Method for preparing beta zeolite with multilevel pore canals

A beta zeolite and channel technology, which is applied in the field of preparation of multi-level channel beta zeolite, can solve problems such as unsuitable catalytic materials, and achieve the effects of enriching internal specific surface area, easy selectivity and huge application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Stir 30ml of methyl orthosilicate, 6g of polyethylene glycol and 30ml of 0.01mol / L acetic acid solution evenly, seal it, and stir at 0°C for 50min. The obtained sol was poured into a polytetrafluoroethylene test tube or a glass tube, and aged in a water bath at 30°C for one day to obtain a wet silica gel column. Then soak the silica gel column with 0.01mol / L ammonia water to prepare mesopores. Then soak the column with 0.1mol / L nitric acid solution, distilled water, 30% ethanol / water ethanol solution and Tween 80 for 6 hours, finally dry and roast to obtain the silica gel monolithic column B 1 .

Embodiment 2

[0036] According to the mass ratio of 1.25 sucrose: 0.14H 2 SO 4 : 5 water to make a solution, put the silica gel monolithic column B1 into it and soak for 30 minutes, then dry at 100°C for 6 hours, 160°C for 6 hours, repeat the process of soaking, drying, and polymerization once, and then carbonize at 900°C for 4 hours to obtain carbon Silicon composite sample C1.

Embodiment 3

[0038] Raw materials: 0.031 g of sodium aluminate, 0.055 g of sodium hydroxide, 1.85 g of tetraethylammonium hydroxide solution, and 0.65 g of carbon-silicon complex.

[0039] Experimental process: Mix and stir sodium aluminate, sodium hydroxide, and tetraethylammonium hydroxide solution evenly, then pour this solution into a reaction kettle equipped with C1, stir to make it fully wet, seal the reaction kettle and place in Crystallization at 150°C for 48 hours. Cool after crystallization, filter and wash, then put into an oven and dry at 100-110°C for 3-4 hours, and then burn the resultant in a muffle furnace at 600°C for 5 hours to obtain the product multi-stage channel zeolite beta sample , denoted as A1.

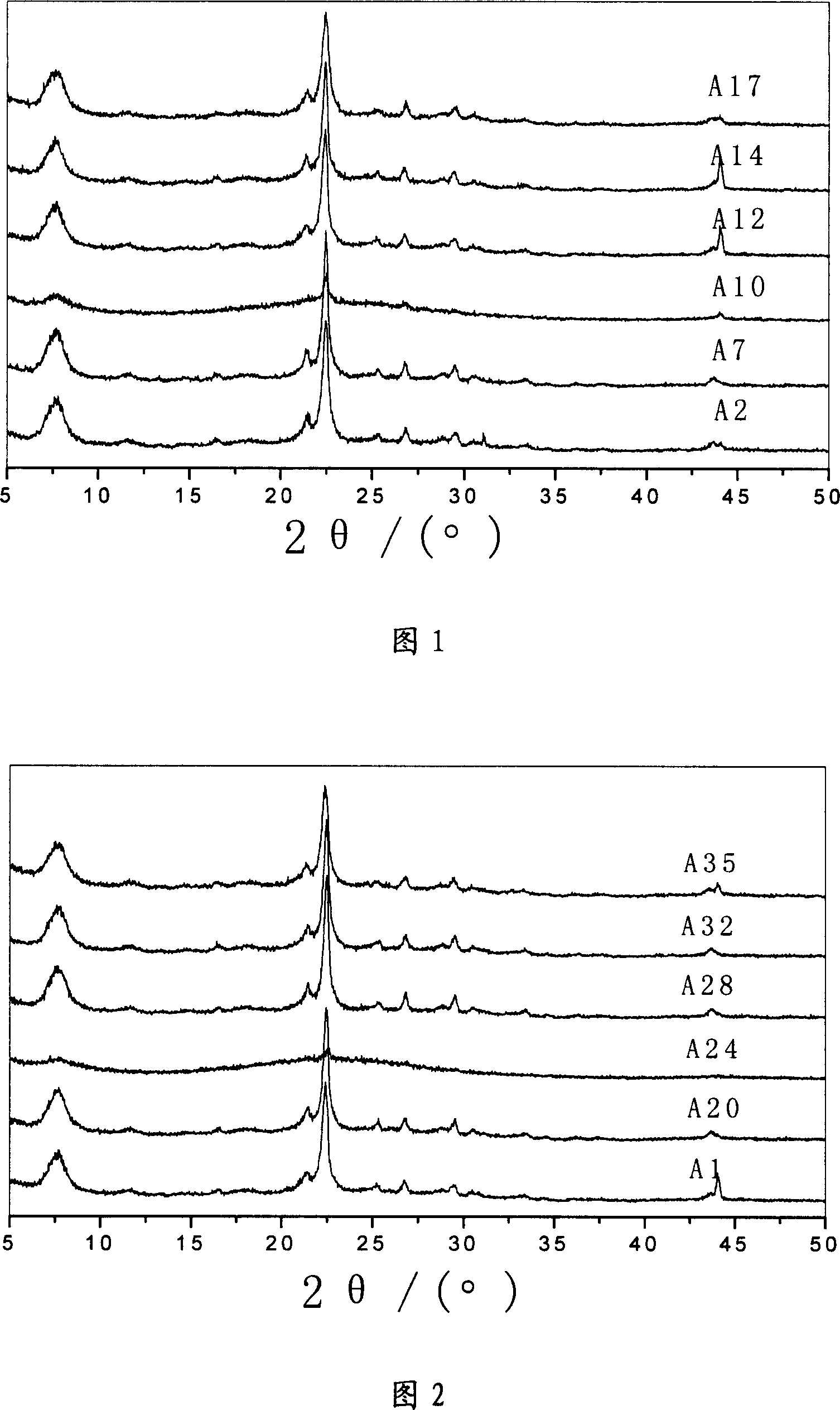

[0040] The XRD spectrum of sample A1 is shown in Figure 2. It can be seen from the figure that there are three peaks at 2θ angles of 7.7°, 21.5°, and 22.4°, and these three peaks are characteristic peaks of zeolite beta, indicating that the preparation The crystal form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com