the supercharging pressure and the intake air quantity per cycle.

Owner:HITACHI LTD

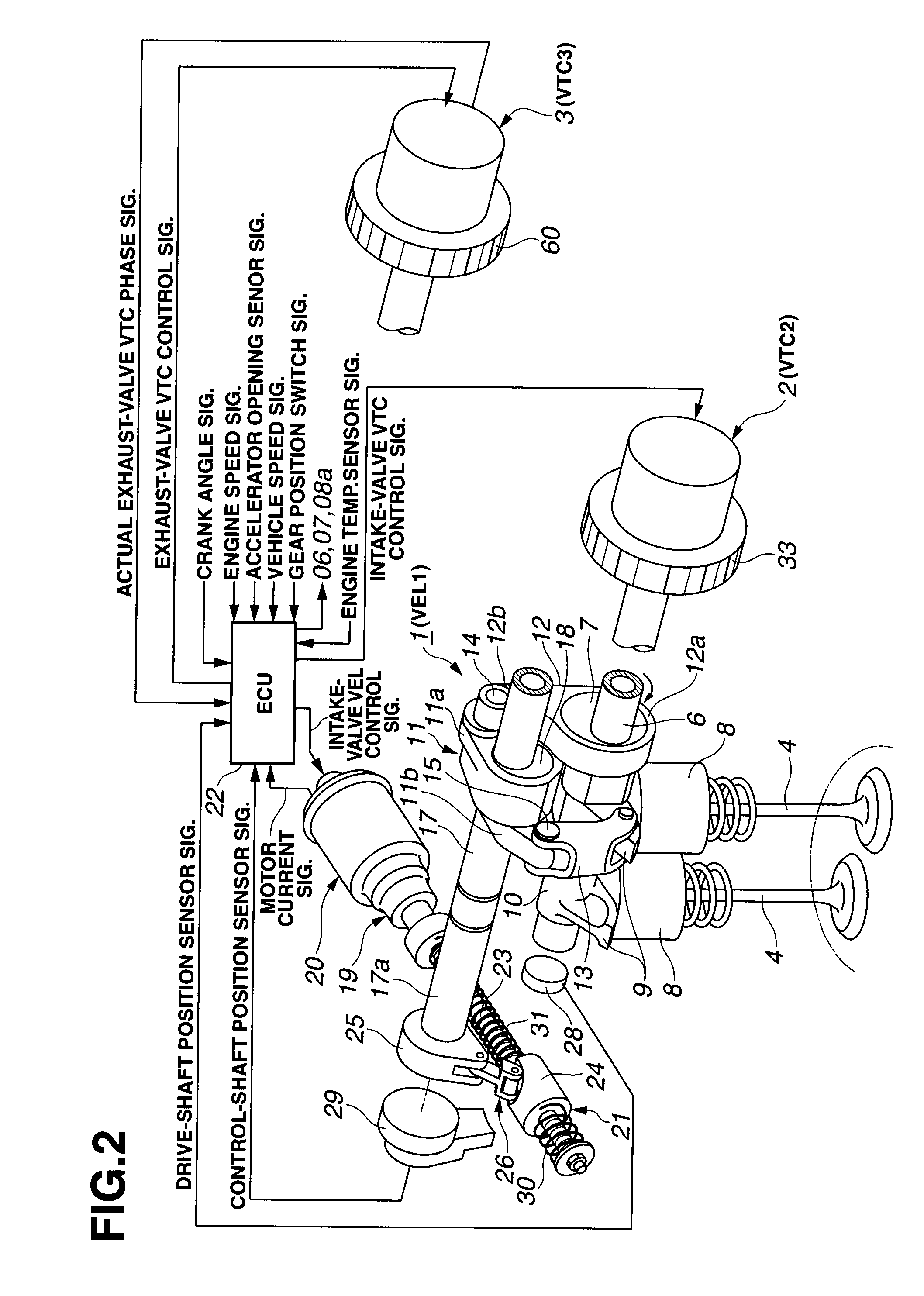

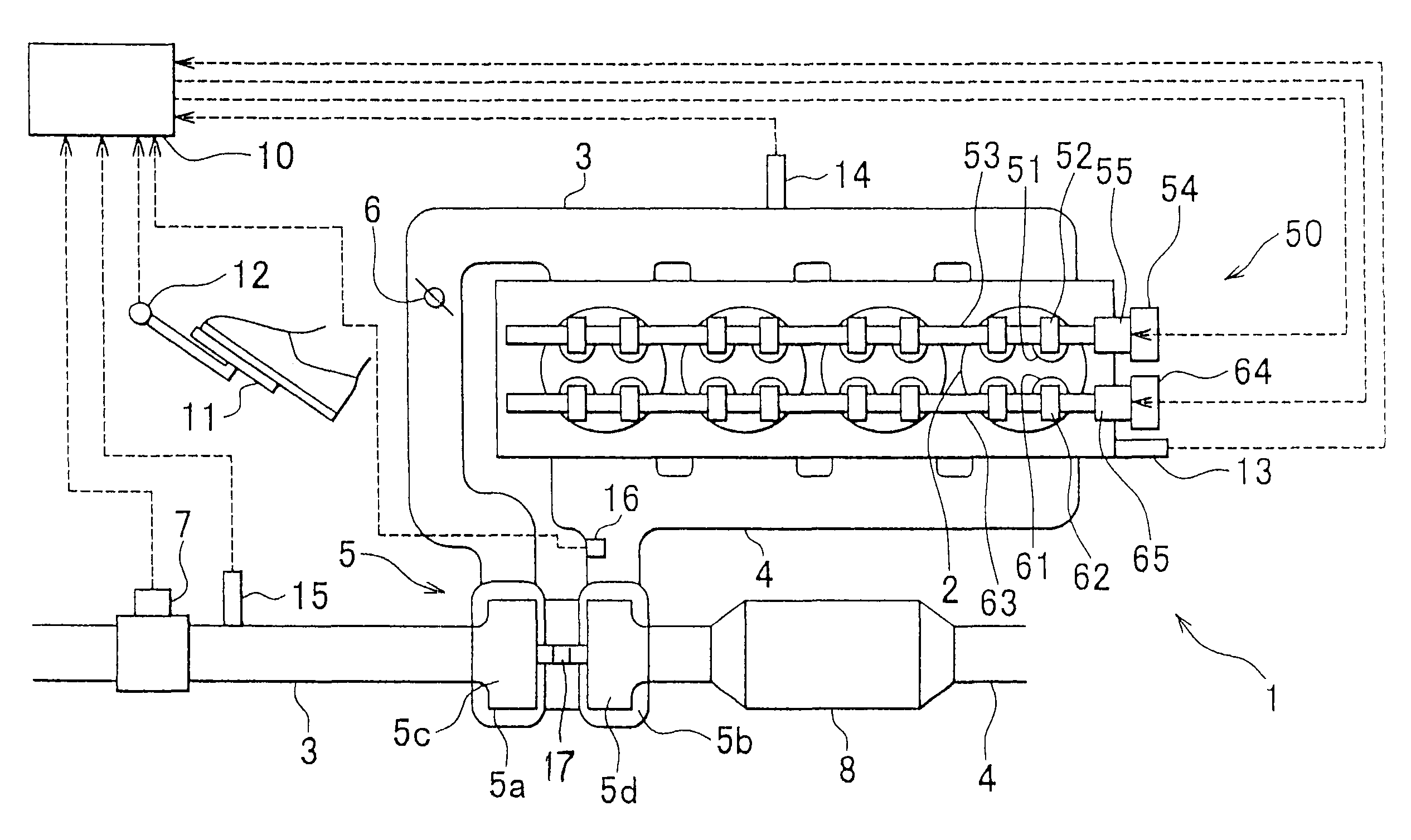

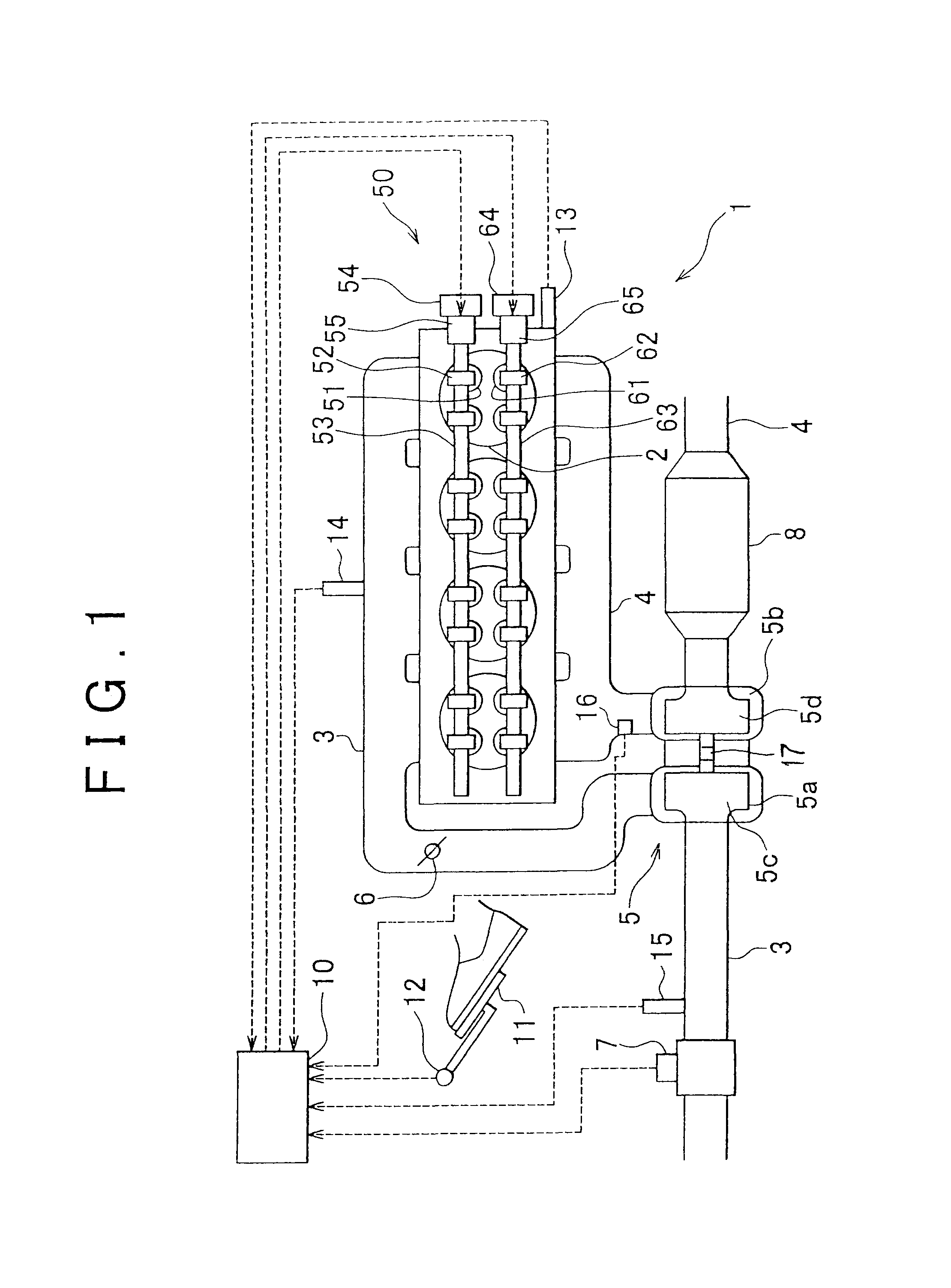

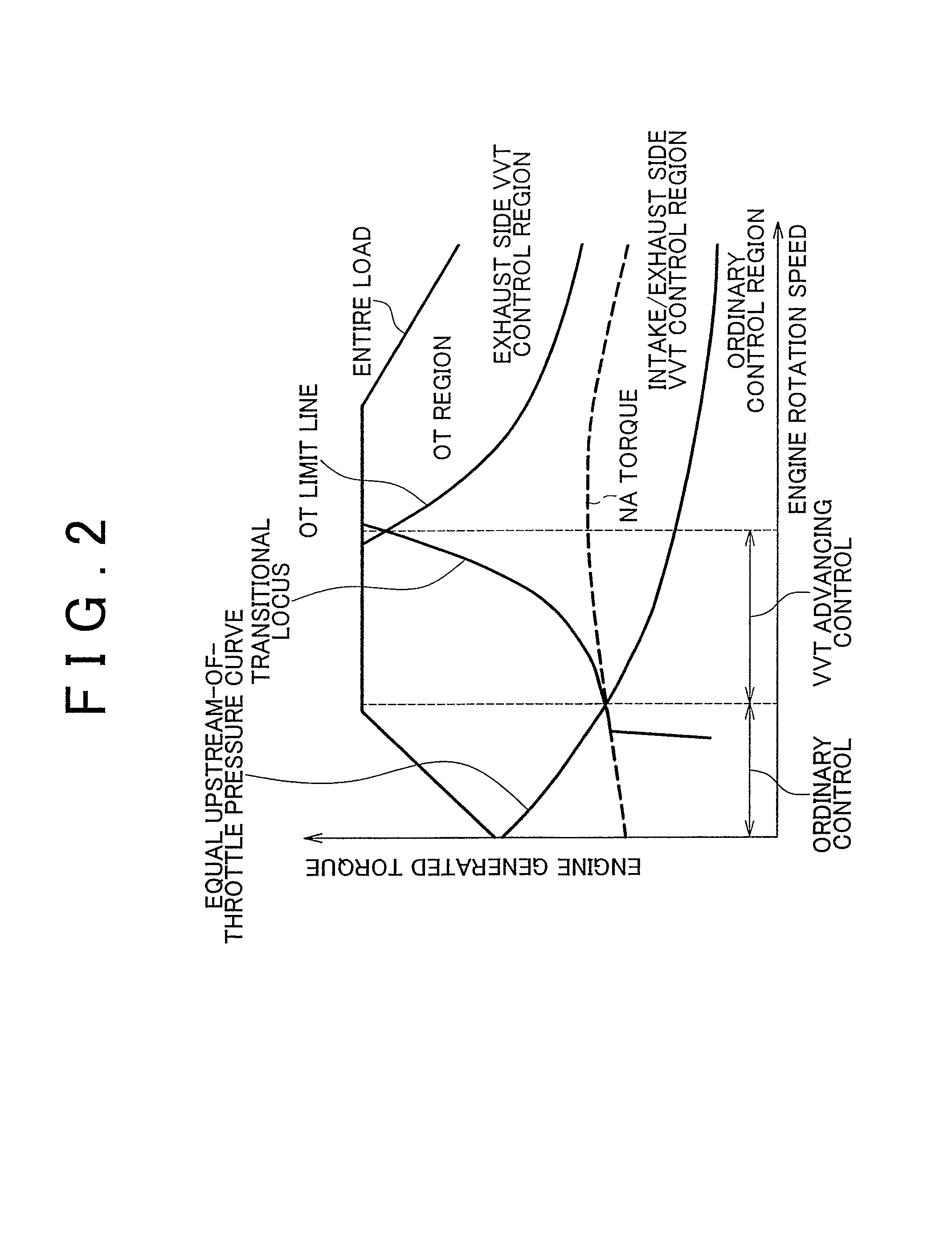

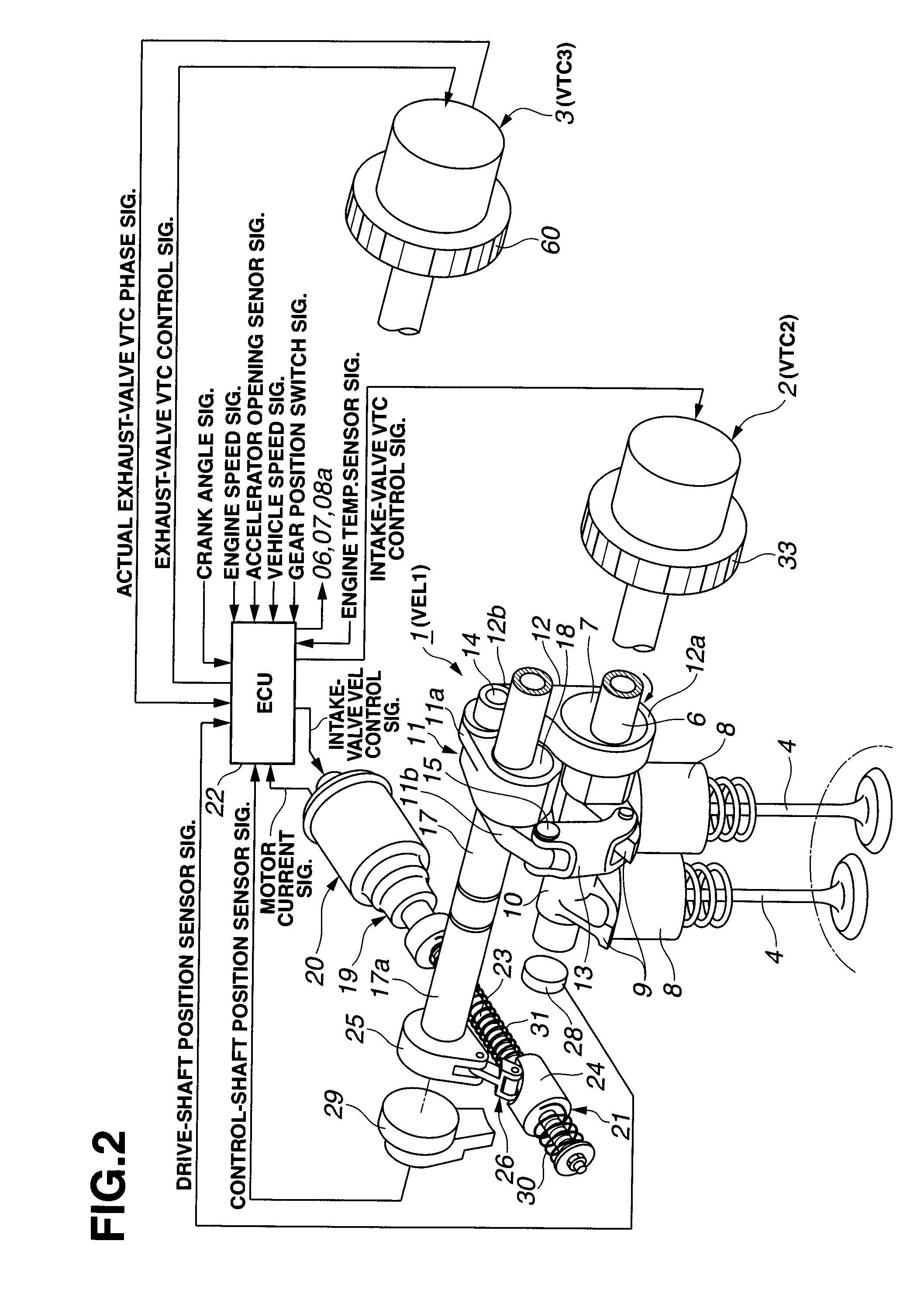

Variable valve actuation system of internal combustion engine and control apparatus of internal combustion engine

ActiveUS20090228187A1Improve responsivenessEngine-torque-increase responsivenessAnalogue computers for vehiclesValve arrangementsExhaust valvePhase shifted

In a control apparatus of a supercharged internal combustion engine, a variable valve actuation system interacts with an engine control system. A controller is configured or programmed to increase an intake-valve lift by a variable valve lift mechanism, which is provided for variably controlling at least the intake-valve lift of engine valves, when starting from a vehicle stand-still state or when accelerating from an idling state or a light load state. The controller is further configured or programmed to increase a valve overlap of intake and exhaust valves by a variable phase control mechanism, which is provided for variably phase-shifting a central phase angle of a valve lift characteristic curve of at least one of the intake and exhaust valves, while increasing a boost pressure of intake air introduced into an engine cylinder by a supercharging device, after the intake-valve lift has been increased.

Owner:HITACHI ASTEMO LTD

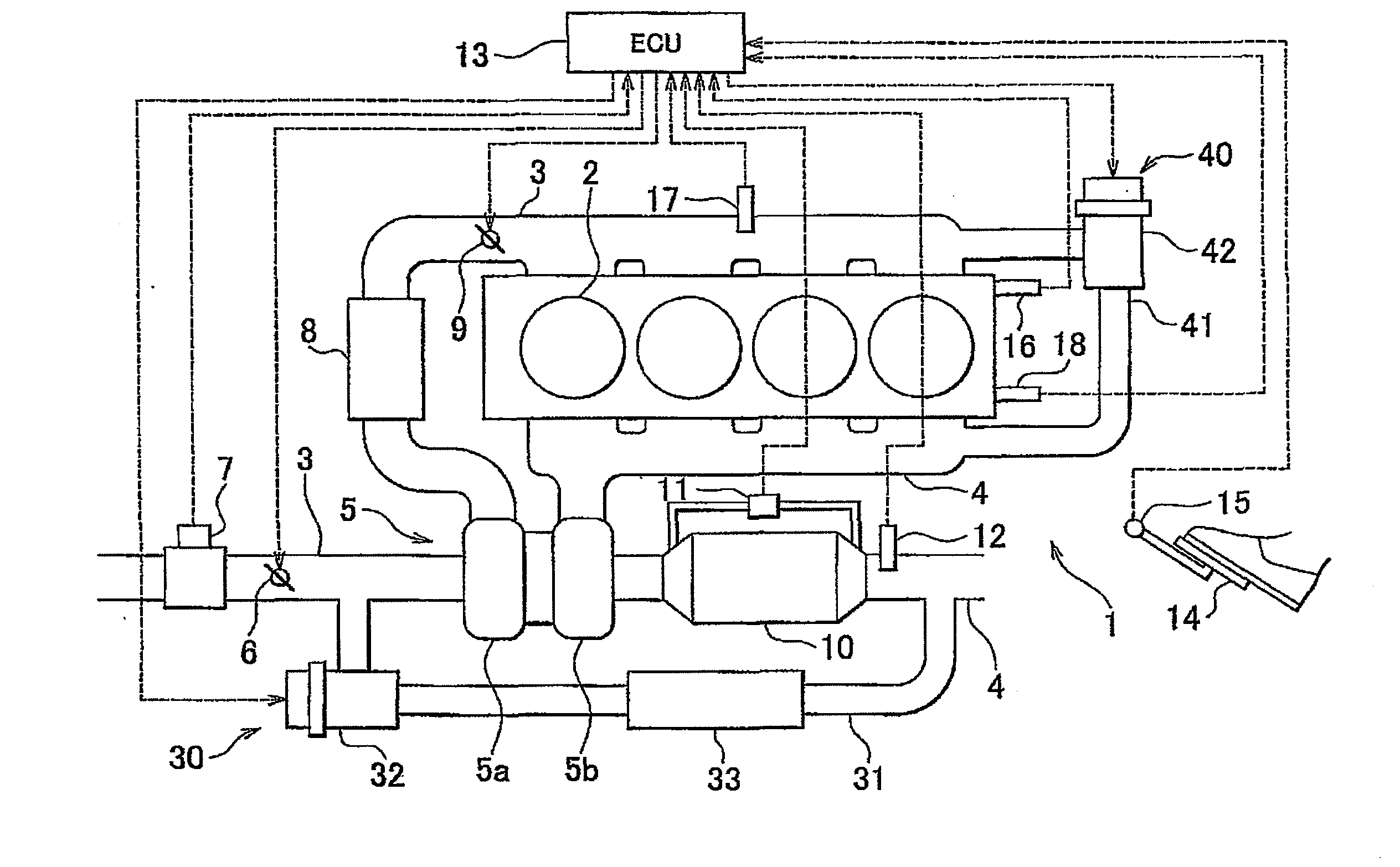

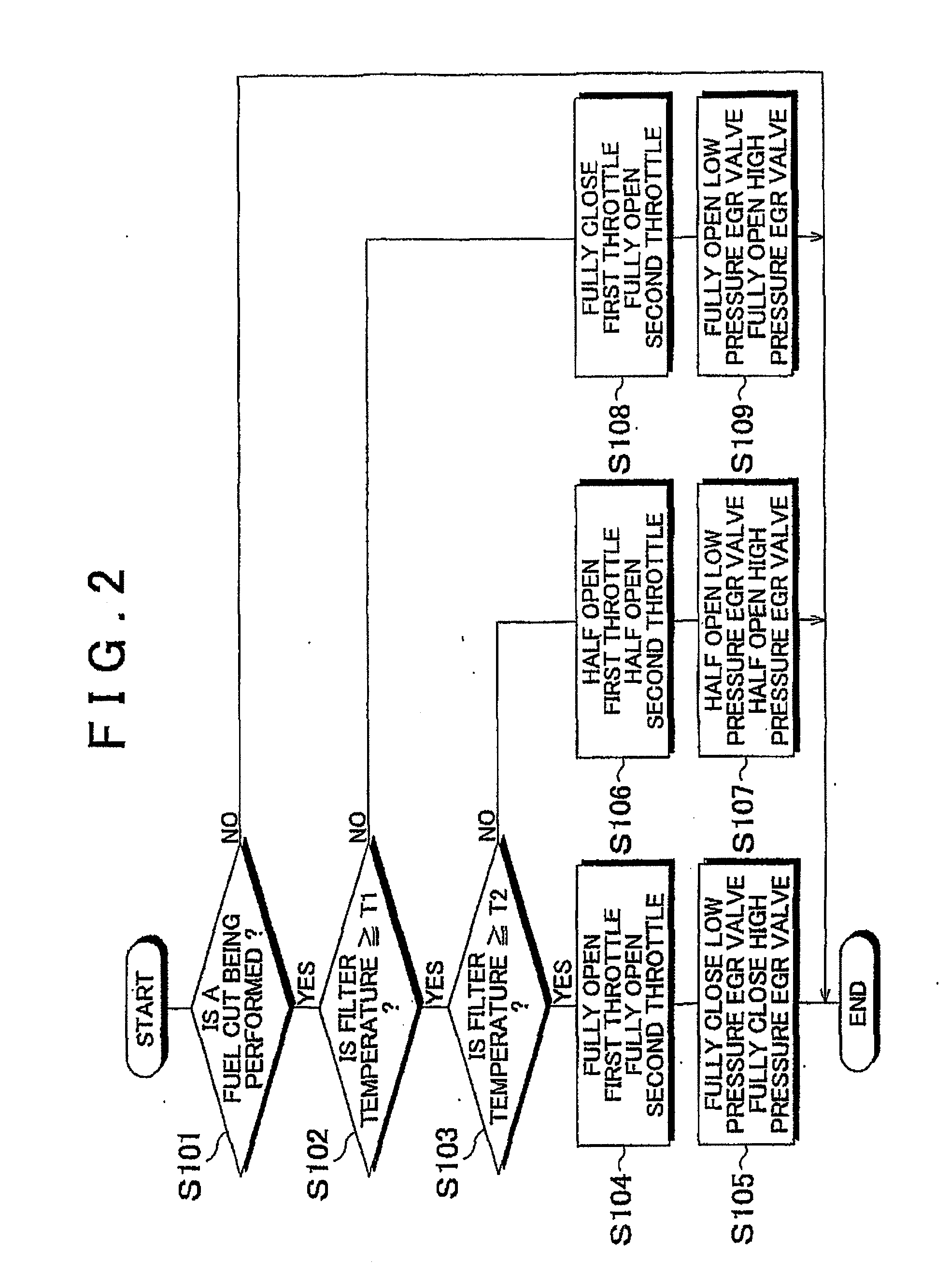

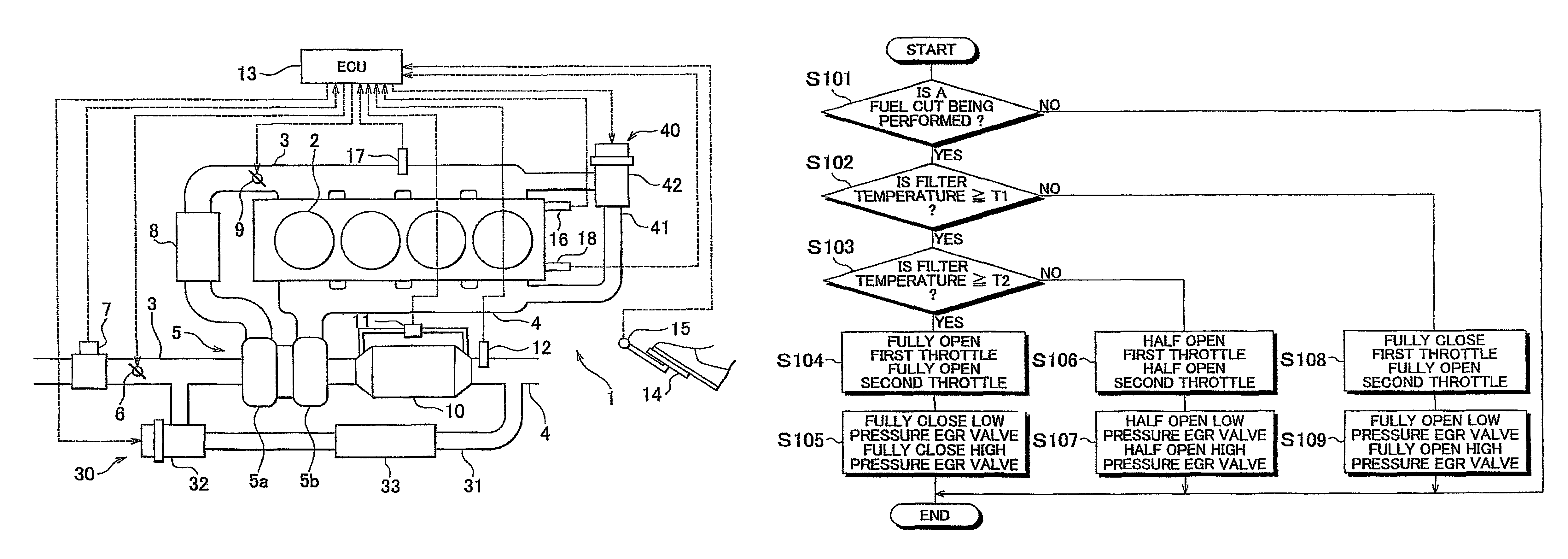

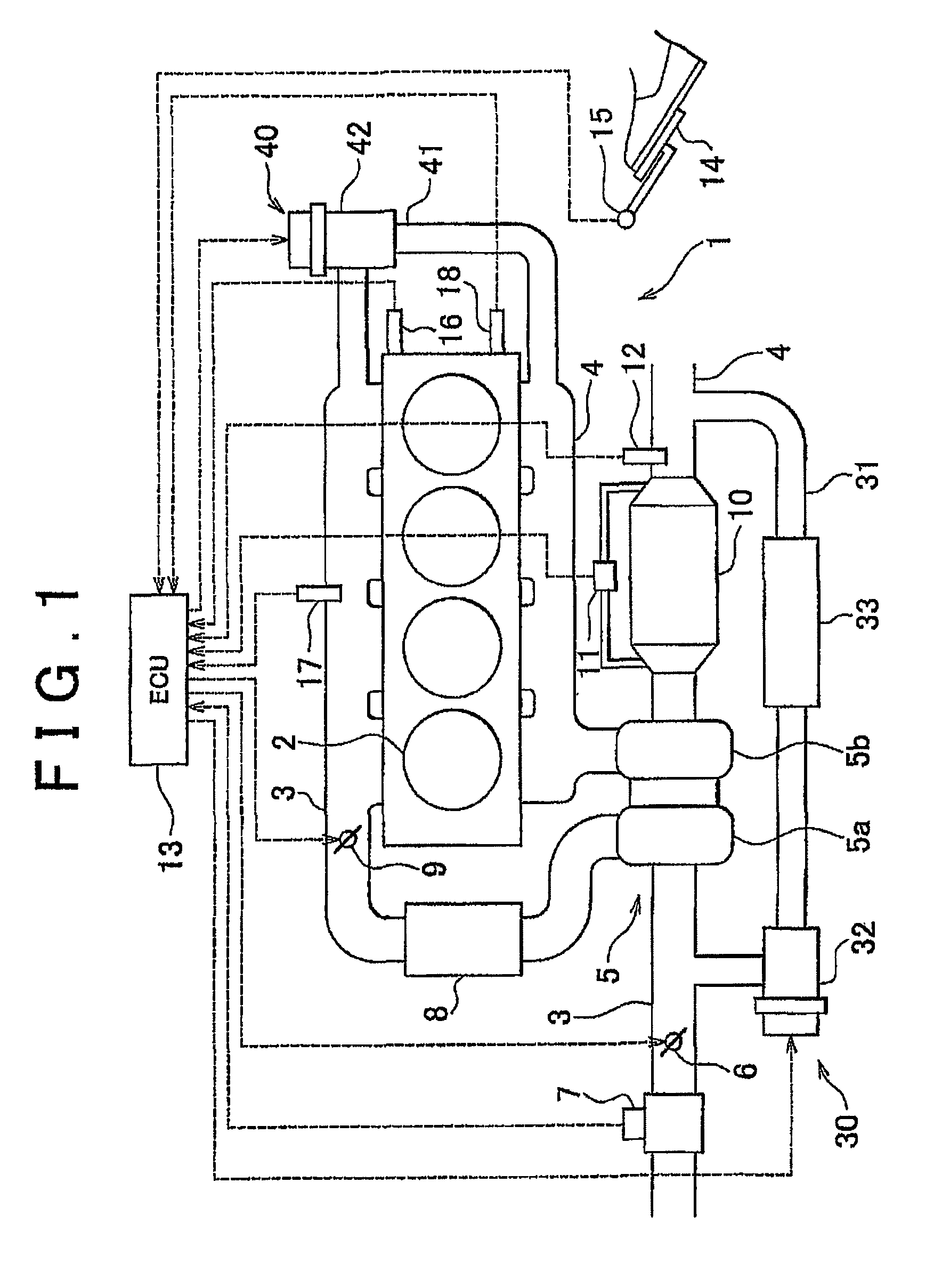

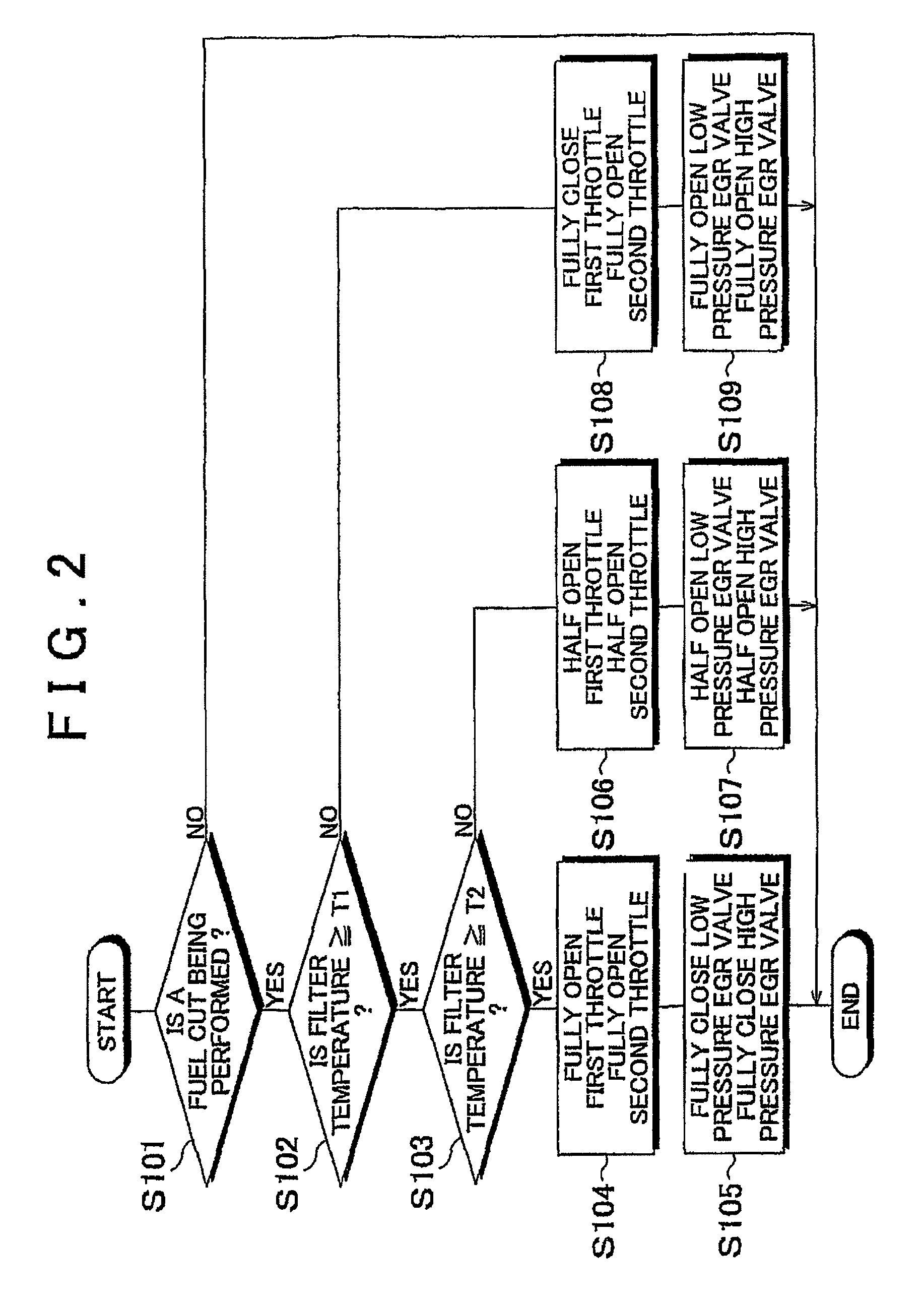

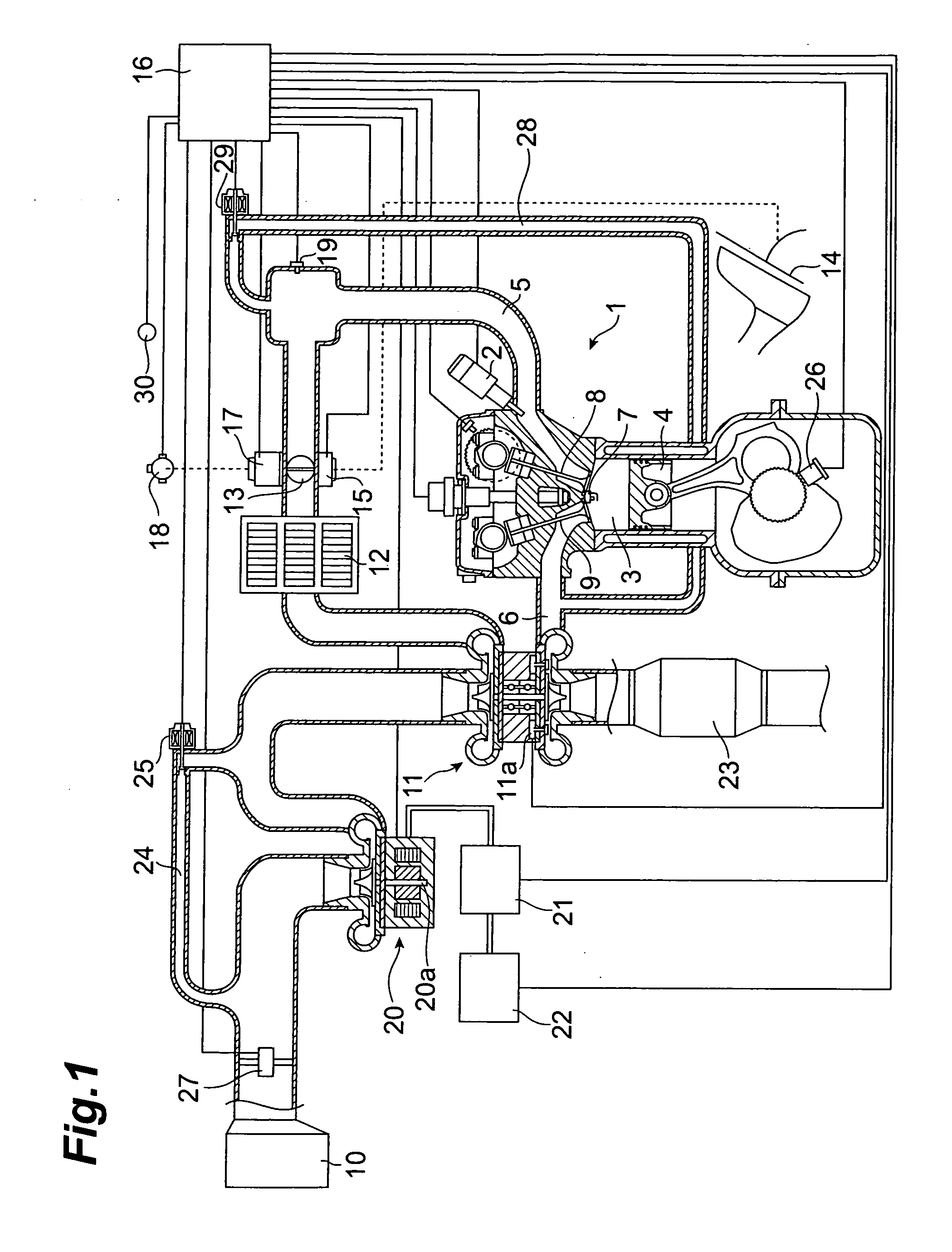

Exhaust Gas Recirculation Apparatus of an Internal Combustion Engine and Control Method Thereof

InactiveUS20080295514A1Reduce the amount requiredReduce the amount of solutionElectrical controlNon-fuel substance addition to fuelExternal combustion engineTurbocharger

An exhaust gas recirculation apparatus of an internal combustion engine includes a turbocharger provided with a turbine in an exhaust passage and a compressor in an intake passage, a low pressure EGR passage which connects the exhaust passage downstream of the turbine with the intake passage upstream of the compressor, a high pressure EGR passage which connects the exhaust passage upstream of the turbine with the intake passage downstream of the compressor; an exhaust gas control catalyst provided in the exhaust passage downstream of the turbine and upstream of the low pressure EGR passage; and EGR gas amount changing means for simultaneously changing amounts of EGR gas flowing through the low pressure EGR passage and the high pressure EGR passage such that a temperature of the exhaust gas control catalyst is within a target range.

Owner:TOYOTA JIDOSHA KK

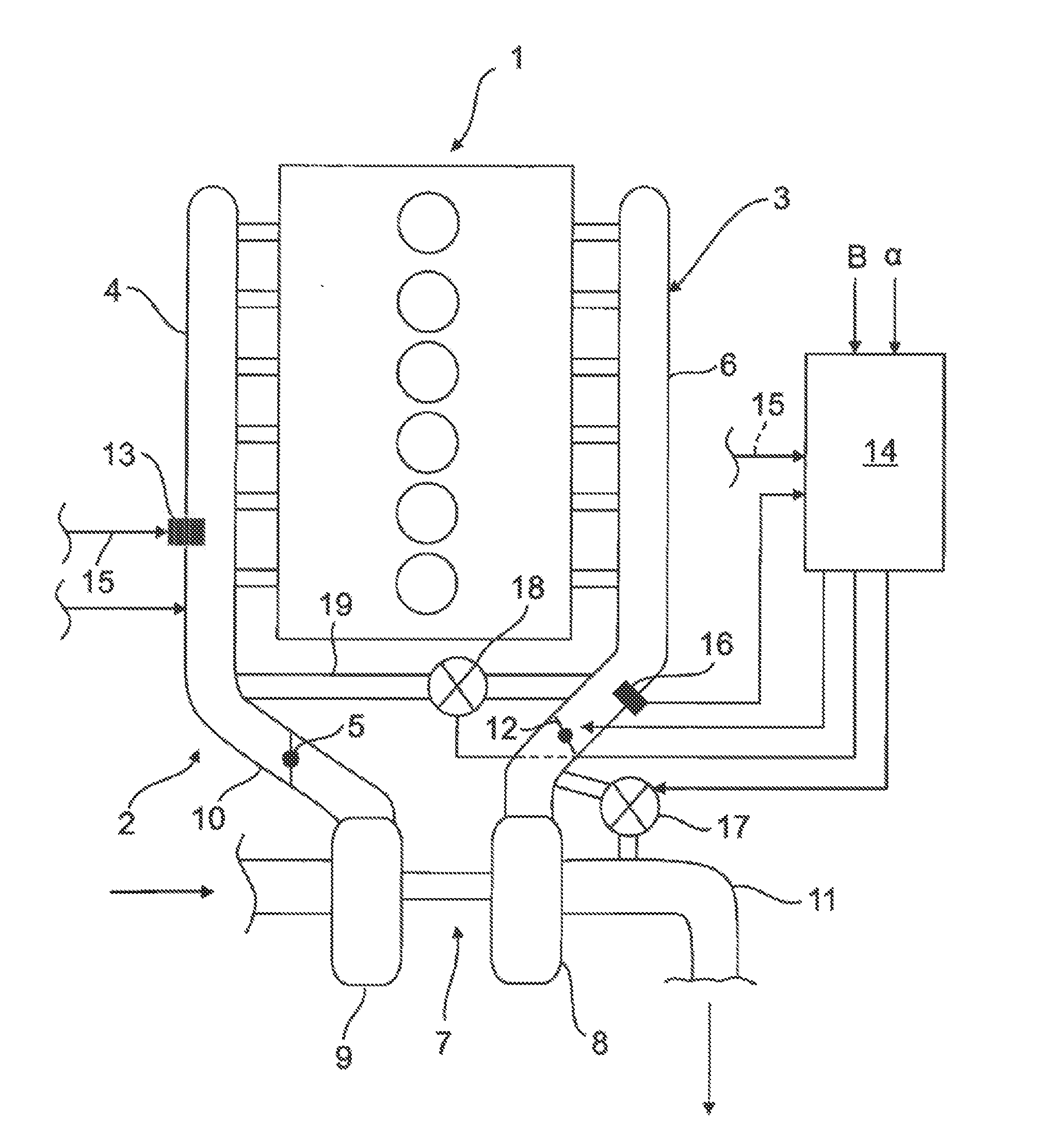

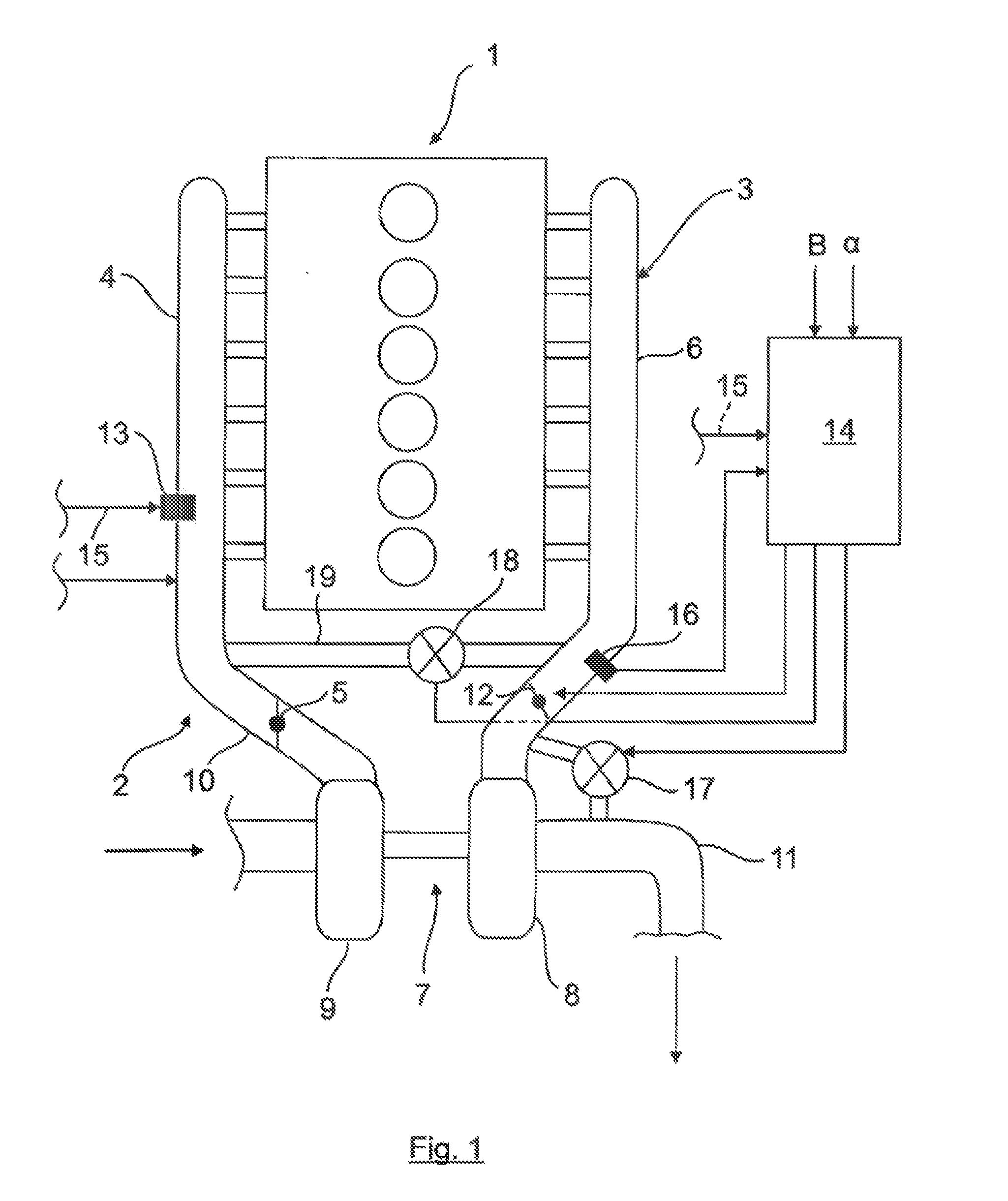

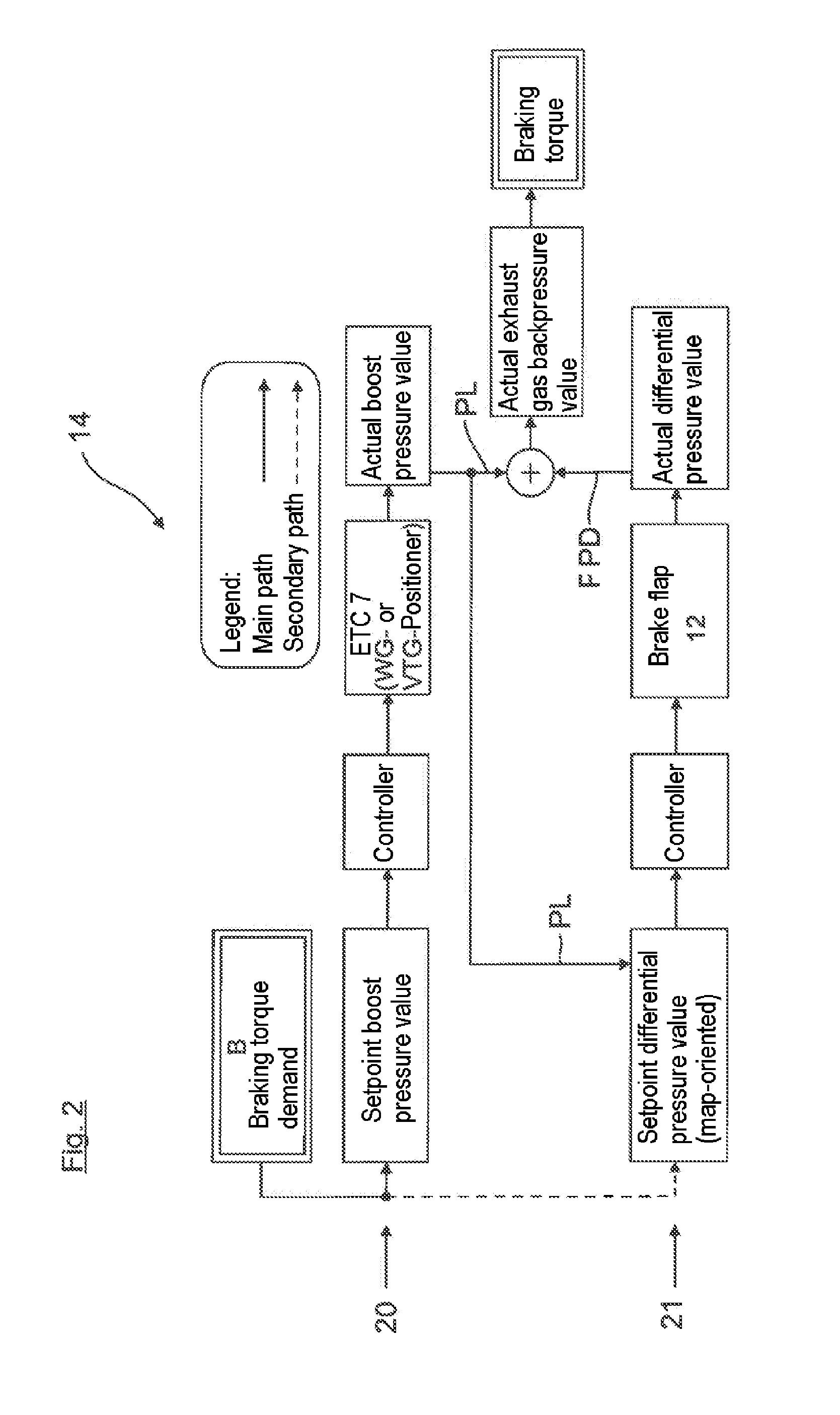

Method for controlling an engine braking device and engine braking device

ActiveUS20160169127A1Increase boost pressureReduced exhaust gas flow rateValve arrangementsInternal combustion piston enginesCombustionTurbocharger

The invention relates to a method for controlling an engine braking device for a combustion engine in motor vehicles, wherein the engine braking device has an intake system, an exhaust system, gas exchange valves associated with the combustion engine, exhaust turbo-charging by at least one exhaust turbocharger integrated into the exhaust system and the intake system, and an engine braking unit, wherein the engine braking unit has a decompression brake, which influences at least one outlet valve of the gas exchange valves and is dependent on the exhaust gas backpressure, and a brake flap, which is arranged in the exhaust system. To achieve a precisely controllable engine braking power in the engine braking mode, the demanded braking torque is controlled in accordance with the boost pressure of the exhaust turbocharger and with the exhaust gas backpressure upstream of the brake flap, which is arranged directly upstream of an exhaust turbine of the exhaust turbocharger. A suitable engine braking device is furthermore proposed.

Owner:MAN TRUCK & BUS OESTERR

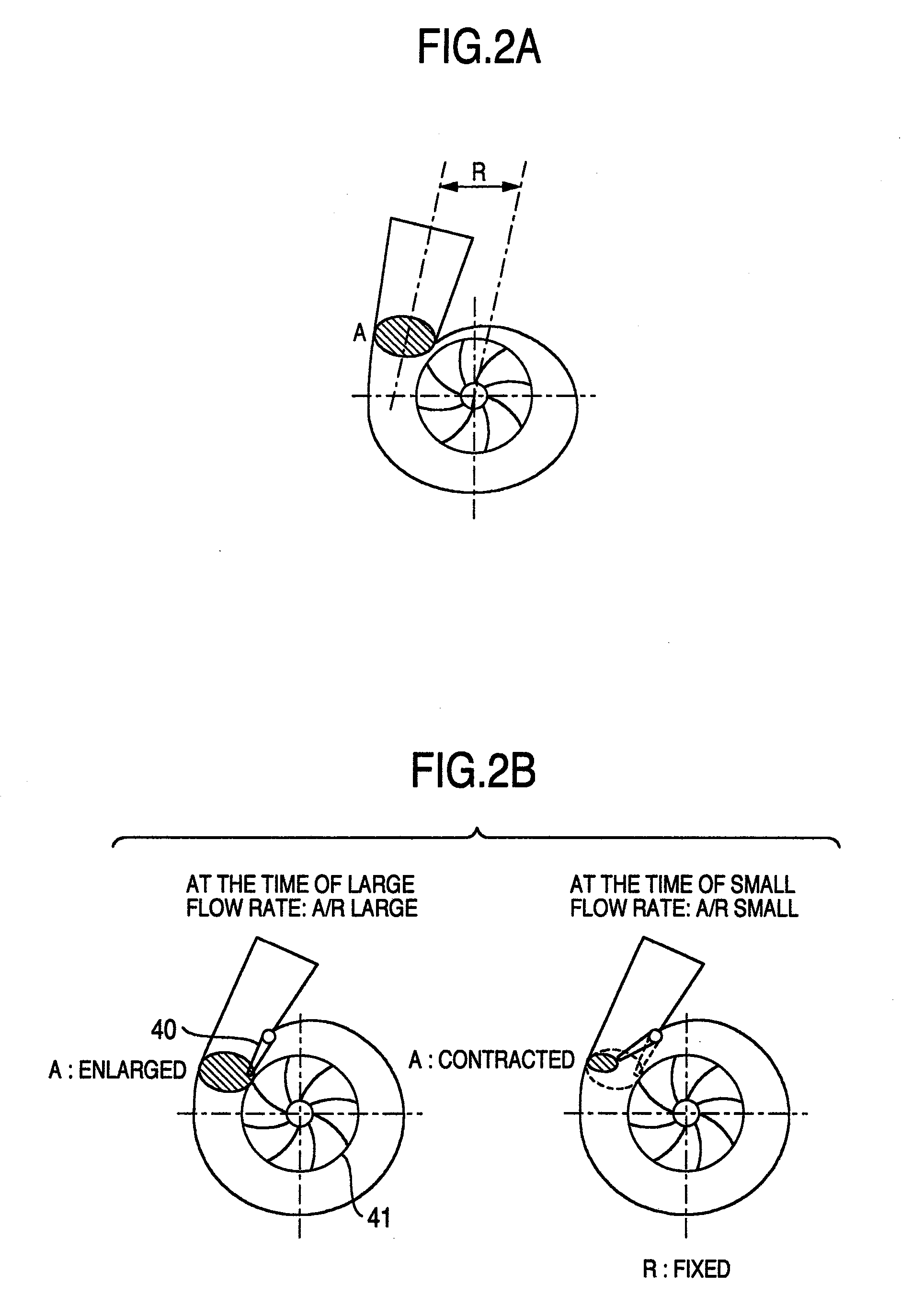

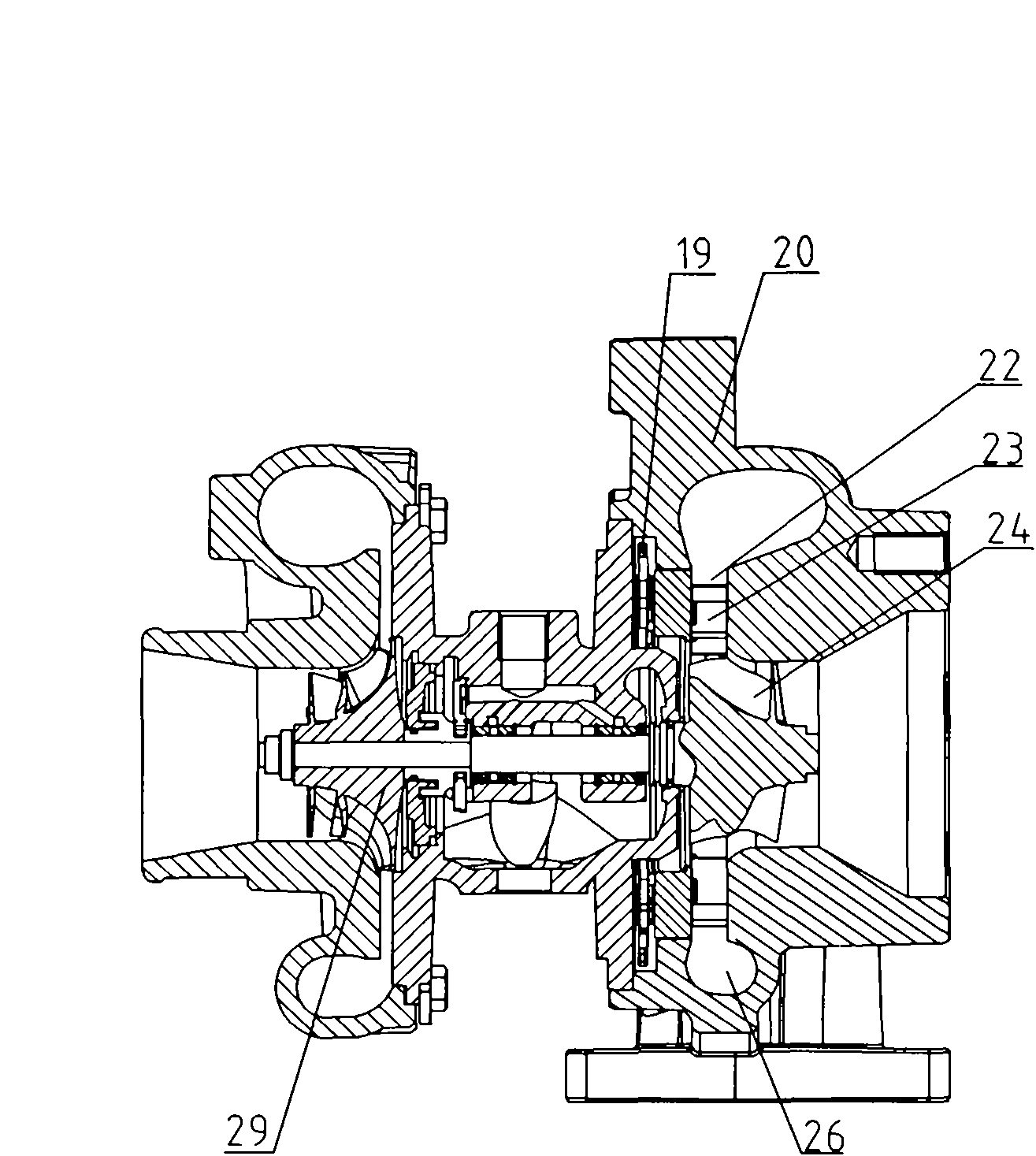

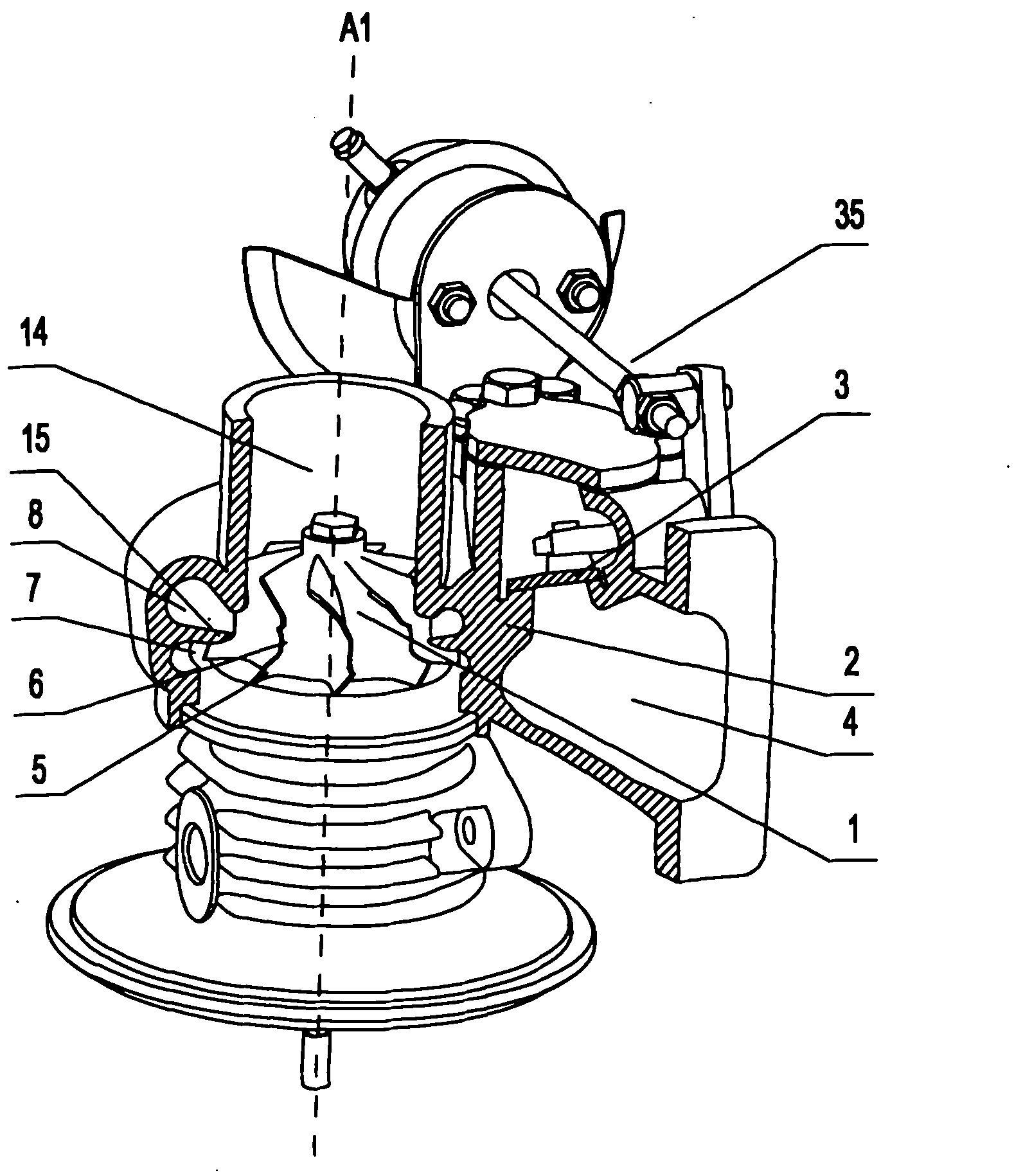

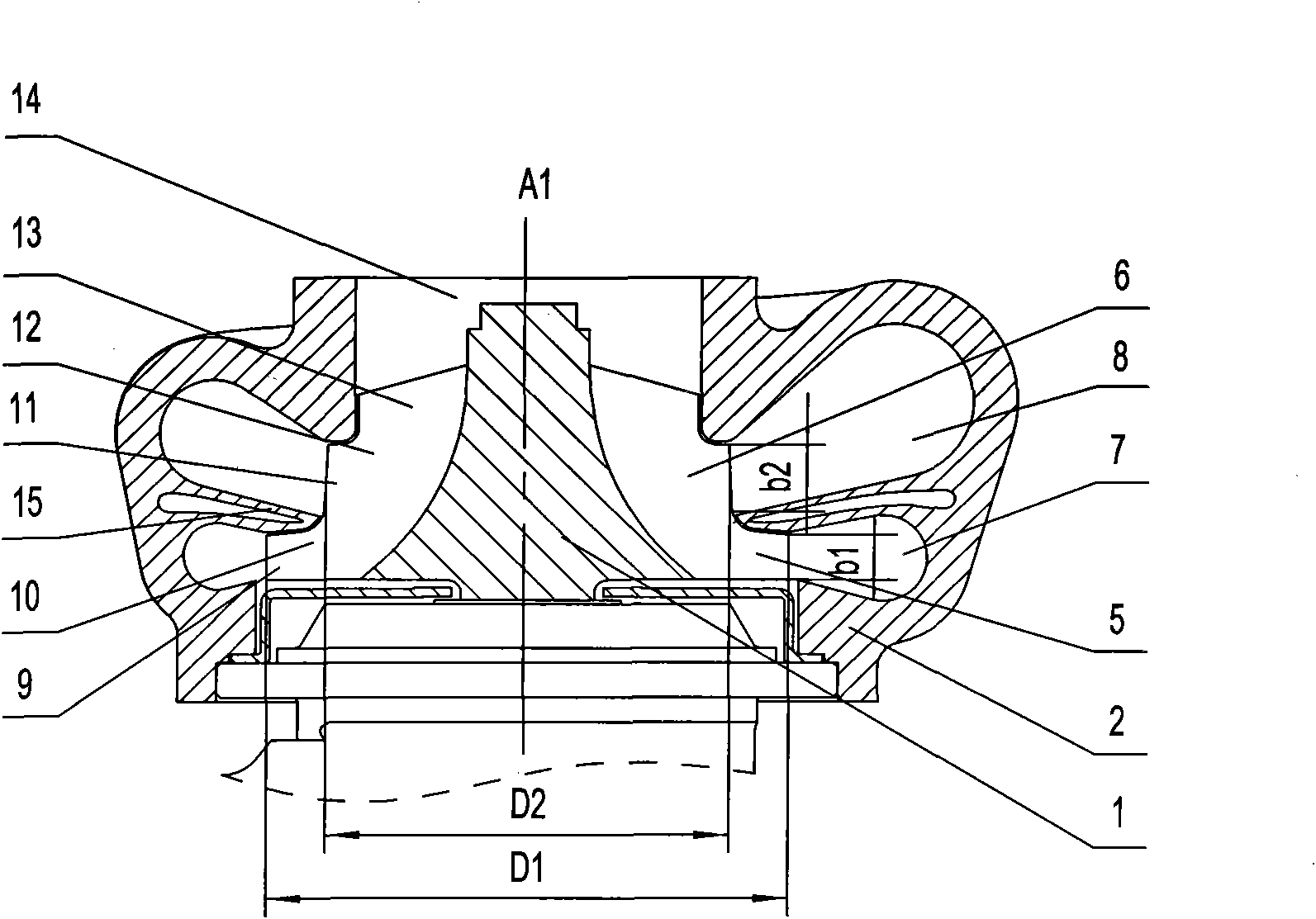

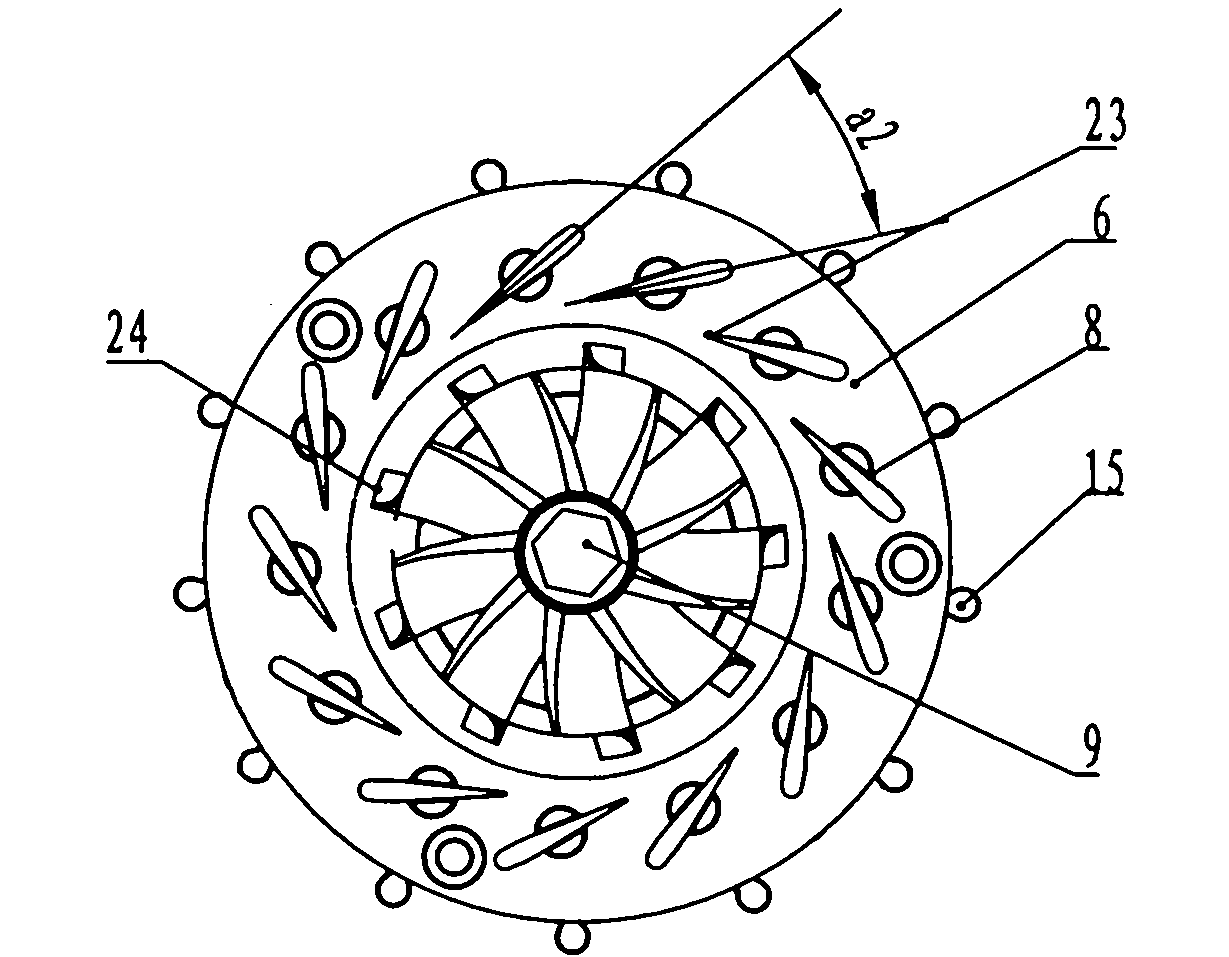

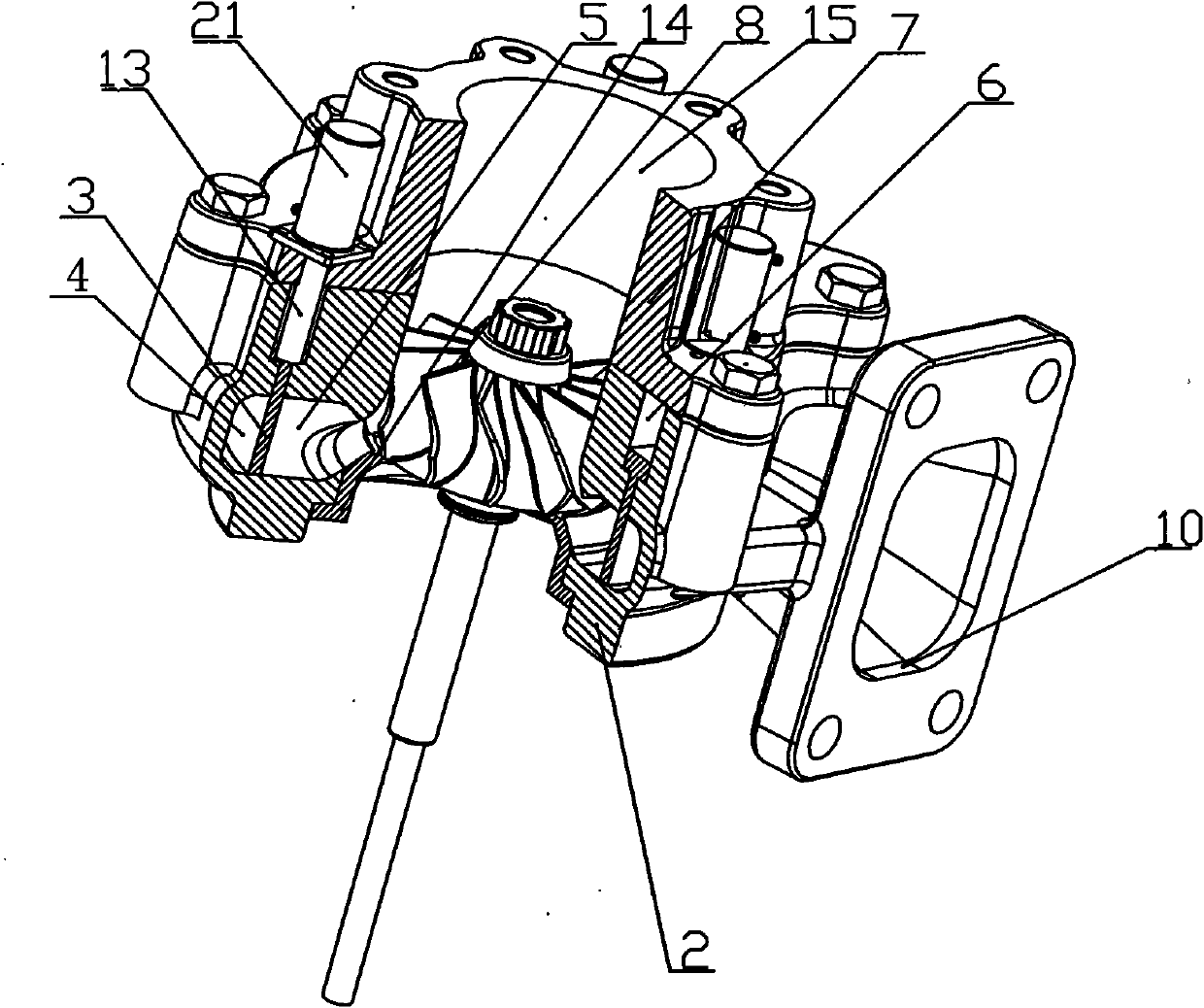

Complex turbine device with variable section

InactiveCN101985897AGuaranteed inflowAvoid enteringInternal combustion piston enginesBlade accessoriesImpellerLow speed

The invention discloses a complex turbine device with a variable section, comprising a double flow channel turbine volute, wherein the double flow channel turbine volute is provided with two air flow passageways; the double flow channel turbine volute is provided with a volute air outlet and a volute air inlet which are communicated with the air flow passageways; a complex turbine impeller is arranged in the double flow channel turbine volute; and the complex turbine impeller is formed by compounding two turbine impellers which correspond to the two air flow passageways one by one. In the invention, the variable section function can be achieved by design and development of the turbine of a turbocharger and by using the complex turbine device, thereby effectively solving the defects of poor reliability and high cost of a vane type turbocharger with the variable section, effectively improving the efficiency of the turbine of an engine in low speed and increasing the torque output of the turbine.

Owner:KANGYUE TECH

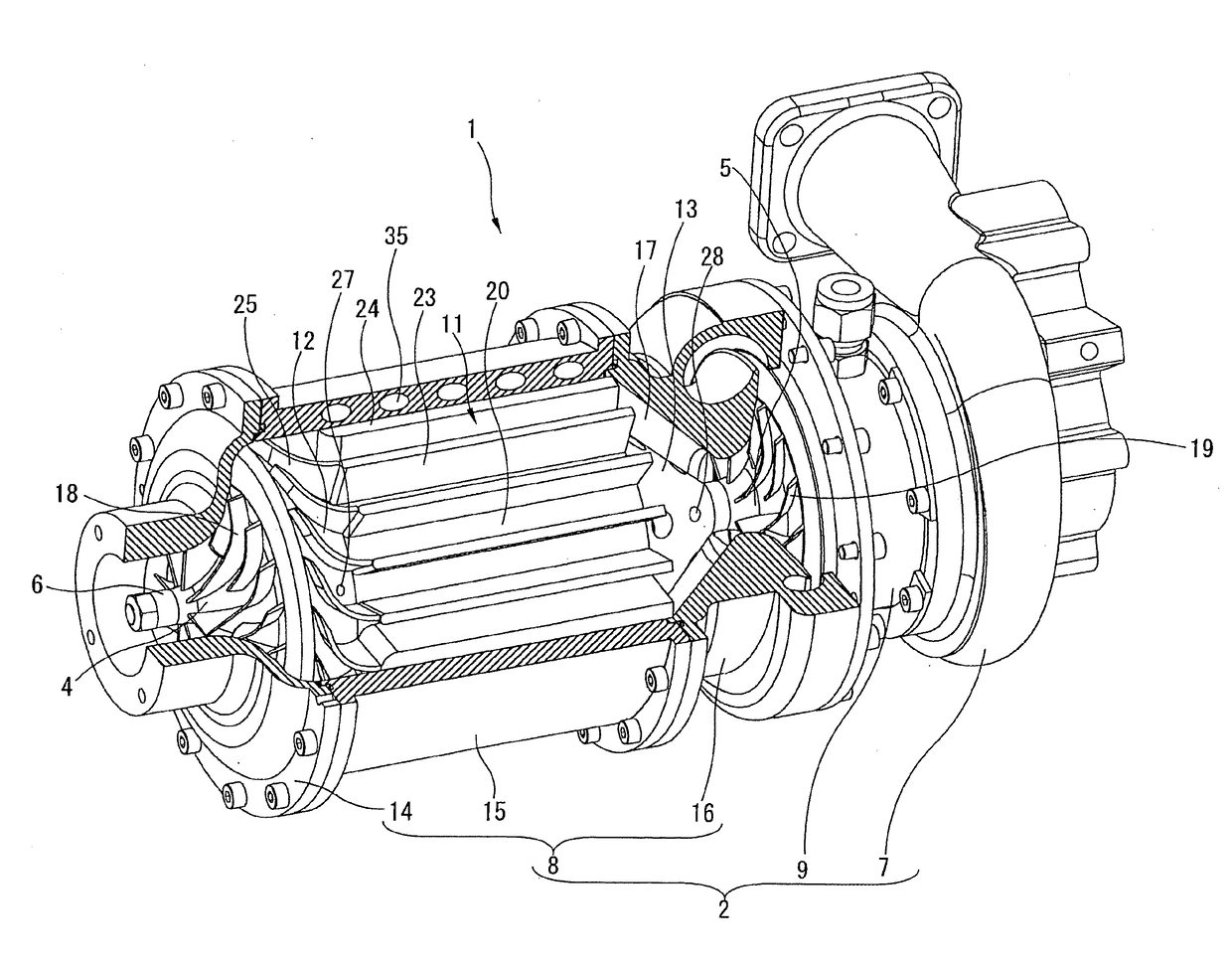

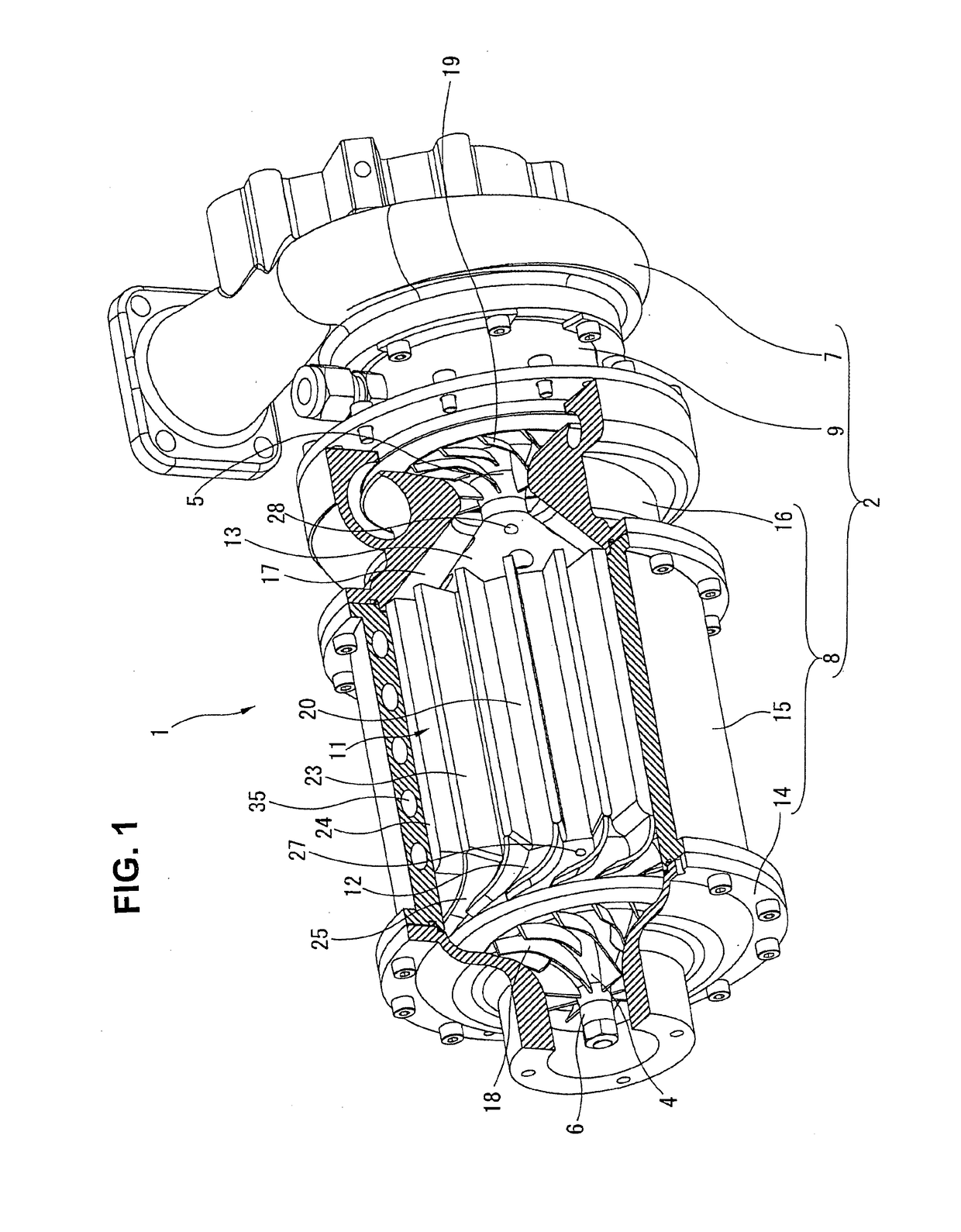

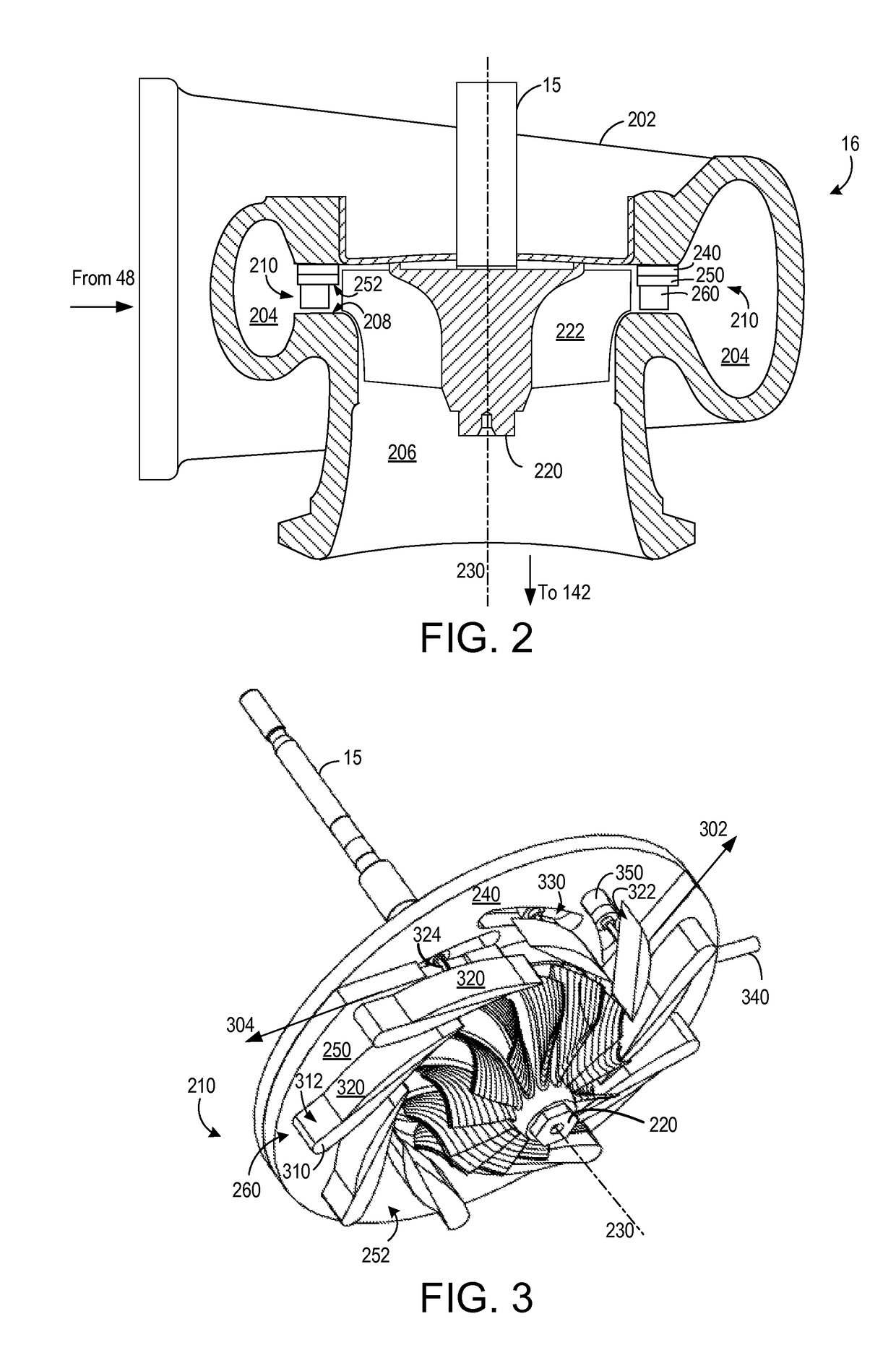

Turbocharger

InactiveUS20170328269A1Increase boost pressureProcess stabilityInternal combustion piston enginesPump componentsImpellerTurbine wheel

In a two-stage supercharging electric-assist turbocharger, a first compressor wheel, a rotor of an electric motor, a second compressor wheel, and a turbine wheel are coaxially coupled to a same, common shaft member, in that order. A compressor housing is structured to define therein a communicating passage to accommodate the electric motor in the communicating passage. A first water jacket is formed in at least one rib integrally formed with an outer periphery of a motor housing and also serving as a radiating fin, for forced-cooling air flowing through the communicating passage. A second water jacket is formed in a motor housing for forced-cooling a stator of the electric motor. A third water jacket is formed in an intermediate housing constructing a part of the compressor housing for forced-cooling a control unit configured to control the electric motor.

Owner:MAHLE FILTER SYST JAPAN CORP

Boost pressure control apparatus and boost pressure control method of internal combustion engine

InactiveUS8011185B2Increase boost pressureValve arrangementsElectrical controlPressure riseExhaust valve

A boost pressure control apparatus includes a turbocharger whose turbine is rotationally driven by exhaust of an internal combustion engine, and an EGR device, wherein EGR is performed at the time of supercharge, or the EGR amount is increased at the time of supercharge in comparison with when supercharge is not performed. If the internal EGR gas amount is increased by changing opening / closure timings of intake valves and / or exhaust valves via the EGR device, the energy of exhaust can be increased, so that the rotation speed of the turbocharger can be enhanced. Therefore, the responsiveness of boost pressure rise can be enhanced. Thus, a technology of more promptly raising the boost pressure is provided.

Owner:TOYOTA JIDOSHA KK

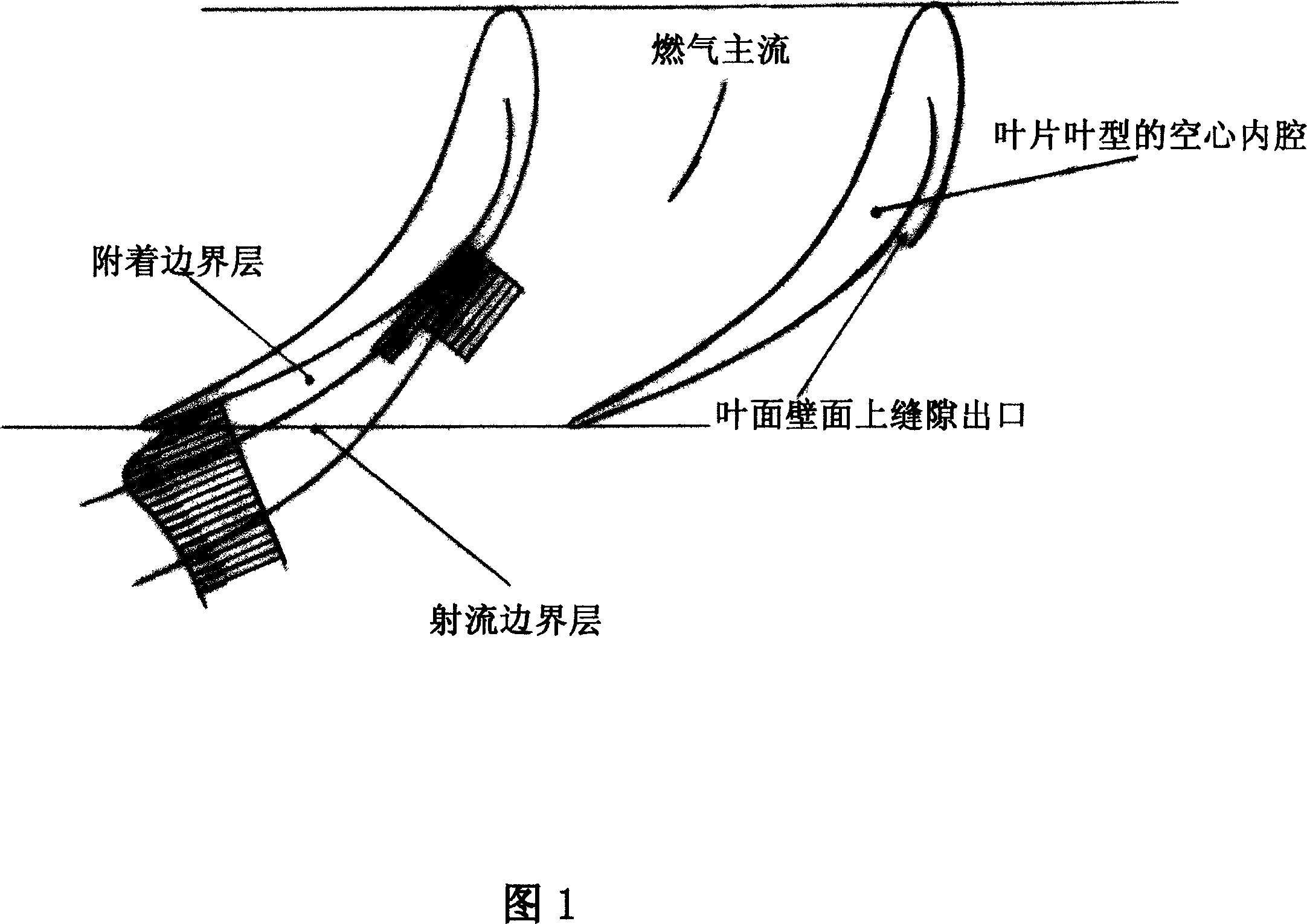

Outlet flowing intersecting surface changing adjustable turbo nozzle ring

InactiveCN101113678ALow efficiencyLarge leak lossInternal combustion piston enginesEngine componentsExternal energyTurbocharger

The invention relates to a turbine nozzle ring used in turbochargers. Compressed air from an outlet of an air compressor of the turbocharger and / or an external source goes through a hollow internal cavity of the nozzle vanes or a hollow sandwich near the internal wall of an intake pipe of a vane-less spiral case and blows directly to the nozzle vane ring or main burning gas flow at a flow passage and / or an outlet of the vane-less spiral case through a ventilation groove gap cut between a vane-shaped back side (or front side) and / or a rear margin part or through circular arc-shaped ventilation gap of the outlet of the hollow sandwich near the zero-degree section of the tip of the vane-less spiral case, making the mixed air of blowing flow from the gaps and the main flow change the flow direction at the outlet of the nozzle ring and causing the change of the flow angle (namely flow section) at the outlet. The invention has the advantages of wide range of control simple structure, low cost, safety and reliability, high efficiency, straightforward control and being applicable for turbochargers and being capable of making use of external air, additional pressure and external energy to supply auxiliary power.

Owner:孙敏超 +1

Variable valve actuation system of internal combustion engine and control apparatus of internal combustion engine

InactiveUS8036806B2Improve responsivenessEngine-torque-increase responsivenessAnalogue computers for vehiclesValve arrangementsExhaust valveVariable valve timing

In a control apparatus of a supercharged internal combustion engine, a variable valve actuation system interacts with an engine control system. A controller is configured or programmed to increase an intake-valve lift by a variable valve lift mechanism, which is provided for variably controlling at least the intake-valve lift of engine valves, when starting from a vehicle stand-still state or when accelerating from an idling state or a light load state. The controller is further configured or programmed to increase a valve overlap of intake and exhaust valves by a variable phase control mechanism, which is provided for variably phase-shifting a central phase angle of a valve lift characteristic curve of at least one of the intake and exhaust valves, while increasing a boost pressure of intake air introduced into an engine cylinder by a supercharging device, after the intake-valve lift has been increased.

Owner:HITACHI ASTEMO LTD

Exhaust gas recirculation apparatus of an internal combustion engine and control method thereof

InactiveUS7895838B2Reduce the amount requiredReduce the amount of solutionElectrical controlNon-fuel substance addition to fuelTurbochargerExternal combustion engine

An exhaust gas recirculation apparatus of an internal combustion engine includes a turbocharger provided with a turbine in an exhaust passage and a compressor in an intake passage, a low pressure EGR passage which connects the exhaust passage downstream of the turbine with the intake passage upstream of the compressor, a high pressure EGR passage which connects the exhaust passage upstream of the turbine with the intake passage downstream of the compressor; an exhaust gas control catalyst provided in the exhaust passage downstream of the turbine and upstream of the low pressure EGR passage; and EGR gas amount changing device for simultaneously changing amounts of EGR gas flowing through the low pressure EGR passage and the high pressure EGR passage such that a temperature of the exhaust gas control catalyst is within a target range.

Owner:TOYOTA JIDOSHA KK

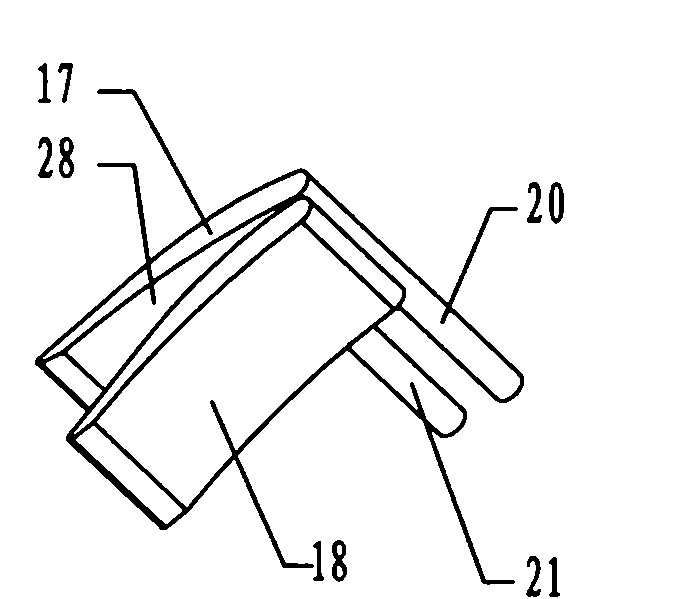

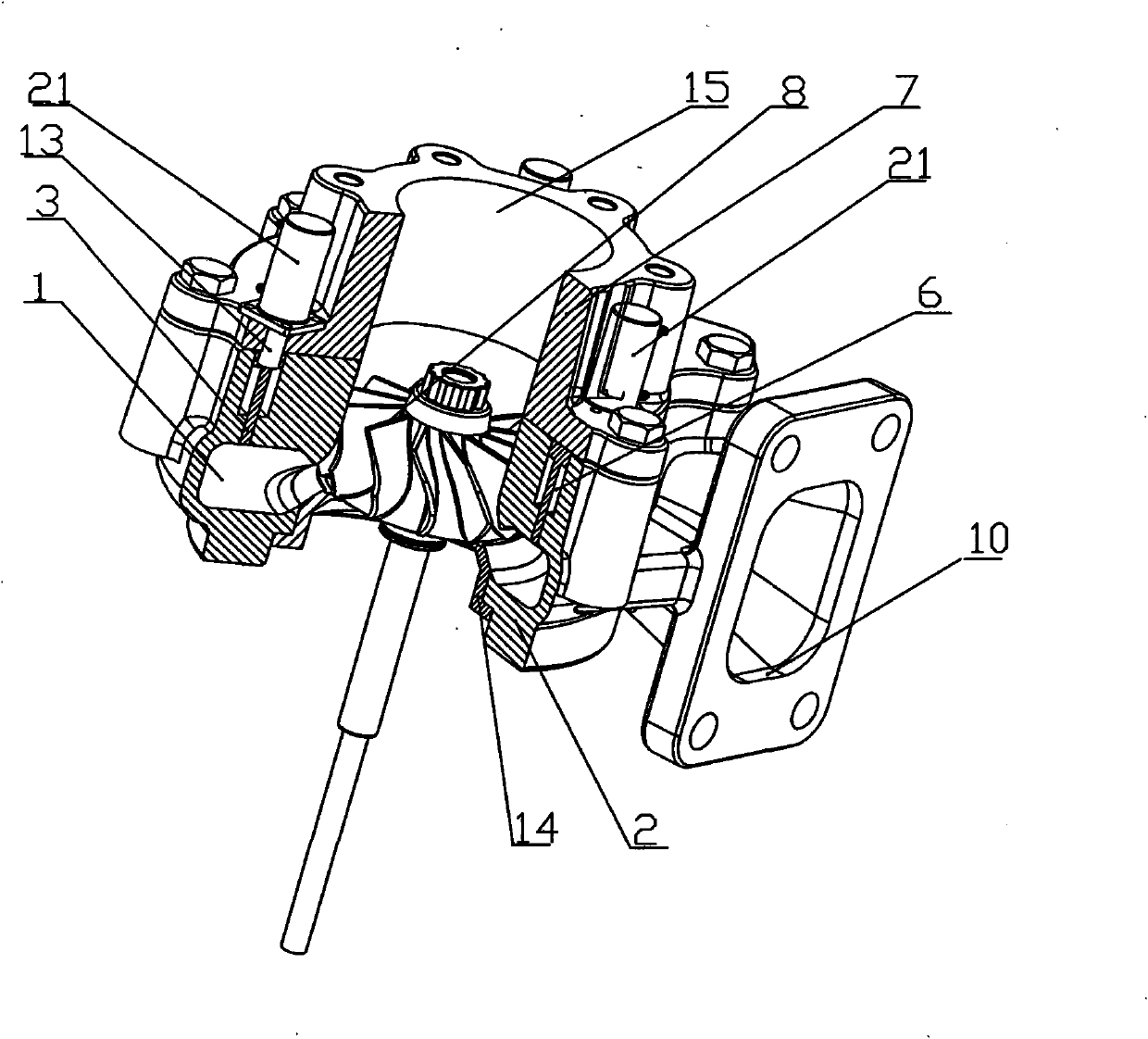

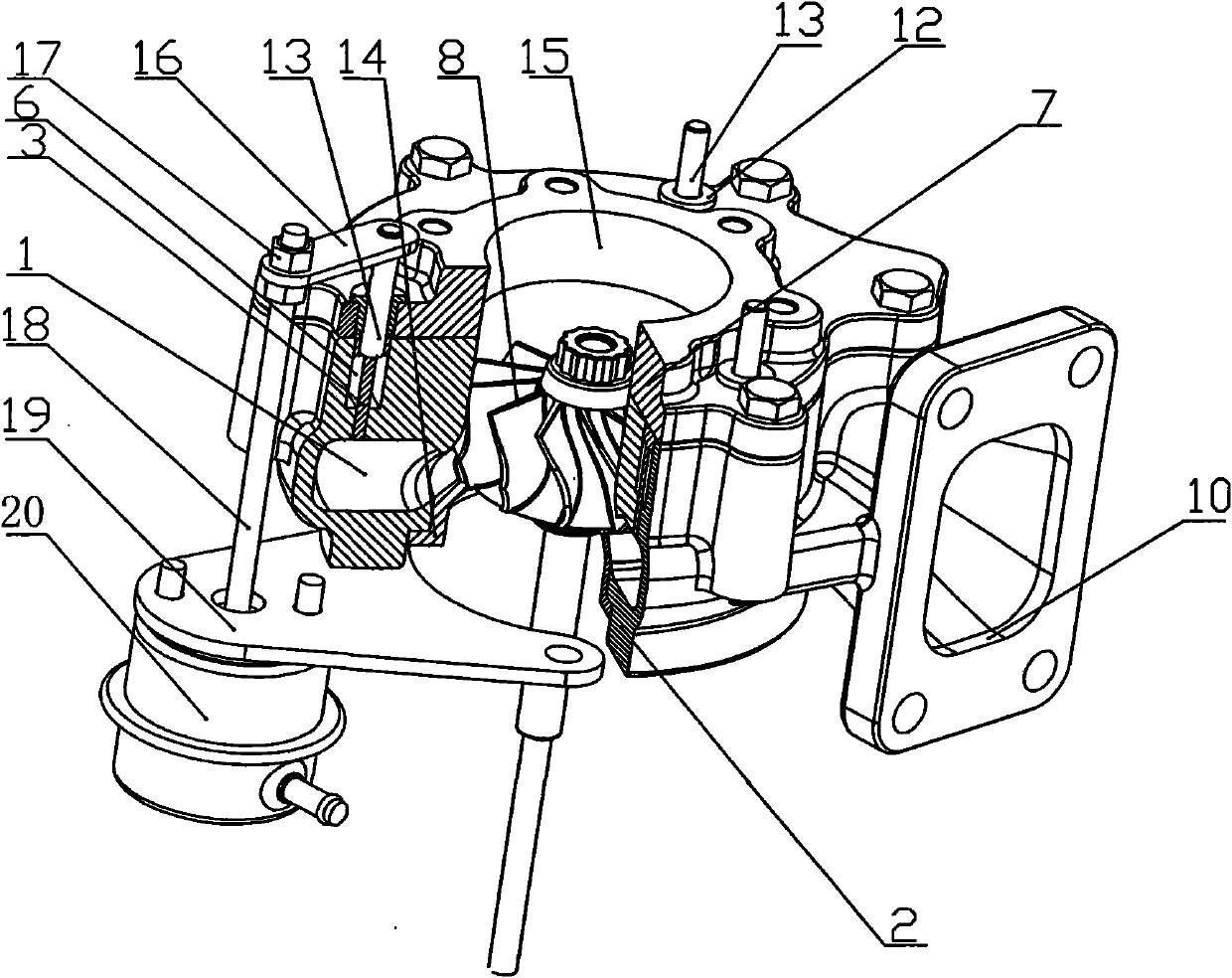

Turbocharger composite nozzle device

ActiveCN101949305AReduce wearImprove working abilityInternal combustion piston enginesBlade accessoriesImpellerTurbine wheel

The invention discloses a turbocharger composite nozzle device, comprising a turbine wheel and a nozzle ring supporting disc mounted coaxially therewith. The nozzle ring supporting disc is provided with a plurality of groups of composite nozzle blades each comprising a movable blade and a fixed blade, the fixed blade is fixedly connected with the nozzle ring supporting disc and the movable blade is in transmission connection with a power transmission device; in case of other working conditions of an engine, a transmission mechanism adjusts the position of the movable blade continuously according to the change of the working conditions of the engine, and the control for waste gas energy is realized by changing the area of volute nozzle outlet, in order to improve aerodynamic performance ofthe turbocharger, especially aerodynamic performance of the engine under the working condition of small flow, thus better matching with the engine is reached.

Owner:康跃科技(山东)有限公司

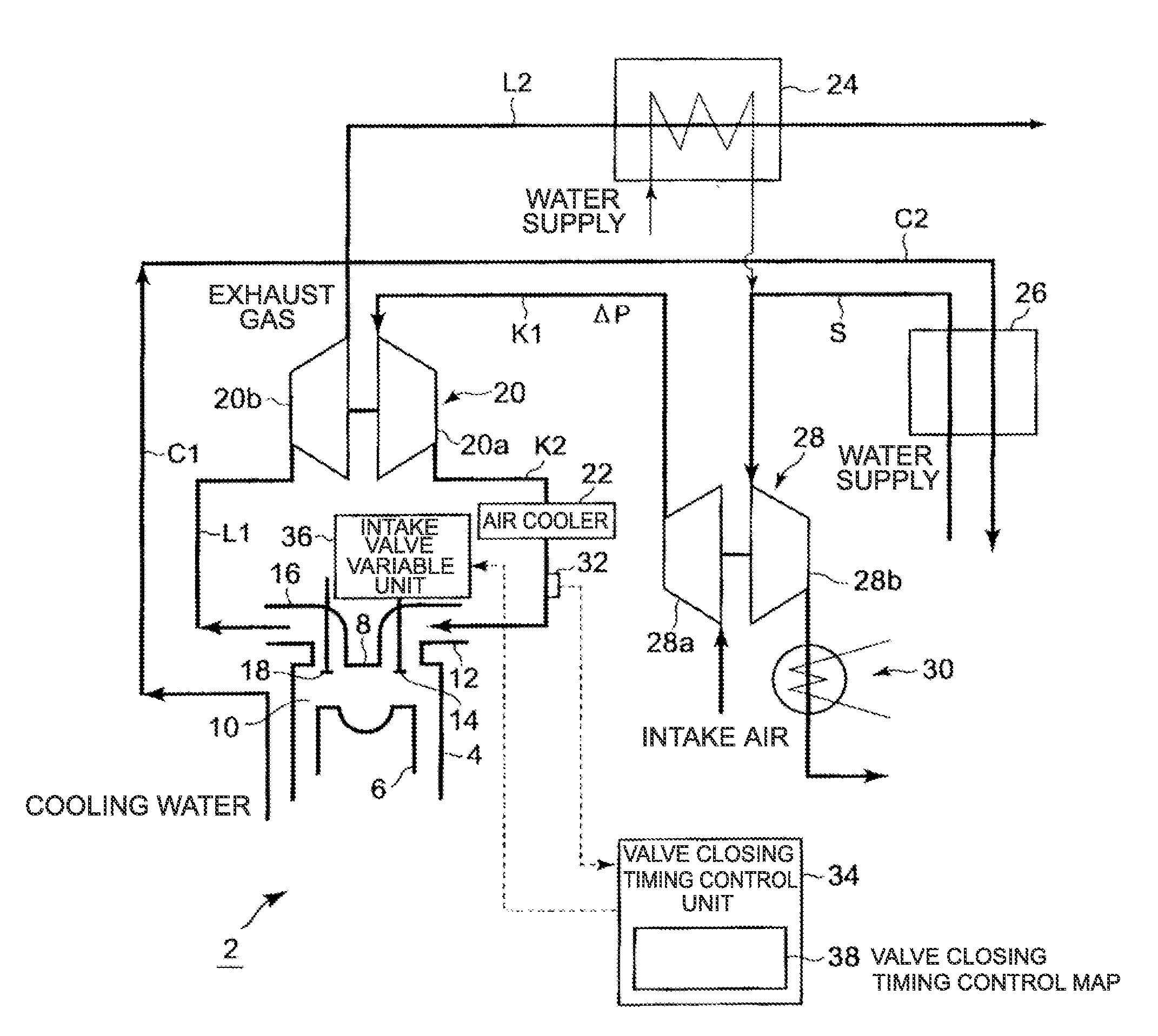

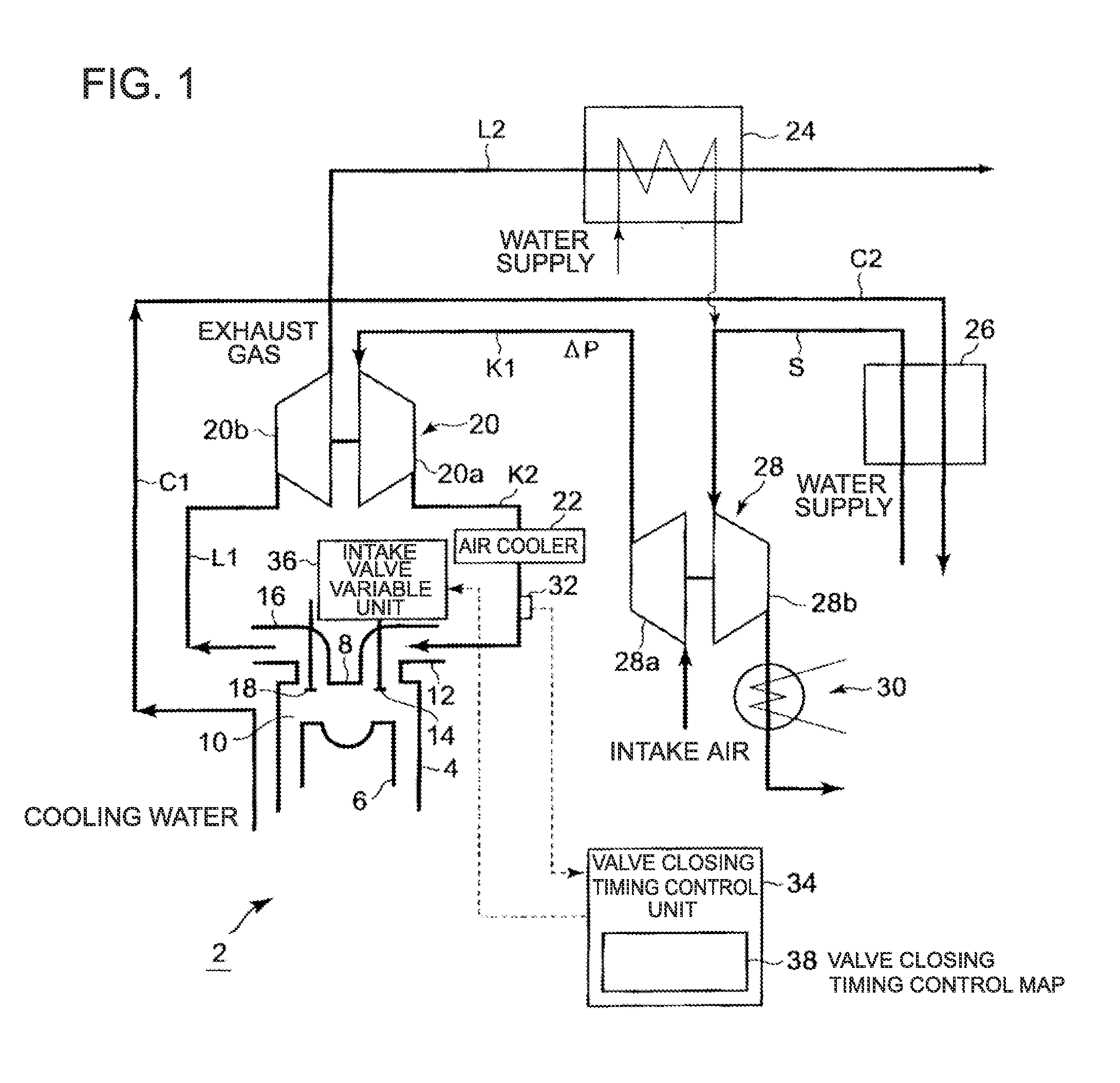

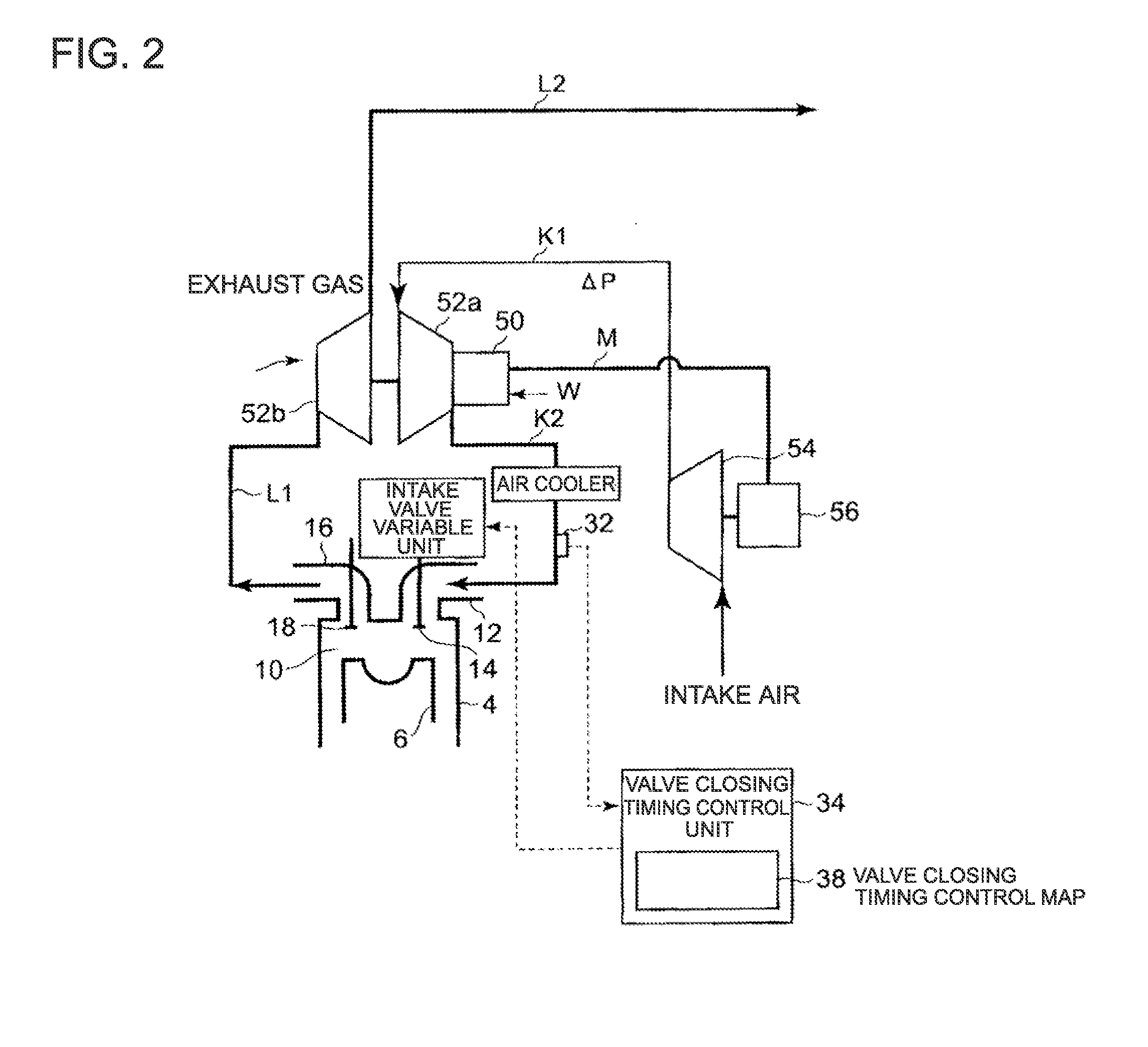

Miller cycle engine

InactiveUS20120279218A1Increase boost pressureConvenience to workInternal combustion piston enginesExhaust apparatusEngineeringThermal efficiency

Provided is a miller cycle engine in which the thermal efficiency is improved by increasing boost pressure, while the reliability of mechanical strength and thermal load of the engine body is secured by maintaining a maximum in-cylinder pressure. The mirror cycle engine includes an intake valve variable unit (36) for controlling timing to open or close an intake valve (14), a steam. turbine (28) serving as a boost pressure adding device which adds an additional boost pressure to the boost pressure increased by a turbocharger (20) so as to increase only the boost pressure, or so as to increase the boost pressure by the additional boost pressure that is larger than increase in exhaust pressure, and a valve closing timing control unit (34) which advances more the timing to close the intake valve (14) as the additional boost pressure added by the steam turbine (28) becomes higher so as to maintain the boost pressure at substantially the same level as a maximum in-cylinder pressure before adding the additional boost pressure.

Owner:MITSUBISHI HEAVY IND LTD

Auxiliary pressurization system adopting waste gas bypass

PendingCN109372662AReduce energy wasteImprove energy utilizationMachines/enginesAir intakes for fuelIntake pressureAutomotive engineering

The invention discloses an auxiliary pressurization system adopting waste gas bypass. An intake port of a pressure accumulator (12) is connected with an intercooler intake pipe through a pressure accumulation pipeline (9); an exhaust port of the pressure accumulator (12) is connected with an engine intake connection pipe (5) through an auxiliary pressurization intake pipeline (14); a pressure accumulation bypass valve (10) and a check valve I (11) are arranged on the pressure accumulation pipeline (9); a pressurization bypass valve (15) and a check valve II (16) are arranged on the auxiliary pressurization intake pipeline (14); an intake pressure sensor (17) is arranged on an engine intake pipe (6); and the pressure accumulation bypass valve (10), the pressurization bypass valve (15) and the intake pressure sensor (17) are electrically connected with an engine ECU (13) separately. The excessive compressed air is collected through the pressure accumulator (12), so that the energy wasteis reduced, and the energy utilization rate is effectively increased.

Owner:DONGFENG COMML VEHICLE CO LTD

Method for operating a supercharged internal combustion engine

InactiveUS20060207253A1Improve efficiencyIncrease speedInternal combustion piston enginesEngine controllersLow loadInternal combustion engine

In a method for operating a supercharged internal combustion engine, the exhaust gas turbine of which is equipped with a variable turbine geometry, if the pressure upstream of the compressor is higher than the pressure downstream of the compressor in the lower load / speed of the internal combustion engine, the variable turbine geometry is adjusted in the direction of its back-up position until the turbine efficiency is at least approximately in the region of the optimum efficiency.

Owner:DAIMLER AG

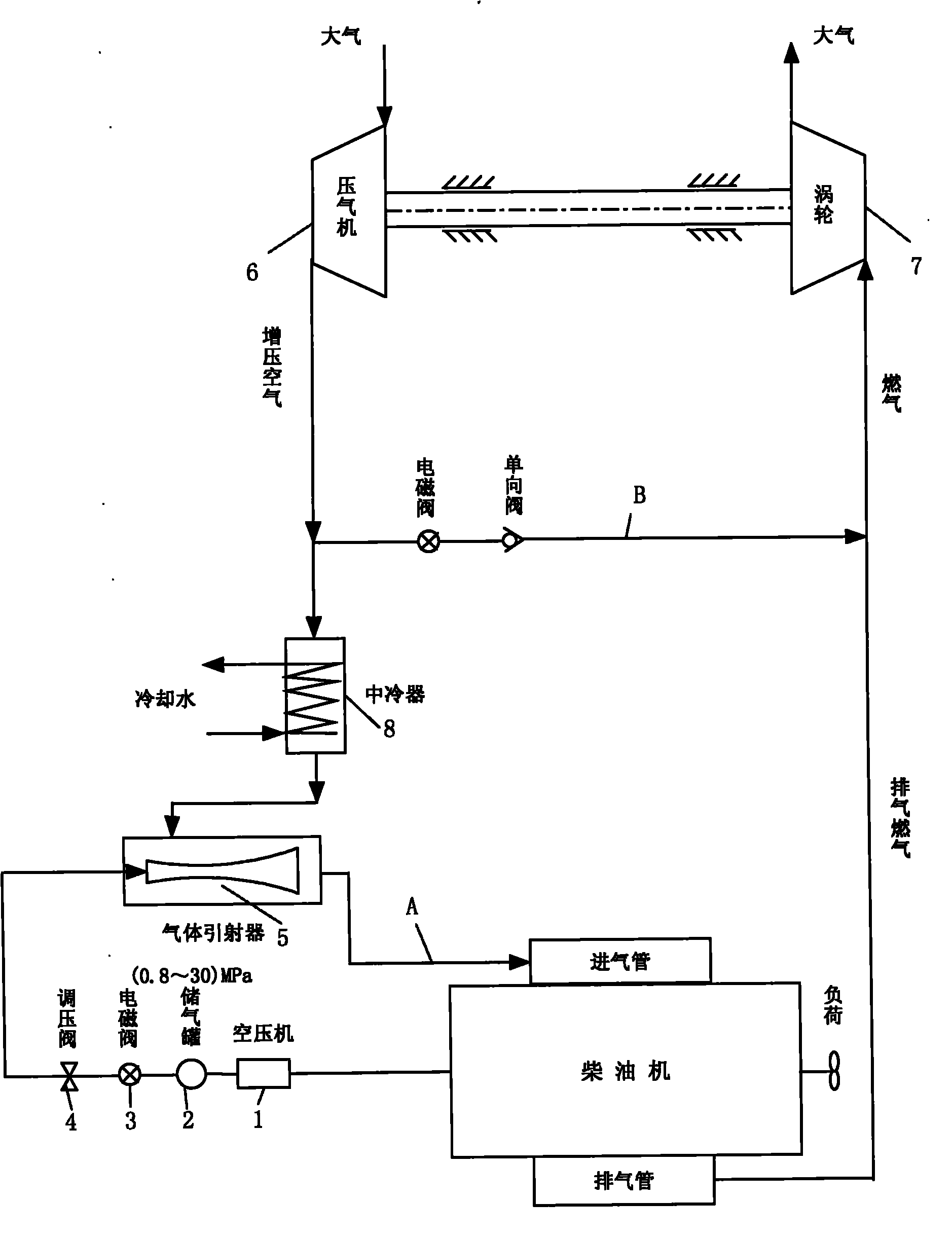

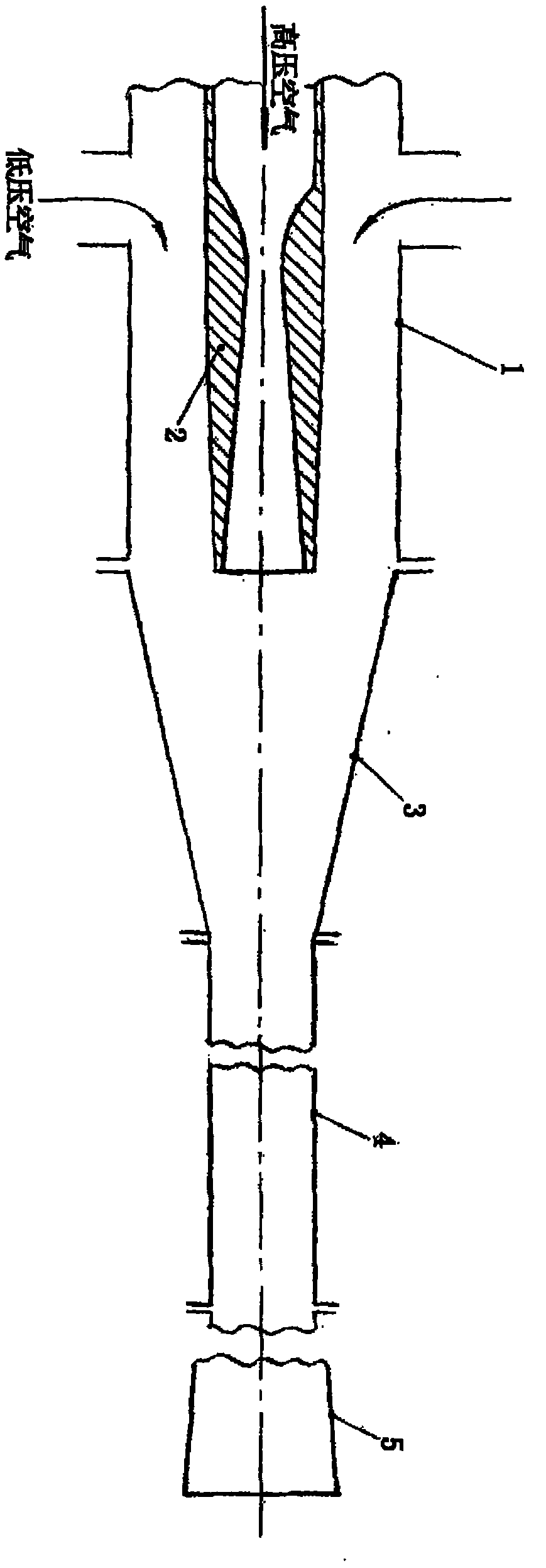

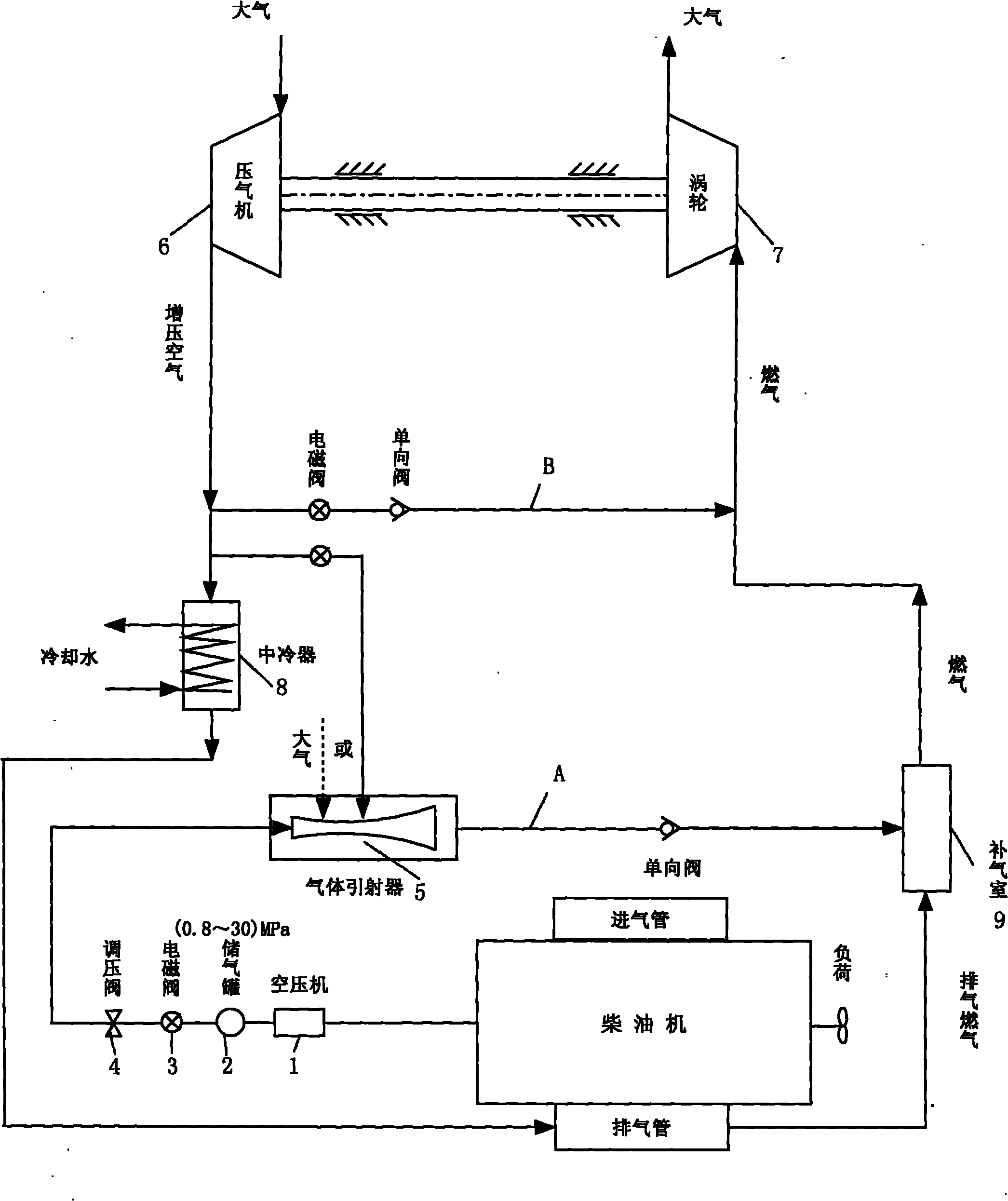

Injection/drainage air-supply turbocharging system

InactiveCN102128079AImprove working abilityIncrease mass flowInternal combustion piston enginesMature technologyHigh pressure

The invention discloses an injection / drainage air-supply turbocharging system which is applied to a turbocharged internal combustion engine of vehicles, ships and engineering machines to improve the low (rotating speed and load) working condition performance and the transient characteristics of the turbocharged internal combustion engine. Through two supplementary air supply structures, namely a high pressure air injection air supply pipeline and a turbocharged air drainage air supply pipeline of the system, charging air flowing into the internal combustion engine and combustion air flowing into a turbine are supplied, so that the power and the turbocharging pressure of the turbine are greatly increased, and the fuel consumption, the exhaust temperature and the harmful emission are obviously reduced. Compared with the prior art, the invention has the advantages of mature technology, simple structure, safe and reliable use, great conditioning degree and good effect.

Owner:孙敏超 +1

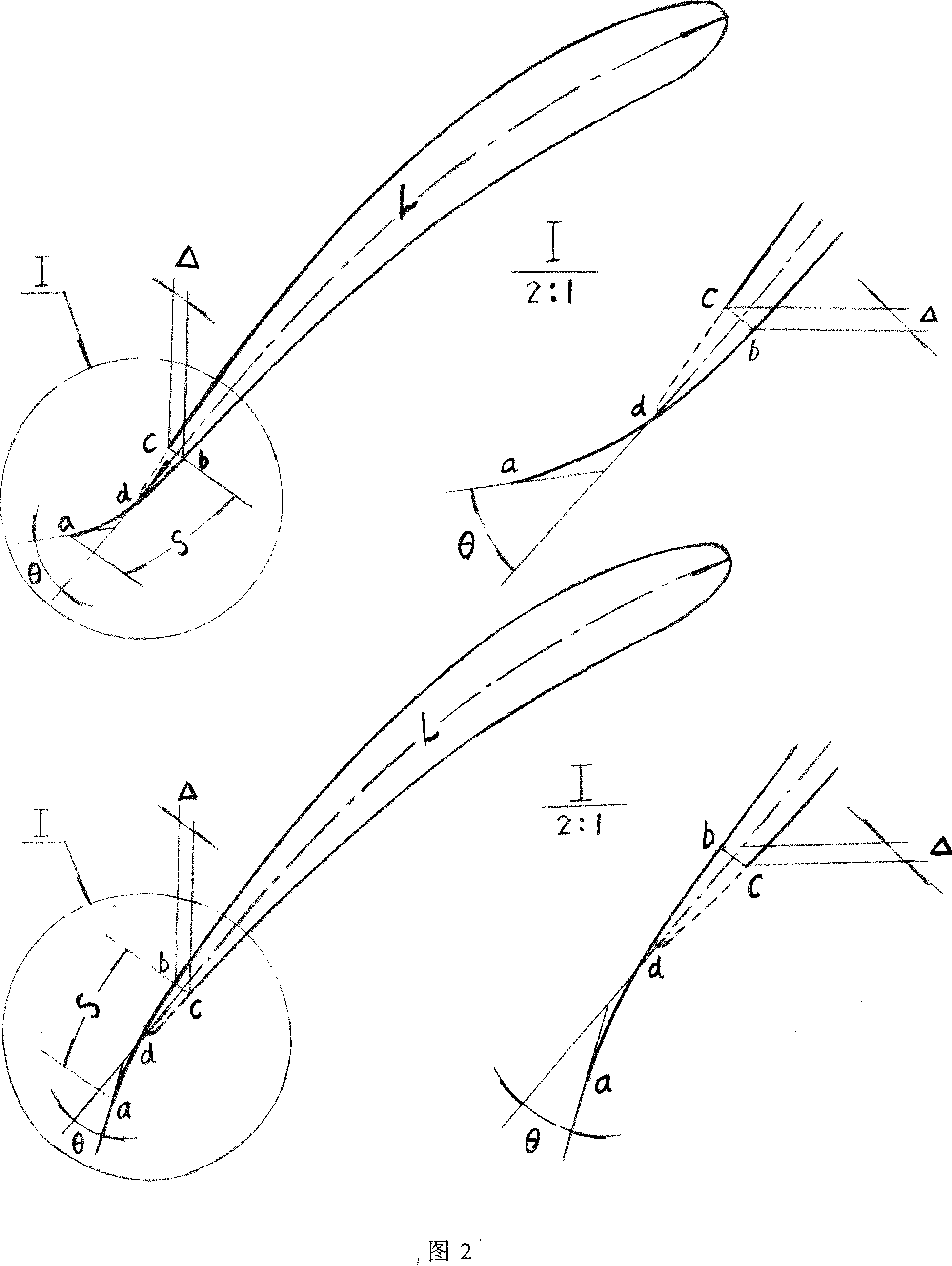

Turbine nozzle ring with adjustable and variable outlet flowing angle

InactiveCN102094705ASmall footprintReduce manufacturing costInternal combustion piston enginesStatorsJet flowTurbocharger

The invention relates to a turbine nozzle ring in a turbocharger. Pressurized air flowing out from an outlet manifold bypass of an air compressor of the turbocharger per se and / or compressed air of an external air source (or exhaust fuel gas flowing out from an outlet manifold bypass of an exhaust pipe of an internal-combustion engine) passes through the hollow cavity of a nozzle blade or a hollow interlayer nearby the inner wall of a bladeless volute inlet pipe, and jets and blows a nozzle blade ring or the interior of a bladeless volute runner and / or a main fuel gas flow in a downstream way from a blade profile back (or ventral face) and / or a through-flow slit cut at the tail edge part (a jet deflection arc guide plate is connected to the back of the tail edge slit) or an annular arc through-flow gap at a hollow interlayer outlet nearby the zero-degree section of a bladeless volute tongue tip and the jet deflection arc guide plate connected thereafter, so that the air flow formed by mixing the gap jet flow and the main flow generates flow direction deflection at the outlet of the nozzle ring to cause the change of an outlet airflow angle (namely outlet flowing section area). The turbine nozzle ring has the advantages of high control strength, simple structure, low cost, safety, reliability, high efficiency, convenience for control and applicability for the gasoline engine turbocharger, and the additional air has the functions of additional pressurization and auxiliary energy application.

Owner:孙敏超 +1

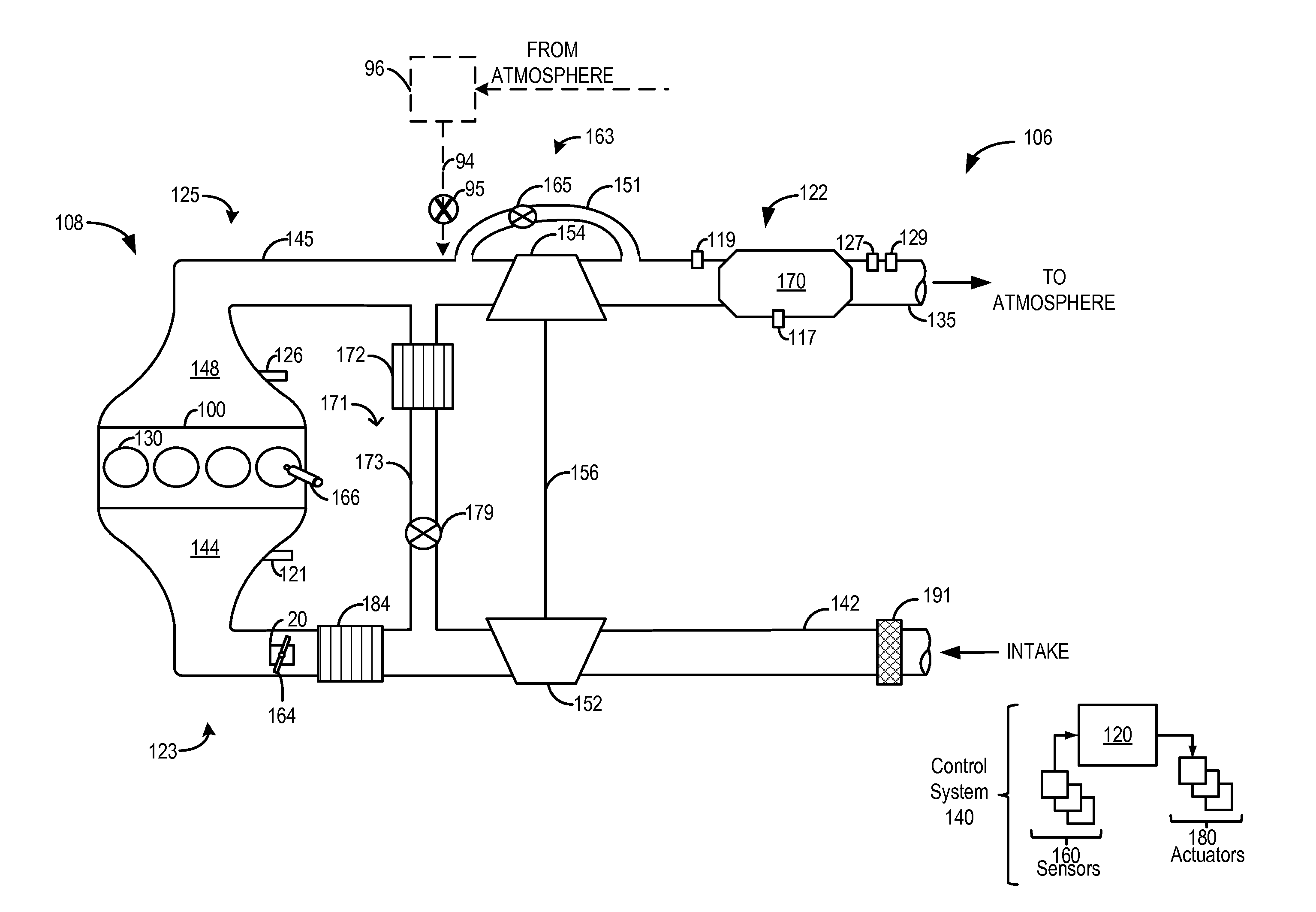

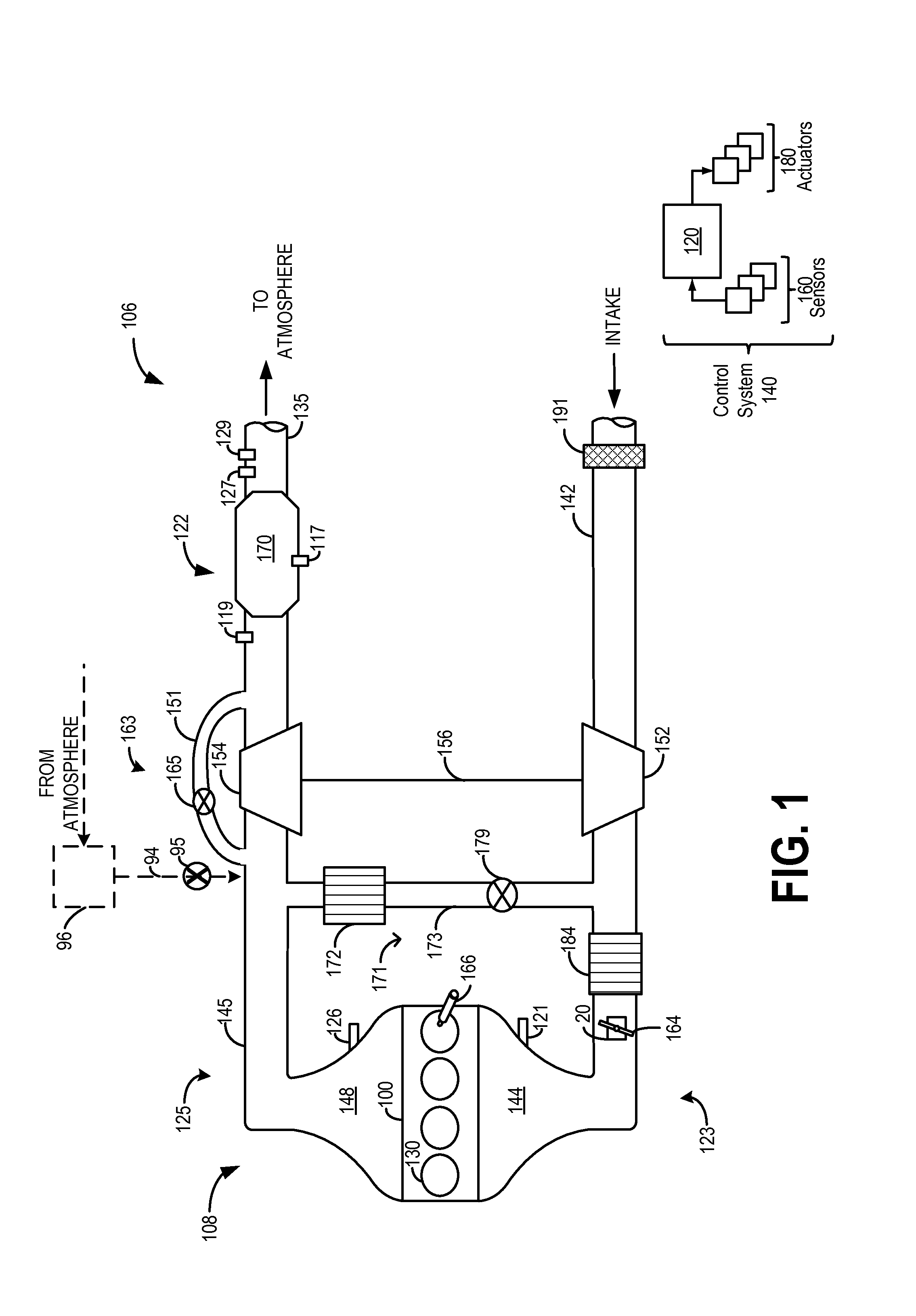

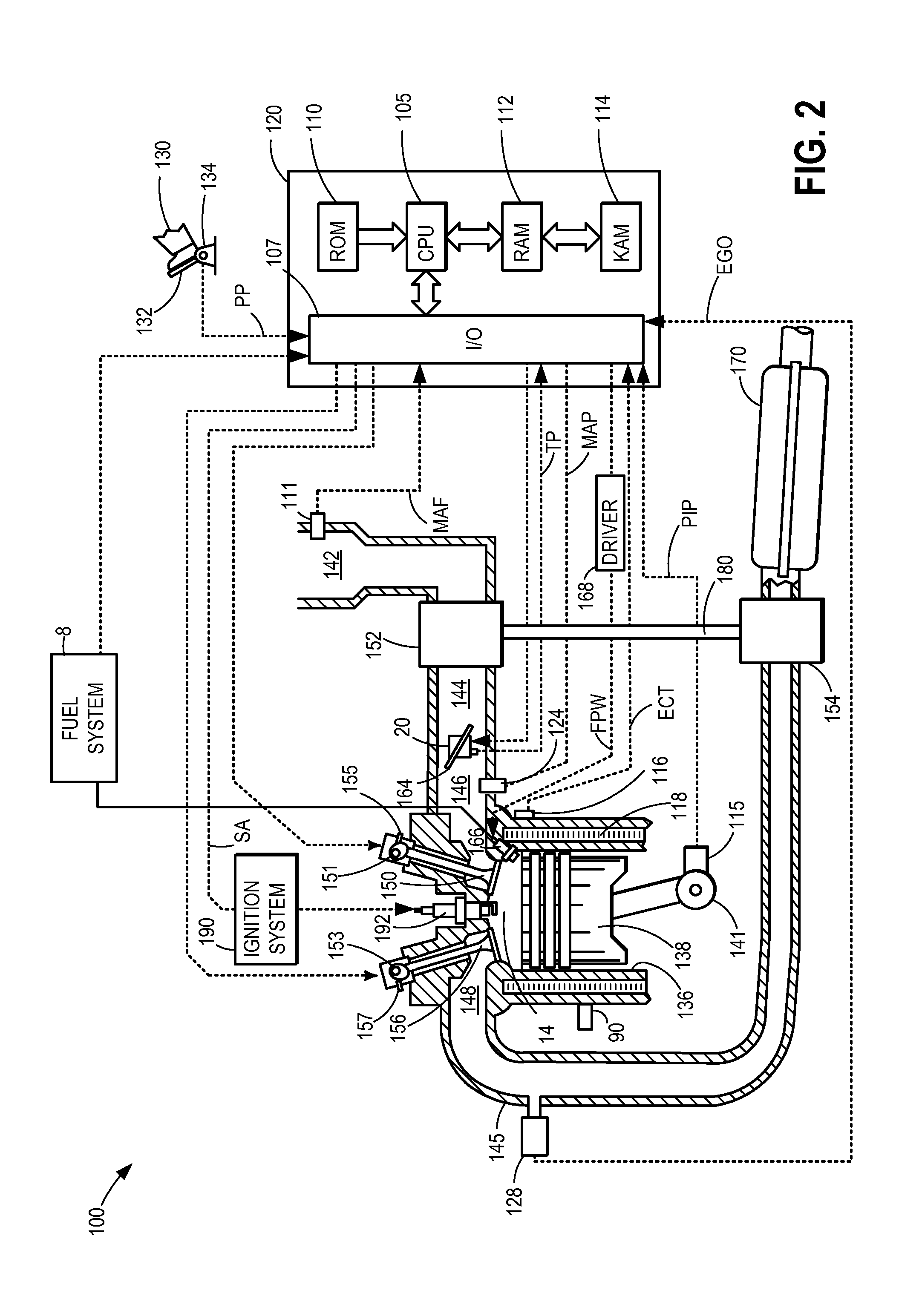

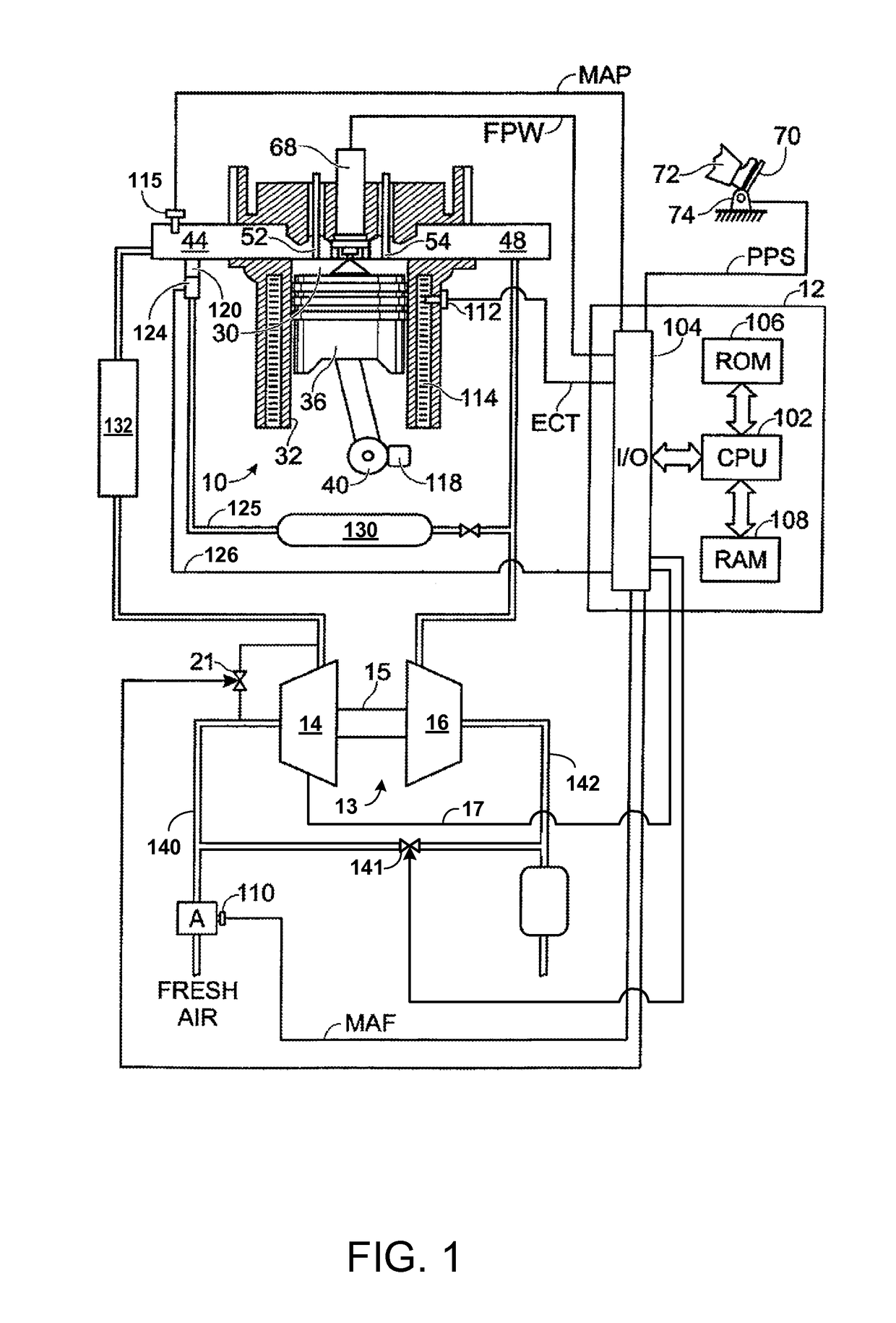

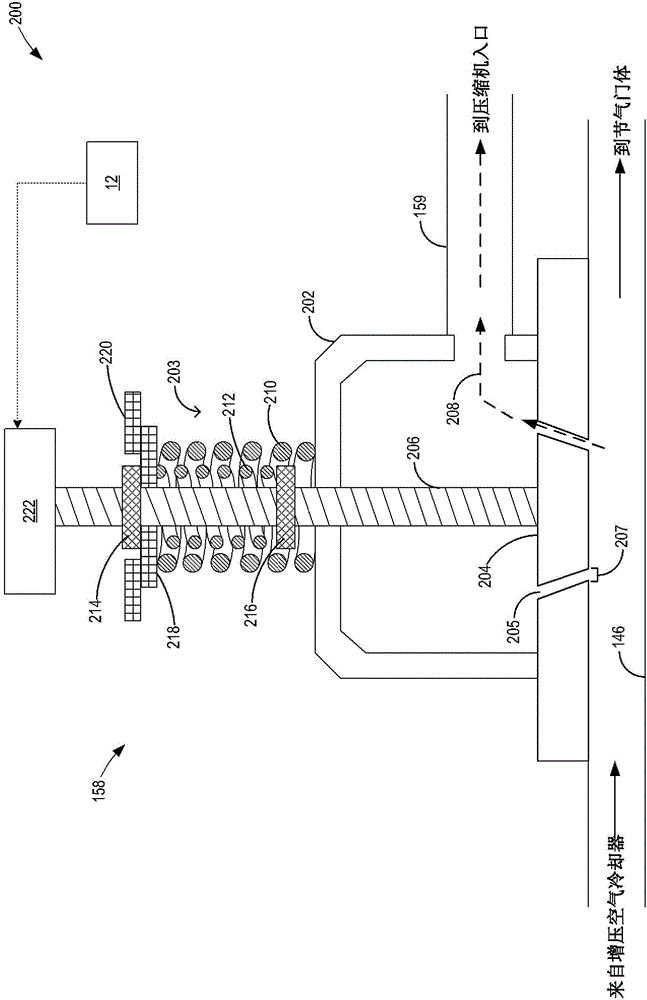

Coordination of secondary air and blow-through air delivery

Methods and systems are provided for controlling and coordinating secondary air injection and blow-through to reduce turbo lag. By utilizing secondary air injection prior to providing blow-through, and deactivating the secondary air pump when a desired boost pressure for blow-through is achieved, turbine spin-up to a desired speed may be expedited and initial torque output may be increased.

Owner:FORD GLOBAL TECH LLC

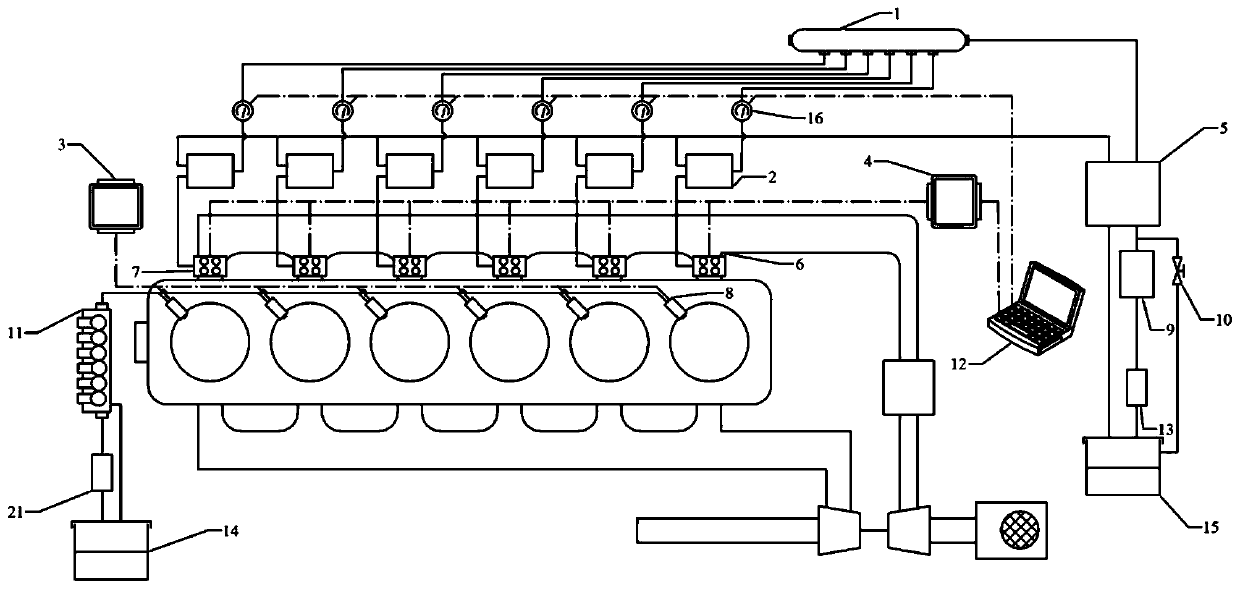

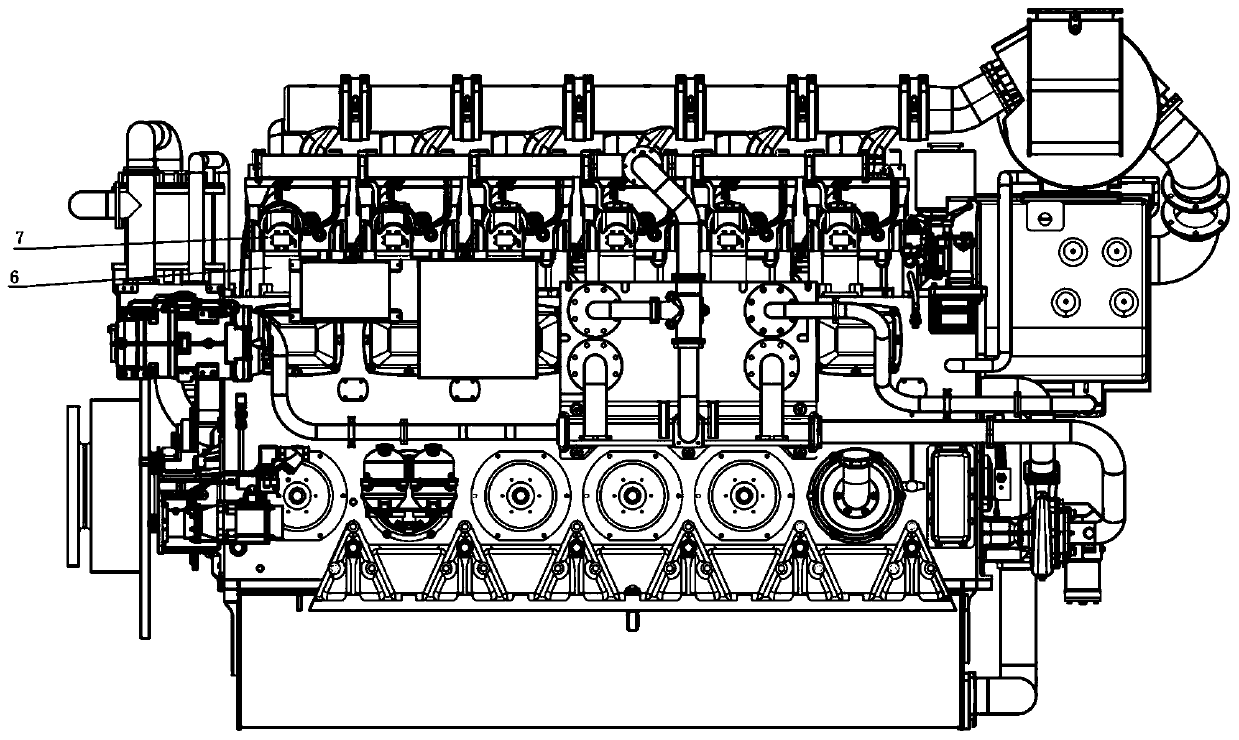

Diesel and methanol dual-fuel system of internal combustion locomotive engine and method

PendingCN110454289AImplement working modeGuaranteed consumption requirementsElectrical controlInternal combustion piston enginesCombustionControl system

The invention discloses a diesel and methanol dual-fuel system of an internal combustion locomotive engine and a method. The dual-fuel system comprises a diesel engine and further comprises a methanolsupplying system, a methanol sprayer assembly and a methanol spraying control system; the methanol supplying system comprises a methanol tank, a methanol filter, a methanol pump, a methanol flowmeter, a distribution box and a methanol pressure-limiting valve, and the methanol tank is sequentially connected with the methanol pump, the methanol flowmeter and the distribution box through pipelines;the distribution box comprises an input end and a plurality of output ends, and each output end is sequentially connected with the methanol pressure-limiting valve and the methanol sprayer assembly through pipelines; the methanol sprayer assembly comprises a methanol rail, a methanol rail pressing plate, a methanol spraying nozzle and a gas inlet bent pipe; and the methanol spraying control systemcomprises a methanol electronic control unit, a control wire harness, an upper computer, a rotating speed sensor, a coolant temperature sensor, a throttle position sensor, a methanol liquid level meter and a fault alarm device.

Owner:TIANJIN UNIV +1

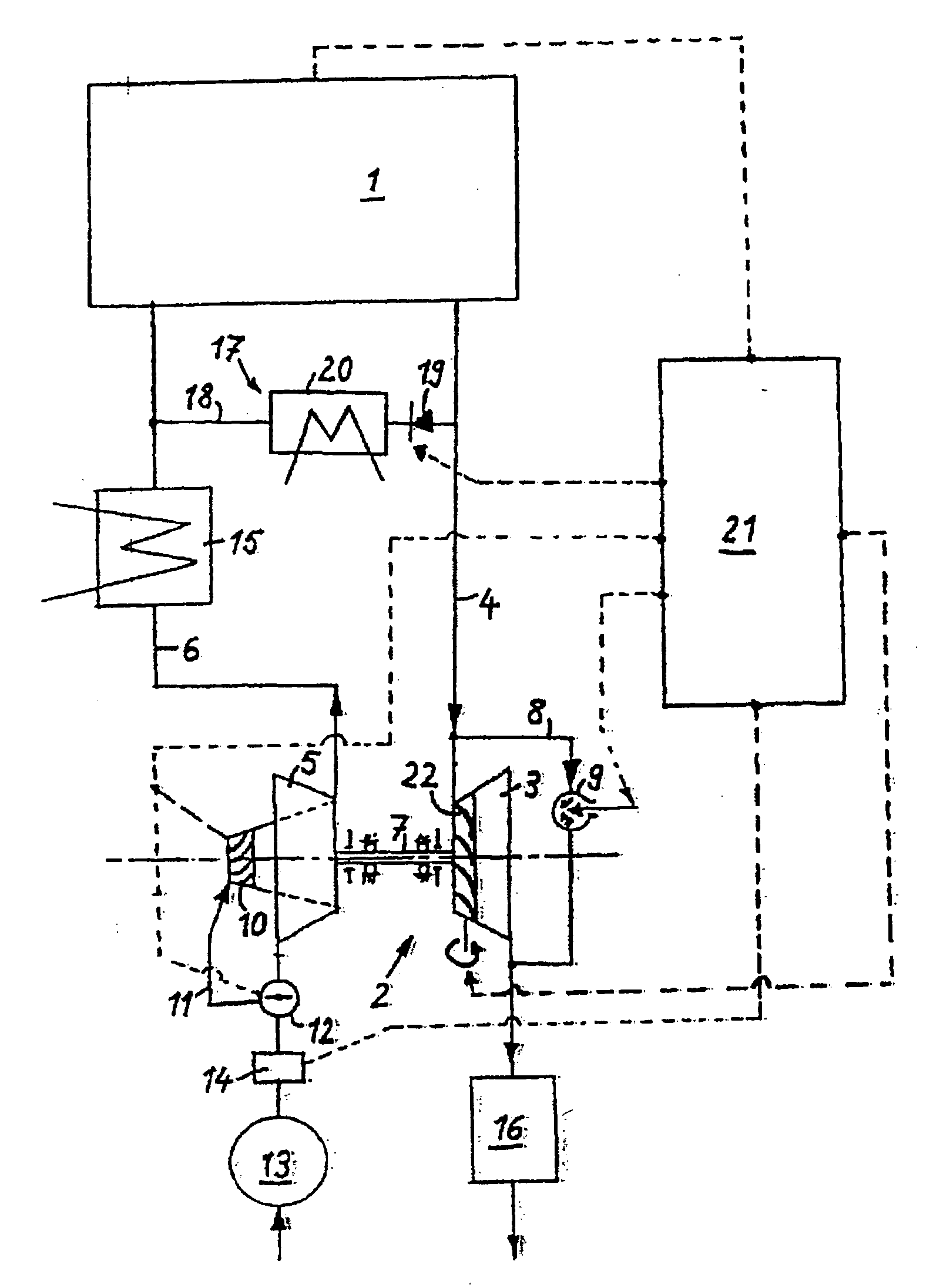

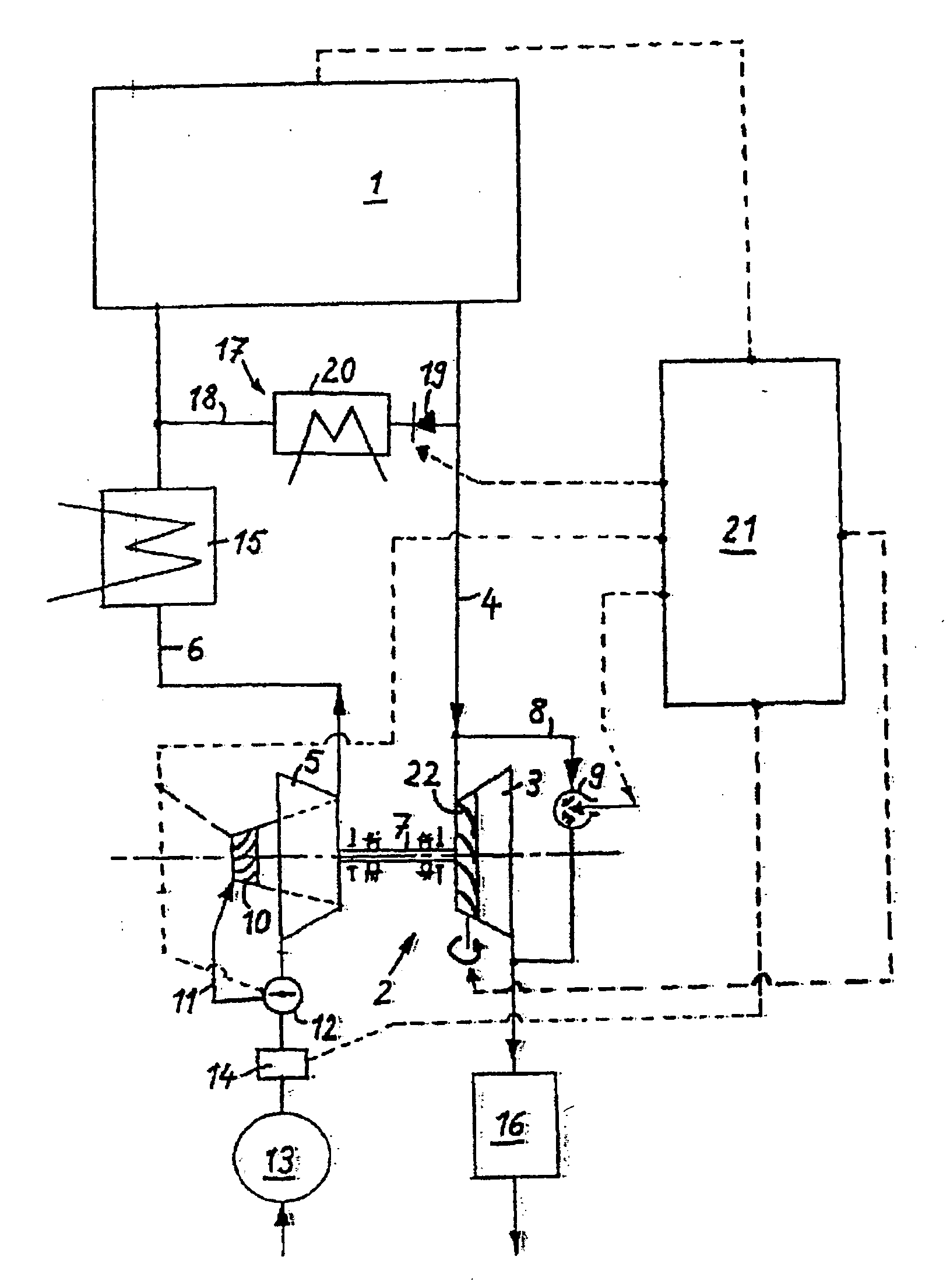

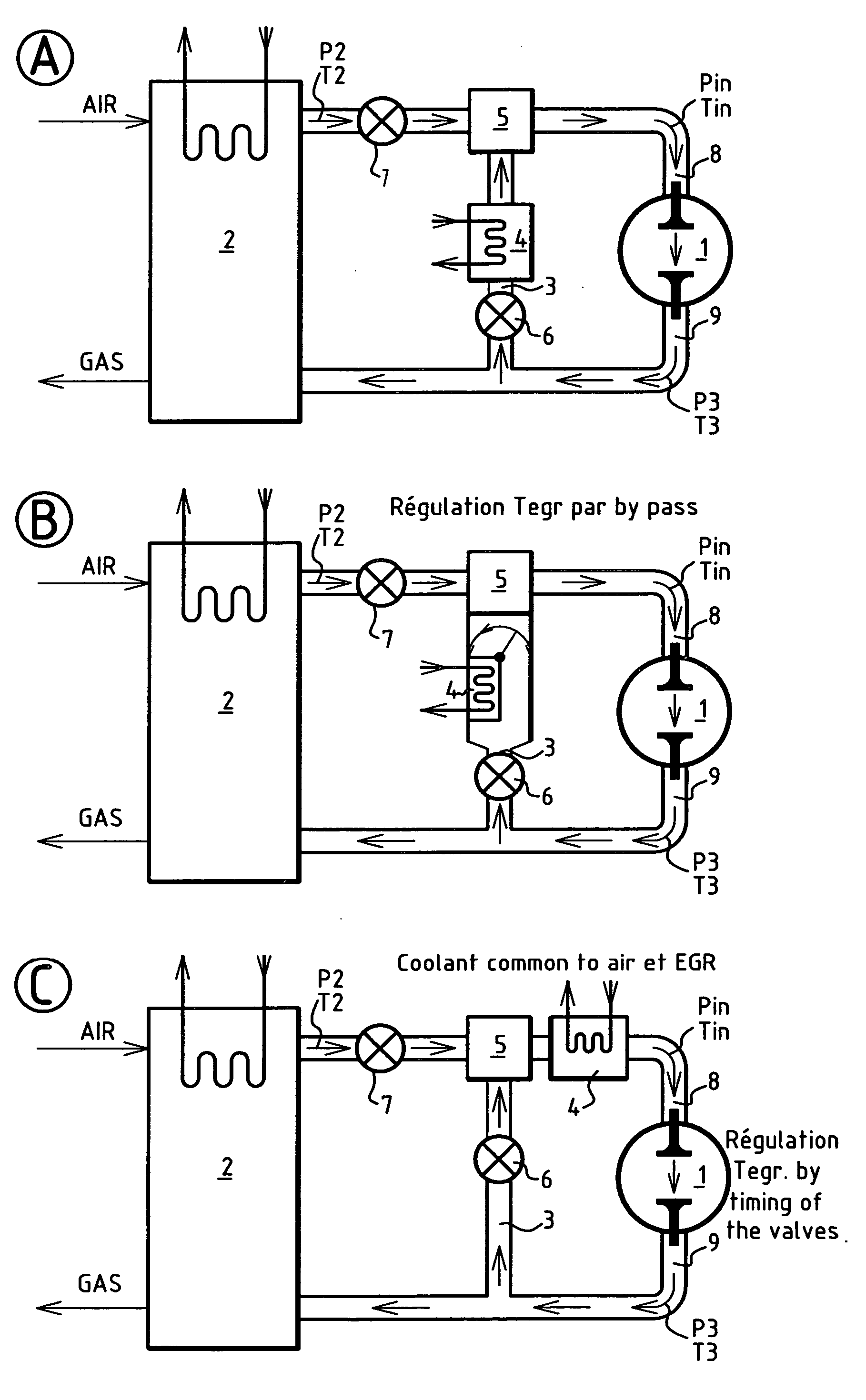

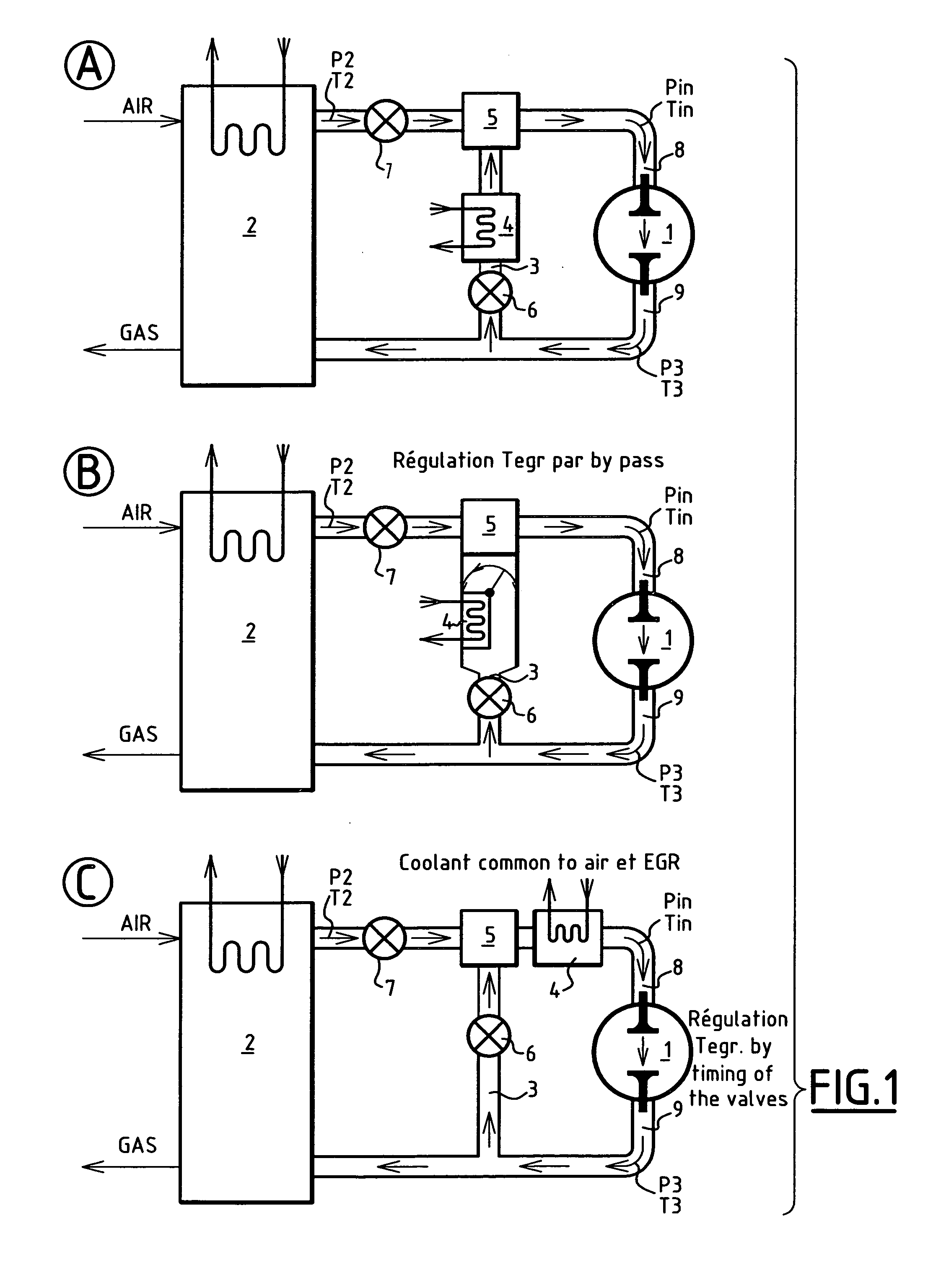

Alternative (reciprocating) engine with recirculation of exhaust gases intended for the propulsion of automobiles and method turbocharging these motors

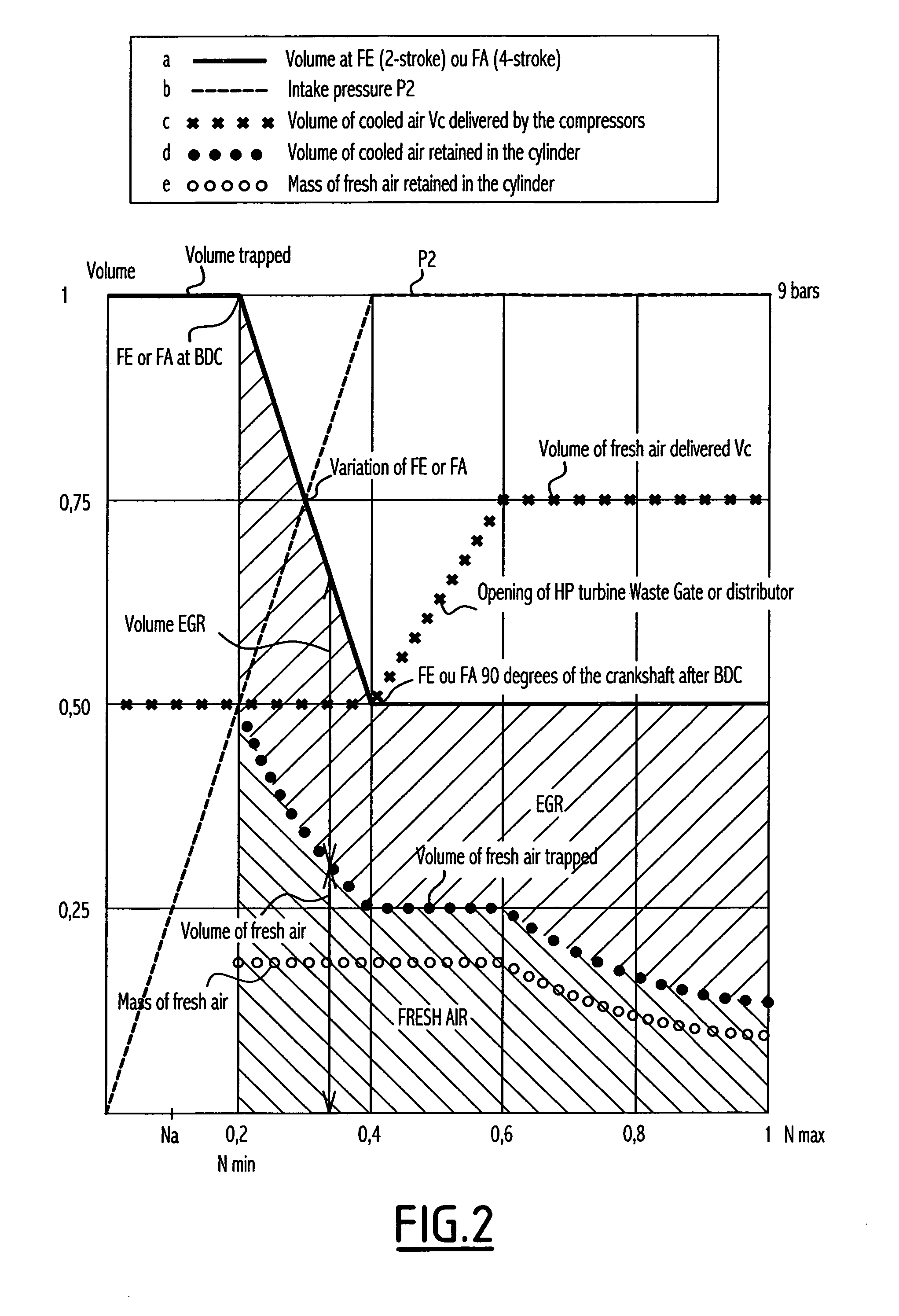

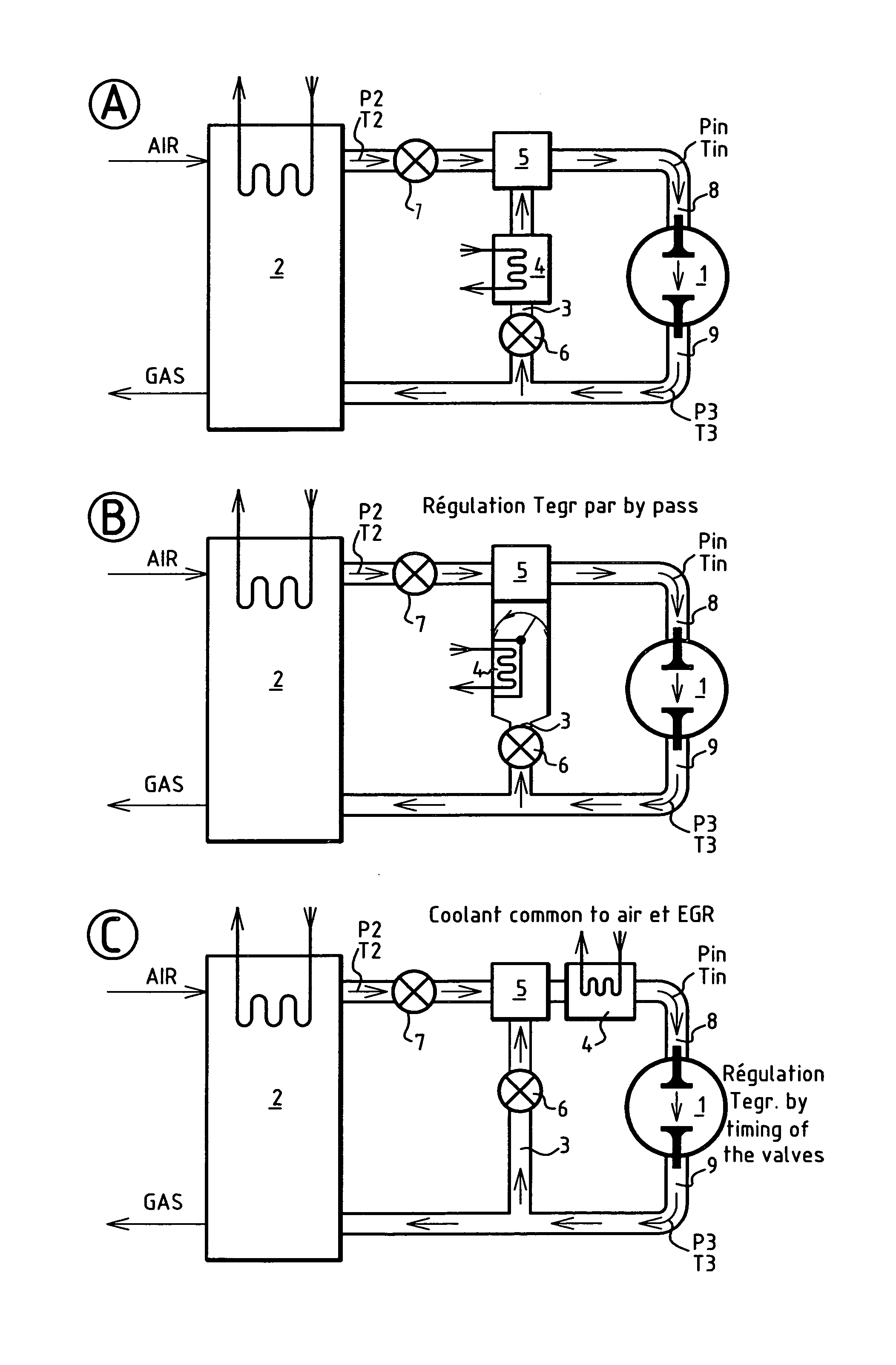

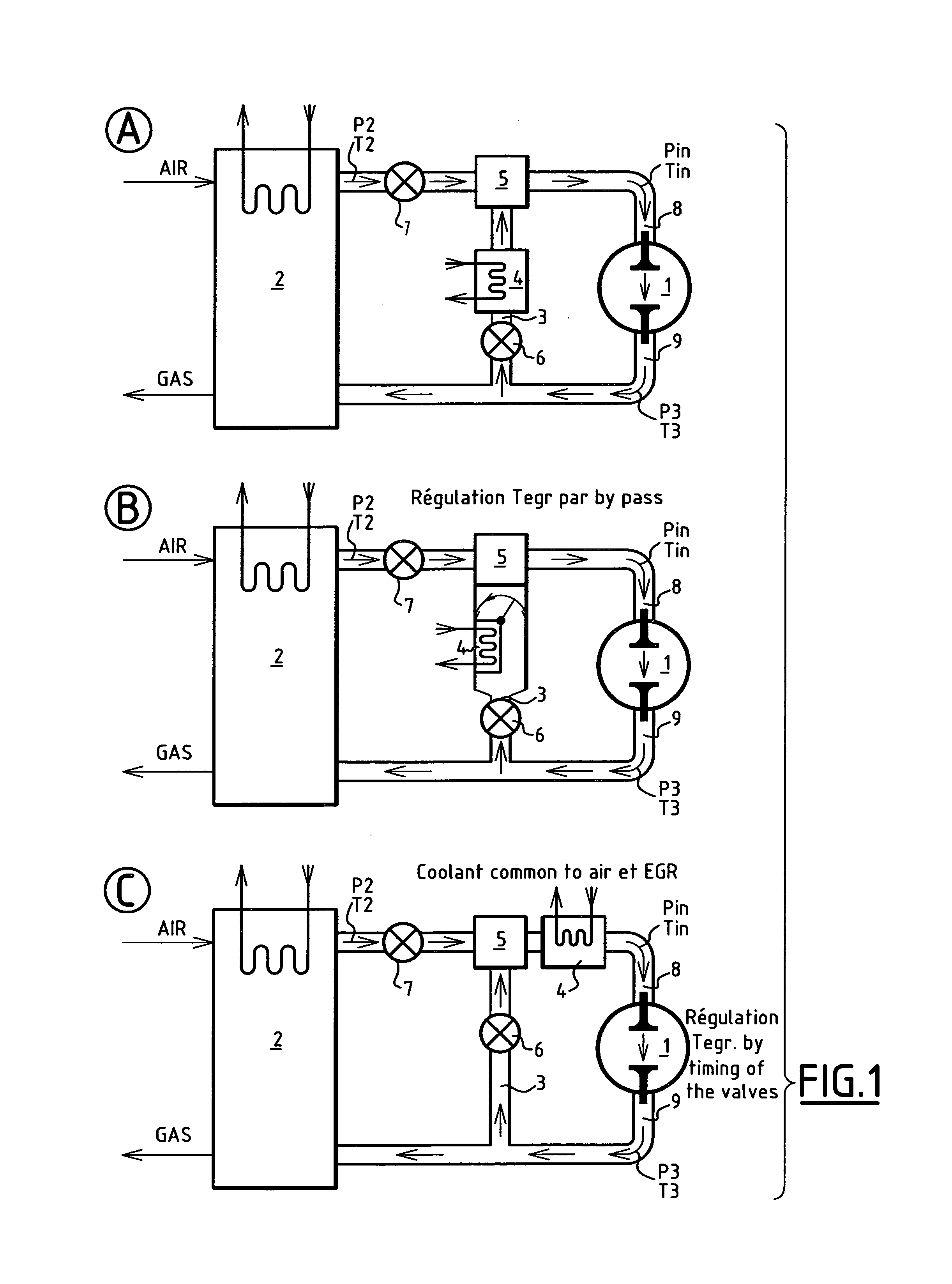

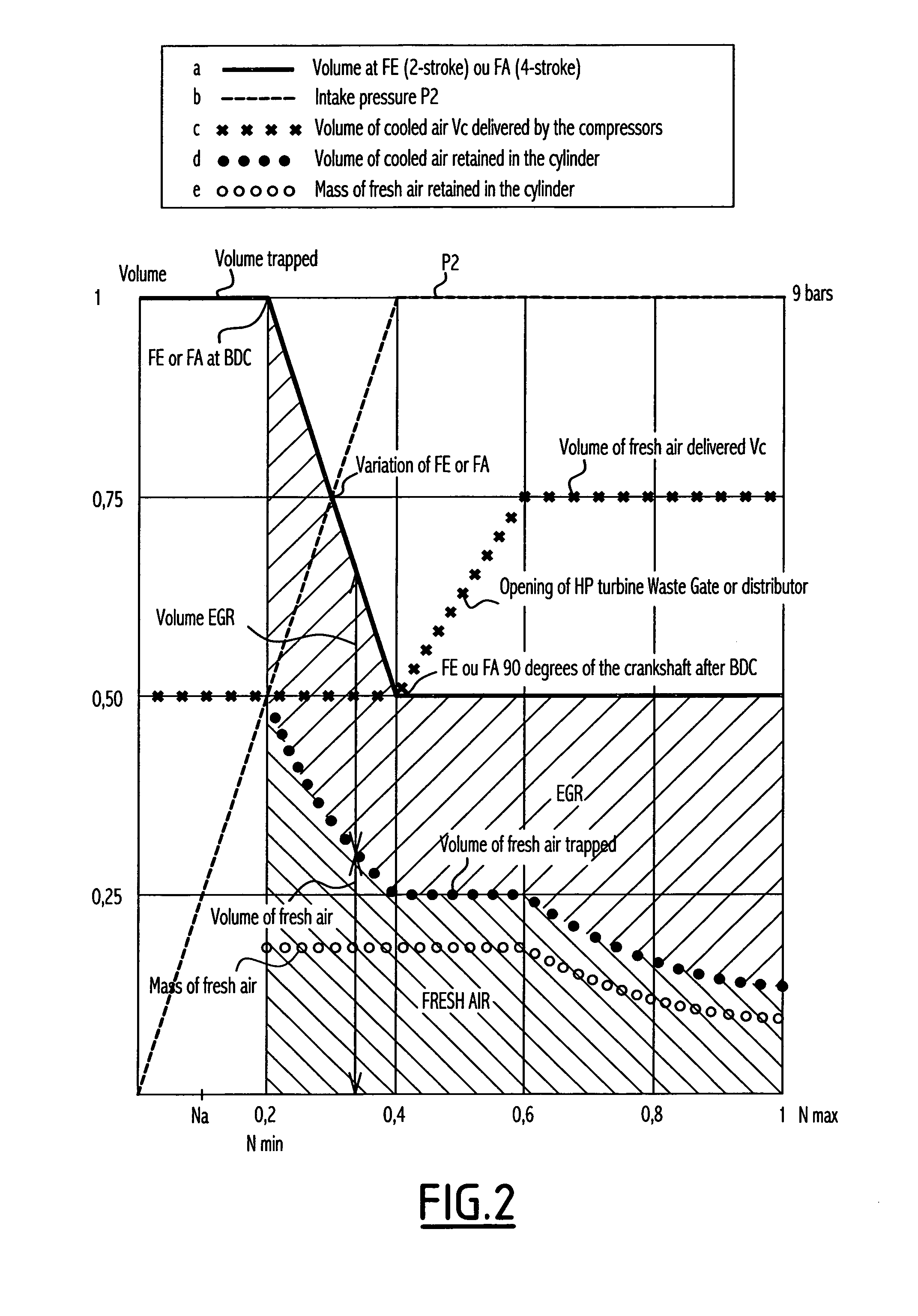

InactiveUS20070271919A1Power dropReduce time lagNon-fuel substance addition to fuelInternal combustion piston enginesTurbineDischarge pressure

A reciprocating engine includes a turbocharging unit that: supplies the intake manifold with air via a coolant; is supplied with gas by the exhaust manifold; and has the turbine supply pressure substantially equal to the compressor discharge pressure. At constant air temperature, the turbocharging unit delivers a substantially constant volume of cooled air when the pressure varies, and the volume is substantially proportional to the turbine outlet section. The turbine pressure is maintained substantially equal to compressor pressure by a EGR bypass between the intake and exhaust manifold. In addition, the volume of air is less than the volume drawn in at the speed so that a flow of hot gases is drawn in again via the bypass above the speed, where the volume drawn in is equal to the volume, and a flow of air is deflected towards the turbine below the speed.

Owner:MELCHIOR

Alternative (reciprocating) engine with recirculation of exhaust gases intended for the propulsion of automobiles and method turbocharging these motors

InactiveUS7313918B2Increase the proportion of EGR and/or the engine torqueIncrease boost pressureNon-fuel substance addition to fuelInternal combustion piston enginesDischarge pressureTurbine

A reciprocating engine includes a turbocharging unit that: supplies the intake manifold with air via a coolant; is supplied with gas by the exhaust manifold; and has the turbine supply pressure substantially equal to the compressor discharge pressure. At constant air temperature, the turbocharging unit delivers a substantially constant volume of cooled air when the pressure varies, and the volume is substantially proportional to the turbine outlet section. The turbine pressure is maintained substantially equal to compressor pressure by a EGR bypass between the intake and exhaust manifold. In addition, the volume of air is less than the volume drawn in at the speed so that a flow of hot gases is drawn in again via the bypass above the speed, where the volume drawn in is equal to the volume, and a flow of air is deflected towards the turbine below the speed.

Owner:MELCHIOR

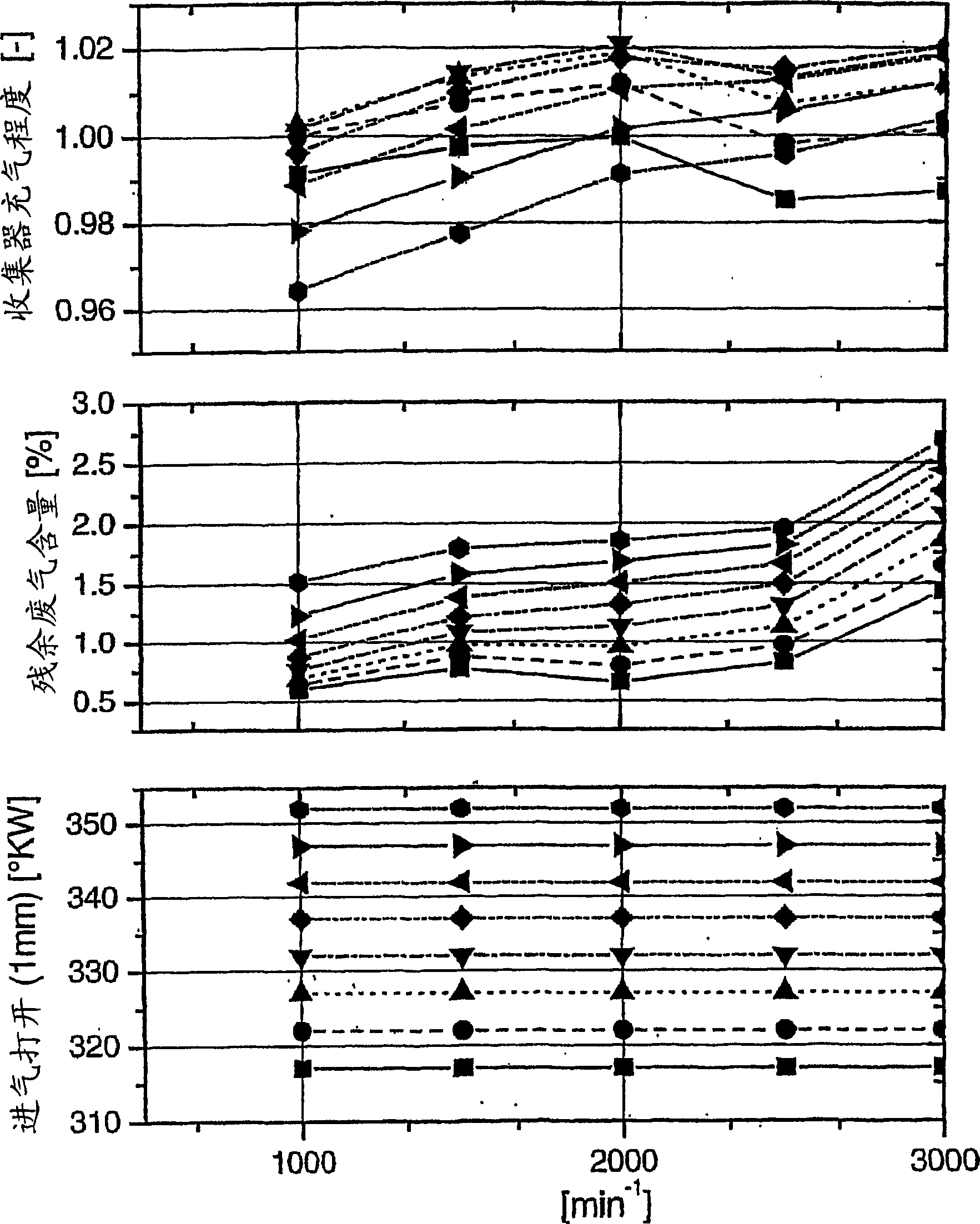

Method for optimizing the operation of a charged reciprocating internal combustion engine in the lower engine speed range

InactiveCN1863993AIncrease consumption levelSweeping reductionElectrical controlInternal combustion piston enginesTop dead centerCharge exchange

The invention relates to a method for operating a fuel-injected, especially a directly fuel-injected, reciprocating internal combustion engine. Said engine comprises at least one outlet valve per cylinder, communicating with an exhaust gas installation, and at least one inlet valve, communicating with an air inlet installation, and means for increasing the boost pressure in the air inlet installation. The method is characterized in that a control device for variably adjusting at least the opening times of the inlet valves is provided and that in the lower engine speed range the inlet opening times of the inlet valves can be adjusted via the control device in such a manner that there is a valve overlap with the closing time of the corresponding outlet valves, thereby scavenging the cylinder with fresh charge air before charge exchange in the area of top dead center.

Owner:FEV

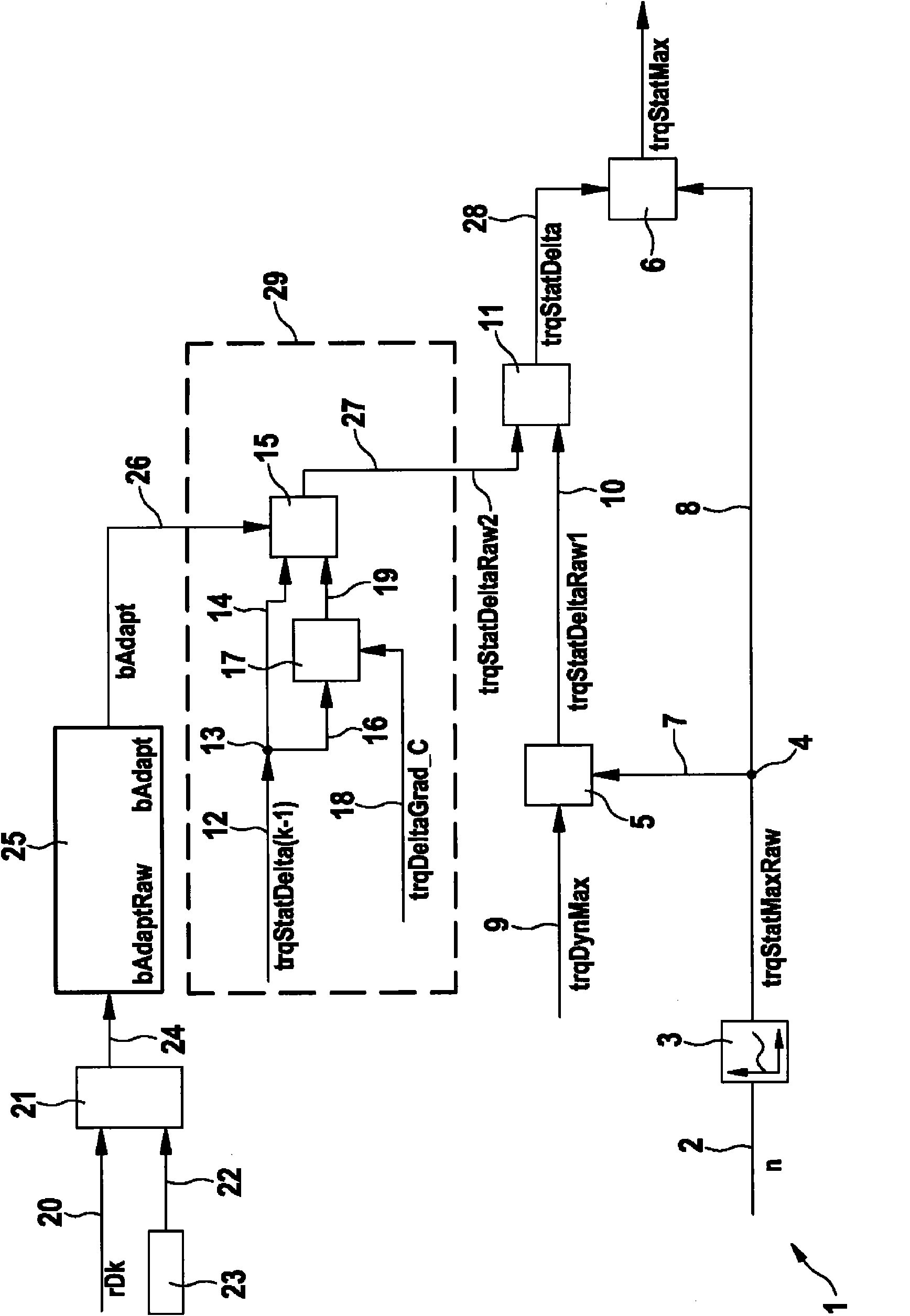

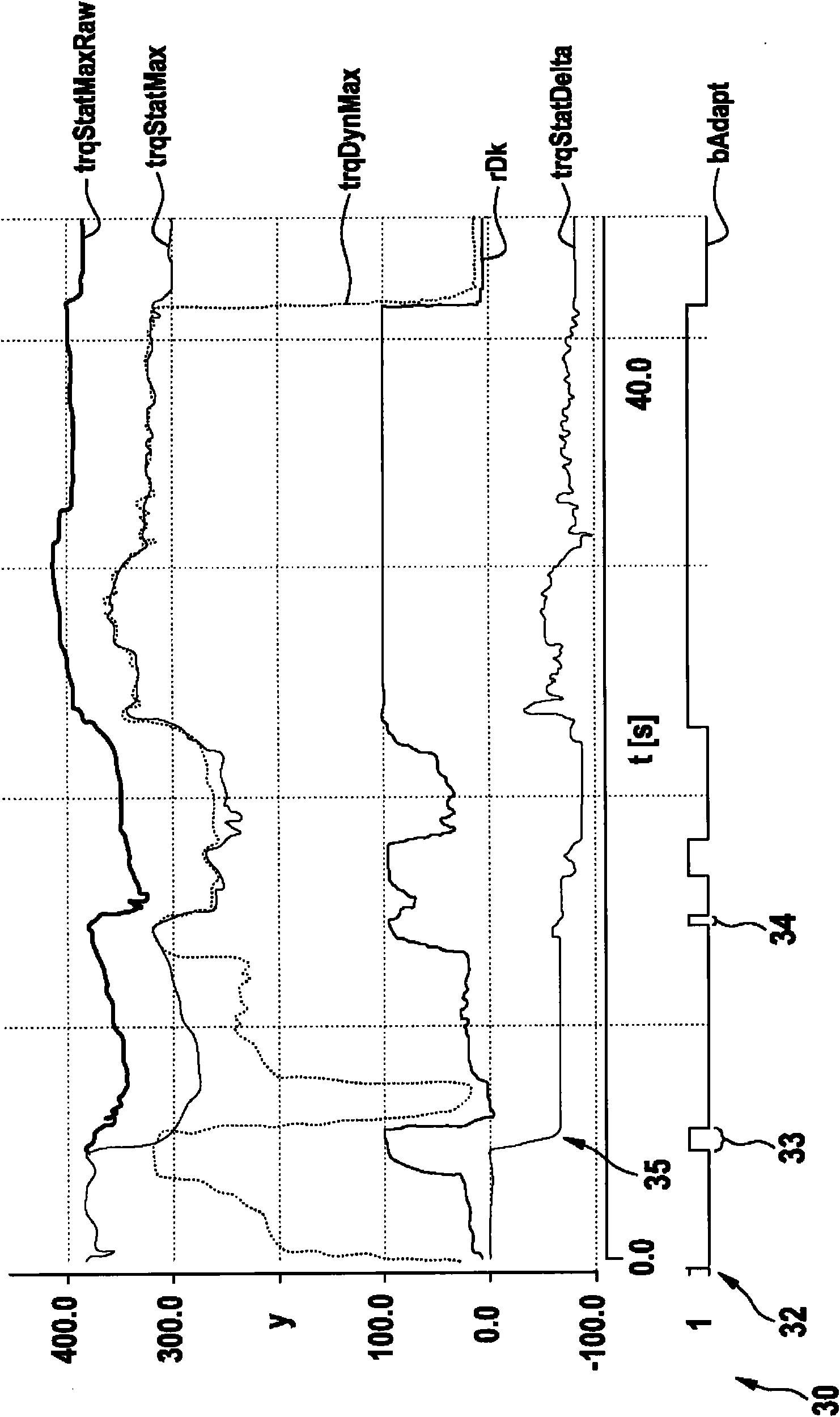

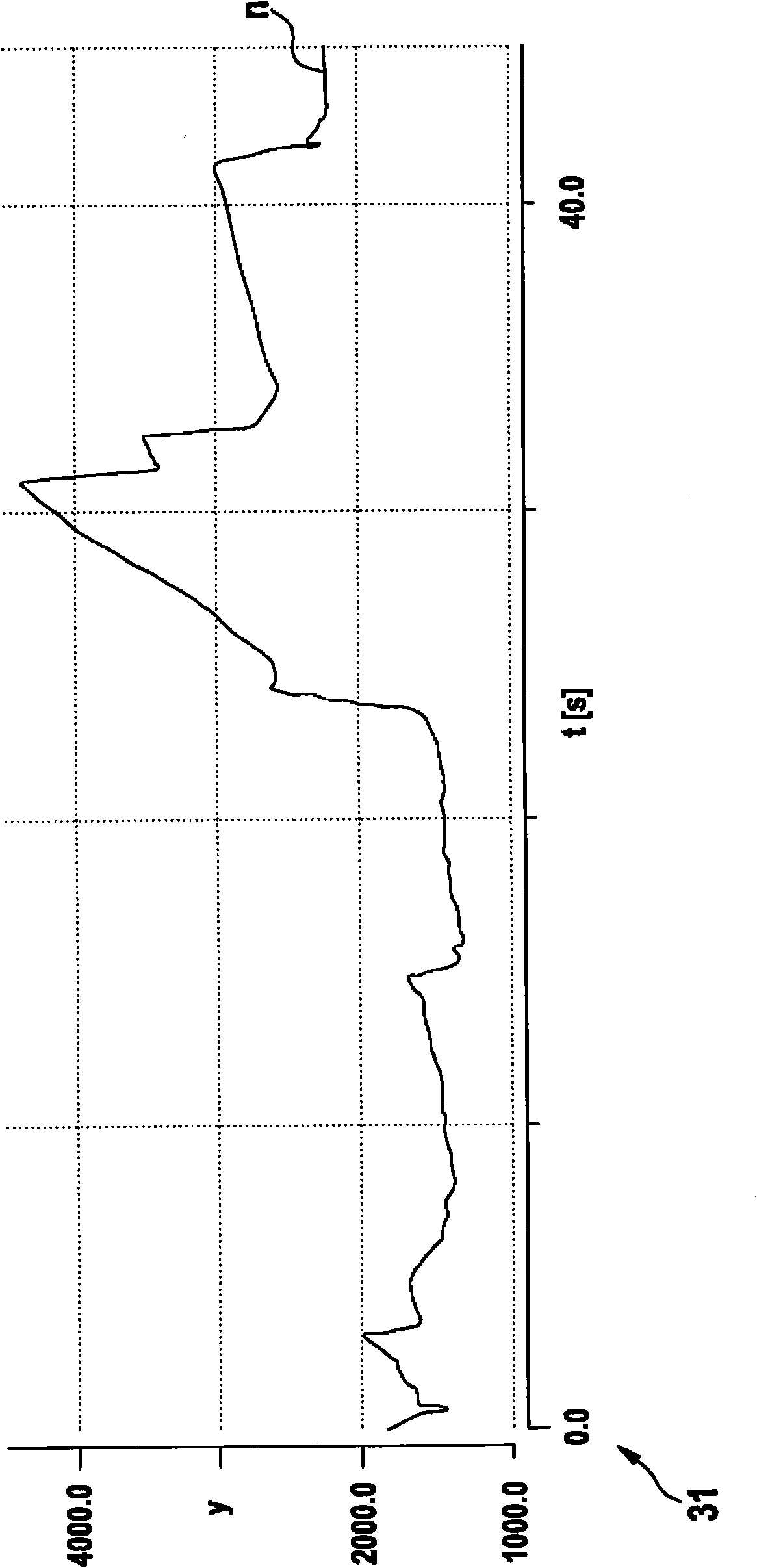

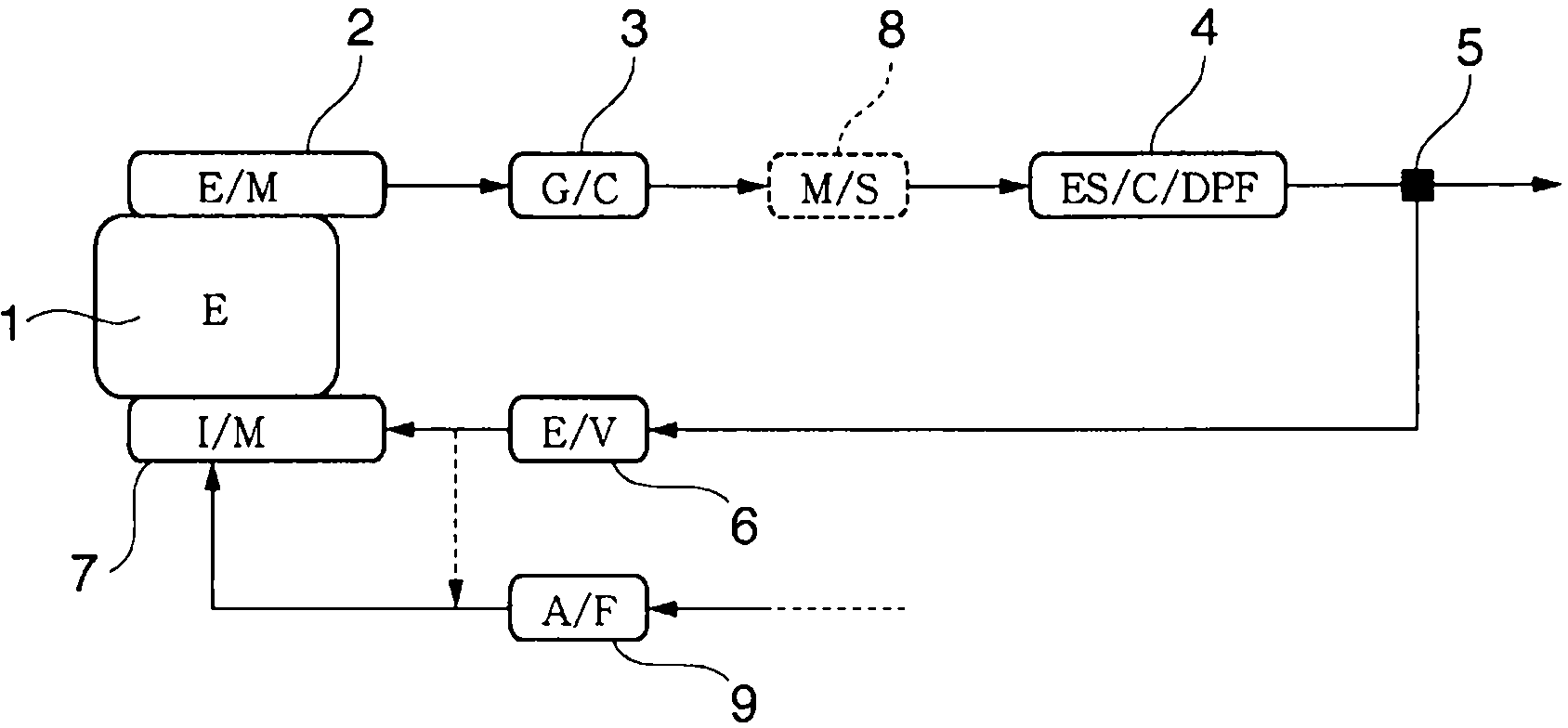

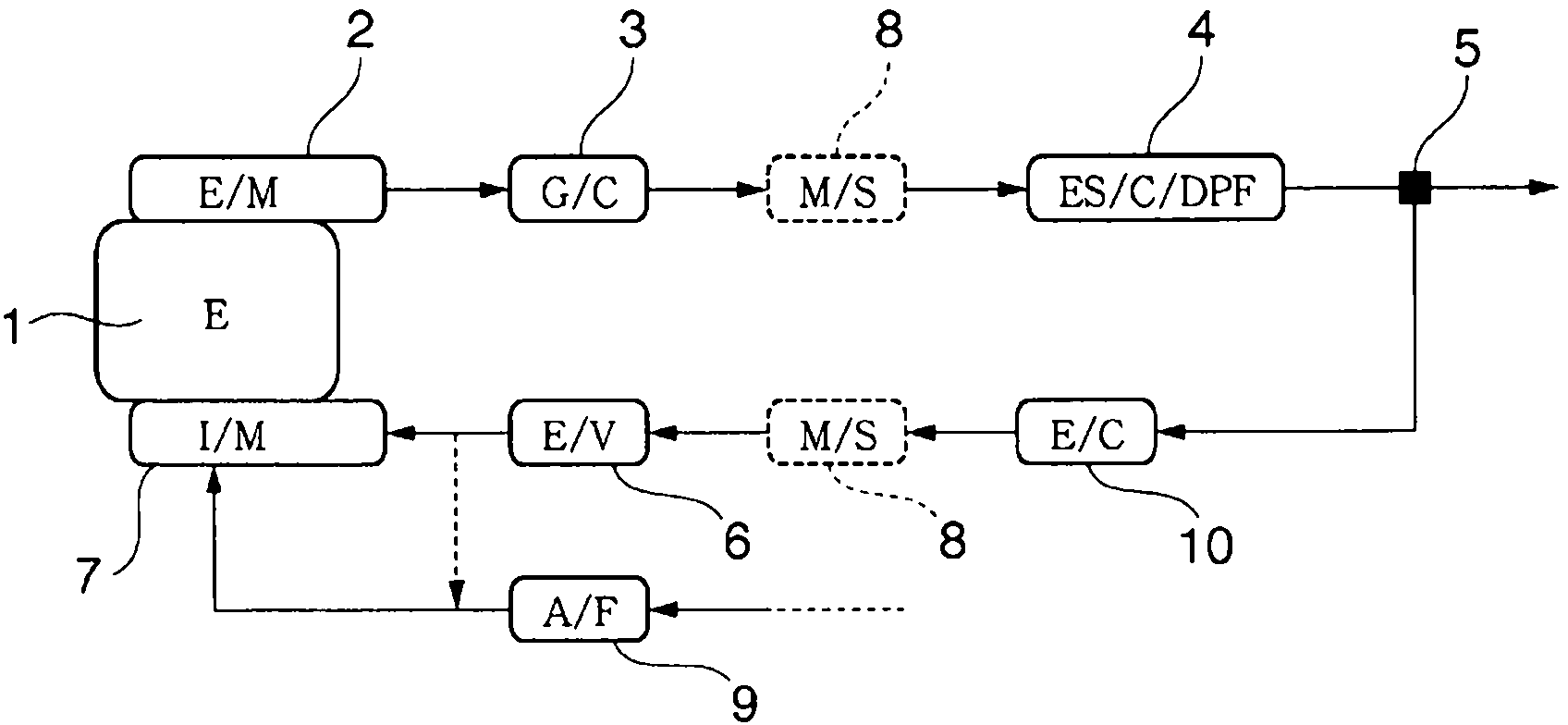

Adaption of a stationary maximum torque of an internal combustion engine

ActiveCN101990596AHigh precisionSteady state maximum torqueHybrid vehiclesElectrical controlMaximum torqueExternal combustion engine

The invention relates to a method for operating an internal combustion engine for which a stationary maximum torque and a dynamic maximum torque are determined. The determined stationary maximum torque is a stationary output maximum torque, modified to a stationary result maximum torque by being adapted in such a manner that it is greater than or equal to the determined dynamic maximum torque. The invention also relates to a corresponding internal combustion engine and to a hybrid drive device.

Owner:ROBERT BOSCH GMBH

Exhaust gas purification device for diesel engine using heavy-oil or lower quality fuel

InactiveCN103261595ANO

<sub>x</sub>

reduceSuppress generationNon-fuel substance addition to fuelInternal combustion piston enginesElectricityFuel oil

Owner:USUI KOKUSAI SANGYO KAISHA LTD

Control device of exhaust gas by-pass valve

InactiveCN1959080AChange the size of the openingIncrease duty cycleInternal combustion piston enginesEngineeringActuator

Owner:CHERY AUTOMOBILE CO LTD

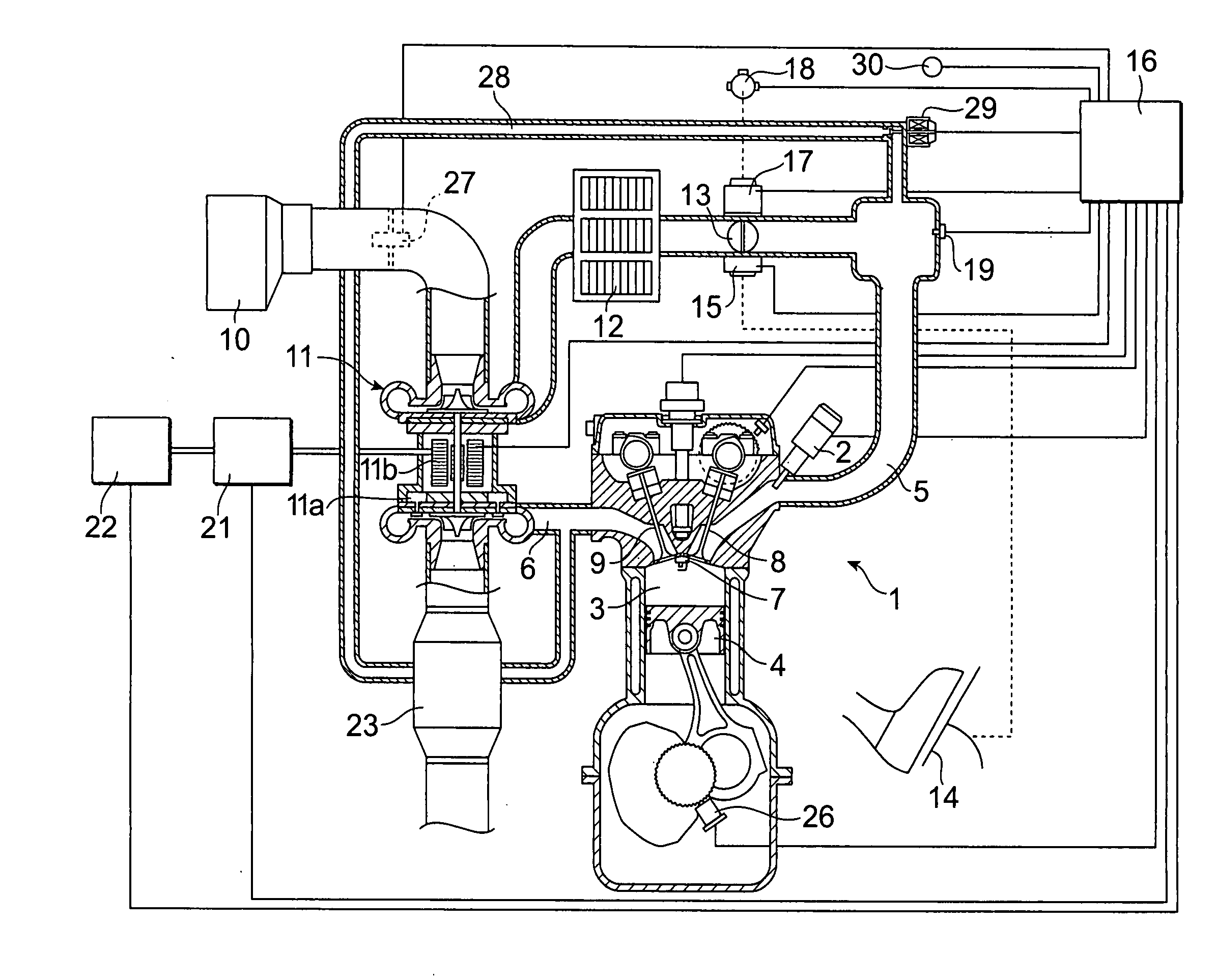

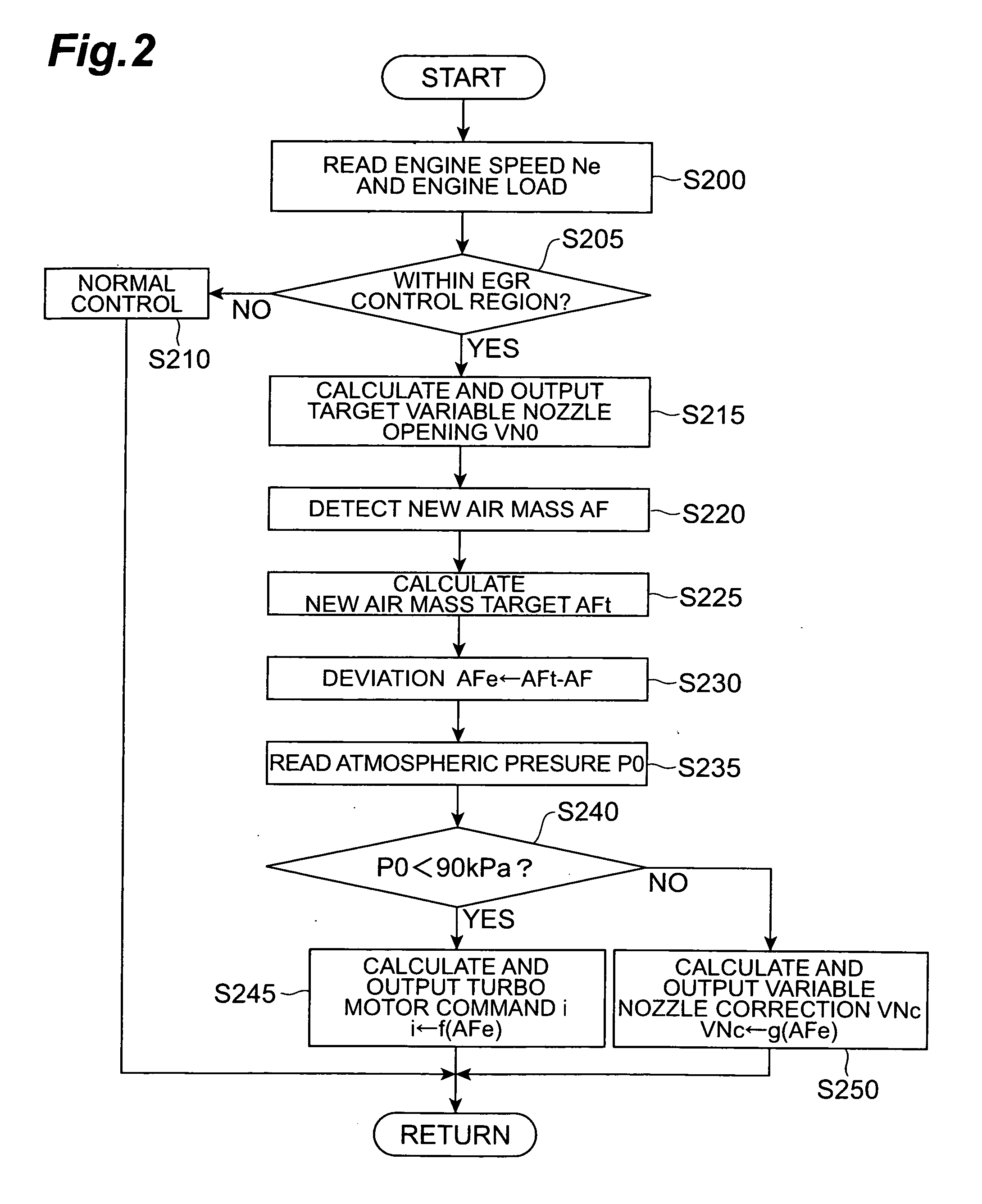

Control Device Supercharger with Electric Motor

InactiveUS20080148730A1Reduce the total massReduce outputElectrical controlInternal combustion piston enginesElectricityAtmospheric pressure

An object of the present invention is to provide a control apparatus for an electrically assisted supercharger capable of effectively compensating for an output drop even with decrease in the atmospheric pressure. A control apparatus for an electrically assisted supercharger according to the present invention has a supercharger 20 disposed on an intake passage 5 of an internal combustion engine 1 mounted on a vehicle, and driven by an electric motor 20a, a controller 16, 21 for controlling the electric motor 20a to control a boost pressure, and a pressure detector 30 for detecting a state of the atmospheric pressure, and is characterized in that when the atmospheric pressure detected by the pressure detector 30 becomes less than a predetermined value, the controller 16, 21 makes a driving force of the electric motor 20a larger than that when the atmospheric pressure is not less than the predetermined value.

Owner:TOYOTA JIDOSHA KK

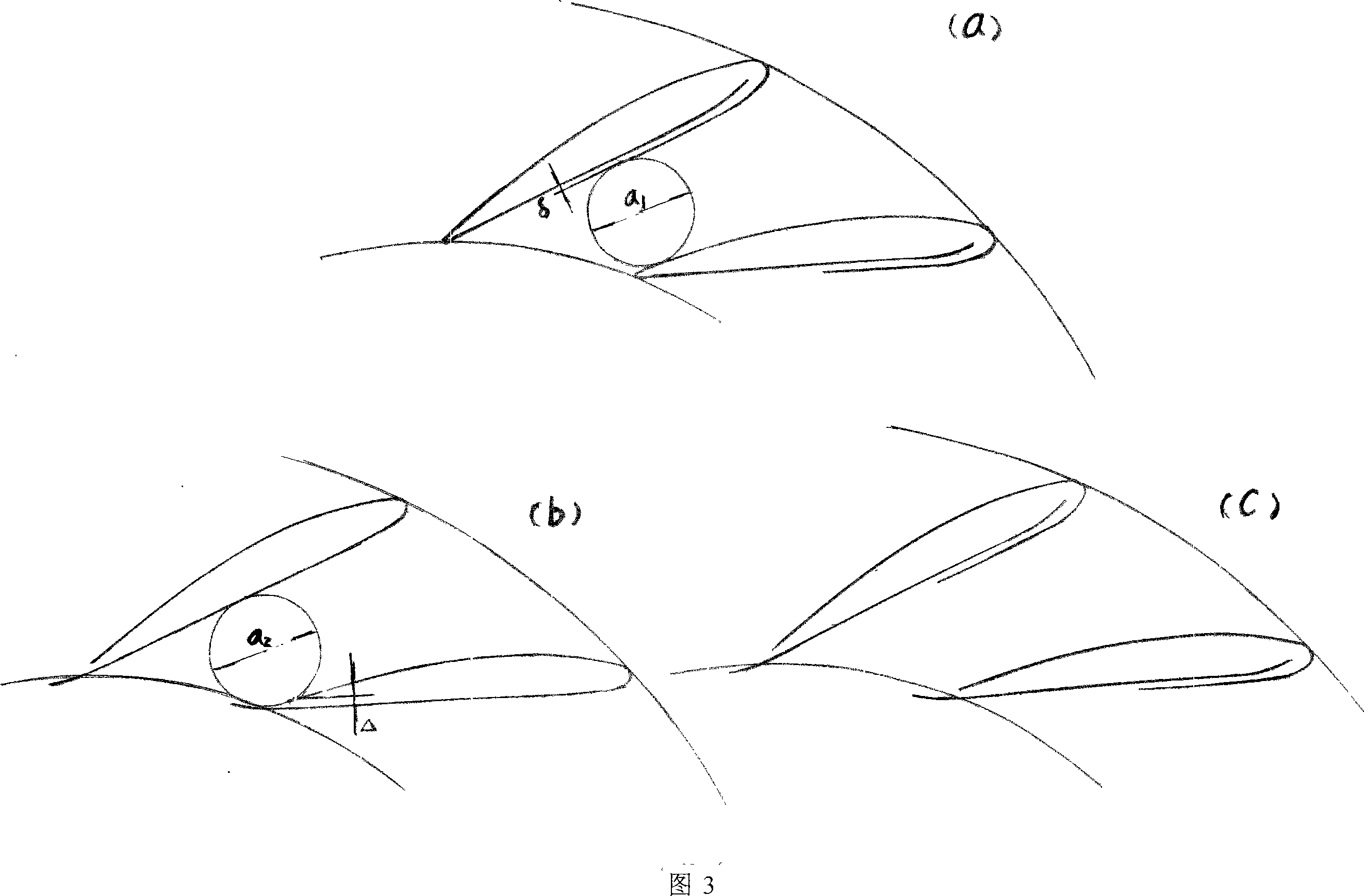

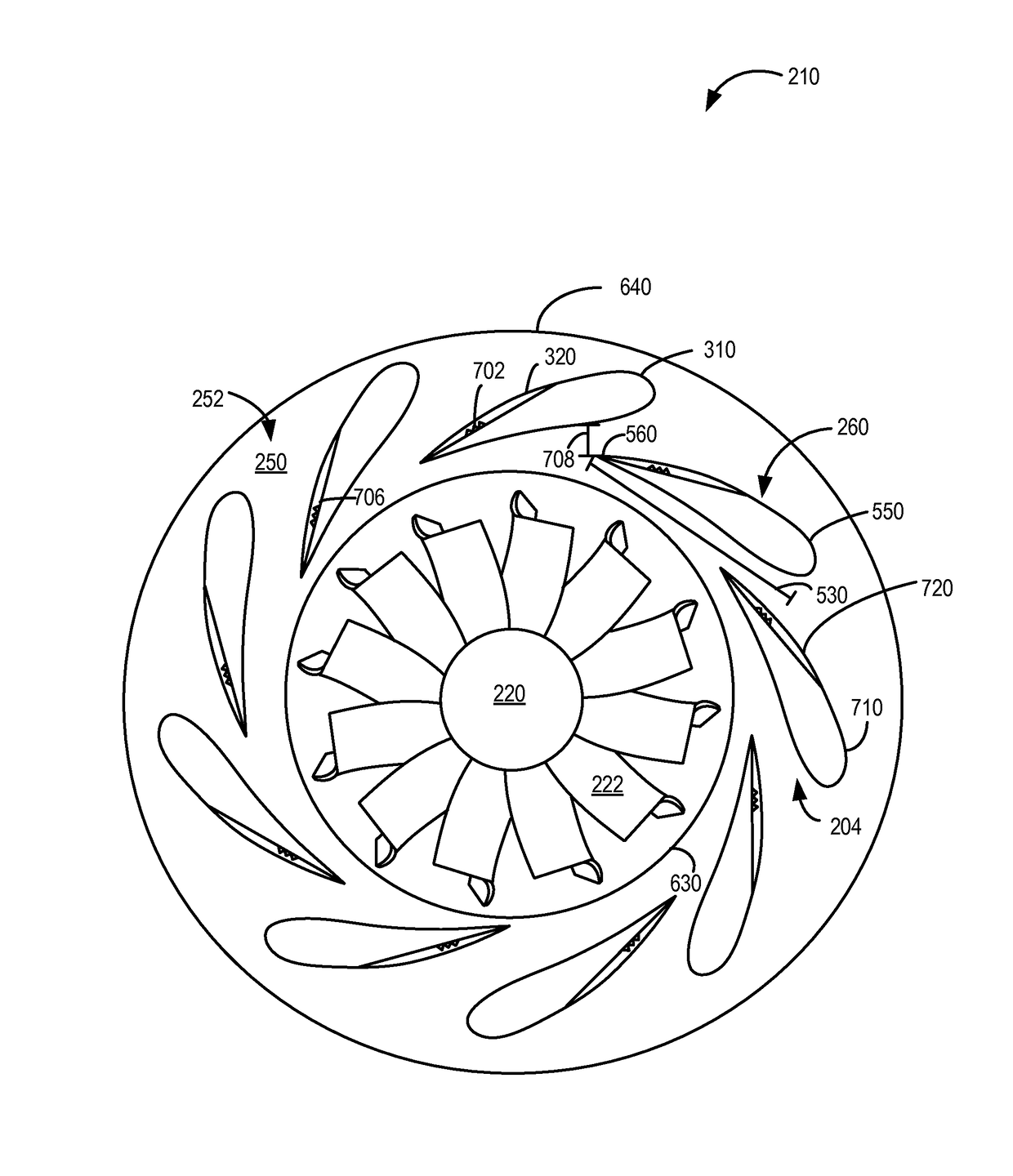

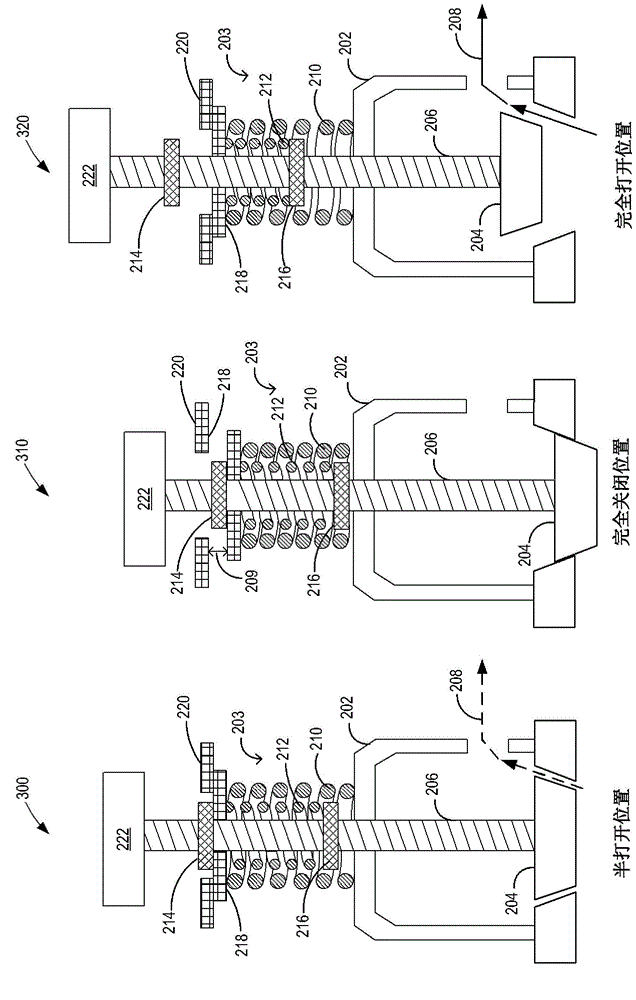

Systems and methods for a variable geometry turbine nozzle

ActiveUS9890700B2Boost pressureSpeed up the flowInternal combustion piston enginesBlade accessoriesVariable geometry turbineTurbine

Various systems and methods are described for a variable geometry turbine. In one example, a nozzle vane includes a stationary having a first cambered sliding surface and a sliding vane having a second cambered sliding surface where the second cambered sliding surface includes a flow disrupting feature in contact with the first sliding cambered surface. The sliding vane may be positioned to slide in a direction from substantially tangent along a curved path to an inner circumference of the turbine nozzle and selectively uncover the flow disrupting feature.

Owner:FORD GLOBAL TECH LLC

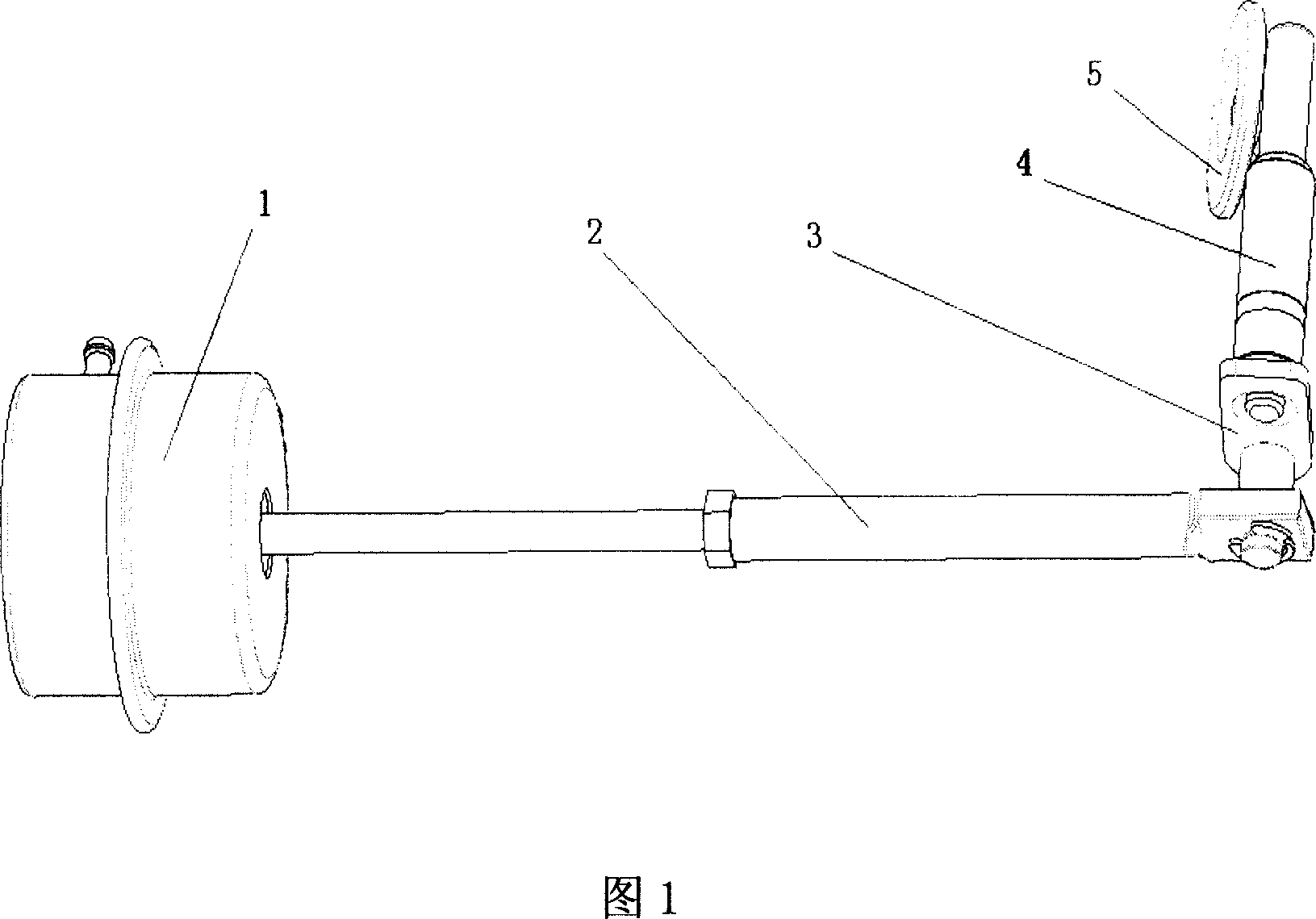

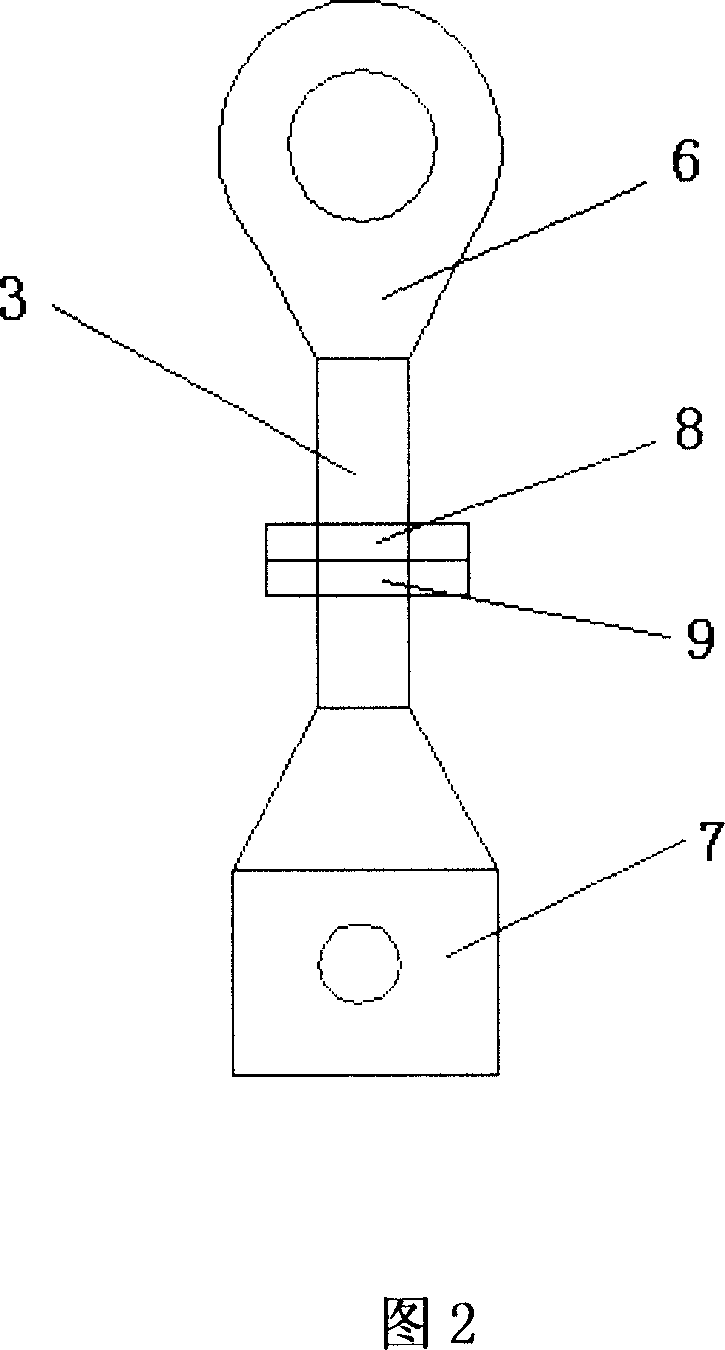

Blowby gas returning apparatus

ActiveUS8122870B2Increase intake resistanceIncrease boost pressureInternal combustion piston enginesNon-fuel substance addition to fuelTurbochargerThrottle

A blowby gas returning apparatus is mounted in an engine provided with a turbocharger in an intake passage and provided with a blowby gas returning passage for flowing blowby gas generated in the engine to return to the engine. This apparatus comprises an intake bypass passage connecting an upstream side and a downstream side of the intake passage with respect to the turbocharger, and a jet pump for generating negative pressure in the intake bypass passage. An exit of the first blowby gas returning passage is connected to the intake bypass passage through the jet pump. The apparatus further includes a second blowby gas returning passage connecting the intake passage downstream of the throttle valve to a head cover. In the head cover, a PCV valve is placed at an entrance of the second blowby gas returning passage.

Owner:AISAN IND CO LTD

Methods and systems for surge control

InactiveCN104373202AReduced need for actuationIncrease marginInternal combustion piston enginesEngine operationsSemi openMechanical engineering

Owner:FORD GLOBAL TECH LLC

Turbine device with changeable runner

InactiveCN101949325AImprove efficiencySimple structureInternal combustion piston enginesEngine componentsImpellerTurbine wheel

The invention discloses a turbine device with a changeable runner. The turbine device comprises a turbine volute, a turbine volute casing cover plate and a turbine wheel, wherein the inside of the turbine volute casing is provided with a turbine volute casing runner; a turbine volute casing gas inlet and a turbine volute casing gas outlet are arranged on the turbine volute casing runner; and a partition board is arranged in the turbine volute casing runner, and the partition board can move along the axial direction of the turbine volute casing. In the turbine device of the invention, the partition wall capable of moving axially is arranged in the turbine volute casing runner, thus the turbine volute casing runner can have different runner sections, the energy of the exhaust gas discharged from the engine can be utilized extremely and the turbines efficiency can be effectively increased. The turbine device with the changeable runner of the invention which contains the partition wall capable of moving axially has simple structure and low cost, is reliable and is easy to realize.

Owner:KANGYUE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com