Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1080results about How to "Reduce intermediate links" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

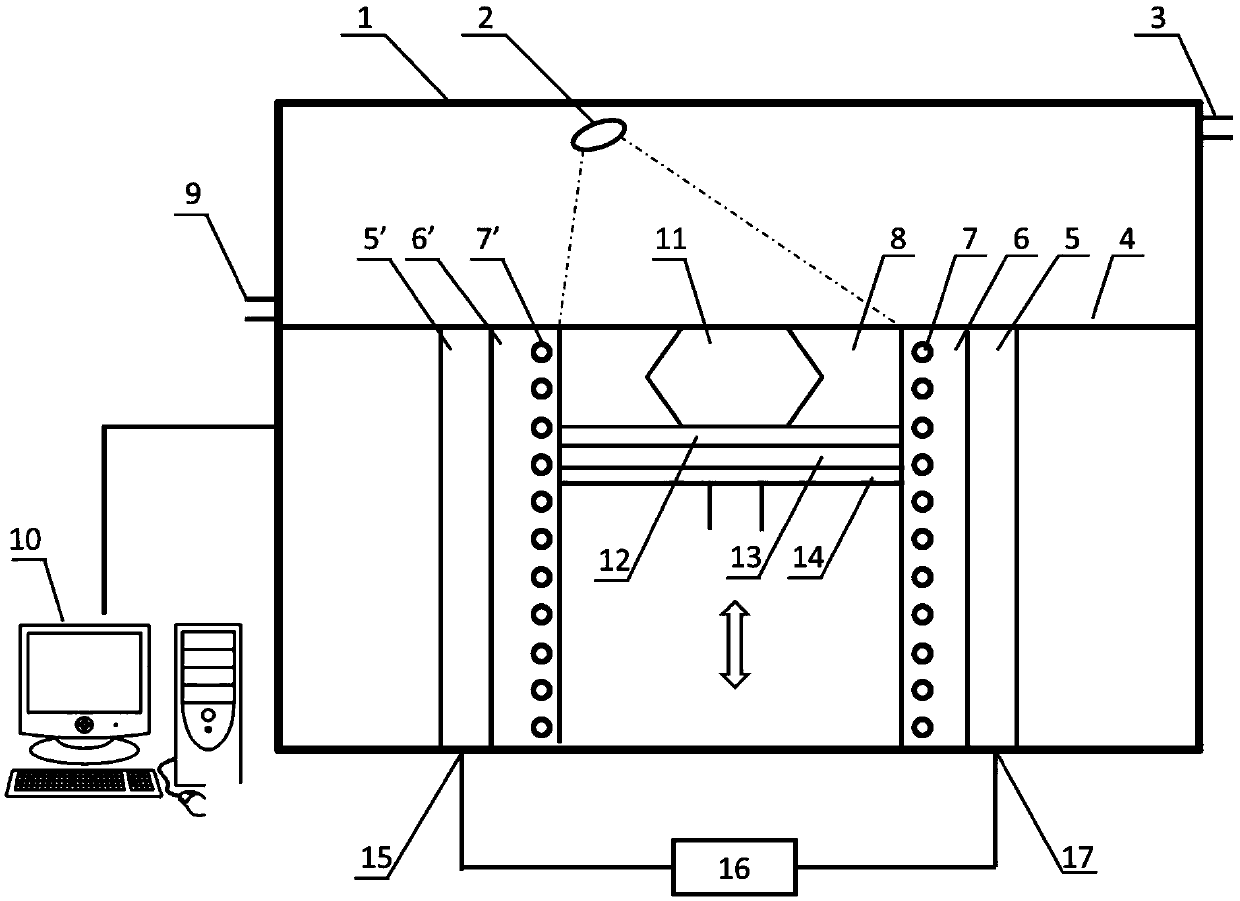

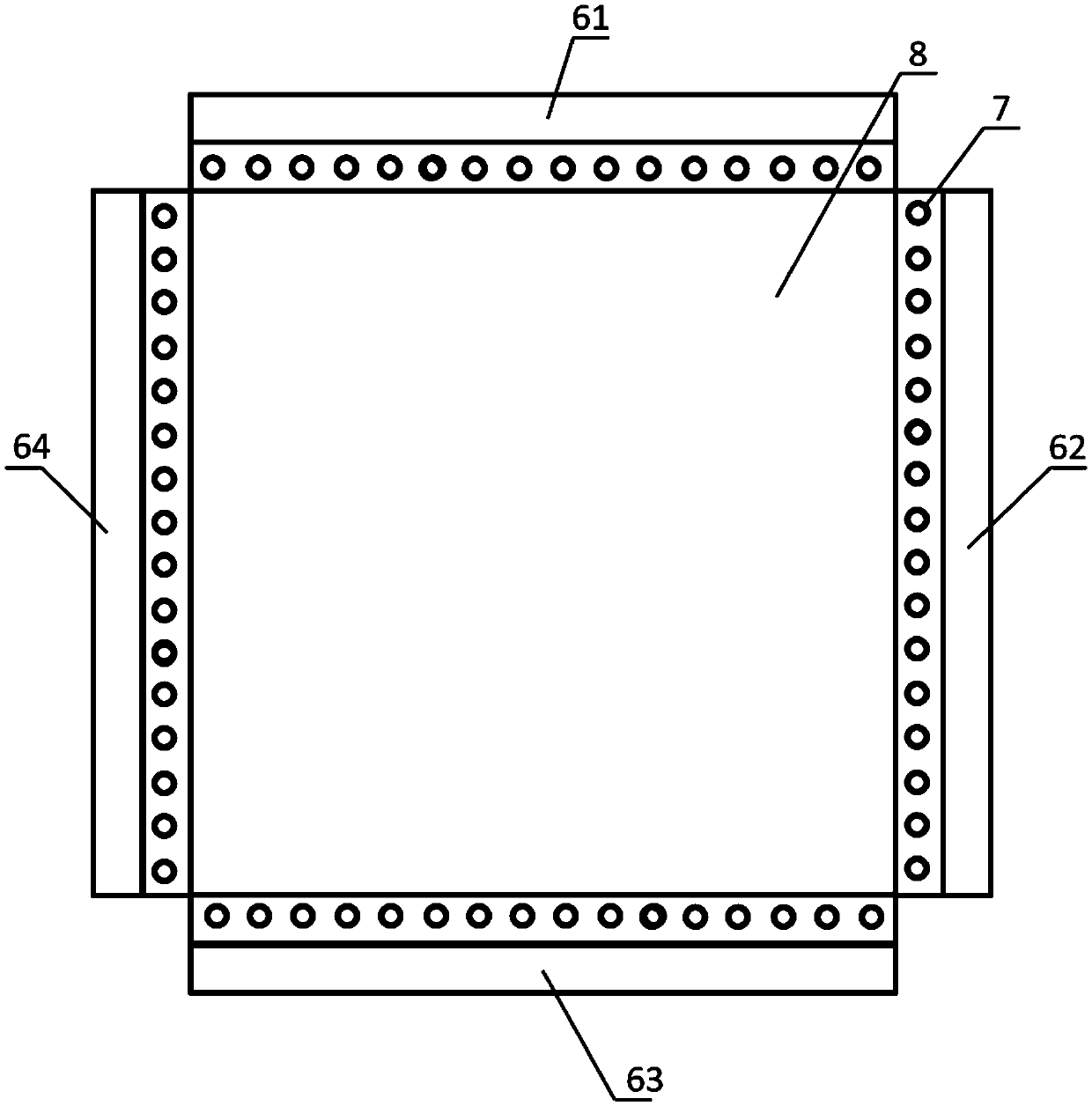

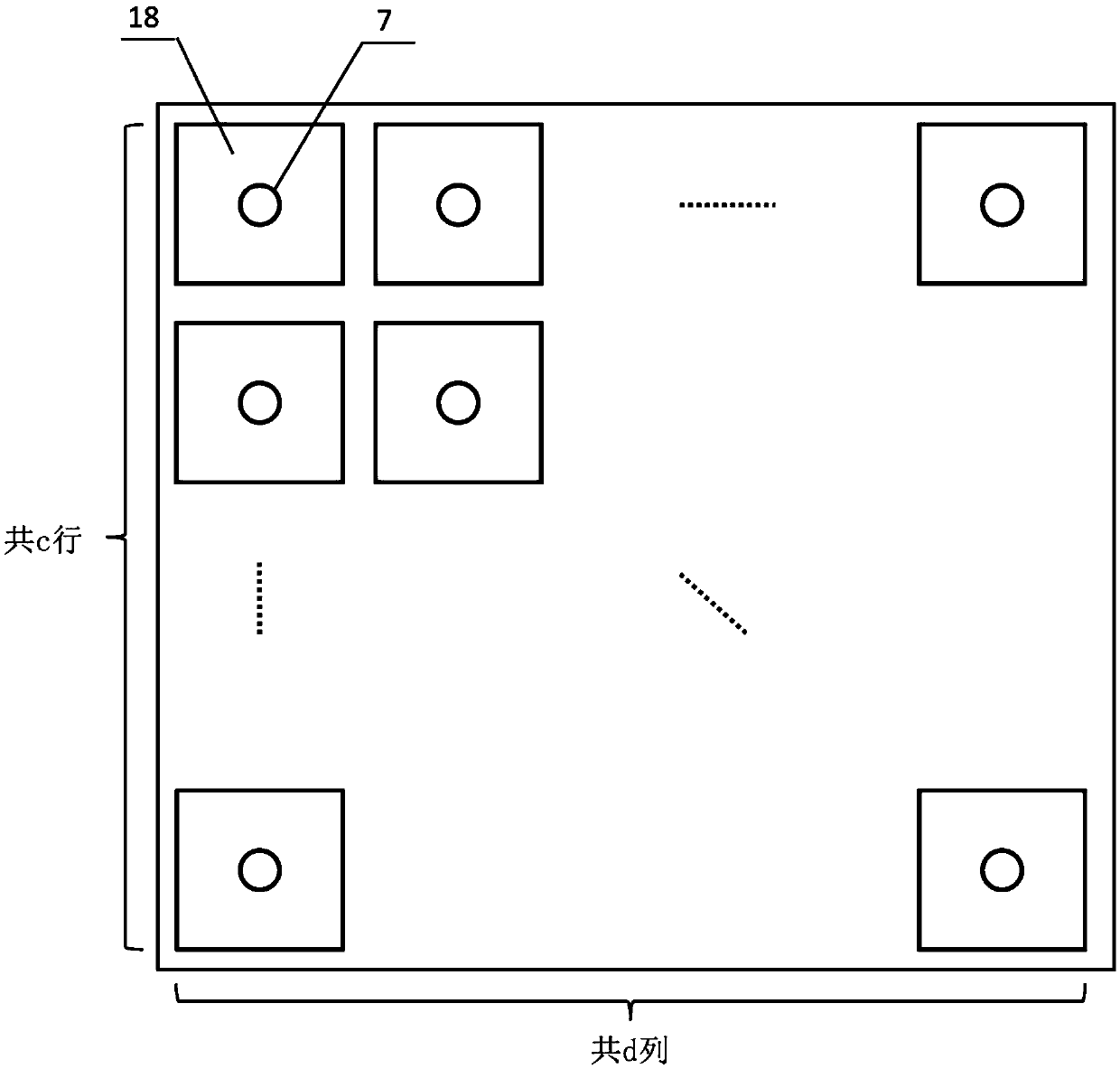

Active temperature field regulating and controlling system for manufacturing high-energy beam reinforced material and control method for active temperature field regulating and controlling system

ActiveCN105499569AShorten heat treatment cycleEnergy savingAdditive manufacturing apparatusIncreasing energy efficiencyHeating systemHolding time

The invention discloses an active gradient temperature field regulating and controlling system and a control method thereof. The system is composed of a temperature field monitoring system, a heating system and a control system, wherein the temperature field monitoring system is used for measuring temperature field information on an XOY plane and at the periphery of a forming region and feeding the temperature field information back to the control system after quantitatively processing the temperature field information; and the heating system is used for independently regulating subregions of a temperature field at the bottom and periphery of a forming tank in real time according to a command of the control system so as to keep the temperature field of the whole machining region constant in the machining process, keep a processed region and an unprocessed region in a reasonable temperature gradient and avoid structural member warping, deforming and cracking caused by thermal stresses. The system can also be used for directly carrying out stress relief annealing on a formed structural member or directly carrying out stress relief on the formed structural member while machining, so that the problems of warping, deforming, cracking and the like easily caused in the forming process are effectively solved, not only is the time shortened, but also energy sources are saved, meanwhile, the holding time of equipment can be effectively shortened, and the utilization ratio of the equipment can be increased.

Owner:HUAZHONG UNIV OF SCI & TECH

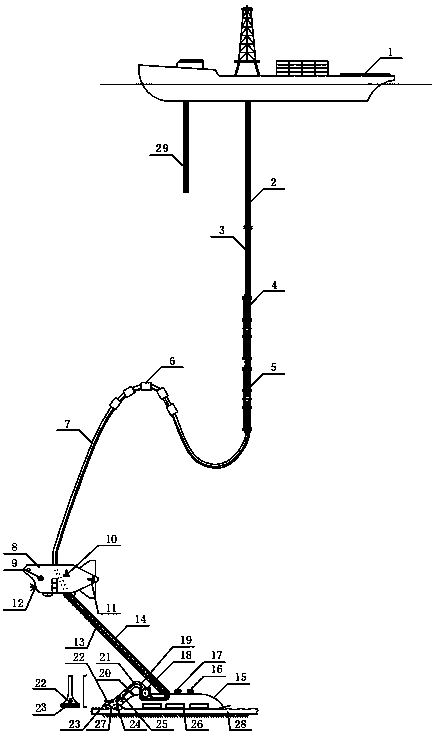

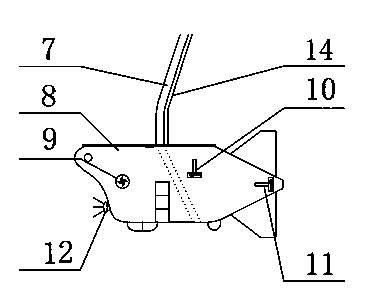

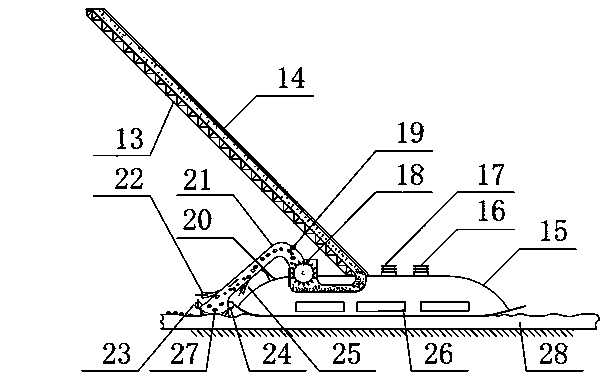

Oceanic mineral resource exploitation device and exploitation method

InactiveCN103628881AReduce disturbanceImprove reliabilityMineral miningFluid removalTerrainElectricity

The invention discloses an oceanic mineral resource exploitation device and exploitation method and aims to overcome the technological difficulty of the existing submarine mining vehicle and the pipeline waterpower lifting exploitation system. The exploitation device comprises a water surface mining vessel, a lifting pipe, a lifting electric pump station, a hose, a mineral crushing mechanism and a mining mechanism, wherein a plurality of perturbance jet flow nozzles, a plurality of ascending jet flow nozzles and a flow guide pipe are mounted on the mining mechanism; the flow guide pipe is communicated with the feeding hole of the mineral crushing mechanism; the lifting pipe, the lifting electric pump station, the hose and the mineral crushing mechanism are sequentially connected with the flow guide pipe in series to form an ore pulp lifting passage; the hose is fixed onto an ROV; the ROV is connected with the mining mechanism through a connecting device. The oceanic mineral resource exploitation device is not limited by the complicated terrain and gradient at the bottom of the sea, avoids the slipping and sinking of the underpan of the submarine mining vehicle on a settled layer, greatly reduces the disturbance of mineral mining to bottom sediments, and also solves the problem that the terrain clearance of the mining mechanism is difficult to control.

Owner:HUNAN UNIV

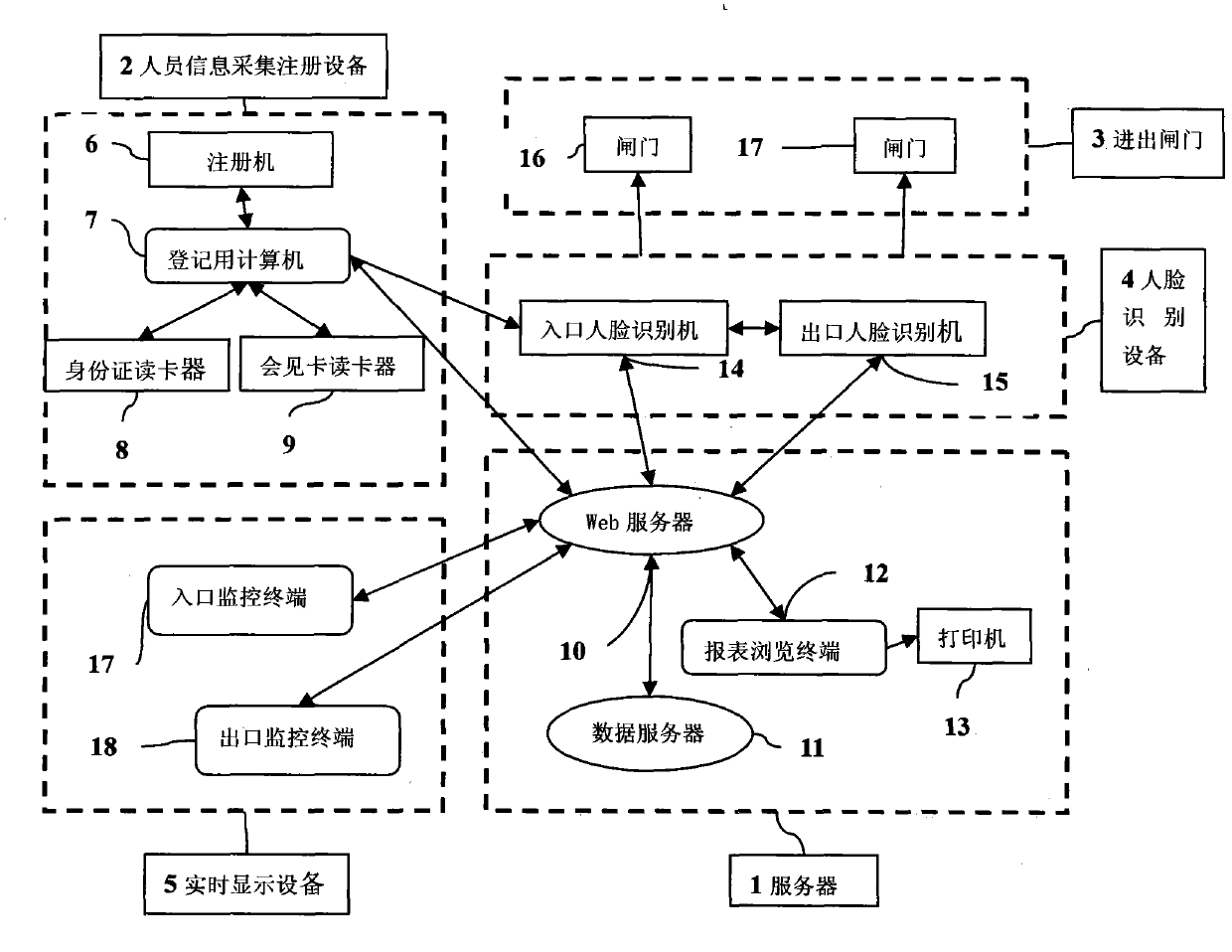

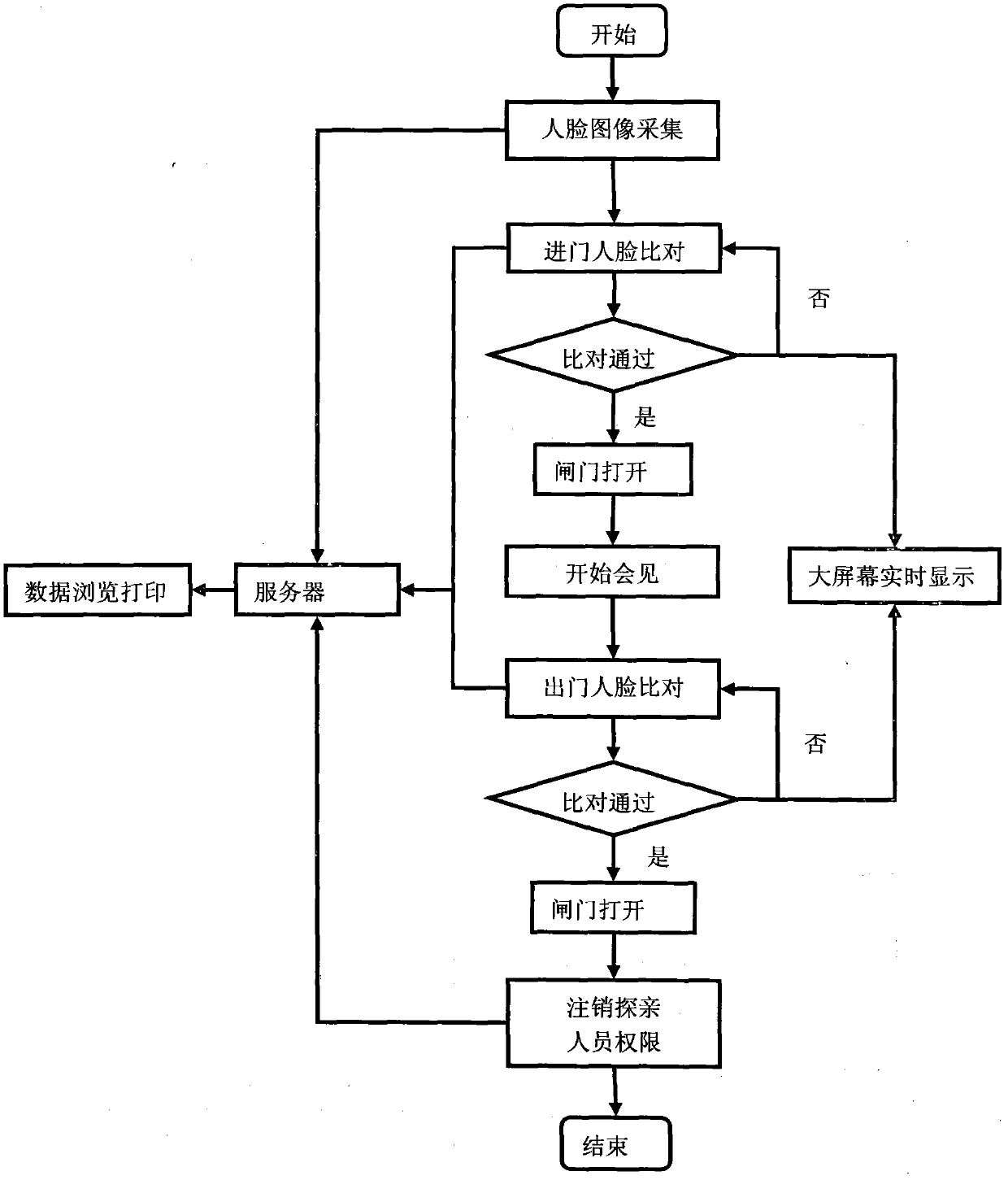

System for monitoring person entering and exiting presence area of prison by recognizing faces of person

ActiveCN102708606AReduce workloadImprove efficiencyCharacter and pattern recognitionClosed circuit television systemsWeb serviceDatabase server

The invention relates to a system for monitoring the person entering and exiting the presence area of a prison by recognizing the face of the person. The system comprises servers, personnel information collecting and registering equipment, an entering and exiting gate, face recognition equipment and real-time displaying equipment; the servers consist of a web server and a database server and is used for storing all the effective historical recordings and browsing and printing the historical recordings; the personnel information collecting and registering equipment comprises a registration machine, a computer for registering and a card reader connected with the computer, and is used for taking a picture for the visiting person, analyzing the face feature data of the visiting person, associating the identity information of the visiting person with the identity information of the visited person and sending the face feature data of the person to the server and the person-face recognizing equipment; the person-face recognizing equipment is used for recognizing the visiting person and controlling the gate to open and close according to the visiting person recognition result; the real-time displaying equipment is used for displaying the picture, the name and the certificate number of the visiting person, the name and the department information of the visited person and the comparisonresult when the person entering and exiting the presence area of the prison so that the operator on duty can monitor the person entering and exiting the presence area of the prison in real time. Due to the adoption of the system, the automatic recognition of the person entering and exiting the presence area of the prison in the prison industry is realized, the visiting person check accuracy and safety are improved effectively, and the visiting person entering and exiting the presence area of the prison can be monitored in real time and checked later.

Owner:南京普惠恒丰信息科技有限公司

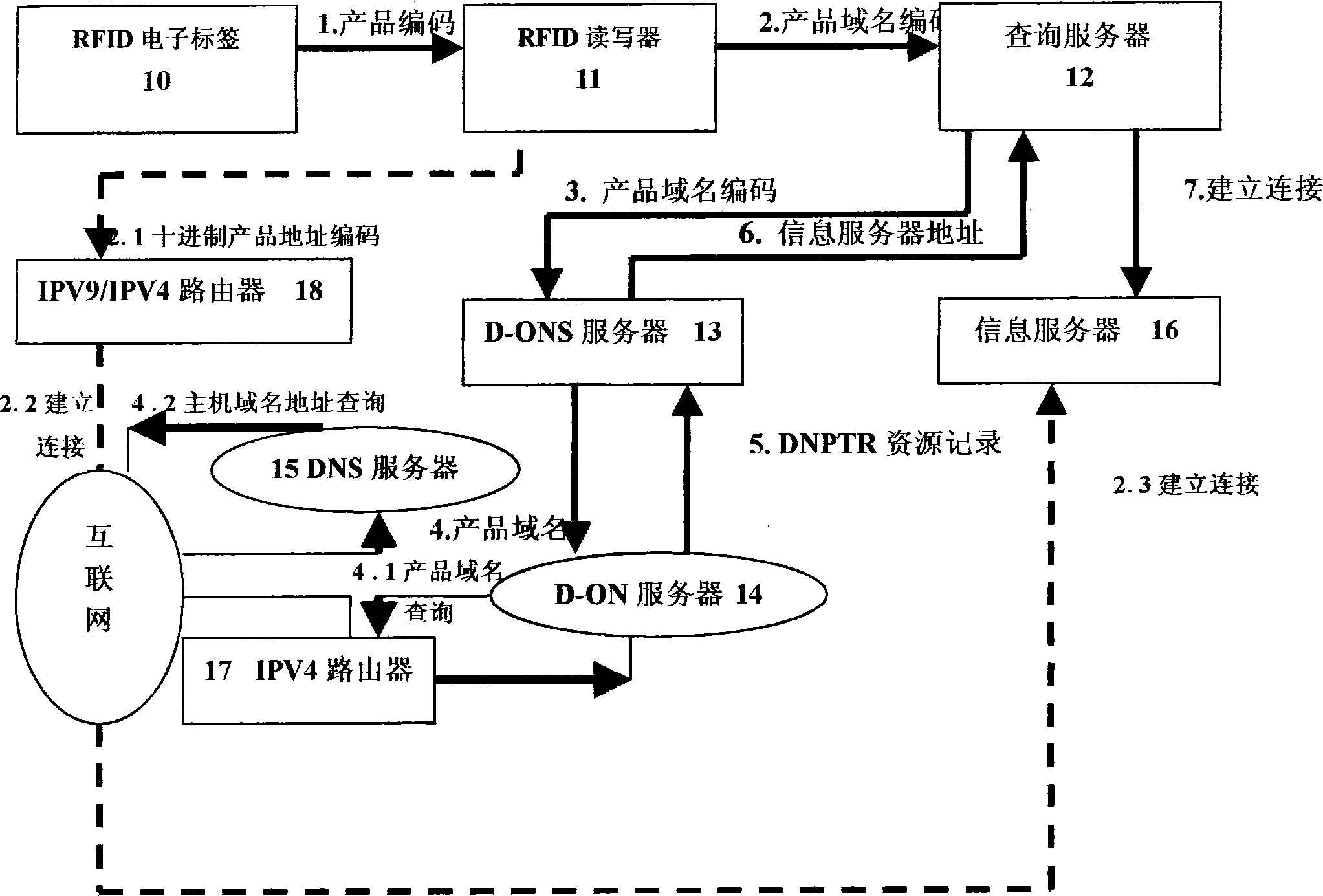

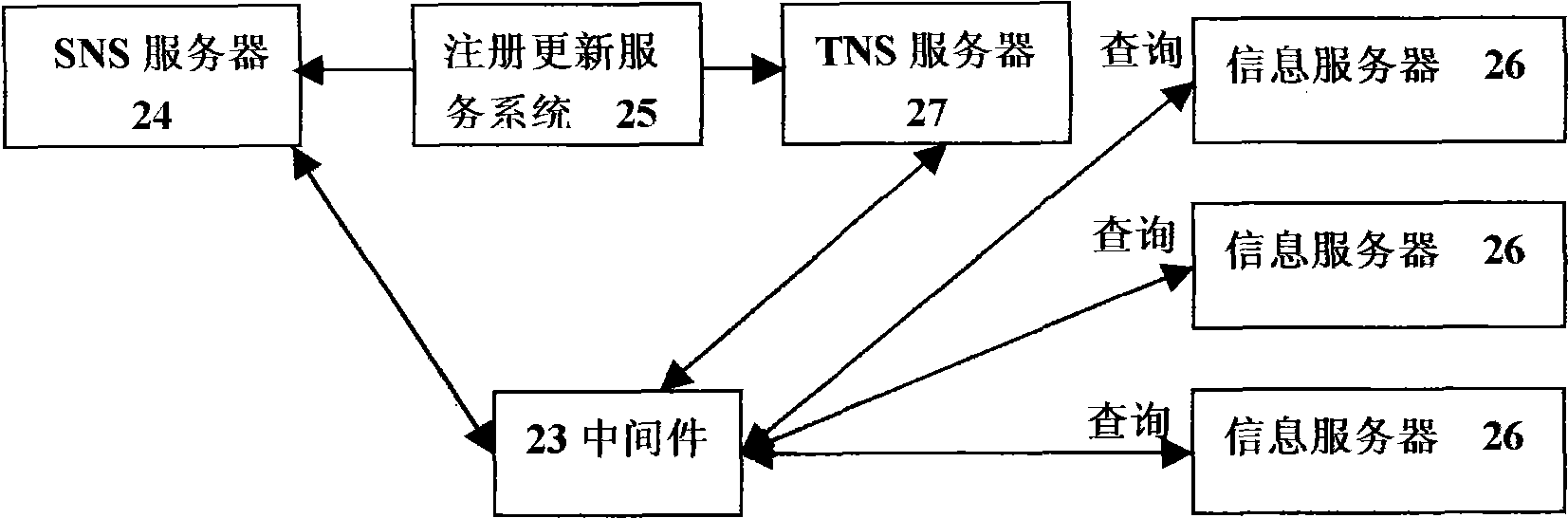

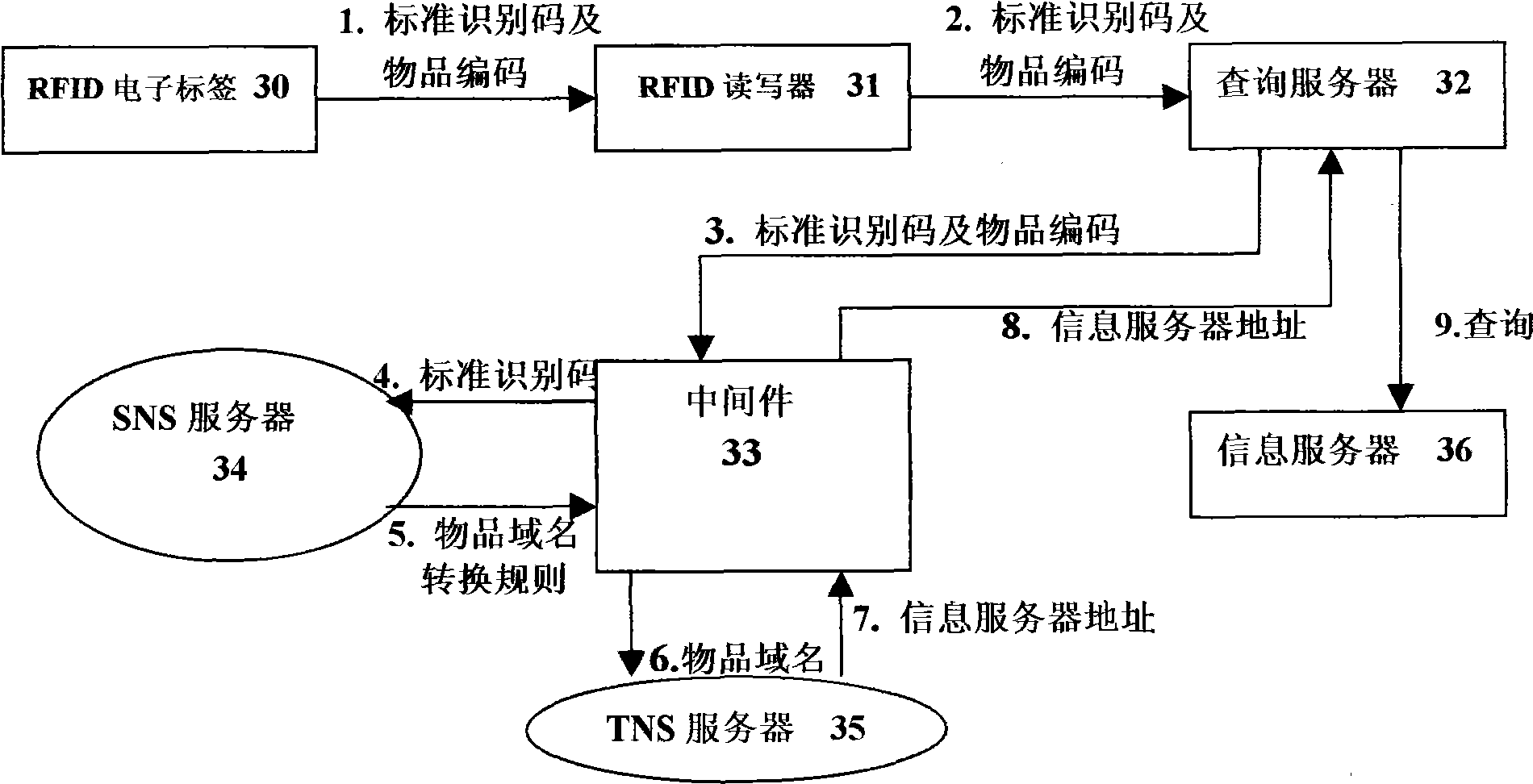

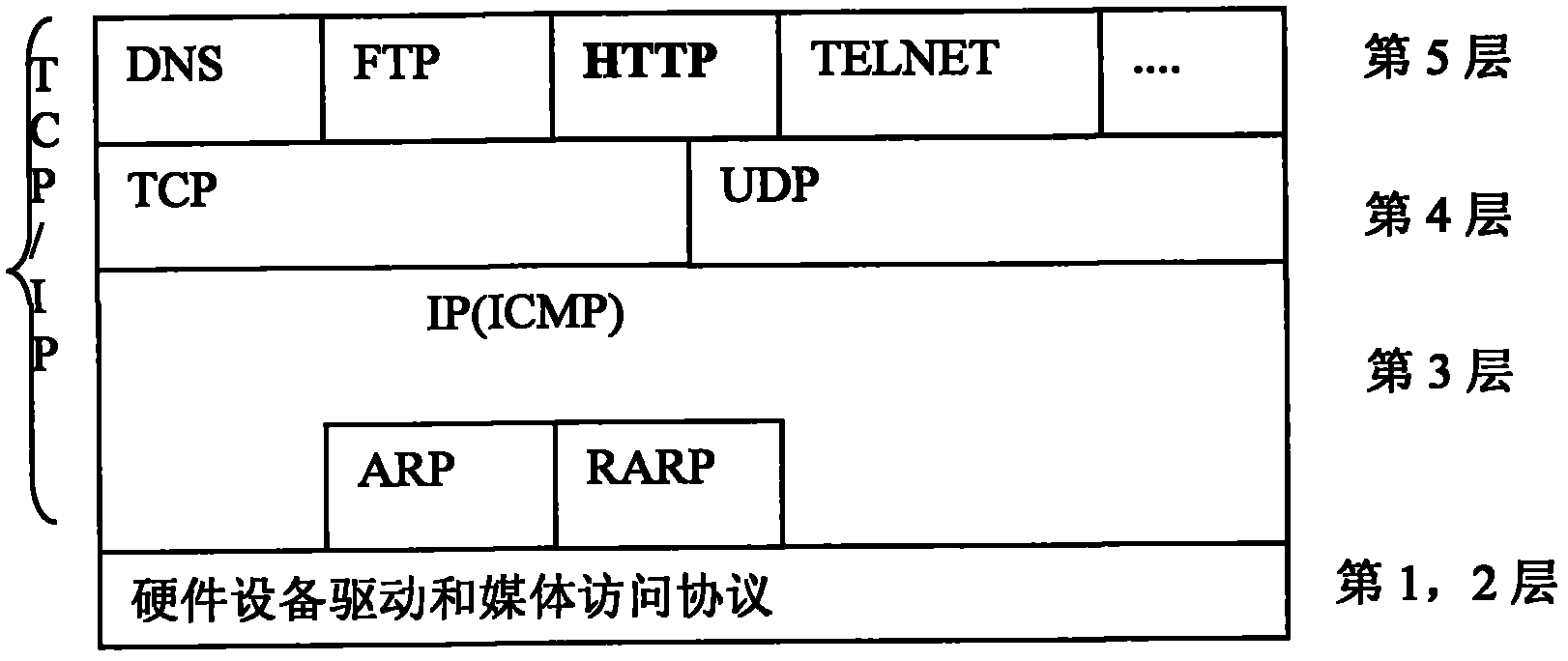

Information search and information exchange search process of business network and internet of things

InactiveCN101533477AImprove compatibilityLow costCo-operative working arrangementsData switching by path configurationDomain nameNetwork architecture

The invention provides an information search process for a business network based on a decimal network architecture and an internet of things based on IPV4 network architecture, as well as an information exchange search process for the business network and the internet of things based on IPV4 / IPV6 protocol and business network-applied IPV9 fully digital address. Information exchange and sharing as well as the transparent management on commodities and things are realized through interconnected computers and wireless or data communication network. The business network is applicable to an electronic label, one or two dimension bar code or other carrier codes to search information on decimal network or the internet interconnected with the decimal network through. In the information search from the internet of things, a standard identification code is converted into CN domain name through regular expression, thus being capable of realizing compatibility with the coding standard of any thing; and a business network-applied IPV9 router directly exchanges electronic codes for the domain name, has the dual functions of routing and analysis and can reduce cost as well as intermediate link.

Owner:SHANGHAI DECIMAL NETWORK INFORMATION SCI & TECH

Wobble plate-type wave power device

InactiveCN102536614AImprove conversion efficiencyReduce intermediate linksMachines/enginesEngine componentsWave power generationSea waves

The invention provides a wobble plate-type wave power device comprising wobble plates, a support column, a gear reversing device, a gearbox, as well as an automatic speed adjusting mechanism, an excitation generator, a permanent-magnet generator and a direction adjusting plate of an intelligent adjusting system, wherein the wobble plates can rotate around the vertical support column with 360 DEG, so as to utilize wave power in different directions; the wobble plates also wobble around a pendulum shaft under the action of waves, so as to convert the wobbling motion into the one-way rotating motion of the wave power device through a mechanical reverse mechanism, and greatly improve the utilization ratio of the wave power. A generating set comprising the excitation generator and the permanent-magnet generator is adopted for power generation, and the permanent-magnet alternator can supply electricity to a control system and the wave power device, so that the wave power device can generate electricity without external power; and the generated output of the wave power device can be adjusted by adjusting excitation voltage, so that the wave power device is suitable for efficiently convert wave energy of waves of different height into electric energy.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

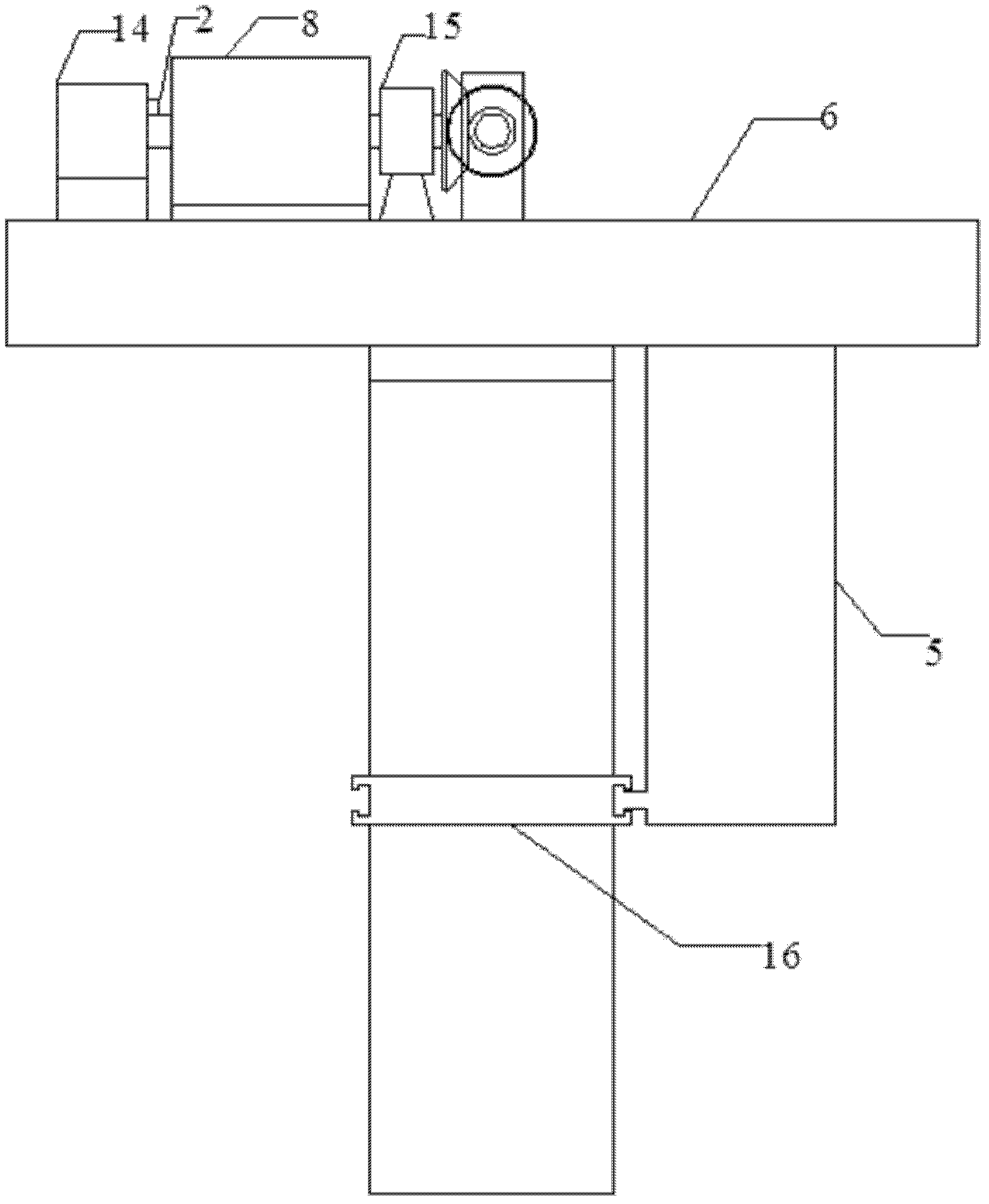

Automatic powder filling and packaging device and method

InactiveCN103523250AReduce intermediate linksReduce environmental pollutionSolid materialPackaging machinesVolume fillingAutomatic control

The invention relates to an automatic powder filling and packaging device and method. Eight sets of turntable mechanical clamps are arranged on the edge of a circular turntable. A bag fetching mechanical arm, an automatic ink-jet printer, a bag opening device, a volume filling device, a weighing filling device, a dust collector, a heat sealer and a knurling shaping device are independently arranged on fixing frames on the periphery of the circular turntable respectively. A rotating shaft of a bag supporting device is arranged in the center of the turntable and is controlled to be lifted through a cam at the lower end. A bag supporting clamp is connected to a rotating shaft through a rotating rod, the bag supporting clamp is controlled pneumatically and is capable of being opened and closed automatically, and a weighing device and a pair of weighing mechanical clamps are arranged on the outlet of a filling machine. A finished product conveying belt is arranged below the shaping device. The method comprises the steps of pretreatment of packaging bags, automatic bag feeding, code spraying of the packaging bags, opening of the packaging bags, fast filling, weighing filling, cleaning of openings of the bags, heat sealing of the openings of the bags, knurling and shaping, and manual casing. The whole process is automatically controlled, intermediate links and environment pollution are reduced, and damage to human bodies is avoided.

Owner:TIANJIN ZHONGHUAN TIANJIA ELECTRONICS

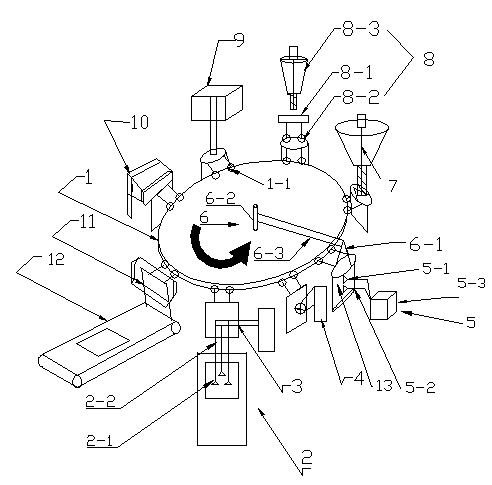

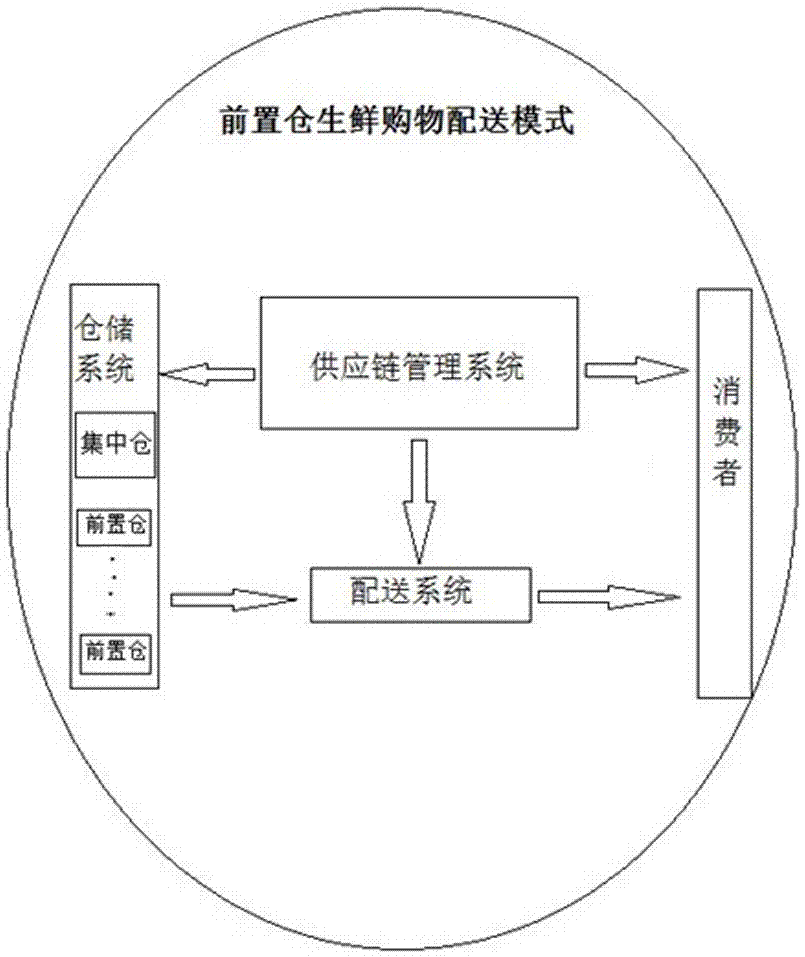

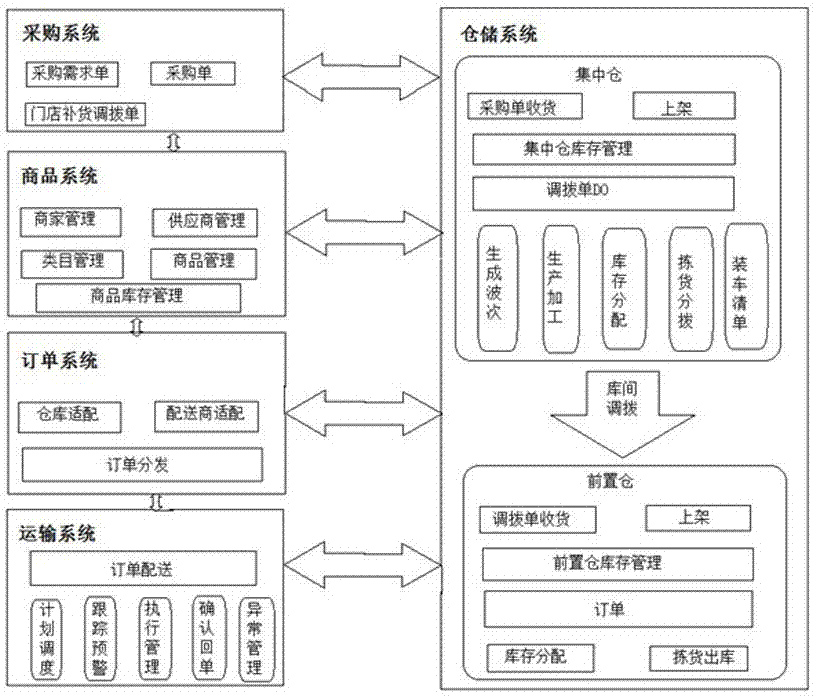

Preposed warehouse fresh food shopping and distribution mode

InactiveCN107292565ATimely distributionImprove on-time deliveryBuying/selling/leasing transactionsLogisticsOrder management systemDistribution system

The invention relates to the field of fresh food supply chain management, and specifically relates to a preposed warehouse fresh food shopping and distribution mode. The preposed warehouse fresh food shopping and distribution mode comprises a warehousing system, a distribution system and a supply chain management system, and the supply chain management system comprises five subsystems of a purchasing system, a warehouse management system, a commodity system, an order management system and a transportation management system. A centralized + distributed management mode is employed, a centralized warehouse and several preposed warehouses are arranged in the urban area, goods are stored in the preposed warehouses, a customer places an order through a mobile phone APP, goods are sent to the customer from the closest preposed warehouse, and therefore one-hour delivery is achieved. Beneficial effects of the preposed warehouse fresh food shopping and distribution mode are that a centralized + distributed warehousing mode is employed, efficient distribution of one-hour deliver in the last one kilometer is achieved; compared with a conventional mode, the intermediate links are less, the distribution efficiency is high, time is short, and the cost is low; by means of distributed storage, supply chain steps can be greatly reduced, the distribution cost of each order can be reduced to 11 yuan, and the distribution time is reduced to one hour.

Owner:浙江优展信息科技有限公司

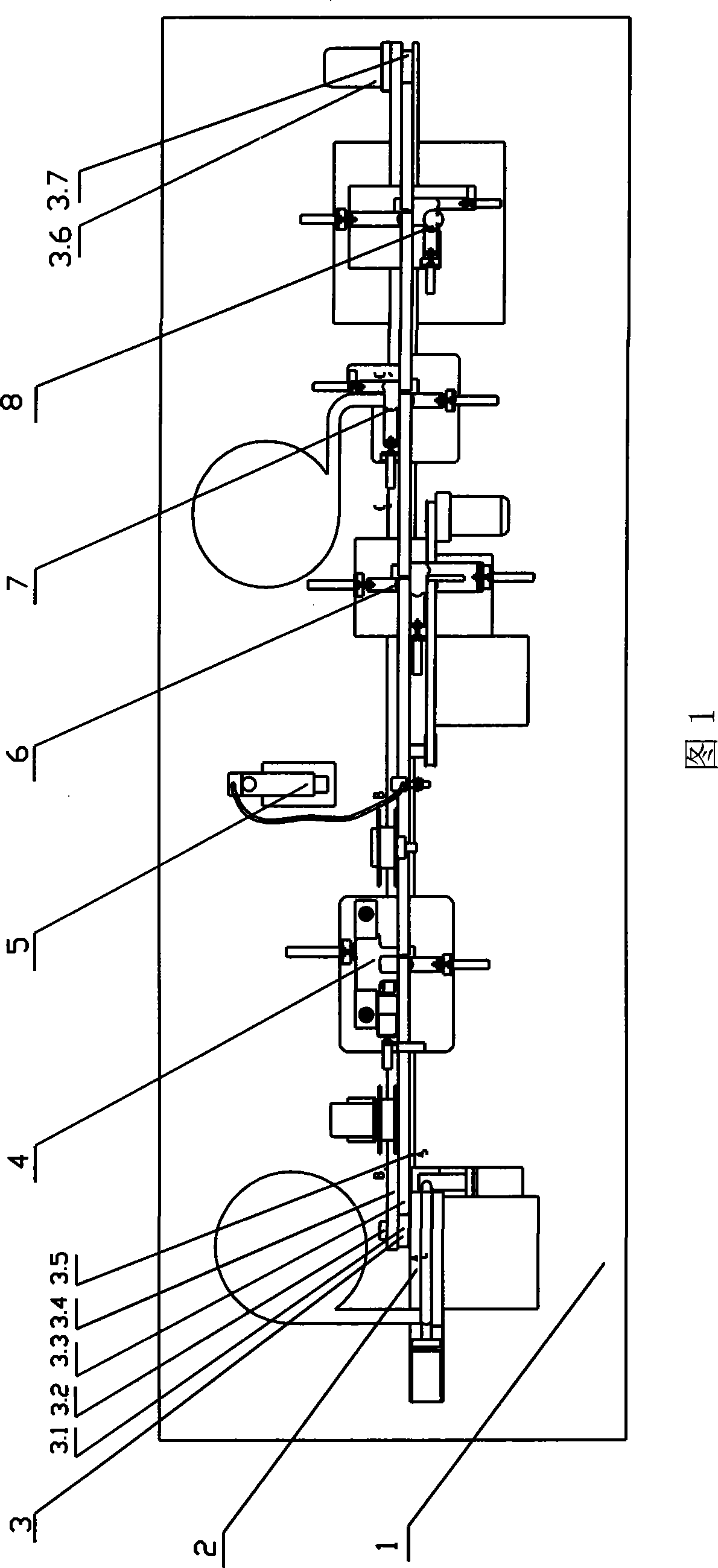

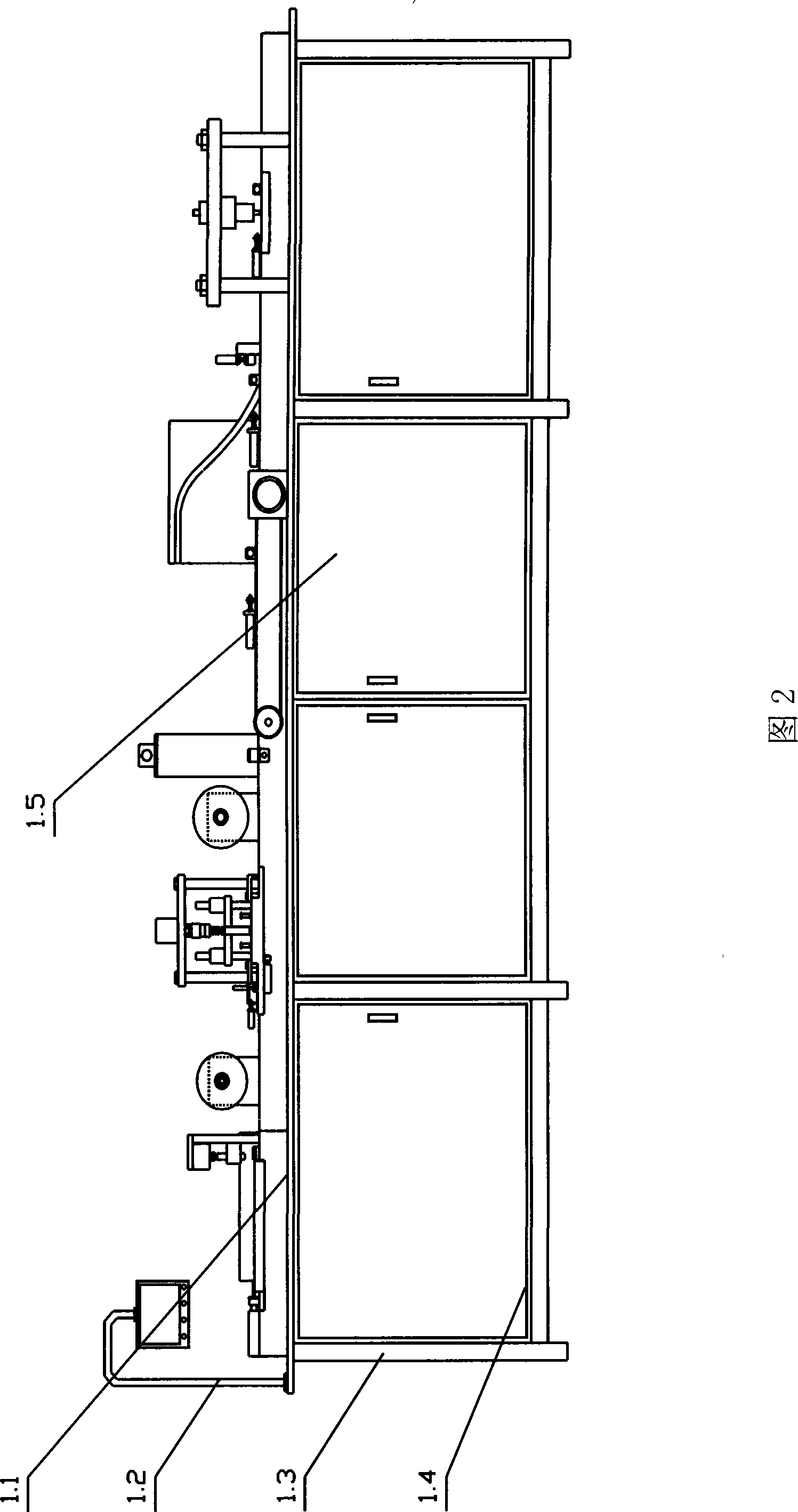

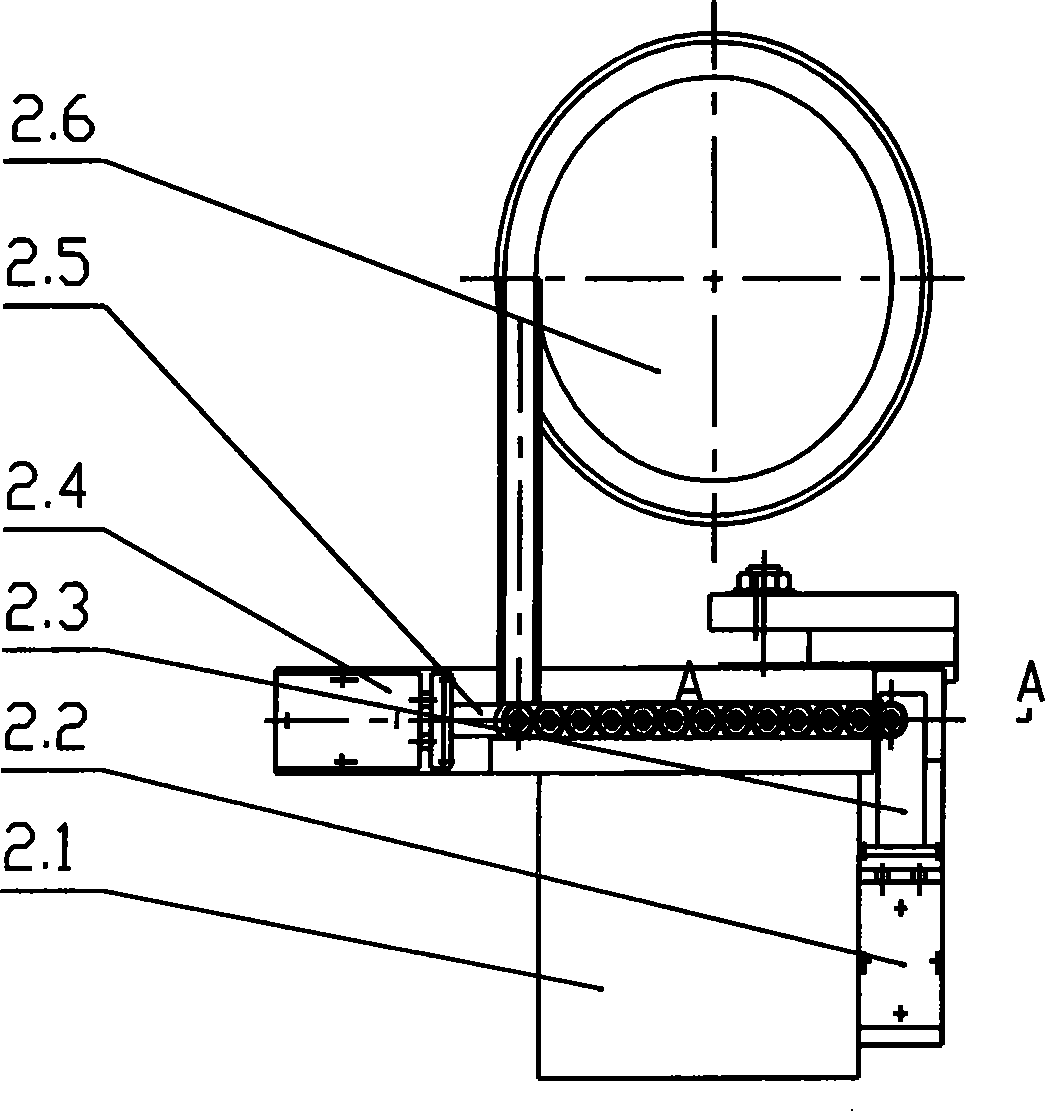

Button cell battery production line

InactiveCN101252194AAdvanced technologyEasy to controlFinal product manufactureNon-aqueous electrolyte cellsProduction lineLithium

The invention relates to a button cell production line, being characterized in comprising a rack component, a lithium chip loading mechanism, a paper cutting mechanism, a filling mechanism, a manganese chip loading mechanism, an anode case loading mechanism, a sealing mechanism, a main transmission mechanism, a pneumatic control system and an electrical apparatus control system as well as a control program; the rack component comprises a large worktable and a rack fastened on the lower surface of the large worktable, a lower base plate of the rack is arranged on a lower beam of the rack, a control cabinet is arranged on the upper part of the lower base plate of the rack; the lithium chip loading mechanism, the main transmission mechanism, the paper cutting mechanism, the filling mechanism, the manganese chip loading mechanism, the anode case loading mechanism and the sealing mechanism are arranged on the large worktable in turn; the pneumatic control system is arranged on the lower base plate of the rack; the electrical apparatus control system and the control program are arranged inside the control cabinet; a touch screen support is vertically arranged on the upper surface of the large worktable close to one end of the lithium chip loading mechanism.

Owner:TIANJIN POLYTECHNIC UNIV

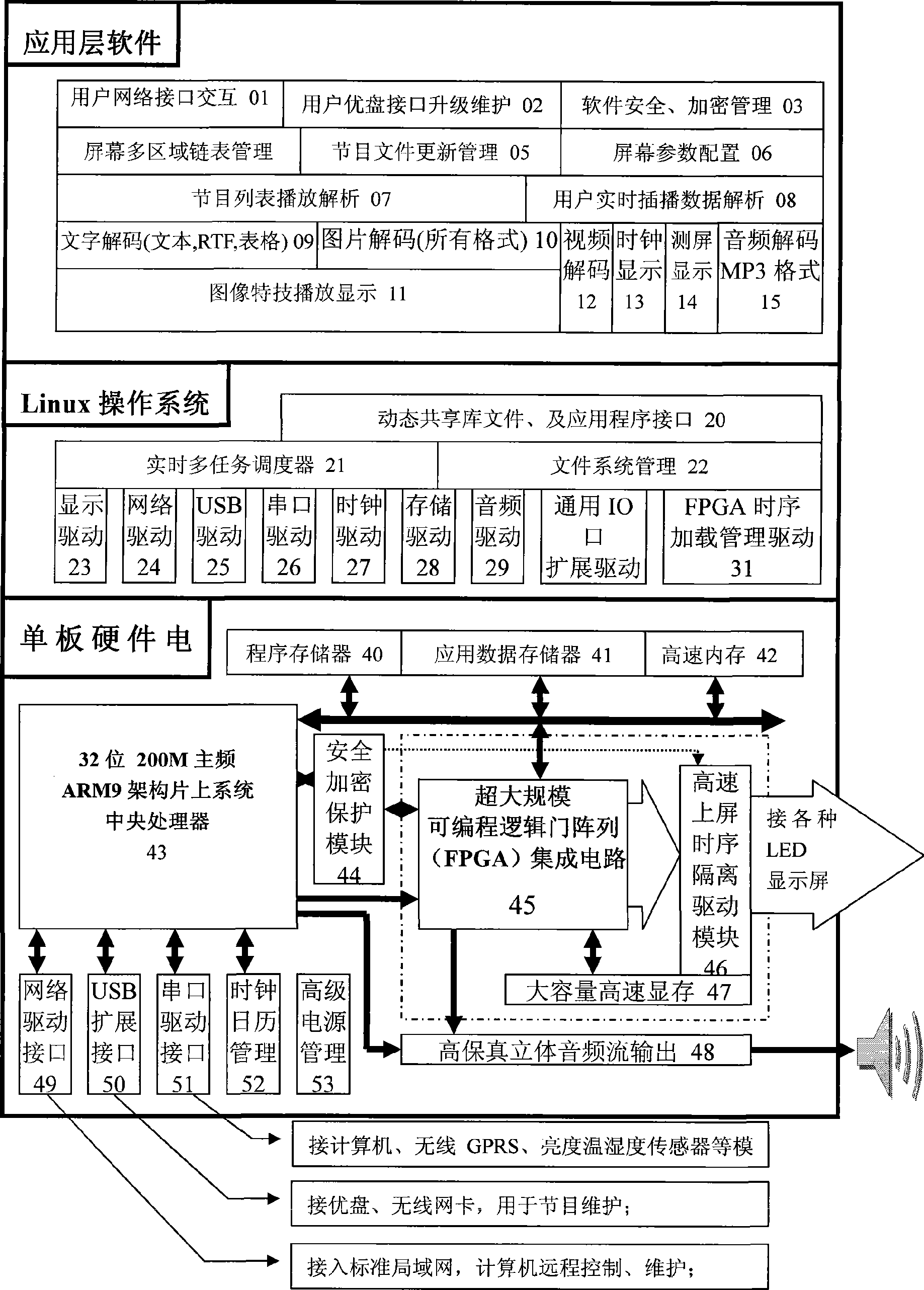

Embedded multimedia LED display screen control system

InactiveCN101447171ASuitable for a wide range of occasionsFreedom to adapt to the occasionCathode-ray tube indicatorsInput/output processes for data processingOperational systemHigh speed memory

The invention relates to an embedded multimedia LED display screen control system, comprising a single board hardware circuit which comprises a program memory, an application data memory, a high-speed memory, a CPU, a safety encrypting protection module, an ultra-large scale field programmable gate array (FPGA) integrated circuit, a high-speed upper screen time-sequence separation driving module, a large-capacity high-speed display memory, a high fidelity solid audio stream output module, a network driving interface, a USB extension interface, a serial driving interface, a clock calendar management module, and a high-class power management module. The embedded multimedia LED display screen control system employs mature and advanced 32-bit SOC (system on chip) high-speed processor and millions of ultra-large scale programmable integrated circuit FPGA as LED display scanning time-sequence signal generators, uses Linux real-time multi-task operation system with open sound code as for software to integrate electrons, software, memory, communication, graphs and images, audio / video decoding, and the like into a whole, and brings qualitative leap for the LED display system.

Owner:上海熙讯电子科技有限公司

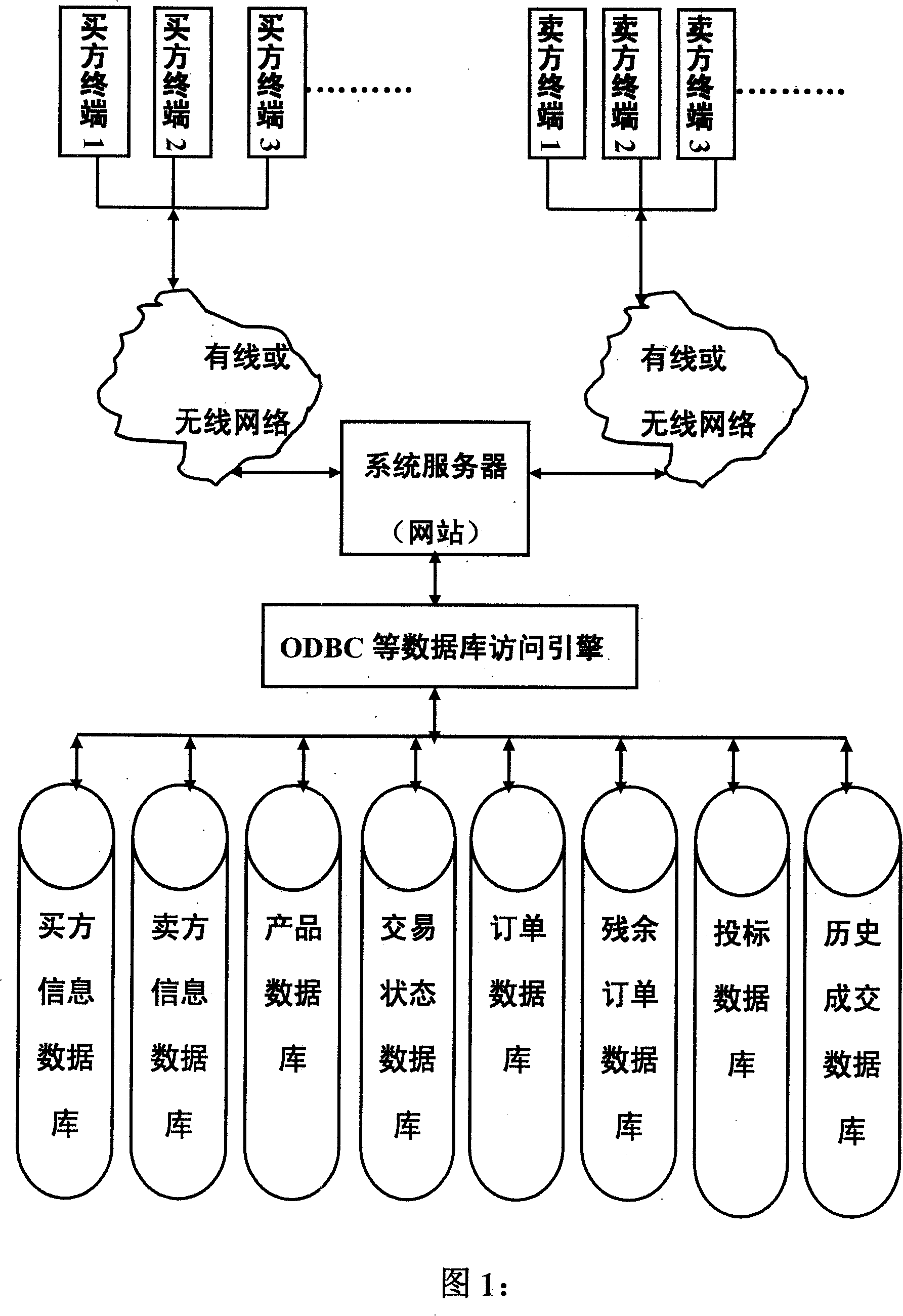

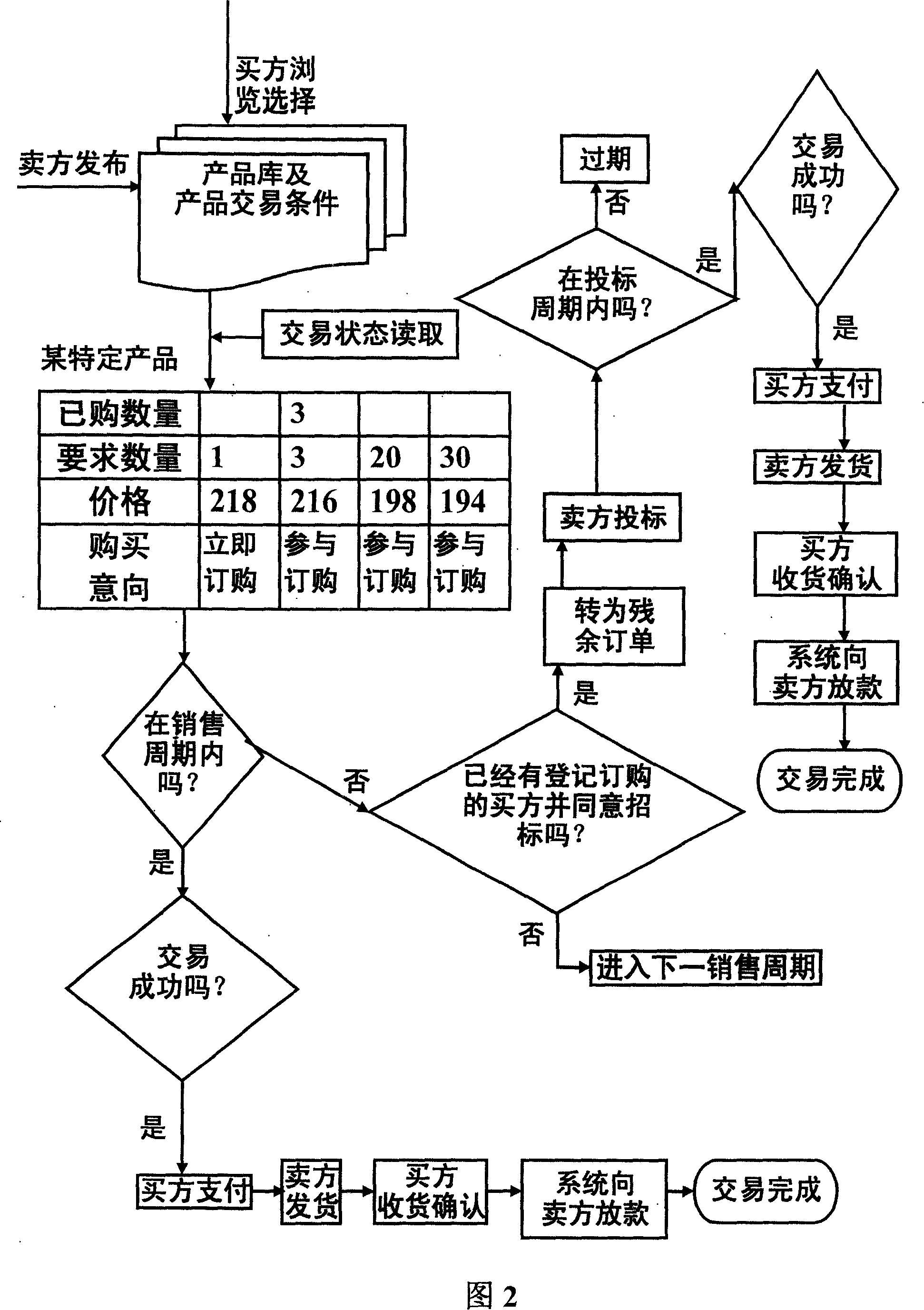

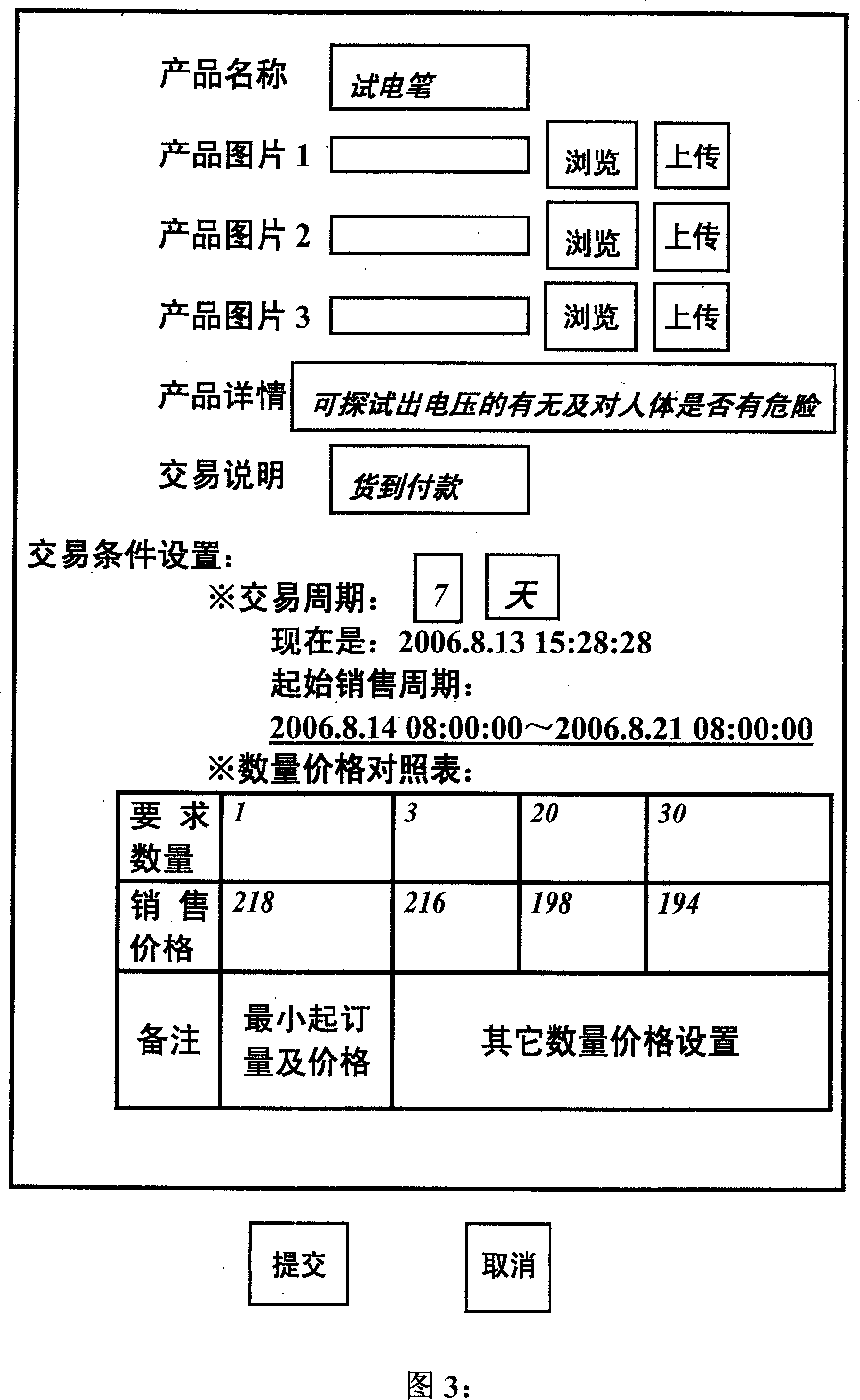

Commodity transaction mode under information network surroundings

InactiveCN101140650AReduce logistics costsReduce intermediate linksBuying/selling/leasing transactionsSystem structureData mining

A commodity exchange mode in an information network environment: The invention relates to a commodity exchange mechanism of group bargaining in the information network environment, as well as a relevant implementation method and a system structure. The invention aims at the following problems that are universally utilized in prior electronic commerce (in particular in B2C, B2B and C2C modes): Buyers are in weaker situations in market in commodity exchange mechanism and relevant implementation method, and market efficiency is rather low and etc. The invention submits a commodity exchange mode with rather high efficiency in the information network environments. Divide the commodity exchange process into the following two stages: Group bargaining stage and remaining order bidding stage. In the group bargaining stage, the conclusion policies include demands polymerization and graded bargaining conclusion. The invention provides the commodity exchange mechanism to enlarge sales opportunity of commodity and products (services) and increase sales speed, considerably increase buyers' negotiation situation levels, increase consumers' effects, and further increase exchange success rate, lower exchange cost and improve market efficiency.

Owner:高思兵

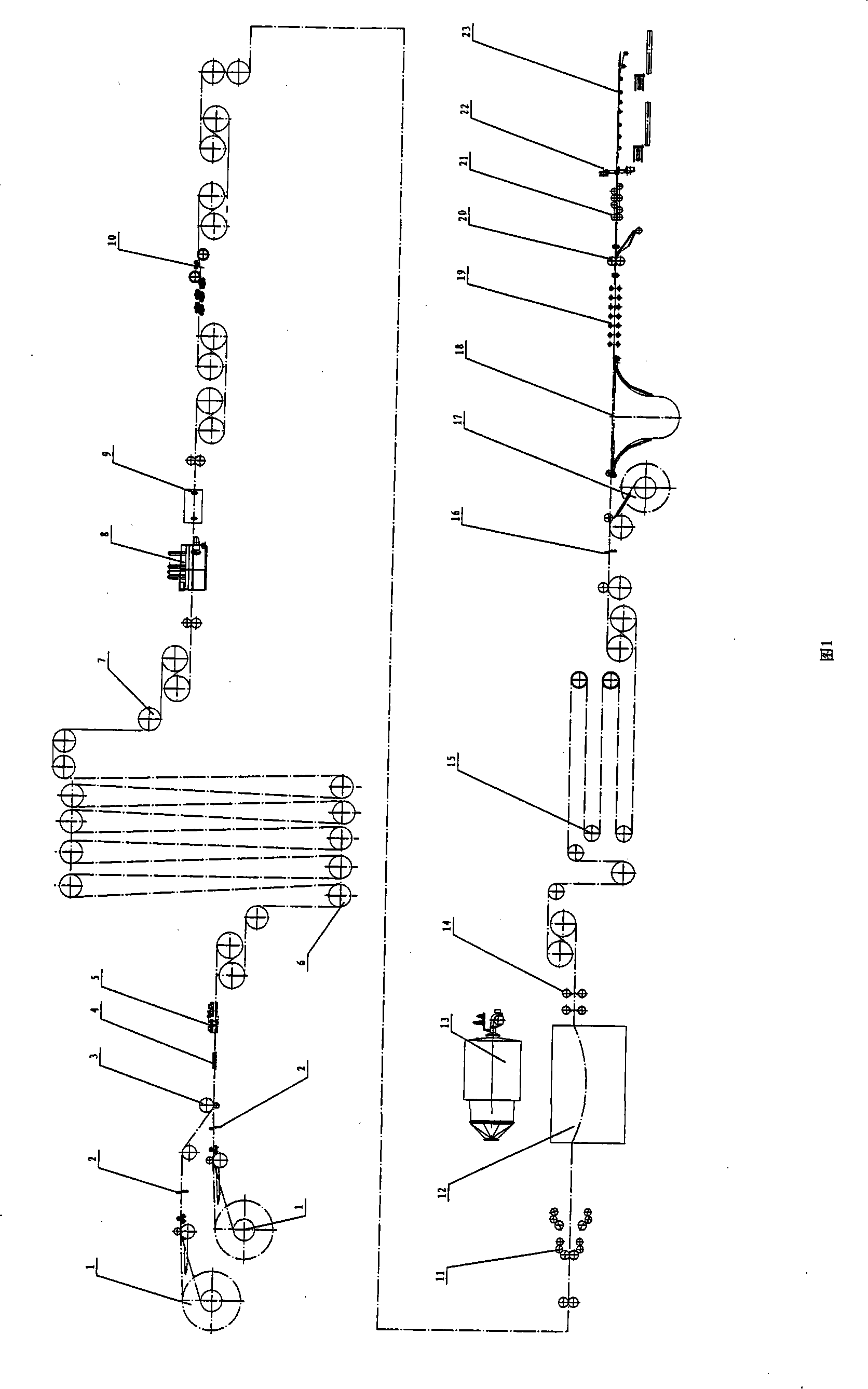

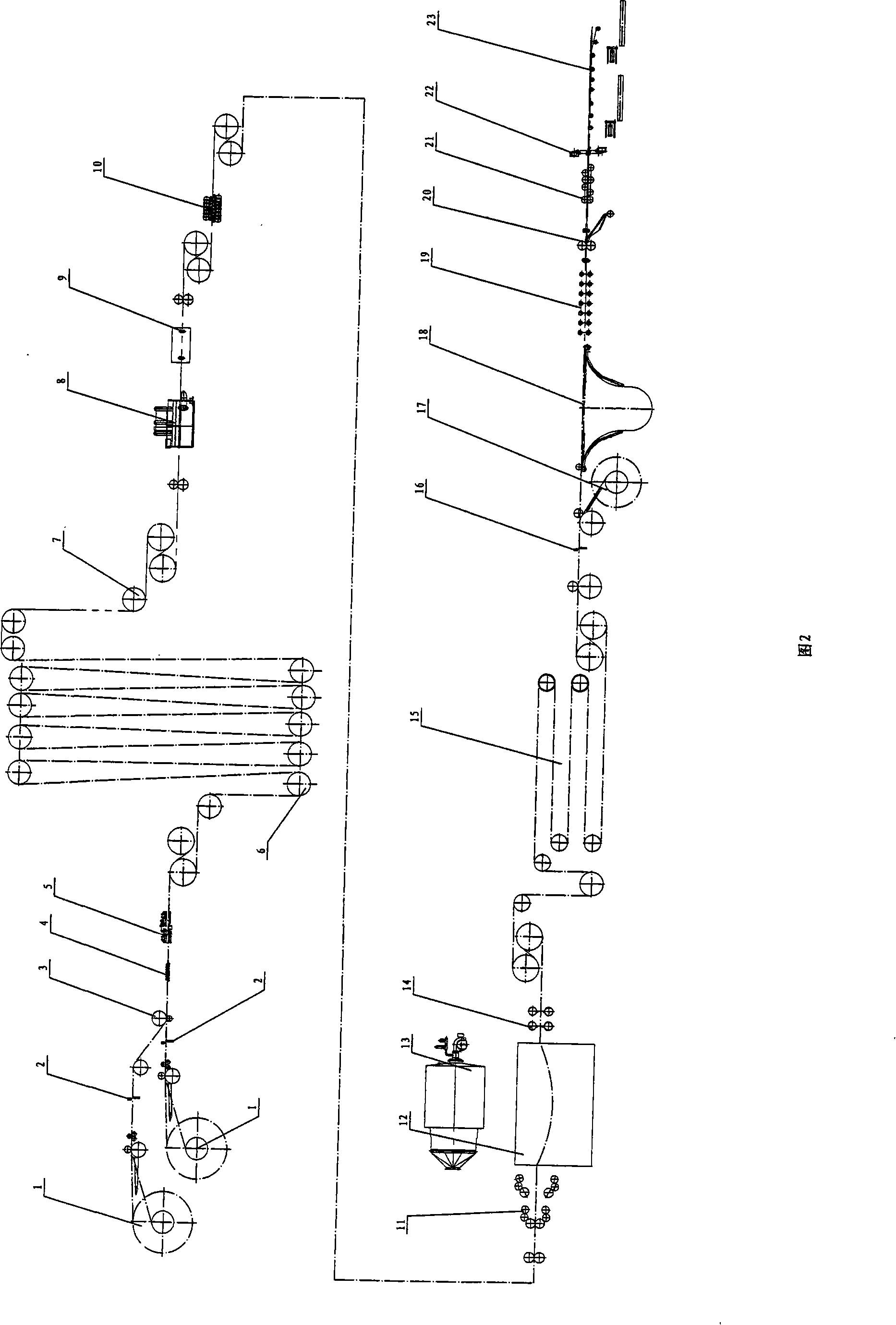

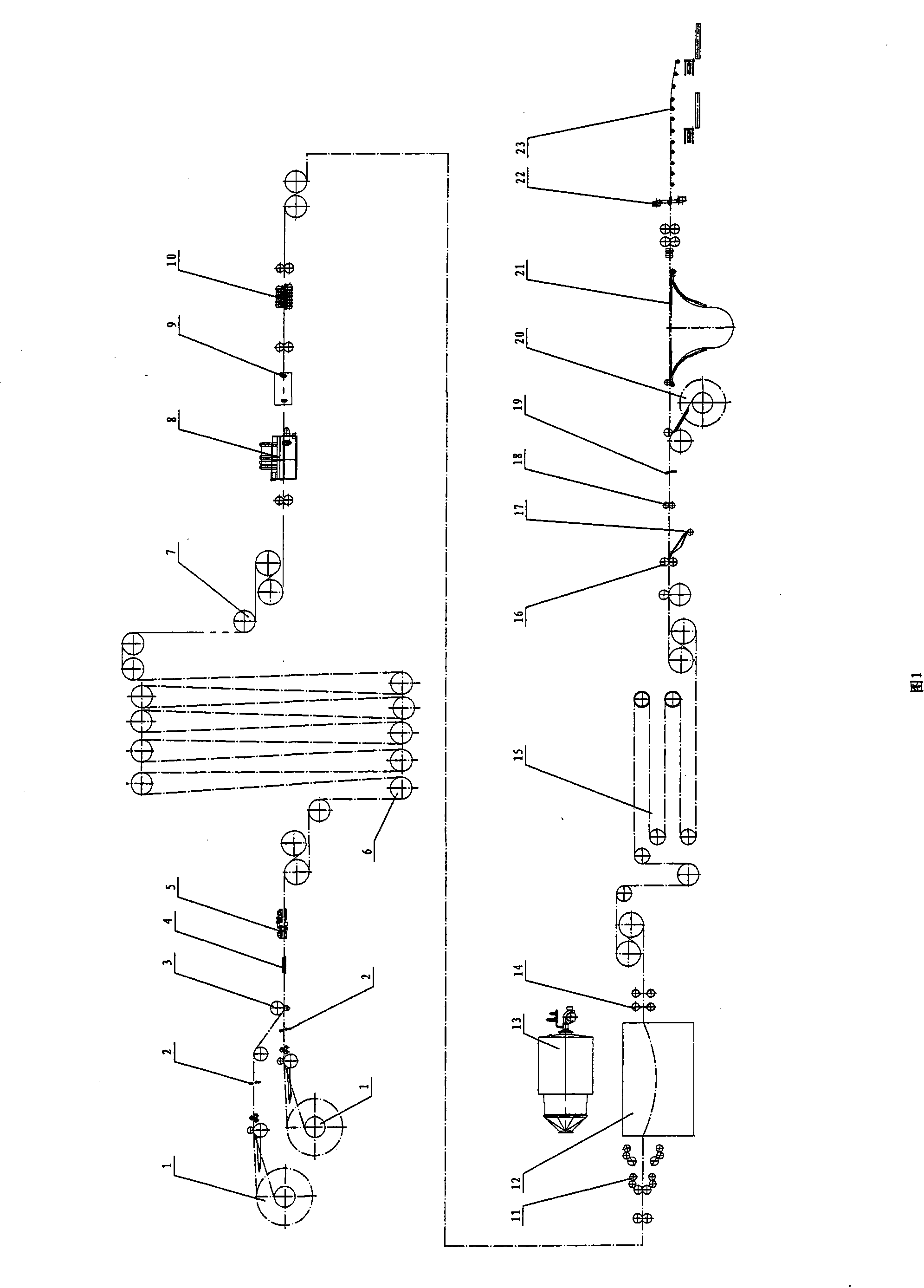

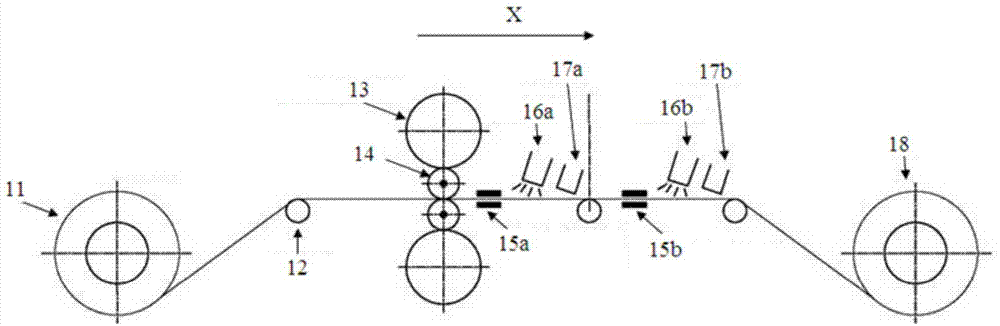

Method and equipment for hot rolled plate colored forming continuous production

ActiveCN101249606AIncrease productivityReduce wastePretreated surfacesSheets/panelsSheet steelSteel belt

The invention provides a method for the continuous production of the color-coated forming of hot-rolled plates and a device thereof. The method is characterized in that all processes are continuously completed on line. The method comprises the following steps: the head and tail of a hot-rolled steel band are welded together; the steel band enters a pickling tank to remove the oxide of the steel band surface and then the steel band enters a hot air drying segment to remove the moisture of the steel band surface; the steel band enters a roll coater 11 to coat the band surface, and then transmitted into a paint curing furnace 12 to cure and dry the band after coating, and the steel band with a certain temperature is blown by cold wind 14 to reduce the temperature of the steel band; the steel band enters the roller forming stage, so the steel band is transmitted into the roller 19 to carry out the roller forming; the steel band is allowed to has a certain waveform; the waveform steel band after the roller forming is transmitted into a flying shear 22 for definite distance cutting, in order to cut the steel plate according to the requirement; finally, the steel band is transmitted into a dual stacking to perform the stacking according to the height. The method improves the efficiency of production and saves the cost.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

Method for continuous producing rust-inhibiting primer coating steel plate

ActiveCN101249605AIncrease productivityReduce wastePretreated surfacesSheets/panelsCircular discSheet steel

The invention provides a method for continuously producing rust-proof primer coated steel plate applied to the coating production field in the metallurgical industry. The method is characterized in that the defect of discontinuous former production is overcome and all processes are continuously completed on line. The method comprises the following steps: the head and tail of a hot-rolled steel band are welded together; the steel band enters a pickling tank to remove the oxide of the surface, and enters a hot air drying segment to remove the moisture of the surface; the steel band enters a roll coater 11 to coat the surface of the steel band and is then transmitted to a paint curing furnace 12 to cure and dry the band; the steel band with a certain temperature is blown by cold wind 14 to reduce the temperature; the steel band enters a horizontal type loop 15, is corrected an error through a loop 21, and then enters a flying shear 22 for definite distance cutting in order to be cut into the required plate according to the requirement; and then the steel band enters a dual stacking 23 to be stacked into a sheet bar with the defined height. When coiled materials are required, the steel band is longitudinally sheared into strip by a disc shear, then is coiled separately by a dividing shear, and enters a rolling machine 20 to form a coiled steel band.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

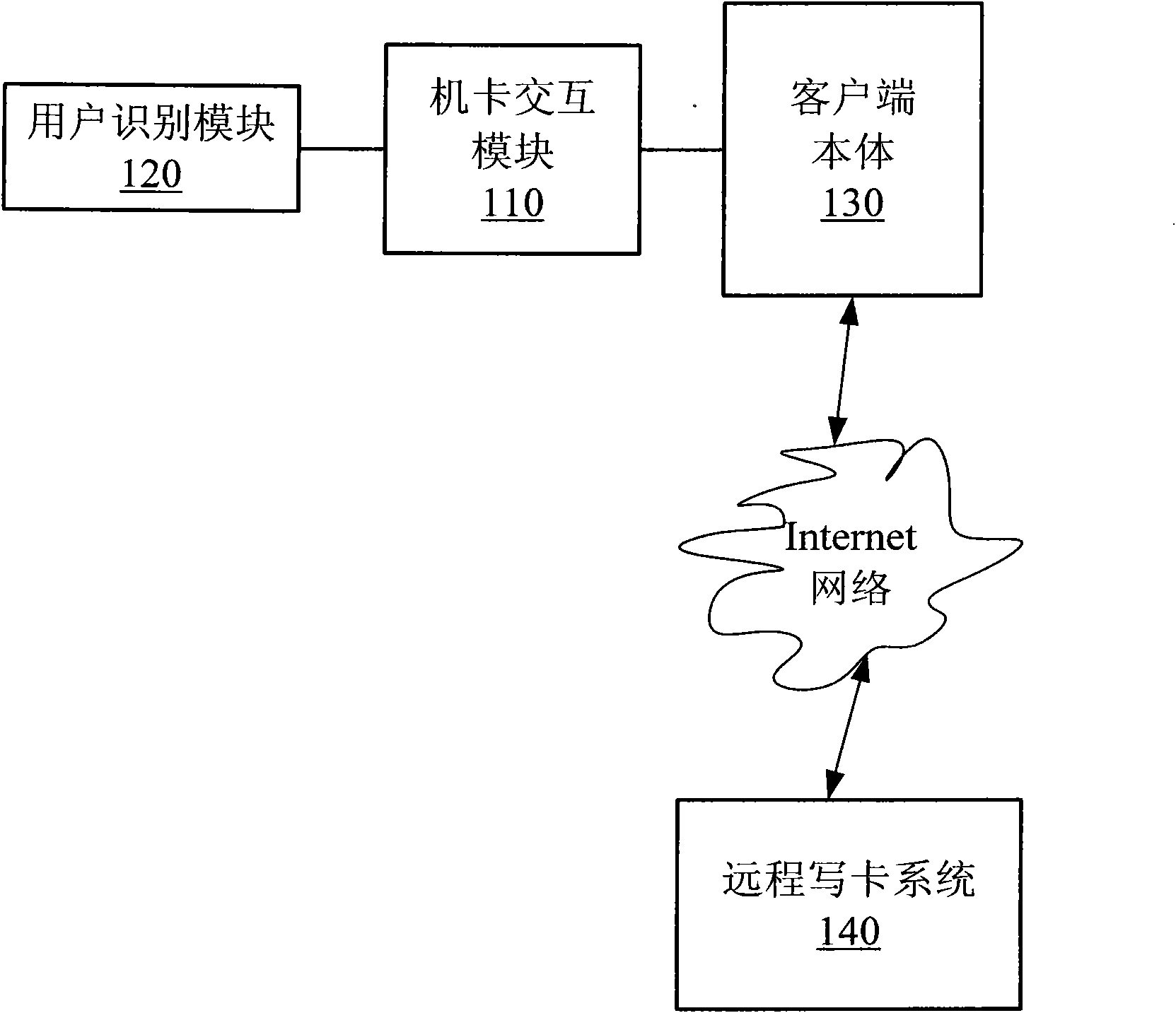

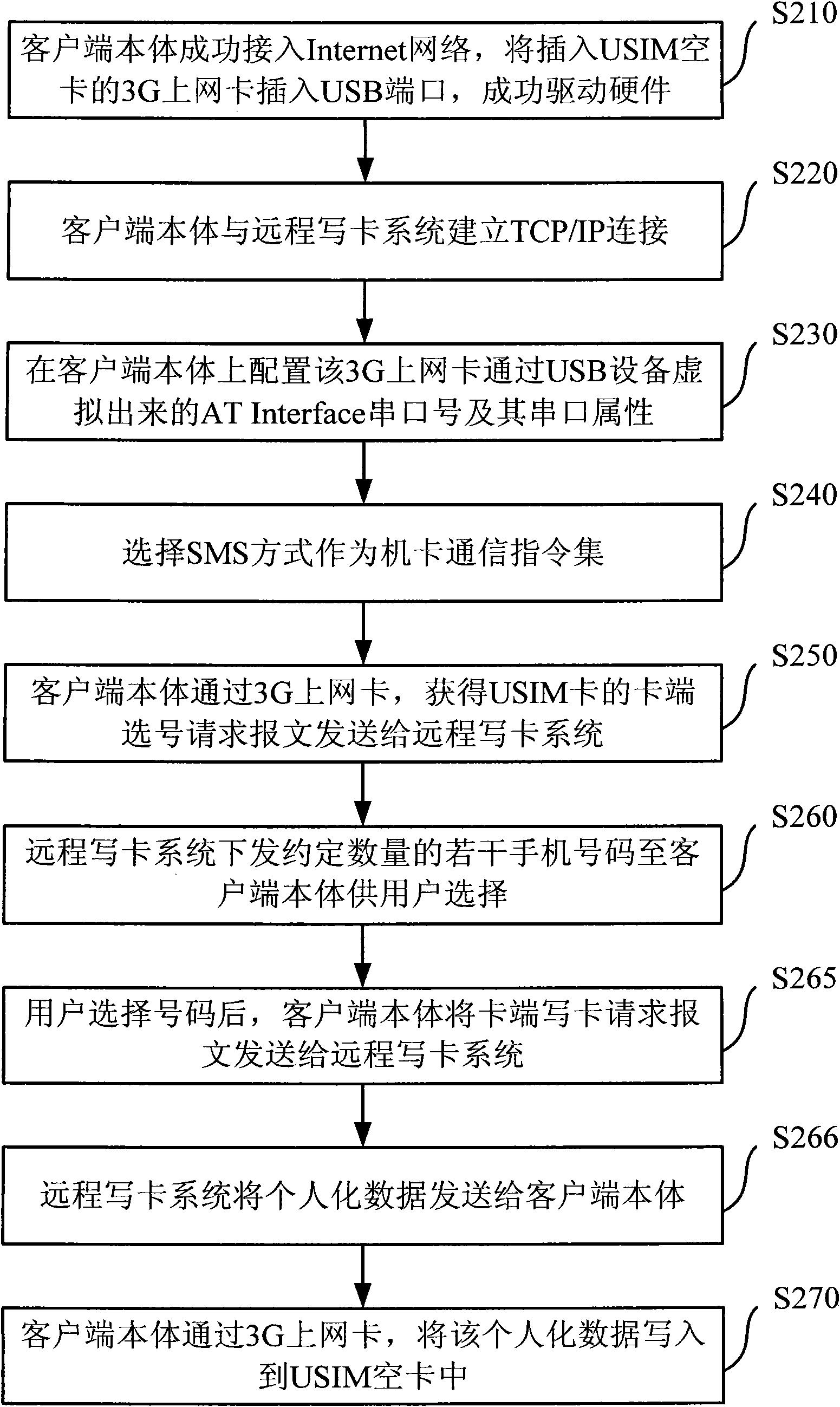

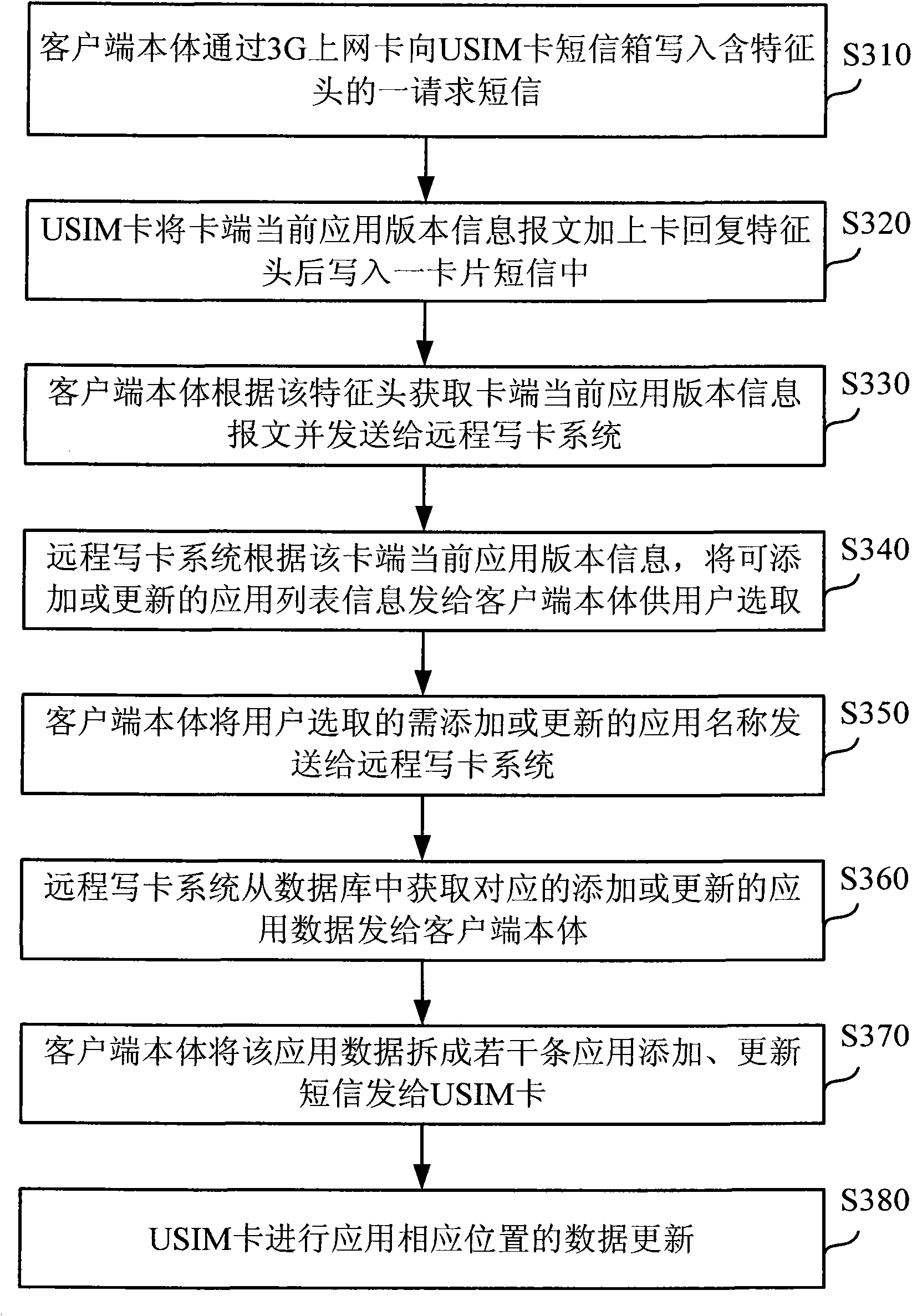

Terminal for registering and opening of user recognition module and/or data writing

ActiveCN101568098ASave card opening costFast processNetwork data managementSide informationClient-side

The invention discloses a terminal for registering and opening of a user recognition module and / or data writing, which is used for registering and opening the user recognition module and / or writing of personalized data and the like. The terminal comprises a computer-card interactive module which is connected with the user recognition module and a client body used for selecting a communication instruction set between the computer-card interactive module and the user recognition module; a card side information message of the user recognition module is obtained by the computer-card interactive module and then is sent to a remote card-writing system; the registering and opening result and / or writing data is sent by the remote card-writing system for completing the registering and opening of the user recognition module and / or determining the writing data according to the card side information message; and the registering and opening result is displayed and / or the writing data is written into the user recognition module, and the writing result is displayed or sent to the remote card-writing system. The invention realizes fast handling of service for opening a card, reduces the middle sections for opening a card and improves working efficiency.

Owner:DATANG MICROELECTRONICS TECH CO LTD

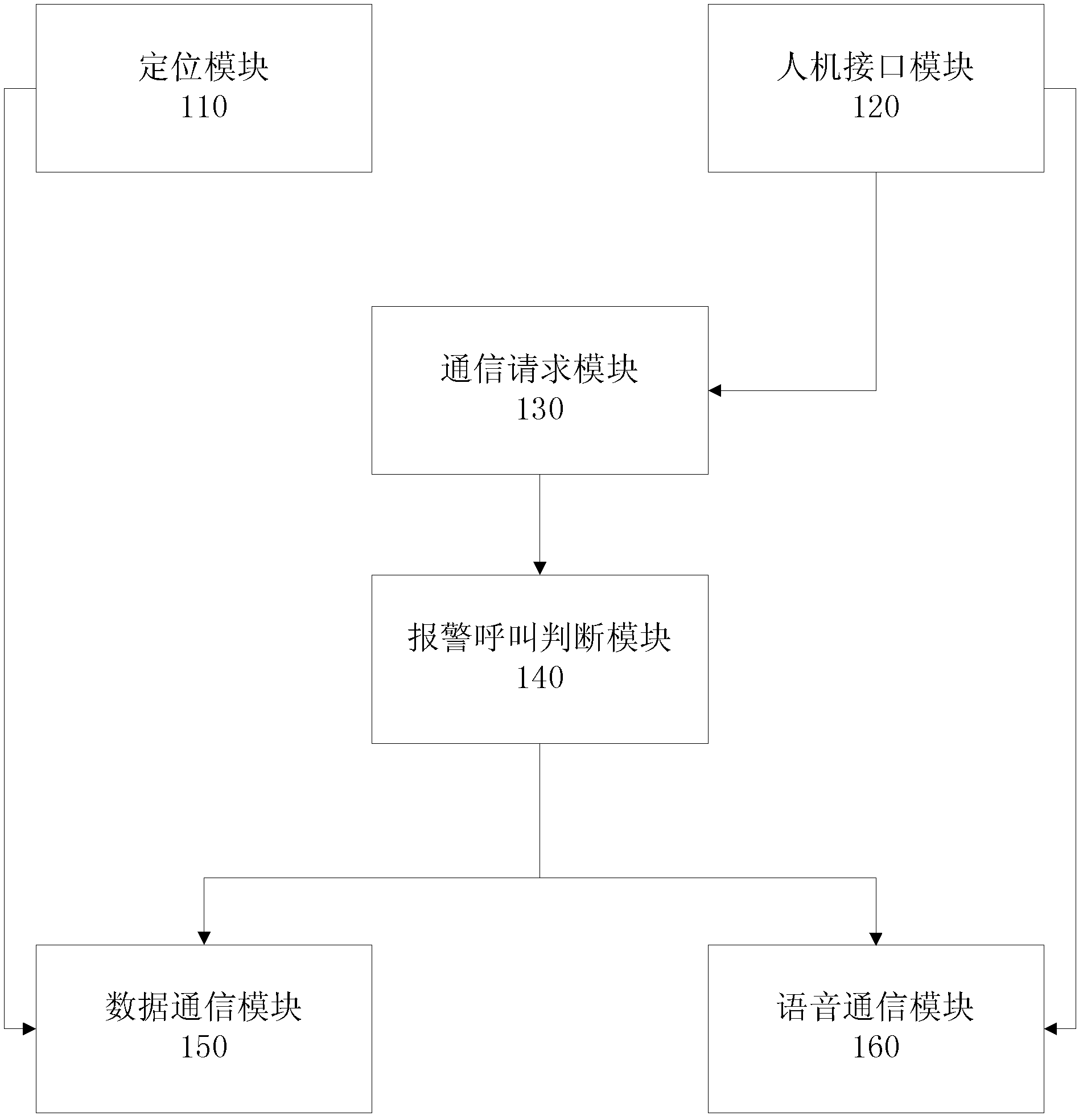

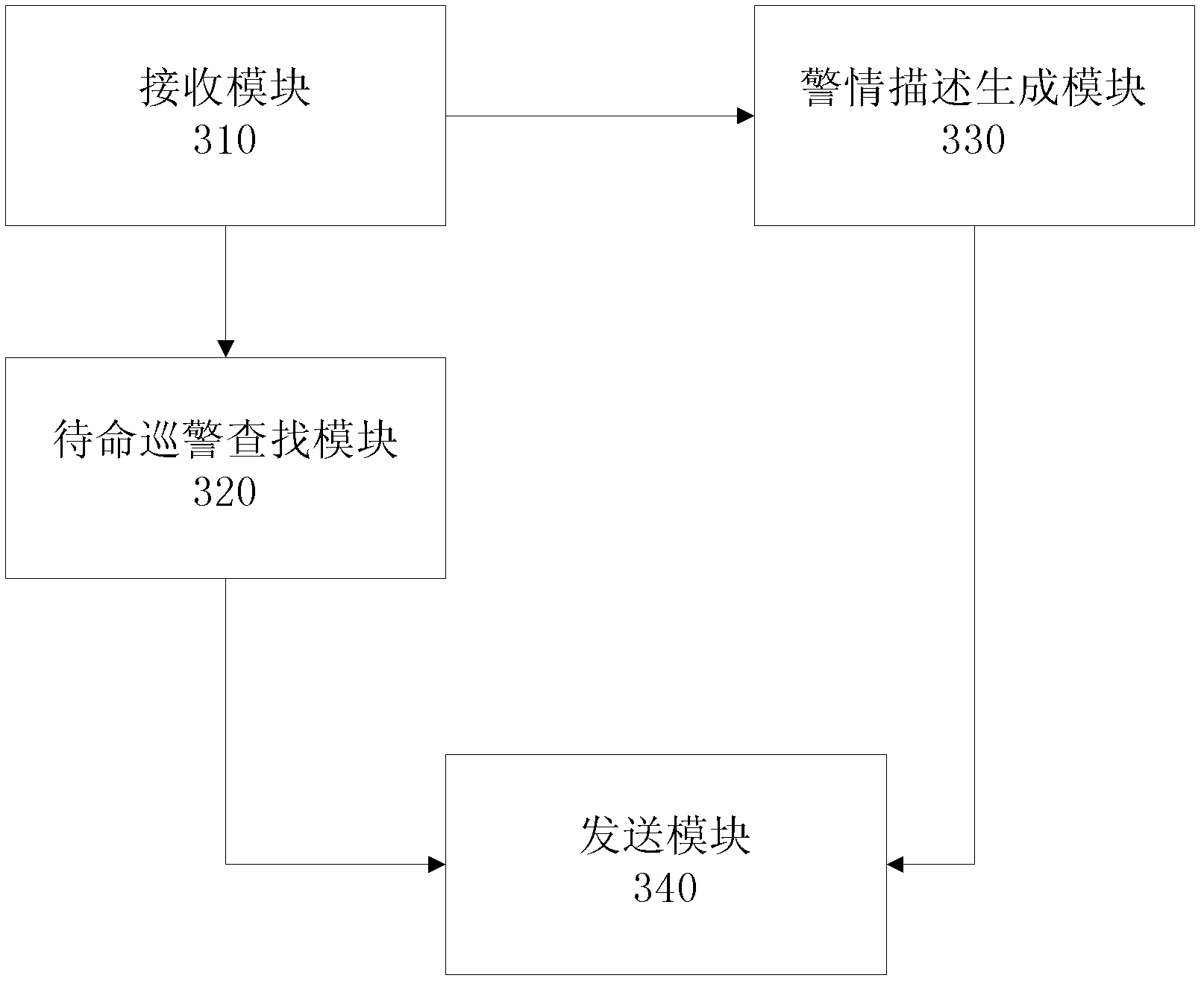

Communication method, communication system, communication terminal and position service platform for receiving and handling alarms

InactiveCN103002399AShorten the timeSave resourcesSatellite radio beaconingLocation information based serviceCommunications systemVoice communication

The invention discloses a communication method, a communication system, a communication terminal and a position service platform for receiving and handling alarms. The communication method includes that S1, the alarm communication terminal receives a call request, corresponding communication connection is established, whether the call request is an alarm call or not is judged, and a step S2 is executed if the call request is the alarm call; S2, the alarm communication terminal generates alarm reporter current position information, the alarm reporter current position information is transmitted in a data communication mode, and voice communication signals are transmitted in a voice communication mode; S3, the police position service platform searches standby policemen in a police geographic information system, and the standby policemen are closest to an alarm reporter; S4, the police position service platform generates alarm situation description information according to the voice communication signals, and the alarm situation description information and the alarm reporter current position information are directly transmitted to the police communication terminal of the standby policemen closest to the alarm reporter; and S5, the police communication terminal performs navigation according to a navigation path. The communication method, the communication system, the communication terminal and the position service platform have the advantage that the policemen can quickly and accurately rush to the position of the alarm reporter to handle an alarm situation.

Owner:SHENZHEN SEG SCI NAVIGATIONS CO LTD

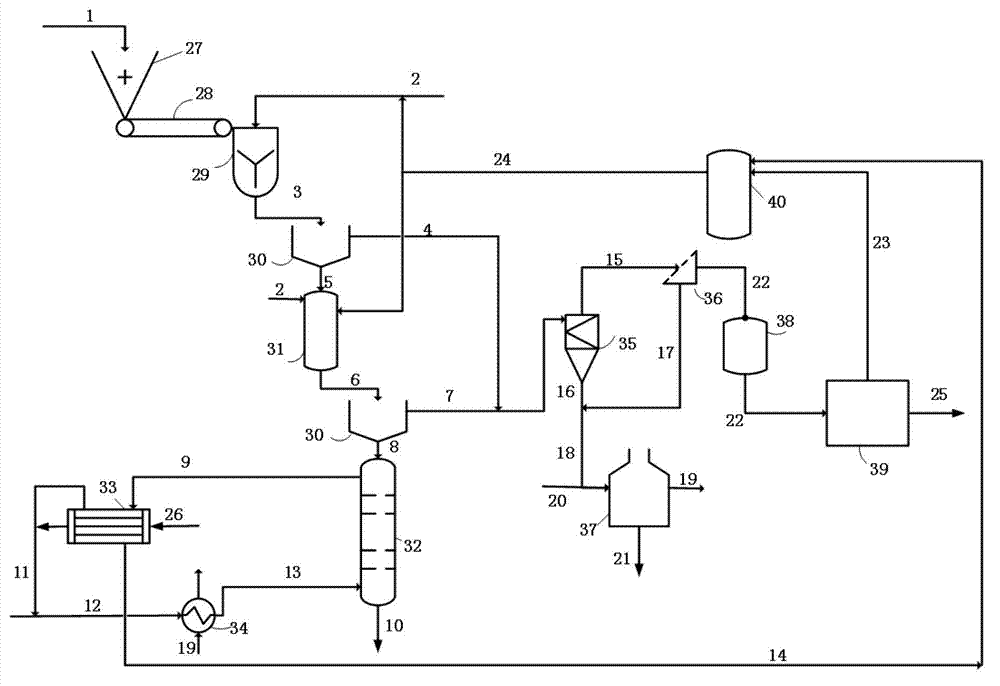

Method and device for separating oil and sand

ActiveCN102925190ALow costReduce intermediate linksLiquid hydrocarbon mixture productionSolventSolid phases

The invention relates to a method and device for separating oil and sands. The device comprises a smashing machine, a material conveying machine, a stirring tank, a secondary extraction tank, a mechanical clarifying tank, a fluidized drying tower, a condenser, a pre-heater, a cyclone hydraulic separator, a filter, an incinerator, a storage tank, a refining unit and a machine pump. The top of the stirring tank and the top of the secondary extraction tank are provided with stirring devices. The fluidized drying tower is provided with a circulating channel and a dedusting system. The incinerator is provided with a dedusting system. The top of a fractionation tower is provided with the condenser, and the bottom of the tower is provided with a reboiler. The oil and the sands are subjected to two-stage extraction, solid-phase residual sands are discharged outside by adopting a fluidized drying desorption solvent, and fluidized gas and the solvent are respectively cycled. Suspending particles in a liquid-phase mixture separated from the extraction tank are removed through the cyclone hydraulic separator and the filter, micro-particles are treated by means of a method for obtaining heat by burning mixed power coal and the like, energy sources are utilized comprehensively, and the environmental pollution is reduced. The recovery problem of solvent pitch in the residual sands after extraction is solved.

Owner:TIANJIN UNIV

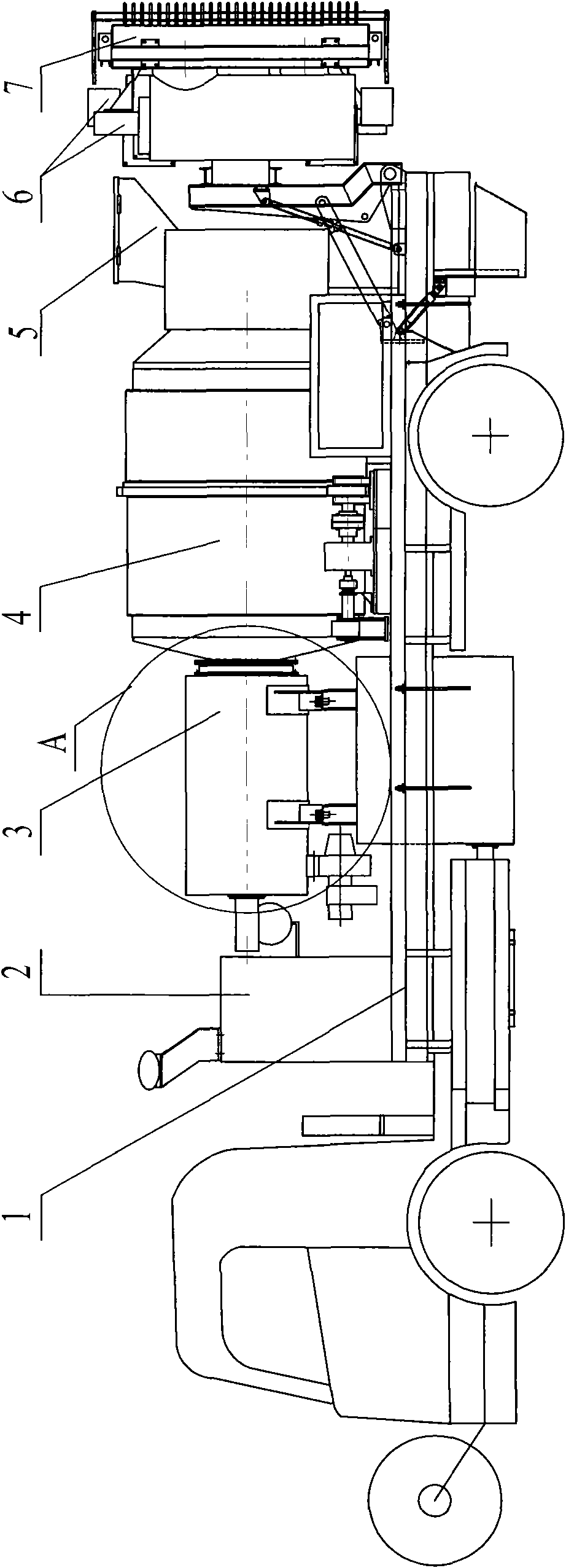

Heated air circulation type regeneration repairing vehicle

InactiveCN101775773AReduce intermediate linksSimple structureRoads maintainenceCombustionControl system

The invention relates to an asphalt pavement thermal regeneration repairing device, in particular to a heated air type asphalt pavement thermal regeneration repairing vehicle, which comprises an automobile chassis, a diesel oil tank, an air heating furnace, an asphalt concrete heating regenerative device, a feeding device, an asphalt pavement heating wall and a control system, wherein the asphalt concrete heating regenerative device is in sealed connection with an air outlet on an end face of the furnace body of the air heating furnace; the air outlet of the air heating furnace is connected with an asphalt concrete heating heated air injector; the asphalt pavement heating wall consists of a heating wall cover, and a left asphalt pavement heating cabinet and a right asphalt pavement heating cabinet arranged in the heating wall cover; the heating wall cover is provided with two heating wall air heating furnaces which are connected with the left and right asphalt pavement heating cabinets respectively; the left and right asphalt pavement heating cabinets are provided with a heating cabinet heated air injector respectively; and combustion controllers on all the air heating furnaces are connected with the control system, and diesel oil pipelines are connected with the diesel oil tank. The heated air type asphalt pavement thermal regeneration repairing vehicle has the advantages of energy conservation, quick heating and high working efficiency.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

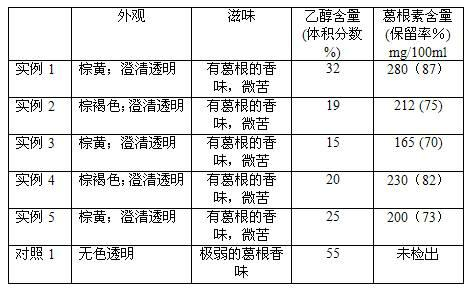

Preparation method of Radix Puerariae wine and product of Radix Puerariae wine

InactiveCN102604782AGood colorHigh clarityMicroorganism based processesAlcoholic beverage preparationAmylaseCoronary heart disease

The invention discloses a preparation method of Radix Puerariae wine. The preparation method comprises the following steps: collecting fresh Radix Puerariae, cleaning, cutting into pieces, adding water, and performing homogenate to obtain a Radix Puerariae homogenate liquid; sterilizing the Radix Puerariae homogenate liquid at 70-110 DEG C for 5-120 minutes, cooling to 50-65 DEG C, and regulatingthe pH value to 5-7 to obtain a sterilized solution; adding amylase into the sterilized solution until the mass percentage of the amylase is 0.01-5, performing enzymolysis at 50-90 DEG C for 0.5-24 hours, adding glucoamylase until the mass percentage of the glucoamylase is 0.01-5, and performing enzymolysis at 50-70 DEG C for 4-12 hours; then increasing the temperature to 70-110 DEG C, holding the temperature for 20-150 minutes, and cooling to 20-60 DEG C to obtain an enzymolysis solution; and finally adding saccharomyces cerevisiae into the enzymolysis solution until the mass percentage of the saccharomyces cerevisiae is 0.01-0.05, fermenting at 24-40 DEG C for 5-10 days, and filtering to obtain the Radix Puerariae wine. The preparation method is simple; and the prepared Radix Puerariae wine is high in Puerarin content and has an alcohol degree of 15-35, and can be applied to adjuvant therapy for diseases such as hypertension, angina pectoris, coronary heart disease, hyperlipidemia and the like.

Owner:SOUTHWEST UNIVERSITY

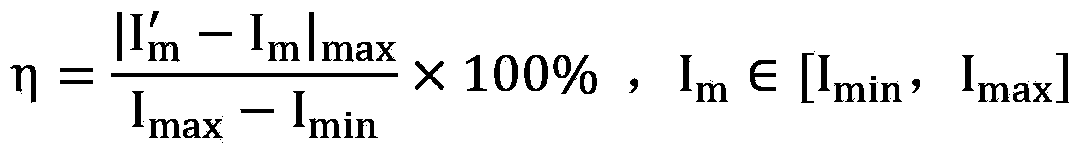

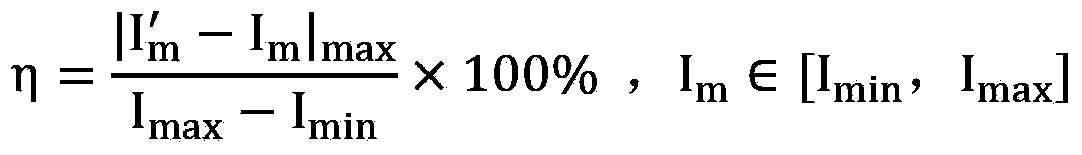

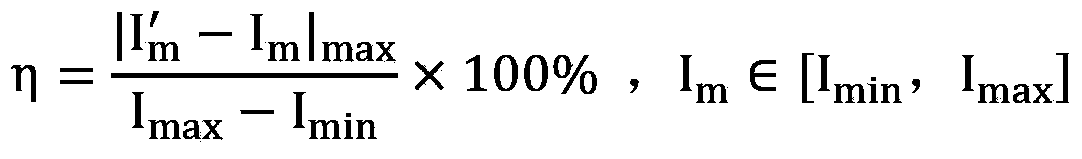

CCD camera nonlinearity degree calibration method based on structured light three-dimensional measurement system

InactiveCN103413309AIncrease the number ofSmall gray gradientImage analysisUsing optical meansThree dimensional measurementCalibration result

The invention provides a CCD camera nonlinearity degree calibration method based on a structured light three-dimensional measurement system. The method comprises the steps that according to the measurement processes of the structured light three-dimensional measurement system, on the basis that a series of standard images which are projected by a projector and accord with linear distribution are collected, a standard image gray scale-camera collected image gray scale distribution curve is drawn after certain data processing so as to further calculate the nonlinearity degree of a CCD camera; because gray scale gradient is small when the standard images are grouped, and the number of images collected by the CCD camera is large, random errors are reduced, and nonlinearity degree measurement precision is improved; the CCD camera nonlinearity degree calibration method based on the structured light three-dimensional measurement system accords with conditions of the structured light three-dimensional measurement system, and is simple in calibration process, less in middle link, and accurate in nonlinearity degree calibration result.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

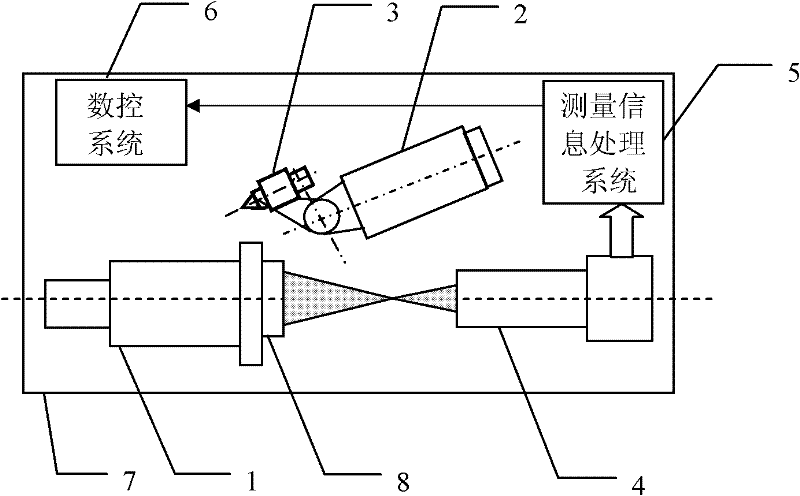

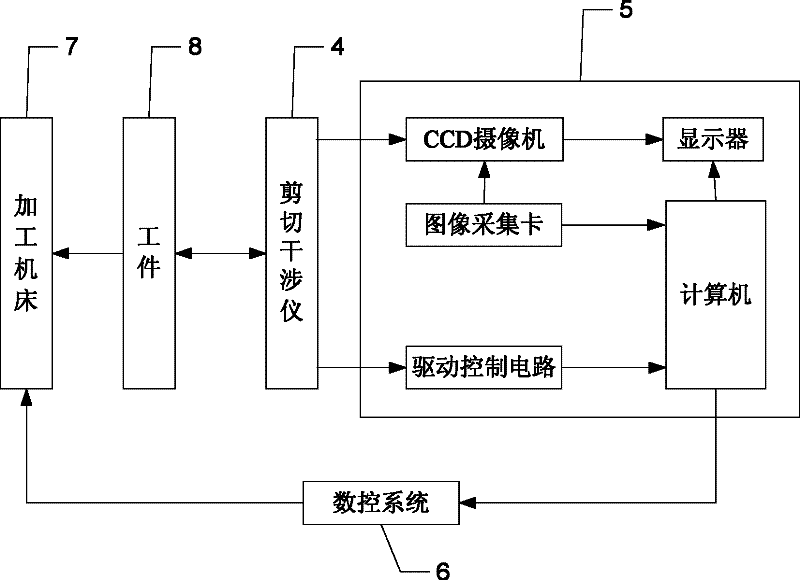

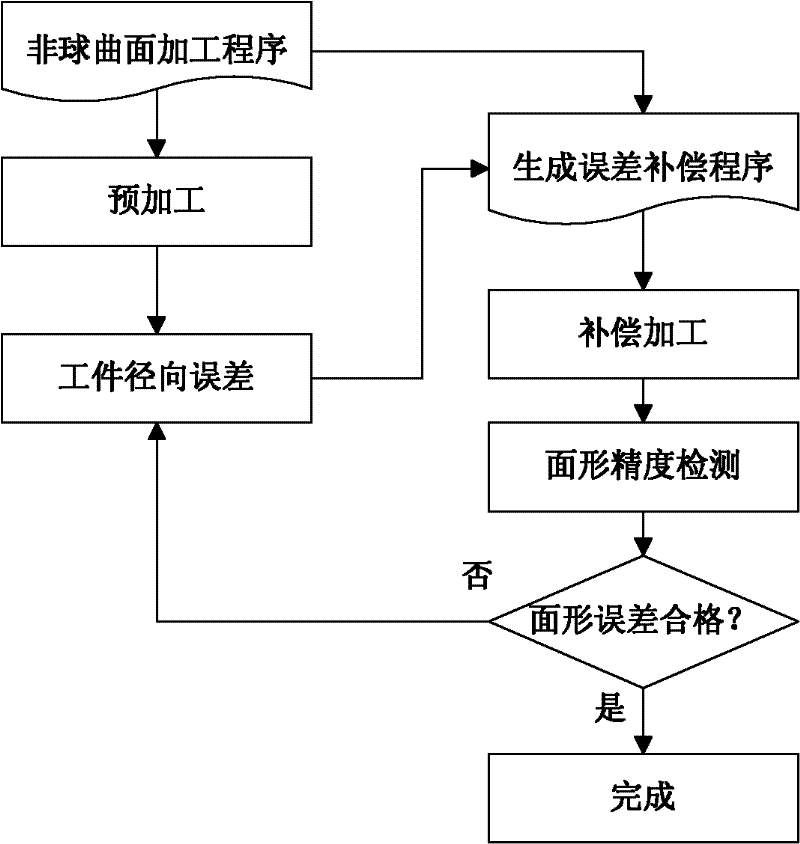

Device and method for integrally machining and measuring optical parts

ActiveCN102303224AReduce intermediate linksRealize feedback compensation machiningMeasurement/indication equipmentsNumerical controlInformation processingOptical axis

The invention relates to a device and method for integrally machining and measuring optical parts, belonging to the field of optical part machining. The invention aims at solving the problems that: an off-line measuring manner is mostly adopted in the traditional optical part machining, thus the machining efficiency is low; and the traditional optical part machining equipment cannot satisfy with the requirement of online measuring. According to the invention, a workpiece main shaft, a cutting tool main shaft and a shearing interferometer are mounted on a worktable surface of a machining machine; a workpiece is mounted on the workpiece main shaft; a cutting tool is mounted on the cutting tool main shaft through an oscillating arm and a tool carrier; a numerical control system is used for driving the cutting tool main shaft to rotate and driving the cutting tool to machine the workpiece; the optical axis of a measuring light beam which is emitted by the shearing interferometer and the central line of the workpiece main shaft are the same straight line; the shearing interferometer is used for emitting the measuring light beam to the workpiece; the shearing interferometer is used for acquiring image information which is returned by the measuring light beam and is used for sending the image information to a measured information processing system; the measured information processingsystem is used for acquiring surface error information of the surface of the workpiece according to the image information and is used for sending the information to the numerical control system; and the numerical control system is used for carrying out compensation machining on the workpiece.

Owner:HARBIN INST OF TECH

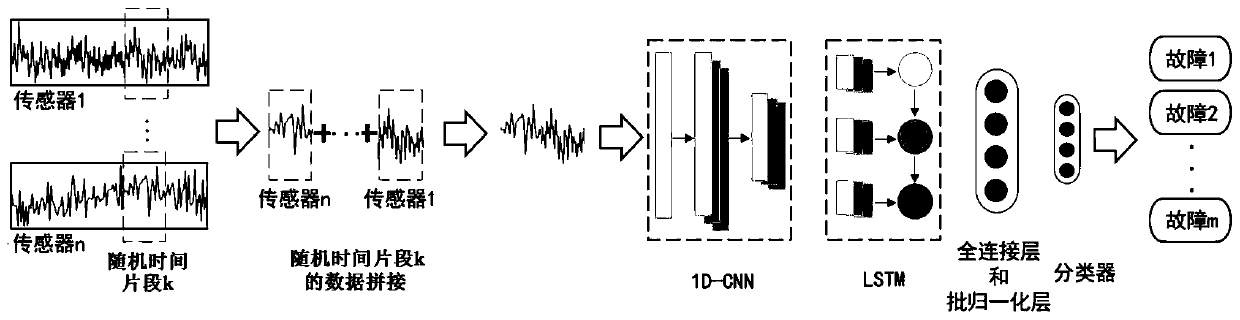

Fault diagnosis method, device and equipment for industrial system and storage medium

PendingCN111340238ASolving Difficult-to-Model ProblemsImprove accuracyMachine bearings testingElectrical testingIndustrial systemsOriginal data

The invention discloses a fault diagnosis method, device and equipment for an industrial system and a storage medium. The method comprises the following steps: obtaining historical original sequencesoutput by a plurality of sensors preset in an industrial system and corresponding industrial system fault types; splicing the data of different sensors in the same time slice in sequence, and normalizing the reconstructed sequence obtained by splicing to obtain a preprocessing sequence corresponding to the time slice as a training sample; training a deep learning model by using all the training samples to obtain an industrial system fault diagnosis model; and obtaining a diagnosis sample from the original sequence obtained in real time according to the same obtaining method as the training sample, and carrying out online diagnosis on the industrial system by using the industrial system fault diagnosis model and the diagnosis sample. The method has no requirements for the sampling rates ofdifferent sensors, can reserve most original data of the sensors, and improves the accuracy of fault diagnosis.

Owner:CENT SOUTH UNIV

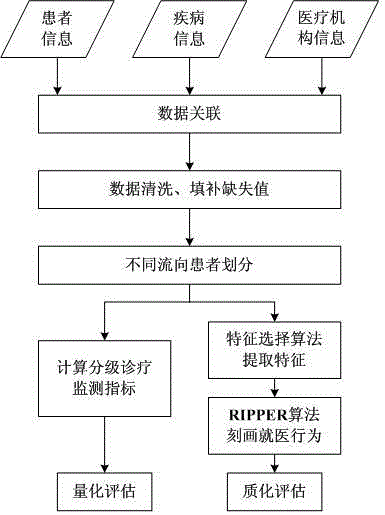

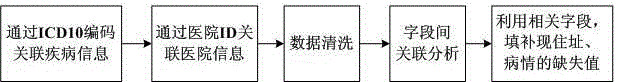

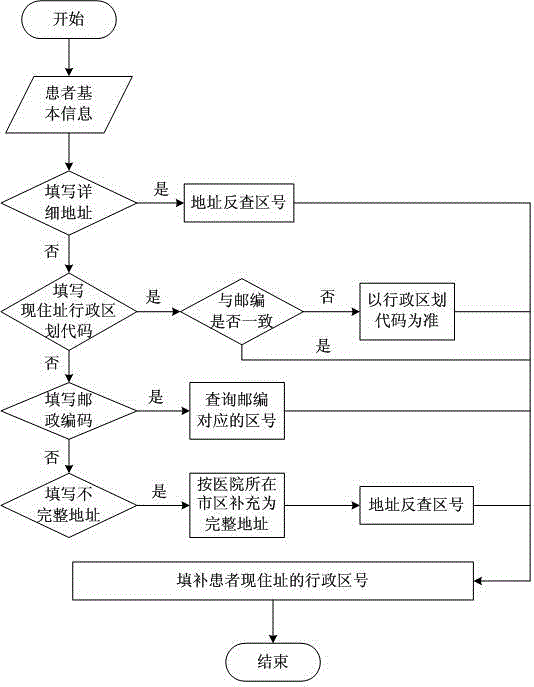

Graded diagnosis and treatment evaluating method based on data mining

ActiveCN105893766AIncrease the amount of effective dataSolve the problem that business data cannot be directly usedMedical data miningHealthcare resources and facilitiesMedical recordSorting algorithm

The invention discloses a graded diagnosis and treatment evaluating method based on data mining. The method comprises the steps: extracting essential information and diagnosis and treatment information on patients from medical records, associating the essential information and the diagnosis and treatment information with disease category information and medical institution information, and firstly, carrying out data cleaning and missing value filling so as to divide the patients into patients of different flow directions; then, calculating graded diagnosis and treatment monitoring indexes by using the data; portraying visiting behaviors and features of different patients by a GainRatioAttributeEva feature selection algorithm and a RIPPER sorting algorithm. According to the method, through evaluating graded diagnosis and treatment by qualitative indexes and quantified indexes, the defects in the current graded diagnosis and treatment evaluating methods that only the quantified indexes exist, the indexes are required to be reported layer upon layer, mis-reporting and confused reporting occur during reporting, and the tracking of reasons behind the indexes is absent are overcome; by using a data mining technology, graded diagnosis and treatment evaluation is more timely and accurate.

Owner:CHENGDU SHULIAN YIKANG TECH CO LTD

Louis iris tissue culture fast seedling establishment and ecological application method

InactiveCN101263787AReduce intermediate linksSeedlings grow fastHorticulture methodsPlant tissue cultureCallus formationBud

The invention relates to a tissue culture, rapid seedling formation and ecological application method for Louisiana iris, which comprises the following steps: 1) material selection: flowers, flower buds, floral axis, blades, roots and other vegetative organs of Louisiana iris are selected as explants; inoculation is carried out after routine disinfection; 2) bud induction and proliferation culture: the sterilized vegetative organs in 1) are inoculated on an induction medium; when callus has an area of 1 to 2 cm2, and forms a 0.5 to 0.8cm green convex block, the vegetative organs are transplanted in a differentiation medium; when the length of the vegetative organs reaches 5 to 8cm, the vegetative organs are transplanted in a rooting medium; 3) root induction: rootless seedlings with consistent growth are transplanted to a root induction medium; when the length of the rootless seedlings reaches 12 to 15cm, seedling adaptation is performed; 4) seedling adaptation: seedling adaptation is carried out for 6 to 8 days under natural light, then seedling emergence can be realized; culture medium at the root section of the seedlings is washed off; the seedlings are transplanted to a sterilized seedling container equipped with mixed substrate; after watering, shading and heat insulation, seedling emergence can be realized. The method has the advantages of fast seedling formation and good quality, and the seedlings can be directly applied to ecology.

Owner:吴月燕

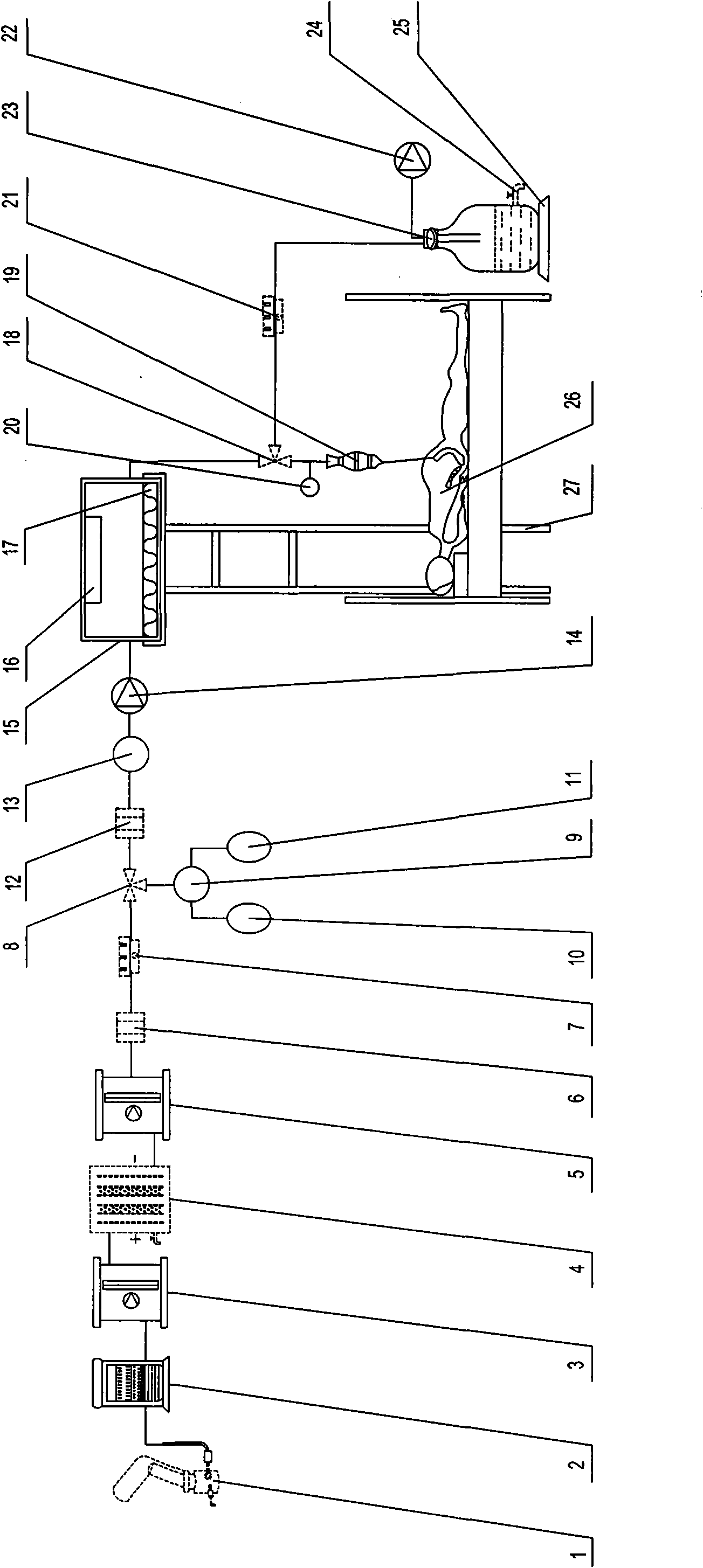

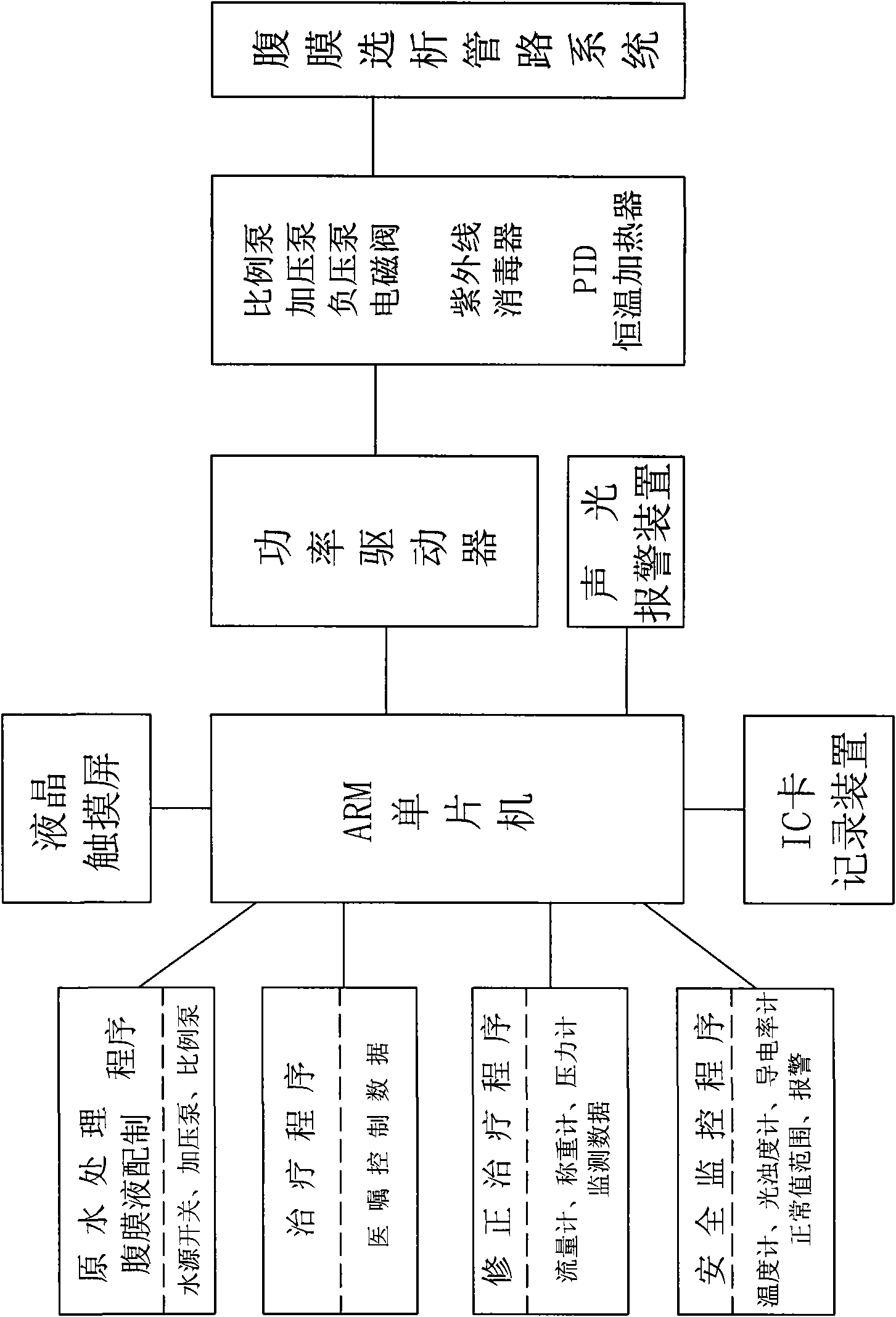

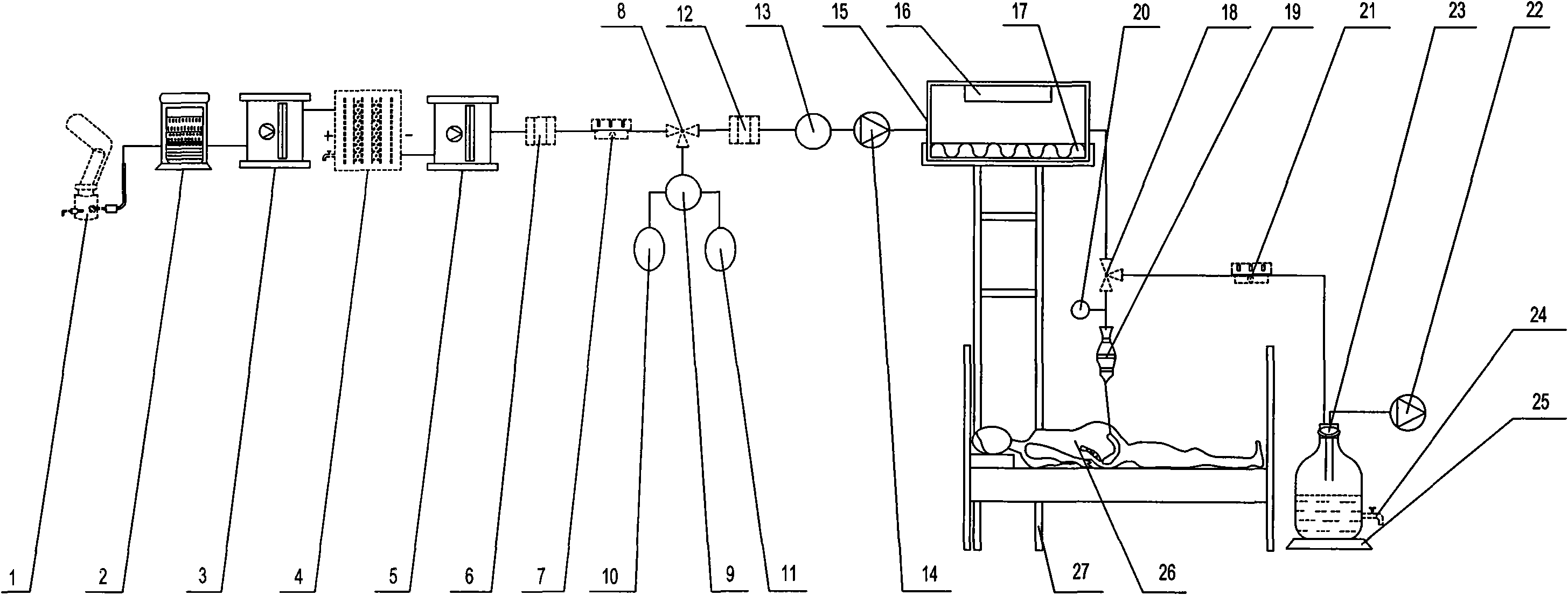

Simple automatic peritoneal dialysis equipment

InactiveCN101862481ARealize fully enclosed one-machine treatmentReduce the chance of infectionPeritoneal dialysisAutomatic controlPeritoneal membrane

The invention relates to medical equipment, in particular to simple automatic peritoneal dialysis equipment. The equipment comprises a raw water filter, an EDI electric deionizater and a raw water processing device composed of I and II class reverse osmosis units, a peritoneal dialysis liquid confecting device composed of a dual-cavity proportioning pump, a peritoneal dialysis liquid confecting three-way solenoid valve and a peritoneal dialysis liquid container, a peritoneal dialysis treating device composed of a peritoneal dialysis treating three-way solenoid valve, an abdominal cavity inner guide coupling, a waste liquid container and a negative pressure pump as well as an automatic control system composed of an ARM singlechip which carries out finishing and programming on the collected signal; wherein the signal input interface of the ARM singlechip is respectively connected with the raw water processing program module, a treating program module, a correction treating program module and a safe monitoring program module, and the signal output interface thereof is connected with a power driver which controls the external parts under the instruction of the ARM singlechip. The invention integrates water treatment, peritoneal dialysis liquid confecting and automatic peritoneal dialysis treatment, totally closed type one machine treatment is realized, and treating expense can be greatly reduced.

Owner:董大泉

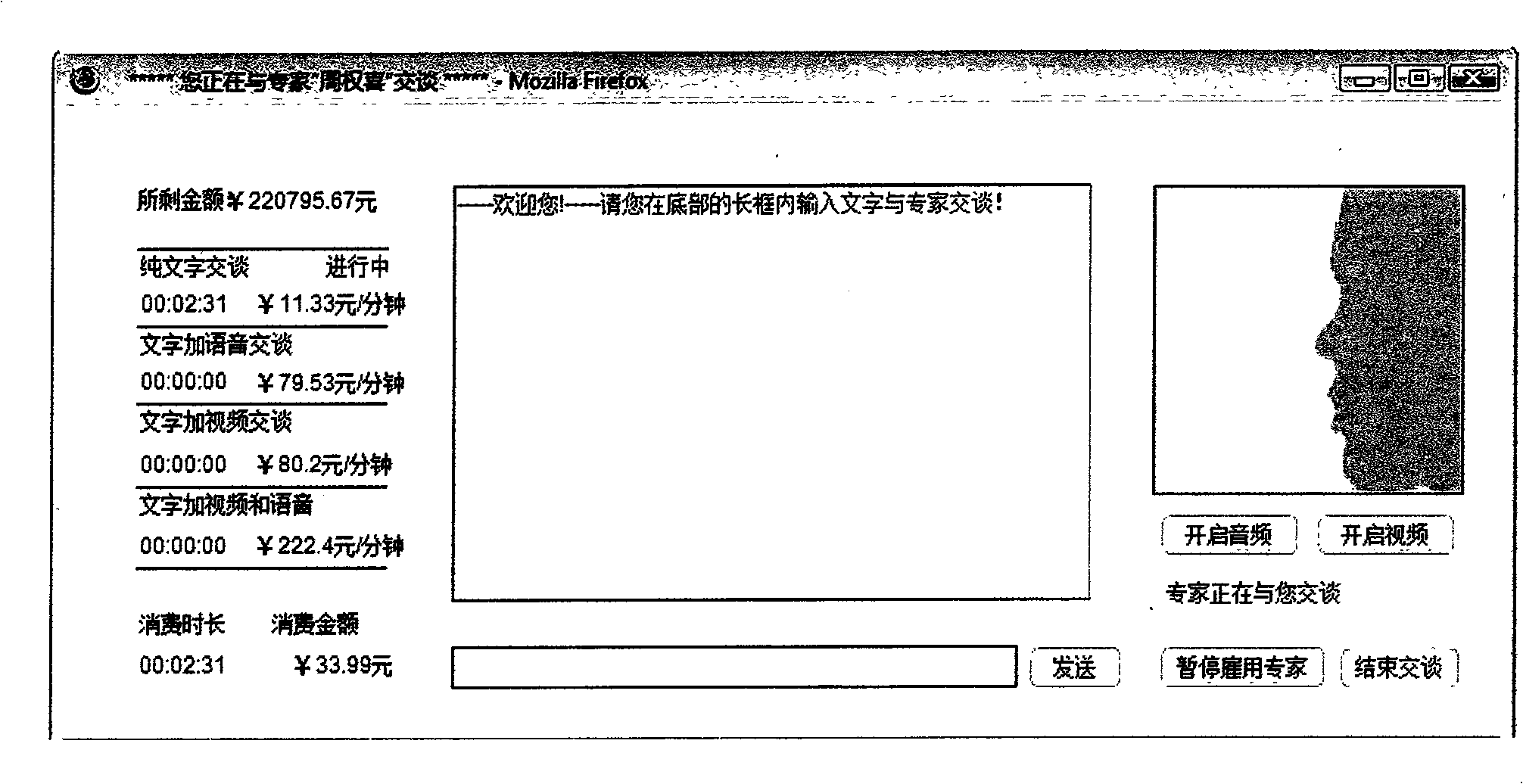

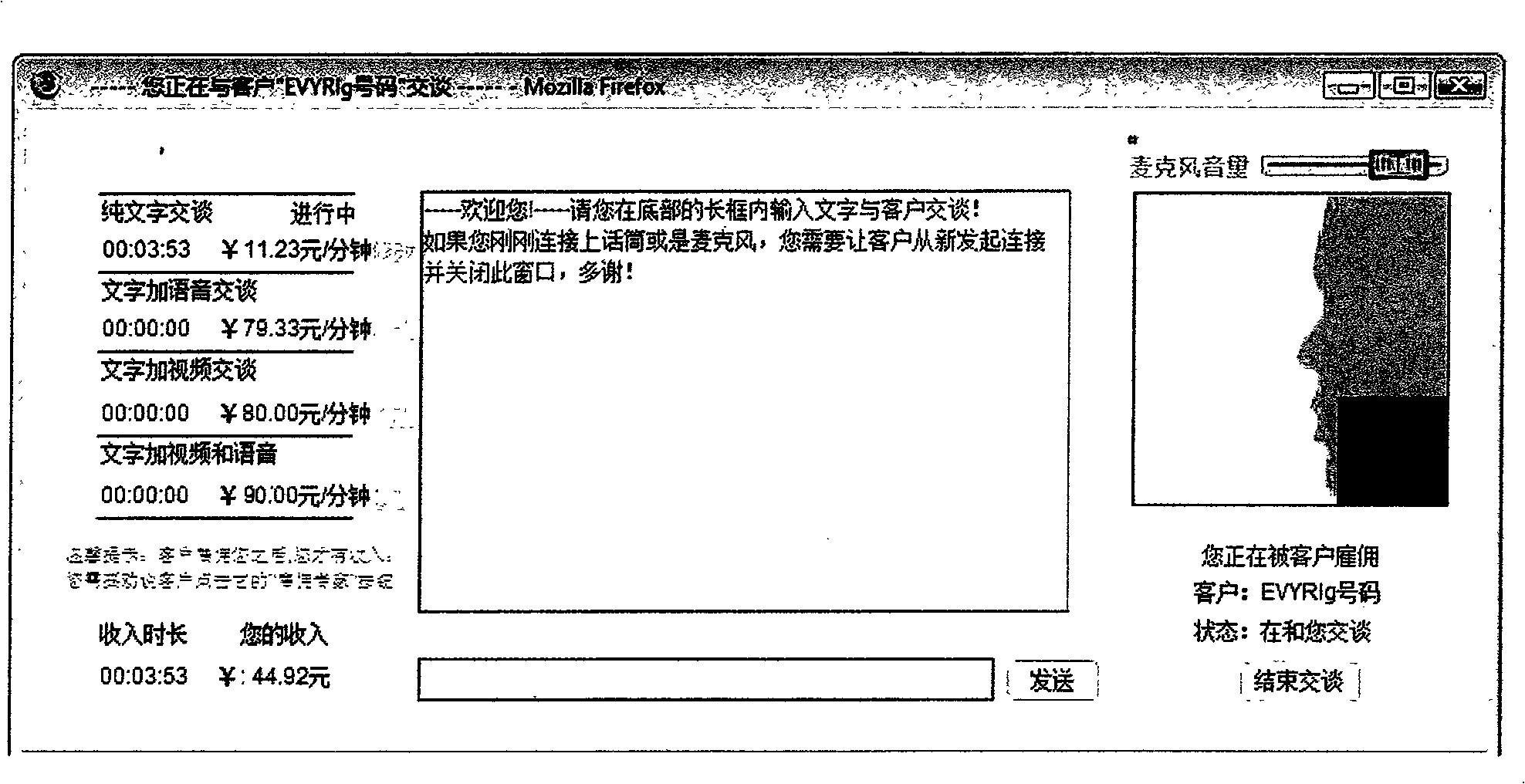

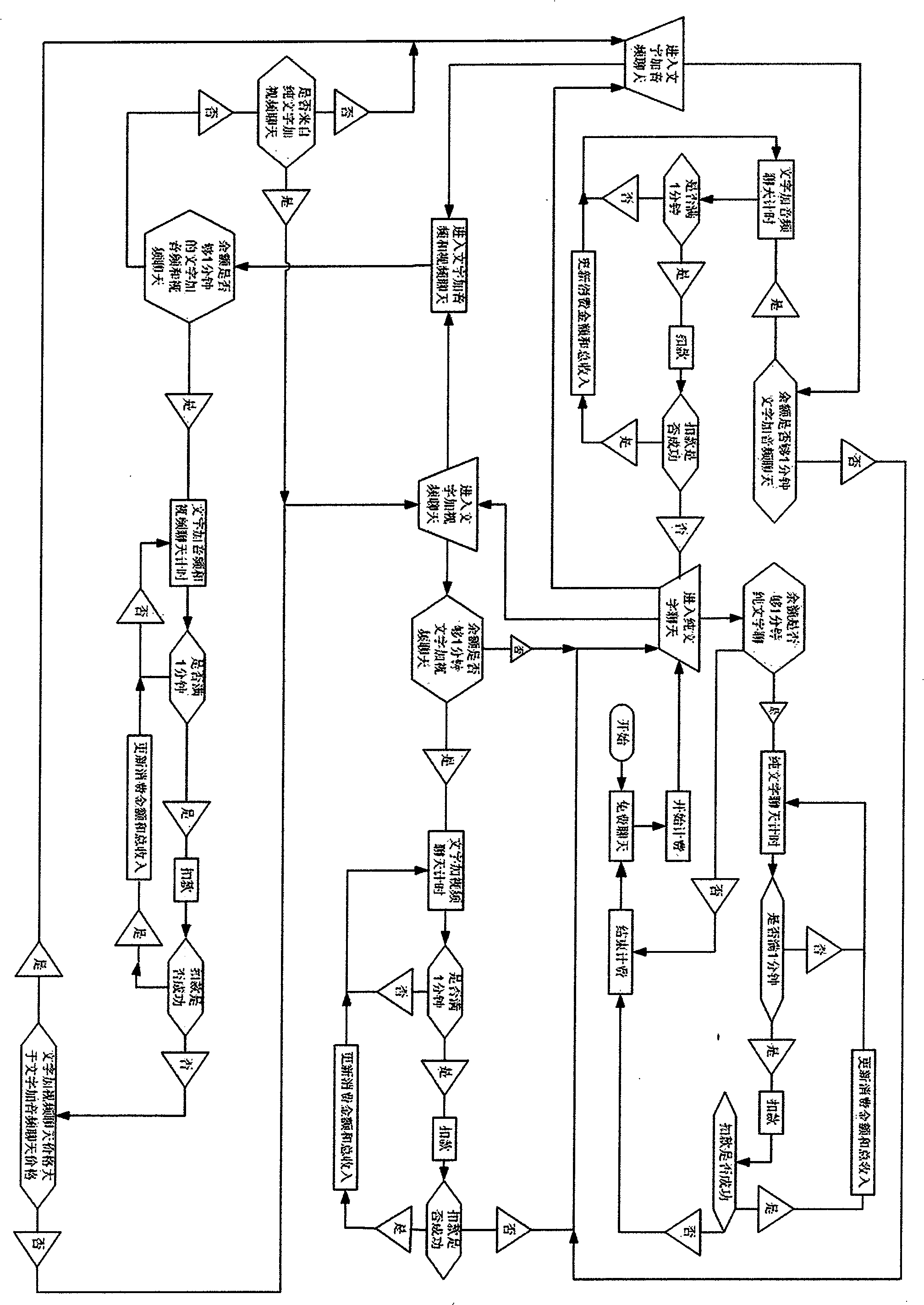

Method for carrying out real-time fee deduction during instant messaging

InactiveCN101527640AReduce intermediate linksMetering/charging/biilling arrangementsE-commerceClient-side

The invention discloses a method for carrying out real-time fee deduction on the user during instant messaging which belongs to the network technical field. An adopted technical proposal is as follows: a flash chat window, a background socket server and a background database are adopted to realize the fee deduction process concretely by a server script and a control component. Firstly, two chatting parties open the chat window to chat, free of charging, if charging is required, the user can carry out the real-time fee deduction on a user account just by clicking a charging-starting button, which is similar as the fee deduction mechanism of telephone, and the difference is that on-line chatting deducts fees from one party and supplements the sum of money to an account of the other party at real time simultaneously. In addition, the system can adjust chatting modes at any time according to the balance of the account automatically and carries out the classified statistic of call duration according to the current mode of the user. The invention does not require the user to install any client end software and promotes the popularization and application of instant communication tools in the field of e-business.

Owner:周佺喜

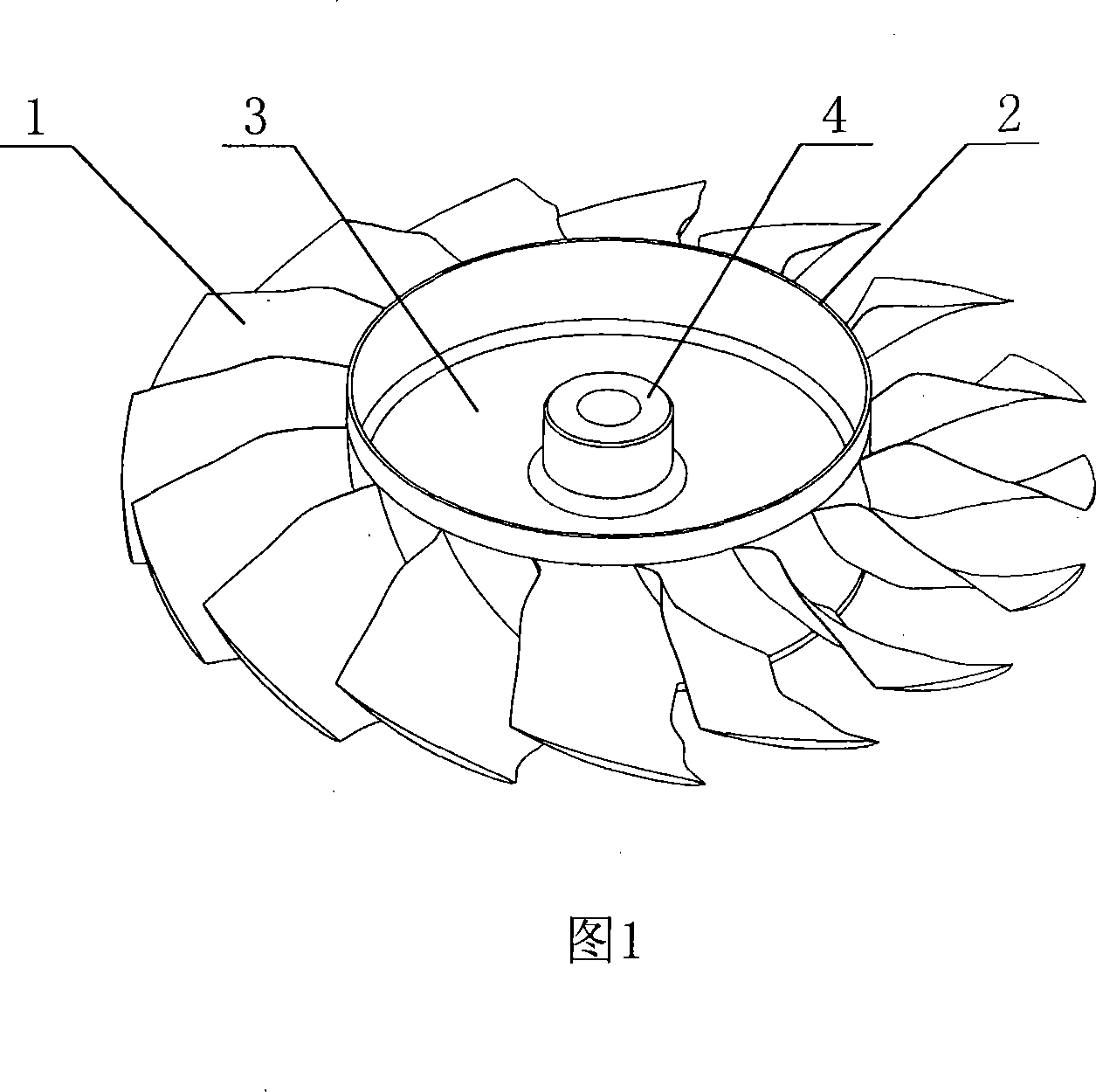

Blower fan integral wheel and method of manufacture

InactiveCN101235827AReduce intermediate linksThere is no false weldingPump componentsFoundry mouldsImpellerWhole body

The invention relates to the technical field of ventilators, in particular to a ventilator integral impeller and method for preparation. An impeller angle is not accurate, which is caused by the affect of many reasons which are machining error, blade installation angle measurement error, electric welding thermal deformation error and worker processing technical level and the like, thereby the intensity of a ventilator fan is reduced, the noise is increased, the work efficiency is low, the power consumption is large and the maintenance ratio is high. In order to overcome the above defects, the invention uses the technical scheme that the ventilator integral impeller comprises a blade, a hub, a spoke and a bearing sleeve, wherein the blade, the hub, the spoke and the bearing sleeve are a whole body which are connected together through casting in one time. The ventilator integral impeller is made through casting in one time, the problems which are common in processing of the impellers such as rosin joint and unclosed riveting and the like do not exist, the intensity is high, the security is excellent, the production cost is low, the energy consumption is saved, the environmental condition is improved, and the economic benefit is increased.

Owner:刘建国 +1

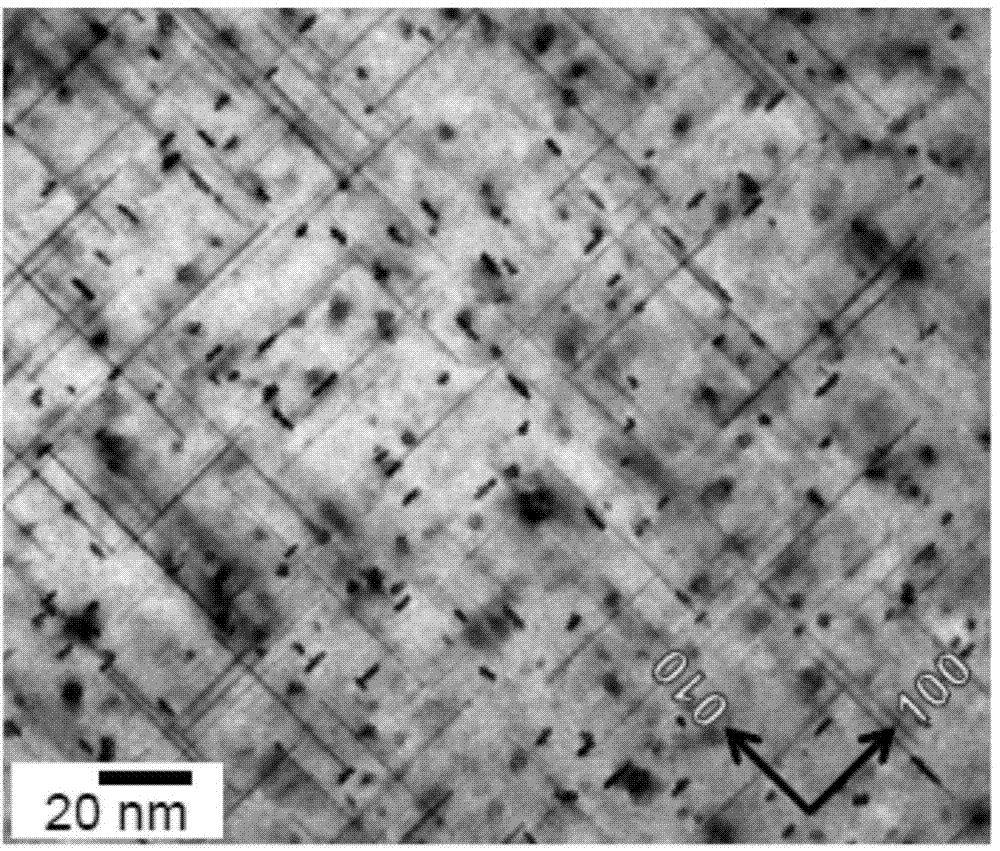

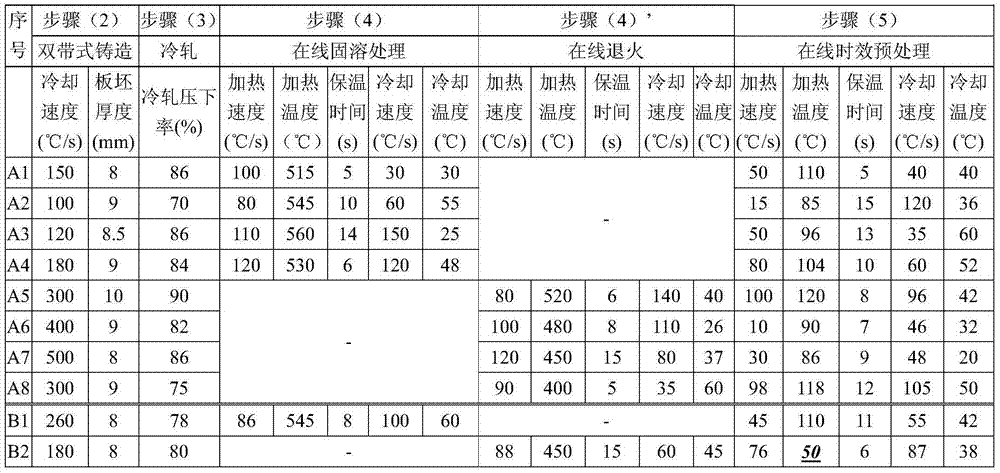

High-strength aluminum-alloy material, aluminum-alloy plate and manufacturing method thereof

The invention discloses a high-strength aluminum-alloy material. The high-strength aluminum-alloy material contains the chemical elements in percentage by mass: not lower than 1.5% and not higher than 3.0% of Mg, not lower than 0.05% and not higher than 0.2% of Si, not lower than 0.1% and not higher than 0.2% of Mn, not lower than 0.2% and not higher than 0.4% of Fe, higher than 0 and not higher than 0.03% of Cu, higher than 0 and not higher than 0.05% of Ti, either not lower than 0.05% and not higher than 0.15% of Ca or not lower than 0.05% and not higher than 0.15% of Sr and the balance of Al and other unavoidable impurities. The invention further discloses an aluminum-alloy plate manufactured from the aluminum-alloy material. The invention further discloses a manufacturing method of the aluminum-alloy plate, wherein the method comprises the steps of carrying out double-strip casting, carrying out cold rolling, carrying out online solid solution treatment and carrying out online aging pretreatment. The high-strength aluminum-alloy material and the aluminum-alloy plate, disclosed by the invention, have relatively high strength and good natural aging stability. After painting and baking, the yield strength of the high-strength aluminum-alloy material and the aluminum-alloy plate is higher than 300Mpa.

Owner:BAOSHAN IRON & STEEL CO LTD

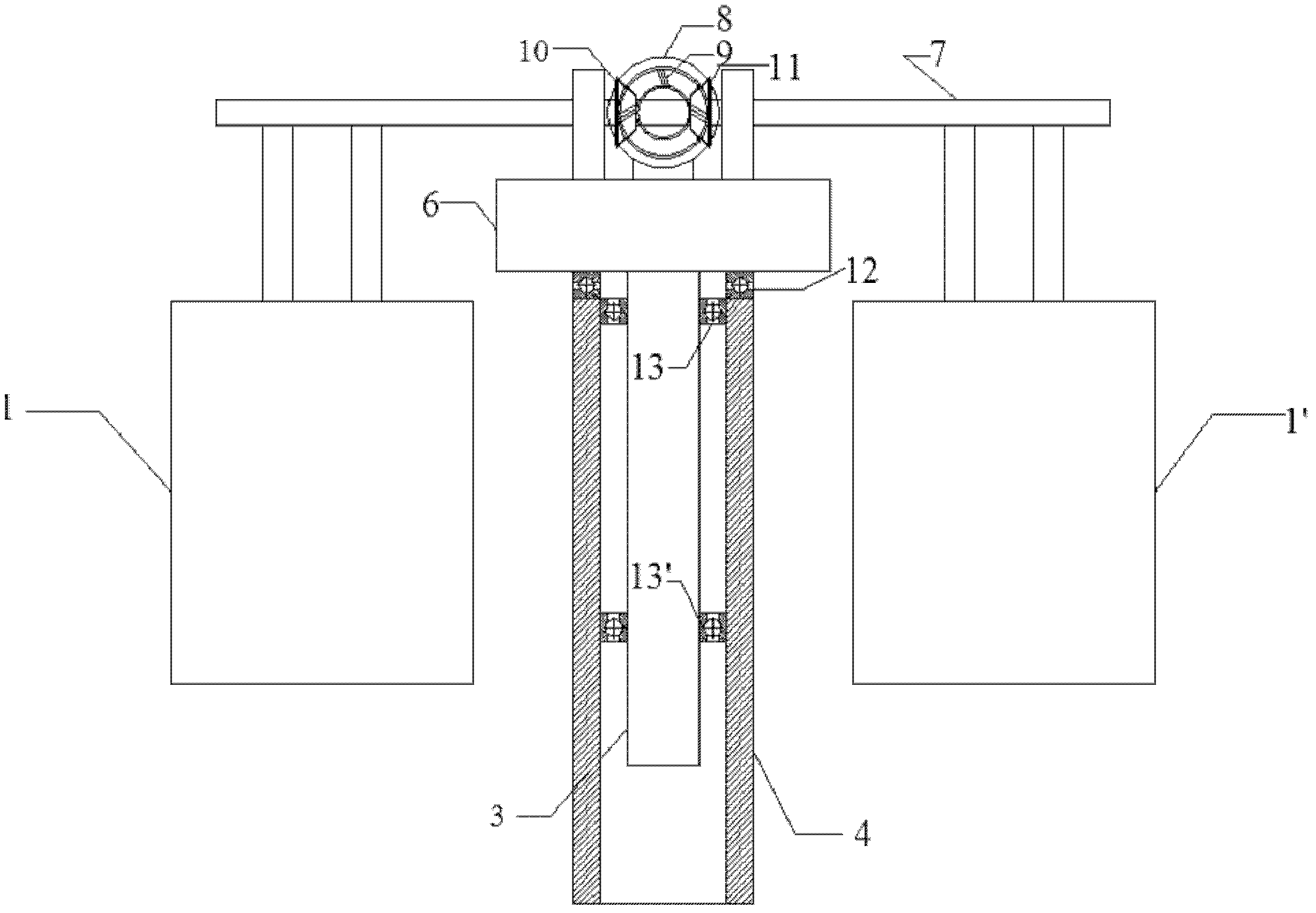

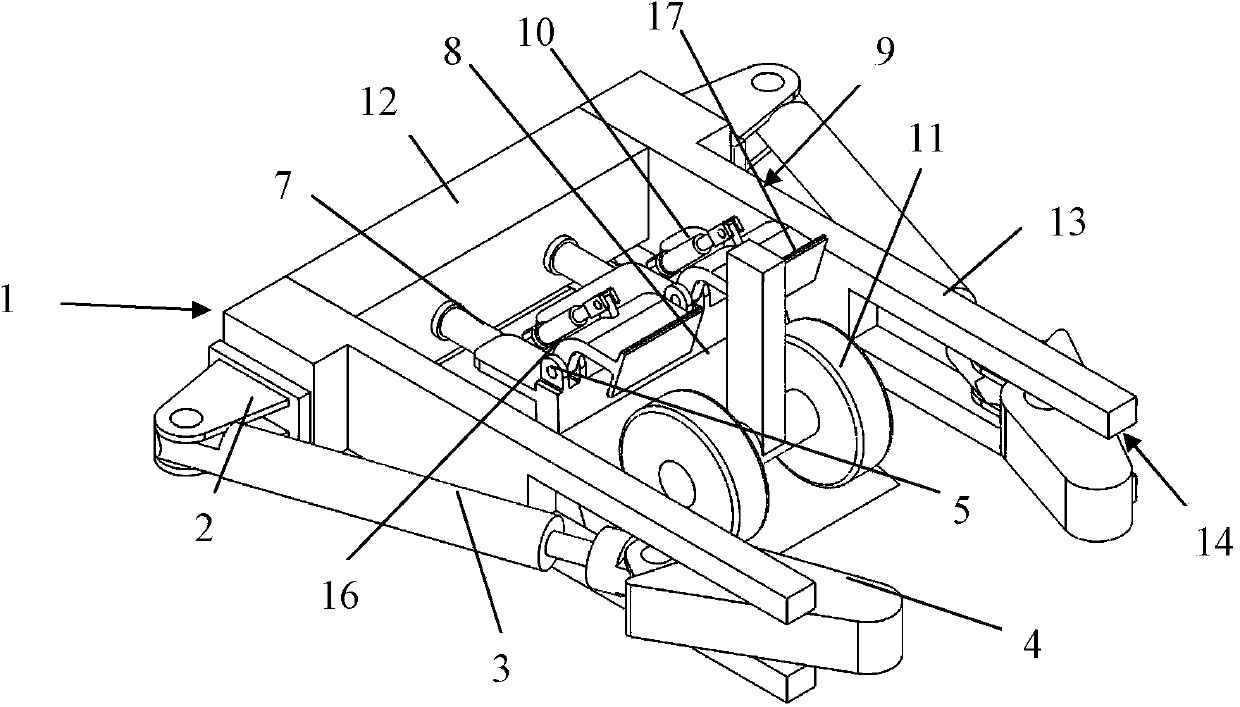

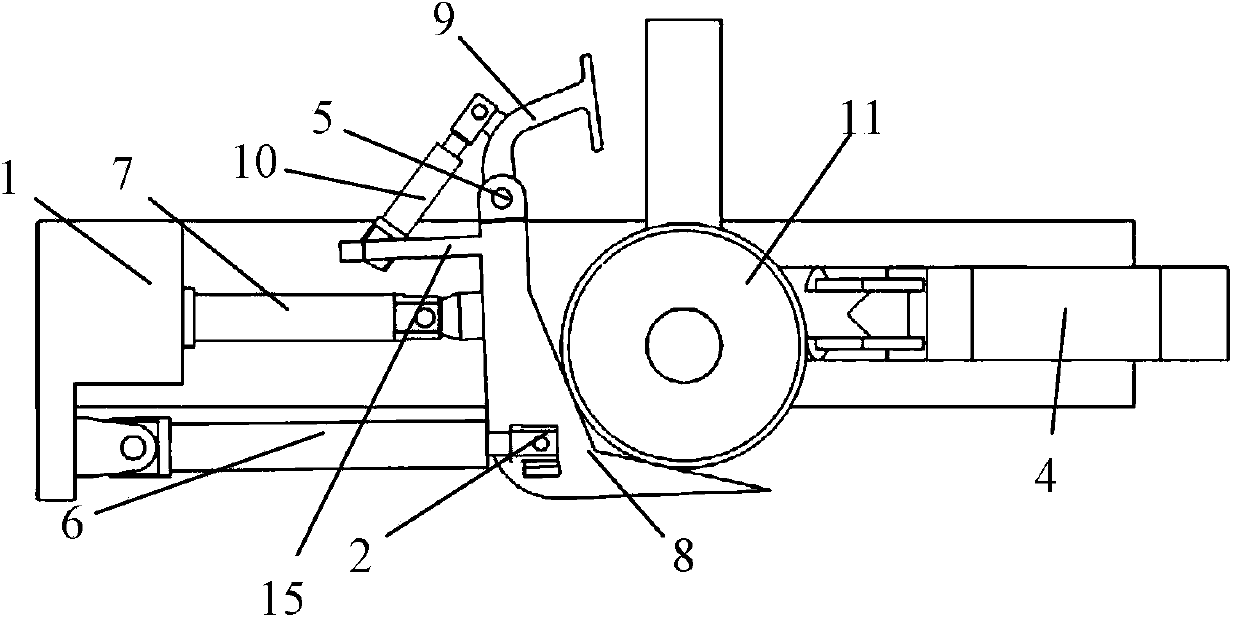

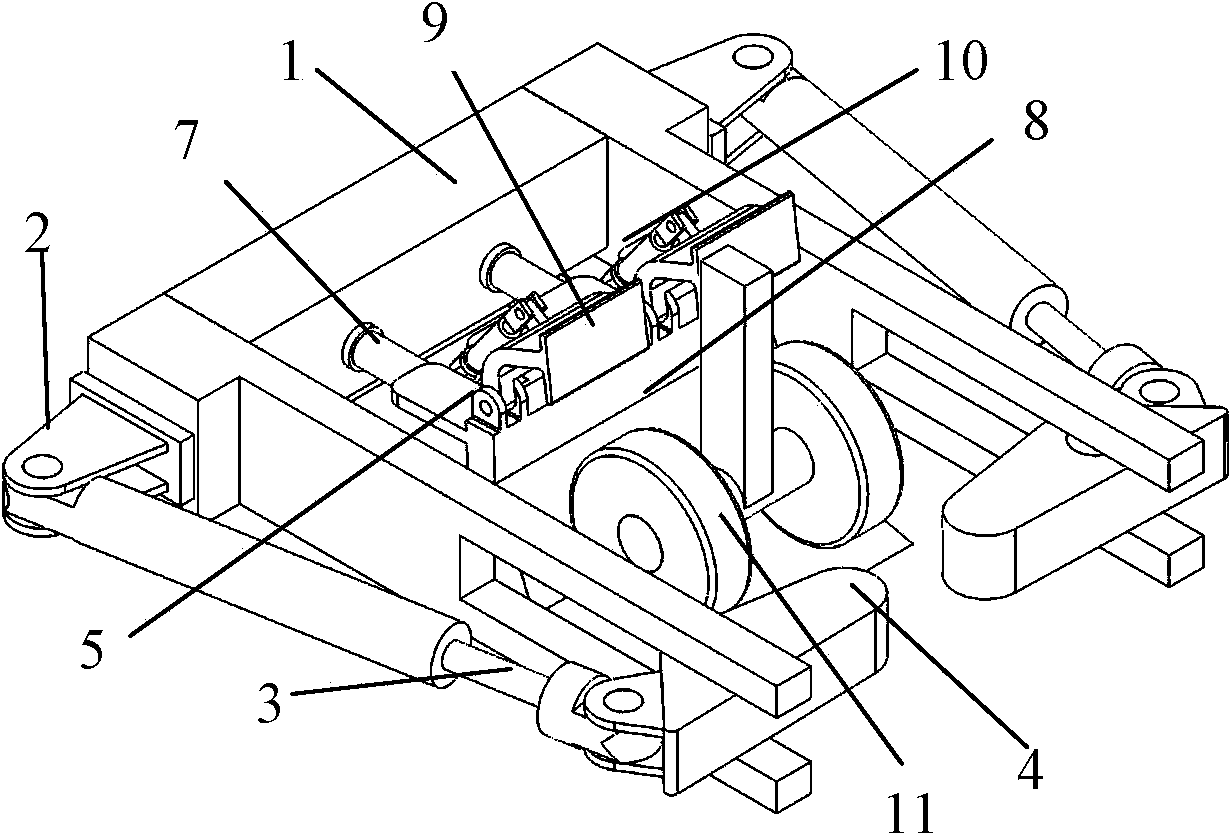

Rodless aircraft tractor clamping and lifting device

InactiveCN104002986AReduce complexityReduce intermediate linksGround installationsAerospace engineeringEngineering

The invention discloses a rodless aircraft tractor clamping and lifting device which comprises a base, two hinge heads, two rotary rear baffles, two rotary rear baffle hydraulic cylinder components, a plurality of cylindrical pins, a lifting bearing bucket, two lifting bearing bucket hydraulic cylinder components, two lifting bearing bucket auxiliary hydraulic cylinder components, two compressing supports and two compressing support hydraulic cylinder components. According to the rodless aircraft tractor clamping and lifting device, the number of the degrees of freedom of a mechanism is changed through the limitation of the stroke of the hydraulic cylinder components, and therefore the lifting bearing bucket is changed to rotate in a vertical plane from the horizontal motion, intermediate links are effectively reduced, safety can be improved, the complexity degree of a control system can be lowered, meanwhile, the safety can be improved, hydraulic loops can be reduced, a power device can be arranged in a centralized mode, and the device has the advantages of being reasonable in structural design, convenient to operate and the like.

Owner:CIVIL AVIATION UNIV OF CHINA

Hot disintegration method for converter steel slag

InactiveCN101280346AImprove granulation effectImprove performanceRecycling and recovery technologiesSlagIsolation layer

The invention relates to the steel slag recovery and reclamation processing technology. The invention provides a disruption method of converter steel slag, which is characterized in that the steel slag is poured into a dross box in a hot slag splashing workshop under the temperature of 1050 to 1150 DEG C, little water is sprayed to reduce the temperature, after an isolation layer is formed, the slag is poured and water is sprayed continuously time and again, and then the broken steel slag is obtained after warming up stuffily. The steel slag processed through the method of the invention has the advantages of good graining effect and performance, and the method and the process are advanced, the investment on the system is low, the operating cost is low, and the economic effect is obvious.

Owner:冀更新

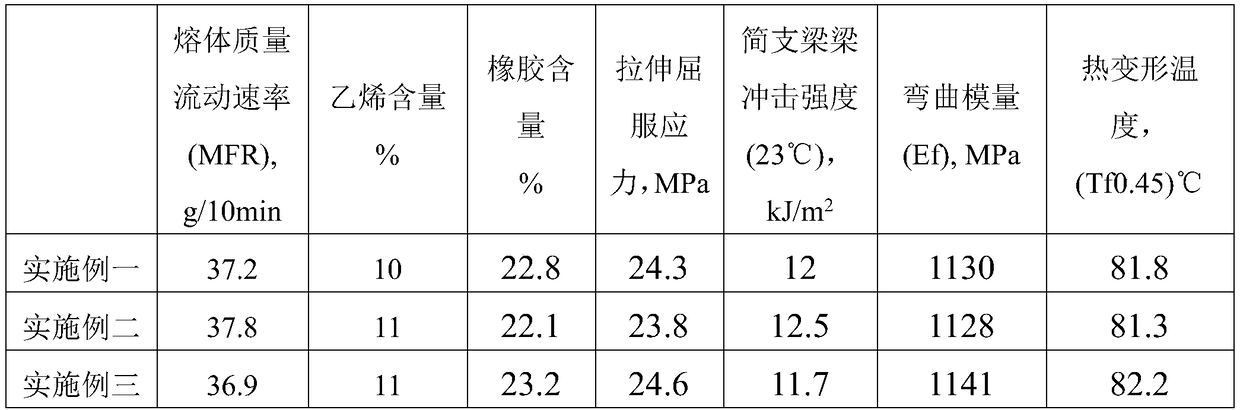

Preparation method of high-flow impact-resistant polypropylene material

The invention discloses a preparation method of a high-flow impact-resistant polypropylene material. The preparation method comprises: (1) polymerizing propylene through a prepolymerization reactor under the action of a main catalyst, a cocatalyst and an external electron donor, (2) feeding the polypropylene, fresh propylene and hydrogen into a first loop reactor and carrying out polymerization, (3) feeding the polymerization product and fresh propylene and hydrogen into a second loop reactor and carrying out polymerization, (4) carrying out flash evaporation on the polymerization product to remove a liquid phase propylene, feeding the polymerization product into a gas phase reactor and carrying out a reaction process to obtain polypropylene powder, and (5) uniformly mixing the polypropylene powder, an antioxidant, an auxiliary antioxidant, a halogen absorbent, a lubricant and a nucleating agent, and carrying out peroxide degradation extrusion through an extruder to obtain a polypropylene material. The polypropylene material has good flow properties and impact resistance and is suitable for injection molding of large thin-walled products.

Owner:CHINA PETROLEUM & CHEM CORP

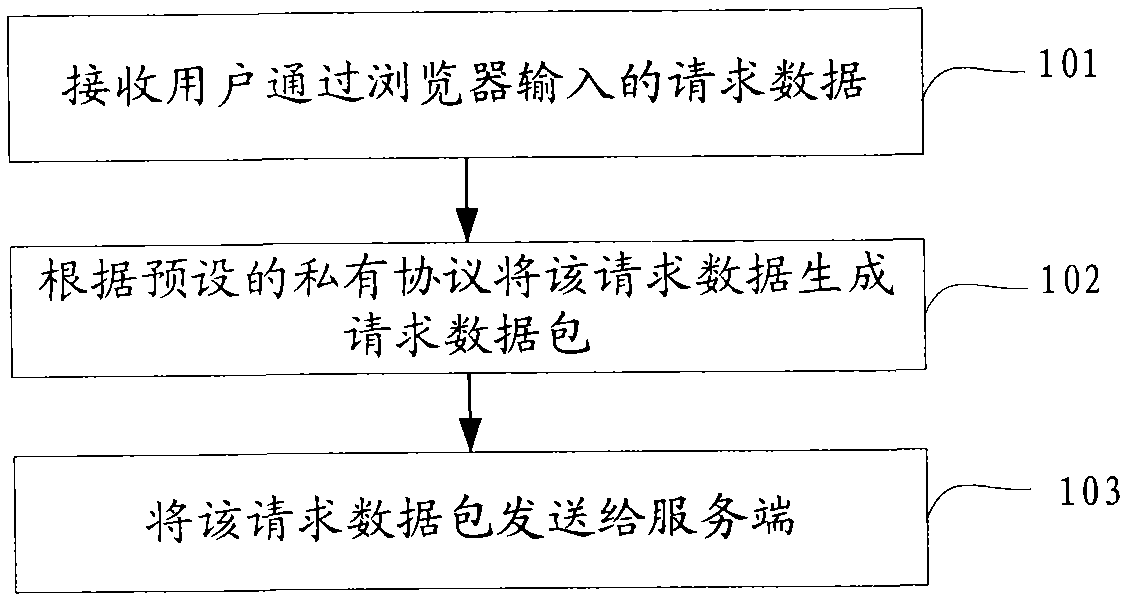

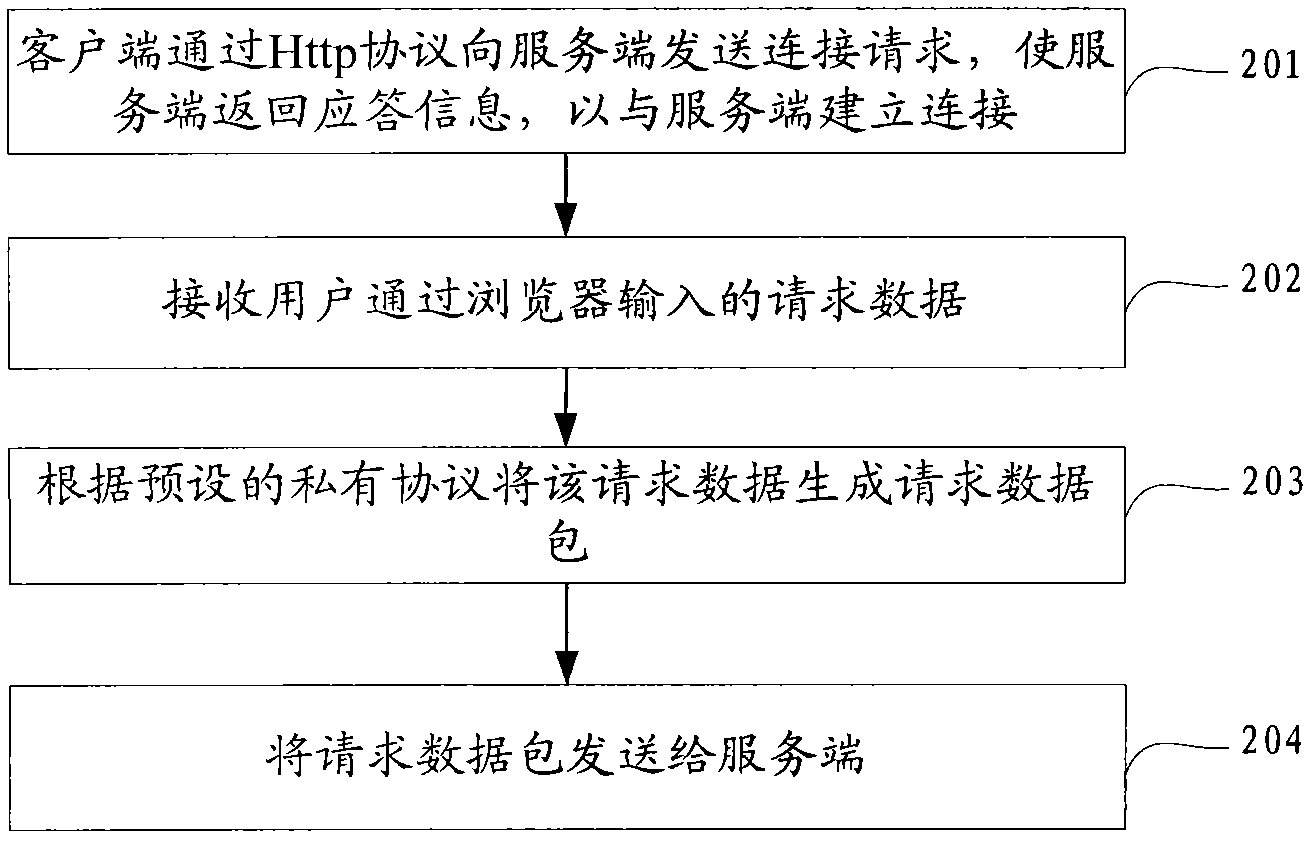

Browser-based data communication method, client and browser-based data interaction system

ActiveCN102571892AImprove transmission efficiencyReduce intermediate linksWeb data indexingComputer security arrangementsInteraction systemsNetwork packet

The invention discloses a browser-based data communication method, a client and a browser-based data interaction system, and belongs to the technical field of networks. The method comprises the following steps of: receiving request data input by a user through a browser; generating a request data packet on the basis of the request data according to a preset private protocol; and sending the request data packet to a server. The client comprises a first receiving unit, a first generating unit and a first sending unit. The data interaction system comprises the client and the server. According to the browser-based data communication method, the request data packet is generated on the basis of the request data according to the private protocol and sent to the server. Compared with the conventional method for sending the request data to the browser through a hyper text transport protocol (Http) and sending the request data to the server by the browser through the Http, the browser-based data communication method has the advantages that: middle loops during data communication are reduced, other protocol fields in the Http are not carried during data communication, the data transmission amount is reduced, the bandwidth is saved, and the data transmission efficiency is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com