Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

60results about How to "Normal delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

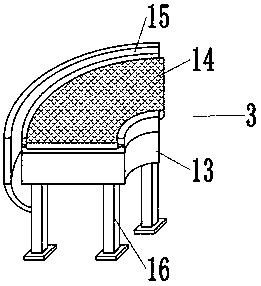

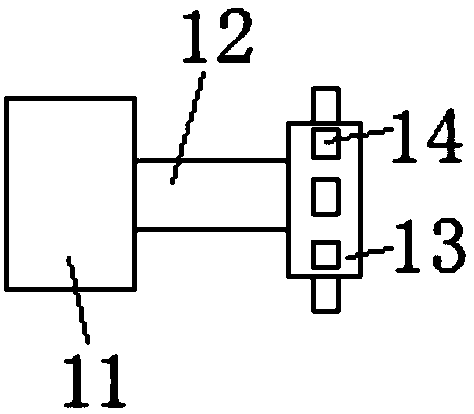

Indexing and subpackaging mechanism used for standard fastening part detection

InactiveCN107176421AThe working process is simple and fastHigh degree of automationControl devices for conveyorsOptically investigating flaws/contaminationCcd cameraComputer science

The invention discloses an indexing and subcontracting mechanism for standard fastener detection. An indexing turntable is arranged above a machine table (5), and a first CCD camera is arranged above the edge of the indexing turntable ( 6), the second CCD camera (7) and the third CCD camera (8) are set next to the indexing turntable, and there is an anti-falling baffle (9) around the periphery of the indexing turntable. A slideway (10) is also provided next to it, and the outlet end of the slideway (10) is bifurcated to form a first distribution channel (10a) and a second distribution channel (10b). There is a first parts box (16), and a parts wrapper (17) with a counter is arranged beside the first parts box (16). The invention can be used to detect various standard fasteners, and can automatically sort and pack parts by category through a sorting and packaging mechanism while preventing the standard fasteners from falling off.

Owner:肇庆市端州区麒诺机械科技有限公司

Communication interface and information transfer method and system based on the same

InactiveCN105282803ANormal deliveryTransmissionWireless communicationCommunication interfaceClient-side

The invention discloses a communication interface. The communication interface is arranged between a controller and a service gateway and a packet data gateway. The communication interface uses the controller as a client side, and uses the service gateway and the packet data gateway as a server side, and is used for communication between the controller and the service gateway and the packet data gateway. The invention also discloses an information transfer method and system based on the communication interface. The information transfer method and system based on the communication interface realizes sending of information that is operated (modified or created) to the service gateway and the packet data gateway when the controller modifies or creates a message as a client side in an SDN-EPS network scene, so as to realize updating of the message to each part of a network, thereby ensuring normal transmission of data.

Owner:ZTE CORP

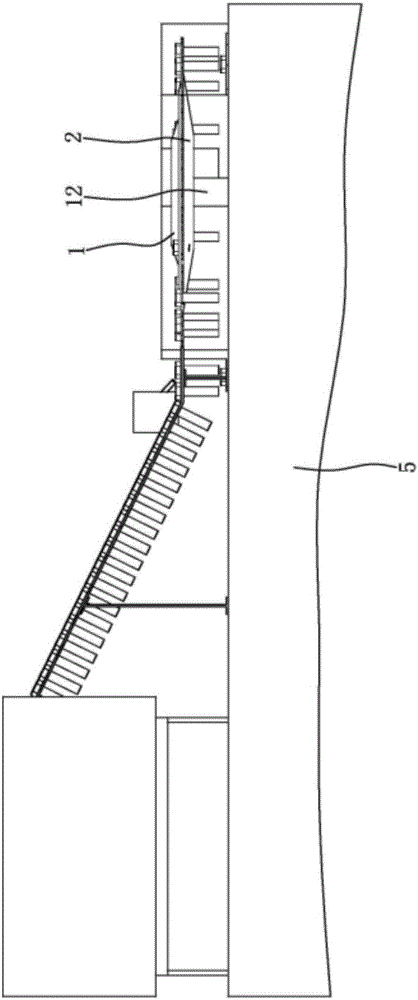

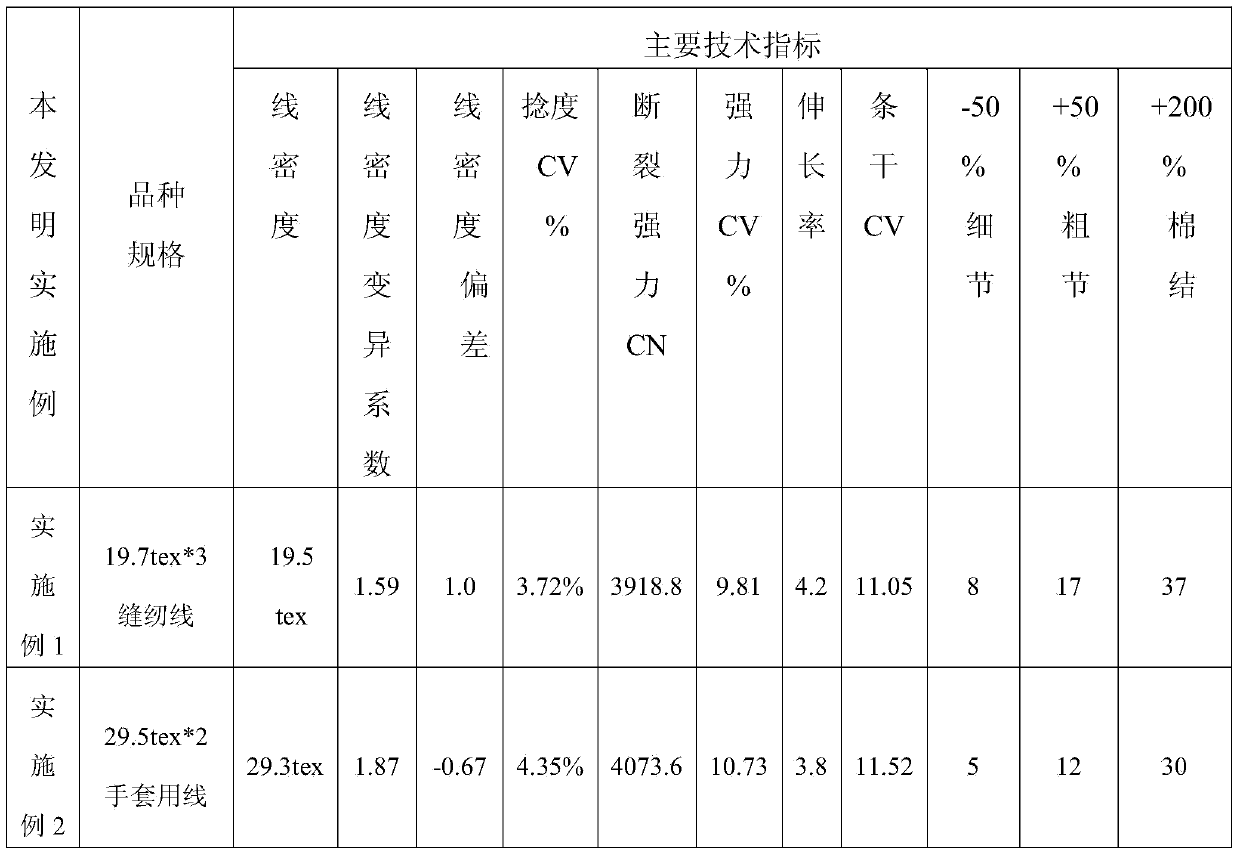

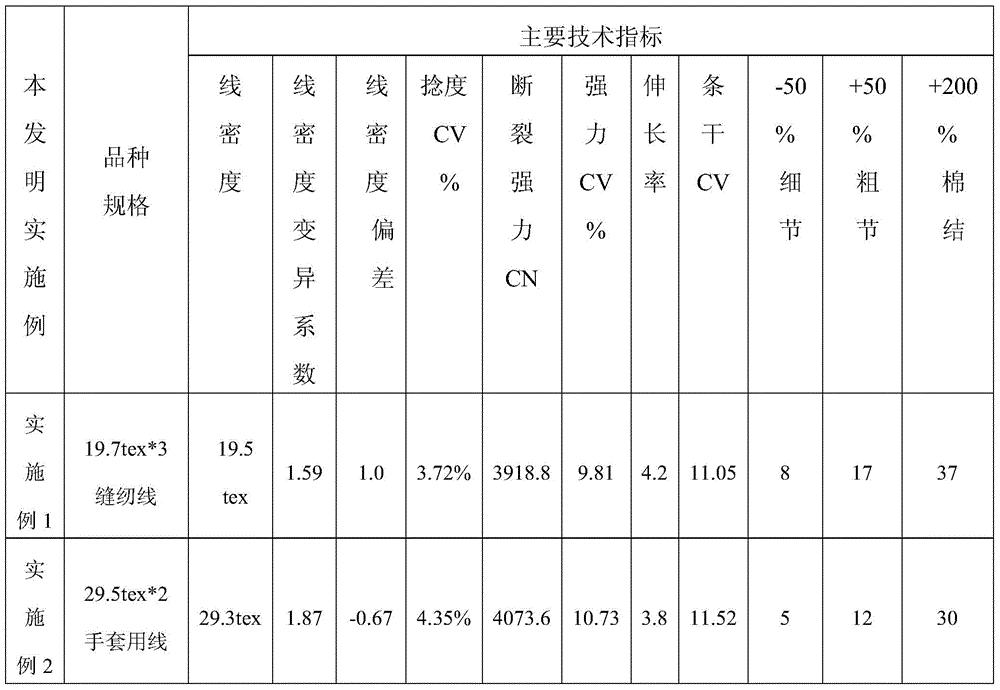

Method for manufacturing yarns with aramid fiber 1414 waste silk short fibers

The invention relates to the technical field of spinning, dyeing and finishing, and discloses a method for manufacturing aramid fiber yarns with aramid fiber 1414 waste silk short fibers. According to the characteristics of aramid fiber 1414 waste silks, on the basis of the traditional work flow, a set of suitable spinning technologies are provided through control over the fiber moisture regain, control over temperature and humidity of each spinning working procedure, allocation of card clothing of a carding machine, control over the speed of a drawing frame and allocation of the hardness of a rubber covered roller. The method can effectively improve the spinning performance of the aramid fiber 1414 waste silk short fibers, and the spinning quality of the aramid fiber 1414 waste silk short fibers can be guaranteed.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

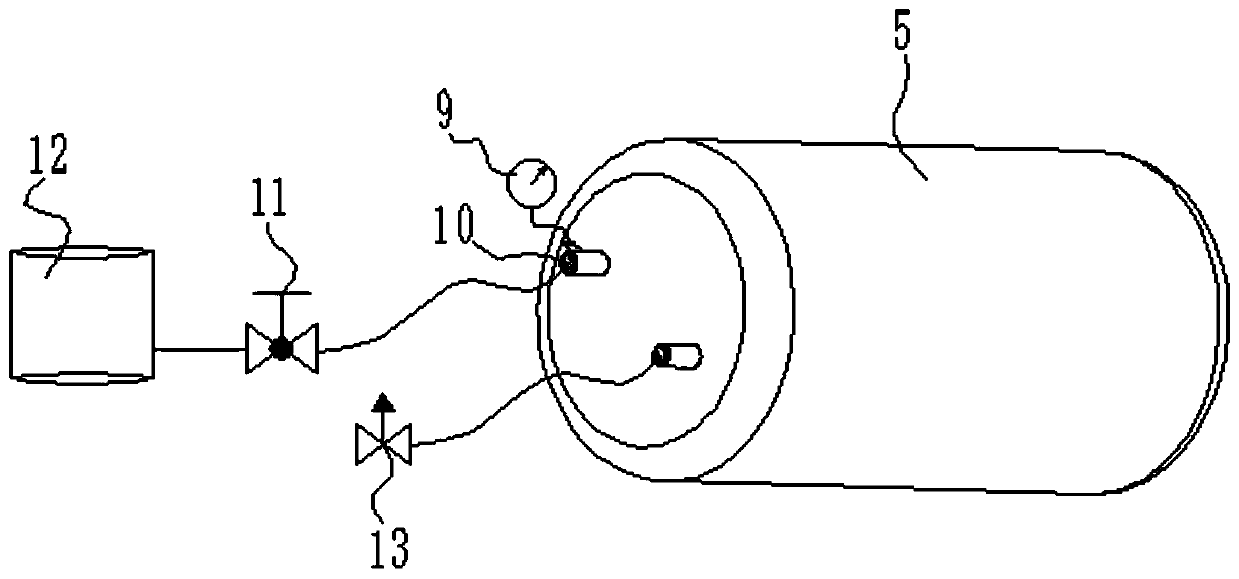

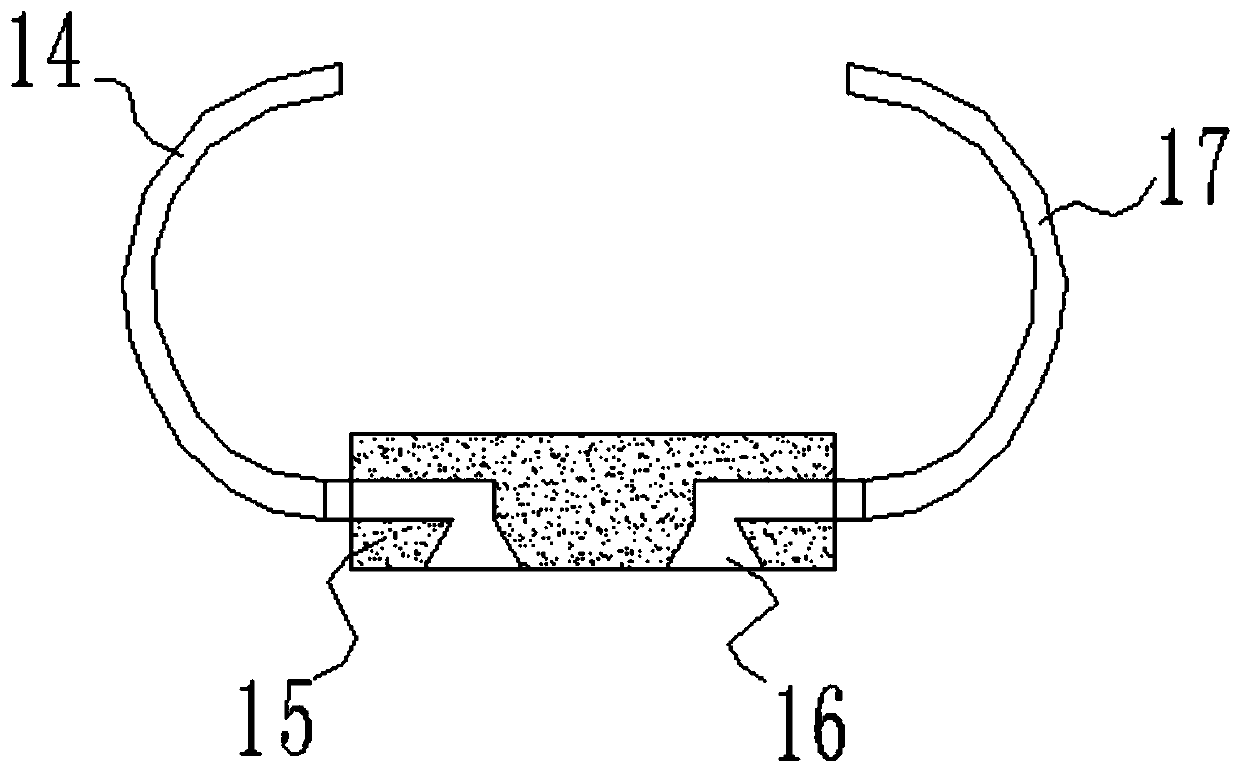

Method for maintaining and replacing natural gas pipeline

InactiveCN110067910ANormal deliveryReduce the amount of nitrogenPipe elementsNon-disconnectible pipe-jointsEngineeringProcess engineering

The invention discloses a method for maintaining and replacing a natural gas pipeline. The method comprises the following steps of step 1, closing an upstream clamping plate valve and a downstream clamping plate valve of an accident section and emptying; step 2, connecting a bypass pipeline; step 3, welding an open hole for short connection; step 4, downwards putting a first layer of isolating bag; step 5, downwards putting a rectangular ventilator; step 6, sealing the open hole; step 7, downwards putting a second layer of isolating bag; step 8, downwards putting a rectangular ventilator; step9, cutting the pipeline; and step 10, taking out the isolating bags and welding to replace the pipeline. According to the method, the first isolating bag and the second isolating bag are arranged toblock the natural gas in the upstream and downstream pipelines of the accident section, so that the blocking property is improved, the safe pipeline replacement and maintenance operation of the accident section can be guaranteed, the liquid nitrogen consumption can be greatly reduced, the normal transmission of the natural gas is guaranteed, and the production operation is not affected.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

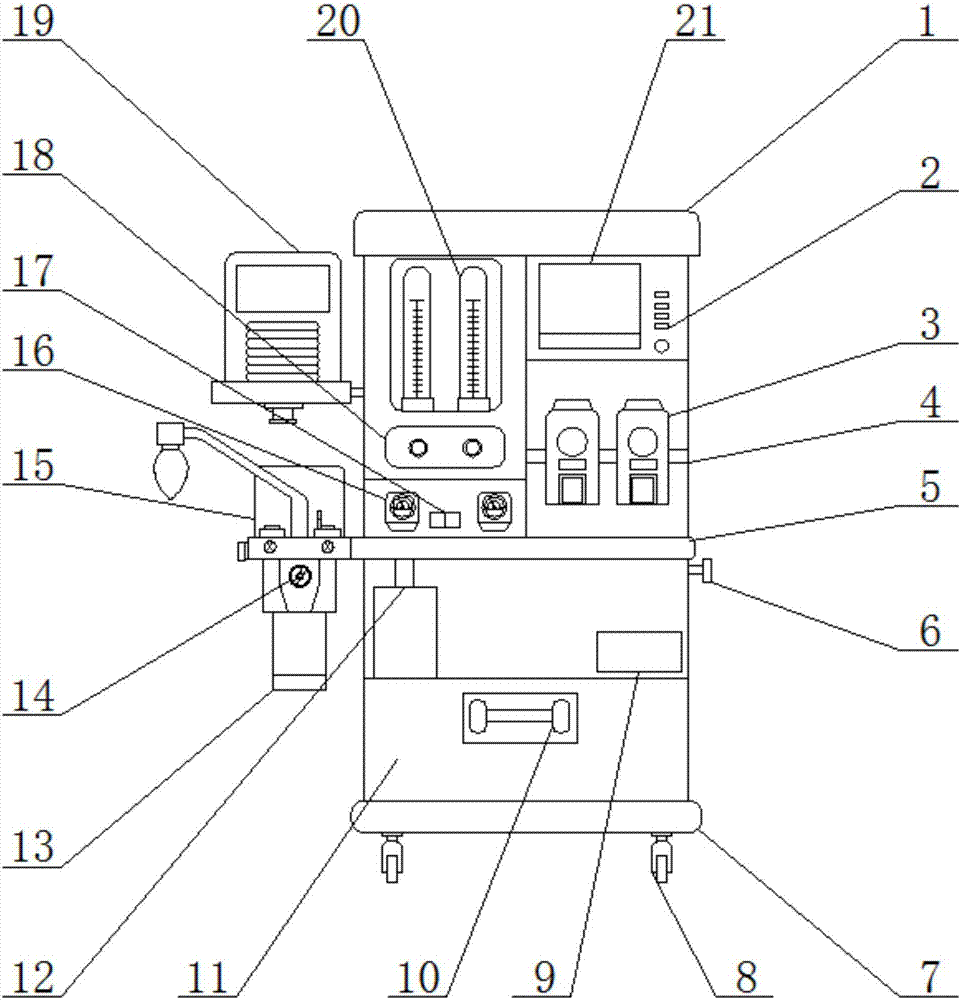

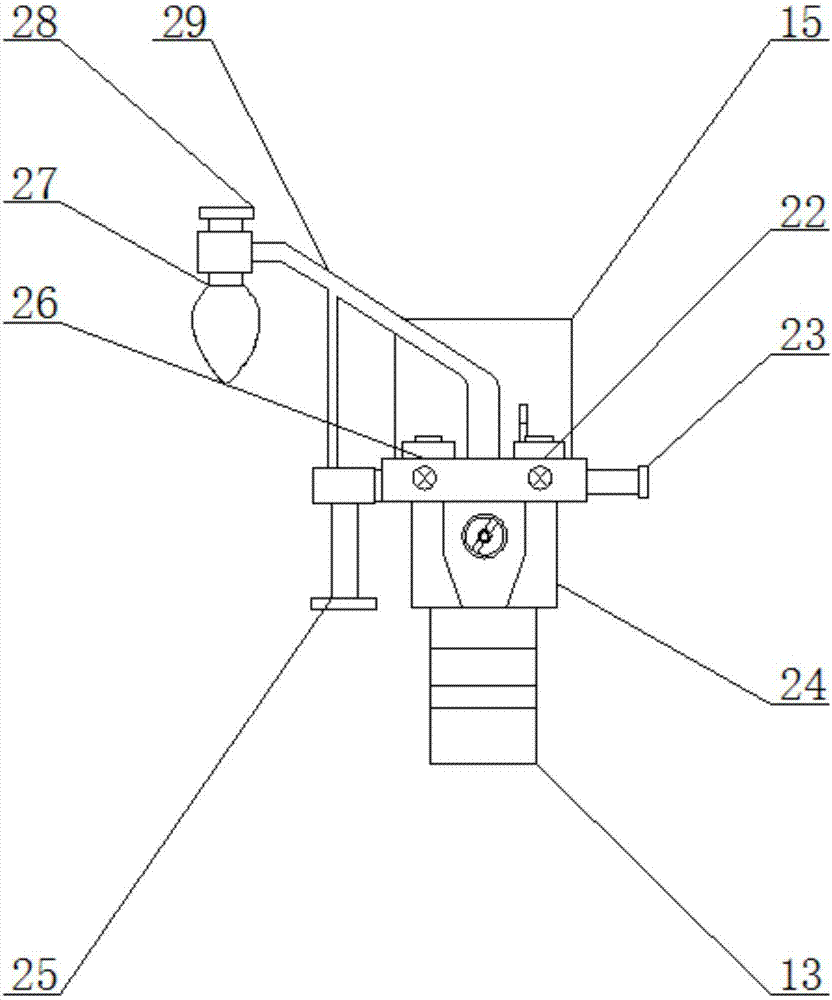

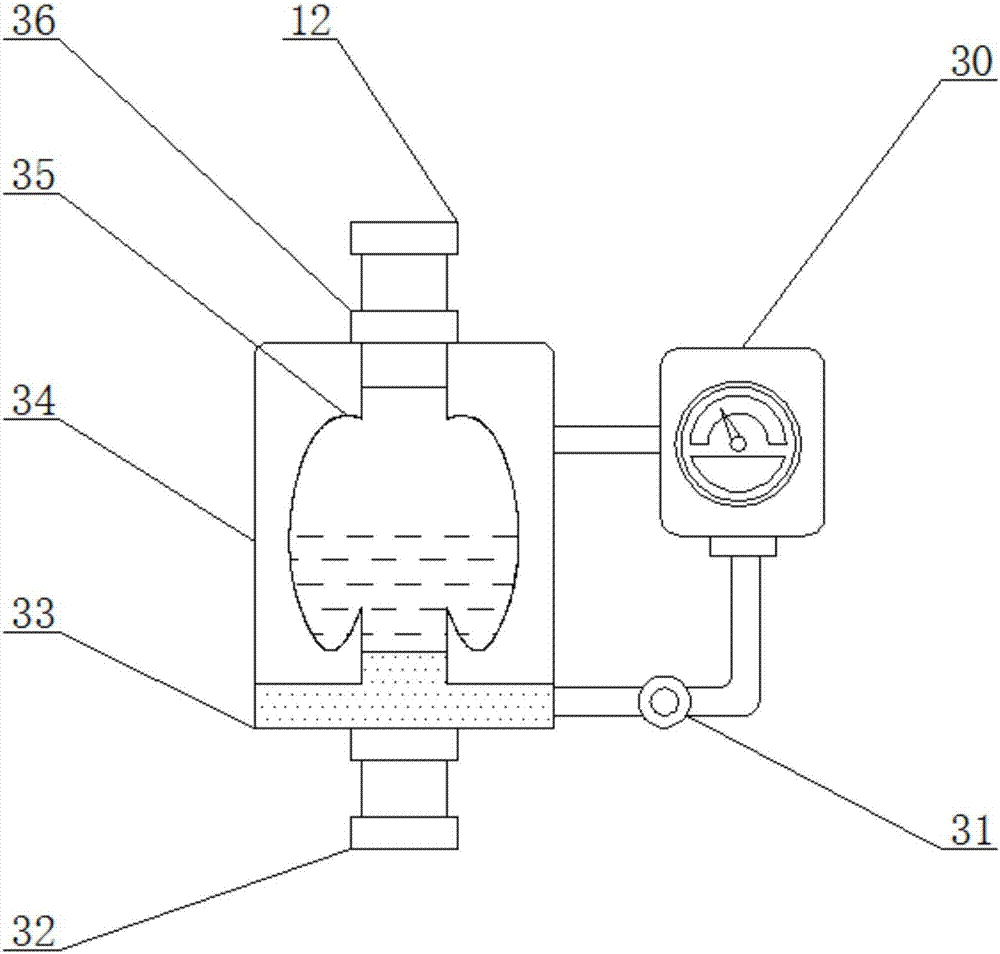

Special anesthesia machine for anesthesiology departments

InactiveCN107376080ADoes not change negative pressureNormal deliveryRespiratorsNitrous oxide captureActivated carbonAnesthetic department

The invention discloses a special anesthesia machine for anesthesiology departments. The special anesthesia machine comprises an anesthesia machine body, an air box, a carbon dioxide concentration sensor and a waste gas treatment tank. Flow meters are arranged on the upper side of the front surface of the anesthesia machine body, a display panel is arranged on the right side of the corresponding flow meter, and index setting buttons are arranged on the right side of the display panel. The special anesthesia machine has the advantages that the special anesthesia machine is additionally provided with the waste gas treatment tank on the basis of the original waste gas treatment system, a filter is arranged in the waste gas treatment tank and is filled with filter liquid, an activated carbon layer is arranged below the filter, most of waste gas can be collected in a pressure tank after the waste gas flows through the waste gas treatment tank and is filtered by double layers, only a small portion of waste gas can be exhausted into an operating room, and the little filtered waste gas is free of harm on doctors; expiration and inspiration of patients can be simulated by the filter, cleaned gas keeps constant with breathing gas of the patients, integral negative pressures of the special anesthesia machine hardly can be changed, anesthetics and oxygen can keep being normally delivered to the respiratory tracts of the patients, and accordingly the stability of anesthesia operation can be guaranteed.

Owner:张乙莲

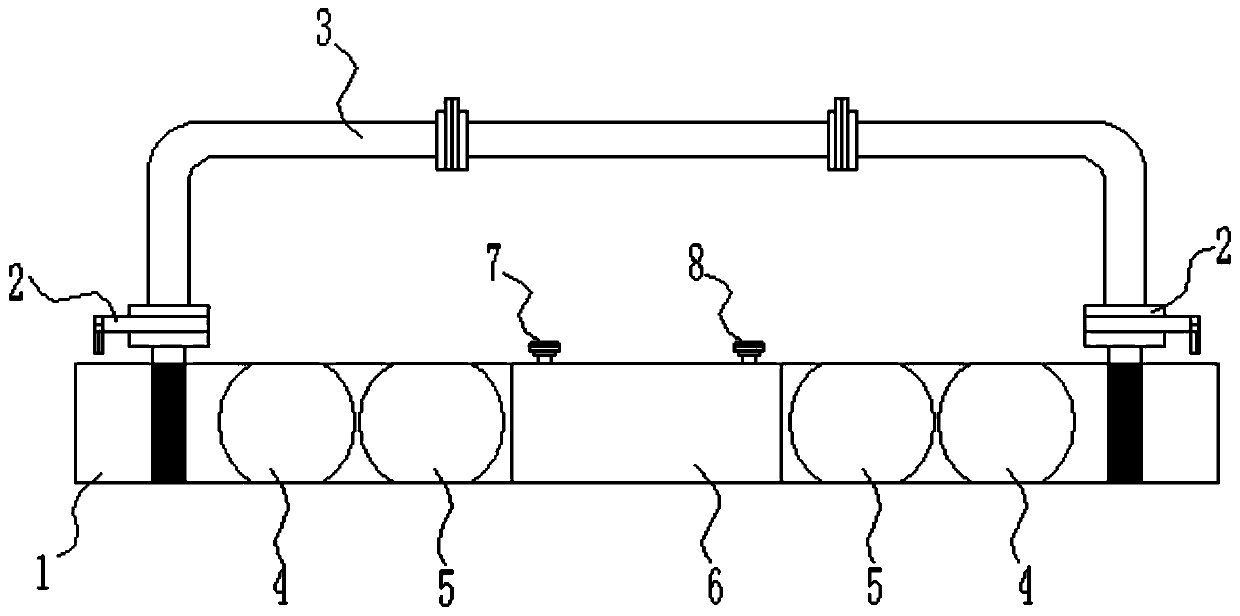

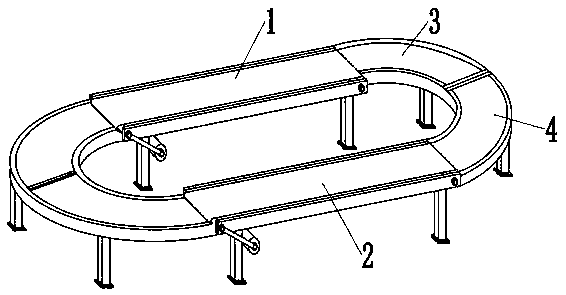

Endless conveyer belt conveyer

InactiveCN109775239AAchieve the purpose of deliveryReduce difficultyConveyorsFixed bearingProduction line

The invention relates to the field of conveyers, in particular to an endless conveyer belt conveyer. The endless conveyer belt conveyer comprises a first linear conveyer belt, a second linear conveyerbelt, a first annular conveyer belt and a second annular conveyer belt. The first linear conveyer belt and the second linear conveyer belt are the same in both specification and shape. The first linear conveyer belt comprises two fixed side plates which are arranged symmetrically and the same in specification, an installation groove is formed in the outer wall of the side, facing the other one, of each of the two fixed side walls, a fixed bearing is fixedly arranged inside each installation groove, and the interior of each fixed bearing is rotationally connected with a carrier roller througha transmission shaft. The endless conveyer belt conveyer has the beneficial effects that an annular production line for conveying goods can be formed to achieve the purpose of conveying the cargo, theoperational difficulty of people is greatly reduced, and the skid situation in the goods conveying process is avoided; and because the annular conveyer belts are connected with the linear conveyer belts, various splicing is achieved, and therefore , the endless conveyer belt conveyer is applicable to usage on various situations.

Owner:JIN HOUNG FUH (CHUZHOU) CONVEYING EQUIP CO LTD

A method for preparing yarn from aramid 1414 waste short fiber

Owner:CHANGSHU BAOFENG SPECIAL FIBER

Dam floating object fishing device and fishing boat

InactiveCN110735425AImprove efficiencyEasy to operateWater cleaningWaterborne vesselsElectric machineryEngineering

The invention discloses a dam floating object fishing device and a fishing boat. The fishing device comprises a collection box and a fishing transportation assembly. The fishing transportation assembly is movably connected and fixed with the collection box. The fishing transportation assembly comprises a rectangular fixing frame. A belt conveyor with a nail rake is erected on two parallel frames of the rectangular fixing frame. A fishing roller with a nail rake driven by a motor is arranged on the frame, far away from the collection box, in the other two parallel frames of the rectangular fixing frame. The fishing transportation assembly fishes floating objects onto a belt conveyor through the fishing roller and then transports the floating objects into the collection box through the beltconveyor. By the adoption of the dam floating object fishing device and the fishing boat, the integral design is novel, the practicability is high, the operation is easy, and the working efficiency offishing floating objects is high.

Owner:GUIZHOU WUJIANG HYDROPOWER DEV

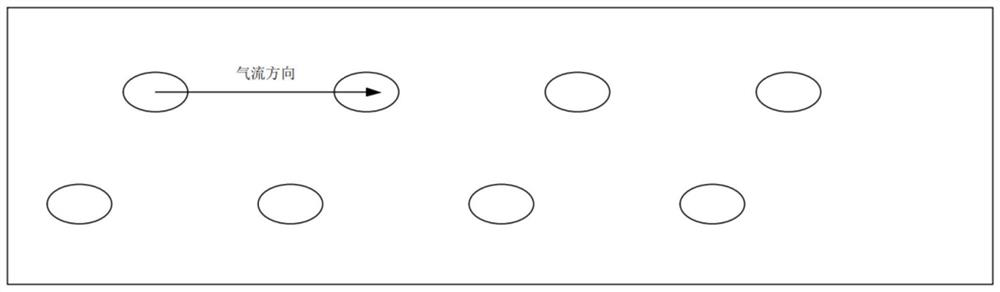

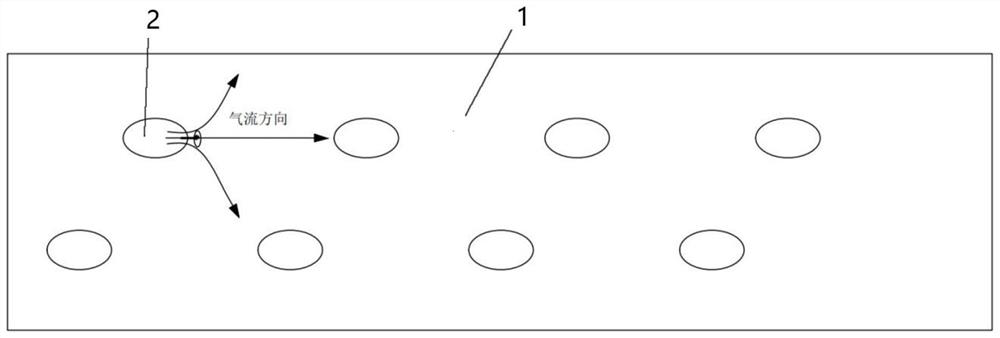

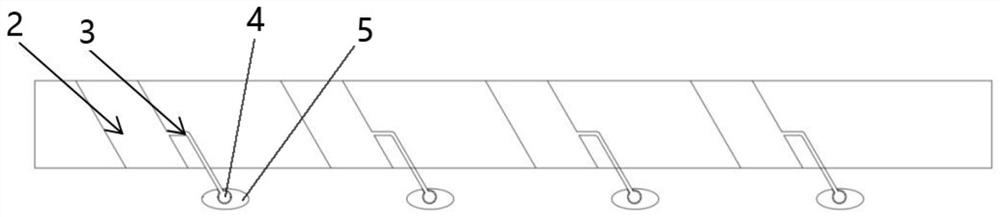

Online non-woven fabric perforating system

InactiveCN106676756ARealization of online punchingEasy to produceSevering textilesNon-woven fabricsEngineeringHigh pressure

The invention discloses an online non-woven fabric perforating system. The online non-woven fabric perforating system comprises a bale opener, an opener, a carding machine and a hot-air adhesion mechanism, wherein the opener corresponds to the bale opener, and the carding machine corresponds to the opener. Fibers pass through the bale opener, the opener, the carding machine and the hot-air adhesion mechanism sequentially, an online perforating device is arranged at the hot-air adhesion mechanism and comprises a negative pressure unit and a high-pressure gas input end, and the negative pressure unit is arranged below the high-pressure gas input end. In a non-woven fabric forming process, corresponding positions on a non-woven fabric are perforated through impact of high-pressure gas before the non-woven fabric becomes a finished product. The online non-woven fabric perforating system has the advantages that the formed non-woven fabric can be perforated on line without being placed in a perforating machine for perforating, so that a production process is simplified greatly, labor cost is reduced and production cost of non-woven fabrics is lowered finally.

Owner:唐新雄

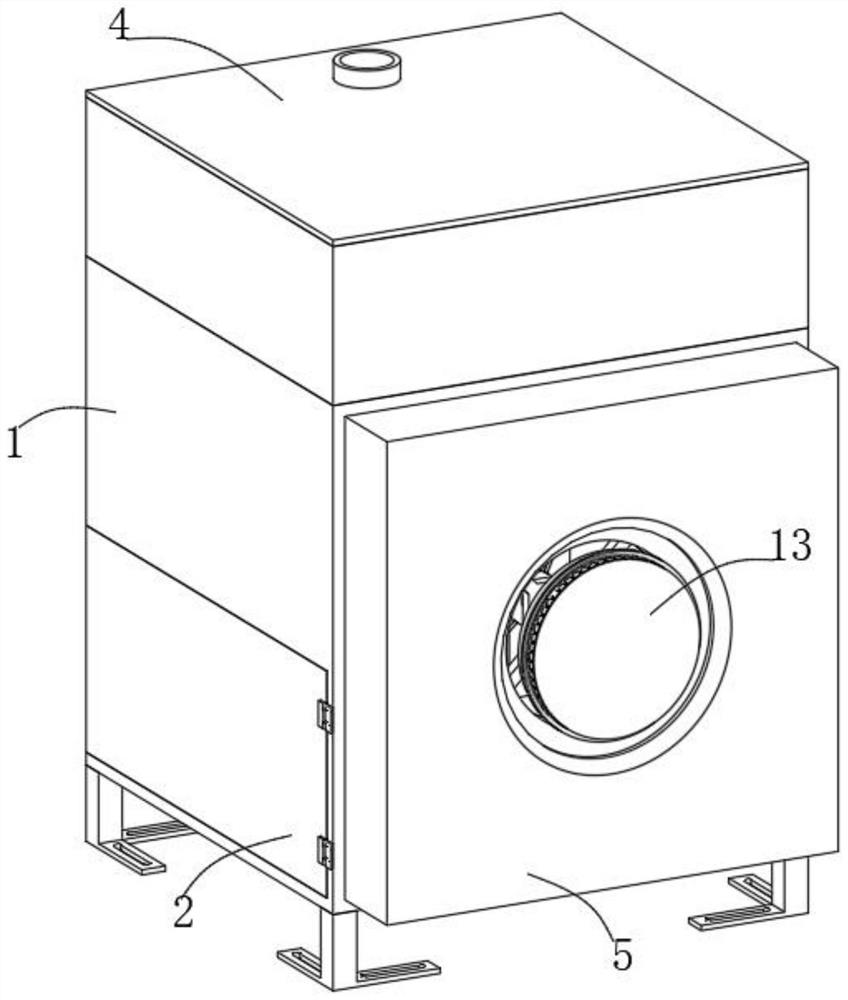

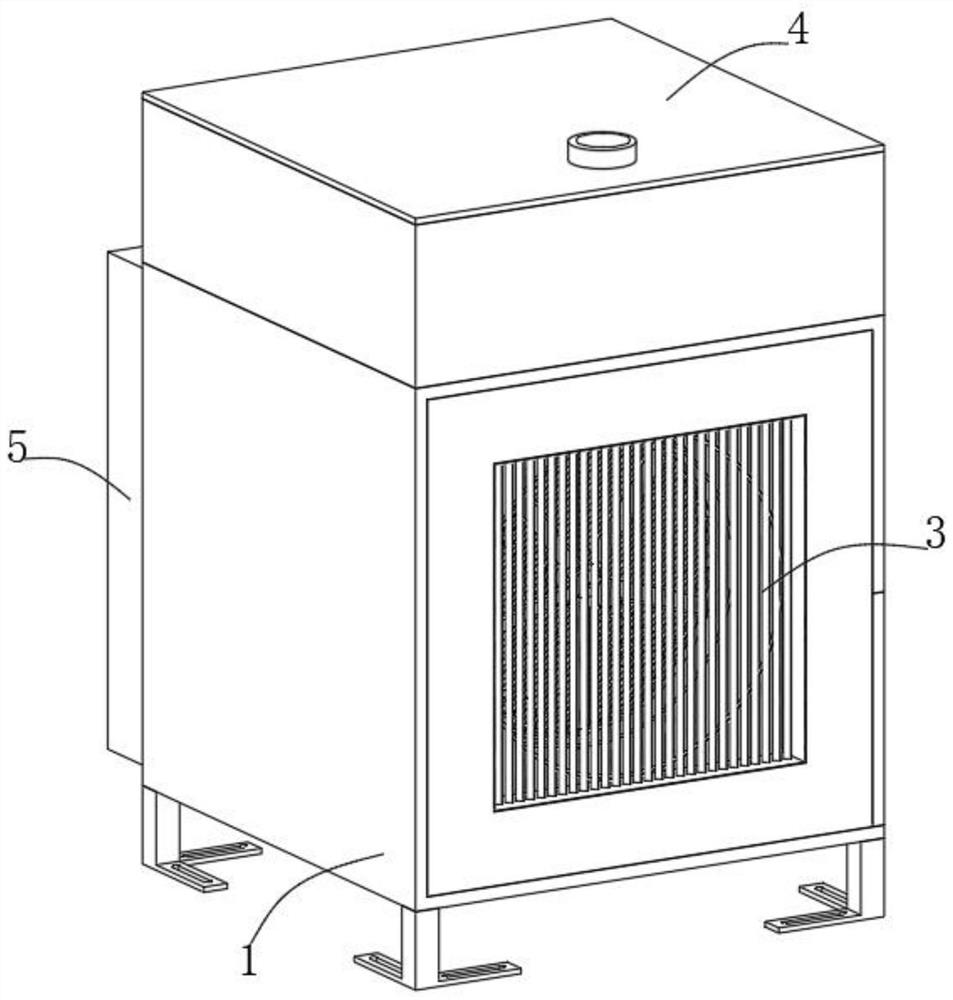

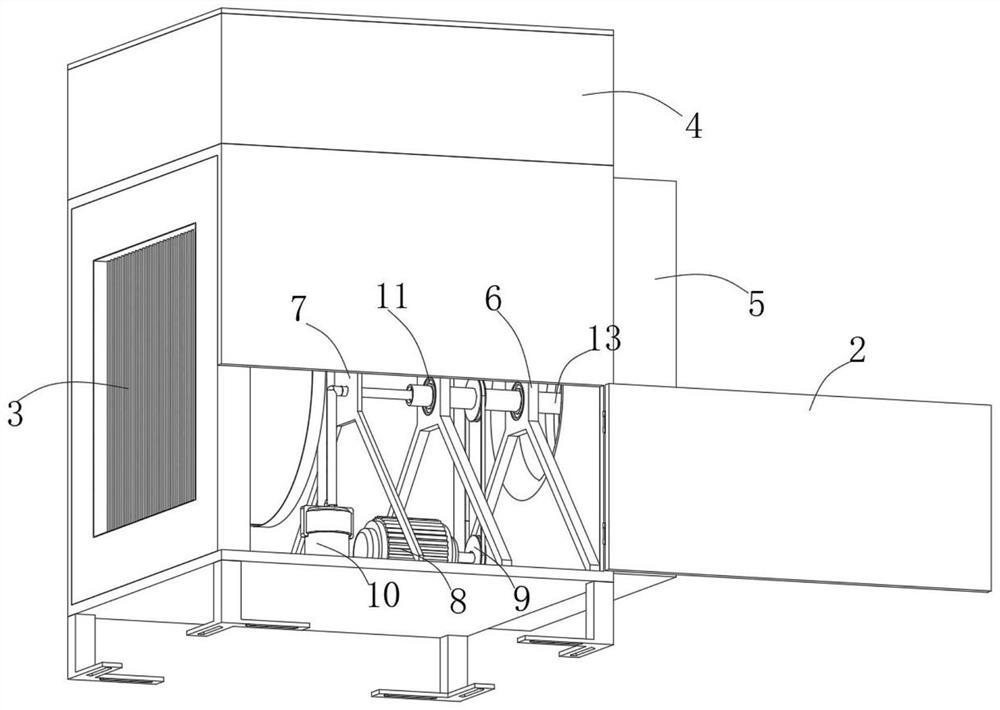

Atomization device and special atomization disc thereof

InactiveCN112246465AEfficient deliveryNormal deliveryLiquid spraying apparatusPhysicsElectric machinery

The invention discloses an atomization device and a special atomization disc thereof. The atomization device comprises a bottom frame and an atomization disc mechanism; an air guide block is embeddedin the front surface of the bottom frame; an air inlet is formed in the back surface of the bottom frame; a fan is embedded in the air inlet; a liquid storage frame is fixedly connected to the top ofthe bottom frame; two first supporting frames are fixedly connected to the position, close to the edge of the front side, in the bottom frame in the horizontal direction; a supporting opening is formed in the center of the front surface of each first supporting frame; and a first bearing is embedded in each supporting opening. During use, through the first supporting frames and the first bearings,after a motor is started, the motor can drive a rotating shaft to effectively rotate through a belt wheel, then a rotating frame can be effectively driven to rotate, and meanwhile, under the condition that the positions of a second supporting frame and a second bearing are fixed, a liquid discharging pipe cannot rotate along with the rotating frame, then the liquid can be normally conveyed, and aproper amount of liquid is injected into the liquid storage frame.

Owner:宿迁市第一人民医院

Slice type medium accumulation and separation device and cash circulation processing equipment

ActiveCN111145426AAvoid hemmingAvoid breakingCoin/currency accepting devicesMechanical engineeringIndustrial engineering

The invention provides a slice type medium accumulation and separation device and cash circulation processing equipment, relates to the technical field of self-service equipment, and is designed for solving the problem that an accumulation and separation device provided by the related technology is easy to cause edge folding of or damage to banknotes. The slice type medium accumulation and separation device comprises a rack, a supporting plate and a paper shifting mechanism, the rack is provided with a containing cavity, a paper inlet is formed in one end of the containing cavity in the slicetype medium stacking direction, and a paper outlet and a separating mechanism are arranged at the other end of the containing cavity; the supporting plate can move in the slice type medium stacking direction and is provided with a paper outlet position and a receiving position. And the paper shifting mechanism is arranged adjacent to the paper outlet and is set to drive the sheet medium to move towards the containing cavity and away from the paper outlet. The cash circulation processing equipment comprises the slice type medium accumulation and separation device. According to the slice type medium accumulation and separation device and the cash circulation processing equipment provided by the invention, the banknotes can be prevented from being folded or damaged when the supporting plate moves to the receiving position.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

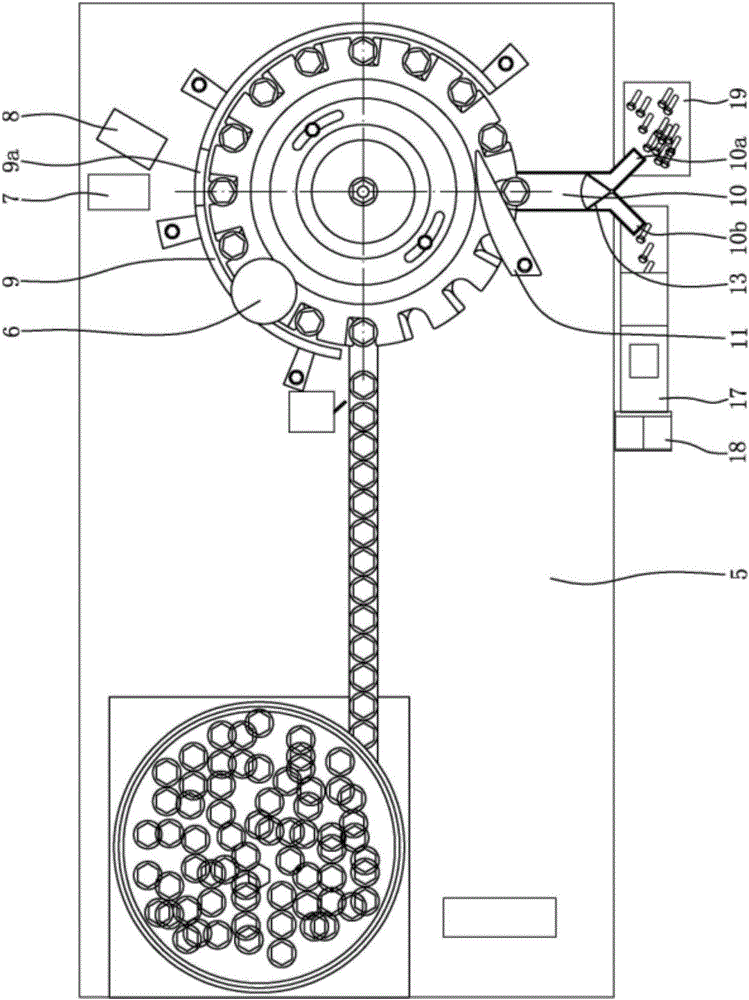

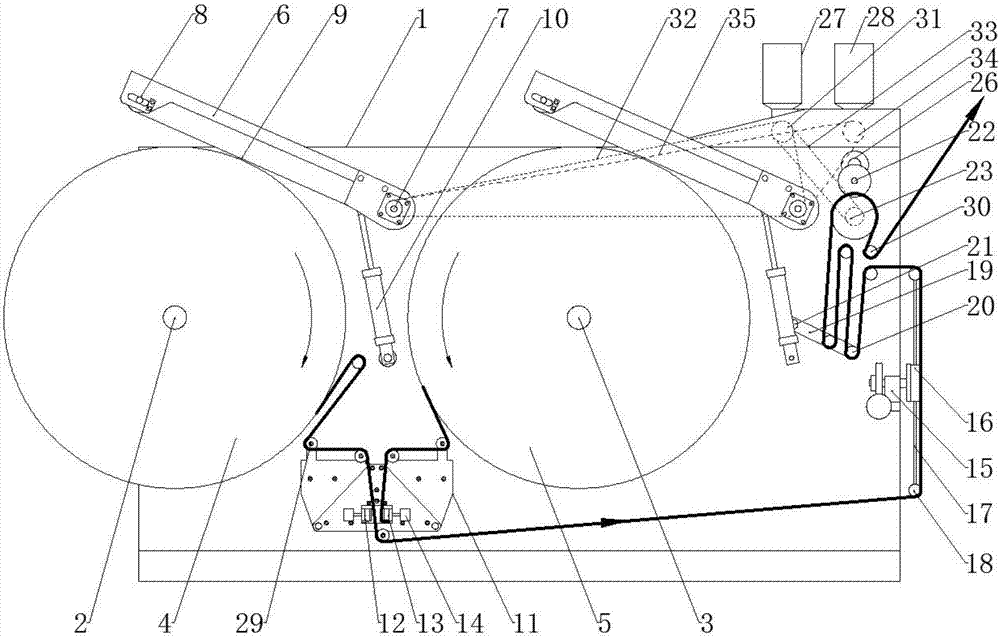

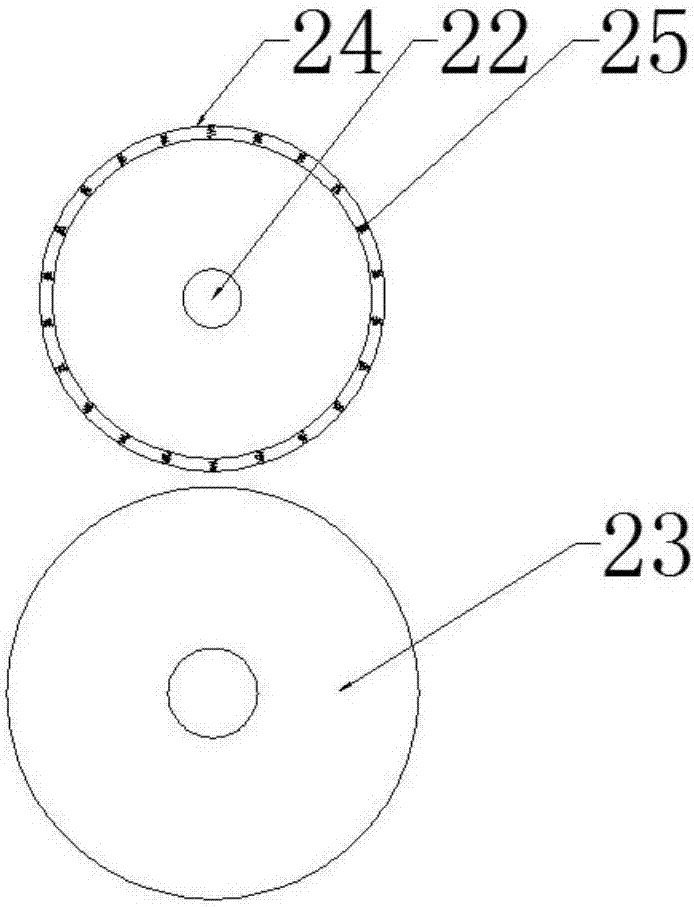

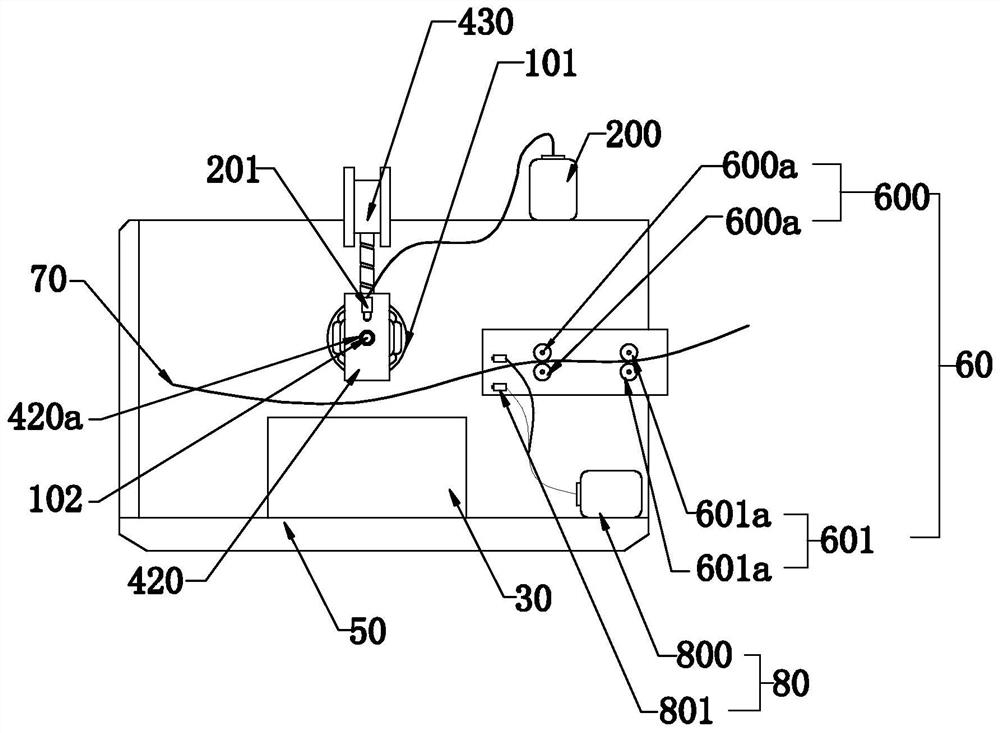

Indexing and subpackaging mechanism for detection of standard fasteners

ActiveCN104150038AThe working process is simple and fastHigh degree of automationPackaging automatic controlCcd cameraComputer science

The invention discloses an indexing and subpackaging mechanism for detection of standard fasteners. The indexing and subpackaging mechanism is characterized in that an indexing turntable is arranged above a machine table (5), a first CCD (charge coupled device) camera (6) is arranged above the edge of the indexing turntable, a second CCD camera (7) and a third CCD camera (8) are arranged beside the indexing turntable, an anti-separation retaining plate (9) is arranged on the periphery of the indexing plate in a semi-surrounding manner, a slide (10) is arranged beside the indexing turntable, the outlet end of the slide (10) forks to form a first distribution channel (10a) and a second distribution channel (10b), a first part box (16) is arranged under the first distribution channel (10a), and a part packager (17) with a counter is arranged beside the first part box (16). The indexing and subpackaging mechanism is applicable to detection of various standard fasteners, the standard fasteners can be prevented from being separated, and parts can be automatically sorted and packaged by category through a sorting and packaging mechanism.

Owner:重庆新颖泉汽车零部件有限公司

Method for consulting port attribute parameters, network node and network system

ActiveCN101610126ANormal deliveryTime-division multiplexData switching networksComputer networkNetworked system

The invention discloses a method for consulting port attribute parameters, a network node and a network system. The method for consulting port attribute parameters comprises the following steps: port information of a first node and a second node in the network is obtained, wherein the port information comprises port attribute parameters; and when the port attribute parameters of the first node and the second node are inconsistent and the port attribute parameter of the first node or the second node can be configured, the configurable port attribute parameter of the second node and / or the first node is adjusted to lead the port attribute parameters of the first node and the second node to be consistent. The technical scheme of the invention can ensure normal business transferring after connection is established.

Owner:HUAWEI TECH CO LTD

Supply chain management system

PendingCN111242541ANormal deliveryAccurate Delivery PlanResourcesLogisticsManagement systemEngineering management

The invention relates to a supply chain management system, belongs to the technical field of supply chain management, and is used for solving the problem that in an existing supply chain management system, a logistics company cannot normally deliver goods to clients after client addresses are temporarily changed. The system comprises an information management system used by a logistics company anda client mobile terminal used by a logistics company client. When the client address is temporarily changed in the cargo distribution process, a client can input a temporary address through the client mobile terminal; and the information management system changes the distribution route information of the corresponding goods according to the temporary address, and the logistics company distributesthe corresponding goods according to the updated distribution route information, so that the logistics company can still normally distribute the goods to the customer when the customer address is temporarily changed.

Owner:浙江康链聚合供应链管理有限公司

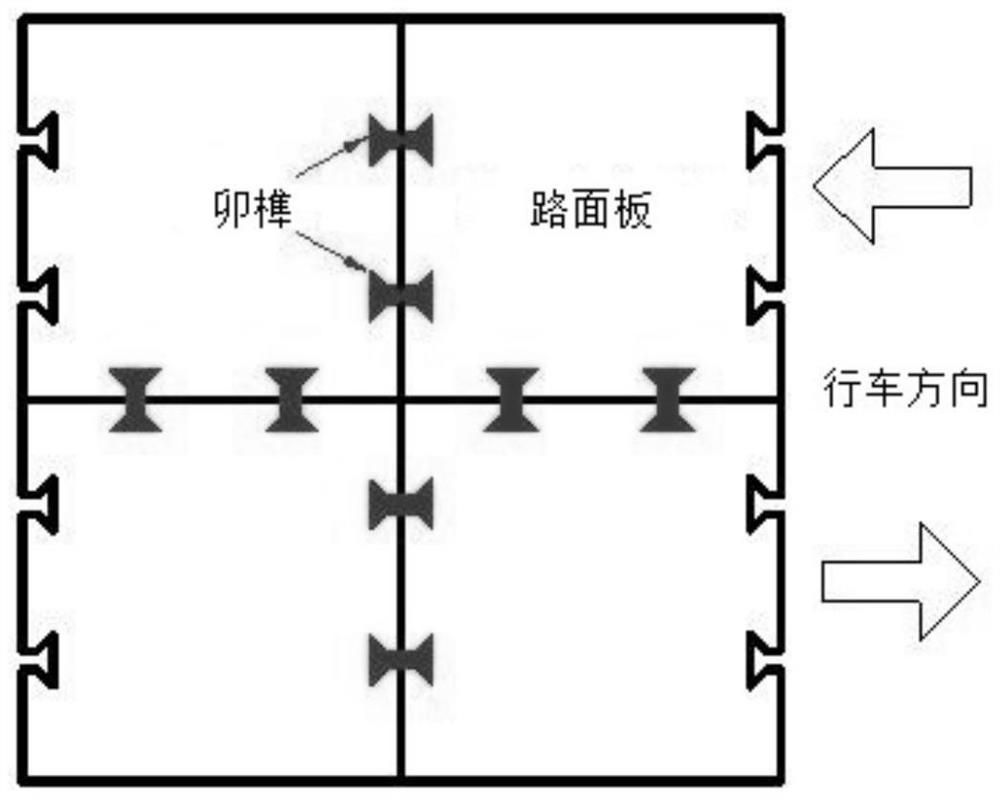

Recyclable ultra-high performance concrete fabricated temporary pavement structure

InactiveCN111636271AIncreased durabilityIncrease frictionTemporary pavingsRoads maintainenceReinforced concreteMortise and tenon

The invention discloses a recyclable ultra-high performance concrete fabricated temporary pavement structure which comprises a plurality of pavement slabs, the pavement slabs are ultra-high performance concrete components, mortises are arranged on the side walls of the pavement slabs, the mortises between the adjacent pavement slabs are correspondingly arranged and connected through tenons, and the tenons are steel components. The pavement slabs made of the ultra-high performance concrete have the characteristics of light weight, high strength, high durability and reusability, has stronger friction force and durability compared with a steel panel, is lighter and higher in strength compared with a traditional concrete or reinforced concrete pavement slab, and can effectively reduce the weight of the pavement slab, so that the transportation cost and the installation difficulty are reduced; the tenons are of steel structures, damage in the installation and use process can be avoided, thewhole mortise and tenon joint structure does not form an acute angle on the pavement slab, the stress concentration phenomenon is relieved, repeated utilization is achieved, the surfaces of the steelstructures are smooth, installation is convenient, and in addition, the mortise and tenon joint pieces are also installation positioning devices of the prefabricated pavement slabs.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

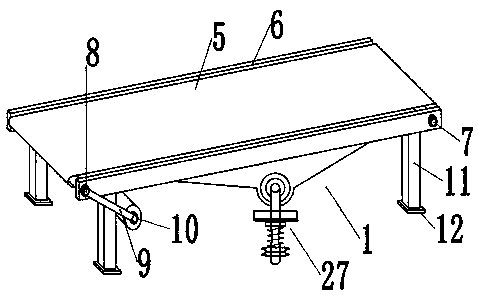

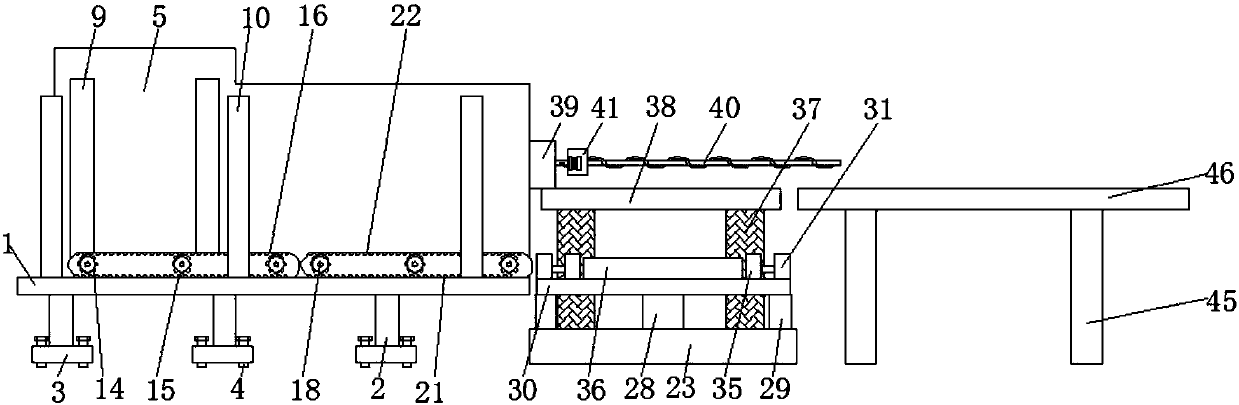

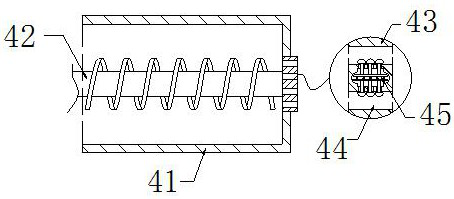

Novel engine cylinder block machining charging device

ActiveCN108045915AGuaranteed efficiencySmooth feedingConveyorsConveyor partsProduction lineEngineering

The invention discloses a novel engine cylinder block machining charging device. The novel engine cylinder block machining charging device comprises a bottom plate. First supporting legs are fixedly connected with the bottom of the bottom plate. Mounting blocks are fixedly connected with the ends, away from the bottom plate, of the first supporting legs. Two mounting bolts in bilateral symmetry are fixedly connected with the top of each mounting block. A limiting baffle is fixedly connected with the top of the bottom plate. By arranging a first conveying belt, a second conveying belt and a third conveying belt, the effect of conveying cylinder blocks to the top of a storage plate stably is achieved, thus, the cylinder blocks are conveyed to a charging preparation position automatically, charging by operators is greatly facilitated, manual carrying or hoisting through hoists are not needed, lots of physical strength of the operators is saved, in addition, the charging number of each time can be increased, the charging period is prolonged, the normal machining efficiency of the cylinder blocks is ensured, the line speed of production lines is more stable, and the effect that the single shift capacity is ensured is achieved.

Owner:绍兴市华获智能装备有限公司

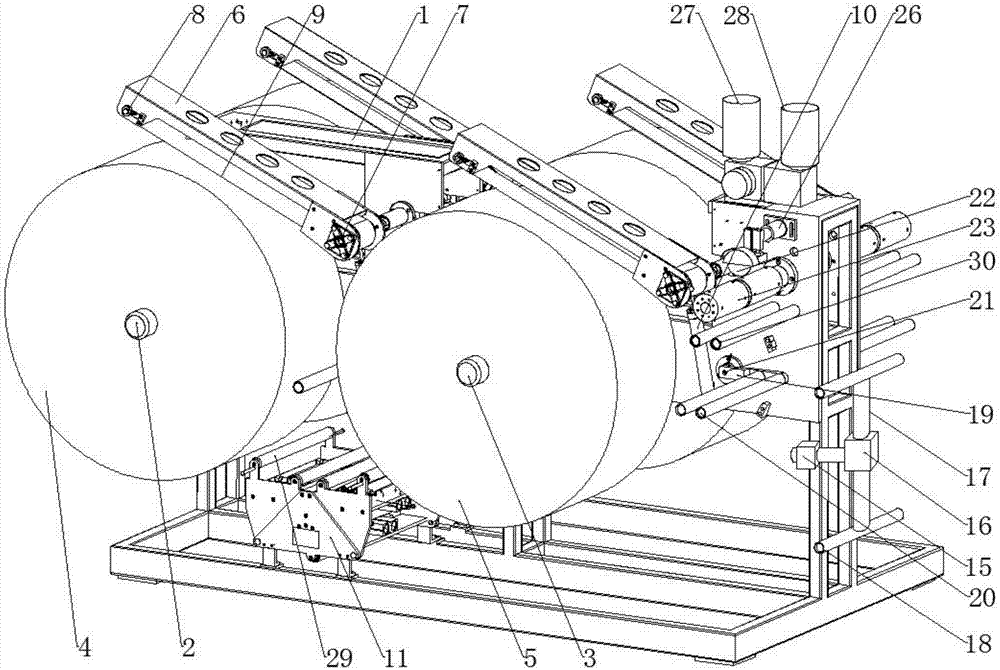

Automatic roll changing and cloth releasing device

InactiveCN107529506AEasy to operateEasy to controlArticle deliveryWebs handlingEconomic benefitsEngineering

The invention relates to an automatic roll changing and cloth releasing device. The automatic roll changing and cloth releasing device comprises a rack, cloth feeding mechanisms, a head and tail rebutting device, a deviation rectifying device, a floating and rolling tension control device and a slitting device, wherein the front side and the rear side of the rack are arranged in a symmetrical structure, and a primary cloth releasing frame and a secondary cloth releasing frame are arranged at the front side of the rack; four cloth feeding mechanisms are respectively arranged above two primary non-woven fabric rolls and above two secondary non-woven fabric rolls; the head and tail rebutting device is arranged below a central position between the primary cloth releasing frame and the secondary cloth releasing frame; the deviation rectifying device is arranged at the right end of the rack and comprises a mounting block and a mounting sleeve; the floating and rolling tension control devicecomprises a control rod, a compensation roller used for conveying non-woven fabrics and a control rod driving part used for driving the control rod to move; and the slitting device comprises a rollingroller and a cutter roller which are arranged up and down. Two rolls of non-woven fabrics can be full-automatically processed every time, continuous processing is carried out on the non-woven fabricswithout halt, both time and labor are saved, operation is easy, control is precise, labor cost is greatly reduced, and working efficiency is improved, so that the automatic roll changing and cloth releasing device provided by the invention has good economic benefit.

Owner:天津比朗德机械制造有限公司

Equal-distance thread progressive type small bolt dismounting tool and using method

The invention relates to the technical field of dismounting tools, in particular to an equal-distance thread progressive type small bolt dismounting tool and a using method. The tool is matched with ahexagonal open wrench for converting a screwdriver or wrench dismounting fastening way which is difficult to implement in a narrow space into a hexagonal open wrench fastening way which is convenientto operate in a wide space, so that the problems such as screwdriver or wrench partial screwing or inclined screwing as a common screwdriver or wrench cannot be normally used if there is no enough operation space in a dismounting process in the prior art are solved; through engagement of a planetary wheel, a first gear and an inner gear, equal-thread advance and retract effect between a performing head and a bolt is realized based on gear variable-speed transmission principle when a drive sleeve rotates, so that the performing head is always tightly combined with a bolt head for synchronous advance and retract, and thus, bolt head damages caused by slip or inclination under force are avoided, and normal and effective transmission of torsion force moment is guaranteed.

Owner:SOUTHERN POWER GRID PEAK LOAD & FREQUENCY REGULATION GENERATING CO LTD

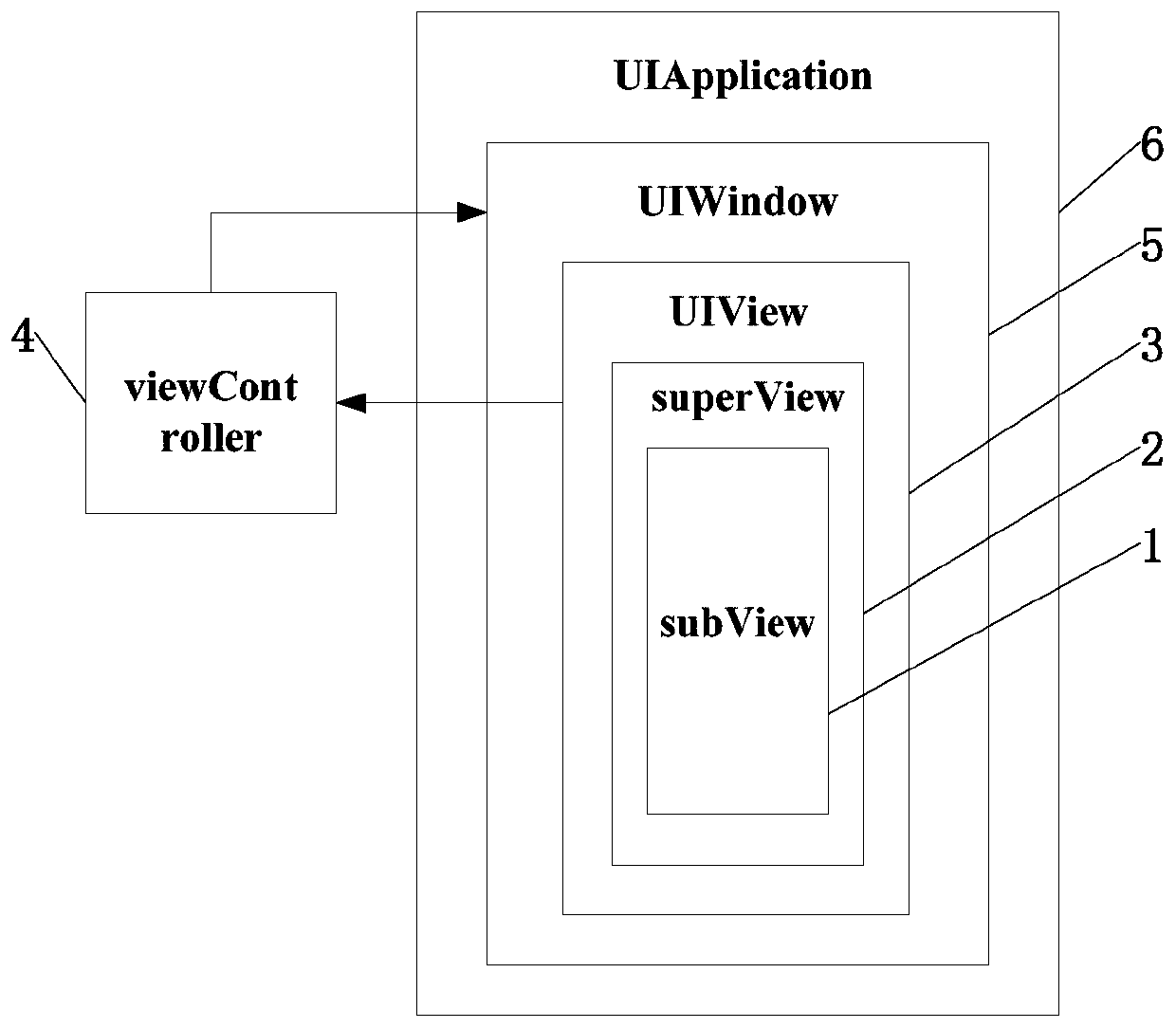

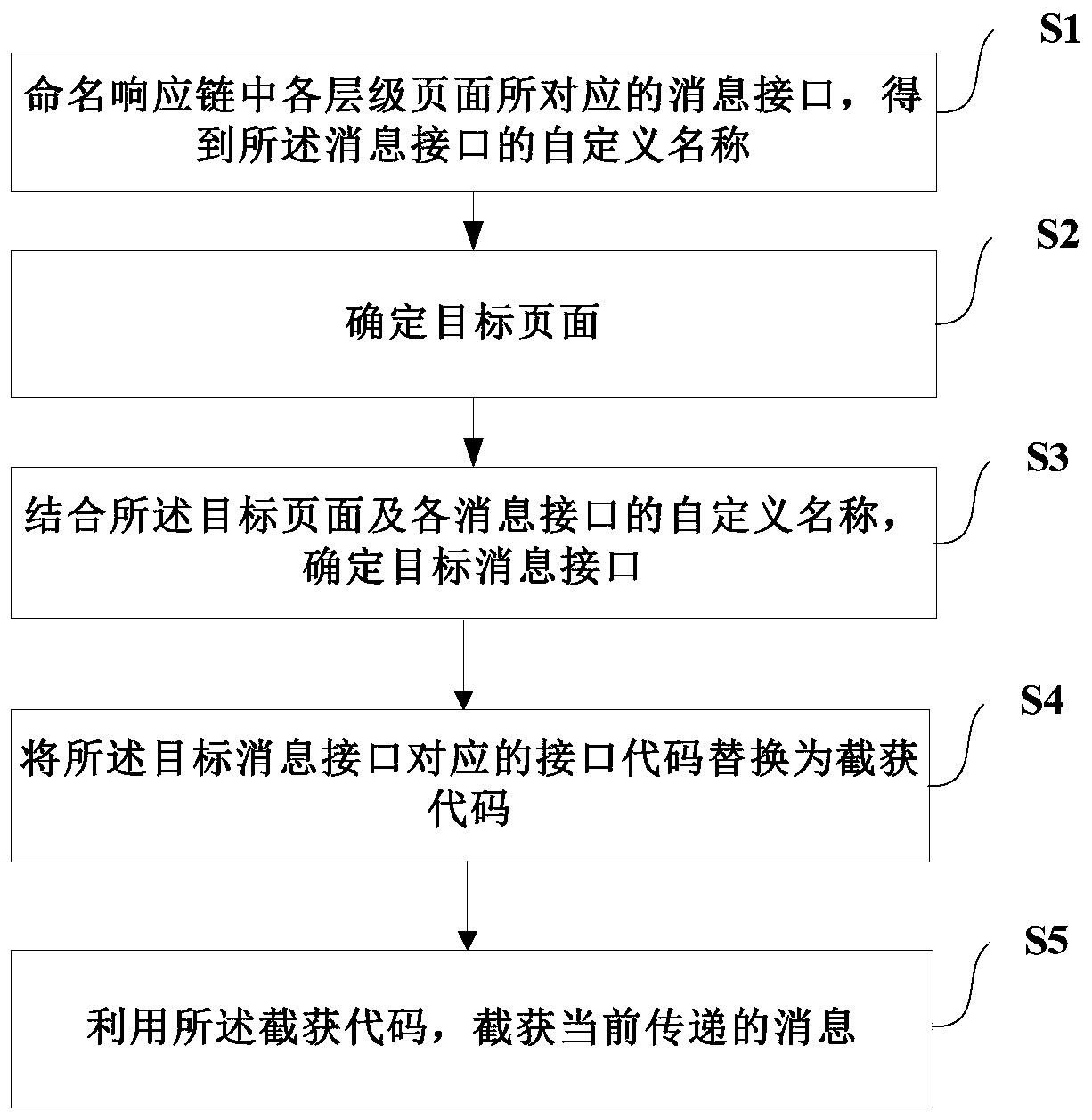

Message interception method and device, electronic equipment and storage medium

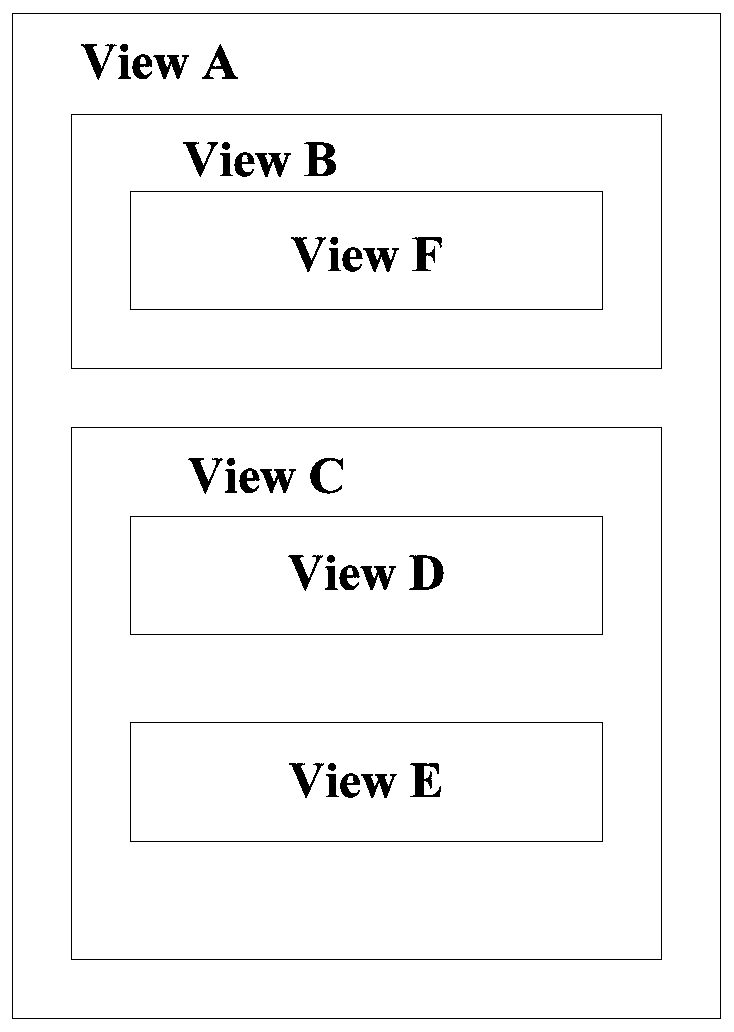

ActiveCN110597647ANormal deliveryDoes not affect normal deliveryInterprogram communicationComputer hardwareMessage passing

The embodiment of the invention provides a message interception method and device, electronic equipment and a storage medium. The method comprises the steps: naming a message interface corresponding to each hierarchical page in a response chain, and obtaining a custom name of the message interface; determining a target page; determining a target message interface in combination with the target page and the custom name of each message interface; replacing an interface code corresponding to the target message interface with an interception code; and intercepting and capturing a currently transmitted message by utilizing the interception and capture code. Therefore, according to the message transmission method provided by the invention, the required message can be accurately intercepted in the page of the specified hierarchy, and meanwhile, the normal transmission of the message is not influenced.

Owner:WUBA

Building solar roof panel conveyer

ActiveCN108861353AReduce installation costsAvoid troubleConveyorsCharge manipulationSolar cellMechanical engineering

The invention discloses a building solar roof panel conveyer, which comprises a first sliding machine body, wherein a rotating first rotating shaft is arranged in the first sliding machine body, two first rotating wheels are arranged on the first rotating shaft, a second sliding machine body is arranged on a building wall body, two sides of the second sliding body are respectively provided with arotating second rotating wheel, conveying pull ropes are arranged between the first rotating wheels and between the second rotating wheels, the conveying pull ropes are provided with supporting suction pipes which are arranged side by side, one end of each supporting suction pipe is provided with a sucker, the adsorption of the solar cell panel through the sucker can be further fixed on the conveying pull ropes, so that the solar panel can be further conveyed through the sliding of the conveying pull ropes, so that the purpose of conveying can be achieved, and the trouble caused by hoisting ofa crane can be further avoided.

Owner:新沂伟博科技有限公司

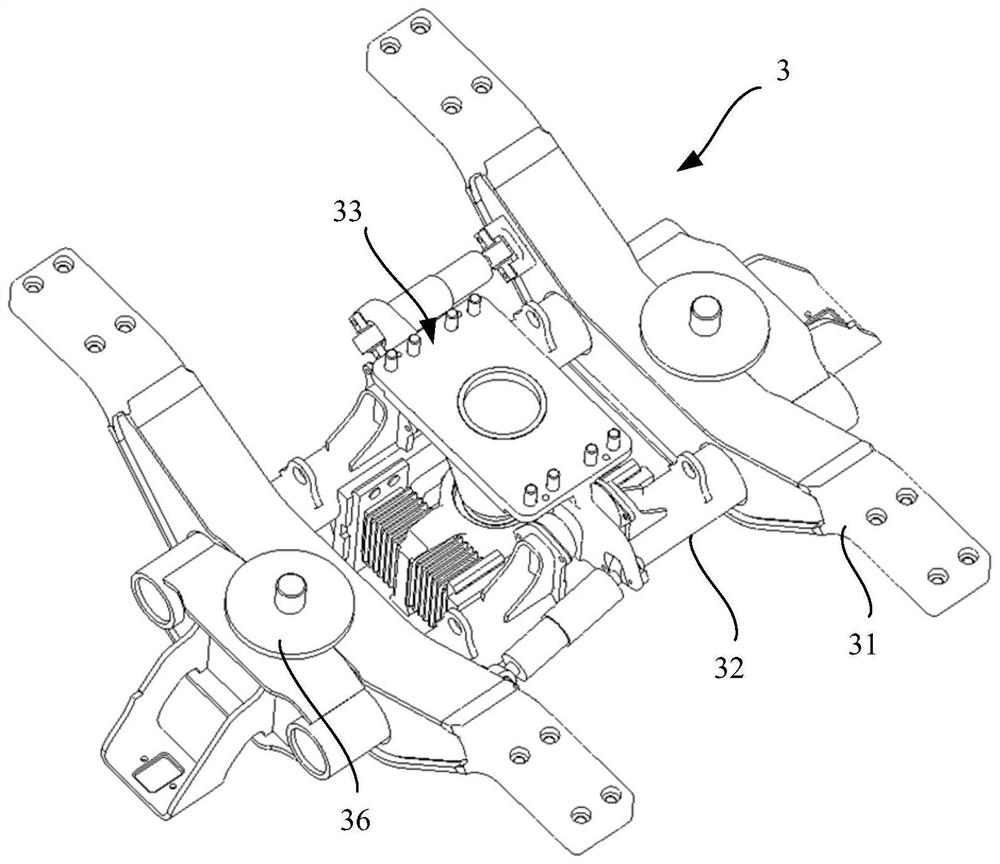

Rubber-tired train

ActiveCN112549934ANormal deliveryGreat tractionSteering linkagesElectric propulsion mountingDrive shaftElectric machinery

The embodiment provides a rubber-tired train which comprises at least two connected train bodies, at least one train body is provided with a bullet train traction driving device, the bullet train traction driving device comprises a traction motor, a driving axle and a transmission shaft, and an output shaft of the traction motor is used for outputting traction force; the input end of the drive axle is connected with the output shaft of the traction motor; the two ends of the transmission shaft are fixedly connected with the output end of the traction motor and the input end of the drive axle respectively, the transmission shaft comprises a first transmission part, a second transmission part and a third transmission part, the first end of the first transmission part is fixedly connected with the output shaft of the traction motor, and the second end of the first transmission part is hinged to the first end of the second transmission part. The second end of the second transmission part is hinged to the first end of the third transmission part, and the second end of the third transmission part is fixedly connected with the input end of the drive axle. The transmission shaft in the rubber-tired train can adapt to the height difference generated between the motor and the drive axle due to various working conditions and transmit torque normally, and the traction effect is good.

Owner:CRRC NANJING PUZHEN CO LTD

Novel medical waste automatic disposal box fullness pushing device

InactiveCN109592250ANormal deliveryEasy to slideRefuse receptaclesMedical wasteArchitectural engineering

The invention discloses a novel medical waste automatic disposal box fullness pushing device. The device comprises a base; the upper end of the base is provided with a vertically arranged support rod;the upper end of the support rod is provided with a shell; the middle of the upper end of the base is provided with a vertically arranged hydraulic rod; the telescopic end of the hydraulic rod extends to the inner side of the shell; the telescopic end of the hydraulic rod is connected with a placement plate; the upper end of the shell is open; the outer walls of the two sides of the shell is provided with a bracket; the upper end of the bracket is provided with a fixing rod; the end, close to the shell, of the fixing rod is provided with a mounting groove; a telescopic rod is inserted into the mounting groove; a spring is arranged between the telescopic rod and the inner wall of the mounting groove; one end of the telescopic rod extends to the outer side of the mounting groove; a first through groove is formed in the side wall of the shell; the telescopic rod extends to the inner side of the shell through the first through groove; and the upper end of the sidewall of the shell is provided with a tray. During usage, a storage bag can be conveniently pushed to the outer side of the device.

Owner:吕宏梅

Geothermal well excavation protection device

ActiveCN110259406AAvoid scratchesImprove protectionDrilling rodsSealing/packingEngineeringGeothermal energy

The invention provides a geothermal well excavation protection device. The geothermal well excavation protection device comprises a guiding head, a protection structure and a guiding structure; the protection structure comprises a fixed cylinder, the inside of the fixed cylinder is of a hollow structure, the fixed cylinder is fixed to the guiding head; the guiding structure is connected to the fixed cylinder, the guiding structure comprises fixing block, sliding slots, springs, fixing plates and rollers, the sliding slots are formed in the fixed cylinder, the sliding slots communicate with the inside of the fixed cylinder, the fixing blocks are slidably connected to the fixed cylinder, the fixing blocks are located in the sliding slots, the fixing plates are fixed to the fixing blocks, and the springs are fixed between the fixing plates and the inner side wall of the fixed cylinder; and the fixing blocks penetrate through the insides of the springs, the rollers are rotatably connected to the fixing blocks, and the rollers are located in the fixed cylinder. The geothermal well excavation protection device has the advantages of facilitating protection of a geothermal pipeline and facilitating geothermal energy transportation.

Owner:广东省地质技术工程咨询公司

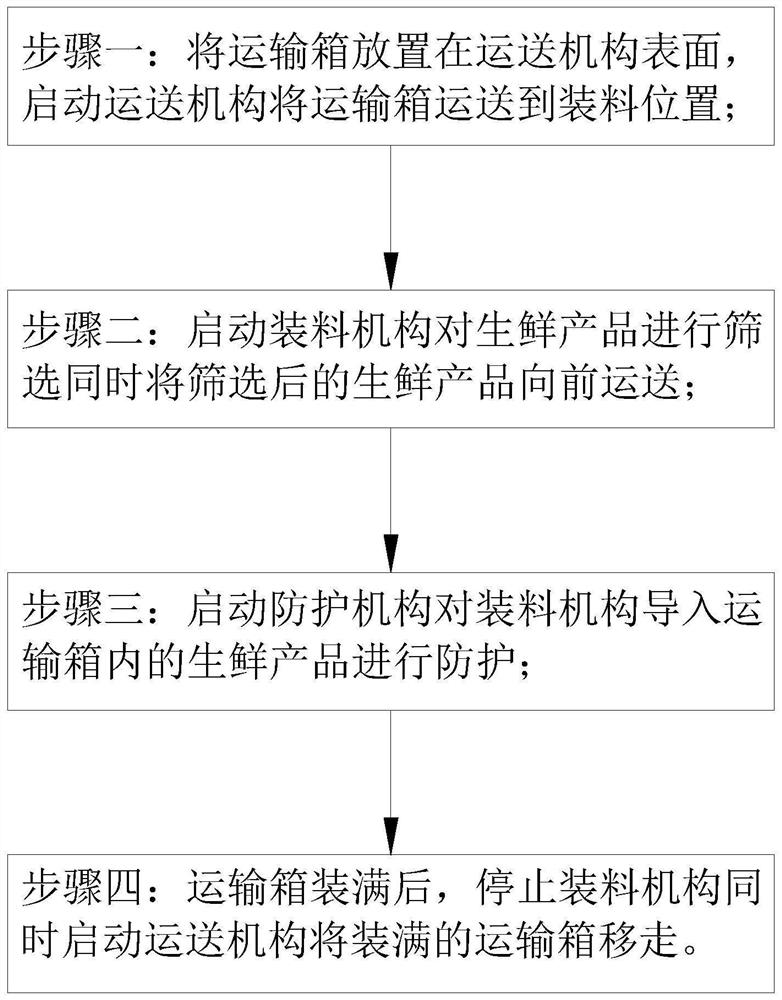

Convenient labor-saving boxing device for fresh food distribution and using method thereof

PendingCN114506497AAvoid breakingQuality improvementSievingBio-packagingFresh foodProcess engineering

The invention discloses a portable labor-saving boxing device for fresh food delivery and a using method thereof in the technical field of fresh food delivery, the portable labor-saving boxing device comprises a bottom plate, a storage box and a conveying belt are arranged at the upper end of the bottom plate, the storage box is fixedly connected with the bottom plate, a loading mechanism is arranged on the surface of the storage box, and the loading mechanism is used for screening fresh products and conveying the fresh products to the conveying belt. The screened fresh products are automatically conveyed to a boxing position; two rotating shafts in the conveying belt are rotationally connected with the bottom plate; a plurality of transport boxes and a conveying mechanism are uniformly arranged at the upper end of the conveyor belt; a protection mechanism is arranged at the front end of the storage box and used for preventing the fresh products from being broken when the loading mechanism pours the fresh products into the transport box. The device is easy to operate, fresh products with different sizes can be automatically distinguished and encasement can be automatically completed, meanwhile, the fresh products can be effectively prevented from being broken in the encasement process, and the transportation quality of the fresh products is effectively improved.

Owner:温州速比鲜农业科技有限公司

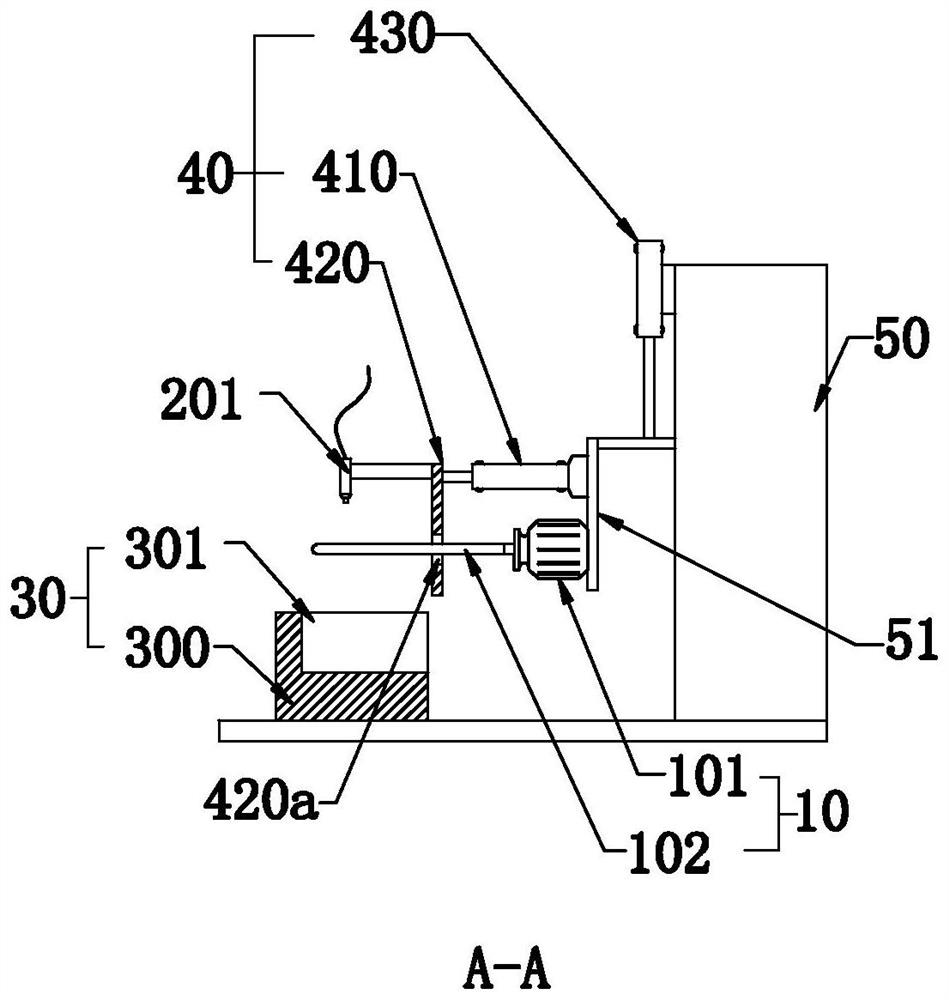

Production device for blank body

The invention relates to a production device for a blank body. The production device is characterized by comprising a twisting and rolling assembly, a sizing assembly and a mold, wherein the mold is provided with at least one forming area, the twisting and rolling assembly is provided with at least one rotatable twisting and rolling part, the twisting and rolling part drives materials to be twisted in the forming area to form the blank body, and the sizing assembly is used for supplying glue to the forming area or the twisting and rolling part. The production device has the beneficial effects that automatic production is achieved, the production efficiency is improved, and the consistency degree of product quality is high.

Owner:浙江钧晟新材料科技有限公司

Open end rotor spinning device

ActiveCN101713111BPrecise positioningOptimum Airflow ConditionsContinuous wound-up machinesOpen-end spinning machinesFiberGuidance channel

The device (1) has a two-piece fiber guidance channel with an output channel section integrated into a channel disk adapter. An input-side channel section is arranged in a releasable roller housing (19), which is pivotably mounted in a limited manner. The channel disk adapter is pivotably mounted relative to a center axis (20) in a limited manner. The channel disk adapter is positioned independent of size of a tower-like attachment piece. Central longitudinal lines of the channel sections of the fiber guidance channel are arranged in an angle position to each other.

Owner:SAURER GERMANY GMBH & CO KG

A New Type of Cooling Structure of Multi-inclined Orifice Plate Ellipsoid Pendulum for Aerospace Engine

ActiveCN113251441BNormal deliveryImprove cooling effectContinuous combustion chamberTurbine/propulsion engine coolingCombustion chamberJet flow

The invention discloses a novel cooling structure of an ellipsoidal pendulum with multi-slanted orifices for an aerospace engine. The cooling slant holes are connected with an air-inducing channel, which extends to the inner side of the combustion chamber flame tube and communicates with a spherical axis. The ellipsoid is located at the Between the front and rear adjacent cooling inclined holes on the inner side of the flame tube wall of the combustion chamber, the long axis of the ellipsoid is forward and backward. The ellipsoid is provided with an inner cavity, and the ball axis is located in the inner cavity of the ellipsoid. The exhaust passage of the inner chamber is provided with a hole on the ball shaft, the ellipsoid can rotate around the ball shaft, and the ball shaft is connected with the ellipsoid through a spring. The present invention can ensure the normal delivery of cold air to the downstream and enhance the cooling effect when the amount of cooling gas is not much. When the amount of cooling gas is large, it can avoid the problem that the downstream cannot stabilize the air film coverage due to the jet flow falling off the wall when the wind speed of blowing cold air is relatively high. question.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A kind of environmental protection straw feed manufacturing equipment

ActiveCN113558262BAccelerate the speed of crushing and conveyingGuarantee unimpededFeeding-stuffCuttersFodderMechanical engineering

The invention discloses an environment-friendly straw feed manufacturing equipment, the structure of which comprises a base, a machine body, a hopper, a crushing cylinder, and a bucket. Since the hardness of the rhizome of the straw is relatively hard and the volume of the rhizome is relatively large, it passes through the extruding hole of the extruding plate. It is easy to get stuck inside the extrusion hole. By installing a crushing mechanism between the extrusion holes, the impact rod of the crushing mechanism can impact and crush the particles, which can reduce the volume of the particles and reduce the large particles stuck in the extrusion hole. It is conducive to keeping the extrusion hole unblocked and speeding up the crushing and conveying speed of the straw. Since the bucket is connected to the bottom of the cylinder through the connecting pipe, when the liquid is not introduced into the cylinder, the particles will fall down and get stuck on the inner wall of the connecting pipe. , by providing a blocking mechanism inside the connecting pipe, it can block the particles, reduce the particles falling down and get stuck on the inner wall of the connecting pipe when the liquid is not passed into the bucket, and keep the connecting pipe unblocked, so that the liquid can be transported normally.

Owner:SHANDONG SHUANGHE MACHINERY MFG CO LTD

Flake medium accumulation and separation device and cash recycling processing equipment

ActiveCN111145426BAvoid hemmingAvoid breakingCoin/currency accepting devicesMechanical engineeringThin sheet

The invention provides a sheet-like medium accumulating and separating device and cash circulation processing equipment, which relate to the technical field of self-service equipment and are designed to solve the problem that the accumulating and separating device provided by the related art tends to fold or damage banknotes. The sheet medium accumulation and separation device includes a frame, a supporting plate and a paper pushing mechanism. The frame is provided with an accommodation cavity. Along the sheet medium stacking direction, one end of the accommodation cavity is provided with a paper inlet, and the other end is provided with a paper outlet. and a separation mechanism; the pallet can move along the sheet medium stacking direction and has a paper output position and a receiving position; the paper-pull mechanism is arranged adjacent to the paper outlet, and the paper-pull mechanism is configured to drive the sheet medium into the accommodation cavity and away from it Movement in the direction of the paper outlet. The cash recycling processing equipment includes the above-mentioned sheet medium accumulation and separation device. The sheet medium accumulating and separating device and the cash circulation processing equipment provided by the present invention can prevent banknotes from being folded or damaged when the supporting plate moves to the receiving position.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

Mechanical lifting device for fluorescent lamp tubes

InactiveCN103465261BSimple structureNormal deliveryProgramme-controlled manipulatorCold cathode manufactureProduction lineLight pipe

The invention relates to a mechanical lifting device, in particular to a mechanical lifting device for fluorescent lamp tubes. The mechanical lifting device is formed by a base, a supporting arm, a crank connecting rod, a rotating shaft A, a rotating shaft B, a lifting air cylinder, a rotating air cylinder and clamping jaws, wherein the supporting arm is fixedly provided with an installation bottom plate, the lower surface of the installation bottom plate is provided with the lifting air cylinder, the end head of a piston rod of the lifting air cylinder is fixedly provided with an installation top plate, and the installation top plate is provided with the rotating shaft A and the rotating shaft B. According to the mechanical lifting device disclosed by the invention, the lifting air cylinder and the rotating air cylinder are sequentially controlled to move through a program control box, the position lifting of small-sized or ultra-small fluorescent lamp tubes in a production line can be completed, and the problem that small-sized or ultra-small fluorescent lamp tubes in an existing production line cannot be normally grabbed by a mechanical hand as the lengths of the small-sized or ultra-small fluorescent lamp tubes are short is solved; the grabbing requirements of the mechanical hand can be met when various types of small-sized or ultra-small fluorescent lamp tubes are produced, and the mechanical lifting device is particularly suitable for being used for position lifting of the small-sized or ultra-small fluorescent lamp tubes in the production line.

Owner:荆州市大明灯业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com