Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce cable costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

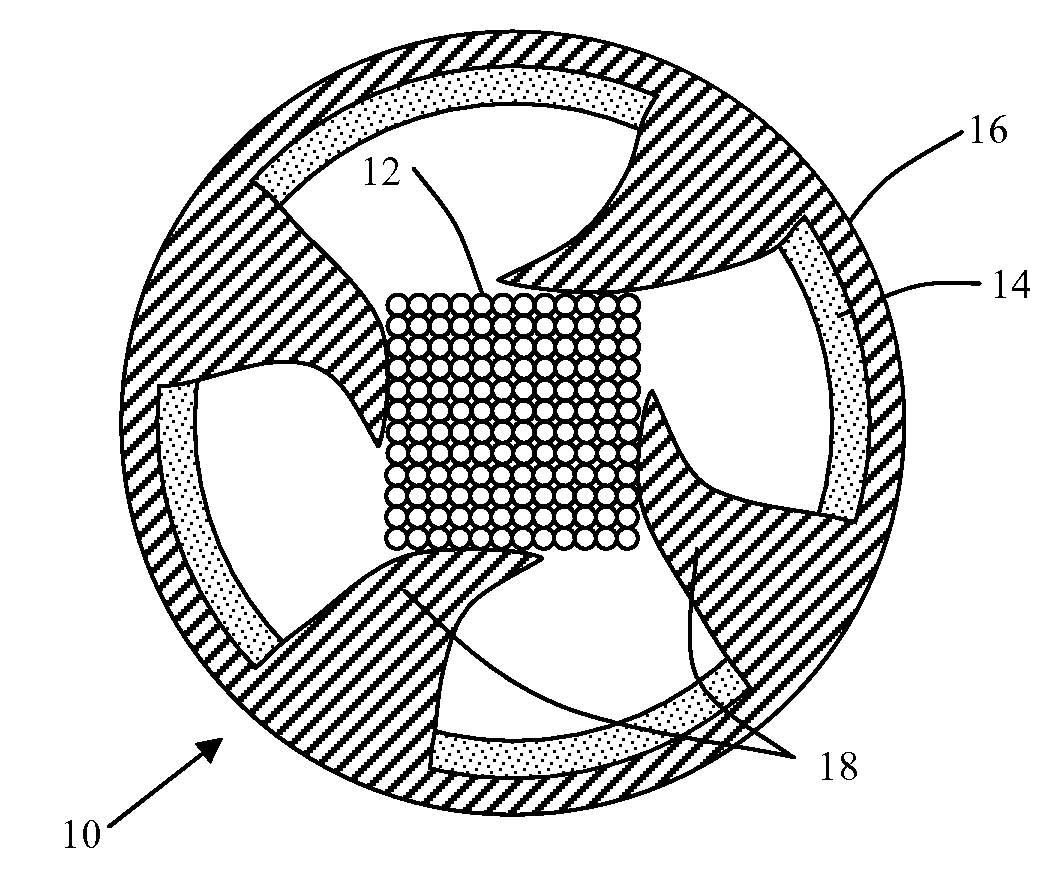

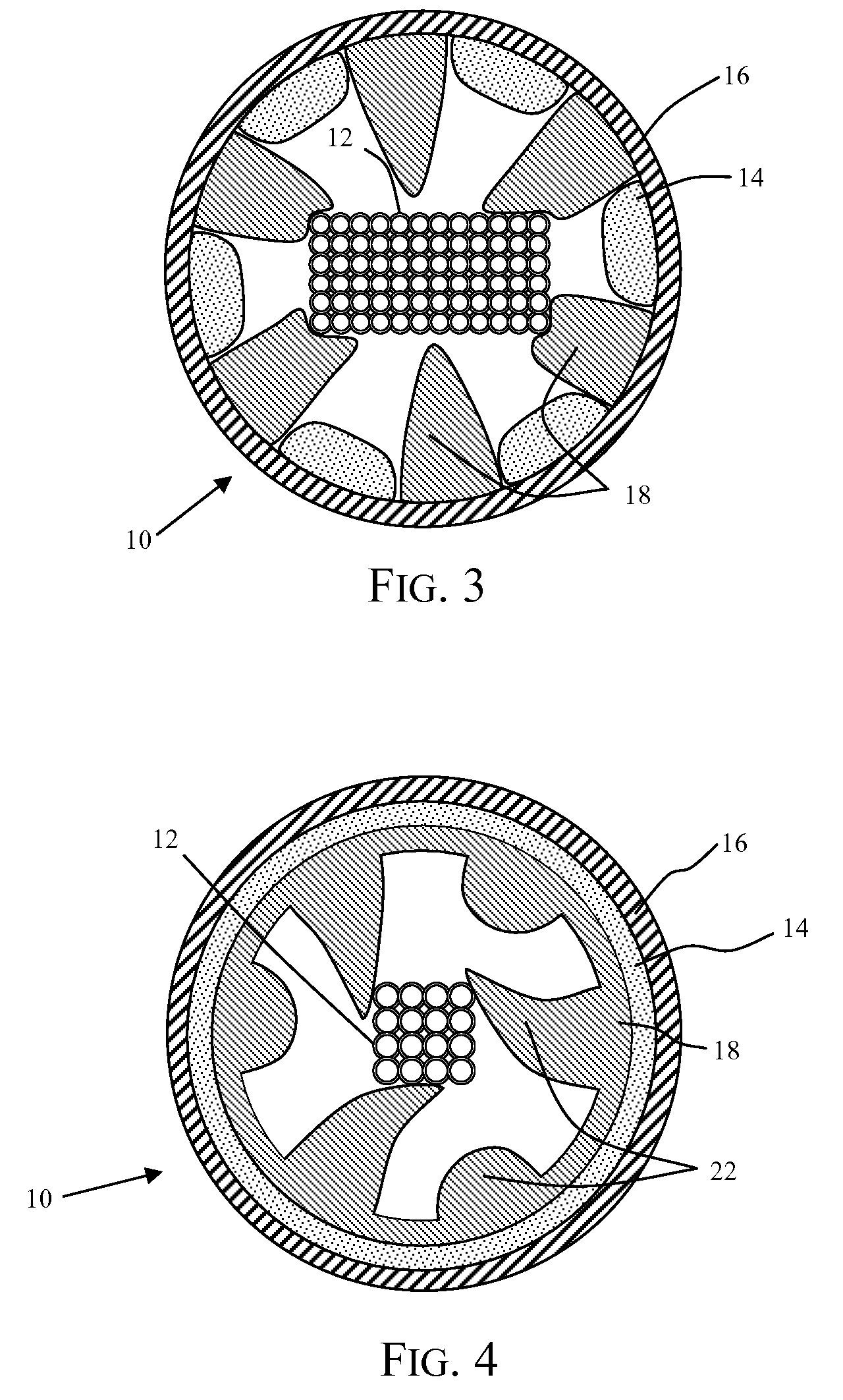

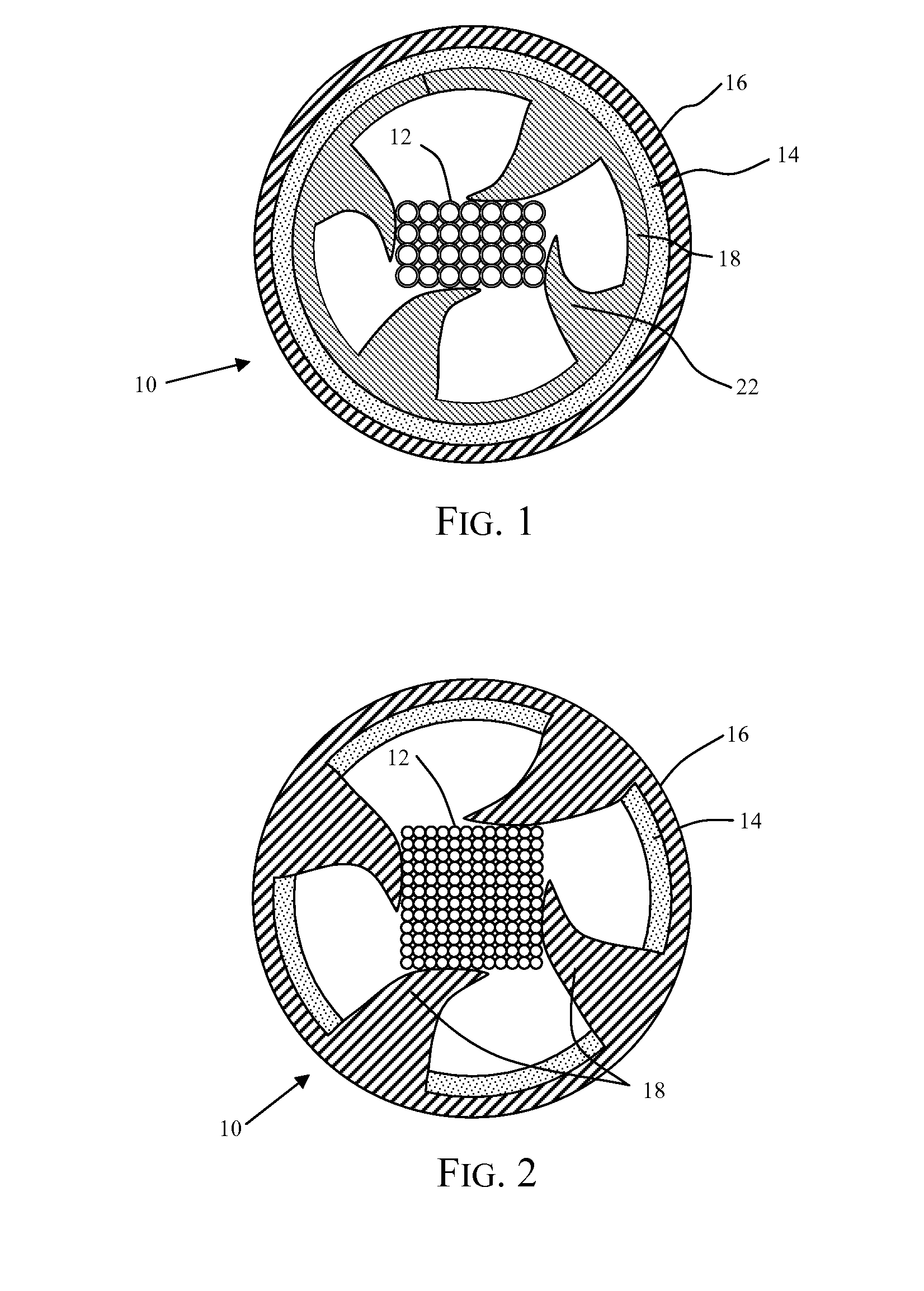

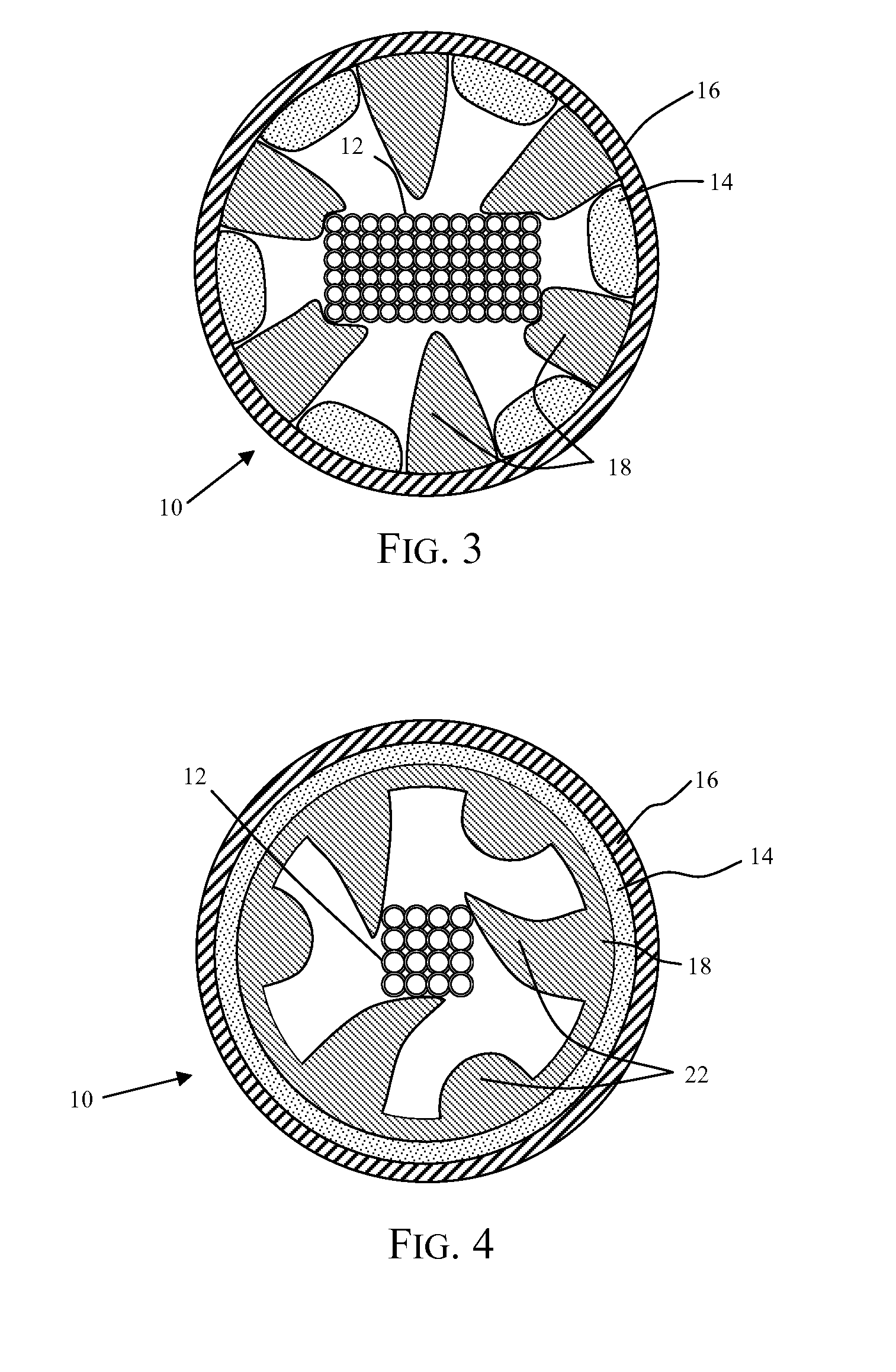

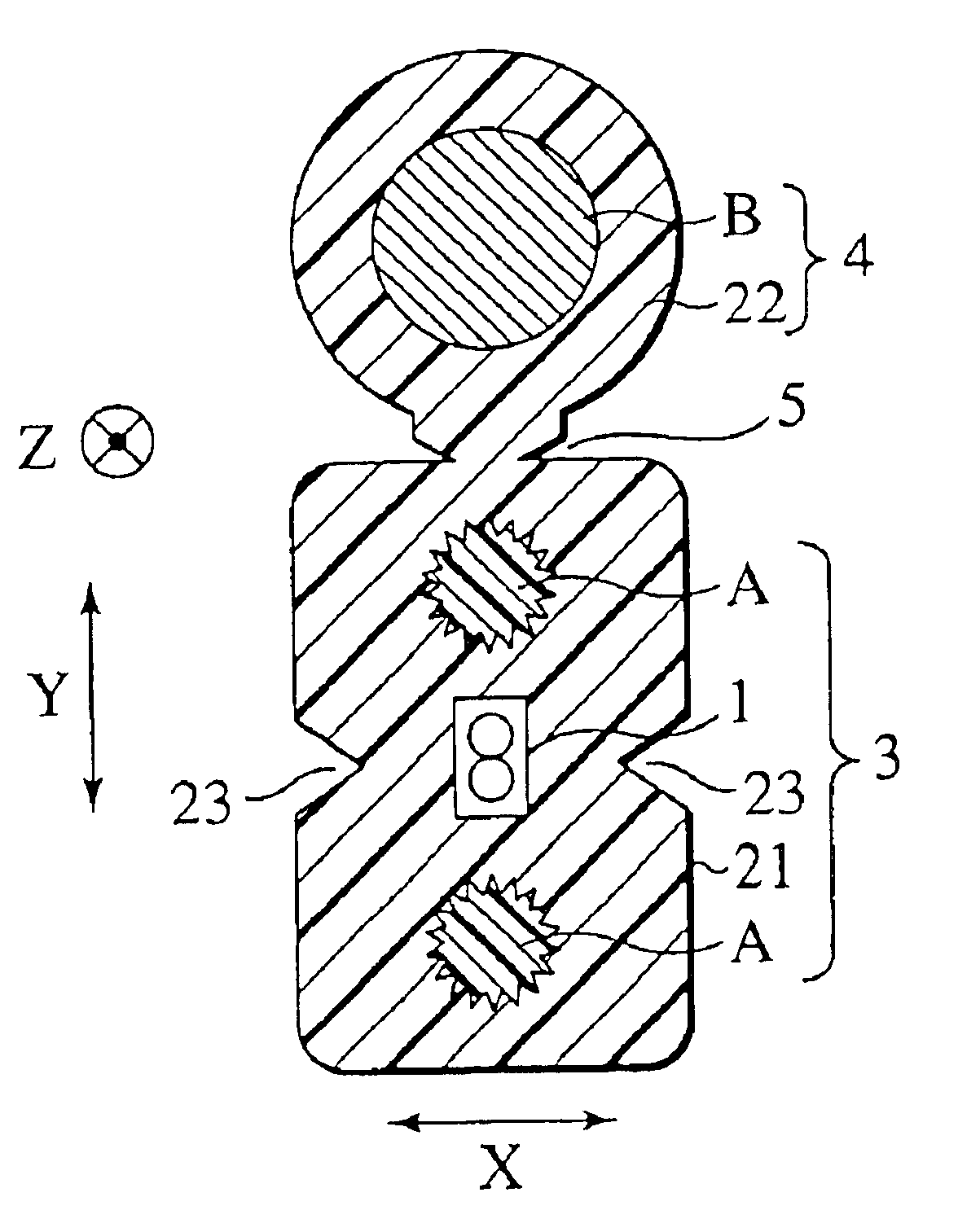

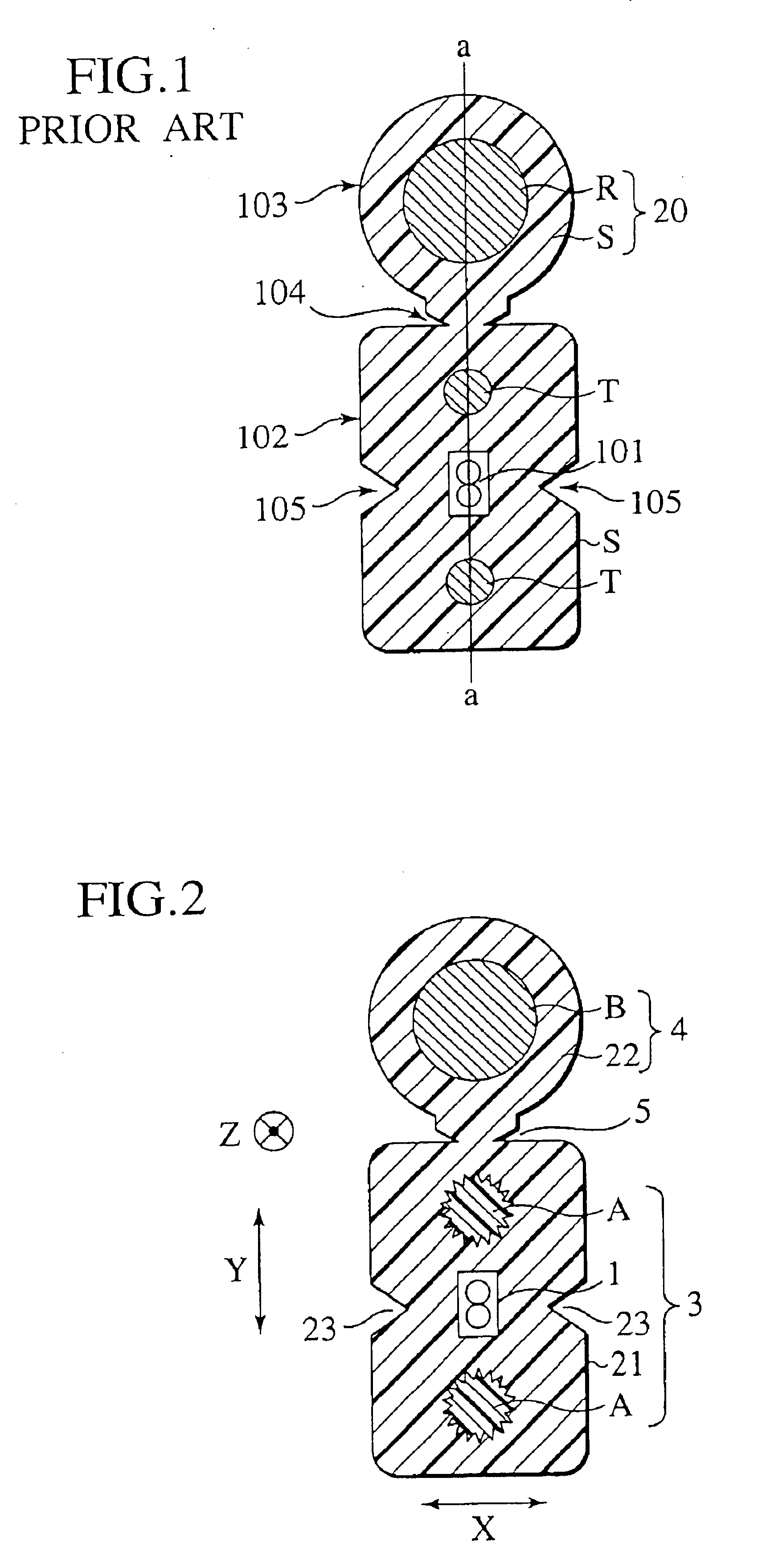

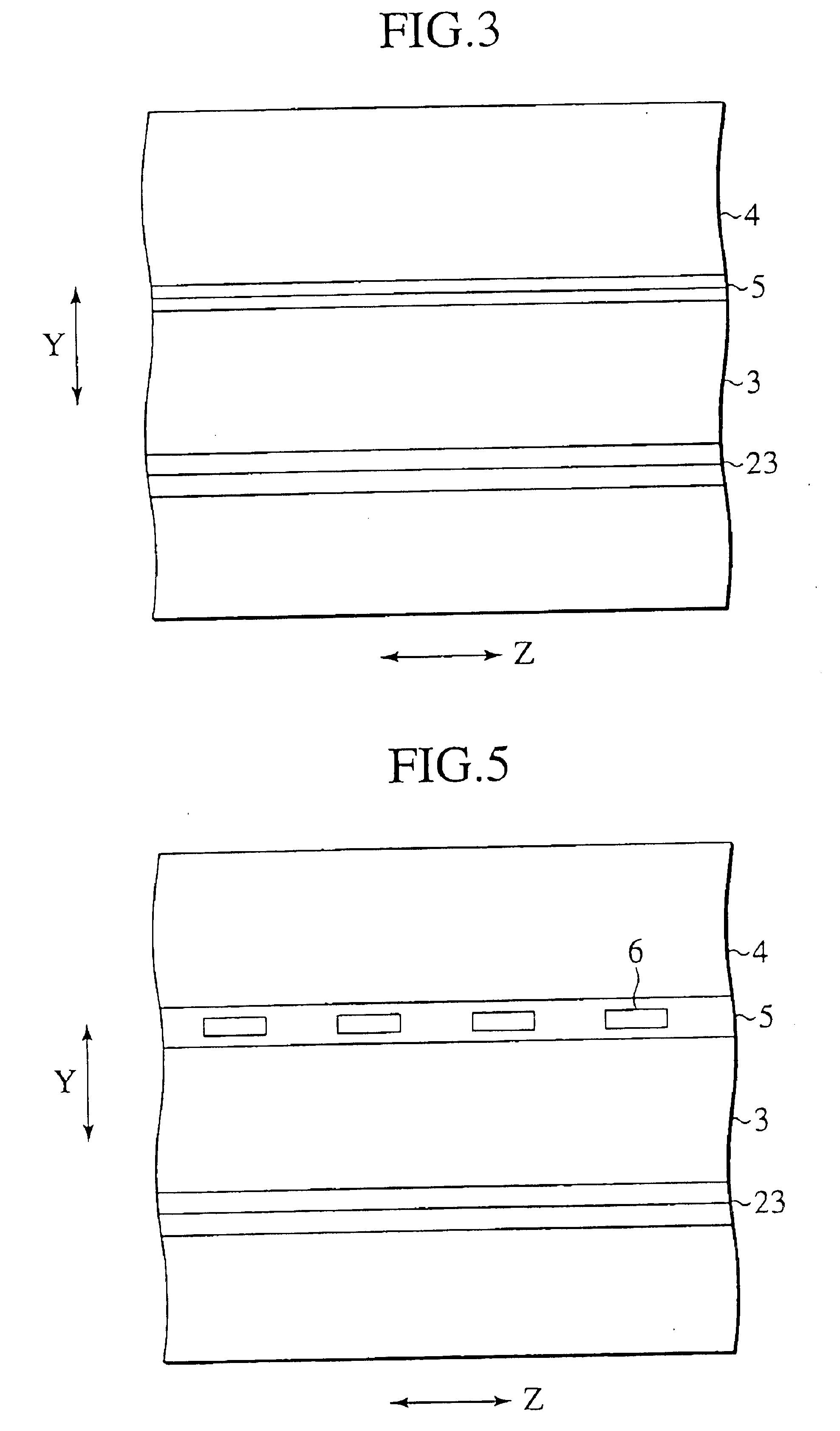

Optical fiber cable having raised coupling supports

InactiveUS7646952B2Limited amountInhibitionGlass making apparatusFibre mechanical structuresCouplingEngineering

Disclosed is an optical fiber cable that includes optical fibers and a deformable coupling element enclosed within a buffer tube. The coupling element is formed from a deformable yet substantially incompressible material and features a number of raised members projecting toward the optical fibers. The design of the coupling element layer permits coupling of the optical fibers to the buffer tube without the use of a compressive cushioning layer. This arrangement distributes the compressive force applied to discrete points along the outer perimeter of the optical fiber element.

Owner:DRAKA COMTEQ BV

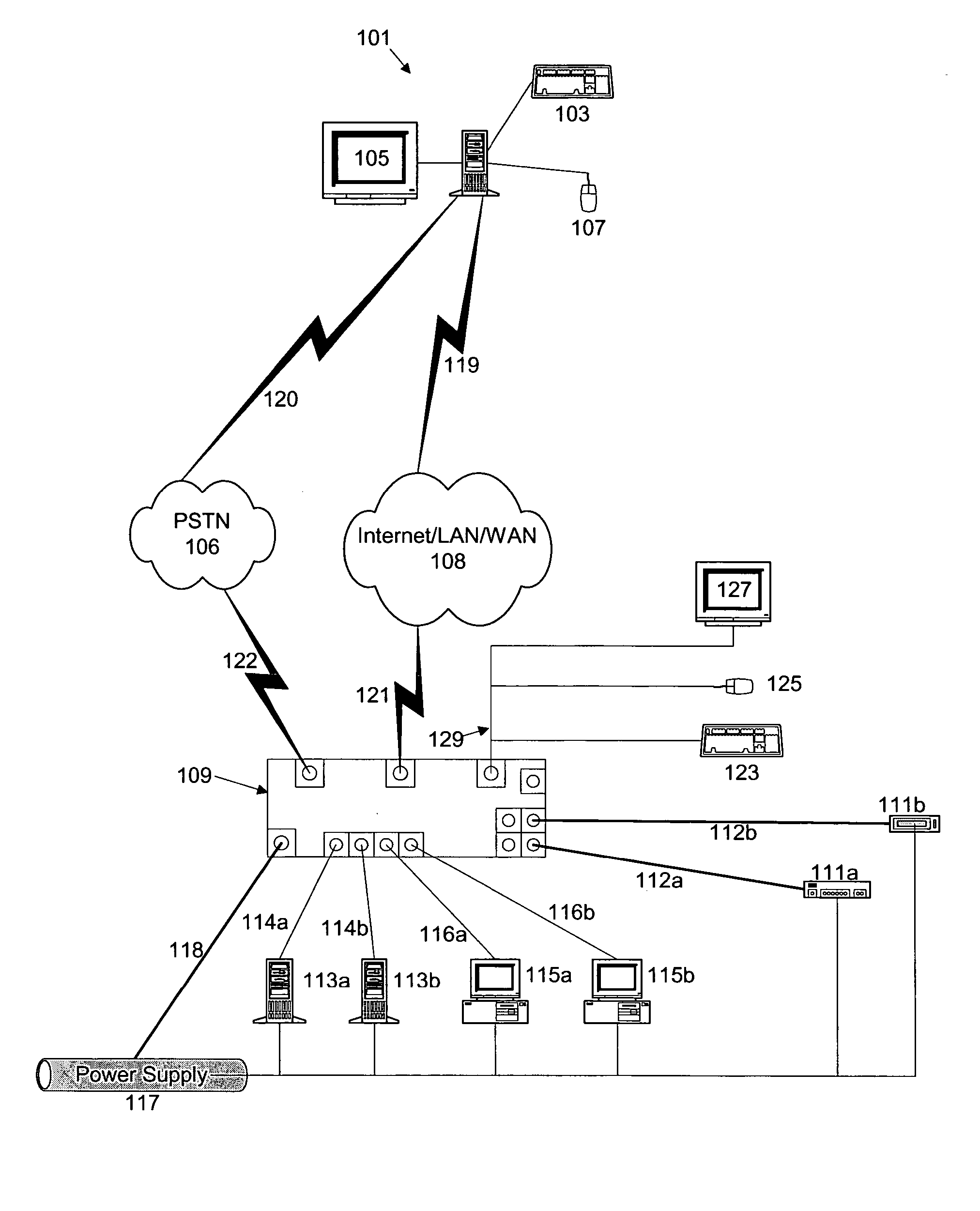

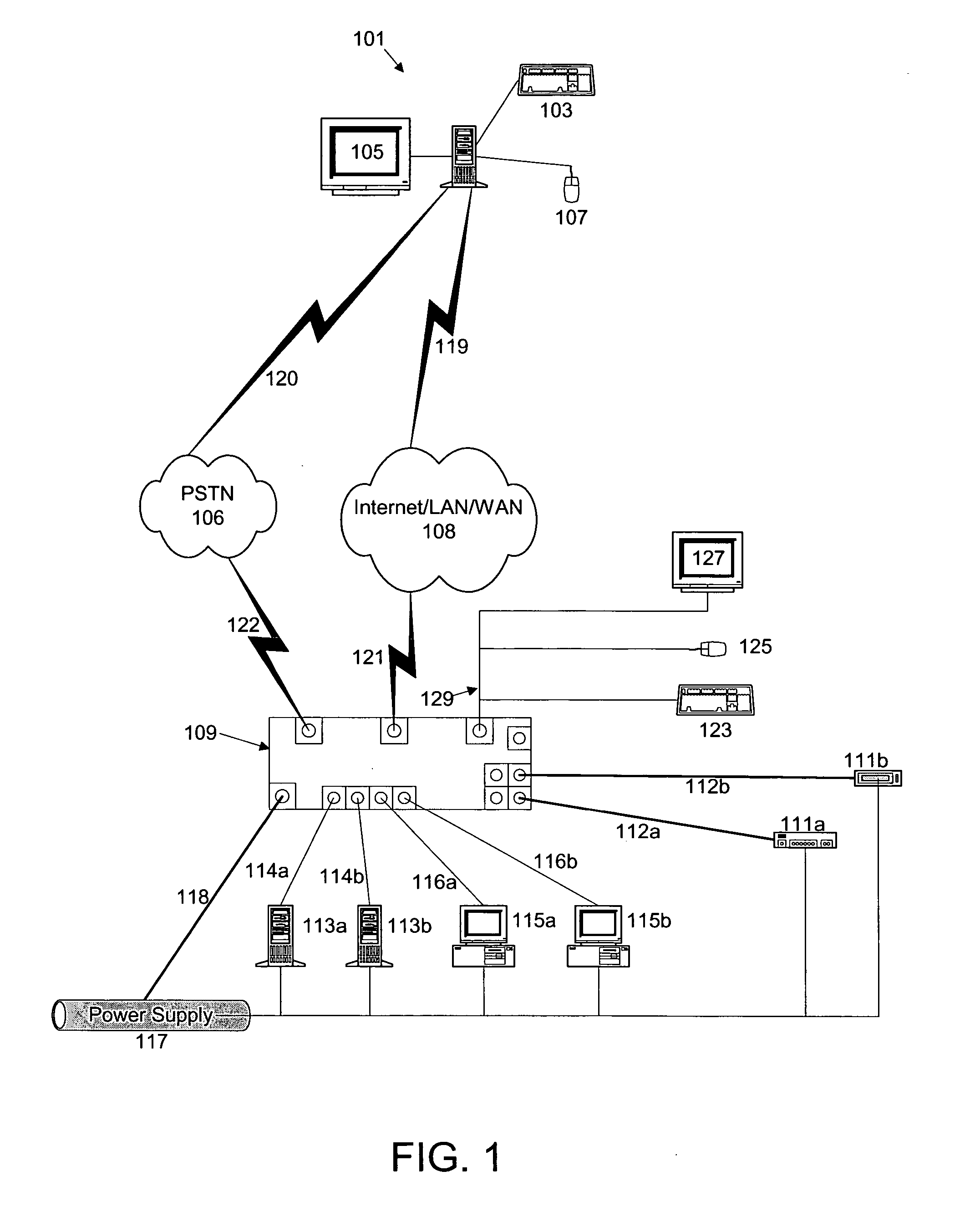

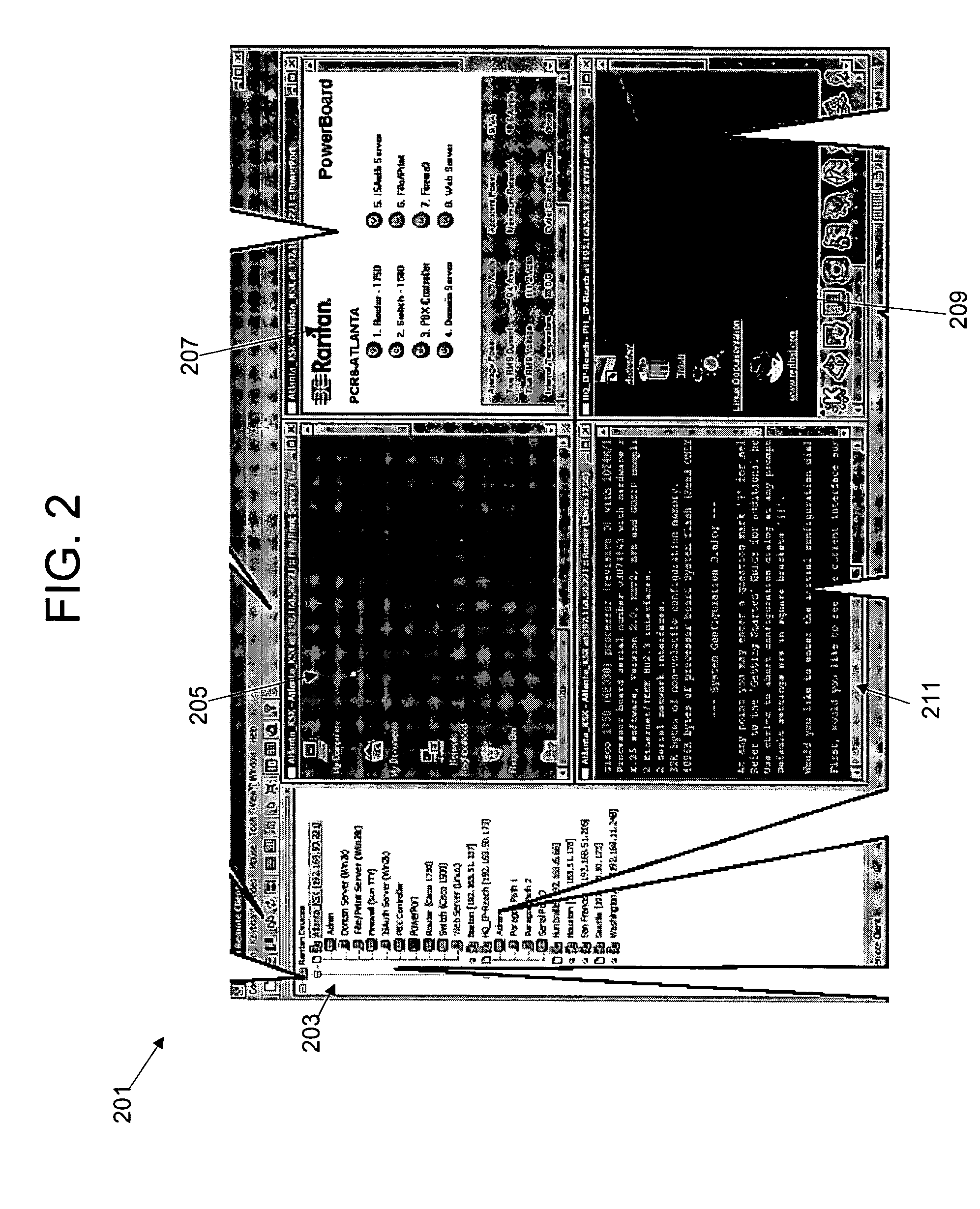

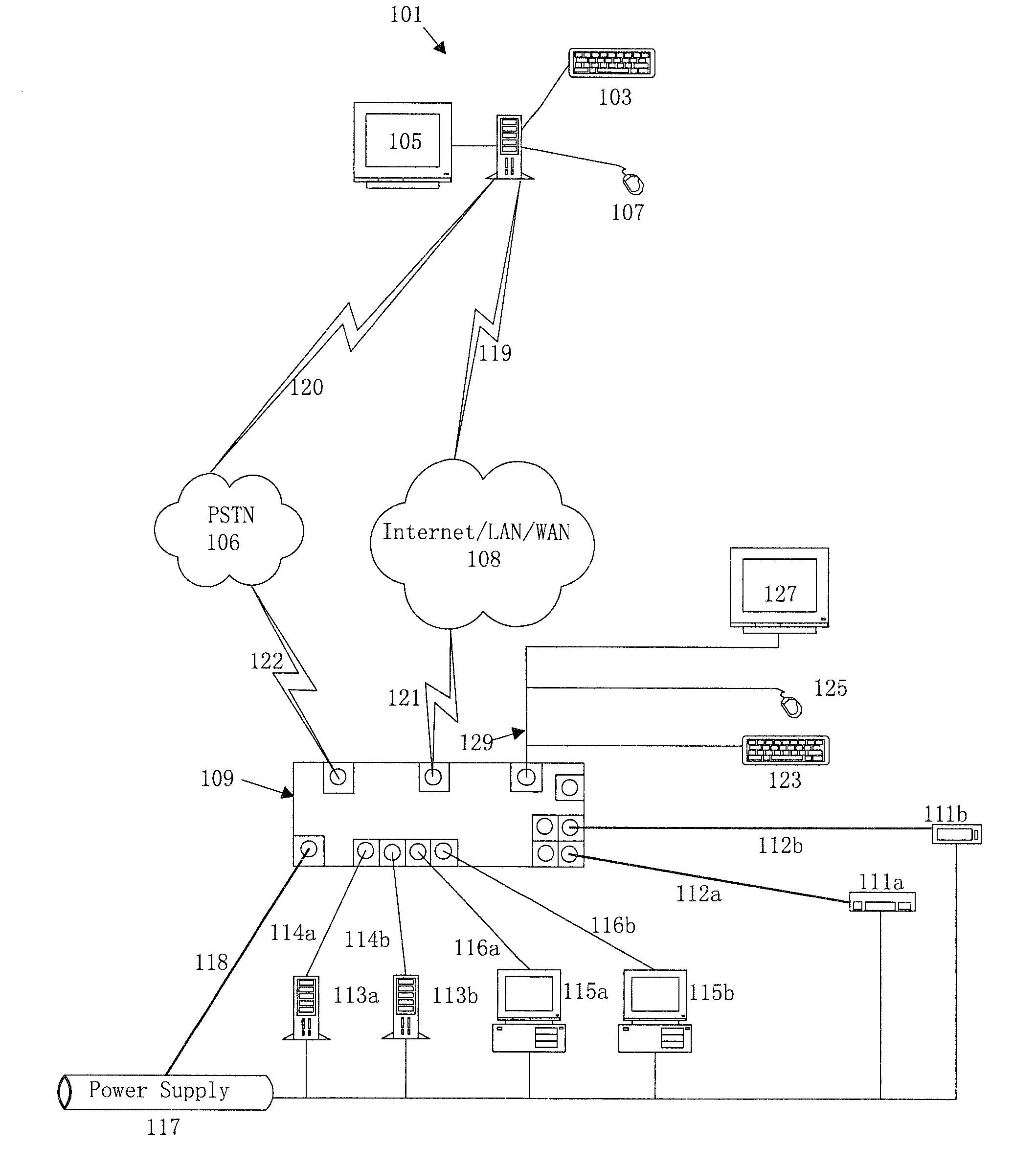

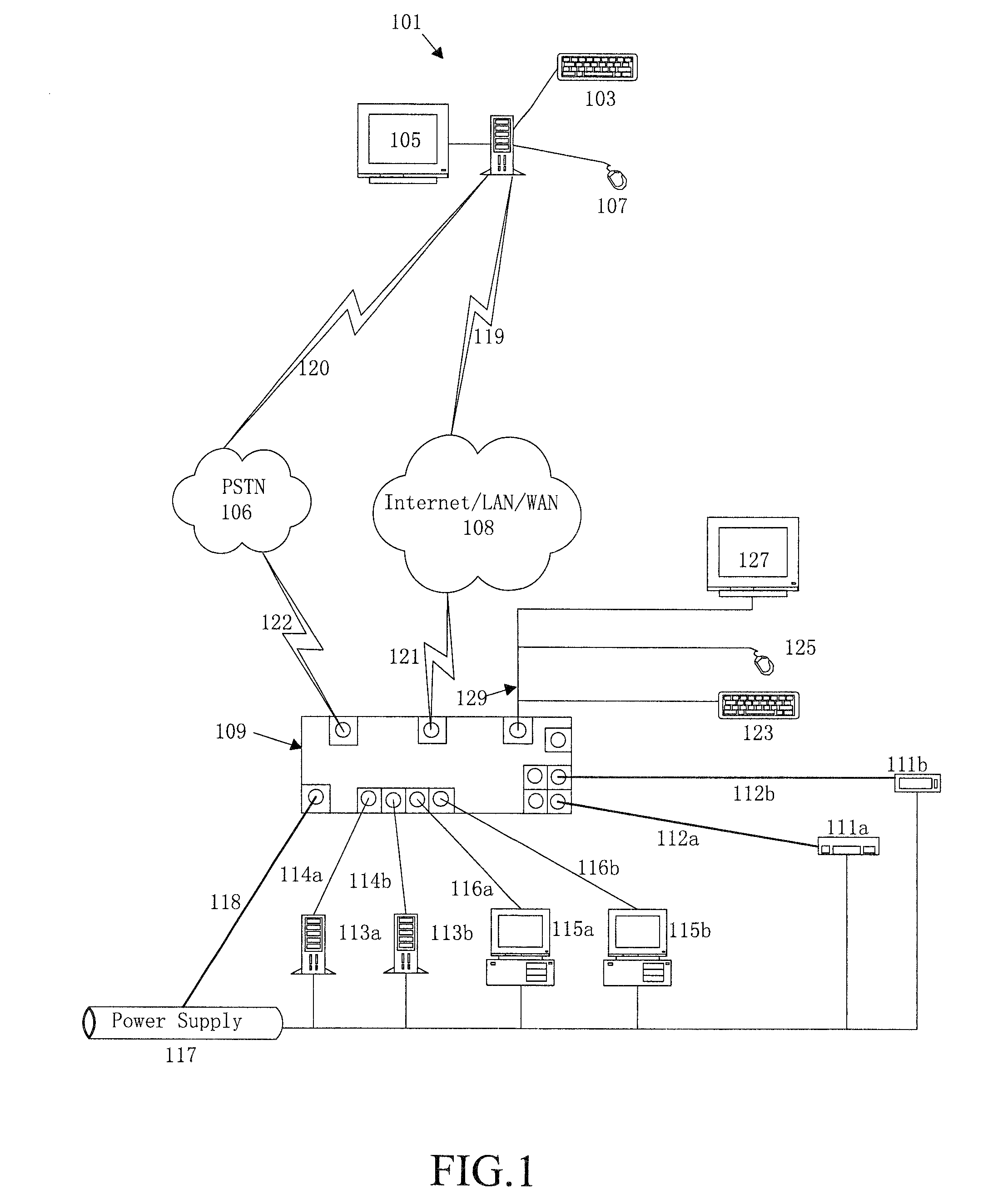

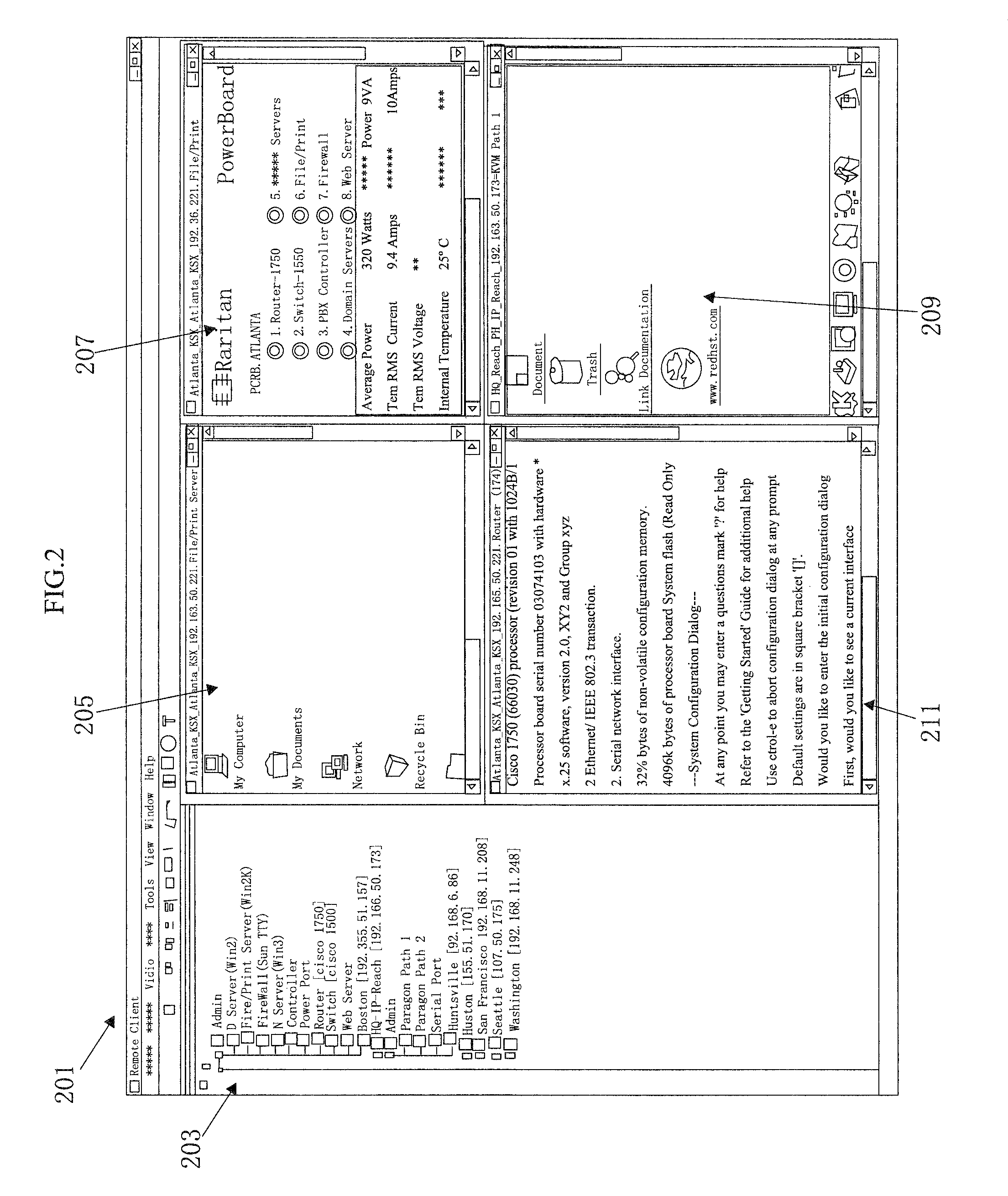

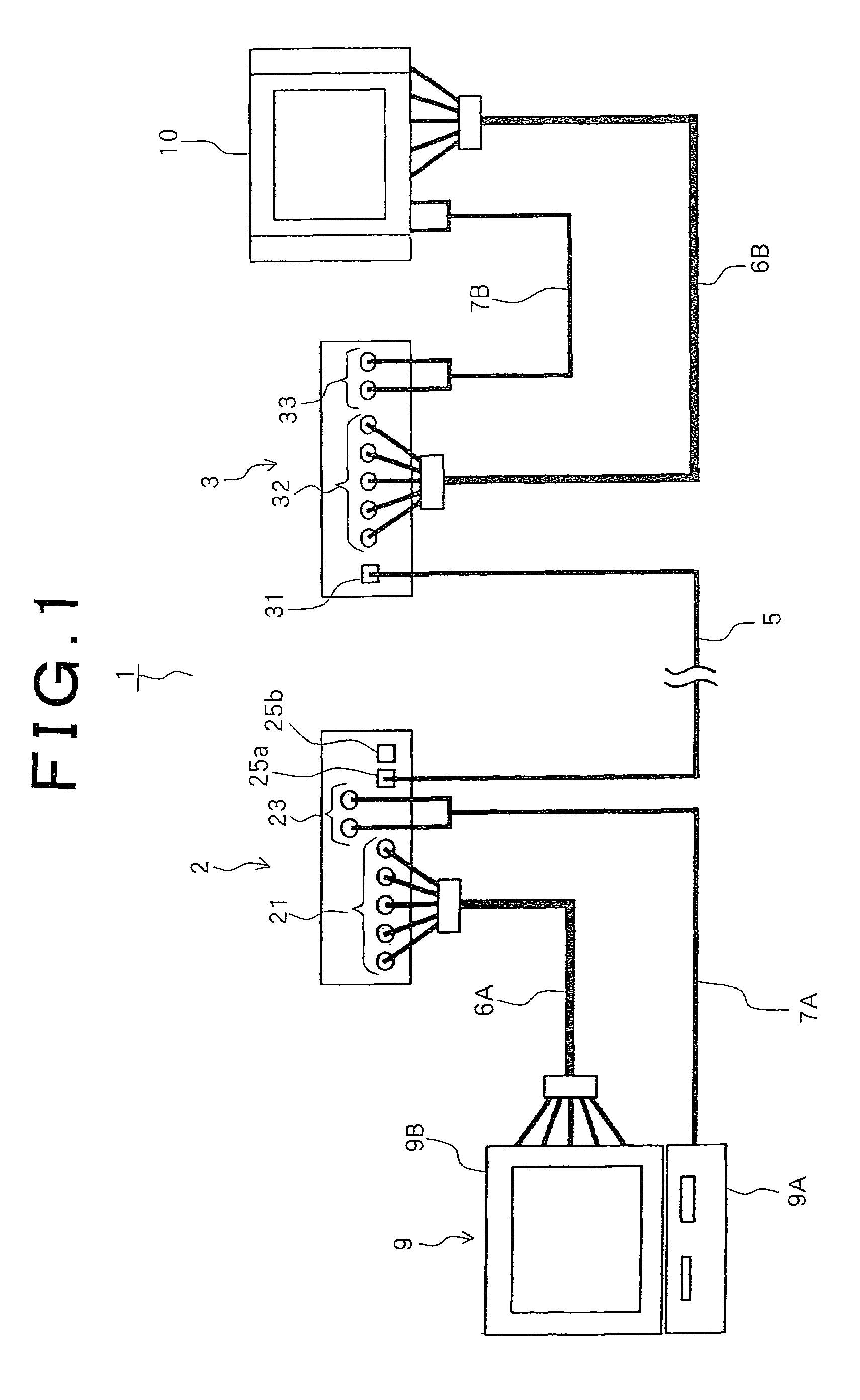

Remote network management system

ActiveUS20050125519A1Easy to install and to operateEasily transmittedStatic indicating devicesPicture reproducers using cathode ray tubesNetwork managementApplication server

Disclosed is a remote network management system for coupling a series of remote domain servers, file / print servers, headless servers, network appliances, serial IT equipment, switches, routers, firewalls, security interfaces, application servers, load balancers, and environmental controls to one or more user workstations allowing for selective access of the remote devices. The remote devices are all connected to a remote management unit which interfaces each user workstation to the remote devices. The power supply of each remote device is similarly connected to the remote management unit through a controllable power supply. An option menu containing a list of all of the remote devices allows a user to select and operate any of the remote devices from the workstation. The option menu is also utilized to selectively control the power to the remote devices, servers, and computers.

Owner:RIIP

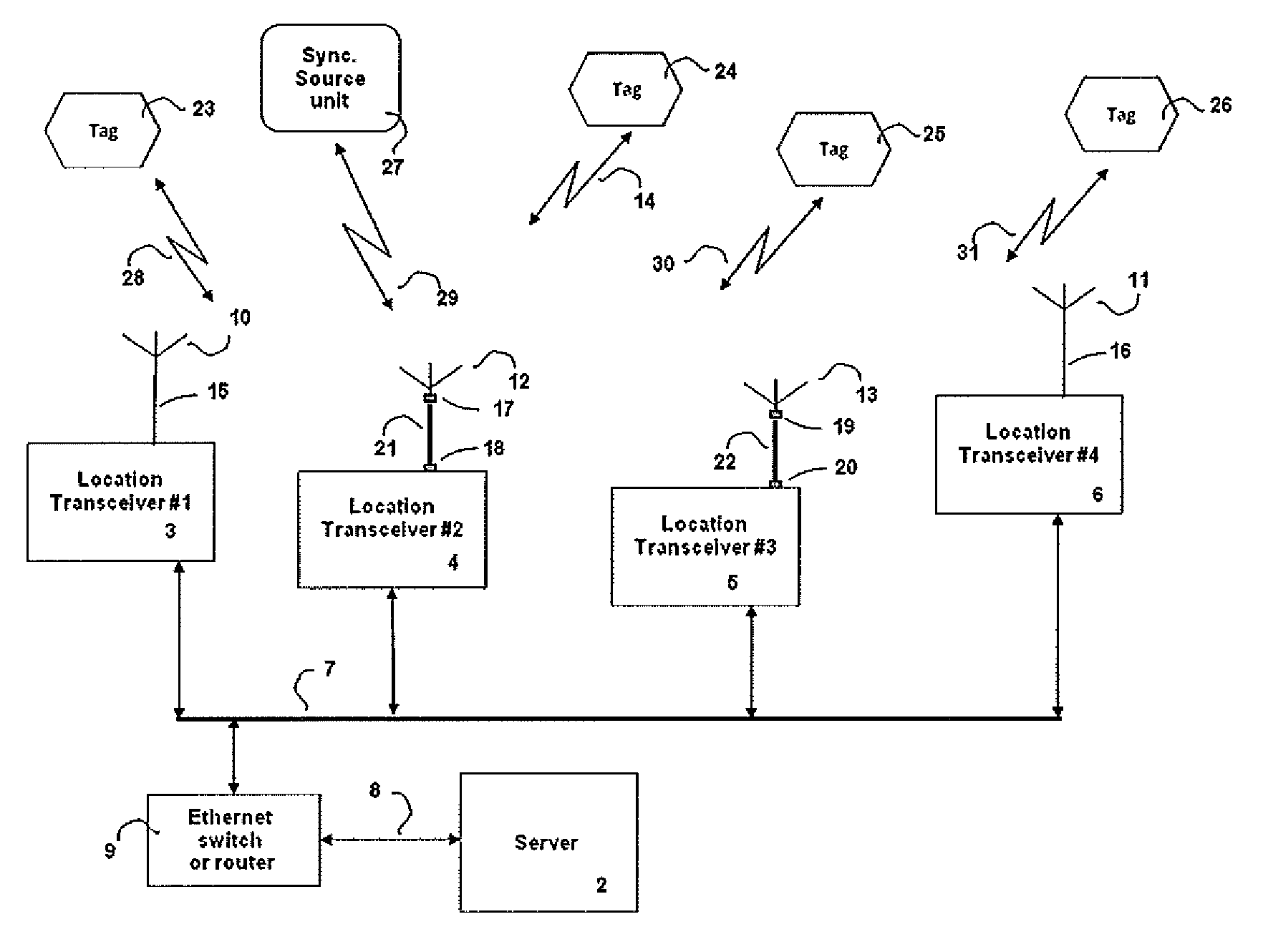

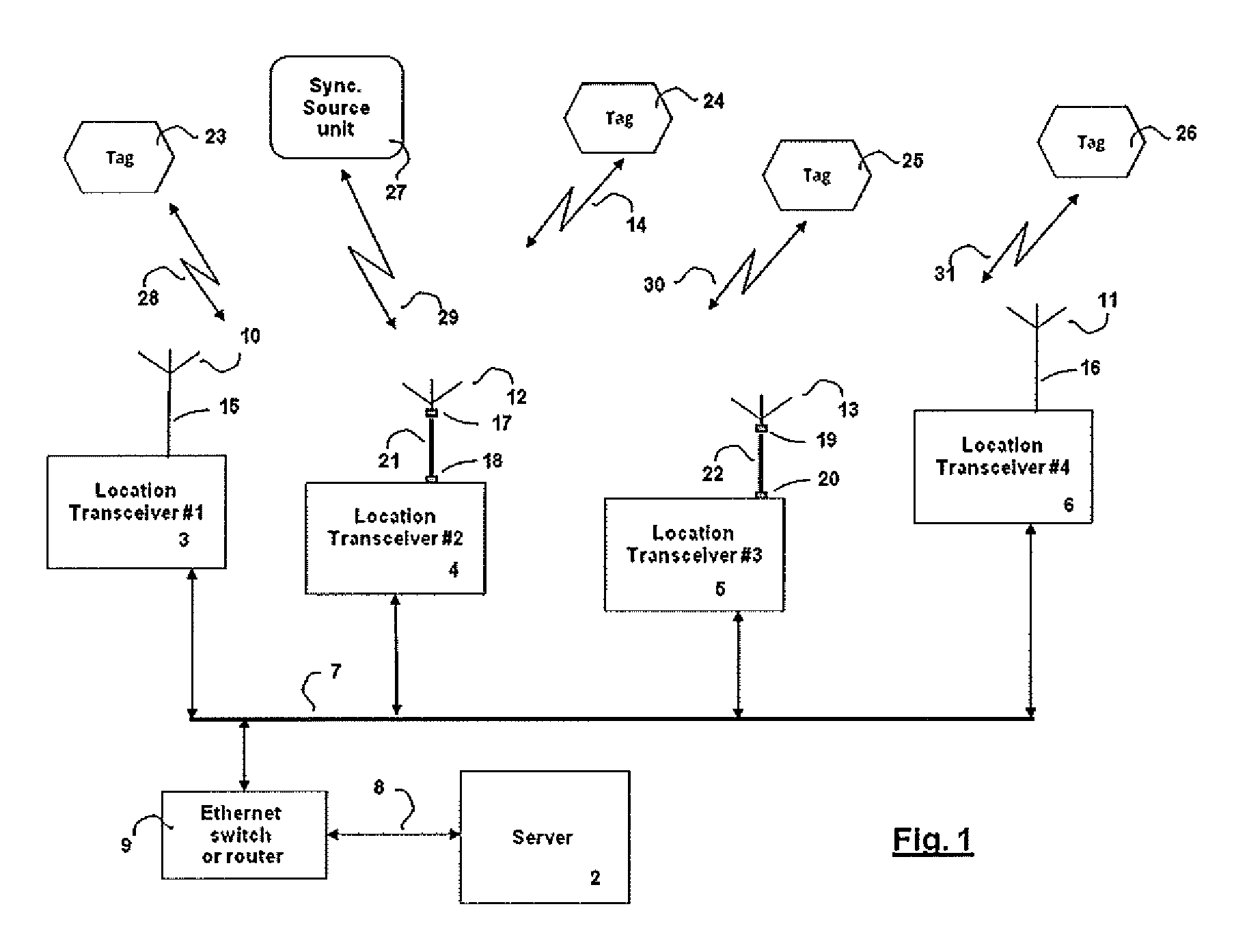

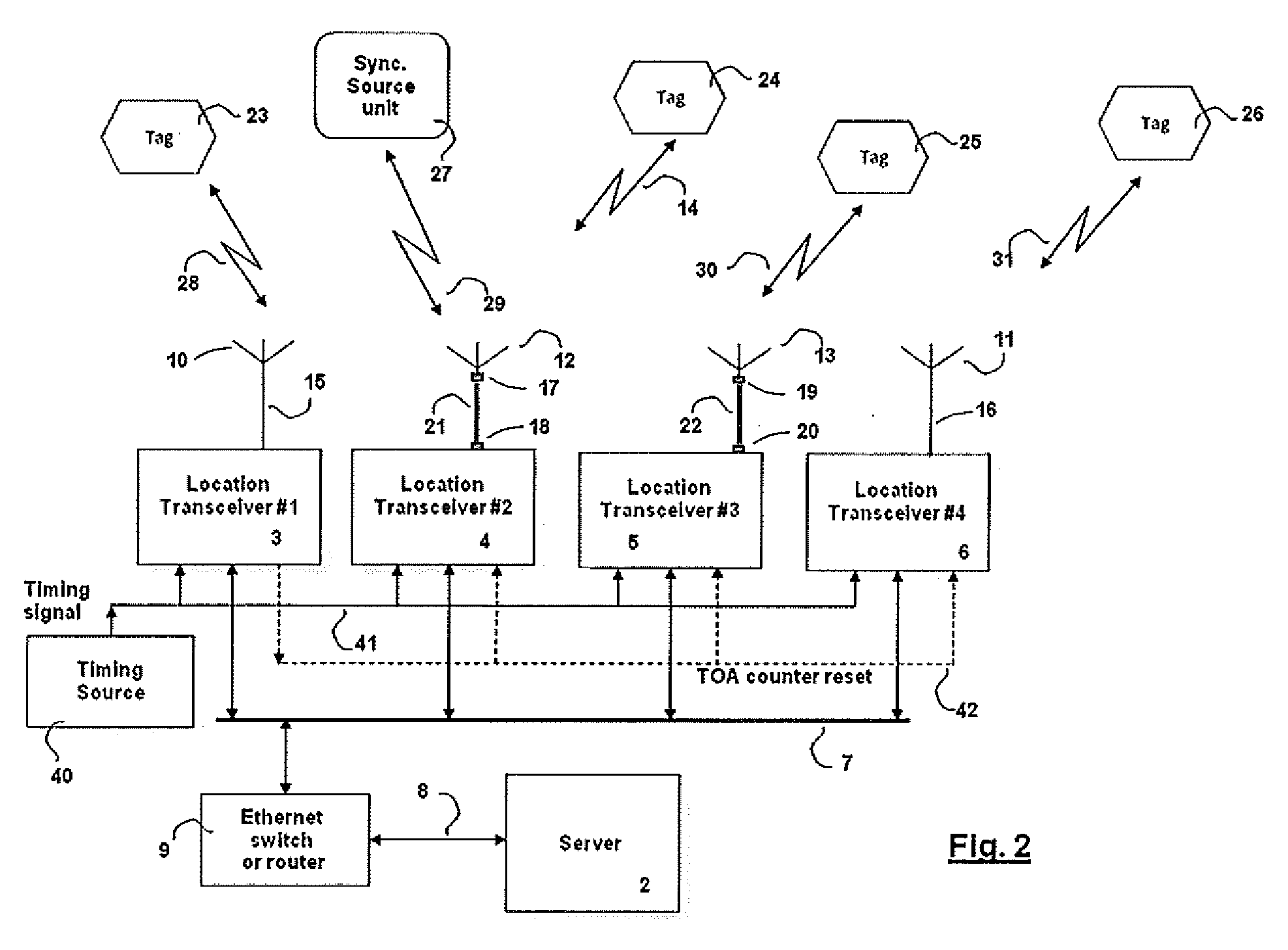

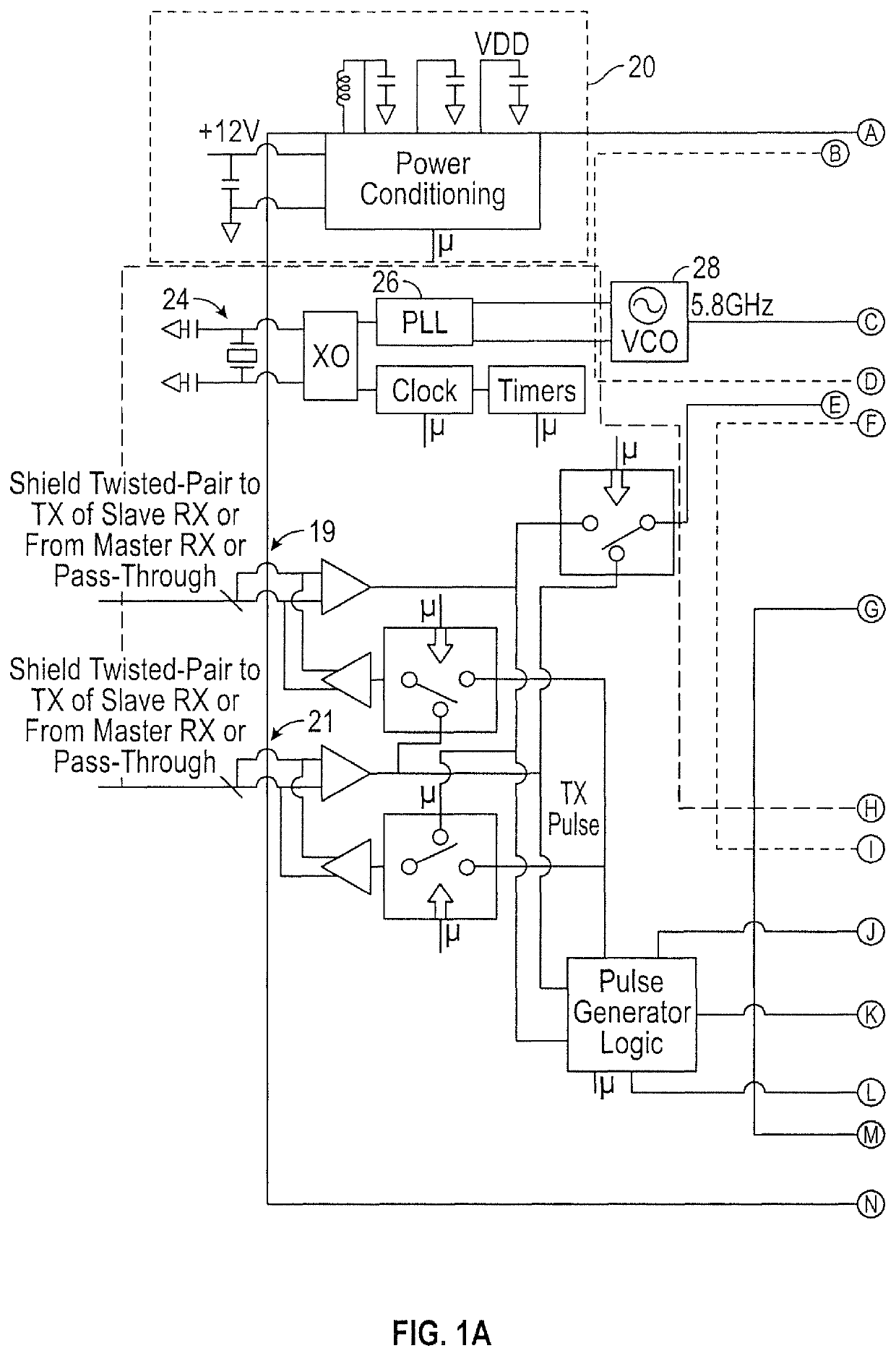

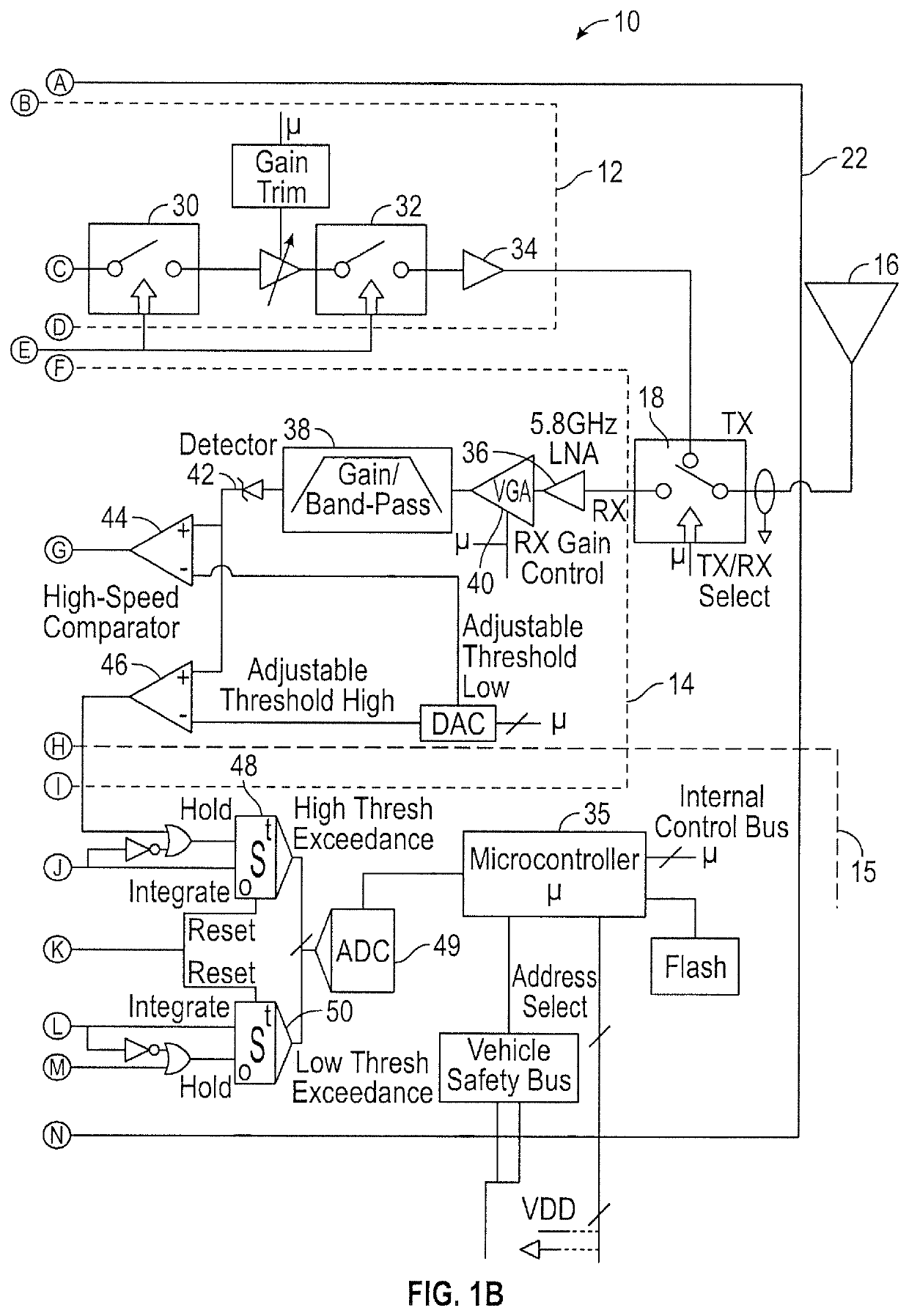

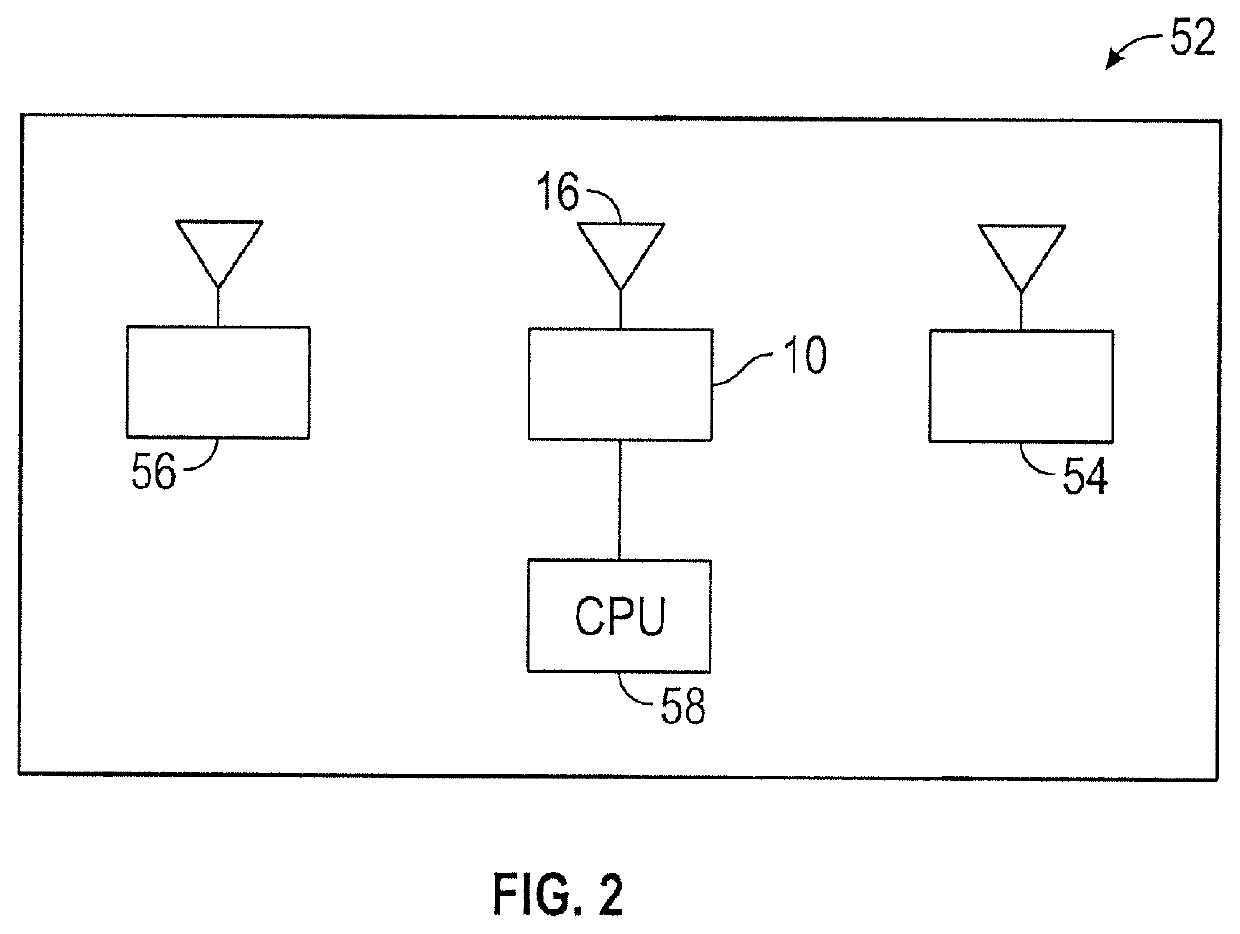

Location system and method with a fiber optic link

InactiveUS20110050501A1Simple processSimplifying the fiber optic link and the transpondersPosition fixationBeacon systemsFiberTransceiver

A TDOA (time difference of arrival) location system, in which mobile wireless devices broadcast wireless signals which are received by two or more transceivers deployed in the vicinity of the mobile wireless device. Each transceiver measures the TOA (time of arrival) of the received broadcasted signal and reports the TOA to a central server. The central server then calculates the mobile device position using multi-lateration of TDOA values. The system uses fiber optic links between the antennas and the transceivers deployed in the location area to provide unique advantages that couldn't be achieved using RF coaxial cables.

Owner:AEROSCOUT

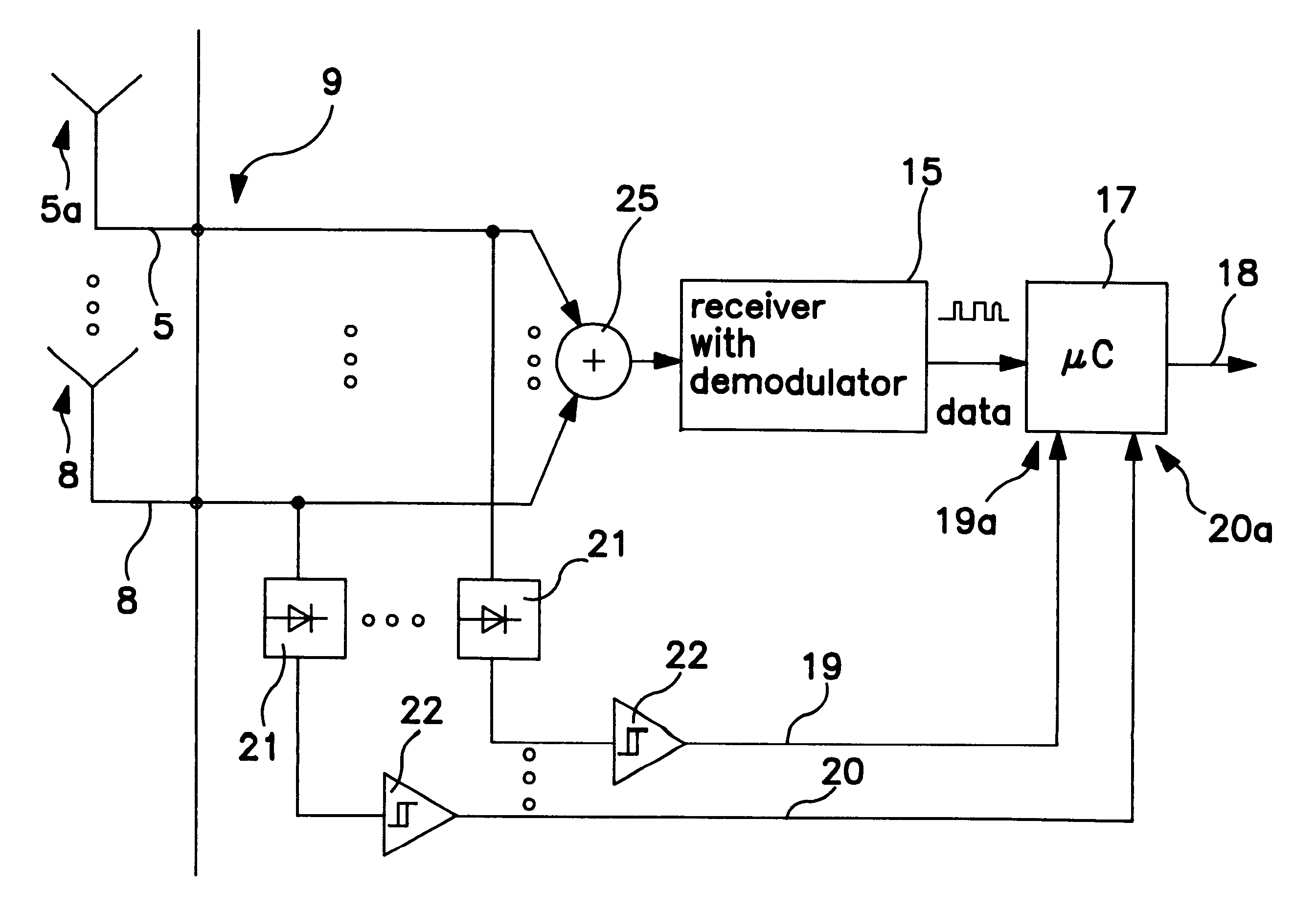

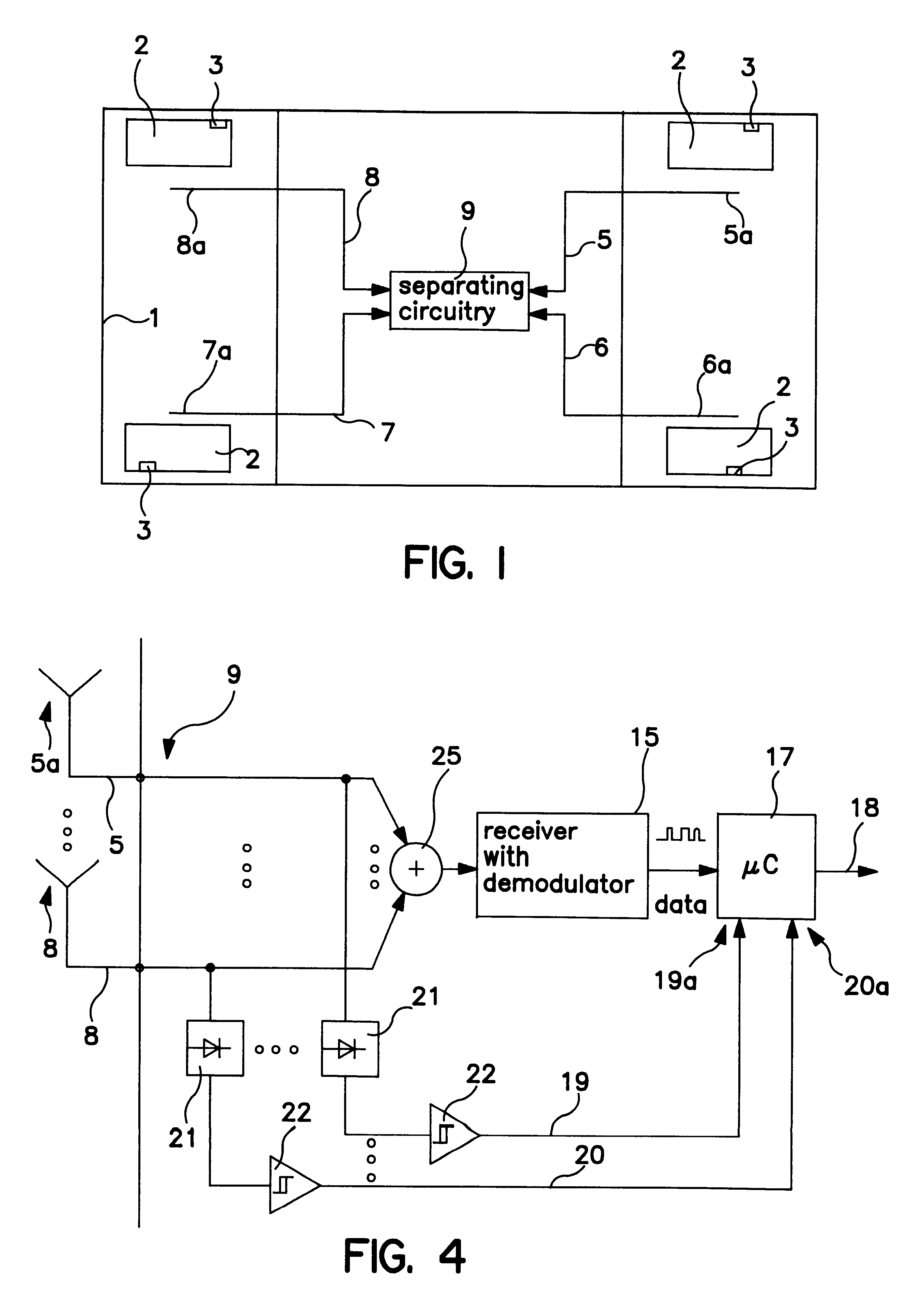

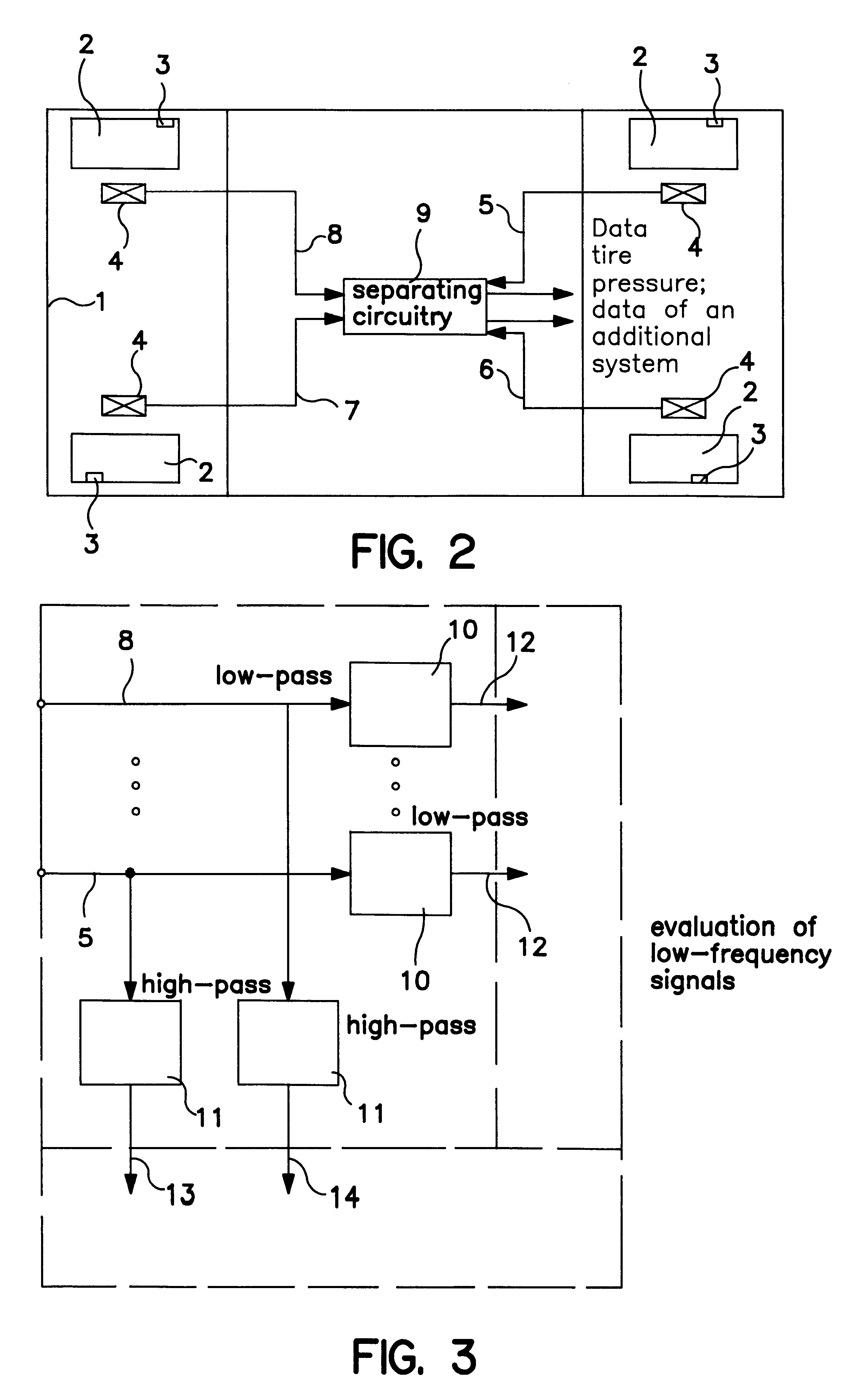

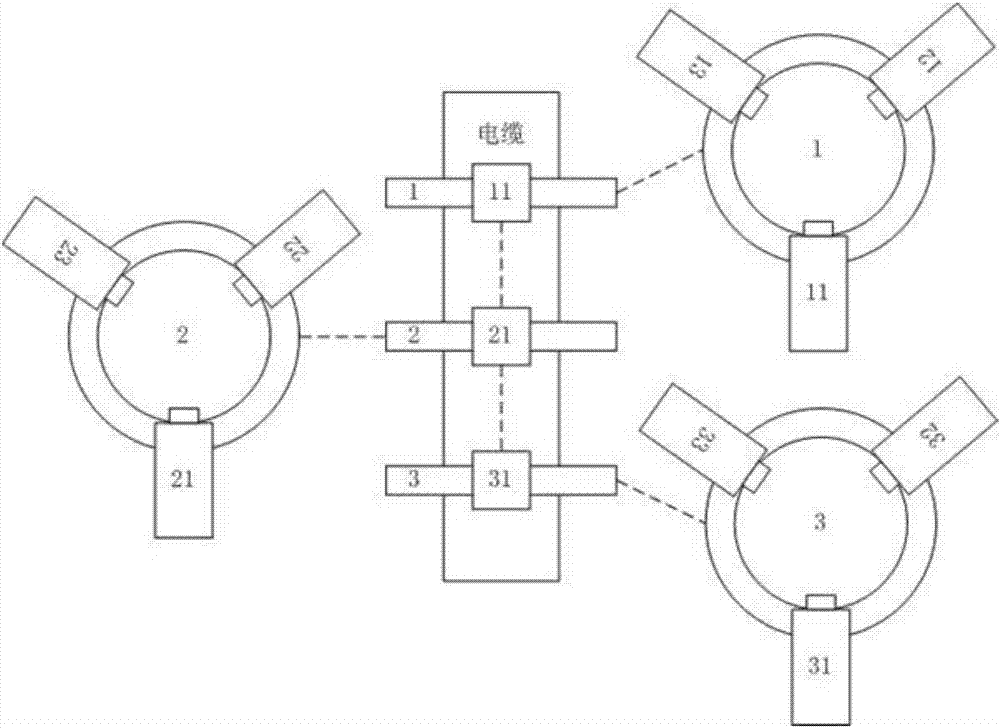

Device fitted on vehicles for monitoring tyre pressure

InactiveUS6194999B1Low costMinimize susceptibilityElectric switchesTyre measurementsEngineeringPressure data

The proposed device is fitted on vehicles equipped with pneumatic tires and is used for monitoring tire pressure. The device comprises: a pressure measurement sensor on each of the wheels (2) being monitored; a transmitter mounted next to each pressure measurement sensor which emits signals carrying the pressure data obtained from the pressure measurement sensor, and a receiver for those signals fitted on the vehicle chassis. An antenna (5a, 6a, 7a, 8a) is arranged next to each wheel (2) as the receiver. The antennae are connected to a common receiving and monitoring circuit (15, 17).

Owner:UHL GUNTER +4

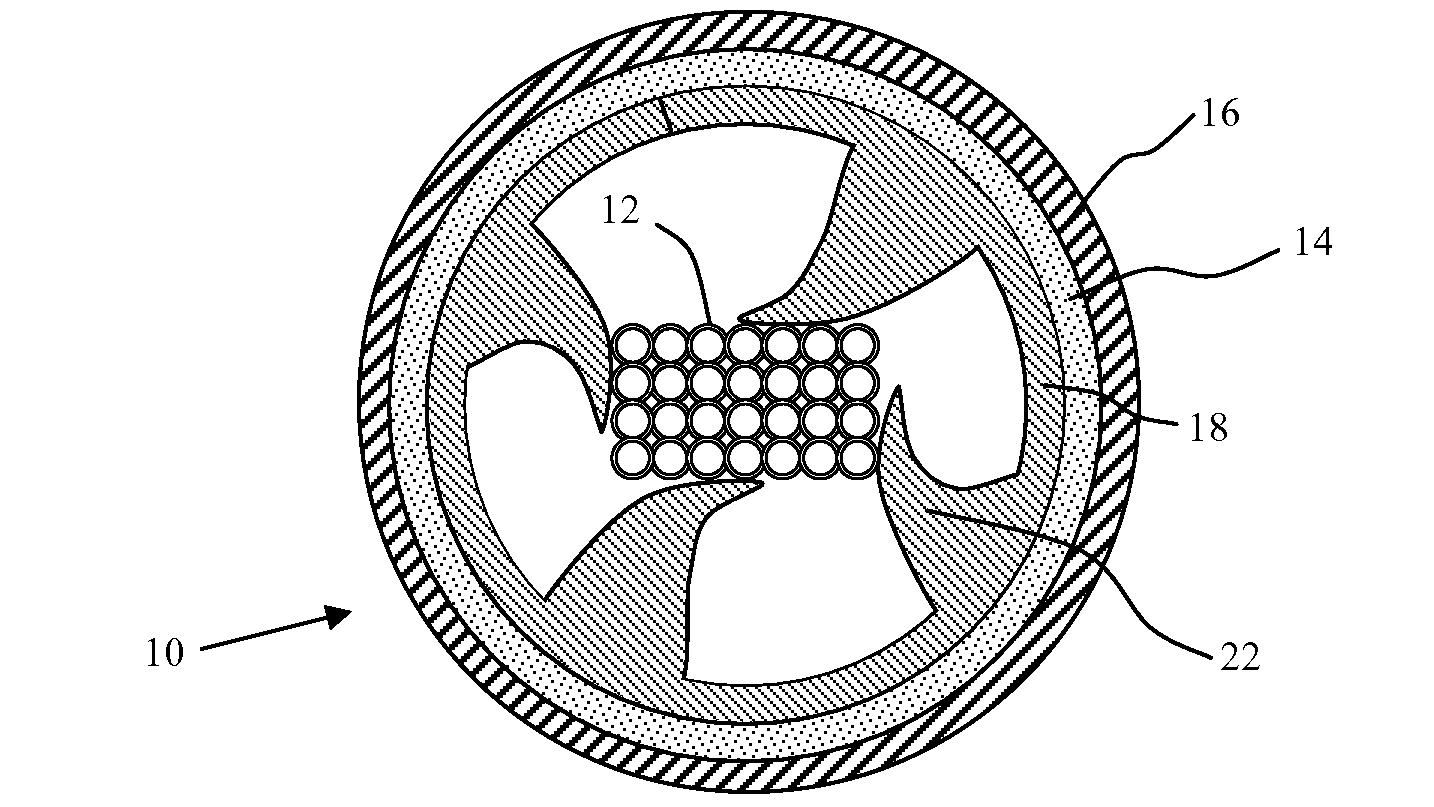

Optical Fiber Cable Having Raised Coupling Supports

InactiveUS20090003779A1Limited amountInhibitionGlass making apparatusFibre mechanical structuresCouplingEngineering

Disclosed is an optical fiber cable that includes optical fibers and a deformable coupling element enclosed within a buffer tube. The coupling element is formed from a deformable yet substantially incompressible material and features a number of raised members projecting toward the optical fibers. The design of the coupling element layer permits coupling of the optical fibers to the buffer tube without the use of a compressive cushioning layer. This arrangement distributes the compressive force applied to discrete points along the outer perimeter of the optical fiber element.

Owner:DRAKA COMTEQ BV

Remote network management system

ActiveUS8176155B2Easily transmittedReduce cable costsStatic indicating devicesPicture reproducers using cathode ray tubesApplication serverIt equipment

Disclosed is a remote network management system for coupling a series of remote domain servers, file / print servers, headless servers, network appliances, serial IT equipment, switches, routers, firewalls, security interfaces, application servers, load balancers, and environmental controls to one or more user workstations allowing for selective access of the remote devices. The remote devices are all connected to a remote management unit which interfaces each user workstation to the remote devices. The power supply of each remote device is similarly connected to the remote management unit through a controllable power supply. An option menu containing a list of all of the remote devices allows a user to select and operate any of the remote devices from the workstation. The option menu is also utilized to selectively control the power to the remote devices, servers, and computers.

Owner:RIIP

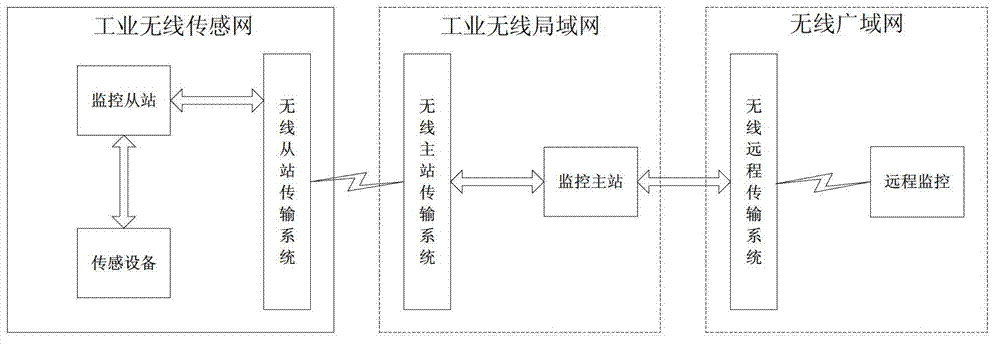

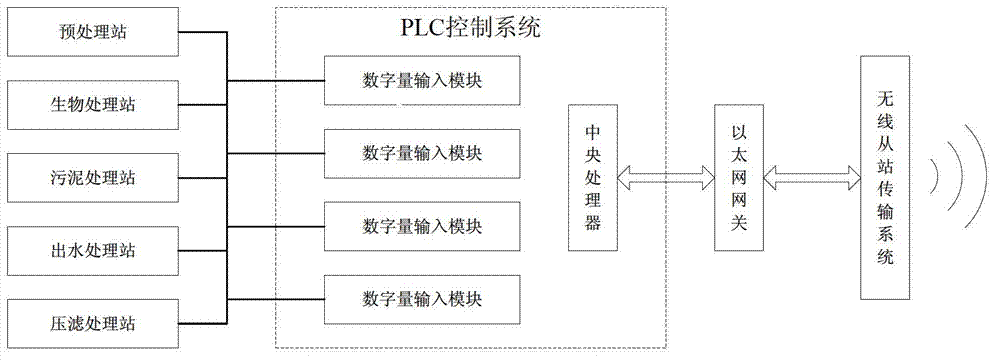

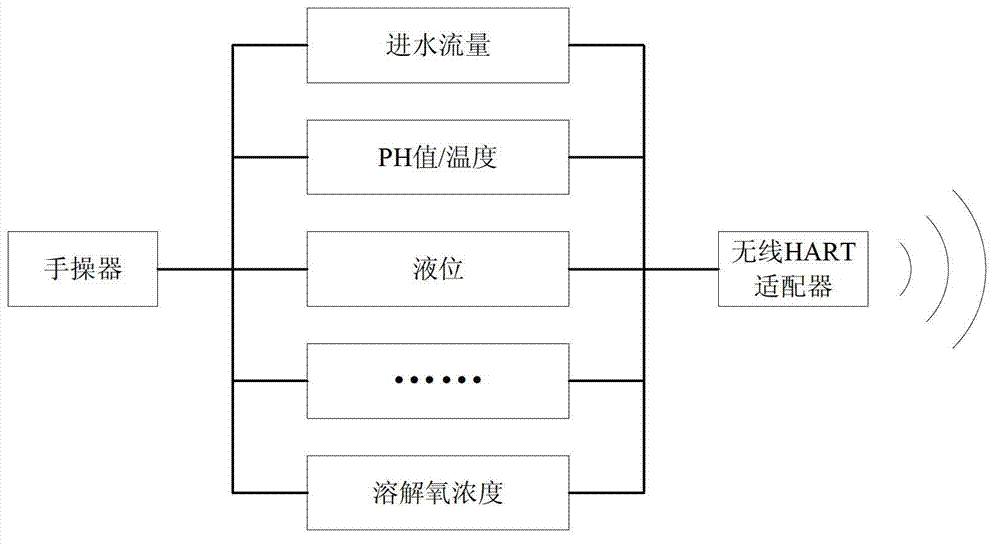

Wastewater treatment process monitoring system based on wireless network

ActiveCN103034211AReduce cable costsEasy and flexible installationTotal factory controlProgramme total factory controlLocal area networkEngineering

The invention discloses a wastewater treatment process monitoring system based on a wireless network. The wastewater treatment process monitoring system based on the wireless network comprises an industrial wireless sensor network, an industrial wireless local area network and a wireless wide area network. The industrial wireless sensor network is responsible for collecting information of field devices of each process of the wastewater treatment. The industrial wireless local area network is responsible for processing the information which is sent by the industrial wireless sensor network and returning the processed data to the field devices at the same time. The wireless wide area network is responsible for transmitting and replying remote monitoring application and sending stoppage information to appointed technical people automatically at regular intervals during the period from stoppage occurrence to stoppage resolution. A traditional distributed collecting and distributing control system is updated to a network control system through different wireless networks, and therefore wireless remote real-time monitoring is truly realized.

Owner:无锡轻大百特环保工程有限公司

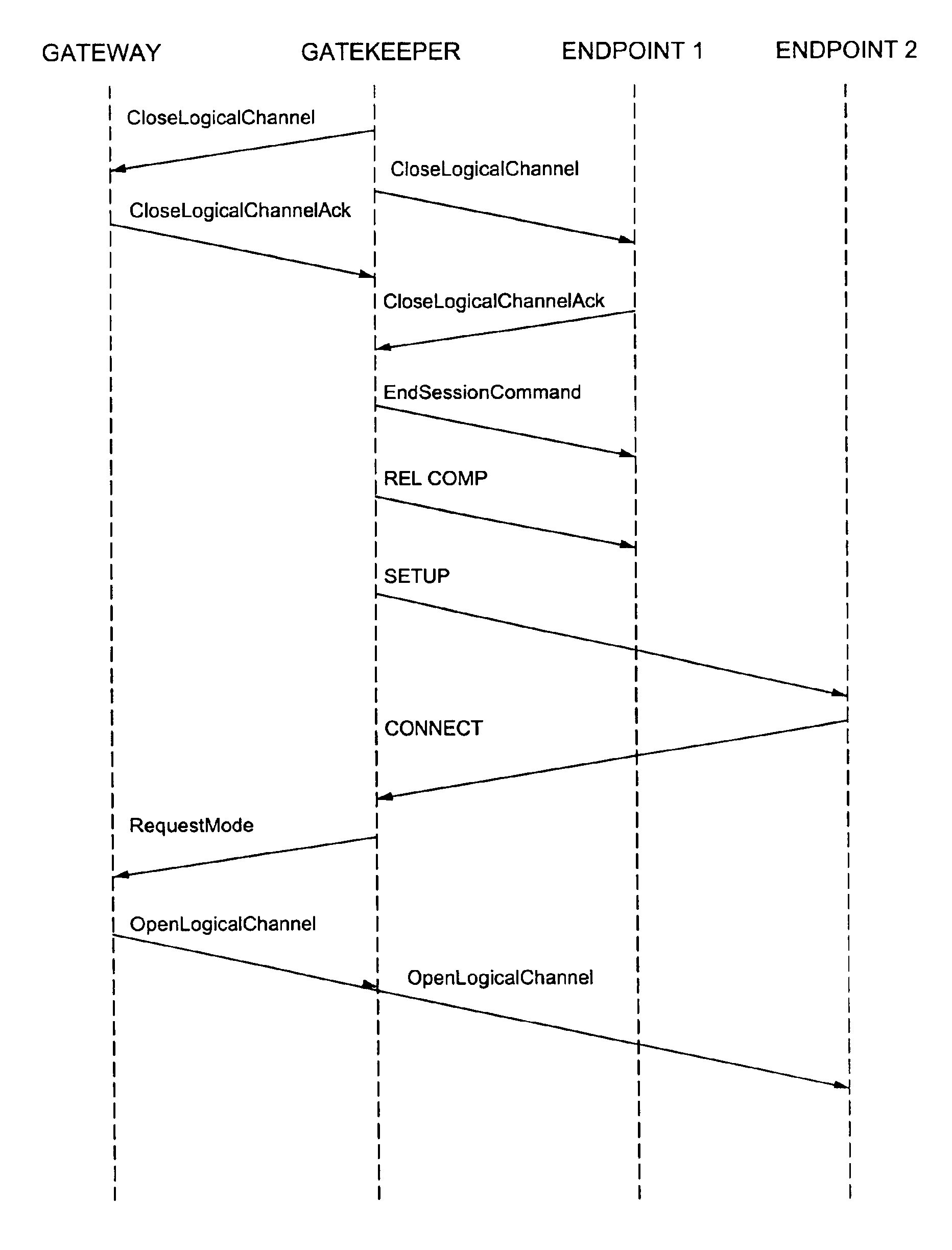

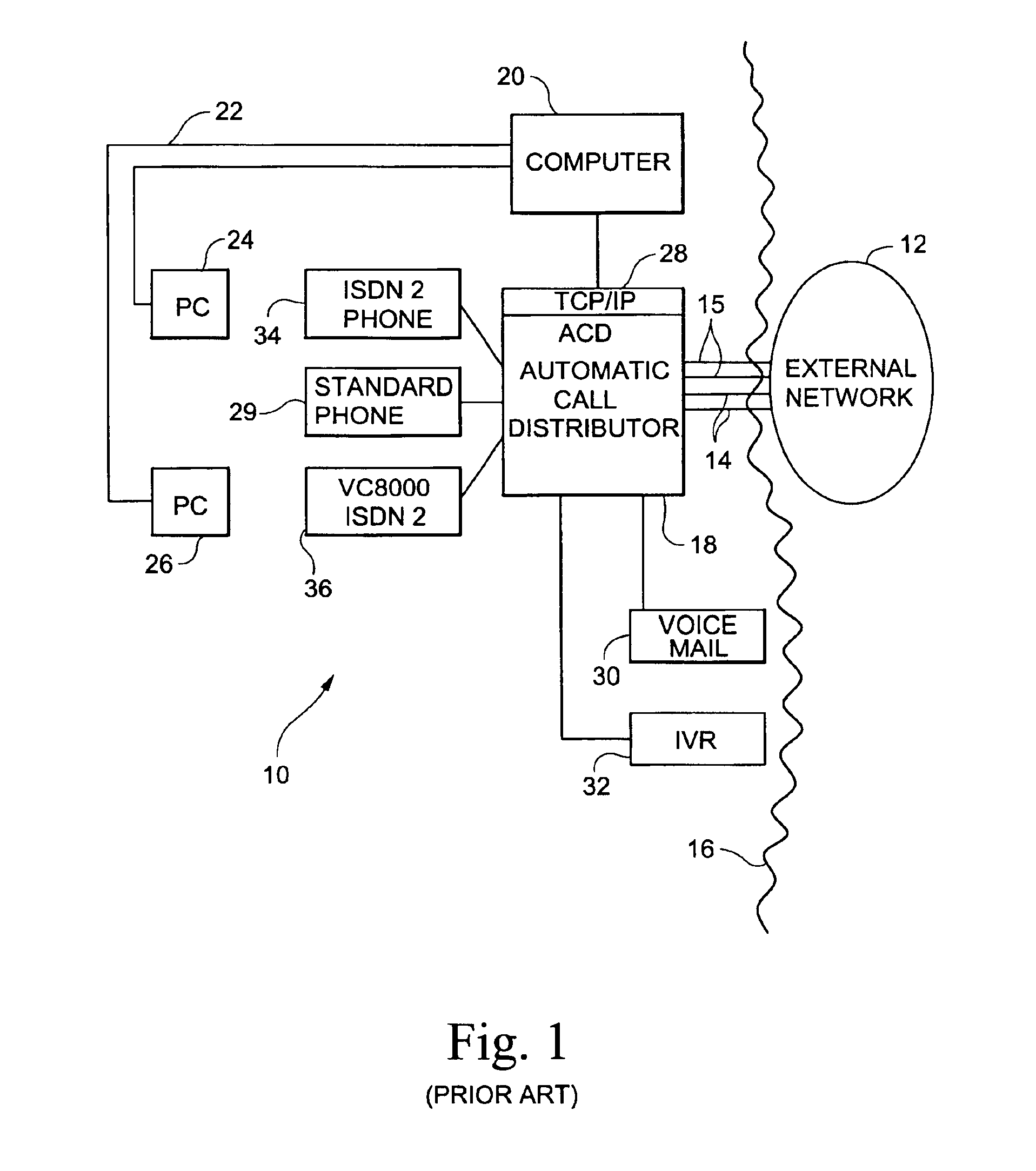

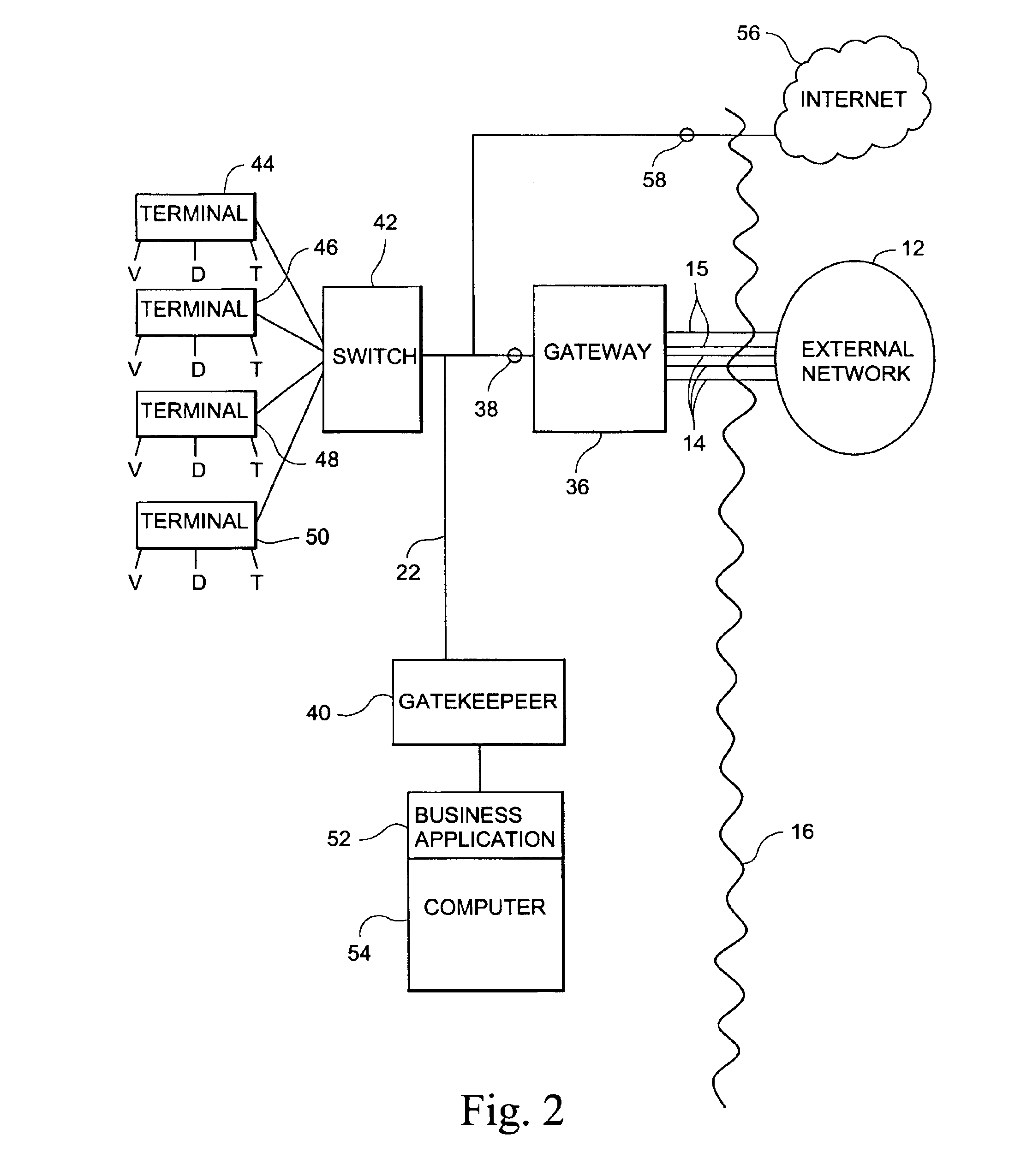

Multimedia call center

InactiveUS7016341B2Low infrastructure costReduce cable costsMultiplex system selection arrangementsSpecial service provision for substationThe InternetWide area network

A Multimedia Telecommunications Call Center provides integrated video, audio, data and telephony functionality, together with connectivity to the Internet, ISCN, PSTN, and other wide-area networks. The Call Center includes a Local Area Network having a Gateway and a Gatekeeper. Incoming multimedia calls are received by the Gateway and are permitted onto the network under control of the Gateway and are permitted onto the network under control of the Gatekeeper. Communications between the Gateway and the Gatekeeper preferably take place across the network and comply with the ITU H.323 standard protocol. Communications between the Gatekeeper and the Call Manager preferably take place across the network and comply with the European Computer Manufacturers Association CSTA standard protocol.

Owner:BRITISH TELECOMM PLC

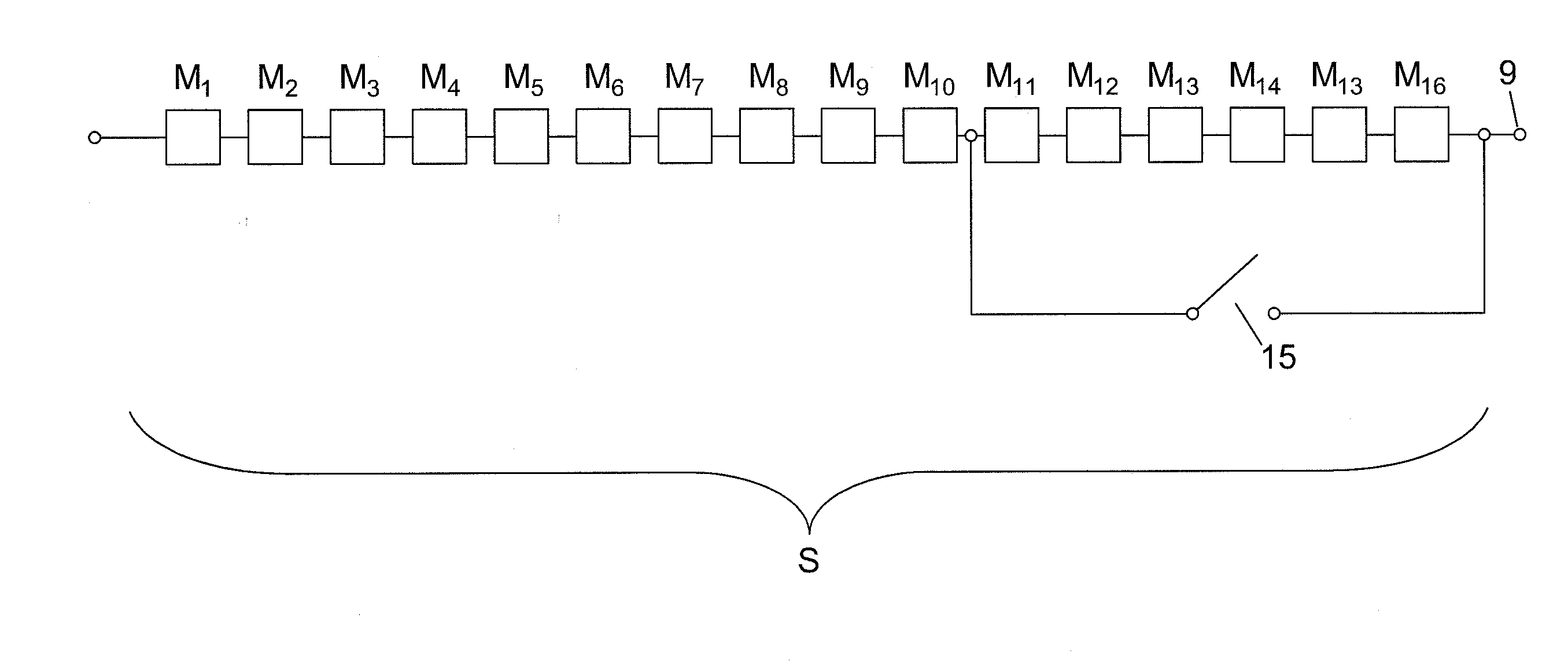

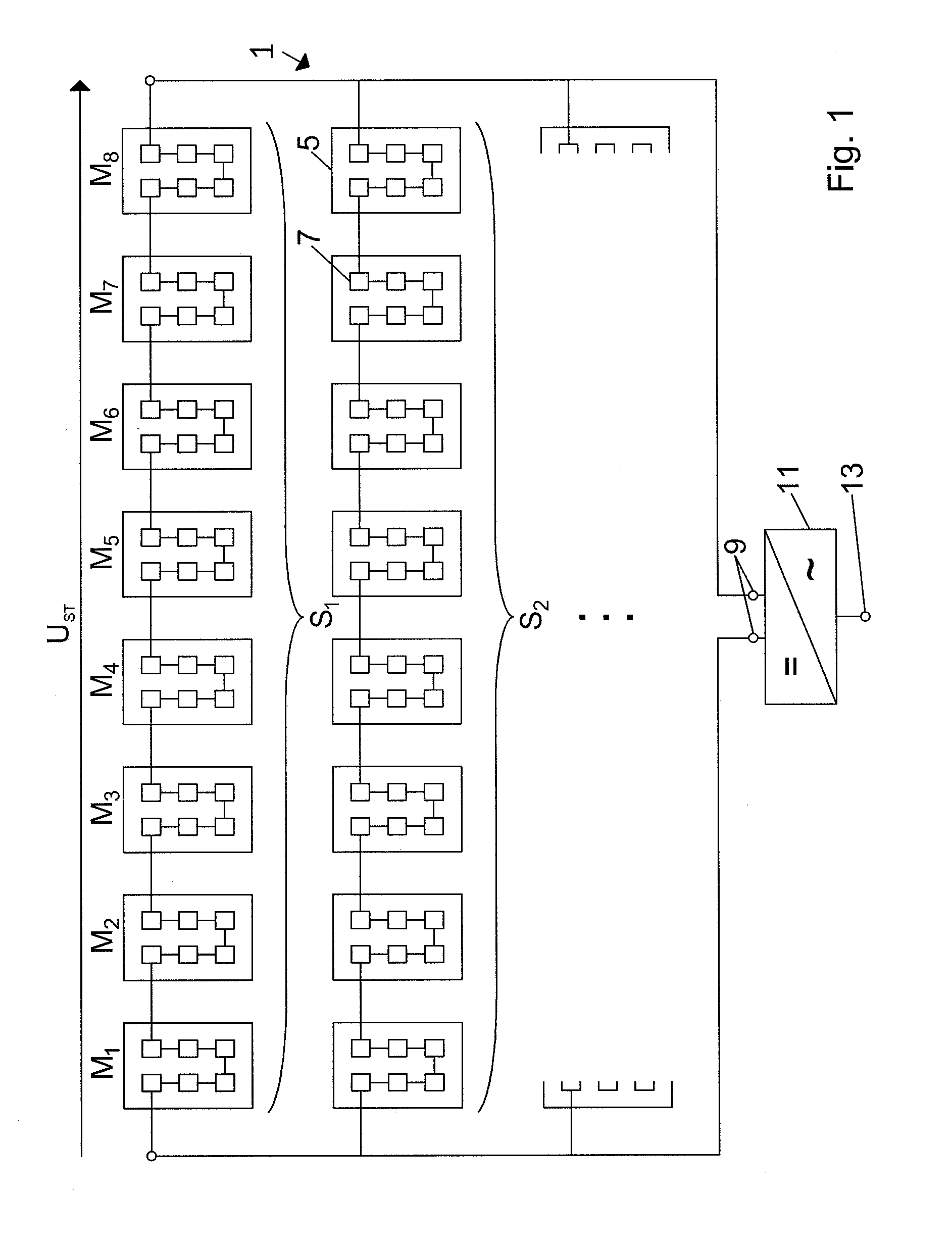

Photovoltaic arrays, in part having switches for short-circuiting of modules

InactiveUS20110203635A1Reduce cable costsOvervoltage protectionPV power plantsPhotovoltaic energy generationPower inverterLow voltage

A photovoltaic generator is provided that has at least one string of multiple series-connected photovoltaic modules, each of which has a plurality of series-connected photovoltaic cells. One quarter to one half of all photovoltaic modules of the at least one string can be short-circuited by means of a switch. Activation of the switch takes place when a predefined voltage value across the string is exceeded. The shorting switch is only present in some of the arrays making up the photovoltaic generator, which reduces cabling costs. Because of the parallel connection of the arrays, the voltage of the arrays without shorting switches is drawn down to a lower voltage that is safe for the inverter.

Owner:ADENSIS

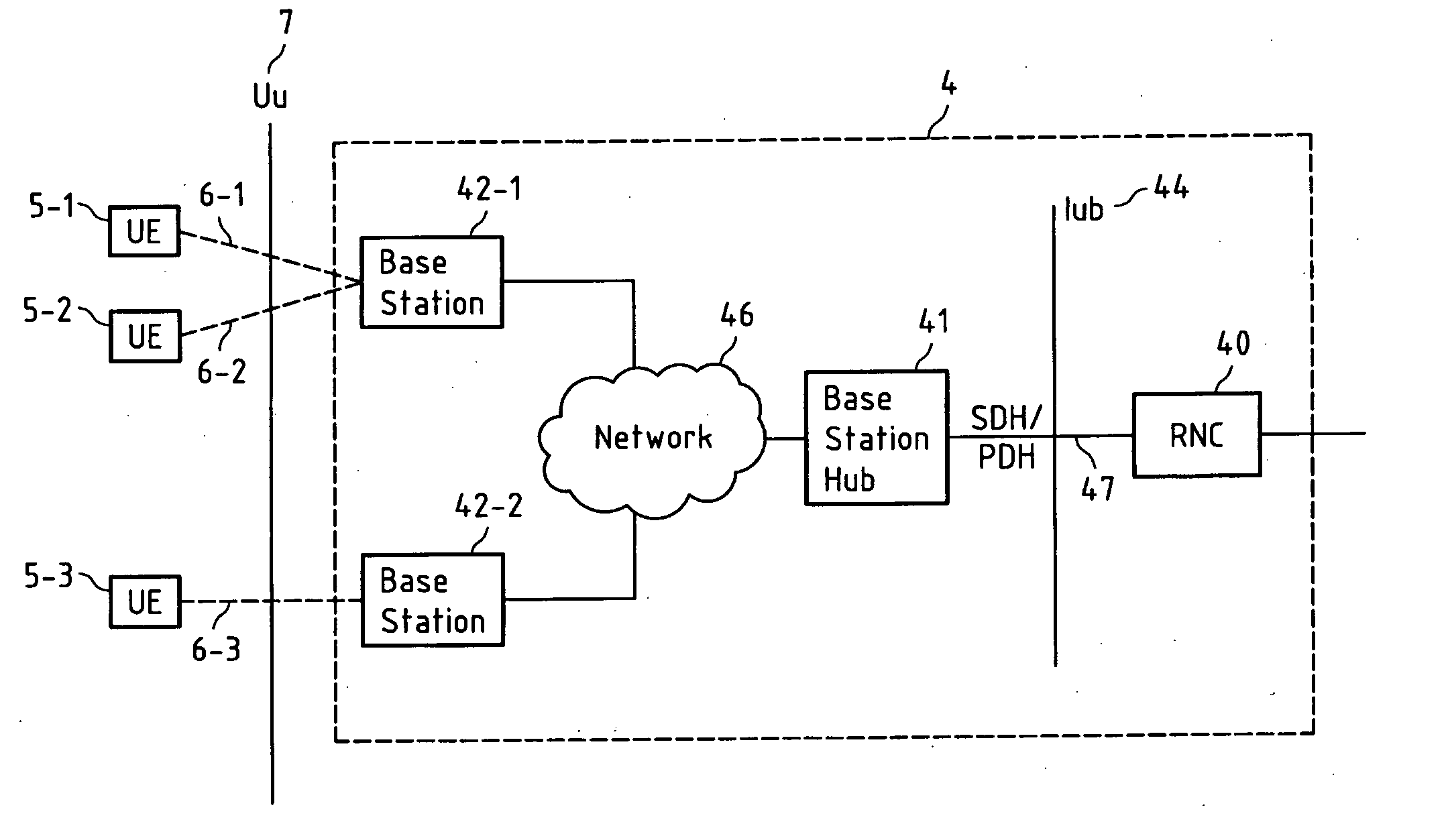

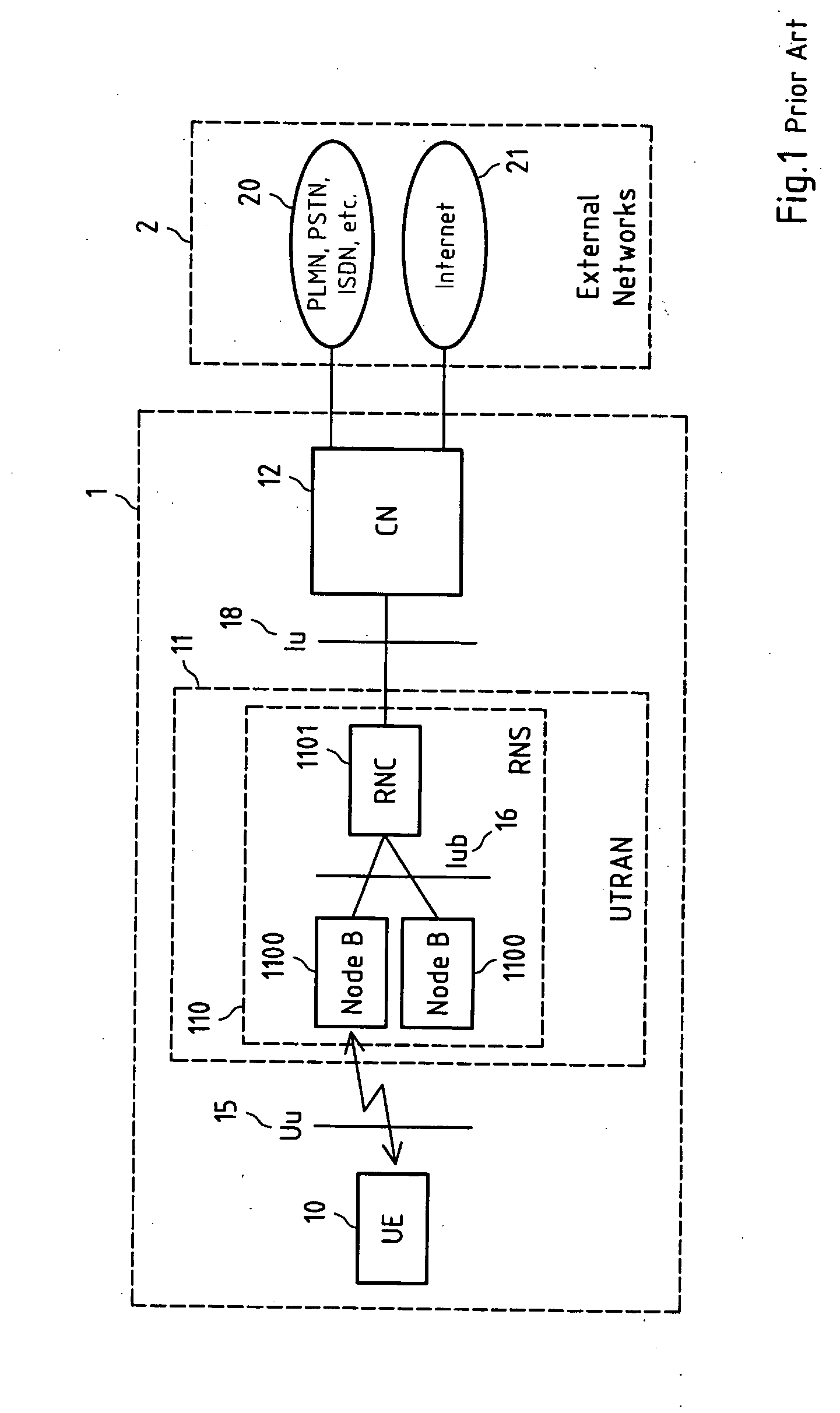

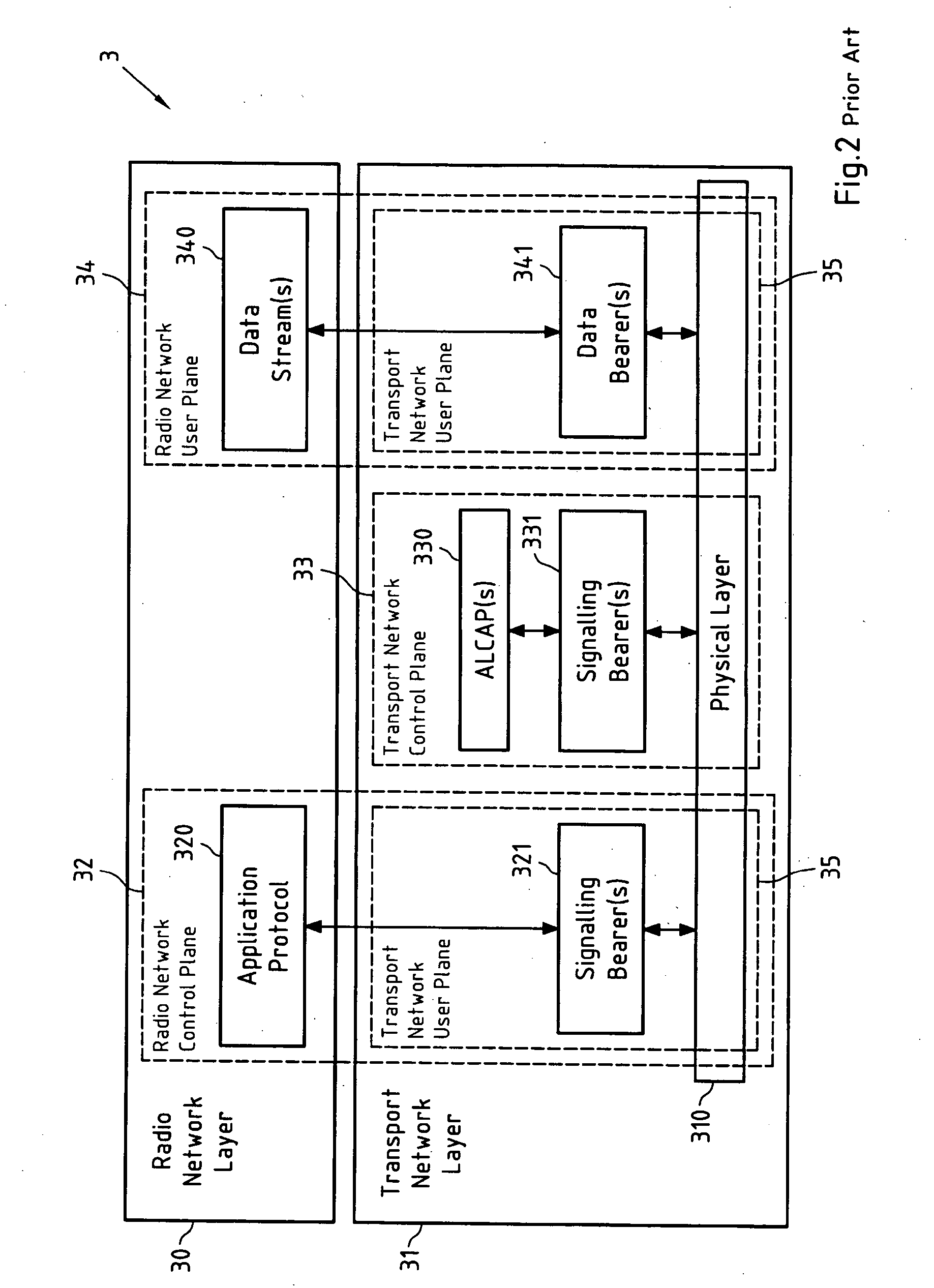

Deployment of different physical layer protocols in a radio access network

InactiveUS20060198336A1Increase freedomLess complexTime-division multiplexWireless network protocolsPhysical layerRadio access network

This invention relates to a method, a system, a base station, a base station hub (41) and software applications for data transmission between at least one base station (42-1, 42-2) and a radio network controller (40) in a radio access network, said method comprising operating a first-type physical layer protocol (46) for a transmission of said data between said at least one base station (42-1, 42-2) and a base station hub (41); operating a second-type physical layer protocol (47) for a transmission of said data between said base station hub (41) and said radio network controller (40); wherein said data comprises user data (340) that is transmitted between said radio network controller (40) and said at least one base station (42-1, 42-2) via said base station hub (41); and wherein said at least one base station (42-1, 42-2) performs at least base band processing for signals that are transmitted via a radio interface (7) and represent said user data (340).

Owner:NOKIA CORP

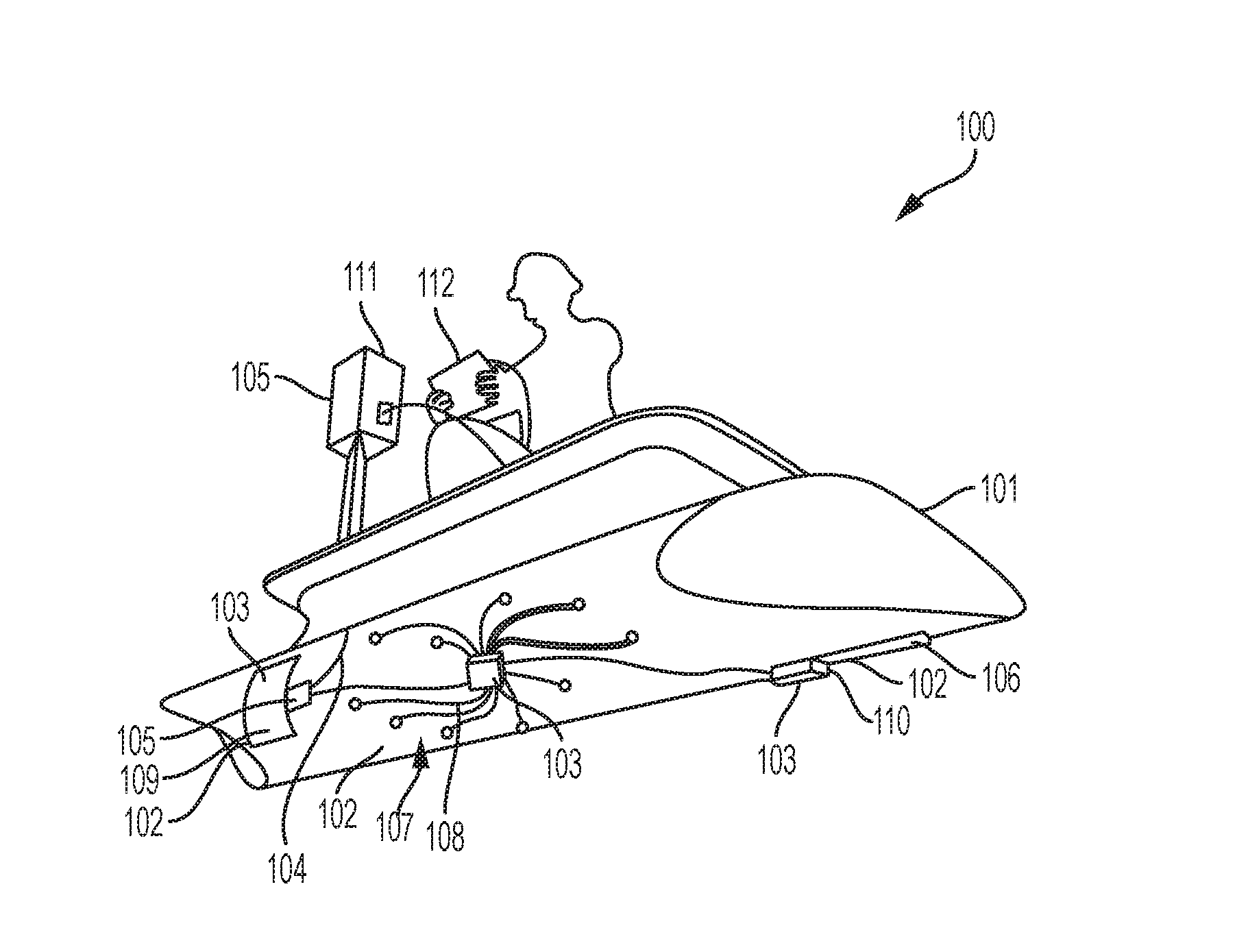

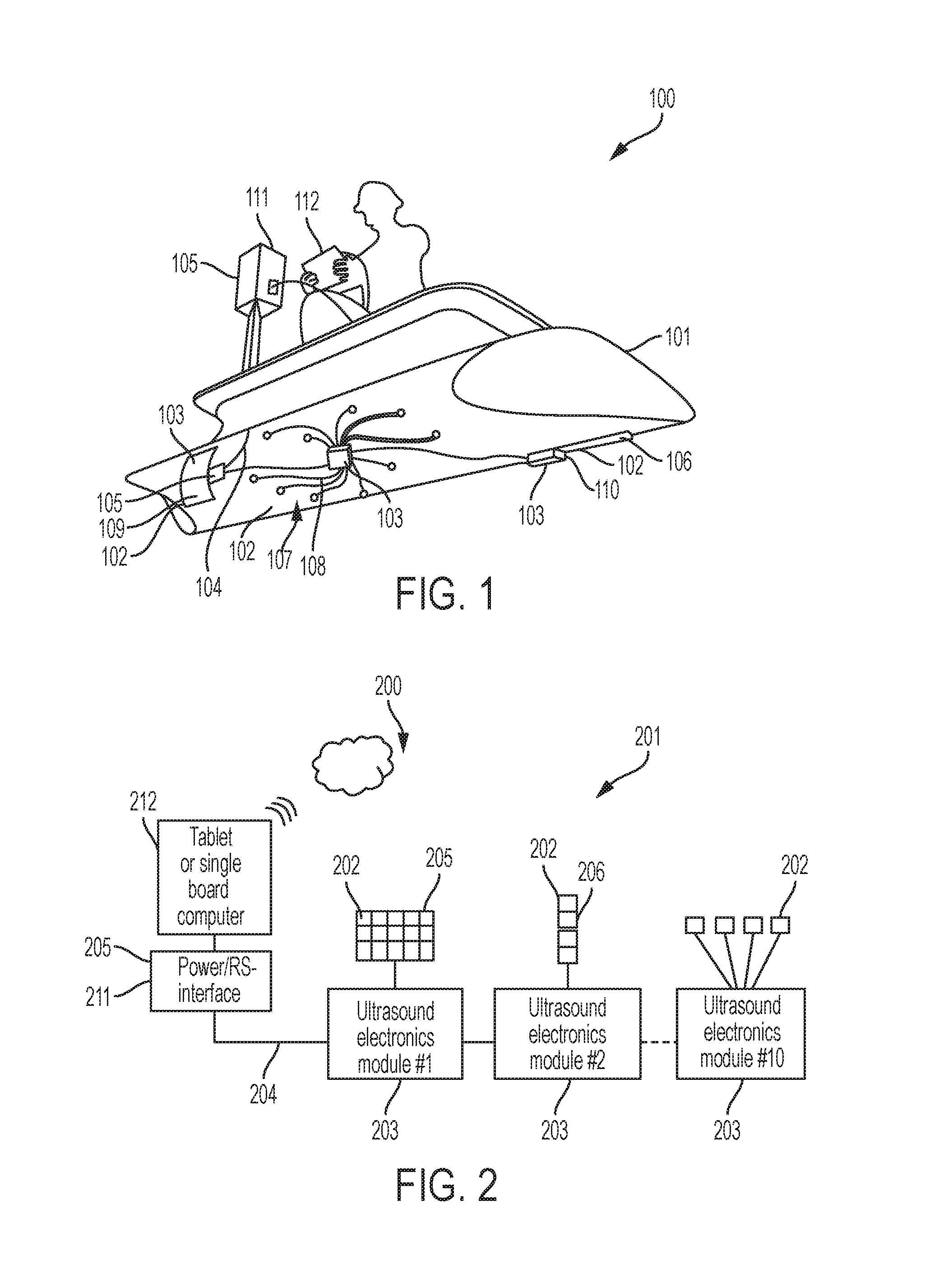

Asset-condition monitoring system

ActiveUS20160109411A1Improve data integrityImparts modularityAnalysing solids using sonic/ultrasonic/infrasonic wavesSonic/ultrasonic/infrasonic transmissionUser interfaceDigital signal

An ultrasound sensing system for monitoring the condition or integrity of a structure, comprising (a) a plurality of ultrasound sensors, each sensor being configured to receive at least one first electrical signal, transmit an ultrasound signal in response to the first electrical signal, receive at least one reflected ultrasound signal, and transmit a second electrical signal in response to the reflected ultrasound signal, the first and second electrical signals being analog; (b) at least one digital sensor interface (DSI) to which at least a portion of the sensors are connectable, the DSI being configured to transmit the first electrical signal and receive the second electrical signal, and to generate an A-scan signal based on the first and second electrical signals for each sensor, the DSI having circuitry for transmitting a digital signal based directly or indirectly on at least the A-scan signal, the digital signal including an address corresponding to the at least one DSI; (c) a digital bus configured to receive the digital signal from the at least one DSI; (d) a user interface connected to the bus to receive the digital signal; and wherein, in one embodiment, the sensors are mounted semi-permanently on the structure and the DSI is also mounted semi-permanently on or adjacent to the structure being monitored.

Owner:SENSOR NETWORKS

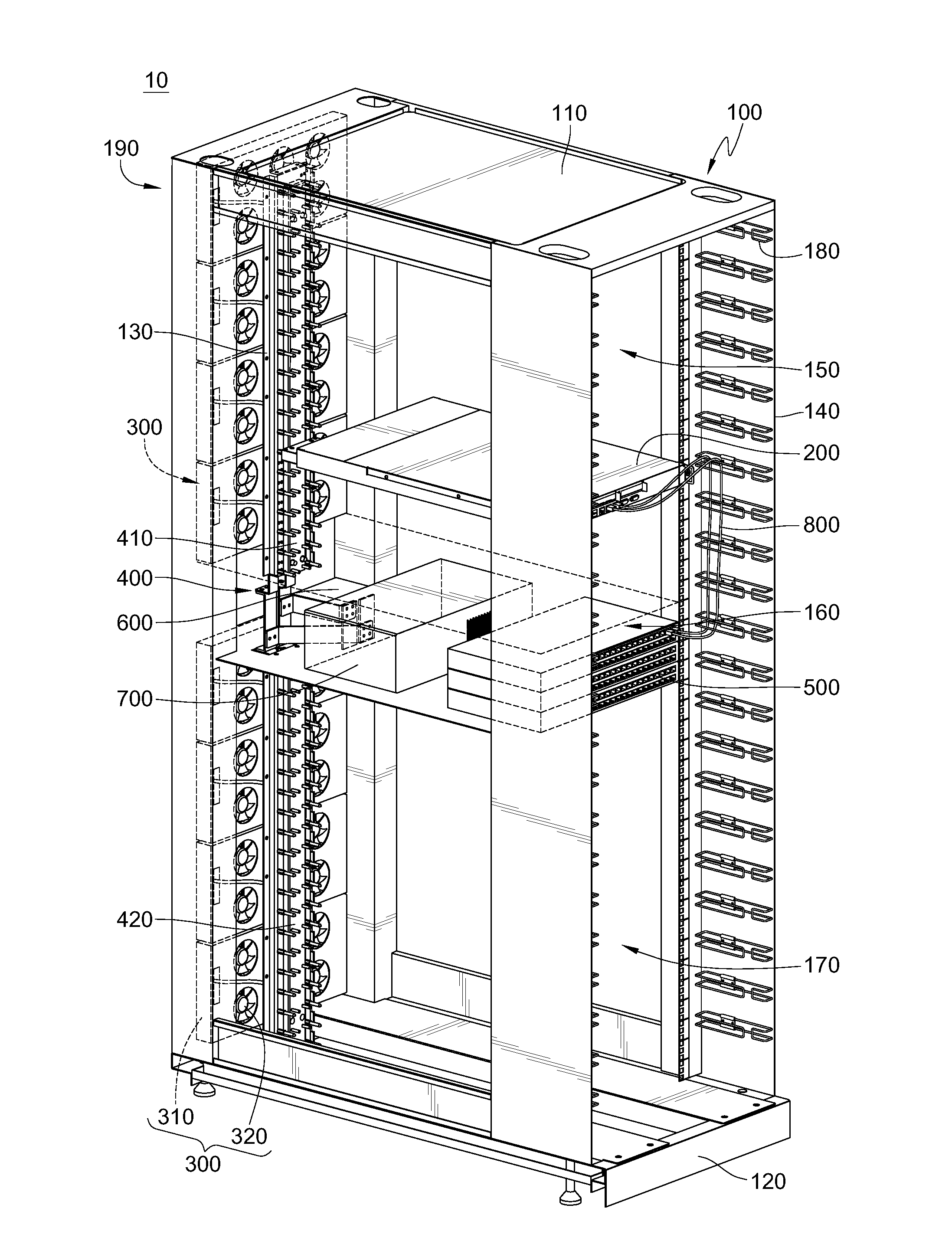

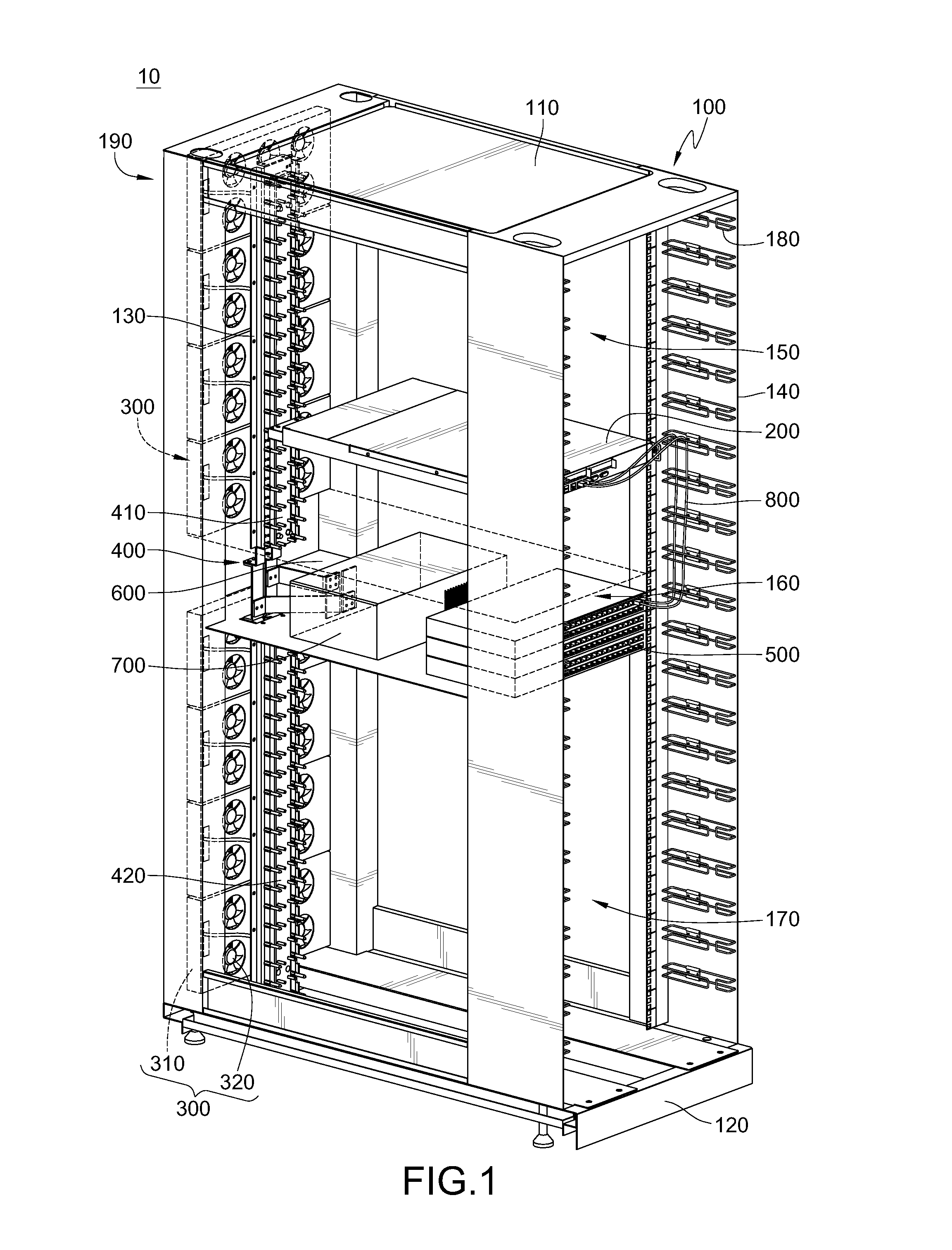

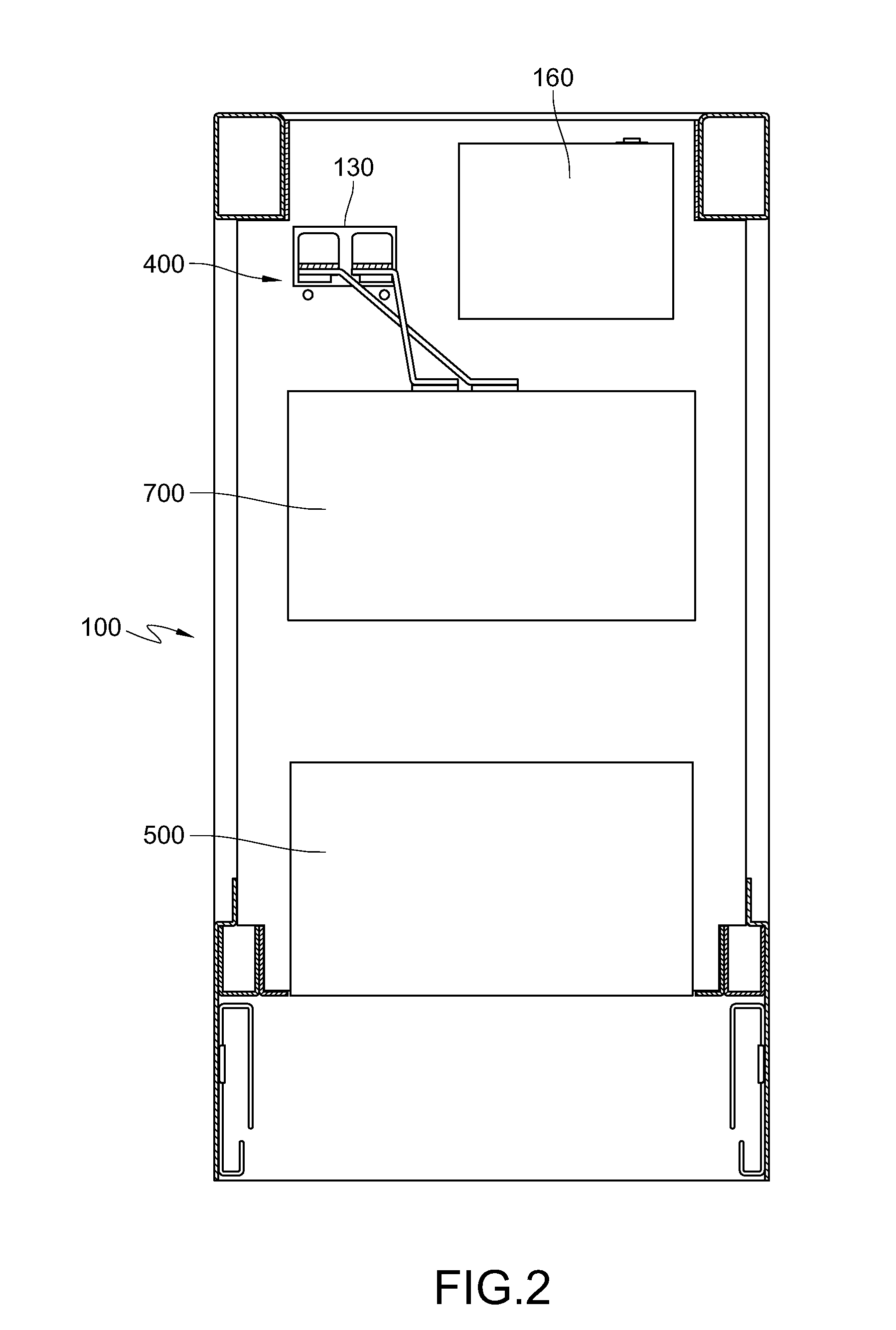

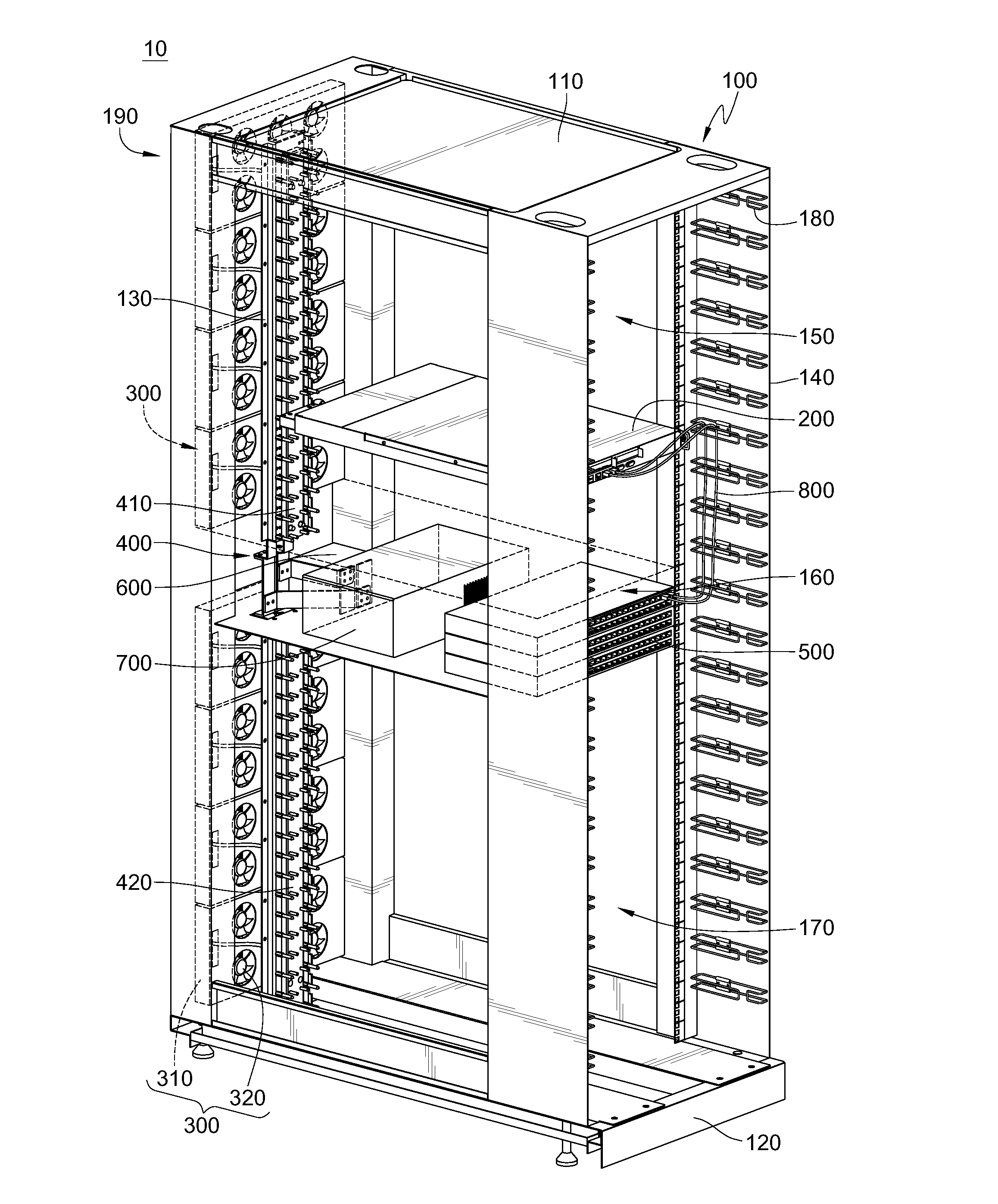

Server system

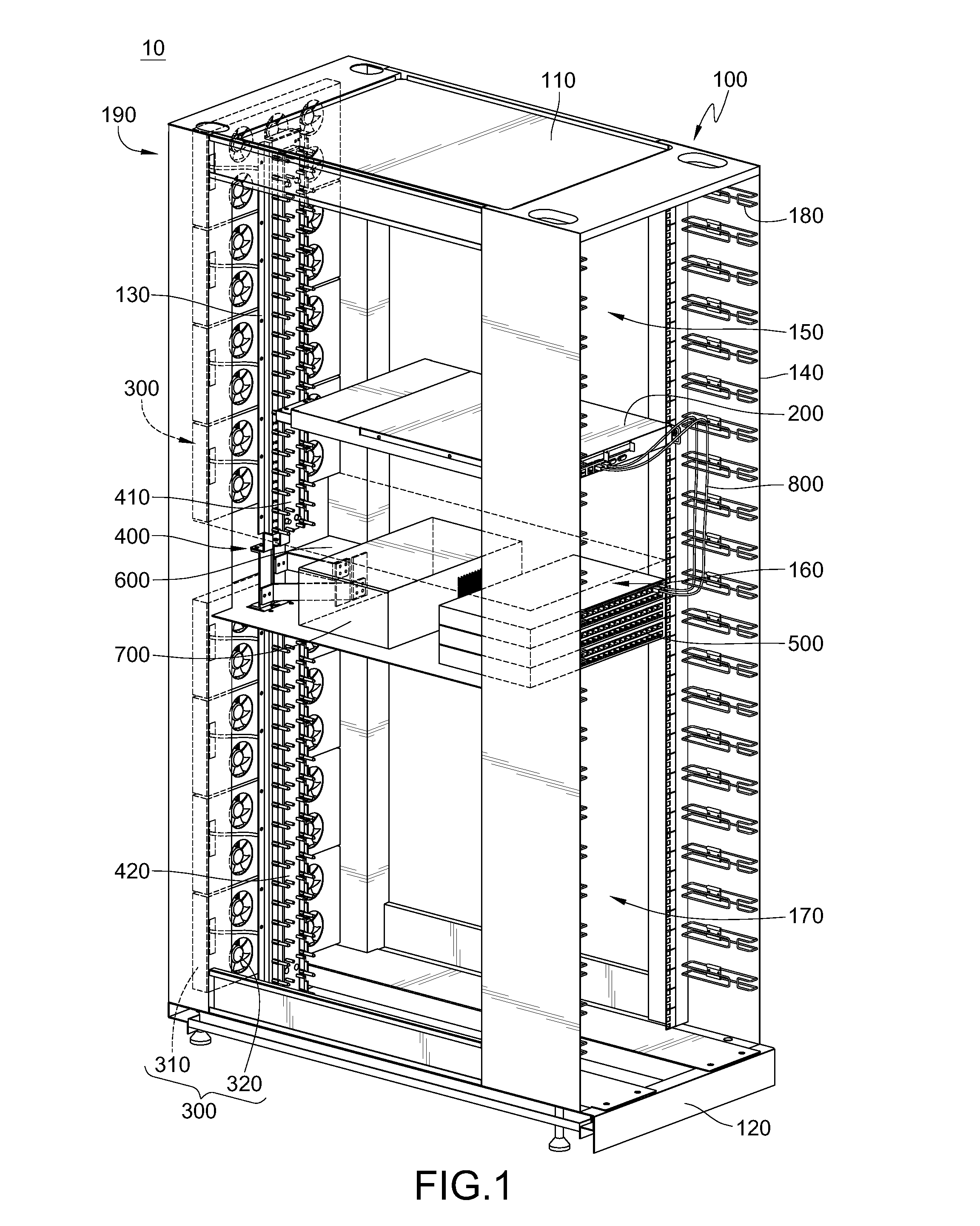

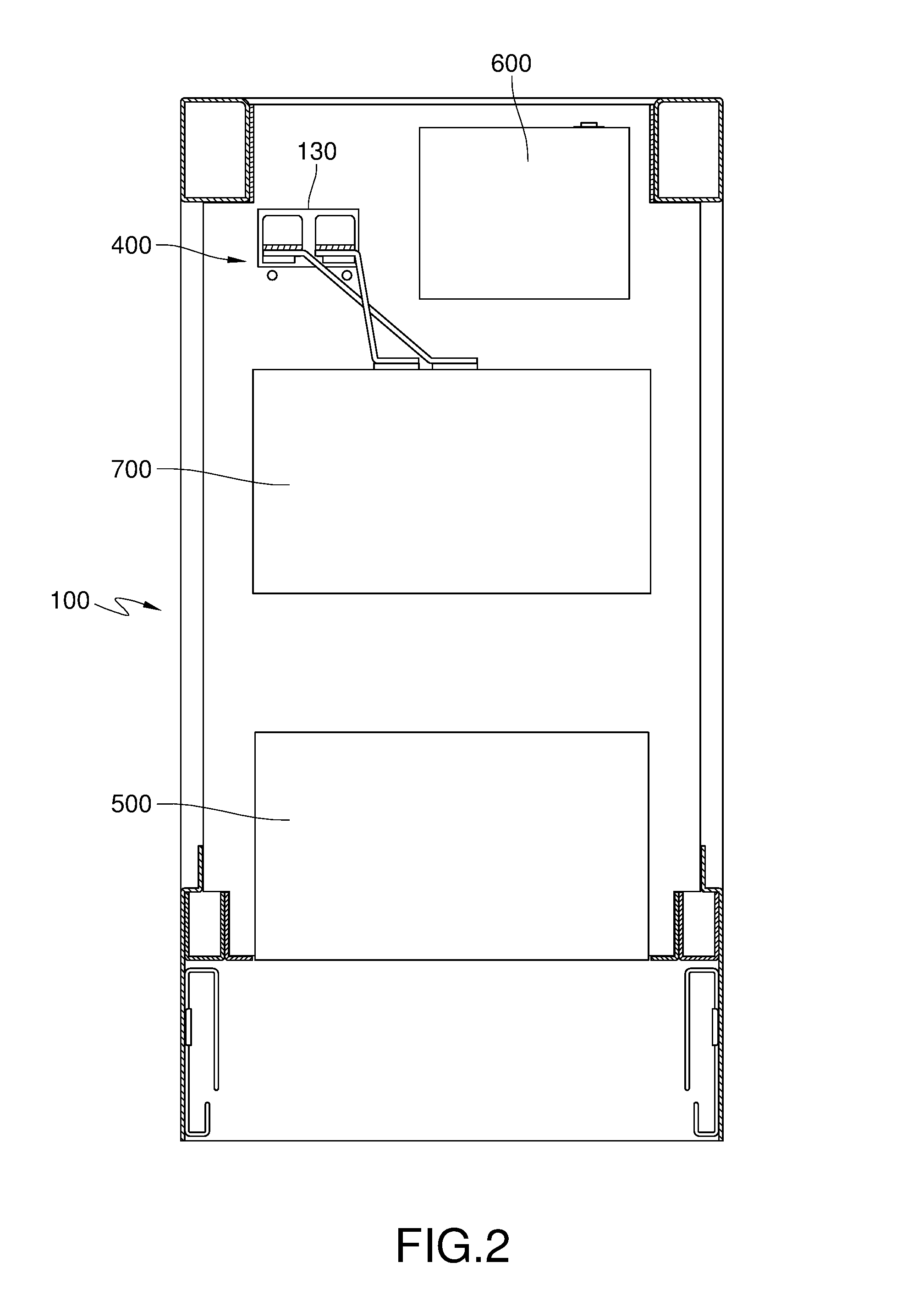

ActiveUS20140085801A1Save spaceEasy to manageServersDigital processing power distributionElectricityEngineering

A server system includes a rack, multiple servers, an electrically conductive component, a switch, a rack management controller and a power supply. The rack has a first storage area, a middle storage area and a second storage area. The servers are positioned in the first storage area and the second storage area. The electrically conductive component is installed inside the rack and includes a first power supply part disposed in the first storage area and a second power supply part disposed in the second storage area. The switch is installed in the middle storage area. The rack management controller is installed in the middle storage area. The power supply, installed in the middle storage area, is electrically connected to the rack management controller and the switch which is disposed farther away from the electrically conductive component than the power supply.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Optical fiber drop cable

InactiveUS6853782B2Avoid problemsReduce cable costsFibre mechanical structuresConductive materialsEngineering

An optical fiber drop cable includes an optical element portion having an optical fiber core wire and a pair of first tension members disposed parallel to the optical fiber core wire on both sides thereof in a sandwiching manner. The optical fiber core wire and the pair of first tension members are coated with a cable sheath. A long-scale cable support wire portion has a second tension member coated with a sheath. The optical element portion and the cable support wire portion are adhered parallel to each other. The first tension members are composed of a nonconductive material. A flexural rigidity of the optical element portion is in a range from 80 to 500 Nmm2.

Owner:THE FUJIKURA CABLE WORKS LTD

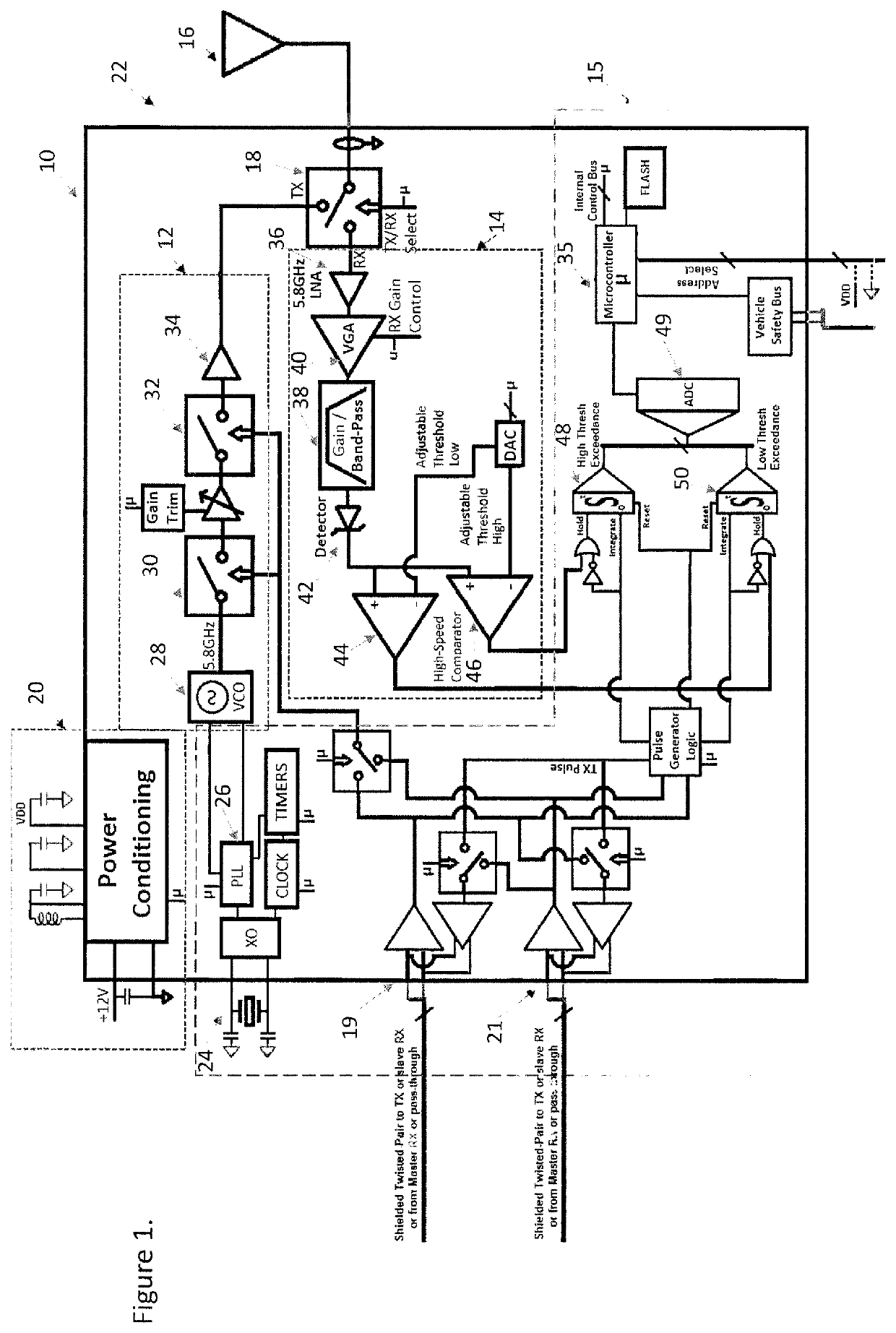

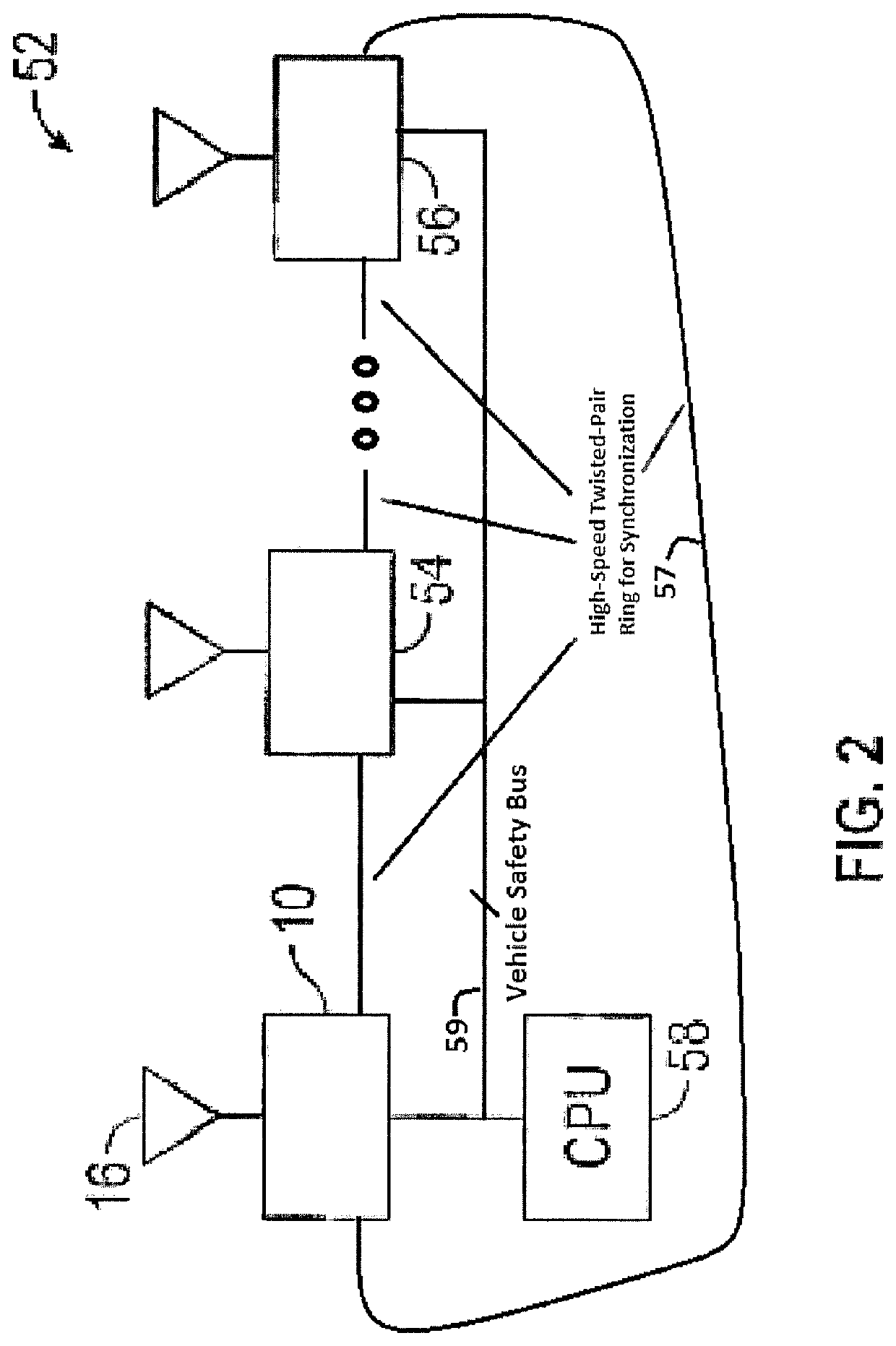

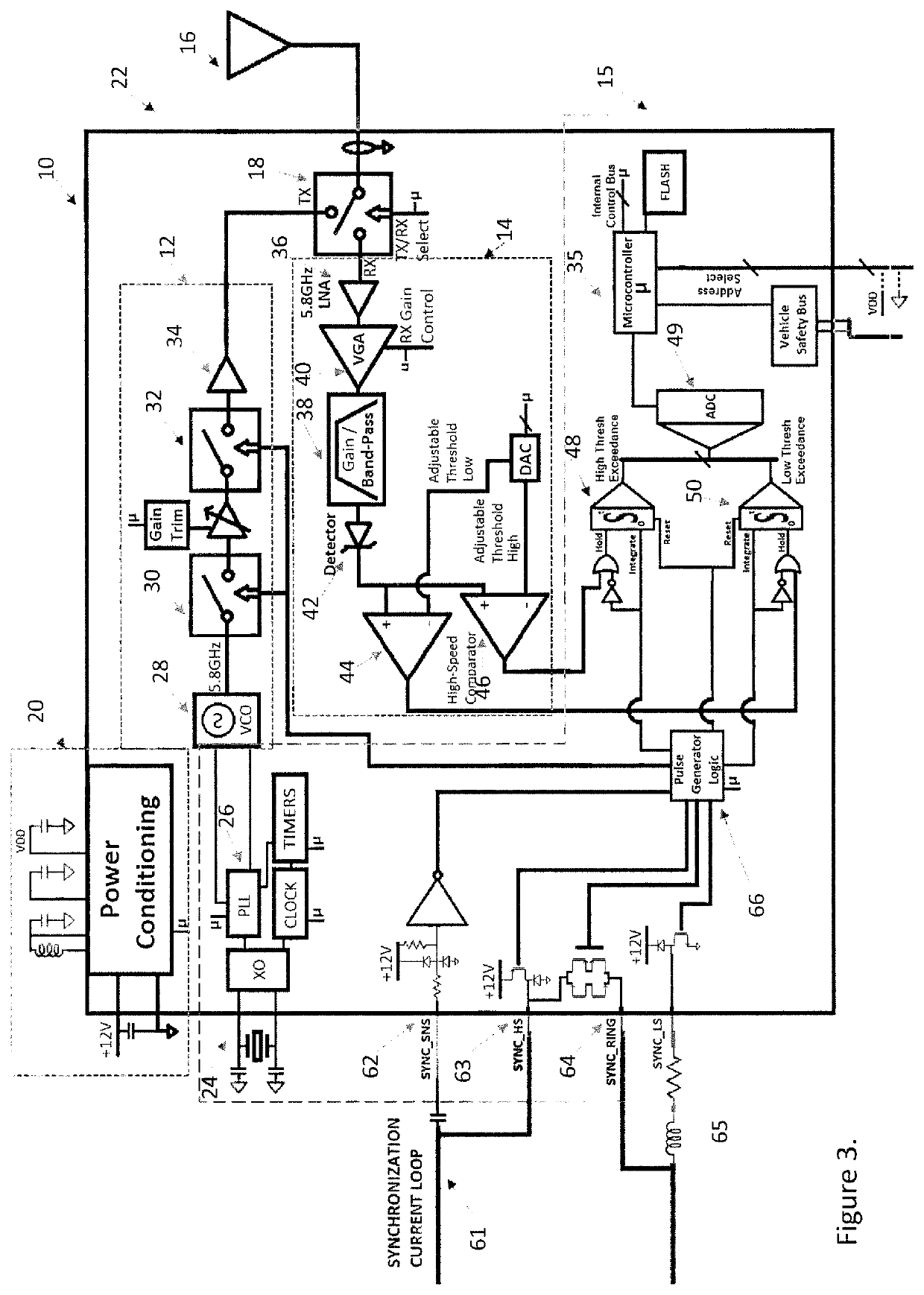

Bistatic radar system for motor vehicle applications

An improved bistatic radar detection system useful for detecting an imminent collision between a vehicle and a tracked object includes at least one radar module having both receiver circuitry and transmitter circuitry to allow a processor to dynamically select operations of the module as either a transmitter or a receiver of a bistatic radar set.

Owner:MOBILE TECH SOLUTIONS LLC

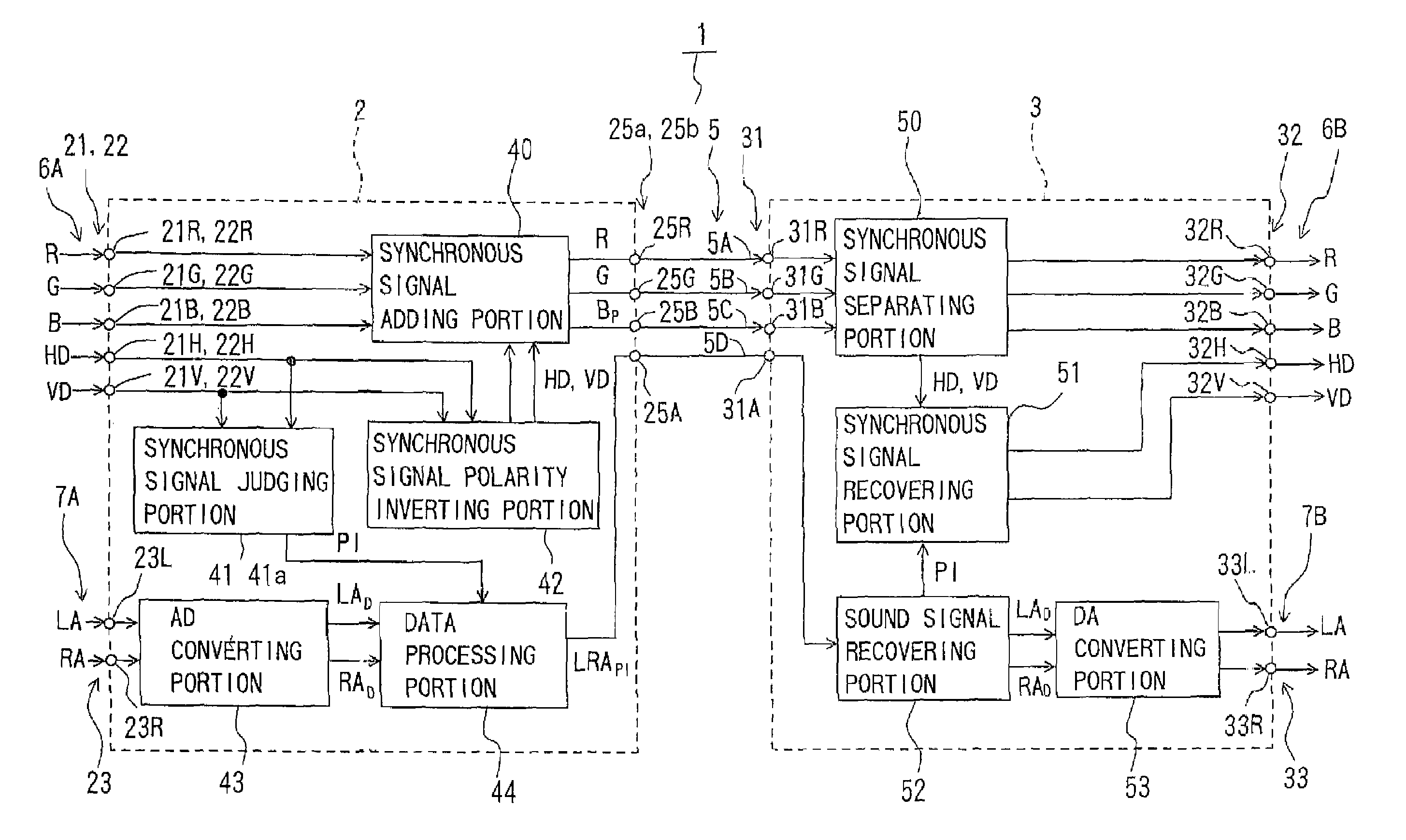

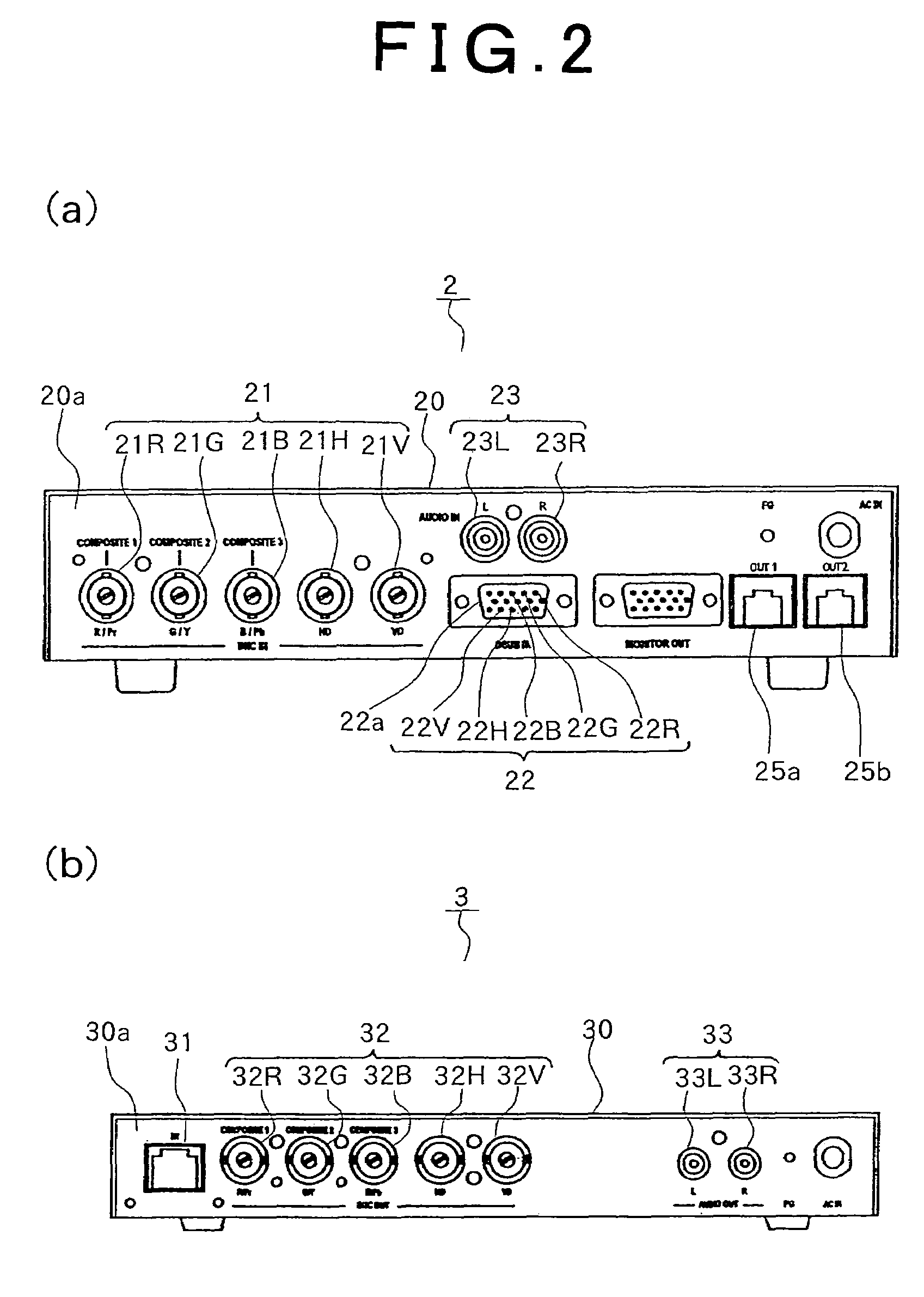

Cable extension unit

InactiveUS7274405B2Reduce cable costsEffective presentationTelevision system detailsPicture reproducers using cathode ray tubesSignal onElectrical polarity

Synchronous signal overlapping and outputting means and sound signal transmitting means of a signal transmitter transmit any color signal which synchronous signals overlapped and the other color signals, and a sound signal on which polarity information of the synchronous signals was added through four signal lines to a signal receiver, respectively. Synchronous signal recovering and outputting means of the signal receiver recovers the synchronous signals on the basis of the synchronous signals separated from the color signal with the polarity information and outputs the signals to an image output unit. Then, it is possible to output sounds together with images inputted from the image inputting source from the image outputting unit with only four signal lines.

Owner:KOWA CO LTD

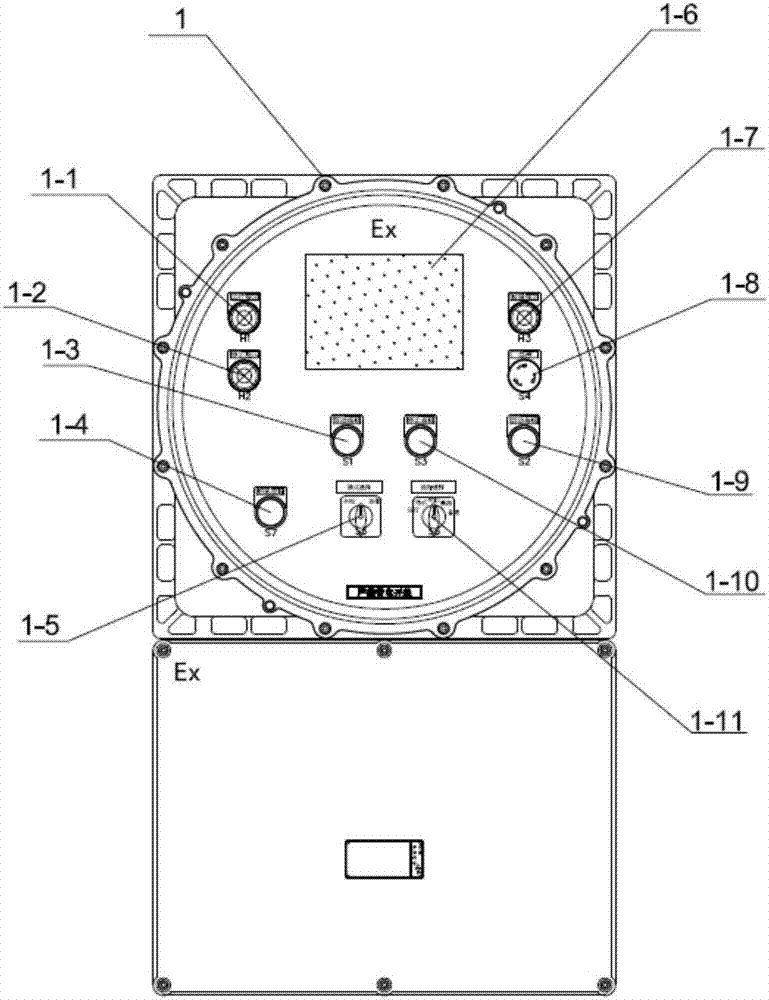

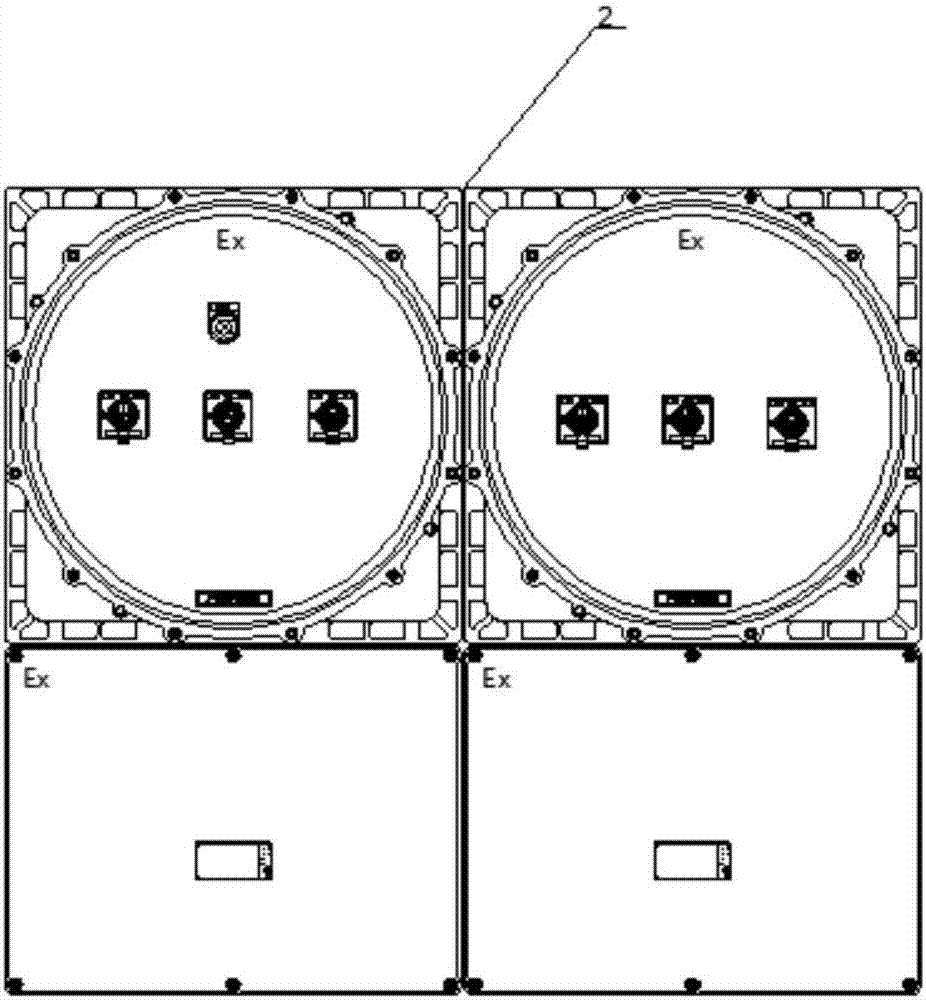

Control system and method for skid-mounted type hydrogen injection device

PendingCN107044585AReduce cable costsShorten the on-site construction periodContainer filling methodsGas handling applicationsAcousto-opticsPressure sensor

The invention discloses a control system and method for a skid-mounted type hydrogen injection device. The control system comprises a process controller and a safety controller. The process controller is connected to a starting button, a pressure sensor and a temperature sensor, receives signals of the starting button, the pressure sensor and the temperature sensor and is connected to a compressor, a cooling fan, a circulation water pump and a valve to control the compressor, the cooling fan, the circulation water pump and the valve to work. The safety controller is connected to an emergency stop signal detecting module, a hydrogen leaking detecting module and a fire detecting module, receives signals of the emergency stop signal detecting module, the hydrogen leaking detecting module and the fire detecting module and is connected to the process controller, the compressor, the valve, an acousto-optic alarming device and a display device to transmit control signals. The control system is provided with the two controllers responsible for process control and safety control correspondingly, and the priority of the safety controller is higher than that of the process controller, so that safety operation of the hydrogen injection device is guaranteed.

Owner:ZHANGJIAGANG FURUI HYDROGEN ENERGY EQUIP CO LTD

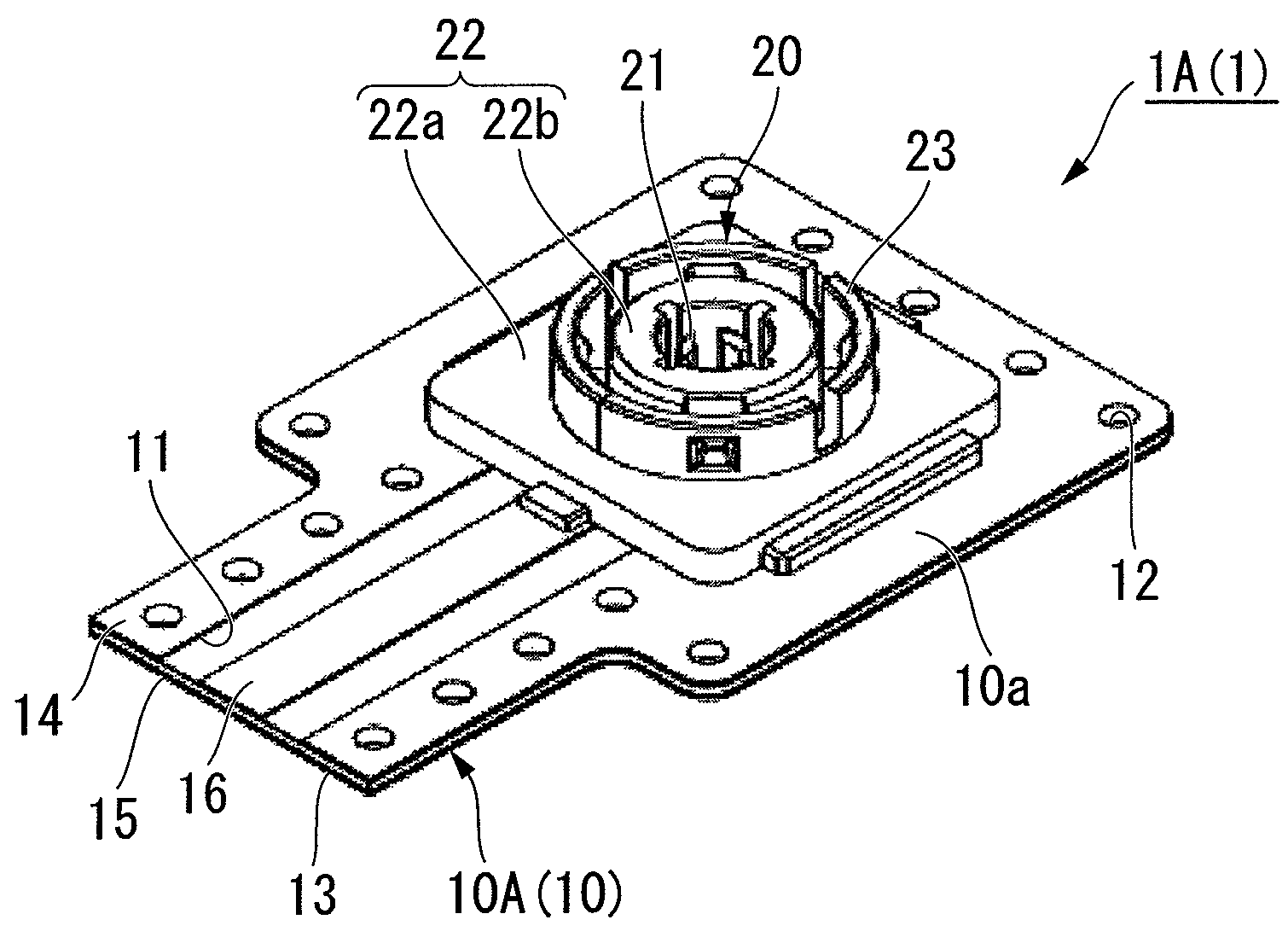

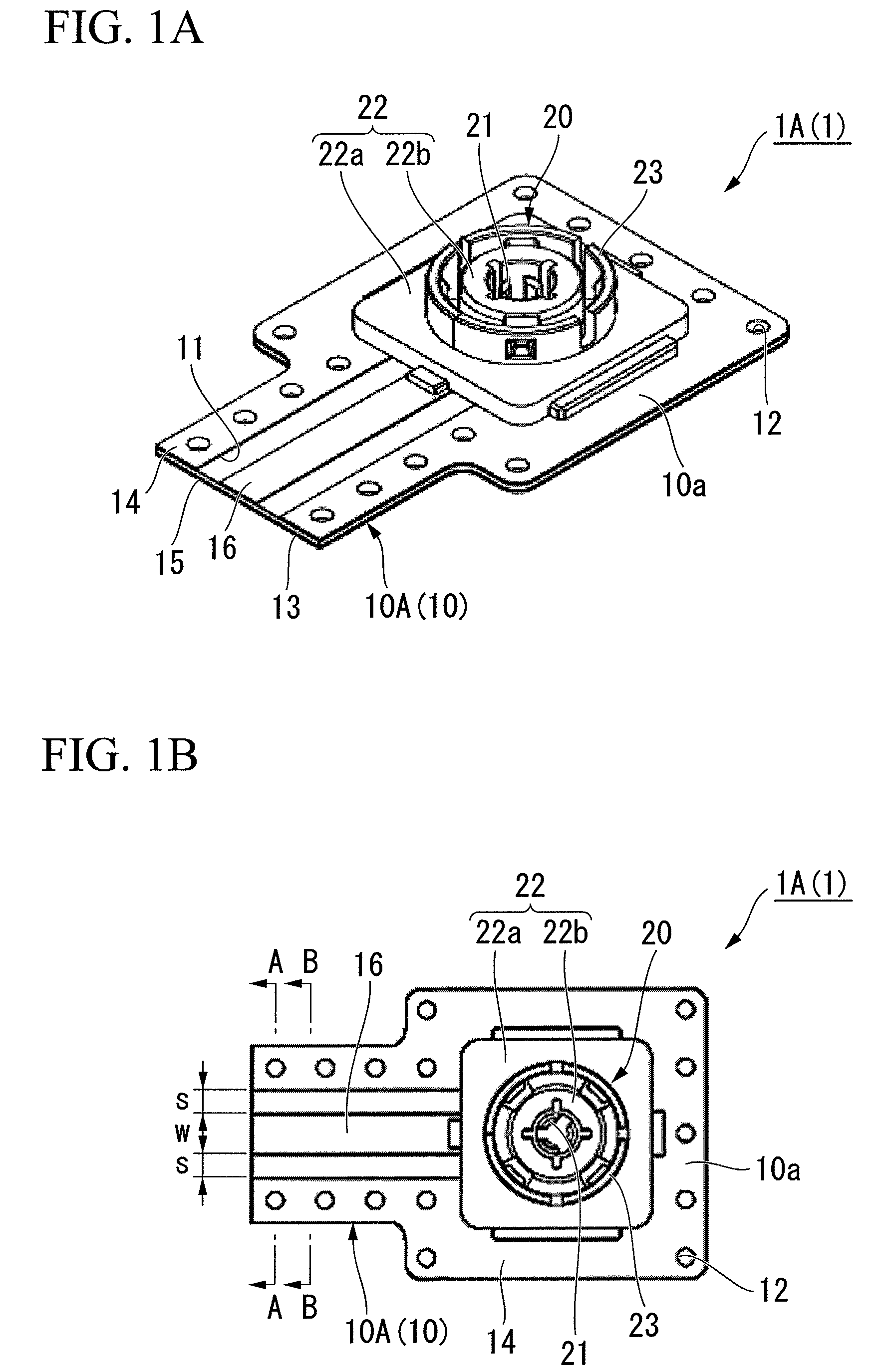

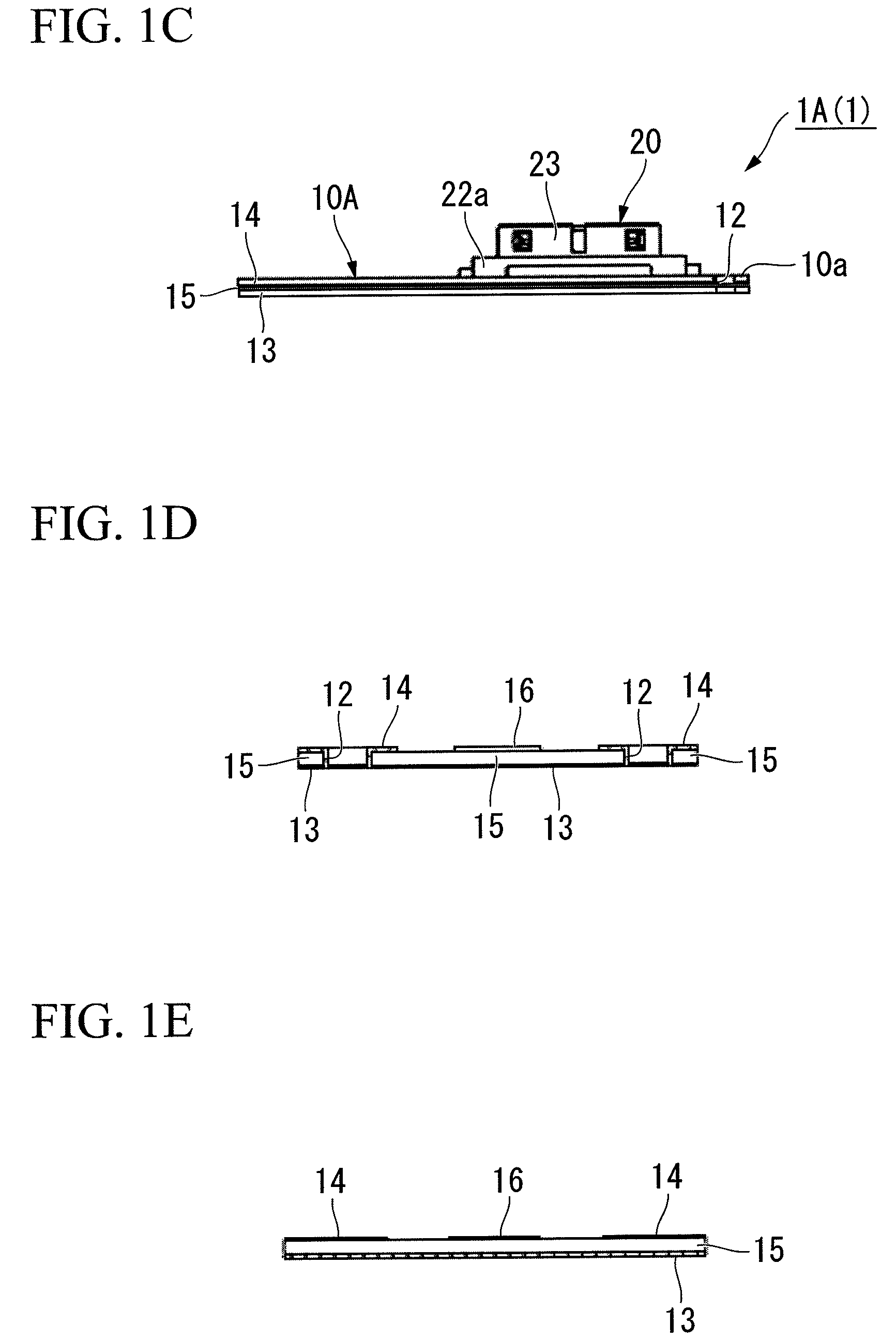

Cable connector and antenna component

InactiveUS8542159B2Plug connector can be installed on the wiring board with easeSimplified assembly stepsElectrically conductive connectionsAntenna supports/mountingsElectrical conductorTransmission line

Owner:THE FUJIKURA CABLE WORKS LTD

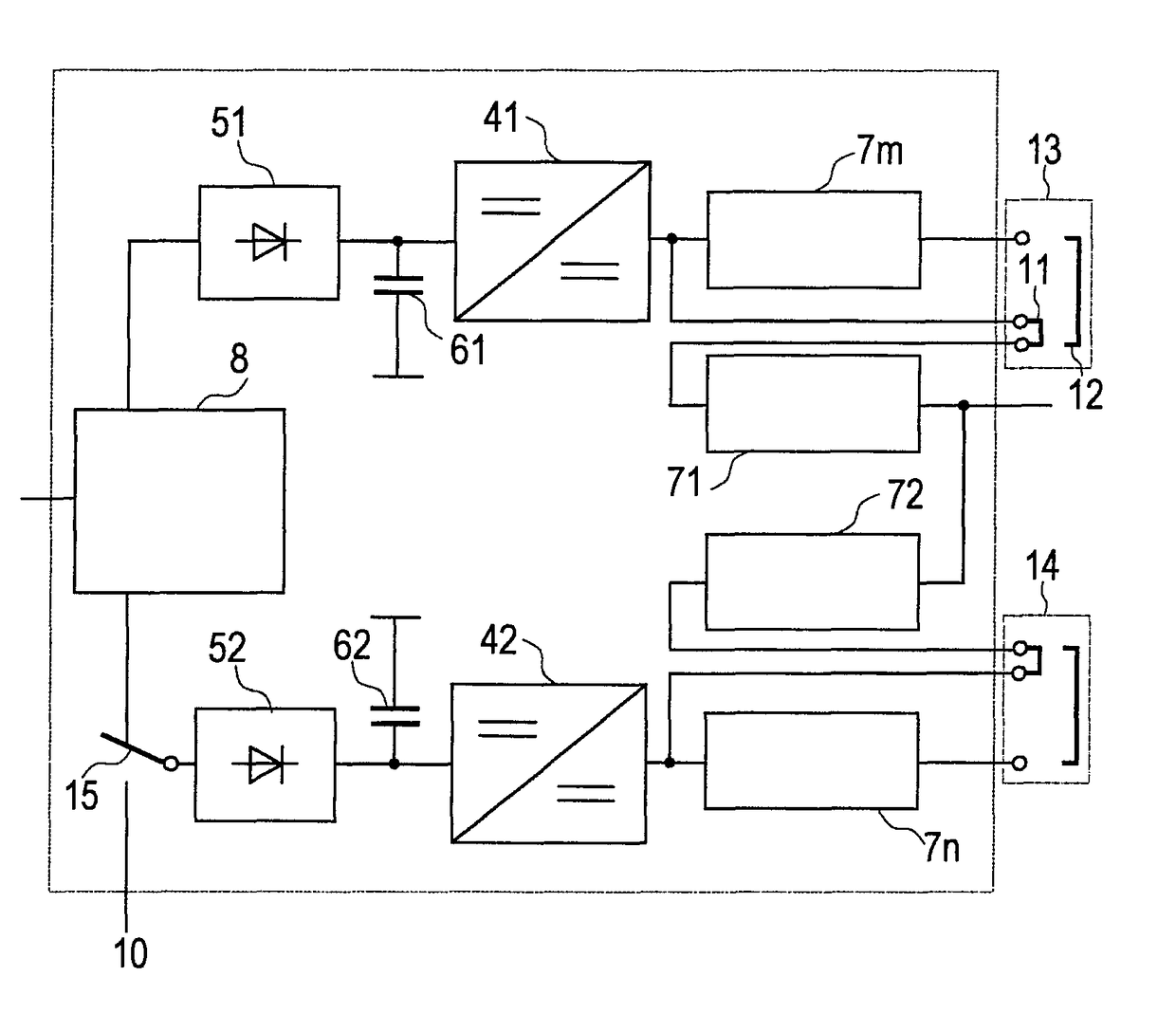

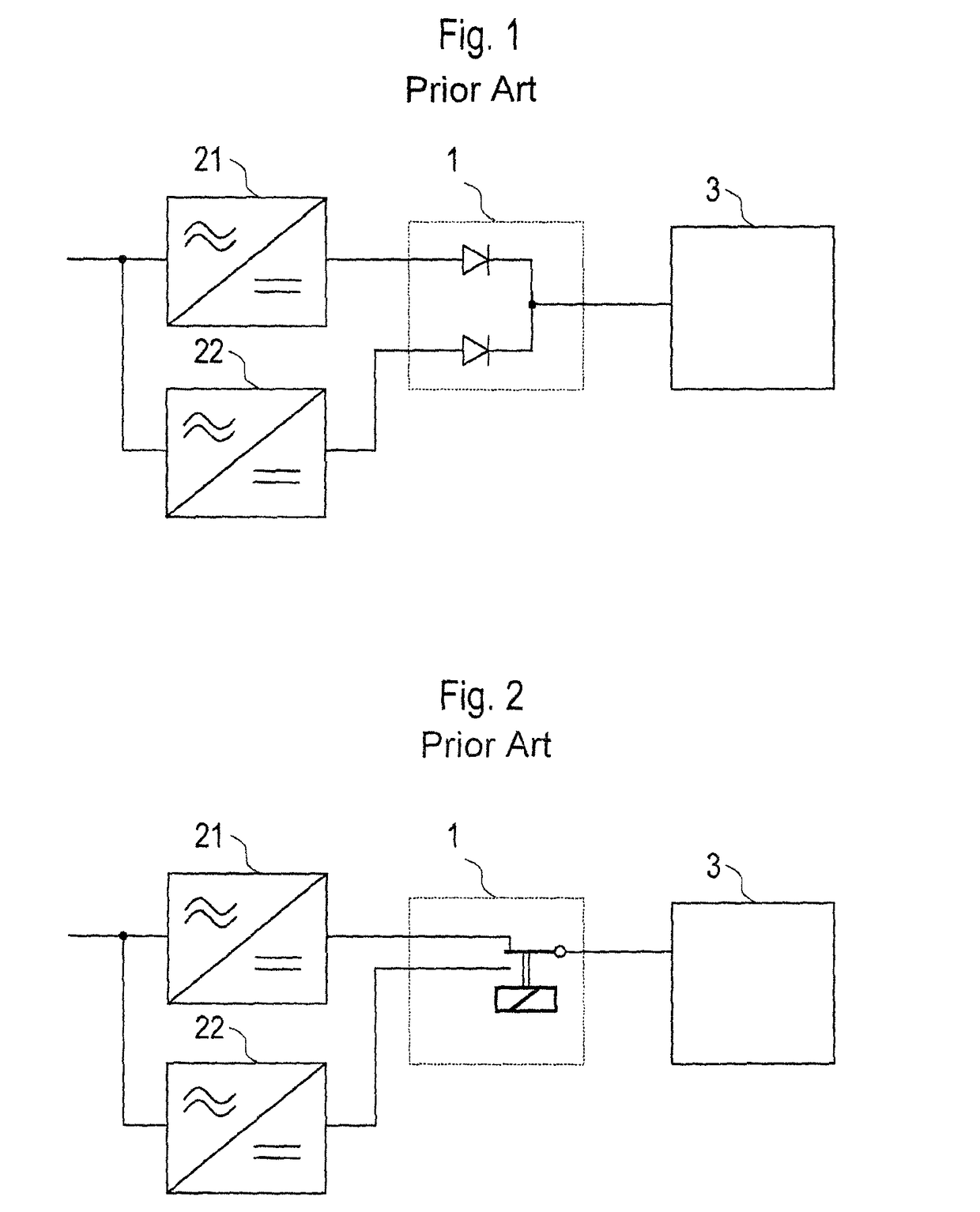

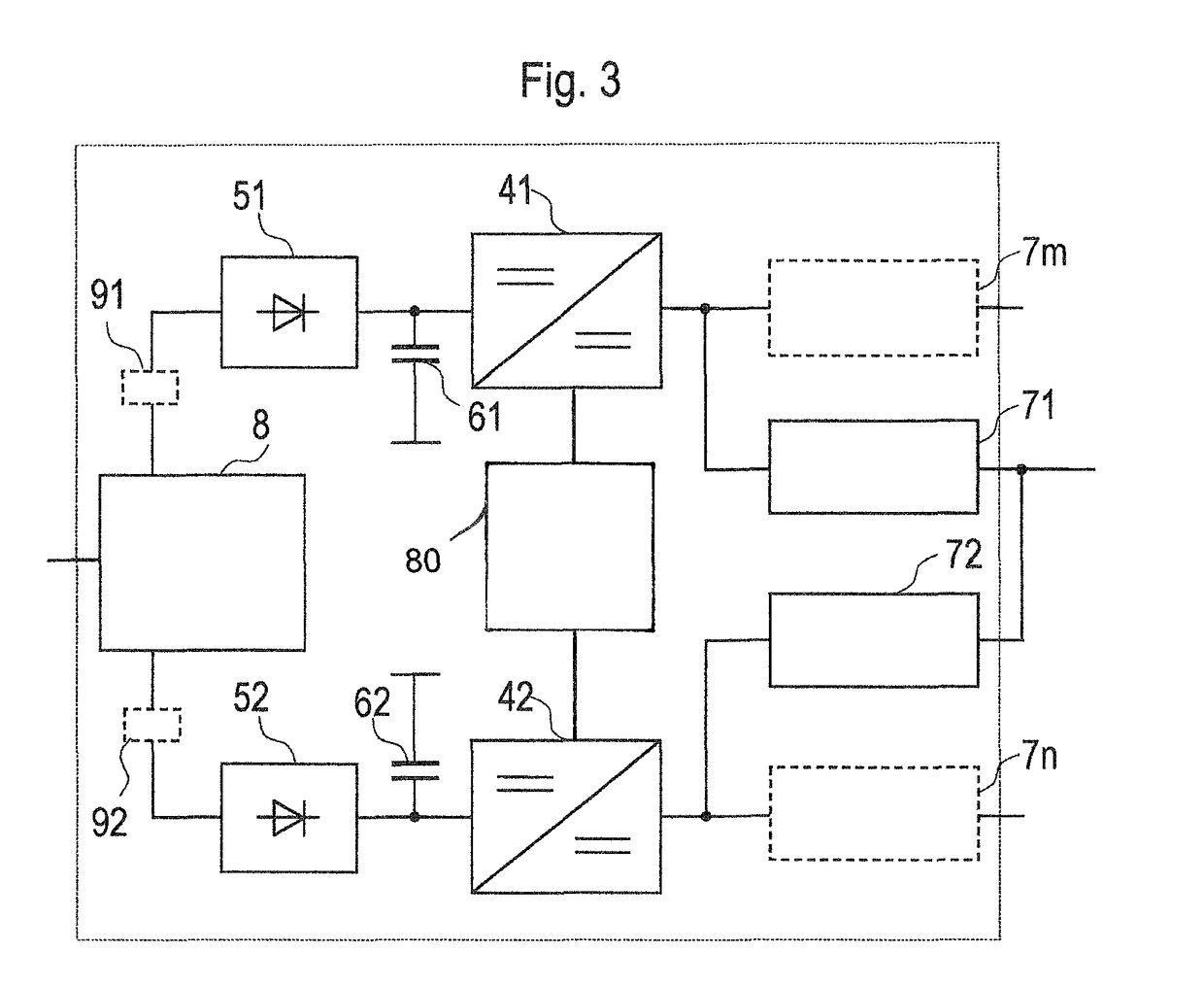

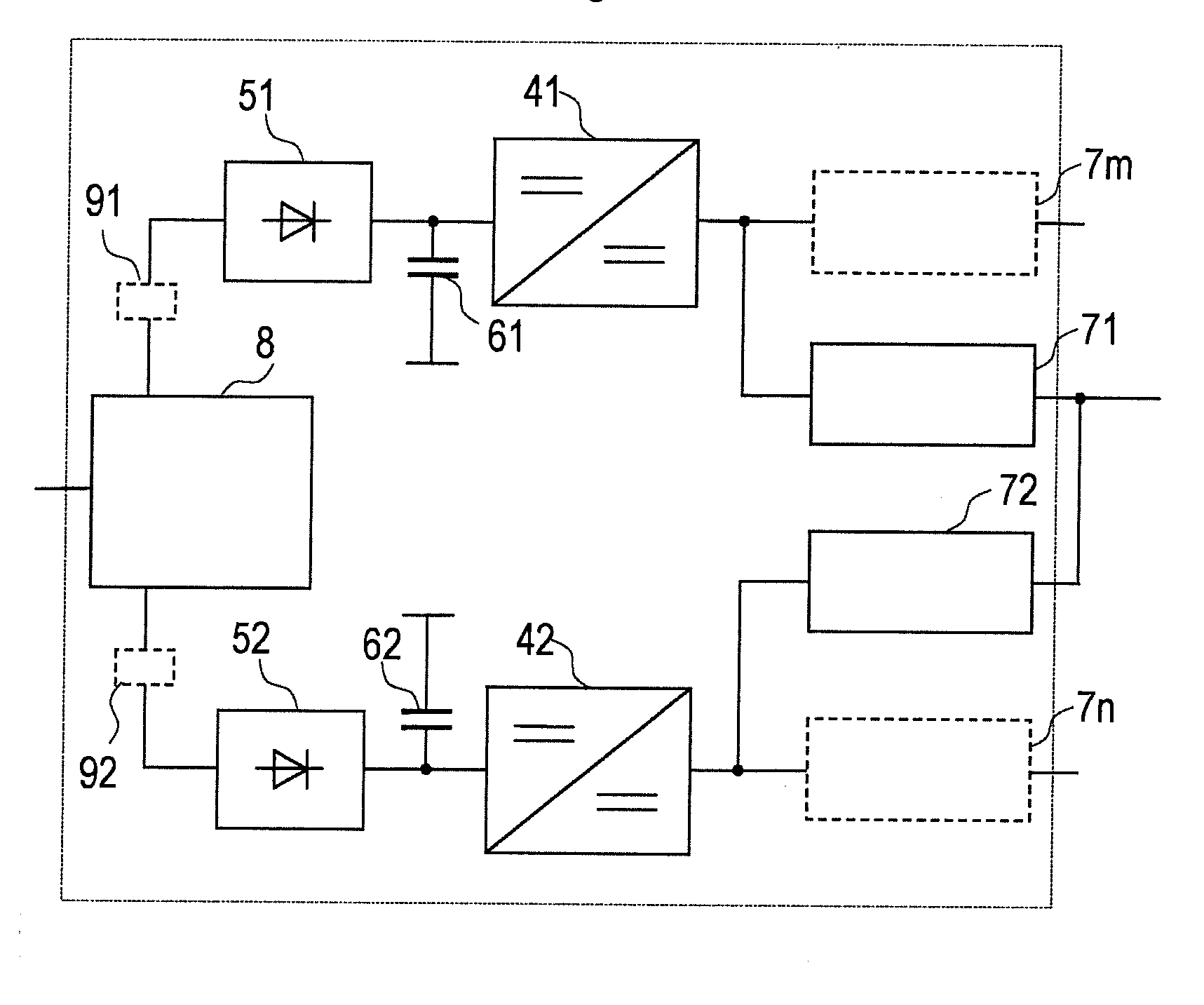

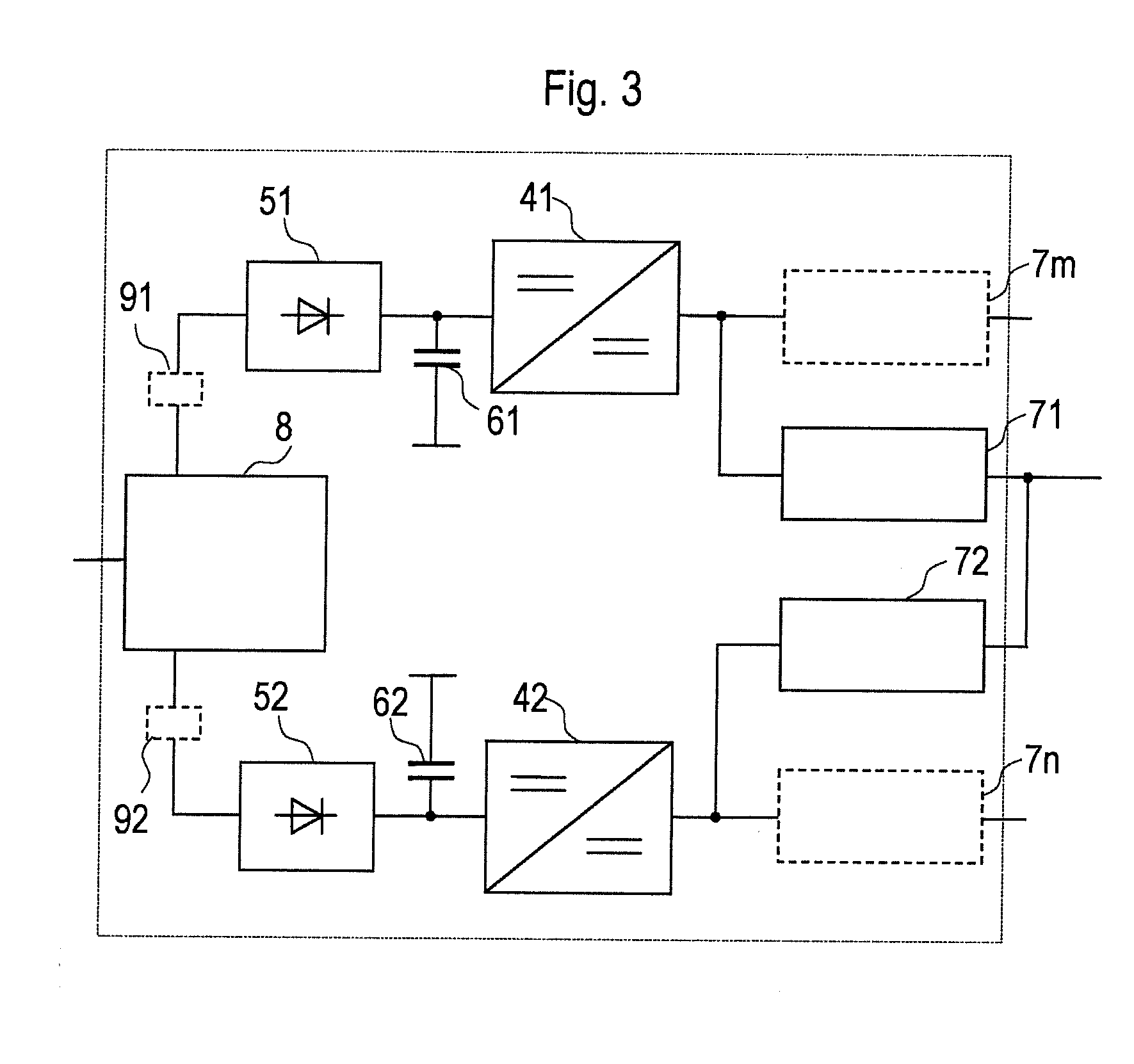

Modularly redundant DC-DC power supply arrangement having outputs that can be connected in parallel

ActiveUS9793711B2Heavy loadLoss of sizingEfficient power electronics conversionElectrical energyDc dc converterControl theory

Owner:SIEMENS AG

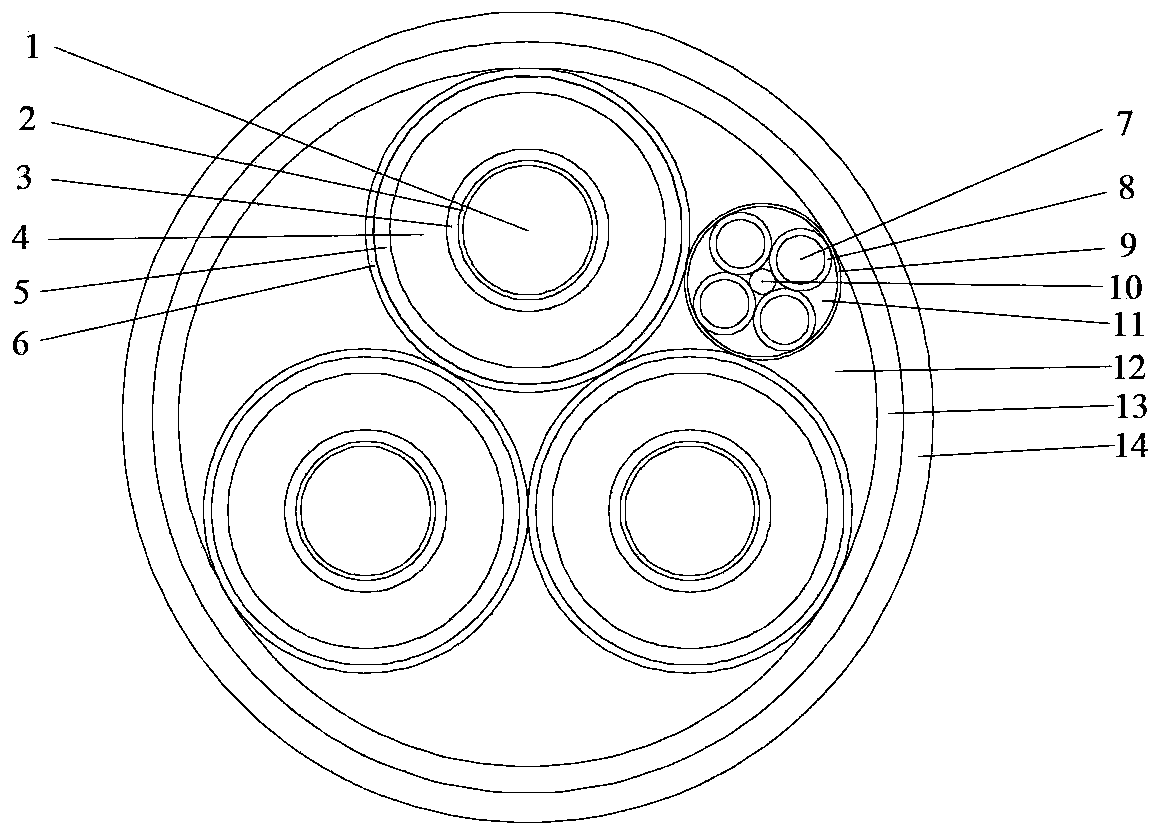

High-flexibility medium voltage cable for use in offshore wind turbine bin

PendingCN107785114AAvoid damageImprove pass rateClimate change adaptationExtensible conductorsElectric power transmissionCopper conductor

The invention discloses a high-flexibility medium voltage cable for use in an offshore wind turbine bin. The high-flexibility medium voltage cable comprises conductive units, a control unit, a light unit, a shielding layer and an outer protecting bush layer, wherein taped covering layers (2), inner shielding layers (3), insulating layers (4), outer shielding layers (5) and metal shielding layers (6) are sequentially arranged outside copper conductors (1) of the conductive units; an insulating layer (8), a filling layer (11) and an inner protecting layer (9) are sequentially arranged outside acopper conductor (7) of the control unit, and the light unit (10) is located in the control unit; a filling layer (12) is located between the conductive units and the control unit; and a total shielding layer (13) and the outer protecting bush layer (14) are arranged outside the conductive units. According to the technical scheme, by utilizing a novel structure and materials, the cable has relatively high flexibility, wear resistance, acidity resistance, low temperature resistance and excellent shielding performance and integrates functions of power transmission, signal control and data transmission, so that the construction cost is lowered, and the cable is relatively applicable to offshore wind generation systems.

Owner:李准

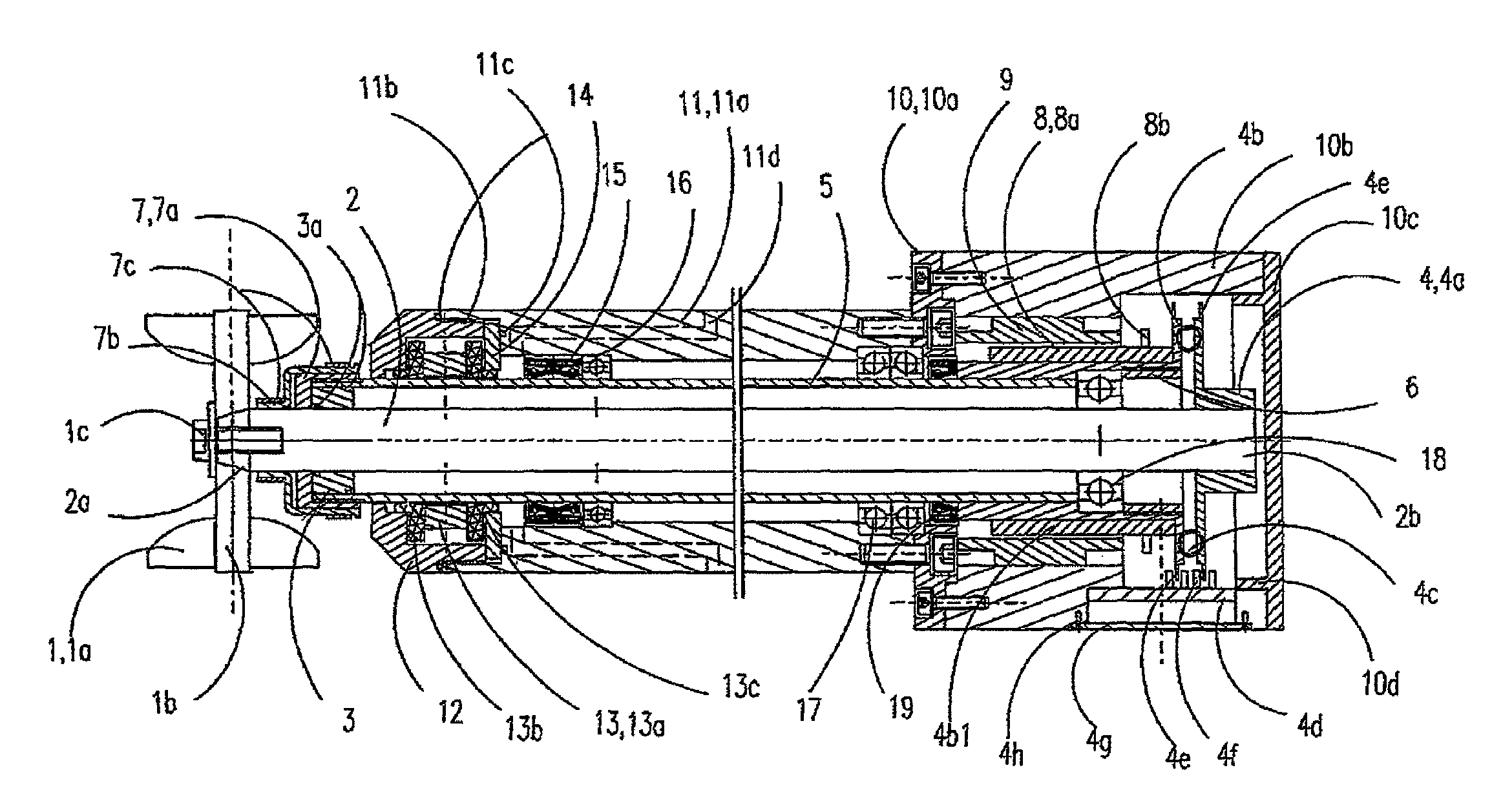

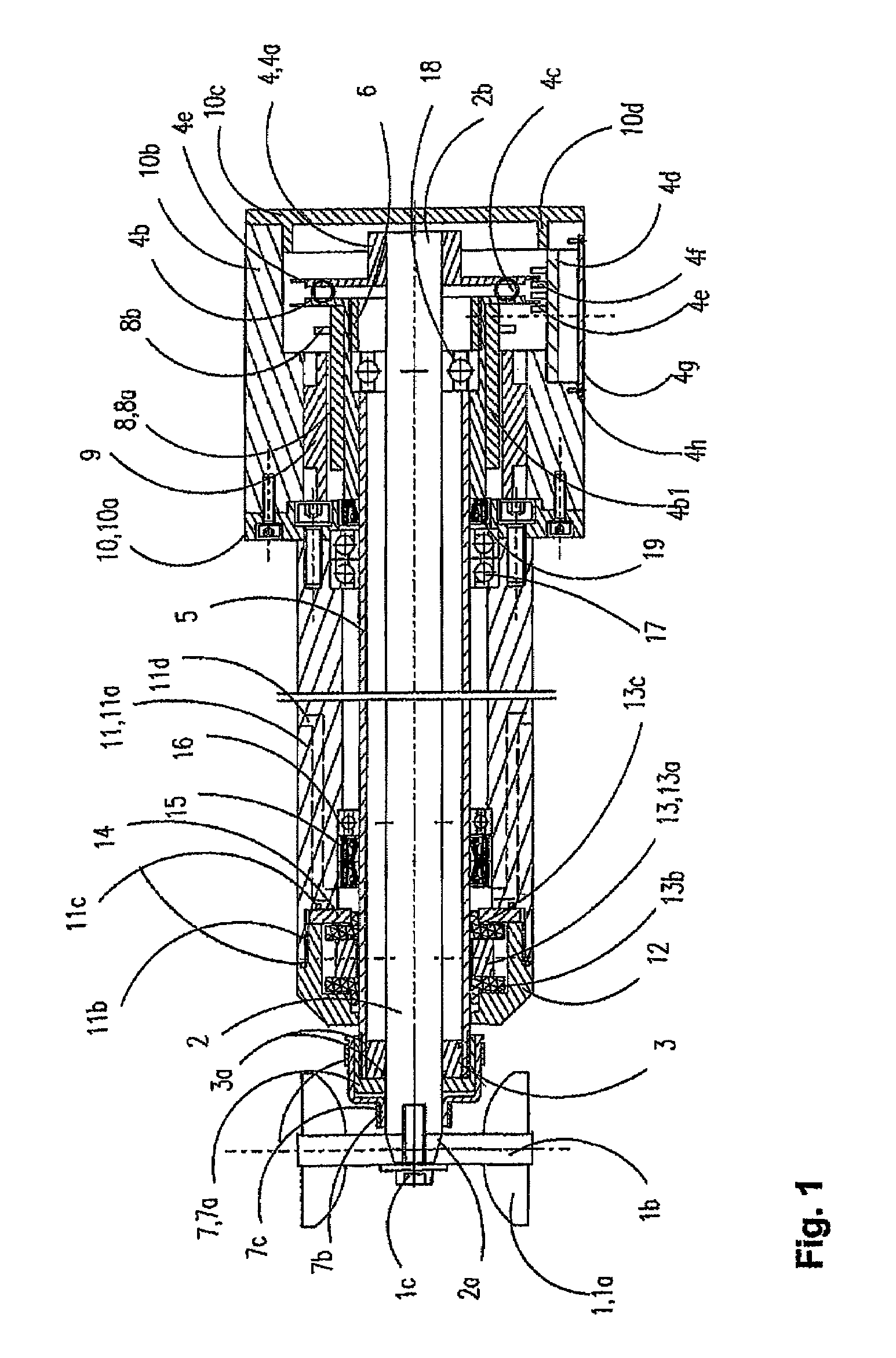

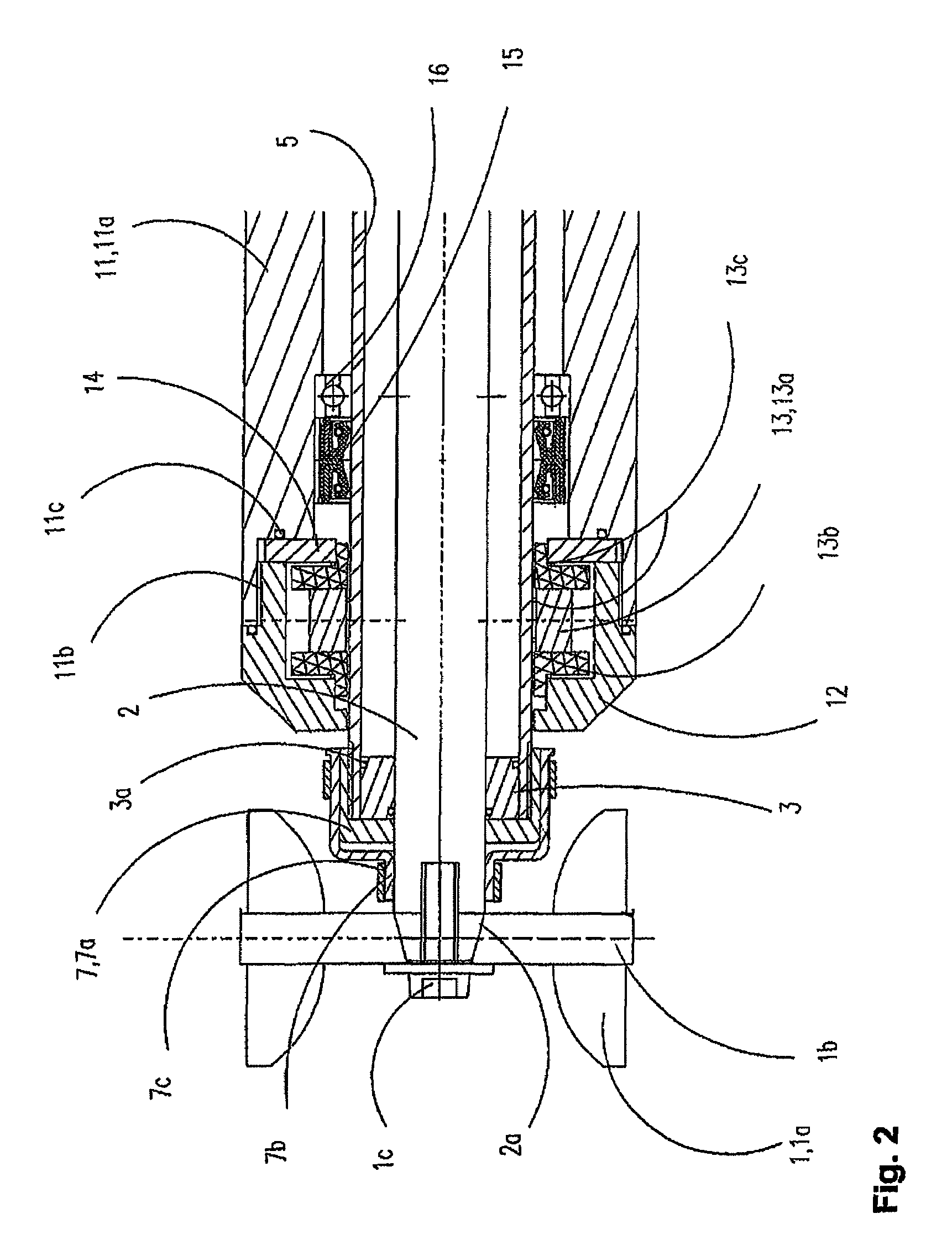

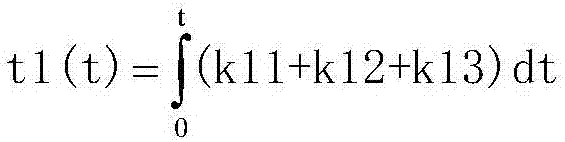

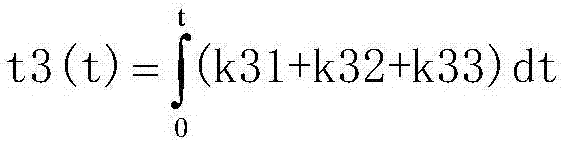

Consistency transmitter

ActiveUS7549324B2Lower costReduce investment and maintenance costFlow propertiesPaper testingTorsional ForcesDrive motor

The present invention is a consistency transmitter for the measurement of consistency, viscosity, and other properties of matter. The transmitter consists of a measuring element, attached to a bearing-mounted shaft and rotated in the matter to be measured by a direct drive motor that is positioned coaxially with the measuring element and its shaft. The stator of the direct drive motor is integrated into the consistency transmitter body, its rotor into the shaft. The stator is coaxially attached to a first flange that transmits the torsional force of the motor with flexible elements to a second flange positioned on the shaft. The first and second flanges are attached to differential elements with which the phase angle between the flanges is measured using measuring elements located near the flanges. The shaft of the measuring element is bearing-mounted inside a tubular torsion shaft. The consistency transmitter can be inserted into an operating process by means of special installation equipment consisting of a shut-off valve combined with an insertion pipe. The insertion pipe includes regulating elements in such a way that they match with the matching elements on the transmitter body. With the help of regulating elements and matching elements, the transmitter can be inserted to the desired depth in the process.

Owner:KAJAANIN PROSESSIMITTAUKSET

Server system

ActiveUS9329645B2Save spaceEasy to manageServersDigital processing power distributionElectricityEngineering

A server system includes a rack, multiple servers, an electrically conductive component, a switch, a rack management controller and a power supply. The rack has a first storage area, a middle storage area and a second storage area. The servers are positioned in the first storage area and the second storage area. The electrically conductive component is installed inside the rack and includes a first power supply part disposed in the first storage area and a second power supply part disposed in the second storage area. The switch is installed in the middle storage area. The rack management controller is installed in the middle storage area. The power supply, installed in the middle storage area, is electrically connected to the rack management controller and the switch which is disposed farther away from the electrically conductive component than the power supply.

Owner:INVENTEC PUDONG TECH CORPOARTION +1

Process for 420-500 micron ultra-thick electrolytic copper foil

ActiveCN110396684AIncrease productivityReduce labor costsLiquid/solution decomposition chemical coatingElectrolysisCopper foil

The invention discloses a process for a 420-500 micron ultra-thick electrolytic copper foil. The process comprises the following steps of 1, unreeling; 2, activating; 3, pickling; 4, coarsening and curing; 5, carrying out barrier layer treatment; 6, carrying out anti-oxidation treatment; 7, carrying out organic treatment; and 8, drying and rolling. According to the process, the effect of radiatingheat generated by components outside a substrate can be achieved, so that the purpose of high-density interconnection of high-power electric appliances is achieved, the original power transmission forms such as cable wiring, metal plate bars and the like are replaced, the production efficiency is improved, and the labor-hour cost, the cost of cables and accessories, the cost of maintenance management and the like of wiring are reduced; the copper foil high-current substrate can effectively reduce the thermal load of a PCB and achieve quality homogenization, so that the reliability of a terminal complete machine product using the high-current PCB is further improved; and by adopting the high-current substrate to replace the original cable wiring form, the design freedom degree of the wiring can be improved, so that the miniaturization of the whole terminal product is achieved.

Owner:惠州联合铜箔电子材料有限公司

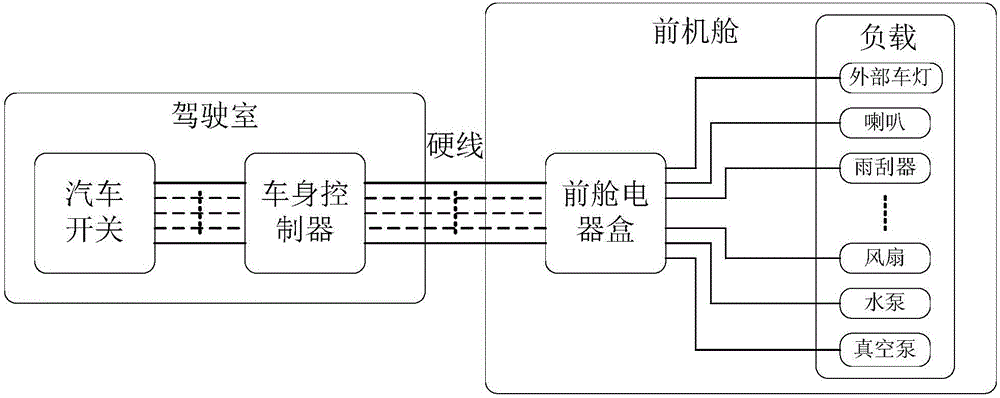

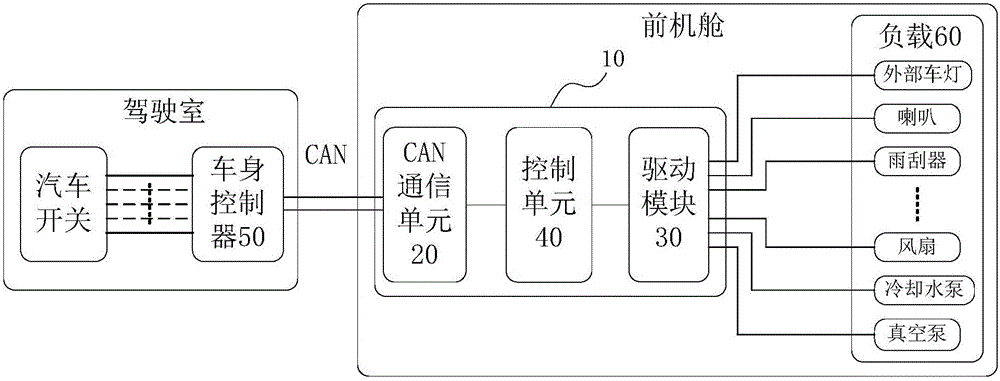

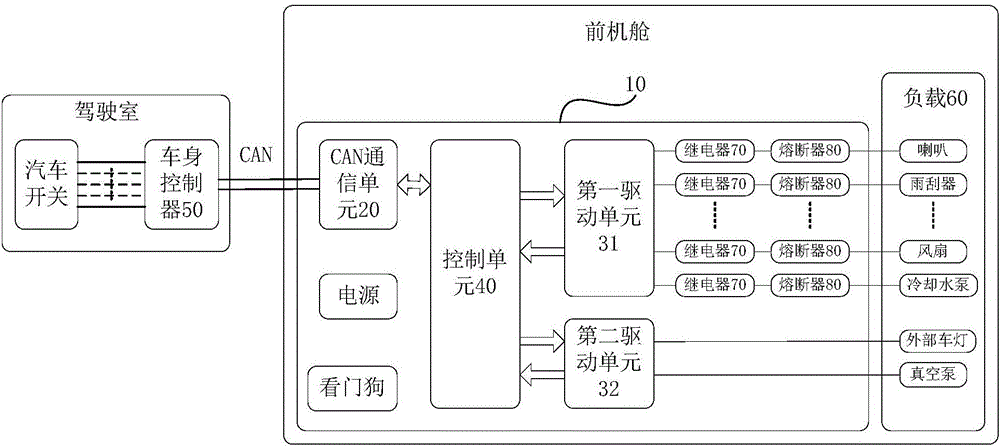

Vehicle and front cabin intelligent electric appliance box thereof

InactiveCN106427833AReduce Hardwired ConnectionsReduce cable costsElectric/fluid circuitAutomotive engineeringCommunication unit

The invention discloses a vehicle and a front cabin intelligent electric appliance box thereof. The front cabin intelligent electric appliance box comprises a shell, a CAN communication unit, a driving module and a control unit, wherein the CAN communication unit is used for conducting CAN communication with a vehicle body controller; the driving module is used for driving a plurality of loads arranged in a front cabin of the vehicle and diagnosing working conditions of the multiple loads so as to obtain fault information of each load; and the control unit is arranged in the shell and used for receiving a control command sent by the vehicle body controller through the CAN communication unit, controlling the multiple loads through the driving module according to the control command, collecting the fault information of each load, and reporting the fault information of each load to the vehicle body controller through the CAN communication unit. Thus, hardwired connection with the vehicle body controller can be effectively reduced, cable cost is lowered, and reliability is improved; and besides, the working conditions of each load can be diagnosed, the fault information is reported to the vehicle body controller, and thus a driver is reminded.

Owner:BEIJING ELECTRIC VEHICLE

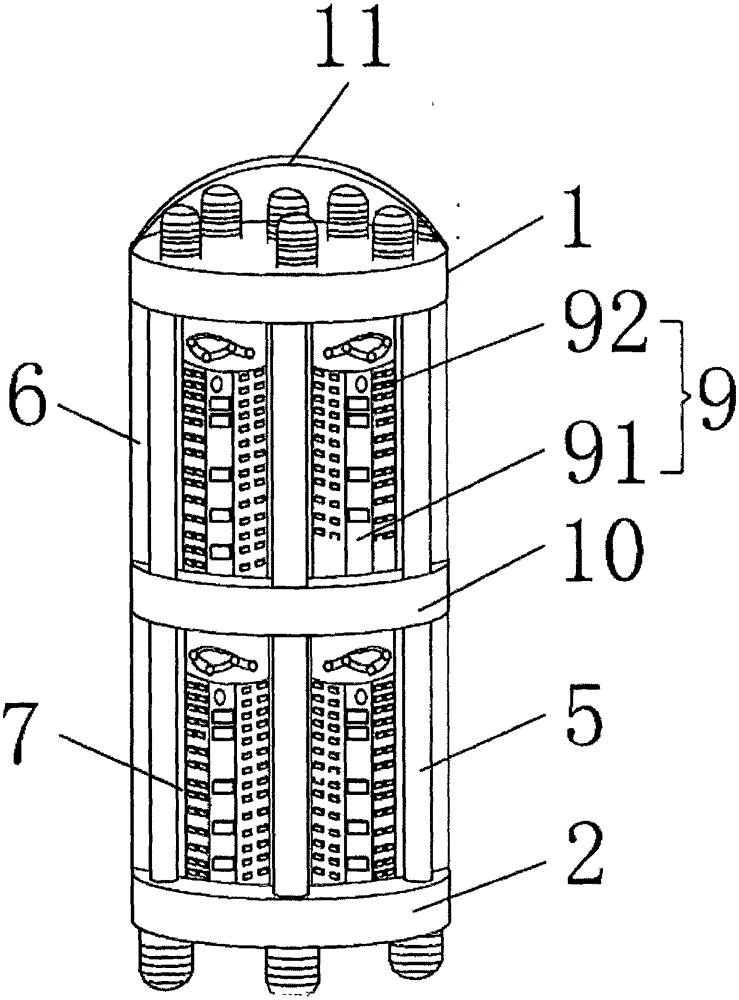

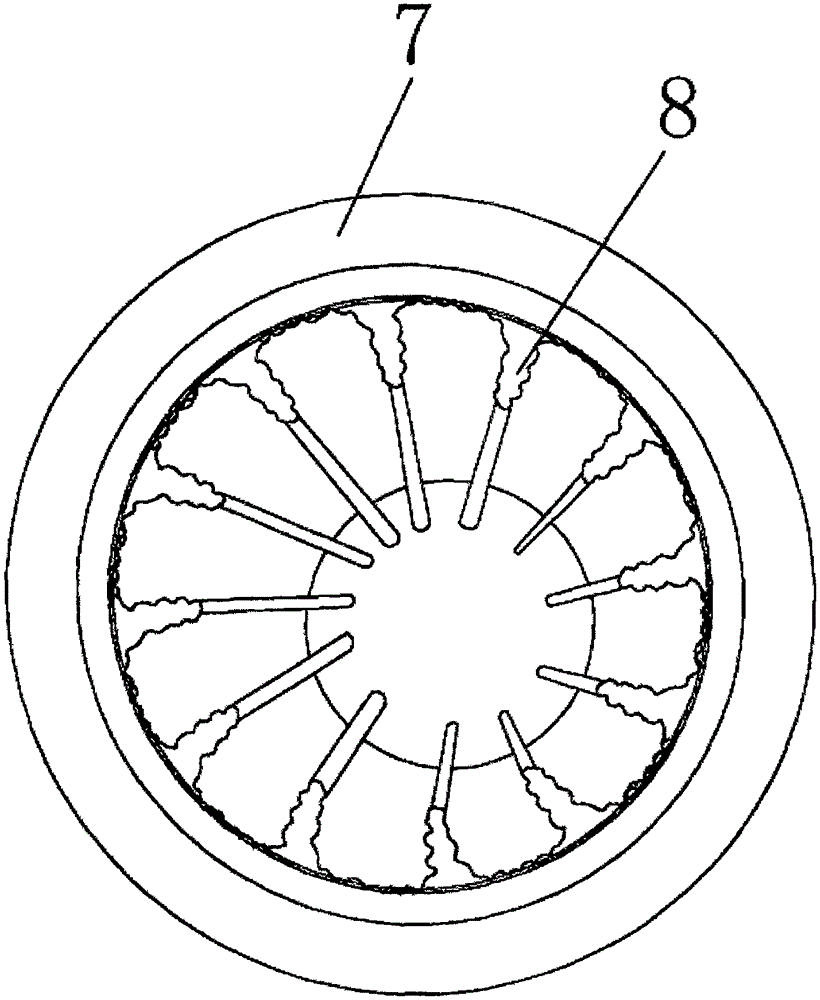

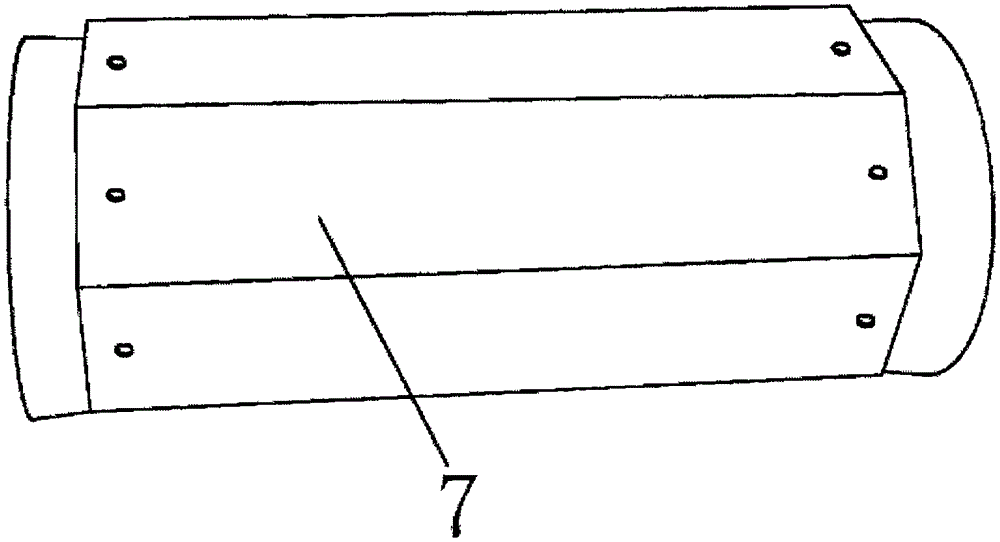

Infrared detection device and detection method for cable aging

ActiveCN107478334AReduce cable costsLow costOptically investigating flaws/contaminationRadiation thermographyPhysicsElectric power

The invention discloses an infrared detection device and a detection method for cable aging, which belong to the technical field of power infrared detection devices and methods. The infrared detection device for cable aging comprises the following elements arranged successively from the top to the bottom: an upper ring, a middle ring and a lower ring as well as infrared cameras uniformly distributed on the rings. The output signals of all cameras are connected to a signal processor; the infrared detection method for cable aging comprises: firstly, determining the horizontal location of aging; and then determining the axial position of the aging, and finally determining the spatial location. The detection method of the invention can rapidly find the aging position of a conducting wire in a cable without damaging the cable, which is favorable for replacing the aged cable and reducing the cost of the cable.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

LED underwater fishing lamp

InactiveCN105570766ASmall diameterReduce cable costsLighting heating/cooling arrangementsGas-tight/water-tight arrangementsTemperature resistanceThermal conductivity

The invention discloses an LED underwater fishing lamp which comprises an upper cover, a lower cover, a heat sink and an LED photoelectric integrated light emitting module. Annular grooves are formed in the upper cover and the lower cover correspondingly. O-shaped sealing rings are arranged in the annular grooves. An acrylic lampshade is fixed to the upper cover and the lower cover through a plurality of outer pull rods annularly arranged outside. The heat sink is pressed to the inner side of the upper cover and the inner side of the lower cover through a plurality of inner and outer pull rods. The LED photoelectric integrated light emitting module is fixed to the surface of the heat sink though high-thermal-conductivity silicone grease and screws. The upper cover 1 and the lower cover 2 of the LED underwater fishing lamp are made of macromolecular nonmetal anti-corrosive materials, so that the upper cover and the lower cover cannot be corroded by seawater while the hardness, toughness, water absorptivity and temperature resistance are ensured, the effect that the lamp and is not corroded after being used in seawater for a long time can be guaranteed, the probability that water enters the lamp since the lamp is corroded by seawater is reduced, damage to the lamp is reduced, and the service life of the lamp is greatly prolonged.

Owner:SHENZHEN BINHAI ELECTRONICS CO LTD

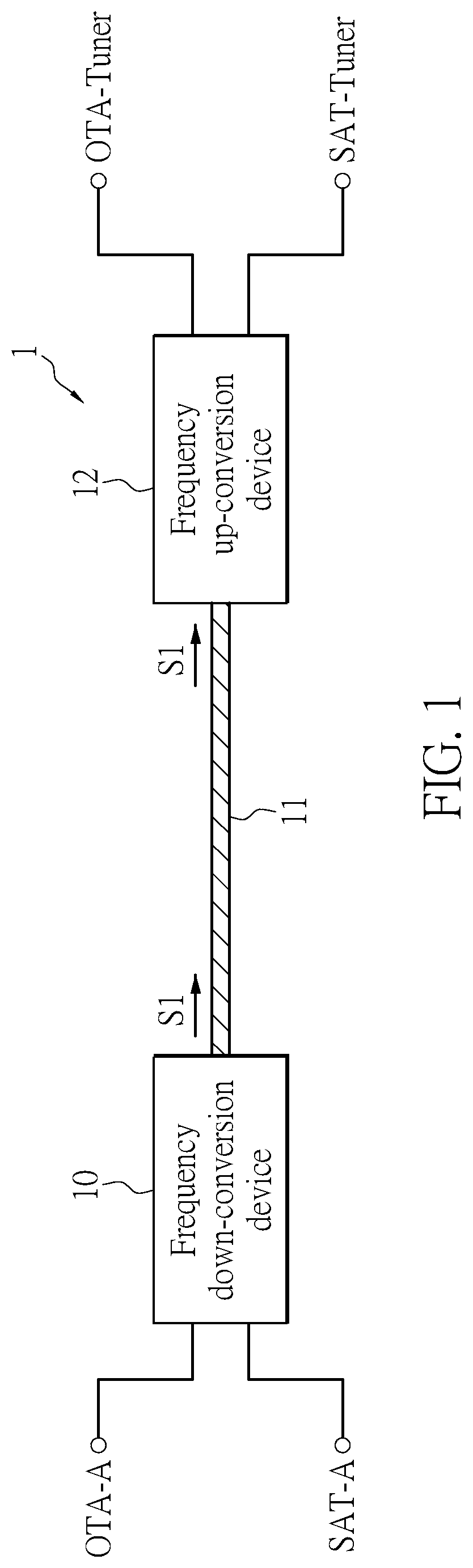

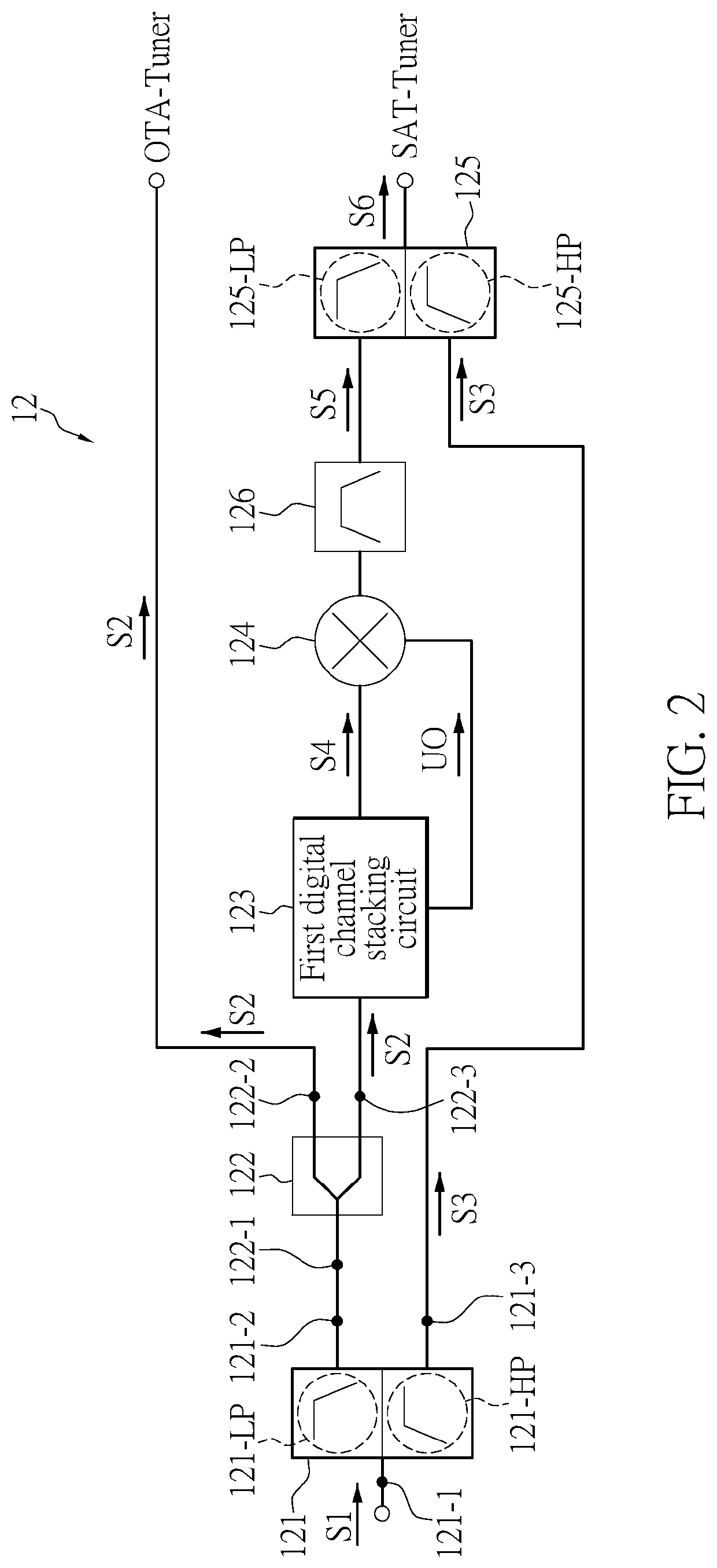

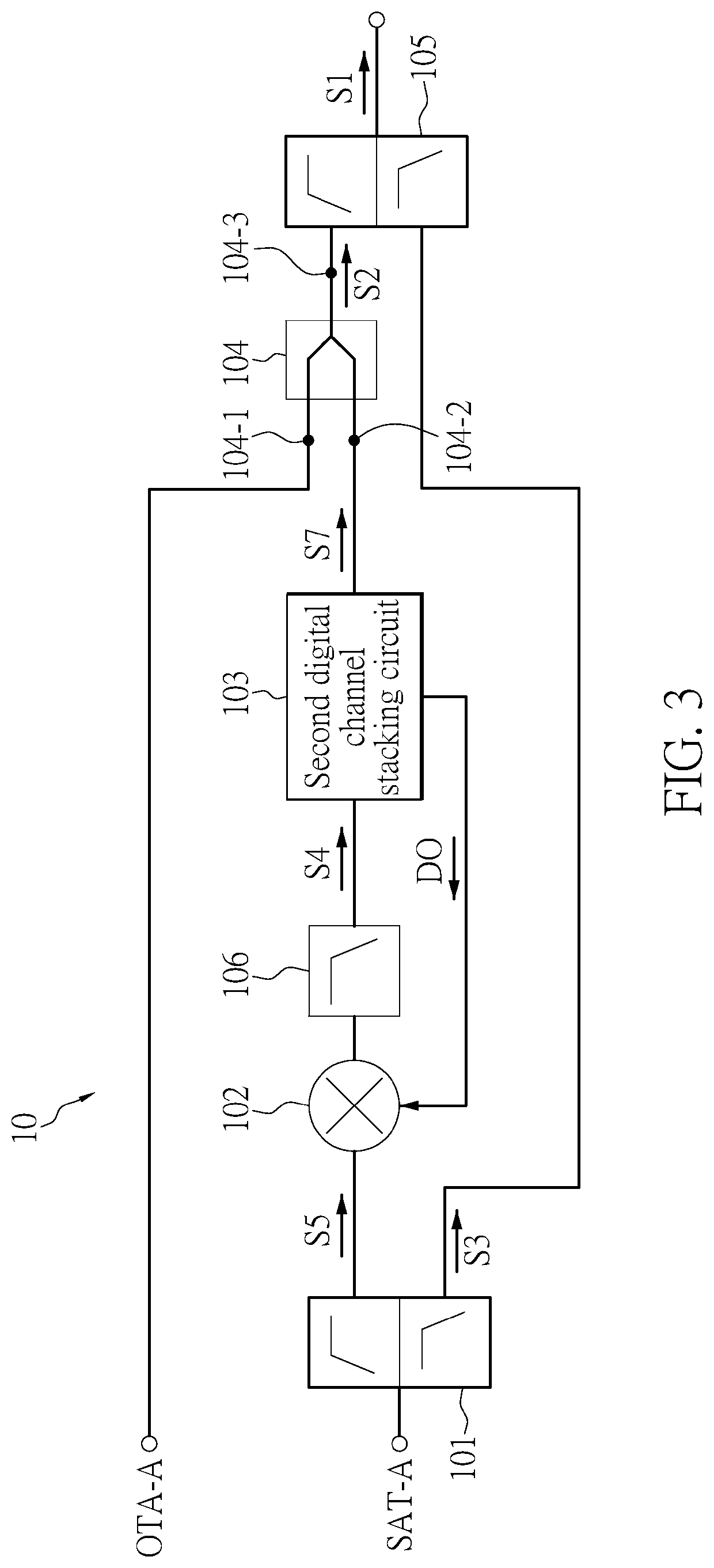

Frequency up-conversion device and signal transmission system

ActiveUS20200067541A1Reduce cable costsReduce design costTransmissionFrequency mixerSoftware engineering

A frequency up-conversion device and a signal transmission system are provided. A frequency up-conversion device includes a first diplexer, a divider, a digital channel stacking circuit, an up-conversion mixer, and a second diplexer. The first diplexer divides a first signal into a second signal and a third signal. The digital channel stacking circuit transforms the second signal to a fourth signal. The up-conversion mixer mixes the fourth signal and an up-conversion oscillating signal to generate a fifth signal. The second diplexer receives the fifth signal and the third signal to generate a sixth signal for output.

Owner:WISTRON NEWEB

Coding method and apparatus

InactiveCN101373974AImprove reliability and transmission efficiencyReduce cable costsParallel/series conversionData transmissionComputer hardware

The invention discloses an encoding method and a device thereof, which can avoid repetitive multiple transition (RMT) in high-speed serial data transmission without increasing cable cost. The encoding method comprises the steps of sequentially reading out data to be encoded from a stream of data to be encoded, and determining a data set composed of data which continuously appears and the appearance frequency of the data; and determining a designation code for designating the frequency according to the appearance frequency of the data in the data set, and generating an encoding sequence of the data set according to the designation code and the data code of the data. The inventive encoding method and the device can be used for data encoding in high-speed serial data transmission technology and avoid RMT in the encoding sequence, thereby ensuring that a receiving terminal can rapidly enter a locked-in state, improving data transmission reliability and transmission efficiency, and reducing cable cost.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

Modularly Redundant DC-DC Power Supply Arrangement Having Outputs That Can Be Connected In Parallel

ActiveUS20160006351A1Effective overvoltage protectionHeavy loadEfficient power electronics conversionDc-dc conversionDc dc converterControl theory

A power supply device for redundantly supplying power to a load comprises a first supply unit, a second supply unit, a first DC-DC converter, a second DC-DC converter, a first output switching controller, and a second output switching controller. The first and second supply units are interconnected. The first output switching controller is connected on the load side of the first DC-DC converter, and the second output switching controller is connected on the load side of the second DC-DC converter. The outputs of the output switching controllers are interconnected.

Owner:SIEMENS AG

Cable connector assembly

ActiveUS10326214B2Reliable electrical connectionLow production costCoupling device detailsSoldered/welded conductive connectionsSolderingElectrical and Electronics engineering

A cable connector assembly includes an insulating body and a cable. The insulating body includes a first terminal group and a second terminal group received in the insulating body. The first terminal group has a first terminal. The first terminal has a first soldering surface at one end thereof. The second terminal group has a second terminal. The second terminal has a second soldering surface disposed opposite to the first soldering surface. The cable has a first core wire disposed between the first soldering surface and the second soldering surface and soldered to the first soldering surface and the second soldering surface. The first terminal and the second terminal have same functions share the first core wire and are directly soldered to the first core wire.

Owner:LOTES

Bistatic radar system for motor vehicle applications

Owner:MOBILE TECH SOLUTIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com