Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

259results about How to "Reduced crack susceptibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-alloying steel for oil gas transport seamless pipeline and its preparation method

InactiveCN101186994AElimination of abnormal tissueImprove toughnessTemperature control deviceForeign matterChemical composition

The invention discloses micro-alloying seamless pipeline steel and process for preparation. According to weight percentage, the range of the chemical components of the invention includes that C holds 0.08% to 0.20%, Si is equal to or less than 0.04%, Mn takes 0.60% to 1. 50%, S is equal to or less than 0.015%, P is equal to or less than 0.025%, Al is equal to or less than 0.04%, Ti is equal to or less than 0.04%, H is equal to or less than 2.5*10-4%, O is equal to or less than 25*10-4%, the rest is Fe and unavoidable foreign matters. The process for preparation comprises technique steps, including smelting, refining, continuous casting, hot rolling and slow cooling. Round steel with the size of phi 70 to 150 millimeters can be produced by the process for preparation. The seamless pipeline steel of the invention has perfect anti-sulphide stress corrosion (SSC resistance) capability and anti-HIC property. The pipeline steel which can substitute for welding pipe can be utilized in the filed of oil pipeline and the like, and the invention increases the reliability of material and adaptability of variety, in particular being adaptable for the low submarine temperature and corrosion-resistant environment and for manufacture of thick-walled tubes.

Owner:LAIWU IRON & STEEL GRP

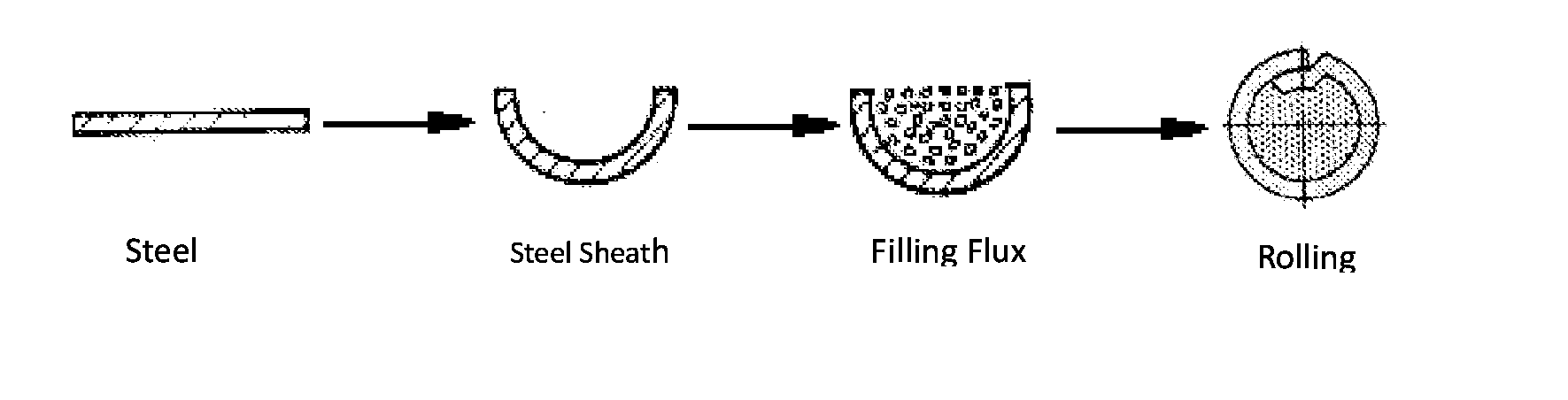

Iron-based abrasion resistant overlaying-welding flux-cored wire

InactiveCN101670501ALow costReduced crack susceptibilityWelding/cutting media/materialsSoldering mediaNiobiumManganese

The invention relates to an iron-based abrasion resistant overlaying-welding flux-cored wire. The current abrasion resistant overlaying-welding wire and alloy are varied, the abrasion resistance of some alloy is favorable but some alloy has large brittleness and lower toughness and is not suitable for the abrasion working condition of an abrasive material with low impact. The iron-based abrasion resistant overlaying-welding flux-cored wire comprises the following alloy elements in percentage by weight: 0.3-1.0 percent of carbon (C), 1.0-7.0 percent of boron (B), 0.2-4.0 percent of titanium (Ti), 0.2-3.0 percent of vanadium (V), 0.1-1.5 percent of silicon (Si), 0.2-2.0 percent of manganese (Mn), 0.00-0.10 percent of rare earth (RE), 0-3.0 percent of chromium (Cr), 0-1.0 percent of molybdenum (Mo), 0-1.0 percent of wolframium (W), 0-2.0 percent of nickel (Ni), 0-0.5 percent of niobium (Nb) and 0-0.5 percent of zirconium (Zr). The invention carries out single-layer overlaying welding on the surface of a steel workpiece to form an abrasion resistant layer with the thickness of 1-3 mm or so, and the abrasion resistant layer has excellent abrasion resistance and toughness, difficult cracking and low cost and can reduce the abrasion of a mechanical fitting or a tool under the working conditions of low impact and strong abrasion of abrasive particles.

Owner:王新虎

Iron-based high-titanium wear-resistant surfacing flux-cored welding wire

InactiveCN101664862AAchieving wear resistanceImprove performanceWelding/cutting media/materialsSoldering mediaBorideCrazing

The invention relates to an iron-based high-titanium wear-resistant surfacing flux-cored welding wire. Among a plurality of types of the prior wear-resistant surfacing welding wires and alloys, some alloys have favorable wearing resistance, and some alloys have great brittleness, lower toughness and easy cracking and are not suitable for the existence of low-impact grinding wear working condition.The iron-based high-titanium wear-resistant surfacing flux-cored welding wire comprises a low-carbon steel ladle clad and core powder as well as the following alloy elements in percentage by weight:1.0-3.0 C, 1.0-12.0 Ti, 0.5-9.0 V, 0.1-1.5 Si, 0.2-2.0 Mn, 0-3.0 B, 0.00-0.10 RE, 0-13.0 Cr, 0-1.0 Mo, 0-1.0 W, 0-2.0 Ni, 0-0.5 Nb and 0-0.5 Zr. The iron-based high-titanium wear-resistant surfacing flux-cored welding wire realizes the wear-resistant performance of the alloys mainly by carbides and borides formed by the alloy elements of C, Ti, V, and the like as well as a small amount of B element and adjusts the combination of the elements of C, Ti, V, Si, Mn, B, and the like to adjust the alloy hardness, enhance the toughness and lower the crack sensitivity.

Owner:王新虎

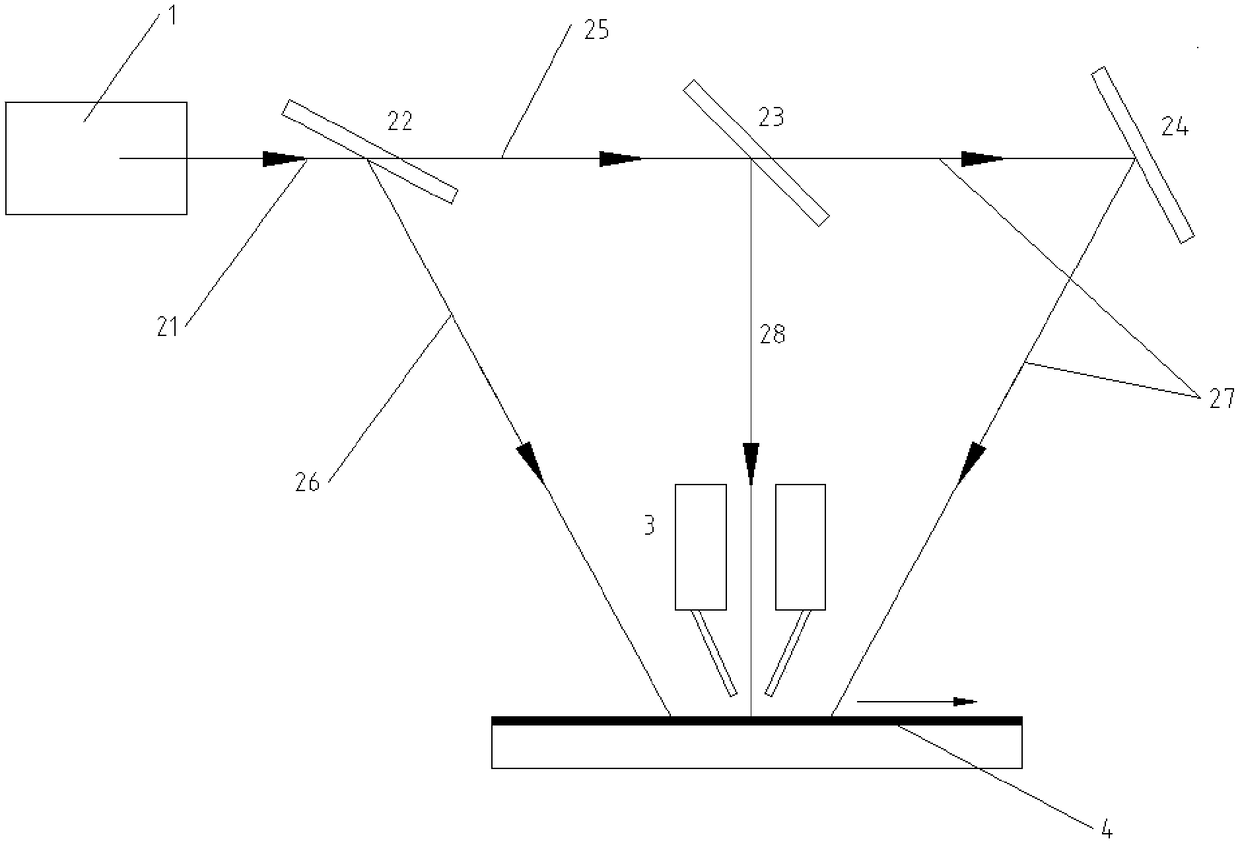

Crack controlling means for laser deposition formed metal parts

InactiveCN1737197AImprove coagulation stateImprove liquidityMetallic material coating processesLaser beam welding apparatusClosed loop feedbackClosed loop

The invention relates to a crack-controlling method of metal parts by laser melting formation in laser material processing domain, which comprises closed-loop control of fused bath temperature, which comprises the two specific steps of exerting closed-loop feedback control on fused bath temperature by using optical imaging system and PID control device with calorific radiation transmitted from melting zone and adjusting horsepower of laser, and introduction of ultrasonic vibration, which comprises the specific steps of introducing ultrasonic vibration under the piece of work when forming by laser melting. The invention can deduce residual stress and crack, improve structure and can be used in multiple relative domains such as forming, manding and surface peening by laser melting.

Owner:SHANGHAI JIAO TONG UNIV

10.9-grade boron-containing spheroidizing-free cold heading steel wire rod and manufacturing method thereof

ActiveCN102321851AImprove hardenabilityGood cold deformation abilityTemperature control deviceWire rodBoron containing

The invention discloses a 10.9-grade boron-containing spheroidizing-free cold heading steel wire rod and a manufacturing method thereof. The wire rod comprises the following components in percentage by weight: 0.23 to 0.33 percent of C, 0.02 to 0.20 percent of Si, 0.50 to 0.90 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.025 percent of S, 0.005 to 0.040 percent of Al, 0.005 to 0.050 percent of Ti, 0.0005 to 0.0035 percent of B, 0.58 to 1.50 percent of Cr, 0.01 to 0.05 percent of Ni and the balance of iron and impurities, and also comprises 0.01 to 0.05 weight percent of V preferably. The manufacturing method sequentially comprises the following steps of: smelting; refining outside a furnace; continuously casting; performing high-speed wire controlled rolling; and cooling. The wire rod has the advantages of low hardness, good plasticity, high cold deformability, high hardenability and the like; and the preparation process is simple, and low in cost. In the process of preparing a fastener from the wire rod, a spheroidizing process before drawing can be saved, and the effects of saving energy, reducing pollution, improving yield and reducing use cost are achieved. The product completely meets the production and use requirements of 10.9-grade fasteners.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

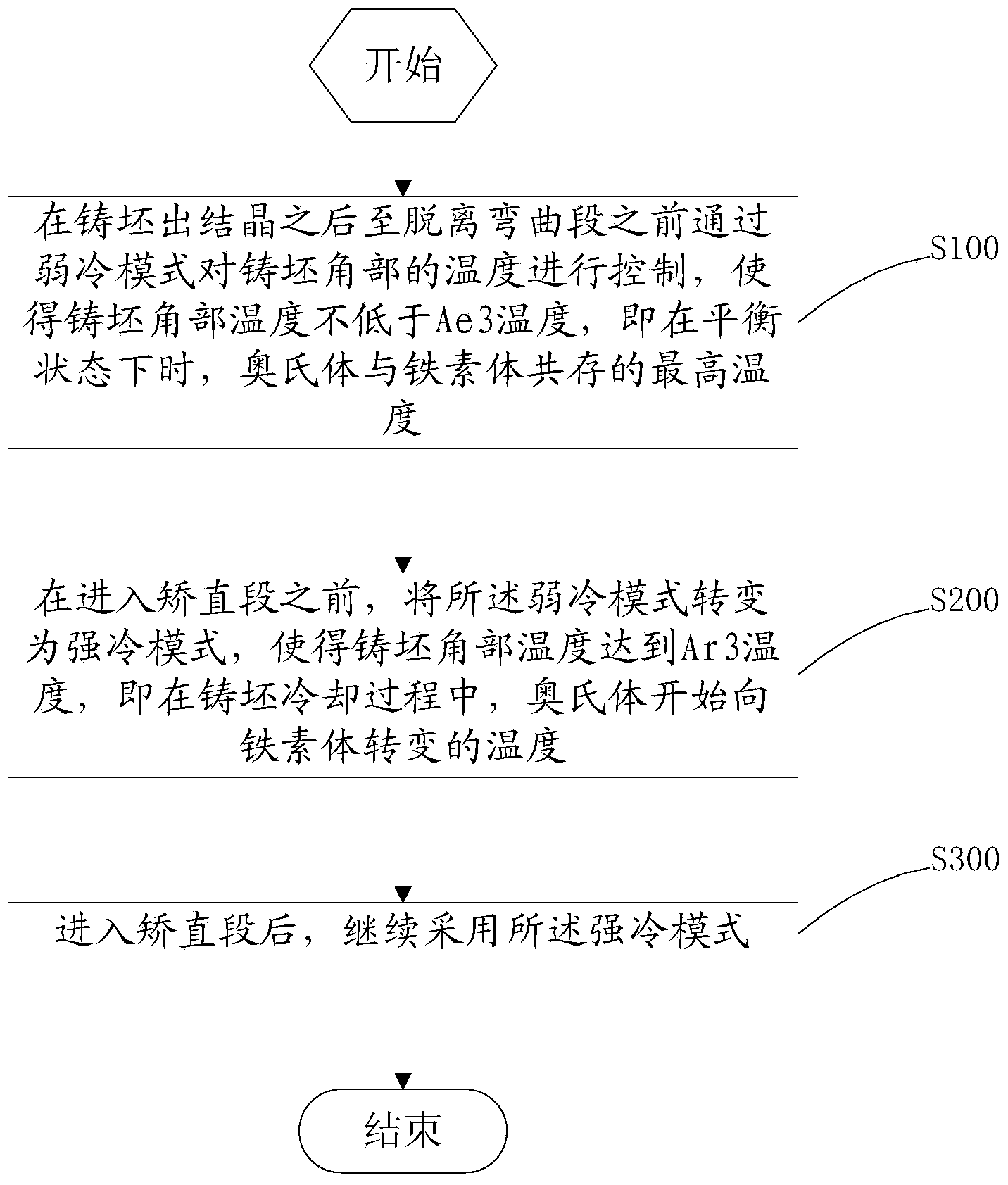

Secondary cooling method for controlling cross cracks in corner of microalloy steel slab

The invention belongs to the technical field of continuous casting, in particular to a secondary cooling method for controlling cross cracks in a corner of a microalloy steel slab. The method comprises the steps of controlling the temperature in the corner of a casting blank by a weak cooling mode after the crystal of the casting blank occurs and before the casting blank is separated from a bending section, so the temperature of the corner of the casting blank is not lower than Ae3 temperature which is the highest temperature at which austenite and ferrite coexist under the balance state; changing the weak cooling mode into an intensified cooling mode before the casting blank enters a straightening section, so the temperature of the corner of the casting blank achieves the Ar3 temperature, namely the temperature at which the austenite begins converting to the ferrite in the cooling process of the casting blank; after the casting blank enters the straightening section, continuously using the intensified cooling mode. The secondary cooling mode control of the continuous slab is optimized, and educts with larger dimension and more dispersed distribution are obtained by the weak cooling mode firstly, so the plasticity of the casting blank is greatly increased; then the transgranular ferrite with large proportion is obtained by the intensified cooling mode, the stress is reduced, the occurrence probability of cross cracks in the corner of the casting blank is greatly reduced, and the method is simple and easy to realize.

Owner:BEIJING SHOUGANG CO LTD

Submerged-arc welding flux for high-strength steel with strength not smaller than 780MPa, manufacture method and welding wire

InactiveCN103008918AImprove mechanical propertiesHigh strengthArc welding apparatusWelding/cutting media/materialsWeld seamHigh intensity

The invention discloses a submerged-arc welding flux for high-strength steel with a strength level not smaller than 780MPa, relating to the field of welding. The welding flux comprises the following components in percentage by weight: 5-13% of SiO2, 30-40% of MgO, 15-30% of Al2O3, 20-30% of CaF2, 1-4% of CaO, 2-6% of MnO and 1-6% of TiO2. The welding rod flux, disclosed by the invention, is matched with a special welding wire to weld the high-strength steel with the strength level not smaller than 780MPa, and a welding seam has the excellent properties such as high strength, high toughness and low crack sensitivity similar to those of a high-strength steel body.

Owner:ATLANTIC CHINA WELDING CONSUMABLES

High-strength corrosion-resistant aluminum alloy profile and preparation method thereof

The invention discloses a high-strength corrosion-resistant aluminum alloy profile and a preparation method thereof. The aluminum alloy profile comprises an aluminum alloy base body and a ceramic coating. The aluminum alloy base body is prepared from Cu, Si, Fe, Cr, Mg, Mn, Zn, Ti, Li, Ni, Zr, Y, W, V and the balance Al. The ceramic coating is prepared from SiC, Cr2O3, NiO, Cr3C2, Al2O3 and Si3N4. According to the high-strength corrosion-resistant aluminum alloy profile, ceramic powder is arranged on the surface of the aluminum alloy base body through plasma cladding, and then laser remelting is conducted, so that the obtained aluminum alloy profile has good mechanical performance such as strength, hardness and impact toughness; and meanwhile, the high-strength corrosion-resistant aluminum alloy profile has the beneficial effects of being resistant to corrosion, good in abrasion resistance, long in service life and the like.

Owner:安徽省煜灿新型材料科技有限公司

A high-boron iron-based wear-resistant surfacing flux-cored wire

InactiveCN102284806ASmall sizeAchieving wear resistanceWelding/cutting media/materialsSoldering mediaBorideWear resistant

The invention relates to a high-boron iron-based wear-resistant surfacing flux-cored welding wire. The welding wire is composed of a low-carbon steel sheath and a core powder. It is characterized in that the iron element in the low-carbon steel sheath and the core powder are contained in the core powder. Elements include boron, carbon, manganese, and silicon. The weight percentage of boron, carbon, manganese, and silicon in the core powder of the welding wire is: boron 6 to 12%, carbon 0.1 to 3%, manganese 0.6 to 2%, silicon 0.3~1.5%, the balance is iron. It can also include Ti0.3~3.5%, Mn 0.6~2%, Si0.3~1.5%, molybdenum 0~1%, K / Na modifier 0~1%, and aluminum-magnesium alloy 0~1.5%. The high boron iron-based wear-resistant cladding flux-cored welding wire of the present invention mainly relies on boron, titanium, carbon and other alloying elements to form boride and a small amount of carbide to achieve the wear resistance of the cladding alloy, and by adding rare earth, nickel, Aluminum-magnesium alloys, etc. improve the overall performance of cladding alloys.

Owner:BEIJING UNIV OF TECH +1

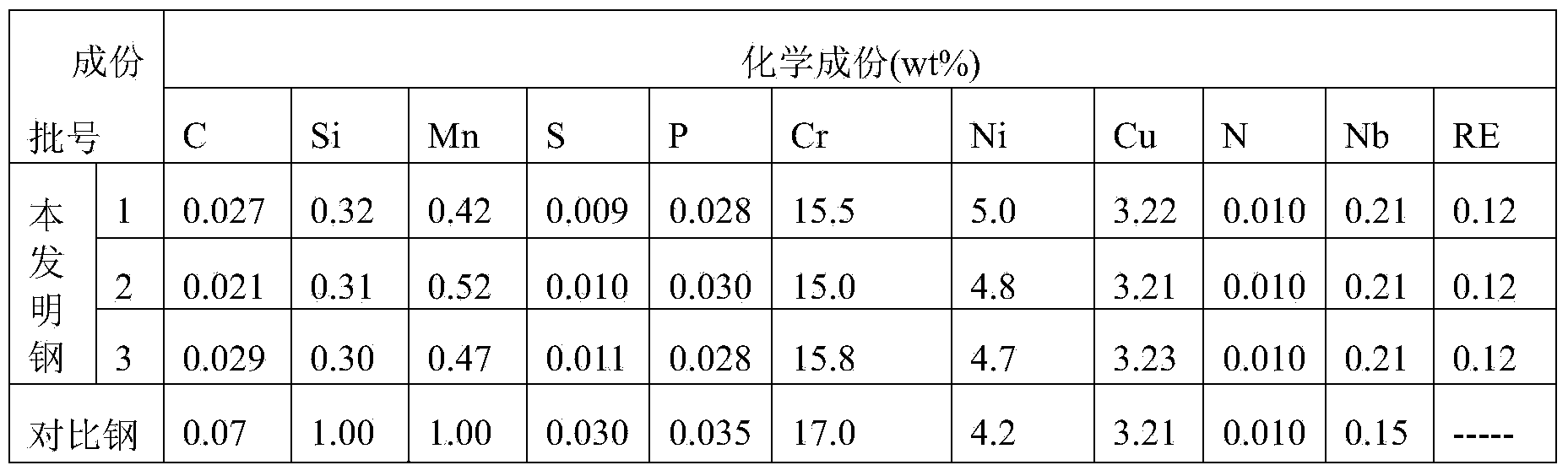

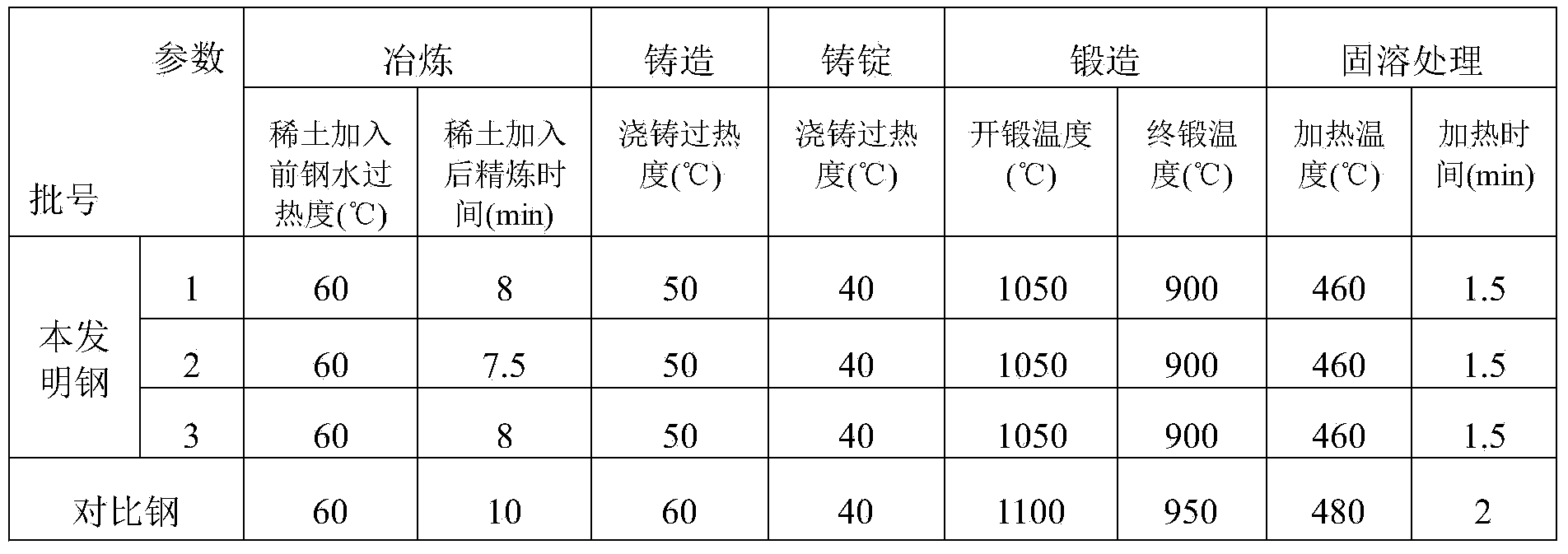

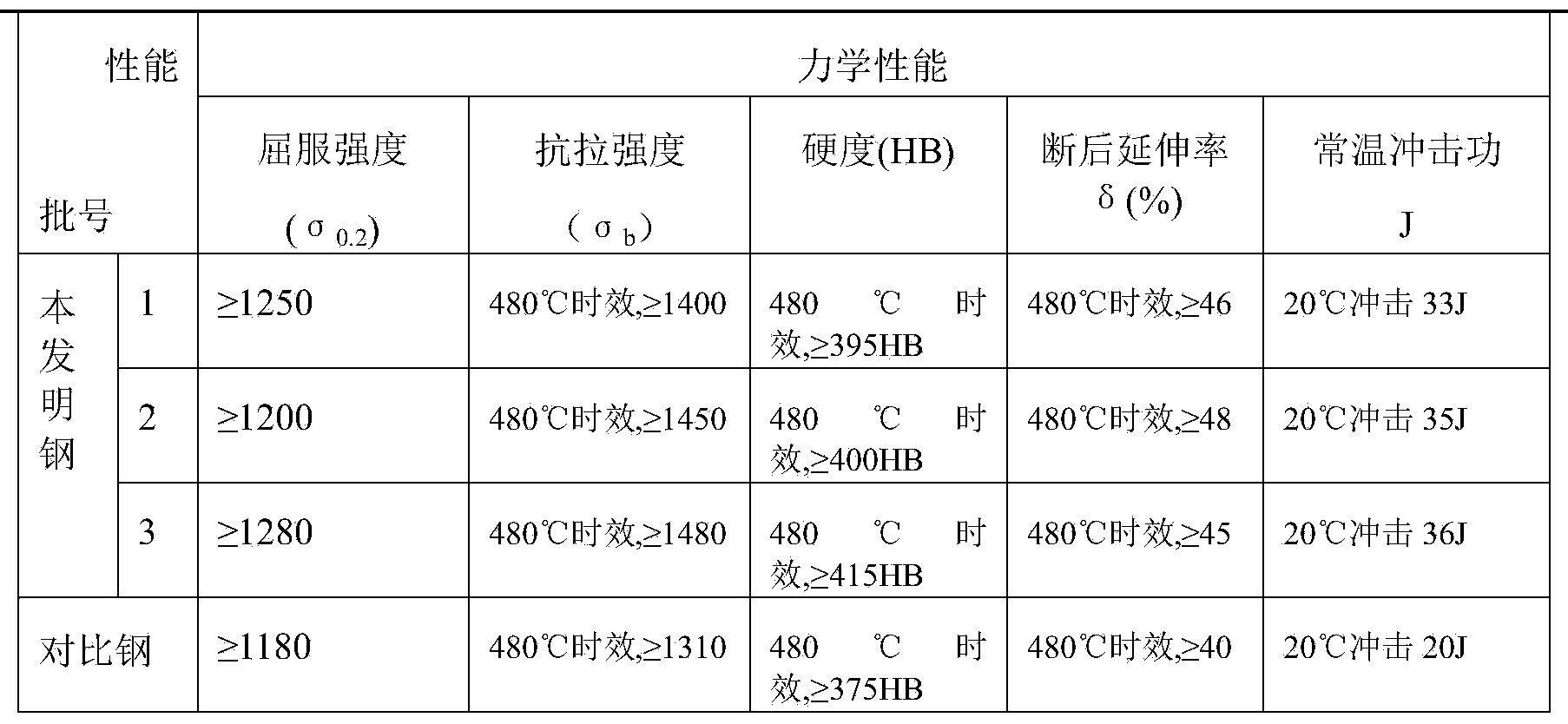

Rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel and preparation method thereof

ActiveCN104328353ARefining solidified tissueImprove performanceSolution treatmentMartensitic stainless steel

The invention discloses rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel is characterized by comprising the following chemical components in percentage by weight: less than or equal to 0.07% of C, less than or equal to 1% of Si, less than or equal to 1% of Mn, less than or equal to 0.035% of P, less than or equal to 0.03% of S, 3.00-5.00% of Ni, 15.5-17.5% of Cr, 3.00-5.00% of Cu, 0.15-0.45% of Nb, 0.05-0.25% of Re and the balance of Fe and belongs to the field of alloy steels. The invention also discloses a preparation method of the rare-earth-type 0Cr17Ni4Cu4Nb martensitic precipitation-hardening stainless steel. The preparation method comprises the steps of smelting, casting, carrying out electroslag remelting, casting ingots, forging or rolling, carrying out solution treatment and the like. The rare-earth-type 0Cr17Ni4Cu4Nb special steel, which is disclosed by the invention, as one of precipitation-hardening martensitic stainless steel, has the characteristics of high strength, high hardness, corrosion resistance and the like and is suitable for various technical fields, such as chemical machinery, food machinery, papermaking machinery, aerospace and marine.

Owner:什邡新工金属材料有限公司

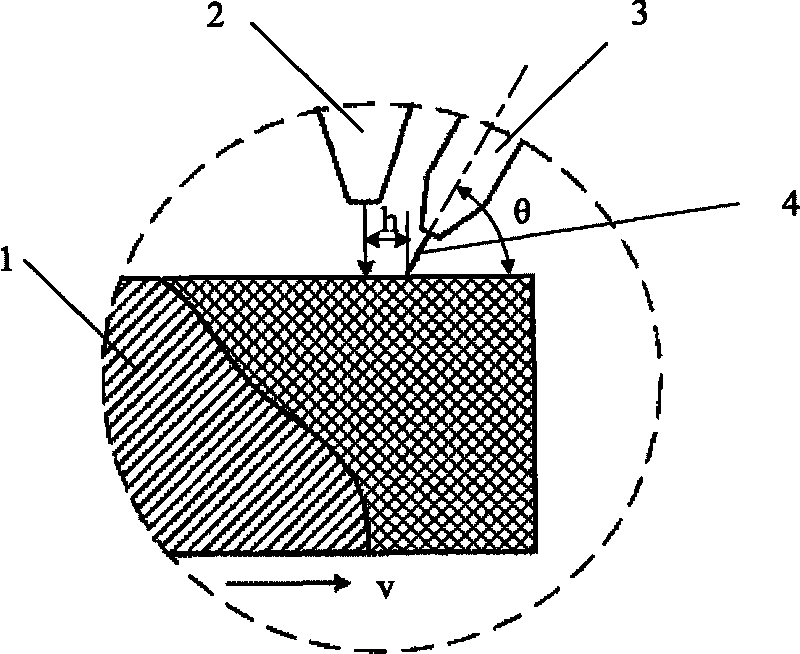

Laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel

InactiveCN101733564AReduced crack susceptibilityAvoid crackingArc welding apparatusLaser beam welding apparatusLaser NozzleSpray nozzle

The invention relates to a laser-electric arc composite heat source high-speed welding method of ultrahigh strength steel, belonging to the technical field of high-strength steel welding. The traditional laser-electric arc composite heat source high-speed welding method of the high-strength or ultrahigh strength steel has overhigh welding linear energy due to low welding speed and large energy input so as to cause the deformation of a welding workpiece; in addition, chevilled silk spacing is overlarge, and stabilization action realized by a laser is reduced because the laser is adopted firstly and the electric arc is adopted subsequently so that a welding process is unstable and easy to generate splashing. The invention adopts laser-electric arc composite heat source welding; the welding workpiece is the high-strength steel or the ultrahigh strength steel; an electric arc welding gun is used for welding firstly and a laser nozzle is used for welding subsequently during welding; the current of electric arc welding is 140-180A, and the voltage of the electric arc welding is 23-25V; an included angle theta between the electric arc welding gun and the surface of the workpiece is 60-65 degrees; the laser power is 3-5kW; the welding speed v is 1-3m / minute; and the chevilled silk spacing h between a laser beam and a welding stick is determined within a range of 1-3mm. The invention realizes the welding of the ultrahigh strength steel without preheating, cold cracks or deformation.

Owner:CHANGCHUN UNIV OF SCI & TECH

High-hardness self-protecting flux-cored welding wire for overlaying repair of continuous casting roller

InactiveCN104690451AHigh hardnessImprove wear resistanceArc welding apparatusWelding/cutting media/materialsArc stabilityHigh carbon

The invention discloses a high-hardness flux-cored welding wire for overlaying repair of a continuous casting roller, and belongs to the technical field of welding in material processing engineering. An H08A cold-rolled steel strip is adopted as an outer cover, a flux core comprises the following components in percentage by weight: 20-40% of TiO2, 5-15% of high-carbon ferrochrome, 12-30% of low-carbon ferrochrome, 0.5-5% of Mn-Si alloy, 0.5-5% of Al-Mg alloy, 5-15% of Ni, 0.5-2.5% of fluoride, 5-15% of Mo, 0.5-2.5% of V, 2-10% of Cr, 0.5-5% of Al2O3 and the balance of iron powder. The filling rate of the traditional Chinese medicine core of the flux-cored welding wire is 20-35%. The welding wire has the advantages that the flux-cored welding wire adopts a self-protecting overlaying manner, and shielding gas and welding flux are not needed in the overlaying repair process of the continuous casting roller, so that the repair cost can be greatly reduced, the manual labor intensity is lowered, and the production efficiency is improved; the welding wire has good arc stability, excellent abrasion-proof property and excellent thermal fatigue resistant property, and the service life of the continuous casting roller is effectively prolonged.

Owner:SHOUGANG CORPORATION

Connecting method for TiNi shape memory alloy and stainless steel dissimilar material

InactiveCN101428371ABarrier formationReduced crack susceptibilityWelding/soldering/cutting articlesLaser beam welding apparatusFilling materialsShape-memory alloy

The invention relates to a method for connecting TiNi-shaped memory alloy and stainless steel dissimilar materials, the method is characterized in that the steps of the process method are as follows: taking nickel wire as filling materials for protection by inactive gases, taking low-power pulse laser as heat sources to weld sheet-shaped TiNi-shaped memory alloy and stainless steel, cleaning the TiNi-shaped memory alloy before welding, using the TiNi-shaped memory alloy sheet after cleaning within 6 hours and protecting both the front side and the rear side of the welding joint by adopting argon gas. The invention has the advantages that the method adopts nickel wire as filling materials so as to effectively obstruct the formation of the fragile intermetallic compound in the welding joint, and the method adopts the protection of bifacial inactive gas to overcome the influence for performances of the welding joint due to oxygen and nitrogen in the atmosphere, thereby reducing the sensibility of the joint cracks and realizing good connection of the sheet-shaped TiNi-shaped memory alloy and stainless steel dissimilar materials.

Owner:NANCHANG HANGKONG UNIVERSITY

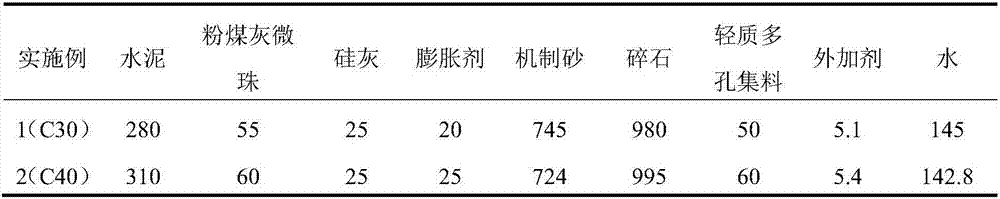

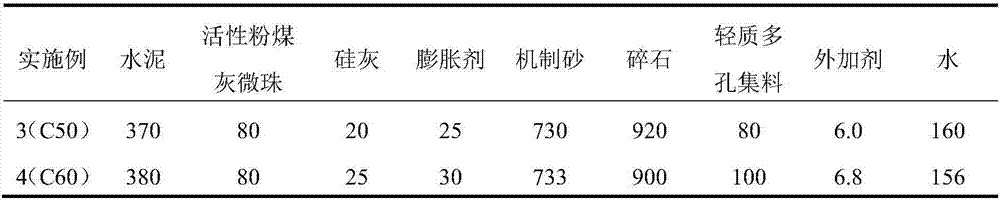

Bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand

The invention discloses a bridge self-compaction anti-crack bare concrete prepared by utilizing high fine powder content machine-made sand. The bridge self-compaction anti-crack bare concrete is prepared from cement, activated fly ash microbeads, silica fume, an expanding agent, machine-made sand, gravel, a light-weight porous aggregate, a high-performance additive and water. The bridge self-compaction anti-crack bare concrete provided by the invention adopts the high fine powder content machine-made sand to replace common natural river sand, utilizes the activated fly ash microbeads and the silica fume for adjusting the viscosity and the fluidity of the concrete so as to improve the homogeneity of a concrete slurry, and further additive is used for reducing the gas content of the concrete, so that a working performance and a fluidity keeping performance of the concrete are improved; meanwhile, the expanding agent and the light-weight porous aggregate are combined, so that the volume stability and an anti-early-age cracking behavior of the bare concrete can be effectively improved. The self-compaction anti-crack bare concrete obtained through the invention has wide adaptability on different fine powder content machine-made sand, excellent working performance, mechanical property, volume stability performance and anti-cracking ability, uniform appearance and color, and better mirror surface effect.

Owner:WUHAN UNIV OF TECH +2

Formula for casting aluminum alloy hubs

The invention discloses a formula for casting aluminum alloy hubs. The formula is prepared from, by weight, 6.5-7.5% of Si, 0.28-0.45% of Mg, 0-0.12% of Fe, 0-0.02% of Cu, 0.02-0.05% of Mn, 0.04-0.05% of Zn, 0.10-0.20% of Ti, 0.2-0.6% of Sr, 0.01-0.05% of Cr, 0.01-0.02% of Zr, 0.025-0.05% of B, 0.4-0.8% of mixed light rare earth and the balance Al. Due to the fact that Sr and the mixed rare earth metal serve as an alterant together, the surface defects of alloy phases can be overcome, surface tension on a new-phase interface and an old-phase interface is reduced, and the problem that compactness is reduced when only Sr is added is avoided. Zr, Ti, Cr and Al work together, the cast structure is further refined, and the hardness and the toughness of aluminum alloy are improved.

Owner:GUANGDONG DCENTI AUTO PARTS STOCK LTD

Low-cost gas shielded flux-cored wire with recycled welding slag

InactiveUS20120241432A1Low costSave resourcesWelding/cutting media/materialsSoldering mediaIron powderSlag

A gas shielded flux-cored wire (FCW) comprises s steel sheath and core flux, in which recycled welding slag powder is used to partially replace the natural rutile. The core flux contains (by weight): 10-50% recycling welding slag powder, 10-45% TiO2, 2-7% Si, 5-20% Mn, 0.5-5% Al—Mg (Al / Mg=1), 0-11.52% Na2CO3, 0-8.85% K2CO3, 0-10% MgO, 0.5-10% fluoride, and iron powder as balance. The recycling welding contains (by weight): TiO2: 20-65%, MnO: 5%-15%, MgO: 5%-15%, SiO2: 5%-15%, Fe2O3: 1%-10%, Al2O3: 1%-10%.

Owner:BEIJING UNIV OF TECH

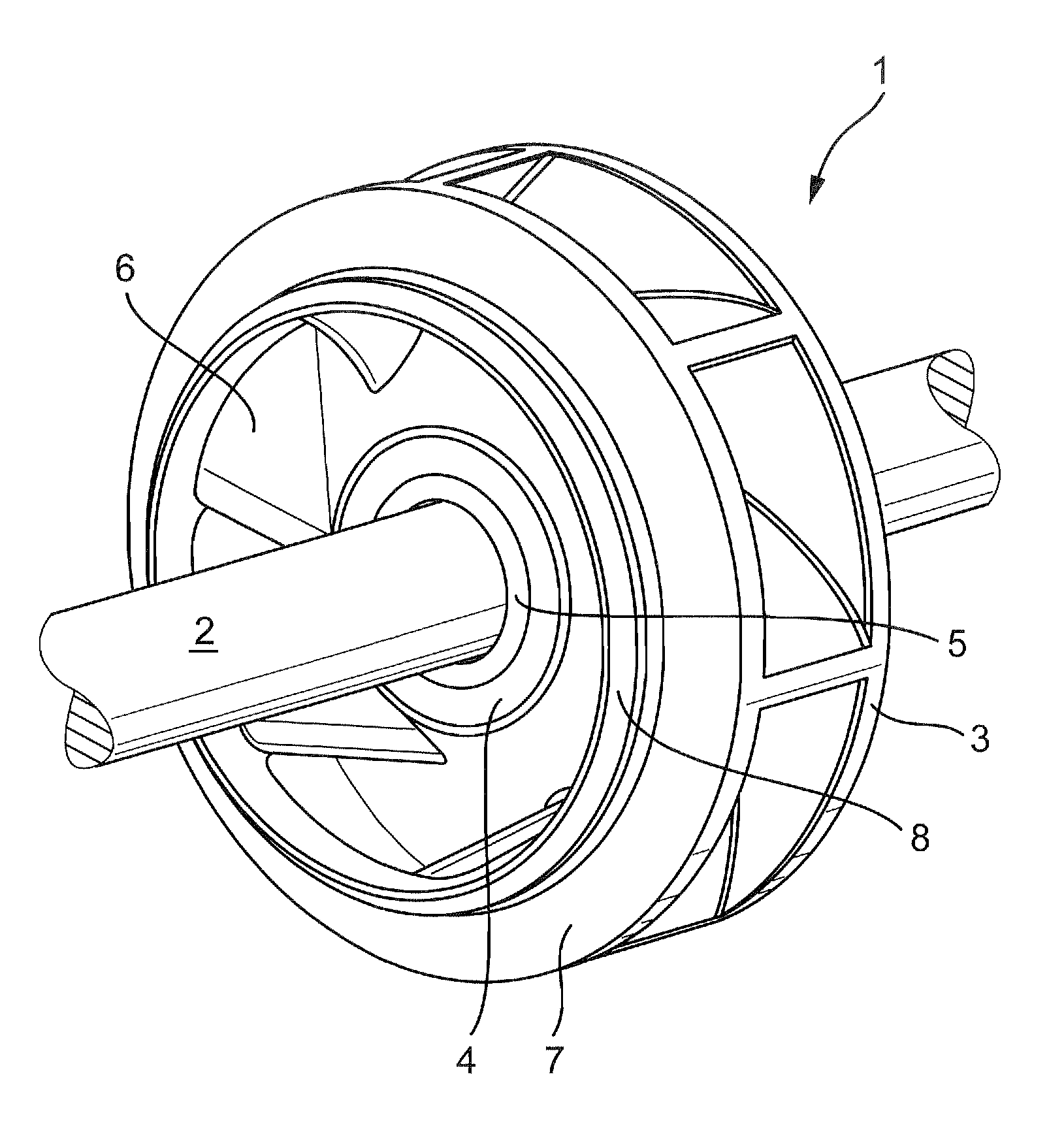

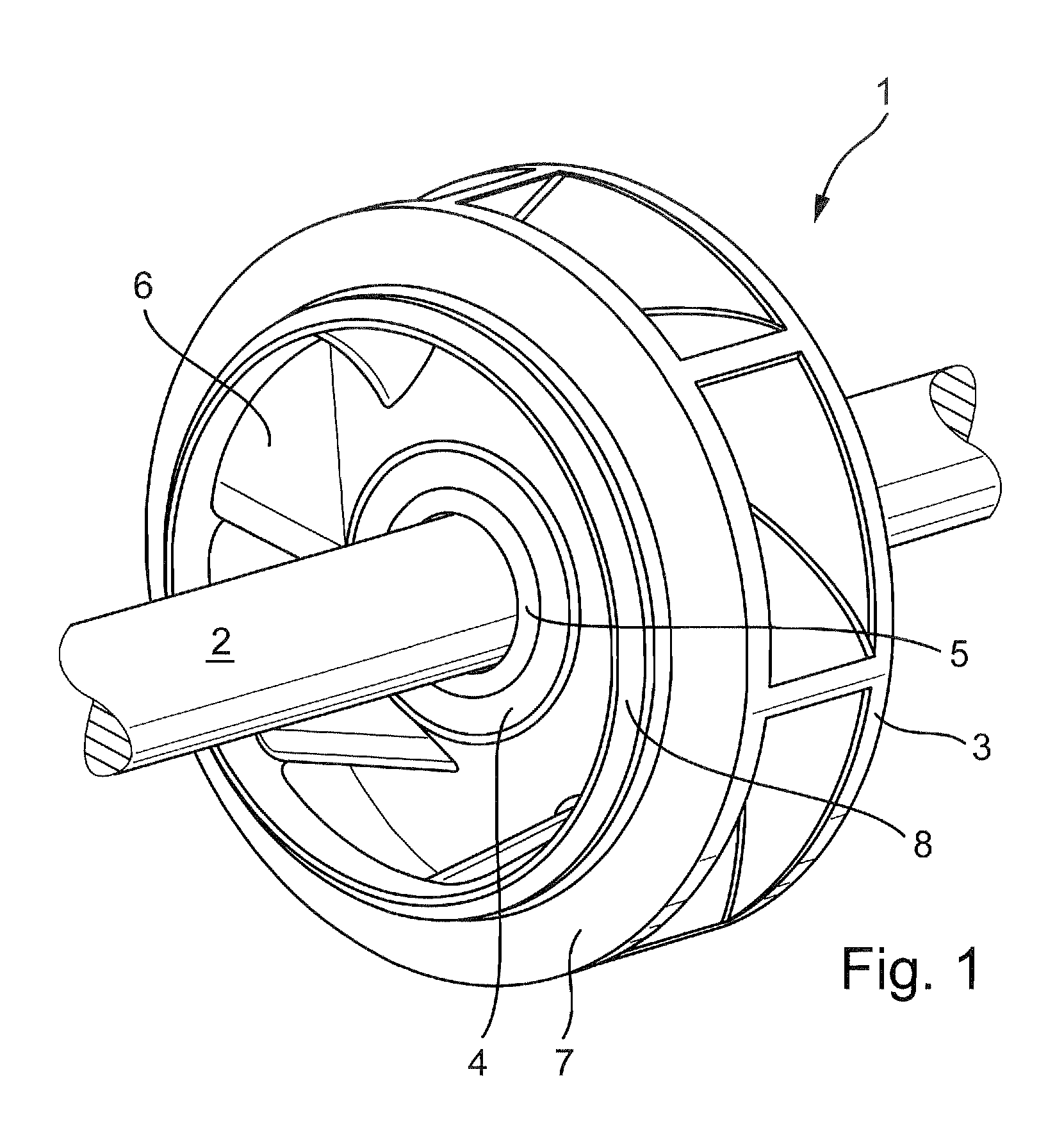

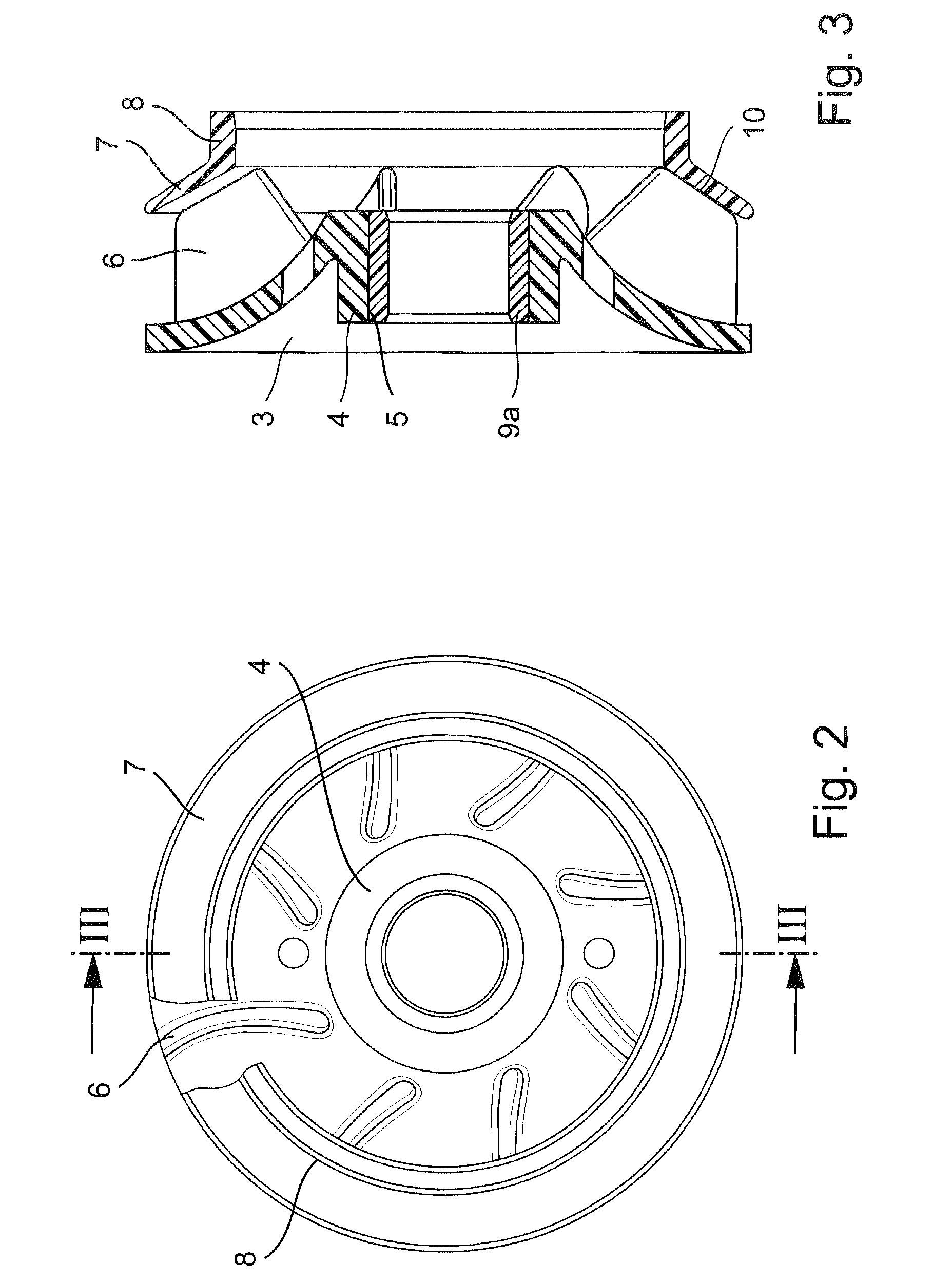

Water Pump Impeller

InactiveUS20080199319A1Enhance resistanceLow crack susceptibilityPropellersRotary propellersImpellerEngineering

Owner:SCHAEFFLER KG

Welding flux for molten salt corrosion resistant nickel-base superalloy fusion welding

ActiveCN106077997AIncrease resistanceFacilitate preparation controlWelding/cutting media/materialsSoldering mediaRare-earth elementFusion welding

The invention discloses a welding flux formolten salt corrosion resistant nickel-base superalloy fusion welding and belongs to the technical field of welding materials. The welding flux comprises the following components in percentage by weight: 0.03%-0.06% of C, 0.04%-0.10% of Mn, 0.3%-0.5% of Si, not greater than 0.10% of Cu, not greater than 0.20% of Co, not greater than 0.015% of P, not greater than 0.015% of S, 0.01%-0.05% of rare earth element, 1.0%-5.0% of Fe, 6.0%-8.0% of Cr, 12.0%-18.0% of Mo, not greater than 0.3% of Al, not greater than 0.2% of Ti, 1.0%-2.0% of Nb and the balance of Ni, wherein Ti+Nb+Al is not greater than 2%. The invention also discloses a welding material for molten salt corrosion resistant nickel-base superalloy fusion welding, a connecting method of a molten salt corrosion resistant nickel-base superalloy and a structural member of the molten salt corrosion resistant nickel-base superalloy. According to the welding flux for molten salt corrosion resistant nickel-base superalloy fusion welding, the toughness and the oxidation resistance of a welded joint can be effectively improved, the excellent molten salt corrosion resistance and the excellent high temperature mechanical property can be guaranteed, the usage demands of molten salt and radiation environments with high usage temperature and performance requirements can be satisfied, and the welding flux is suitable for welding of a molten salt reactor structural material.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

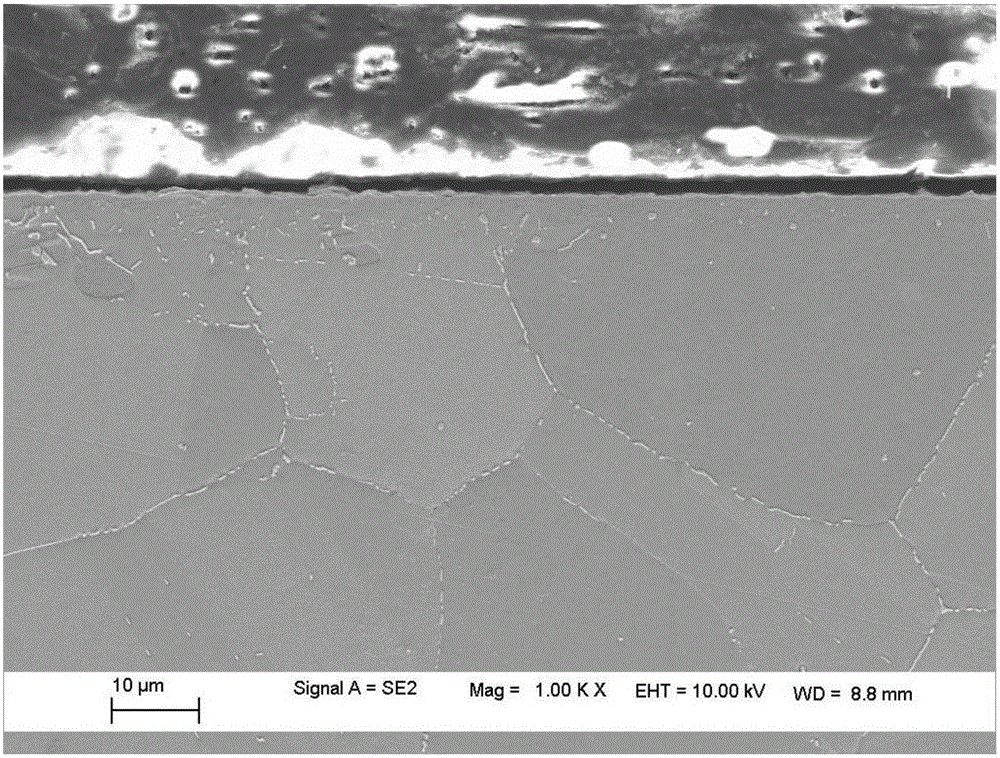

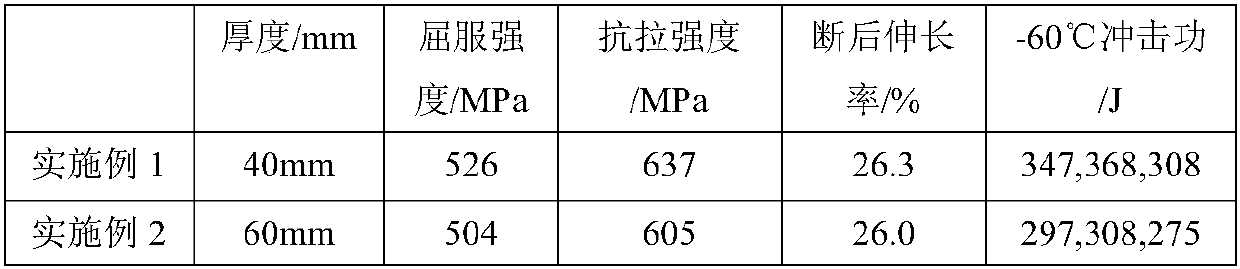

Low-crack sensitive pipe fitting steel plate used under low temperature condition and manufacturing method thereof

The invention relates to a low-crack sensitive pipe fitting steel plate used under a low temperature condition. The mechanical component (wt%) of the steel plate comprises 0.03-0.08 of C, 0.2-0.35 of Si, 0.9-1.6 of Mn, 0.02-0.04 of Al, 0.01-0.07 of Nb, 0.01-0.07 of V, 0.01-0.02 of Ti, less than or equal to 0.15% of Nb+V+Ti, less than or equal to 0.5 of Cr, less than or equal to 0.5 of Ni, less than or equal to 0.4 of Mo, less than or equal to 0.3 of Cu, less than or equal to 0.18 of Pcm and the balance Fe and inevitable impurities. The method sequentially comprises the steps of KR molten iron pretreatment, converter smelting, LF refining, RH vacuum degassing, 370-450 mm thickness continuous casting blank continuous casting, continuous casting blank capping slow cooling, continuous casting blank checking and cleaning, casting blank heating, high-pressure water descaling, rolling, cooling, straightening and offline tempering. The steel plate structure is controlled to be a single tempered bainite structure, the grain size is within the range of 3-6 microns, and the steel plate has very excellent low-temperature toughness and can meet the use requirements of X70 pipeline steel underthe low-temperature condition of -60 DEG C.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

High-toughness low-alloy solid welding wire

ActiveCN101905392AQuality improvementReduced crack susceptibilityWelding/cutting media/materialsSoldering mediaSheet steelChemical composition

The invention relates to a high-toughness low-alloy solid welding wire which comprises the following chemical components in percentage by weight: not more than 0.10 percent of C, 0.4 to 0.8 percent of Si, 1.2 to 1.9 percent of Mn, 1.0 to 2.5 percent of Ni, 0.25 to 0.55 percent of Mo, 0.18 to 0.35 percent of Cr, 0.05 to 0.20 percent of Ti, 0.0005 to 0.005 percent of B, not more than 0.015 percent of S, not more than 0.015 percent of P and the balance of Fe and other inevitable impurities. The high-toughness low-alloy solid welding wire has the tensile strength of deposited metal more than 830MPa, the yield strength of the deposited metal more than 730MPa, and the reduced alloy content by near 50 percent compared with the welding wire ER83-1 on the premises of ensuring the strength and the impact toughness, can satisfy the welding of 830MPa-grade and 900MPa-grade steel plates and greatly reduce the cost and is suitable for large-scale popularization and application.

Owner:YICHANG MONKEY KING WELDING WIRE

Non-preheating strength gradient matched welding technology for low-alloy high-strength steel with yield strength of 800MPa

The invention provides a non-preheating strength gradient matched welding technology for low-alloy high-strength steel with the yield strength of 800MPa, which belongs to the field of the non-preheating welding technology for the low-alloy high-strength steel. The welding technology mainly adopts welding wires with the tensile strength of 500MPa for backing welding and welding wires with the tensile strength of 800MPa for padding and cosmetic welding. The technology mainly solves the technical problem that in the background art, as backing welded joints in a high restraint-intensity welding structure have higher tensile strength, cracks can not be thoroughly eliminated under a non-preheating condition. The technology is used for the non-preheating high-quality welding for the low-alloy high-strength steel with the yield strength of 800MPa.

Owner:HARBIN WELDING INST LTD

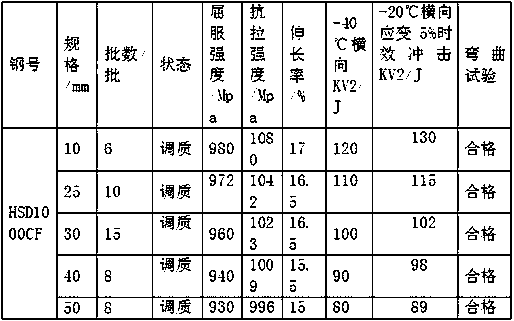

10-80-mm high-strength low-crack sensitive steel SX780CF for large-scale hydroelectric project and preparation method thereof

The invention discloses 10-80-mm high-strength low-crack sensitive steel SX780CF for the large-scale hydroelectric project and a preparation method thereof. The high-strength low-crack sensitive steel SX780CF comprises the following chemical components in percentage by mass (unit, wt%): 0.05-0.09% of C, 0.1-0.2% of Si, 1.0-1.3% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.6-0.9% of Ni, 0.15-0.25% of Cu, 0.2-0.4% of Cr, 0.4-0.6% of Mo, less than or equal to 0.1% of V+Nb+Ti, 0.015-0.045% of Als and the balance Fe and residual elements, wherein Ceq of the high-strength low-crack sensitive steel SX780CF is less than or equal to 0.52, and Pcm of the high-strength low-crack sensitive steel SX780CF is less than or equal to 0.25. By virtue of reasonable component design and a series of processing measures, a 10-80-mm-thick high-strength low-crack sensitive SX780CF steel plate, which is low in cost, is high in production efficiency, is high in yield and is good in surface quality, for the large-scale hydroelectric project is successfully developed; and according to an oblique Y type groove cold crack resistant test, the 10-80-mm high-strength low-crack sensitive SX780CF steel plate has good weldability.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

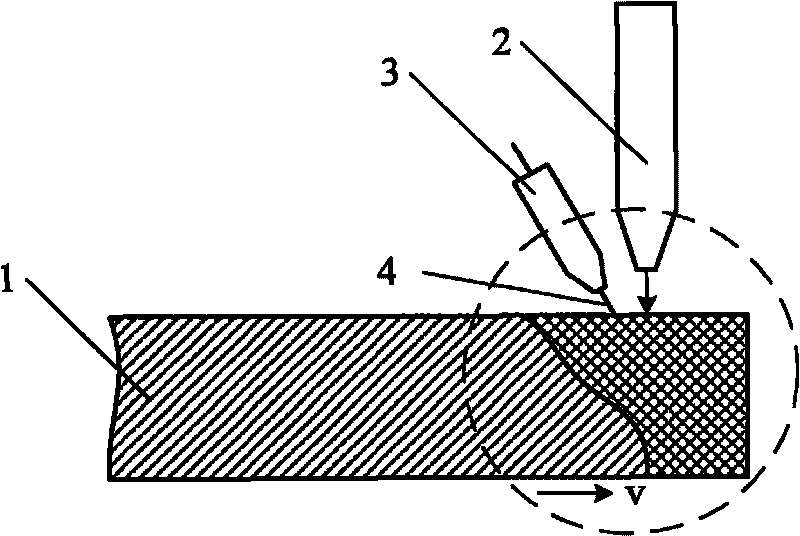

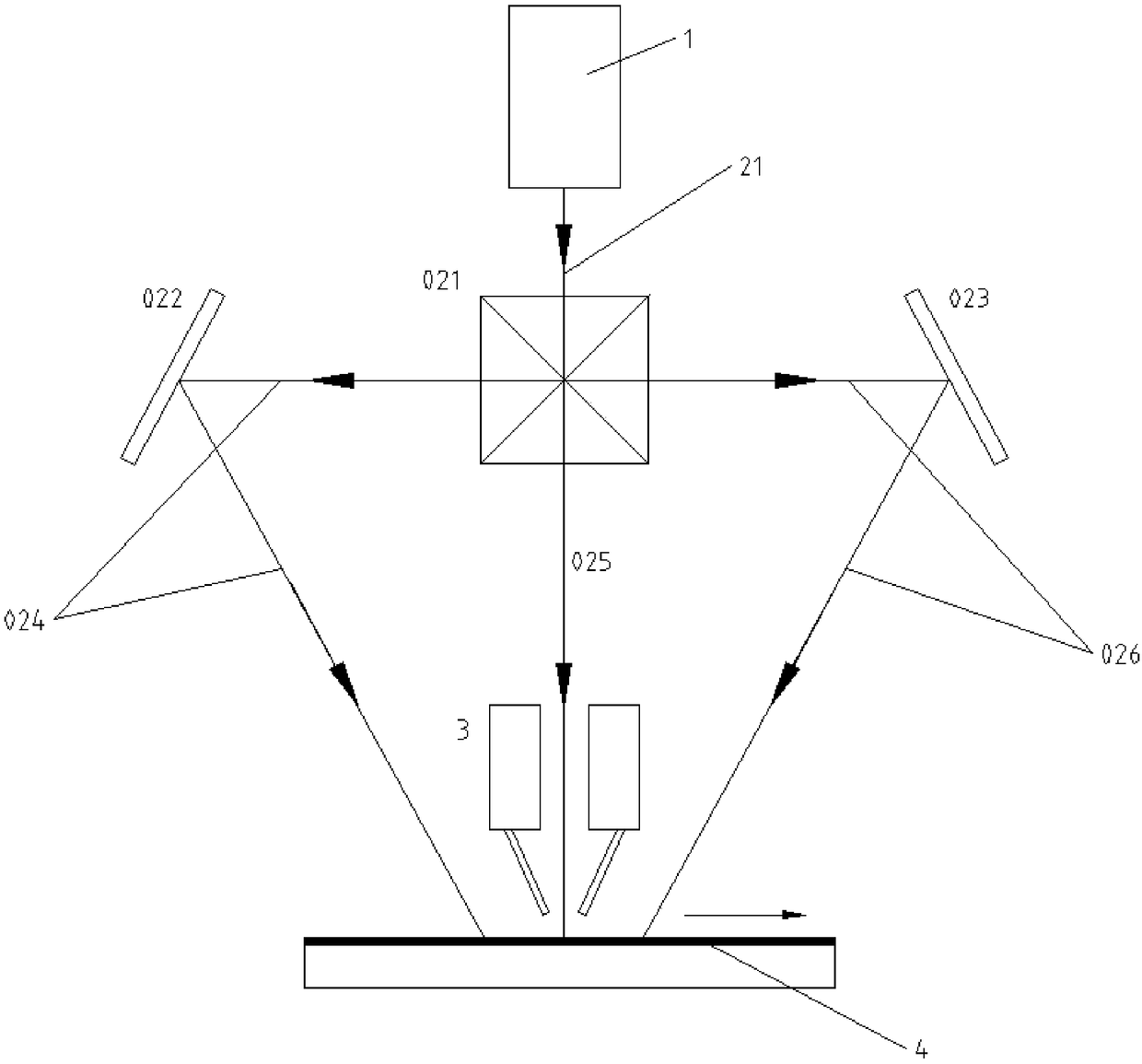

Laser cladding method, laser head, laser and cladding system for realizing laser cladding method

PendingCN108411301AReduces the possibility of crackingAvoid crackingMetallic material coating processesAlloyOptoelectronics

The invention relates to the technical field of laser cladding, and provides a laser cladding method, and a laser head, a laser and a cladding system for realizing the laser cladding method aiming atthe problems of deformation and performance degradation due to the fact that an existing method of laser cladding preheating on a machined workpiece base body cannot realize real-time online heat treatment and high heating input for preheating. The laser cladding method comprises the following steps that 1, outgoing lasers of the laser are divided into preheating lasers, cladding lasers and post-processing lasers; 2, the preheating lasers are irradiated on a workpiece to be processed, and the workpiece is preheated; 3, the cladding lasers are irradiated on the preheated workpiece to be processed to form a molten pool, and at the same time, alloy powder is blown into the molten pool formed on the surface of the workpiece to be processed; and 4, the post-processing lasers are irradiated on acladding layer after cladding, and post-annealing treatment is carried out on the cladding layer.

Owner:XIAN BESAME LASER TECH CO LTD

Laser-cladding cobalt-base alloy powder and repairing method for repairing damaged expander blade

ActiveCN105349995AImprove corrosion resistanceImprove hardenabilityMetallic material coating processesMo elementLaser scanning

The invention discloses laser-cladding cobalt-base alloy powder and a repairing method for repairing a damaged expander blade. The laser-cladding cobalt-base alloy powder comprises the following raw materials in percentage by mass: 20.0% to 50% of Co, 1.0% to 3.0% of W, 2.0% to 5.0% of Mo, 20.0% to 26.0% of Cr, 19.0% to 45.0% of Fe, 0 to 9% of Ni and the balance of Si. The repairing method comprises the following steps: pre-treating the damaged expander blade before laser cladding; performing reverse modeling by three-dimensional laser scanning; determining the to-be-repaired position and size of the blade; performing multi-track lapped laser cladding repair on the damaged expander blade by using the laser-cladding cobalt-base alloy powder. The laser-cladding cobalt-base alloy powder disclosed by the invention adopts austenite as a main phase; Co and Ni elements are used for stabilizing the main phase; W and Mo elements are added, and meanwhile, the content of Si and B elements is reduced, so the toughness and corrosion resistance are improved, and the phenomenon of cracking generated during multi-track lapping of a laser cladding layer is reduced. The alloy powder component has the effects of lowering the cost and improving the stability of a cladding technique, and the laser repair quality and the effective service life of the blade of an energy recycling turbo expander are guaranteed.

Owner:汉中艾斯达特新材料科技有限公司

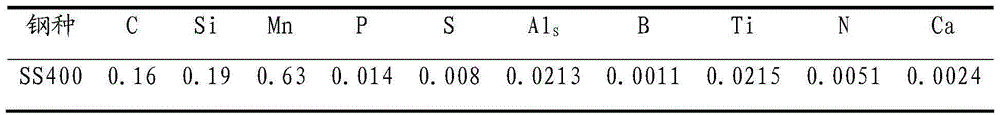

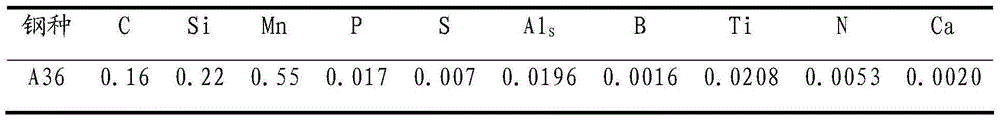

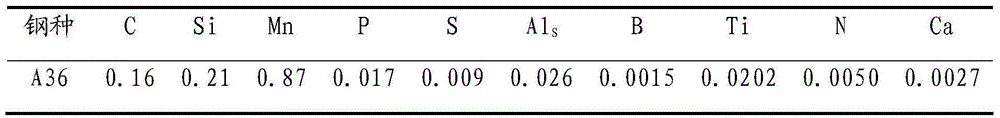

1000MPa grade low-crack hydroelectric steel plate for large-scale hydropower engineering and production method thereof

InactiveCN108504960AReduced crack susceptibilityHigh strengthProcess efficiency improvementChemical compositionHigh intensity

The invention discloses a 1000MPa grade low-crack-sensitive steel hydroelectric steel plate for large-scale hydropower engineering, the 1000MPa grade low-crack sensitive steel hydroelectric steel plate has a thickness of 10 to 50 mm, and comprises the following chemical components by mass: 0.06-0.17% of C, <=0. 15% of Si, 0.8 to 2.0% of Mn, <= 0.010% of P, <= 0.003% of S, 1.0 to 2.0% of Ni, 0.10 to 0.25 % of Cu, 0.3 to 1.5% of Cr, 0.4 to 0.7% of Mo, <= 0.1% of V + Nb + Ti, 0.015 to 0.045% of Als, Ce <= 0.020% of, CEV <= 0.64% of, Pcm <= 0.28% of, and balance of Fe and residual elements. Compared with the prior art, the 1000MPa grade low-crack sensitive steel hydroelectric steel plate has the advantages of high strength, high toughness, low crack sensitivity, good surface quality, good weldability and the like.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Method for preventing selective laser melting nickel-based superalloy from cracking

ActiveCN111906311AHigh densityNo crack defectAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingSuperalloy

The invention provides a method for preventing a selective laser melting nickel-based superalloy from cracking, and belongs to the field of additive manufacturing. According to the method, a workpiecewhich is high in density, free of crack defects and excellent in mechanical property is prepared by reducing low-melting-point phase forming elements Zr and B in the nickel-based superalloy and adjusting the total content of Al and Ti in the alloy to be smaller than or equal to 4.5wt% in combination with special selective laser melting (SLM) process parameter control. Through the method, component design is reasonable, the preparation process is simple, and the obtained workpiece has excellent properties and is convenient to apply on a large scale.

Owner:CENT SOUTH UNIV

Method for controlling corner cracks of boron micro-alloy steel continuous-casting billet

The invention discloses a method for controlling corner cracks of a boron micro-alloy steel continuous-casting billet. The method comprises the following steps: a refining step: after adjusting components and temperature, feeding an aluminum wire to steel liquid, wherein in the treated steel liquid: S is less than or equal to 0.01 percent, Mn / S is more than or equal to 40, N is less than or equal to 0.0055 percent, Als is equal to 0.015 to 0.035 percent; after feeding the aluminum wire, slightly blowing argon for four minutes, adding ferrotitanium into the steel liquid, wherein the content of Ti in the steel liquid is 0.015 to 0.025 percent, then feeding ferro-boron into the steel three minutes later, carrying out the calcium treatment for the steel liquid; a continuous casting step: the width of the casting billet is 1600mm to 2100mm, the thickness of the casting billet is 180mm to 250mm, controlling the pulling speed at 0.9 to 1.4 m / min when pouring the steel liquid; oscillating a crystallizer in a non-sinusoidal manner when the steel liquid is poured, the waveform deflection rate of the non-sinusoidal oscillation curve is 10 percent, and the negative slip time tn is 0.137 to 0.145s; stabilizing the water amount on a wide surface and a narrow surface of the crystallizerat 4100 to 4500L / min and 410 to 450L / min; adding protection residue into the crystallizer, wherein the alkalinity of the protection residue is 1.2+ / -0.1, a melting point is 1140+ / -20DEG C, and the viscosity at 1300 DEG C is 0.15+ / -0.05Pa.s; controlling the secondary cooling water amount at 0.5 to 0.55 L / kg during the continuous casting process.

Owner:TIANJIN IRON & STEEL GRP

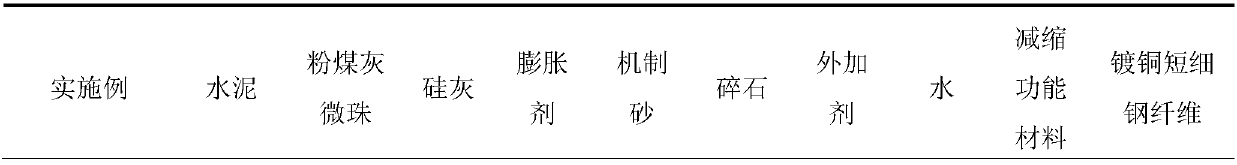

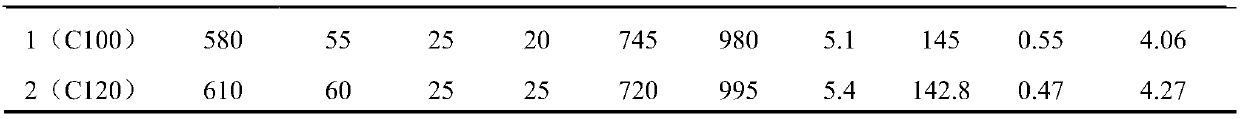

Ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete and preparation method thereof

The invention discloses ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete and a preparation method of the ultrahigh-strength self-compaction micro-expansion steel pipe-encased concrete. The steel pipe-encased concrete comprises the following raw materials in parts by weight: 580-680 parts of cement, 30-60 parts of pulverized fuel ash microbeads, 25-50 parts of silica fume, 20-35 parts of an expanding agent, 700-750 parts of manufactured sand, 800-1050 parts of macadam, 0.4-1.2 parts of a shrinkage reducing functional material, 3.5-7 parts of an additive, 120-160 parts of water and 4-5.5 parts of copper plated short and fine steel fibers. The manufactured sand with a high stone powder content is used for replacing natural river sand; the stone powder serves as an inert admixture; the high activity pulverized fuel ash microbeads and silica fume are adopted; and workability, compactness, and homogeneity of the concrete are improved by using a ball effect and amicro-aggregate effect of the high activity pulverized fuel ash microbeads and the silica fume. A novel expanding agent is prepared from the pulverized fuel ash and phosphogypsum; the strength is improved; moreover, an air content is further reduced by using the additive to improve the compactness. The obtained manufactured sand concrete with the high stone powder content is excellent in serviceability, mechanical property, volume stability and crack resistance.

Owner:WUHAN UNIV OF TECH

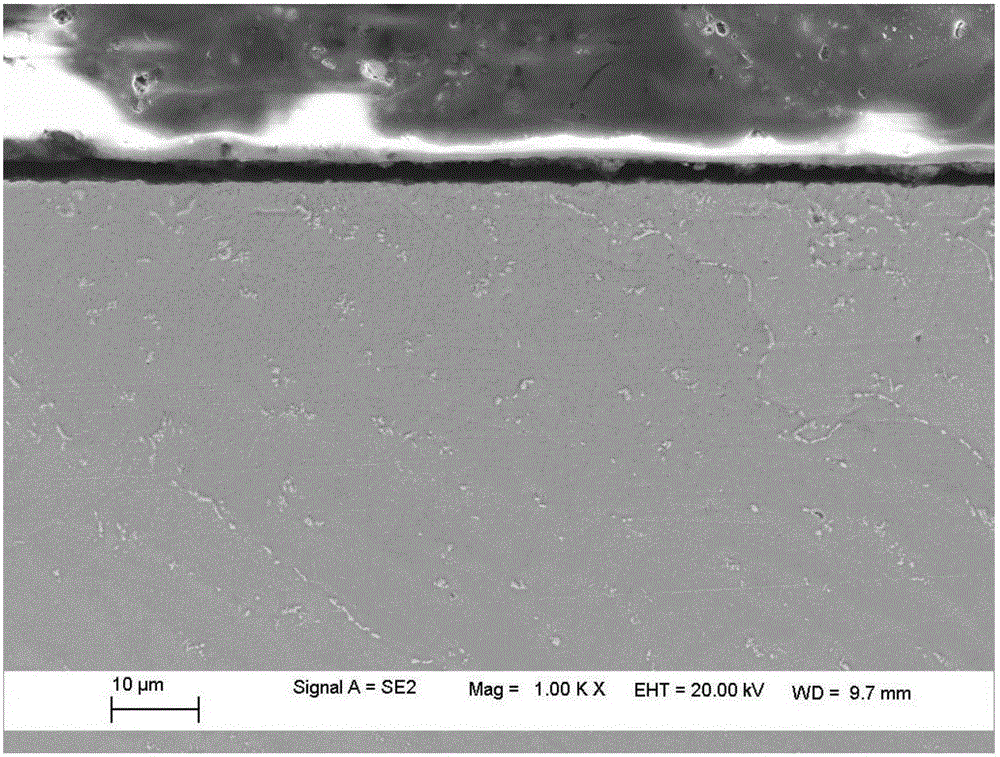

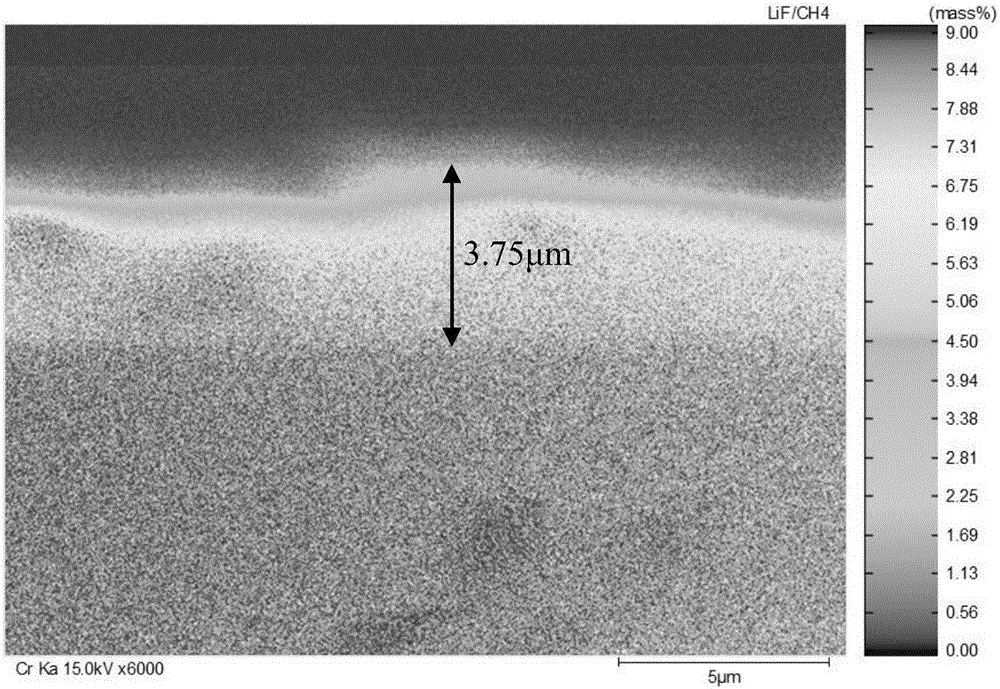

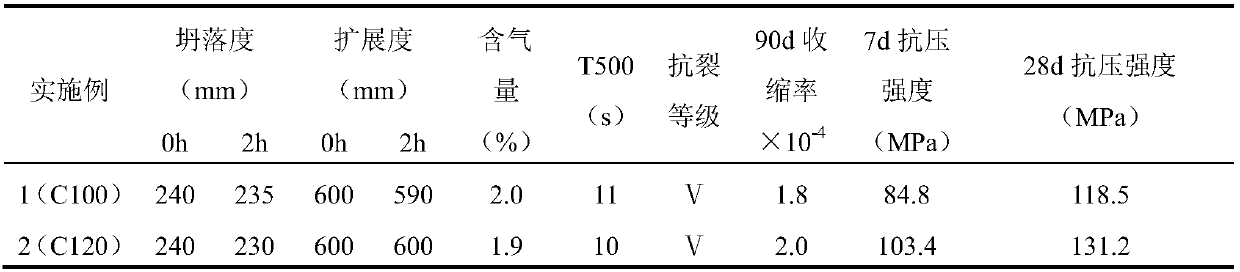

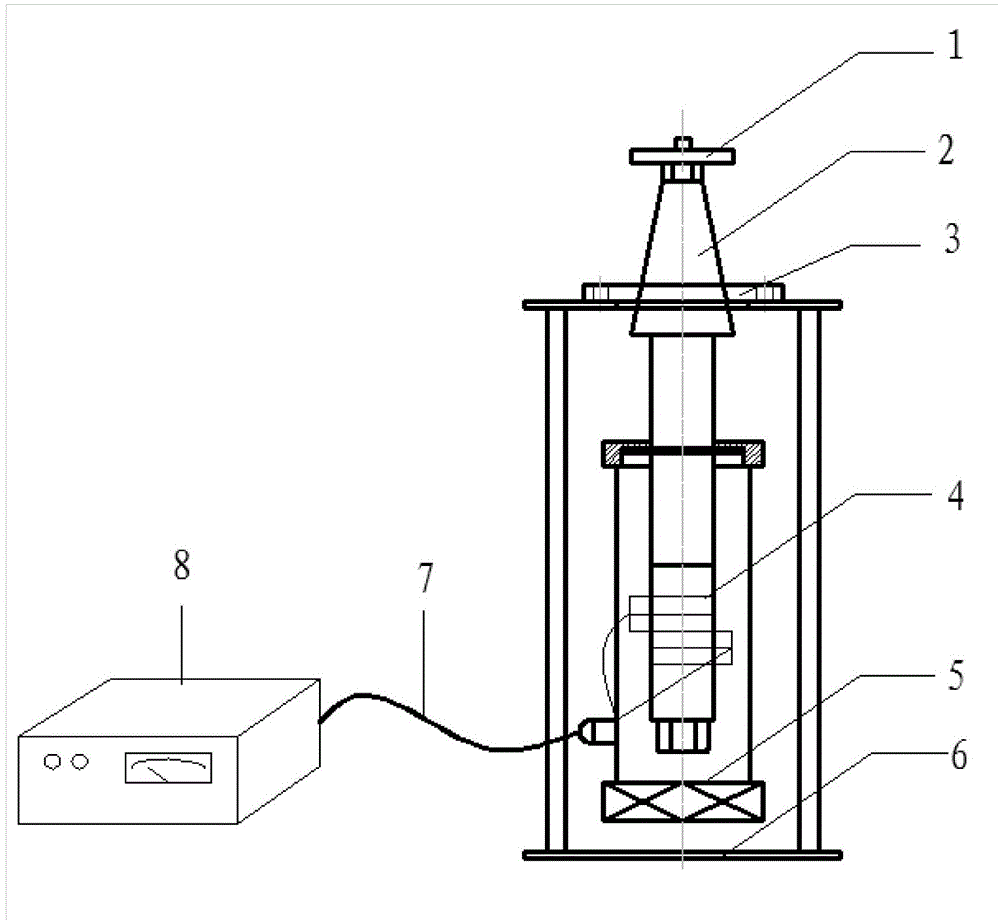

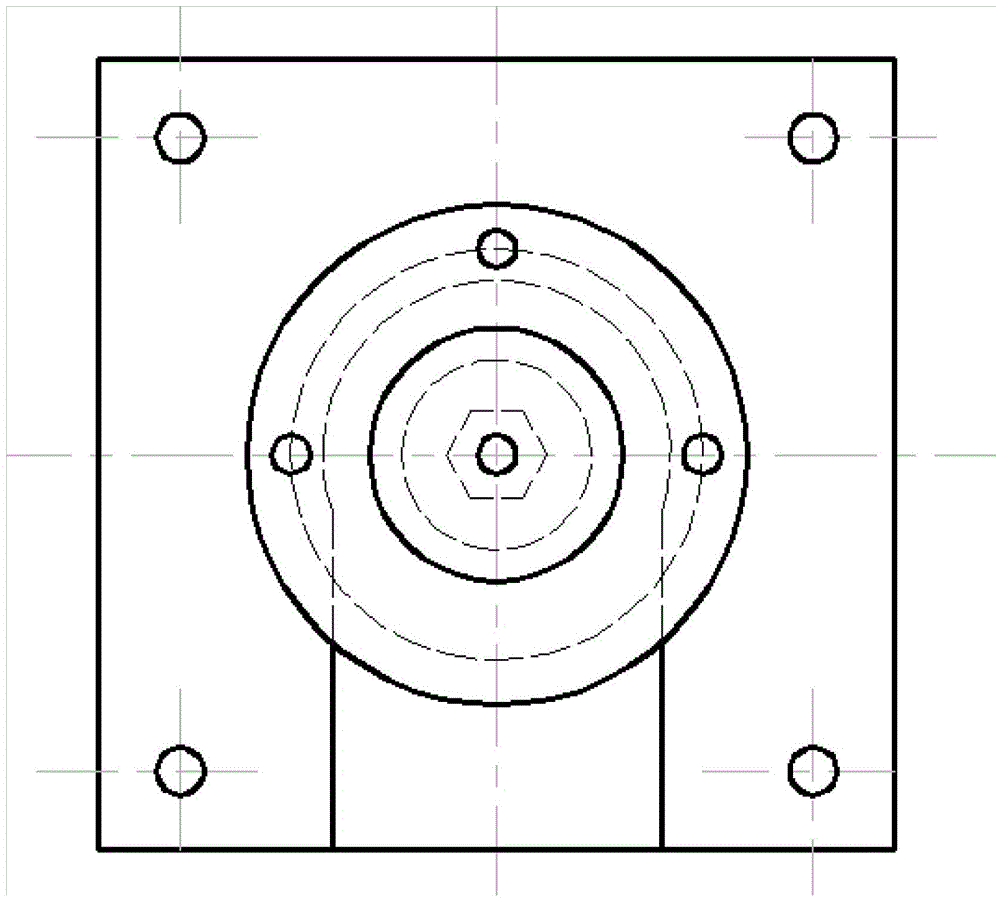

Supersonic vibration-assisted laser cladding composite processing equipment

InactiveCN104419925AImprove wear resistanceVery fine tissueMetallic material coating processesUltrasonic generatorAfter treatment

The invention relates to supersonic vibration-assisted laser cladding composite processing equipment. Supersonic vibration is synchronously exerted on a matrix sample in a laser cladding process; the crack sensitivity of a laser cladding layer is reduced; and the tissue is refined. The laser cladding composite processing equipment is characterized in that 1 the composite processing equipment comprises a test block (1), an amplitude-change pole (2), a flange (3), a transducer (4), a cooling fan (5), an upright post bracket (6), a cable wire (7) and an ultrasonic generator (8); 2 a base plate is a flat test block; preheating is not required before treatment; and slow cooling is not required after treatment; 3 the variety of cladding powder is not limited; 4 the test block (1) is connected with the amplitude-change pole (2) through bolts; 5 the cooling fan (5) is used for discharging heat generated when the device works; and 6 the ultrasonic generator (8) is connected with the transducer (4) through the cable wire (7); and ultrasonic vibration is transmitted to the test block (1) through the amplitude-change pole (2). The supersonic vibration-assisted laser cladding composite processing equipment is high in processing efficiency, simple to operate, and free of pollution to environment, and a cladding layer which is free of a crack in surface and fine in internal texture is obtained.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing, using method therefore and nickel-based high-temperature alloy component

ActiveCN112921206AGood printabilityImprove high temperature mechanical propertiesAdditive manufacturing apparatusSelective laser meltingChemical composition

The invention provides high-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing, a using method therefore and a nickel-based high-temperature alloy component, and relates to the technical field of powder-based additive manufacturing. The high-gamma'-content nickel-based high-temperature alloy powder for additive manufacturing comprises the following chemical components in percentage by weight: 12-14% of Cr, 8-9% of Co, 3.8-4.2% of Al, 3.8-4.2% of Ti, 2.4-2.8% of W, 1.9-2.1% of Ta, 1.6-2.0% of Mo, 1.0-1.2% of Nb, 0.1-5% of Fe, 0.1-2.0% of Hf, 0.12% or less of C, 0.1% or less of Si, 0.02% or less of n, less than 0.03% of Zr, 0.01% or less of B, and the balance Ni and impurity elements. By using the high-temperature alloy powder, compact and crack-free complex parts meeting the strength requirement in the ultrahigh-temperature environment can be printed through the selective laser melting technology.

Owner:常州钢研极光增材制造有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com