Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

127results about How to "Play a role in protecting the environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

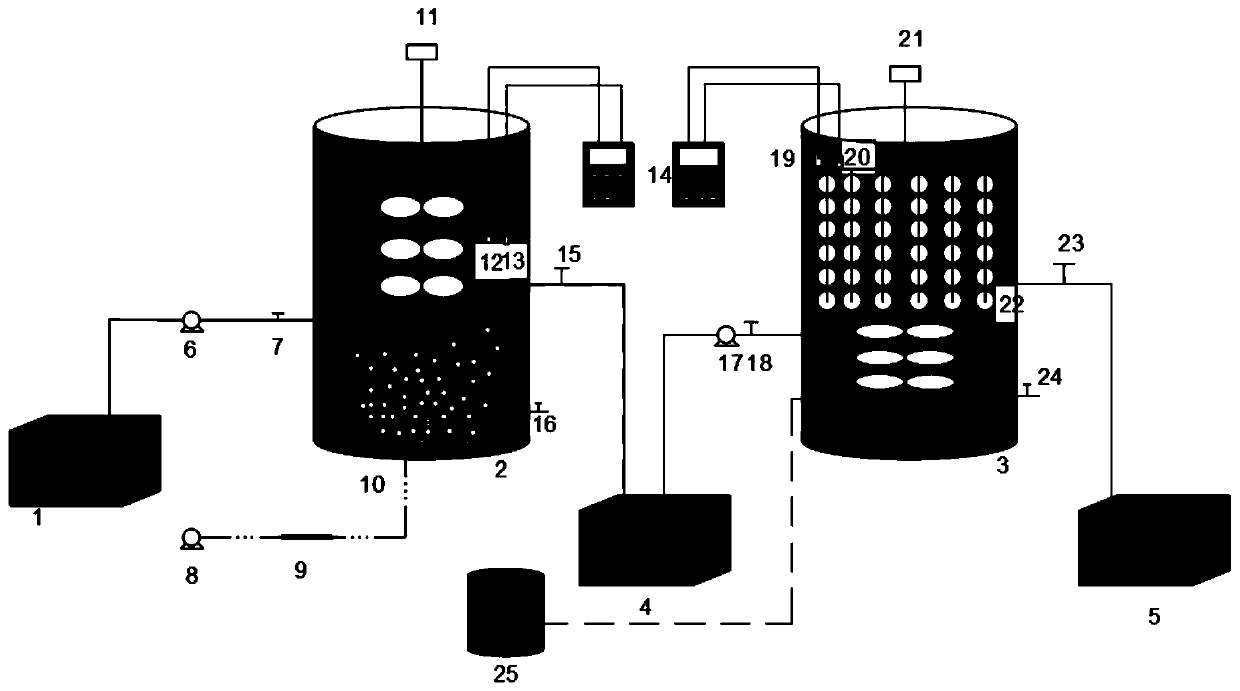

Technology for treating domestic sewage by realizing partial short-cut nitrification, sludge fermentation coupling denitrification and anaerobic ammonia oxidation in sequencing batch reactor

ActiveCN108585202AEasy to upgradeAchieve reductionTreatment with aerobic and anaerobic processesSustainable biological treatmentSequencing batch reactorNitration

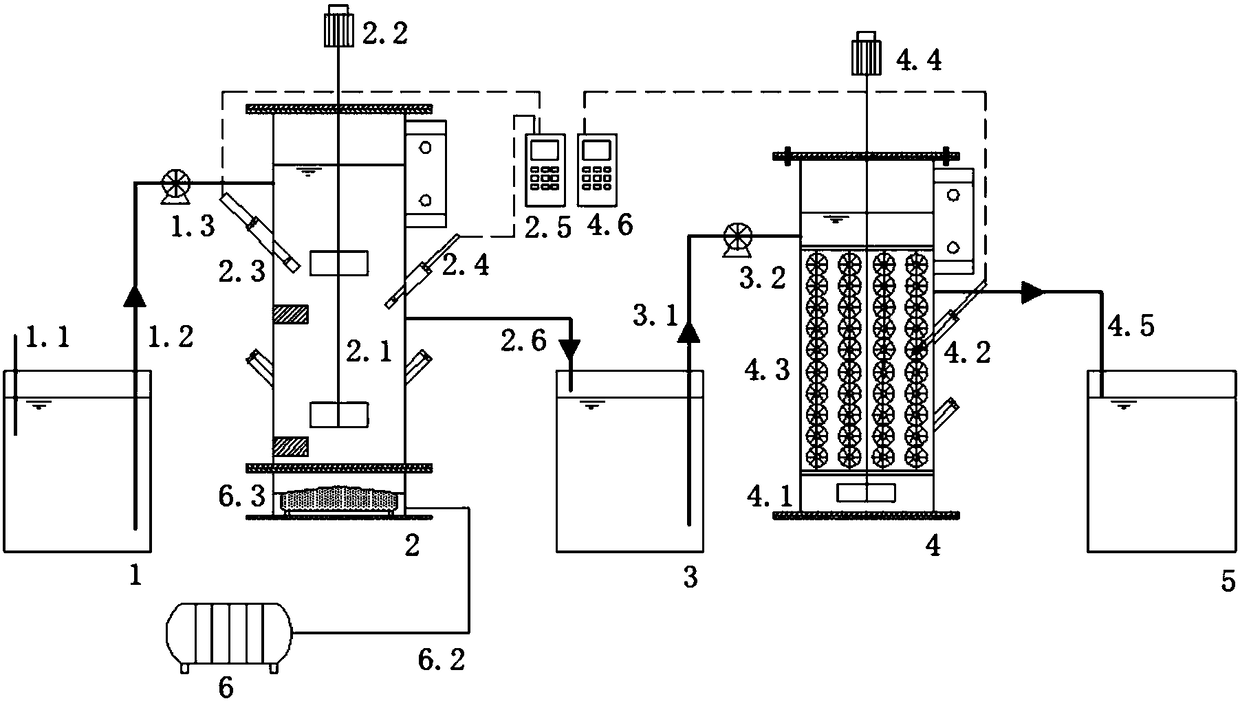

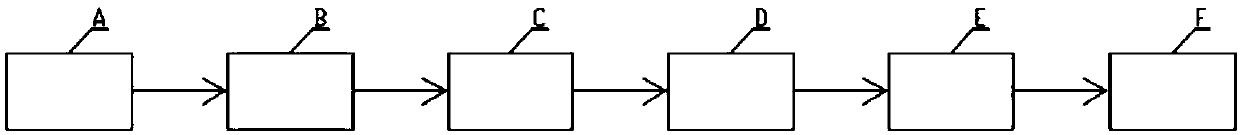

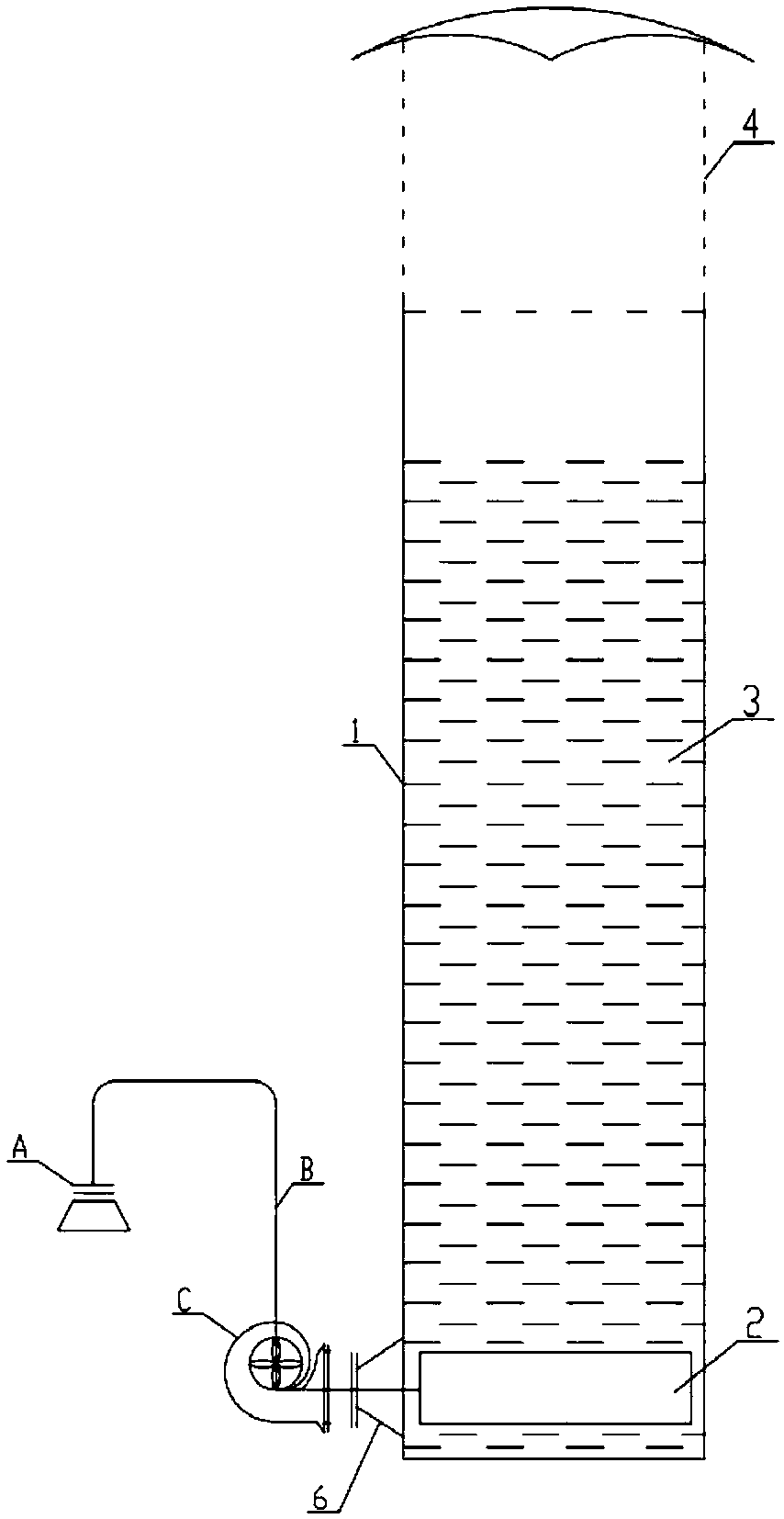

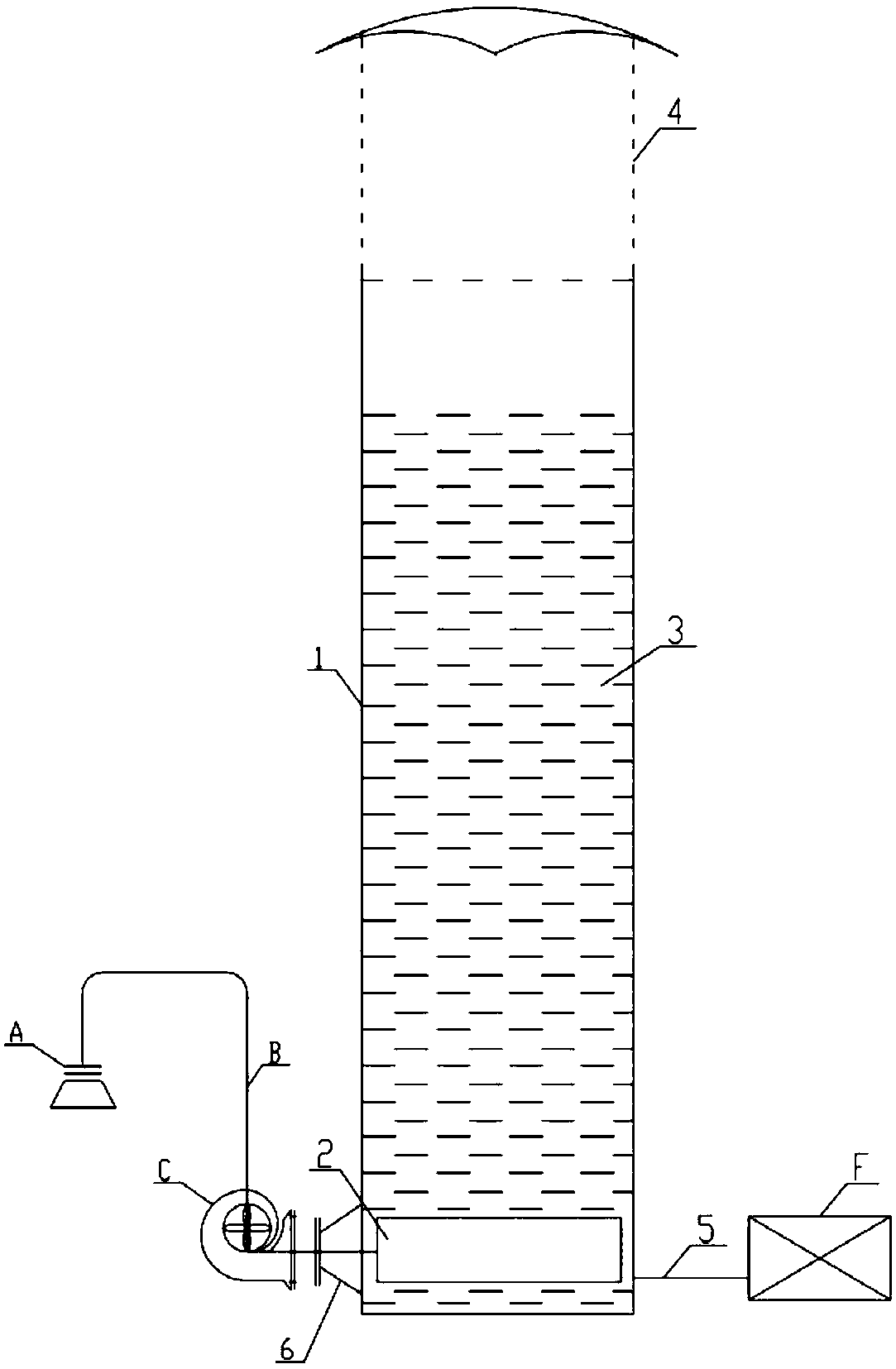

The invention discloses a technology for treating domestic sewage by realizing partial short-cut nitrification, sludge fermentation coupling denitrification and anaerobic ammonia oxidation in a sequencing batch reactor, and belongs to the field of the sewage sludge biological treatment. The technology comprises an inlet water tank, a partial short-cut nitrification reactor (PN-SBR), an intermediate water tank, an anaerobic ammonia oxidation coupling sludge fermentation and denitrification reactor (ASFD-SBR), and an outlet water tank. The partial short-cut nitrification is performed in the partial short-cut nitrification reactor (PN-SBR), and a part of ammonia nitrogen in raw water is converted to nitrite nitrogen. The influent ammonia nitrogen and the nitrite nitrogen are converted to a nitrogen gas and a little of nitrate nitrogen by anaerobic ammonium oxidation bacteria in the anaerobic ammonia oxidation coupling sludge fermentation and denitrification reactor (ASFD-SBR), and the generated nitrate nitrogen is reduced to the nitrogen gas by a carbon source generated by sludge fermentation, wherein static bed filler is used for retaining the anaerobic ammonium oxidation bacteria, and denitrification and sludge fermentation processes are performed in floc sludge. The technology is capable of saving energy consumption, and simultaneously realizing the deep denitrification of theurban domestic sewage in a low carbon nitrogen ratio (C / N) and the recycling of the sludge.

Owner:BEIJING UNIV OF TECH

Organic-inorganic multifunctional water-retaining agent for resisting saline and alkaline and preparation method thereof

InactiveCN102775992ALow costMeet needsAgriculture tools and machinesOrganic fertilisersPotassiumPlant growth

The invention discloses an organic-inorganic multifunctional water-retaining agent for resisting saline and alkaline and a preparation method of the organic-inorganic multifunctional water-retaining agent. The organic-inorganic multifunctional water-retaining agent for resisting saline and alkaline is characterized in that the formula of the water-retaining agent includes humic acid, crylic acid, industrial starch, additives and attapulgite which are taken as raw materials, and a crosslinking polymerization process is adopted for preparing the organic-inorganic multifunctional water-retaining agent. According to the water-retaining agent, inorganic minerals, the attapulgite and organic minerals, namely humic acid are adopted to improve the saline-alkaline resistance, and simultaneously, trace elements such as nitrogen, phosphorus and potassium necessary for the growth of plants are provided, so that the double functions of water retaining and nutrient elements providing can be met by applying the water-retaining agent, further, the multiple functions are endowed to the water-retaining agent, and the requirements of forest planting in high saline-alkaline and barren soils in western area can be met.

Owner:乌鲁木齐中汇国豪生物科技有限公司

Alkali deweighting wastewater processing method and device

InactiveCN101244857AEliminate purification processEliminate polluting emissionsOrganic chemistryWater contaminantsDimethyl terephthalateIndustrial effluent

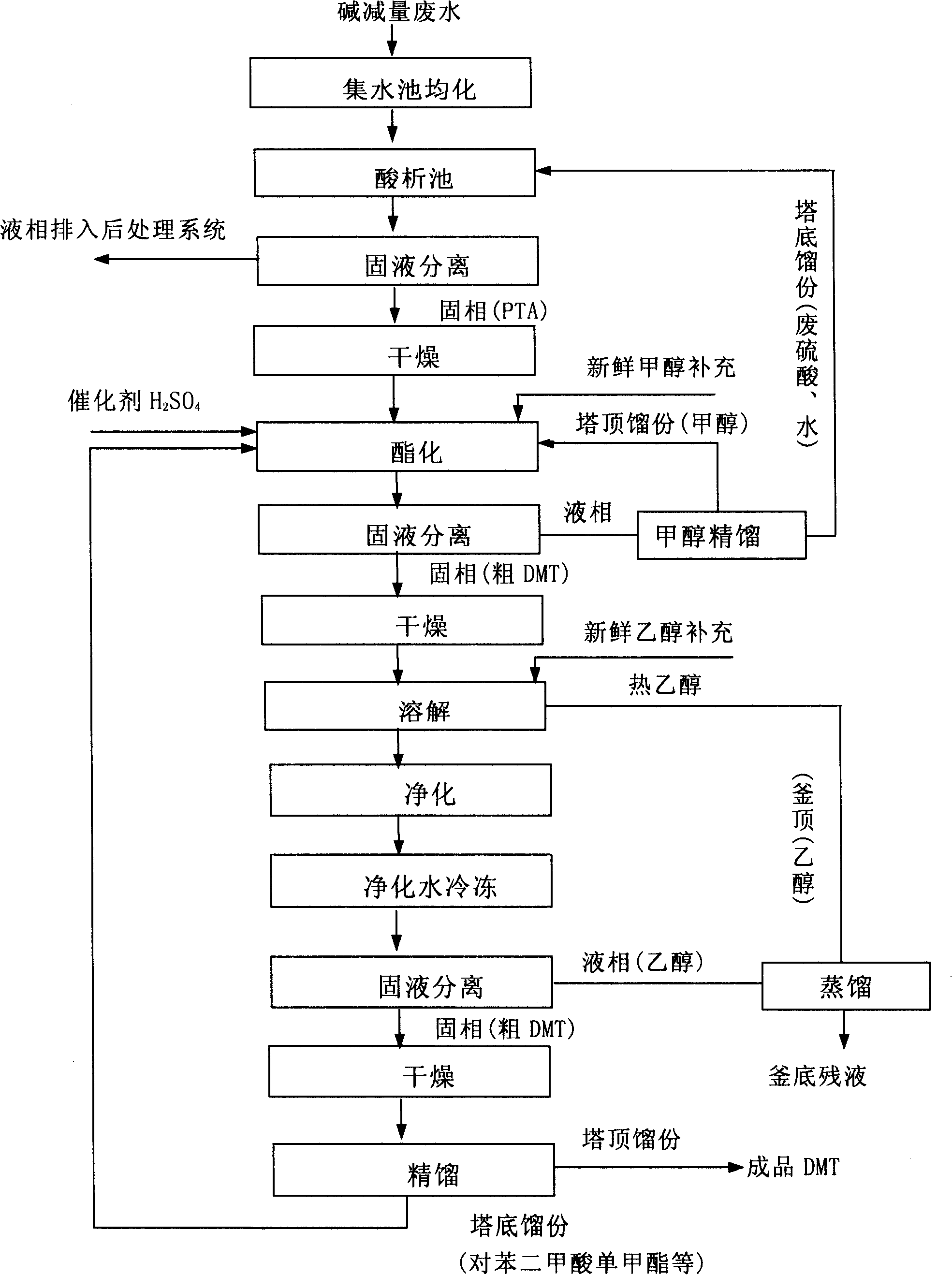

The invention provides a processing method for alkali-minimization wastewater, comprising a plurality of steps: (a) adjusting the PH value of alkali-minimization wastewater into 6.5 to 7, using the method of acid precipitation to obtain liquid phase and the solid phase with terephthalic acid; (b) carrying out esterification reaction for the solid phase from the procedure (a) in the presence of methanol to obtain a crude dimethyl terephthalate product. The method recovering terephthalic acid from alkali-minimization wastewater makes CODcr value of the wastewater removal of more than 75% and modifies the wastewater into Biodegradable industrial wastewater and at the same time changes the phthalic acid into dimethyl terephthalate.

Owner:SHAOXING COUNTY JINGSHENG RESIN TECH CO LTD

Solar wind-light complementary type streetlamp capable of serving as charging pile

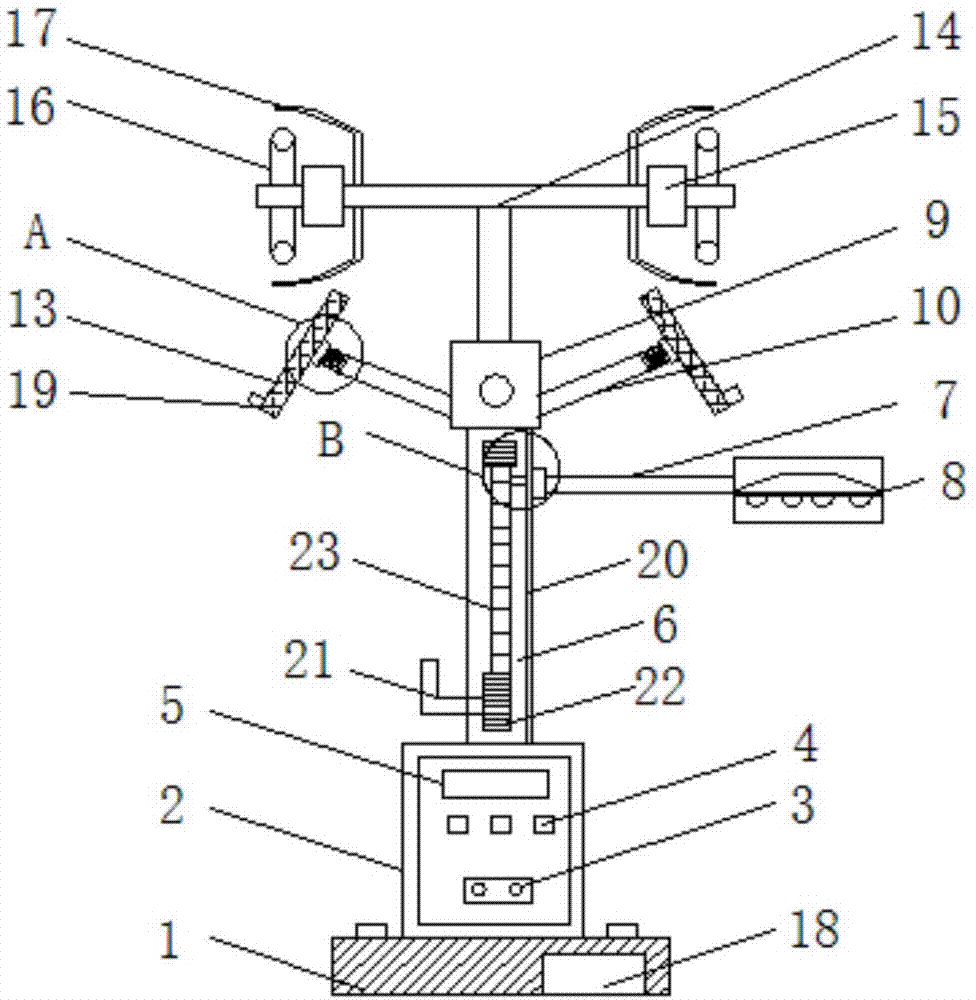

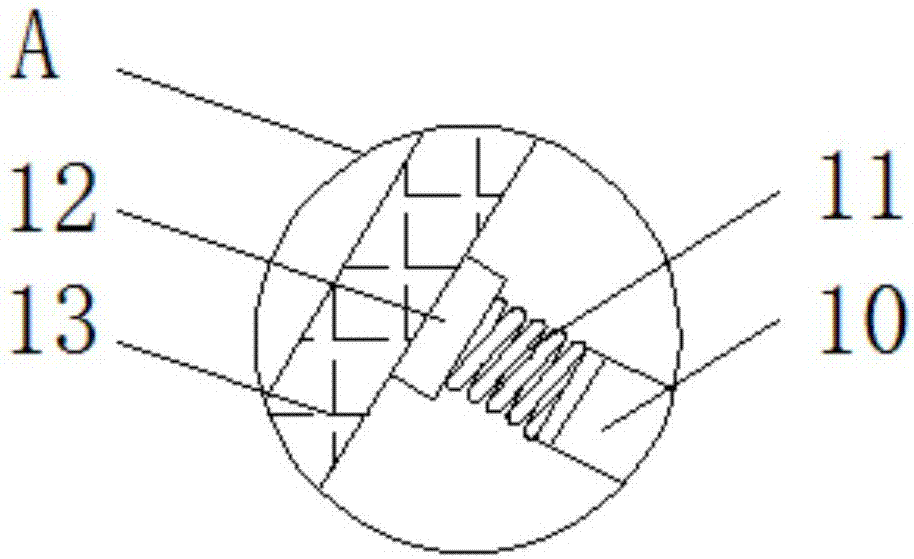

InactiveCN107965722ASimple structureEasy to useLighting support devicesElectric circuit arrangementsFixed frameEffect light

The invention discloses a solar wind-light complementary type streetlamp capable of serving as a charging pile in the technical field of streetlamps. The solar wind-light complementary type streetlampcomprises a base and a light sensor. The charging pile is arranged on the top of the base. A lamp post is arranged on the top of the charging pile. Streetlamp fixing frames are arranged on the outerwalls of the left side and the right side of the lamp post. A lighting lamp is arranged at the other end of one streetlamp fixing frame. A rotation device is arranged on the top of the lamp post. A T-shaped support is arranged on the top of the rotation device. Power generators are arranged at the left end and the right end of the T-shaped support. Fans are arranged at the output ends of the powergenerators. The device is simple in structure, safe and convenient to use. The charging pile and the streetlamp are combined, and when a vehicle needs to be charged, the vehicle only needs to be parked beside the roadside streetlamp to be charged, and the problem of troubles of charging is solved. Solar energy and wind energy are converted into electric energy to be used by the streetlamp and thecharging pile, waste of electric resources is effectively reduced, meanwhile, the function of environment protection is achieved, and pollution is avoided.

Owner:GAOYOU JIUCHUANG INFORMATION TECH CO LTD

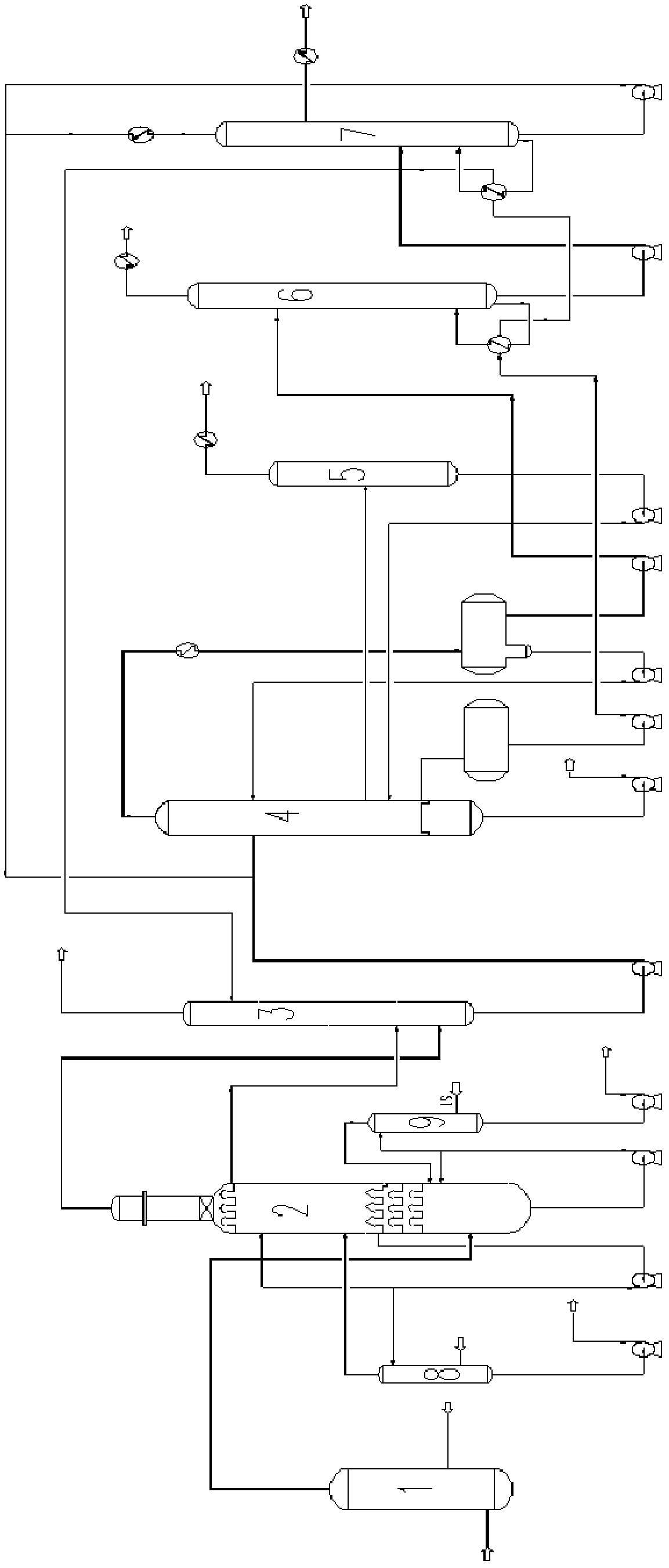

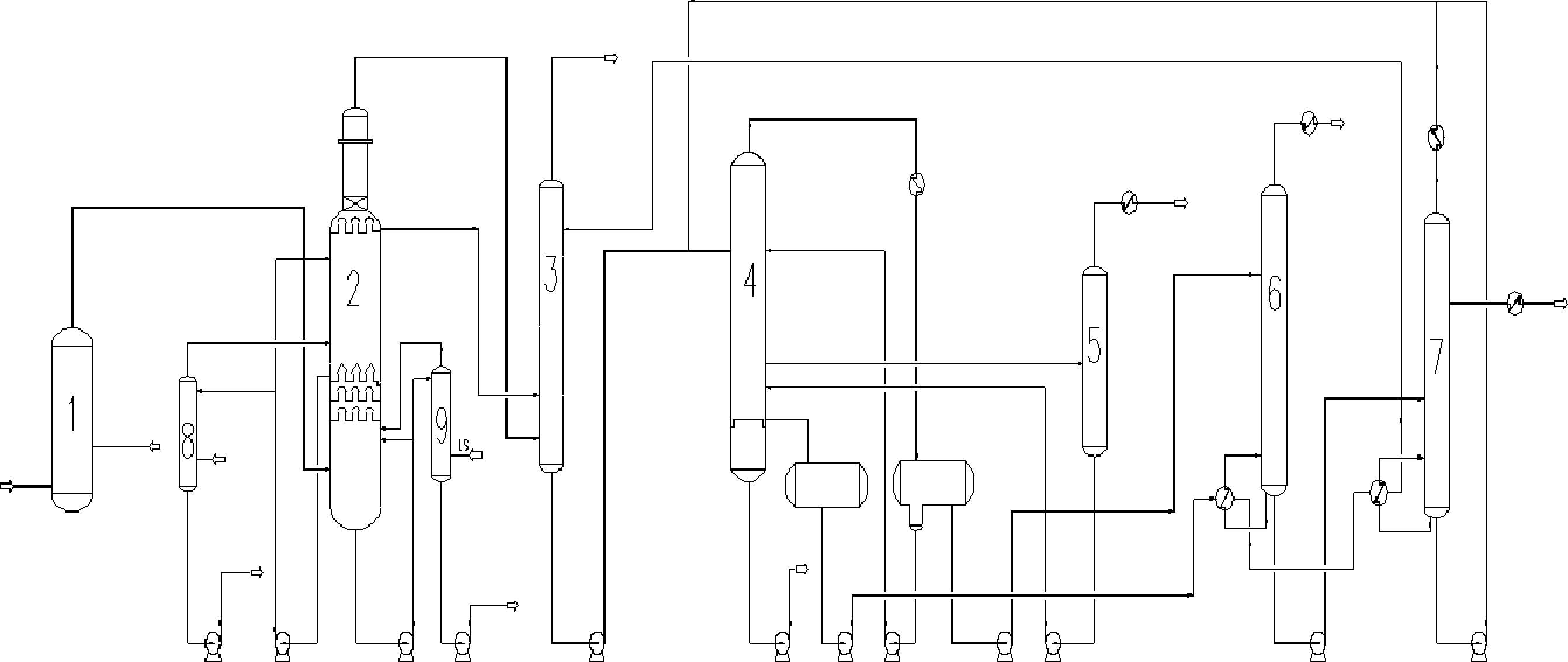

Industrial production method of acrylonitrile

ActiveCN102659625AIncrease device functionFunction increaseCarboxylic acid nitrile preparationOrganic compound preparationWater vaporGas phase

The invention provides an industrial production method of acrylonitrile, which comprises that the air, propylene and ammonia are subjected to ammoxidation inside a reactor and generate a reaction gas containing the acrylonitrile; the reaction gas enters a first tower and shock cooling, neutralization and cooling are achieved; the reaction gas which is subjected to shock cooling, neutralization and cooling enters a second tower and the water absorbs organic materials contained in the reaction gas; the water absorbing liquid enters a third tower, the acrylonitrile, hydrocyanic acid and water vapor steamed out by the third tower are subjected to condensation, and then separation of an aqueous phase and an organic phase is achieved in a quantizer of the third tower; the water phase inside the quantizer of the third tower are delivered to the third tower; the water phase introduced from a last piece of tower plates of a tower kettle of the third tower is subjected to heat exchange and then serves as absorbing water of the second tower; a gas phase containing acetonitrile is extracted from the side lines of the third tower and sent into a fourth tower and a rough acetonitrile product is obtained; and the organic phase in the quantizer of the third tower enters a fifth tower and a sixth tower sequentially and hydrocyanic acid and a acrylonitrile product are respectively obtained. According to the method, the reliability of a device is improved and the energy utilization is high.

Owner:CHINA TIANCHEN ENG +3

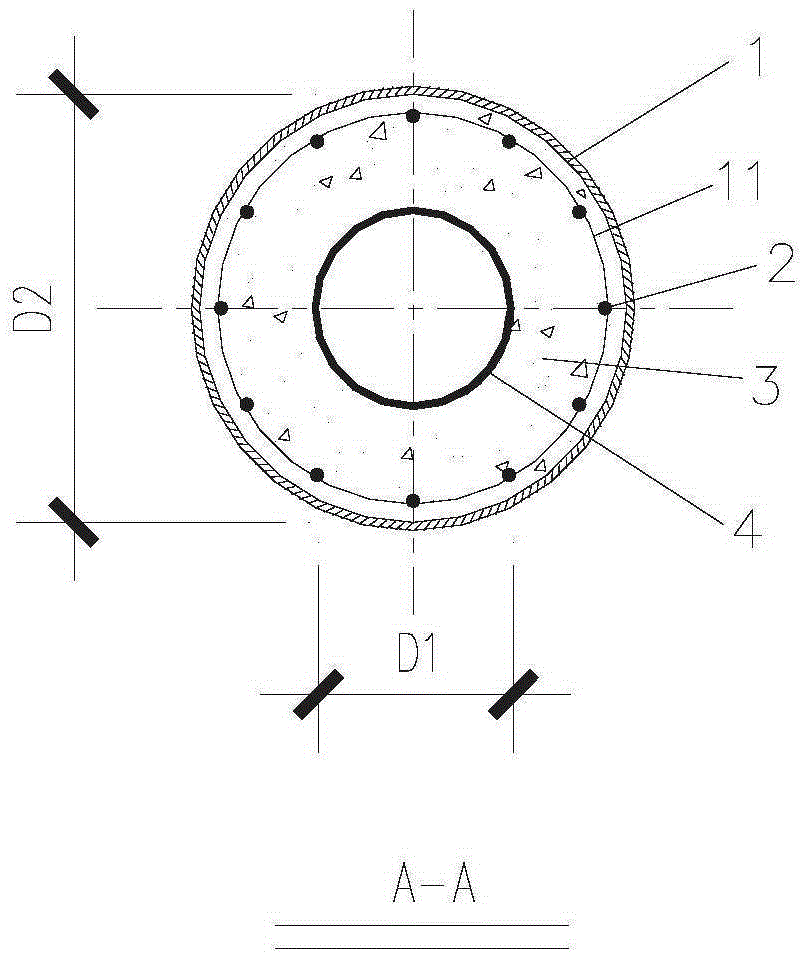

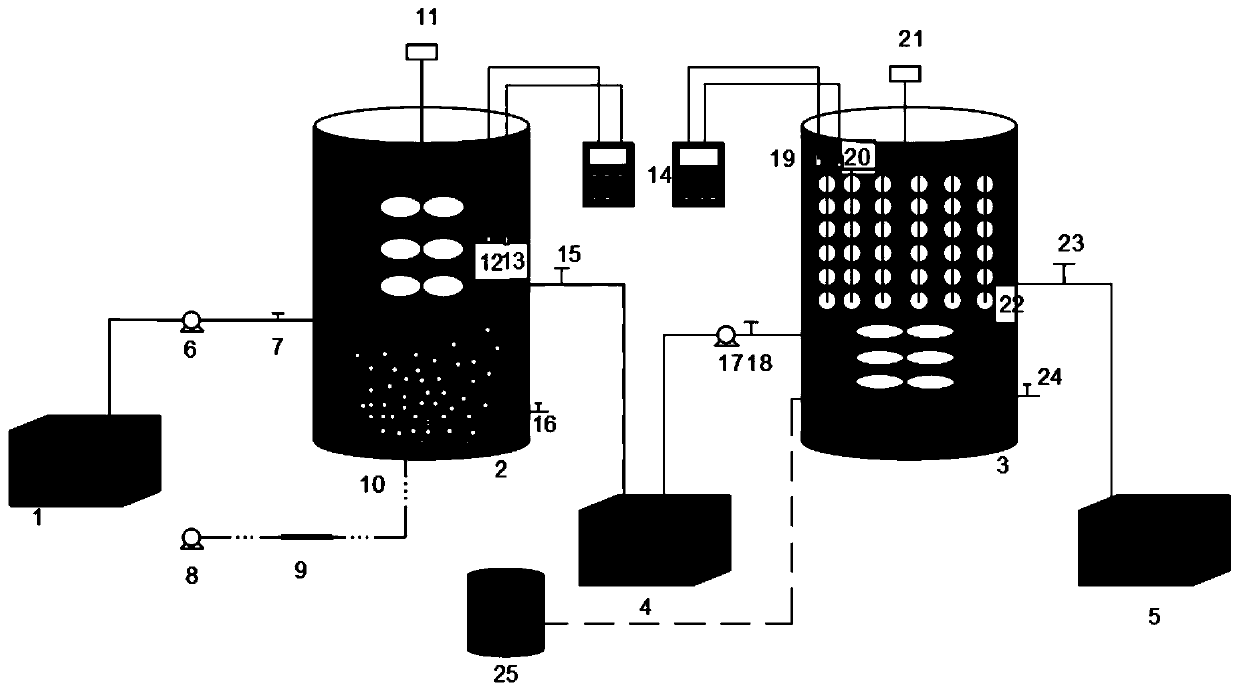

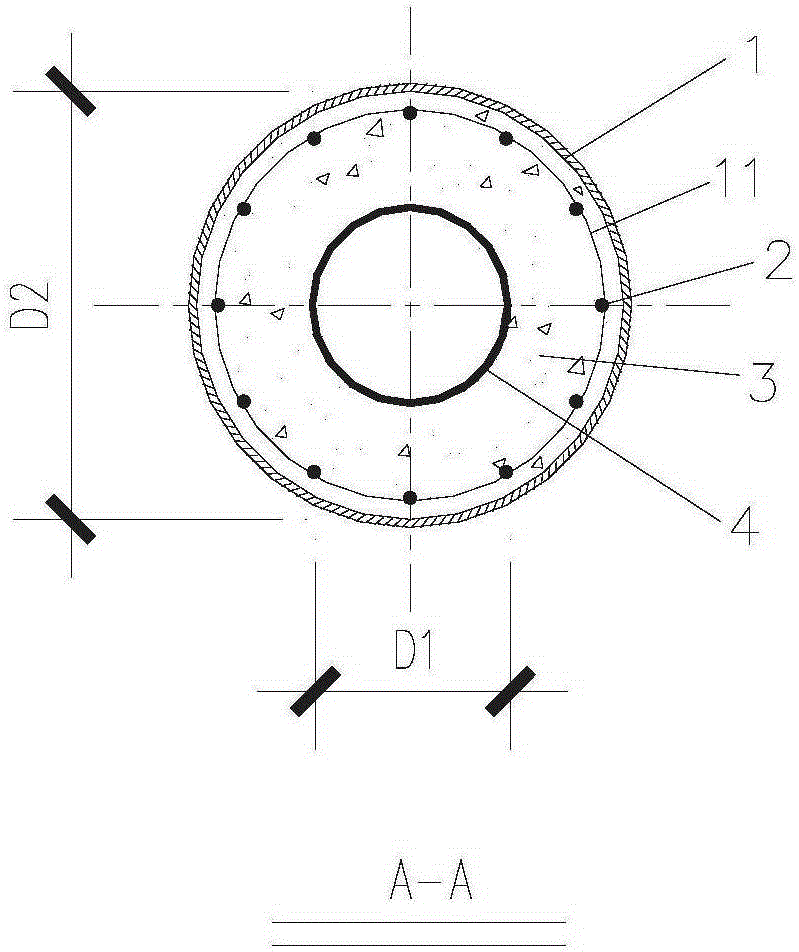

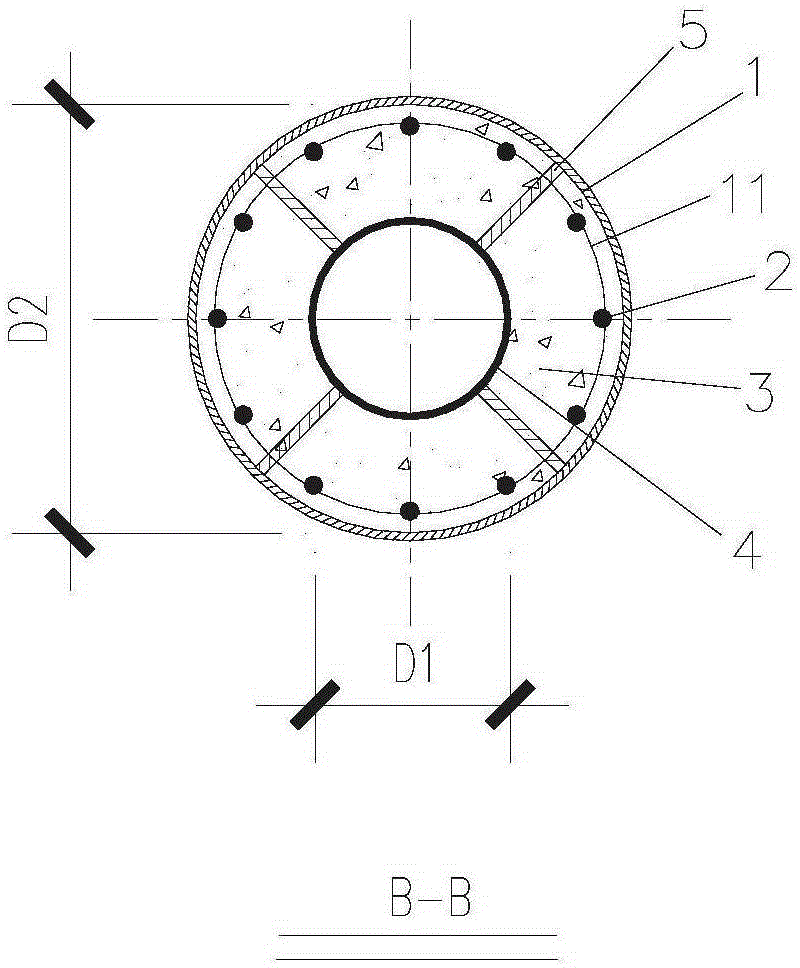

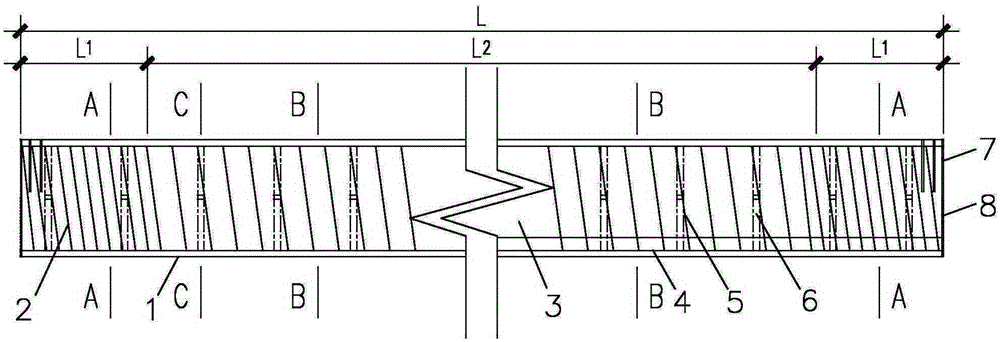

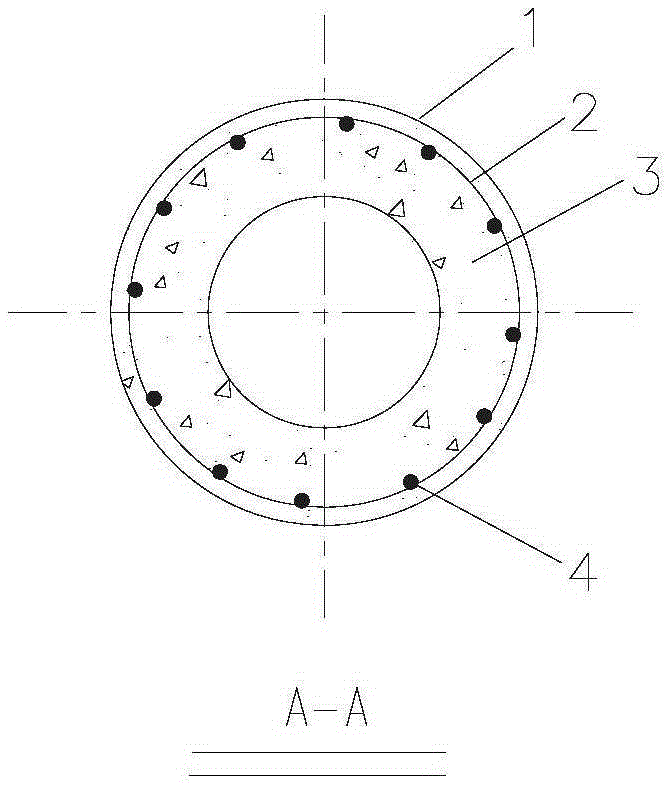

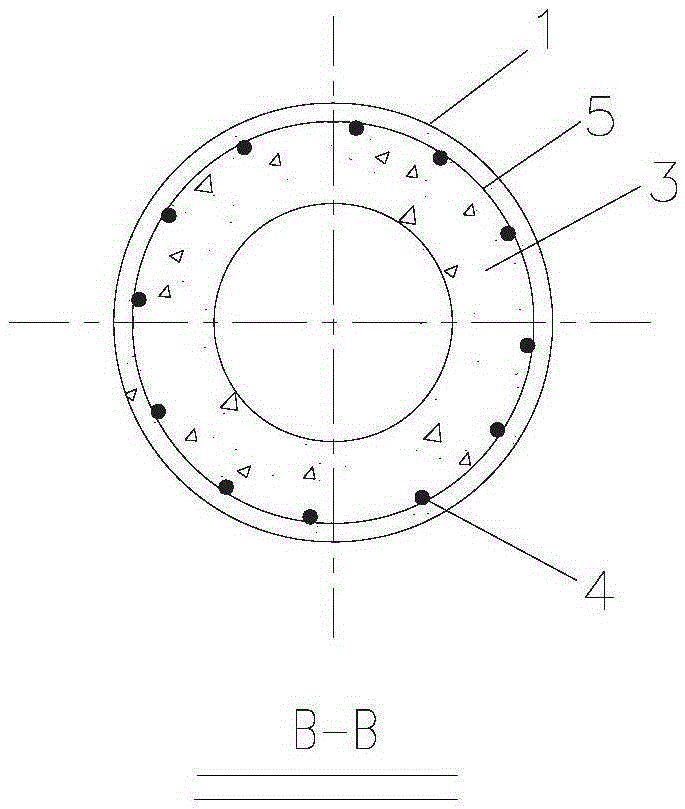

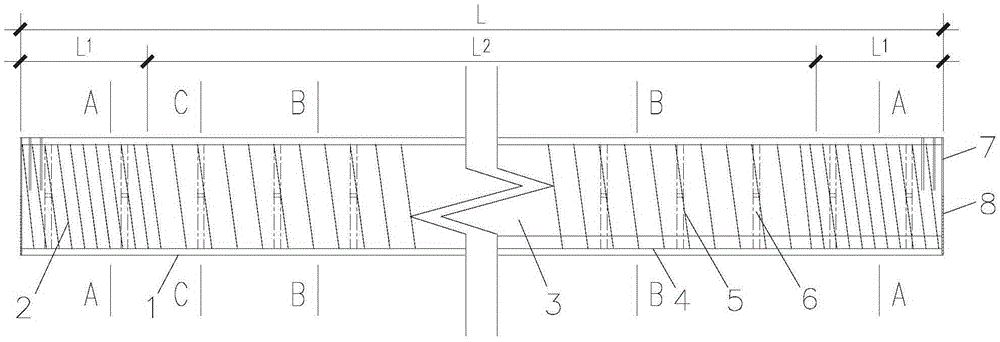

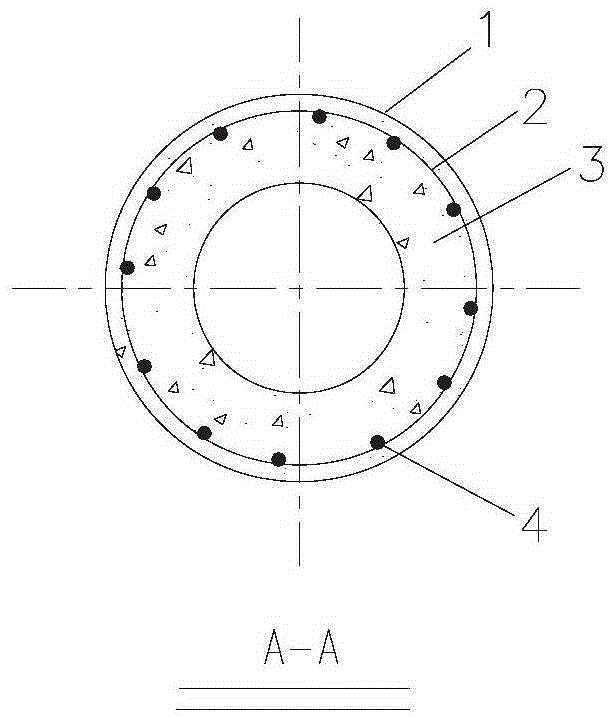

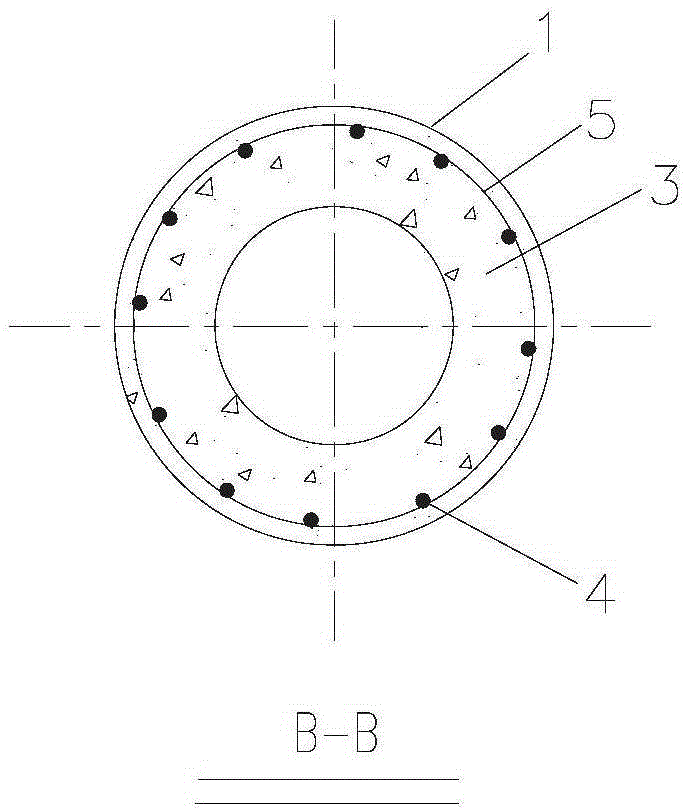

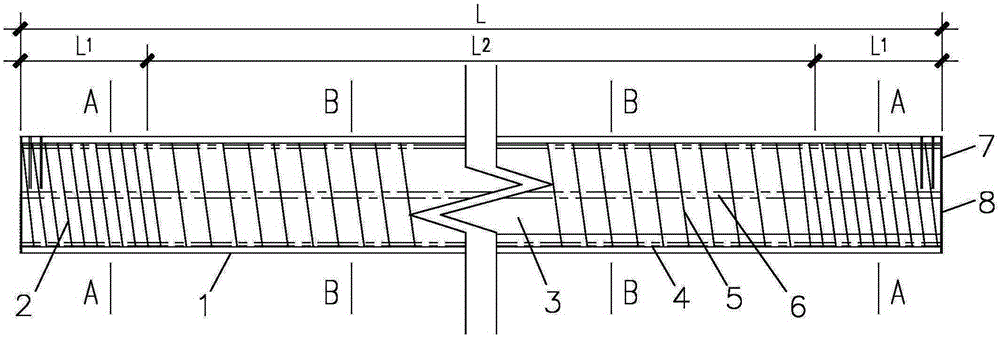

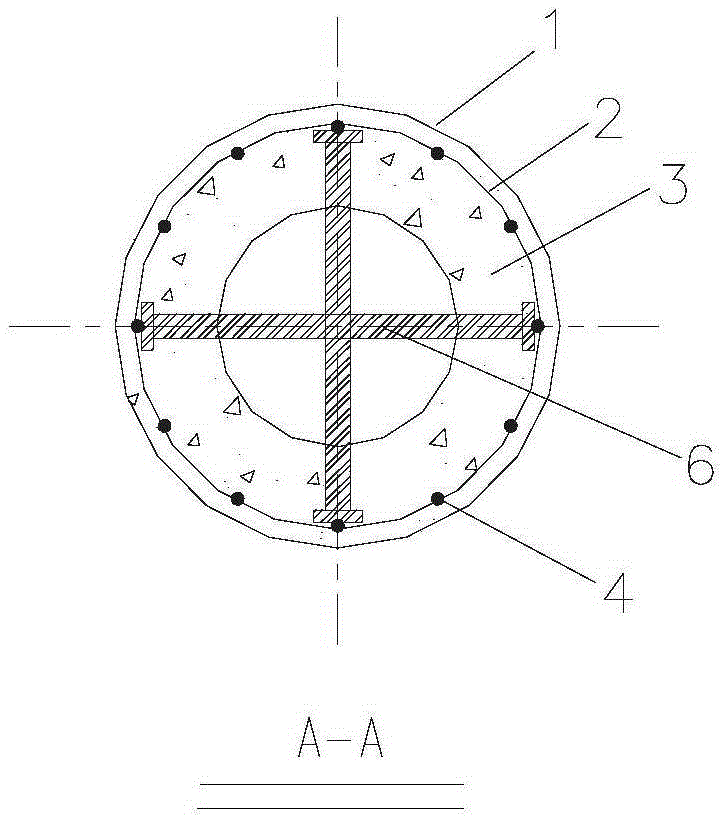

FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile

InactiveCN105386443AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses an FRP pipe and thick-wall steel pipe compounding hollow recycled concrete pile which is mainly formed by an FRP pipe, a round reinforcement cage framework, a thick-wall steel pipe and recycled concrete. The round reinforcement cage framework and the thick-wall steel pipe are arranged in the FRP pipe, and the round reinforcement cage framework, the thick-wall steel pipe and the FRP pipe are arranged concentrically. The recycled concrete is poured in annular space between the FRP pipe and the thick-wall steel pipe. The bearing capacity and deformation resisting capacity of the single pile can be greatly improved through the built-in thick-wall steel pipe. The wrapping FRP pipe can effectively prevent a pile body from being corroded, and the durability of the pile body is improved. Meanwhile, the FRP pipe and spiral stirrups are combined to restrain the inner recycled concrete, and the bearing force of the compounding pile is further improved. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated. In a word, the compounding hollow recycled concrete pile has the advantages of being good in pile forming quality, high in bearing force, good in deformation resisting capacity and durability, small in influence on the environment, high in construction speed and the like.

Owner:GUANGXI UNIV

Microwave catalytic remediation method for organic matter-heavy metal compound contaminated soil

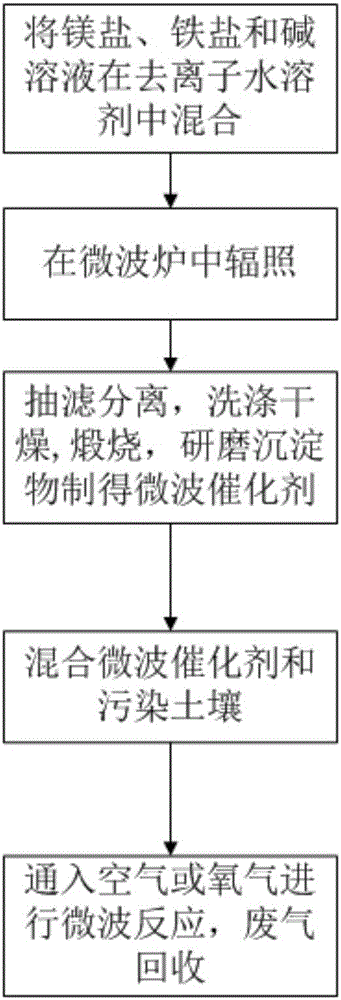

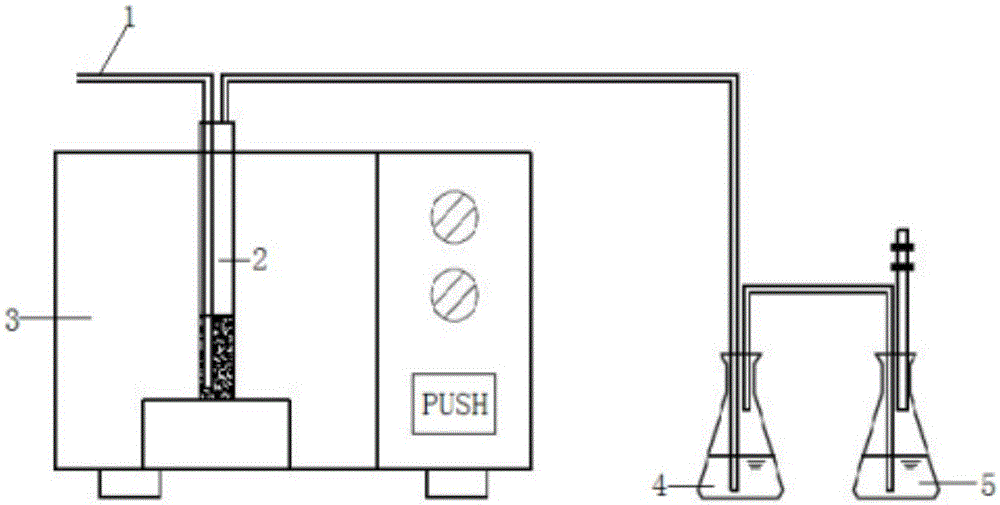

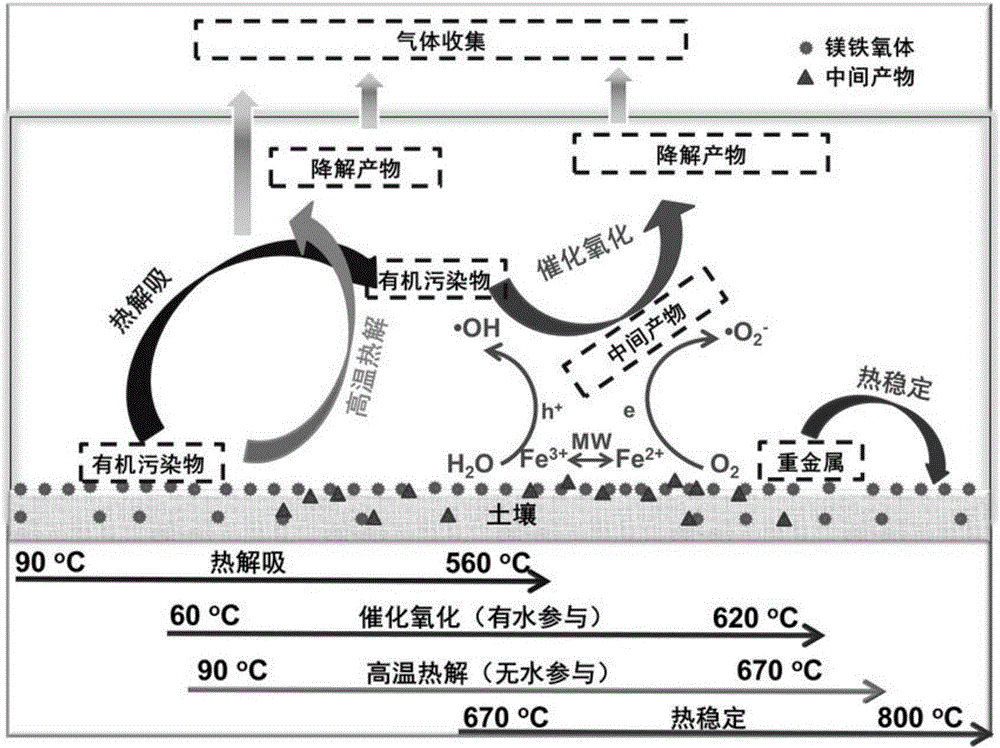

The invention belongs to the technical field relevant to soil remediation and particularly relates to a microwave catalytic remediation method for organic matter-heavy metal compound contaminated soil. The microwave catalytic remediation method for the organic matter-heavy metal compound contaminated soil comprises the steps that magnesium salt, ferric salt and aqueous alkali are added into deionized water and then mixed and stirred; turbid liquid is irradiated in a microwave oven; suction filtration is conducted on the turbid liquid after a reaction so that sediment can be separated out, and the sediment is washed and dried; a microwave catalyst is obtained through cooling and grinding after calcination; the microwave catalyst and the contaminated soil are mixed; the mixture is placed in a microwave reactor, and oxygen or air is led into the microwave reactor for a microwave reaction; and gas generated during the reaction is collected at the same time, and thus required remediation of the contaminated soil is completed. By the adoption of the microwave catalytic remediation method for the organic matter-heavy metal compound contaminated soil, the contaminated soil can be remediated in the way that environment protection is facilitated, quality control is convenient and the efficiency is high; and the microwave catalyst is used for adsorbing heavy metal ions in the contaminated soil and degrading organic matter in the contaminated soil, and meanwhile secondary pollution is avoided by collecting waste gas.

Owner:HUAZHONG UNIV OF SCI & TECH +2

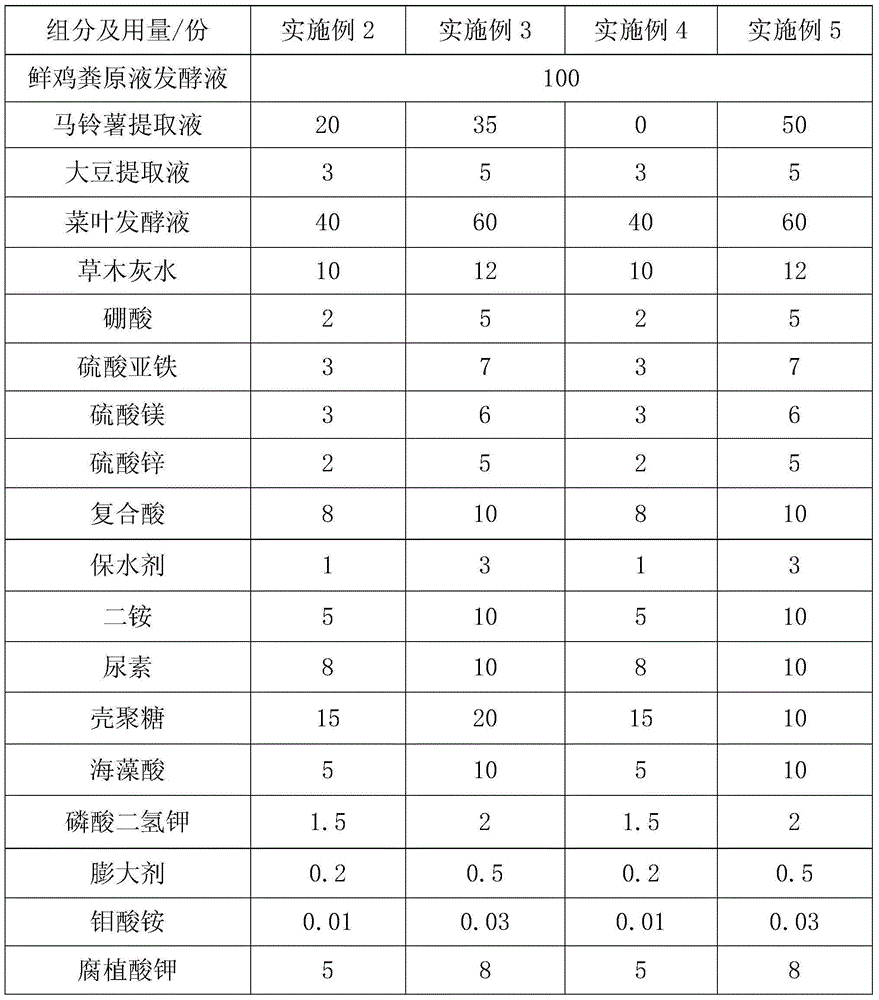

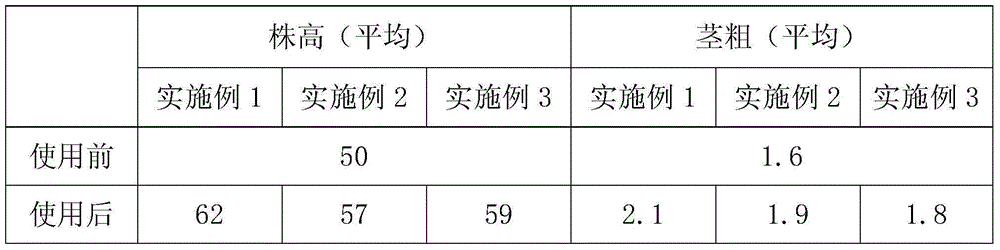

Special liquid water flush fertilizer for potatoes and preparation method for special liquid water flush fertilizer for potatoes

ActiveCN105036851ANot afraid of the tideNo problem of decreased solubilityFertilizer mixturesLiquid waterMonopotassium phosphate

The invention discloses a special liquid water flush fertilizer for potatoes. The special liquid water flush fertilizer for potatoes is characterized by being prepared from the following raw materials in parts by weight: 100 parts of fresh chicken manure raw liquid fermentation liquor, 8-10 parts of urea, 1.5-2 parts of monopotassium phosphate, 5-8 parts of potassium humate, 0.01-0.03 part of ammonium molybdate, 2-5 parts of boric acid, 3-7 parts of ferrous sulfate, 3-6 parts of magnesium sulfate, 2-5 parts of zinc sulfate, 8-10 parts of a compound acid, 1-3 parts of a water-retaining agent, 5-10 parts of diammonium, 20-35 parts of a potato extraction solution, 15-20 parts of chitosan, 5-10 parts of alginic acid, 3-5 parts of a soybean extraction solution, 0.2-0.5 part of a swelling agent, 10-12 parts of plant ash water and 40-60 parts of vegetable fermentation liquor. By taking chicken manure and vegetable fermentation liquor as main organic matters, the fertilizer is comprehensive and abundant in nutrient and the two organic matters are waste which is low in price. The two organic matters are applied to the fertilizer, so that the waste is turned into wealth, an effect of protecting the environment is exerted, and the special liquid water flush fertilizer for potatoes has good social and economical benefits.

Owner:甘肃省昕农福农业科技有限责任公司

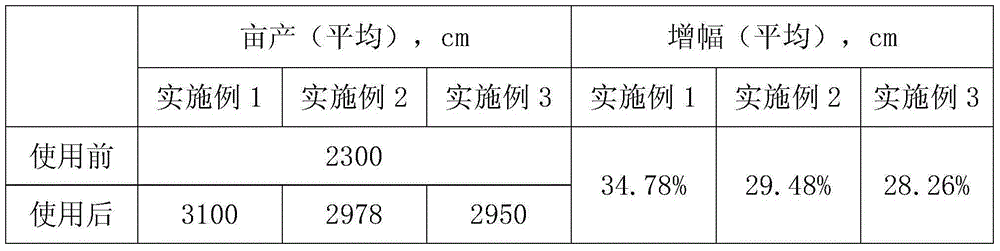

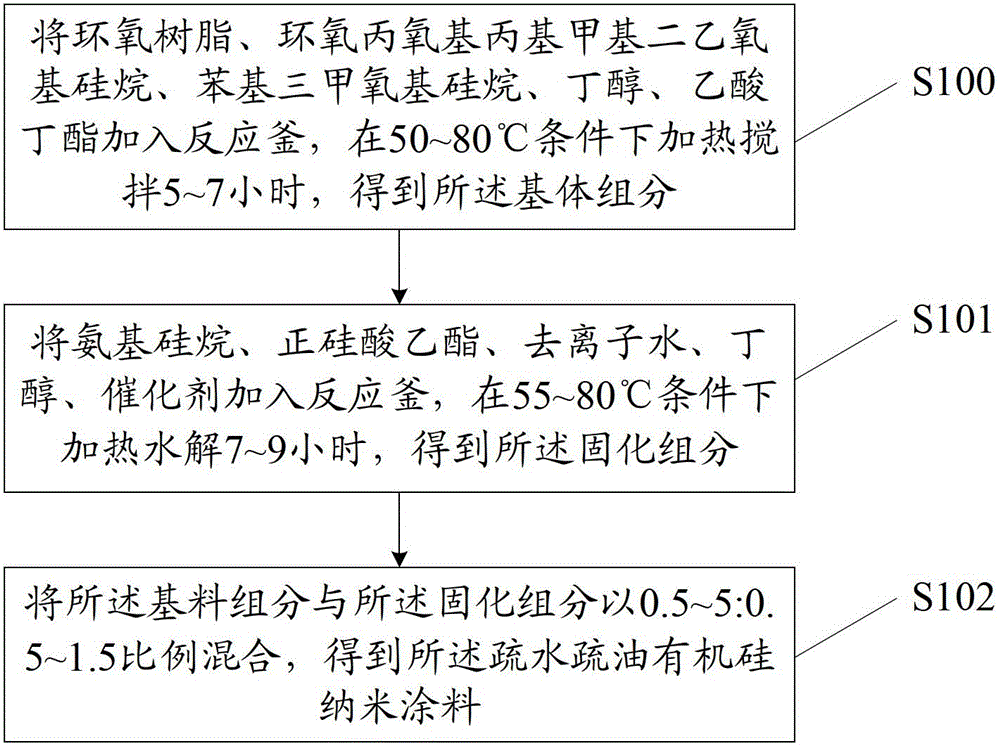

Anti-graffiti anti-sticking nano coating and preparation method thereof

ActiveCN102911584AGood anti-graffiti and anti-stick effectEvenly dispersedAntifouling/underwater paintsPaints with biocidesEpoxySurface brightness

The invention discloses an anti-graffiti anti-sticking nano coating which comprises a base component and a curing component, wherein the ratio of the base component to the curing component is (0.5-5):(0.5-1.5); the base component comprises epoxy resin, (epoxypropoxy)propyl methyldiethoxysilane, phenyltrimethoxysilane, butanol and butyl acetate; and the curing component comprises a precursor, tetraethyl orthosilicate, deionized water, butanol and a catalyst. The embodiment of the invention also discloses a preparation method of the anti-graffiti anti-sticking nano coating. Through the invention, the nano coating realizes an excellent anti-graffiti anti-sticking effect, and has the characteristics of high permeability, high adhesive power, self-cleaning function, adjustable surface brightness, no pollution, low manufacturing cost, wide application range, low construction requirements and the like.

Owner:戚城

Purifying equipment for processing hazes in air

InactiveCN104436961ASimple structureImprove adsorption capacityCombination devicesAir-treating devicesWater storageActivated carbon filtration

The invention discloses purifying equipment for processing hazes in air. The purifying equipment comprises a tank body, a filter device, an adsorption device and an air exhaustion device, wherein a fixing frame fixed with a car is arranged on the bottom surface of the tank body; the filter device comprises a first filter screen arranged on the inner side of the front end of the tank body and a second filter screen arranged on the inner sides of the left end, the right end and the rear end of the tank body; a plurality of first air holes are respectively formed in the front, the rear, the left and the right side wall of the tank body, and an air inlet opening for introducing air is further formed in the front end of the tank body; the adsorption device comprises filter cotton, a drawer type water storage grid is arranged on the lower part of the tank body, and the filter cotton is arranged in the drawer type water storage grid; the air exhaustion device comprises a plurality of wind-powered exhaust fans arranged on an upper cover of the tank body. The purifying equipment disclosed by the invention can be fixed on the car, and can be used for effectively adsorbing and purifying the atmosphere by moving along with the car; the air resistance of the filter screens is reduced through four-face ventilation design, and the active carbon filter cotton can be used for effectively adsorbing and filtering polluted particles and harmful gases in air.

Owner:芜湖中艺科技服务有限公司

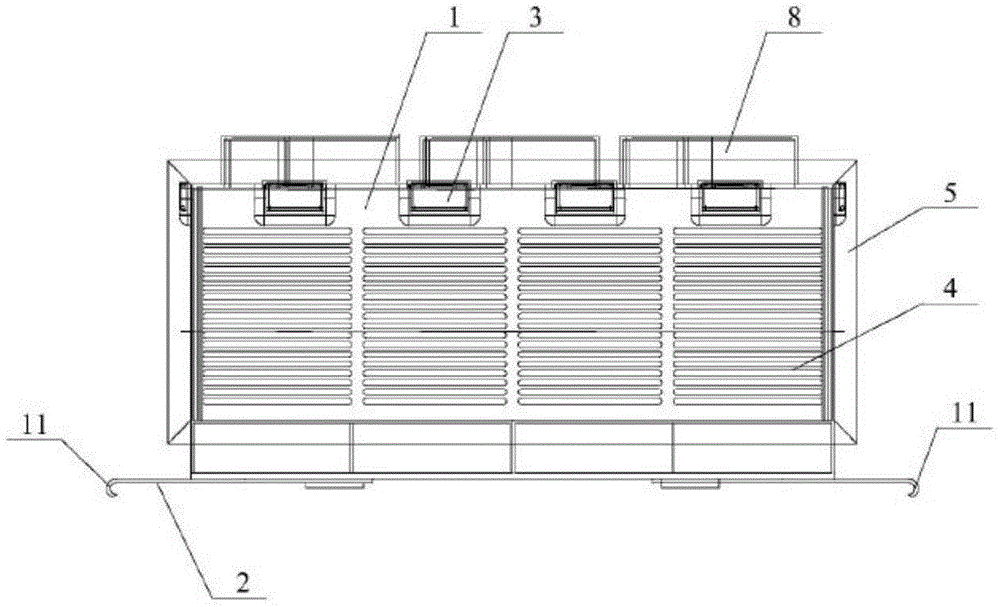

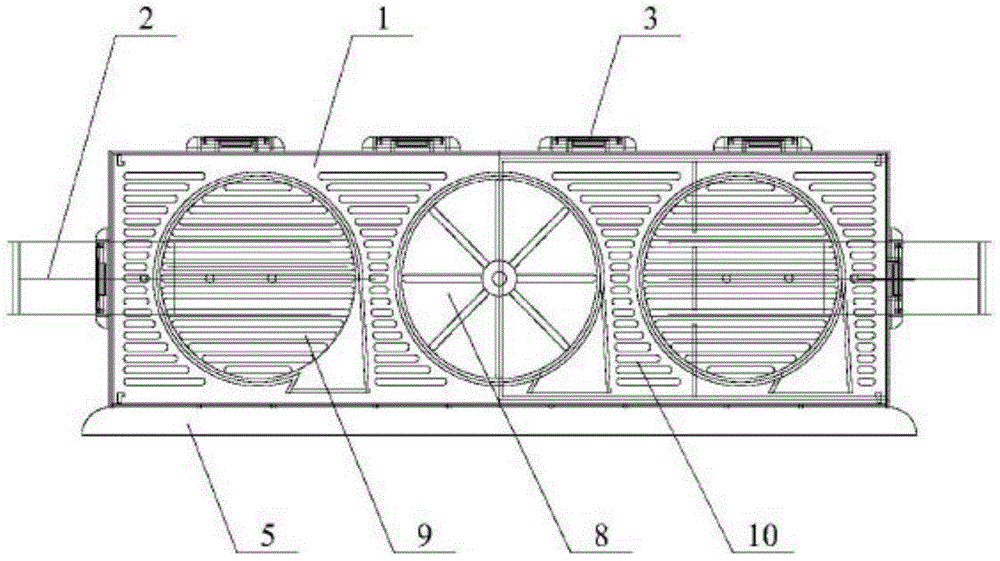

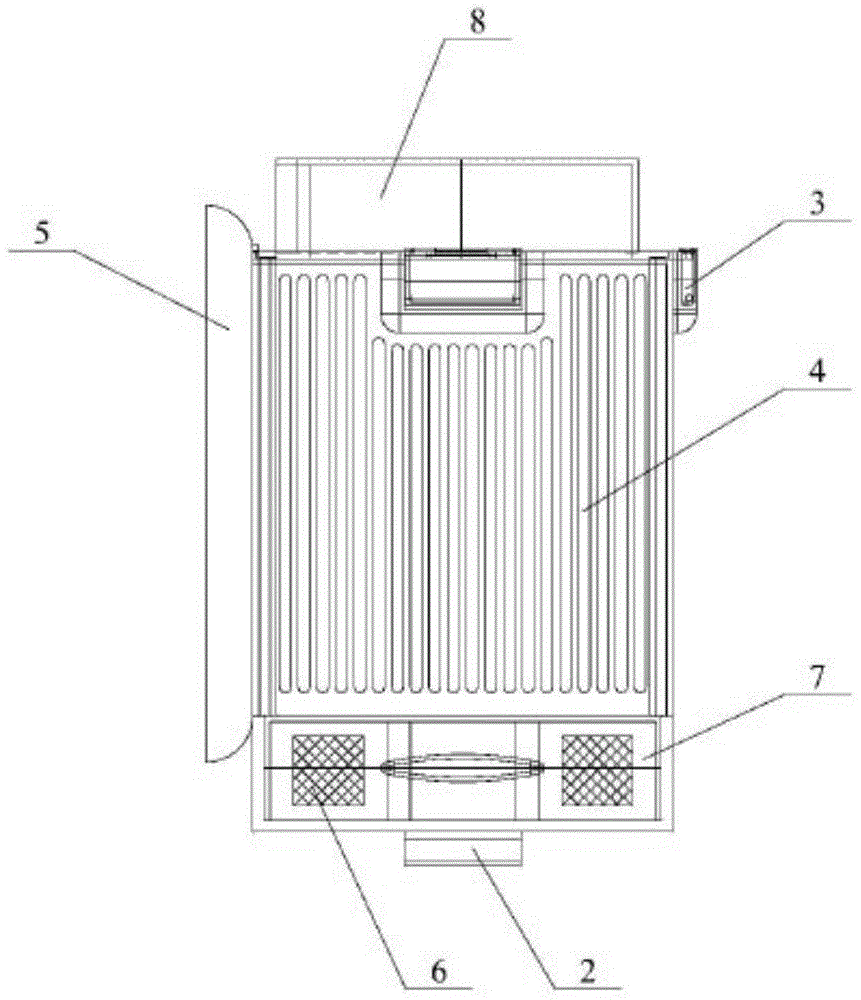

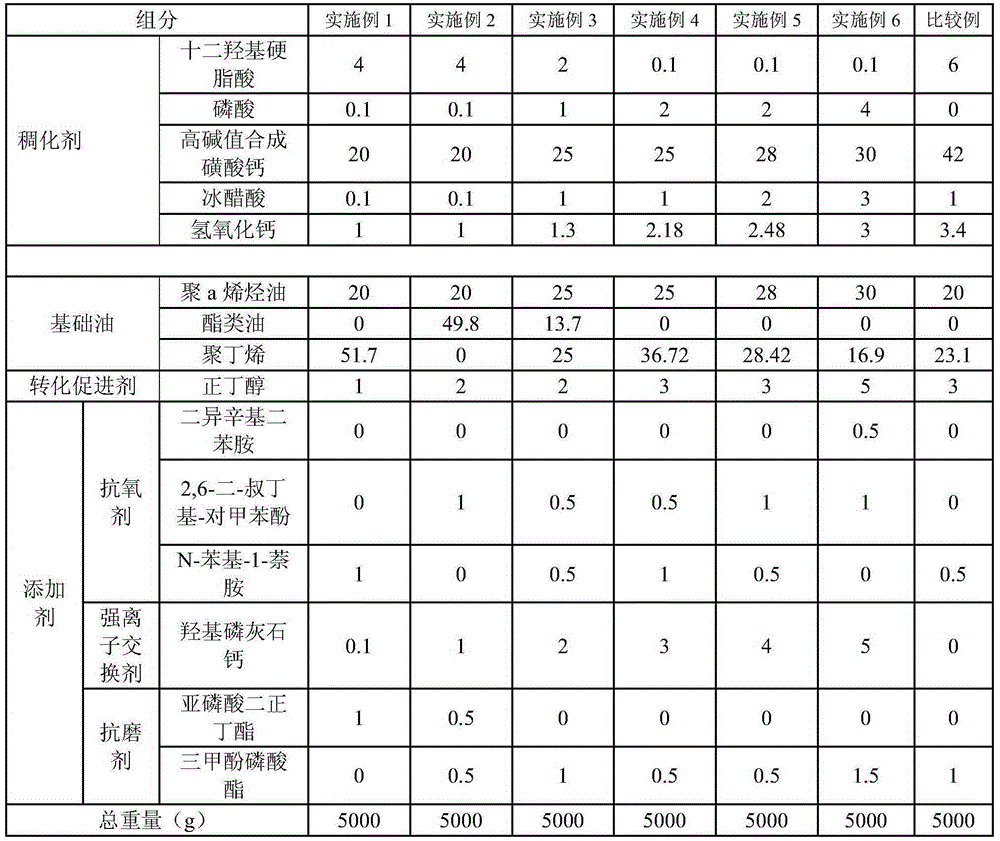

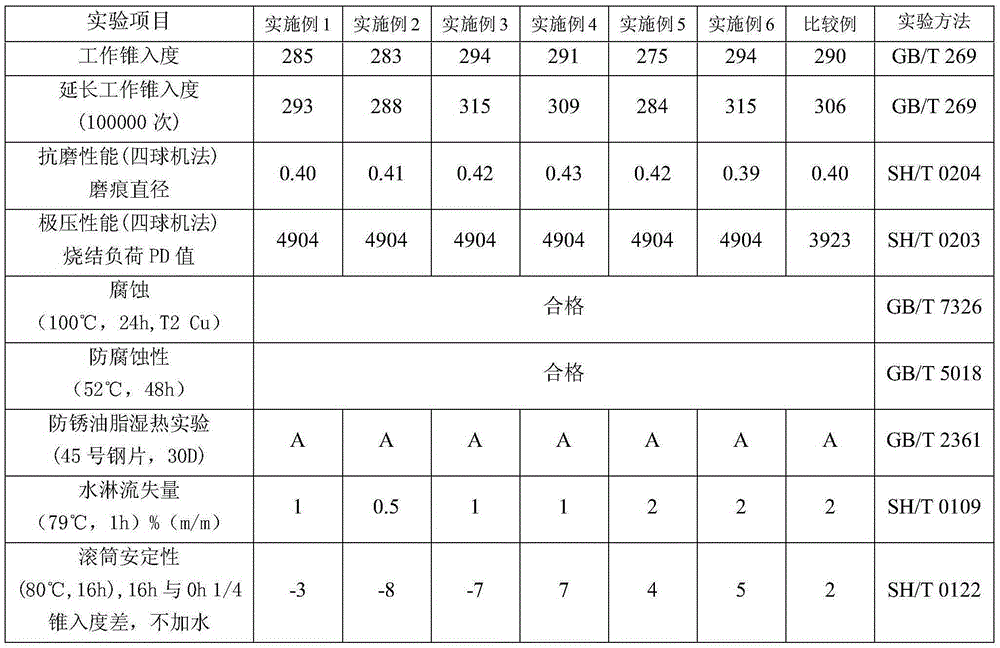

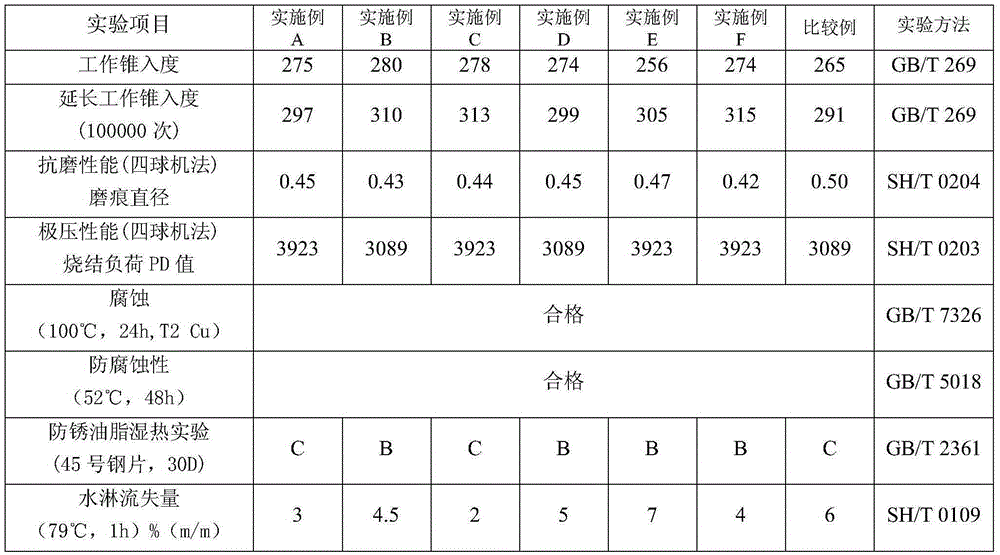

Acid-and-alkali-corrosion-resistant environment-friendly lubricating grease composition and preparation method

ActiveCN105255553AGood acid and alkali resistanceReduce the content of heavy metal ionsAdditivesPhosphoric acidIon exchange

The invention relates to an acid-and-alkali-corrosion-resistant environment-friendly lubricating grease composition and a preparation method. The acid-and-alkali-corrosion-resistant environment-friendly lubricating grease composition is prepared from 20%-30% of high alkali synthesis calcium sulfonate, 0.1%-2% of conversion accelerant, 0.1%-3% of glacial acetic acid, 1%-4% of fatty acid, 0.1%-4% of phosphoric acid, 1%-3% of calcium hydroxide, 1.5%-7.5% of additives and high-viscosity synthetic base oil. An acid solution or an alkaline solution with the mass fraction of 10% is added to lubricating grease for conducting performance testing again, and the lubricating grease prepared from high alkali synthesis calcium sulfonate has the better water resistance, corrosion resistance, shearing resistance and extreme pressure antiwear property. Due to the characteristics of the high-viscosity synthetic base oil and a calcium sulfonate thickening agent, no emulsification or thinning phenomenon occurs to the lubricating grease when the lubricating grease is immersed in the acid solution or the alkaline solution, and the good adhesion property is achieved. Due to the fact that a strong ion exchanger, namely, calcium hydroxylapatite is added, calcium ions in molecules can replace heavy metal ions and the like in a water solution, and the good environment-friendly effect is shown.

Owner:CHINA PETROLEUM & CHEM CORP

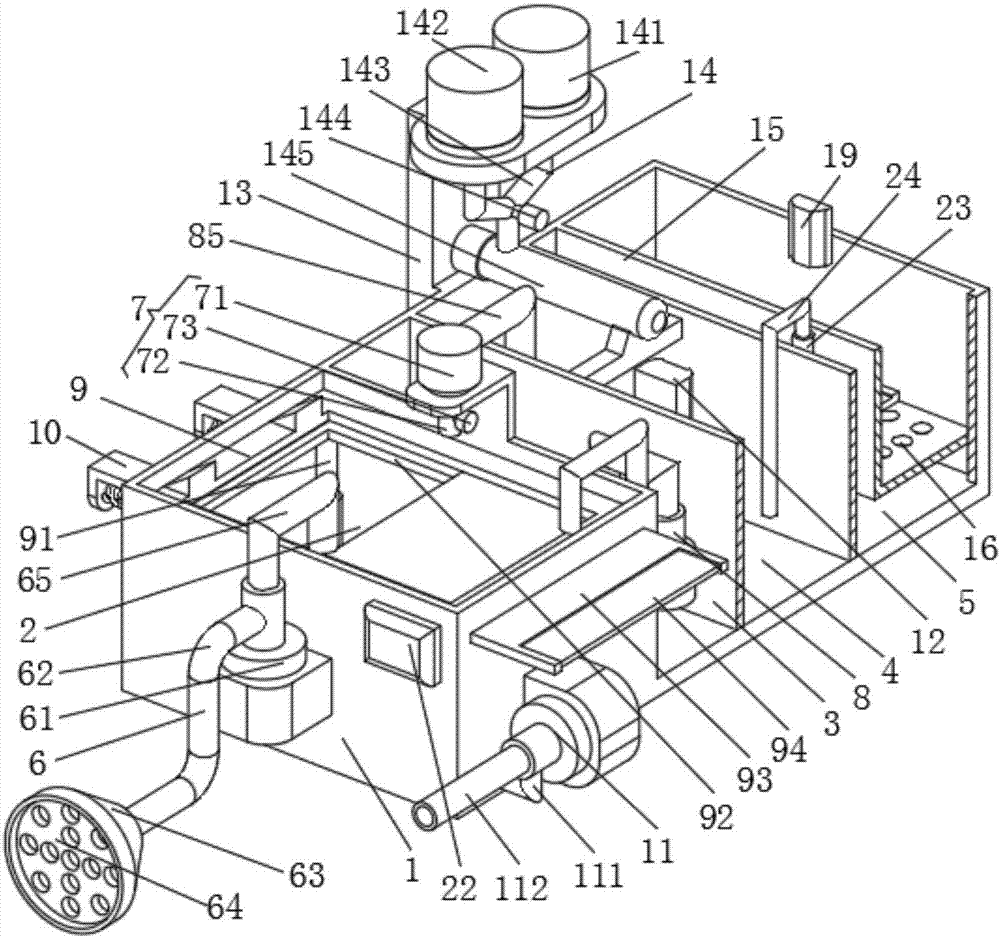

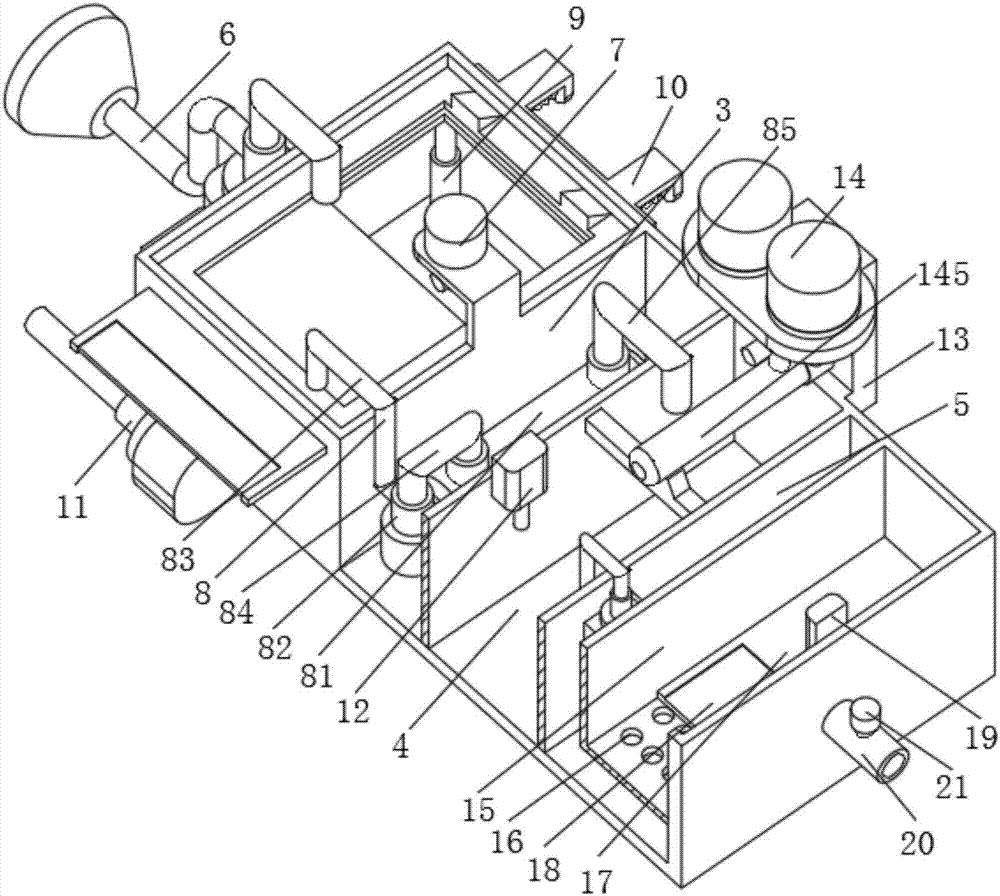

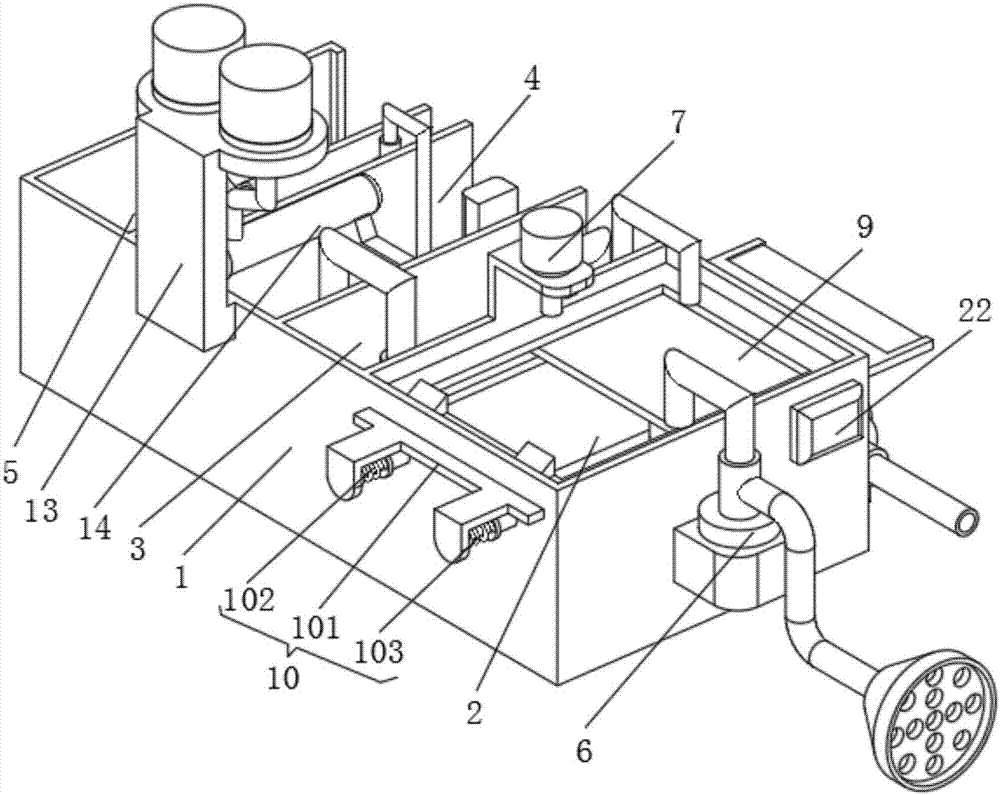

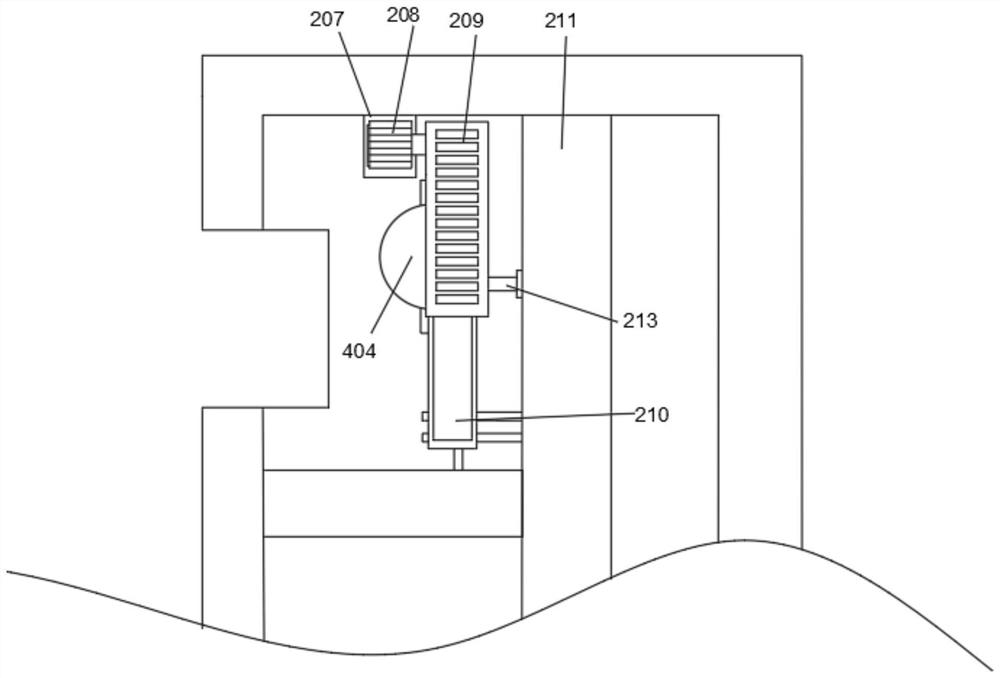

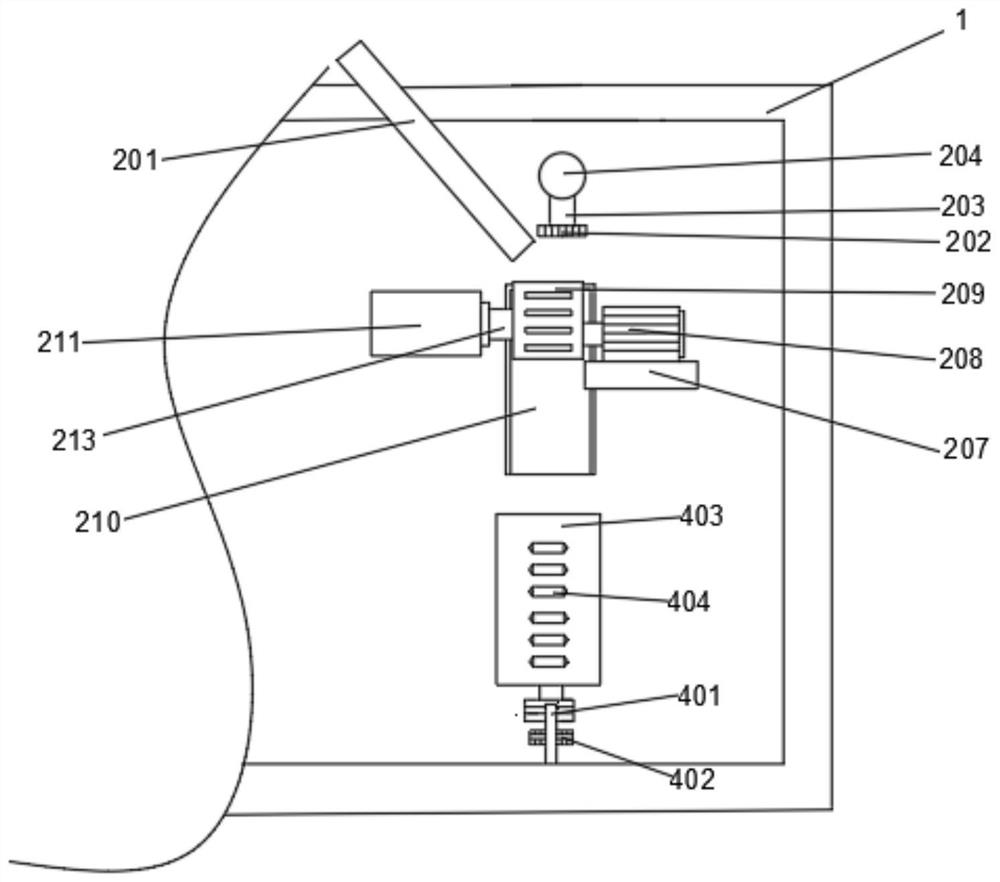

Mud discharge system of integrated sewage treatment equipment

InactiveCN107986562AEasy to useImprove purification effectWater treatment parameter controlWater/sewage treatment by irradiationFiltrationSludge

The invention discloses a mud discharge system of integrated sewage treatment equipment. The system comprises a purification pond which comprises a settling pond, a disinfection pond, an acid-alkali neutralization pond and a microbial degradation pond, wherein the settling pond, the disinfection pond, the acid-alkali neutralization pond and the microbial degradation pond are successively distributed from left to right; a sewage extraction device is arranged at the lower end of the left side face of the settling pond, and a suction pump of the sewage extraction device is fixedly connected to the settling pond; a PLC is arranged at the upper end of the left side face of the settling pond; the input end of the PLC is electrically connected to the output end of an external power supply; and afiltering and settling device is arranged at the upper end of the settling pond. The mud discharge system of the integrated sewage treatment equipment can carry out flocculent precipitation and extrusion filtration on sewage, so that the sludge is discharged conveniently. Meanwhile, settlement of sludge in the sewage, disinfection of the sewage, neutralization of the acidic or alkaline sewage anddegradation of indissoluble matters can be carried out successively, so that the purification effect of the sewage is improved and the practicality is high.

Owner:赵伟康

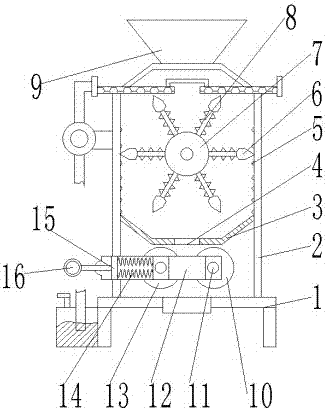

Environmentally-friendly ore crushing equipment

InactiveCN107457037APlay a role in protecting the environmentSimple structureGrain treatmentsEngineeringManufacturing enterprises

The invention discloses environmentally-friendly ore crushing equipment. The environmentally-friendly ore crushing equipment comprises a base, wherein a crushing box is welded on the outer wall of the top of the base; a horizontally arranged arc-shaped baffle plate is welded on the inner walls of the two sides of the crushing box; the outer walls of the periphery of the arc-shaped baffle plate are in contact with the inner walls of the periphery of the crushing box; a crushed ore channel is formed in the middle of the top of the arc-shaped baffle plate; equidistantly distributed convex blocks are welded on the inner walls of the two sides of the crushing box; a transmission bar is welded on the inner wall of one side of the crushing box; a clockwise turntable is welded on the outer wall of the transmission bar; equidistantly distributed supporting bars are welded on the outer wall of the clockwise turntable; and the outer wall of the end, far away from the clockwise turntable, of each supporting bar is connected to a crushing hammer by a bolt. The environmentally-friendly ore crushing equipment is simple in structure, reasonable in design, low in manufacturing cost and suitable for self-manufacturing enterprises and small and medium-sized enterprises, has relatively high production efficiency and is capable of creating relatively high production benefit.

Owner:FOSHAN SHENYAN INFORMATION TECH CO LTD

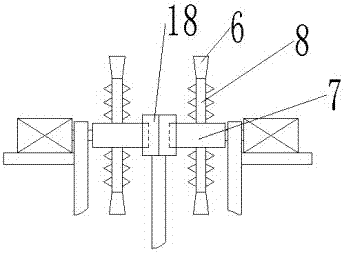

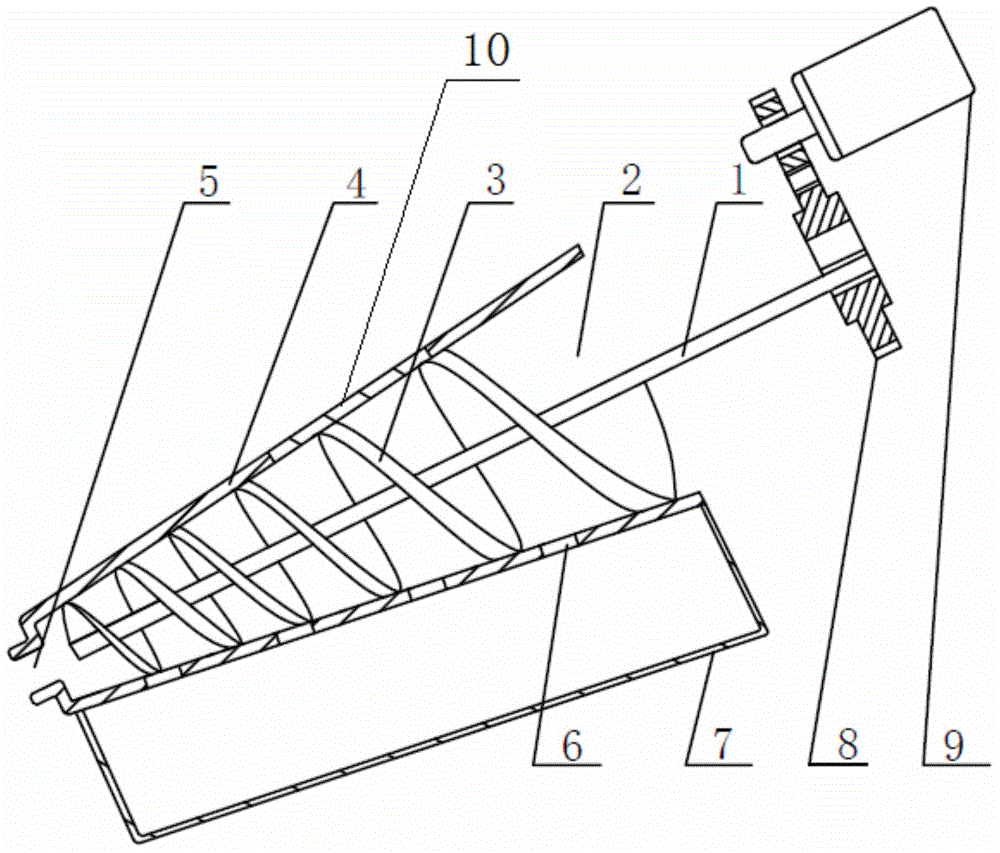

Conical screw crusher

The invention discloses a conical screw crusher which comprises a conical housing (4) and a main rotating shaft (1) arranged in the conical housing (4), wherein a screw fan blade (3) is fixedly arranged on the main rotating shaft (1), a connecting gear (8) is arranged at one end, which extends out from the conical housing (4), of the main rotating shaft (1), the connecting gear (8) is meshed with a gear on an output shaft of the motor (9); a feeding hole (2) is formed in the top of the conical housing (4), an outlet hole (5) is formed in the bottom end of the conical housing (4), and a plurality of discharging holes (6) are uniformly formed in the lower side edge of the conical housing (4) and the lower side of the conical housing (4) is connected with a collecting box (7). The conical screw crusher is small in occupation space, uniform in crushed particles; meanwhile, due to the adoption of the feeding hole and the discharging holes, dust generated during crushing can be prevented from flying in air, so that a certain environment-friendly function is achieved; a window is arranged on the housing, so that the crusher can be periodically checked and cleaned and the service life of the conical screw crusher is prolonged.

Owner:GUANGXI UNIV

Treatment process for realizing urban sewage denitrification and phosphorous removal coupled sludge fermentation by two-stage sequencing batch reactor

InactiveCN110002595ARealize denitrification and dephosphorizationAchieve reductionWater treatment parameter controlSpecific water treatment objectivesBioaugmentationChemistry

The invention discloses a treatment process for realizing urban sewage denitrification and phosphorous removal coupled sludge fermentation by a two-stage sequencing batch reactor, and belongs to the field of sewage sludge biological treatment. The process comprises: a water inlet water tank, a bio-reinforced phosphorus removal coupled partial short-range nitrification reactor (EBPR-PN-SBR), an intermediate water tank, an anaerobic ammonium oxidation coupled sludge fermentation and denitrification reactor (ASFD-SBR), and a water outlet water tank. Biological phosphorous removal and short-rangenitrification are carried out in the EBPR-PN-SBR, an internal carbon source stored in the raw water COD is used for phosphorus removal, and phosphorus removal and the conversion of a part of ammonia nitrogen to nitrite nitrogen is carried out in an aerobic section. The anaerobic ammonium oxidation bacteria in ASFD-SBR convert the influent ammonia nitrogen and nitrite nitrogen into nitrogen and a small amount of nitrate nitrogen, the produced nitrate nitrogen is reduced to nitrogen by a carbon source produced by sludge fermentation, the fixed bed filler is used for holding anaerobic ammonium oxidation bacteria, and the denitrification and sludge fermentation process occurs in floc sludge. According to the process, the energy consumption is saved, and denitrification, phosphorus removal andsludge reuse of low-carbon-to-nitrogen ratio (C / N) urban domestic sewage are realized.

Owner:BEIJING UNIV OF TECH

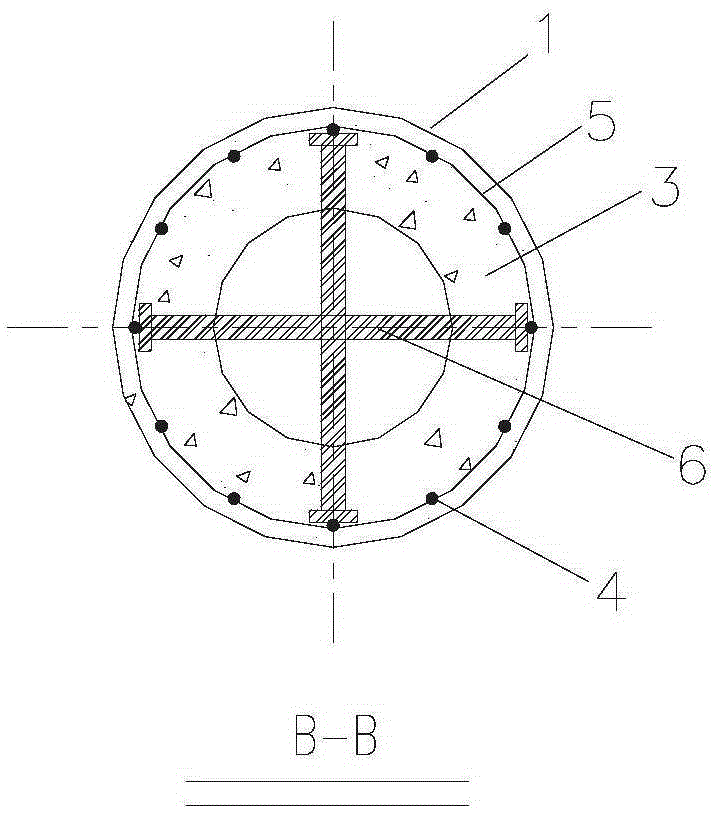

PVC pipe and thick wall steel tube composite hollow recycled concrete pile

InactiveCN105200983AStop erosionInhibit deteriorationBulkheads/pilesThick wallFoundation engineering

The invention discloses a PVC pipe and thick wall steel tube composite hollow recycled concrete pile, which is mainly prepared from PVC pipes, a round reinforcement cage framework, thick wall steel tubes and recycled concrete, wherein the round reinforcement cage framework and the thick wall steel tubes are arranged in PVC pipes, and the three are concentrically arranged; recycled concrete is poured into the PVC pipes and the thick wall steel tubes; the built-in thick wall steel tubes are capable of improving single-pile bearing capacity and non-deformability by a large margin; the externally covered PVC pipes are capable of effectively preventing pile bodies from being corroded and improving pipe body durability; at the same time, the recycled concrete inside can be jointed restrained by the PVC pipes and spiral stirrups, thus further enhancing composite pile bearing capacity; and waste concrete can be used as recycled aggregate, thus being favor of popularization and application of recycled concrete in building foundation engineering. In short, the PVC pipe and thick wall steel tube composite hollow recycled concrete pile has the advantages of good pile formation quality, high bearing capability, good non-deformability, good durability, small environment influence, quick construction speed and the like.

Owner:GUANGXI UNIV

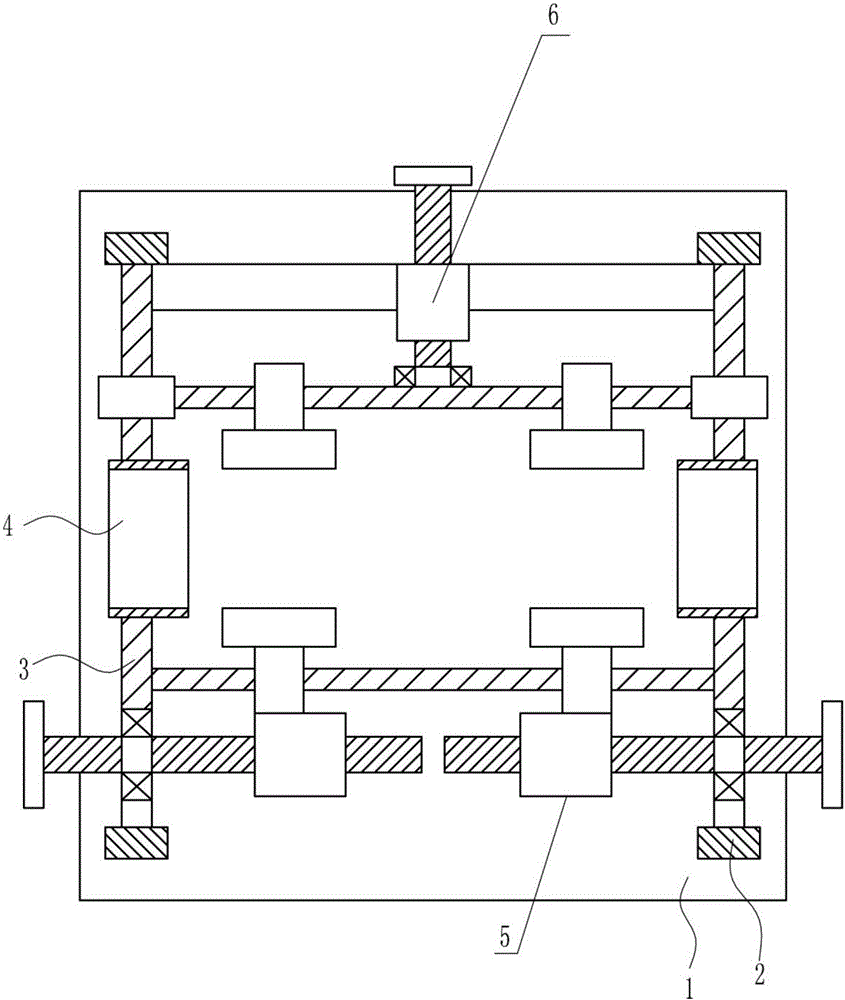

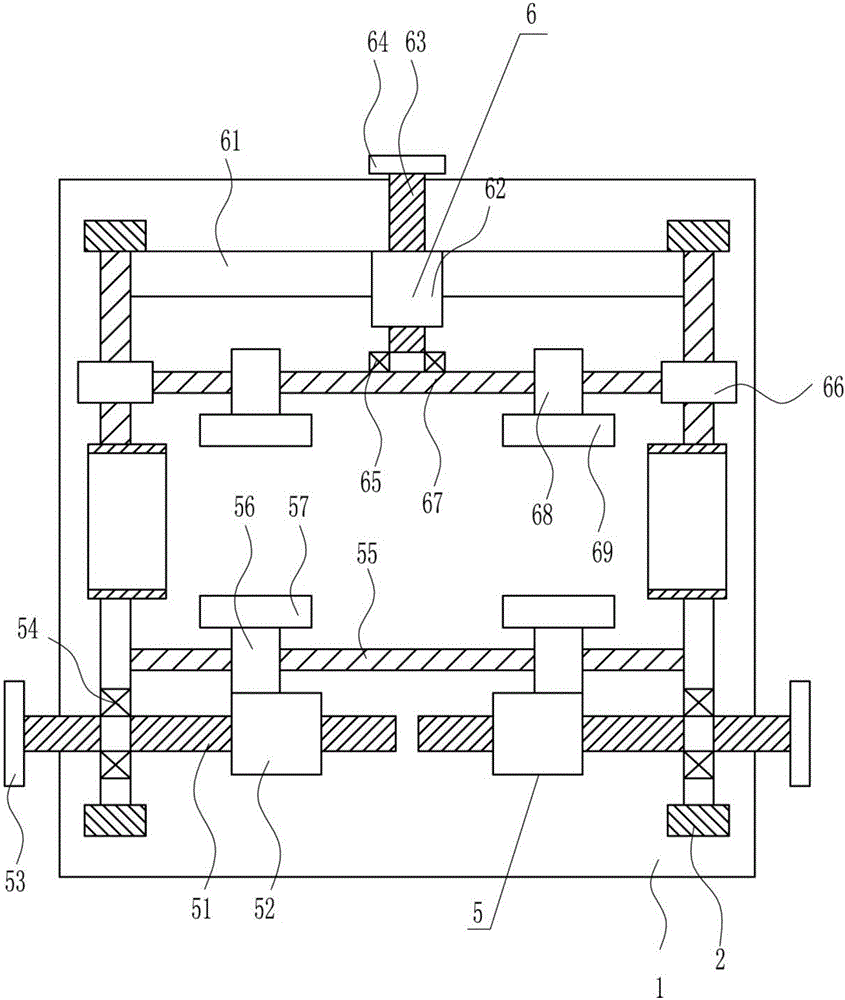

Welding assisting device for petroleum pipeline

ActiveCN107520563APlay a role in protecting the environmentWelding/cutting auxillary devicesPipeline systemsSlagPetroleum

The invention relates to an assisting device, and in particular relates to a welding assisting device for a petroleum pipeline. The welding assisting device for the petroleum pipeline is firm to clamp, capable of aligning pipelines, and small in damage to the environment. The welding assisting device for the petroleum pipeline comprises a base, etc., wherein four supporting rods are mounted on the base; connecting rods are correspondingly connected between the top ends of the supporting rods at the front side and the rear side; positioning grooves are formed in the middle parts of the two connecting rods; an abutting device is arranged between the front parts of the two connecting rods; a clamping device is arranged between the rear parts of the two connecting rods. According to the welding assisting device for the petroleum pipeline, the petroleum pipelines are clamped through the clamping device, and then two petroleum pipelines are abutted through the abutting device in order to be welded; in addition, slag falling during the welding process can be collected and treated through a collecting device, so that the environment is certainly protected.

Owner:新昌县益旭龙机械科技有限公司

Treatment method for soybean straw woven wicker product

InactiveCN106272820AReduce manufacturing costPlay a role in protecting the environmentWood treatment detailsCane mechanical workingChemical compositionToughness

The invention discloses a treatment method for a soybean straw woven wicker product. The treatment method comprises the following steps of soaking, air drying, core removing organizing, weaving processing, fumigating, dying, paint spraying, waxing and finished product drying. According to the provided treatment method for the soybean straw woven wicker product, a soak solution is reasonably prepared according to the chemical component of soybean straw, and a processing mode suitable for the soybean straw is adopted; and the manufactured wicker product is good in condition and toughness and not prone to being deformed and moreover has anticorrosion and anti-insect functions.

Owner:安徽阜南县万家和工艺品有限公司

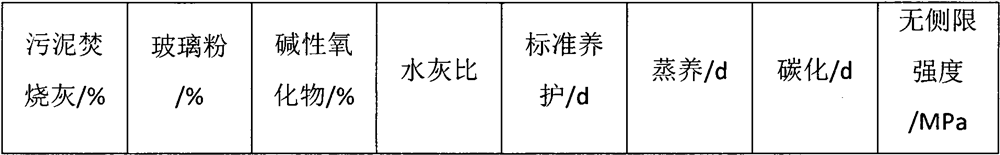

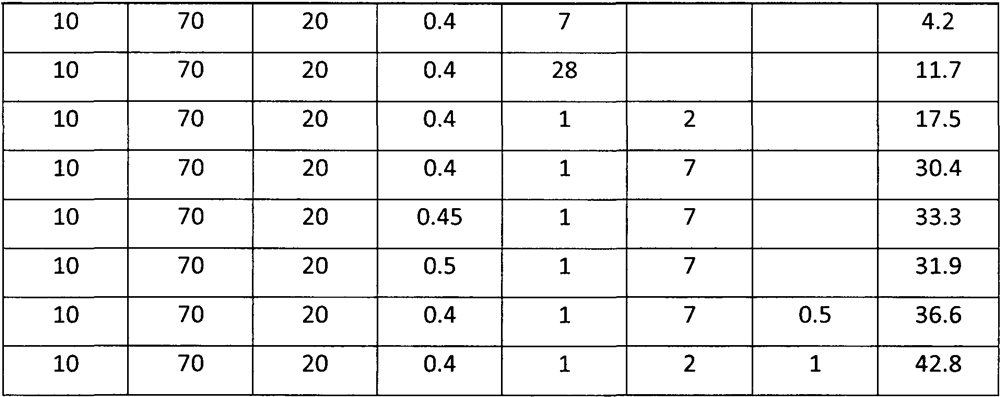

Carbon dioxide carbonized regenerated water permeable brick and preparation process thereof

The invention belongs to the field of solid waste resource reutilization of civil environmental engineering, and particularly relates to a carbon dioxide carbonized regenerated water permeable brick and a preparation process thereof. Solid-phase components of the recycled water permeable brick are mixed according to the mass percent, the solid-phase components comprise 20%-30% of fine-grained ash,5%-10% of bottom mud, 25%-35% of recycled aggregate, 0.5%-2.0% of fiber, 15%-30% of waste glass powder and 15%-35% of alkaline materials, and the mass ratio of waste is 70% or above. According to theinvention, the regenerated water permeable brick with high strength and good crack resistance is formed by uniformly stirring all the components, conducting forming with a brick mold and carrying outvibration pressing and sequentially carrying out conventional curing, steam curing and carbonization curing, and the mechanical property and the water permeability of the brick body are far superiorto those of a brick body subjected to independent curing, steam curing or carbonization curing; and in addition, a large amount of carbon dioxide gas is adsorbed in the process, and greenhouse benefits can be reduced. The method overcomes the problems of low comprehensive utilization rate of solid wastes, shortage of traditional brick making raw materials, low efficiency, long period, poor environmental benefits and the like, and has remarkable environmental benefits, social benefits and economic benefits.

Owner:NANJING FORESTRY UNIV

Preparation method for landscape bonsai

InactiveCN102248851AEasy access to raw materialsReduce manufacturing costSpecial ornamental structuresMossMaterials science

The invention discloses a preparation method for landscape bonsai, and relates to the field of agroforestry gardening. The preparation method is characterized by: mixing special-type vermiculite, carbonizing rice hull, cement, 108 glue, water and the like according to a ratio of 4:2.5:1:1:3r; or casting the resulting mixture into a die to form a artificial hill; or piling the resulting mixture to solidify into a artificial hill blank, followed by carrying out sculpturing to form the artificial hill. The landscape bonsai provided by the present invention has advantages of easy and available raw materials, low cost, and facilitates the growth of plants and mosses. In addition, the preparation method provided by the present invention can be applicable for preparation of the miniature bonsai or the large-scale landscape.

Owner:梁文荣

PVC pipe wrapped inner supporting cross prestress recycled concrete tubular pile

The invention discloses a PVC pipe wrapped inner supporting cross prestress recycled concrete tubular pile mainly formed by a PVC pipe, a round reinforcement cage framework, cross steel ribs and recycled concrete. The round reinforcement cage framework and the cross steel ribs are arranged in the PVC pipe, and a round inner cavity is formed in the PVC pipe by the recycled concrete. The round reinforcement cage framework is formed by welding longitudinal prestressed tendons and spiral stirrups. A PVC pipe wrapped pile body resistant to corrosion, light and high in strength can be effectively prevented from being corroded, the corrosion problem of the tubular pile is solved, and the durability of a pile foundation is improved. The inner supporting cross steel ribs can fully achieve the respective advantages of steel, prestressed reinforcement and concrete, the stress performance of the recycled concrete is improved, the bearing capacity and stability of the single pile are improved, the lateral rigidity of the pile body is increased, and transverse deformation is reduced. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated.

Owner:GUANGXI UNIV

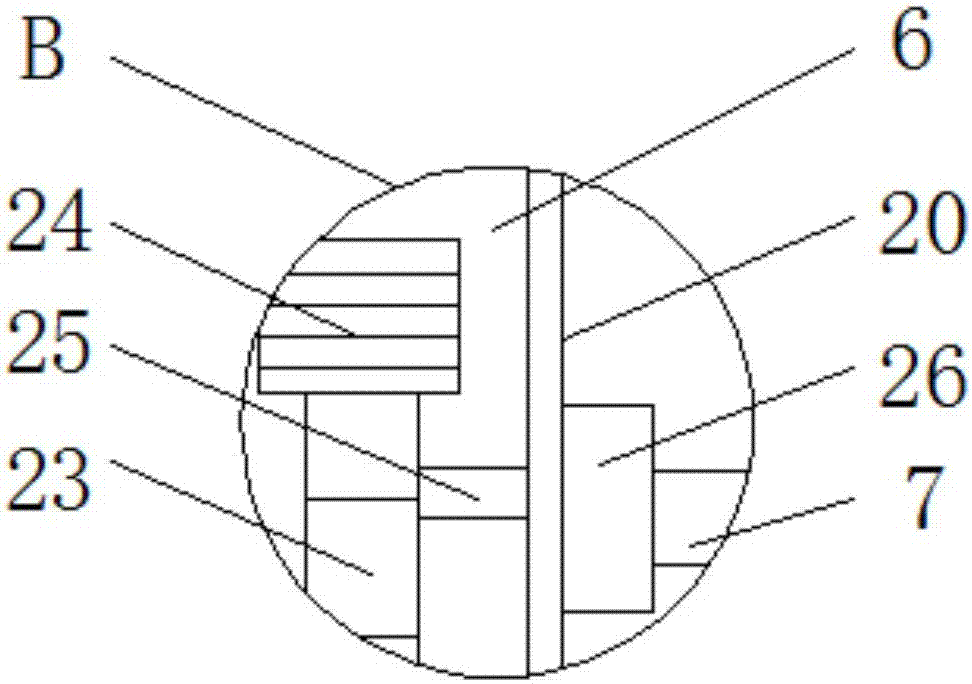

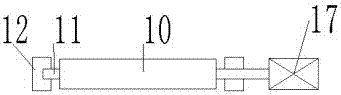

Pressure-controllable conical screw crusher

The invention discloses a pressure-controllable conical screw crusher. The pressure-controllable conical screw crusher comprises a conical housing, wherein a main rotary shaft with spiral blades is installed in the conical housing, and a connection gear connected with a motor is arranged at one end of the main rotary shaft; a charge hole is formed in the top of the conical housing, an unloading hole is formed in the lower end, a plurality of discharge holes are formed in the lower side of the conical housing and connected with a detachable collection box, an adjustment-control device is arranged at the discharge holes and the unloading hole, the adjustment-control device is composed of a slide plate, a pulley, the motor, the connection gear, a rack and a sub-controller, the rack driven by the motor is arranged at one side of the slide plate, a groove clamped on the pulley is formed at the other side of the slide plate, the slide plate is driven to move through the motor, and the action of the motor is controlled by the sub-controller. The crusher disclosed by the invention is small in occupied space, the crushed grains are uniform, the sizes of the unloading hole and the discharge holes can be adjusted through the adjustment-control device to realize control on a pressure in the conical housing and avoid too high or too low pressure in the machine, thus keeping the pressure value in a stable range.

Owner:GUANGXI UNIV

FRP wrapped prestress recycled concrete tubular pile

The invention discloses an FRP wrapped prestress recycled concrete tubular pile mainly formed by an FRP pipe, a round reinforcement cage framework, cross steel ribs and recycled concrete. The round reinforcement cage framework and the cross steel ribs are arranged in the FRP pipe, and a round inner cavity is formed in the FRP pipe through the recycled concrete. The round reinforcement cage framework is formed by welding longitudinal prestressed tendons and spiral stirrups. An FRP pipe wrapped pile body resistant to corrosion, light and high in strength can be effectively prevented from being corroded, the corrosion problem of the tubular pile is solved, and the durability of a pile foundation is improved. The inner supporting cross steel ribs can fully achieve the respective advantages of steel, prestressed reinforcement and concrete, the stress performance of the recycled concrete is improved, the bearing capacity and stability of the single pile are improved, the lateral rigidity of the pile body is increased, and transverse deformation is reduced. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated.

Owner:GUANGXI UNIV

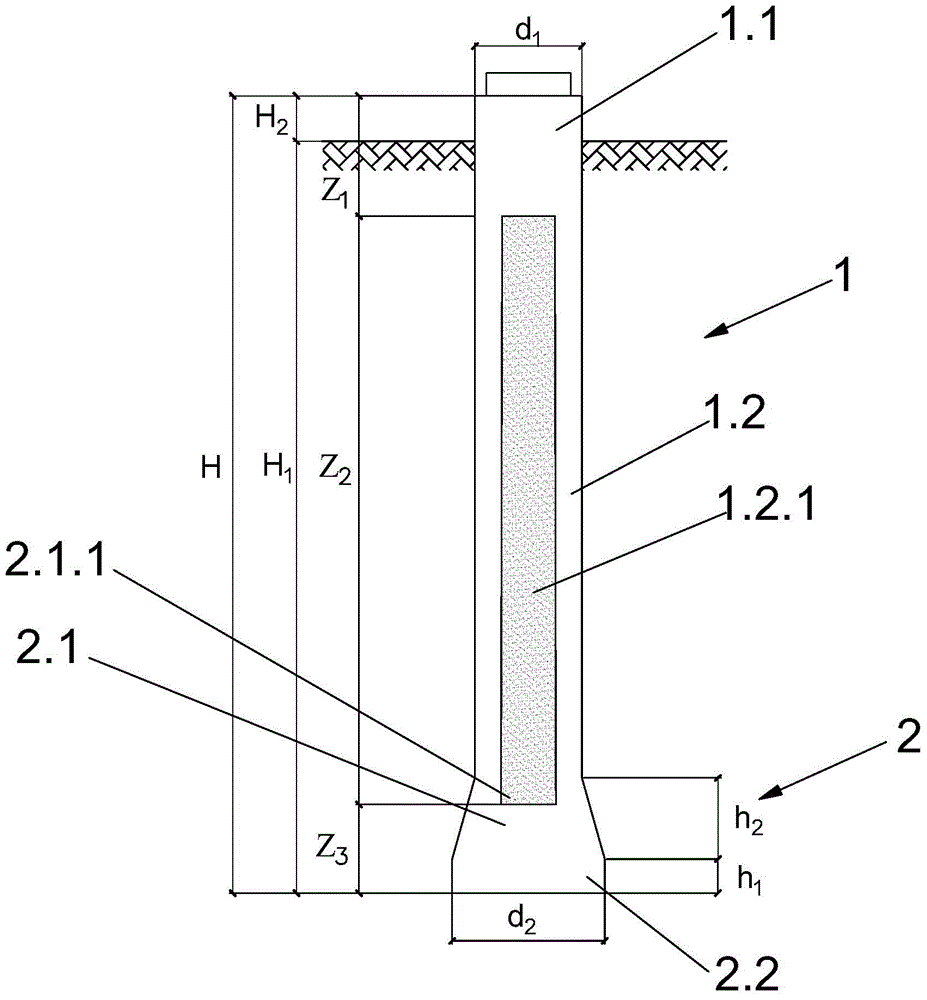

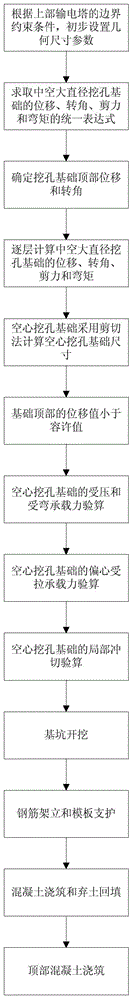

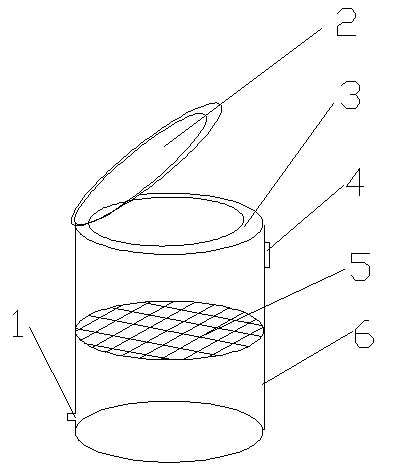

Hollow hole-digging foundation with major diameter and manufacture method thereof

The invention discloses a hollow hole-digging foundation with a major diameter. The hollow hole-digging foundation with the major diameter comprises a basic main post and a basic wide bottom; the basic main post comprises a basic outcrop and a basic burial depth section, and the basic burial depth section is internally provided with a main post cavity; the basic wide bottom comprises a round table and a bottom cylinder, and the round table is internally provided with a bottom cavity; the main post cavity and the bottom cavity are filled with spoil; main post main reinforcements are connected with cylinder main reinforcements through round table main reinforcements, external stirrups are arranged on the outer sides of the main post main reinforcements, the round table main reinforcements and the cylinder main reinforcements, and erection stirrups are arranged on the inner sides of the main post main reinforcements, the round table main reinforcements and the cylinder main reinforcements. The invention further discloses a manufacture method of the hollow hole-digging foundation with the major diameter. The method comprises the following steps that 1, hole-digging foundation size parameters are initially set; 2, bending moment, shearing force, displacement and corner of the hole-digging foundation are calculated; 3, section size is checked; 4, normal section bearing capacity is calculated; 5, site construction is conducted. According to the hollow hole-digging foundation with the major diameter and the manufacture method thereof, use of foundation concrete and amount of the spoil are effectively reduced, the environment is protected, and the hollow hole-digging foundation with the major diameter can be widely applied to the technical field of electric power engineering.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

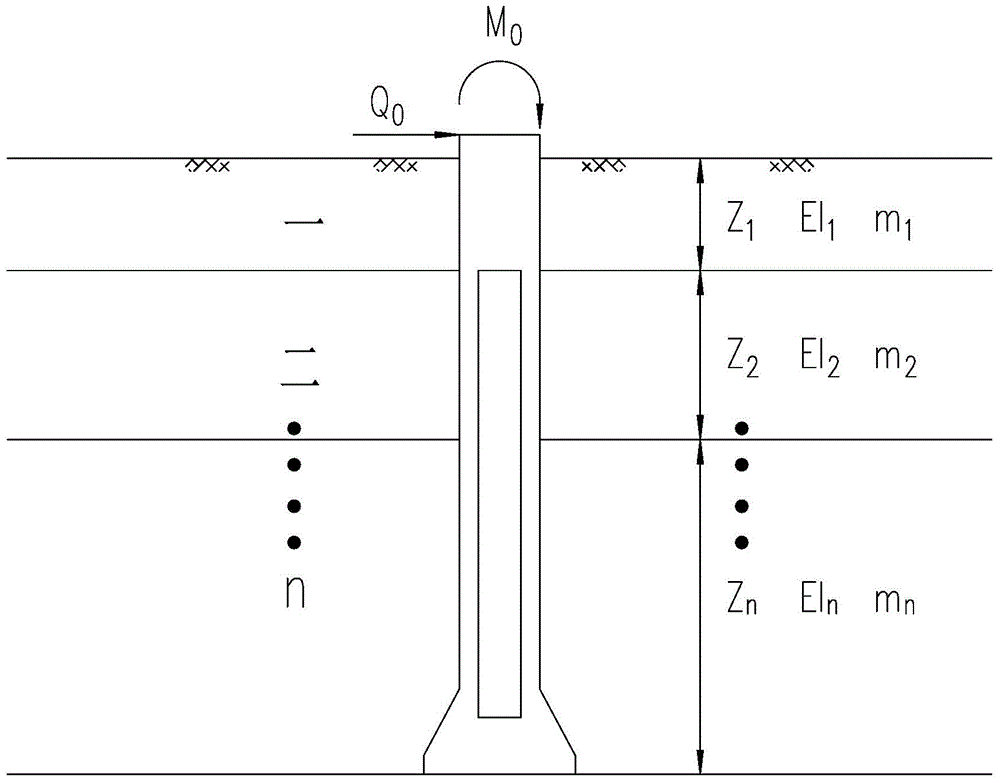

Automatic sensing garbage can

InactiveCN103693327AEasy to classifySimple structureWaste collection and transferRefuse receptaclesPulp and paper industry

The invention discloses an automatic sensing garbage can, which comprises a can body and a can lid, wherein the can body is connected with the can lid through a connecting piece; a filter screen is arranged in the can body; the garbage can is divided into an upper part and a lower part by the filter screen; a sealing ring is arranged between the can body and the can lid; a drain pipe is arranged at the bottom of the lower part of the can body. The automatic sensing garbage can is simple in structure and convenient to use; solids and liquid can be separated by the filter screen, and liquid garbage can be drained through the drain pipe, so that garbage can be well classified for treatment; in addition, due to the arrangement of the sealing ring, odor can be well isolated, and a function of protecting the environment is realized; an automatic sensing device can be used for sensing persons to automatically open the can lid, so that the automatic sensing garbage can is convenient and rapid.

Owner:叶小平

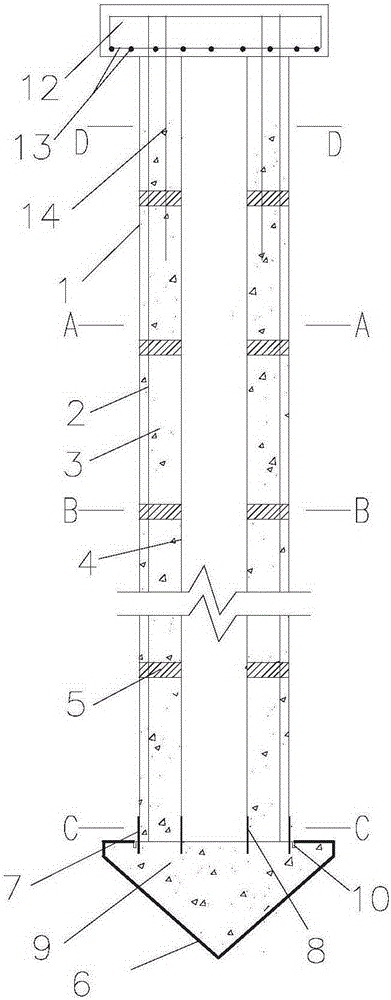

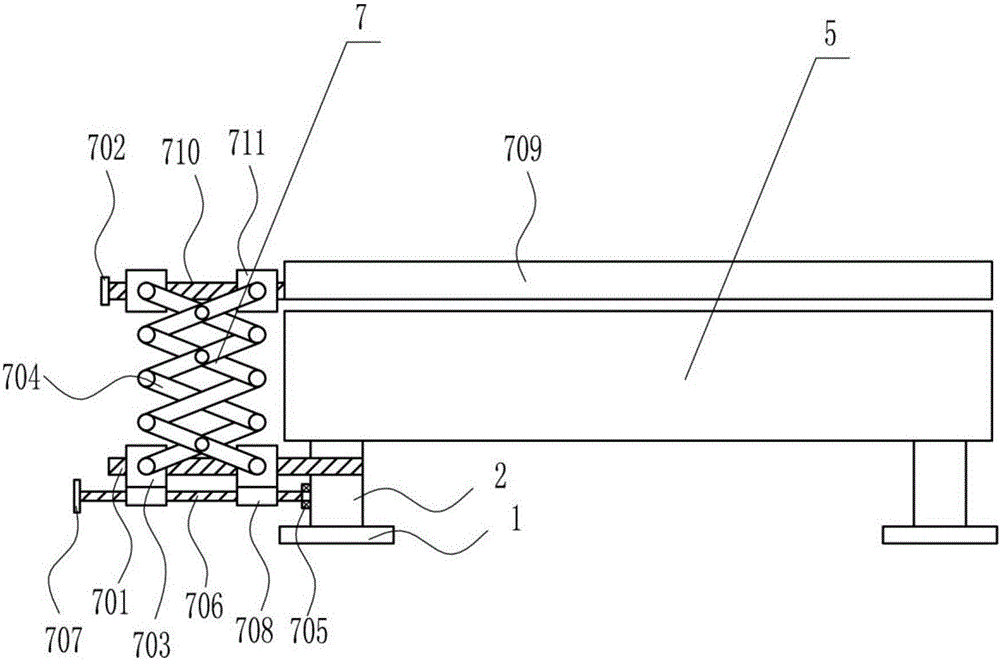

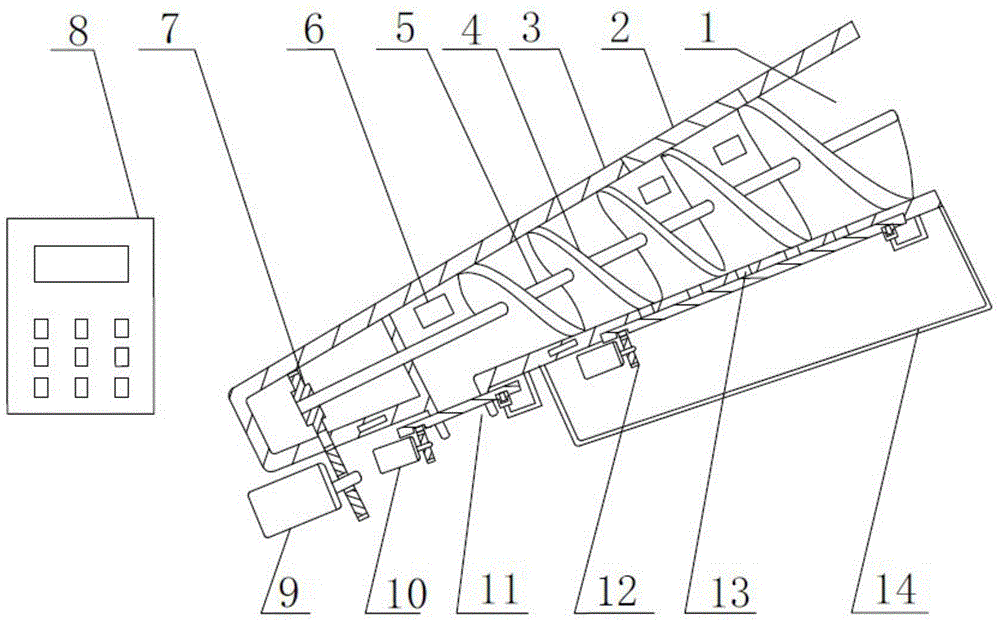

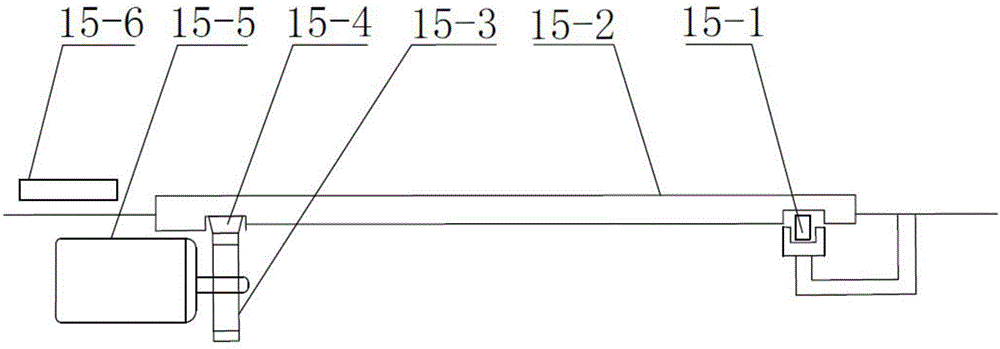

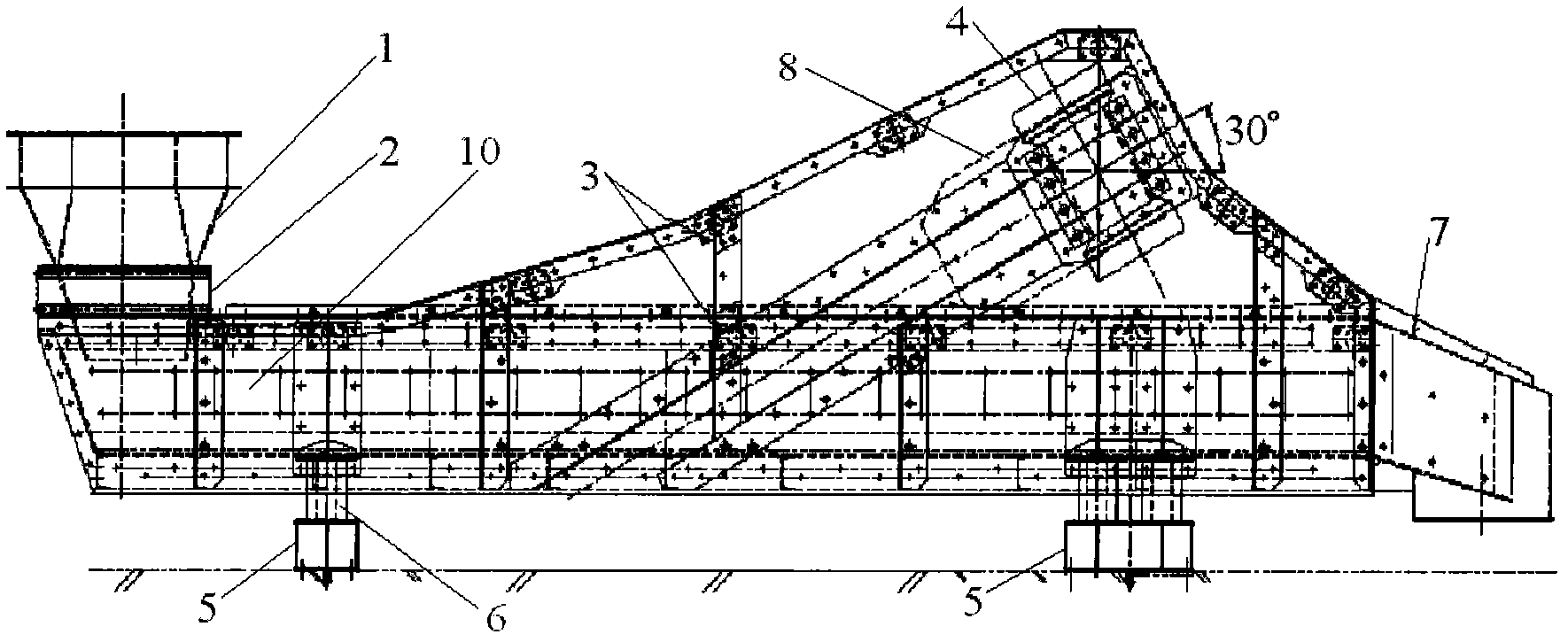

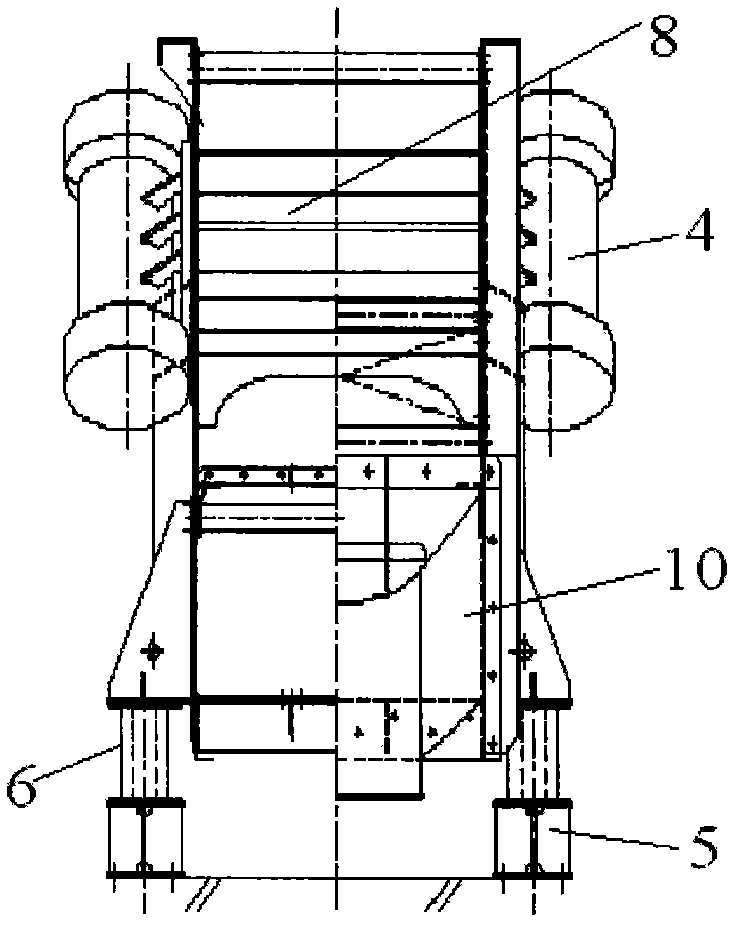

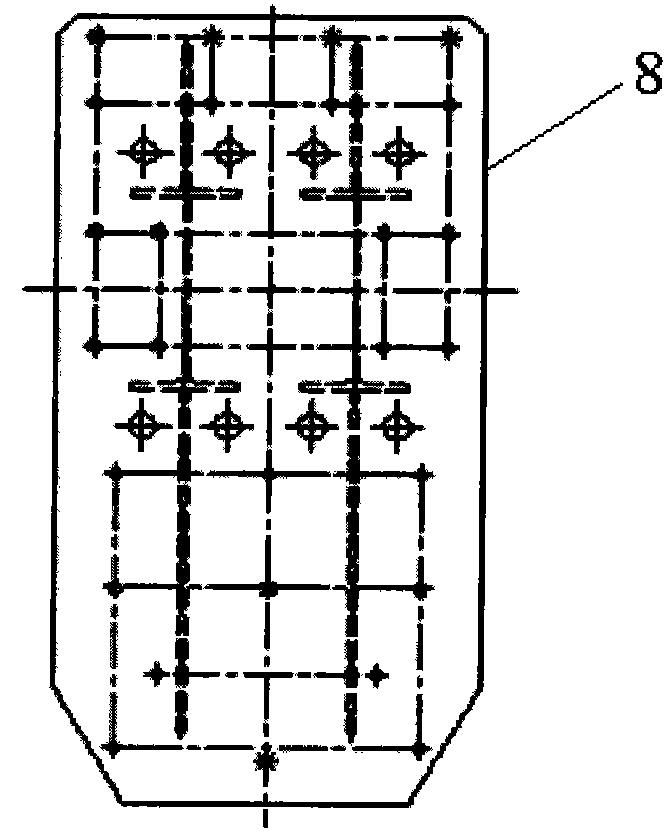

Earth residue conveyor K-P vibratory feeder in cement production technique

InactiveCN101955052AExtended service lifePlay a role in protecting the environmentJigging conveyorsCentral planeEngineering

The invention discloses an earth residue conveyor K-P vibratory feeder in a cement production technique, which comprises a feeder body conveying chute (10), vibration motors (4), a vibration motor base (8), a feed trough (1) and a discharge trough (7), wherein the feeder body conveying chute (10) is arranged horizontally; the vibration motors (4) are fixed on the vibration motor base (8); by the way that the symmetrical plane of the two vibration motors (4) is the longitudinal vertical central plane of the feeder body conveying chute (10), the two vibration motors (4) are installed on two side faces of the vibration motor base (8); and the axial line of each vibration motor (4) is slanted relative to the feeder body conveying chute (10). By using the technical scheme, the invention can prolong the service life of the vibratory feeder and perform the function of environment protection. The vibratory feeder has the advantages of reasonable structure and convenient processing, and can effectively lower the manufacturing and operating cost.

Owner:ANHUI CONCH KAWASAKI EQUIP MFG

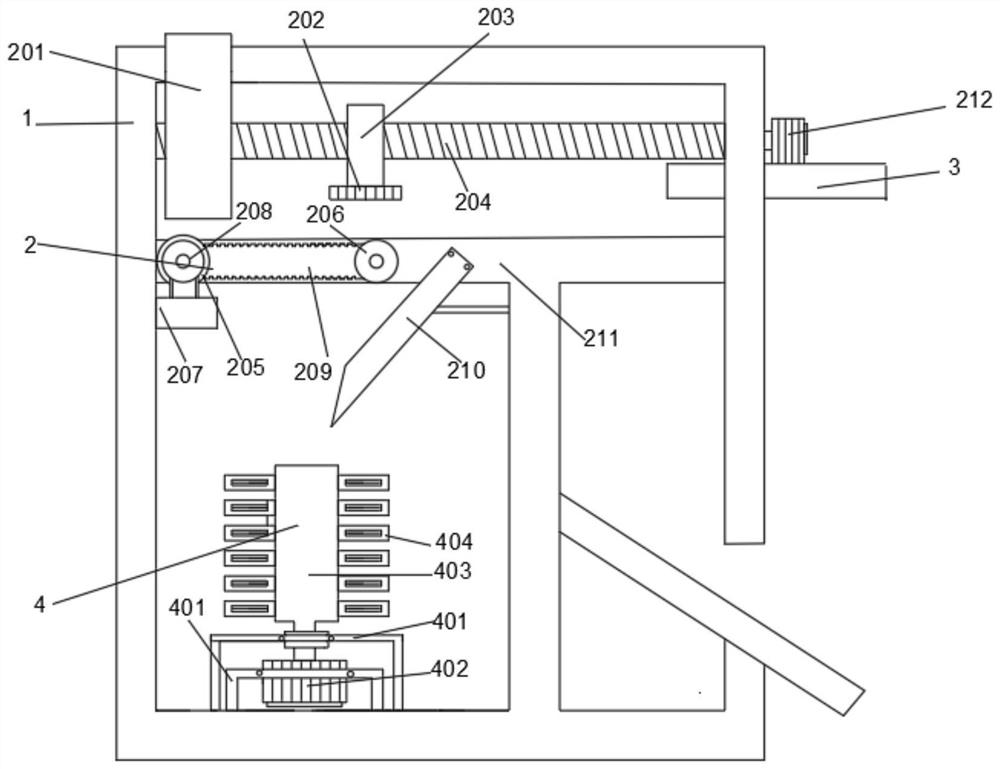

Recycling and screening device

InactiveCN112387416AAchieve reuseLow costSolid waste disposalMagnetic separationProcess engineeringMechanical engineering

The invention provides a recycling and screening device, and relates to the technical field of screening devices. The device comprises a box body, a screening mechanism is arranged at a position, close to the top, in the box body, a supporting plate is fixedly embedded at a position, close to the top, in the outer wall of the right side of the box body, and a mincing mechanism is arranged on the inner surface of the left side of the box body. Iron parts containing electronic product tools and waste plastic are poured into the device from an inlet of a feeding pipeline, the feeding pipeline isobliquely installed at the top of the box body, the fine iron parts and waste plastic slide to the upper surface of a conveying belt through the interior of the feeding pipeline, and an electromagnetadsorbing iron to the parts comes to the position above a discharging opening; and an external power supply is turned off, so that the electromagnet losing the magnetic force cannot adsorb iron, and the iron falls into a discharge port, and therefore, the effects of screening fine iron-containing parts of electronic products from waste plastics, realizing resource reutilization and saving the costare achieved.

Owner:南京冉科信息技术有限公司

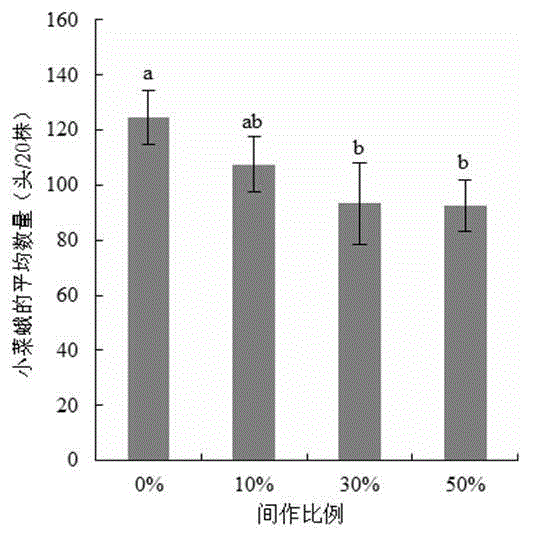

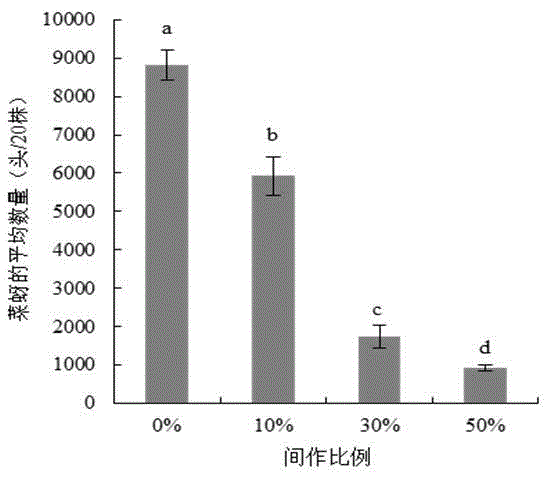

Tomato intercropping method for improving income-guaranteeing and insect pest controlling functions of brassica oleracea field

ActiveCN104641907AIncrease population sizeReduce weed damagePlant cultivationCultivating equipmentsBrassica oleraceaPesticide

The invention discloses a tomato intercropping method for improving income-guaranteeing and insect pest controlling functions of a brassica oleracea field and belongs to the field of environment-friendly control on plant diseases and insect pests of agriculture. The method comprises the step of carrying out intercropping on brassica oleracea and tomatoes in accordance with that the number of tomato plants accounts for 30% the total number of plants of the field. Through the intercropping of the brassica oleracea and the tomatoes, primary pests on the brassica oleracea can be effectively prevented and treated, the pest control effect of natural enemies is improved, the consumption of pesticides is reduced, and the quality of the brassica oleracea is improved. The method disclosed by the invention is simple, the damage to the brassica oleracea caused by the pests is greatly lowered by using a most appropriate tomato intercropping ratio, and the pest control effect of the natural enemies is protected and utilized; the method has the advantages of lowered chemical pesticide consumption, convenience in management and the like and is beneficial to ecological environment protection and agricultural sustainable development.

Owner:FUJIAN AGRI & FORESTRY UNIV

Dioxin elimination system

PendingCN109569210AIncrease contact areaPromote absorptionGas treatmentDispersed particle separationSolventEngineering

The invention relates to the technical field of environmental protection devices, and particularly discloses a dioxin elimination system. The dioxin elimination system comprises a dioxin absorption device, a fan and a dioxin dissolution device. The dioxin absorption device is connected with the suction end of the fan through an air hose, and the exhaust end of the fan is connected with the dioxindissolution device; the dioxin dissolution device is filled with a dioxin solvent for dissolving dioxin; the fan is used for driving the outside atmosphere to enter the dioxin absorption device, and the outside atmosphere is delivered to the dioxin dissolution device through the air hose to be dissolved by the dioxin solvent. The dioxin in the atmosphere is dissolved by the dioxin solvent, so thatthe dioxin elimination system is beneficial to purification of the atmosphere and protects the environment.

Owner:王全龄

FRP wrapped recycled concrete composite tubular pile

The invention discloses an FRP wrapped recycled concrete composite tubular pile mainly formed by an FRP pipe, a round reinforcement cage framework, cross steel ribs and recycled concrete. The round reinforcement cage framework and the cross steel ribs are arranged in the FRP pipe, and a round inner cavity is formed in the FRP pipe by the recycled concrete. An FRP pipe wrapped pile body resistant to corrosion, light and high in strength can be effectively prevented from being corroded, the corrosion problem of the tubular pile is solved, and the durability of a pile foundation is improved. The inner supporting cross steel ribs can fully achieve the respective advantages of steel, prestressed reinforcement and concrete, the stress performance of the recycled concrete is improved, and the bearing capacity and stability of the single pile are improved. Waste concrete is fully utilized as recycled aggregate, and application and popularization of the recycled concrete in building foundation engineering are facilitated.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com