Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce solid particle content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

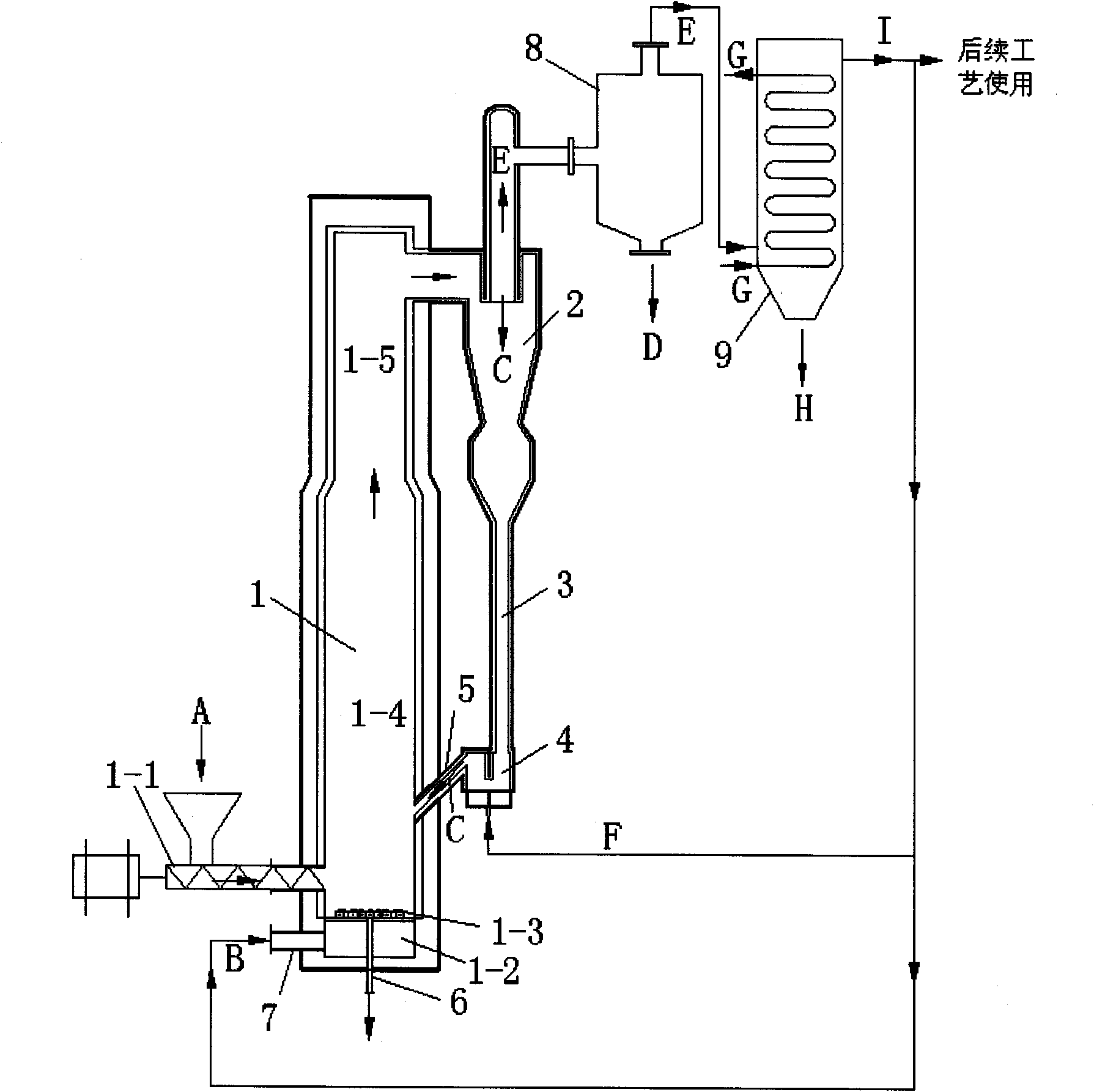

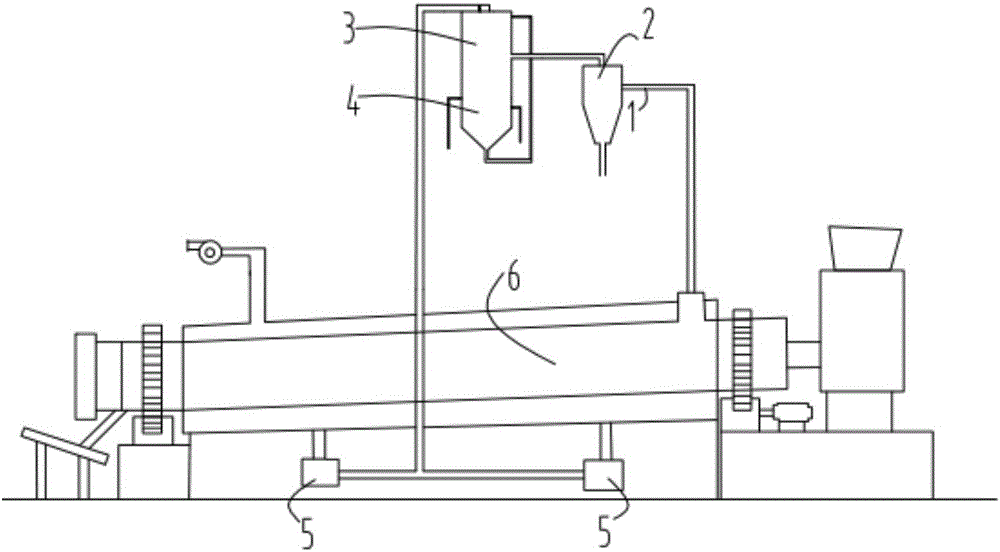

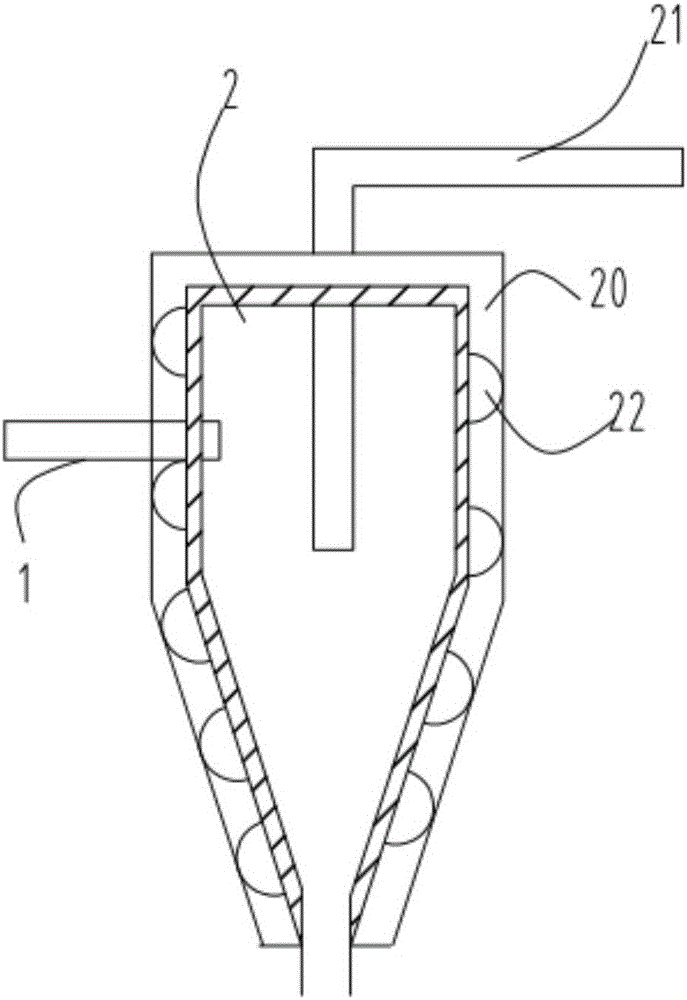

Method for pyrolyzing municipal sludge and preparing biological oil and active carbon simultaneously

InactiveCN101845311AShort stayIncrease productionSludge treatment by pyrolysisDirect heating destructive distillationActivated carbonSludge

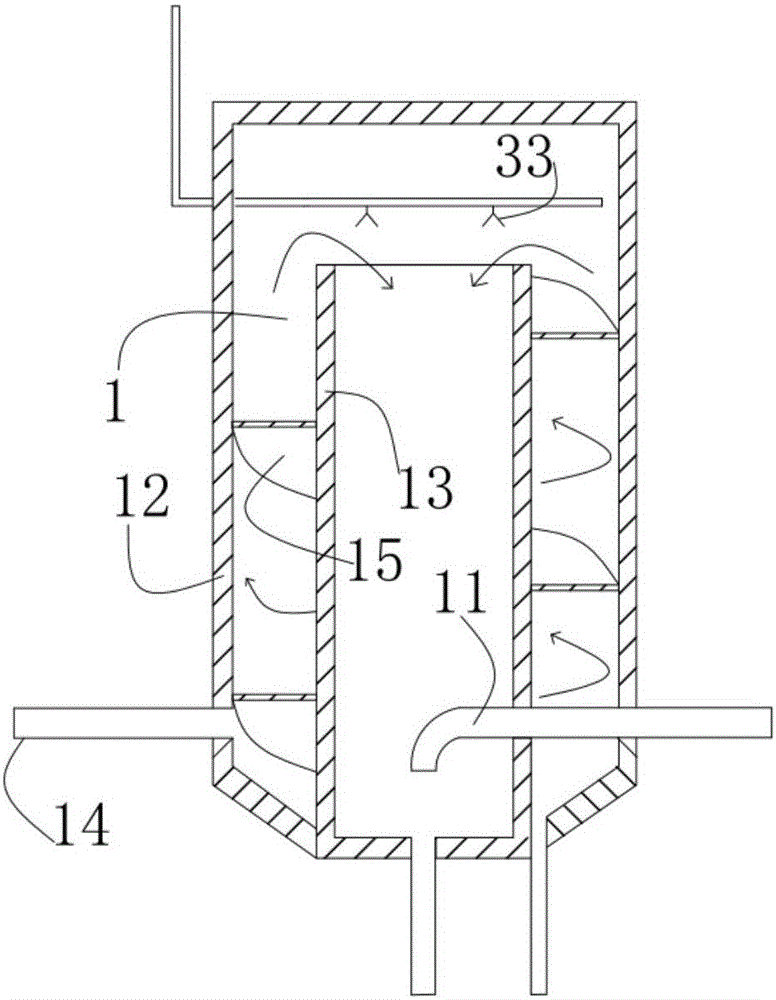

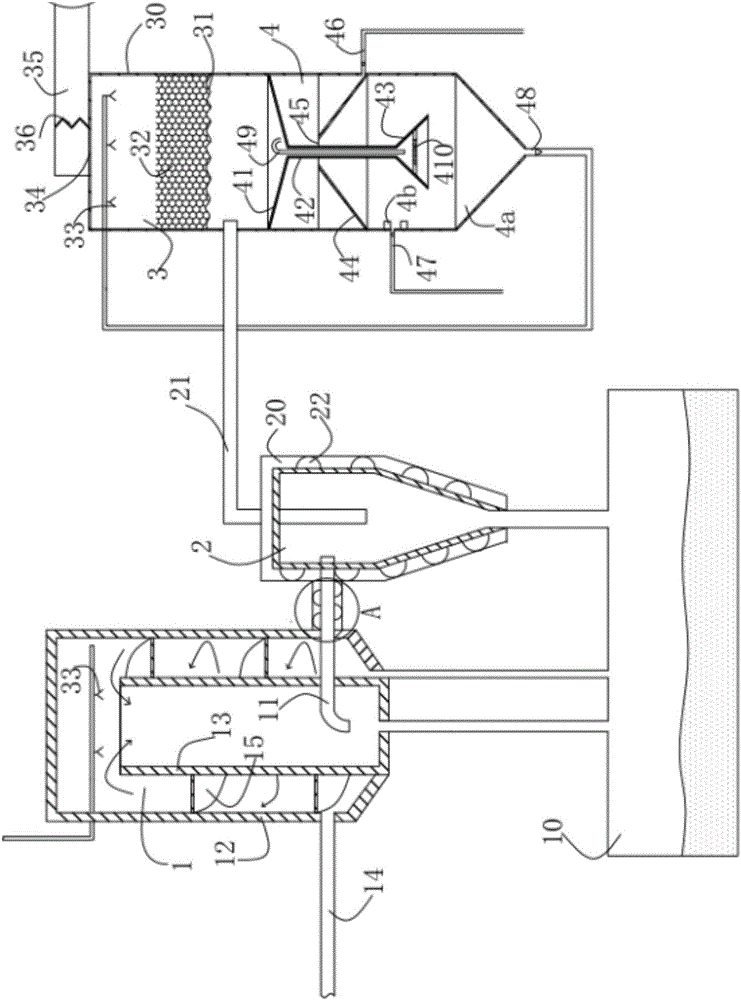

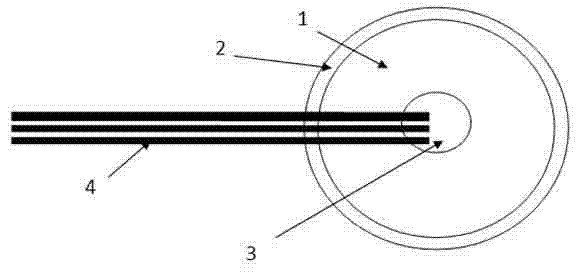

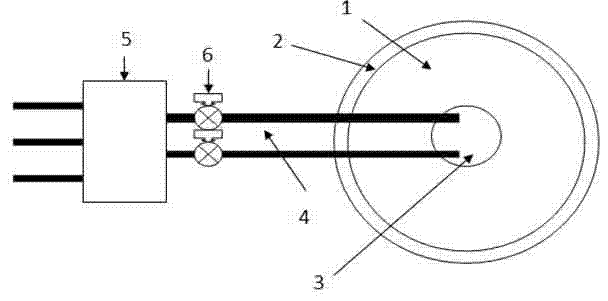

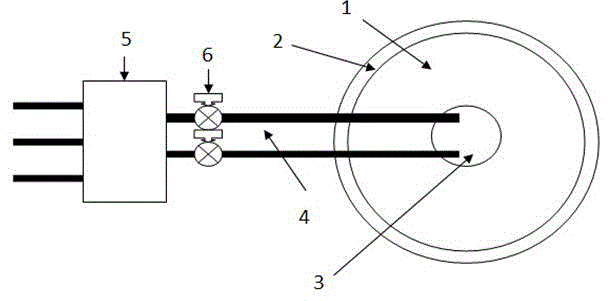

The invention discloses a method for pyrolyzing municipal sludge and preparing biological oil and active carbon simultaneously, which can obtain high-quality biological oil and active carbon simultaneously and solves the problem that the conventional sludge pyrolysis method only can obtain a single recycled product. In the method, sludge (A) enters a pyrolysis reactor (1) through a vane feeder (1-1); fluidized wind (B) enters the pyrolysis reactor (1) through a wind chamber (1-2) and a wind distribution plate (1-3); a cyclone separator (2) catches and collects fallen pyrolytic carbon (C) and returns the pyrolytic carbon (C) to the pyrolysis reactor (1) for circulation through a blank pipe (3), a material feedback device (4) and a material returning pipe (5); the pyrolytic carbon (C) becomes active carbon (D) after repeated circulation; and then, the active carbon (D), together with pyrolytic gas (E), enters a ceramic filter (8) and is caught and collected by the ceramic filter (8); the pyrolytic gas (E) discharged by the ceramic filter (8) enters a condenser (9); and the lower part of the condenser recovers biologic oil (H) and discharges noncondensing gas (I).

Owner:JIANGSU ZHONGRONG ELECTRIC +1

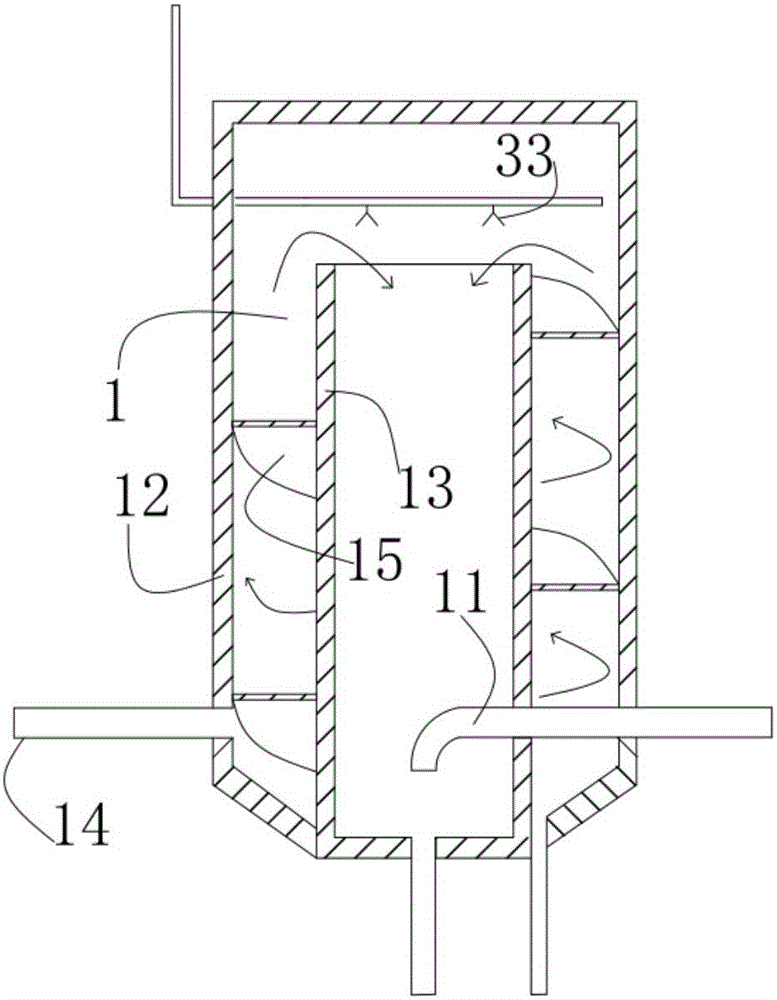

Improved waste heat power generation system for cement industry

InactiveCN102865746AReduce solid particle contentIncrease profitIncreasing energy efficiencyClinker productionSuperheaterEngineering

The invention discloses an improved waste heat power generation system for the cement industry. The improved waste heat power generation system comprises a clinker cooler, a kiln front boiler, a kiln tail boiler and a steam turbine, wherein the kiln front boiler and the kiln tail boiler respectively comprise an evaporator, a superheater and a steam pocket. Flue gas generated by the clinker cooler is respectively conveyed to the kiln front boiler and the kiln tail boiler, the kiln front boiler and the kiln tail boiler are respectively provided with a vertical structure, and the kiln front boiler and the kiln tail boiler share an economizer and a high-temperature superheater. Preheated water is respectively conveyed to the kiln front boiler and the kiln tail boiler by the economizer, the steam temperature of the kiln front boiler and the kiln tail boiler is adjusted by the high-temperature superheater, steam conveyed into the steam turbine is low in temperature difference or the same in temperature, the waste heat power generation system is small in occupied area, convenient to arrange, high in boiler heat efficiency and economical, and the kiln front boiler is low in abrasion.

Owner:GUANGDONG KAINENG ENVIRONMENTAL PROTECTION & ENERGY

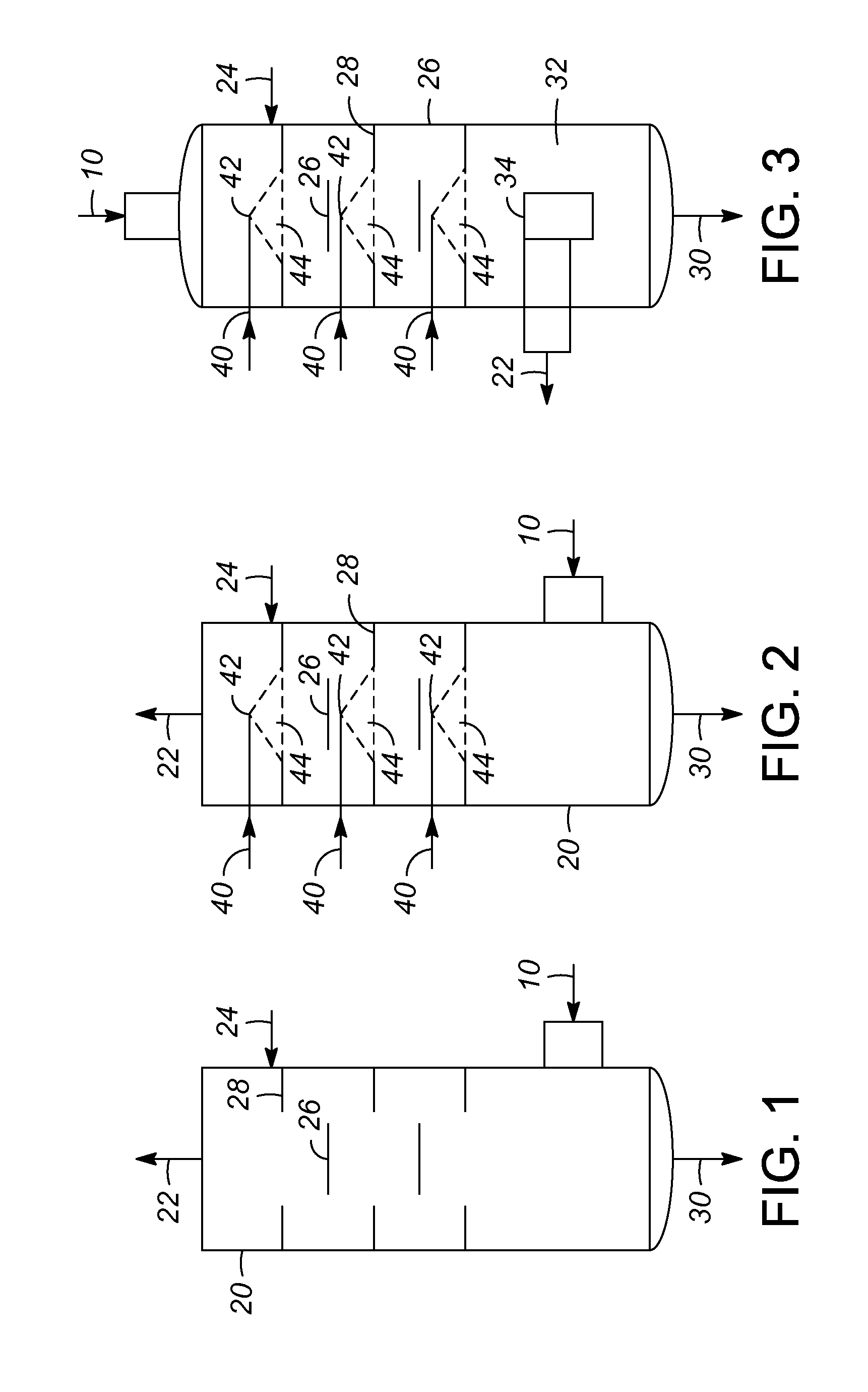

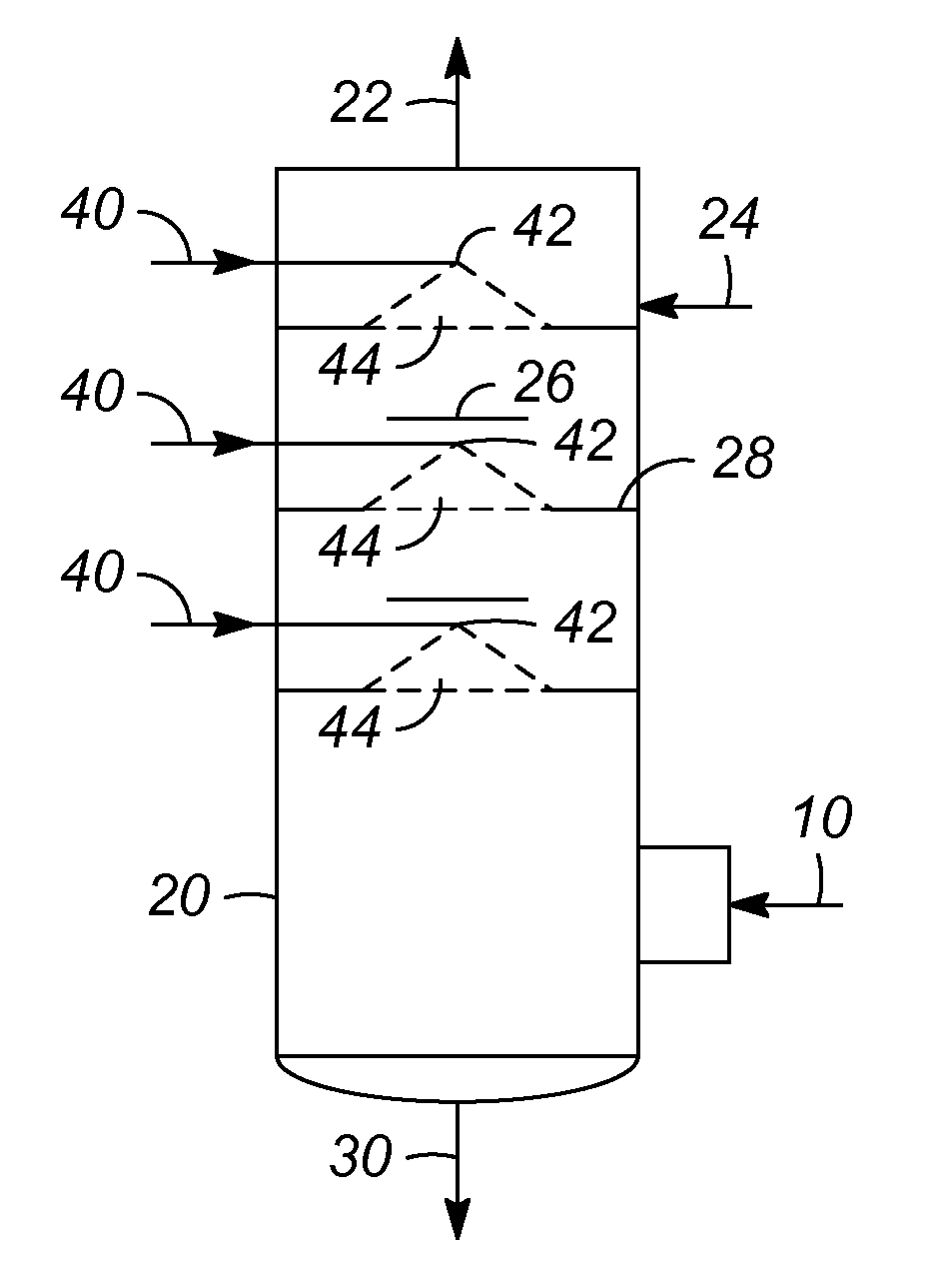

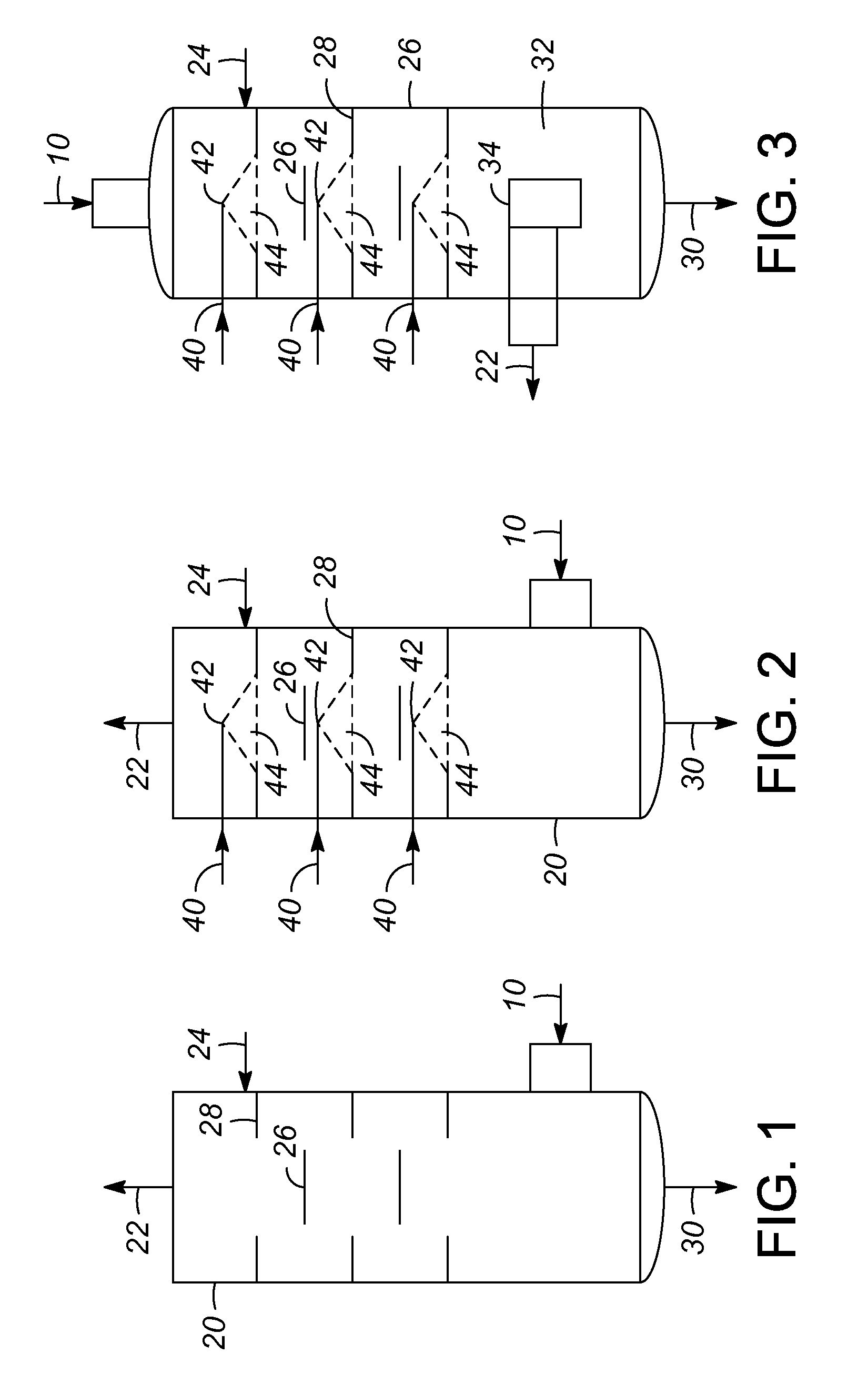

Quench tower catalyst recovery

ActiveUS20120157740A1Good removal effectReduce solid particle contentUsing liquid separation agentHydrocarbon purification/separationSolid particleTower

A process and apparatus is presented for the removal of solid particles from a gas stream. The process and apparatus includes adding a second stream of liquid that is sprayed over the openings in trays in a quench tower. The second spray stream provides for a veil of liquid to wash out solid particles from the vapor stream.

Owner:UOP LLC

Novel flue gas purification tower

PendingCN110975584ASmall particle sizeA large amountGas treatmentUsing liquid separation agentPhysicsProcess engineering

The invention discloses a novel flue gas purification tower which comprises at least two stages of purification chambers, namely, a drying purification chamber and a main purification chamber from bottom to top. The two stages of purification chambers are of urn-shaped structures with narrow upper parts and narrow lower parts and wide middle parts, the lower end of the main purification chamber extends into the drying purification chamber and is communicated with the drying purification chamber, and a guide cylinder is arranged in the center of the communication joint. An arch shoulder is formed at the wider part of the drying purification chamber, a flue gas inlet connecting pipe is arranged at the arch shoulder, and absorbent slurry spraying devices are arranged in inner cavities of themain purification chamber and the drying purification chamber. Flue gas in the purification tower moves from bottom to top, and water drops in desulfurization slurry sprayed by flue gas in the dryingpurification chamber and the main purification chamber are subjected to a continuous self-circulation process of evaporation and condensation. In the self-circulation process, complex heat transfer and mass transfer effects are generated on the water drops and the flue gas, and flue gas purification is achieved. The novel flue gas purification tower has the advantages of being simple in structure,high in flue gas purification efficiency, free of waste water, low in operation and maintenance cost and the like.

Owner:陈军武

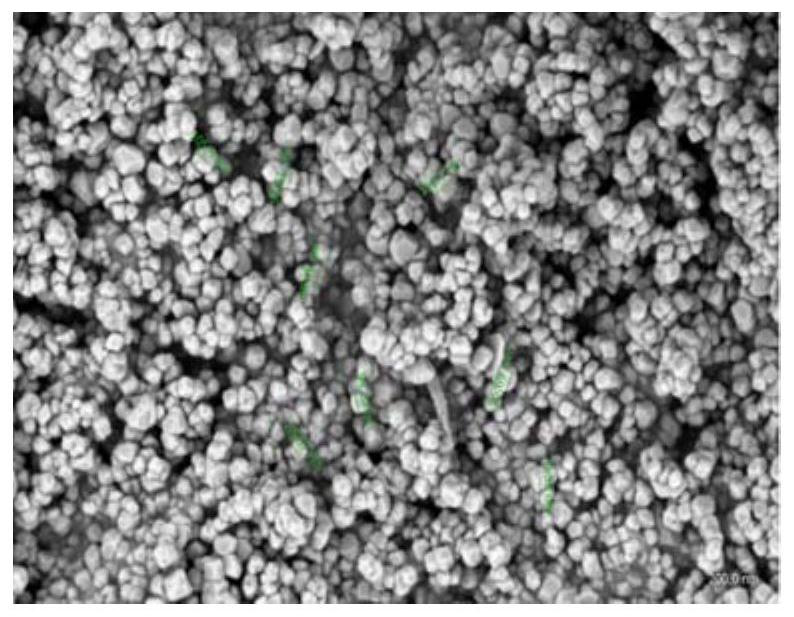

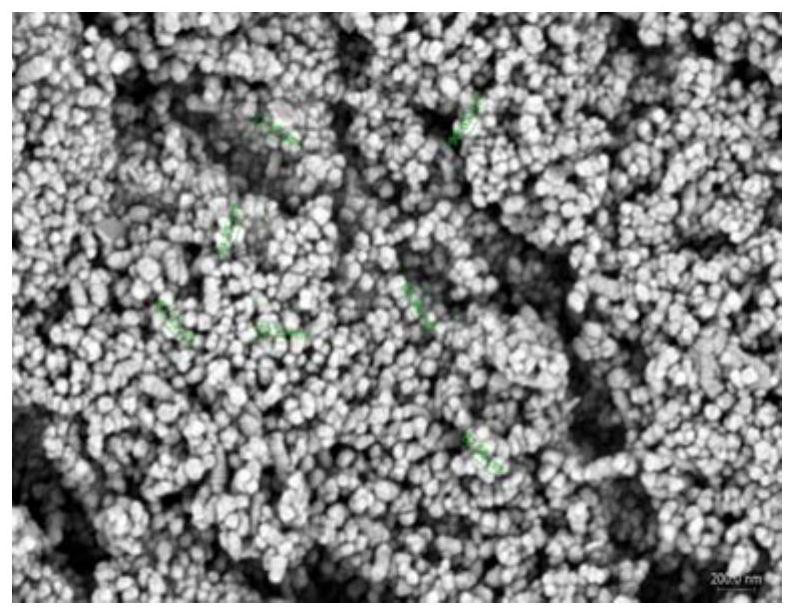

A kind of graphene organic silver conductive ink and preparation method thereof

The invention discloses a graphene organic silver conductive printing ink and a preparation method thereof. The conductive printing ink comprises a conductive function unit precursor, an organic silver complexing agent, an adhesive, a solvent and auxiliaries. The preparation method comprises the following steps: (A) stirring and ultrasonically dispersing the organic silver, the solvent and the organic silver complexing agent under a lucifugal condition to obtain an organic silver complexing solution; and (B) putting the graphene, the resin adhesive, the auxiliaries and the organic silver complexing solution in the lucifugal condition and stirring and ultrasonically dispersing in an environment lower than 10 DEG C, wherein the obtained uniform mixture is the graphene organic silver conductive printing ink. The graphene organic silver conductive printing ink prepared by the method disclosed by the invention is low in solid content, good in stability, good in printing performance and wide in application.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Quench tower catalyst recovery

ActiveUS8877997B2Good removal effectReduce solid particle contentUsing liquid separation agentHydrocarbon purification/separationSolid particleTower

A process and apparatus is presented for the removal of solid particles from a gas stream. The process and apparatus includes adding a second stream of liquid that is sprayed over the openings in trays in a quench tower. The second spray stream provides for a veil of liquid to wash out solid particles from the vapor stream.

Owner:UOP LLC

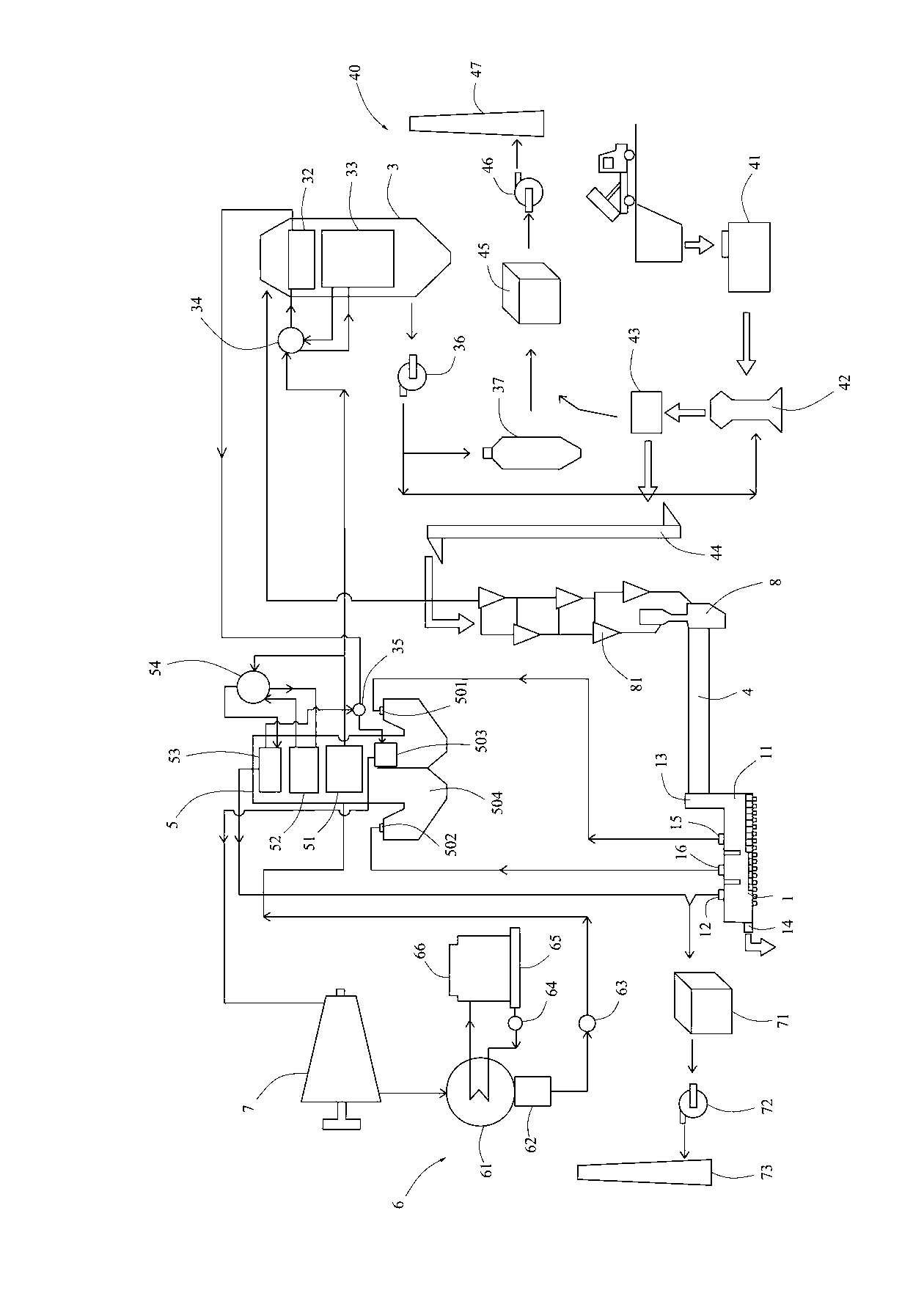

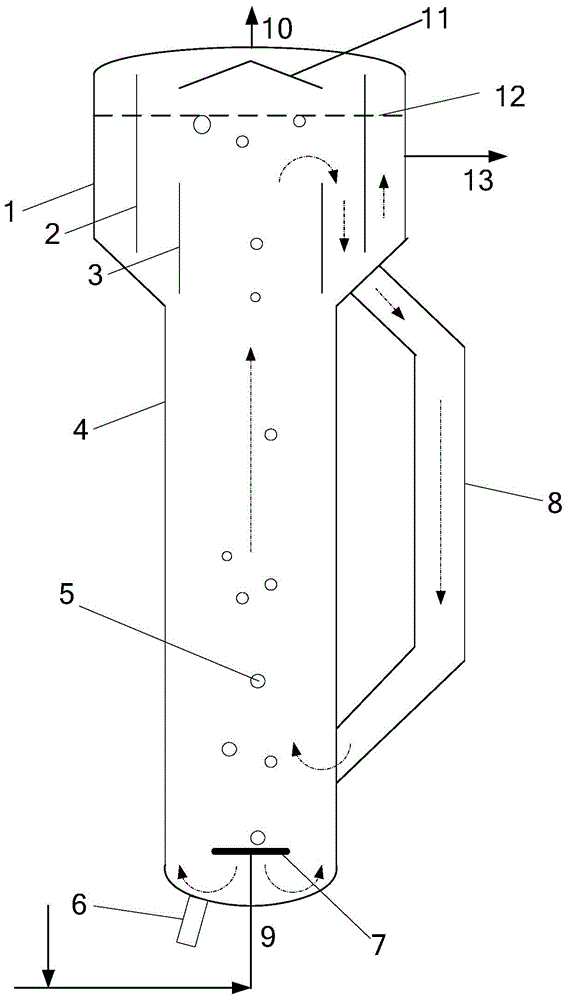

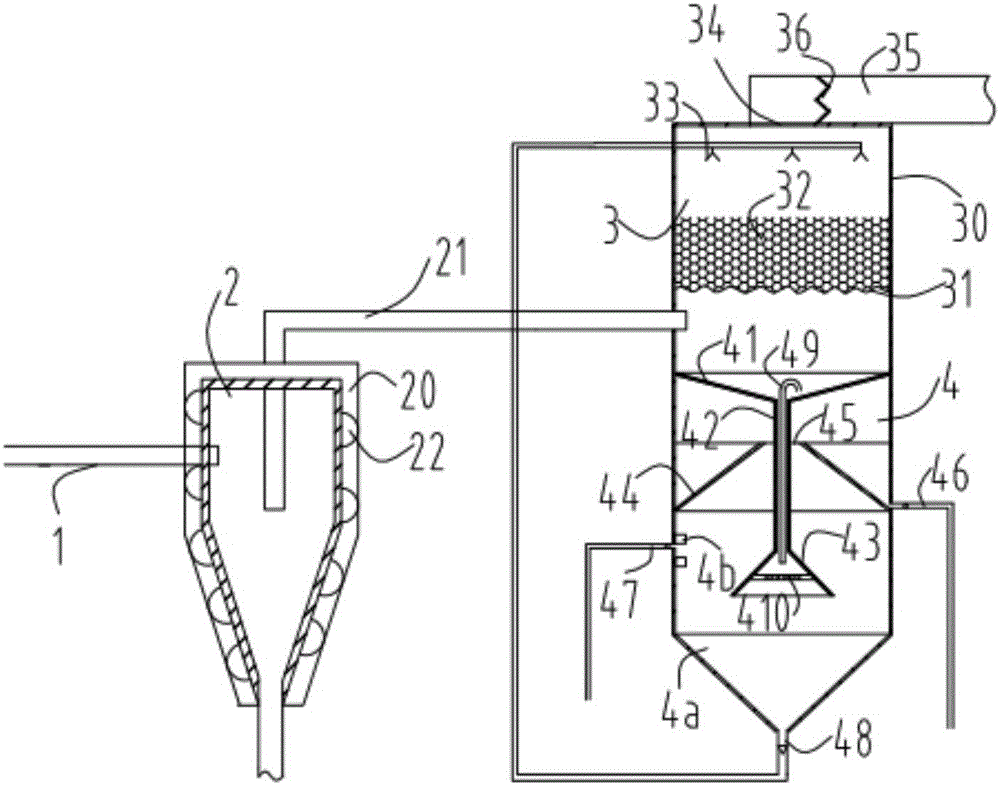

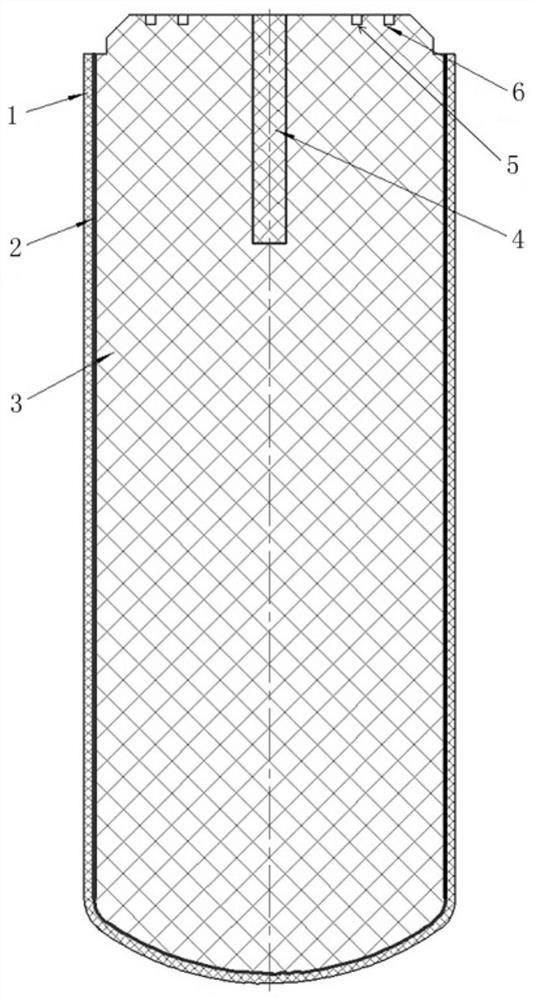

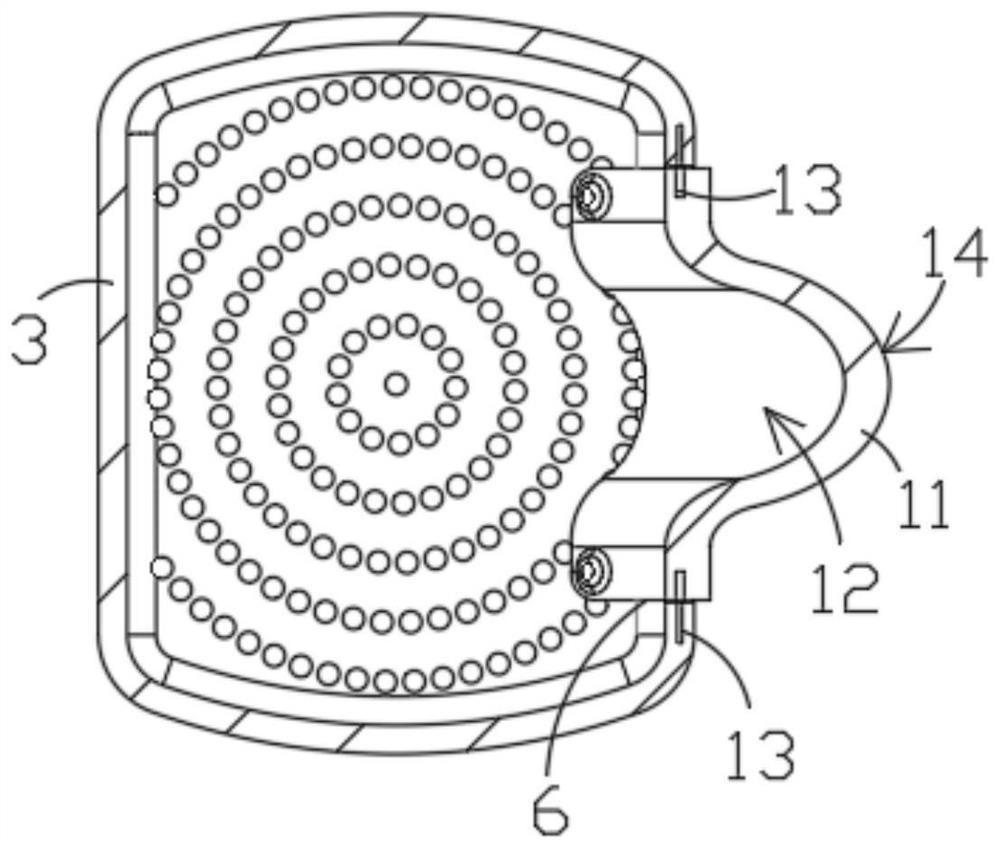

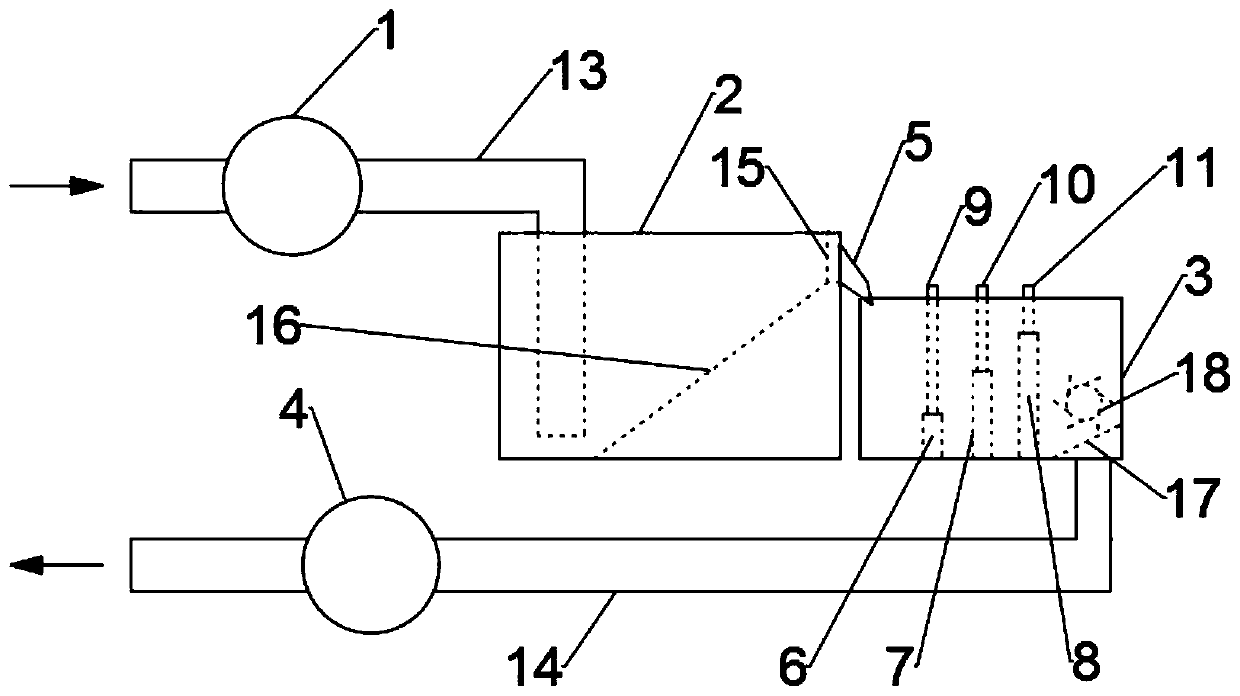

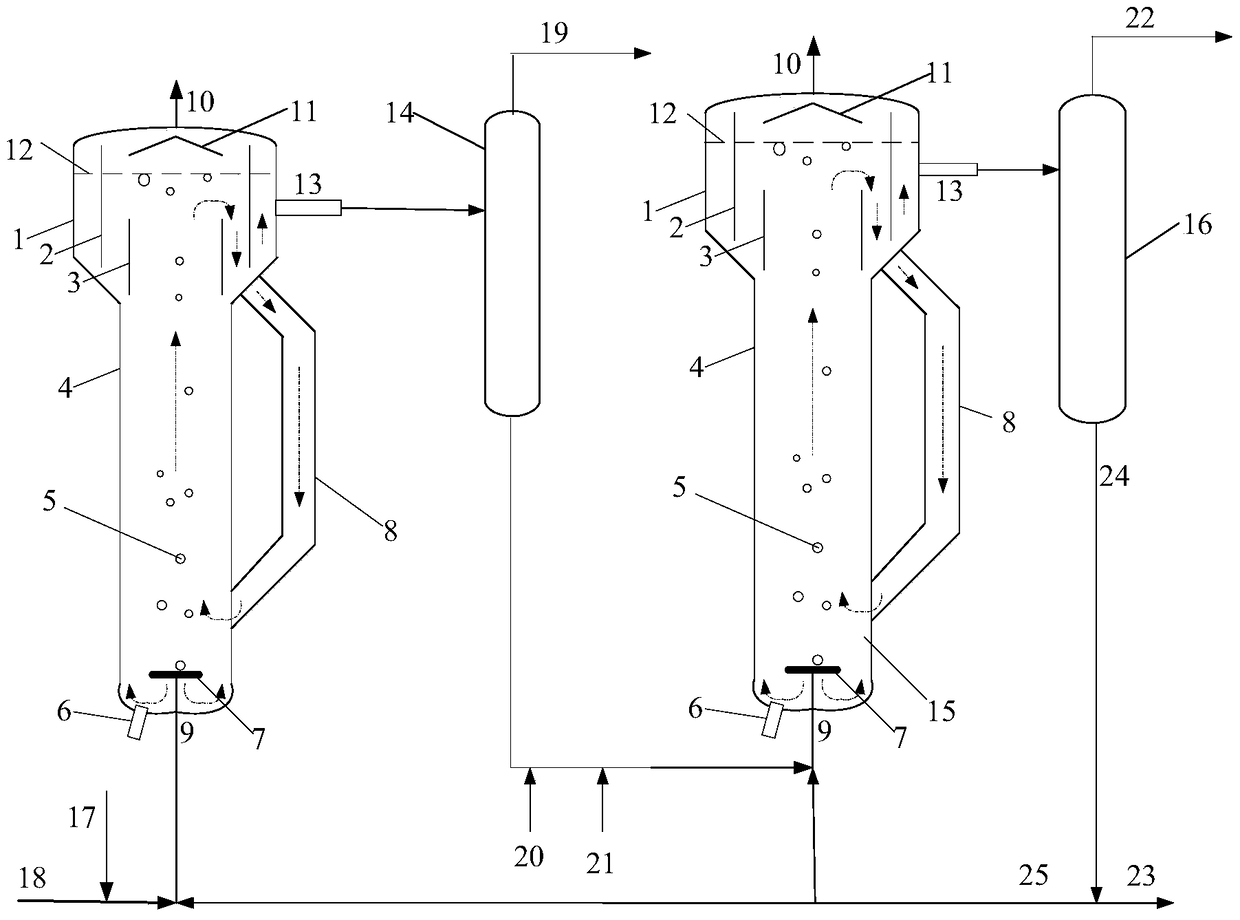

Heavy oil hydrogenation slurry bed reactor and heavy oil hydrogenation method

InactiveCN104549062ASimple structureExtended operating cycleHydrocarbon oil crackingChemical/physical processesGas phaseHydrogenation reaction

The invention relates to a heavy oil hydrogenation slurry bed reactor and a heavy oil hydrogenation method. The heavy oil hydrogenation slurry bed reactor comprises a riser (4), an expansion section (1) at the top of the riser and a downcomer (8), wherein the expansion section (1) is communicated with the upper part of the downcomer (8), the lower part of the riser (4) is communicated with the bottom of the downcomer (8), a slurry phase separator is arranged in the expansion section (1), the slurry phase separator is of a sleeve structure comprising an inner cylinder (3) and an outer cylinder (2), a mist eliminator (11) is arranged at the upper part of the slurry phase separator, a gas phase outlet (10) is formed in the top of the expansion section, a material outlet (13) is formed in the side wall of the expansion section, a fluid distributor (7) is arranged at the bottom of the riser (4), and a raw material outlet (9) is formed in the bottom of the riser (4). The heavy oil hydrogenation slurry bed reactor provided by the invention can realize hydrogenation reaction to separate a light oil product and an unreacted heavy oil product. The heavy oil hydrogenation slurry bed reactor provided by the invention can also inhibit the generation of coke particles of a heavy oil reaction system and effectively prolong the operation period of the reactor.

Owner:CHINA PETROLEUM & CHEM CORP +1

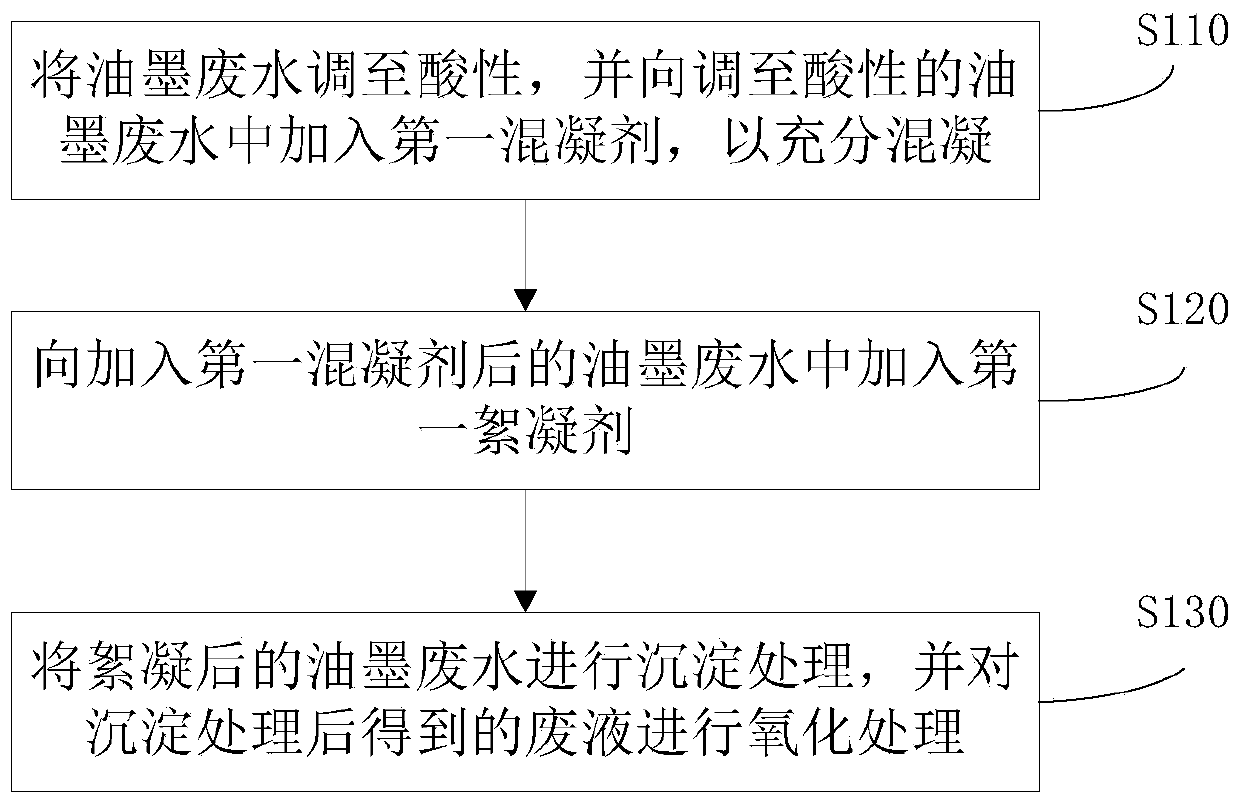

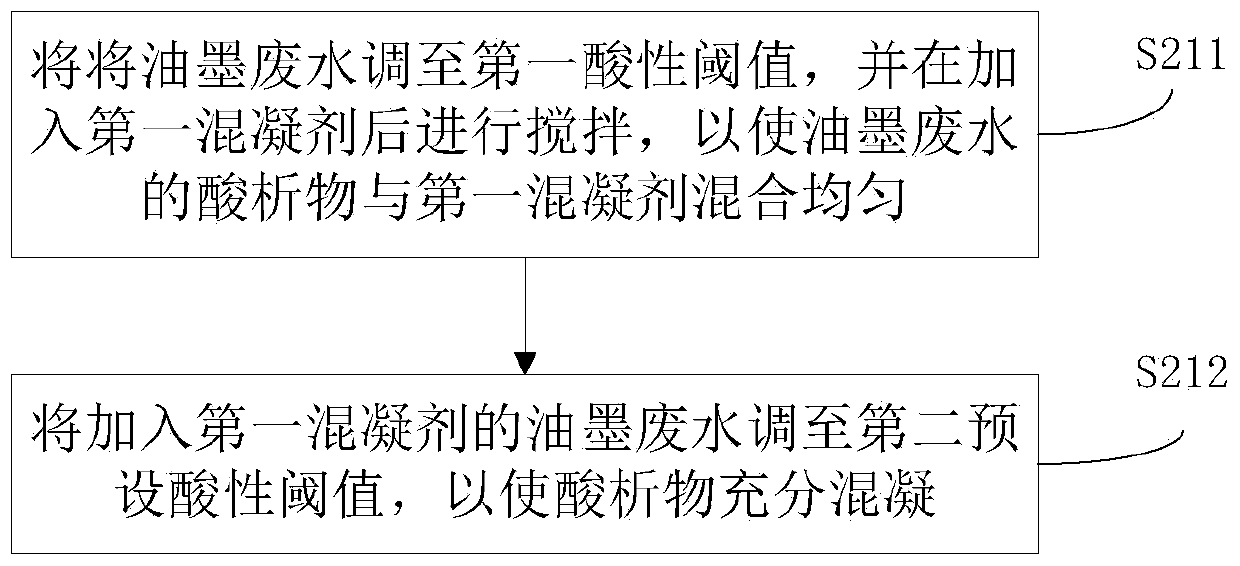

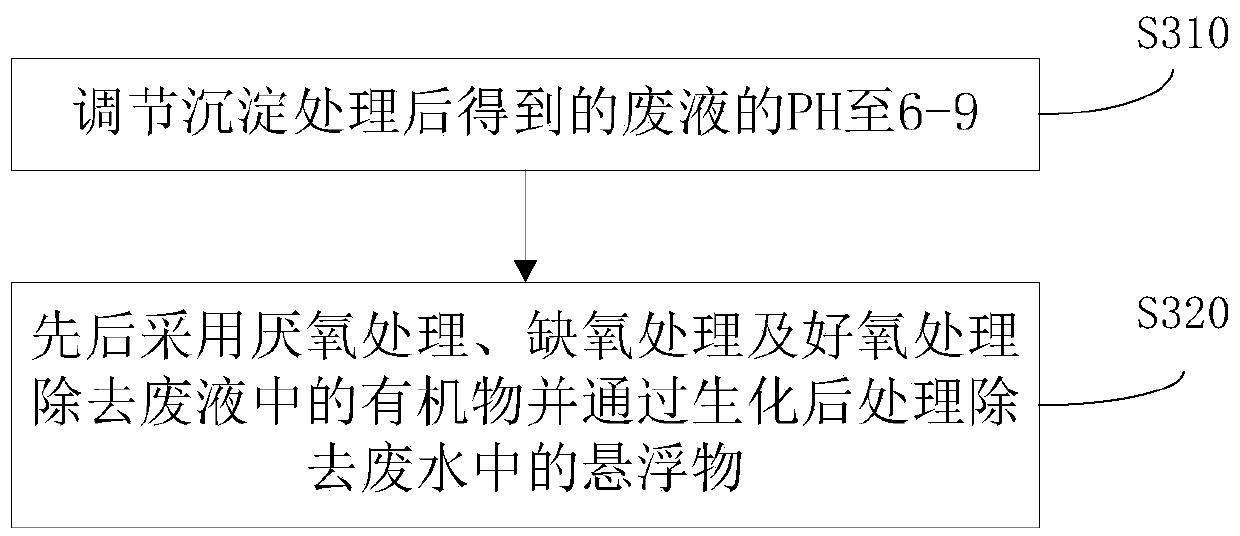

Treatment method for printed circuit board sewage

InactiveCN109987745AReduce solid particle contentReduce compactionTreatment involving filtrationWaste water treatment from metallurgical processLiquid wasteChemical oxygen demand

The invention discloses a treatment method for printed circuit board sewage. The method comprises the following steps: adjusting ink wastewater to be acidic, and adding a first coagulant into the inkwastewater adjusted to be acidic for full coagulation; adding a first flocculating agent into the ink wastewater in which the first coagulant is added; and performing precipitation treatment on the flocculated ink wastewater, and performing oxidation treatment on the waste liquid obtained after the precipitation treatment. By the above manner, the method provided by the invention can reduce hardening of sludge at the bottom of a precipitation tank and further reduce a chemical oxygen demand of the sewage.

Owner:SHENNAN CIRCUITS

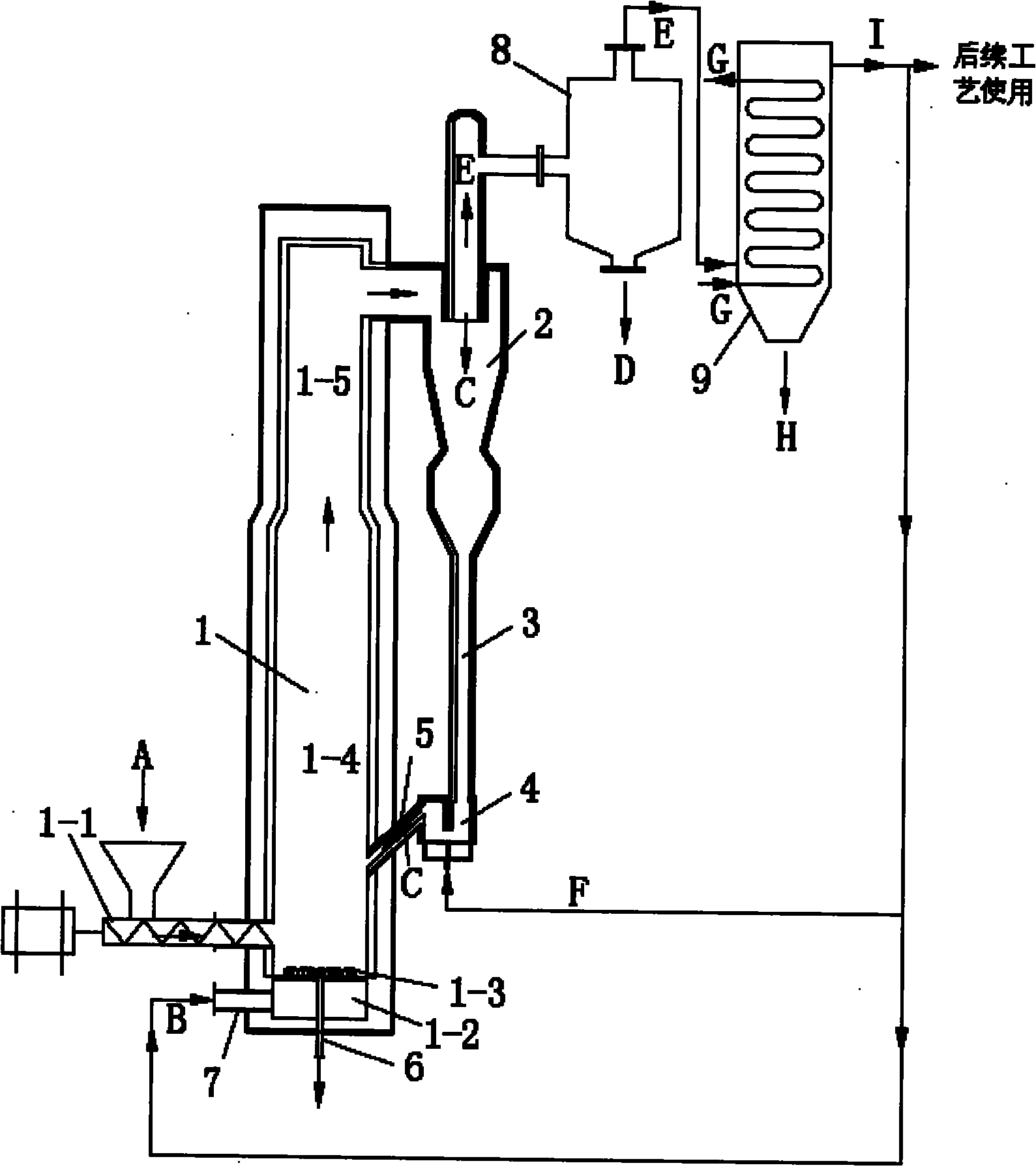

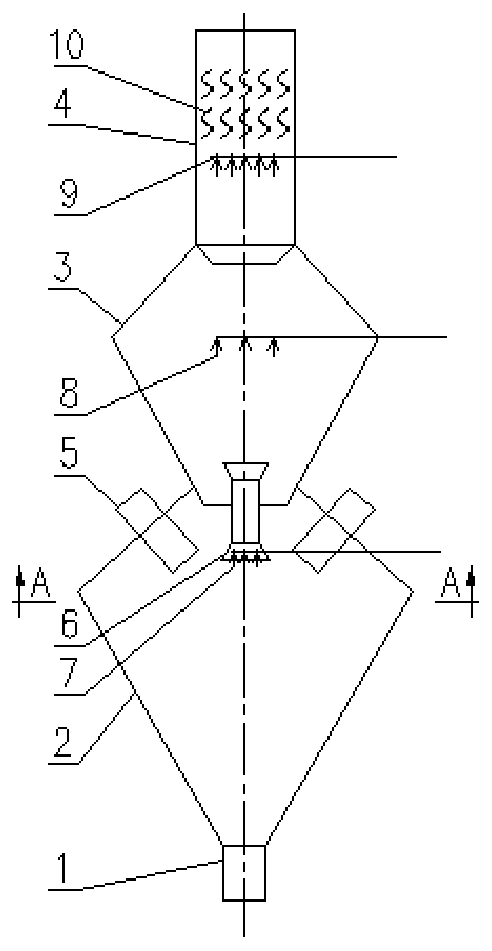

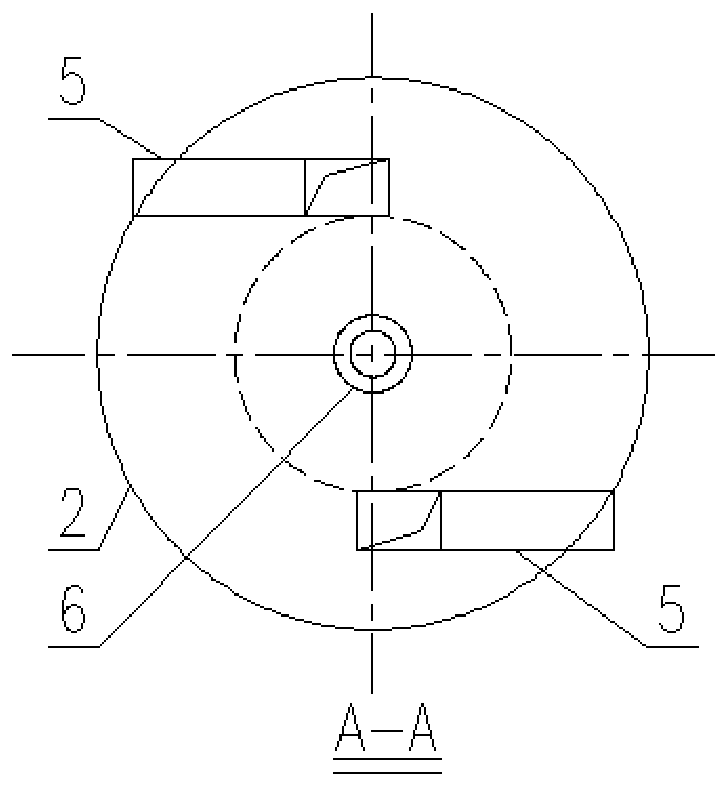

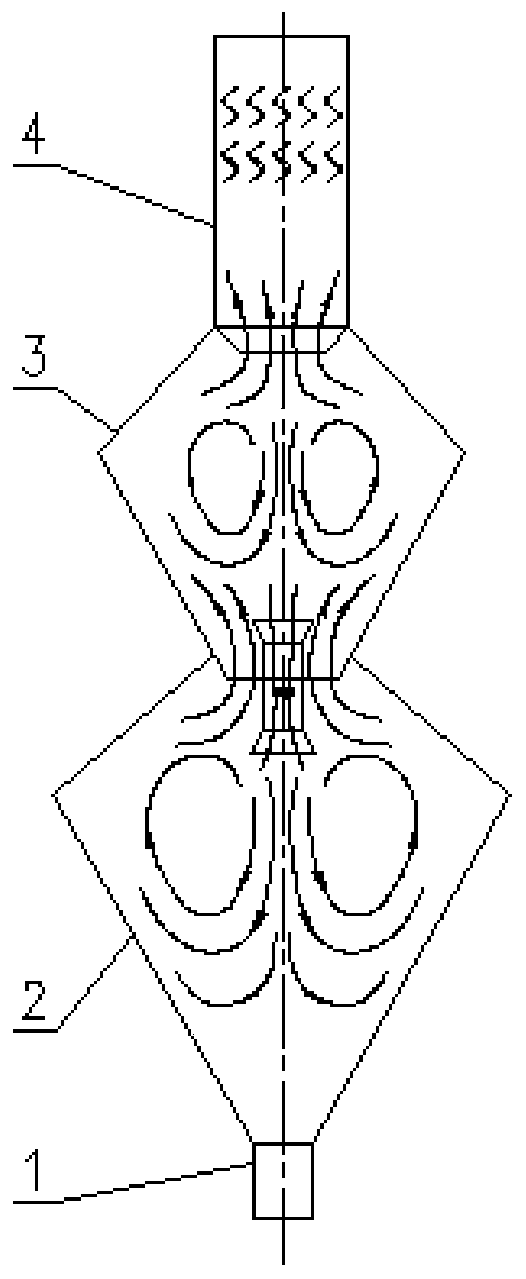

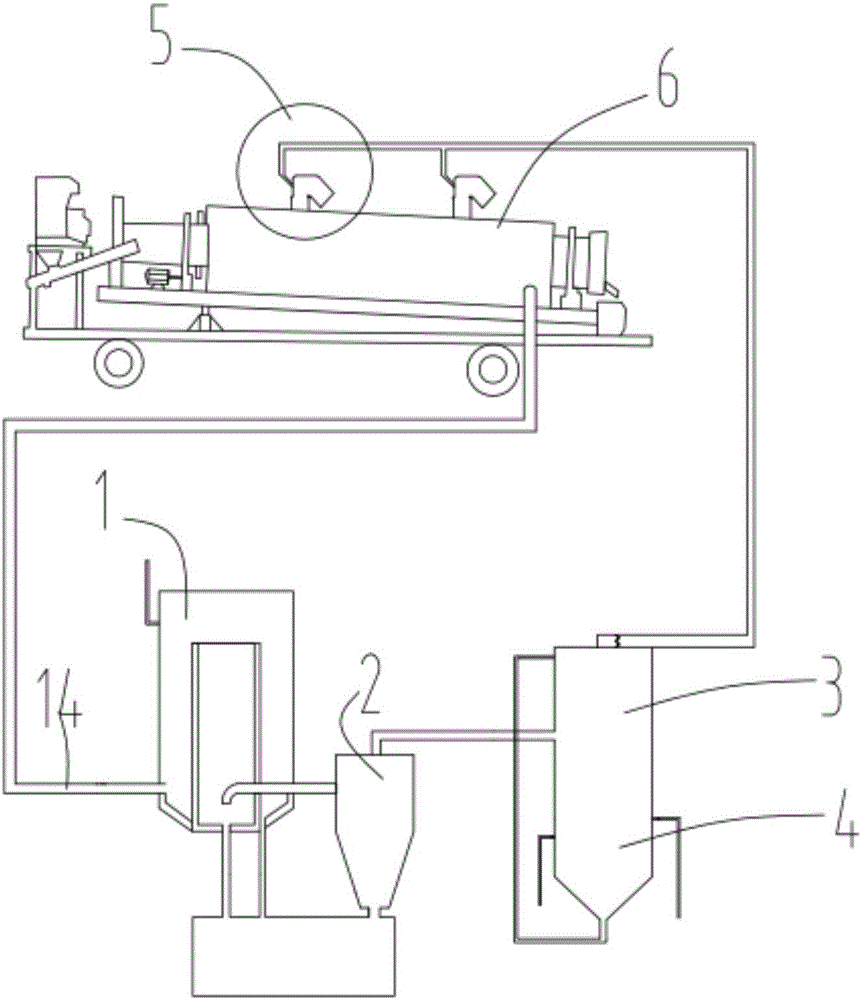

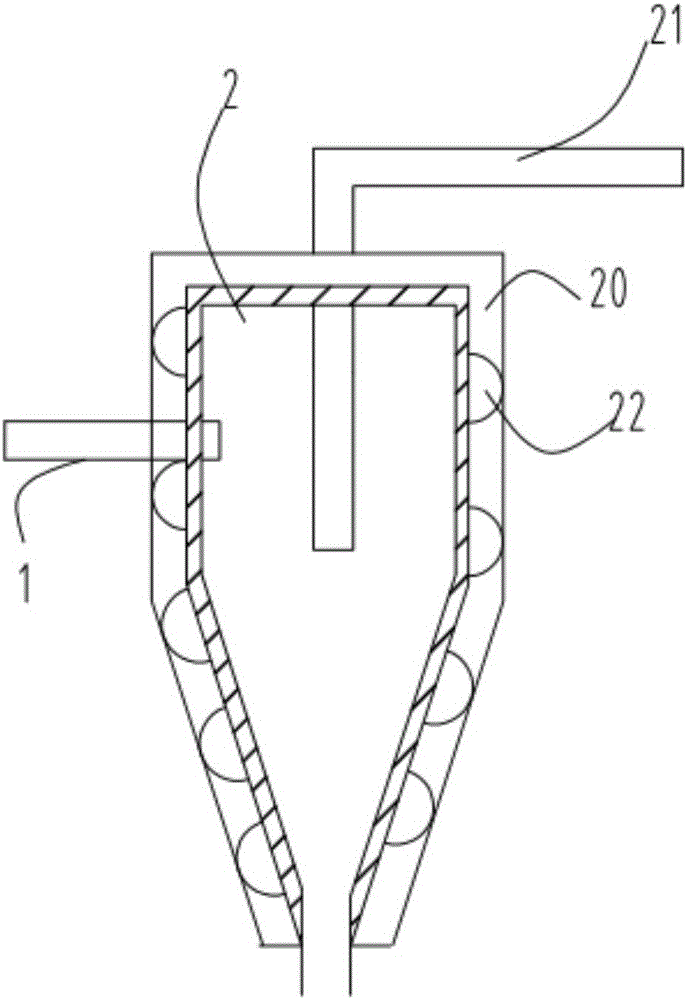

Diseased animal pyrolysis and charring treatment system

InactiveCN105688570AAvoid separationSeparation avoids increasingCombination devicesBurner safety arrangementsNitrogen oxidesCombustor

The invention relates to a diseased animal pyrolysis and charring treatment system. The diseased animal pyrolysis and charring treatment system comprises a cyclone deduster, a spraying treatment tower, an oil and water separator, a combustor and a pyrolysis and charring furnace, wherein the oil and water separator comprises a conical inlet, a vertical passage, a conical outlet and a conical separating plate; a sediment chamber is arranged at the lower end of the oil and water separator, and a water drain passage is arranged at the lowermost end of the sediment chamber, and is connected with a spraying nozzle in the spraying treatment tower; a heating sleeve is arranged at the outer surface of the cyclone deduster, and a heating coil is arranged between the heating sleeve and the cyclone deduster; the combustor comprises a fuel discharge assembly, an air pipeline, a combustor wall, an igniter and a venturi pipe, the fuel discharge assembly comprises a discharge end, a fuel lifting pipe and a flame stabilizing structure, and the flame stabilizing structure is arranged at the first inside of one side of the axis of the combustor wall. The diseased animal pyrolysis and charring treatment system has the advantage that the problem of large emission amount of NOX (nitrogen oxide) is solved, the gas produced by pyrolysis and charring is sufficiently utilized, and the purifying stress of tail gas is decreased.

Owner:CHANGXING JINNUO MACHINERY CO LTD

Diseased animal pyrolysis and charring treatment system

InactiveCN105688572AAvoid separationSeparation avoids increasingBurner safety arrangementsCombination devicesNitrogen oxidesCombustor

The invention relates to a diseased animal pyrolysis and charring treatment system. The diseased animal pyrolysis and charring treatment system comprises a cyclone deduster, a spraying treatment tower, an oil and water separator, a combustor and a pyrolysis and charring furnace, wherein the oil and water separator comprises a conical inlet, a vertical passage, a conical outlet and a conical separating plate; a sediment chamber is arranged at the lower end of the oil and water separator, and a water drain passage is arranged at the lowermost end of the sediment chamber, and is connected with a spraying nozzle in the spraying treatment tower; a heating sleeve is arranged at the outer surface of the cyclone deduster, and a heating coil is arranged between the heating sleeve and the cyclone deduster; the combustor comprises a fuel discharge assembly, an air pipeline, a combustor wall, an igniter and a venturi pipe, the fuel discharge assembly comprises a discharge end, a fuel lifting pipe and a flame stabilizing structure, and the flame stabilizing structure is arranged at the first inside of one side of the axis of the combustor wall. The diseased animal pyrolysis and charring treatment system has the advantage that the problem of large emission amount of NOX (nitrogen oxide) is solved, the gas produced by pyrolysis and charring is sufficiently utilized, and the purifying stress of tail gas is decreased.

Owner:CHANGXING JINNUO MACHINERY CO LTD

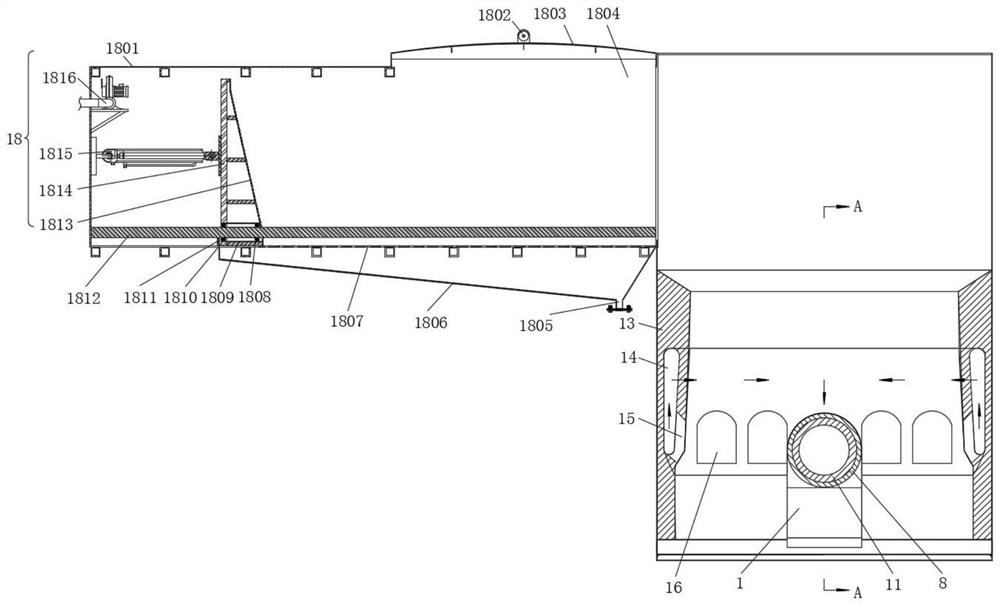

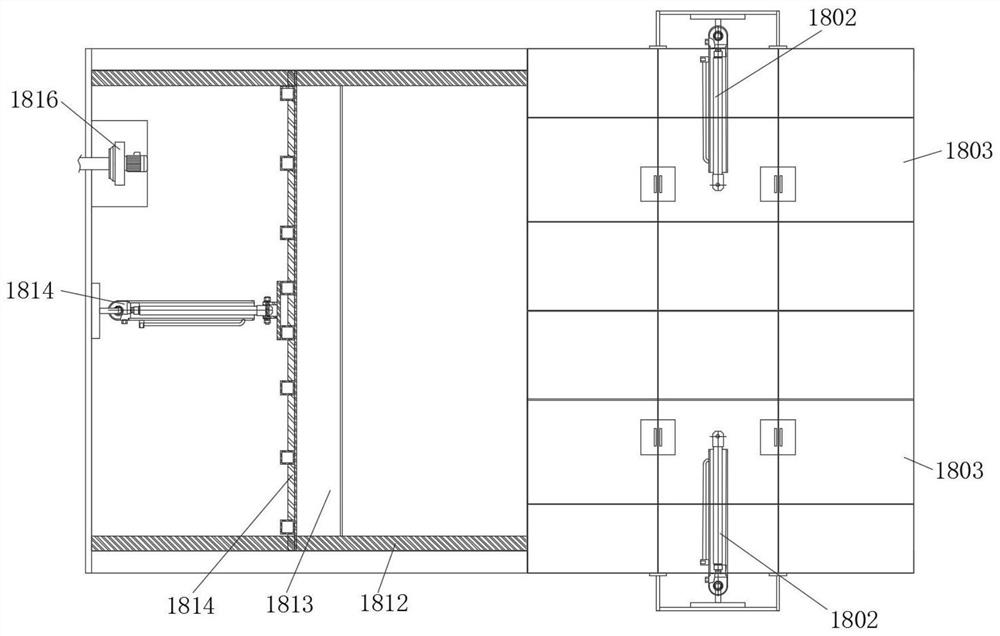

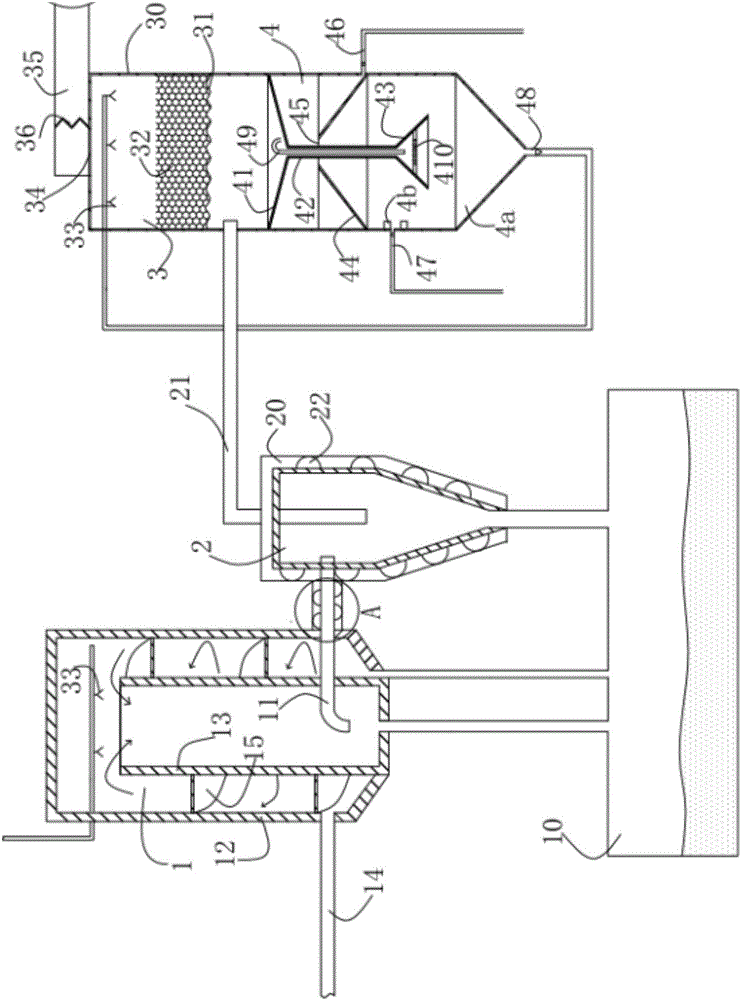

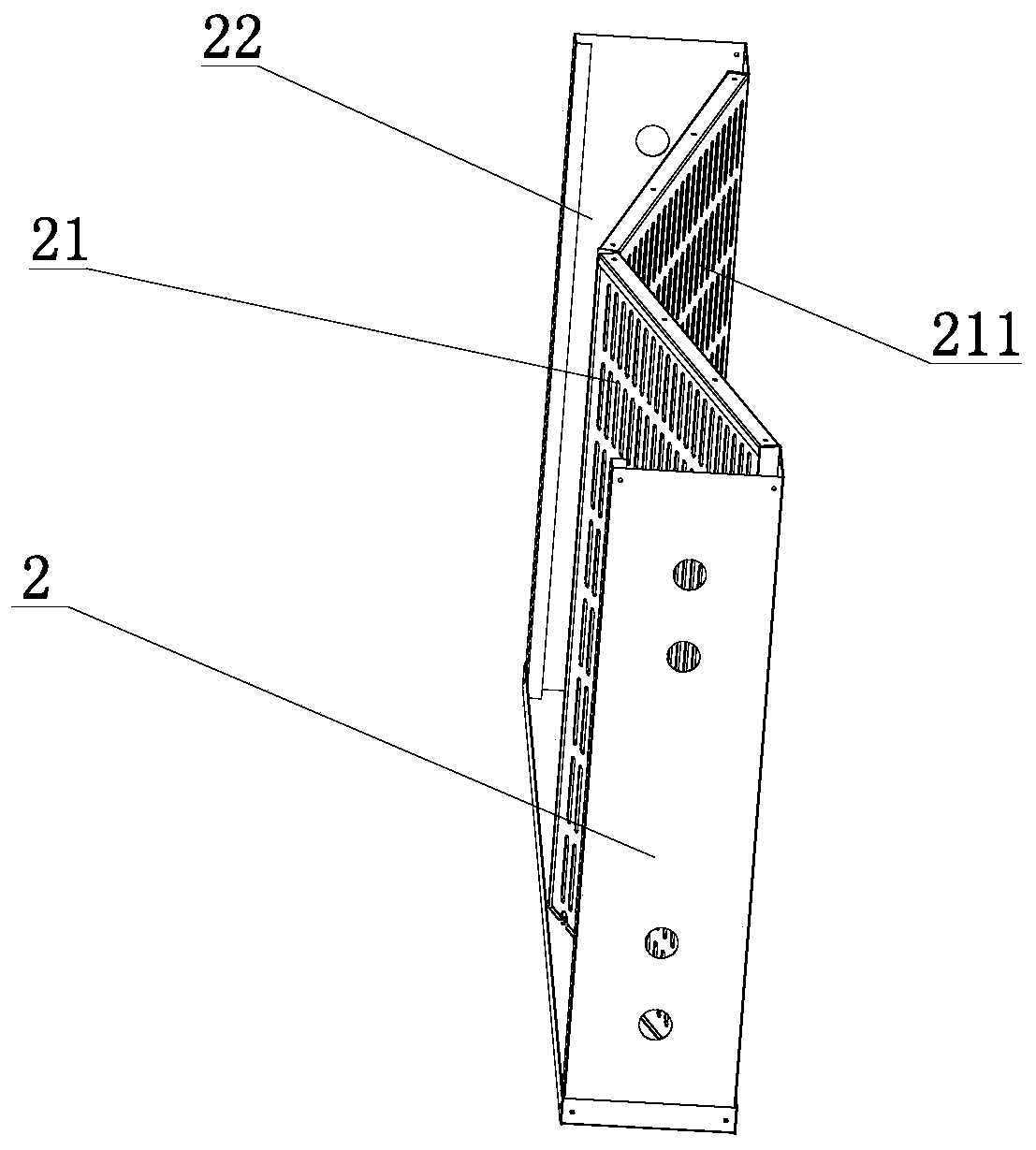

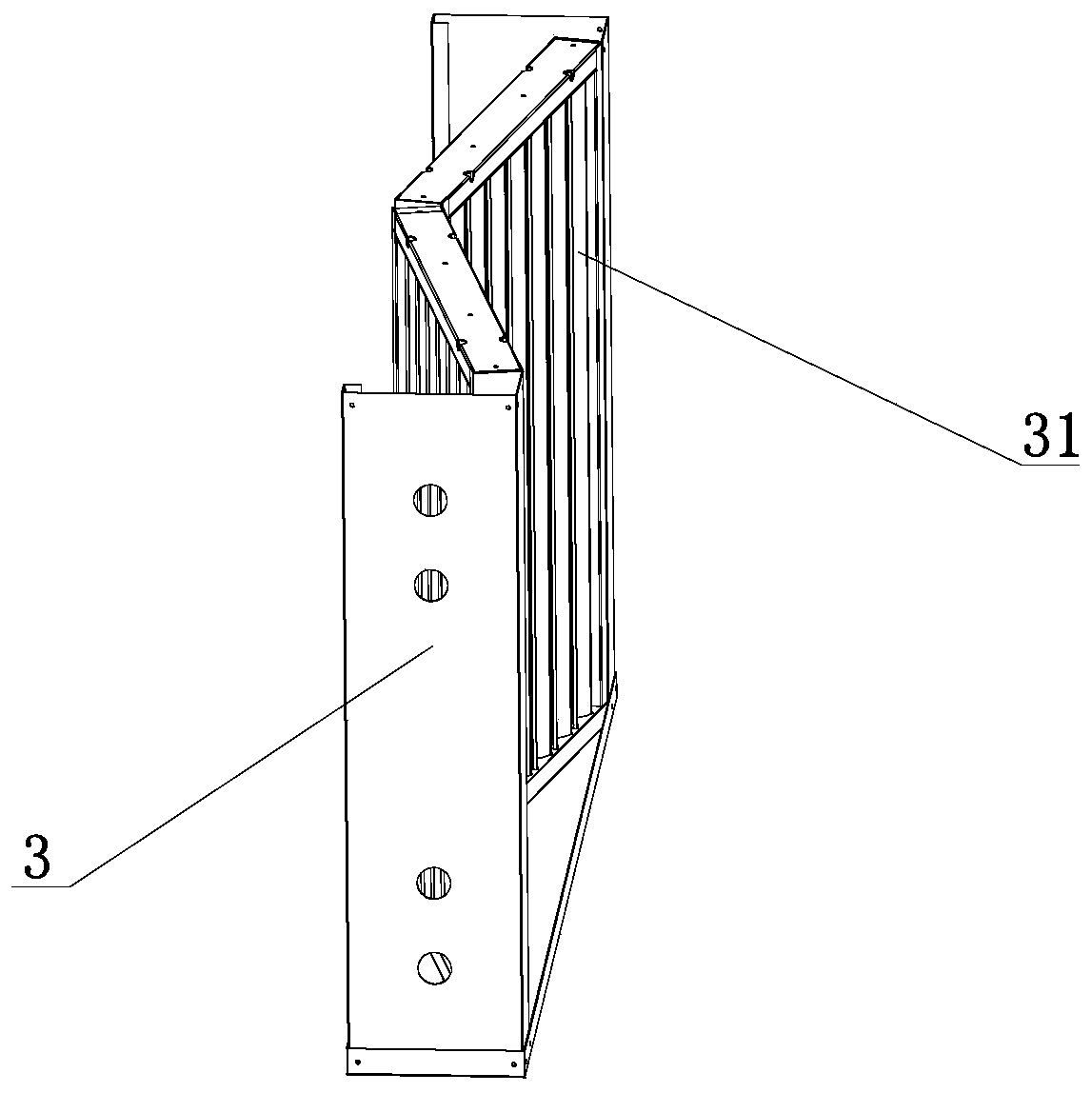

Modular garbage oxidation treatment device

PendingCN113390085ARealize secondary oxidation operationReduce solid particle contentSolid waste disposalIncinerator apparatusThermodynamicsFlue gas

The invention discloses a modularized garbage oxidation treatment device, and relates to the technical field of garbage treatment. The modularized garbage oxidation treatment device comprises a machine box part, wherein a dehydration and feeding module is arranged on the side portion of the machine box part; the dehydration and feeding module comprises a box body part connected with the upper portion of the case part; a material pushing plate body is arranged in the box body part; filter holes are formed in the bottom of the box body part; a shell is arranged below the filter holes; a flue gas inner side air channel is arranged in the machine box part in a surrounding mode; and an opening for flue gas to enter is formed in the lower portion of the flue gas inner side air channel. According to the device, dehydration and feeding operation can be conducted on garbage, secondary oxidation operation can be conducted on flue gas, sufficient secondary oxidation of the garbage flue gas is achieved, and the content of solid particles of carbonaceous compounds in the whole waste gas of the device is greatly reduced; and the device is further provided with a supporting bridge body, which is of a spliced bridge type structure, and a plurality of important parts are made into a split type connecting structure, so that a flue gas conveying pipeline is prevented from being violently deformed in a large-batch garbage combustion treatment process, and the service life of the whole combustion device is prolonged.

Owner:湖南未名环保科技有限公司

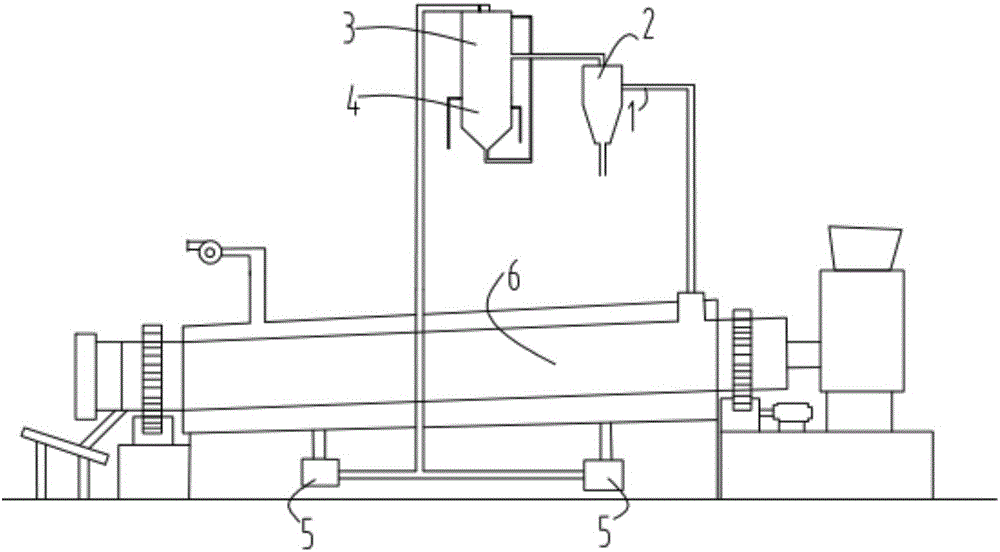

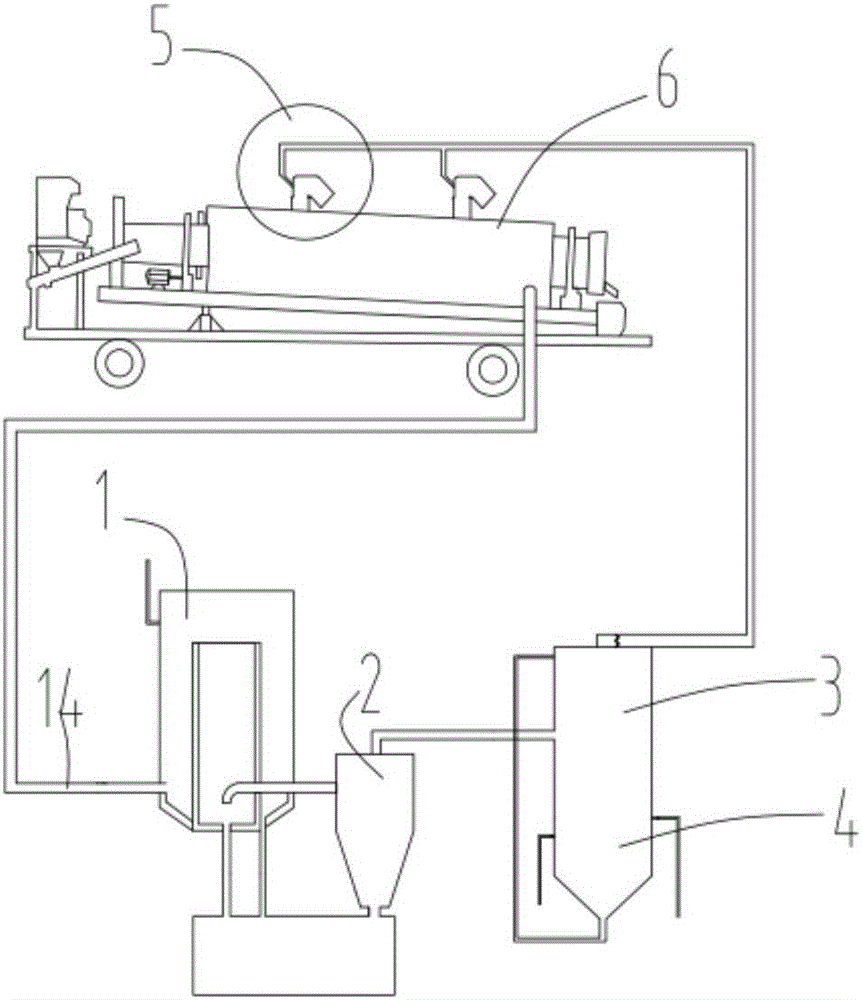

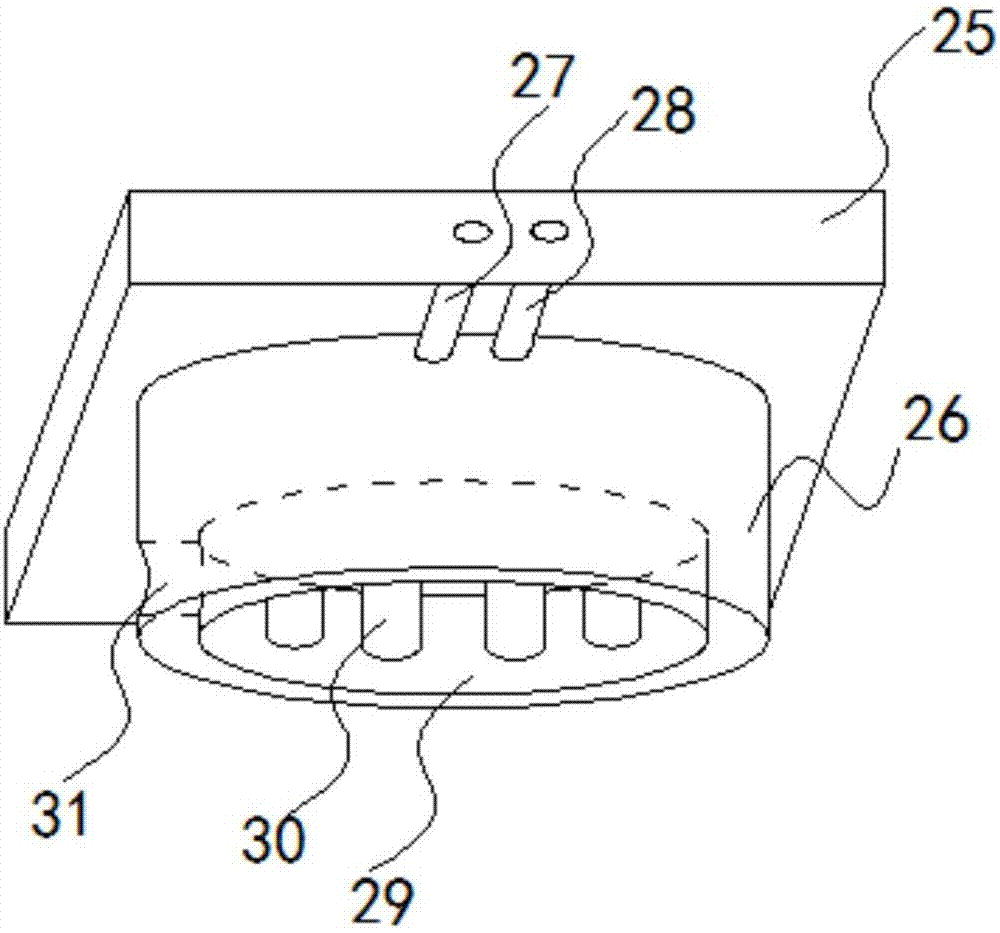

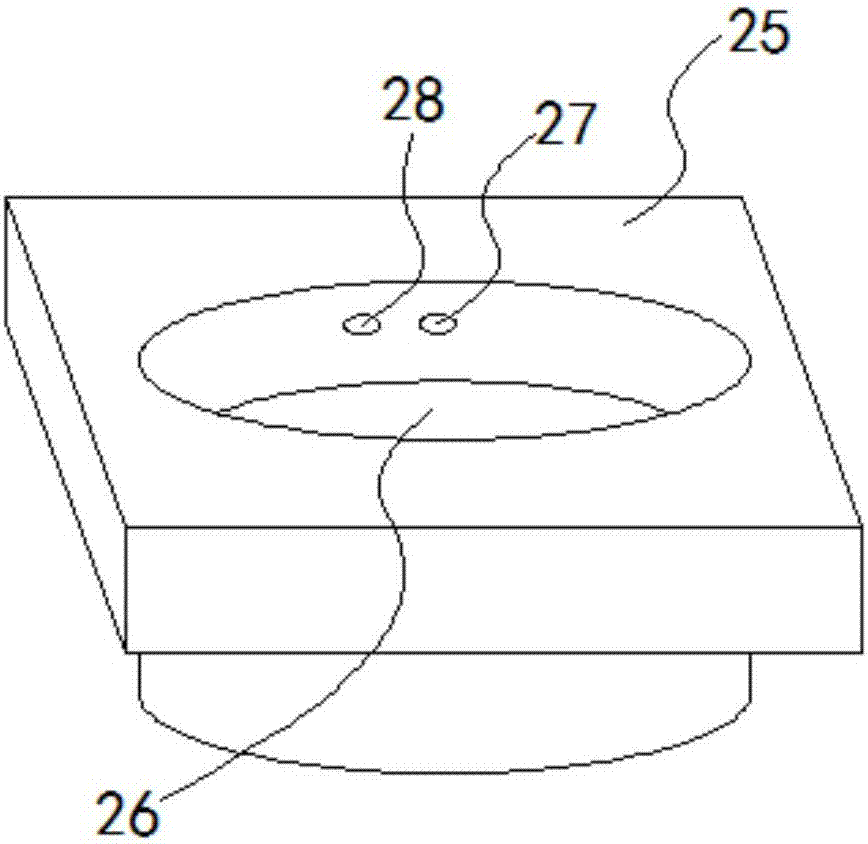

Pyrolytic charring apparatus for diseased livestock

InactiveCN105664644ASave man hoursLow costBurner safety arrangementsCombination devicesLivestockProcess engineering

The invention relates to a pyrolytic charring apparatus for diseased livestock, comprising a primary treatment column, a cyclone dust collector, a secondary treatment column, an oil-water separator, a combustor, and a pyrolytic charring furnace; the outer surface of the cyclone dust collector is provided with a heating jacket, and a heating coil is disposed between the heating jacket and the cyclone dust collector; the combustor comprises a fuel discharge assembly, an air pipeline, a combustor wall, an igniter and a Venturi tube; the fuel discharge assembly comprises a discharge end, a fuel lifting pipe and a flame stabilizing structure, flue gas passing through the secondary treatment column enters an air passage of the combustor, air is preheated and combusted, and high-temperature flue gas is produced to externally heat the pyrolytic charring furnace. The problem of high NOx emission is solved, dust and oil are fully recycled, the blockage problem is thoroughly solved, and equipment runs more smoothly.

Owner:CHANGXING JINNUO MACHINERY CO LTD

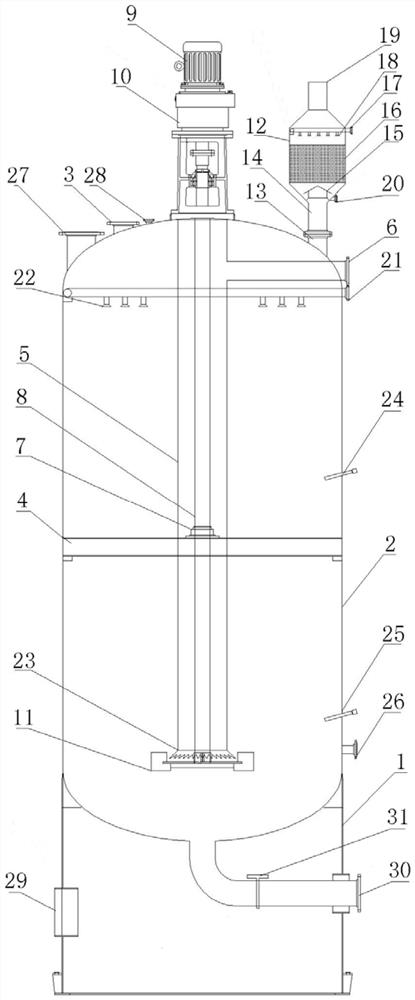

Environment-friendly nano calcium carbonate carbonation method

ActiveCN112678858AAccelerate and promote the rate of nucleationAvoid problems with uneven particle size distributionCalcium/strontium/barium carbonatesMaterial nanotechnologySlurryNanostructured carbon

The invention discloses an environment-friendly nano calcium carbonate carbonation method which comprises the following steps: S1, injecting lime slurry into a reaction kettle, stopping feeding when the feeding amount is 1 / 5-2 / 5 of the volume of the reaction kettle, and adjusting the rotating speed at the same time; introducing kiln gas into the reaction kettle, and discharging reaction tail gas after treatment; when the pH value of the slurry in the reaction kettle is 7.5-8.0, stopping air intake, and adjusting the rotating speed; and s2, injecting lime slurry into the reaction kettle containing the seed crystal, stopping feeding when the feeding amount reaches 4 / 5 of the volume of the reaction kettle, adjusting the rotating speed, stirring and aging; and introducing the kiln gas again, and when the pH value of the slurry in the reaction kettle is 7 and the slurry at the upper part and the lower part in the reaction kettle has no relative temperature difference, enabling the carbonation reaction to reach the end point. According to the method, the nano calcium carbonate with the average particle size of 40-100 nm is stably produced, and meanwhile, in the production process, the generated tail gas is treated and then discharged, so that the atmosphere is hardly influenced, and the environmental protection requirement is met.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

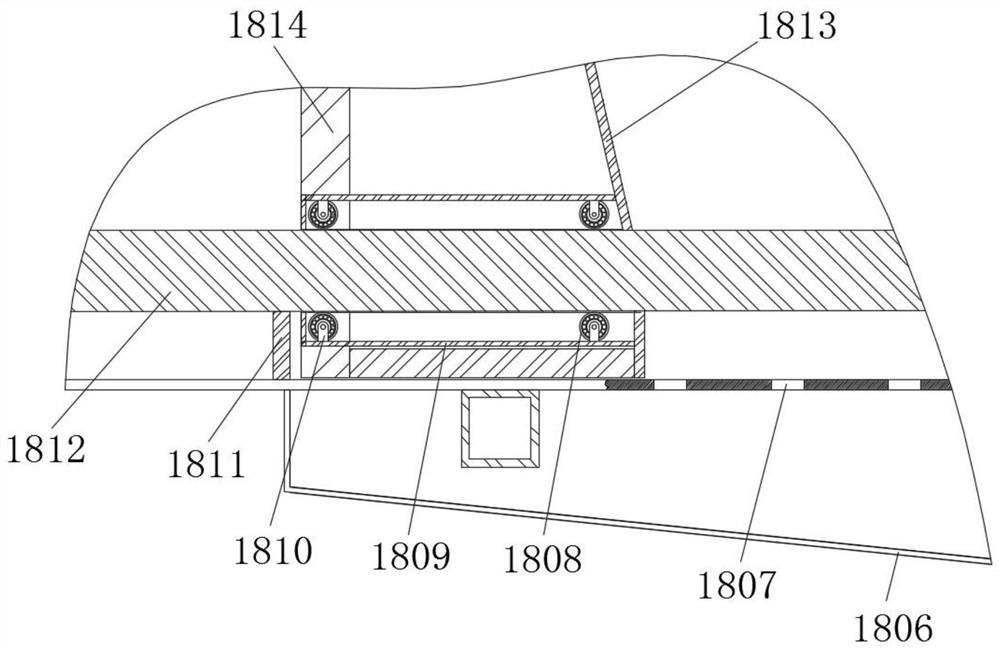

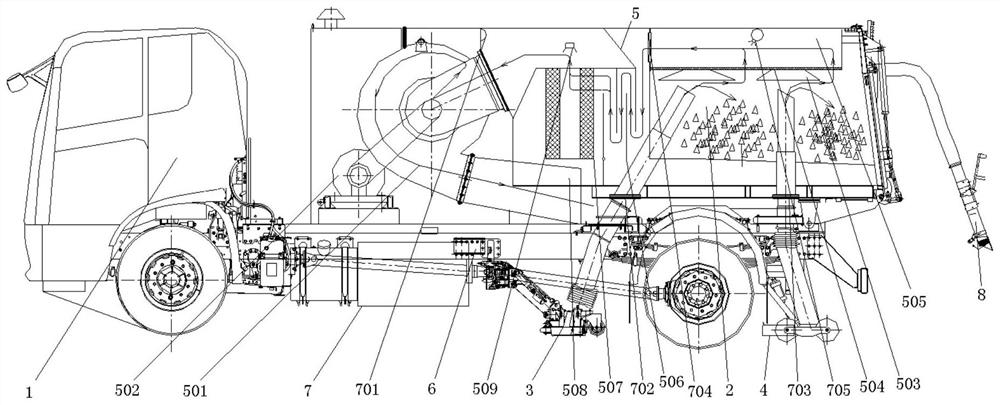

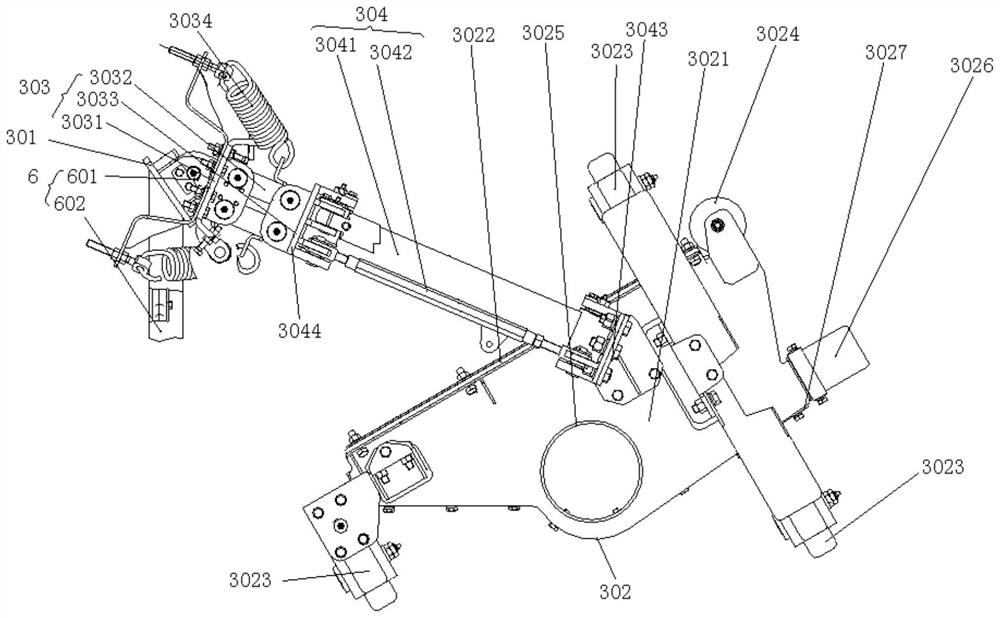

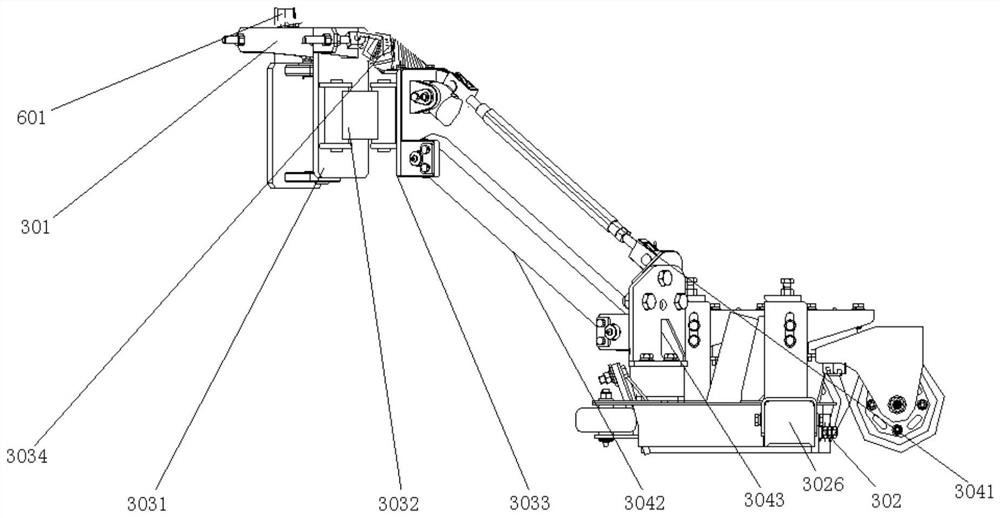

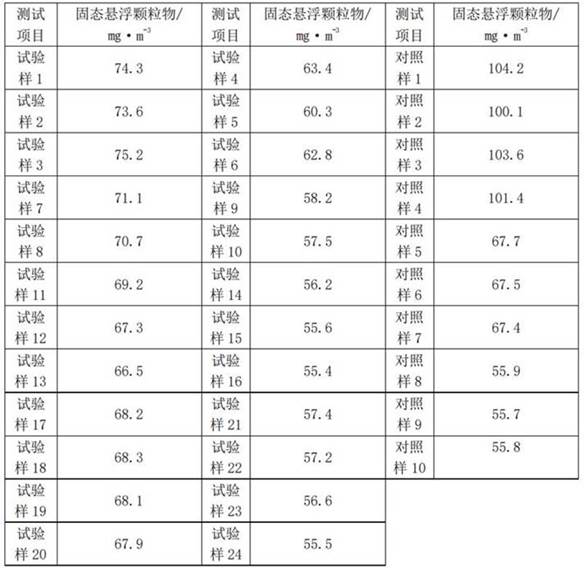

Dry type pure suction sweeper truck

The invention discloses a dry type pure suction sweeper truck which comprises a chassis and a dustbin body, the chassis is provided with side suction devices located on the two sides of the middle section of the chassis, a rear suction device located on the tail section of the chassis and a pneumatic conveying device located on the chassis. The pneumatic conveying device is positioned in an area between the vehicle head on the chassis and the dustbin; a multi-stage dry type dust removal device is arranged at the airflow input end of the pneumatic conveying device, and the pneumatic conveying device communicates with the inner cavity of the dustbin through the multi-stage dry type dust removal device so that vacuum negative pressure is formed in the inner cavity of the dustbin, and dust particles in the dustbin can are prevented from entering the atmosphere through the pneumatic conveying device; the side suction device and the rear suction and pickup device are independently arranged and communicate with the interior of the dustbin so as to suck and pick up garbage on the road surface through vacuum negative pressure in the dustbin. The road edge garbage can be effectively swept, operation flying dust can be effectively controlled, the content of solid particles in exhausted gas is small, and the environmental protection requirement can be met.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

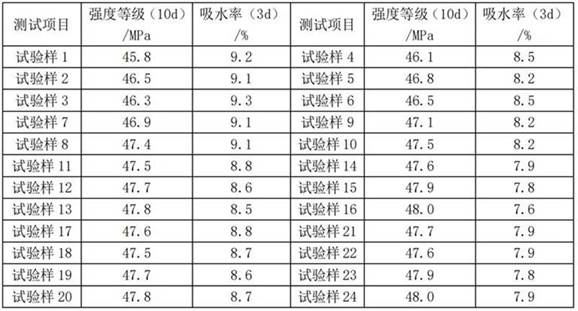

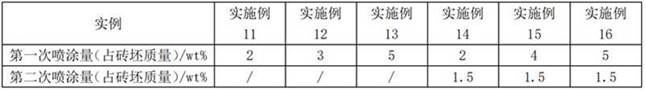

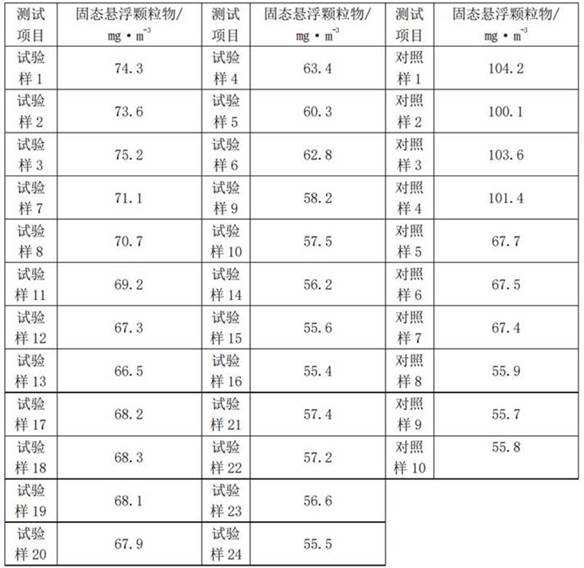

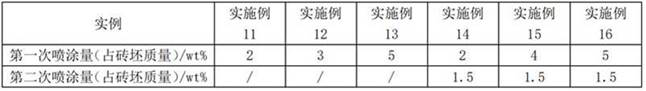

Standard brick preparation process and standard brick

ActiveCN111635255AImprove high temperature resistance and air flow erosion resistanceReduce contentCeramic materials productionClaywaresBrickPolyvinyl alcohol

The invention relates to a standard brick preparation process and a standard brick, and relates to the field of building bricks and preparation thereof. The process includes the steps of: 1. making agreen brick; 2, spraying a surface treatment liquid I accounting for 1-5wt% of the mass of the green brick to the surface of the green brick; wherein the surface treatment liquid I is prepared from the following components by mass percentage: A. 5-8% of inorganic mineral powder with a particle size of less than or equal to 1.5mm, B. 3-5% of a water-soluble polymer, C. 1.5-3.0% of fumed silica, andD. the balance water; the inorganic mineral powder is a mixture of nano aluminum oxide, cryolite powder and mica powder; and the water-soluble polymer is a mixture of polyvinyl alcohol and water-soluble chitosan; 3. under the condition of 70-90DEG C, drying the green brick sprayed with the treatment liquid I; and 4, performing roasting. The standard brick preparation process provided by the invention has the advantages that the content of solid particles in the brick making waste gas can be effectively reduced and the emission of solid particles is reduced from the source, and the prepared standard brick has the advantages of excellent physical and mechanical properties and good permeation resistance.

Owner:余姚市恒祥新型建材有限公司

Diseased animal pyrolysis and charring treatment system

InactiveCN105688575AAvoid separationSeparation avoids increasingBurner safety arrangementsCombination devicesNitrogen oxidesCombustor

The invention relates to a diseased animal pyrolysis and charring treatment system. The diseased animal pyrolysis and charring treatment system comprises a cyclone deduster, a spraying treatment tower, an oil and water separator, a combustor and a pyrolysis and charring furnace, wherein the oil and water separator comprises a conical inlet, a vertical passage, a conical outlet and a conical separating plate; a sediment chamber is arranged at the lower end of the oil and water separator, and a water drain passage is arranged at the lowermost end of the sediment chamber, and is connected with a spraying nozzle in the spraying treatment tower; a heating sleeve is arranged at the outer surface of the cyclone deduster, and a heating coil is arranged between the heating sleeve and the cyclone deduster; the combustor comprises a fuel discharge assembly, an air pipeline, a combustor wall and an igniter, the fuel discharge assembly comprises a discharge end, a fuel lifting pipe and a flame stabilizing structure, and the flame stabilizing structure is arranged at the first inside of one side of the axis of the combustor wall. The diseased animal pyrolysis and charring treatment system has the advantage that the problem of large emission amount of NOX (nitrogen oxide) is solved, the gas produced by pyrolysis and charring is sufficiently utilized, and the purifying stress of tail gas is decreased.

Owner:CHANGXING JINNUO MACHINERY CO LTD

Standard brick preparation process and standard brick

ActiveCN111635255BImprove high temperature resistance and air flow erosion resistanceReduce contentCeramic materials productionClaywaresBrickPolyvinyl alcohol

The invention relates to a standard brick preparation process and a standard brick, and relates to the field of building bricks and their preparation. The process comprises steps: 1. Making a brick; 2. Spraying a surface treatment liquid accounting for 1-5 wt% of the brick mass on the surface of the brick I; surface treatment liquid I is composed of: A, 5-8% of inorganic mineral powder with particle size ≤ 1.5mm, B, 3-5% of water-soluble polymer, C, 1.5-3.0% of fumed silica , D, water balance, composition; Inorganic mineral powder is the mixture of nano-alumina, cryolite powder and mica powder; Water-soluble polymer is the mixture of polyvinyl alcohol and water-soluble chitosan; 3, under the condition of 70-90 ℃ Drying the adobe sprayed with the treatment solution I; 4. Roasting. The standard brick preparation process of the present invention can effectively reduce the content of solid particles in brick-making waste gas, and has the advantage of reducing the emission of solid particles from the source, and the prepared standard brick has the advantages of good physical and mechanical properties and good permeability resistance.

Owner:余姚市恒祥新型建材有限公司

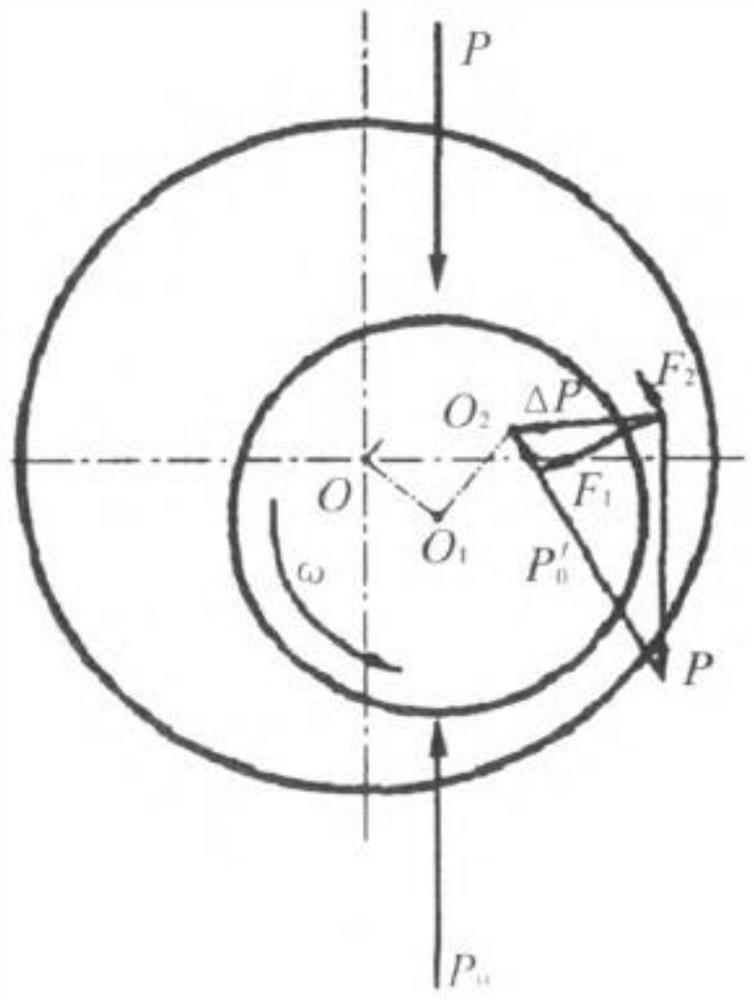

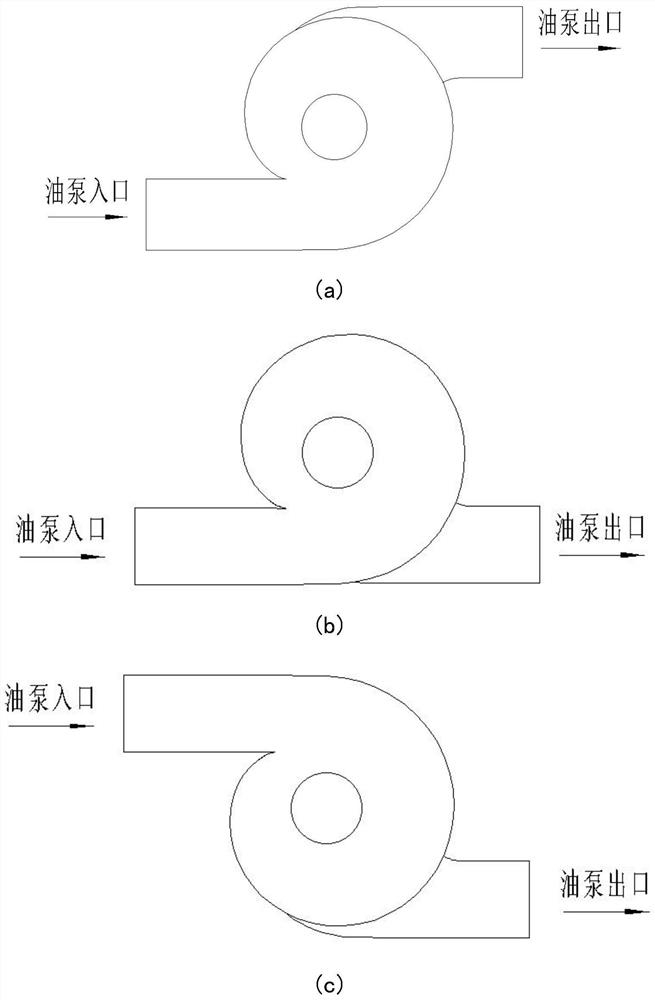

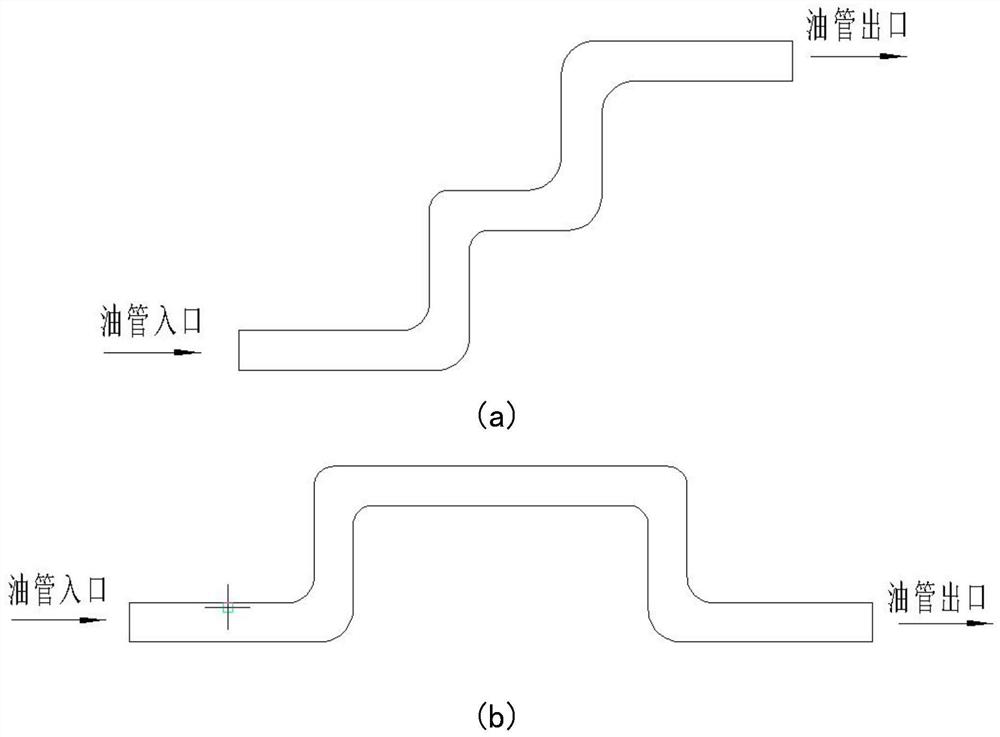

Method for reducing oil film oscillation harm

InactiveCN112728391AStrong targetingEasy to measureLubricant transferHydro energy generationAir entrainmentSolid particle

The invention provides a method for reducing the oil film oscillation harm of a steam turbine generator. The vibration harm caused by oil film oscillation can be reduced. The method mainly comprises the three steps that firstly, a lower-inlet and upper-outlet lubricating oil supply pump is designed and selected, and a lower-inlet and lower-outlet oil supply pump or an upper-inlet and lower-outlet type oil supply pump is not adopted, so that air entrainment in lubricating oil caused by air suffocation and air clogging in the oil supply pump is avoided; secondly, in the design and arrangement of a lubricating oil conveying pipeline, the lubricating oil conveying pipeline is arranged in a mode of only ascending and not descending in the flowing direction, and an upward convex pipeline design is not adopted, so that the situation that gas is suffocated in the upward convex part and mixed in the lubricating oil to be conveyed to a bearing is avoided; and thirdly, the lubricating oil is frequently filtered so as to reduce the content of solid particles and bubbles carried by the solid particles, and the lubricating oil is heated before startup to reduce the bubble content.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

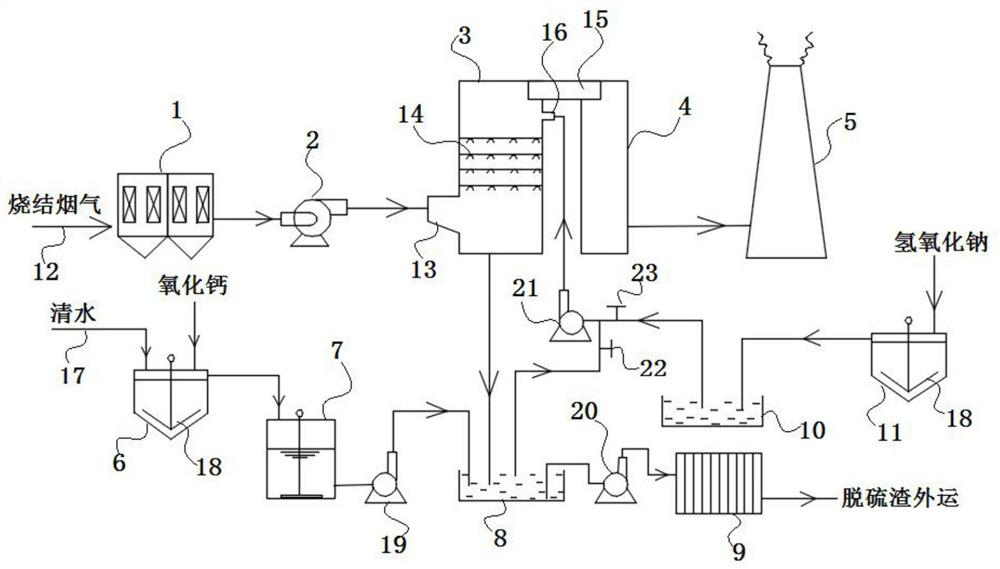

Sodium-calcium dual-alkali method sintering flue gas desulfurization device adopting sodium-calcium dual-alkali method

InactiveCN112275123AReduce solid particle contentLean structureGas treatmentDispersed particle filtrationFlue gasProcess engineering

The invention discloses a sodium-calcium dual-alkali method sintering flue gas desulfurization device, and relates to the technical field of flue gas desulfurization. The device comprises a bag-type dust collector, a fan, an absorption tower, a demisting tower, a first slurrying tank, a first alkali liquor tank, a sedimentation tank, a second slurrying tank, a second alkali liquor tank, a filter pressing device and a chimney. According to the invention, the problems of serious scaling and blockage of system equipment and pipelines due to the fact that circulating spray liquid still contains solid-phase particles such as gypsum in practical application of the dual-alkali desulfurization device are solved, and the device is provided with the first slurrying tank, the second slurrying tank and the stirring device, sodium hydroxide and calcium oxide are more fully dissolved in water so that sodium hydroxide and calcium oxide react with flue gas more fully to connect the first liquid suction pipe and the first liquid suction pipe; the first liquid suction pipe sucks supernatant on the surface of the sedimentation tank so that the content of solid particles in spraying liquid is reduced,and the serious structure and blockage of equipment are reduced.

Owner:安徽昊天生物科技有限公司

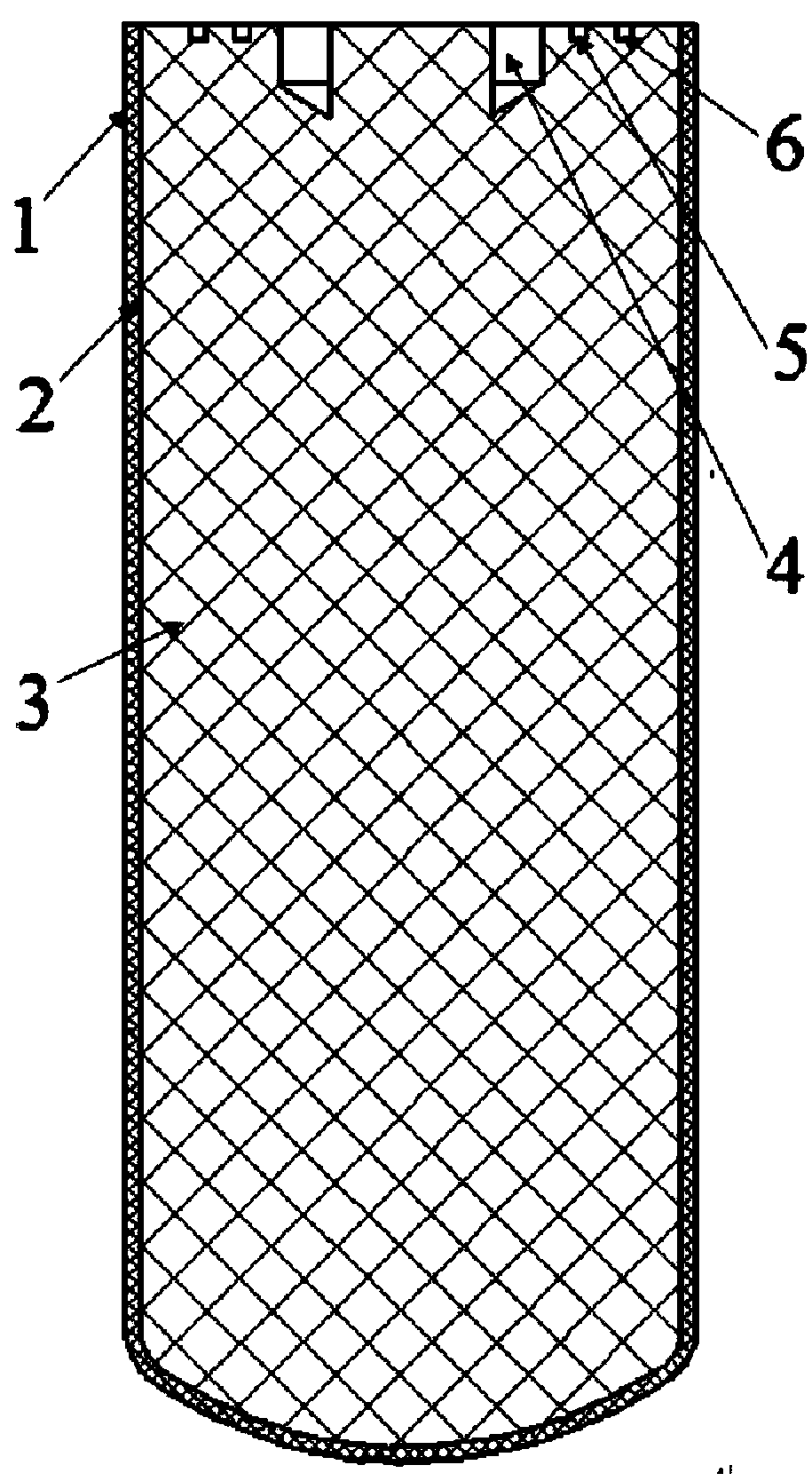

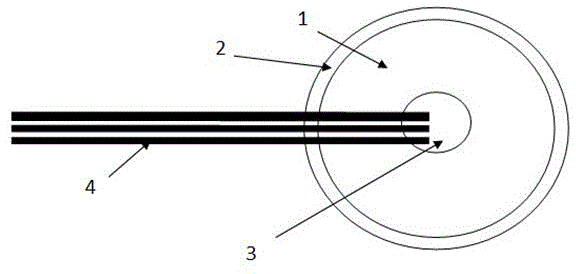

A double working condition gas generating agent grain

The invention relates to a dual-working-condition gas generating agent powder column. The gas generating agent is installed in a heat-insulating sleeve. The center of the gas generating agent is provided with a high-burning-velocity drug strip, and the surface of the gas generating agent is provided with an inner ring. The combustion-supporting groove and the outer ring combustion-supporting groove, a liner is provided at the side where the side of the gas generating agent is in contact with the heat insulating sleeve. The gas generating agent grain under dual working conditions starts to burn simultaneously from the surface of the gas generating agent, the surface of the combustion-supporting groove and the surface of the high-burning rate grain, and the burning surface shows a slow decreasing trend, and this trend lasts for a long time. The invention is used in a missile servo power device, and has the advantages of low combustion temperature, long duration of slowing down tendency of the combustion surface, multi-stage charge and multi-working-condition pressure through a single combustion rate charge, and the like.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Pyrolytic charring apparatus for diseased livestock

InactiveCN105664645AAvoid separationSeparation avoids increasingBurner safety arrangementsCombination devicesCombustorFlue gas

The invention relates to a pyrolytic charring apparatus for diseased livestock, comprising a primary treatment column, a cyclone dust collector, a secondary treatment column, an oil-water separator, a combustor, and a pyrolytic charring furnace; the outer surface of the cyclone dust collector is provided with a heating jacket, and a heating coil is disposed between the heating jacket and the cyclone dust collector; the combustor comprises a fuel discharge assembly, an air pipeline, a combustor wall, and an igniter; the fuel discharge assembly comprises a discharge end, a fuel lifting pipe and a flame stabilizing structure, the flame stabilizing structure is disposed on a first inner side of one side of the axis of the combustor wall, flue gas passing through the secondary treatment column enters an air passage of the combustor for combusting reaction, and high-temperature flue gas is produced to externally heat the pyrolytic charring furnace. The problem of high NOx emission is solved, dust and oil are fully recycled, the blockage problem is thoroughly solved, and equipment runs more smoothly.

Owner:CHANGXING JINNUO MACHINERY CO LTD

Energy-saving cooking range

PendingCN106931466AImprove utilization efficiencyImprove protectionLighting and heating apparatusStove/ranges for heating waterCombustion chamberWaste heat

The invention discloses an energy-saving cooking range. The energy-saving cooking range comprises a fuel cavity, a main combustion chamber, a waste heat recovery chamber, a screw feeder, a driving device and a fan, wherein the main combustion chamber is internally provided with a fire scattering basin used for containing a combustion medium, the screw feeder is driven by the driving device to run, the bottom of the fuel cavity communicates to the head end of the screw feeder, the tail end of the screw feeder communicates to the inner wall of the fire scattering basin, the bottom of the fire scattering basin is provided with multiple vent holes, an air outlet of the fan communicates to the vent holes, a first through hole is formed between the main combustion chamber and the waste heat recovery chamber to make the main combustion chamber communicate with the waste heat recovery chamber, and an air outlet is formed in the waste heat recovery chamber. The energy-saving cooking range is used for solving the problems that an existing cooking range cannot fully utilize energy, and the flame is nonuniform and difficult to control in the burning process.

Owner:广东灶王科技有限公司

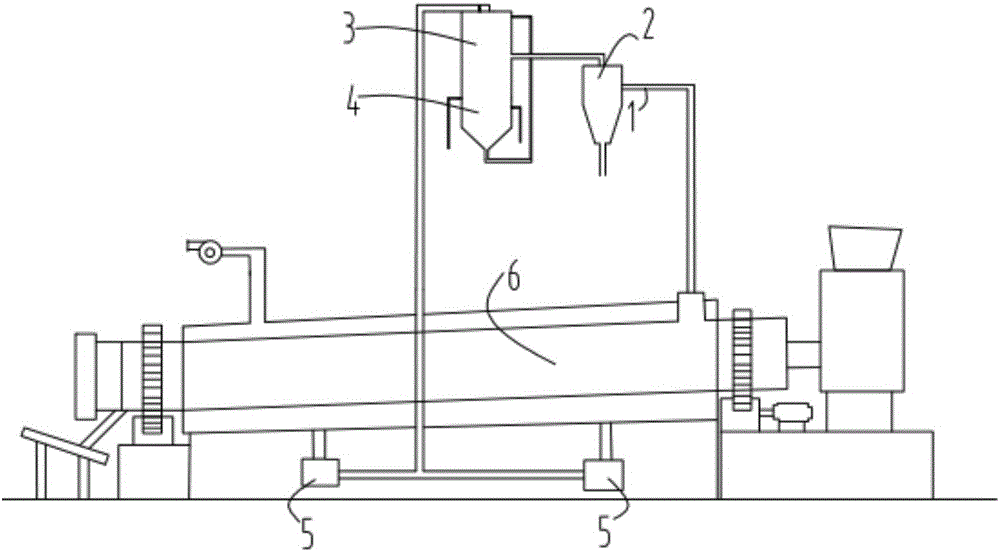

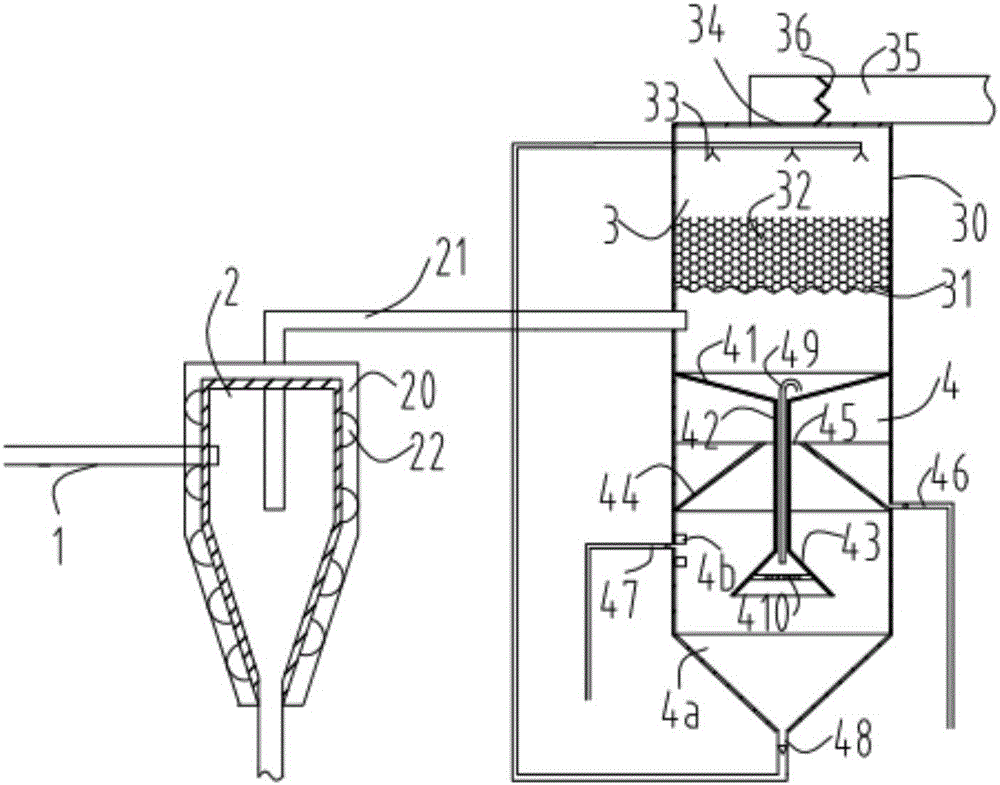

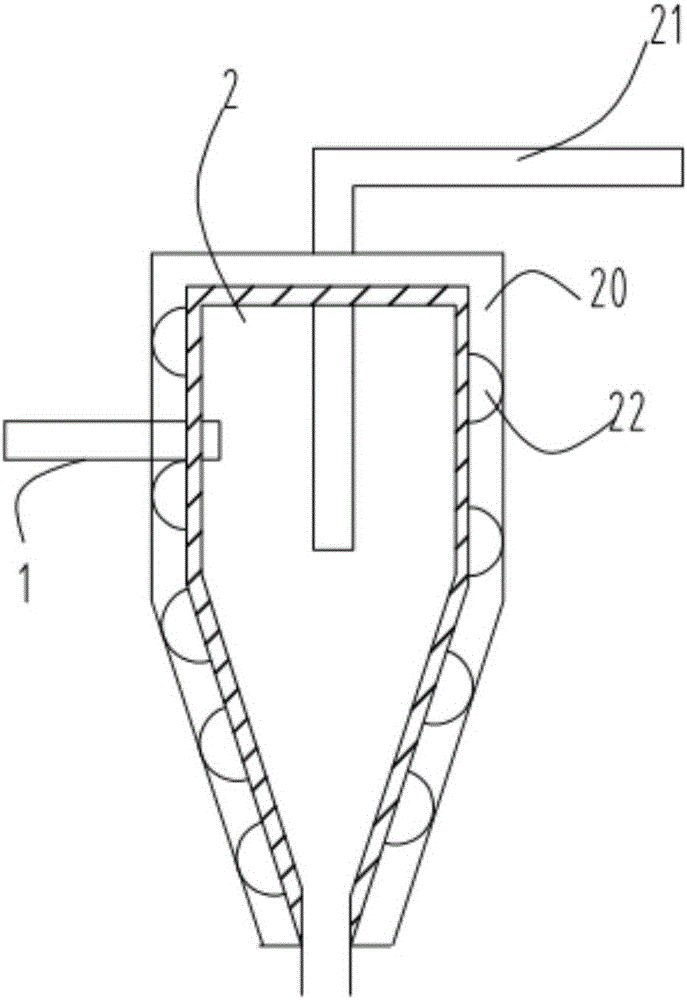

Treatment system for concentration tank of iron ore concentrates

ActiveCN103191590AReduce solid particle contentEasy to handleSettling tanks feed/dischargeSedimentation settling tanksEngineeringSolid particle

The invention relates to a treatment system for a concentration tank of iron ore concentrates. The treatment system comprises the concentration tank, a concentration tank overflow tank, a central distribution barrel and ore concentrate pipelines, wherein output ports of the ore concentrate pipelines are connected with the central distribution barrel; the concentration tank is arranged at the outer side of the central distribution barrel; the concentration tank overflow tank is arranged at the outer side of the concentration tank; the ore concentrate pipelines are composed of a plurality of thin ore concentrate pipelines and a plurality of thick ore concentrate pipelines; the plurality of thin ore concentrate pipelines are communicated with the plurality of thick ore concentrate pipelines through a fed ore distribution box; the number of the thin ore concentrate pipelines is larger than that of the thick ore concentrate pipelines; and one ends of the thick ore concentrate pipelines are connected with the central distribution barrel, and the other ends of the thick ore concentrate pipelines are connected with the fed ore distribution box. The ore concentrate pipelines are composed of the thin ore concentrate pipelines and the thick ore concentrate pipelines, so that the ore feeding flow rate is reduced to ensure that the content of solid particles in overflow water cannot exceed the standard under the condition that the concentration tank operates over a design, and furthermore, the treatment capacity of the concentration tank is enhanced, and the content of the solid particles in the overflow water is reduced.

Owner:YUNNAN DAHONGSHAN PIPELINE

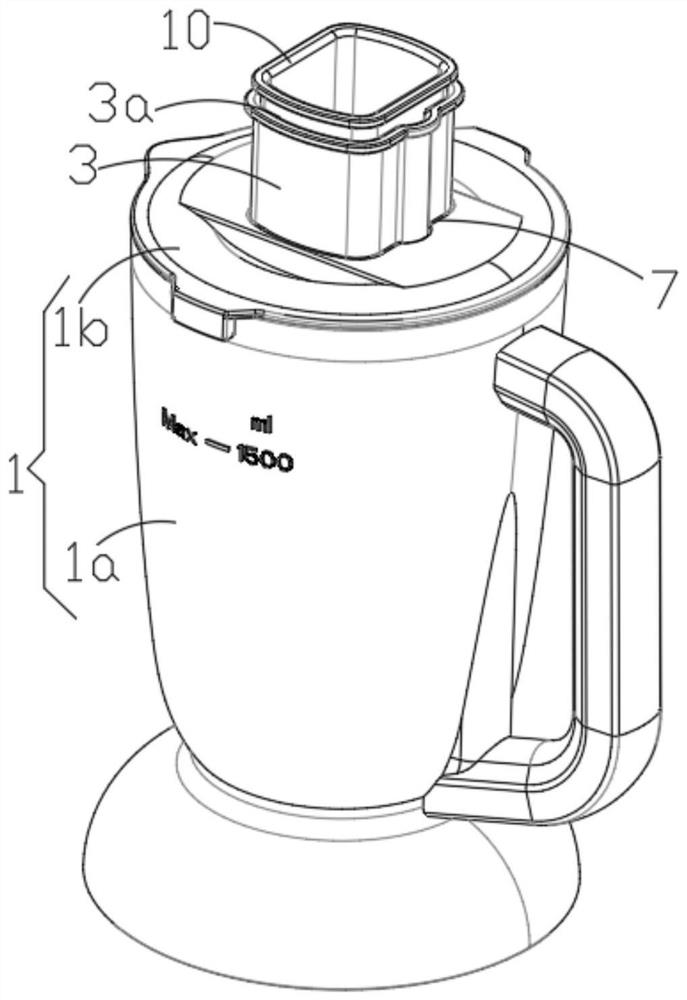

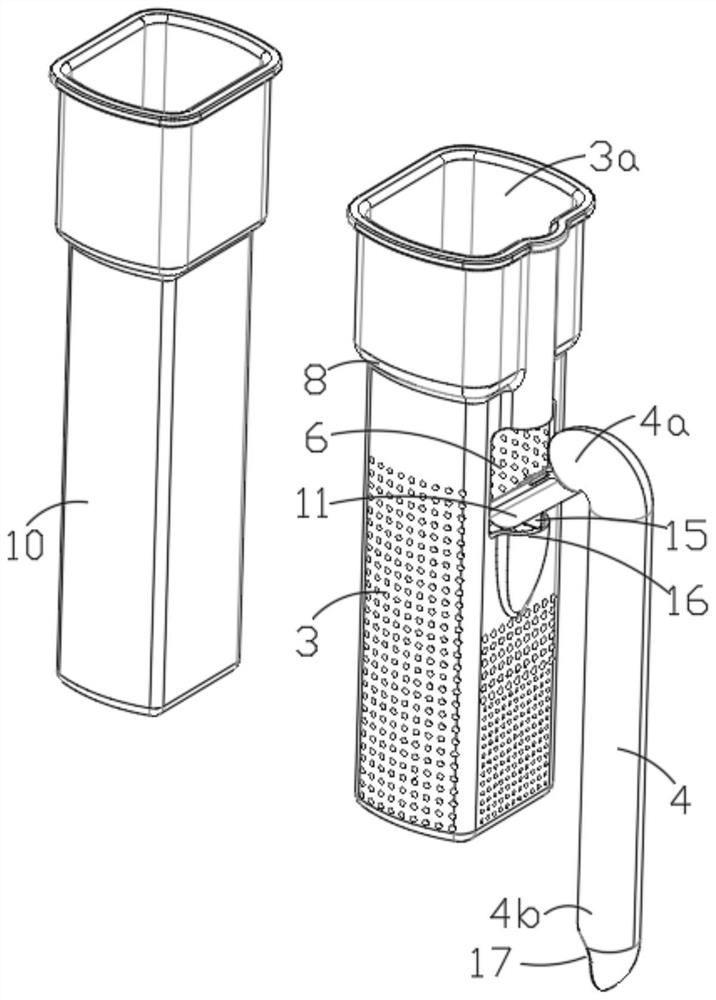

Juicer with autonomous circulation filtering function and use method thereof

PendingCN114698985AReduce solid particle contentRich product featuresStrainersFruit juiceMechanical engineering

The invention relates to a juicer with an autonomous circulation filtering function and a use method thereof.The juicer comprises a container and a rotary cutter arranged at the bottom of the container and is characterized by further comprising a filter barrel and a backflow pipe enabling juice in the container to flow back into the filter barrel to be filtered; the lower end of the filter barrel is positioned in the container; a juice outlet end and a juice inlet end for guiding juice into the filter barrel are formed at the upper end and the lower end of the backflow pipe respectively, a press-in part for pressing the juice into the juice inlet end is eccentrically arranged on the rotary cutter, and a liquid inlet corresponding to an outlet of the backflow pipe is formed in the filter barrel; according to the juicer, through mutual cooperation of the press-in part, the backflow pipe and the specially-made filter barrel, the content of solid particles such as residues and kernels in vegetable and fruit juice can be effectively and obviously reduced, the blocking situation can be prevented, the product functions of the juicer are enriched, and the use experience feeling of a user is improved.

Owner:T F ELECTRICAL TECH SHENZHEN

Anti-blocking cutting fluid filtering device of boring-milling machine

InactiveCN111013822AImprove filtering effectReduce solid particle contentMagnetic separationStructural engineeringMechanical engineering

The invention discloses an anti-blocking cutting fluid filtering device of a boring-milling machine. The device comprises an input liquid pump, a first filter tank, a second filter tank and an outputwater pump, the water outlet of the input liquid pump is connected with a water conveying pipe; the water conveying pipe is inserted into the first filter tank and extends to the bottom of the first filter tank; a drainage notch is formed in one side of the top end of the first filter tank; a drainage diversion trench is connected to the drainage notch; the tail end of the drainage diversion trench communicates with the second filter tank; a first baffle, a second baffle and a third baffle are sequentially arranged in the second filter tank; a first electromagnetic grid plate, a second electromagnetic grid plate and a third electromagnetic grid plate are correspondingly mounted at the tops of the first baffle, the second baffle and the third baffle respectively, a water outlet is formed inthe side, away from the drainage diversion trench, of the bottom of the second filter tank, and a water pumping pipe is connected between the water outlet and the output water pump.

Owner:江西乔扬数控设备有限公司

Double-working-condition gas generator propellant grain

InactiveCN108645288ACombustion state is stableReasonable structureAmmunitionSelf-propelled projectilesFuel gasGas generator

The invention relates to a double-working-condition gas generator propellant grain. A gas generator propellant is contained in a wrapping sleeve. The middle of the surface of the gas generator propellant is provided with a sharp combustion supporting groove. An inner ring combustion supporting groove and an outer ring combustion supporting groove are sequentially arranged outside the sharp combustion supporting groove. A lining layer is arranged at the contact portion between the side face of the gas generator propellant and the wrapping sleeve. The double-working-condition gas generator propellant grain starts combustion on the surface of the gas generator propellant and the surface of the combustion supporting groove at the same time, the combustion surface is large in the early stage, the combustion surface tends to be reduced after 12 seconds, and the combustion surface tends to be stable after 16 seconds. The double-working-condition gas generator propellant grain is used for a guided missile servo power device and has the advantages of being low in combustion temperature, changeable in combustion surface, capable of achieving double-working-condition pressures of two-graded charge through single-combustion-rate charge and the like.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Treatment system for concentration tank of iron ore concentrates

ActiveCN103191590BReduce solid particle contentEasy to handleSettling tanks feed/dischargeSedimentation settling tanksEngineeringSolid particle

The invention relates to a treatment system for a concentration tank of iron ore concentrates. The treatment system comprises the concentration tank, a concentration tank overflow tank, a central distribution barrel and ore concentrate pipelines, wherein output ports of the ore concentrate pipelines are connected with the central distribution barrel; the concentration tank is arranged at the outer side of the central distribution barrel; the concentration tank overflow tank is arranged at the outer side of the concentration tank; the ore concentrate pipelines are composed of a plurality of thin ore concentrate pipelines and a plurality of thick ore concentrate pipelines; the plurality of thin ore concentrate pipelines are communicated with the plurality of thick ore concentrate pipelines through a fed ore distribution box; the number of the thin ore concentrate pipelines is larger than that of the thick ore concentrate pipelines; and one ends of the thick ore concentrate pipelines are connected with the central distribution barrel, and the other ends of the thick ore concentrate pipelines are connected with the fed ore distribution box. The ore concentrate pipelines are composed of the thin ore concentrate pipelines and the thick ore concentrate pipelines, so that the ore feeding flow rate is reduced to ensure that the content of solid particles in overflow water cannot exceed the standard under the condition that the concentration tank operates over a design, and furthermore, the treatment capacity of the concentration tank is enhanced, and the content of the solid particles in the overflow water is reduced.

Owner:YUNNAN DAHONGSHAN PIPELINE

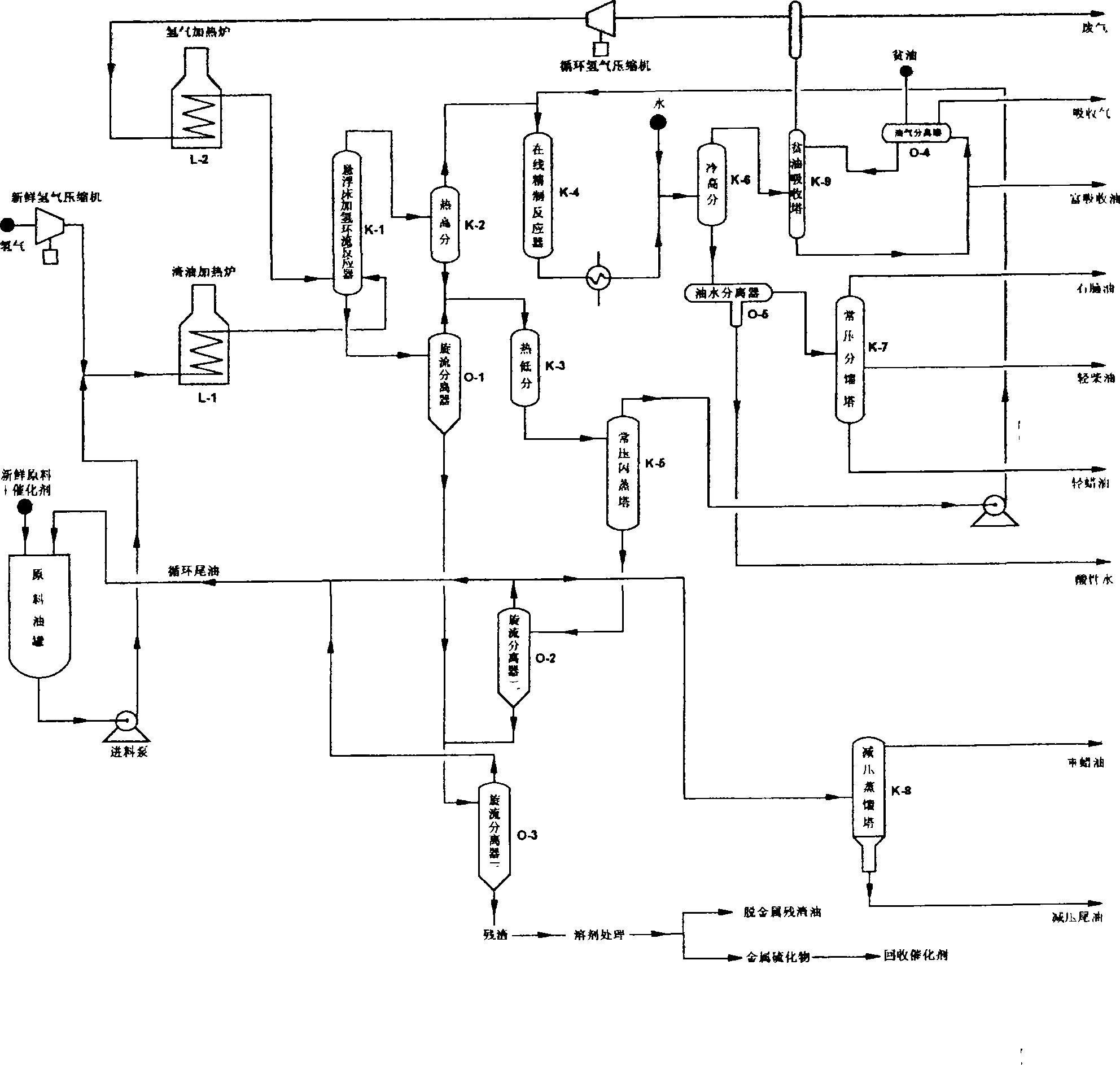

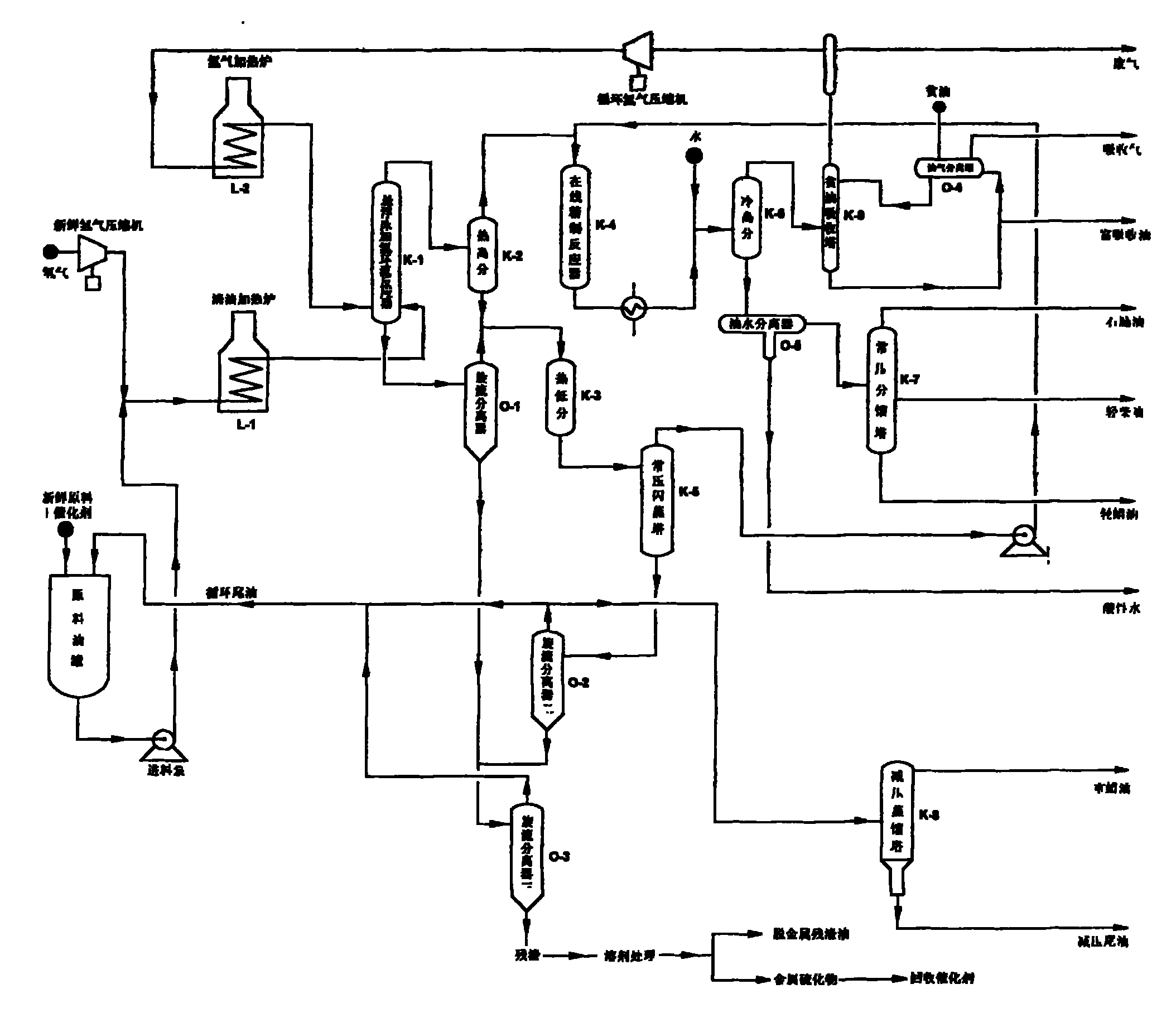

Technology of heavy oil floating bed hydrocracking

InactiveCN100513532CReduce solid particle contentLow costTreatment with hydrotreatment processesFixed bedEngineering

A new heavy oil suspended bed hydrocracking process, the hydrocracking reactor used in the process is a full back-mixing loop reactor, and a fixed-bed hydrofinishing reactor matched with it is attached. The catalyst used in this process is a catalyst compounded by iron-nickel-manganese-molybdenum-cobalt and other multi-metal water-soluble salts, and its co-catalyst is a water-soluble sulfur-containing compound. Multiple cyclone separators are installed in the product separation system, thereby greatly reducing the solid content of circulating tail oil and vacuum tail oil. The process also has a solvent separation system, and the residue obtained from the bottom of the cyclone separator can be further processed for solvent treatment and catalyst recovery. This process has a high conversion rate and distillate oil yield and very good naphtha and diesel products for the treatment of inferior heavy oil and its atmospheric pressure and vacuum residue.

Owner:PETROCHINA CO LTD +1

Consumable-free particle specified flue gas solid particle treatment equipment

The invention relates to consumable-free particle specified flue gas solid particle treatment equipment. The equipment comprises a box body provided with a gas inlet and a gas outlet formed in two sides of the body, respectively; a mechanical collision assembly, a gas flow collision assembly, a spraying assembly, a specified particle interception assembly and a gas-liquid separation assembly are sequentially arranged on one side, between the gas inlet and the gas outlet, in the box body; the mechanical collision assembly comprises a collision frame with vent holes formed in two sides of the collision frame; vent holes in the two sides are formed in a staggered manner; a plurality of flow guide profiles are arranged in the gas flow collision assembly; the spraying assembly comprises a spraying pipe and a spraying head, wherein the spraying head faces the gas inlet; the particle interception assembly at least comprises one intercepting pore plate; and the gas-liquid separation assembly comprises a gas-liquid separation net. The consumable-free specified particle flue gas solid particle treatment equipment is free of consumables, can save cost, is thorough in flue gas treatment, and can achieve up-to-standard emission.

Owner:WUXI BODI ENVIRONMENTAL TECH CO LTD

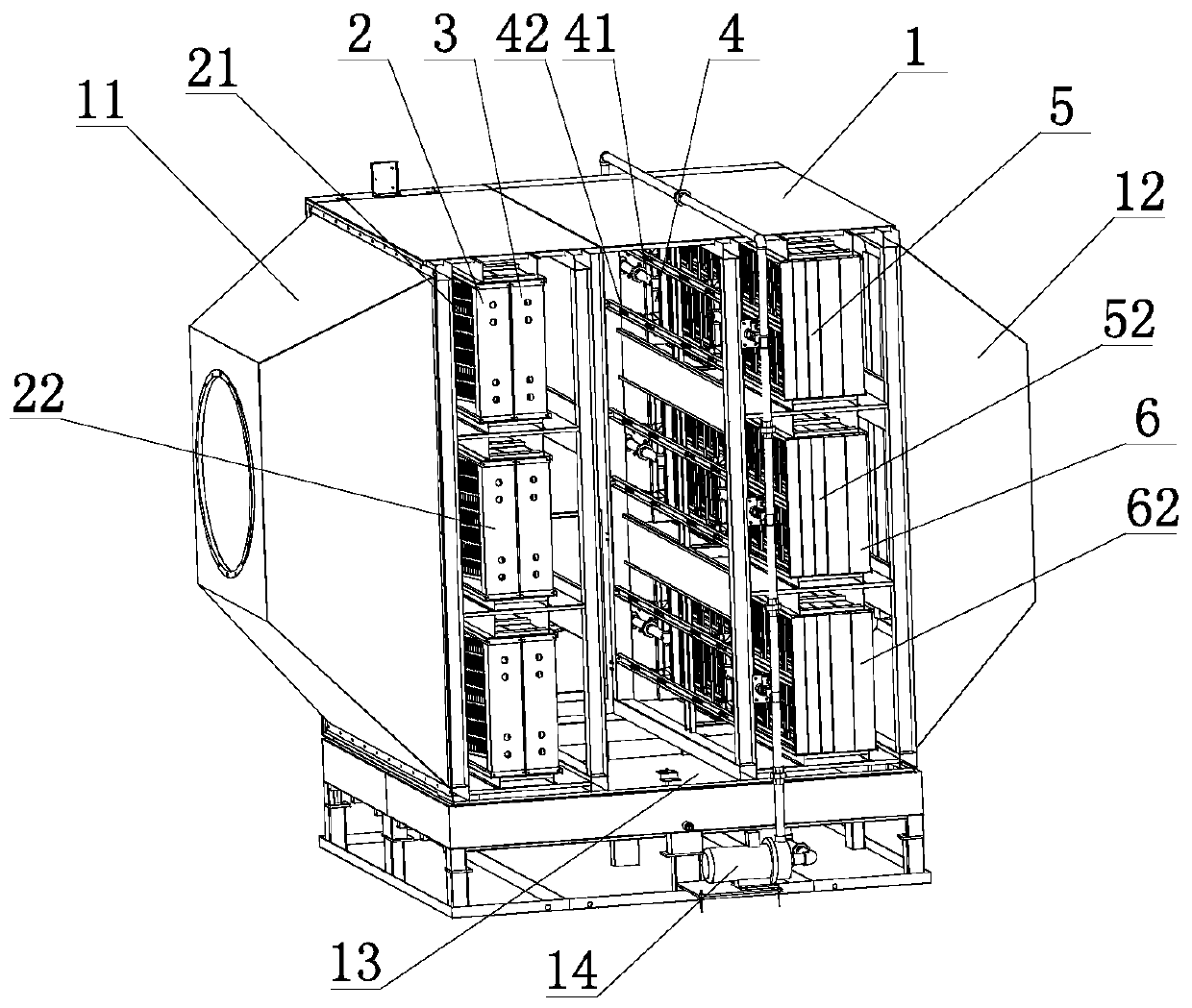

A two-stage heavy oil slurry bed hydrogenation equipment and method

ActiveCN106147848BImprove conversion rateImprove stabilityTreatment with hydrotreatment processesFuel oilSlurry

The invention discloses heavy oil hydrogenation equipment adopting a two-section type slurry bed and a heavy oil hydrogenation method. The equipment comprises a first slurry bed reactor, a first separation unit, a second slurry bed reactor and a second separation unit which communicate sequentially, wherein each of the first slurry bed reactor and the second slurry bed reactor comprises a riser (4), an expansion section (1) and a downcomer (8), the expansion section (1) communicates with the upper part of the downcomer (8), the lower part of the riser (4) communicates with the bottom of the downcomer (8), a slurry phase separator is arranged in the expansion section (1), a demister (11) is arranged at the upper part of the slurry phase separator, a gas outlet (10) is formed in the top of the expansion section, a material outlet (13) is formed in the side wall of the expansion section, and a fluid distributor (7) and a raw material inlet (9) are formed in the bottom of the riser (4). By means of the provided heavy oil hydrogenation equipment adopting the two-section type slurry bed and the heavy oil hydrogenation method, long-period running of reactors is facilitated, the hydrogenation conversion rate of heavy oil is increased, and processing of follow-up equipment to slurry is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com