Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

325results about How to "Little loss of strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

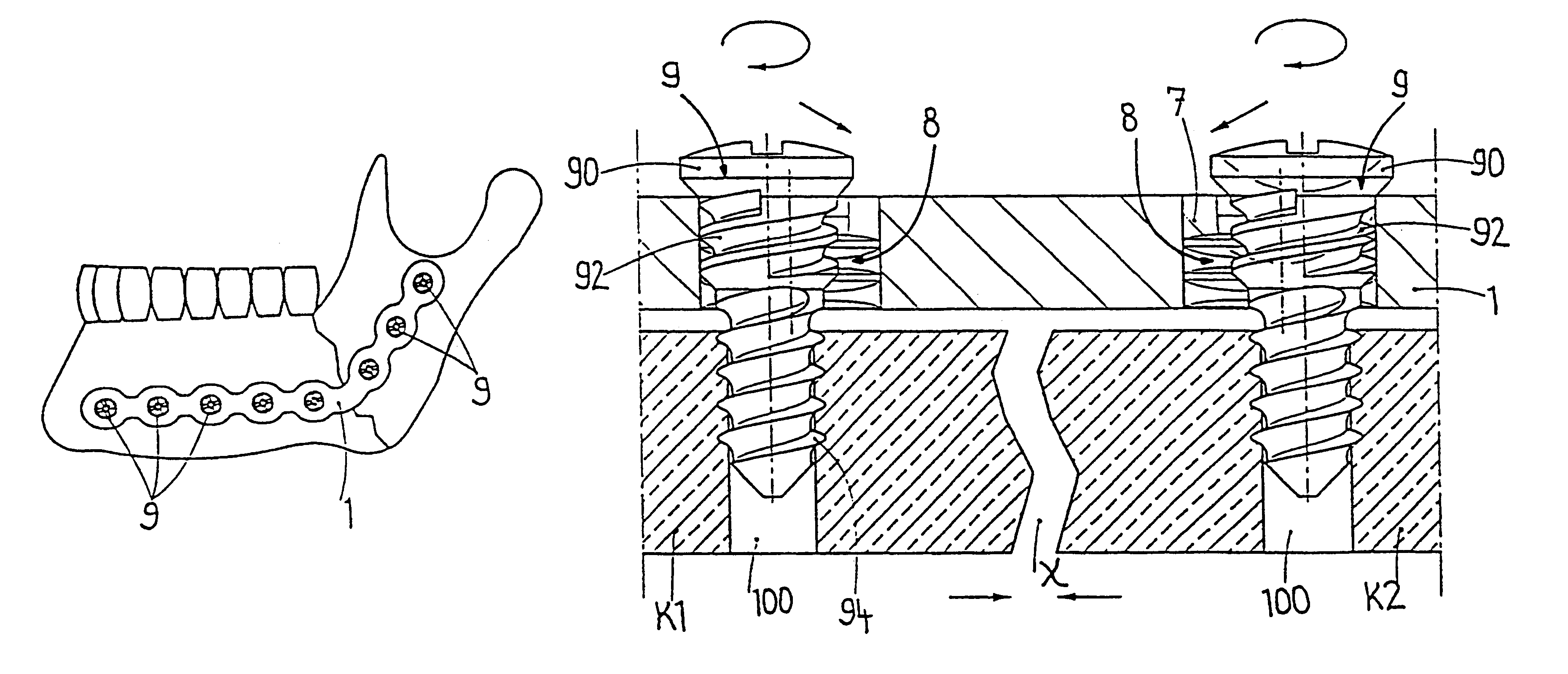

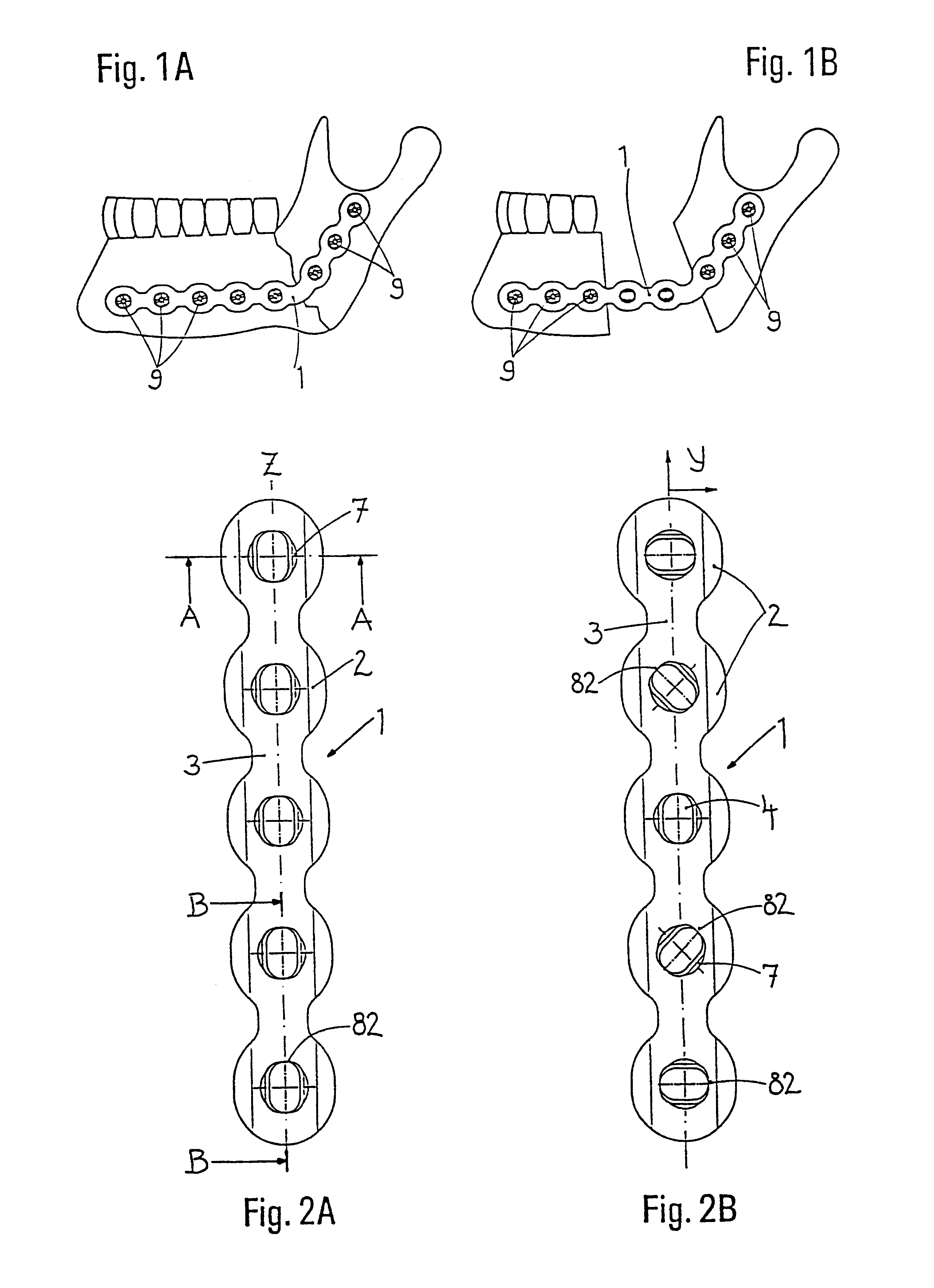

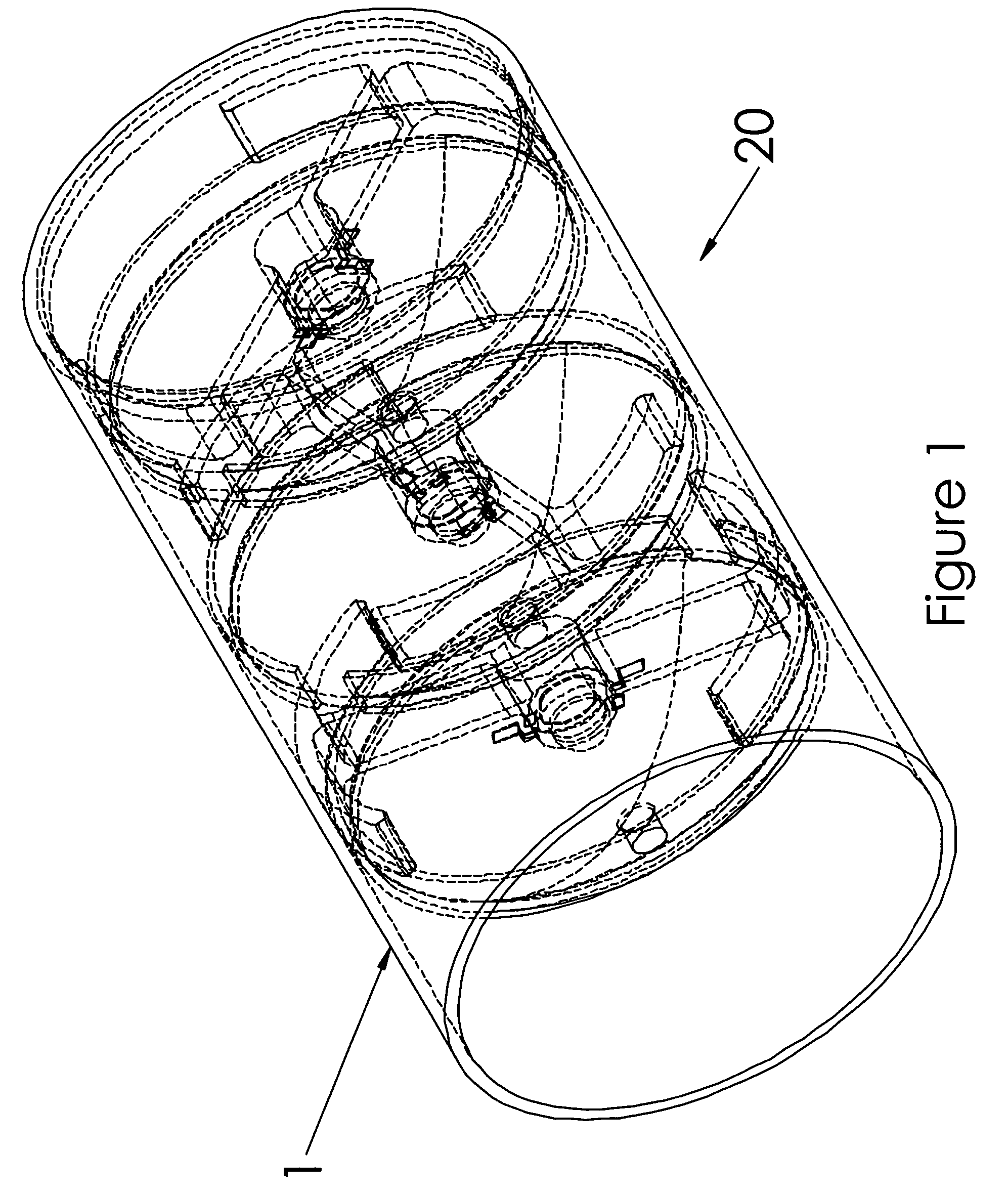

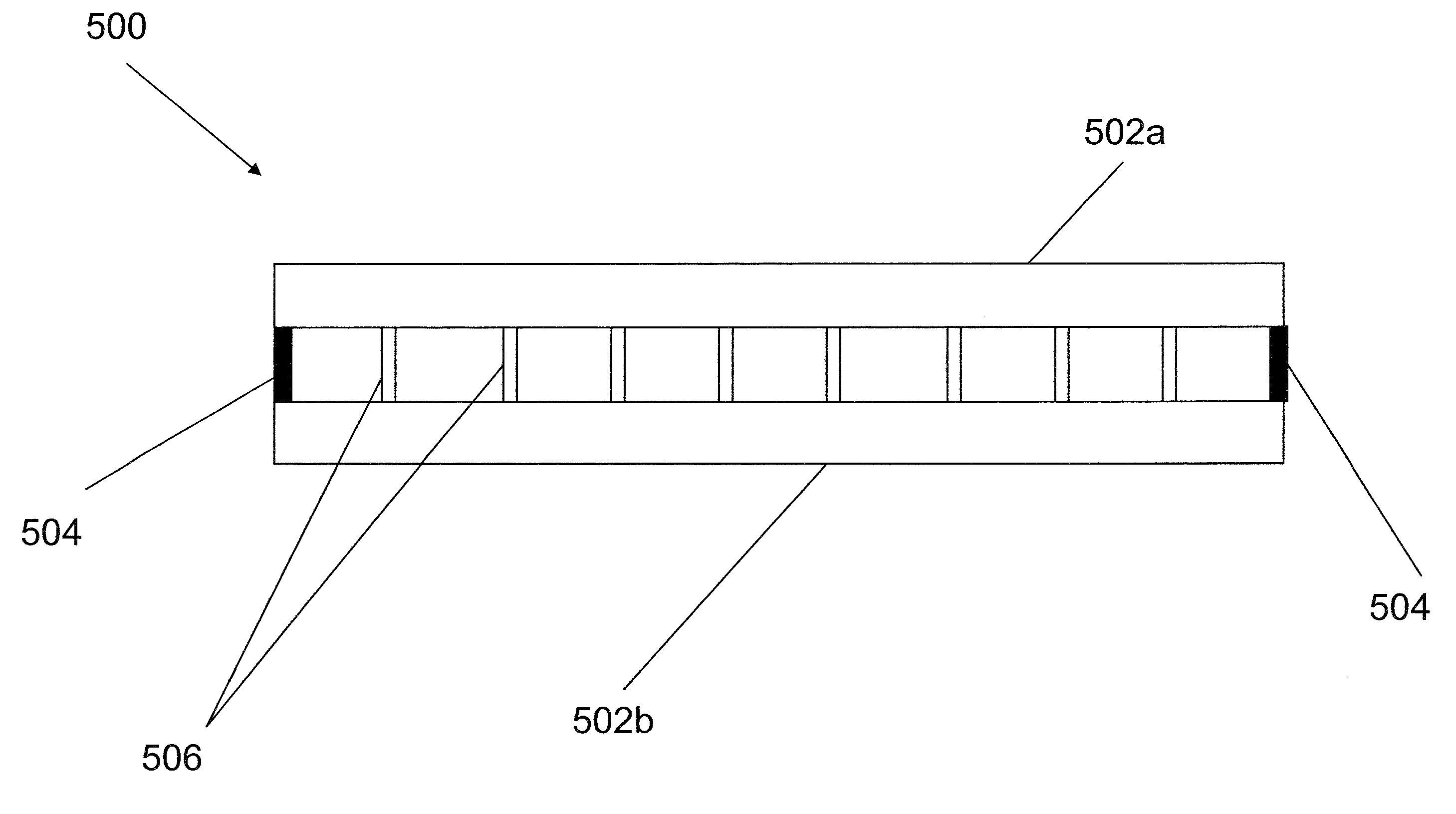

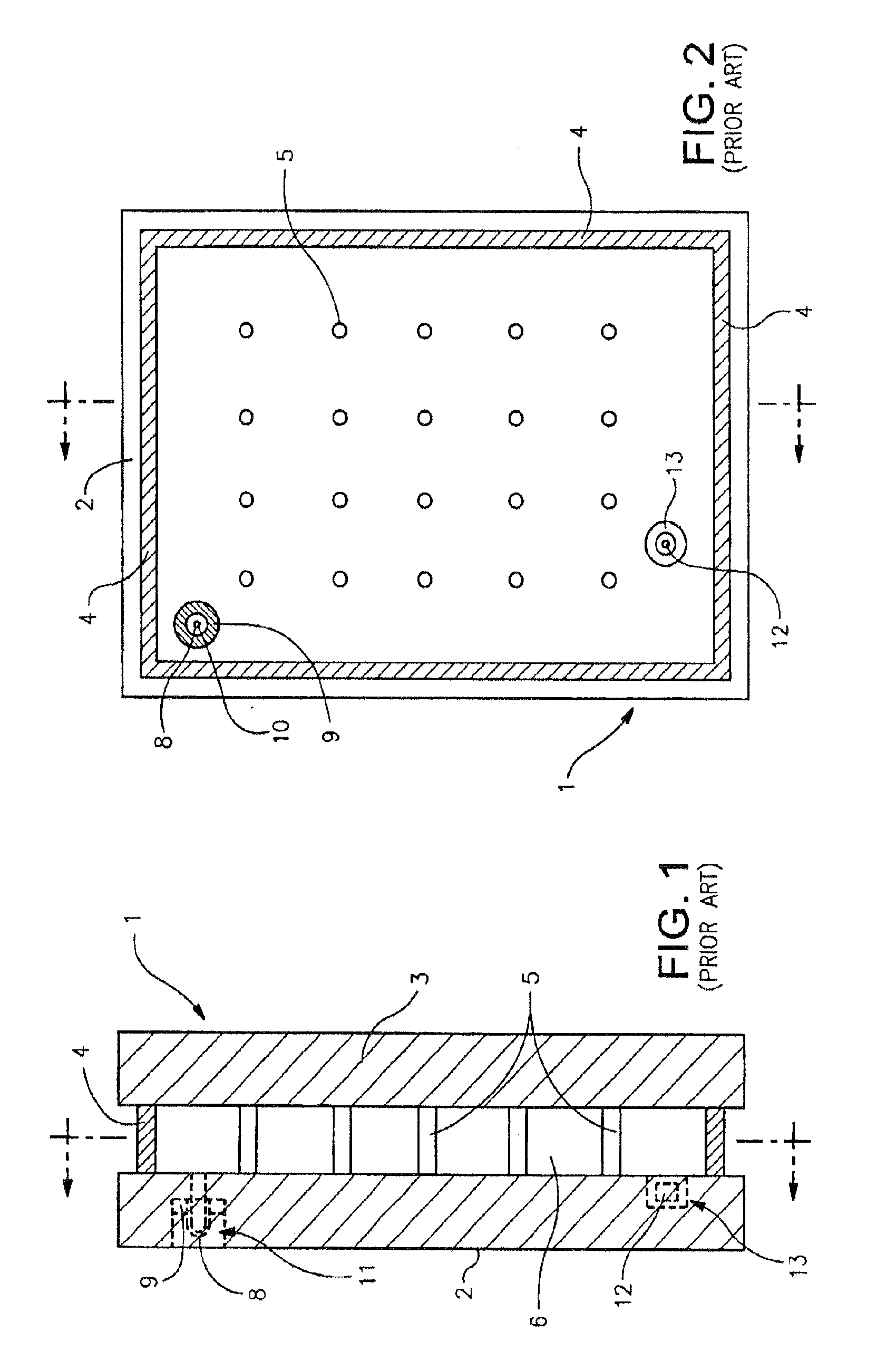

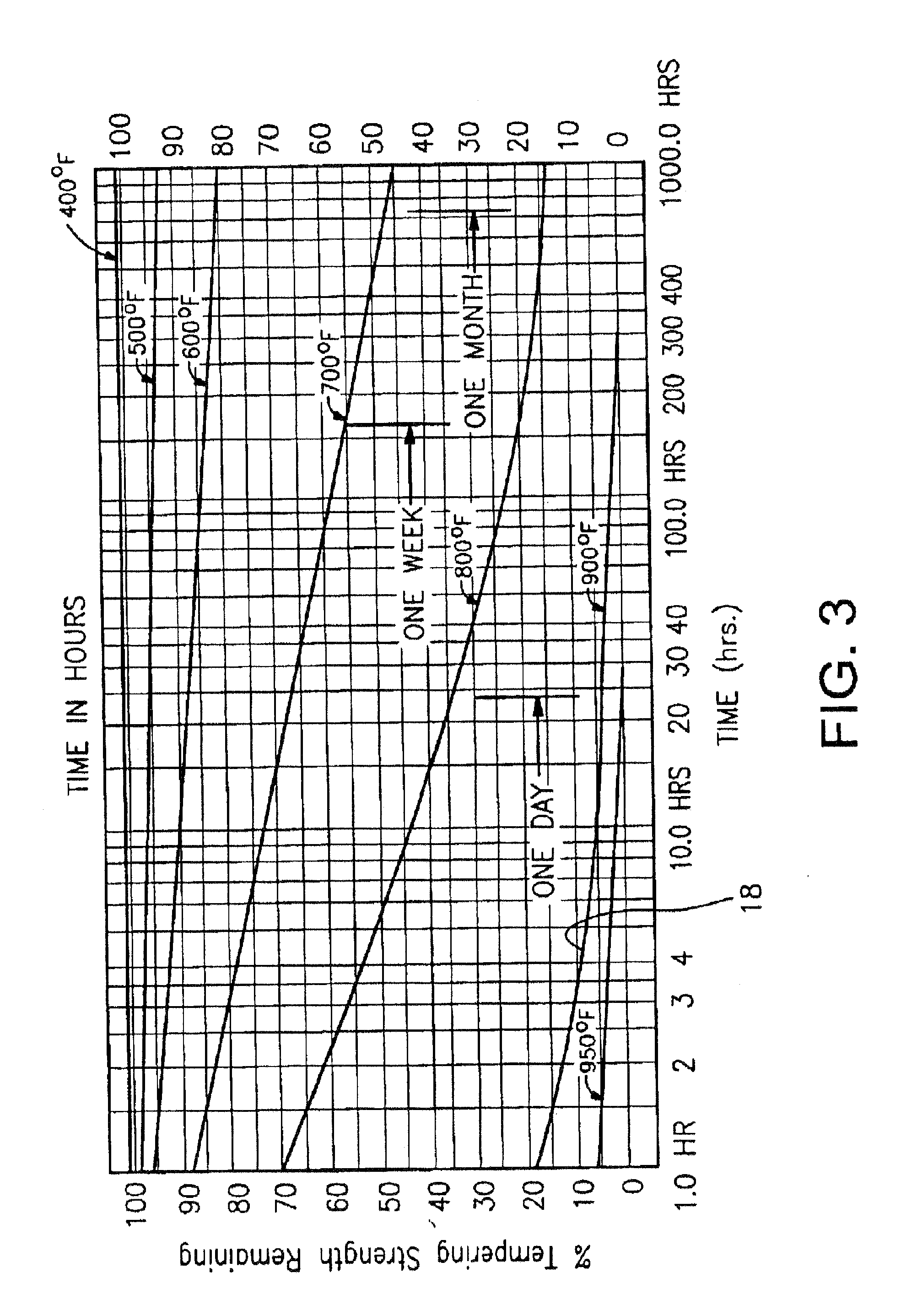

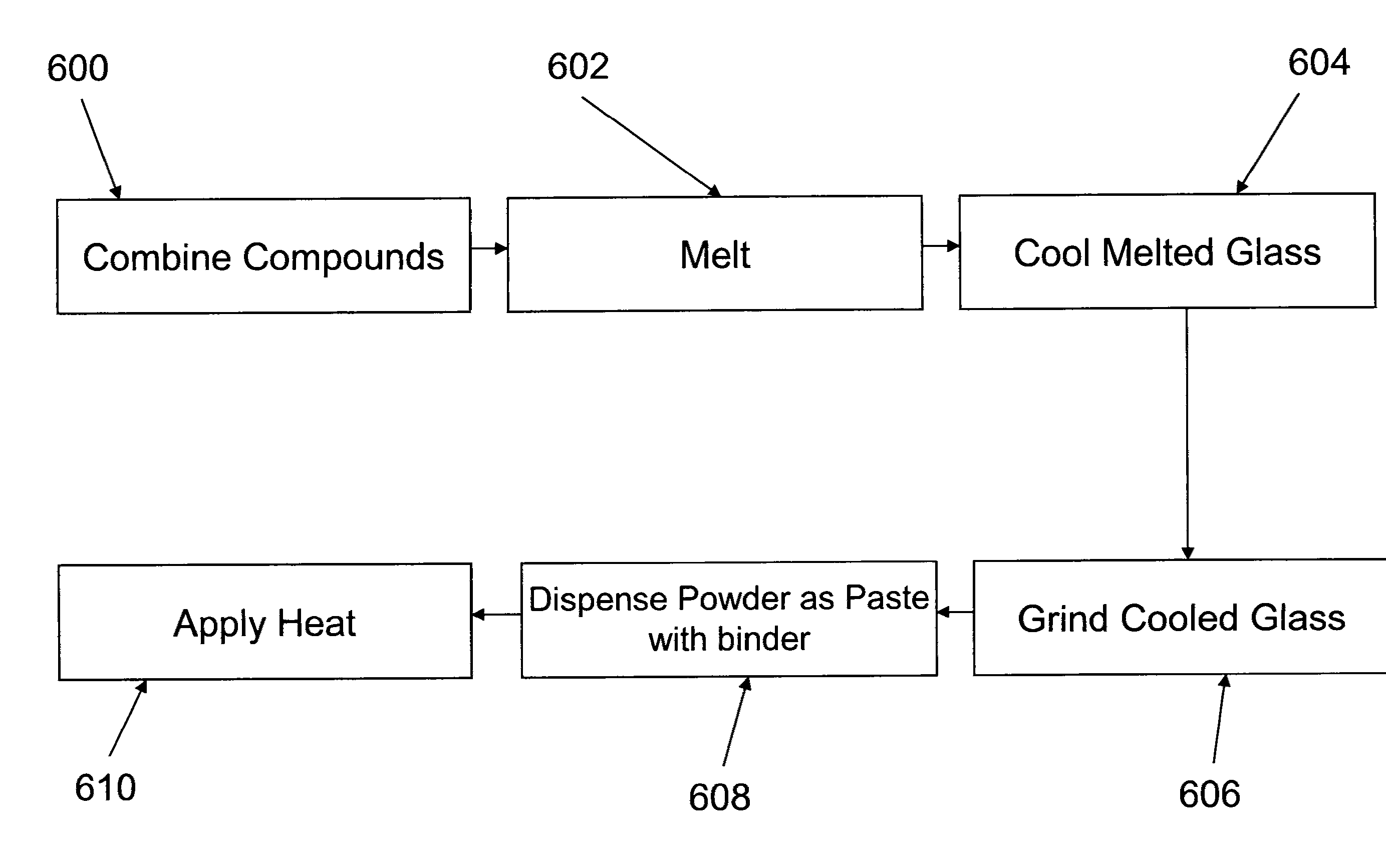

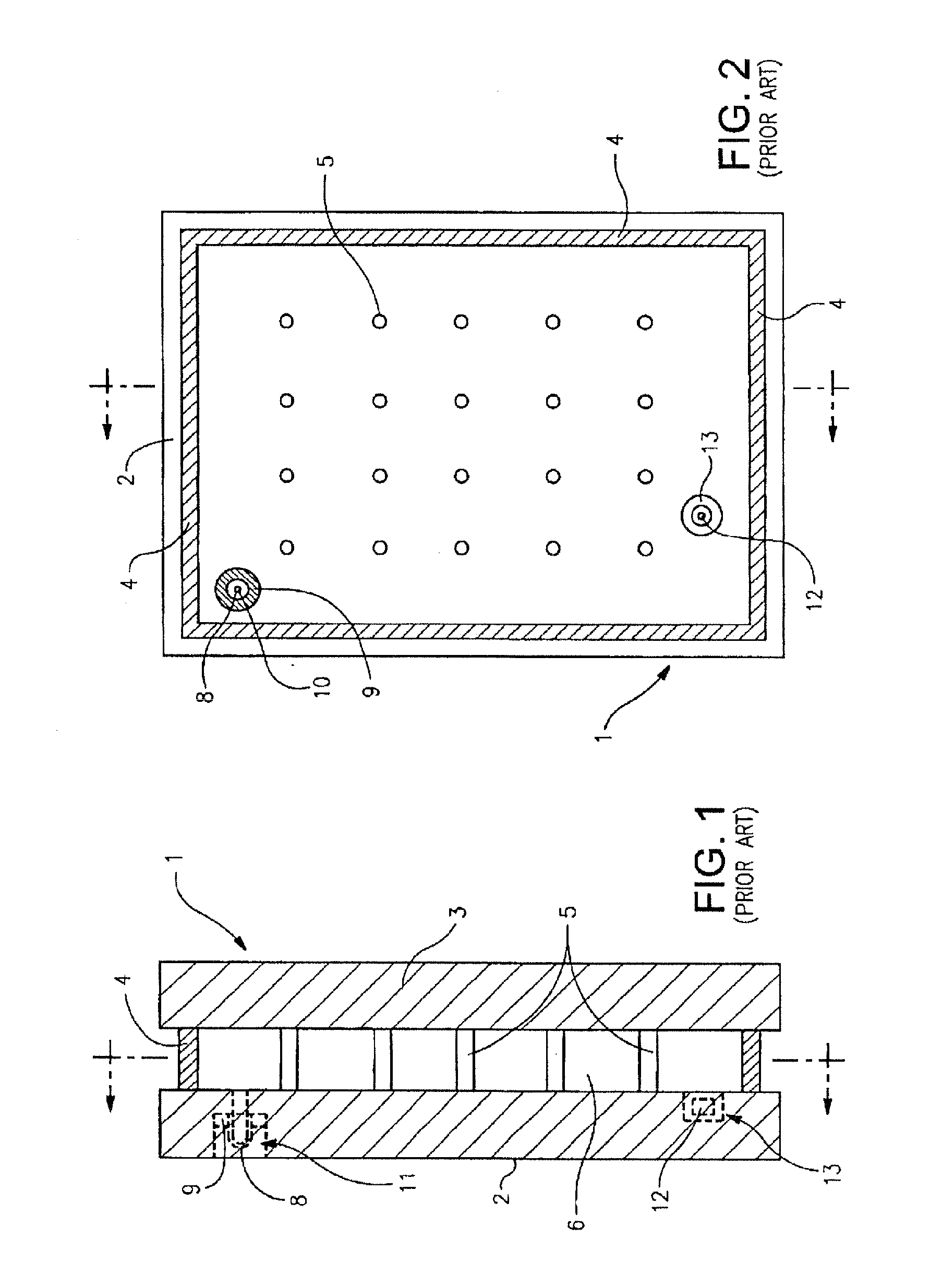

Blockable bone plate

InactiveUS6730091B1Cost effective productionLow costSuture equipmentsInternal osteosythesisEngineeringIliac screw

The blockable bone plate consists of a plurality of plate members which are connected to each other via webs. A screw hole is provided in at least some plate members, preferably in each plate member. The screw hole is surrounded by a spherical countersink on the upper surface of the plate. Provided internally in the screw hole there is an engagement contour which consists of contour valleys and contour peaks partially running in a horizontal and radial peripheral direction on the wall of the screw hole. The engagement contour is preferably produced by milling and has for example a pointed, round, trapezoidal or serrated configuration. A blocking thread is provided under the screw head of the screw intended for blocking. As the screw is screwed in, the blocking thread engages in the engagement contour. The particular advantages lie in increased security against the screw coming loose and in the possibility of also inserting the screw through the plate at an inclination. Furthermore, a bone plate is proposed which has the shape of an arc of a circle in the longitudinal axis of the plate and which requires less bending, particularly on the human lower jaw, and adapts to the bone in a more ideal manner.

Owner:MEDARTIS AG

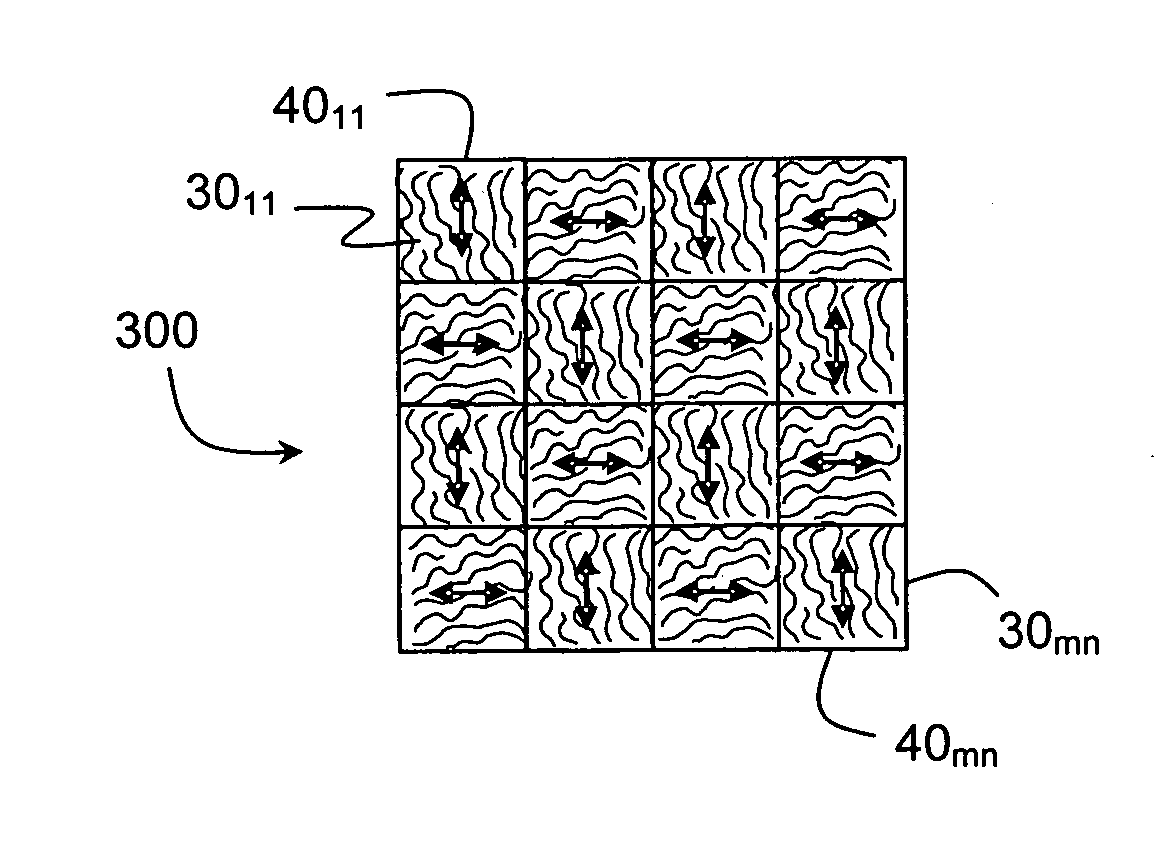

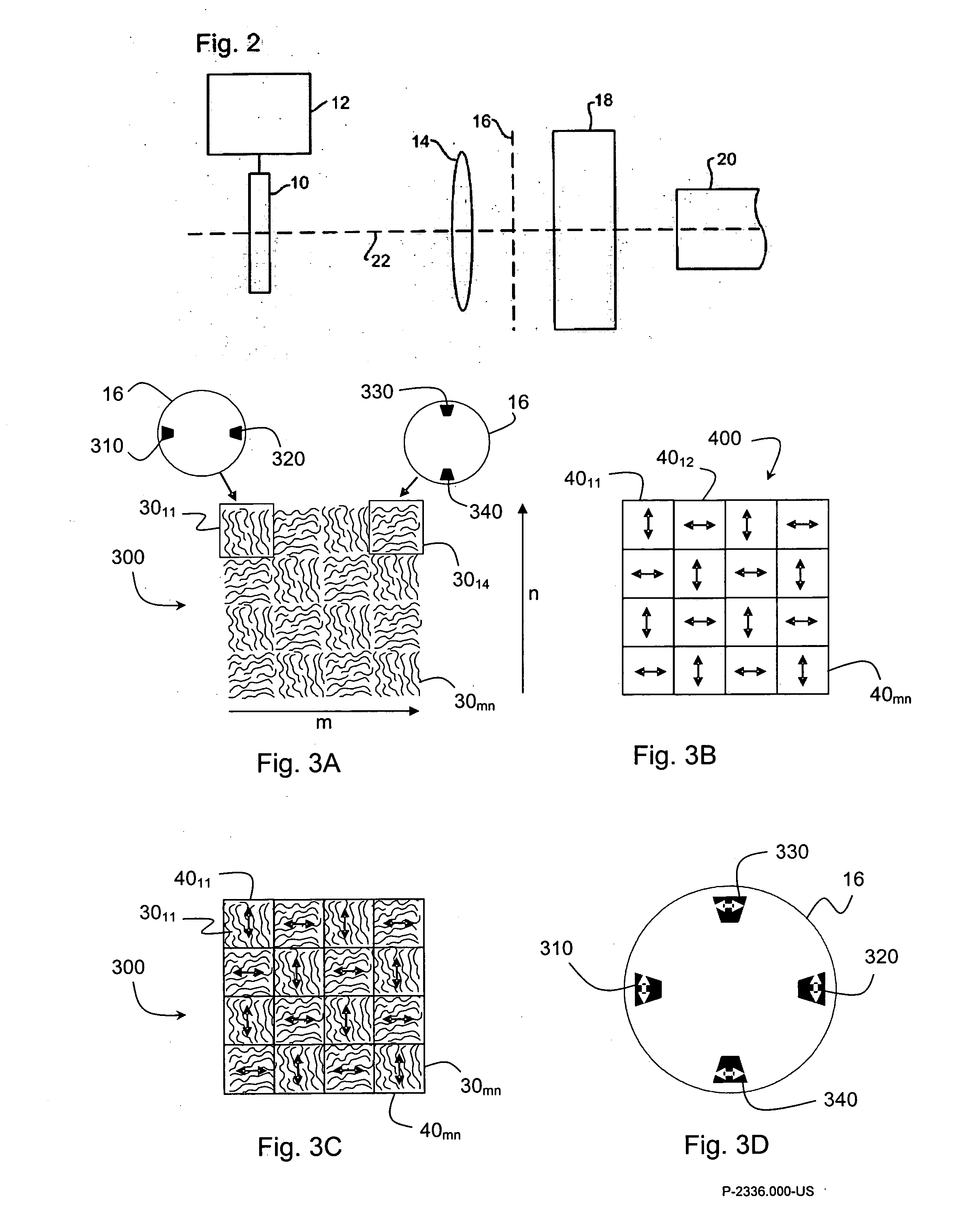

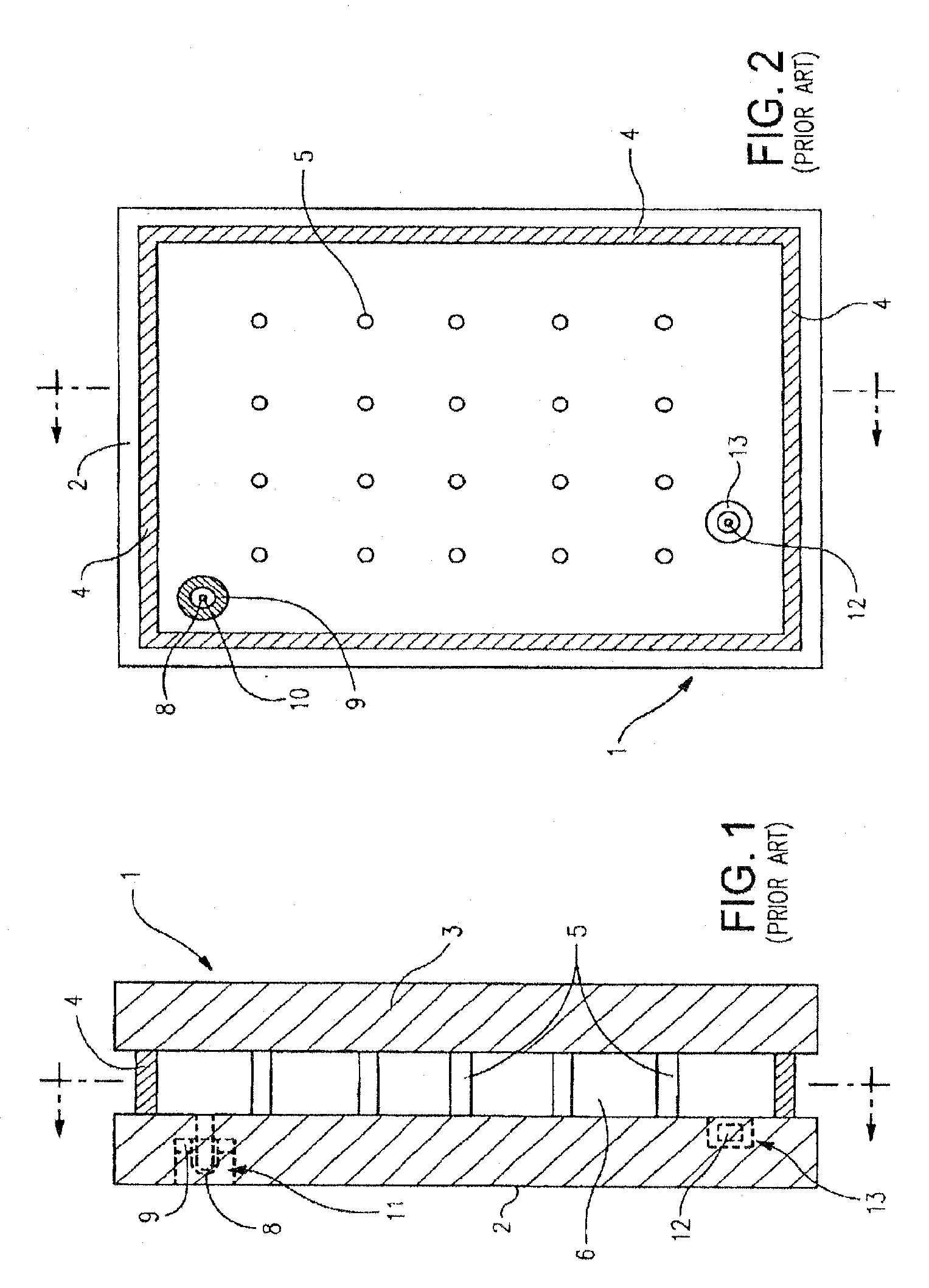

Optical element for use in lithography apparatus and method of conditioning radiation beam

InactiveUS20070058151A1Little loss of strengthPhotomechanical apparatusPhotographic printingLithographic artistLighting system

An optical element for effecting a desired change in incident radiation at a plane of an illumination system of a lithographic apparatus comprises an array of cells manufactured as a single unit, each cell being arranged to redirect the incident radiation in a predetermined direction. An array of polarizing regions is also provided, each polarizing region being associated with a corresponding cell. Each cell arranged to redirect radiation in a first direction has associated with it a polarizing region ensuring that the redirected radiation has a first polarization, so that all of the radiation redirected in the first direction has the same polarization.

Owner:ASML NETHERLANDS BV +1

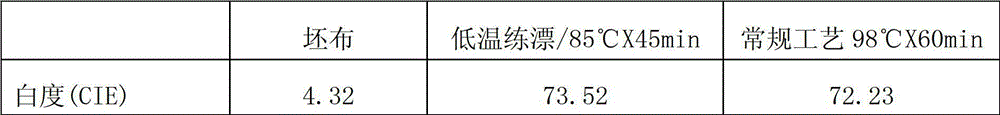

Apparatus and method of using light sources of differing wavelengths in an unitized beam

ActiveUS7083304B2Minimize the numberSmall spacingMechanical apparatusPoint-like light sourceOptical axisLight beam

A plurality of light sources, each radiating a color of light; a corresponding plurality of reflectors are arranged and configured so that the reflector reflects light from a predetermined one of the plurality of light sources. The reflected light from the plurality of reflectors is mixed to generate a composite light from the plurality of light sources. A sequenced or stacked array of the light sources and dichroic reflectors mixes the reflected light from the reflectors. Each reflector is positioned on a common optical axis with an aligned corresponding one of the plurality of light sources to provide a light source and reflector pair. Each reflector is coated with a dichroic filter material which reflects the color of light radiated by the corresponding light source of the pair, and which transmits light radiated by all preceding light sources in the sequenced array.

Owner:SIGNIFY HLDG BV

Steel plate with low welding crack sensitivity and production method thereof

InactiveCN101096738AHigh strengthMeet the requirements of different site construction process conditionsRoll mill control devicesHeat treatment process controlChemical compositionSheet steel

The invention discloses a low-welding crack sensitivity steel board and manufacturing method, which comprises the following parts: not more than 0.07% C, 0.15-0.40% Si, 1.00-1.60% Mn, not more than 0.015% P, not more than 0.010% S, not more than 0.30% Cu, not more than 0.50% Ni, not more than 0.30% Cr, not more than 0.30% Mo, not more than 0.08% V, not more than 0.08% Nb, 0.010-0.020% Ti, not more than 0.003% B, Fe and inevitable impurity. The invention is characterized by the following: (1)displaying lower welding crack sensitivity component with Pcm not more than 0.20%; (2)mating the strength and flexibility reasonably with fitful yielding ratio; (3)making the price and property of the steel board superior to the congeneric import product; (4)making the maximum breadth of steel board to 4000mm; (5)simplifying the technique to ensure higher flatness without quenching water.

Owner:WUYANG IRON & STEEL

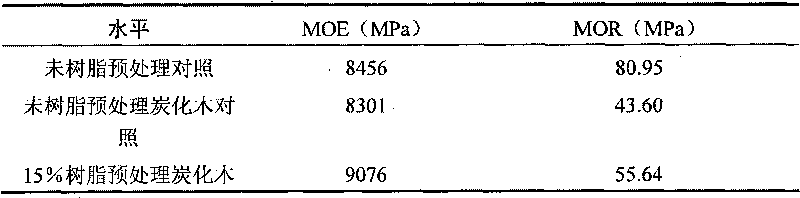

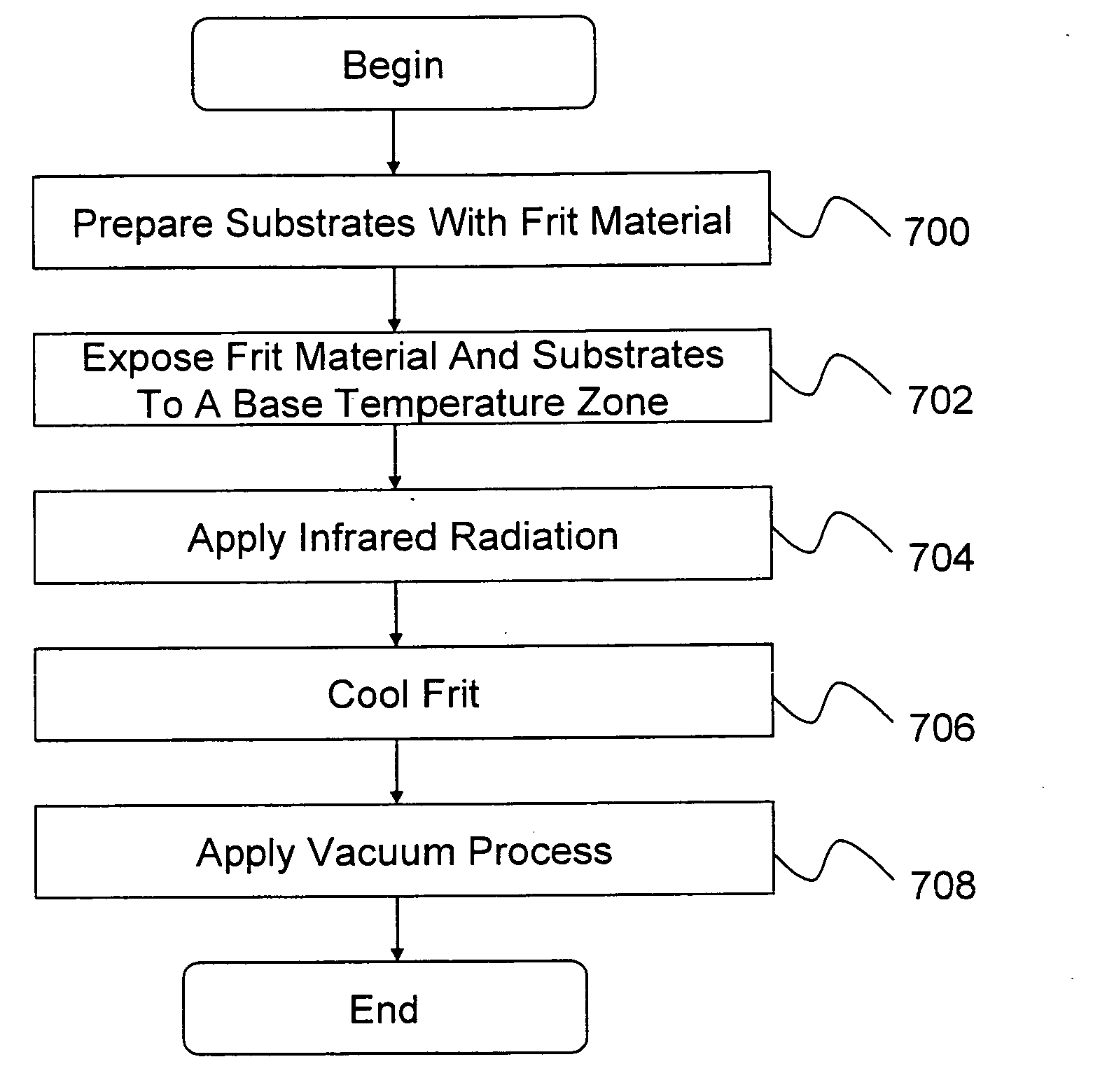

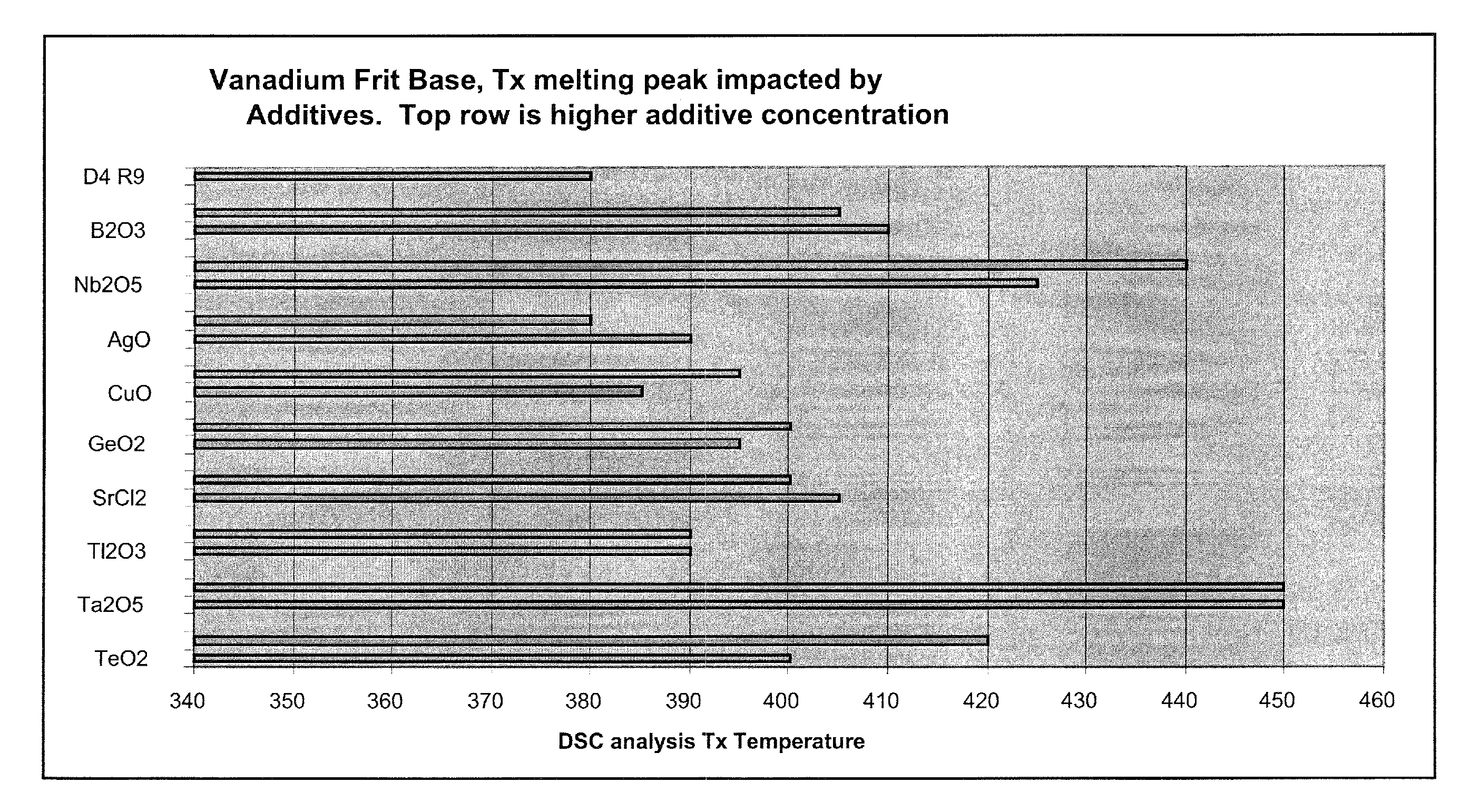

Coefficient of thermal expansion filler for vanadium-based frit materials and/or methods of making and/or using the same

ActiveUS20120213954A1Improve sealingReduce sealClimate change adaptationWindows/door improvementMetal chlorideFrit

Certain example embodiments relate to seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a composition may be combined with a binder solution that substantially or completely burns out by the time the composition is melted. In certain example embodiments, a CTE filler is included with a frit material. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

Vanadium-based frit materials, and/or methods of making the same

ActiveUS20120213952A1Little loss of strengthImprove sealingGlass blowing apparatusGlass reforming apparatusMetal chlorideFrit

Certain example embodiments relate to improved seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

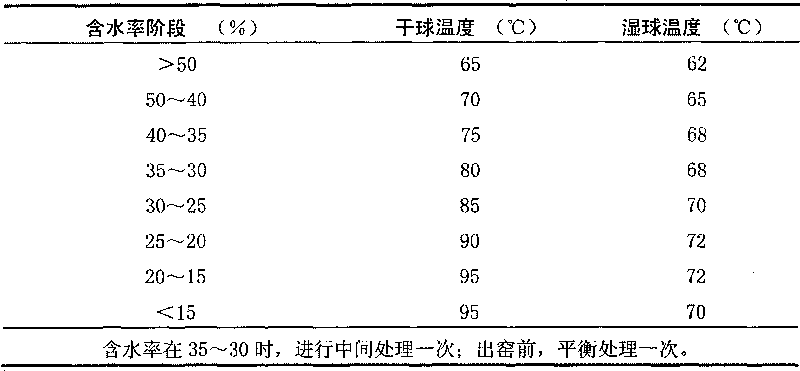

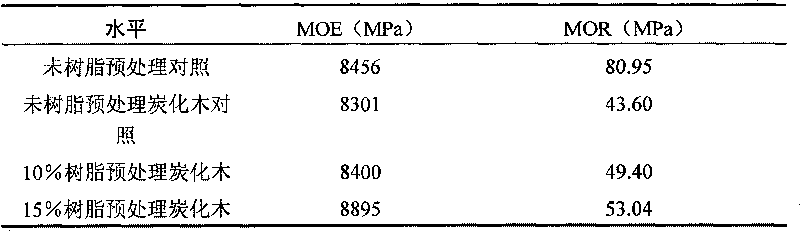

Method for producing rubber tree carbonized wood by resin pretreatment

ActiveCN101716790AHigh strengthIncrease added valuePressure impregnationWood impregnation detailsPulp and paper industryAdditional values

The invention belongs to the technical field of wood modification, in particular relating to a method for producing rubber tree carbonized wood by resin pretreatment. The method comprises the following steps: putting the rubber saw wood of which the water content is less than 15% in a vacuum treatment tank for impregnating; then, stacking and airing the wood, putting the wood in a kiln, routinely drying the wood in the kiln until the water content is less than 12%, and then, taking the wood out of the kiln; and putting the obtained wood in heat treatment equipment for high-temperature heat treatment, and taking the wood out of the kiln to obtain the rubber tree carbonized wood, wherein the water content of the wood is 4-6%. The invention has simple processes, high heating rate in the heat treatment process and high production efficiency, can increase the strength of the rubber tree carbonized wood by vacuum pressurization and impregnation of resin, and can effectively prevent the wood from deforming and cracking in the heat treatment process. The obtained rubber tree carbonized wood has the advantages of little loss of strength of the wood, elegant color, more excellent dimensional stability and durability and the like, and can be widely used for indoor and outdoor floors, landscapes, decorative materials and the like, thereby widening the application field of the rubber tree wood and increasing the additional value of the rubber tree wood.

Owner:RUBBER RES INST CHINESE ACADEMY OF TROPICAL AGRI SCI +1

Vanadium-based frit materials, and/or methods of making the same

ActiveUS20120213951A1Improve sealingDegrade sealLaminationLamination apparatusMetal chloridePolymer chemistry

Certain example embodiments relate to improved seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

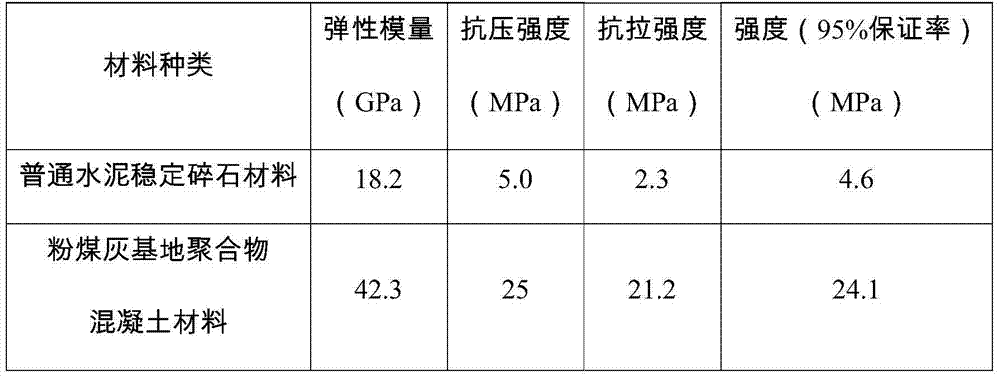

Flyash-based polymer concrete material and preparation method thereof

ActiveCN104496333APromote environmental protectionImprove mechanical propertiesPolymer sciencePolymer concrete

The invention discloses a flyash-based polymer concrete material and a preparation method and an application thereof. The flyash-based polymer concrete material comprises the following components in percentage by mass: 25%-45% of flyash, 0-15% of metakaolin, 10%-15% of cement, 0-5% of coal gangue and slag, 25%-35% of an alkali activator, 0.5%-1% of a retarder and 1%-5% of deionized water. An alkali-activated flyash-based polymer is adopted as a main gel material, so as to prepare an inorganic polymer concrete material; the polymer concrete material has the characteristics of high environmental protection property, good mechanical property and high early strength.

Owner:SHANGHAI PUDONG NEW AREA CONSTR GRP CO LTD

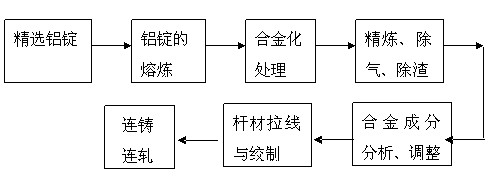

High-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and production method thereof

InactiveCN102634695ASave construction investmentImproved resistance to overloadIngotUltimate tensile strength

The invention discloses a high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and a production method of the high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire. The high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire is produced by finely selecting ingredients and contents of aluminum alloy and conducting process control. The specific steps are as follows: selecting Fe, Si, Mg, Cu and Re with different weight percents, melting aluminum ingot with the content not more than 0.03% in a vertical melting furnace, adding alloying elements in a heat insulation furnace, stirring, refining, conducting on-the-spot contents rapid analysis, carrying out content adjustment, and standing, enabling the aluminum ingot and the alloying element into a continuous casting machine for casting, rolling to be a circular aluminum alloy rod on a continuous rolling machine, pulling the circular aluminum alloy rod to be a circular aluminum alloy wire and twisting the circular aluminum alloy wire to be a conductor for aerial power transmission and distribution. According to the application of the aluminum alloy wire and the production method of the aluminum alloy wire, the aluminum alloy wire directly replaces the generally used aluminum conductor steel reinforced and is an energy-saving, environment-friendly and novel wire.

Owner:FAR EAST CABLE

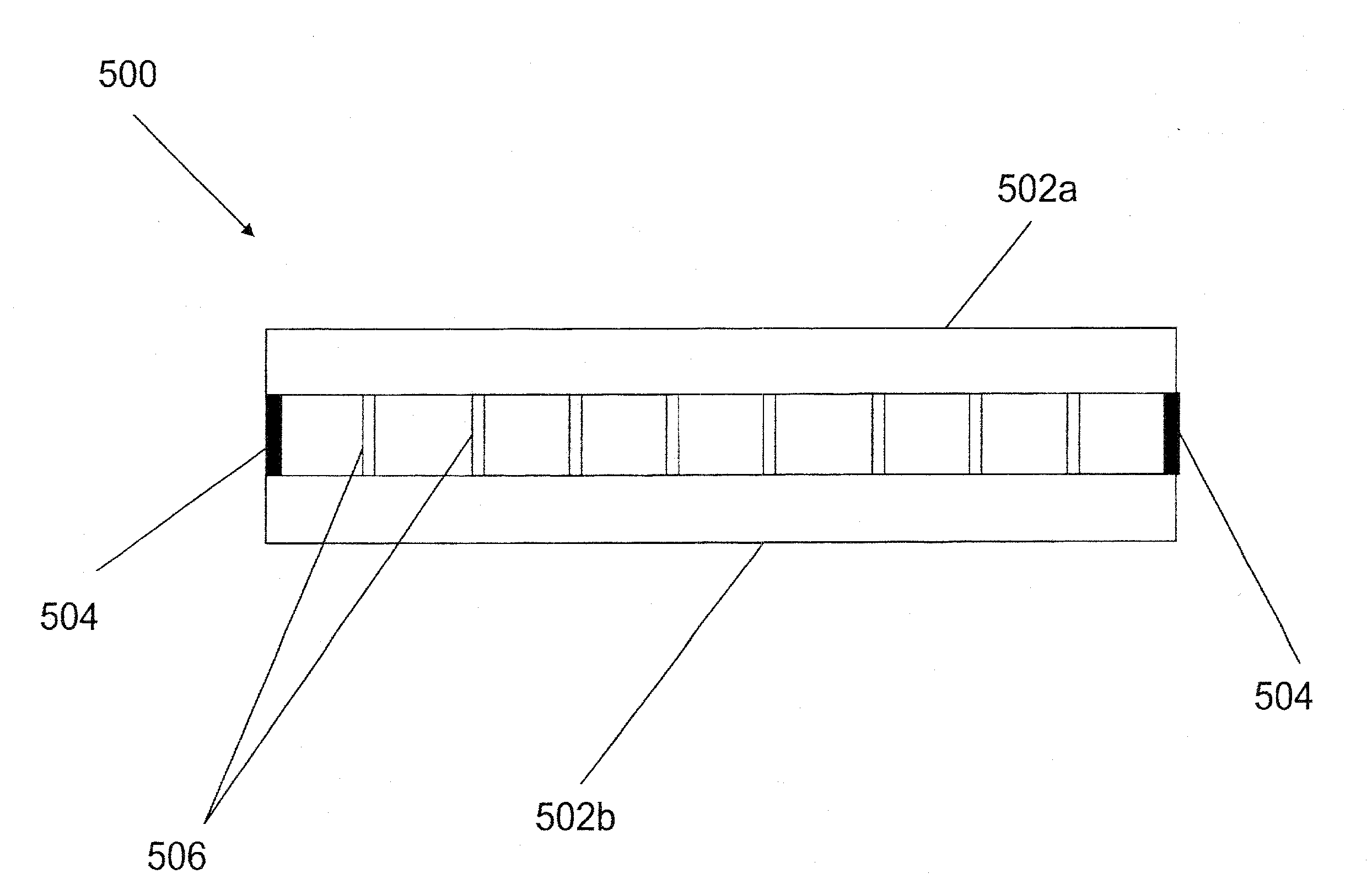

Materials and/or method of making vacuum insulating glass units including the same

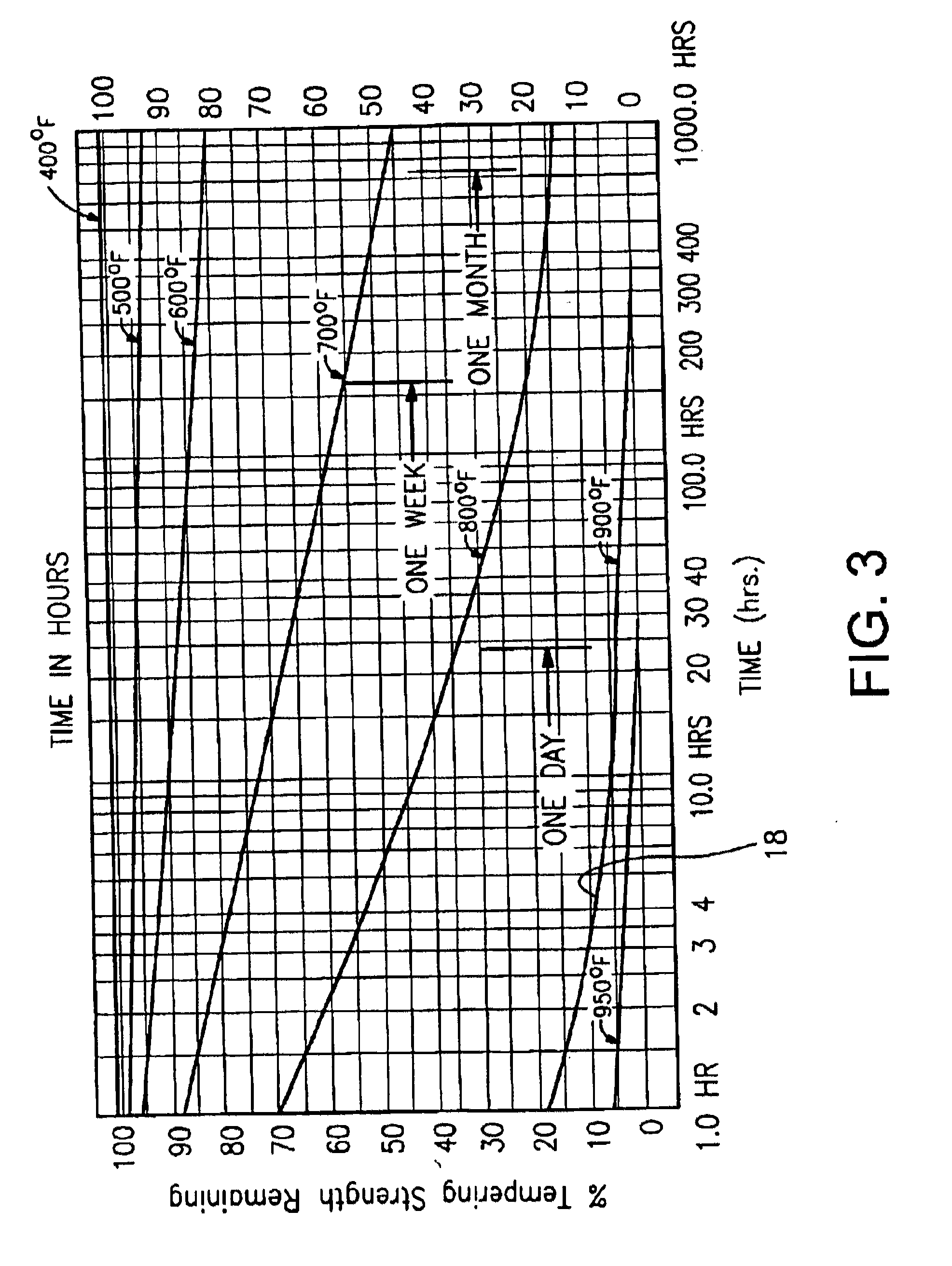

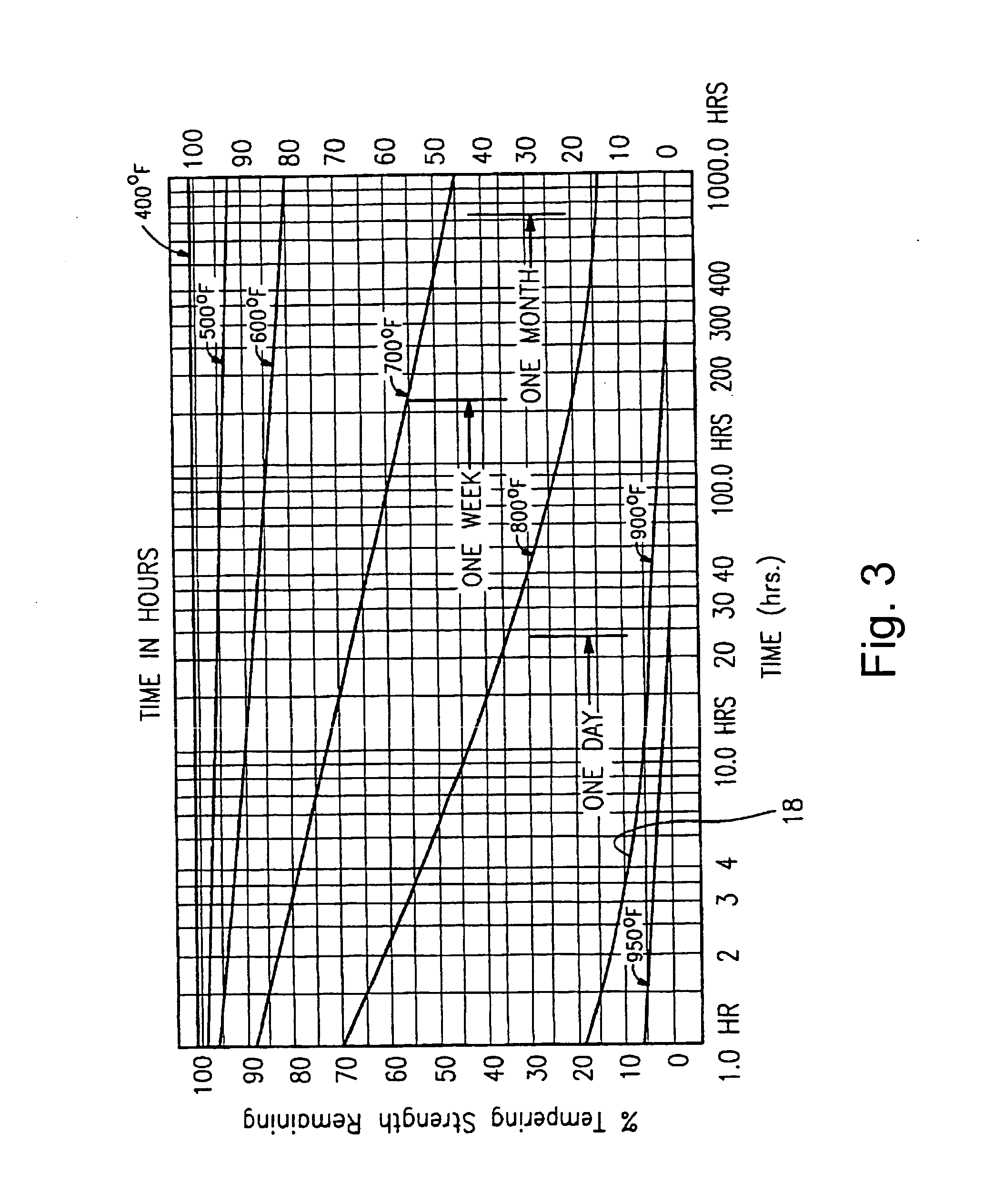

ActiveUS20120211146A1Shorten the time periodLittle loss of strengthDoors/windowsGlass reforming apparatusFritIr absorption

Certain example embodiments relate to frit materials that have an improved IR absorption property. Certain examples relate to frit materials that substantially melt in about 3 minutes at a temperature of about 525° C. Certain examples relate to a method of making an edge seal by using IR energy. Certain examples relate to adjusting the IR energy applied to a frit material to form an edge seal. Certain examples also relate to making a VIG unit by applying IR energy and adjusting the amount of IR energy over multiple periods of time, e.g., in an oscillating manner.

Owner:GUARDIAN GLASS LLC

Vanadium-based frit materials, binders, and/or solvents and methods of making the same

ActiveUS20120213953A1Improve sealingReduce sealLiquid surface applicatorsClimate change adaptationMetal chlorideFrit

Certain example embodiments relate to seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a composition may be combined with a binder solution that substantially or completely burns out by the time the composition is melted. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

One dosage type low temperature scouring and bleaching agent and application thereof

ActiveCN103061104AWide application processEasy to packBleaching apparatusDefoamerSurface-active agents

The invention discloses one dosage type low temperature scouring and bleaching agent which comprises a surface active agent, a hydrogen peroxide activator, a bleaching synergist, a chelating agent, a hydrogen peroxide stabilizer, a defoamer and a filler in a mixing mode. The one dosage type low temperature scouring and bleaching agent can be used for scouring and bleaching cotton, cotton blend knitted fabric or cotton loose fiber in a low temperature bath of 60 DEG C- 85 DEG C and cotton or cotton mixed and blended yarns in a low temperature bath of 80 DEG C -95 DEG C and for cold pad-batch processing of cotton fabric. The one dosage type agent is a solid product which is convenient to pack and transport. One agent can replace more than three agents such as alternative scouring agent, hydrogen peroxide activator, chelating agent, brightening agent and oxygen bleaching stabilizer during processing, which is convenient to feed and process. The one dosage type low temperature scouring and bleaching agent is widely applicable to processes such as scouring and bleaching in bath and cold pad-batch processing.

Owner:NICCA CHEM CHINA CO LTD

Coefficient of thermal expansion filler for vanadium-based frit materials and/or methods of making and/or using the same

ActiveUS20120308747A1Little loss of strengthImprove sealingWindows/door improvementGlass blowing apparatusMetal chlorideFrit

Certain example embodiments relate to seals for glass articles. Certain example embodiments relate to a composition used for sealing an insulted glass unit. In certain example embodiments the composition includes vanadium oxide, barium oxide, zinc oxide, and at least one additional additive. For instance, another additive that is a different metal oxide or different metal chloride may be provided. In certain example embodiments, a composition may be combined with a binder solution that substantially or completely burns out by the time the composition is melted. In certain example embodiments, a CTE filler is included with a frit material. In certain example embodiments, a vacuum insulated glass unit includes first and second glass substrates that are sealed together with a seal that includes the above-described composition.

Owner:GUARDIAN GLASS LLC

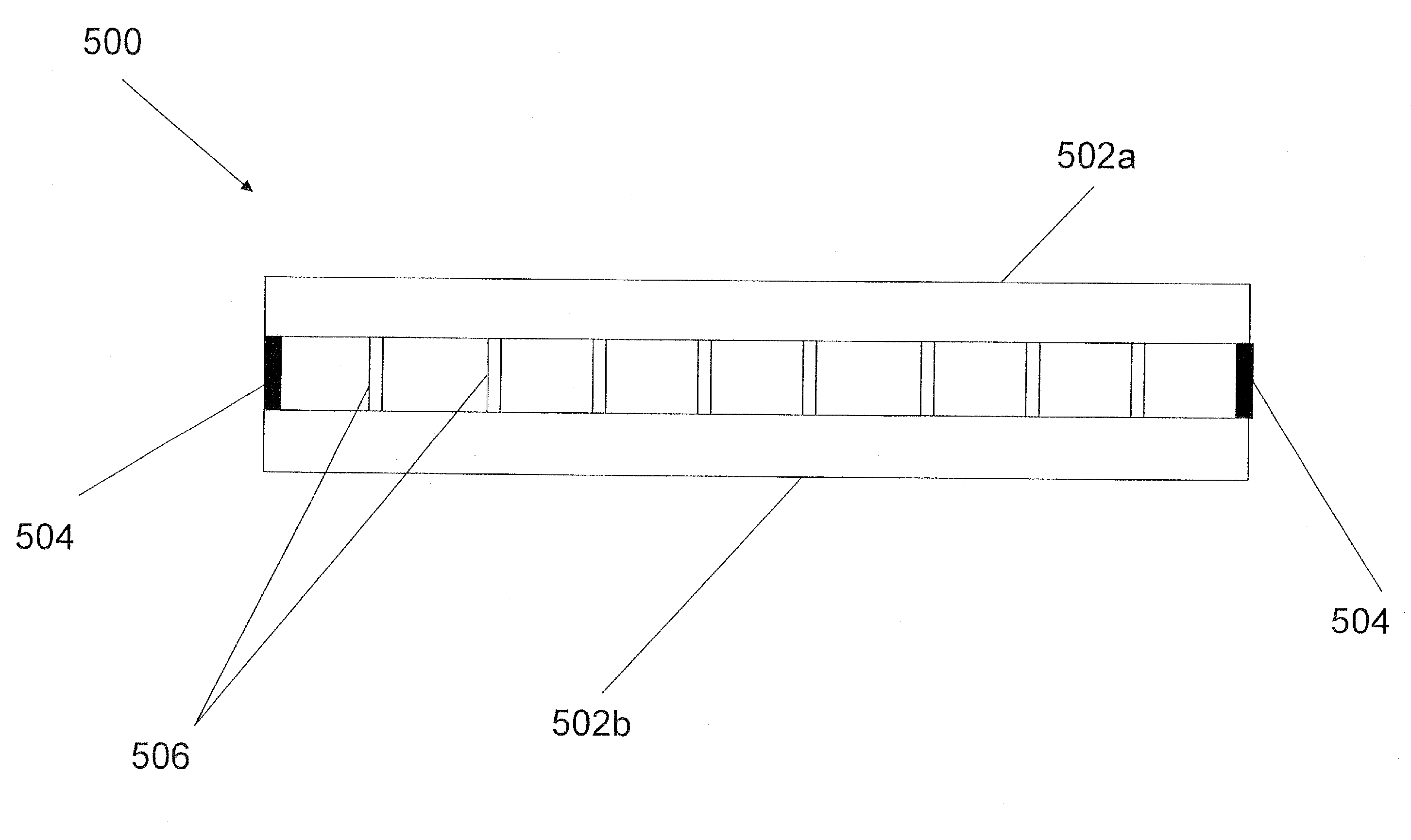

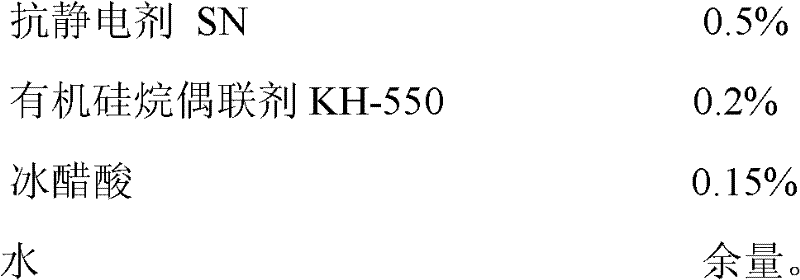

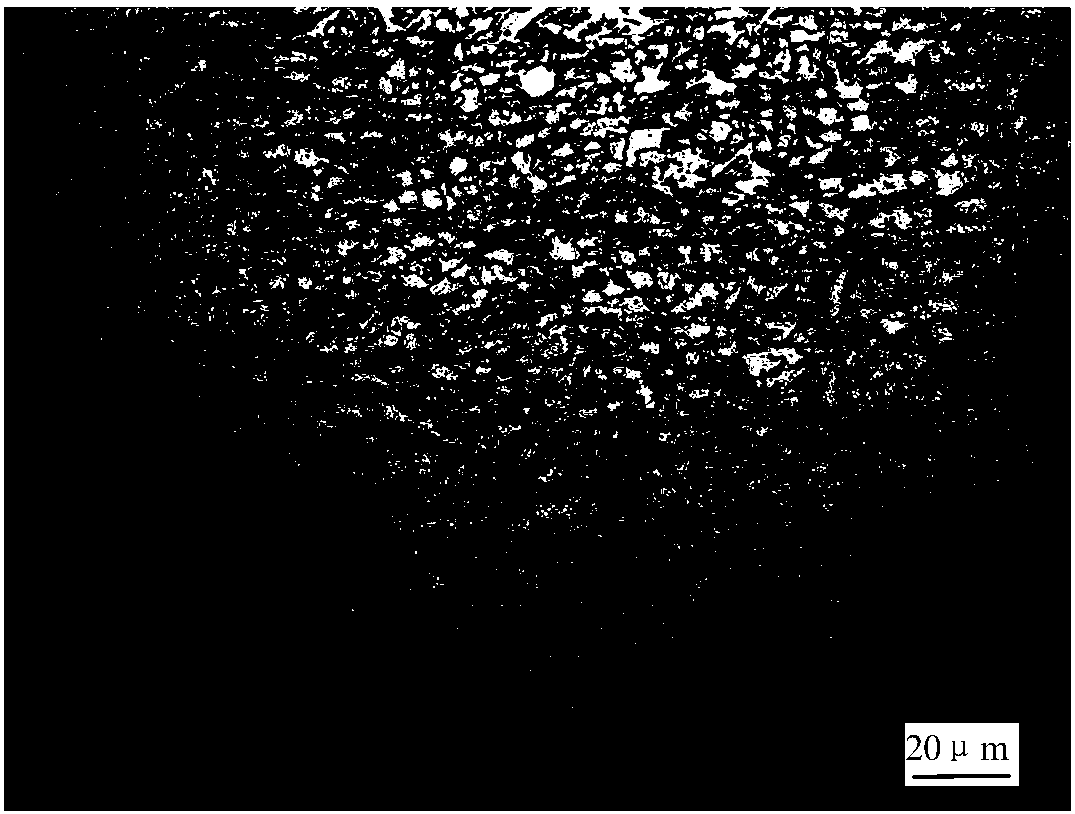

Pre-processing reinforced type impregnating agent for basalt fiber chopped spun yarn and preparation method of pre-processing reinforced type impregnating agent

The invention relates to a pre-processing reinforced type impregnating agent for a basalt fiber chopped spun yarn and a preparation method of the pre-processing reinforced type impregnating agent and belongs to the technical field of the impregnating agent. The pre-processing reinforced type impregnating agent comprises the following components by weight percent: 2-4% of water-soluble epoxy resins, 2-4% of water-soluble polyurethanes, 0.5-1% of organic silicon latexes, 0-0.1% of cation surface active agents, 0.5-1% of antistatic agents, 0.2-0.5% of organic silane coupling agents, 0.1-0.2% of pH adjusting agents and the balance water. The pre-processing reinforced type impregnating agent and the preparation method provided by the invention are simple in technology and are suitable for the production of the basalt fiber chopped spun yarn with a single fiber diameter of 3.5-7.5 microns. The basalt fiber chopped spun yarn produced by utilizing the pre-processing reinforced type impregnating agent is high in strength and excellent in flexibility; a produced high-temperature acupuncture filter felt is free from being subjected to heat treatment; silicon oil and tetrafluoro coatings can be directly coated; energy source is saved; environmental pollution is reduced; and the pre-processing reinforced type impregnating agent is excellently combined with an interface of a produced product substrate and is high in strength.

Owner:山东兴国大成特种纤维科技有限公司

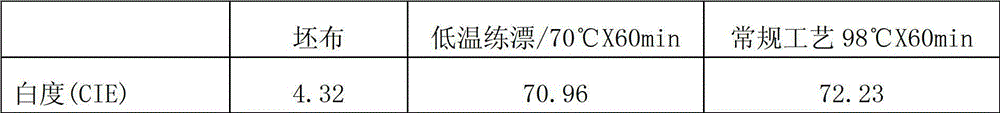

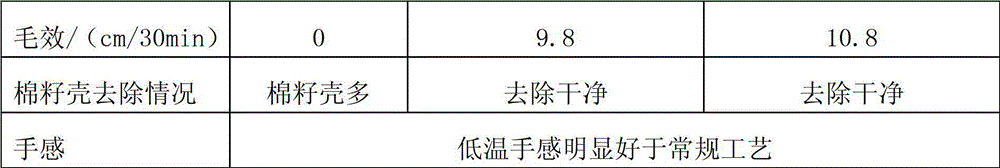

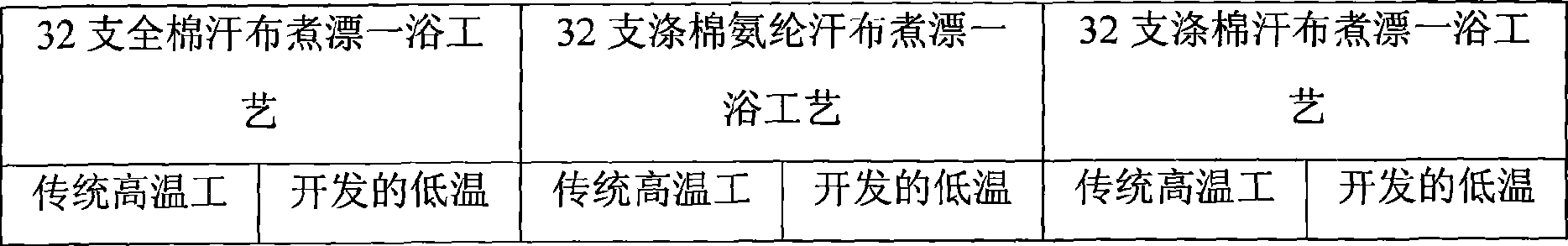

Method for environment-friendly low-temperature scouring and bleaching in spinning dyeing and finishing

ActiveCN101487183ASuitable for processingLittle loss of strengthBleaching apparatusVegetal fibresOxygenTextile dyeing

The invention relates to a method of environment-protective low-temperature scouring and bleaching used for textile dyeing and finishing, comprising the following steps: a dyeing and finishing solution which consists of low-temperature scouring and bleaching promoter composition, 25-30% of hydrogen peroxide and caustic soda, with the mass percentage of 2:8-12:2.5-3 is prepared; subsequently, the dyeing and finishing solution is used for processing cotton knitted fabric with the bath proportion of 1:8-15, the temperature of 75-80 DEG C and the time of 40-60s. The method carries out scouring and bleaching one bath processing at the temperature of 75-80 DEG C, with the scouring and bleaching effect achieving the whiteness and capillary effect standard of the traditional high-temperature alkali-oxygen one bath process at the temperature of 98-100 DEG C or even 130 DEG C; furthermore, the cost is low, the processing time is saved, and the possibility of wrinkle of cotton and cotton blended fabric (such as blended polyurethane and cotton) is reduced.

Owner:NINGBO GUANG YUAN FABRIC

Preparation method and application of gypsum retarder

The invention discloses a preparation method and an application of a gypsum retarder. The gypsum retarder is prepared from a diacid or anhydride material and an ammoniacal material or L-aspartic acid; the retarder prepared by use of the preparation method is added to gypsum so as to increase the setting time of a gypsum building material and reduce the strength loss of a hardened gypsum body. The retarder is a water-soluble amino acid degradable polymer, has excellent biodegradability and is a green and environment-friendly polymer material. The molecular structure of the retarder contains a large number of groups such as carboxyl, carbonyl and acyl, and the groups can be combined with Ca<2+> into complexes so that the dissolution velocity of the gypsum can be reduced, the diffusion of Ca<2+> to gypsum crystals can be restricted and hydration of gypsum particles can be hindered, and therefore, the retarding effect of the retarder is realized. Meanwhile, the strength loss caused by structural degradation of gypsum holes due to a high water-gypsum ratio is reduced.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

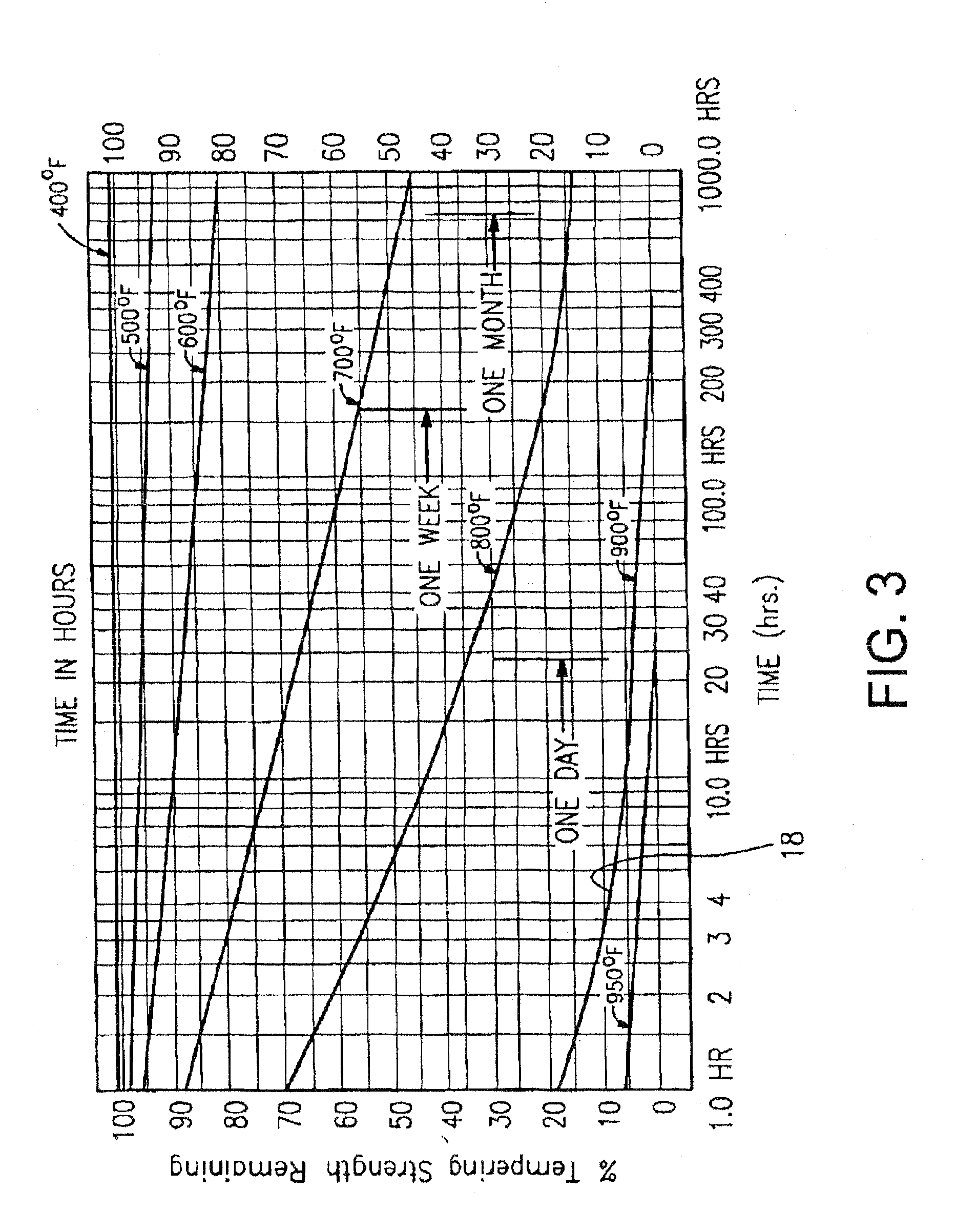

Ultra-wide high-toughness hot-rolled thick plate for low-temperature pipeline, and production method thereof

The invention discloses an ultra-wide high-toughness hot-rolled thick plate for a low-temperature pipeline, and a production method thereof. The steel is prepared from 0.030 percent to 0.055 percent of C, 0.16 percent to 0.30 percent of Si, 1.45 percent to 1.70 percent of Mn, 0.04 percent to 0.07 percent of Nb, 0.012 percent to 0.025 percent of Ti, 0.20 percent to 0.40 percent of Cr, less than orequal to 0.14 percent of Mo, less than or equal to 0.20 percent of Ni, less than or equal to 0.15 percent of Cu, less than or equal to 0.030 percent of Al, less than or equal to 0.010 percent of P, less than or equal to 0.0015 percent of S, 0.0005 percent to 0.0020 percent of O, 0.001 percent to 0.004 percent of N, 0.0010 percent to 0.0045 percent of Ca, larger than or equal to 1.8 percent of Ca / S, 0.30 percent to 0.60 percent of (Mo+Ni+Cr+Cu), and the balance Fe and inevitable impurities. The rough rolling starting temperature is 1080 to 1130 DEG C, the finish rolling temperature is 980 to 1030 DEG C, the precision rolling starting temperature is 820 to 860 DEG C, the precision rolling finish rolling temperature is 740 to 760 DEG C, the cooling speed is 8 to 15 DEG C / s, and the hot straightening speed is 0.7 to 1.2m / s. The finished product steel plate has the thickness being larger than or equal to 21mm and the width being larger than 4300mm, and has excellent low-temperature toughness.

Owner:ANGANG STEEL CO LTD

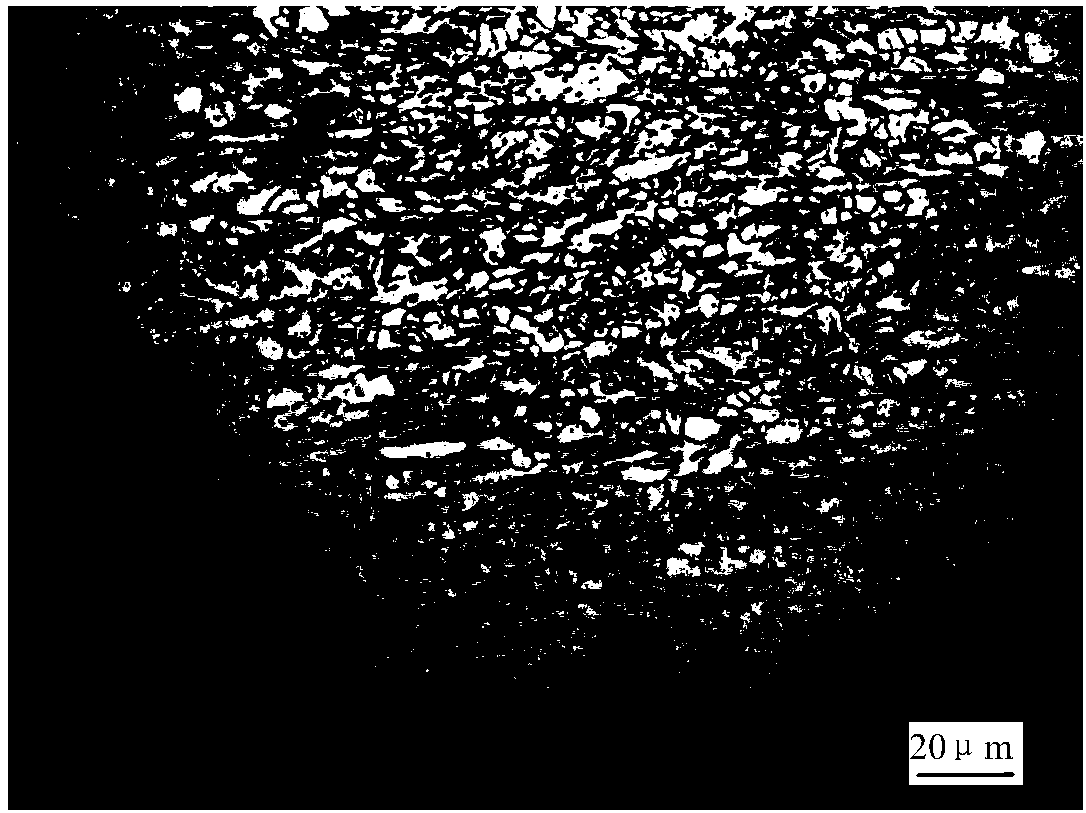

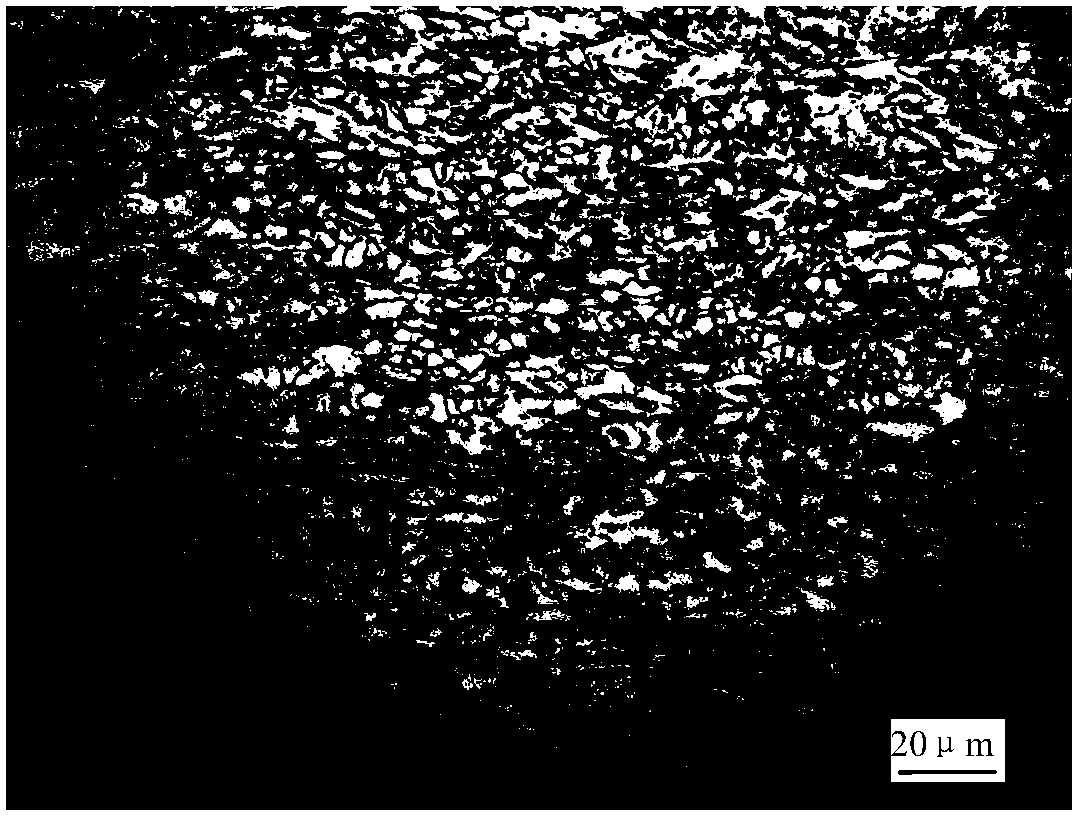

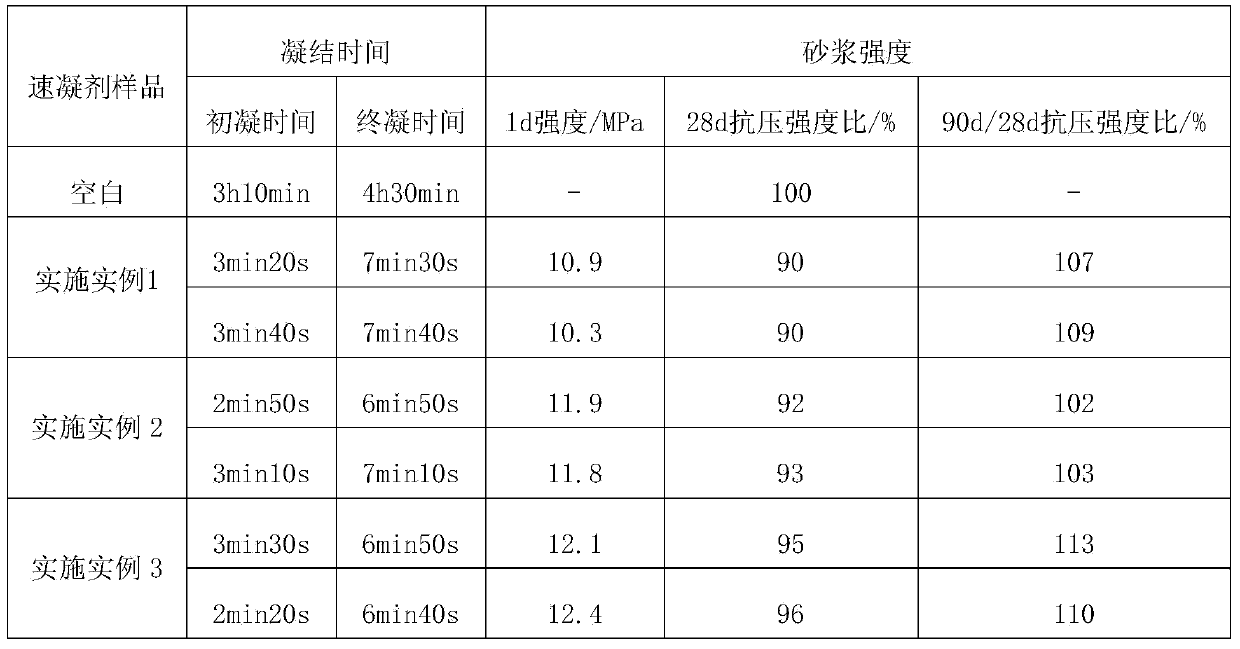

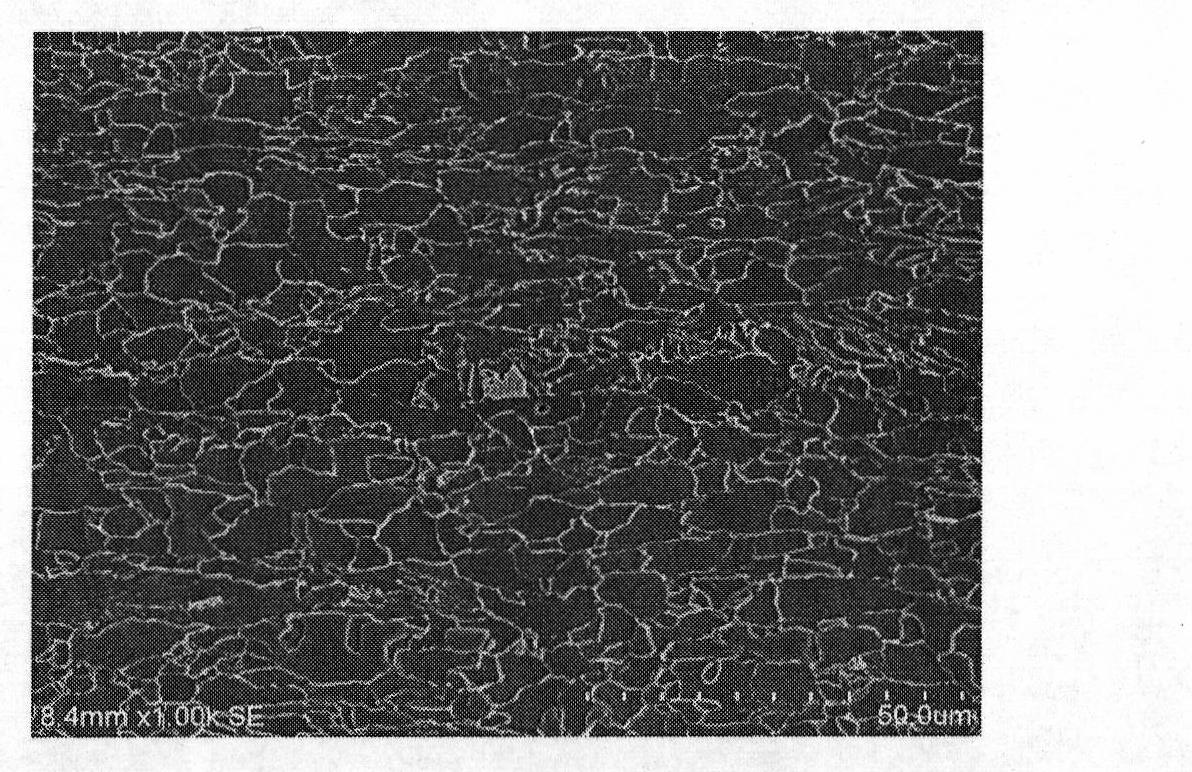

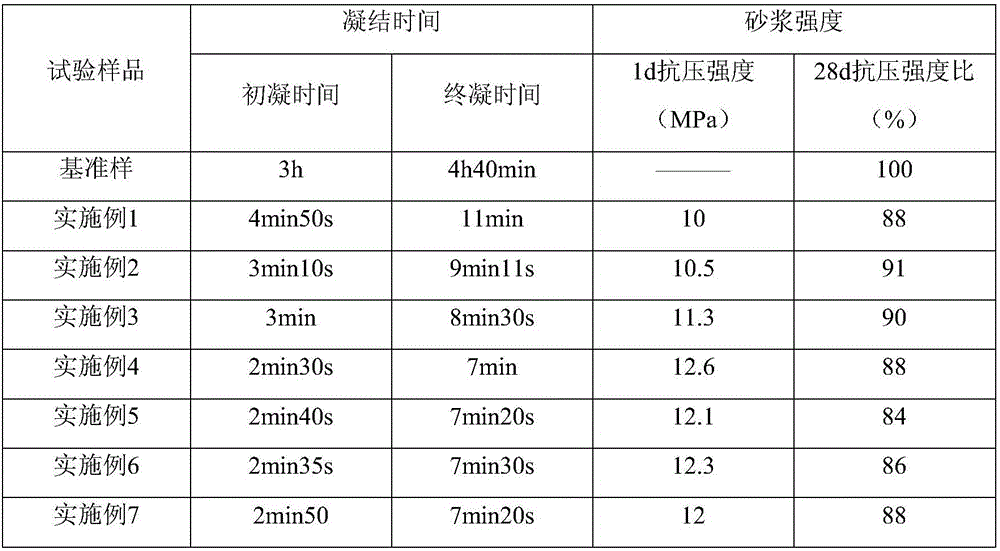

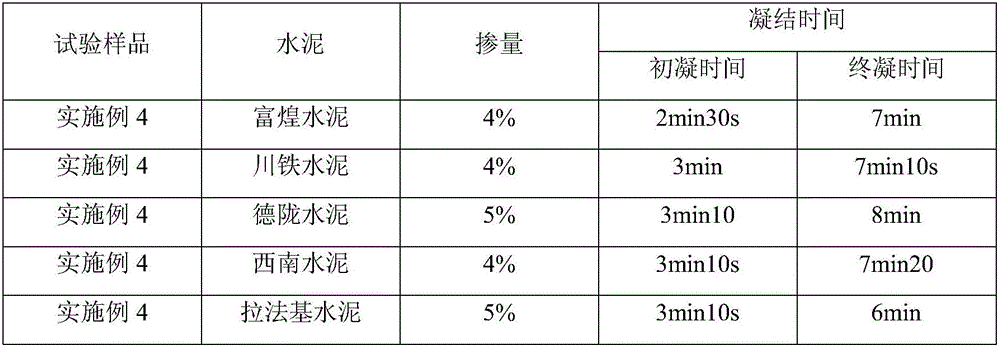

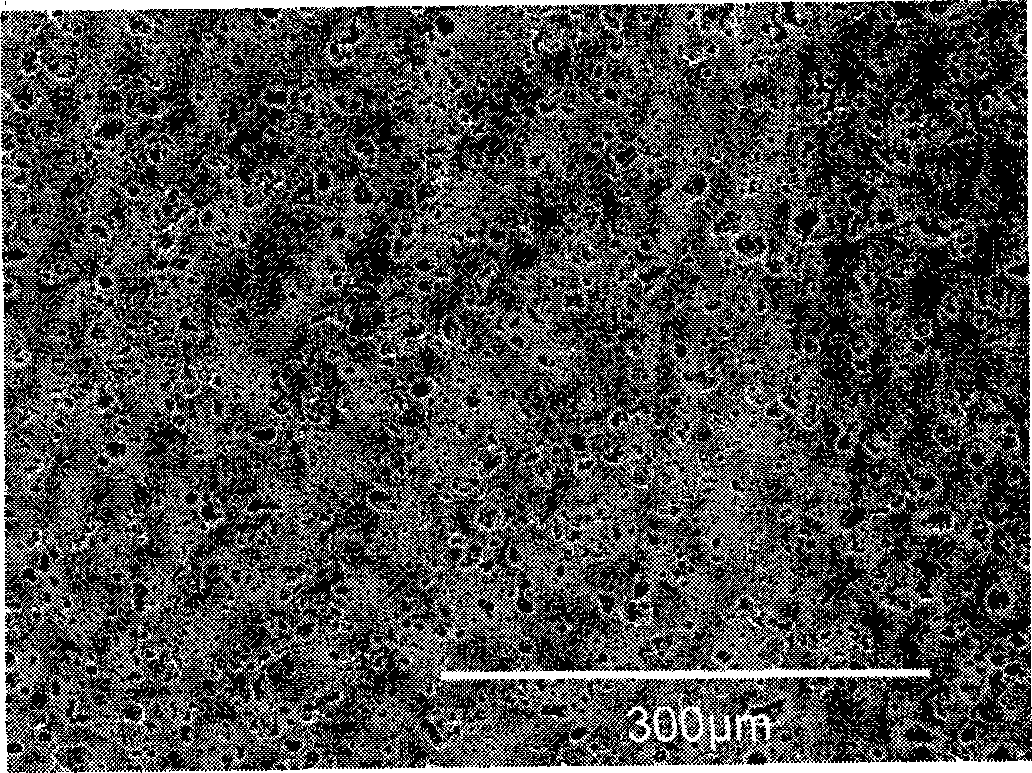

Low-resilience and low-alkaline liquid accelerator for sprayed concrete and preparation method thereof

The invention relates to a low-resilience and low-alkaline liquid accelerator for sprayed concrete and a preparation method thereof. The accelerator is prepared from the following raw materials: an aluminate mother liquid, a modifier, hydramine and a stabilizer, wherein the mass ratio of the modifier and the aluminate mother liquid is 1: (1-5), the dosage of hydramine is 0.5-2.5% of the sum of the modifier and the aluminate mother liquid in mass, the dosage of the stabilizer is 0.3-2% of the sum of the modifier and the aluminate mother liquid in mass; the stabilizer is one of vinylon glue, EDTA (Ethylene Diamine Tetraacetic Acid) and xanthan gum. The preparation method comprises the following steps: preparing the aluminate mother liquid; preparing the modifier; and preparing the low-alkaline liquid accelerator. The adulterate amount of the accelerator provided by the invention is 3-6% mass of cement, the initial setting time is 3 minutes and the final setting time is 8 minutes, and the requirements of JC477-2005 accelerator for sprayed concrete are satisfied. The accelerator is uniform and stable and strong in adaptability with cement, can be used for effectively reducing resilience and dust amount in construction of prayed concrete, and is short in setting time and less in loss of long-term strength.

Owner:刘翠芬

Environment-friendly high-strength permeable brick

The invention discloses an environment-friendly high-strength permeable brick which comprises permeable abrasion-resistant layers and permeable layers. The permeable abrasion-resistant layers comprise cement, quartz sand, porous fine aggregate, silica fume, water, reinforcing agents and pigment; the permeable layers comprise carbide slurry, fly ash, mineral powder, cement, ceramsite, porous coarse aggregate, permeable agents and water. The environment-friendly high-strength permeable brick has the advantages that permeable gaps and holes can be prevented from being blocked by dust or slurry owing to closed holes and the water absorption of the porous fine aggregate, the porous coarse aggregate and the ceramsite, and accordingly the pollution resistance and the permeability of the environment-friendly high-strength permeable brick can be enhanced; the compressive strength of the environment-friendly high-strength permeable brick is higher than or equal to 40.0 Mpa, the lengths of abrasion pits are shorter than or equal to 28 mm, the water retention of the environment-friendly high-strength permeable brick is higher than 0.8 g / cm<3>, the permeability coefficient of the environment-friendly high-strength permeable brick (at the temperature of 15 DEG C) is larger than 7.2*10<-2> cm / s, and decrease of the permeability of the environment-friendly high-strength permeable brick is lower than or equal to 20% after the environment-friendly high-strength permeable brick is used for 3 years.

Owner:SHANDONG JINYI GARDEN SHARES CO LTD

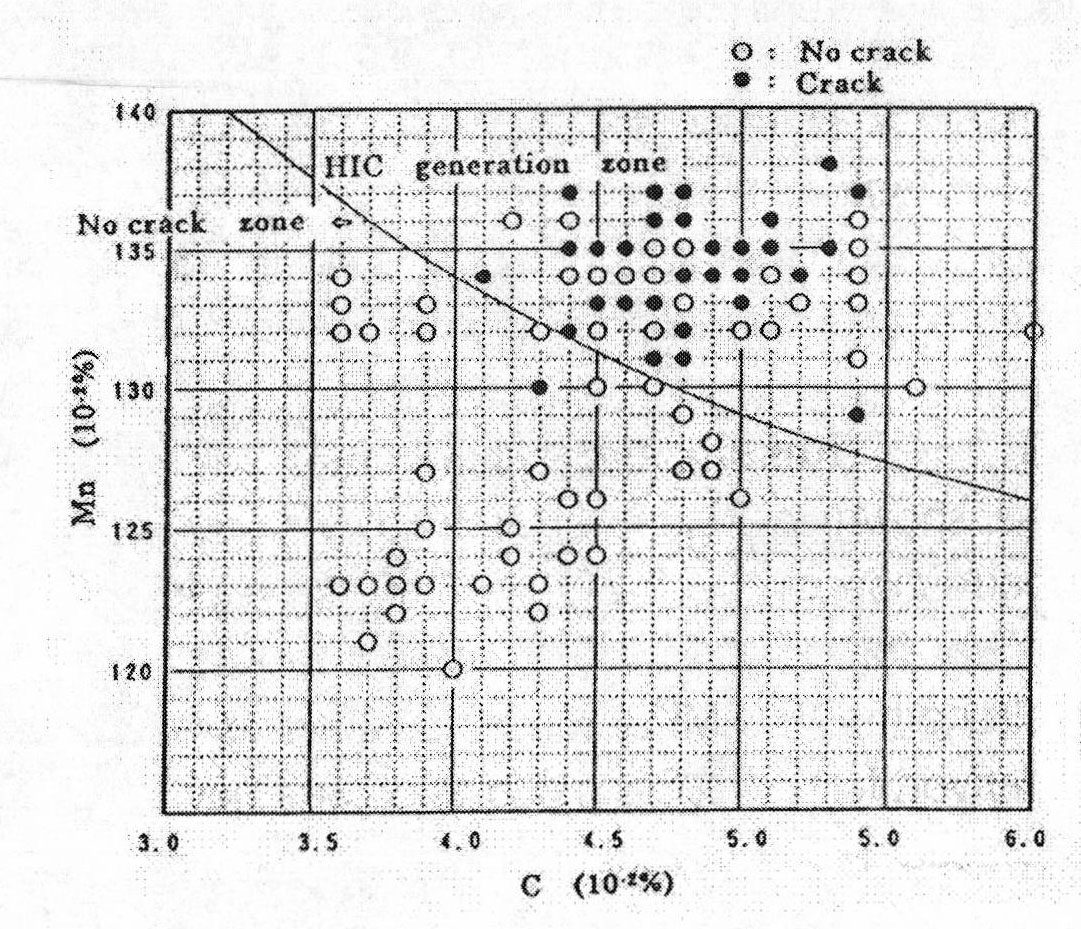

X65 hot-rolled coil for use in acidic environment and manufacturing method thereof

InactiveCN101775556ALow costLittle loss of strengthTemperature control deviceMetal rolling arrangementsSteelmakingNiobium

The invention relates to an X65 hot-rolled coil for use in an acidic environment and a manufacturing method thereof. The X65 hot-rolled coil comprises the following components by weight percent: 0.02-0.06 weight percent of carbon, 0.15-0.25 weight percent of silicon, 0.80-1.20 weight percent of manganese, 0.02-0.05 weight percent of niobium, 0.020-0.040 weight percent of vanadium, 0.010-0.020 weight percent of titanium, less than or equal to 0.30 weight percent of copper, less than or equal to 0.30 weight percent of nickel, 0.10-0.30 weight percent of Cr, less than or equal to 0.015 weight percent of phosphorus, less than or equal to 0.0015 weight percent of sulfur, 0.0020-0.0050 weight percent of calcium, more than or equal to 2.0 weight percent of Ca / S, less than or equal to 0.0005 weight percent of boron and less than or equal to 0.006 weight percent of nitrogen. Other components are ferrum and trace impurities. The steelmaking process route and key control points are hot metal pretreatment, converter steelmaking, LF furnace refining, RH furnace refining, slab casting, billet finishing and storage. The refining procedures outside the furnaces comprise Ca treatment to modify inclusions. The key points of the rolling process are as follows: the heating temperature is 1150-1200 DEG C, the rough rolling outlet temperature is 920-1020 DEG C, the final rolling temperature is 780-860 DEG C, and the rolling temperature is 560-620 DEG C. The invention adopts low-price alloy (Cr and V) to substitute expensive alloy (Mo and Nb) so as to produce steel hot-rolled coils for X65 pipelines with more stable performance and lower alloy cost. Moreover, the hot-rolled coils for X65 pipelines have anti-HIC performance, high strength and high toughness.

Owner:SHOUGANG CORPORATION +1

Low-resilience liquid accelerator for shotcrete and preparation method thereof

The invention discloses a low-resilience liquid accelerator for shotcrete and a preparation method thereof. The accelerator is prepared from the following raw materials in percent by mass: 20%-40% of sodium hydroxide, 25%-40% of aluminium hydroxide, 3%-10% of a synergist, 0.5%-2% of a setting accelerator, 0.003%-0.02% of a viscosity adjusting agent, and the balance water, wherein, the synergist is sodium silicate, the setting accelerator is an alcohol amine substance, and the viscosity adjusting agent is potassium chromate or sodium nitrite. The preparation method comprises the following technical steps: adding sodium hydroxide and the synergist into a reaction kettle, adding water, and starting an agitator and a heater; keeping the temperature after the temperature reaches a set temperature, adding aluminium hydroxide, and reacting with the constant temperature; adding the viscosity adjusting agent, stirring, heating, reacting with a constant temperature, then stopping heating, and naturally cooling; and adding the setting accelerator after the reaction system is cooled, and cooling to room temperature, so as to obtain the accelerator. The accelerator is short in setting time, low in resilience and moderate in viscosity, generates a little sediment, has good cement adaptability, and the preparation method for the accelerator is simple, practicable and energy-saving.

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

Low expansion heat resisting porous ceramic and preparation thereof

InactiveCN101475396AHigh strengthImprove thermal shock resistanceCeramicwareKaolin clayThermal expansion

The invention relates to low-expansion heat-resistant ceramics and a preparation method thereof. The porous ceramics take beta-spodumene / zirconium silicate as a main crystal phase. The ceramics comprise the following compositions: 65 to 90 percent of spodumene ores, 10 to 20 percent of zirconia, 0 to 10 percent of quartz sand, 0 to 15 percent of zircon sand and 0 to 10 percent of kaolin. The diphase ceramics with a uniformly distributed cellular structure is obtained through preparation technology such as grinding, mixing, forming and sintering. The thermal expansion coefficient of the material is between 2.0 and 20.0*10 / DEG C, and the bending strength is more than 100 Mpa. Due to the uniform cellular structure, the low-expansion heat-resistant ceramics have superior thermal shock resistance. The products can be widely applied to heating high-temperature environments such as heat-resistant kitchenware and high-temperature baffle plates.

Owner:北京盛康宁科技开发有限公司

Warp knitted fabric containing cotton and processing method for warp knitted fabric

ActiveCN104131408AReduce uniformityHigh elongation at breakSucessive textile treatmentsFibre treatmentPolymer scienceSpinning

The invention discloses a warp knitted fabric containing cotton. The warp knitted fabric containing the cotton is formed by face filaments and middle filaments or face filaments, middle filaments and bottom filaments in a warp knitting mode, wherein the face filaments are polyester filament yarns, the middle filaments are natural fiber yarns, the bottom filaments are spandex stretch yarns, and the natural fiber yarns are processed through spinning, singeing, reeling, concentrated alkaline mercerizing, drying, wet waxing, dry waxing, rewinding and the like. The natural fiber yarns have the advantages of being high in strength, even in yarn evenness, good in wear resistance and the like, and can meet the requirement of warp knitting, and thus the natural fiber yarns can be used on a 28-stitch high stitch length warp knitting machine to serve as raw knitting materials of the warp knitted fabric containing the cotton. The natural fiber yarns contained in the warp knitted fabric containing the cotton have the skin friendly performance, and the warp knitted fabric containing the cotton is suitable for being worn by all people. The invention further discloses a processing method for the warp knitted fabric containing the cotton.

Owner:楠华技术信息(江苏)有限公司

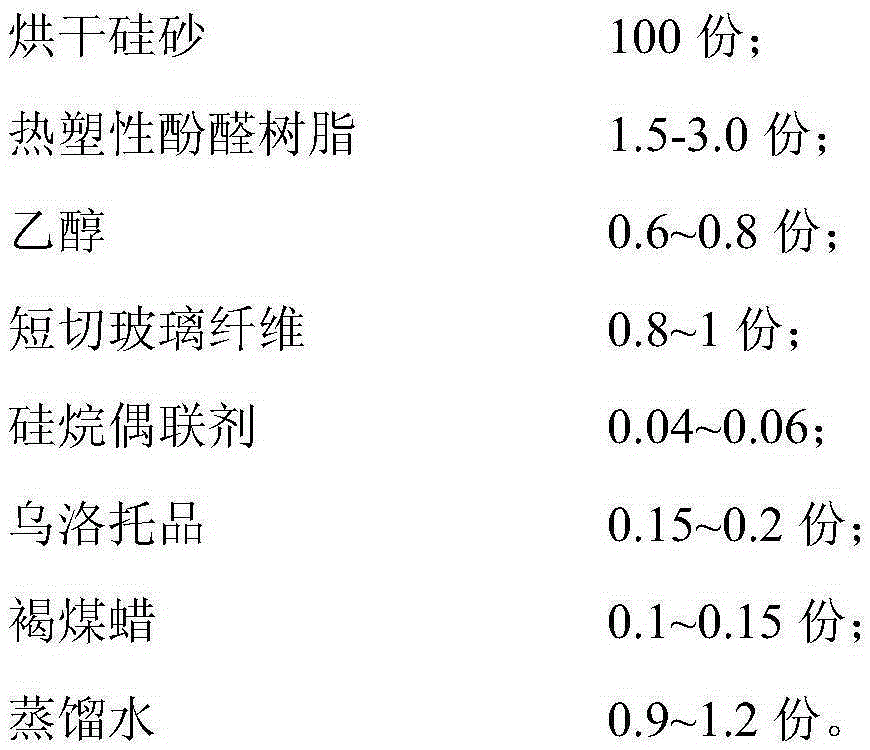

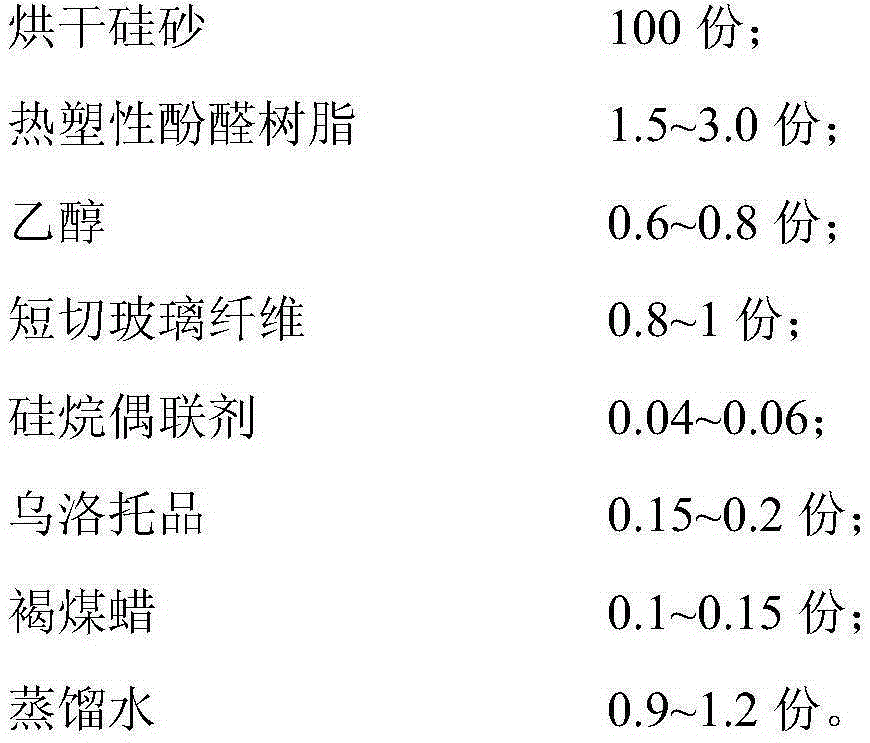

High-temperature-resistance and high-strength precoated sand and preparation method thereof

ActiveCN105234342ASimple preparation processGood value for moneyFoundry mouldsFoundry coresHexamethylenetetramineTemperature resistance

The invention discloses high-temperature-resistance and high-strength precoated sand and a preparation method thereof, and belongs to the technical field of shaping materials in casting production. Firstly, thermoplastic phenolic resins are dissolved to solution by ethanol, and are added with chopped glass fibers and a silane coupling agent; then, dried sand is preheated to a temperature of 120-135 DEG C; the thermoplastic phenolic resin solution is added for sand mixing by 60-70 s; urotropin water solution is added for sand mixing by 50-55 s; and finally, lignite wax is added for sand mixing by 15-20 s. The precoated sand comprises the components of: 100 parts of dried sand, 1-1.3 parts of thermoplastic phenolic resins, 0.6-0.8 part of ethanol, 0.8-1 part of chopped glass fibers, 0.04-0.06 part of silane coupling agent, 0.15-0.2 part of urotropin, 0.9-1.1 parts of distilled water and 0.1-0.15 part of lignite wax. The precoated sand is simple in preparation method, and can solve such problems as weak thermal stability and low strength in traditional precoated sand at high temperature.

Owner:ZHANGWU LIANXIN JINYING CASTING MATERIAL CO LTD

Immersion method bioenzyme pretreatment technology of hemp and its cospinned fabric

The present invention relates to an enzymatic pretreatment process of bast and its blended fabric impregnation method. It successively includes the following steps: firstly, adopting hot water with 75-90deg.C to make pretreatment, then adopting impregnation bio-enzyme composite treatment liquor to make uncooking one-bath process, inactivating enzyme and water-washing, utilizing compound treatment liquor to make pretreatment before steep bleaching process, finally adopting steep hydroperoxide bleaching liquor to make treatment and water-washing.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

Auxiliary composition and application thereof for low-temperature one-bath scouring and bleaching process of cotton textiles

ActiveCN102268814AAvoid affecting the effect of bleachingBleach smoothBleaching apparatusTextile printerSustained Release Capsule

The invention relates to an auxiliary agent composition used in a low temperature one-bath scouring and bleaching process for cotton textile and application thereof, belonging to the technical field of textile printing and dyeing. The auxiliary agent composition comprises, by weight, 10 to 15% of a hydrogen peroxide activator, 2 to 5% of low temperature activating catalyst sustained release capsule, 10 to 15% of a chelating agent, 30 to 40% of diatomite, 10 to 15% of a surfactant and 19 to 31% of a bulking agent. The invention also provides a low temperature one-bath scouring and bleaching process for cotton textile. The process comprises the steps of adding an effective amount of the auxiliary agent composition, hydrogen peroxide and caustic soda into cotton textile and carrying out scouring and bleaching at a temperature of 55 to 60 DEG C for 45 to 60 minutes. According to the invention, cooperative utilization of the auxiliary agent composition, hydrogen peroxide H2O2 and caustic soda enables the low temperature one-bath scouring and bleaching process in the invention to be realized and scouring and bleaching one-bath treatment at or below a temperature 60 DEG C to be carried out, and the effects of scouring and bleaching by using the process provided in the invention are identical with the whiteness and capillary effects of conventional high temperature alkali hydrogen peroxide one-bath process carried out at a temperature of 98 to 100 DEG C, or even at 130 DEG C.

Owner:义乌市中力工贸有限公司 +1

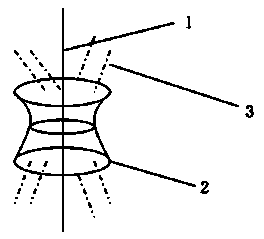

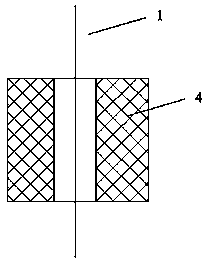

Cylindrical beam large visual field X-ray computed tomography (CT) imaging system

InactiveCN104597062AHigh resolutionNo stitching requiredUsing wave/particle radiation meansMaterial analysis by transmitting radiationData acquisitionX-ray

The invention relates to a cylindrical beam large visual field X-ray computed tomography (CT) imaging system. The system consists of a radiation source system, a capillary modulation system, a sample platform system and a detector system which are sequentially and coaxially connected in an optical way, wherein a capillary device which is used for forming a modulation radiation source so as to enable a cylindrical beam X-ray to be formed by the modulation radiation source is arranged between imaging target samples of the radiation source system and the sample platform system; an X-ray source of the radiation source system is connected with a capillary tube of the capillary modulation system, so that a cylindrical parallel beam is obtained; the detector system is used for acquiring data by adopting a multi-channel signal processor. According to the imaging system, the radiation source system and the detector system are fixed, a rotary table can rotate, the radiation source is capable of emitting the cylindrical beam X-ray after being modulated by the capillary modulation system, and the conventional scanning can be completed for once only by rotating the sample platform at 180 degrees, so that the acquired data is complete; parallel beam is used for reconstruction, and the reconstruction belongs to accurate reconstruction; compared with the conventional system, the cylindrical beam large visual field X-ray CT imaging system is capable of shortening half of the scanning time.

Owner:天津三英精密仪器股份有限公司

Copper-containing low-carbon high-strength high-ductility steel for ocean platform and preparation method thereof

InactiveCN108179351AImprove low temperature toughnessReduce carbon contentChemical compositionIn process control

The invention belongs to the technical field of metallurgy and particularly relates to copper-containing low-carbon high-strength high-ductility steel for an ocean platform and a preparation method thereof. The copper-containing low-carbon high-strength high-ductility steel for oceanographic engineering consists of the following chemical components in percentage by weight: 0.06-0.11% of C, 0.15-0.35% of Si, 0.95-1.3% of Mn, 0.4-0.6% of Mo, 2.3-2.8% of Ni, 0.5-1.0% of Cr, 1.0-2.0% of Cu, less than and equal to 0.05% of Nb, less than and equal to 0.08% of V, greater than and equal to 0.02% of Al, less than and equal to 0.025% of P, less than and equal to 0.010% of S and the balance of Fe, wherein yield strength is 785-820 MPa, tensile strength is 870-925 MPa, and low-temperature impact powerat (-)40 DEG C is 140-220 MPa. The preparation method comprises the following steps of: roughly milling and finely milling forged steel billets in an austenite re-crystallization region and an austenite a non-recrystallization region to obtain a hot-rolled steel plate; and performing QLT two-step critical thermal treatment on air-cooled steel, wherein a quenching temperature is 850 DEG C, a critical annealing temperature is 680 DEG C, a critical tempering temperature is 620 DEG C and heat-preservation time is 60 minutes. The copper-containing low-carbon high-strength high-ductility steel is reasonable in component design, and is simple and easy in process control; and the obtained steel has ultrahigh strength and good low-temperature toughness.

Owner:NORTHEASTERN UNIV

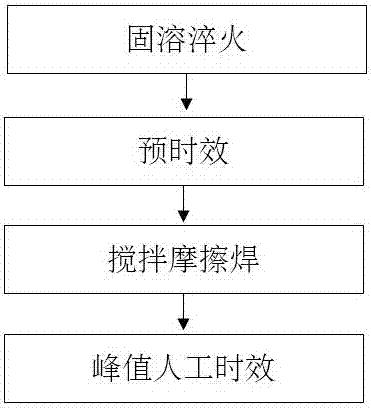

Preparation technology of 6-series aluminum alloy friction stir welding member

ActiveCN107570862AReduce manufacturing costLittle loss of strengthNon-electric welding apparatusFriction weldingPeak value

The invention discloses a preparation technology of a 6-series aluminum alloy friction stir welding member. The preparation technology mainly comprises the steps of on-line or off-line solution hardening, preageing, friction stir welding, peak-value artificial ageing and the like. According to the preparation technology of the 6-series aluminum alloy friction stir welding member, a 6-series aluminum alloy material is subjected to low-temperature preageing treatment after being subjected to solution hardening to enable the strength of aluminum alloy to keep low in a certain time, then frictionstir welding is conducted, forced cooling is conducted in a welded high-temperature area while welding is conducted to enable a solution hardening effect to be achieved, and peak-value artificial ageing is conducted on the overall member after welding is completed, so that it is guaranteed that the strength loss at the welded portion is low, and the ratio of the tensile strength of a weld joint tothe tensile strength of a base material is larger than or equal to 0.85.

Owner:广西南南铝加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com