Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1143results about How to "Lower overall pressure drop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium feldspar aluminum titanate for high temperature applications

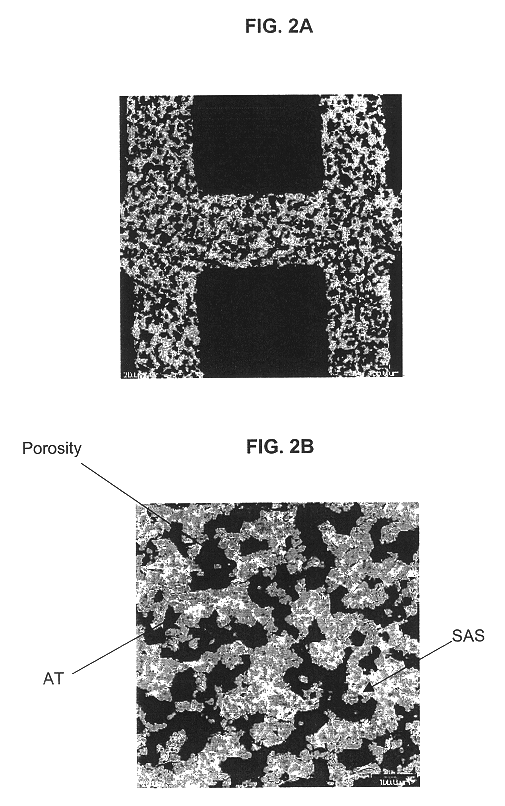

InactiveUS6620751B1Improve stabilityReduce bloatInternal combustion piston enginesDispersed particle filtrationMicrometerRoom temperature

A structure for use in high temperature applications and including a porous ceramic material consisting essentially of about 50-90 percent by weight iron or magnesium stabilized aluminum titanate (AlTiO5) and about 10-50 percent by weight strontium feldspar (SrO.Al2O3.2SiO2), and having a coefficient of thermal expansion over a temperature range from room temperature to 1000° C. of about -10x10-7 / ° C. to +15x10-7 / ° C., a heat capacity at 500° C. greater than 3.2 J / cm3K, a porosity of about 15-50 percent by volume, preferably 40-50 percent by volume, and a median pore size of about 5-50 micrometers, preferably 8-15 micrometers. The structure is especially useful as a diesel exhaust particulate filter.

Owner:CORNING INC

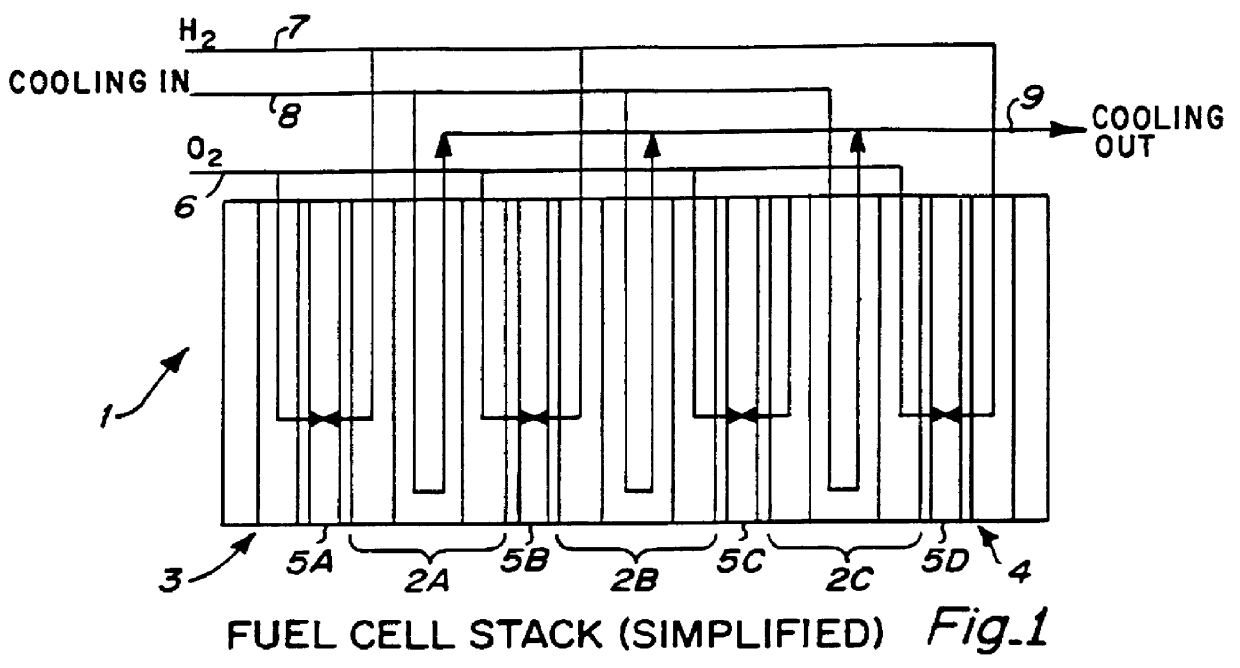

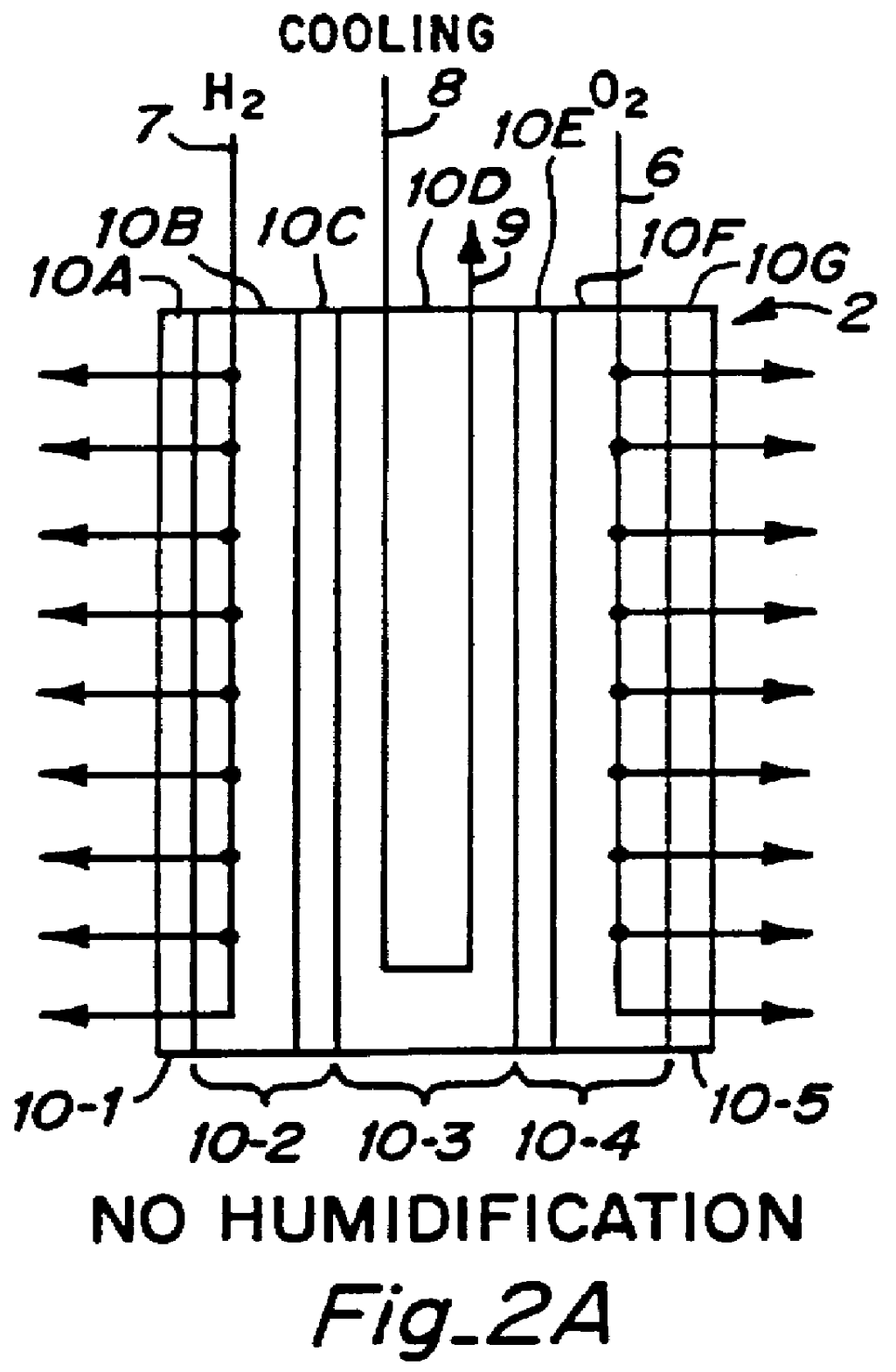

Fuel cell platelet separators having coordinate features

InactiveUS6051331ASimple designEvenly distributedSolid electrolytesFuel cells groupingLaser etchingFuel cells

PCT No. PCT / US95 / 13325 Sec. 371 Date Sep. 28, 1997 Sec. 102(e) Date Sep. 28, 1997 PCT Filed Oct. 10, 1995 PCT Pub. No. WO96 / 12316 PCT Pub. Date Apr. 25, 1996Fuel cell stacks comprising stacked separator / membrane electrode assembly fuel cells in which the separators comprise a series of thin sheet platelets, having individually configured serpentine micro-channel reactant gas humidification active areas and cooling fields therein. The individual platelets are stacked with coordinate features aligned in contact with adjacent platelets and bonded to form a monolithic separator. Post-bonding processing includes passivation, such as nitriding. Preferred platelet material is 4-25 mil Ti, in which the features, serpentine channels, tabs, lands, vias, manifolds and holes, are formed by chemical and laser etching, cutting, pressing or embossing, with combinations of depth and through etching preferred. The platelet manufacturing process is continuous and fast. By employing CAD based platelet design and photolithography, rapid change in feature design can accommodate a wide range of thermal management and humidification techniques. One hundred H2-O2 / PEM fuel cell stacks of this IFMT platelet design will exhibit outputs on the order of 0.75 kW / kg, some 3-6 times greater than the current graphite plate PEM stacks.

Owner:H POWER

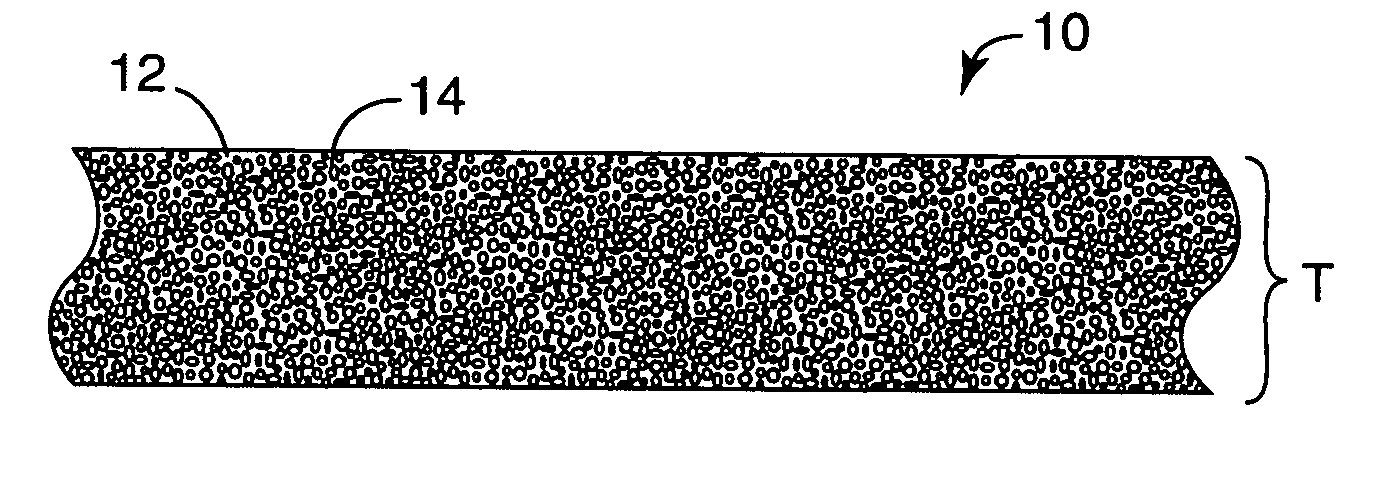

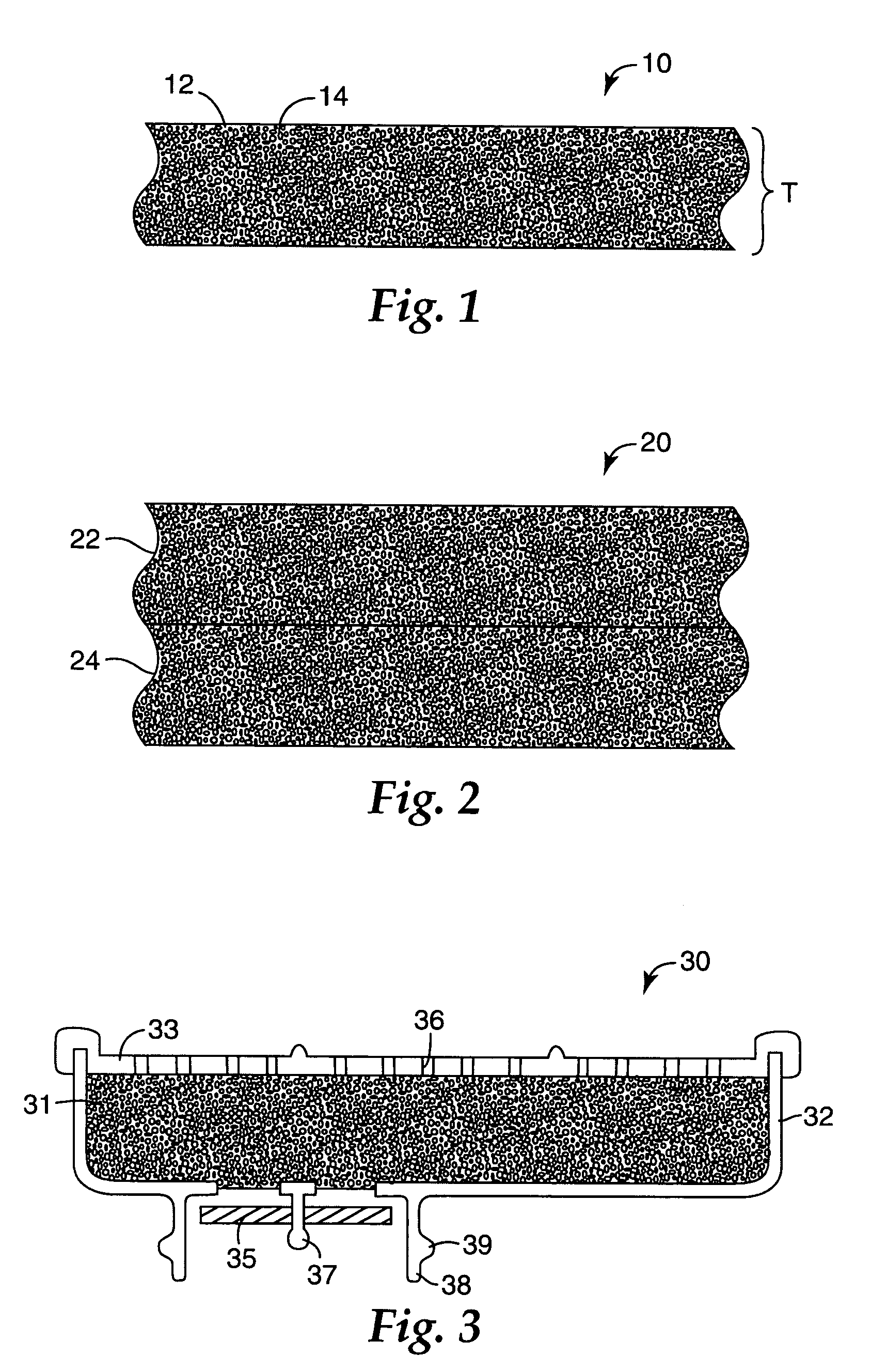

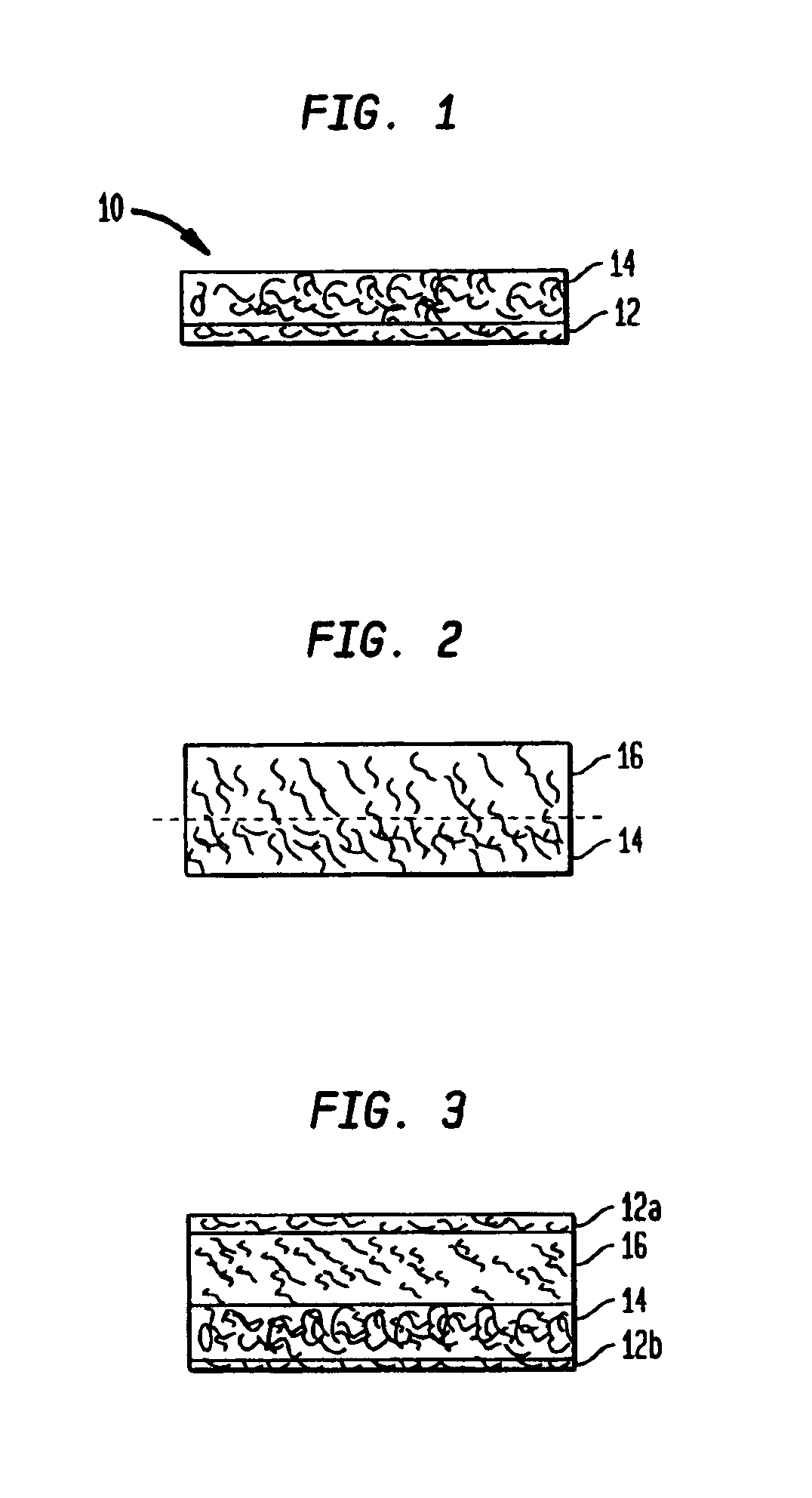

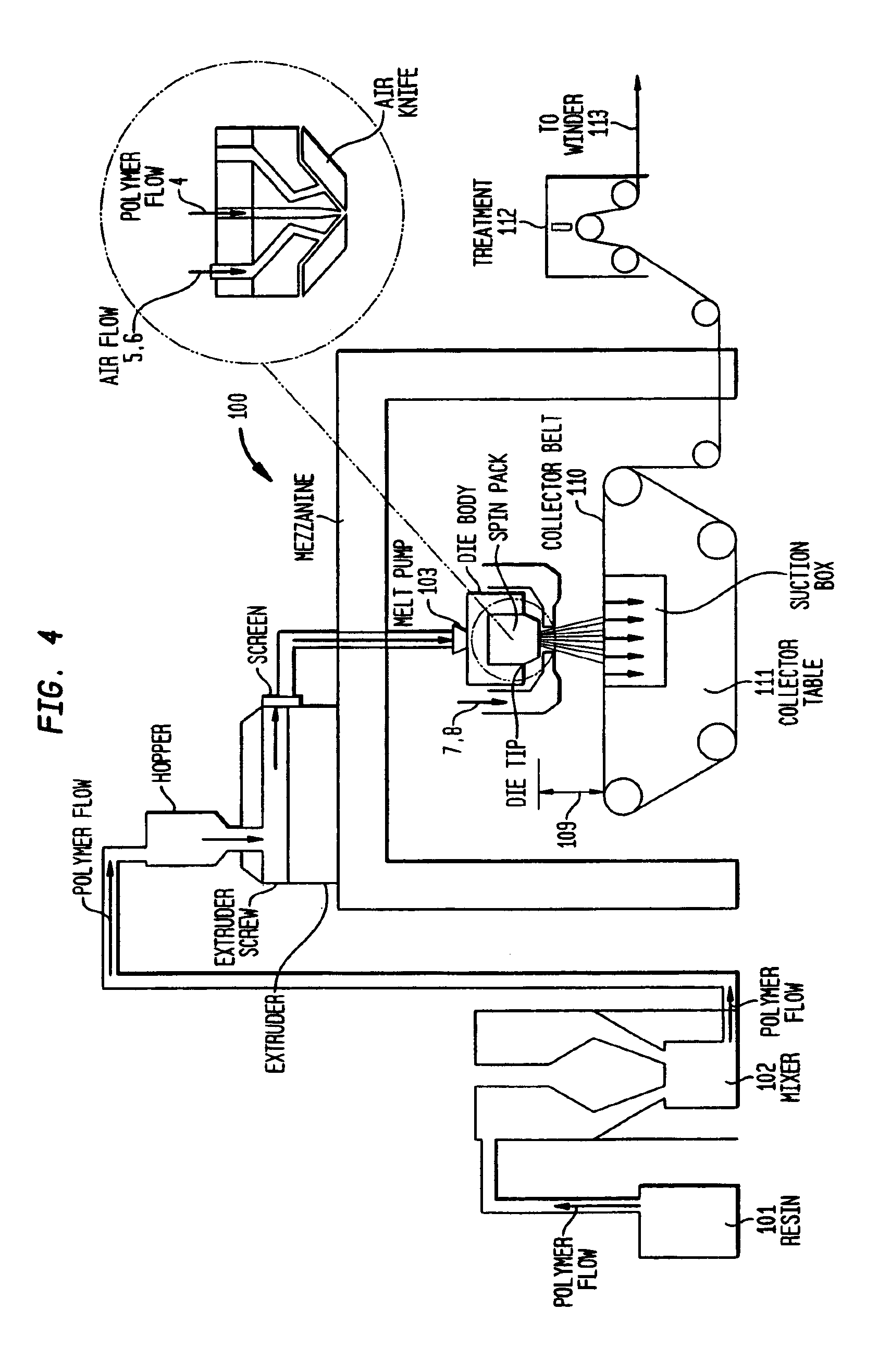

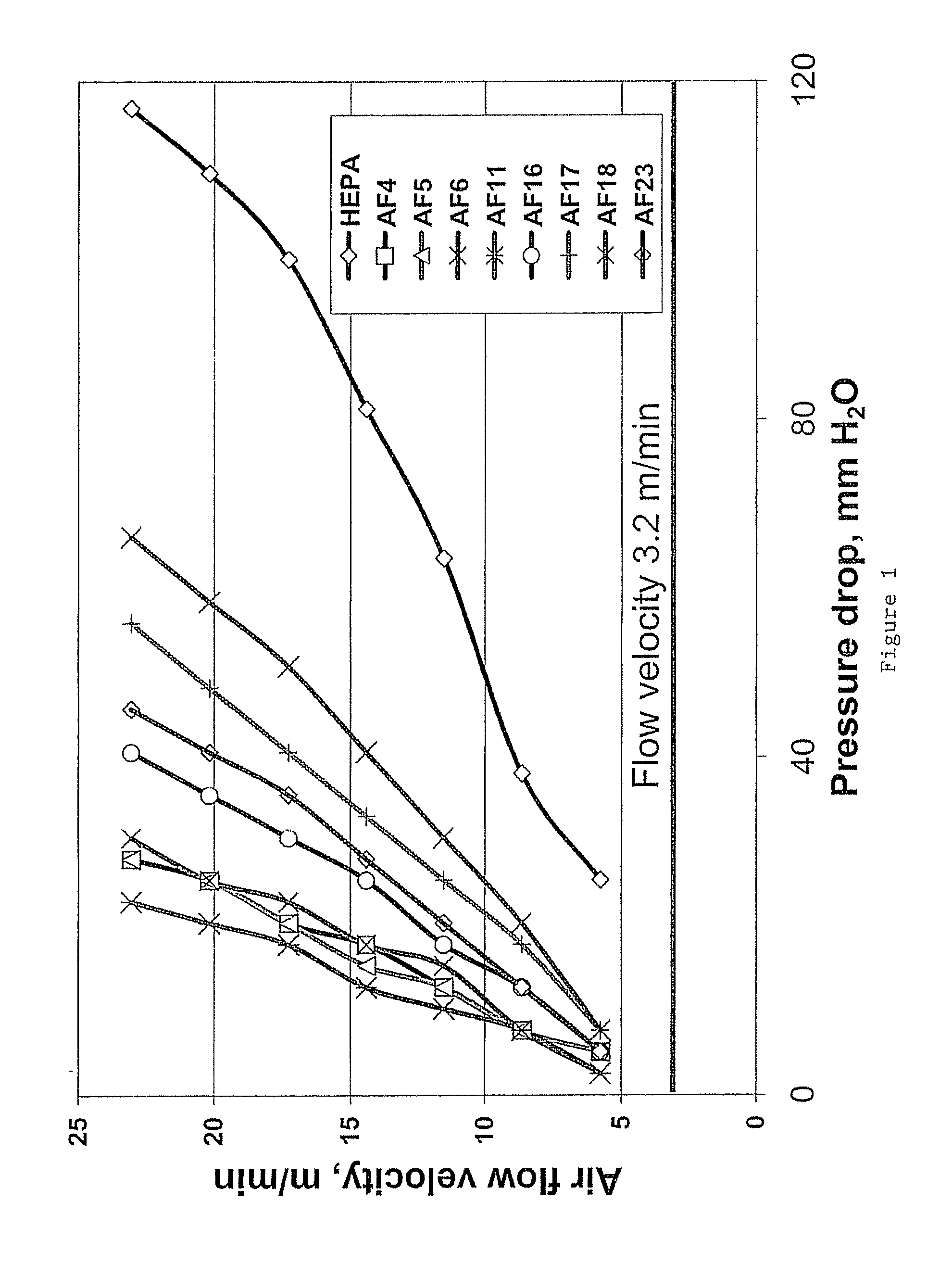

Particle-containing fibrous web

InactiveUS20060096911A1Lower overall pressure dropLow carbon shedding tendencyBreathing filtersDispersed particle separationPolymer scienceSorbent

A porous sheet article comprising a self-supporting nonwoven web of polymeric fibers and at least 80 weight percent sorbent particles enmeshed in the web, the fibers having sufficiently greater elasticity or sufficiently greater crystallization shrinkage than similar caliper polypropylene fibers and the sorbent particles being sufficiently evenly distributed in the web so that the web has an Adsorption Factor A of at least 1.6×104 / mm water. The articles have low pressure drop and can provide filter elements having long service life and an Adsorption Factor approaching and in some instances exceeding that of a packed carbon bed.

Owner:3M INNOVATIVE PROPERTIES CO

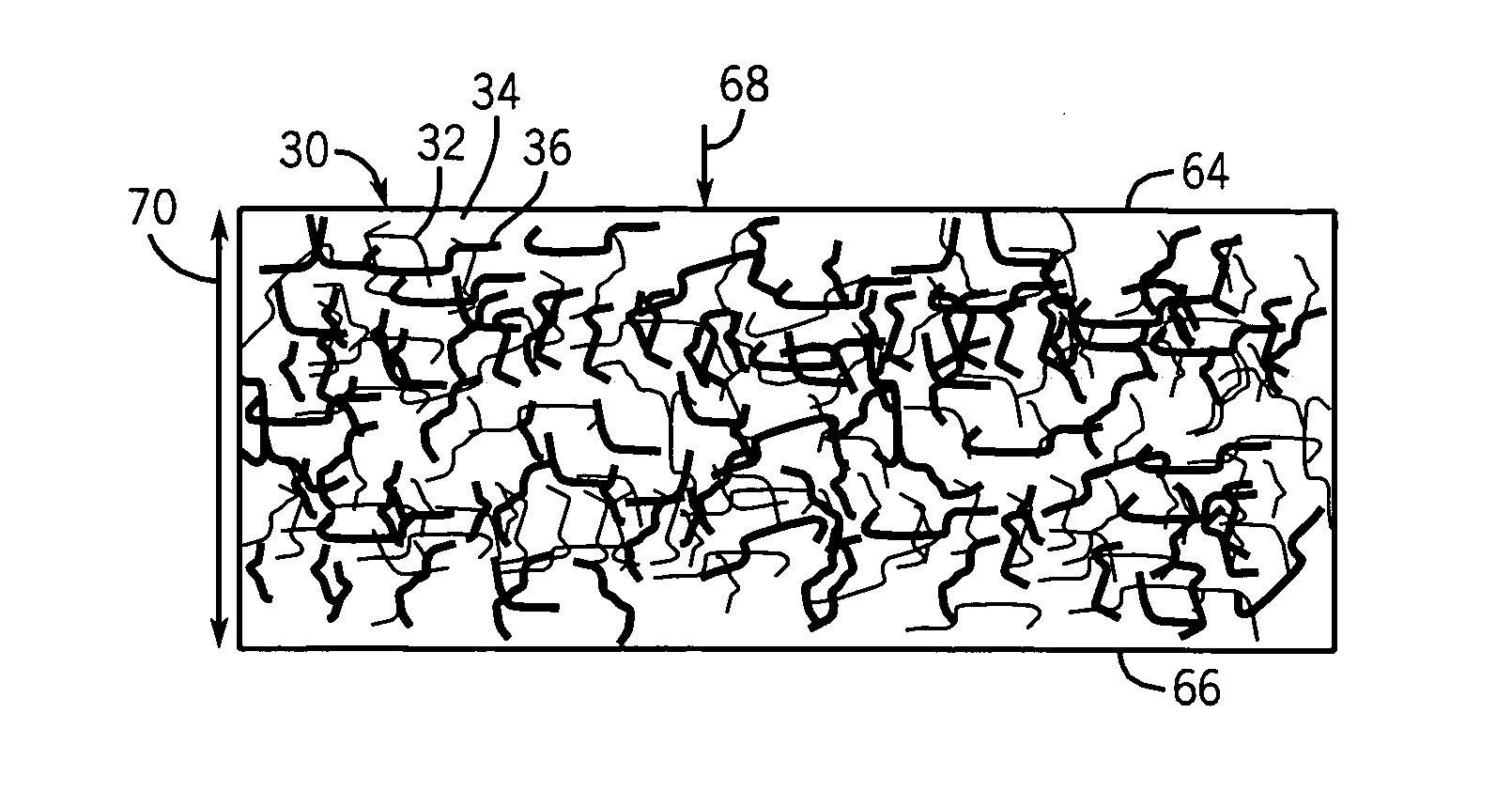

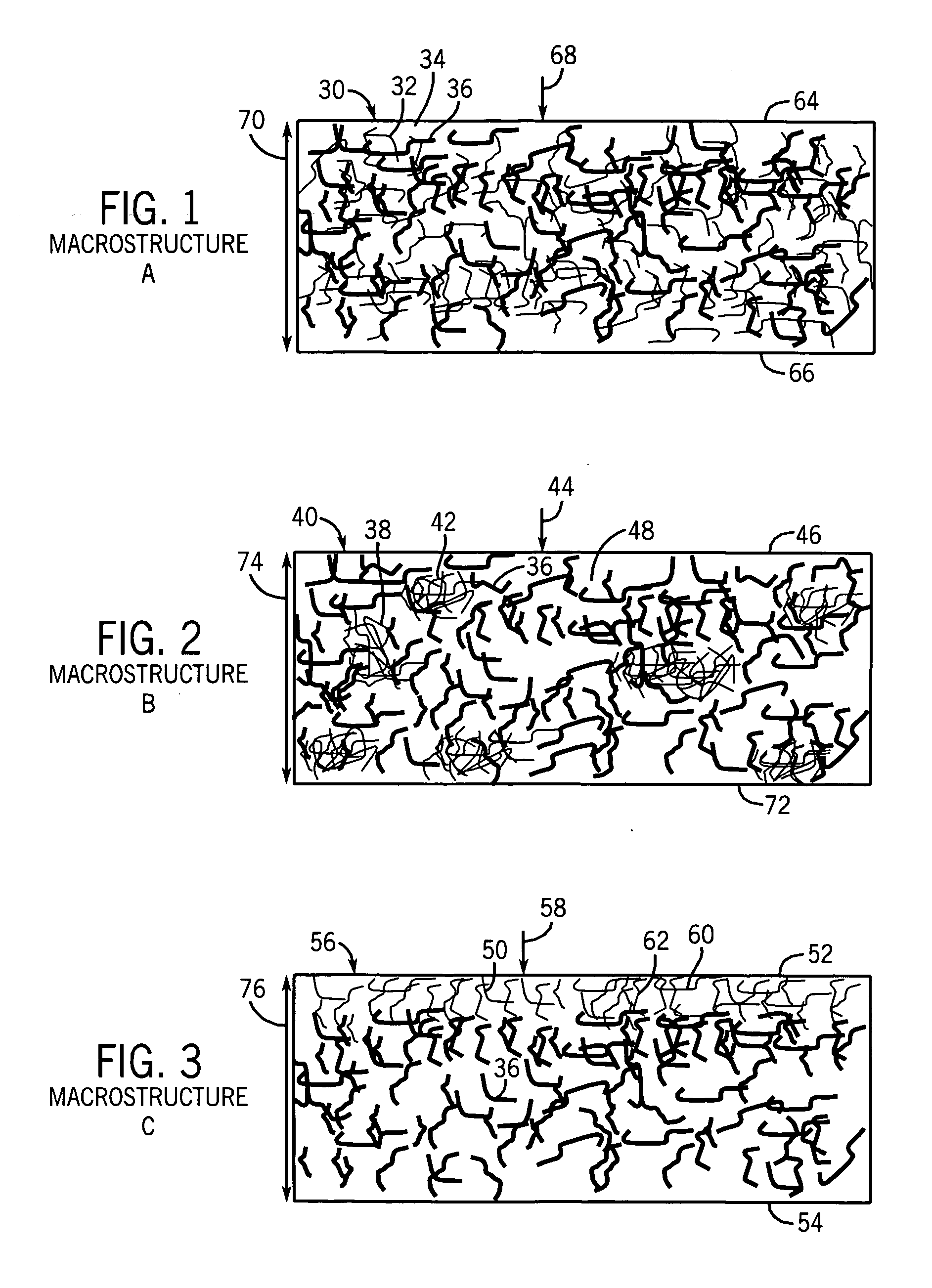

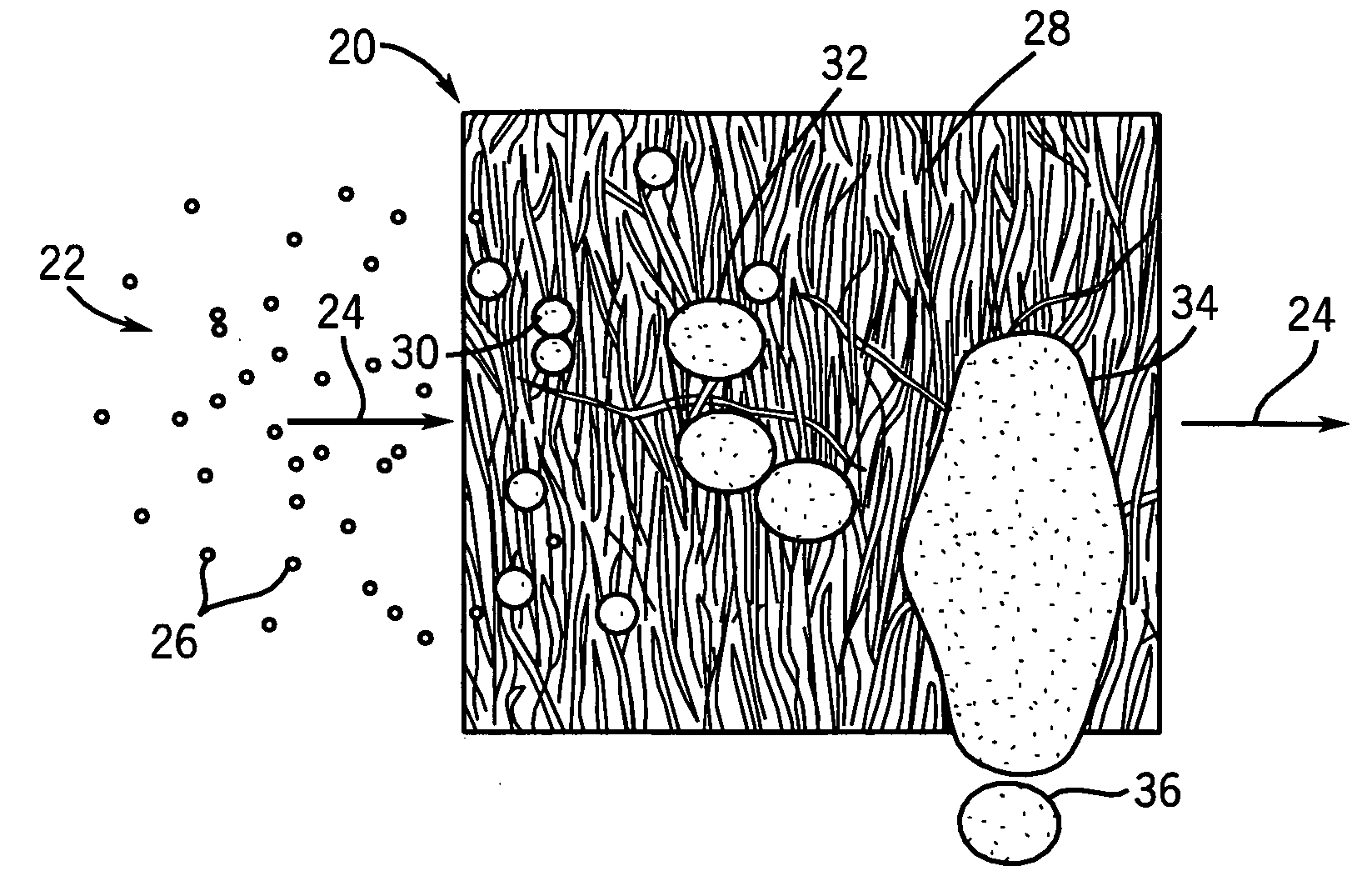

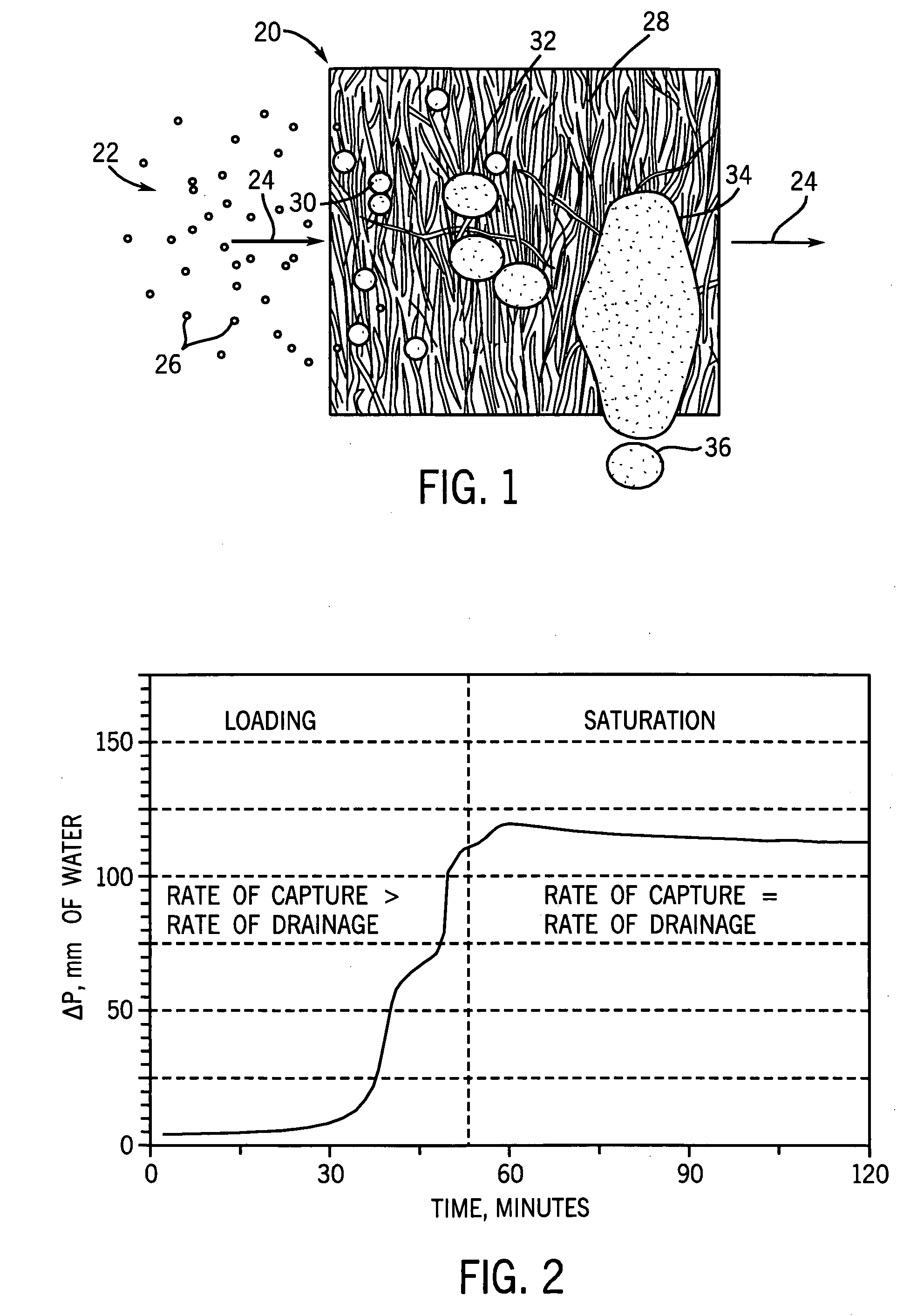

Fiber containing filter media

InactiveUS20040038014A1Efficient removalLow efficiencySynthetic resin layered productsUltrafiltrationPolymer scienceFilter media

Improved filtration media or filter bodies can be made from fine fiber and can be formed into a filtration structure having no internal defects. The filter media or filter body comprises a collection of spot in fiber with defined fiber diameter, layer thickness and media solidity. The fine fiber is formed into a media body and obtains substantial flux and filtration efficiency. The filtration media or body can comprise single or multiple layers of fine fiber combined into the improved filter body.

Owner:DONALDSON CO INC

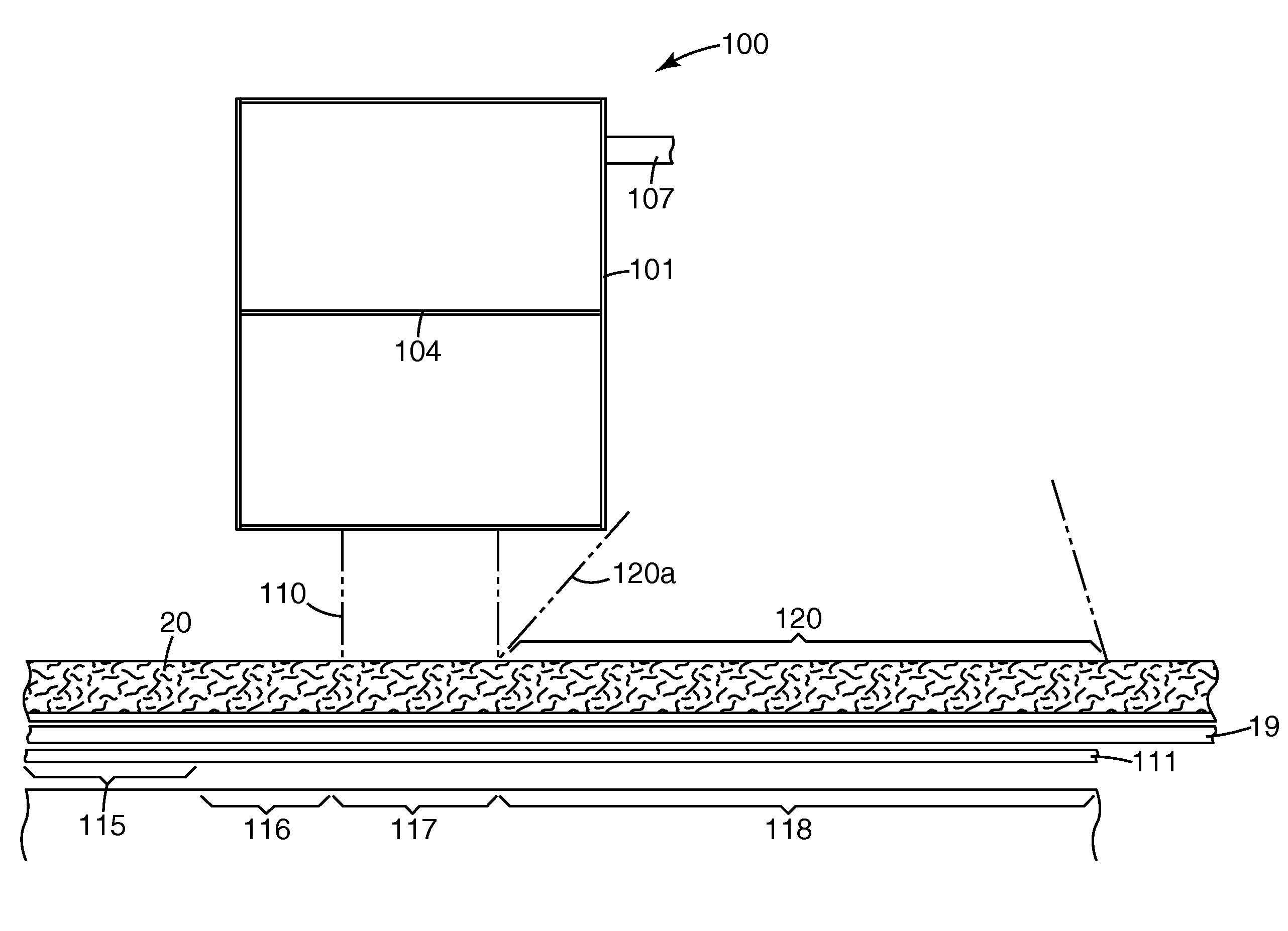

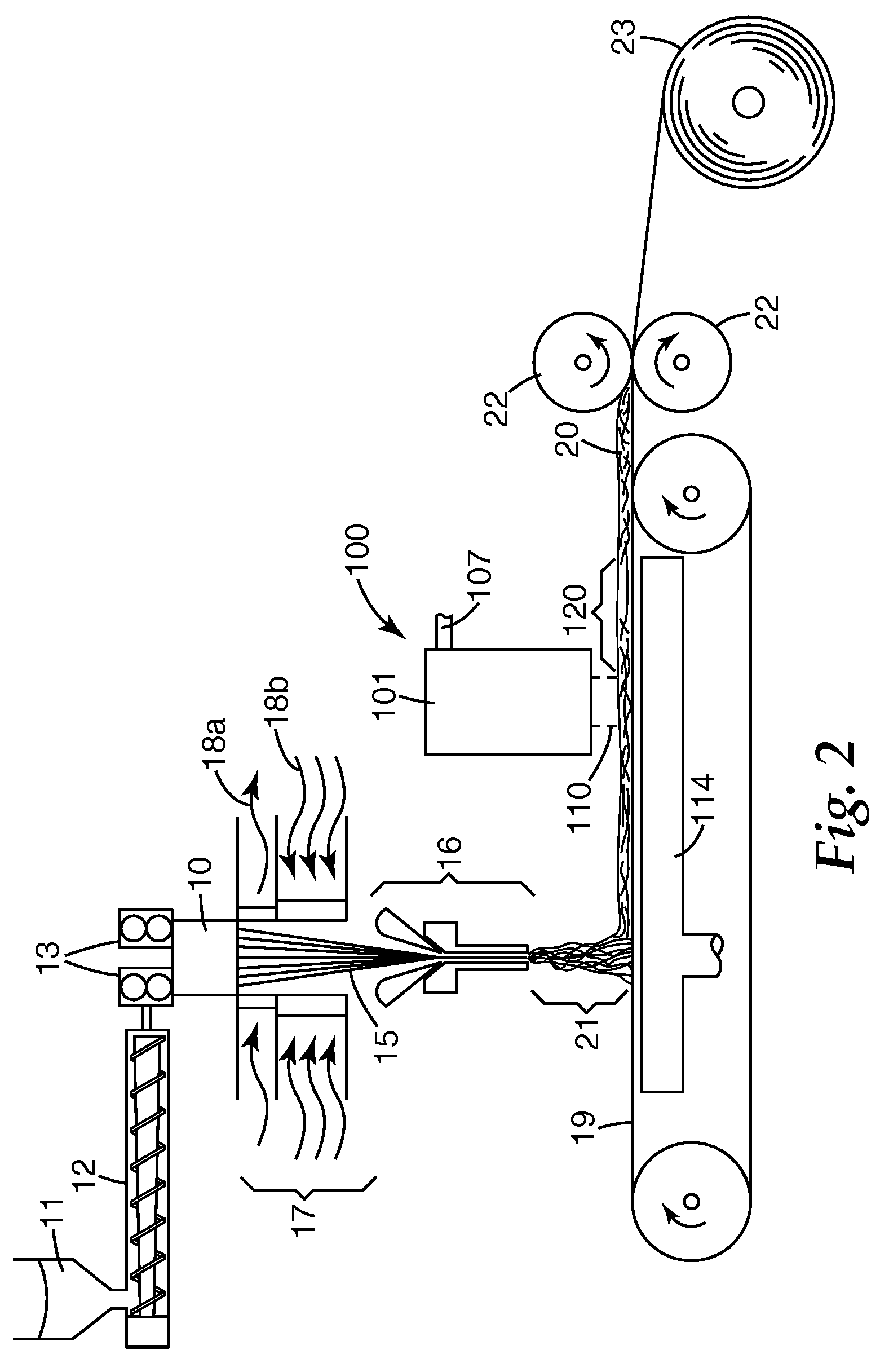

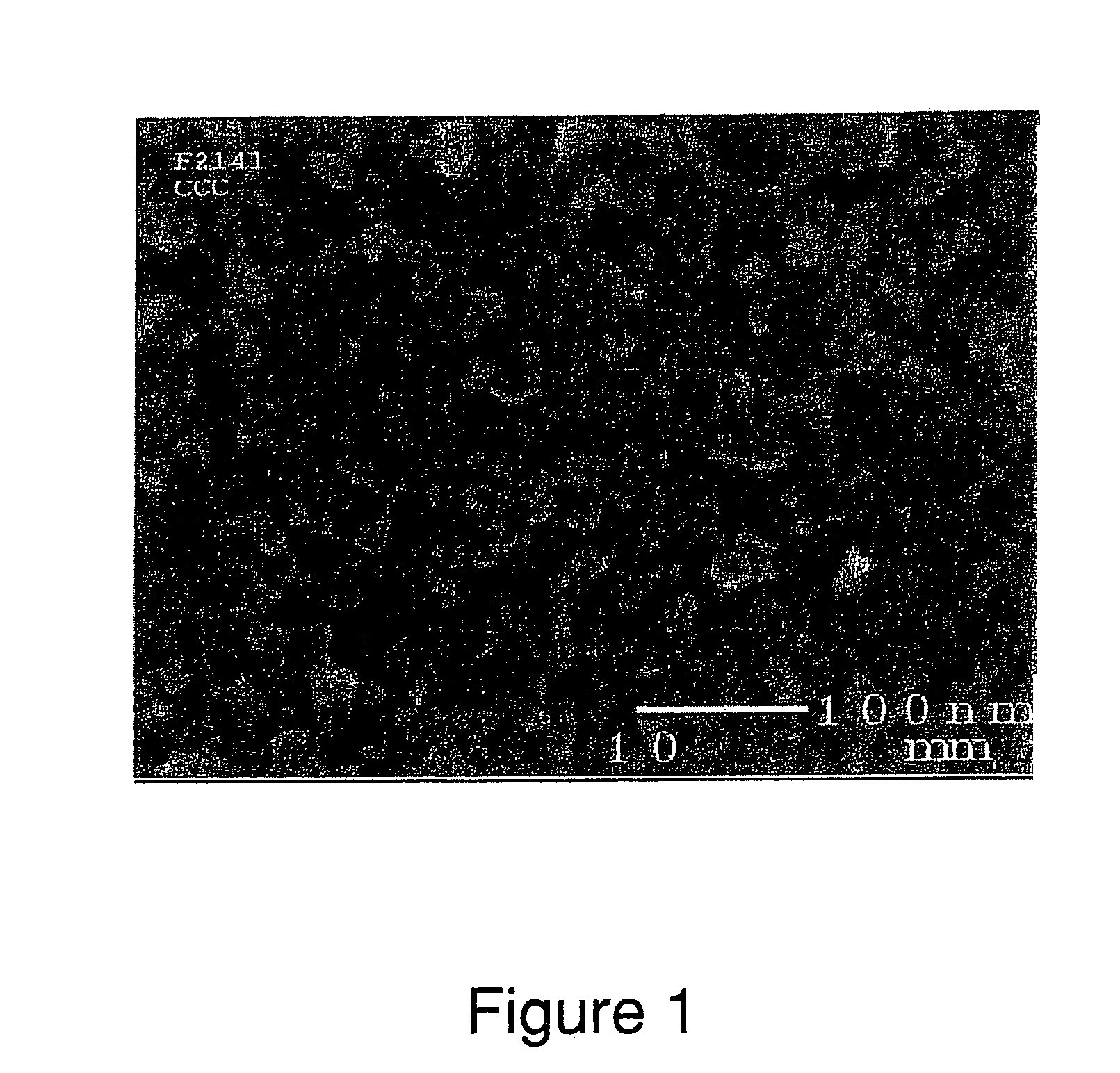

High performance filter media with internal nanofiber structure and manufacturing methodology

InactiveUS20050026526A1Improve performanceImprove efficiencyOther chemical processesIndividual molecule manipulationFiberNanofiber

High performance filter media and manufacturing methodology provides nanofibers of diameter less than 1 μm incorporated and processed into internal structure of a filter medium dominantly composed of coarse fibers of diameter greater than 1 μm, to change the internal media structure.

Owner:FLEETGUARD INC

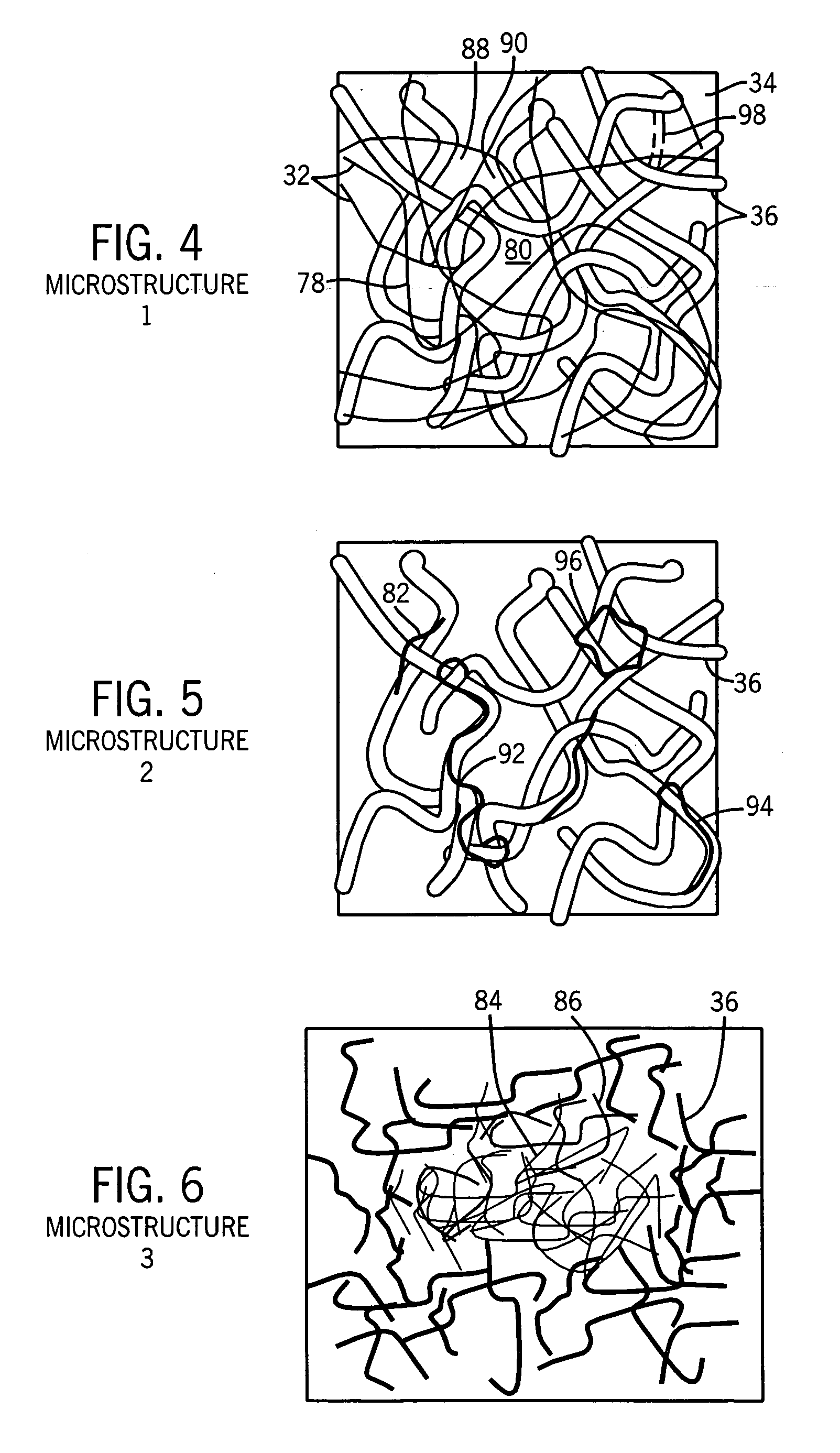

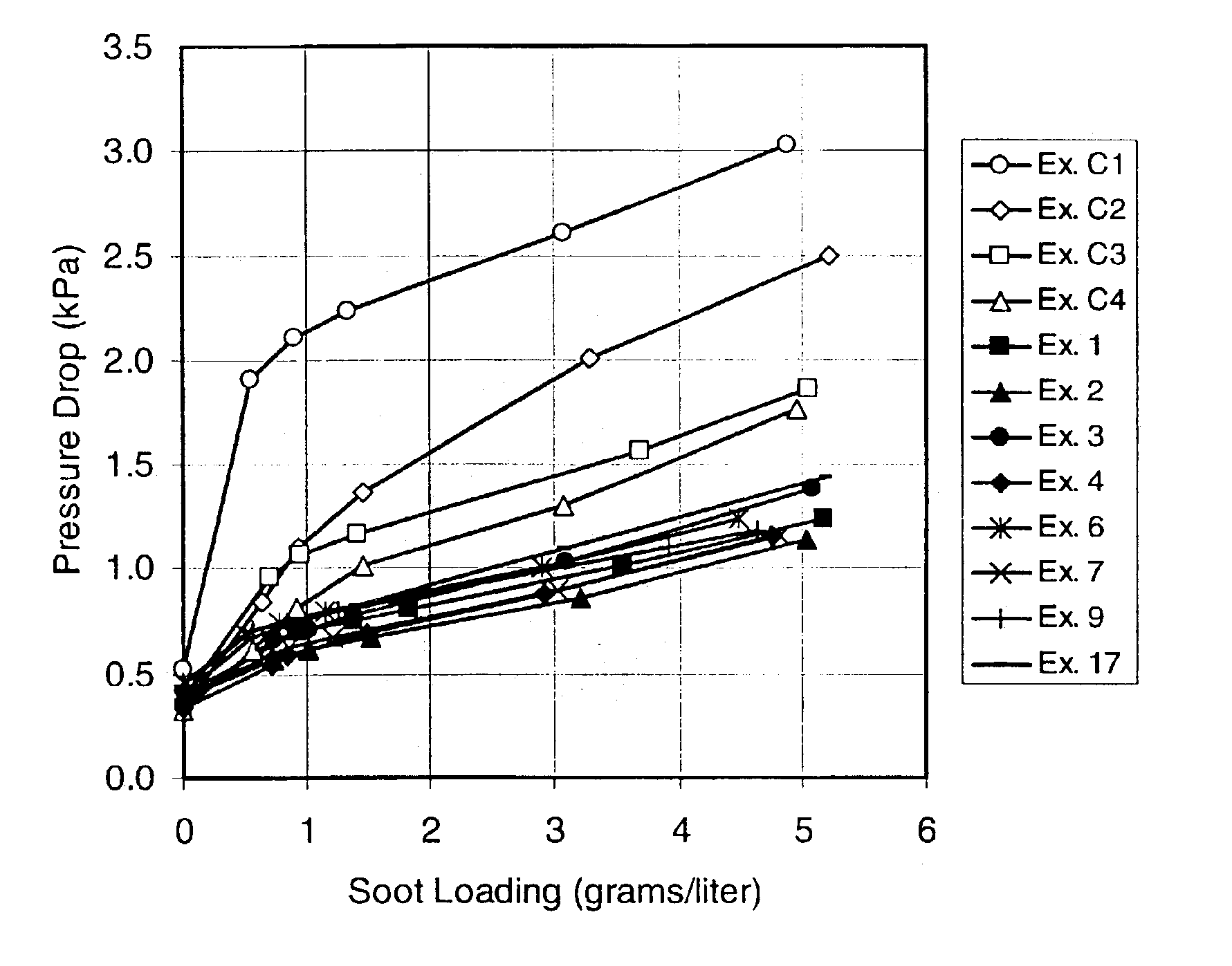

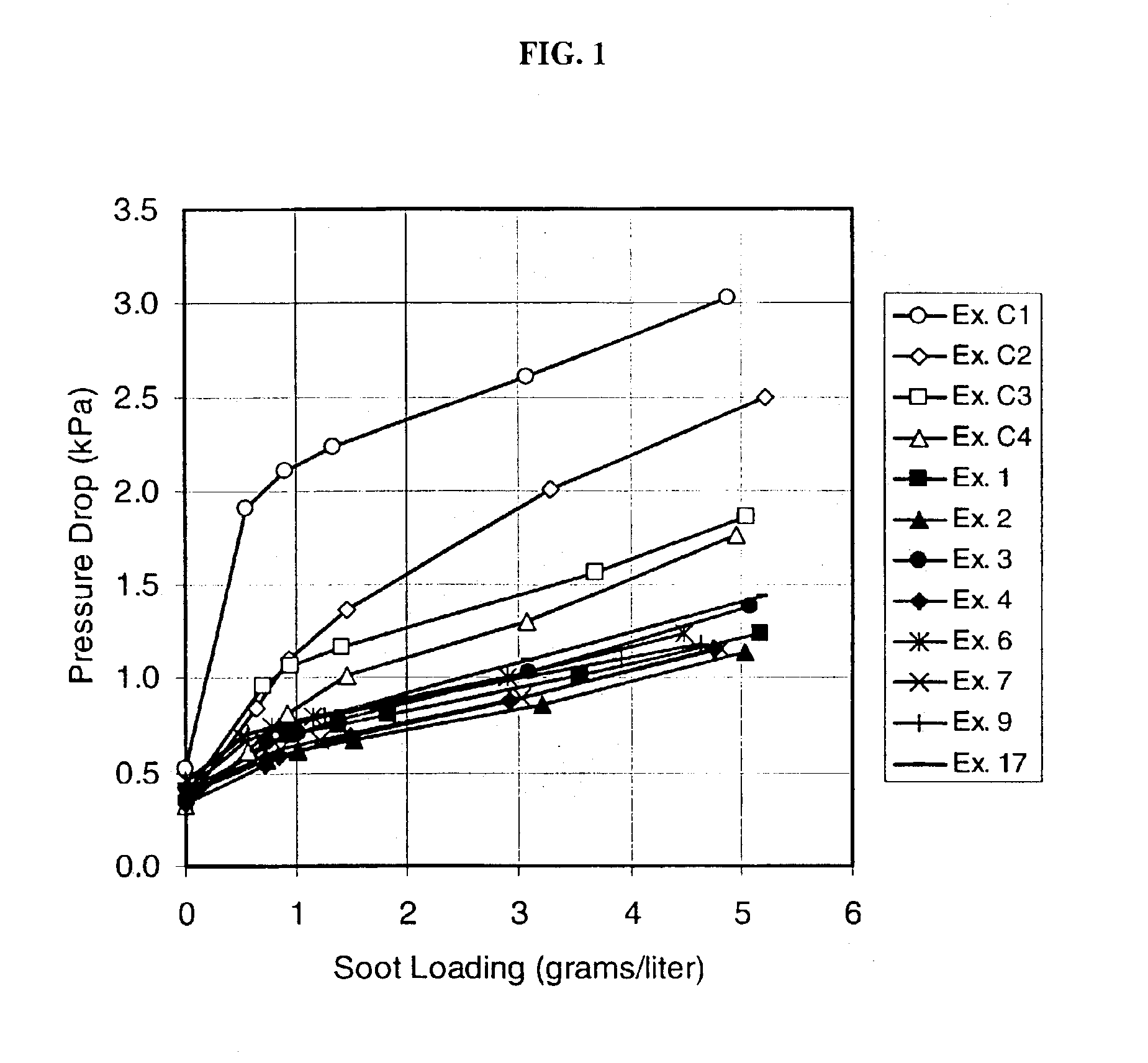

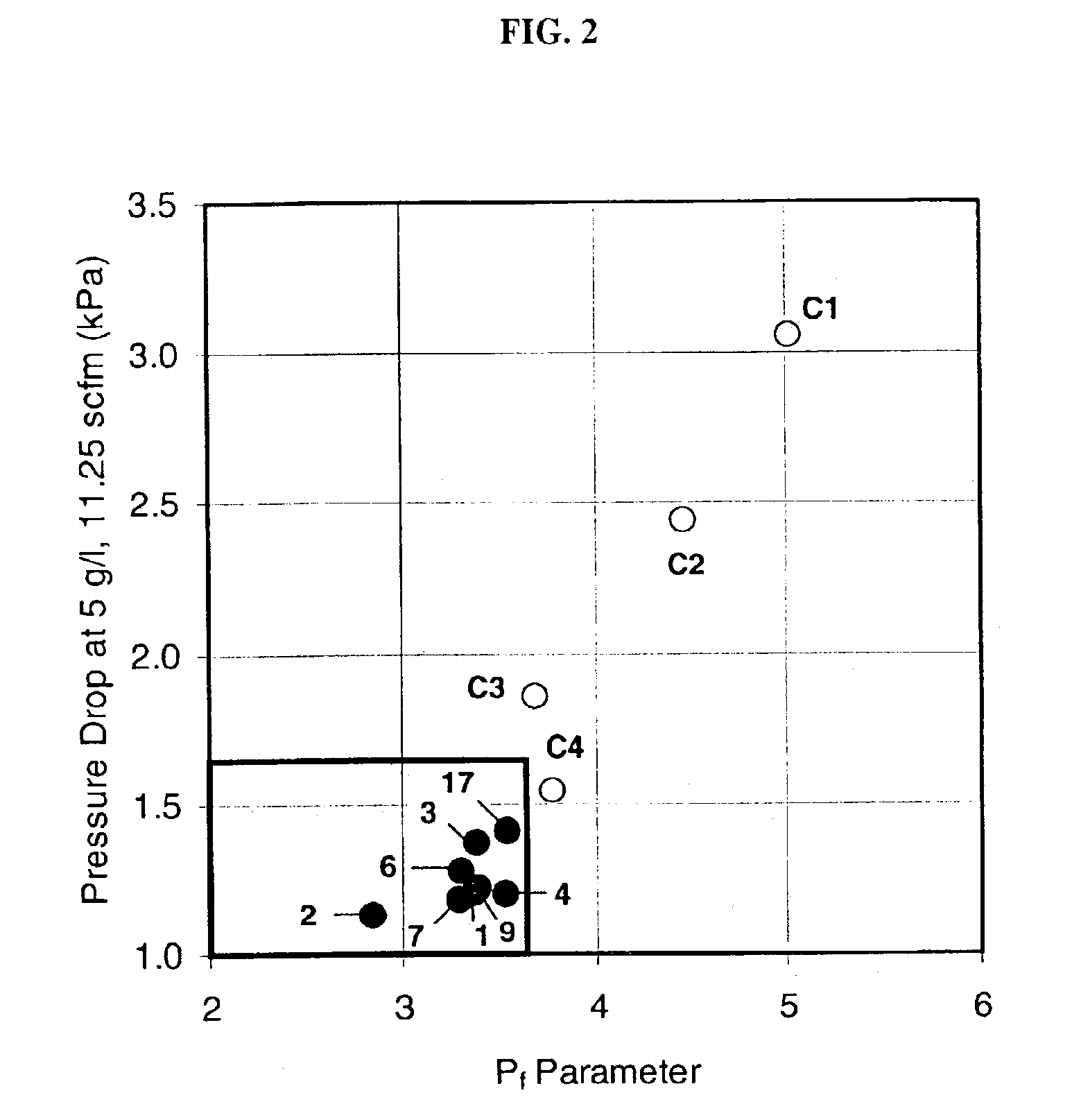

Cordierite ceramic body and method

InactiveUS6864198B2Lower overall pressure dropHigh filtration efficiencyDispersed particle filtrationTransportation and packagingPorosityFiltration

Owner:CORNING INC

Filter media

InactiveUS6858057B2Lower performance requirementsEnhanced filtration performance characteristicCombination devicesOther chemical processesFilter mediaEngineering

A filter media comprising a synthetic microfiber polymer fine fiber web wherein the diameter of the fibers is between about 0.8 to about 1.5 microns. The filter media is acceptable for use in ASHRAE applications. Constructions with a low DP backing, support or prefilter layers of coarse fiber provide large area filter webs of high efficiency and a stable and high threshold value of alpha above eleven.

Owner:HOLLINGSWORTH VOSE

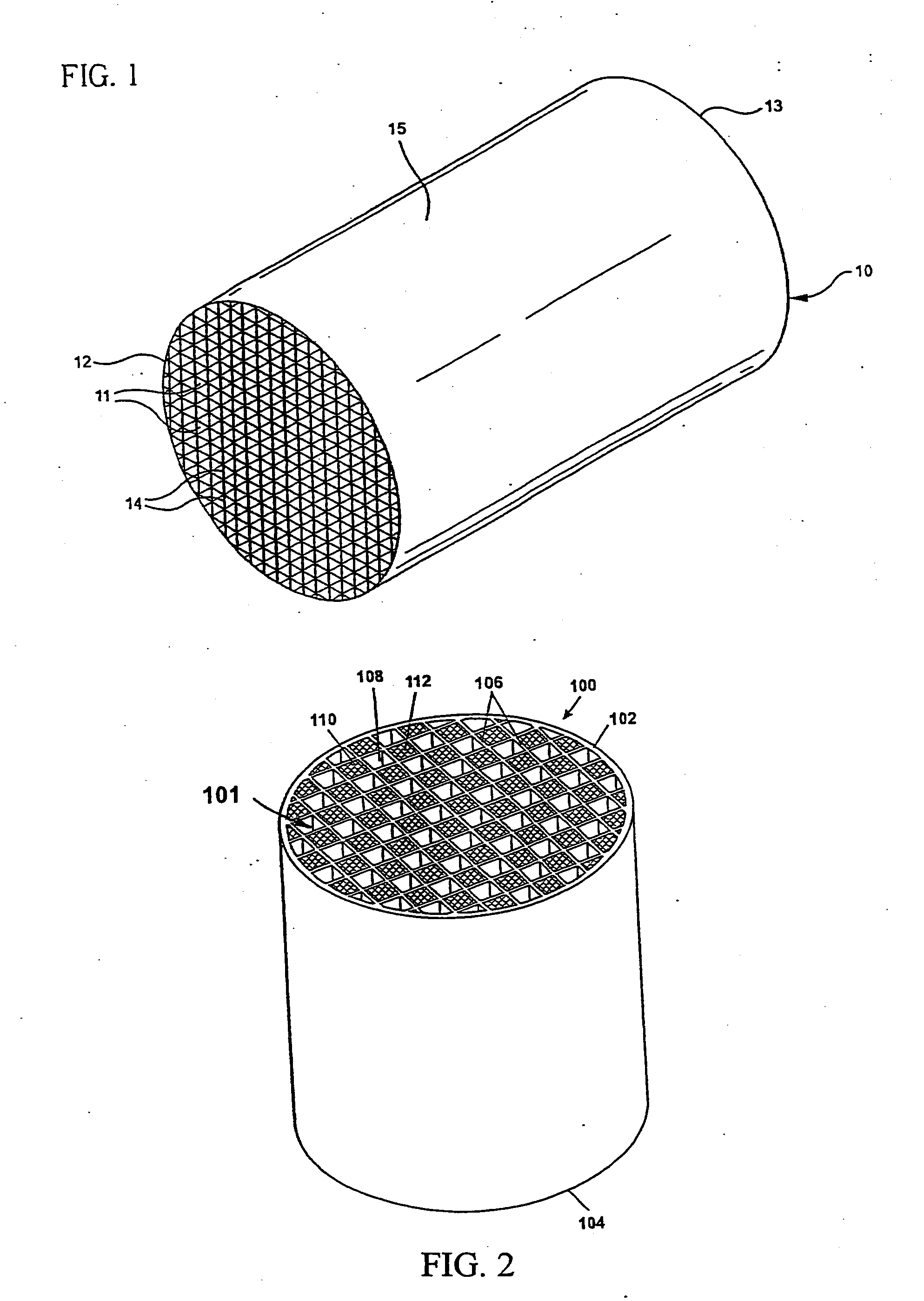

Mullite-aluminum titanate diesel exhaust filter

InactiveUS6849181B2High porosityLarge apertureIron oxides/hydroxidesExhaust apparatusFiltrationMullite

The invention is directed at a mullite-aluminum titanate porous diesel particulate filter constituting a porous ceramic body containing, expressed in terms of weight percent of the total body, of 60-90%, preferably 70-80%, most preferably 70% iron-aluminum titanate solid solution having a stoichiometry of Al2(1−x)Fe2xTiO5, where x is 0-0.1, and 10-40%, preferably 20-30%, most preferably 30% mullite (3Al2O3.2SiO2), and consists essentially, expressed in terms of weigh percent on the oxide basis, of 3 to 15% SiO2, 55 to 65% Al2O3, 22 to 40% TiO2, and 0 to 10% Fe2O3, and being useful for filtration of diesel exhaust. The inventive diesel particulate filter exhibits high interconnected open porosity and large median pore size, in combination with high permeability when fired to a temperature of between 1650° to 1700° C., along with high thermal shock resistance and good filtration capability.

Owner:CORNING INC

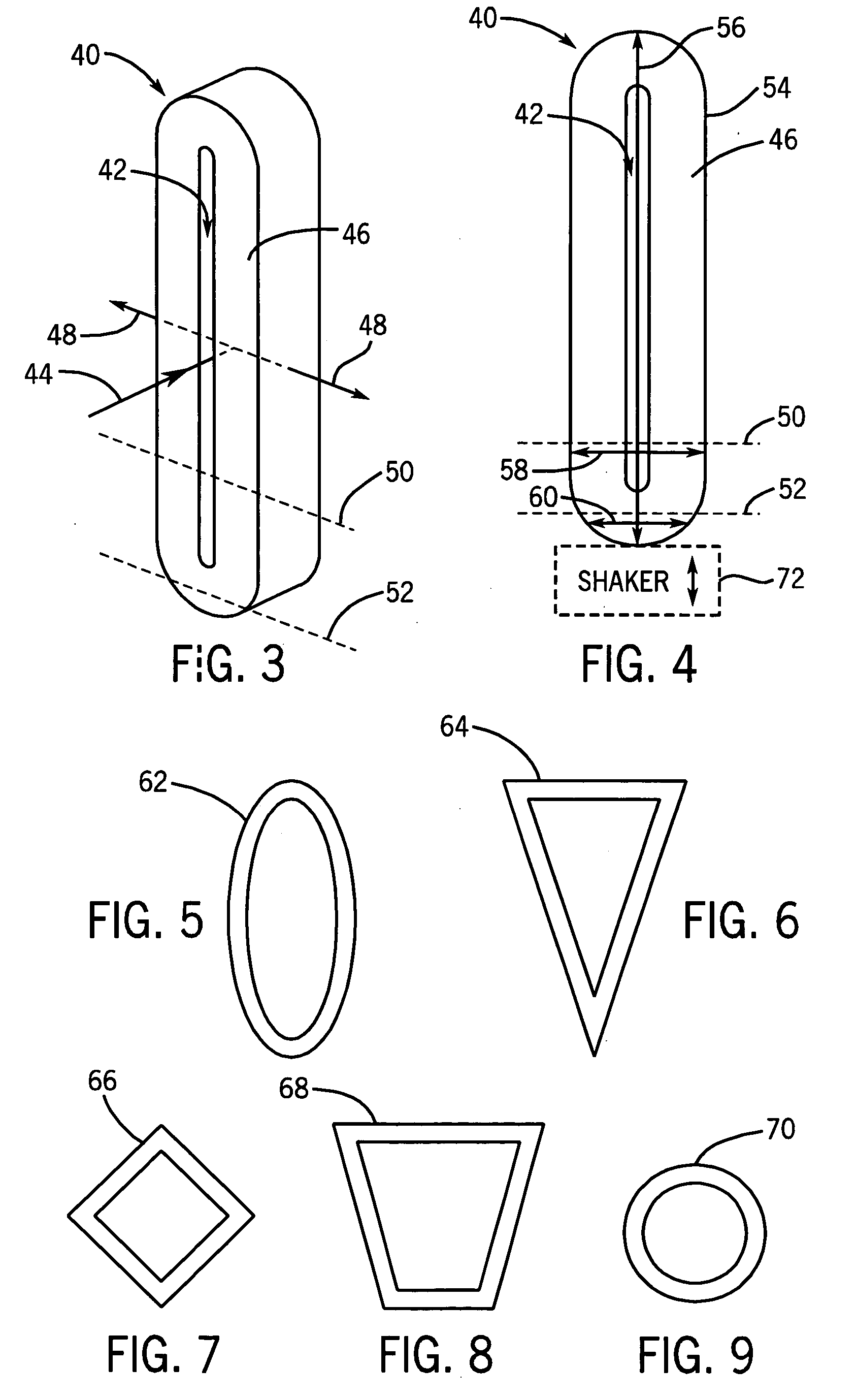

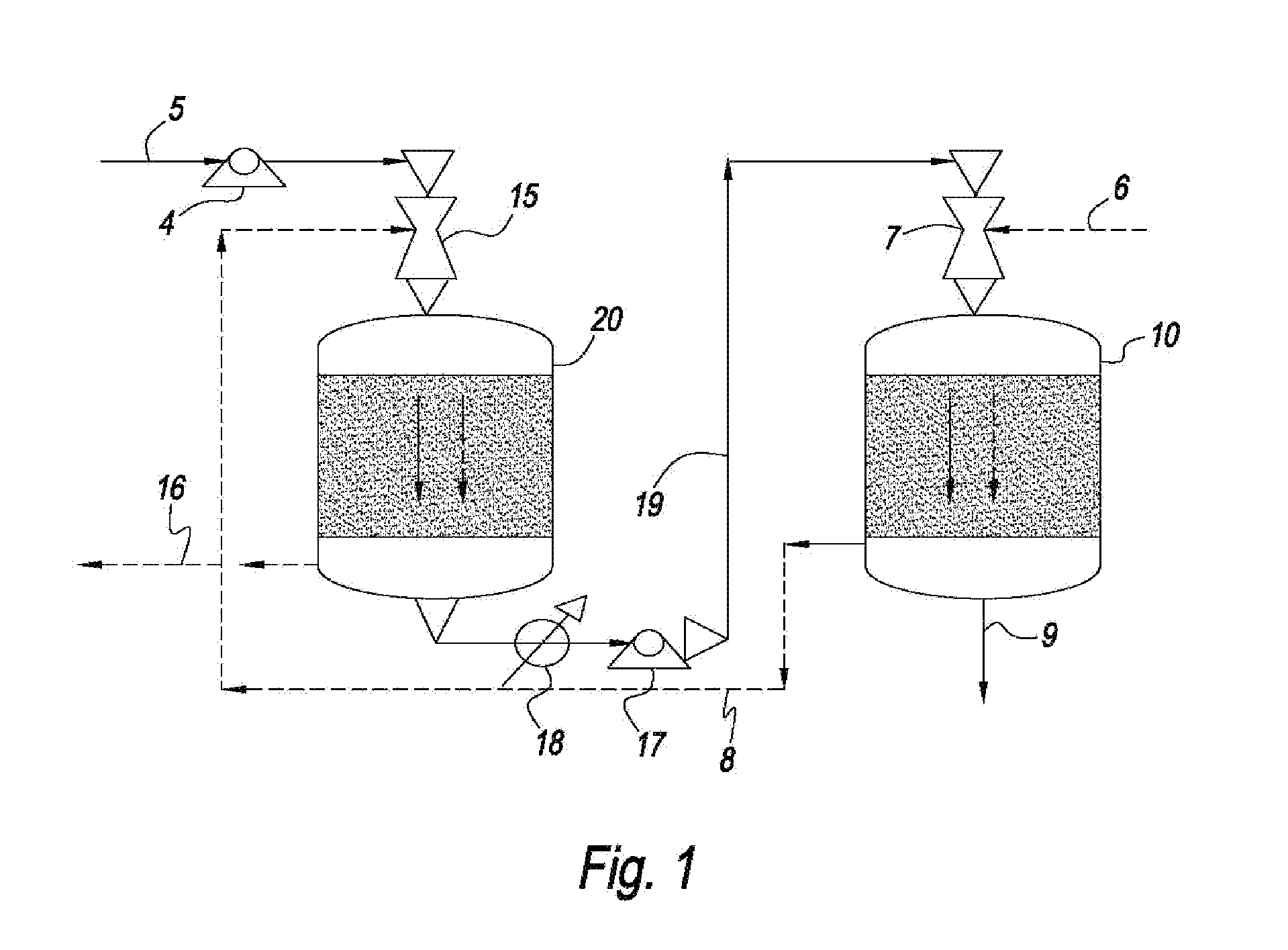

Space optimized coalescer

ActiveUS20070062887A1Improve removal efficiencyLower overall pressure dropDispersed particle filtrationLiquid suspension thickening by filtrationEngineeringTrade offs

A coalescer is provided minimizing trade-offs among high removal efficiency, low pressure drop, long service life, and small size.

Owner:CUMMINS FILTRATION IP INC

Non-woven media incorporating ultrafine or nanosize powders

InactiveUS20080026041A1Improve efficiencyLarge capacityMaterial nanotechnologyTreatment involving filtrationFiberActivated carbon

The invention is a fibrous structure for fluid streams that is a mixture of nano alumina fibers and second fibers arranged in a matrix to create asymmetrical pores and to which fine, ultrafine, or nanosize particles such as powdered activated carbon are attached without the use of binders. The fibrous structure containing powdered activated carbon intercepts contaminants from fluid streams. The invention is also a method of manufacturing and using the fibrous structure.

Owner:ARGONIDE CORP

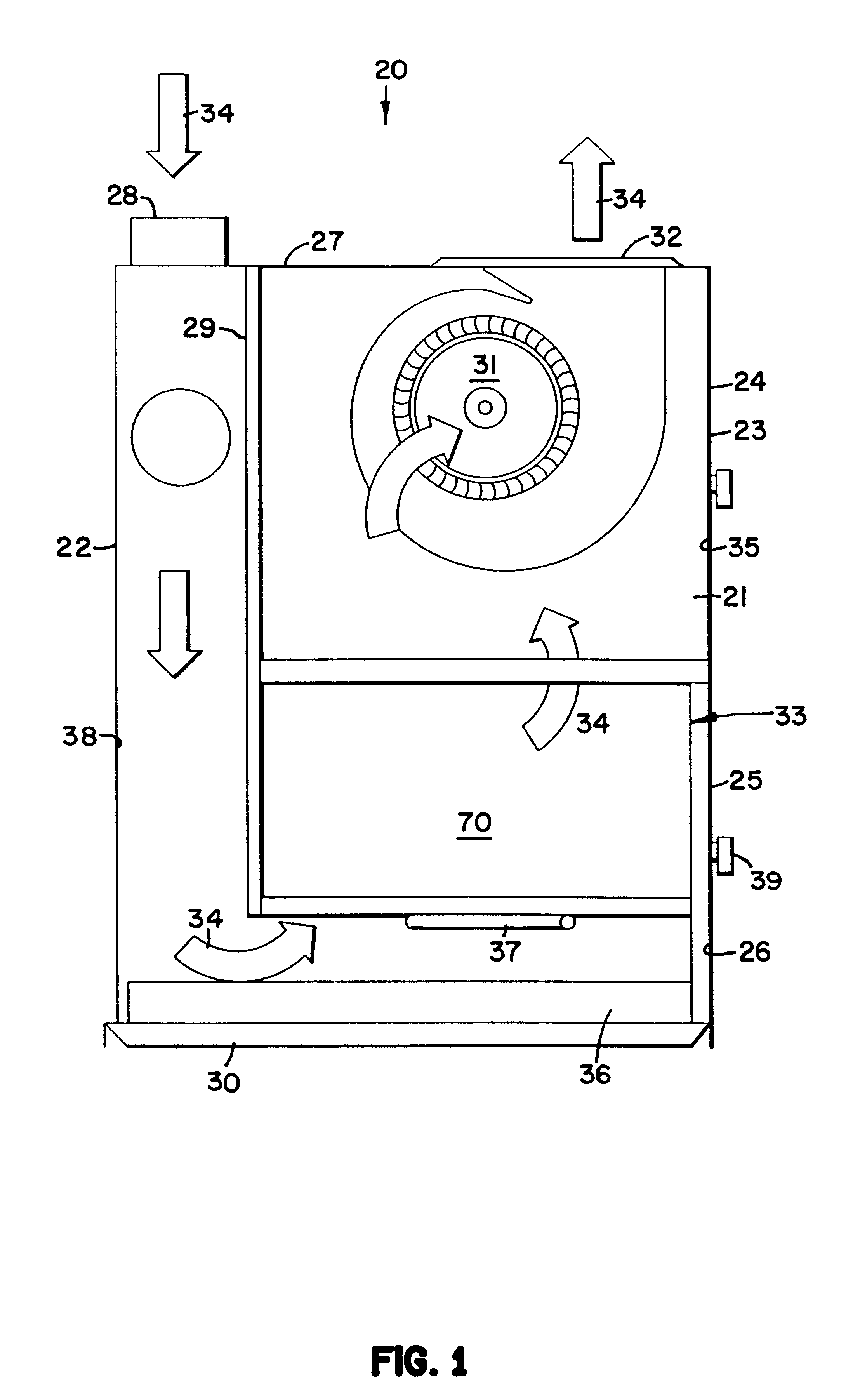

Method of evaporative cooling of a fluid and apparatus therefor

InactiveUS6854278B2Reduce the temperatureLess pressure dropMechanical apparatusSpace heating and ventilation safety systemsDesiccantMechanical engineering

The operating efficiency of indirect evaporative cooling processes and indirect evaporative cooling apparatus employing a dry side channel and a wet side channel separated by a heat exchange plate are improved by placement of holes in the heat exchange plate. Further improvements are obtained when the flow direction in the wet side channel is cross-current to the flow direction in the dry side channel. Placement of desiccant materials in the dry side channel also serve to improve the operating efficiencies of these processes and apparatus.

Owner:IDALEX TECH INC

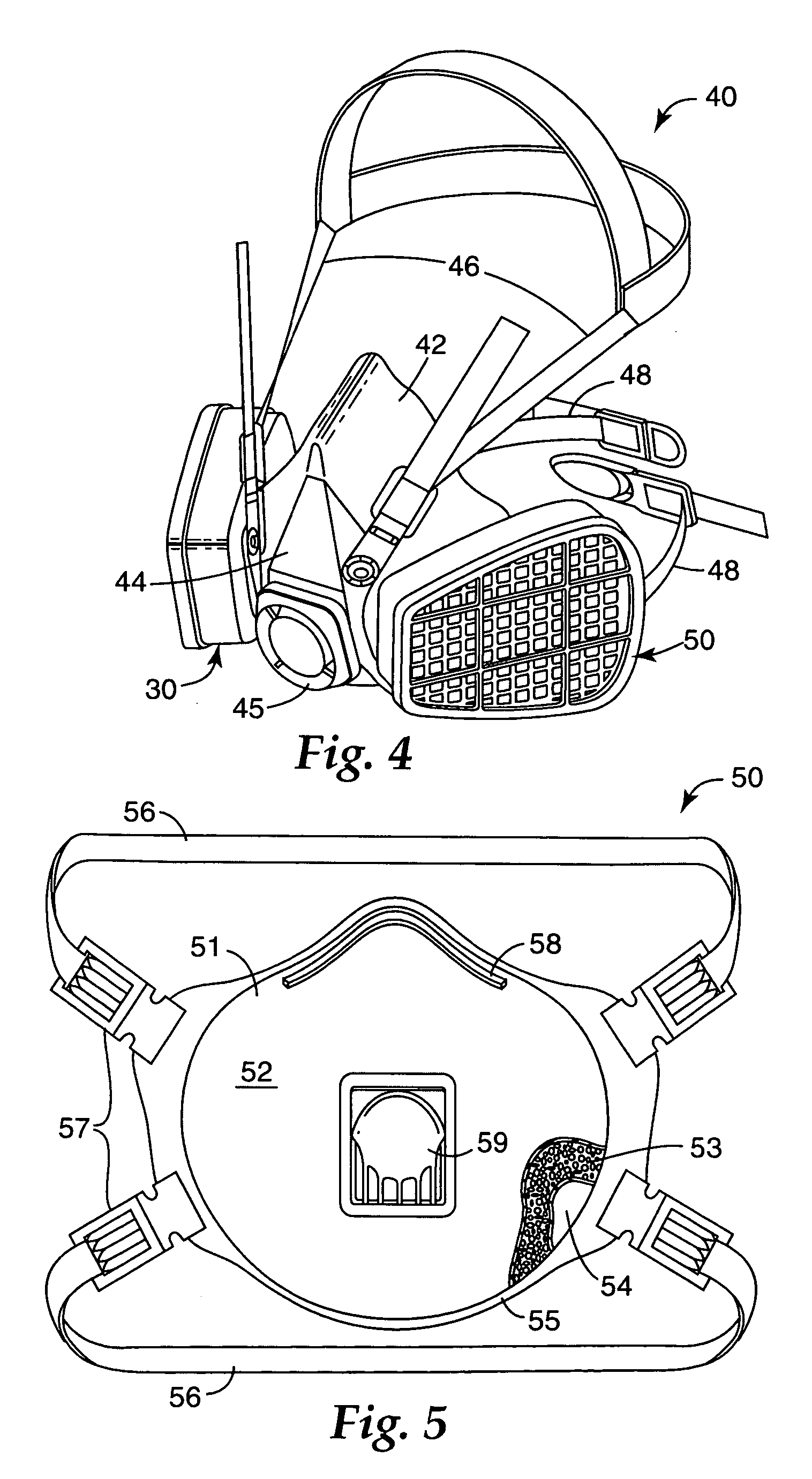

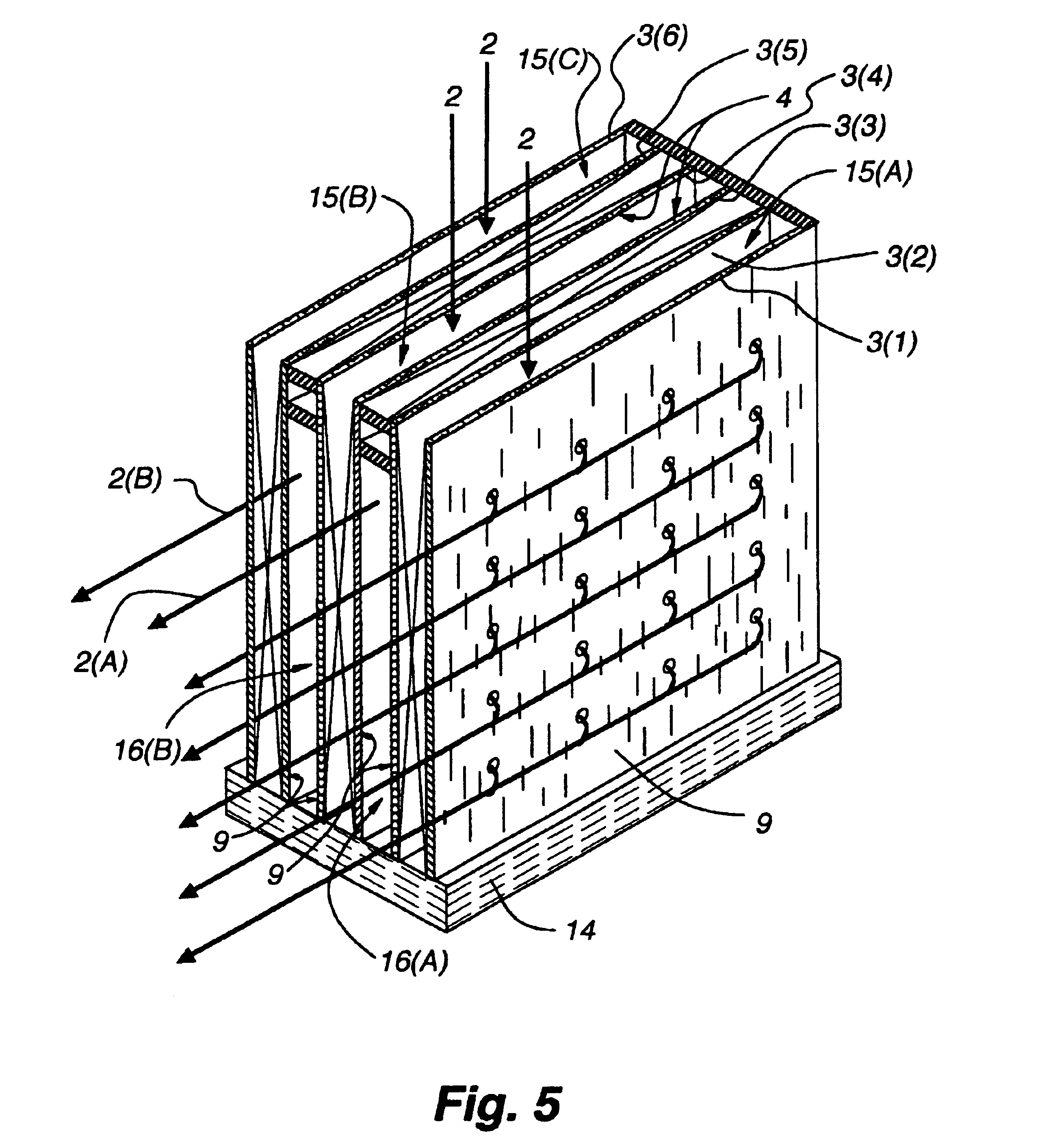

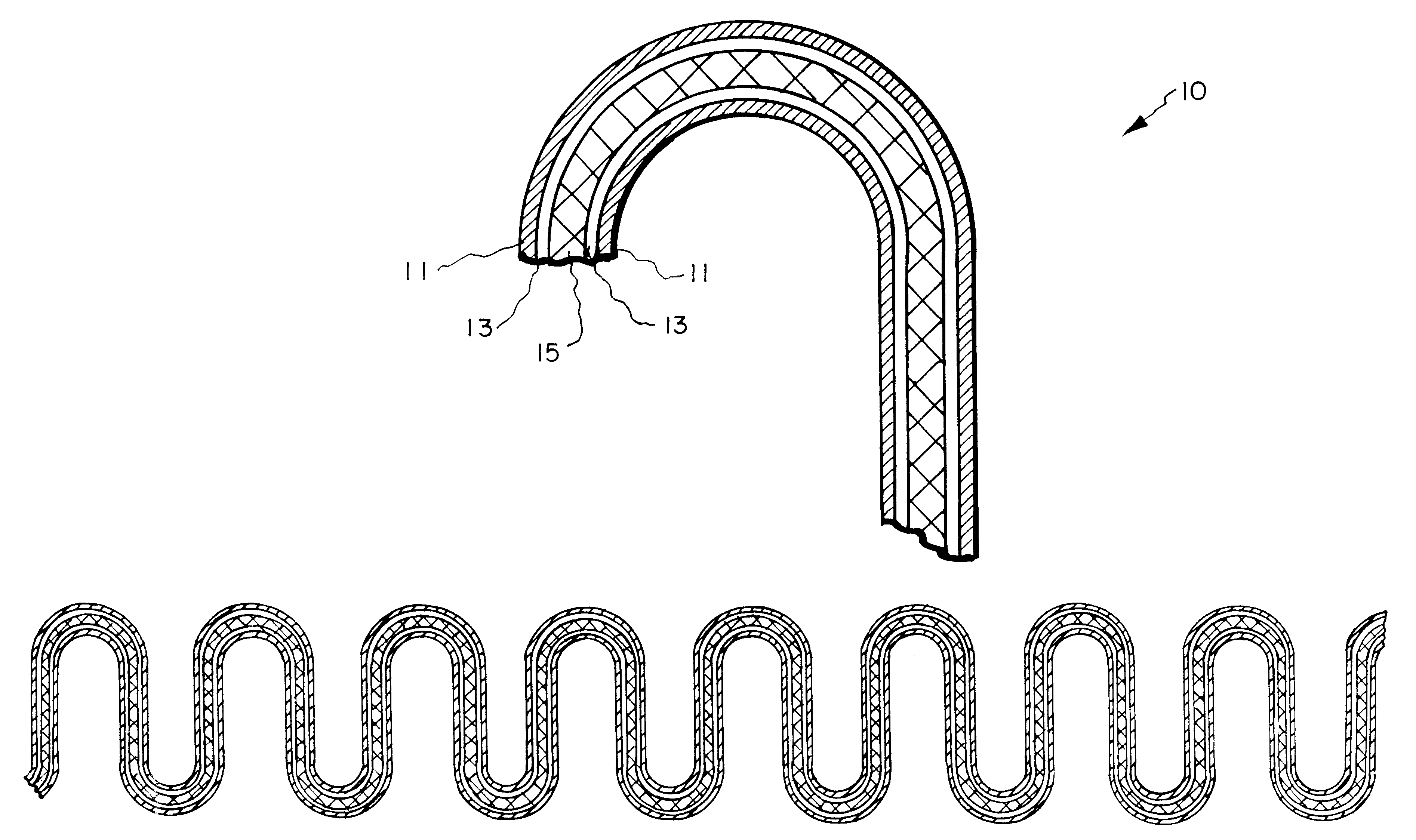

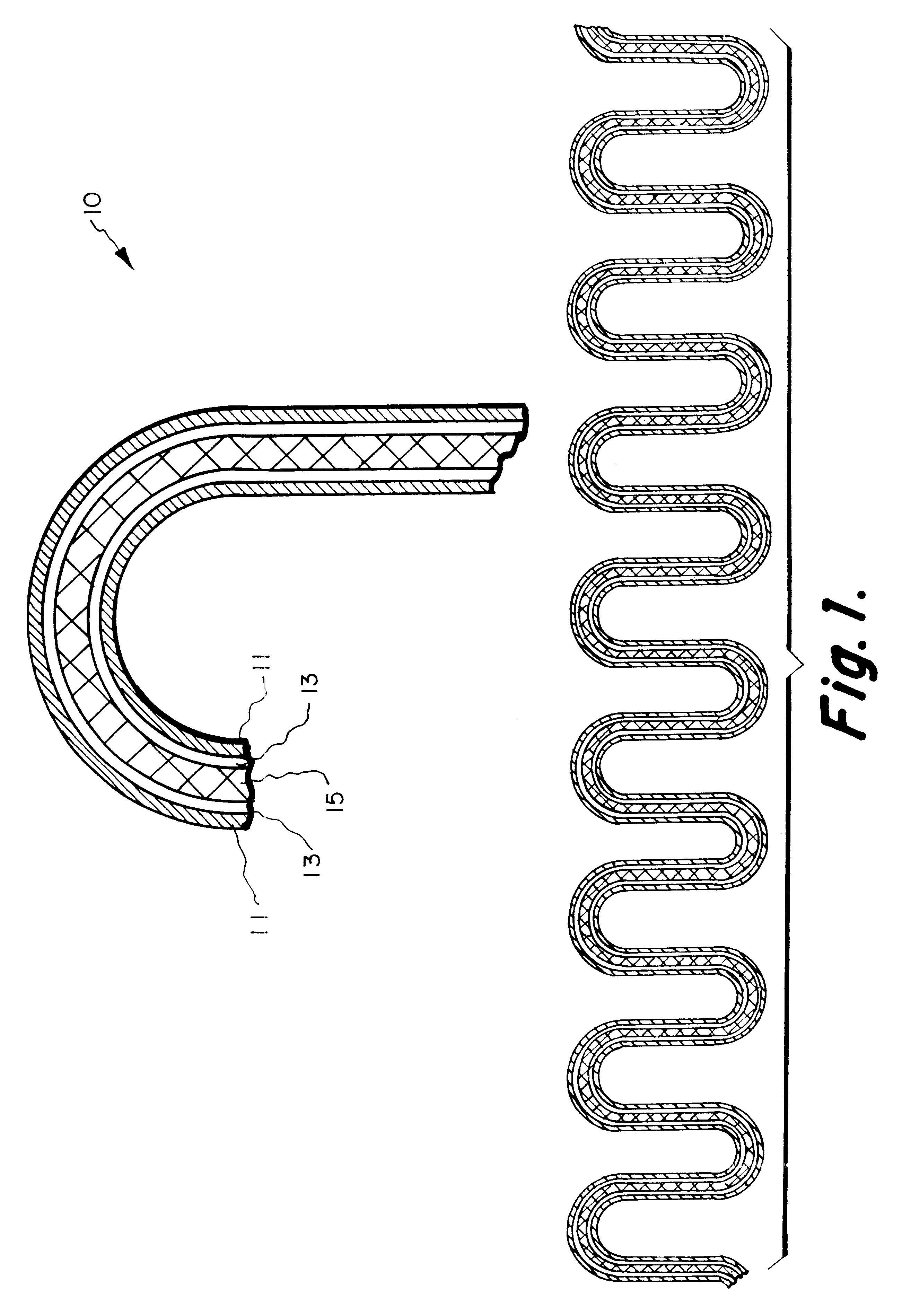

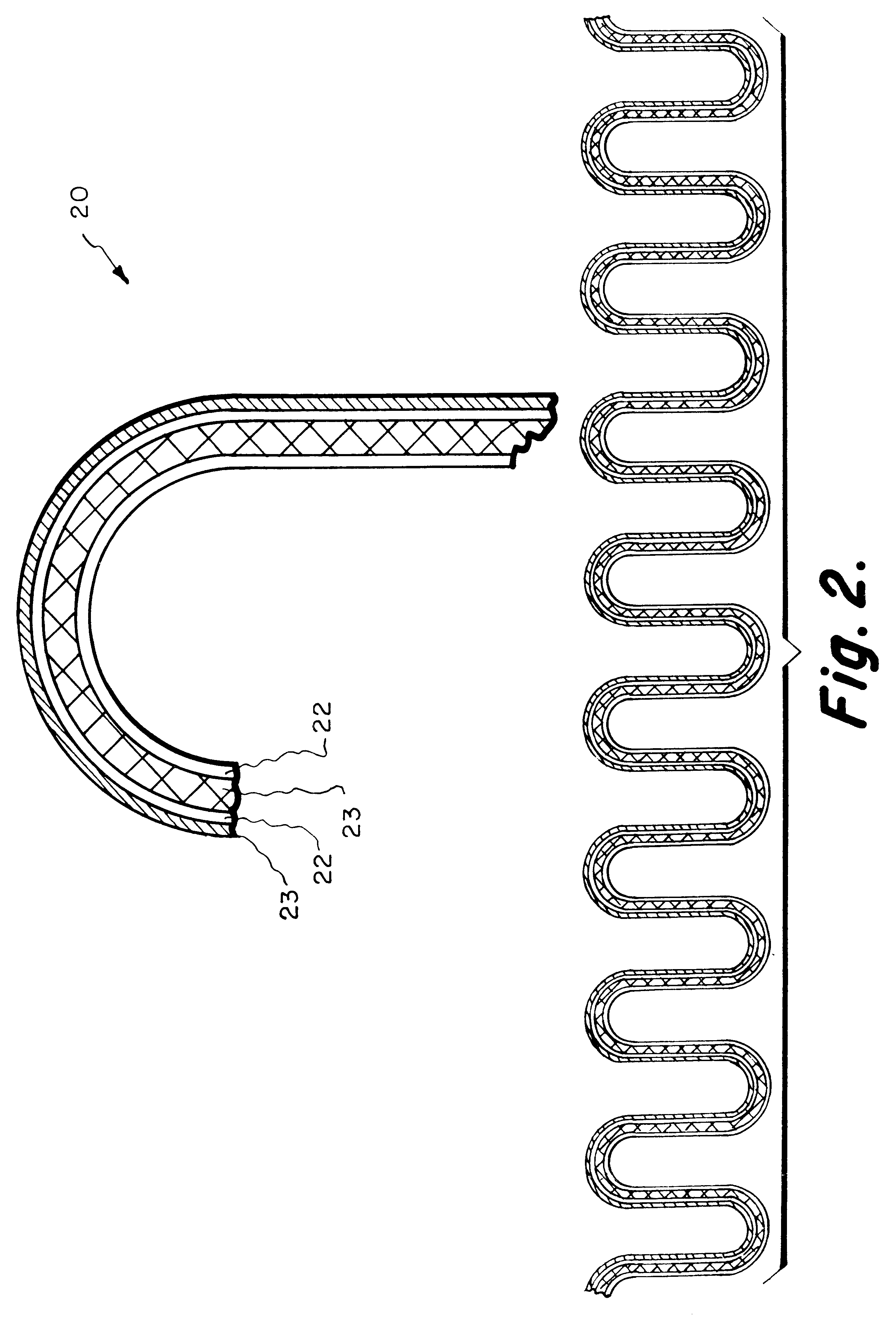

Pleated filter with monolayer monocomponent meltspun media

ActiveUS7947142B2Lower overall pressure dropEfficient captureDispersed particle filtrationLaminationFilter mediaEngineering

A pleated filter is made from a monocomponent monolayer nonwoven web of continuous monocomponent meltspun partially crystalline and partially amorphous oriented fibers of the same polymeric composition that are bonded to form a coherent and handleable web having a Gurley Stiffness of at least 100 mg and which further may be softened while retaining orientation and fiber structure. Rows of pleats are formed in the nonwoven web, and the web is cut to a desired size and shape to provide a pleated filter element containing a self-supporting porous monocomponent monolayer matrix of fibers bonded to one another at least some points of fiber intersection and having an average initial submicron efficiency of at least 15% at a 1.52 meters / sec face velocity. The filter element is deformation resistant without requiring stiffening layers, bicomponent fibers, adhesive or other reinforcement in the filter media layer.

Owner:3M INNOVATIVE PROPERTIES CO

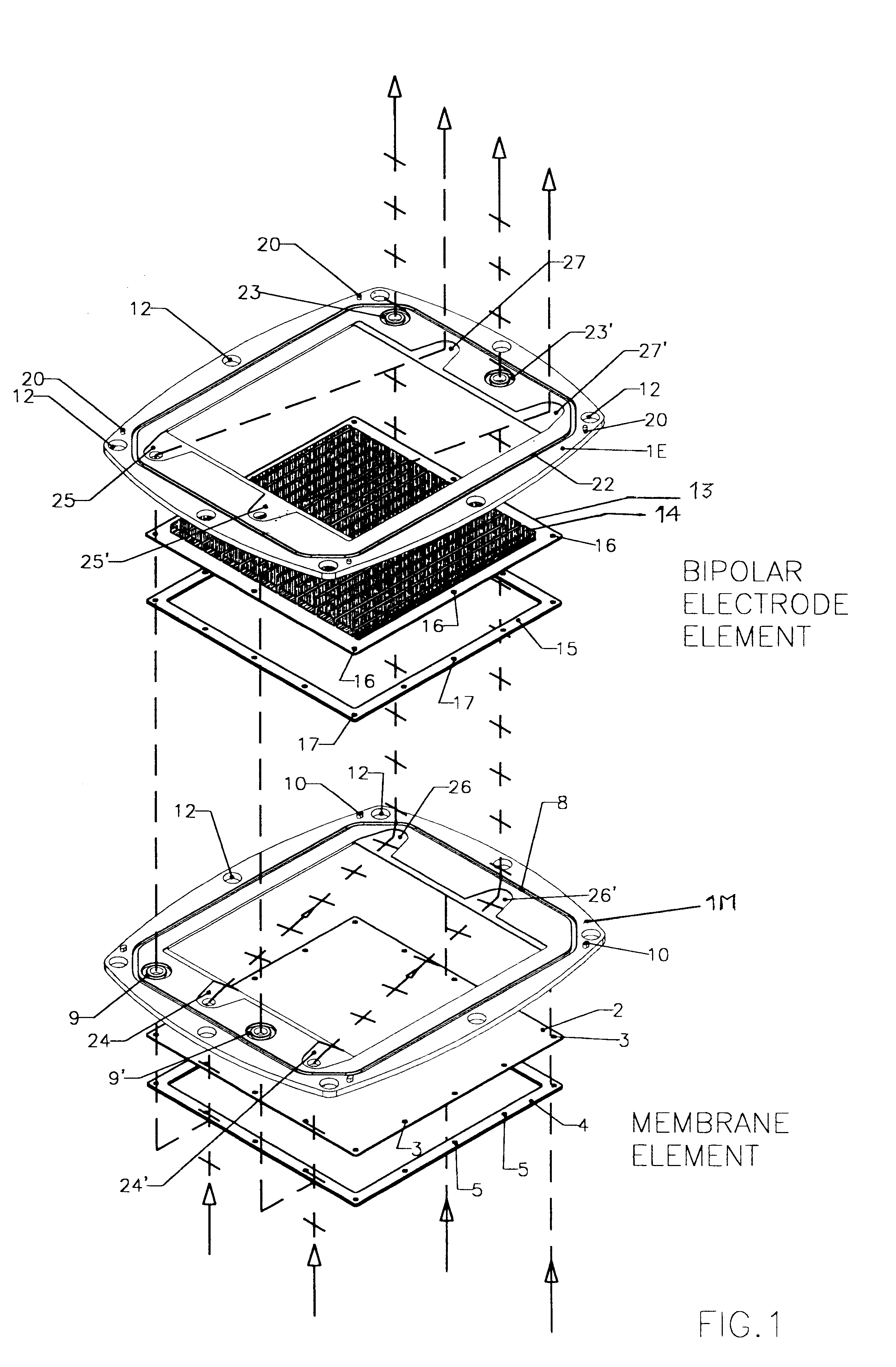

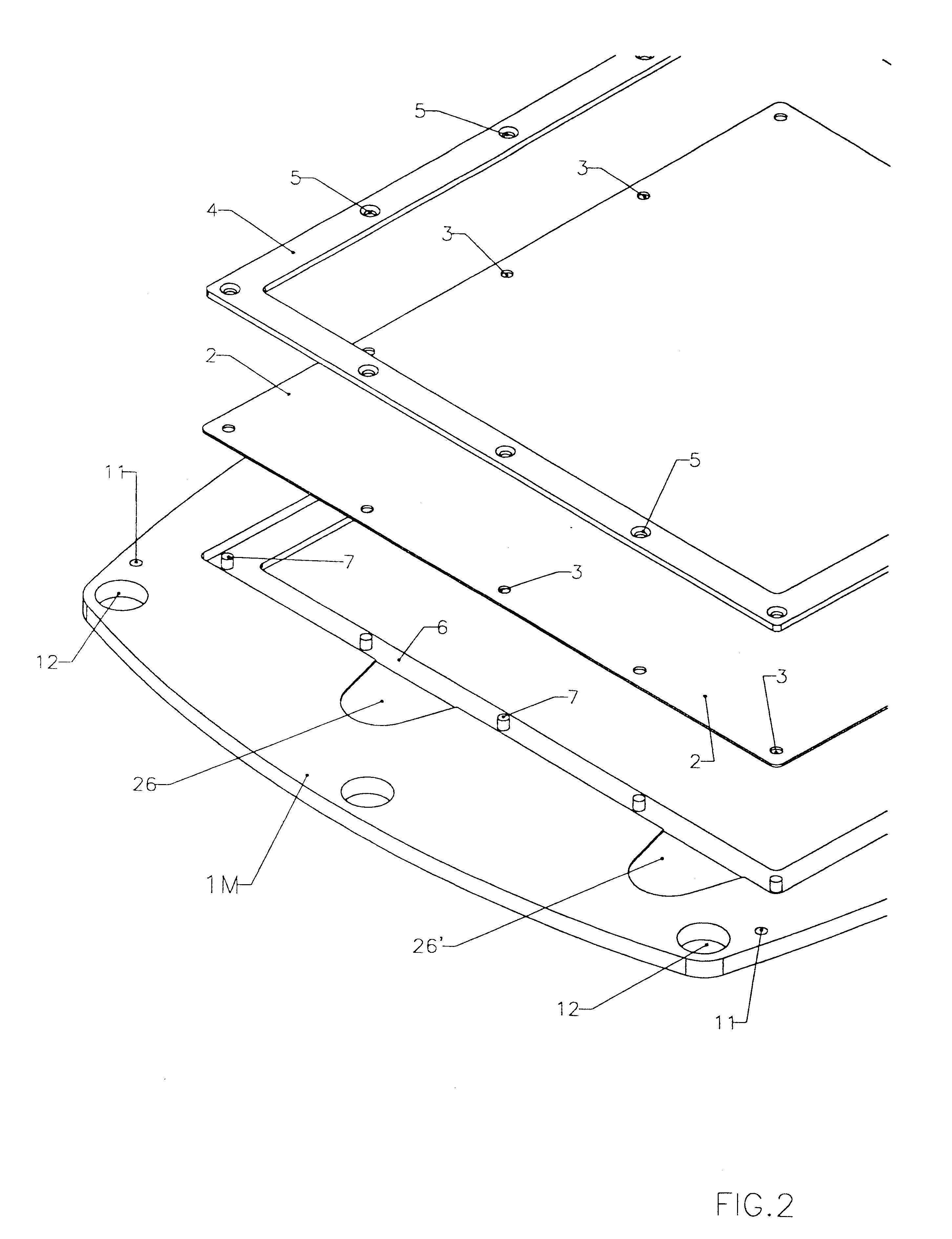

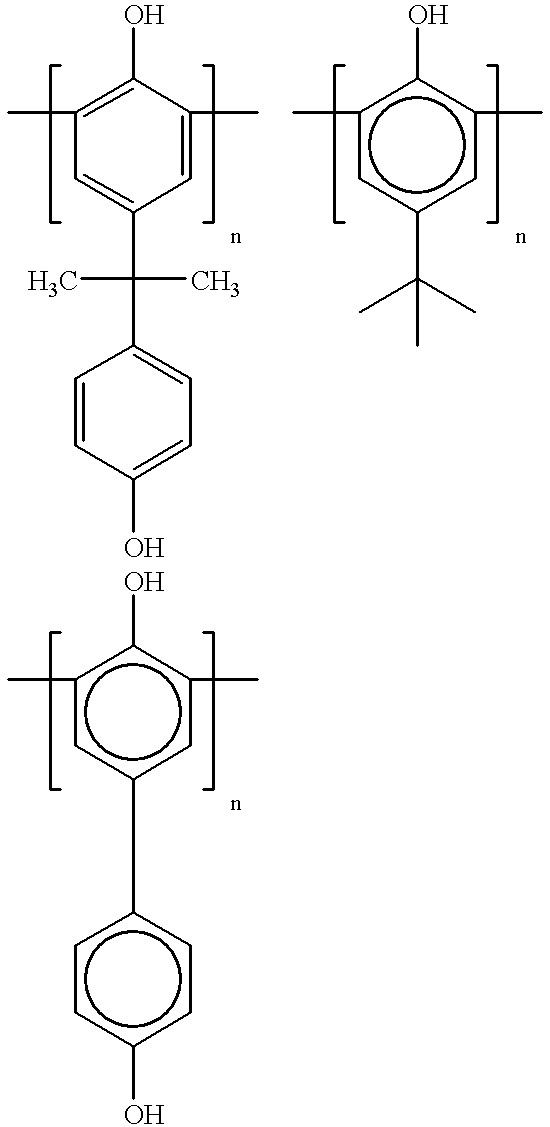

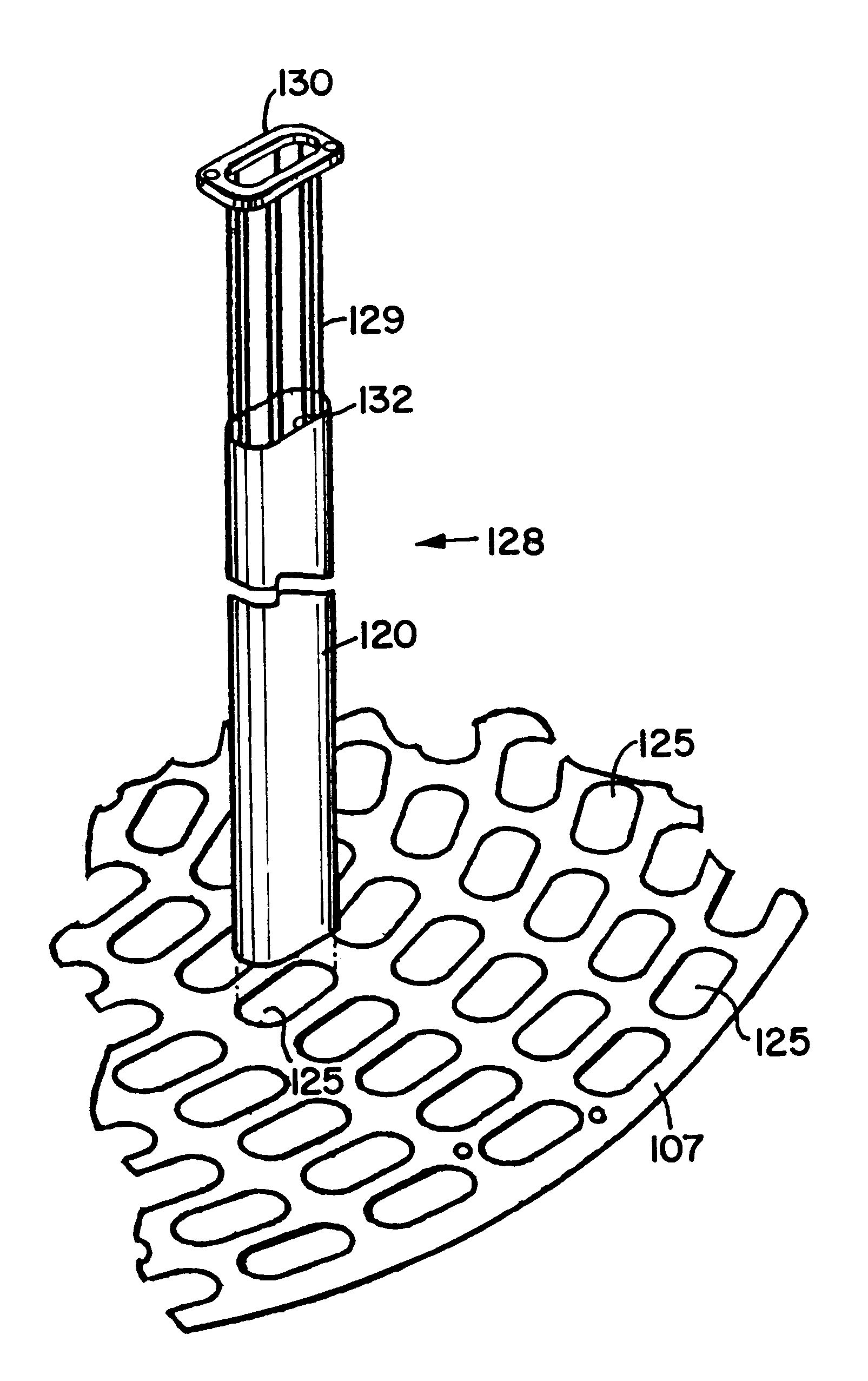

Membrane-separated, bipolar multicell electrochemical reactor

InactiveUS6555267B1Improve electrochemical performanceLower overall pressure dropFuel cells groupingFuel cell auxillariesPlastic materialsIon-exchange membranes

A multicell assembly is constituted by alternately stacking two types of pre-assembled elements: a bipolar electrode holding subassembly and a membrane holding subassembly. The alternate stack of elements is piled over a bottom end element and the stack is terminated by placing over the last membrane holding element a top end electrode element. Each bipolar plate electrode holding element and each ion exchange membrane separator holding element includes a substantially similar rectangular frame piece, made of an electrically nonconductive and chemically resistant material, typically of molded plastic material, having on its upper (assembly) face grooves for receiving O-ring type gasket means, and having through holes and recesses in coordinated locations disposed along two opposite sides of the rectangular frame forming, upon completion of the assembling, ducts for the separate circulation of the negative electrolyte and of the positive electrolyte through all the negative electrolyte flow chambers and all positive electrolyte flow chambers, respectively, in cascade.

Owner:SQUIRREL HLDG

Industrial bag house elements

InactiveUS6740142B2Low efficiencyShort lifeCombination devicesMaterial nanotechnologyAir filterFilter media

The filter structures commonly known as a bag house or a filter bag or an air filter with a bag construction can be made by preparing the bag assembly, either in a tubular or a bi-fold construction by placing a layer of fine fiber on the upstream surface of the filter media structure. The filter assembly includes a filter cabinet with an interior component. The filter component is suspended within the filter cabinet interior. The filter component includes a frame or support for the filter media. The frame or support holds the filter bags such that the filter bags are suspended from the frame in the cabinet interior. The intake air enters the cabinet, passes through the filter assembly and exits the cabinet. The air must pass first into the fine fiber layer, the filter media and then the exterior of the cabinet.

Owner:DONALDSON CO INC

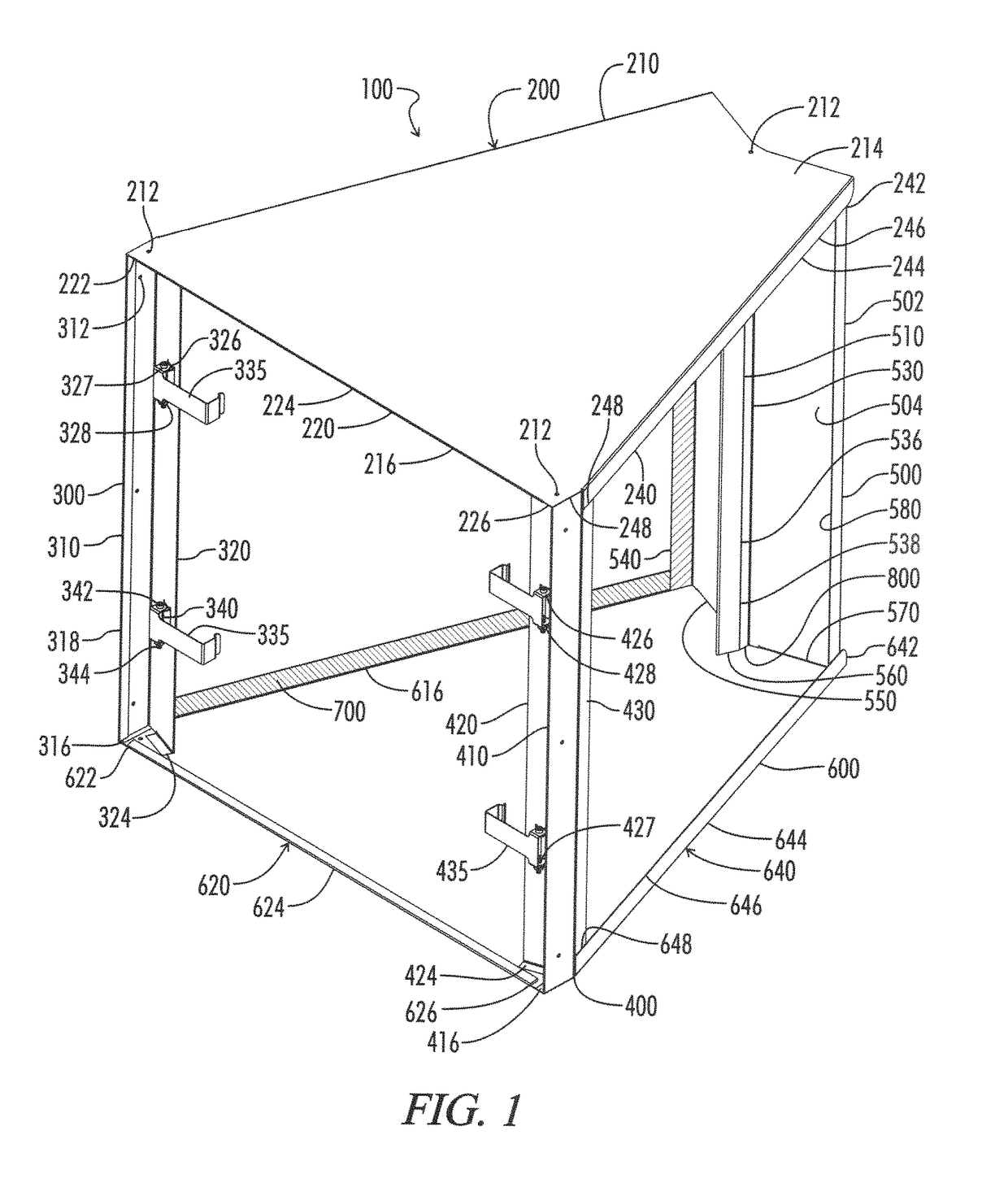

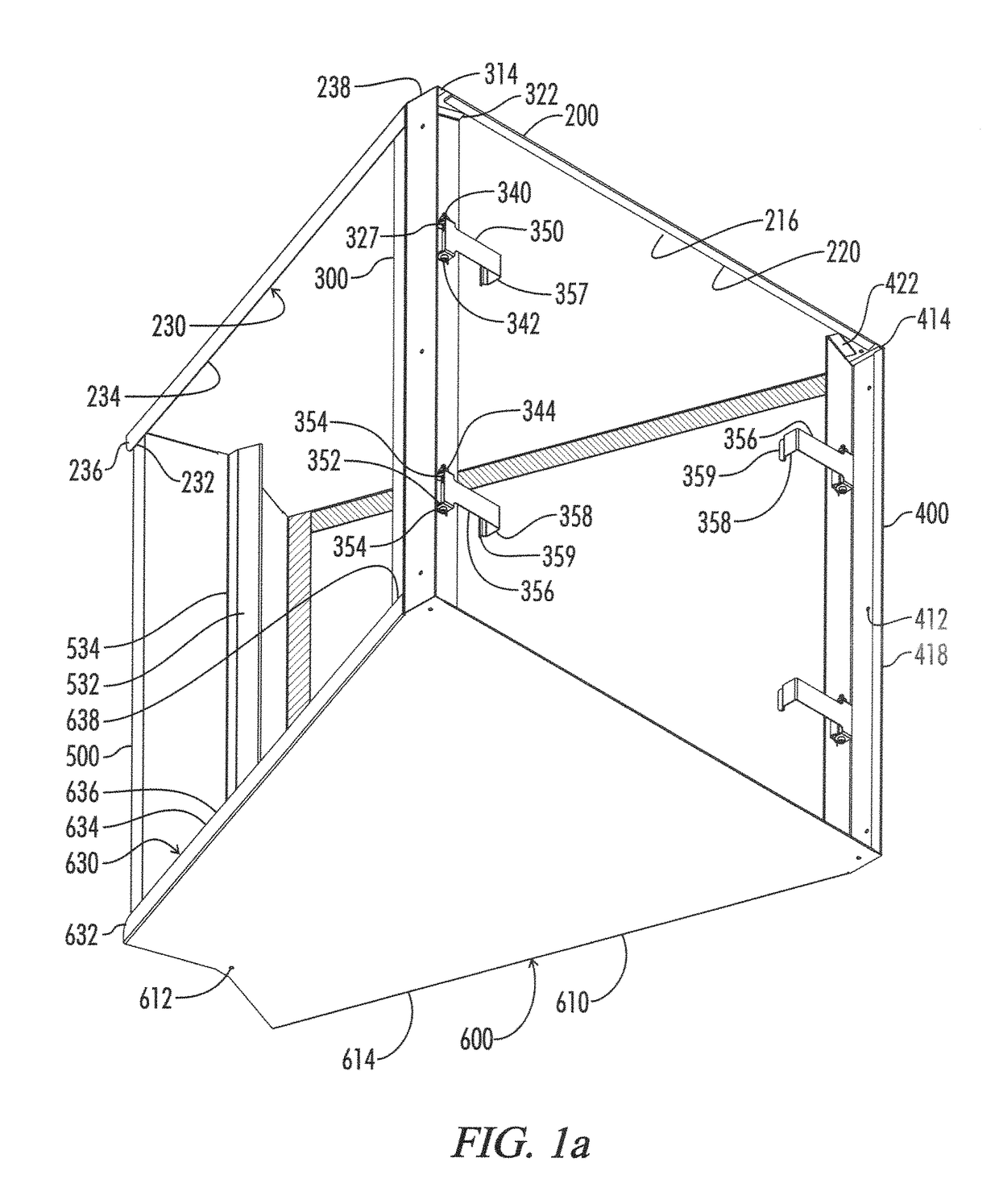

Modular air filter housing

ActiveUS9764266B1Improve sealingImprove efficiencyDispersed particle filtrationTransportation and packagingAir filterMechanical engineering

An air filter module for modularly mounting angled air filters. The module includes a top plate, bottom plate, left and right front corners with the corners defining perpendicular side walls, angled filter end retention walls, angled side walls, and a back wall with angled side walls, parallel end retention walls, and a positioning guide. The positioning guide is constructed from clips or a guide face and an inner side positioning wall.

Owner:CARTER SCOTT

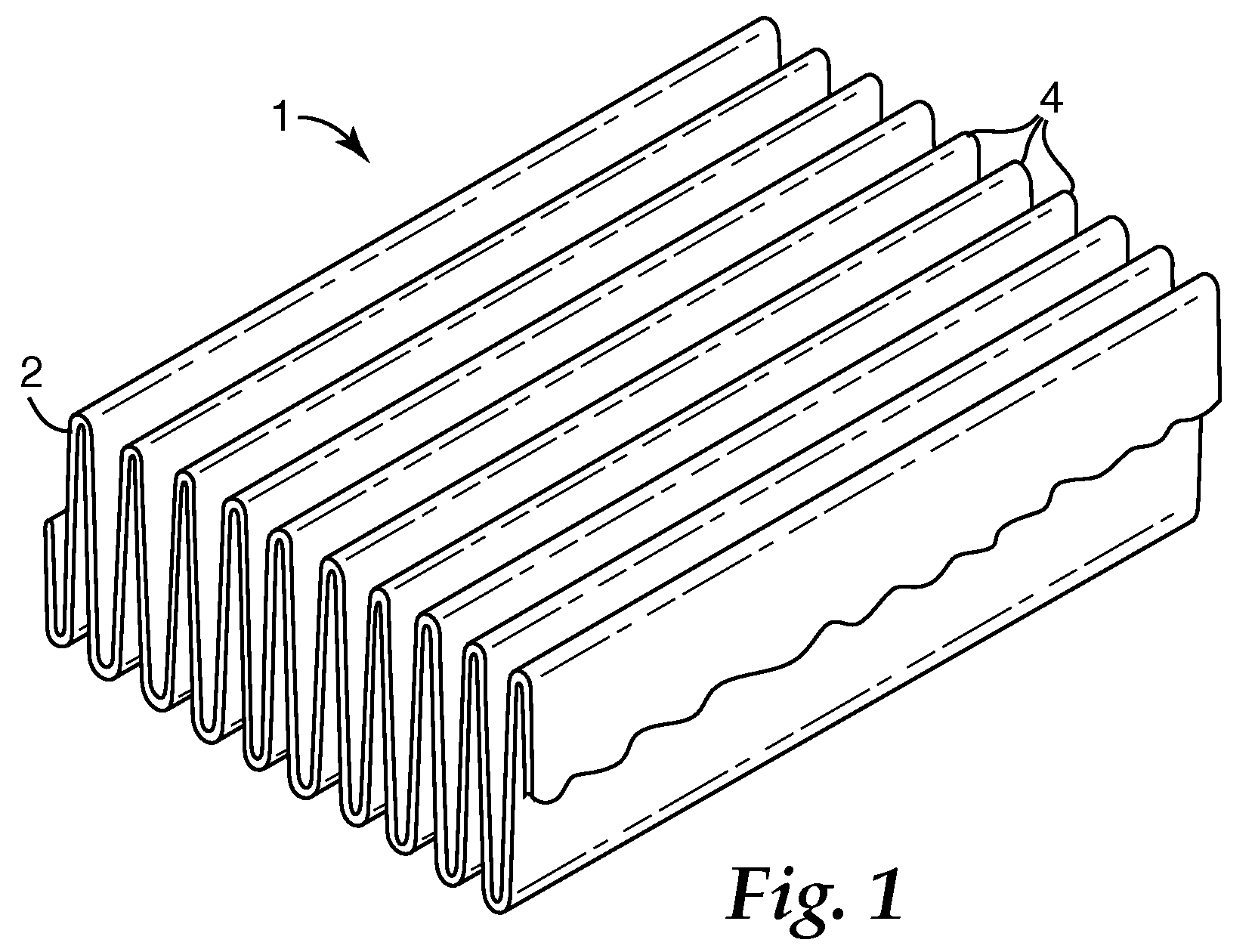

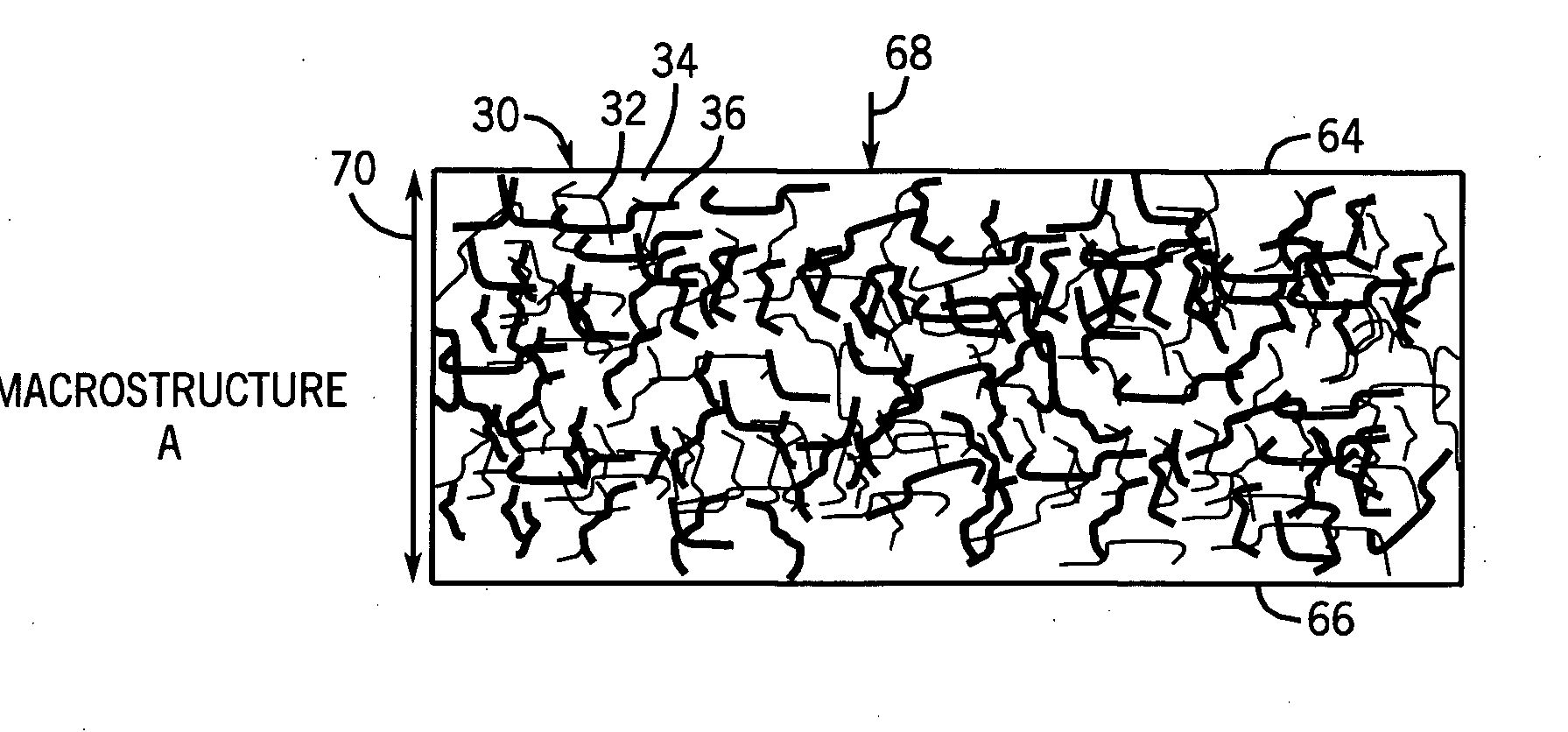

Adsorbent sheet material for parallel passage contactors

ActiveUS7077891B2Maximize capacityImprove efficiencyMaterial nanotechnologyOther chemical processesParticulatesSorbent

An adsorbent material fabricated into a reinforcement-free, self-supported coherent thin sheet and configured for use as a parallel passage contactor element in adsorption / separation applications with gases and liquids is disclosed. The adsorbent sheet material is obtained by enmeshing fine adsorbent particulates in a polymer binder. Particulates include but are not limited to carbon particles, inorganic oxides particles, or ceramic particles, or synthetic polymer resin particles. The adsorbent sheet advantageously contains a large volume percentage of active adsorbent particles. The parallel passage contactor device fabricated from the adsorbent sheet material is characterized by minimal mass transfer resistance and better separation efficiency expressed as height equivalent to a theoretical plate, while it maintains most of the adsorptive properties of the starting particulates, and can be used in gas separation applications with short adsorption cycles, such as rapid pressure swing adsorption, rotary concentrators, rapid electric swing adsorption.

Owner:AIR PROD & CHEM INC

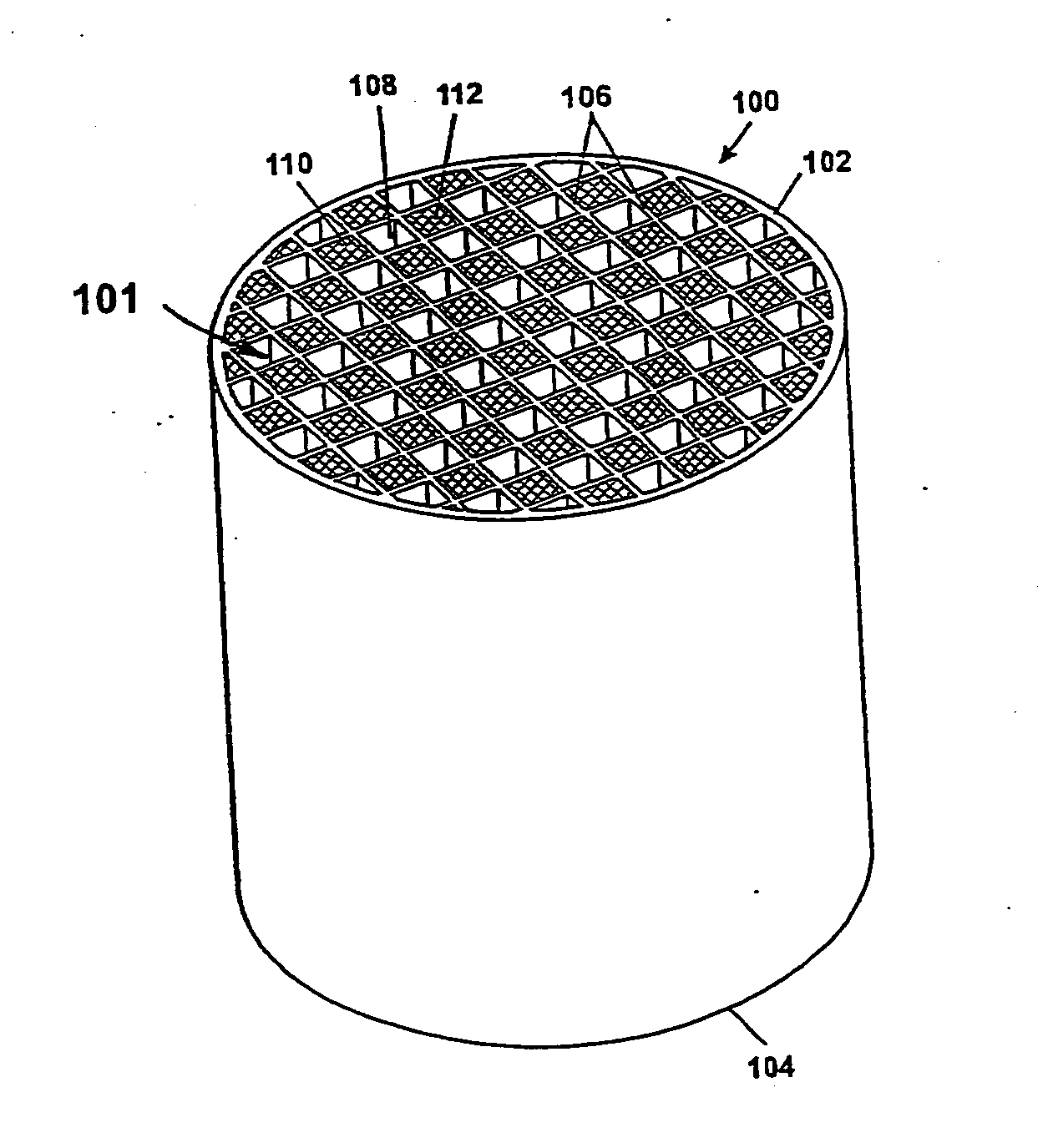

Controlled pore size distribution porous ceramic honeycomb filter, honeycomb green body, batch mixture and manufacturing method therefor

ActiveUS20070119135A1Lower wash-coated pressure dropQuantity minimizationCombination devicesExhaust apparatusSago palmSource material

A porous ceramic honeycomb filter manufactured from an oxide-based ceramic material having a pore size distribution with d1≧7.0 microns. Preferably, the oxide-based material is cordierite or aluminum titanate. Alternatively, the filter contains a cordierite-containing ceramic body with a narrow pore size distribution with db≦1.00, wherein db=(d90−d10) / d50. Also disclosed is a batch mixture, method and honeycomb green body made from mixture of inorganic source materials selected from the group of magnesia sources, alumina sources, and silica sources, and a pore former having a narrow particle size distribution with dps≦0.90, wherein dps={(dp90−dp10) / dp50}. The pore former is preferably selected from a group consisting of canna starch, sago palm starch, green mung bean starch, and single-mode potato starch.

Owner:CORNING INC

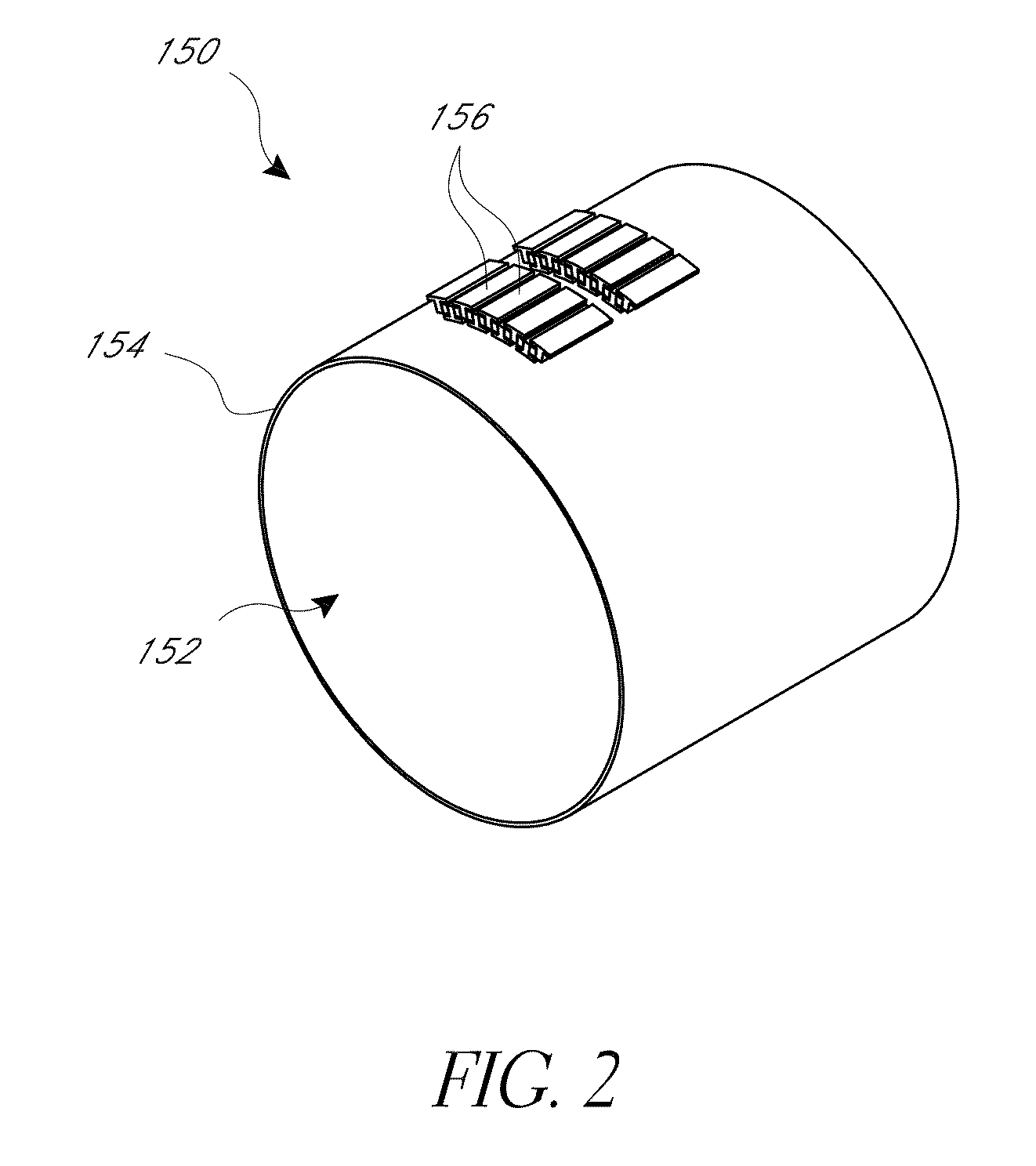

Thermoelectric-based power generation systems and methods

InactiveUS20110067742A1Lower overall pressure dropInternal combustion piston enginesRecuperative heat exchangersExhaust valveEngineering

Some embodiments provide a waste heat recovery apparatus including an exhaust tube having a cylindrical outer shell configured to contain a flow of exhaust fluid; a first heat exchanger extending through a first region of the exhaust tube, the first heat exchanger in thermal communication with the cylindrical outer shell; a second region of the exhaust tube extending through the exhaust tube, the second region having a low exhaust fluid pressure drop; an exhaust valve operatively disposed within the second region and configured to allow exhaust fluid to flow through the second region only when a flow rate of the exhaust fluid becomes great enough to result in back pressure beyond an allowable limit; and a plurality of thermoelectric elements in thermal communication with an outer surface of the outer shell.

Owner:GENTHERM INC

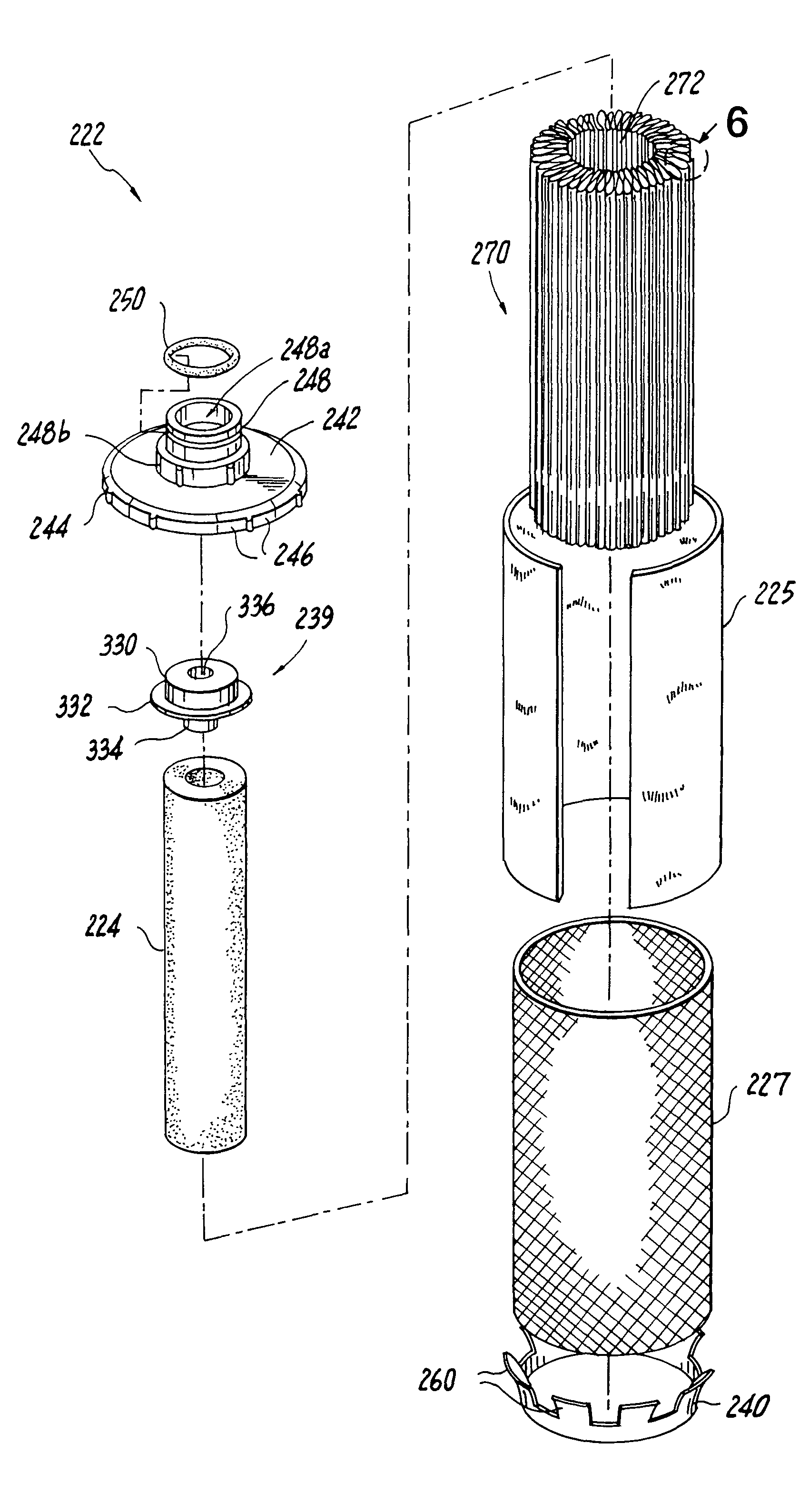

Encapsulated filter cartridge

InactiveUS7081201B2Easy to disconnectIncreased ease of manufacturingUltrafiltrationTreatment involving filtrationFiberEngineering

An encapsulated filter cartridge is disclosed, which includes a filter assembly including a carbon block filter element and a microporous filter element. The filter cartridge has a permanently sealed sump defining an interior chamber configured to accommodate the filter assembly, the sump having an inlet for permitting unfiltered fluid to enter the interior chamber for communicating with the radially outer surface of the filter assembly and an outlet for permitting filtered fluid to exit the interior chamber from the axial portion of the filter assembly. The microporous filter element of the filter assembly may include a hollow fiber subassembly housed within the axial cavity of the carbon block element, said fiber subassembly including a plurality of hollow microporous fibers, or a pleated filter element surrounding the radially outer surface of the carbon block element.

Owner:3M INNOVATIVE PROPERTIES CO

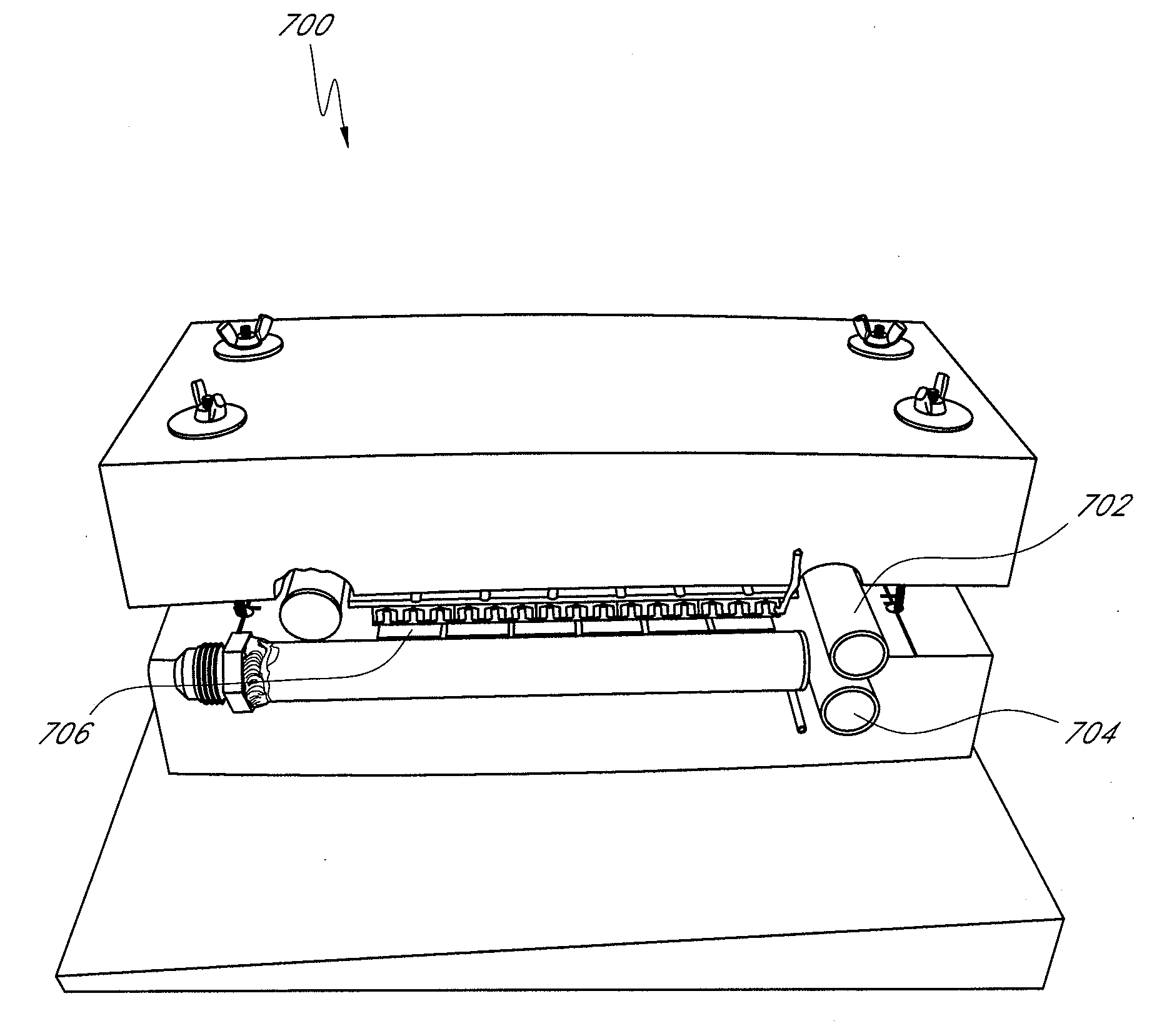

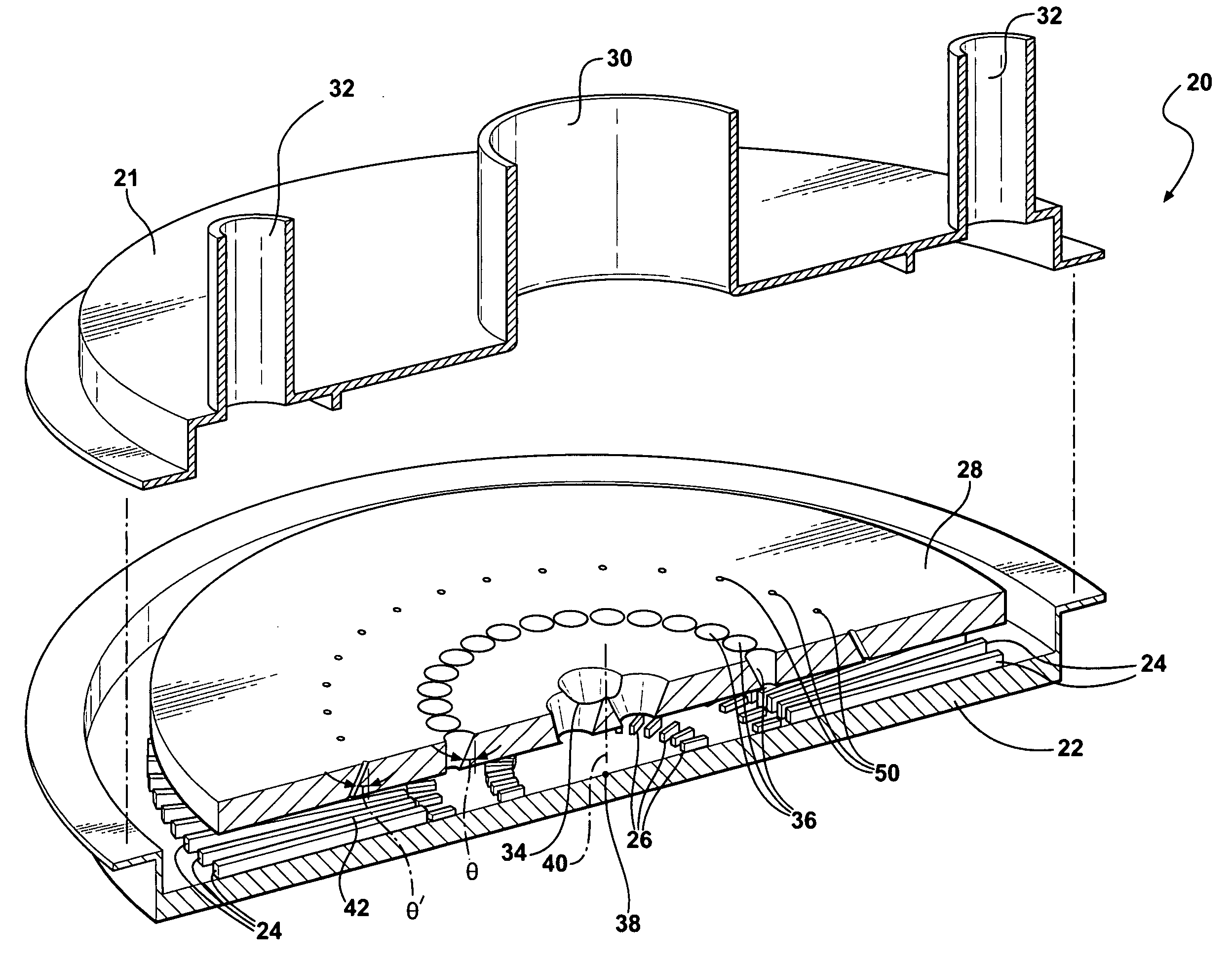

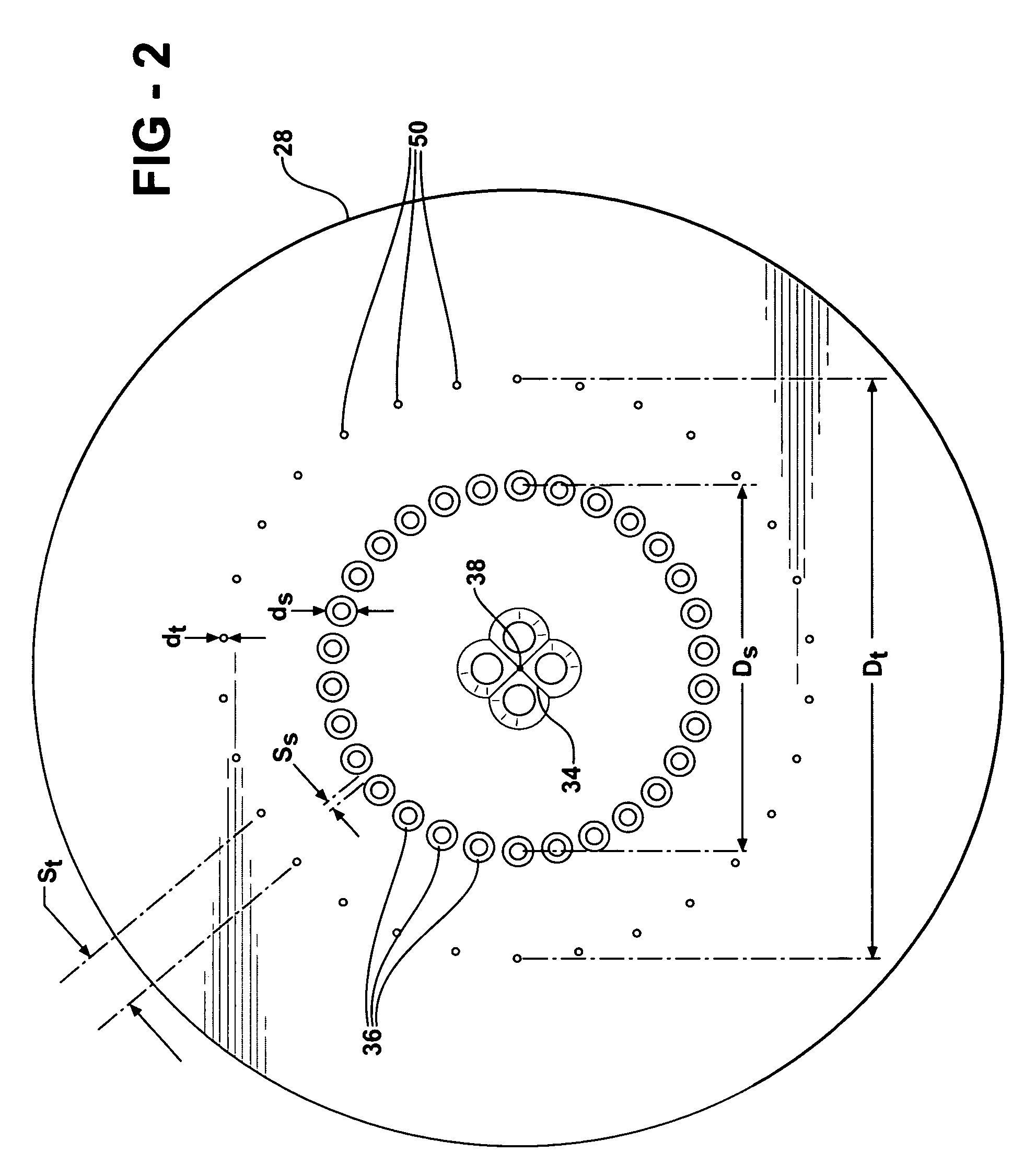

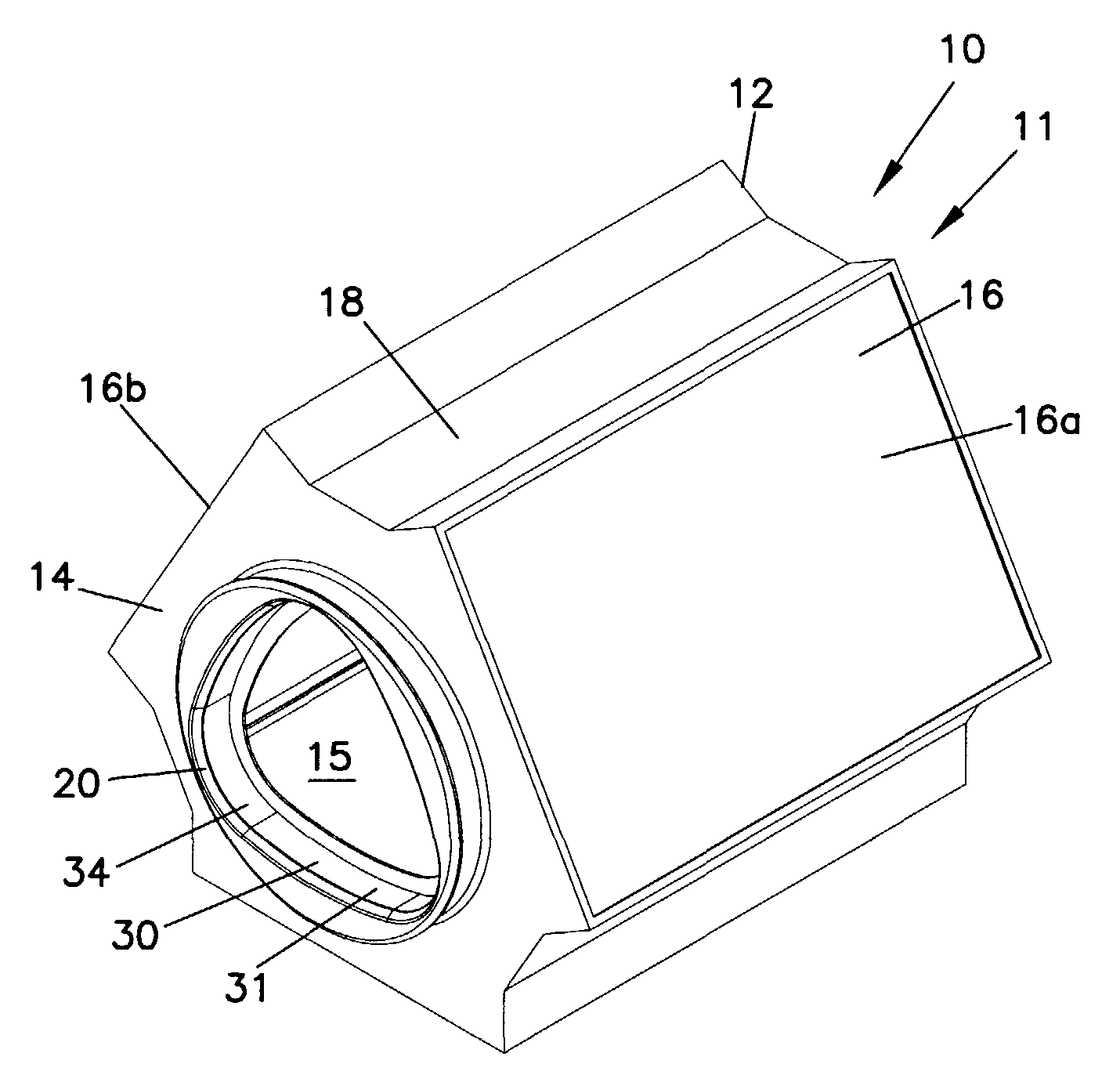

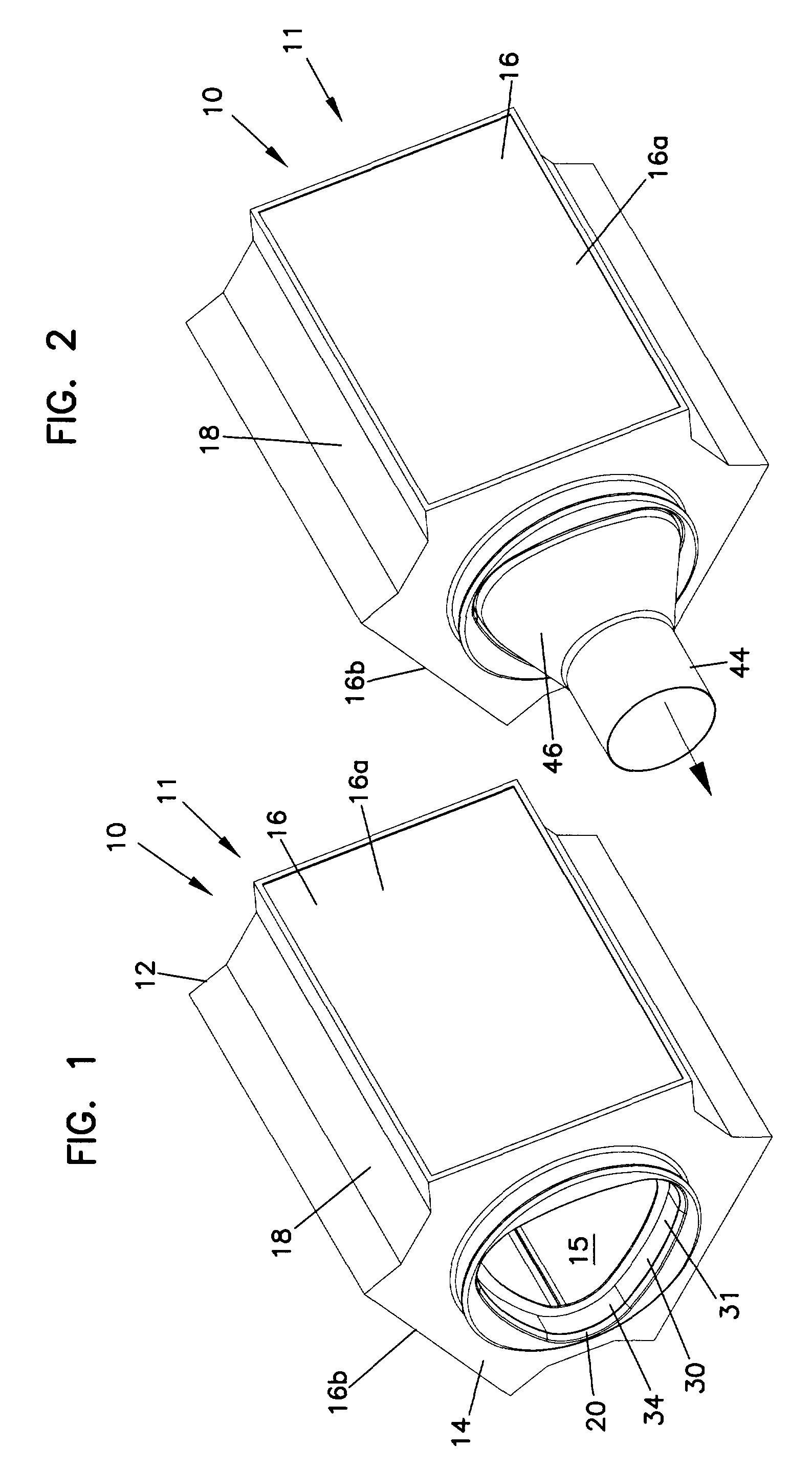

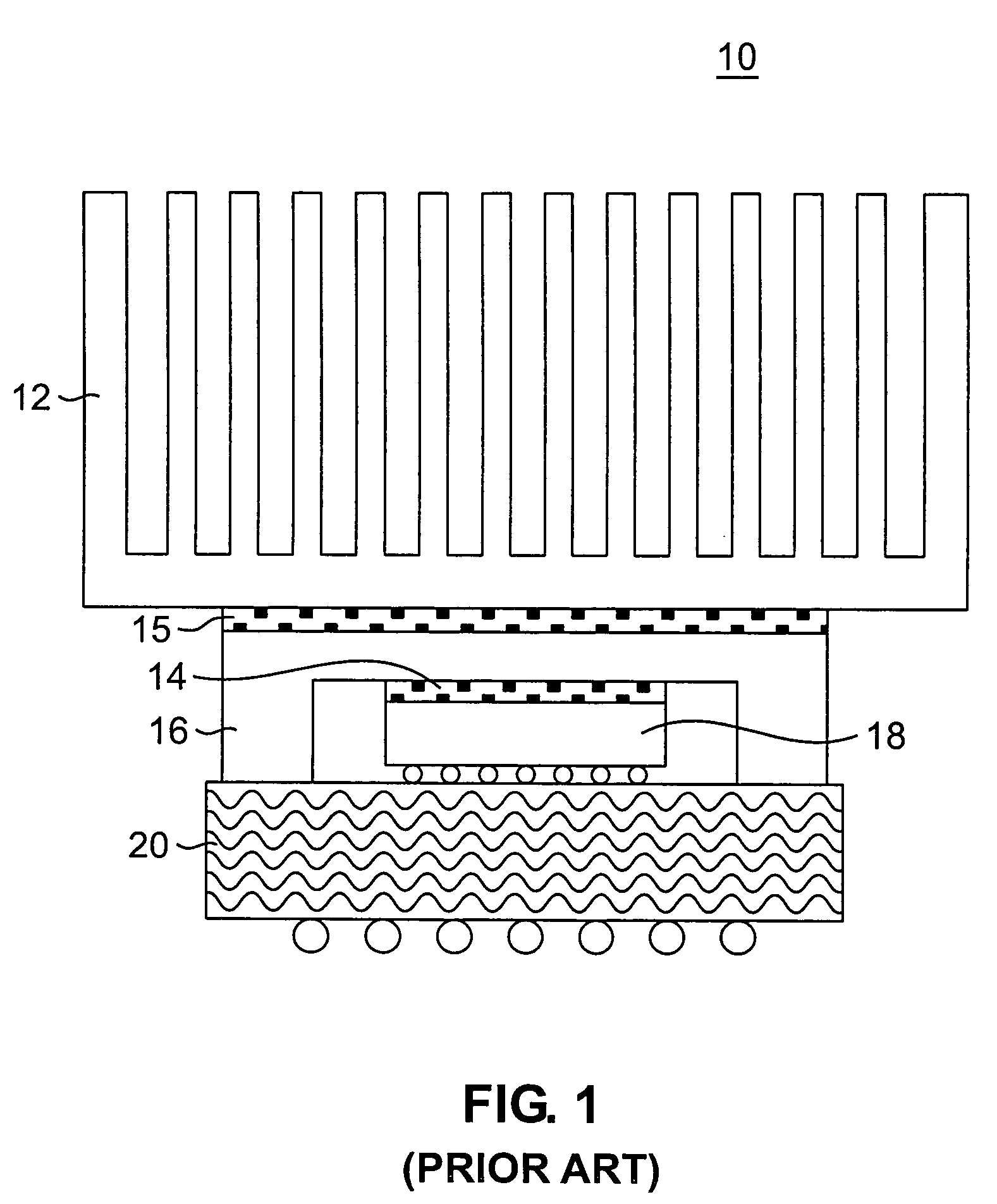

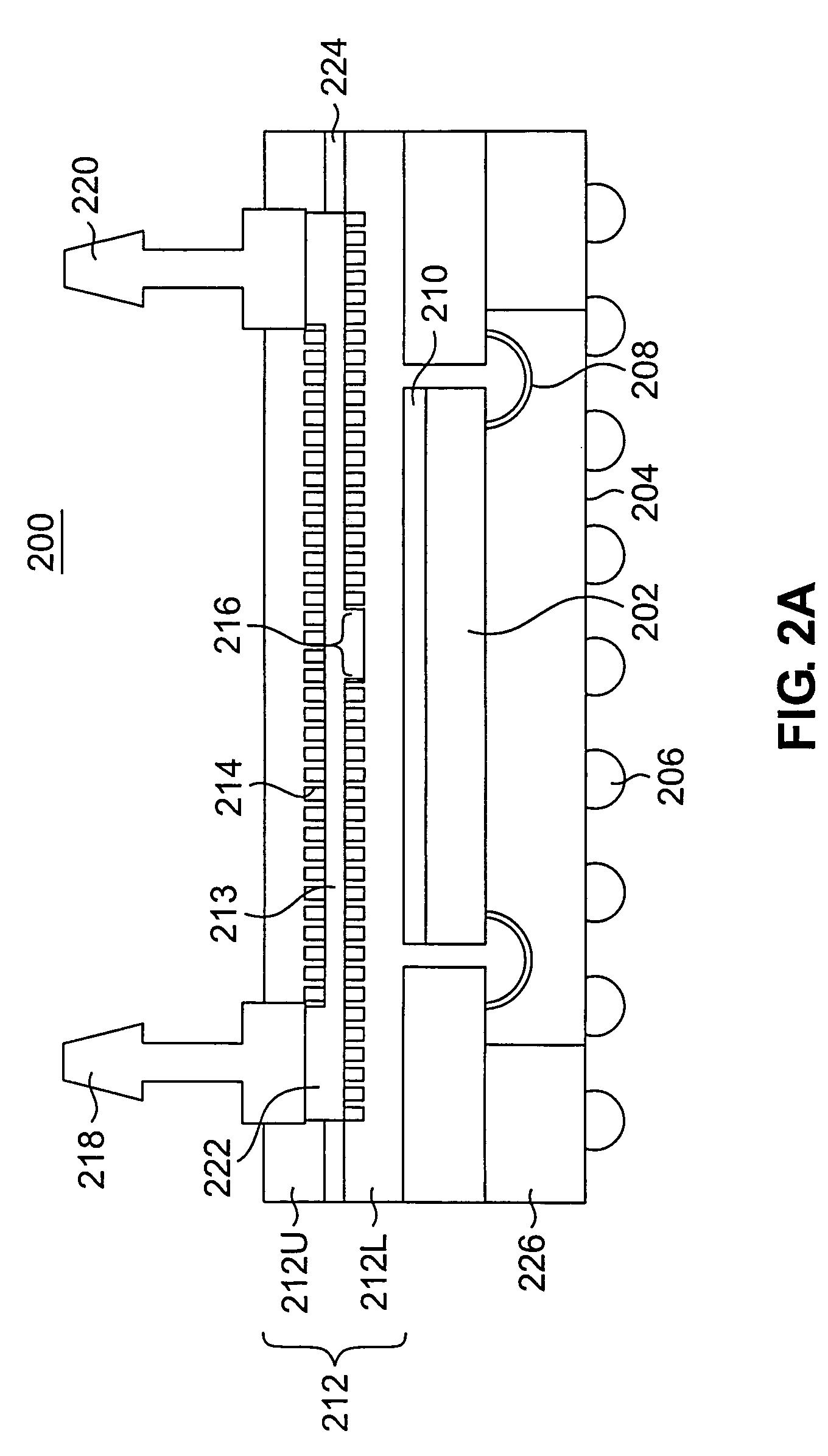

Impingement cooled heat sink with low pressure drop

InactiveUS20070272392A1Reduced life-timeIncrease pressureSemiconductor/solid-state device detailsSolid-state devicesSystem pressureEngineering

Two embodiments of a heat exchanger assembly for cooling an electronic device are shown respectively in FIGS. 1 and 3 and each comprises a housing, a plurality of high fins, a plurality of low fins, a nozzle plate, an inlet, at least one outlet, a primary nozzle, and a plurality of secondary nozzles. In the first embodiment shown in FIG. 1, the housing and the nozzle plate are circular in shape. In the second embodiment shown in FIG. 3, the housing and the nozzle plate are rectangular in shape. Both embodiments include a plurality of secondary nozzles that are aligned outwardly of the primary nozzle and the center axis of the nozzle plate. The secondary nozzles direct the flow of the cooling liquid outwardly of the primary nozzle from the center thus creating an overall system pressure drop lower than that of other assemblies without a plurality of secondary nozzles.

Owner:COOLIT SYSTEMS INC

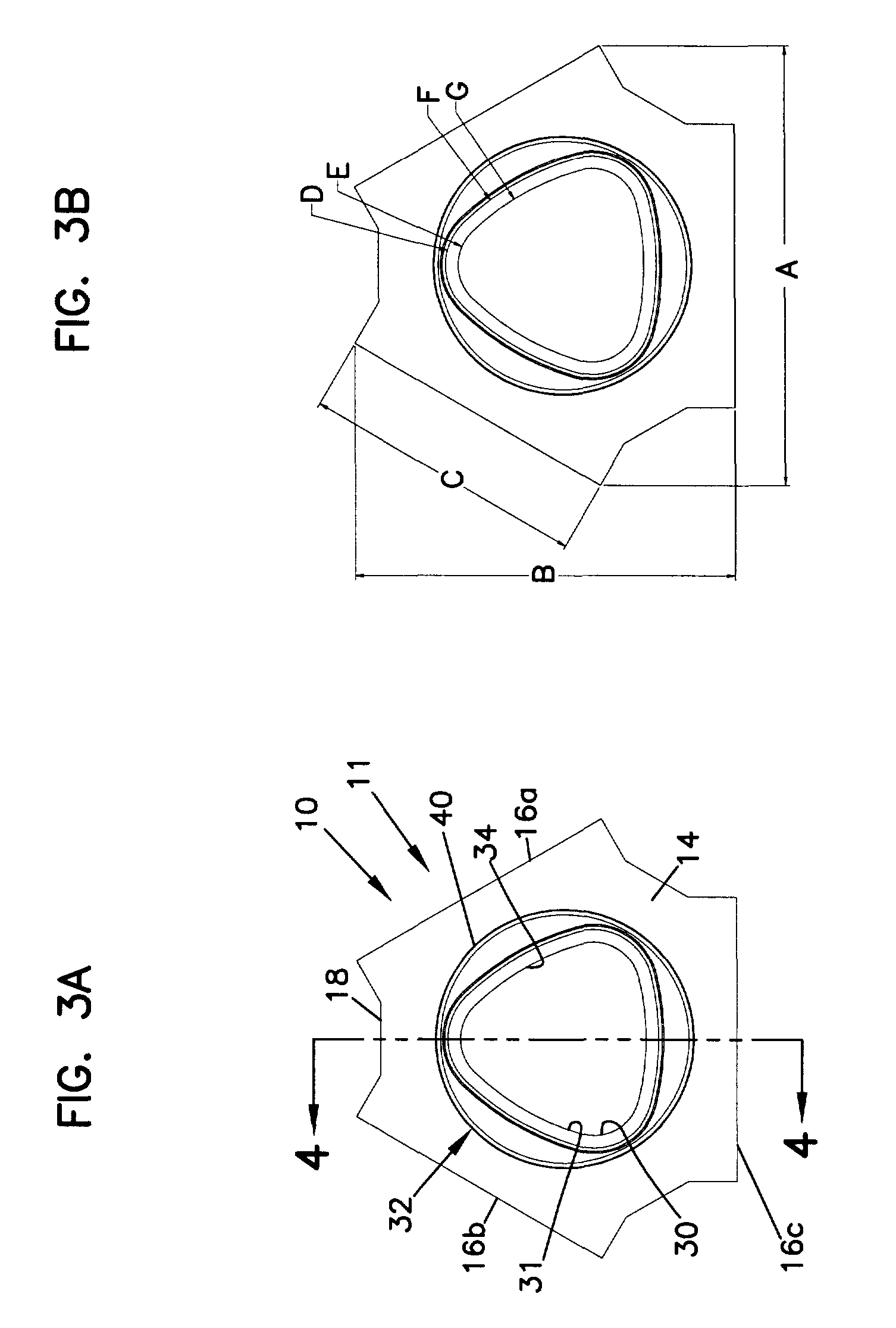

Non-cylindrical filter elements, and methods

ActiveUS7520913B2Increase the areaReduce exit speedCombination devicesDispersed particle filtrationFiltrationFilter element

A filter element that has at least two, planar, non-curved filtration panels. In a preferred embodiment, the filter element has three panels, providing a generally triangular filter element. The outlet aperture, from the filter element, generally follows the configuration of the filter. That is, a filter element having three filtration panels will have a generally three-sided outlet aperture. The outlet aperture preferably is not a true polygon, but rather, includes rounded or curved sides and / or corners. The filter element includes an outlet sealing configuration that may provide both axial and radial sealing to outlet ductwork.

Owner:DONALDSON CO INC

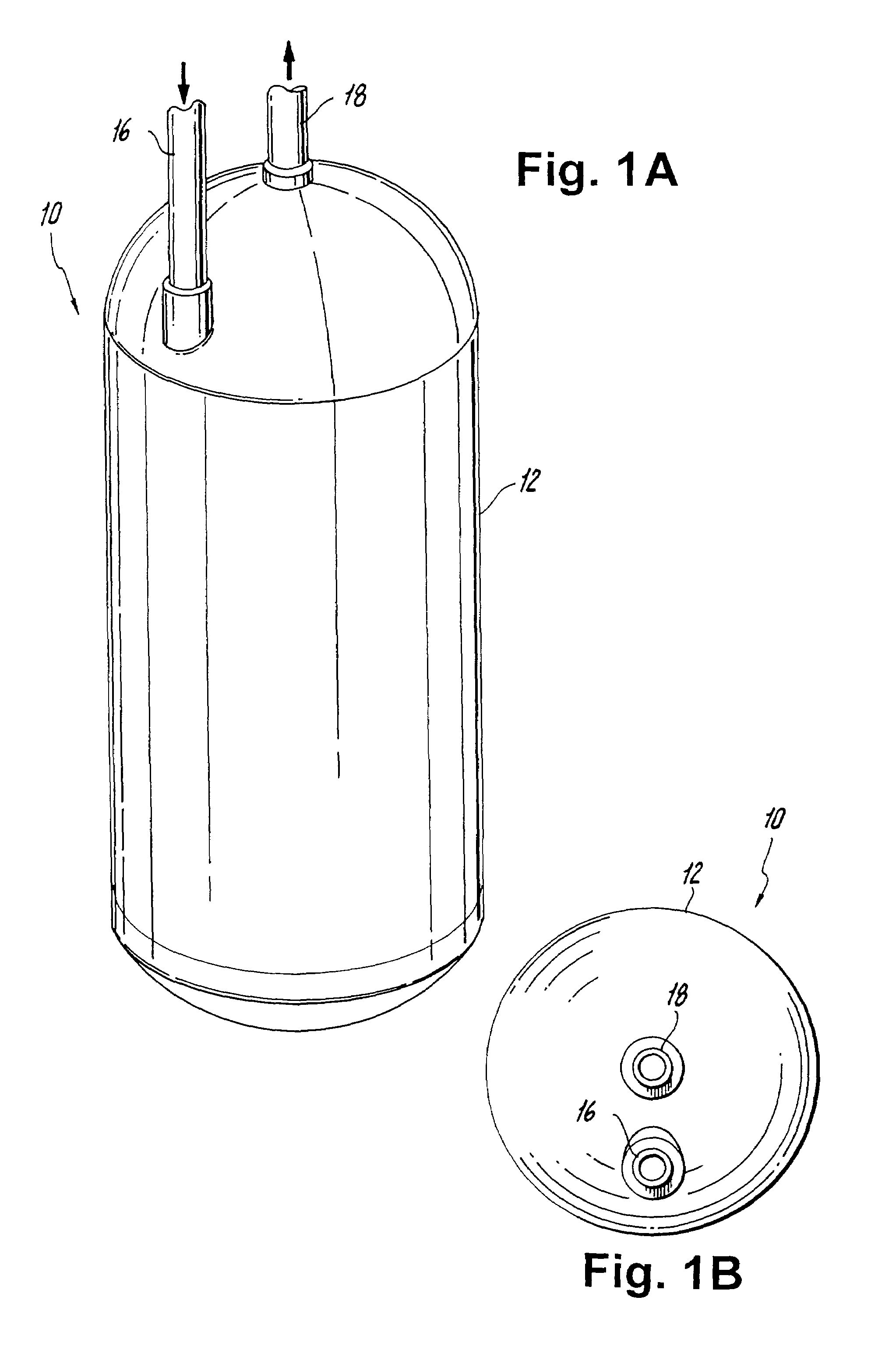

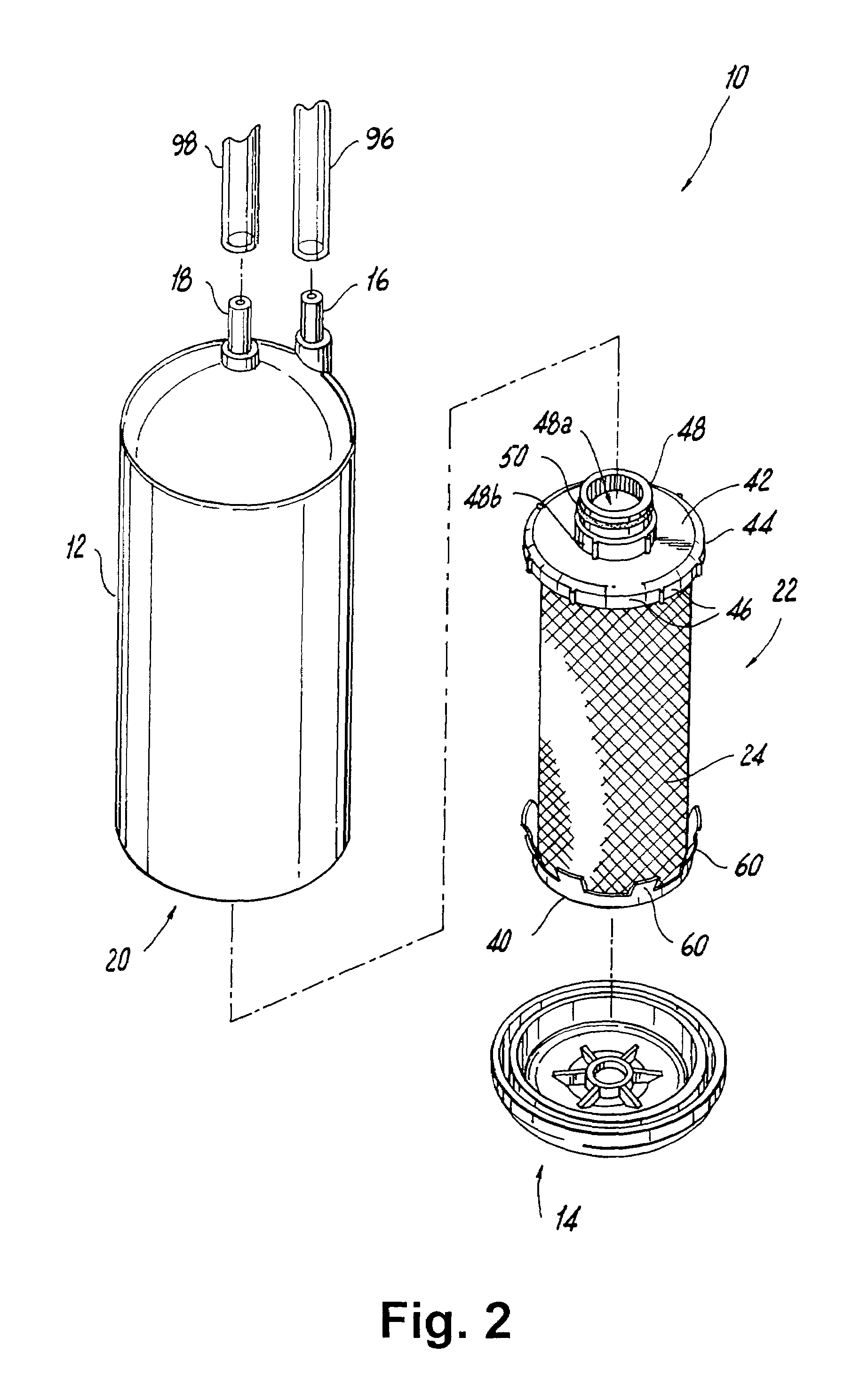

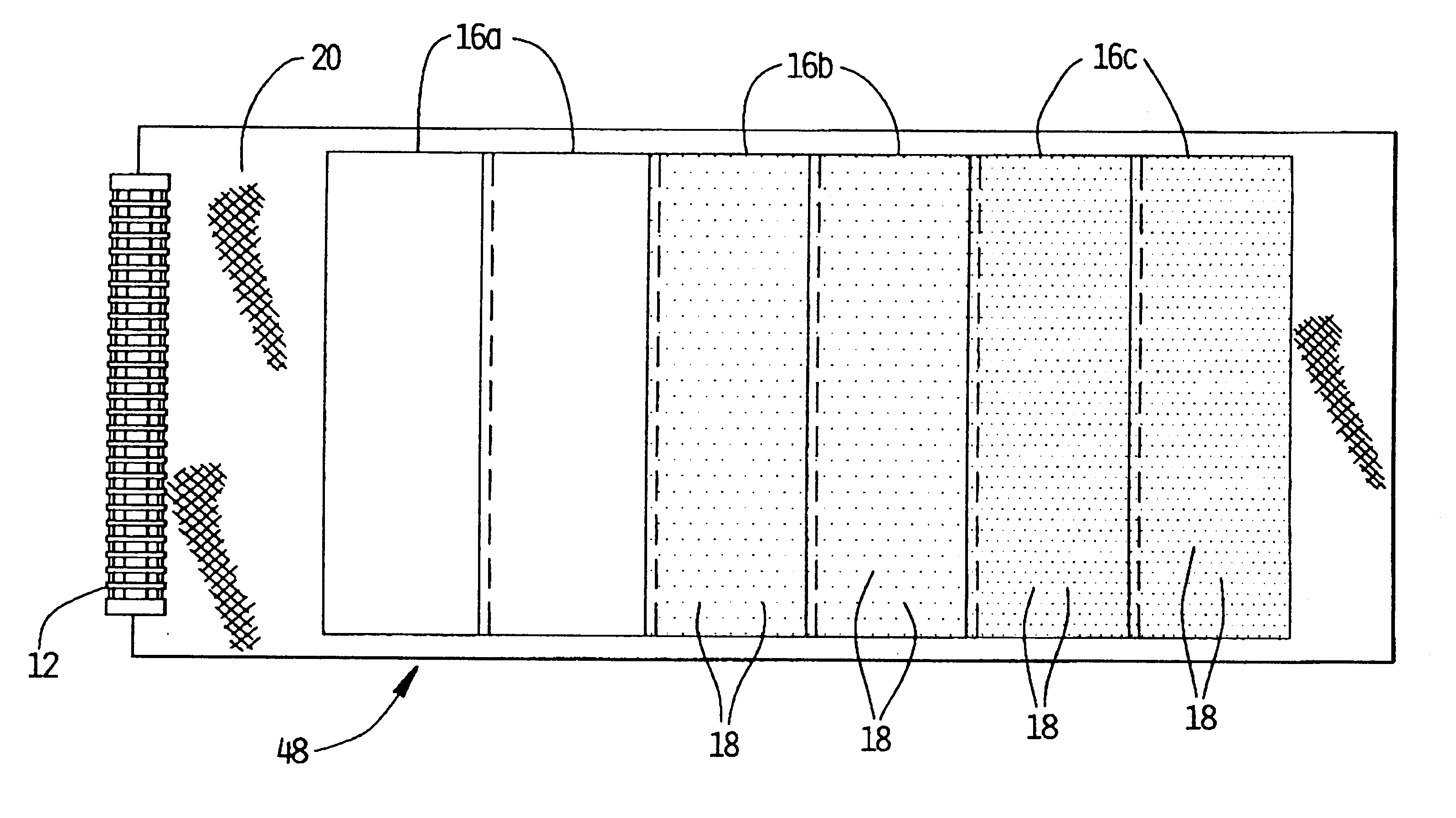

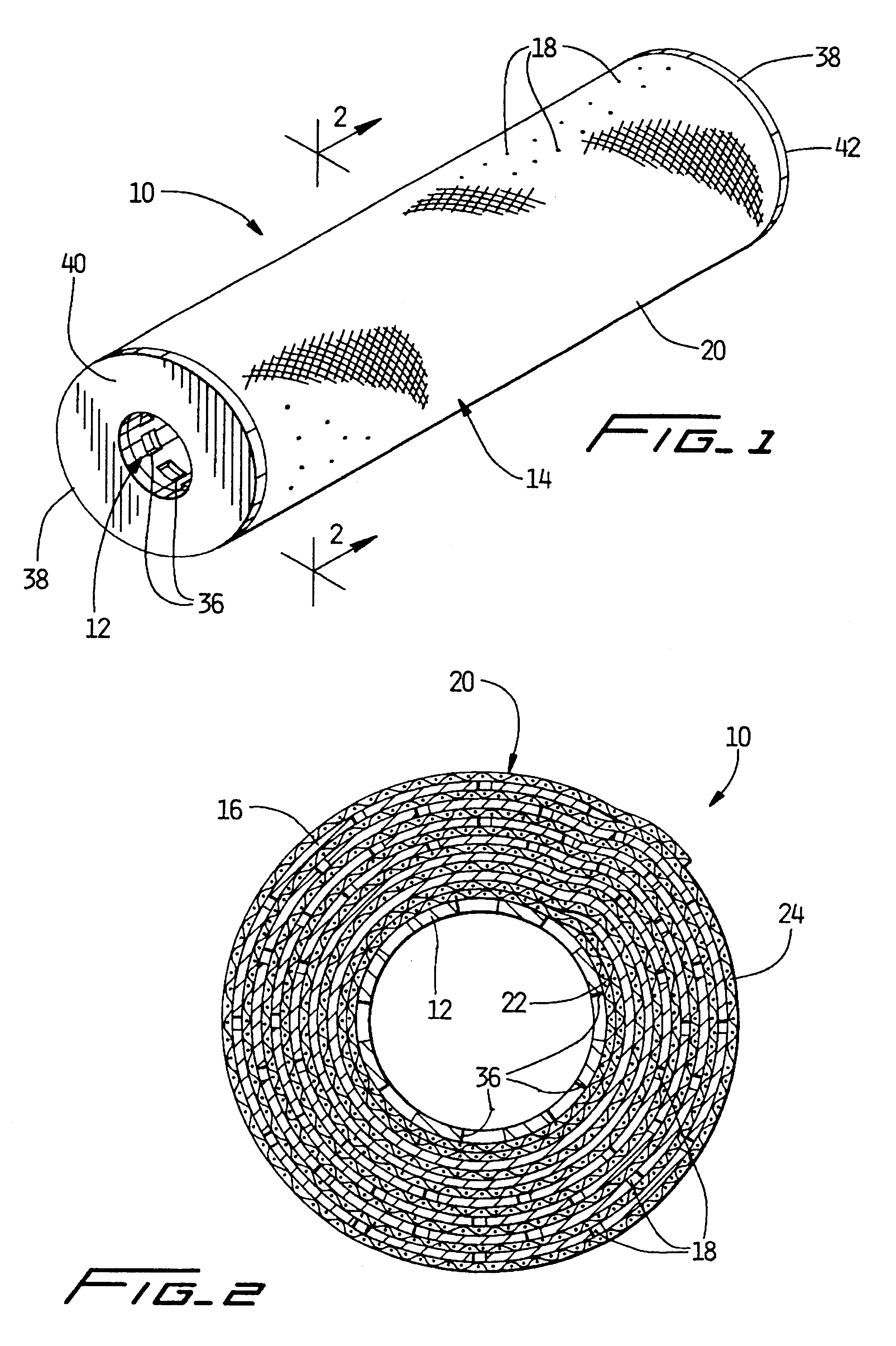

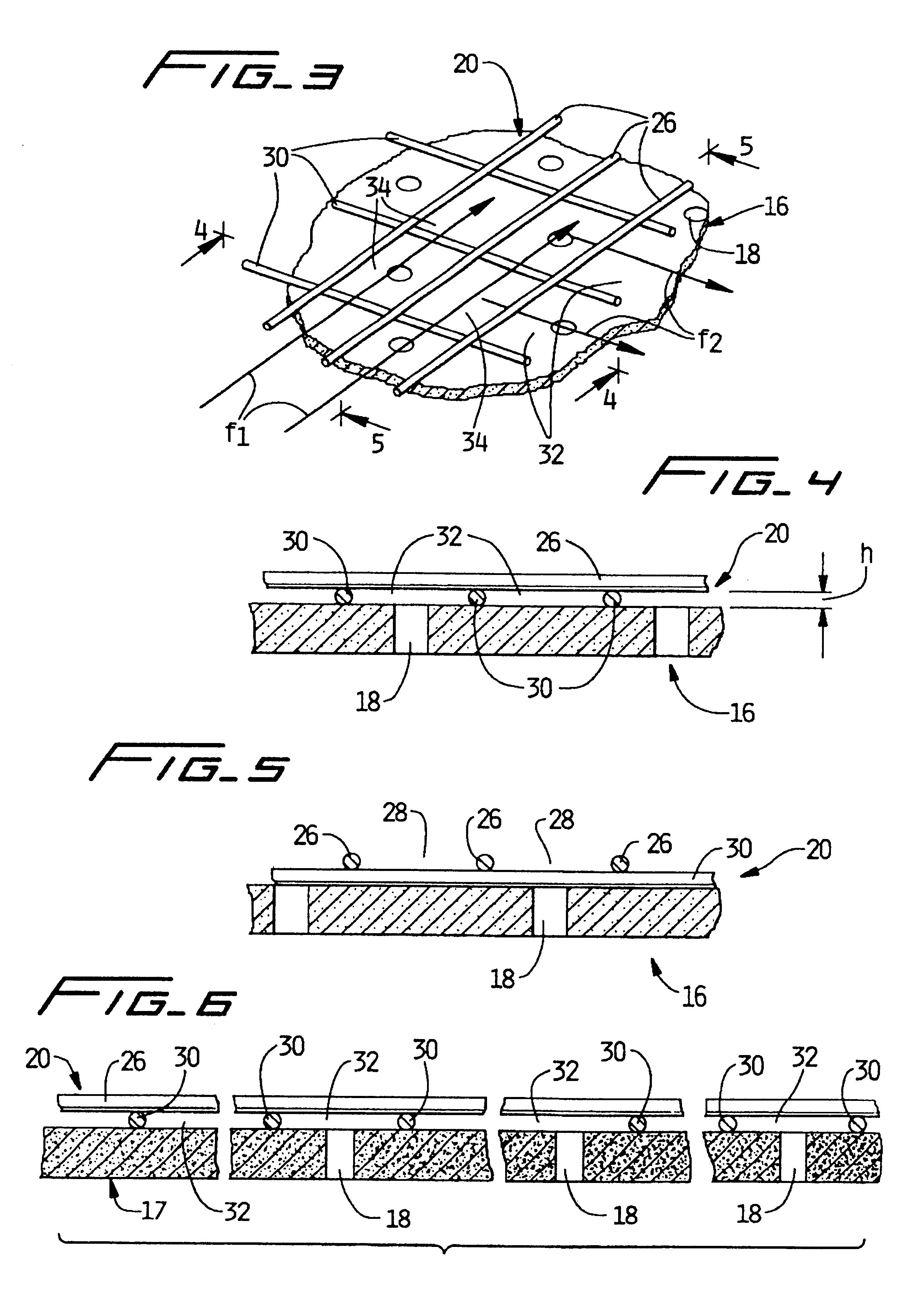

Filter and method of filtering a fluid

InactiveUS6391200B2Improve distributionProlong lifeCombination devicesSemi-permeable membranesFilter mediaSpiral wound

A spiral wound filter element is disclosed which includes alternating layers of filter medium and diffusion medium wrapped about a cylindrical core defining a central axis of the filter element. The alternating layers extend from a radially innermost layer of the filter element to a radially outermost layer of the filter element, the diffusion medium is defined by a continuous lengthwise sheet of mesh material, and the filter medium is defined by at least one sheet of filter material arranged along the length of the continuous sheet of mesh material. The alternating layers of filter medium and diffusion medium define three distinct radially disposed layered filtering sections surrounding the cylindrical core, and include a first filtering section having radially outer prequalifying layers, a second filtering section having middle prequalifying layers and a third filtering section having radially inner qualifying layers. The radially outer prequalifying layers and the middle prequalifying layers define about two-thirds of the radial distance from the radially outermost layer of the filter element to the radially innermost layer of the filter element.

Owner:3M INNOVATIVE PROPERTIES CO

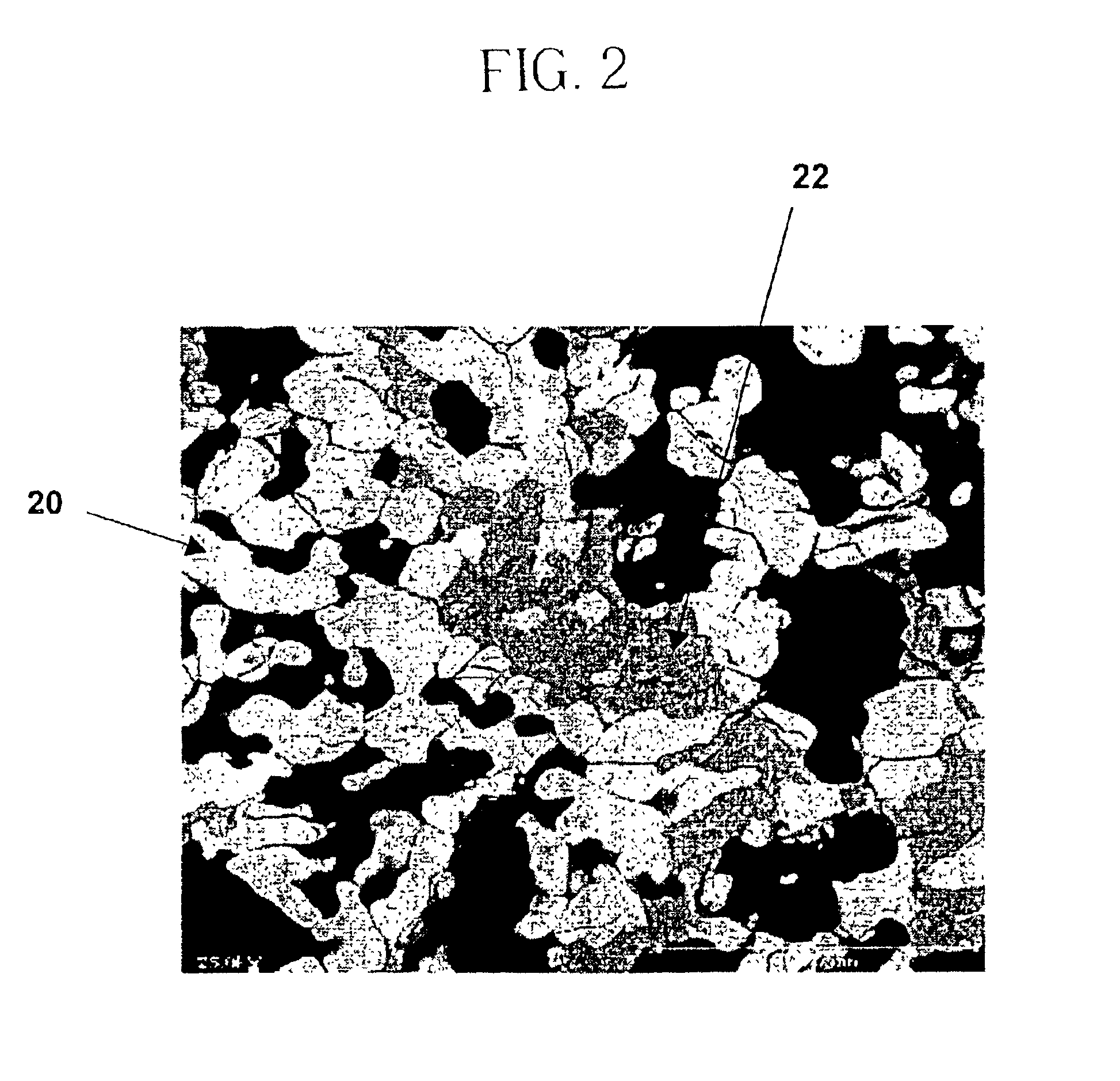

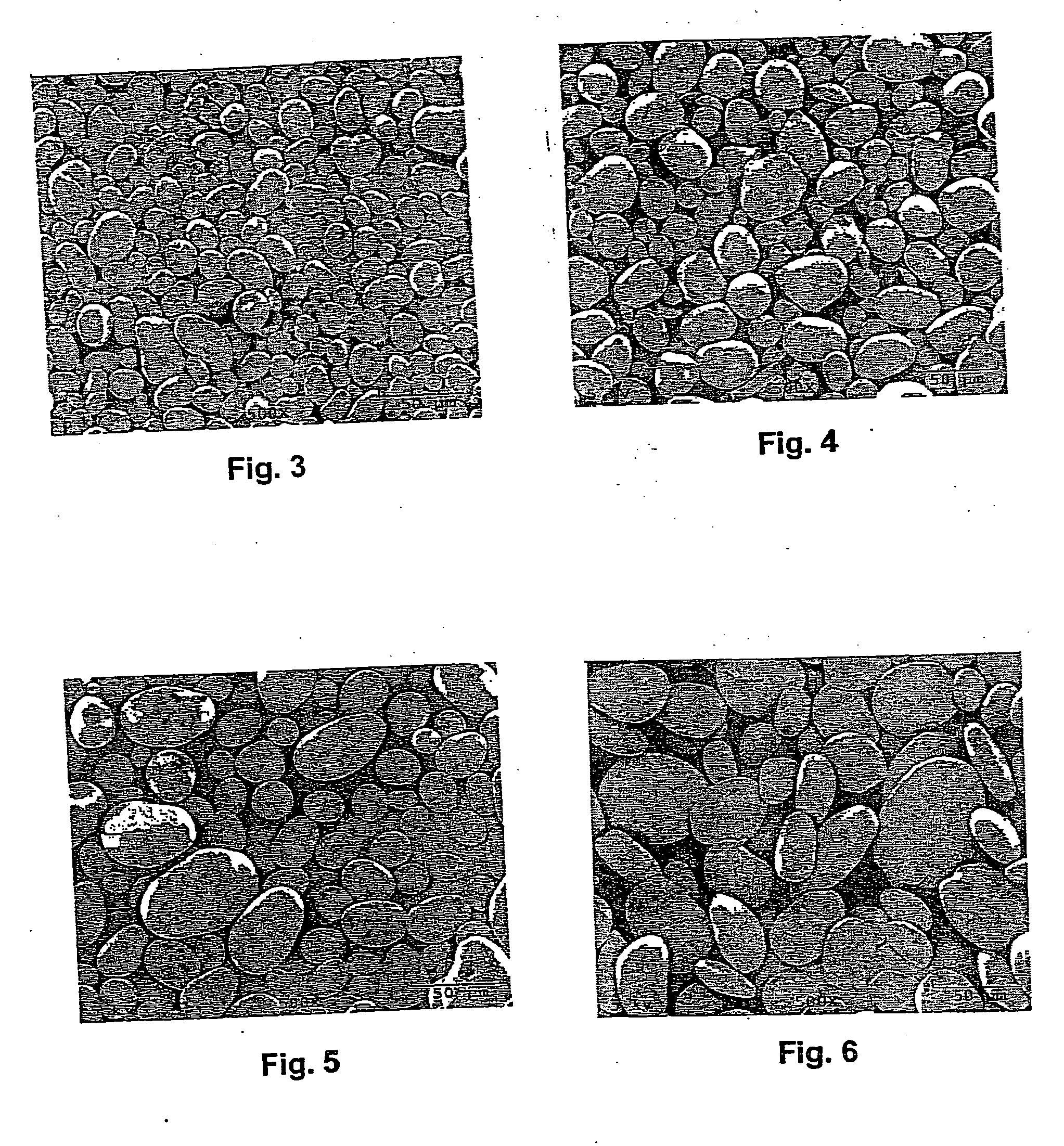

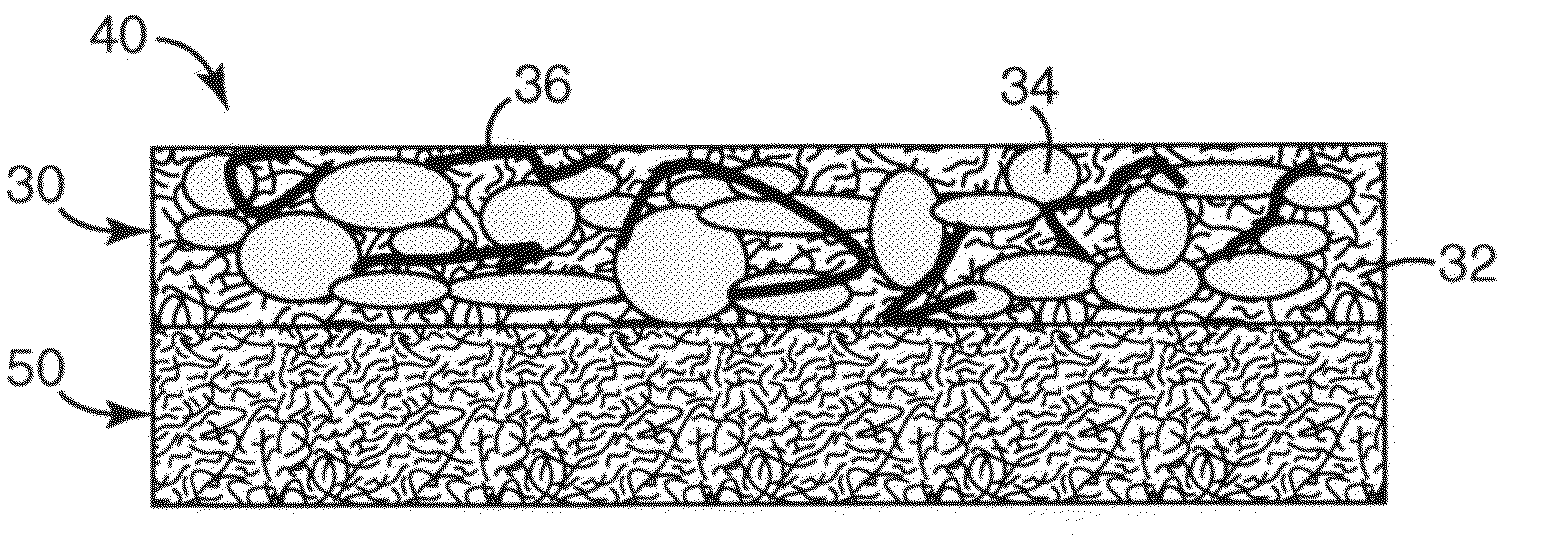

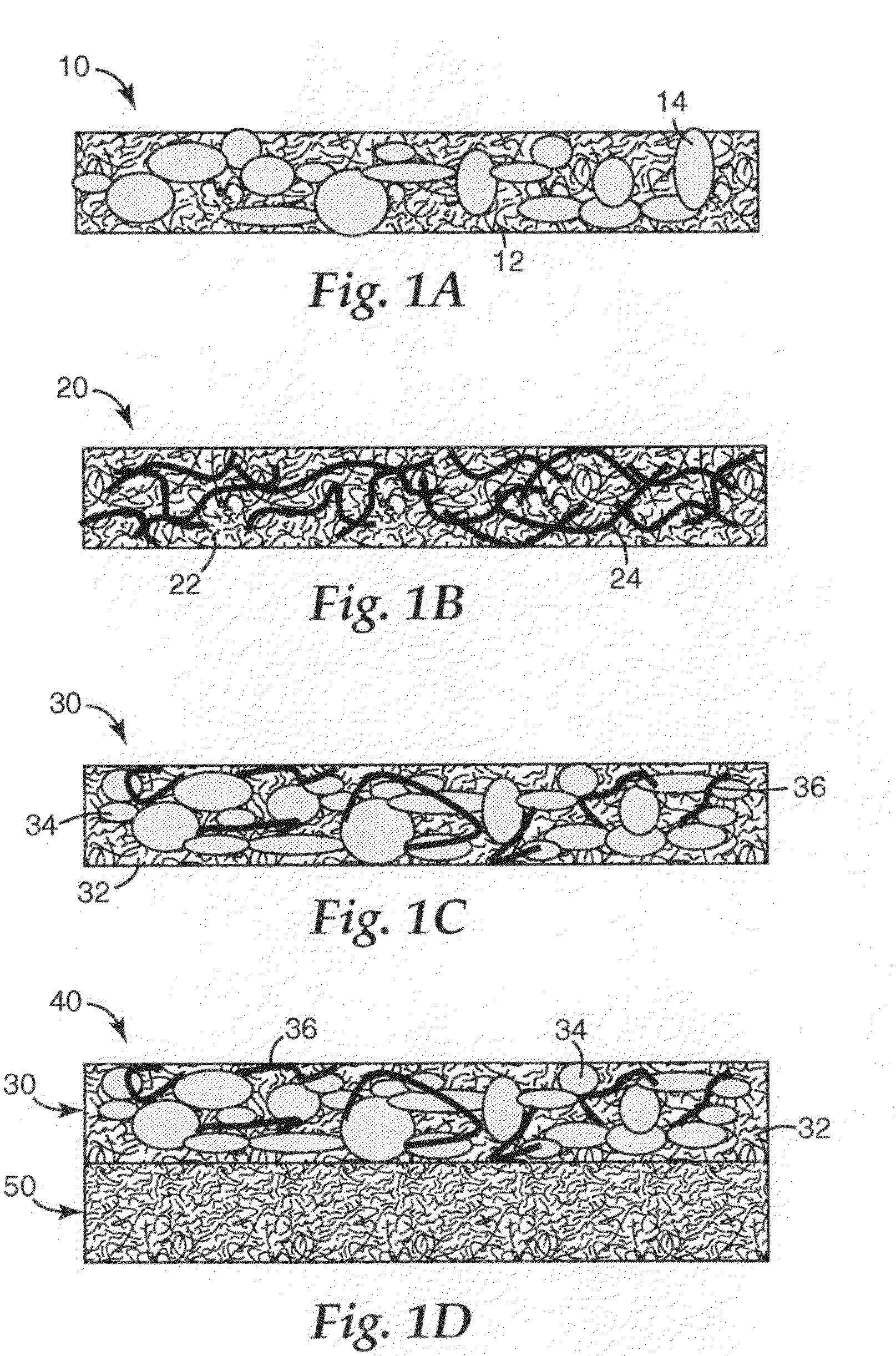

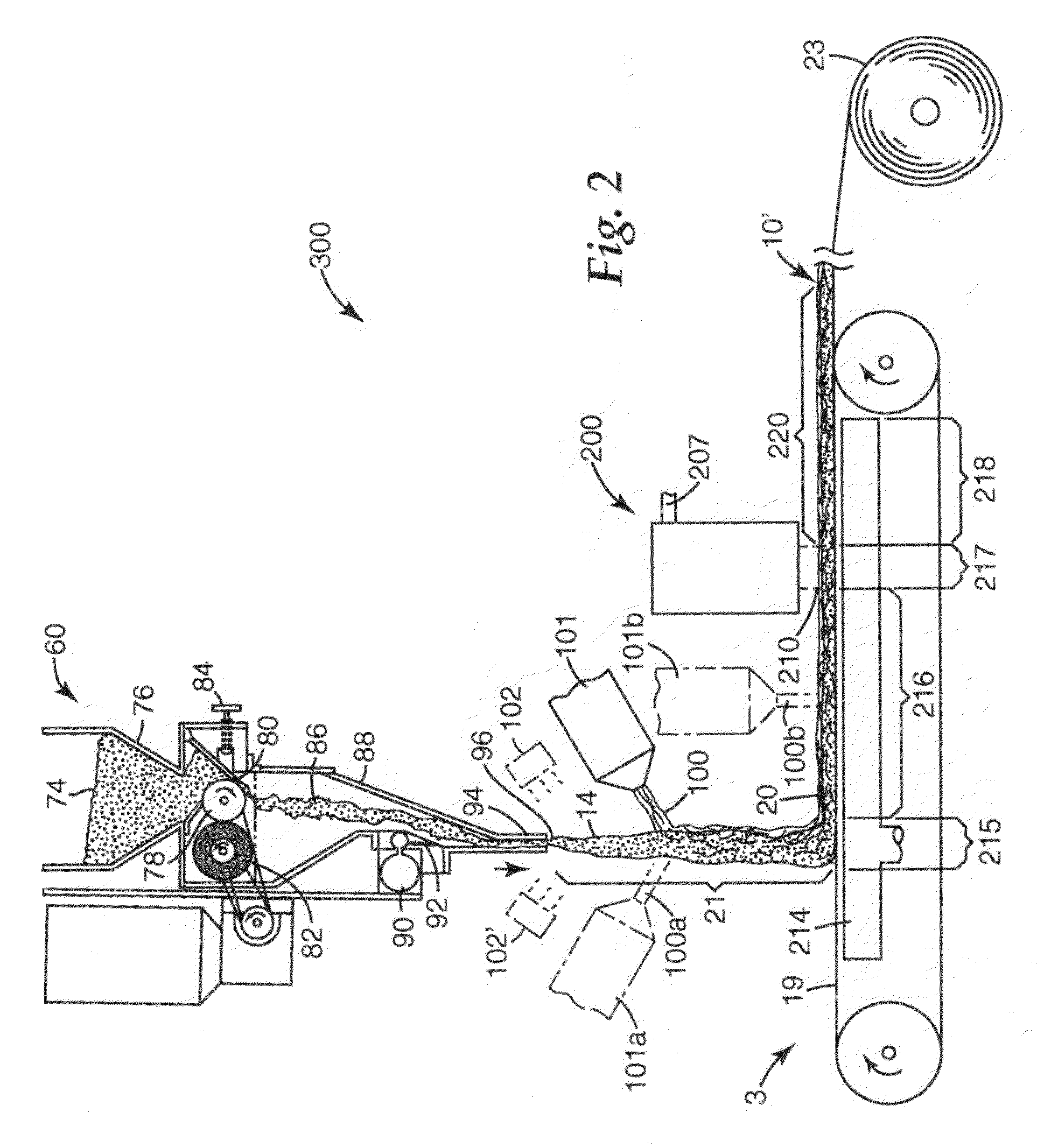

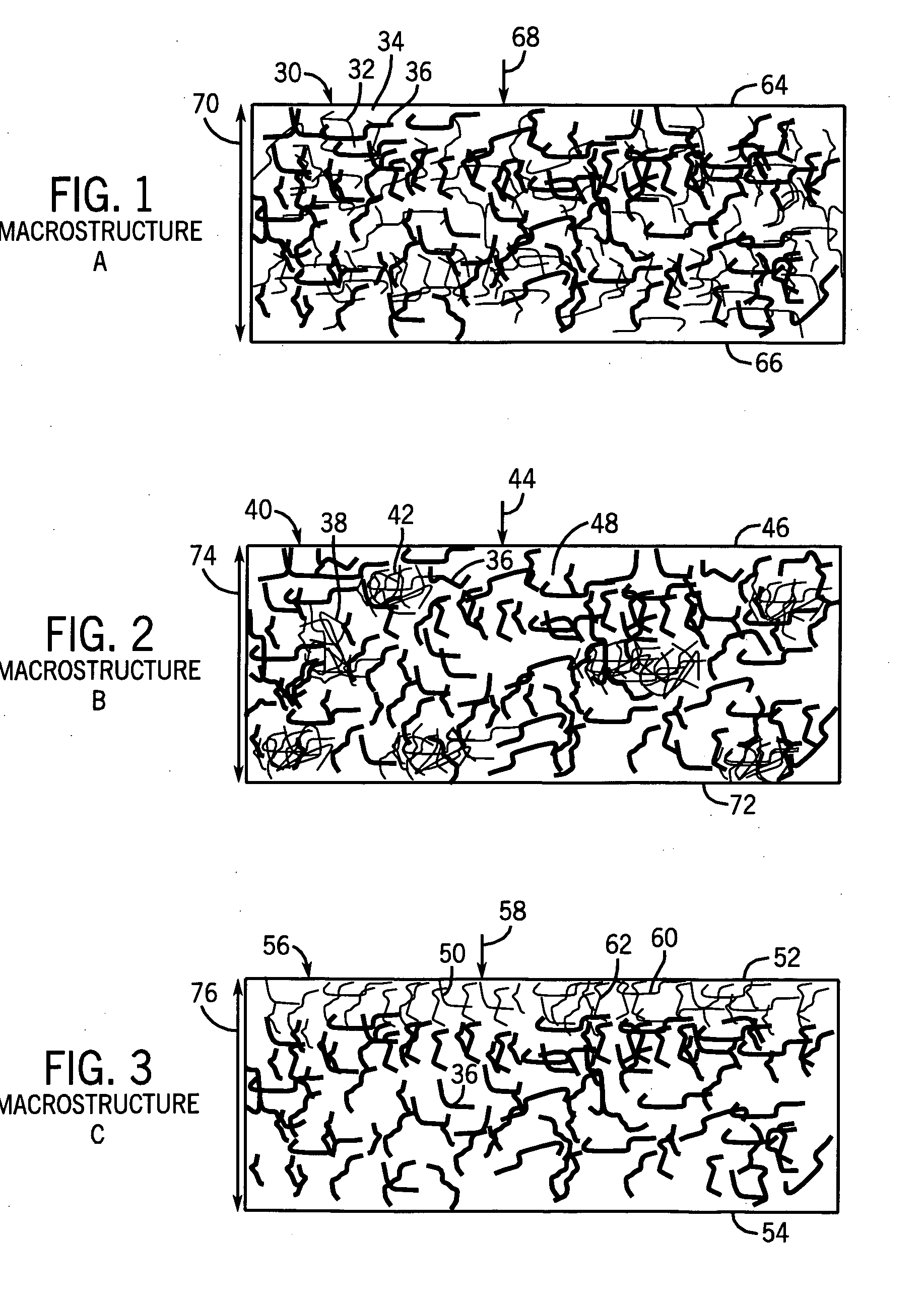

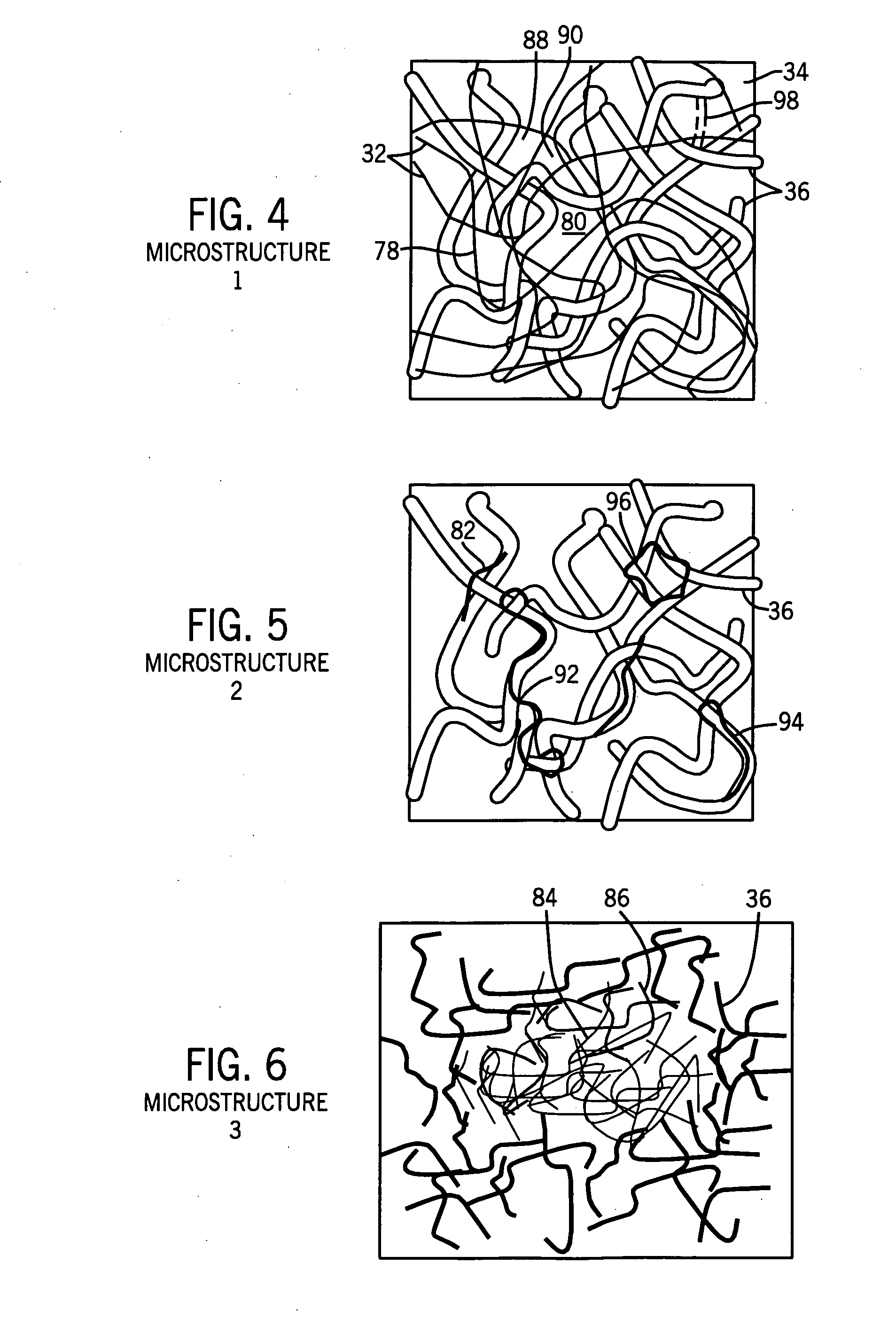

Composite non-woven fibrous webs having continuous particulate phase and methods of making and using the same

InactiveUS20100291213A1Prevent releaseImprove service life and filtration effectivenessPowder deliveryWarp knittingDrug deliveryPopulation

The disclosure relates to composite nonwoven fibrous web including an embedded phase having a population of particulates forming a substantially continuous three-dimensional network, and a matrix phase comprising a population of fibers forming a three-dimensional network around the particulates. The disclosure also relates to methods of making a composite nonwoven fibrous web including forming an embedded phase having a population of particulates in a substantially continuous three-dimensional network, and forming a matrix phase comprising a population of fibers forming a three-dimensional network around the particulates. Articles made from a composite nonwoven fibrous web prepared according to the methods as described above are also disclosed. In exemplary embodiments, the articles may include gas filtration articles, liquid filtration articles, sound absorption articles, surface cleaning articles, cellular growth support articles, drug delivery articles, personal hygiene articles, and wound dressing articles.

Owner:3M INNOVATIVE PROPERTIES CO

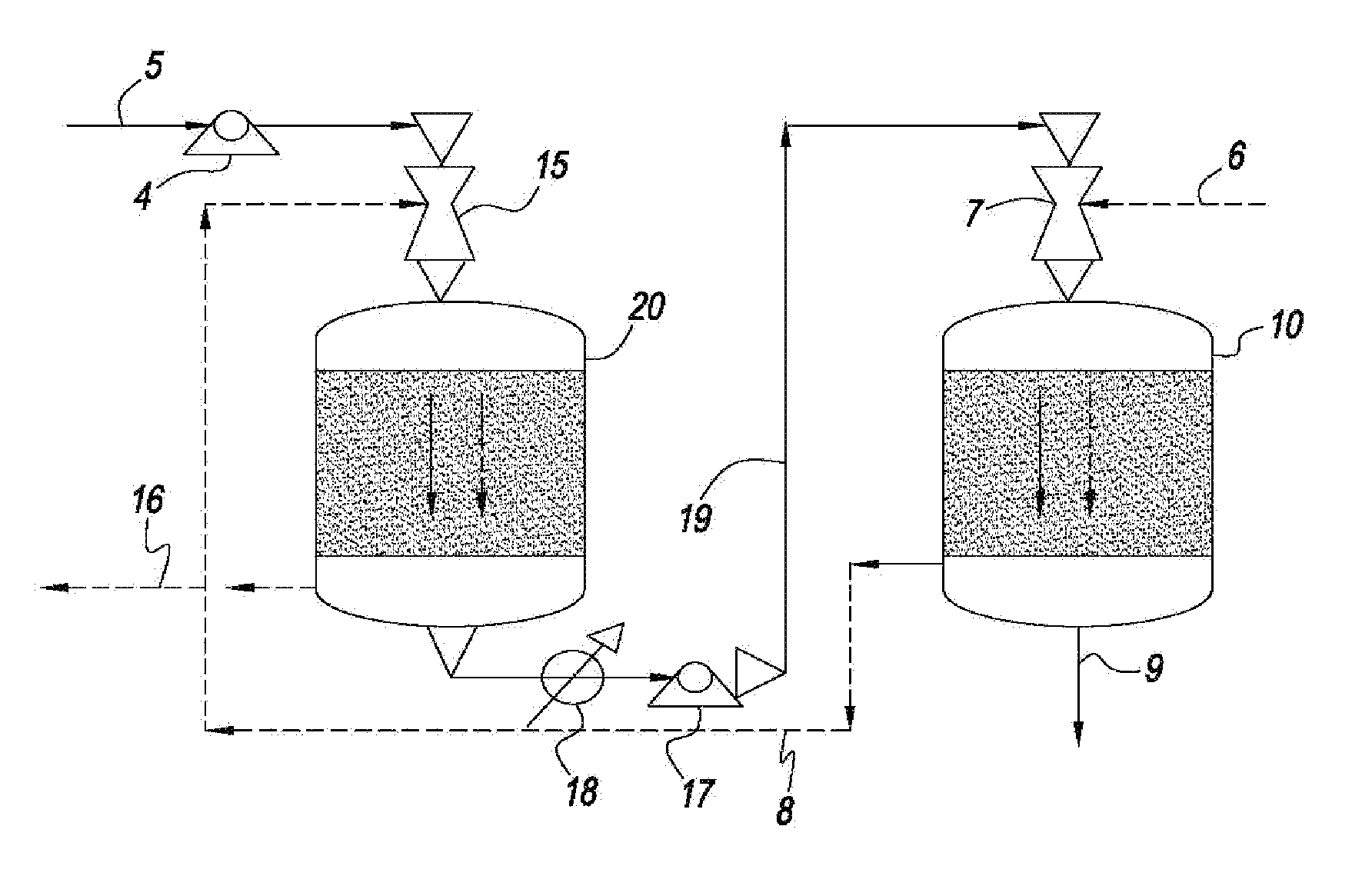

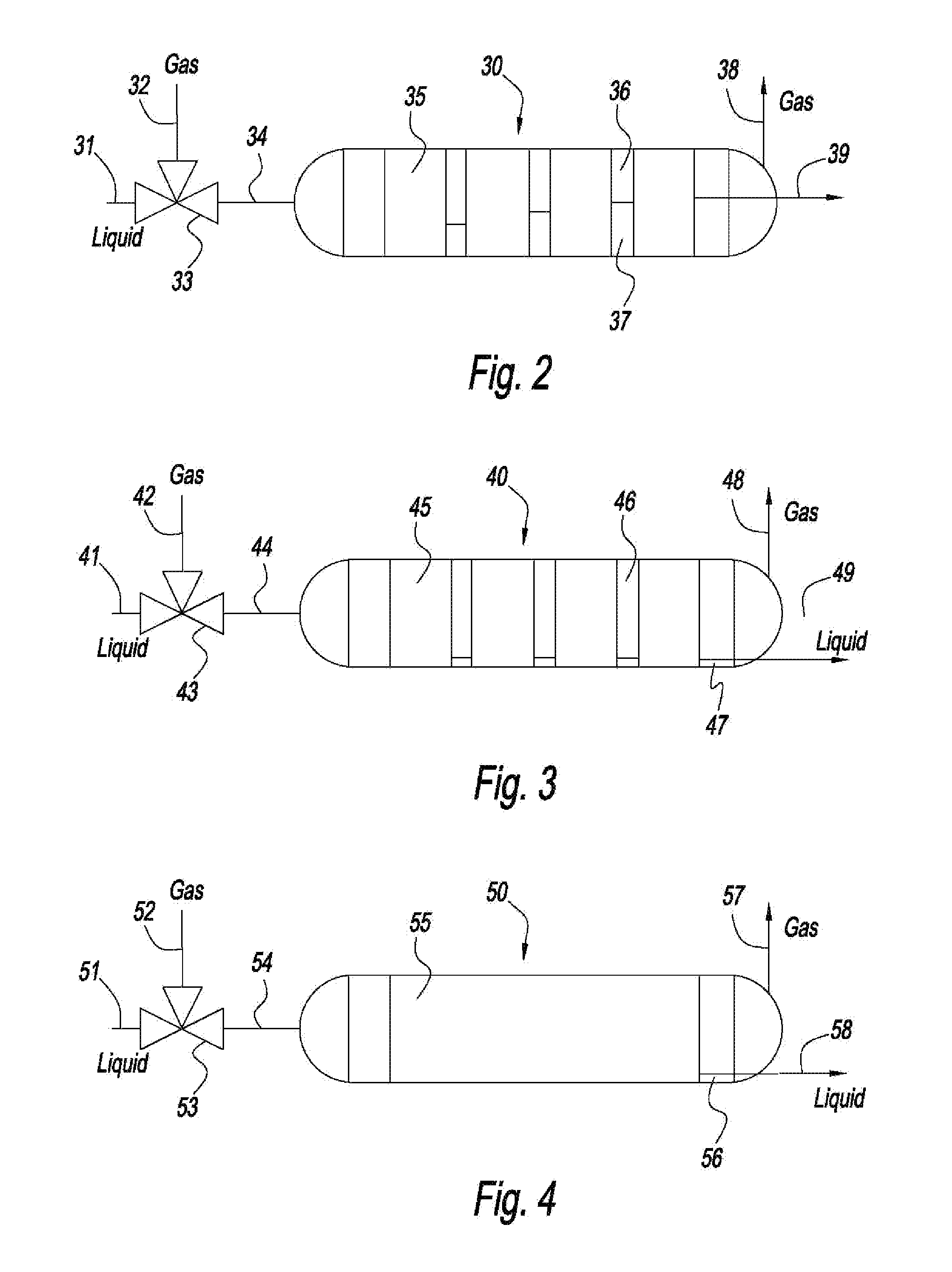

Systems and Methods for Acid Gas Removal

InactiveUS20110217218A1Reduce and eliminate needReduce investmentGas treatmentDispersed particle separationDesorptionProduct gas

A method and system for the selective removal of CO2 and / or H2S from a gaseous stream containing one or more acid gases. In particular, a system and method for separating CO2 and / or H2S from a gas mixture containing an acid gas using an absorbent solution and one or more ejector venturi nozzles in flow communication with one or more absorbent contactors. The method involves contacting a gas mixture containing at least one acid gas with the absorbent solution under conditions sufficient to cause absorption of at least a portion of said acid gas. The absorbent contactors operate in co-current flow and are arranged in a counter-current configuration to increase the driving force for mass transfer. Monoliths can be used that operate in a Taylor flow or slug flow regime. The absorbent solution is treated under conditions sufficient to cause desorption of at least a portion of the acid gas.

Owner:EXXON RES & ENG CO

High performance filter media with internal nanofiber structure and manufacturing methodology

ActiveUS20070021021A1Improve performanceImprove efficiencyOther chemical processesIndividual molecule manipulationFiberFilter media

High performance filter media and manufacturing methodology provides nanofibers of diameter less than 1 μm incorporated and processed into internal structure of a filter medium dominantly composed of coarse fibers of diameter greater than 1 μm, to change the internal media structure.

Owner:FLEETGUARD INC

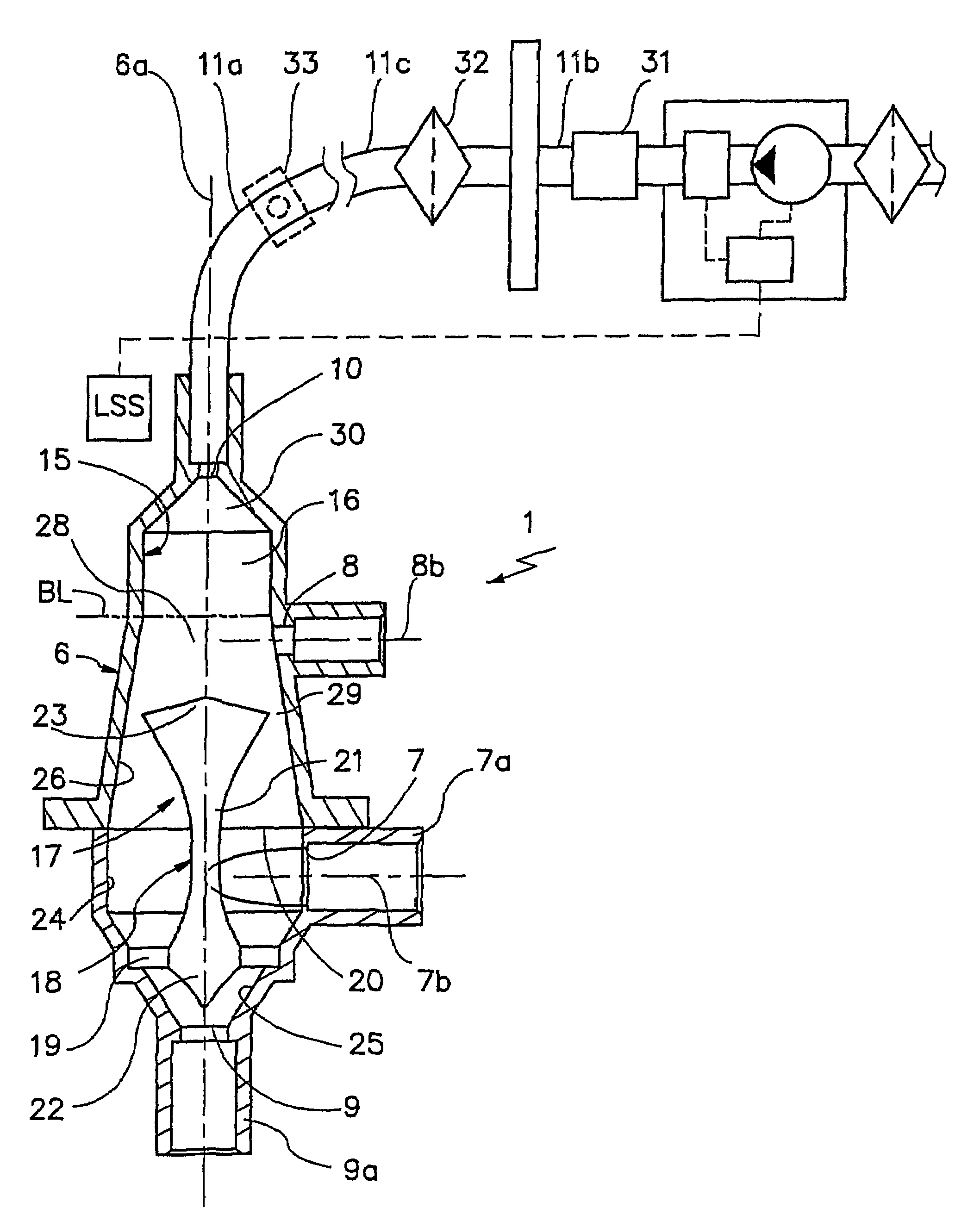

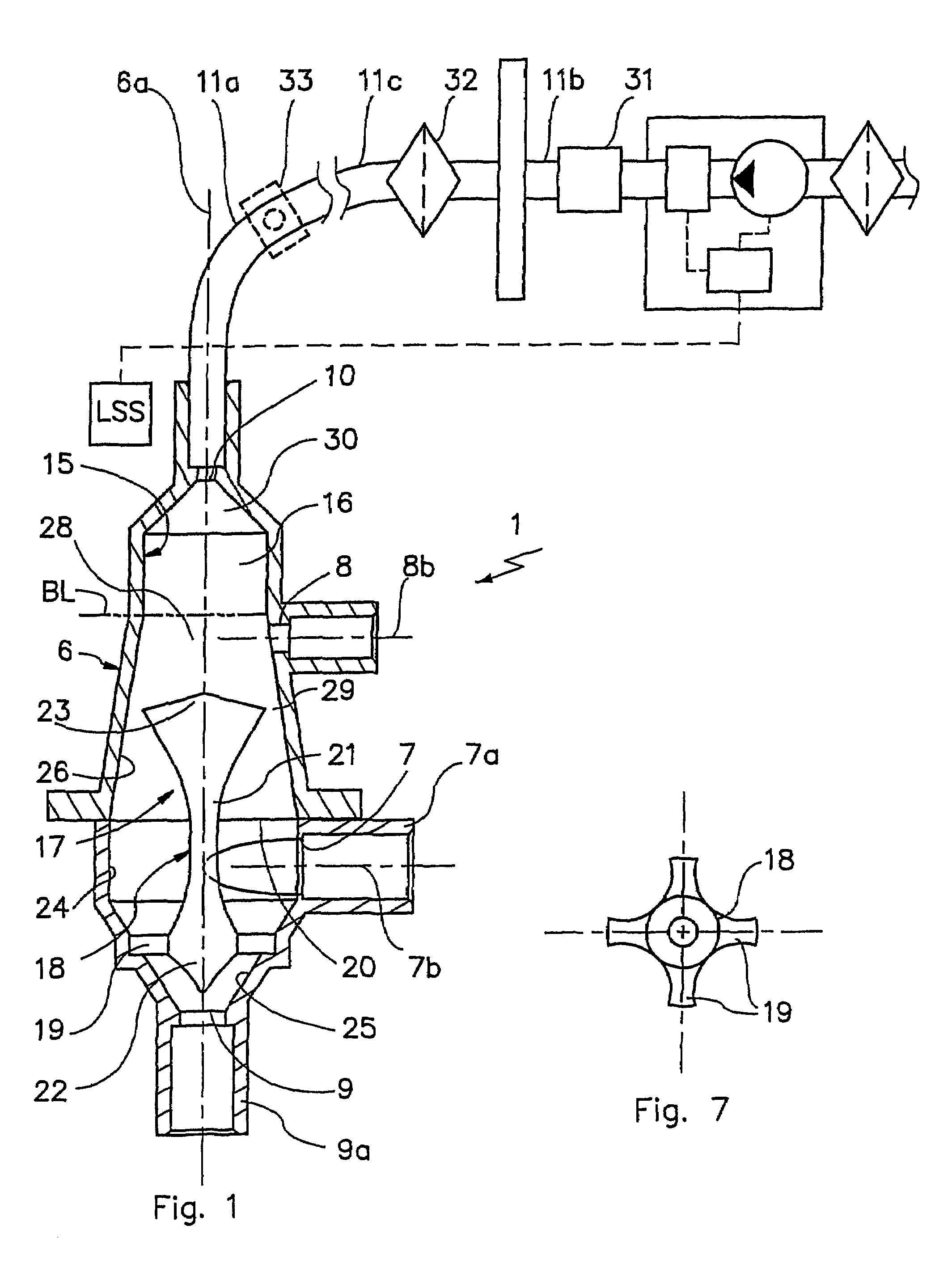

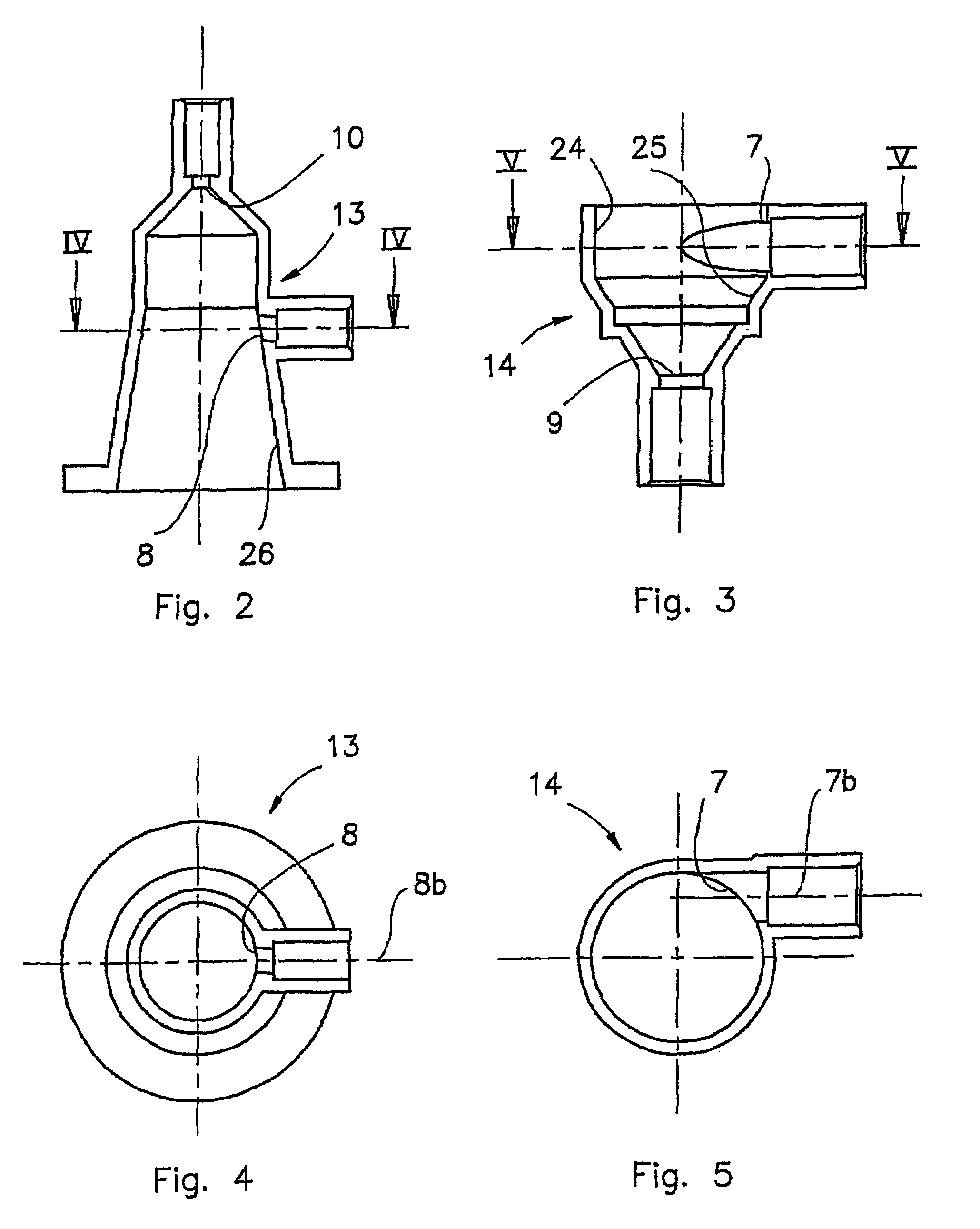

Gas separation devices

ActiveUS7517387B2Minimized volumeEasy to operateLiquid degasificationReversed direction vortexPhysiological fluidEffective surface

A description is given of a gas separation device for a physiological fluid, comprising a containing body (6) having at least a first inlet aperture (7) for a physiological fluid, positioned with a tangential direction of access, at least one outlet aperture (9) for the said fluid, spaced apart from the said inlet aperture, and a guide element (17) housed within the said body. The guide element (17) has a continuous active surface (15) designed to contact and guide the said fluid and delimits, together with the containing body (6), a first annular chamber (20) into which the first inlet aperture (7) opens directly.

Owner:GAMBRO LUNDIA AB

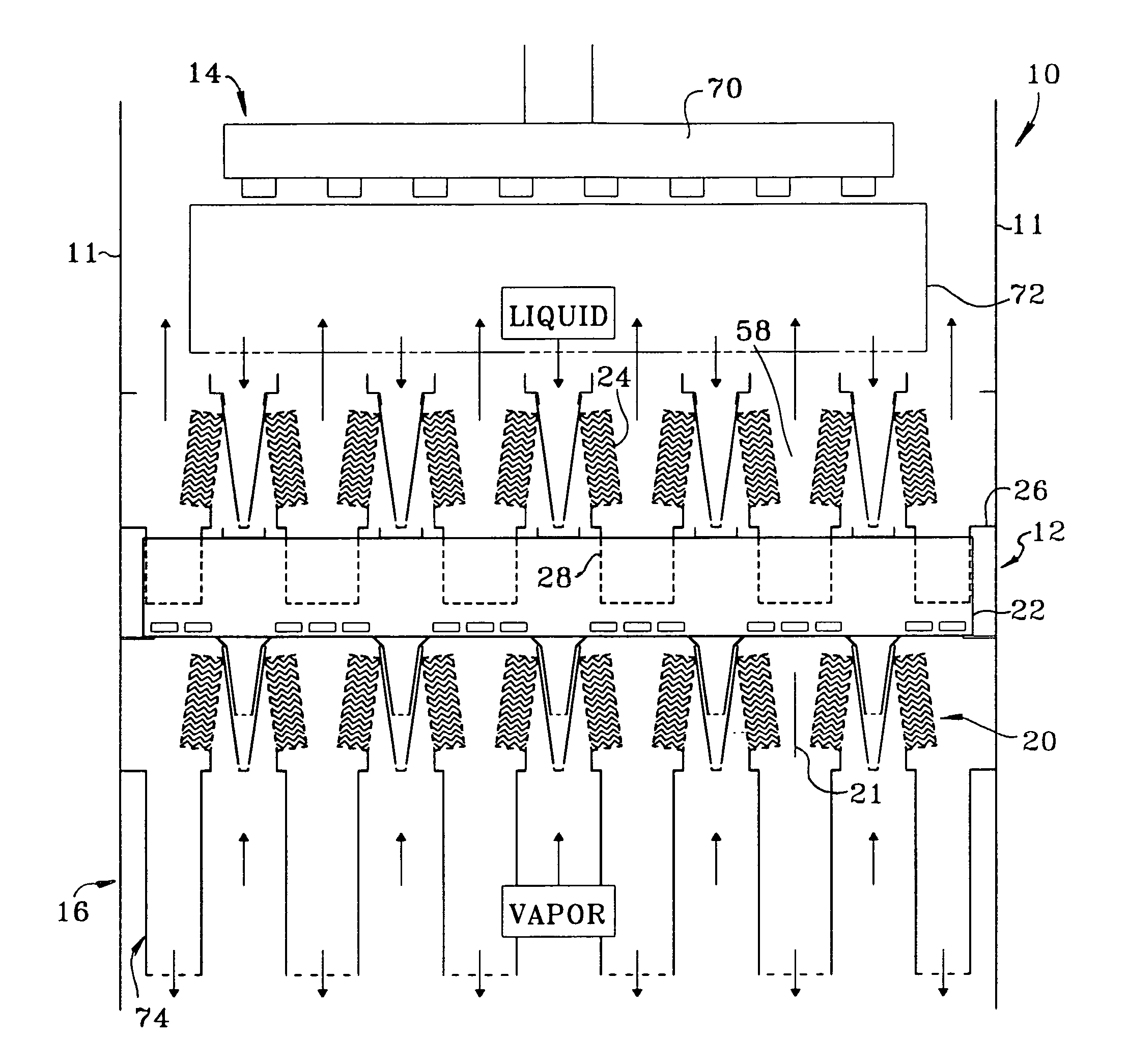

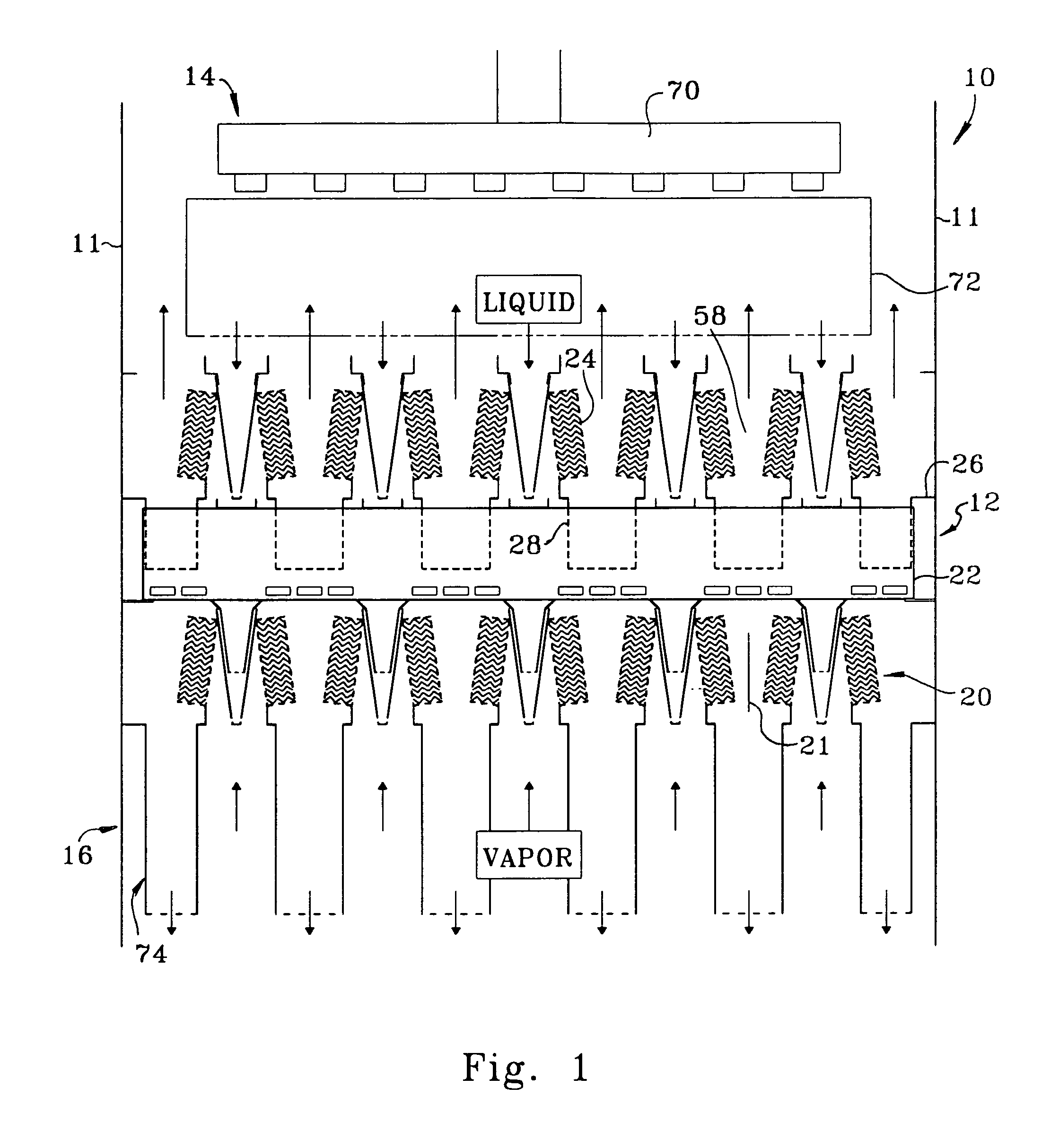

Co-current vapor-liquid contacting apparatus

ActiveUS7424999B2Easily redistributedIncrease capacityCombination devicesLiquid degasificationVapor liquidFractionating column

Owner:UOP LLC

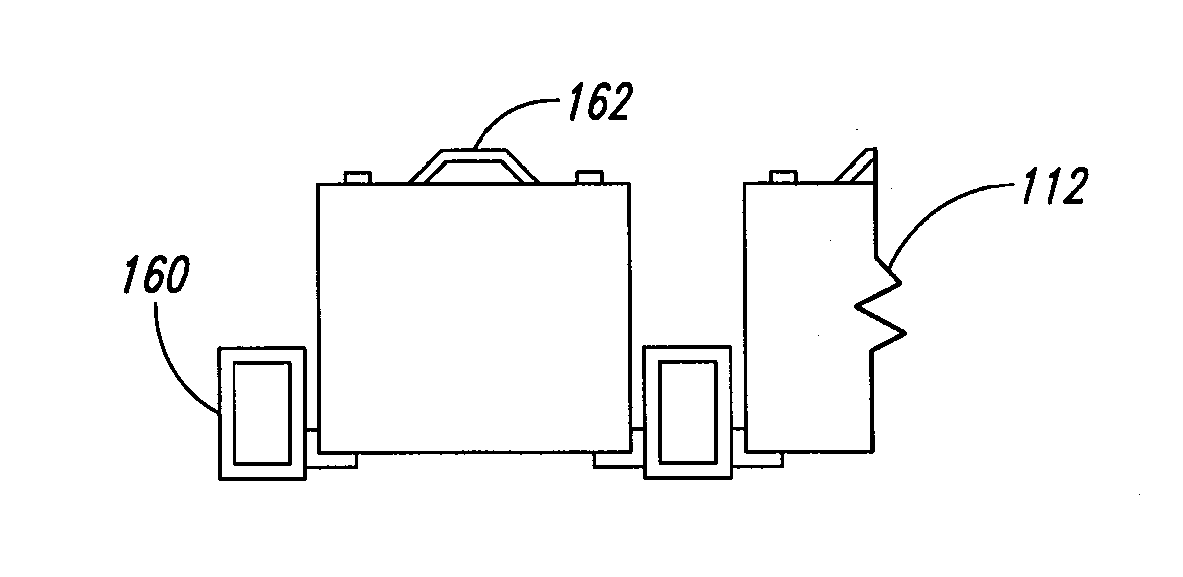

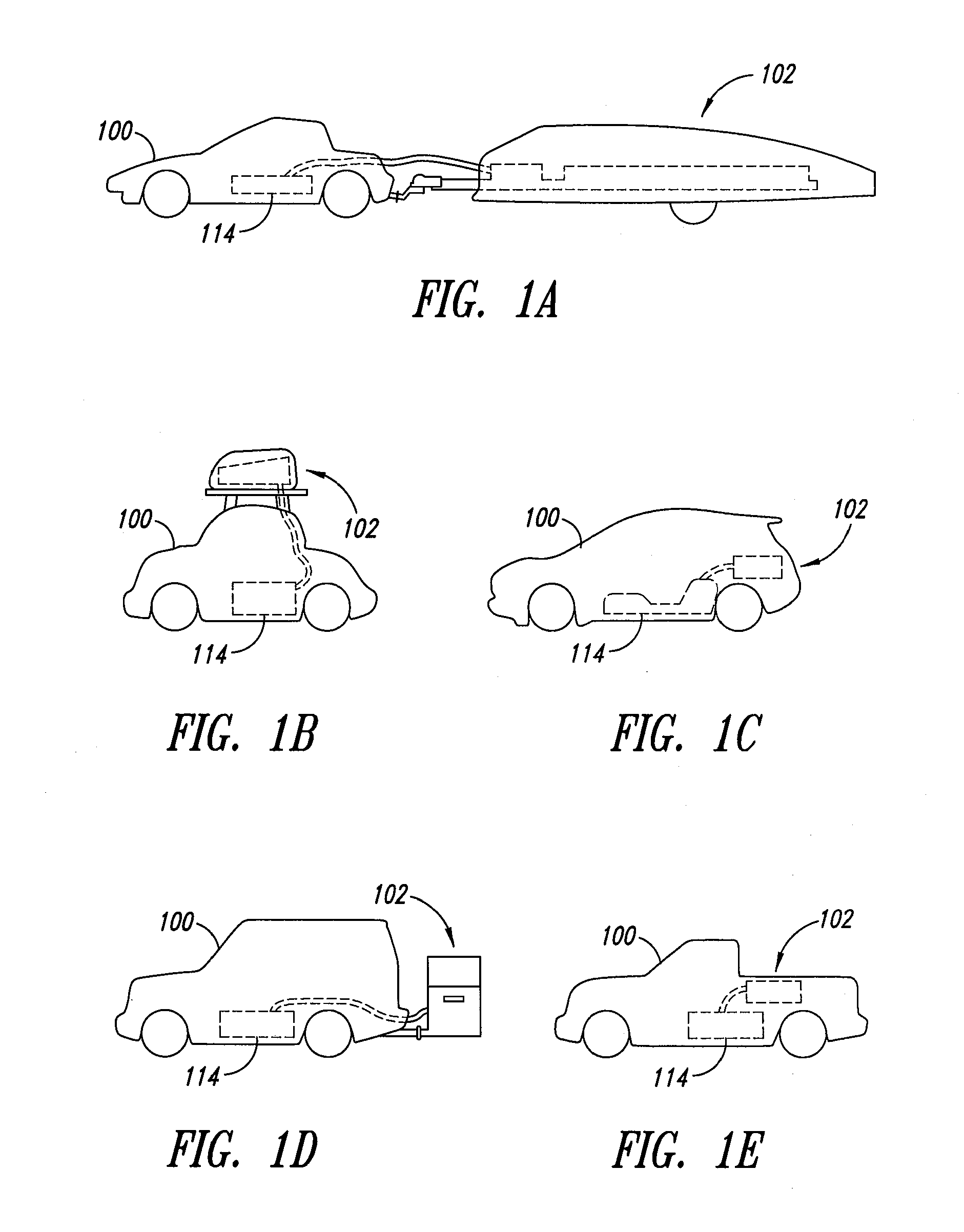

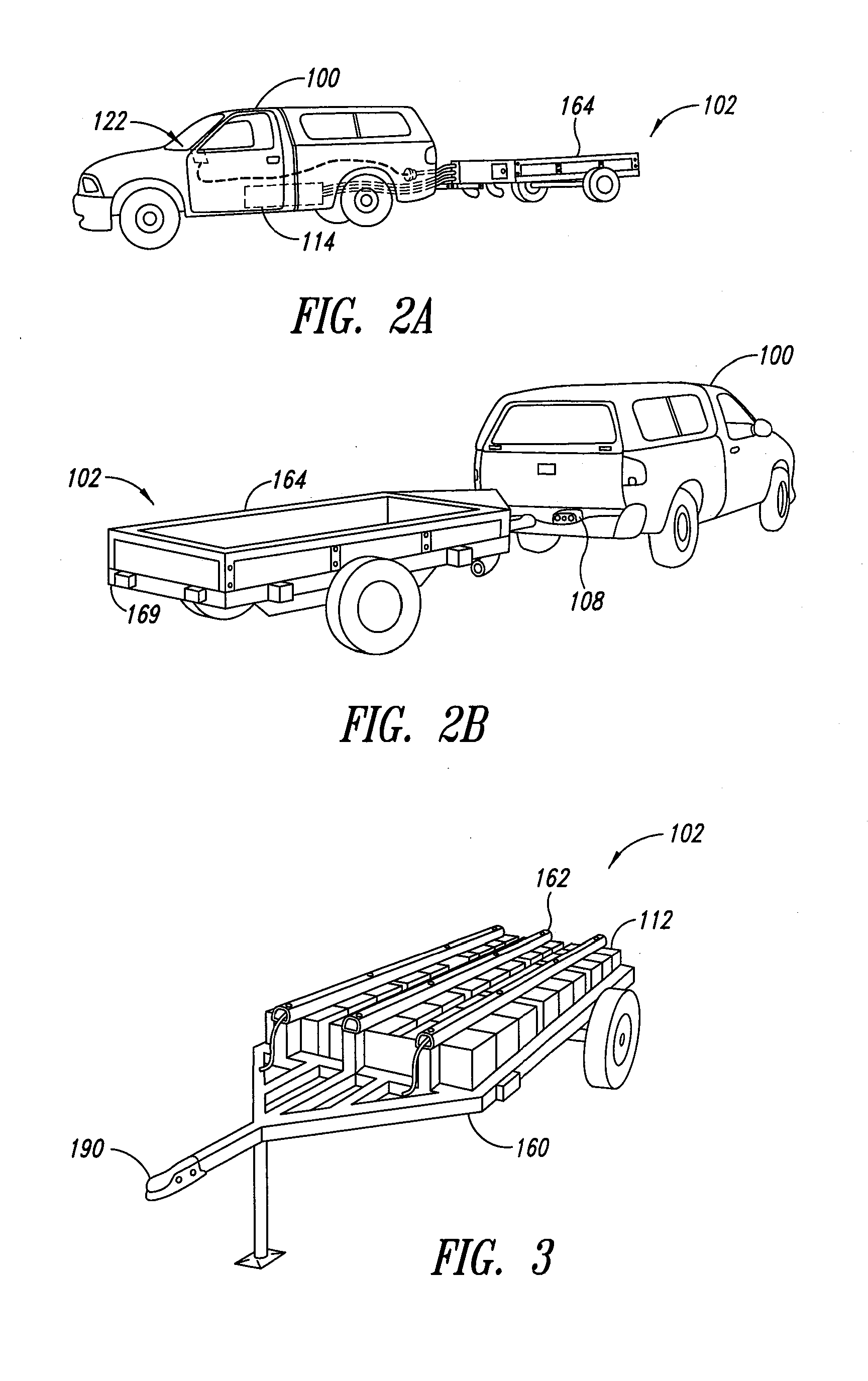

Mobile variable power system and method

ActiveUS20140375272A1Improve performanceExtend range of useRailway vehiclesPropulsion by batteries/cellsElectrical batteryAutomotive engineering

A mobile energy storage apparatus comprised of: a. at least one variable energy control device which converts DC to DC, AC to DC and DC to AC and b. at least one energy storage device (such as a battery) and c. a means to adjust said at least one variable energy control device to various electrical output powers and d. a means to connect said mobile energy storage apparatus to an EV (electric vehicle) or other device electrically and mechanically to enable transferring energy even when in motion and e. optionally a means for attaching various covers to said mobile energy storage apparatus to suit various applications. The mobile energy storage apparatus allows the transfer of energy to or from: an EV, a building or any other electrical facility or device and can be configured with built-in or attached to various power sources.

Owner:JOHNSEN STEPHEN G +3

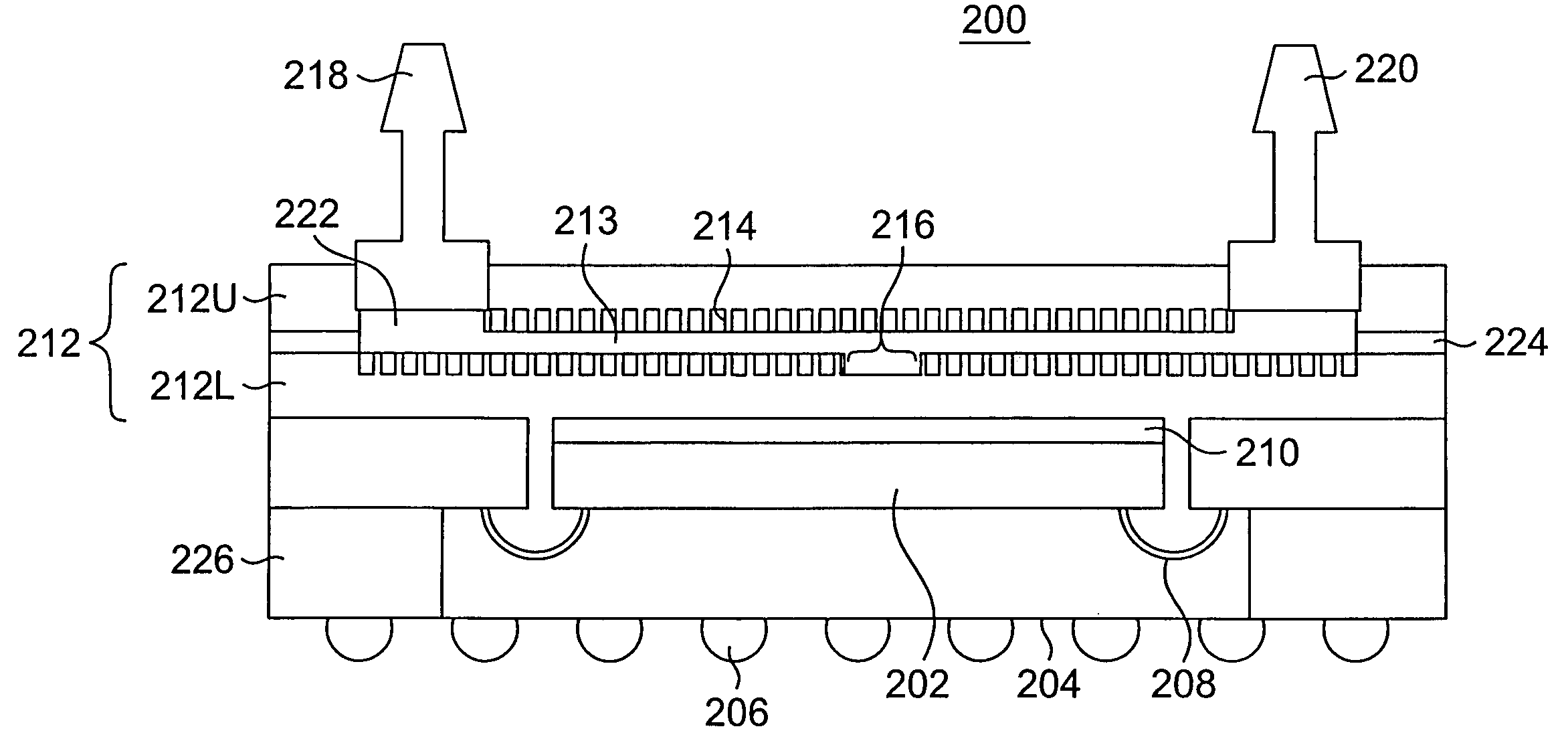

Techniques for microchannel cooling

ActiveUS7204298B2Lower overall pressure dropEffective regulationSemiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer fluid

Owner:LUCENT TECH INC

High efficiency active electrostatic air filter and method of manufacture

InactiveUS6514324B1Improve efficiencyLower overall flow resistanceCombination devicesMechanical apparatusAir filterCharge control

A washable air filter for removing particles from the inlet air to a heating and / or air conditioning system formed of an assembly of a central polymeric pad containing actively charged charge control agents of a first polarity, a polymeric net containing a dispersion of charged charge control agents of a second polarity in the polymer on each side of the pad and a stiff, deformable metal or plastic grill on each side of the net to form an assembly which can be corrugated and placed in a perimeter frame. The charging is preferably accomplished as the assembly passes over the surface of a roller with a conductive surface.

Owner:CHAPMAN RICK L

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com